Page 1

B

H

Package Units

& Air Handlers

• R-410A DX or Chilled Water Cooling

• Gas, Electric or Hot Water Heat

• Bottom or Side Discharge

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• EXTINGUISH ANY OPEN FLAME

• DO NOT TOUCH ANY ELECTRICAL SWITCH

• DO NOT TRY TO LIGHT ANY APPLIANCE

• DO NOT USE ANY PHONE IN YOUR BUILDING

• IMMEDIATELY CALL YOUR GAS SUPPLIER

FROM A NEIGHBOR’S PHONE. FOLLOW THE

GAS SUPPLIER’S INSTRUCTIONS.

• IF YOU CANNOT REACH YOUR GAS

SUPPLIER, CALL THE FIRE DEPARTMENT.

Series

Installation and User Manual

R-410A Package

Air Handler

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

Page 2

Owner should pay particular attention to the words: NOTE, CAUTION, and WARNING. NOTES are

intended to clarify or make the installation easier. CAUTIONS are given to prevent equipment damage.

Contents

WARNINGS are given to alert owner that personal injury and/or equipment damage may result if installation

is not handled properly.

1. Description ………………………………... 3

Important Safety Information

Package Unit Orientation

Air Handling Unit Orientation

2. Model Number Description ....………….. 6

Unit Model Number

3. User’s Information ……….....…………… 7

DX Cooling Units (and Remote Cond. Units)

Hydronic Cooling & Heating

Gas or Electric Heating

Filter Sizes

Multiple Unit Operation

Wiring Diagrams

Condensate Piping

Normal Thermostat Operation

Night and Vacancy Operation

Gas Heating System

Hot Gas Reheat & Hot Gas Bypass System

Filter Sizes

Cabinet Construction

4. Delivery ……………………………………. 10

Receipt & Inspection

Storage

5. Installation ………………………………… 10

General

Codes & Ordinances

Handling

Heating and Cooling Systems

Service & Installation Clearances

Setting the Unit

Electrical

Standard Control Board

Optional Control Board

Optional Control Board

Table Index: Figure Index

4.1

5.1

9.1

16.1

16.2

16.3

21.1

21.2

27.1

Package Unit Dimensions

AHU Dimensions

Filter Sizes

Blink Codes: Standard Board

Blink Codes: Optional Board

Low Voltage Wiring Sizes

Minimum Gas Piping Sizes

Gas Piping Support Intervals

Filter Sizes

4a

5a

7a

8a

9a

9b

12a

12b

12c

Thermostat

6. Start-Up …………………………….. 23

7. Operation & Maintenance ……….. 26

8. Hot Gas Bypass (External) …..….. 28

9. Hot Gas Reheat (Modulating) …... 28

10. Pressure-Temperature Chart …… 31

Economizer Option

Return Air Bypass Option

Modulating Hot Gas Reheat

Gas Piping

Condensate Piping

General

Procedures

Air Balancing

Water Balancing

Controls

General

Maintenance Schedule

Cooling

Condenser Fan

Blower Assembly

Heating Sequence

Chilled Water

Filters

Cleaning

Service

Pkg. Unit Orientation

AHU Orientation

Piping Chase Location

Heat Exchangers

MHGRH+HGBP System

Foam Panel (HPCP)

Service Clearances

Airflow Clearances

Other Clearances

2

13a

14a

15a

18a

20a

22a

26a

27a

28a

Removing Shipping Brackets

Lifting Lugs and Outside Air Hood

Power and Control Wiring

External Control Inputs to Control Board

Reheated Supply Air Temperature

Gas Piping

Blower Section

Filter Section

Hot Gas Reheat System

Page 3

1. Description

Important Safety Information

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM INSTALLATION, OPERATION, AND

MAINTENANCE OF EQUIPMENT DESCRIBED IN

THIS MANUAL.

HB series package units are designed for safe

operation when installed, operated, and maintained

within design specifications, and the instructions set

forth in this manual. It is necessary to follow these

instructions to avoid personal injury or damage to

equipment or property during equipment installation,

operation, and maintenance.

This equipment is protected by a standard limited

warranty under the condition that initial installation,

service, and maintenance is performed according

to the instructions set forth in this manual. This

manual should be read in its entirety prior to

installation, and before performing any service or

maintenance work.

Units described in this manual are available with

many optional accessories. If you have questions

after reading this manual in its entirety, consult

other factory documentation, or contact your sales

representative to obtain further information before

manipulating this equipment, or its optional

accessories.

IMPORTANT!

WARNING

RISK OF DAMAGE, INJURY, AND LOSS OF LIFE

- Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury, or loss of life. A qualified

installer or service agency must perform

installation and service.

NOTE

RISK OF ELECTRICAL SHOCK Before attempting to perform any service or

maintenance, turn the electrical power to the unit

OFF at disconnect switch(es). Unit may have

multiple power supplies.

WARNING

RISK OF INJURY FROM MOVING PARTS Disconnect all power before servicing to prevent

serious injury resulting from automatic starts. Unit

may have multiple power supplies.

WARNING

WARNING

ON 3 PHASE UNITS ONLY - Scroll compressors

will be damaged by operation with the wrong

rotation. THE LOW PRESSURE SWITCH HAS

BEEN DISCONNECTED AFTER TESTING AT

THE FACTORY. The wiring must be reconnected

and proper rotation determined at the time of startup by a qualified service technician using suction

and discharge pressure gauges. Any alteration

should only be made at the unit power connection.

This equipment uses R-410A only, and operates at

higher pressures than standard R-22 systems. Do

not use R-22 service equipment or tools on R410A systems. Improper use or service may result

in injuries from parts under high pressure.

WARNING

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC’s and HCFC’s) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for noncompliance.

WARNING

3

Page 4

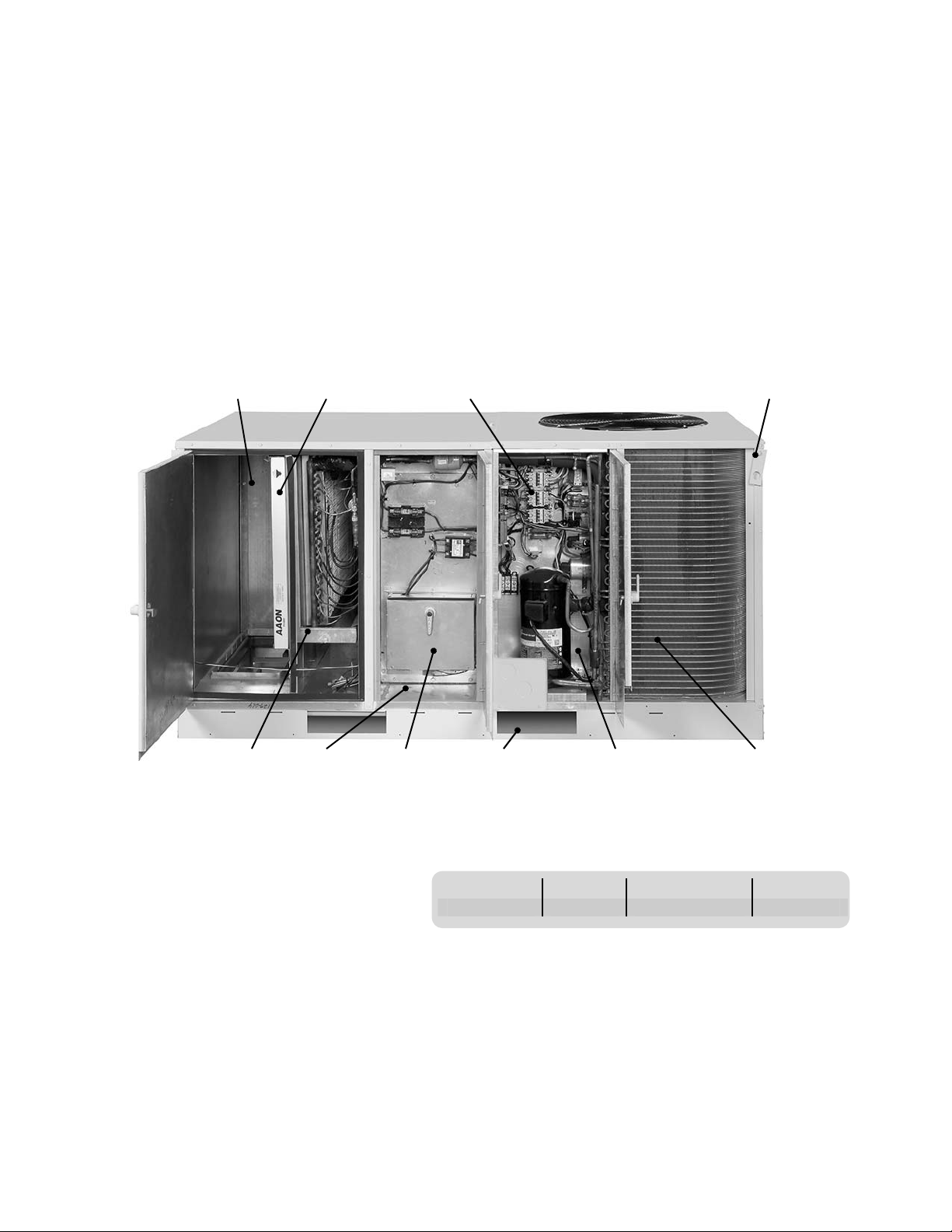

Package Unit Orientation (Compressorized)

Service access is from the front of the unit.

As you face the front of the unit, the condensing section will be on

the right end of the unit, and the air handling section on the left.

The drain connection is located on the back.

Figure 4a, Package Unit Orientation

Return /

Outside Air /

Economizer

Section

Filter

Section

Controls

Section

Evaporator

Section

Supply Air

Section

Heating

Section

Forklift

Openings

Table 4.1, Package Unit Dimensions

Model Width Length Height

002 - 005 42.25” 74.25” (93.25”)* 38”

*If present, the outside air hood will increase the overall

installed unit length by 19” for a total length of 93.25”.

Compressor

Compartment

Top Lifting Lugs

on Each Corner

Condenser

Section

4

Page 5

Air Handling Unit Orientation (Non-Compressorized)

Service access is from the front of the unit.

As you face the front of the unit, the controls section will be on the

right end of the unit, and the air handling section on the left.

The drain connection is located on the back.

Figure 5a, Air Handler (Non-Compressorized) Unit Orientation

Return /

Outside Air /

Economizer

Section

Filter

Section

Coil Section

Heating

Section

Table 5.1, AHU Dimensions

Model Width Length Height

002 - 005 42.25” 44.75” (63.75”)* 38”

*If present, the outside air hood will increase the overall

installed unit length by 19” for a total length of 63.75”.

