Aaon LN-075 Installation Manual

LN Series

Chillers and Outdoor Mechanical Rooms

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in serious injury,

death or property damage.

Be sure to read and understand the

installation, operation and service

instructions in this manual.

Improper installation, adjustment,

alteration, service or maintenance

can cause serious injury, death or

property damage.

A copy of this IOM should be kept

with the unit.

Do not store gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch;

do not use any phone in your

building.

Leave the building immediately.

Immediately call you gas supplier

from a phone remote from the

building. Follow the gas supplier’s

instructions.

If you cannot reach your gas

supplier call the fire department.

Startup and service must be

performed by a Factory Trained

Service Technician.

Installation, Operation,

& Maintenance

3

Table of Contents

Safety .............................................................................................................................................. 6

LN Series Feature String Nomenclature ....................................................................................... 11

General Information ...................................................................................................................... 16

Codes and Ordinances ............................................................................................................... 16

Receiving Unit ........................................................................................................................... 16

Storage ....................................................................................................................................... 16

Chiller ........................................................................................................................................ 17

Wiring Diagrams ....................................................................................................................... 18

General Maintenance ................................................................................................................. 18

Chiller Primary Pumping .......................................................................................................... 18

Automatic Air Vent ................................................................................................................... 18

Dual Pumps ............................................................................................................................... 19

Pressure Gauges and Thermometers ......................................................................................... 19

Pipe Insulation ........................................................................................................................... 19

Installation..................................................................................................................................... 20

Chiller Placement ...................................................................................................................... 20

Curb and Steel Mount Installation ............................................................................................ 20

Lifting and Handling ................................................................................................................. 21

Water Connection ...................................................................................................................... 23

Mounting Isolation .................................................................................................................... 23

Access Doors ............................................................................................................................. 23

End Flashing Installation ........................................................................................................... 23

Low Ambient Operation ............................................................................................................ 24

Electrical .................................................................................................................................... 24

Startup ........................................................................................................................................... 26

Axial Flow Condenser Fans ...................................................................................................... 27

Maintenance .................................................................................................................................. 30

General ...................................................................................................................................... 30

Compressors .............................................................................................................................. 30

Adjusting Refrigerant Charge ................................................................................................... 30

Lubrication ................................................................................................................................ 34

Air-Cooled Condenser ............................................................................................................... 34

Brazed Plate Heat Exchanger Cleaning..................................................................................... 34

E-Coated Coil Cleaning ............................................................................................................ 34

Recommended Coil Cleaner .................................................................................................. 35

Recommended Chloride Remover ......................................................................................... 35

Microchannel Coil Cleaning ..................................................................................................... 36

Service ....................................................................................................................................... 36

Replacement Parts ..................................................................................................................... 38

AAON Warranty, Service and Parts Department ...................................................................... 38

Appendix - Water Piping Component Information ...................................................................... 39

Automatic Air Vent Valves ....................................................................................................... 39

Pumps - Installation and Operating Instructions ....................................................................... 41

Pump Piping - General .............................................................................................................. 42

Pump Operation ......................................................................................................................... 43

General Care .............................................................................................................................. 44

Dual Pump Specific Information ............................................................................................... 46

Suction Guides .......................................................................................................................... 51

Flo-Trex Combination Valve .................................................................................................... 52

LN Series Startup Form ................................................................................................................ 58

Maintenance Log .......................................................................................................................... 61

Literature Change History............................................................................................................. 62

V28980 · Rev. A · 150724

4

5

Index of Tables and Figures

Tables:

Table 1 - Service Clearances ......................................................................................................... 20

Table 2 - Mounting Dimensions ................................................................................................... 21

Table 3 - Return/Exhaust Fan Pin Location .................................................................................. 28

Table 4 - Return/Exhaust Fan Pin Location .................................................................................. 28

Table 5 - Fan Assembly Bushing Torque Specifications.............................................................. 29

Table 6 - Acceptable Refrigeration Circuit Values ....................................................................... 31

Table 7 - R-410A Refrigerant Temperature-Pressure Chart ......................................................... 33

Figures:

Figure 1 - Curb Mounting with Dimensions ................................................................................. 20

Figure 2 - Steel Mounting Rail with Dimensions ......................................................................... 21

Figure 3 - Lifting Points ................................................................................................................ 21

Figure 4 - Lifting Detail of a 45-60 ton Unit ................................................................................ 22

Figure 5 - Lifting Detail of a 75-140 ton Unit .............................................................................. 22

Figure 6 - Factory Supplied End Flashings ................................................................................... 23

Figure 7 - Front View of Utility Entry and Power Switch from Control Compartment ............... 24

Figure 8 - Fan with the HUB on the top and RET on the bottom. ................................................ 27

Figure 9 - Bushing Mount Location .............................................................................................. 27

Figure 10 - RET with Pin in Groove 4 .......................................................................................... 27

Figure 11 - Fan HUB and RET Castings ...................................................................................... 28

Figure 12 - Pitch Insert ................................................................................................................. 29