Top Lifting Lugs

on Each Corner

Controls

Section

Power Disconnect

Switch

Forklift

Openings

5

Page 6

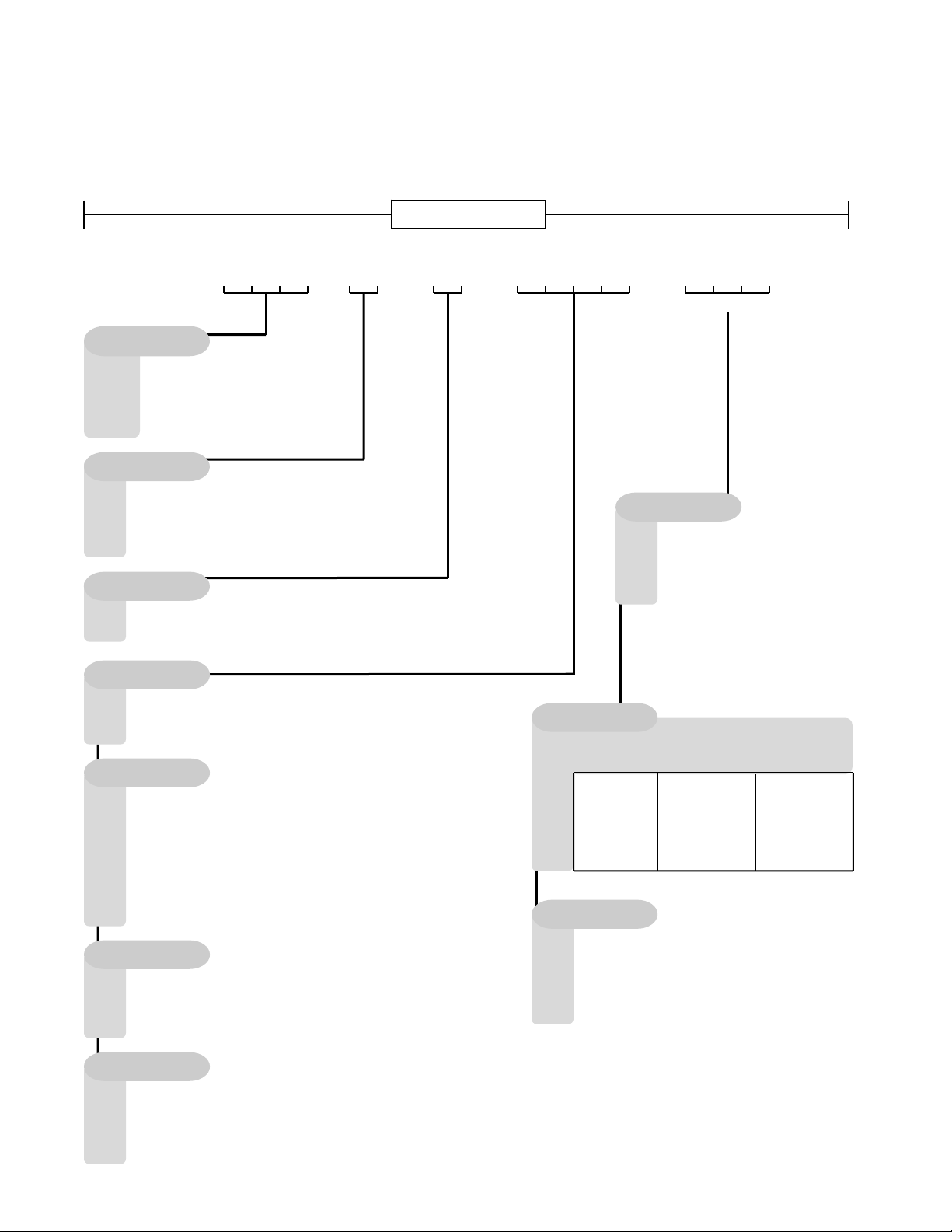

2. Model Number Description

Unit Model Number

002 =

003 =

004 =

005 =

3 =

A =

B =

V =

H =

A1

0 =

A =

B =

A2

0 =

2 =

3 =

A =

Q =

U =

W =

Y =

Z =

A3

0 =

1 =

8 =

9 =

A4

Nom. Tons Model

HB

Nominal Tons

2 Tons

3 Tons

4 Tons

5 Tons

Voltage

460V/3∅/60HZ

208-230V/1∅/60HZ

208-230V/3∅/60HZ

- -

Discharge

Vertical

Horizontal

Style

No Refrigerant

R-410A

R-410A w/ 2 Step Compressor

Configuration

No Cooling

Non-comp. w/ Std. DX Coil

Non-comp. w/ Std. DX Coil w/ RA Bypass

Air Cooled Cond. w/ Std. DX Coil

Air Cooled Cond. w/ Std. DX Coil w/ RA Bypass

Chilled Water 4 Row Coil

Chilled Water 4 Row Coil w/ RA Bypass

Chilled Water 3 Row Coil w/ 1 Row Preheat

Chilled Water 3 Row Coil w/ RA Bypass & 1 Row Preheat

Coating

No Coating

Phenolic Coated Coils - Evap. & Cond.

Phenolic Coated Condenser Coil Only

Phenolic Coated Evaporator Coil Only

Staging

No Cooling

0 =

Single Stage

1 =

Dual Stage (w/ 2 step compressor)

2 =

Single Serpentine Chilled Water

M =

Half Serpentine Chilled Water

N =

Voltage

Main Features

Discharge

Location

- - -

A1 A2 A3 A4

Cooling

Heating

B1 B2 B3

B1

Type*

0 =

No Heat

1 =

Electric Heat

2 =

Natural Gas Aluminized

E =

Hot Water

F =

Hot Water w/ Phenolic Coating

Note: LP gas and high altitude

conversion kits are available

for field installation.

B2

Designation

Gas Capacity Electric Capacity

Mbtu kW 208V kW 240-480V

0 =

1 =

2 =

3 =

4 =

5 =

No Heat

45

60

75

100

125

-

7.5

15

22.5

-

-

B3

Staging

No Heat

0 =

1 Stage (Gas or Electric)

1 =

2 Stage (Gas or Electric)

2 =

3 Stage (Electric Only)

3 =

Single Serpentine (Hot Water)

M =

Half Serpentine (Hot Water)

N =

6

10

20

30

-

-

Page 7

3. User’s Information

Failure to observe the following instructions may

result in premature failure of your system, and

possible voiding of the warranty.

WARNING

DX (Direct Expansion) Package Units and DX

Units with Remote Condenser

Never cut off the main power supply to the unit, except

for complete shutdown.

Always control the system from the thermostat, or

control panel, and never at the main power supply

(except in an emergency, or complete shutdown of the

system).

During the cooling season, if the airflow is reduced due

to dirty air filters, or other reasons, the cooling coils will

get too cold and result in excessive liquid return to the

compressor. As the liquid concentration accumulates,

oil is washed out of the compressor leaving it starved

for lubrication.

The compressors must be on a minimum of four

minutes, and off for a minimum of five minutes. The

cycle rate must not exceed eight starts per hour.

THE COMPRESSOR LIFE WILL BE SERIOUSLY

SHORTENED BY RESULTING REDUCED

LUBRICATION, AND THE PUMPING OF EXCESS

AMOUNTS OF LIQUID OIL AND REFRIGERANT.

Hydronic Cooling and Heating

Non-compressorized units may contain chilled water

and/or hot water coils. Units are provided with internal

header connections for field piping. Vent and drain

connections can be accessed within the unit.

Piping is to be run via the 4” x 7” piping chase located

in the cabinet floor inside the coil compartment,

accessible through the coil compartment access door

on the front of the unit. Piping to coil header

connections must be supported independently of the

coil to prevent undue stress from weakening

connections over time. Allow adequate flexibility for

thermal expansion of the piping.

Use proper glycol solutions or brines to help prevent

coil freezing. Consult the designer or project engineer

if you have concerns about lower than normal entering

air temperatures (typically air temperatures below

40°F) that could cause coils to freeze.

Figure 7a, Piping Chase Location

Utility Entry

4” x 2 1/2”

Shipping

Bracket

Piping Chase

4” x 7”

Front

Return Supply

Back

Gas or Electric Heating

The system is designed to heat a given amount of air

each minute of operation. If the amount of air heated

is greatly reduced (approximately 1/3 capacity), the

heat exchanger (or heater coil if electric) temperature

will increase above acceptable levels, and will result in

shut down by a high temperature safety switch

incorporated into either the heat exchanger, or the

heater area.

GAS HEAT UNITS – If heat shuts off due to safety

switch, or gas supply shut off failure, then always

close manual gas valve to unit prior to any

electrical service. Prolonged overheating of the

heat exchanger will shorten its life.

Improper installation, adjustment, alteration,

service, or maintenance can cause property

damage, personal injury, or loss of life. Installation

and service must be performed by a qualified

installer, service agency, or if gas fired units, the

gas supplier. Refer to installation instructions

provided with the unit, and this manual.

WARNING

WARNING

7

Page 8

Multiple Unit Operation

When several units are used in conditioning the space,

and any are combination heating-cooling units, all

system thermostat switches must be set at either

heating, cooling, or set at ‘OFF’. Do not run part of a

system switched to an opposite mode. Cooling only

units should be switched to ‘OFF’ at the thermostat

during the heating season.

Wiring Diagrams

A complete set of unit specific wiring diagrams in both

ladder and point-to-point form are laminated in plastic

and affixed to the inside of the service access door.

Condensate Piping

A drain trap must be connected to the drain connection

located on the back of the unit. If codes require a

condensate drain line, it should be the same pipe size

as the drain nipple and should pitch downward for its

entire length toward the drain.

A “P” Trap is factory supplied and shipped in the

control access compartment for field installation. An

air break should be used with long runs of cond ensate

lines.

Normal Thermostat Operation

For Heating

- Set system switch to ‘HEAT’

- Set fan switch to ‘AUTO’ or ‘ON’

- Set the desired temperature

For Cooling

- Set system switch to ‘COOL’

- Set fan switch to ‘AUTO’ or ‘ON’

Air Circulation

Set the system switch to ‘OFF’

-

Set the fan switch to ‘ON’

System Off

-

Set the system switch to ‘OFF’

Set the fan switch to ‘AUTO’

-

-

Do not change temperature setting

With these settings the system is shut down,

-

except for the 24-volt control system power, and

the compressor crankcase heater (approx. 60W).

Night and Vacancy Operation

To reduce the operation time during low load periods,

it is recommended that the temperature setting be

increased by 5°F during non-occupied periods of the

cooling season in commercial buildings, such as nights

and weekends. Decrease the temperature by 10°F at

these times during the heating season.

Gas Heating System

The heating section is for use with natural gas supply

pressure of 6” to 10.5” w.g. The unit may also utilize

propane gas (after installation of a field conversion kit)

with a supply pressure to the valve of 11” to 12” w.g.

The rating plate on the furnace must be inspected to

make sure the unit is stamped for proper gas. A 1/8”

pressure tap should be field supplied by the installer in

the piping just ahead of the gas valve. The pressure

tap on the outlet end of the gas valve can be checked

to verify manifold pressure of 3.2” to 3.5” w.g. for

natural gas or 11” to 12” w.g. for propane.

A centrifugal blower that draws in outside air through a

protected opening supplies combustion air.

This induced draft blower introduces the air to the

blower tubes, which assures even primary and

secondary airflow.

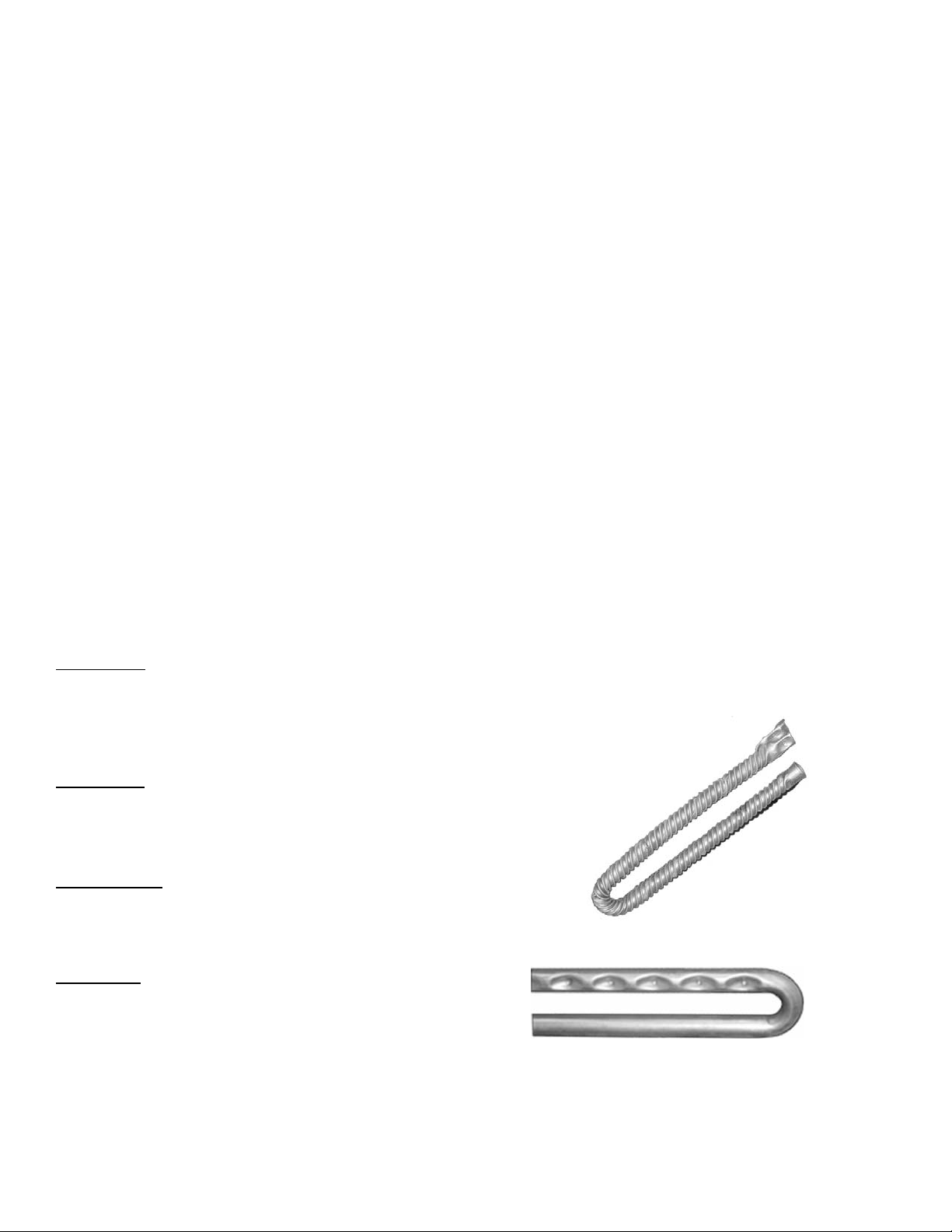

Gas heating units use AAON’s patented high efficiency

twisted tube, or dimpled heat exchanger. All heating

system and related safety controls are 100% tested on

each unit prior to shipment.

Figure 8a, HB Gas Heat Exchangers

Dimpled Tube

Twisted Tube

8

Page 9

Modulating Hot Gas Reheat and Hot Gas

Bypass Systems on DX Units

Some DX cooling units may contain Modulating Hot

Gas Reheat (MHGRH) and/or Hot Gas Bypass

(HGBP) systems as factory installed options. Piping

and valves for these systems will be located on the

inside wall of the condenser section. The condenser

top must be removed for access to these components.

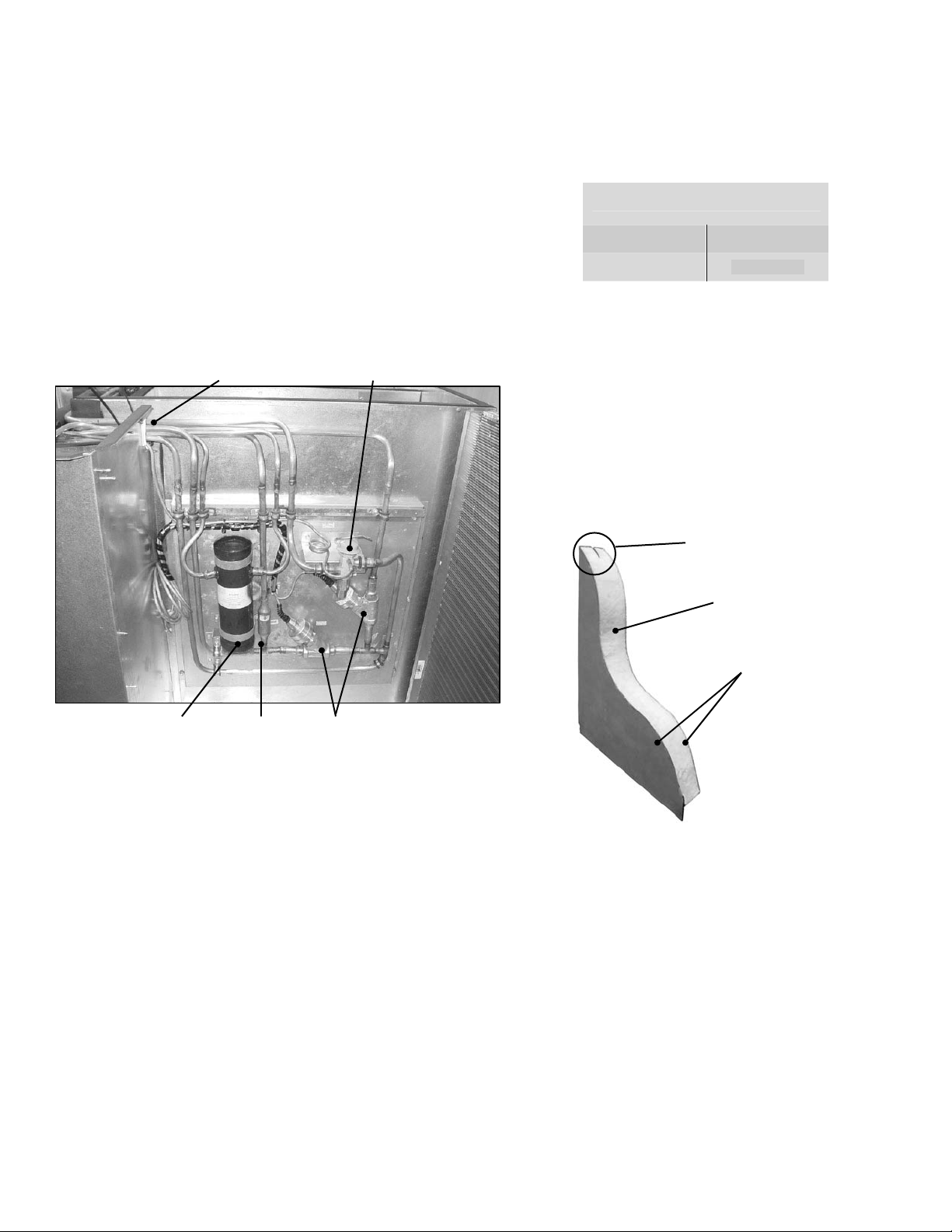

Figure 9a, MHGRH and HGBP System

Piping to

Compressor and

Coil Compartments

HGBP

Valve

Receiver

Tank

Check

Valve

MHGRH

Valves

Filter Sizes

Table 9.1, Pleated Filter Sizes

All 2-5 Ton HB Packaged Units

Qty. Size

2 20” x 25” x 2”

Cabinet Construction

All HB units are insulated with closed-cell polyurethane

foam, which has twice the R-value of fiberglass

insulation. All cabinet walls and roof use double-wall

G90 galvanized steel. The solid core foam interior

provides a rigid, impact resistant surface. All panels

have a thermal break with no metal-to-metal contact

from outside to inside.