AAON® LN Series Features and Options Introduction

Energy Efficiency

High Efficiency Air-Cooled

Microchannel Condenser

Staged or VFD Controlled Variable

Speed R-410A Scroll Compressors

Two Inch Double Wall Rigid

Polyurethane Foam Panel Construction

VFD Controlled Pumping Package

Glycol Chillers

Constant or Variable Flow Factory

Installed Pumping System

VFD Controlled Condenser Fan Head

Pressure Control

Factory Installed EXVs

Outdoor Mechanical Room

Lighted Service Compartment

Shell and Tube or Brazed Plate Heat

Evaporators

Factory Engineered Primary Pumping

Package

Safety

Phase and Brownout Protection

Compressor Isolation Valves

Installation and Maintenance

Run Test Report and Installation Manuals

Included in Controls Compartment

Color Coded Wiring Diagrams

Sight Glass

Compressors include Rubber Isolation

Mounts

Auxiliary Electric Heating in Service

Compartment

System Integration

Complete System with AAON Chilled

Water Air Handling Units

Single Point Power

Glycol Chillers

Compressor Isolation Valves

Grooved End Water Piping Connections

Constant or Variable Flow Factory

Installed Pumping System

BMS Connectivity

Environmentally Friendly

R-410A Refrigerant

Extended Life

2,500 Hour Salt Spray Tested Exterior

Corrosion Paint

Optional 5 Year Non-Prorated

Compressor Warranty

Polymer E-Coated Condenser Coils

Exterior Cabinet Paint Exceeds 2,500

Salt Spray Test

Condenser Coil Guards

6

7

Safety

ELECTRIC SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in dangerous

operation, serious injury, death or

property damage.

Improper servicing could result in

dangerous operation, serious injury,

death, or property damage.

Before servicing, disconnect all

electrical power to the furnace.

More than one disconnect may be

provided.

When servicing controls, label all

wires prior to disconnecting.

Reconnect wires correctly.

Verify proper operation after

servicing. Secure all doors with

key-lock or nut and bolt.

Attention should be paid to the following statements:

NOTE - Notes are intended to clarify the unit installation, operation and maintenance.

CAUTION - Caution statements are given to prevent actions that may result in

equipment damage, property damage, or personal injury.

WARNING - Warning statements are given to prevent actions that could result in

equipment damage, property damage, personal injury or death.

DANGER - Danger statements are given to prevent actions that will result in equipment

damage, property damage, severe personal injury or death.

QUALIFIED INSTALLER

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

A copy of this IOM should be kept

with the unit.

WHAT TO DO IF YOU SMELL GAS

Do not try to turn on unit.

Shut off main gas supply.

Do not touch any electric switch.

Do not use any phone in the

building.

Never test for gas leaks with an

open flame.

Use a gas detection soap solution

and check all gas connections

and shut off valves.

8

FIRE, EXPLOSION OR CARBON

MONOXIDE POISONING HAZARD

Failure to replace proper controls

could result in fire, explosion or

carbon monoxide poisoning. Failure

to follow safety warnings exactly

could result in serious injury, death or

property damage. Do not store or use

gasoline or other flammable vapors

and liquids in the vicinity of this

appliance.

Electric shock hazard. Before

servicing, shut off all electrical power

to the unit, including remote

disconnects, to avoid shock hazard

or injury from rotating parts. Follow

proper Lockout-Tagout procedures.

VARIABLE FREQUENCY DRIVES

Do not leave VFDs unattended in

hand mode or manual bypass.

Damage to personnel or equipment

can occur if left unattended. When in

hand mode or manual bypass mode

VFDs will not respond to controls or

alarms.

During installation, testing, servicing,

and troubleshooting of the equipment

it may be necessary to work with live

electrical components. Only a

qualified licensed electrician or

individual properly trained in handling

live electrical components shall

perform these tasks.

Standard NFPA-70E, an OSHA

regulation requiring an Arc Flash

Boundary to be field established and

marked for identification of where

appropriate Personal Protective

Equipment (PPE) be worn, should be

followed.

GROUNDING REQUIRED

All field installed wiring must be

completed by qualified personnel.

Field installed wiring must comply

with NEC/CEC, local and state

electrical code requirements. Failure

to follow code requirements could

result in serious injury or death.

Provide proper unit ground in

accordance with these code

requirements.

Electric motor over-current protection

and overload protection may be a

function of the Variable Frequency

Drive to which the motors are wired.

Never defeat the VFD motor overload

feature. The overload ampere setting

must not exceed 115% of the electric

motors FLA rating as shown on the

motor nameplate.

9

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack by certain

chemicals. Polyolester (POE) oils

used with R-410A and other

refrigerants, even in trace amounts,

in a PVC or CPVC piping system will

result in stress cracking of the piping

and fittings and complete piping

system failure.

CAUTION

UNIT HANDLING

To prevent injury or death lifting

equipment capacity shall exceed unit

weight by an adequate safety factor.

Always test-lift unit not more than 24

inches high to verify proper center of

gravity lift point to avoid unit damage,

injury or death.

Door compartments containing

hazardous voltage or rotating parts

are equipped with door latches to

allow locks. Door latch are shipped

with nut and bolts requiring tooled

access. If you do not replace the

shipping hardware with a pad lock

always re-install the nut & bolt after

closing the door.

Rotation must be checked on all

MOTORS AND COMPRESSORS of

3 phase units at startup by a qualified

service technician. Scroll

compressors are directional and can

be damaged if rotated in the wrong

direction. Compressor rotation must

be checked using suction and

discharge gauges. Fan motor rotation

should be checked for proper

operation. Alterations should only be

made at the unit power connection

CAUTION

Do not use oxygen, acetylene or air

in place of refrigerant and dry

nitrogen for leak testing. A violent

explosion may result causing injury or

death.

WARNING

To prevent damage to the unit, do not

use acidic chemical coil cleaners.

Use alkaline chemical coil cleaners

with a pH value of 5-9, after mixing,

without first using an aluminum

corrosion inhibitor in the cleaning

solution.

CAUTION

Some chemical coil cleaning

compounds are caustic or toxic. Use

these substances only in accordance

with the manufacturer’s usage

instructions. Failure to follow

instructions may result in equipment

damage, injury or death.

WARNING

Do not clean DX refrigerant coils with

hot water or steam. The use of hot

water or steam on refrigerant coils

will cause high pressure inside the

coil tubing and damage to the coil.