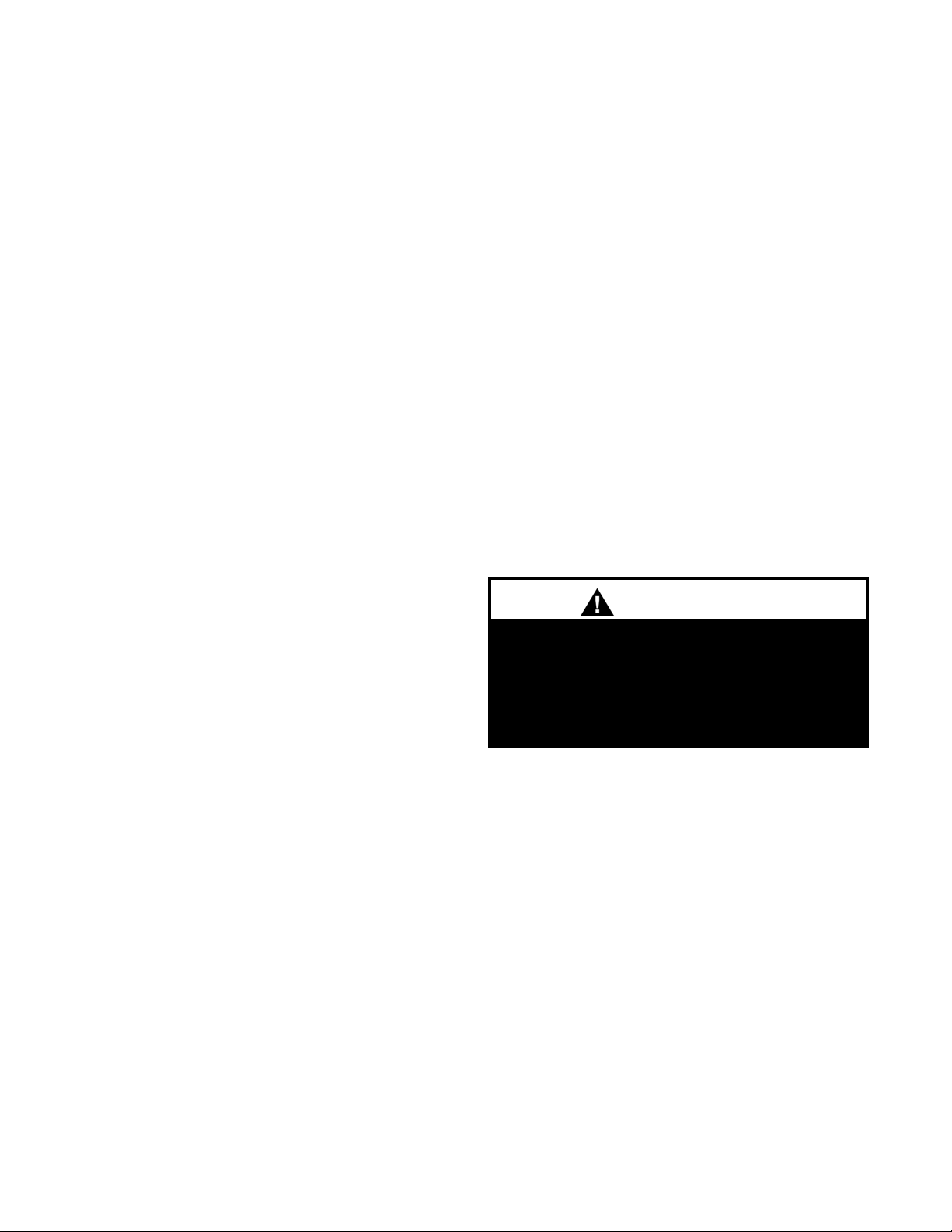

Figure 9b, High Performance Composite Panel

Thermal Break

Foam Core

Double-Wall

9

Page 10

4. Delivery

ALL SHIPMENTS ARE F.O.B. THE FACTORY. IT IS

THE RESPONSIBILITY OF THE RECEIVING PARTY

TO INSPECT THE EQUIPMENT UPON ARRIVAL.

Receipt & Inspection

The unit should be inspected for damage that may

have occurred in transit. Do the following upon

receipt:

1. Inspect all items for internal, external, and

concealed damage before accepting

2. Assure carrier is in compliance with Bill of

Lading instructions

If damage is found:

1. Note all damage on Bill of Lading immediately

− Photograph damage if possible

− Do not move or discard damaged

packaging materials

2. Call carrier immediately to file a freight claim,

and to schedule a freight inspection

3. When damage is repairable, contact the

factory for replacement parts: 918-583-2266

4. With permission of carrier, make the repairs

5. Stay in contact with carrier to ensure payment

of your claim

If repairs must be made to damaged goods, the factory

must be notified before any repair action is taken.

Equipment alteration, repair, or unauthorized

manipulation of damaged equipment without the

manufacturer’s consent will void all product warranties.

Contact the AAON Warranty Department for

assistance with handling damaged goods, repairs, and

freight claims: 918-583-2266.

Verify the equipment against the order documents

upon delivery. If what you received does not match

your order exactly, then notify your Sales

Representative at once.

Storage

This equipment is designed for outdoor use. However,

if installation will not occur immediately following

delivery, then store equipment in a protected area, and

in the proper orientation as marked on the packaging

with all internal packaging in place. Secure all looseshipped items.

5. Installation

General

DX models of this unit use R-410A refrigerant only,

and should not be used with any other refrigerant. HB

package units are for outdoor installation only.

Codes & Ordinances

System should be sized in accordance with National

Warm Air Heating and Air Conditioning Association

Literature, or the Guide of American Society of

Heating, Refrigeration and Air Conditioning Engineers.

The installation must conform with local building

codes, or in the absence of local codes, with (United

States) National Fuel Gas Code “ANSI-Z223.1”,

(Canada) current CAN/CGA-B149.1 or B149.2.

Installation codes for Gas Burning Appliances and

Equipment, current C.S.A. Standard C22.1, Canadian

Electrical Code Part 1, and C.S.A. Standard B52

Mechanical Refrigeration Code, and Local Plumbing or

Waste Water Codes.

It is the responsibility of the installing contractor to

comply with codes, ordinances, local and

municipal building laws, and manufacturer’s

instructions. Personal injury and/or equipment

damage may result if proper procedures are not

followed.

Handling

Be aware of what is contained in the equipment!

Dependent upon the optional accessories that were

ordered, this equipment may contain fragile

components and delicate electronics. Although the

unit is constructed of sturdy materials, avoid impacts

and handling methods that may damage internal

apparatus and structure, or the exterior painted

surfaces of the unit. Take care not to apply destructive

force to coils, or other parts protruding beyond the

extents of the unit casing. Always handle the unit by

its exterior casing.

Keep equipment free from debris, and construction

waste during installation. Foreign materials may

adversely affect unit operation resulting in premature

failures that will not be covered by the manufacturer’s

WARNING

10

Page 11

warranty. Attach all service panels, and cover all

exposed equipment when work is not being performed.

Leave unit protected from other construction until startup is to occur.

Always wear hand and eye protection when

handling, installing, servicing, or maintaining

equipment. Sharp or pointed edges, moving parts,

and flying debris may cause personal injury.

WARNING

Heating & Cooling Systems

GAS HEATING SYSTEM

The units are equipped with a direct spark ignition

system that proves the burner operation with each call

for heat. Power to the ignition control is 24V to reduce

hazards. Burner ignition is by a high intensity spark.

When heat is called for, the cooling system is

inoperable except for the indoor blower motor.

Heating is accomplished by firing gas into the heat

exchanger assembly.

Those sensitive to odors or gases from trace

amounts of residual oils should NOT be present in

the conditioned space during the start-up of a gasfired installation.

IMPORTANT NOTICE - All gas-fired heat exchangers

are completely tested at the factory before shipment.

This will remove nearly all of the oils that have been

used in the manufacturing process, however trace

amounts may remain. When performing the initial

start-up at the jobsite it is highly recommended that

people, or any other living animals, that may be

sensitive to the residual odors or gases, NOT be

present in the conditioned space during start-up. In all

cases, including the initial factory firing and testing, all

of the gases will be under the minimum acceptable

level of concentration for human occupancy.

WARNING

ELECTRIC HEATING SYSTEM

Heating is accomplished by passing electrical current

through a specified amount of resistance heaters that

produce the required heat. The indoor blower motor

energizes at the same time as the heaters.

DX COOLING SECTION

All direct expansion refrigeration systems are factory

assembled, charged with refrigerant, tested, and

operated. These systems include liquid line filter

driers, expansion valves, and fully hermetic scroll

compressors. Compressors are equipped with a

positive pressure forced lubrication system. The aircooled condenser coil is constructed of copper tubes

and mechanically bonded aluminum fins, and air is

pulled through by a propeller fan. The evaporator coil

is draw through type constructed of copper tubes and

mechanically bonded aluminum fins.

These appliances have been found acceptable with

applicable provisions of “ANSI/UL 1995” and current

“C.S.A. Standard C22.2” by E.T.L.

CHILLED WATER or NON-COMPRESSORIZED

COOLING SECTION

Chilled water, or non-compressorized units, have

factory-installed coils. Systems are provided with

internal header connections for field piping.

Coils are constructed of copper tubes and

mechanically bonded aluminum fins.

CAUTION

DO NOT DRILL OR PUNCH HOLES IN THE UNIT

– The walls of this unit are foam insulated. Field

modifications to the unit casing may compromise

the unit’s superior insulating capability, in which

case excessive leakage, or condensation may

occur.

Very high temperatures can damage foam core

insulation. High heat may cause off gassing of

harmful fumes. Do not apply direct flame to unit

cabinet.

WARNING

11

Page 12

Service & Installation Clearances

Before setting the unit into place, caution must be

taken to provide clearance for unit panels/doors that

must be accessible for periodic service. These areas

contain the controls, safety devices, refrigerant, shutoff valves and filter access.

HB package units have minimum service and airflow

clearance requirements.

Service Clearance Minimums:

- 36 inches to the front

- 10 inches to the back

- 20 inches to right and left ends

Airflow Clearance Minimums:

- 20 inches around the entire condenser intake

- 24 inches between condenser and obstructions

- 48 inches of clearance over the condenser air

discharge, and from adjacent condenser intakes

Figure 12a, Service Clearance Minimums

RA

Back

10”

Air In

20”

Air Out

Air In

36”

Service Access Clearance

Front

Air In

Right Left

20”

Airflow to and from the condensing unit must not be

restricted. Obstruction to airflow will result in

decreased performance and efficiency. The

installation position must provide at least 20 inches

of condenser clearance for proper airflow into the

condenser coil. When the unit’s condenser is

positioned adjacent to another condenser, 48

inches of clearance is required between air intakes

for proper airflow and operation.

Figure 12b, Airflow Clearance Minimums

Adjacent

Condenser

10”

48”

Air In

Air In

Air Out

Condenser

Airflow

Minimum 20”

Clearance

Air In Air In

SA

Wall or Obstruction

RA

HB Package Unit

Figure 12c, Other Airflow Clearance Minimums

Required condenser

clearance doubles to 40

inches in recessed areas

.

48”

Air Out

40”

The HB package unit has a vertical air discharge.

There must be at least 48 inches of clearance

above the vertical air discharge. There must not be

any obstruction above the equipment that may

deflect discharge air back into the unit’s air inlets.

It is advisable to never place the unit directly under

an overhang. Condensing units should not be

installed in an enclosure or pit that is deeper than

the height of the unit. When the unit is installed in

a recessed area the coil side clearance is doubled

to 40 inches for inlet air.

12

20”

Page 13

Setting the Unit

Units should always be installed level, and above

water drainage routes. Unit operation can be affected

by wind. It is good practice to position unit condensing

sections away from prevailing winds.

Protective Shipping Brackets

Before setting the unit into its final position on the slab

or curb, be sure to remove the protective shipping

brackets, or “bumpers” from the perimeter of the unit’s

base.

Figure 13a, Removing Shipping Brackets

Ground Setting

Set the unit on a solid slab high enough above the soil

grade to allow water to drain away from the base of

the unit. The unit should be set on a slab that has

been placed over compact, level earth. A poured

concrete (permanent) slab is recommended.

Roof Setting w/ Curb

Mount roof curbs first, and locate so duct connections

will clear any structural members of the building.

When using the factory curb, make openings in roof

decking large enough to allow for duct penetrations

and workspace only. Do not make openings larger

than necessary. Set the curb to coincide with the

openings. CURB MUST BE LEVEL.

PRIOR TO SETTING UNIT ON CURB – To ensure

proper isolation and seal between the unit and the

curb, gasket material MUST BE APPLIED to the

curb on ALL SURFACES meeting with the unit.

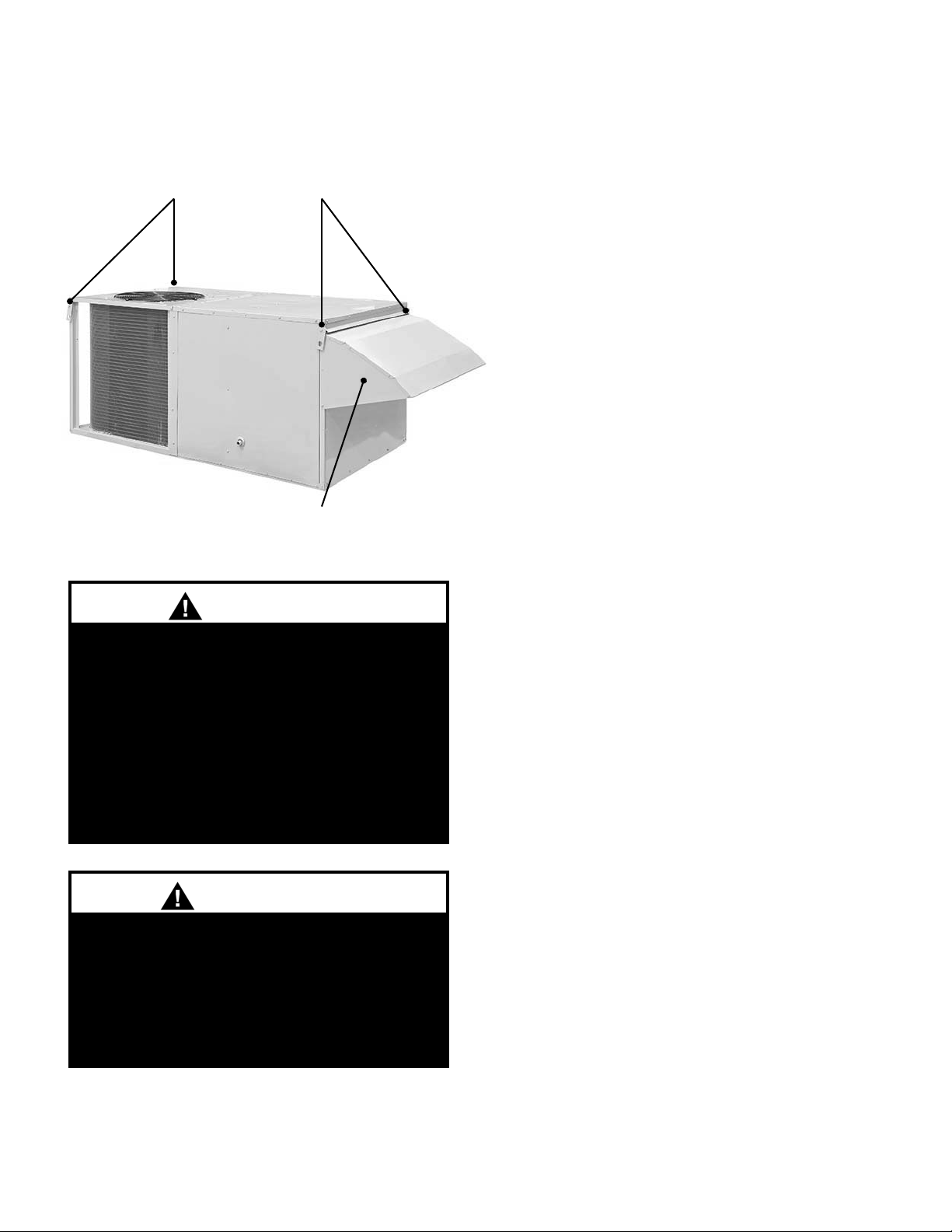

Hoisting

Lifting lugs are provided on each corner of the top of

the unit.

If cables or chains are used to hoist the unit, they must

be the same length, and care should be taken to

prevent damage to the unit.

It is recommended that the unit be hoisted with the

outside air hood (if present) in the shipped position.

However, the unit may be hoisted with the outside air

hood in an open position.

Before lifting unit, be sure that all shipping material is

removed. Secure hooks and cables at all lifting

points/lugs provided on the unit.

Prior to setting the unit onto the roof curb, be sure that

the gasket material has been applied to all curb

surfaces meeting with the unit.

Hoist unit to a point directly above the curb and duct

openings. Carefully lower and align the unit’s utility

and duct openings so the unit perimeter fits around the

curb. Make sure the unit is properly seated on the

curb and is level.

Outside Air Hood (Optional)

Units equipped with outside air intake will have an

outside air hood. The outside air hood must be

opened prior to unit operation.

NOTE

Remove shipping screws from each side of the hood in

the “closed” position. Lift hood to the “open” position,

seal flange, and secure with sheet metal screws.

Outdoor air intake adjustments should be made

according to building ventilation, or local code

requirements.

13

Page 14

Figure 14a, Lifting Lugs and Outside Air Hood

Lifting lug on each corner

Outside Air Hood (Optional)

CAUTION

If the supply or warm air duct passes through a

combustible roof, a clearance of one inch must be

maintained between the outside edges of the duct

and combustible material in accordance with

National Fire Protection Association Standard No.

90A. Provide flashings or enclosure between

structure, and roof. All joints must be sealed with

mastic to ensure a watertight seal.

All roofing work should be performed by qualified

roofing contractors.

WARNING

Install gas fired units so that the flue discharge

vent is located a minimum of 120” from openings

through which combustion products can enter the

building. Never point flue discharge in direction of

air intake for other equipment. Unit location must

assure combustion and ventilation airflows are

never obstructed.

Electrical

Check the unit data plate to make sure it matches the

power supply. Connect power to the unit according to

the wiring diagram provided with the unit. The power

and control wiring may be brought in through the utility

entry. Do not run power and control wires in the same

conduit.

Protect the branch circuit in accordance with code

requirements. The units must be electrically grounded

in accordance with the National Electric Code, ANSI /

NFPA No. 70. In Canada use current C.S.A. Standard

C22.1, Canadian Electric Code Part 1.

Connect power wiring to the terminal block, or optional

disconnect switch. The manufacturer has done all

wiring beyond this point, and cannot be modified

without affecting the unit’s agency and/or safety

certification, and warranty.

Power can be applied to the unit after the control

wiring is connected.

Standard Control Board

This printed circuit board is the central control point for

all the electrical components in the unit. Low voltage

terminals are provided for connection to the wall

mounted thermostat of the customer’s selection, or as

furnished by AAON.

Confirm the optional features that were specified and

purchased with the HB conditioner. This will allow

proper selection of the number of control options listed

below that may need additional wiring.

14

Page 15

Figure 15a, Power and Control Wiring

Standard Control Board

Red, yellow and green LEDs for

fault, mode, and power indicators.

Standard Control Board has low

voltage terminals for R, G, Y1, Y2,

W1, W2, W3 & GND. GND is the

ground, or “C” side of the low

voltage power supply transformer.

Optional Control Board

Optional Control Board has

expanded capability to support

optional unit features.

Connect control wiring to low

voltage terminal block.

Power Terminal Block

Connect power wiring to terminal

block, or the optional disconnect

switch next to compressor.

Compressor and Control Compartment

Utility Entry

Run power supply wiring in conduit

through utility entry to terminal block.

Low voltage control wiring must run

through separate conduit from power

wiring.

15

Page 16

Each HB has a standard Cooling Lock-out feature that

prevents the compressor cooling mode when the

outdoor temperature is below 55°F. Each unit also

has a condenser fan cycle feature that delays the start

of the condenser fan until there is satisfactory

compressor discharge pressure.

Three colored LEDs are furnished on the circuit board

immediately above the low voltage terminals to provide

status information as listed in the Table 14.1.

Every unit is furnished with a high and low pressure

sensor, as well as an outdoor air temperature sensor.

These sensors provide a signal to the control board

that also present a fault condition or Mode indicator at

the LEDs with a blink rate code.

Blink Rate

:

1 second ON and 1 second OFF.

3 seconds OFF before repeating.

Table 16.1, Standard Control Board Blink Codes

Standard Control Board Blink Codes

Fault Condition Blinks

Hi Pres Lockout 2

Lo Pres Lockout 3

Bad Outdoor Air Temp Sensor 5

Clogged Filter 7

When no fault exists, red LED is off.

Lowest number is highest priority.

Red LED

Mode Indicator Blinks

Vent Mode 1

Heating Mode 2

Cooling Mode 3

When unit is off, yellow LED is off.

Yellow LED

Power Status Only – Blinking Indicates Communications

Green LED

Optional Control Board

This Control Board is supplied within the HB Model

when it has been furnished with certain optional

features specified by the customer. Among these are

an Economizer, Return Air Bypass, and Hot Gas

Reheat.