CAUTION

10

Polyolester (POE) and Polyvinylether

(PVE) oils are two types of lubricants

used in hydrofluorocarbon (HFC)

refrigeration systems. Refer to the

compressor label for the proper

compressor lubricant type.

CAUTION

COMPRESSOR CYCLING

5 MINUTE MINIMUM OFF TIME

To prevent motor overheating

compressors must cycle off for a

minimum of 5 minutes.

5 MINUTE MINIMUM ON TIME

To maintain the proper oil level

compressors must cycle on for a

minimum of 5 minutes.

The cycle rate must not exceed 6

starts per hour.

WARNING

1. Startup and service must be performed

by a Factory Trained Service Technician

2. The unit is for outdoor use only. See

General Information section for more

information.

3. Every unit has a unique equipment

nameplate with electrical, operational,

and unit clearance specifications.

Always refer to the unit nameplate for

specific ratings unique to the model you

have purchased.

4. READ THE ENTIRE INSTALLATION,

OPERATION AND MAINTENANCE

MANUAL. OTHER IMPORTANT

SAFETY PRECAUTIONS ARE

PROVIDED THROUGHOUT THIS

MANUAL.

5. Keep this manual and all literature

safeguarded near or on the unit.

11

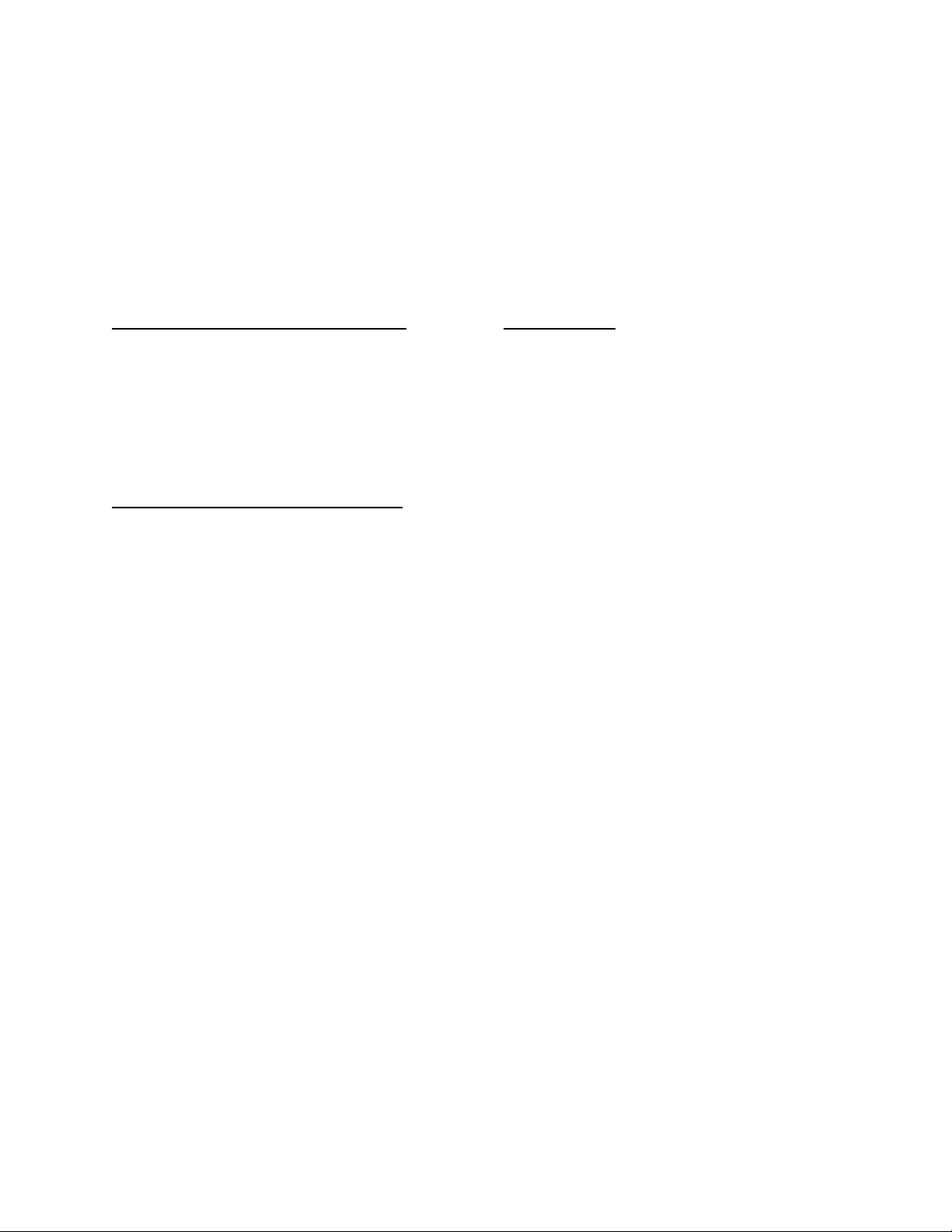

LN Series Feature String Nomenclature

Model Options

:

Unit Feature Options

GEN

MJREV

SIZE SERIES MNREV

VLT A1

A2

A3

A4

A5

B1

B2

B3

B4

1

2

3A

3B

3C

3D

4A

4B

4C

4D

5A

5B

5C

5D 6

7 8A

8B

8C 9 10A

10B

10C

10D

LN A – 140 – C – 0 – 3 – F A C 0 E – 0 0 0 0 : A 0 – 0 0 0 0 – 0 0 0 0 – 0 0 0 0 – 0 0 – 0 0 0 – 0 – 0 E 0 0 –

0 0 0 0 0 – 0 A 0 0 0 – 0 0 0 0 0 – 0 0 0 0 0 0 – 0 0 0 0 0 – 0 0 0 B

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26A

26B

26C

26D

26E

26F

27

28

29

30

31

32

33

34

35

MODEL OPTIONS

SERIES AND GENERATION

LN

MAJOR REVISION

A

UNIT SIZE

045 = 45 ton Capacity

055 = 55 ton Capacity

060 = 60 ton Capacity

075 = 75 ton Capacity

095 = 95 ton Capacity

105 = 105 ton Capacity

120 = 120 ton Capacity

140 = 140 ton Capacity

SERIES

A = 45-60 ton units

B = 75 ton unit

C = 95-140 ton units

MINOR REVISION

0

VOLTAGE

2 = 230V/3Φ/60Hz

3 = 460V/3Φ/60Hz

4 = 575V/3Φ/60Hz

8 = 208V/3Φ/60Hz

A1: COMPRESSOR STYLE

F = R-410A Tandem VFD Compatible Scroll

Compressor

A2: CONDENSER STYLE

A = Air-Cooled Microchannel Condenser

A3: EVAPORATOR CONFIGURATION

A = Standard Brazed Plate Constant Flow

B = Oversized Brazed Plate Constant Flow

C = Standard Shell & Tube Constant Flow

D = Oversized Shell & Tube Constant Flow

A4: COATING

0 = Standard

E = Polymer E-Coated Condenser Coil

A5: STAGING

0 = Staged Compressors

E = All Circuits with Variable Capacity Compressors

- 2 Circuits

G = Half Circuits with Variable Capacity

Compressors - 2 Circuits

B1: BLANK

0 = Standard

B2: BLANK

0 = Standard

B3: BLANK

0 = Standard

B4: BLANK

0 = Standard

UNIT FEATURE OPTIONS

1: UNIT ORIENTATION

A = Standard Access Left Water Connections

B = Standard Access Right Water Connections

C = Standard Access Bottom Water Connections

2: PUMPING STYLE

0 = No Pumps

B = Constant Flow Primary Pumping System - Large

Pipe Size

D = Variable Flow Primary Pumping System - Large

Pipe Size

12

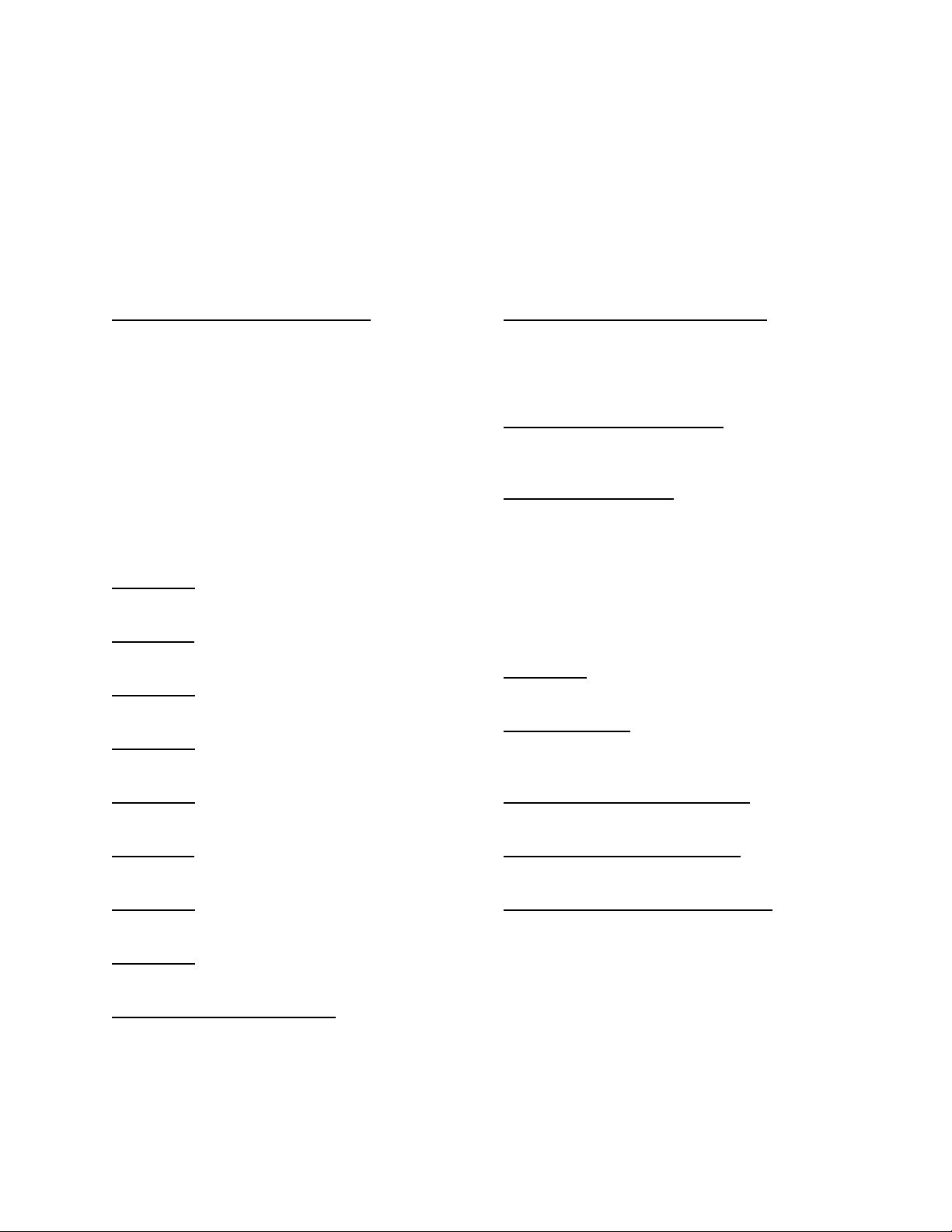

LN Series Feature String Nomenclature

Model Options

:

Unit Feature Options

GEN

MJREV

SIZE SERIES

MNREV VLT

A1

A2

A3

A4

A5

B1

B2

B3

B4 1 2

3A

3B

3C

3D

4A

4B

4C

4D

5A

5B

5C

5D 6 7 8A

8B

8C 9

10A

10B

10C

10D

LN A – 140 – C – 0 – 3 – F A C 0 E – 0 0 0 0 : A 0 – 0 0 0 0 – 0 0 0 0 – 0 0 0 0 – 0 0 – 0 0 0 – 0 – 0 E 0 0 –

0 0 0 0 0 – 0 A 0 0 0 – 0 0 0 0 0 – 0 0 0 0 0 0 – 0 0 0 0 0 – 0 0 0 B

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26A

26B

26C

26D

26E

26F

27

28

29

30

31

32

33

34

35

3A: BUILDING PUMP CONFIGURATION

0 = No Building Pumps

A = 1 Pump + High Eff Motor

B = 1 Dual Pump + High Eff Motors

D = 1 Pump + VFD + High Eff Motor

E = 1 Dual Pump + 2 VFD's + High Eff Motors

K = 1 Pump + Field Installed VFD + High Eff Motor

L = 1 Dual Pump + 2 Field Installed VFD's + High

Eff Motors

3B: BUILDING PUMP SERIES AND RPM

0 = No Building Pumps

A = 4360 (1,170 nominal rpm)

B = 4360 (1,760 nominal rpm)

C = 4360 (3,520 nominal rpm)

D = 4380 (1,170 nominal rpm)

E = 4380 (1,760 nominal rpm)

F = 4380 (3,520 nominal rpm)

K = 4382 (1,170 nominal rpm)

L = 4382 (1,760 nominal rpm)

M = 4382 (3,520 nominal rpm)

3C: PUMP SIZE

0 = No Building Pumps

A = 1.5B

B = 2B

C = 2D

D = 3D

E = 1.5x1.5x6

F = 2x2x6

G = 3x3x6

H = 4x4x6

J = 6x6x6

K = 1.5x1.5x8

L = 2x2x8

M = 3x3x8

N = 4x4x8

P= 5x5x8

Q = 6x6x8

R = 8x8x8

S = 2x2x10

T = 3x3x10

U = 4x4x10

V = 6x6x10

W = 8x8x10

Y = 4x4x11.5

Z = 5x5x11.5

1 = 6x6x11.5

2 = 8x8x11.5

3 = 4x4x13

4 = 6x6x13

5 = 8x8x13

13

LN Series Feature String Nomenclature

GEN

MJREV

SIZE SERIES

MNREV VLT

A1

A2

A3

A4

A5

B1

B2

B3

B4 1 2 3A

3B

3C

3D

4A

4B

4C

4D

5A

5B

5C

5D

6 7 8A

8B

8C

9 10A

10B

10C

10D

LN A – 140 – C – 0 – 3 – F A C 0 E – 0 0 0 0 : A 0 – 0 0 0 0 – 0 0 0 0 – 0 0 0 0 – 0 0 – 0 0 0 – 0 – 0 E 0 0 -

0 0 0 0 0 – 0 A 0 0 0 – 0 0 0 0 0 – 0 0 0 0 0 0 – 0 0 0 0 0 – 0 0 0 B

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26A

26B

26C

26D

26E

26F

27

28

29

30

31

32

33

34

35

Model Options

:

Unit Feature Options

3D: BUILDING PUMP MOTOR SIZE

0 = No Building Pumps

C = 1 hp

E = 2 hp

F = 3 hp

G = 5 hp

H = 7.5 hp

J = 10 hp

K = 15 hp

L = 20 hp

M = 25 hp

N = 30 hp

P = 40 hp

Q = 50 hp

4A: BLANK

0 = Standard

4B: BLANK

0 = Standard

4C: BLANK

0 = Standard

4D: BLANK

0 = Standard

5A: BLANK

0 = Standard

5B: BLANK

0 = Standard

5C: BLANK

0 = Standard

5D: BLANK

0 = Standard

6: REFRIGERATION OPTIONS

0 = Standard

A = Hot Gas Bypass on Non-Variable Capacity

Circuits

B = Hot Gas Bypass - All Circuits

7: REFRIGERATION ACCESSORIES

0 = Standard

A = Sight Glass

B = Compressor Isolation Valves

C = Option A + B

8A: UNIT DISCONNECT TYPE

0 = Standard Single Point Power Block

A = Single Point Power Non-fused Disconnect

8B: DISCONNECT SIZE

0 = Power Block

N = 100 amps

R = 150 amps

U = 225 amps

Z = 400 amps

3 = 600 amps

5 = 800 amps

7 = 1200 amps

8C: BLANK

0 = Standard

9: ACCESSORIES

0 = Standard

B = Phase & Brown Out Protection

10A: UNIT CONTROL SEQUENCE

0 = Standard Controls

10B: UNIT CONTROL SUPPLIER

E = MCS Controls

10C: CONTROL SUPPLIER OPTIONS

0 = Standard

A = Touchscreen Interface

C = Modem

G = Option A + C

14

LN Series Feature String Nomenclature

Model Options

:

Unit Feature Options

GEN

MJREV

SIZE SERIES

MNREV VLT

A1

A2

A3

A4

A5

B1

B2

B3

B4 1 2

3A

3B

3C

3D

4A

4B

4C

4D

5A

5B

5C

5D 6 7 8A

8B

8C 9

10A

10B

10C

10D

LN A – 140 – C – 0 – 3 – F A C 0 E – 0 0 0 0 : A 0 – 0 0 0 0 – 0 0 0 0 – 0 0 0 0 – 0 0 – 0 0 0 – 0 – 0 E 0 0 –

0 0 0 0 0 – 0 A 0 0 0 – 0 0 0 0 0 – 0 0 0 0 0 0 – 0 0 0 0 0 – 0 0 0 B

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26A

26B

26C

26D

26E

26F

27

28

29

30

31

32

33

34

35

10D: BMS CONNECTION & DIAGNOSTICS

0 = None

A = BACnet IP

B = BACnet MSTP

C = Modbus IP

D = Modbus RTU

E = Lontalk

H = No BMS Connection with Diagnostics

J = BACnet IP with Diagnostics

K = BACnet MSTP with Diagnostics

L = Modbus IP with Diagnostics

M = Modbus RTU with Diagnostics

N = Lontalk with Diagnostics

11: BLANK

0 = Standard

12: VESTIBULE ACCESSORIES

0 = Standard

C = Vestibule Heating (Electric)

13: MAINTENANCE ACCESSORIES

0 = Standard

A = 115VAC Convenience Outlet Factory Wired

B = 115VAC Convenience Outlet Field Wired

C = Service Lights

F = Options A + C

J = Options B + C

14: BLANK

0 = Standard

15: CODE OPTIONS

0 = Standard ETL U.S.A. Listing

A = Chicago Code

B = ETL U.S.A. + Canada Listing

16: SHIPPING SPLITS

0 = One Piece Unit

17: AIR-COOLED CONDENSER

ACCESSORIES

H = Cond Coil Guards + Three Phase Cond Fan

Motor + Fan Cycling- 25°F Low Ambient

J = Cond Coil Guards + VFD Cond Fan Head

Pressure Control - 0°F Low Ambient

18: BLANK

0 = Standard

19: BLANK

0 = Standard

20: BLANK

0 = Standard

21: BLANK

0 = Standard

22: BLANK

0 = Standard

23: BLANK

0 = Standard

24: CHILLER ACCESSORIES 1

0 = Standard

A = Glycol Chiller

C = Thermometers & Pressure Gauges

G = Option A + C

25: BLANK

0 = Standard

26A: BLANK

0 = Standard

26B: BLANK

0 = Standard

26C: BLANK

0 = Standard

15

LN Series Feature String Nomenclature

Model Options

:

Unit Feature Options

GEN

MJREV

SIZE SERIES

MNREV VLT

A1

A2

A3

A4

A5

B1

B2

B3

B4 1 2

3A

3B

3C

3D

4A

4B

4C

4D

5A

5B

5C

5D 6 7 8A

8B

8C 9

10A

10B

10C

10D

LN A – 140 – C – 0 – 3 – F A C 0 E – 0 0 0 0 : A 0 – 0 0 0 0 – 0 0 0 0 – 0 0 0 0 – 0 0 – 0 0 0 – 0 – 0 E 0 0 –

0 0 0 0 0 – 0 A 0 0 0 – 0 0 0 0 0 – 0 0 0 0 0 0 – 0 0 0 0 0 – 0 0 0 B

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26A

26B

26C

26D

26E

26F

27

28

29

30

31

32

33

34

35

26D: BLANK

0 = Standard

26E: BLANK

0 = Standard

26F: BLANK

0 = Standard

27: BLANK

0 = Standard

28: BLANK

0 = Standard

29: BLANK

0 = Standard

30: BLANK

0 = Standard

31: BLANK

0 = Standard

32: BLANK

0 = Standard

33: WARRANTY

0 = Standard Warranty

D = Compressor Warranty Years 2-5

34: CABINET MATERIAL

0 = Standard - Double Wall + R-13 Foam Insulation

35: PAINT & SPECIAL PRICING

AUTHORIZATIONS

B = Premium AAON Gray Paint Exterior

E = Premium AAON Gray Paint Exterior + Shrink

Wrap

X = Special Pricing Authorization + Premium AAON

Gray Paint Exterior

1 = SPA + Premium AAON Gray Paint Exterior +

Shrink Wrap

4 = Special Pricing Authorization + Special Exterior

Paint Color

7 = SPA + Special Exterior Paint Color + Shrink

Wrap

16

General Information

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

The Clean Air Act of 1990 bans the

intentional venting of refrigerant as of

July 1, 1992. Approved methods of

recovery, recycling, or reclaiming

must be followed.

Coils and sheet metal surfaces

present sharp edges and care must

be taken when working with

equipment.

Failure to observe the following

instructions will result in premature

failure of your system and possible

voiding of the warranty.

AAON LN Series chillers are complete selfcontained liquid chilling units. They are

assembled, wired, charged and run-tested.

Models are available for air-cooled

applications. Chiller primary pumping

packages are available as optional features.

Codes and Ordinances

LN Series units have been tested and

certified, by ETL, in accordance with UL

Safety Standard 1995/CSA C22.2 No. 236.

System should be sized in accordance with

the American Society of Heating,

Refrigeration and Air Conditioning

Engineers Handbook.

Installation of LN Series units must conform

to the ICC standards of the International

Mechanical Code, the International Building

Code, and local building, plumbing and

waste water codes. All appliances must be

electrically grounded in accordance with

local codes, or in the absence of local codes,

the current National Electric Code,

ANSI/NFPA 70 or the current Canadian

Electrical Code CSA C22.1.

Receiving Unit

When received, the unit should be checked

for damage that might have occurred in

transit. If damage is found it should be noted

on the carrier’s Freight Bill. A request for

inspection by carrier’s agent should be made

in writing at once. Nameplate should be

checked to ensure the correct model sizes

and voltages have been received to match

the job requirements.

Storage

If installation will not occur immediately

following delivery, store equipment in a dry

protected area away from construction

traffic and in the proper orientation as

marked on the packaging with all internal

packaging in place. Secure all loose-shipped

items.