Table 16.2, Optional Control Board Blink Codes

Optional Control Board Blink Codes

Fault Condition Blinks

Hi Safety Lockout 1

Hi Pres Lockout 2

Lo Pres Lockout 3

Bad Supply Air Temp Sensor 4

Bad Outdoor Air Temp Sensor 5

Clogged Filter 7

When no fault exists, red LED is off.

Lowest number is highest priority.

Red LED

Mode Indicator Blinks

Vent Mode 1

Heating Mode 2

Cooling Mode 3

Economizer Cooling 4

Dehumidification Mode 5

Economizer Dehumidification Mode 6

When unit is off, yellow LED is off..

Yellow LED

Power Status Only – Blinking Indicates Communications

Green LED

Thermostat

The low voltage room thermostat should be located on

an inside wall 4 to 5 feet above the floor where it will

not be subjected to drafts, sun exposure or heat from

electrical fixtures or appliances. The control wire size

must be large enough to prevent excess voltage drop

that may cause improper operation of the equipment.

The HB control board has approximately a 1/2 amp

current flow through the thermostat. Follow the

thermostat manufacturer’s instructions to set the heat

anticipator.

Table 16.3, Low Voltage Thermostat Field Wiring Size

Length of Wire Run

T-stat Load Amps 50 Ft. 100 Ft. 150 Ft.

HB - Less than 1.0 18ga. 18ga. 16ga.

Single Stage Heating & Cooling

The R, G, Y & W terminals on a single stage

thermostat should be connected to the similarly

labeled terminals on the Control Board in the HB unit.

16

Page 17

2 Step Compressor Cooling Models

− The HB models with a 2 step cooling compressor

may use a 2 step cooling thermostat with the R, G,

Y1, Y2 & W terminals connected to the similarly

labeled terminals on the Control Board in the HB

unit.

− These HB models can also be connected to a

single step cooling thermostat with the Y terminal

on the thermostat connected to the Y2 terminal on

the Control Board in the HB unit. A built-in time

delay in the Control Board will cycle the 2 stages

of cooling as required.

Multiple Stage Heating

− HB models with 2 or 3 stage heating should have

the W1, W2 and W3 terminals on the thermostat

connected to the similarly labeled terminals on the

Control Board in the HB unit.

− These models can also be connected to a single

step heating thermostat with the W terminal on the

thermostat connected to the W2 terminal on the

Control Board in the HB unit for 2 step heating or

the W3 terminal for 3 step heating. A built-in time

delay in the Control Board will cycle the stages of

heating as required.

Programmable Thermostats

If a programmable thermostat be used, then the C

terminal on the thermostat should be connected to the

C or GND terminal on the Control Board.

Economizer Option

The economizer option is used to provide cooling at

lower outdoor air temperatures and to provide a

quantity of ventilation air to the occupied space. The

economizer option can be selected with either a

sensible outdoor air temperature sensor or an enthalpy

sensor that measures the heat content in the outdoor

air. The economizer controller can be field installed or

factory installed by AAON as selected by the

customer.

Supply Air Temperature Sensor

A supply air temperature sensor is factory wired and

provided within the equipment at the end of a coil of

wire. This sensor must be installed in the downstream

supply air ductwork at a sufficient distance from the

equipment to provide a correctly mixed supply air

temperature back to the unit control board.

Factory Installed

When factory installed the control board will use the

outdoor air sensor and the cooling signal from the

thermostat to provide a first stage of cooling using the

outside air when possible before starting the

compressor and mechanical cooling cycle. The

thermostat wiring to the control board with single or

multi-stages should be wired as listed previously.

Field Installed

When the control is field installed the 2 to 10 VDC

signal for the economizer damper motor must be wired

to the Control Circuit Board in the HB unit. See Figure

18a. Note that the jumper must be moved to the

“external” position and the signal wired to the ECONO

POS and GND terminals on the control board.

Return Air Bypass Option

The Return Air Bypass option is used to provide

additional moisture removal capacity to the HB unit.

For this application a humidistat must also be installed

in the conditioned space to provide a signal to initiate

the dehumidification. The humidistat may be

purchased from AAON or from others.

A return air bypass control system by others may be

field installed as selected by the customer instead of

factory installed by AAON.

Factory Installed

The control board in the HB unit must be wired to the

humidistat in the occupied space at the R and RH

terminals. The thermostat wiring to the control board

with single or multi-stages should be installed as listed

previously.

When the Humidistat is calling for moisture removal

from the occupied space, the compressor will operate

with the return air bypass damper in the open position

and the supply fan running in the low speed mode. If

the Thermostat calls for cooling, the bypass damper

will close and the fan will operate at high speed until

the thermostat is satisfied.

Field Installed

When the control is field installed, the 0 to 10 VDC

signal for the return air bypass damper motor must be

wired to the Control Circuit Board in the HB unit. See

Figure 16a. Note that the jumper must be moved to

the “external” position and the signal wired to the RAB

and GND terminals on the control board.

17

Page 18

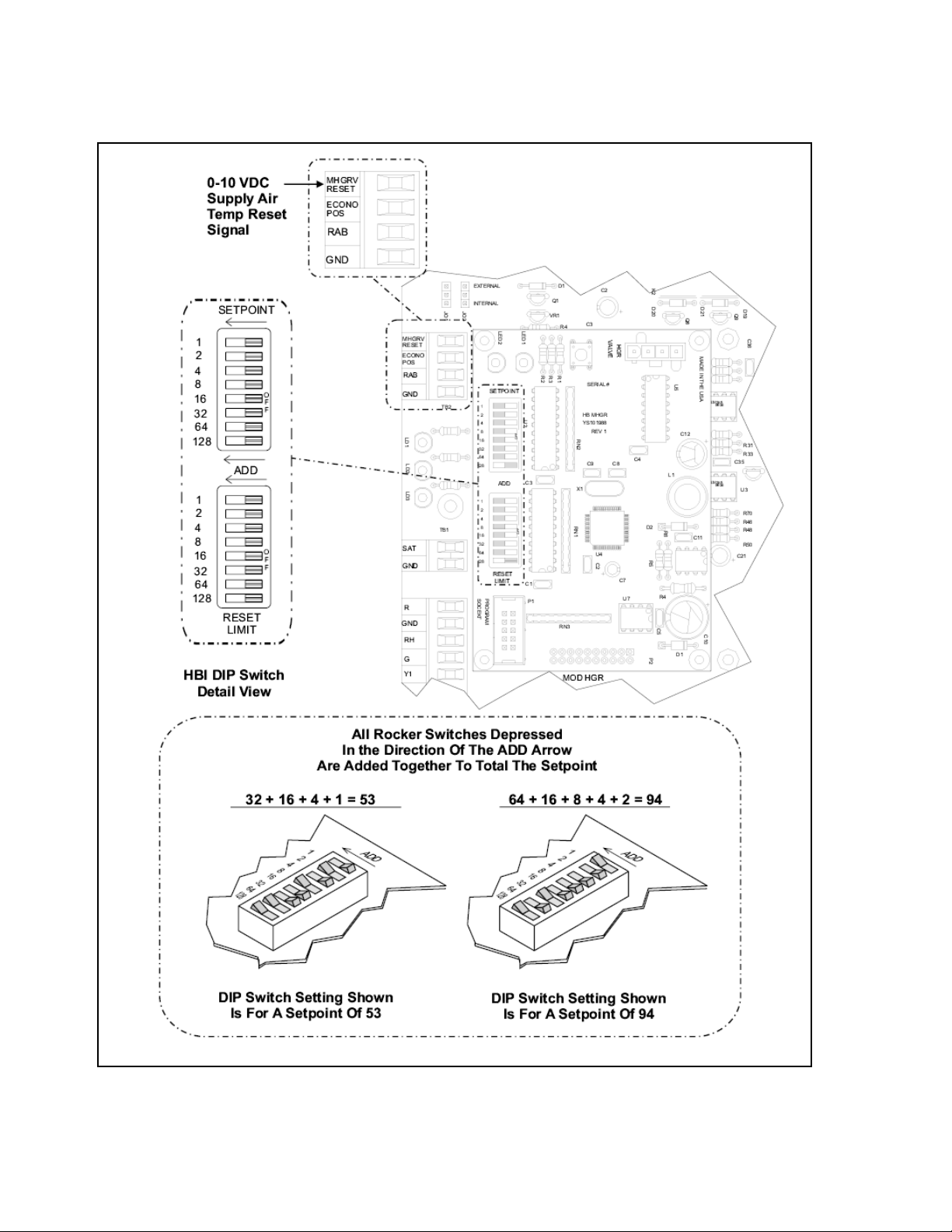

Figure 18a, External Control Inputs to Control Board

18

Page 19

Modulating Hot Gas Reheat

The modulating hot gas reheat option is used to

provide additional moisture removal capacity to the HB

unit. Hot refrigerant gas discharged from the

compressor is sent as needed to a reheat coil

mounted immediately after the cooling coil.

For this application a humidistat must also be installed

in the conditioned space to provide a signal to initiate

the dehumidification by operating the hot gas reheat to

deliver dehumidified air at a specified temperature into

the occupied space. The humidistat may be

purchased from AAON or from others. The thermostat

wiring to the control board with single or multi-stages

should be installed as listed previously.

Supply Air Temperature Sensor

A supply air temperature sensor is factory wired and

provided within the equipment at the end of a coil of

wire. This must be installed in the downstream supply

air ductwork at a sufficient distance from the

equipment to provide a correct mixed air temperature

to the unit control board.

Reheated Supply Air Temperature

The desired discharge air temperature setpoint can be

preset and later adjusted by using the DIP switch

labeled SETPOINT on the circuit board. See Figure

18a for the location and DIP switch setting instructions.

The controller will allow the user to set a Supply Air

Temperature Setpoint between 50°F and 100°F. If a

value of less than 50°F is set, then the controller will

default to a 50°F Supply Air Temperature Setpoint. A

value greater than 100° F will cause the unit to default

to a 100°F Supply Air Temperature Setpoint.

Supply Air Temperature Reset Limit

The controller will also allow a reset of the temperature

by a 0 to 10 VDC signal from an outside source to the

terminal as shown in Figure 18a. The reset range is

determined by the setting configured on the DIP switch

labeled RESET LIMIT. The controller will reset the

supply air temperature setpoint from the value set on

the SETPOINT DIP switch to the value set on the

RESET LIMIT DIP switch, as the Reset Input (MHGRV

RSET) signal is increased from 0 Volts to 10 Volts.

Example:

We want the Discharge Air Temperature Setpoint to

increase from 55°F when the Reset Input signal is at 0

Volts, to 75°F when the Reset Input signal is at 10

Volts.

• Set the SETPOINT DIP Switch to 55°F

• Set the RESET LIMIT DIP Switch to 75°F

The discharge air temperature will now increase from

55°F to 75°F as the Reset Input voltage signal ramps

from 0 Volts to 10 Volts.

Note: It is possible to create a “reverse acting” control

sequence. Using the temperatures from the example

above by setting the SETPOINT DIP Switch to 75°F

and the RESET LIMIT DIP Switch to 55°F the reset

would be reverse acting. In this case the controller will

maintain a 75°F discharge temperature when the

Reset Input signal is at 0 Volts and will reduce it to

55°F when the Reset Input signal is at 10 Volts.

Lockout Modes

Gas Heating

The heating mode will be locked out if the ignition

system safety monitors trip 3 times during a call for

heating.

Electric Heating

The heating mode will be locked out if the high

temperature limit switch trips 3 times during a call for

heating.

Cooling

The cooling mode will be locked out if the low pressure

switch safety switch trips 3 times during a call f or

cooling or dehumidification.

Cooling operation will be locked out if the Outside Air

Sensor is missing or defective.

The economizer and reheat operation during

dehumidification will be locked out if the Supply Air

Sensor is missing or defective.

To reset the lockout condition, either remove the call

for heating, cooling, dehumidification, or cycle the

power to the HB unit.

19

Page 20

Figure 20a, Reheated Supply Air Temperature

20

Page 21

Gas Piping

Size gas piping to supply the unit with 6” to 10.5” water

column (w.g.) pressure for natural gas, or 11” w.g. for

propane (when a natural gas to propane conversion kit

has been field installed) when all gas consuming

devices in the building connected to the same gas

system are operating. Install piping in accordance with

local codes, the piping must conform with the latest

ANSI-Z223.1 National Fuel Gas Code; in Canada,

Current Standard CAN/CGA-B149, Installation for Gas

Burning Appliances and Equipment.

Gas piping MUST BE supported DIRECTLY AT

CONNECTION TO UNIT, and must not be strained or

bent, and must be supported by metal straps, blocks,

or hooks at intervals not to exceed that shown in Table

21.2.

Pipe joint compounds used on all gas piping

connections must be resistant to the action of

petroleum gases. A 1/8” NPT plugged tap is required

immediately ahead of the unit gas control valve.

All piping connections should be checked for gas leaks

before operating the unit. The furnace must be

isolated by closing the manual shut off valve, or

disconnected from the gas supply during pressure

testing of the piping system with pressures in excess

of 1/2 PSIG.

Gas Pressure Regulator & Over-Pressure

Protection Device (Optional)

On applications where gas service to the unit is

greater than 10.5” w.g., and less than 2 PSI, a gas

pressure regulator must be installed.

In compliance with the ANSI Z21.80 Line Regulator

Standard, installations with gas supply pressures in

excess of 2 PSI, and less than 5 PSI require a tested

and approved over-pressure protection device (OPD)

for use with the regulator as a means to limit the

downstream pressure to 2 PSI maximum in the event

of regulator failure.

For proper heating operation, pressure to the regulator

MUST NOT BE greater than 5 PSI.

Table 21.1, Minimum Gas Piping Sizes

Unit Size (Tons) Input (MBH) Pipe Size (In.)

Note: Some utility companies will require pipe sizes larger than the

minimum listed above. Local codes may require the use of a

manual main gas shut-off valve and union (field furnished),

installed in the gas line external to the unit.

2 – 5 45 – 120 3/4

Table 21.2, Gas Piping Support Intervals

Pipe Size (In.) Intervals (Ft.)

3/4 or 1 (horizontal or vertical) 8

1 1/4 or larger (horizontal) 10

1 1/4 or larger (vertical) Every floor level

WARNING

DO NOT USE OPEN FLAME OR OTHER

SOURCE OF IGNITION FOR LEAK TESTING.

When pressure testing the gas supply piping, the

furnace must be isolated, or disconnected by

closing the individual manual shut-off valve from

the gas supply. Gas valves can be damaged if

subjected to more than 0.5 PSIG pressure.

CAUTION

Some soaps commonly used for leak detection are

corrosive to certain metals. If you leak test with

soap, then thoroughly rinse soap from piping after

leak checks are completed.

WARNING

Those sensitive to odors or gases from trace

amounts of residual oils should NOT be present in

the conditioned space during the start-up of a gas

fired installation.

21

Page 22

Figure 22a, Gas Piping

Gas valve installed at factory.

Run piping through utility entry in front of unit,

or through entry in floor of unit located next to

the compressor. Then run piping through

sidewall into heating cabinet.

Remember to seal around all exterior cabinet

penetrations at utility entries.

Gas Valve

Sidewall

Entry

Bottom or Side Utility

Entry Options

Piping to gas valve inlet must

be completed in field.

Piping assembly ready to connect to field

supplied gas line.

22

Valve Inlet

Page 23

Condensate Piping

HB package units are equipped with a condensate

drain connection, and ‘P’ traps are furnished with the

equipment. The drain connection must be used and

individually trapped to ensure a minimum amount of

condensate accumulation in the drain pans.

Although drainage of condensate directly onto the roof

may be acceptable in certain areas, is not

recommended as it can damage some types of

roofing, and roofing materials. Refer to local codes for

legalities concerning condensate drainage.

Condensate can be piped to a gutter system, or away

from the building into other drainage. Ideally,

condensate will be piped into the building drainage

system, in which case the drainpipe may need to

penetrate the roof external to the unit itself.

The drain line should be pitched away from the unit

with at least 1/8” of slope per foot. On longer runs, an

air break should be used to ensure proper drainage.

Drain pans in air conditioning equipment have

moisture present and require periodic cleaning to

remove build up of algae, and/or bacteria. Cleaning

the drain pans reduces the probability of plugged drain

lines and overflow of the pan itself. All cleaning of the

drain pans and inside of the equipment should be

done by qualified personnel.

6. Start-Up

General

ONLY QUALIFIED, AUTHORIZED PERSONNEL

SHOULD POWER ON, OR START-UP THIS

EQUIPMENT.

The use of common sense, and good practice in the

installation, and start-up of equipment will prevent

many potential problems with the system in the future.

Before starting up the equipment, building construction

should be complete, and start-up personnel should:

− Have a working knowledge of general HVAC

and mechanical commissioning procedures

and practices;

− Be familiar with unit functions, features,

optional unit accessories, and all control

sequences;

− Have appropriate literature on hand for

consultation.

Procedures

Equipment operation during construction is not

recommended. Construction site pollution can

affect unit operation, and seriously degrade

performance. Operation during construction will

void all manufacturer’s warranties.

Before the structure is occupied, the installation,

and/or start-up personnel must take three essential

steps:

1. Pre-Startup Check Out

2. Start-Up

3. Commissioning

Pre-Startup Check Out

All equipment should be thoroughly checked for loose

wiring, free spinning condenser fan and blower wheel,

and well fitting access panels. Unit should not be

operated without proper ductwork, and access panels

installed, except as required during start-up and air

balancing.

Install gauges, voltmeter, and ammeter before startup. Observe refrigerant pressures during initial

operation. Note, and determine the cause of any

CAUTION

23

Page 24

excessive sound, or vibration. Follow procedures

outlined below to start each piece of equipment.

Before powering on, or starting the unit:

1. Check the unit for external damage.

2. Note all accessories installed.

3. Ensure all field and factory high and low

voltage electrical connections are correct, and

tight.

4. Check all terminal blocks, fuses, fuse blocks,

and contactors for correctness

5. Open all access panels, and remove all

shipping screws, or restraints.

6. Remove any debris that may have been left.

7. Ensure electrical supply matches the unit

nameplate.

8. Ensure condensate lines are connected and

glued.

9. Install air filters of the proper size and type.

10. Check local codes for any special provisions.

11. Replace, and/or close all access panels.

12. Ensure that return, and/or supply dampers in

ductwork are open.

13. Check all equipment, ductwork, and piping to

verify that all work is complete, and equipment

is properly installed and mounted.

Start-Up

Failure to adhere to the following start-up

procedures will void all manufacturer’s warranties.

Completed factory test sheets are in the equipment

literature packet shipped inside the unit. Factory

run-test readings recorded on the test sheets may

be helpful to reference during start-up.

NOTE

NOTE

IMPORTANT FOR 3 PHASE UNITS ONLY!

CHECK COMPRESSOR FOR PROPER

ROTATION BY STARTING UNIT ONLY AFTER

CONNECTING PRESSURE GAUGES TO

SUCTION AND DISCHARGE LINES. SCROLL

COMPRESSORS WILL BE DESTROYED IF

OPERATED IN THE WRONG DIRECTION.

CAUTION

DX Cooling:

1. Ensure that drain P-trap is installed.

2. Turn the unit power on.

3. Turn the unit blower on, and check for correct

4. If correct, take blower amp readings, and

5. Check and record ambient temperature.

6. Start the first stage cooling circuit, and blower

7. After all stages of cooling have been on for at

8. Check the temperature difference across the

9. If equipped with an economizer, after testing

10. Call for the economizer circuit to operate.

11. Check for economizer blades to open fully with

rotation.

compare to see if the amp draw is within the

safety factor area of the motor.

circuit.

least five minutes, record the return air

temperature, and supply air temperature.

evaporator coil.

of cooling circuits is complete, turn cooling

circuits off, and leave blower running.

no binding.

Gas Heating:

1. Ensure that gas lines have been purged of air

– wait 5 minutes after purging to allow gas to

clear before continuing with startup.

2. Turn the unit power on.

3. Turn the unit blower on, and check for correct

rotation.

4. If correct, take blower amp readings, and

compare to see if the amp draw is within the

safety factor area of the motor. Once correct,

turn blower off.

5. Check gas input and manifold pressure, and

adjust if necessary.

6. Turn on the first stage of heating.

7. Check to see that induced draft motor starts.

8. Check to see that main burner lights within 5

seconds of the heating call.

9. Ensure blower started after burner ignition.

10. Observe burner flames for light blue color, and

even flames across burner (propane flames

will have yellow tips).

11. Check temperature rise across heating section

while all stages are on.

12. If temperature rise is within range, turn all

heating calls off.

13. Check that blower stops after heat turns off

24

Page 25

Electric Heating:

1. Turn the unit power on.

2. Turn the unit blower on, and check for correct

rotation.

3. If correct, take blower amp readings, and

compare to see if the amp draw is within the

safety factor area of the motor. Once correct,

turn blower off.

4. Turn on the first stage of heating.

5. Check amp draw of each element of each

stage.