17

Chiller

Rotation must be checked on all

MOTORS AND COMPRESSORS of

three phase units. All motors, to

include and not be limited to pump

motors and condenser fan motors,

should all be checked by a qualified

service technician at startup and any

wiring alteration should only be made

at the unit power connection.

Scroll compressors are directional

and will be damaged by operation in

the wrong direction. Low pressure

switches on compressors have been

disconnected after factory testing.

Rotation should be checked by a

qualified service technician at startup

using suction and discharge pressure

gauges and any wiring alteration

should only be made at the unit

power connection.

CRANKCASE HEATER

OPERATION

Units may be equipped with

compressor crankcase heaters,

which should be energized at least

24 hours prior to cooling operation, to

clear any liquid refrigerant from the

compressors.

COMPRESSOR CYCLING

5 MINUTE MINIMUM OFF TIME

To prevent motor overheating

compressors must cycle off for a

minimum of 5 minutes.

5 MINUTE MINIMUM ON TIME

To maintain the proper oil level

compressors must cycle on for a

minimum of 5 minutes.

The cycle rate must not exceed 6

starts per hour.

WARNING

Failure to observe the following instructions

will result in premature failure of your

system, and possible voiding of the

warranty.

Never turn off the main power supply to the

unit, except for complete shutdown. When

power is cut off from the unit, any

compressors using crankcase heaters cannot

prevent refrigerant migration. This means

the compressor will cool down, and liquid

refrigerant may accumulate in the

compressor. The compressor is designed to

pump refrigerant gas and damage may occur

when power is restored if liquid enters the

compressor.

Before unit operation, the main power

switch must be turned on for at least 24

hours for units with compressor crankcase

heaters. This will give the crankcase heater

time to clear any liquid accumulation out of

the compressor before it is required to run.

Never cut off the main power supply to the

unit, except for complete shutdown. Always

control the system from the building

management system, or control panel, never

at the main power supply (except for

emergency or for complete shutdown of the

system).

18

Scroll compressors must be on a minimum

of 5 minutes and off for a minimum of 5

minutes. The cycle rate must be no more

than 6 starts per hour.

The chiller is furnished with a pressure

differential switch that is factory installed

between the chilled water supply and return

connections. This sensor must not be

bypassed since it provides a signal to the

unit controller that water flow is present in

the heat exchanger and the unit can operate

without the danger of freezing the liquid.

Compressor life will be seriously shortened

by reduced lubrication, and the pumping of

excessive amounts of liquid oil and liquid

refrigerant.

Wiring Diagrams

A complete set of unit specific wiring

diagrams in both ladder and point-to-point

form are laminated in plastic and located

inside the control compartment door.

General Maintenance

When the initial startup is made and on a

periodic schedule during operation, it is

necessary to perform routine service checks

on the performance of the chiller. This

includes reading and recording suction

pressures and checking for normal subcooling and superheat. See the air-cooled

condenser sections in this manual for

specific details.

Chiller Primary Pumping

Primary pumping uses a single pump to

move water (or glycol) through the chiller

barrel and back to the building. This

pumping package provides a constant flow

of water to the system. The pump is

activated whenever the chiller is given a run

signal.

Water enters the unit through the return

water piping, and then travels through an air

separator to remove any air that is entrapped

in the water. Following this, the water flows

through a suction guide with strainer. The

end of the suction guide is removable for

strainer access. The strainer assembly is

composed of two parts, the operational

strainer and the startup strainer, (located

inside the operational strainer) which is to

be removed 24 hours after startup.

The pump is installed after the suction

guide, and before a combination valve (FloTrex). This combination valve acts as

isolation valve, check valve, and flow

balancing valve. The shell and tube or

brazed plate evaporator, is placed after the

combination valve in the water circuit, with

a differential pressure switch installed across

its inlet and outlet. This pressure switch

closes when the differential pressure

increases above the setpoint, which should

be set 1-2 psig below the pressure drop

across the heat exchanger at design flow

rate. The closing differential pressure switch

signals the control system to indicate flow

through the heat exchanger and allow

cooling to activate as required to maintain

the setpoint. The water exiting the shell and

tube or brazed plate evaporator, leaves the

unit through the water out connection.

Automatic Air Vent

There is an automatic air vent installed at the

high point of the system inside the pumping

package compartment. The air vent valve

must be in the proper position for operation.

Ensure that the small vent cap is loosened

two turns from the closed position, allowing

air to be vented from the system. It is

advisable to leave the cap on to prevent

impurities from entering the valve. See

appendix for additional information.

19

Dual Pumps

When redundant pumping is required,

factory installed dual pumps can be ordered.

A dual pump is a pump with two

independent motors and pumps in a single

casing. This dual pump has a swing splitflapper valve in the discharge port to prevent

liquid recirculation when only one pump is

operating. Isolation valves in the casing

allow one pump to be isolated and removed

for service while the other pump is still

operating.

The controls package will activate the pump

when the unit is given a run command. If the

controls do not recognize flow in 60

seconds, the second pump will be activated

and an alarm signal will be generated. If the

second pump does not activate, the cooling

will be locked out. See appendix for

additional information.

Pressure Gauges and Thermometers

Pressure gauges and thermometers are

available as a factory installed option.

Thermometers are installed on the inlet and

outlet of the unit. One pressure gauge is

installed at each pump. This pressure gauge

is connected in three places to the water

piping before the suction guide/strainer,

after the suction guide and before the pump,

and after the pump. There is also a needle

valve at each of these points to isolate the

pressure. To measure the pressure at any

given point, open the needle valve at that

point and close the other two needle valves.

One gauge is used so that the calibration of

the pressure gauge is irrelevant in the

calculation of the differential pressure.

Pipe Insulation

The water piping and components on units

with pumping packages are not insulated at

the factory. Insulation should be installed on

the water piping after the system has been

checked for leaks.

20

Installation

Location

Unit Size

45-140 tons

Front -

(Controls Side)

72”

Back

72”

Ends

96”

Top

Unobstructed

All roofing work should be performed

by competent roofing contractors to

avoid any possible leakage.

CAUTION

Chiller Placement

The AAON LN Series is designed for

outdoor applications and mounting at

ground level or on a rooftop. It must be

placed on a level and solid foundation that

has been prepared to support its weight.

The placement relative to the building air

intakes and other structures must be

carefully selected. Be sure to observe the

dimensions that are on the rating plate of the

chiller for operational and service

clearances.

Table 1 - Service Clearances

Condenser coils and fans must be free of any

obstructions in order to start and operate

properly with a correct amount of airflow.

For proper unit operation, the immediate

area around condenser must remain free of

debris that may be drawn in and obstruct

airflow in the condensing section.

Consideration must be given to obstruction

caused by snow accumulation when placing

the unit.

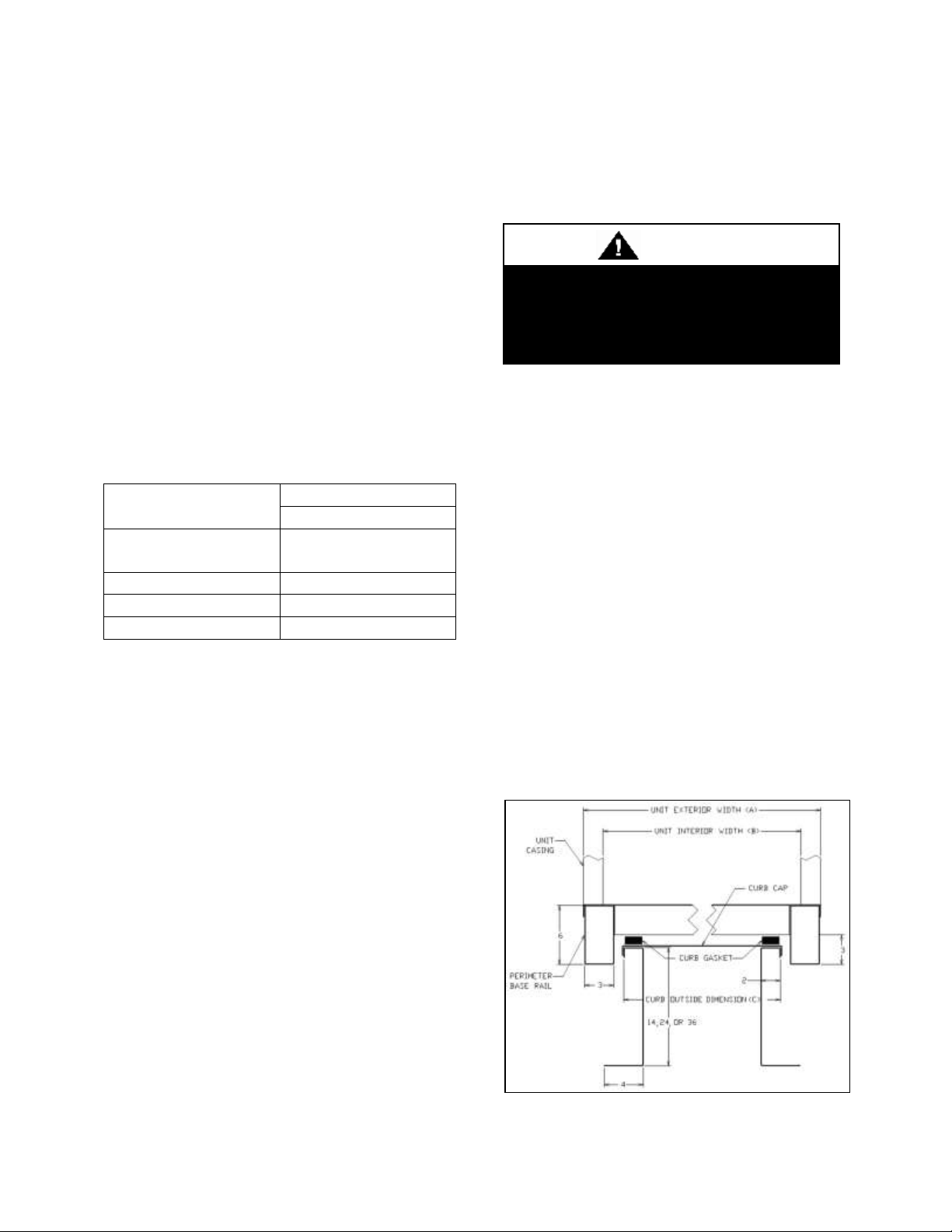

Curb and Steel Mount Installation

Make openings in the roof decking large

enough to allow for water piping, electrical

penetrations, and workspace only. Do not

make openings larger than necessary. Set the

curb to coincide with the openings. Make

sure curb is level.

Unit specific curb drawing is included with

job submittal. See SMACNA Architectural

Sheet Metal Manual for curb installation

details.

Units require rail support along all four sides

of the unit base.

When installed at ground level, a one-piece

concrete slab should be used with footings

that extend below the frost line. Care must

also be taken to protect the coil and fins

from damage due to vandalism or other

causes.

If unit is elevated a field supplied catwalk is

recommended to allow access to unit service

doors.

This unit ships with a curb gasket that is

1¼” wide and 1½” tall. It is recommended

that this or another similar gasket be used

between the curb and the unit to reduce

vibration from the unit to the building.

Figure 1 - Curb Mounting with Dimensions

Loading...

Loading...