6. Ensure blower started with heat.

7. Check temperature rise across heating section

while all stages are on.

8. If temperature rise is within range, turn all

heating calls off.

9. Check to see that blower stops.

Optional Equipment

Operation of each of the following, if equipped in the

unit, must be checked according to that item’s

manufacturer’s specifications:

− Clogged filter switch

− Supply air smoke detector

− Return air smoke detector

− Modulating Hot gas reheat

− Hot gas bypass

Commissioning

The commissioning of an HVAC system is the process

of achieving, verifying, and documenting the

performance of that system to meet the operational

needs of the building. This may not be a formal

process in smaller structures, such as a normal

residence, but some form of owner acceptance will

occur. Adjustments made during the commissioning

phase may include air balancing, or configuration of

controls, and operational sequences.

Air Balancing

High performance systems commonly have complex

air distribution and fan systems. Unqualified personnel

should not attempt to adjust fan operation, or air

circulation, as all systems have unique operating

characteristics. Professional air balance specialists

should be employed to establish actual operating

conditions, and to configure the air delivery system for

optimal performance.

Water Balancing

A hydronic specialist with a complete working

knowledge of water systems, controls, and operation

must be employed to properly balance the entire

system. Unqualified personnel should not attempt to

manipulate temperatures, pressures, or flow rates, as

all systems have unique operating characteristics, and

improper balancing can result in undesirable noises

and operation.

Controls

A variety of controls and electrical accessories may be

provided with the equipment. Identify the controls on

each unit by consulting appropriate submittal, or order

documents, and operate according to the control

manufacturer’s instructions. If you cannot locate

installation, operation, or maintenance information for

the specific controls, then contact your sales

representative, or the control manufacturer for

assistance.

Do not alter factory wiring. Deviation from the

supplied wiring diagram will void all warranties,

and may result in equipment damage or personal

injury. Contact the factory with wiring

discrepancies.

WARNING

25

Page 26

7. Operation & Maintenance

General

Immediately following building occupancy, the air

conditioning system requires a maintenance schedule

to assure continued successful operation. A

maintenance program similar to the example given

below should be scheduled for routine maintenance of

this equipment in order to provide continued efficient

and reliable operation for the owner.

Maintenance Schedule

One week after start-up:

− Check heating and cooling functions.

− Check cycling of compressor and fan. Correct

unusual cycling.

Monthly:

− Inspect evaporator, and condenser coils. Clean if

dirty, or obstructed in any way.

− Inspect air filters. Replace if required.

Annually:

− Clean the condenser, and evaporator coils with

steam, or a non-corrosive coil cleaner.

− Check refrigerant pressures and temperatures

every spring, and correct unusual operation.

Cooling

Coils should be inspected and cleaned at least once

per year to ensure there is no obstruction to airflow.

Evaporator Coil

Dirty evaporator coils will eventually freeze up, and

often result in a time consuming, and expensive

service call. Clean filters will help to prevent dirt from

accumulating on the evaporator; however the

evaporator should be cleaned annually with a soft

bristled brush, and/or a non-corrosive coil cleaning

solution.

Condenser Coil

One of the most overlooked maintenance

requirements is the need to keep air moving freely

across air-cooled condensing coils. Dirty condensers,

like evaporators, can significantly increase cooling

costs during the year. As a minimum, clean the

condenser coil at the beginning of each cooling

season. It is preferable to use a medium pressure

water spray from the inside of the condenser cabinet

with a non-corrosive coil cleaning solution. TURN

OFF all power to the unit before cleaning.

Comb out any visible exterior fin damage to help

maintain unit efficiency.

Condenser Fan

Always check condenser fan blades to ensure

unobstructed, free rotation after manipulating the unit

cabinet in any way, and before turning power back on

to the condenser. Clean the fan blades if they are

dirty.

Blower Assembly

HB package units use direct drive, backward inclined

airfoil blower wheels that are non-overloading, very

efficient, and very easy to clean. There are no fan

belts or fan bearings to maintain.

Clean blower wheels are necessary to reduce

electrical use, maintain capacity and reduce stress on

the unit. The blower wheel and blower section need to

be inspected periodically, and cleaned of dust, or

debris.

To inspect and clean the blower; set thermostat to the

“OFF” position; turn the electrical power to the unit to

the “OFF” position at the disconnect switch.

Figure 26a, Blower Section

26

Page 27

Heating Sequence

On a call for heating, the supply fan will go to high

speed, and the first stage of heating will be energized.

The unit will go through a 5 second pre-purge of air in

the heat exchanger, then it will come on, or ignite if

gas heat. If the unit has a second heating stage, then

stage two will come on with a call for W2 after the

stage up delay. If W2 is called for before W1, then

heat stage one will come on first, then heat stage two

will follow after the stage up delay.

High Temperature Cut-off

If the supply air temperature (SAT) rises above the

150°F limit, then the heating will stage off, but the

supply fan will continue to operate on low speed until

the SAT falls below 80°F, at which point the heat will

come back on. If the SAT rises above the limit a

second time (consecutively) during a heating call, then

the heat will lock out. To restore normal operation,

remove the call for heating, or cycle the power.

Low Temperature Cut-off

If the supply air temperature (SAT) falls below the

40°F limit, then the outside air damper will close. If the

SAT remains below the low limit for 15 minutes, then

the heating, and supply fan will be locked out. To

restore normal operation, remove the call for heating,

or cycle the power.

Safety Lock Out

The standard heating safety devices used as part of

the Heat Safety Monitor are MLS, ALS, ROS, and

DPS. If any of these devices trip 3 times during a

heating call, then the heating will be locked out. To

restore normal operation, remove the call for heating,

or cycle the power.

Chilled Water

Check remote chiller operations as per the

manufacturer’s instructions. Check coolant flow valves

for correct operation and settings.

Filters

Open the filter access door. Slide filters towards you

to inspect. Replace old filters with the size indicated

on each filter. Be sure arrow points toward the blower.

Filters should be checked every 30 days and replaced

or cleaned as necessary.

IT IS IMPORTANT TO KEEP FILTERS, COILS, AND

BLOWERS CLEAN!

Table 27.1, Filter Sizes

Unit Size (Tons) Size Depth

2 – 5 20” x 25” 2”

Figure 27a, Filter Section

Cleaning

Inspect and clean unit interior at the beginning of each

heating and cooling season and as operating

conditions require

.

Service

In the event the unit is not functioning correctly and a

service company is required, only a company with

service technicians qualified and experienced in both

heating and air conditioning should be permitted to

service the systems in order to keep warranties in

effect. The service tech may call the factory if

assistance is required.

BEFORE CALLING, THE MODEL AND SERIAL

NUMBER OF THE UNIT WILL BE NEEDED FOR THE

WARRANTY SERVICE DEPARTMENT TO HELP

ANSWER QUESTIONS REGARDING THE UNIT.

AAON Warranty Department: 918-583-2266

27

Page 28

8. Hot Gas Bypass

The purpose of external hot gas bypass (HGBP) is to

prevent coil freeze-up and compressor damage from

liquid slugging during periods of low airflow operation,

or with low entering air temperatures.

HGBP is useful when the air conditioning system is

subject to variations in load caused by varying air

volume or large proportions of outside air. The HGBP

valve meters discharge refrigerant gas to the

distributor downstream of the expansion valve, and at

the entrance to the evaporator distributor tubes. The

quantity of gas varies to control a constant suction

pressure, allowing more gas to flow as suction

pressure decreases.

HGBP is available as a factory installed option on HB

package units, in order to meet various design

conditions.

9. Hot Gas Reheat (Modulating)

Although the evaporator reduces moisture content

from warm, moist air being conditioned, the space

thermostat is a dry bulb device and will not call for

refrigeration if outdoor and space temperatures are

mild but very humid and the space temperature is

satisfied. However, the humidity level may cause the

space to be uncomfortable. A reheat system is used

to correct this condition. To prompt operation of the air

conditioning system, a humidistat is required and to

avoid cooling the space excessively while removing

moisture, a coil which accepts discharge gas from the

compressor is located downstream of the evaporator.

The function of this coil is to heat the air that has been

cooled by the evaporator to approximate room

temperature. A reheat valve is installed in the

compressor discharge line to divert discharge gas to

the reheat coil when the humidistat calls for

dehumidification but returns all discharge gas to the

condenser when cooling is required.

After the room temperature thermostat is satisfied and

the humidistat continues to call for moisture removal,

the modulating valve will allow a controlled amount of

hot gas to enter the reheat coil. A discharge air

temperature sensor mounted within the unit provides

input to an electronic control board. The valve position

is controlled to provide a specific supply air

temperature set point that is set on the control board,

or sent to the control board by a remote 0 to 10 VDC

signal.

The modulating hot gas valve is factory mounted and

wired. The control board is shipped with a default

setting for a neutral discharge air temperature of 75°F.

The factory setting can be overridden by connection to

a 0 to 10 VDC signal from another control system.

Figure 28a, AAON’s Modulating Reheat System

Evaporator

Coil

Suction Line

Liquid Line

Reheat Coil

Control

Board

Wiring to

Reheat Control

Valve

Supply Air

Condenser

Coil

Compressor

Reheat

Control

Valves

28

Sensor

Page 29

29

Page 30

30

Page 31

Pressure – Temperature Chart

R-410A

PSIG

(° F)

20 78.3 50 142.2 80 234.9 110 364.1 140 540.1

21 80.0 51 144.8 81 238.6 111 369.1 141 547.0

22 81.8 52 147.4 82 242.3 112 374.2 142 553.9

23 83.6 53 150.1 83 246.0 113 379.4 143 560.9

24 85.4 54 152.8 84 249.8 114 384.6 144 567.9

25 87.2 55 155.5 85 253.7 115 389.9 145 575.1

26 89.1 56 158.2 86 257.5 116 395.2 146 582.3

27 91.0 57 161.0 87 261.4 117 400.5 147 589.6

28 92.9 58 163.8 88 265.4 118 405.9 148 596.9

29 94.9 59 166.7 89 269.4 119 411.4 149 604.4

30 96.8 60 169.6 90 273.5 120 416.9 150 611.9

(° F)

PSIG

(° F)

PSIG

(° F)

PSIG

(° F)

PSIG

31 98.8 61 172.5 91 277.6 121 422.5

32 100.9 62 175.4 92 281.7 122 428.2

33 102.9 63 178.4 93 285.9 123 433.9

34 105.0 64 181.5 94 290.1 124 439.6

35 107.1 65 184.5 95 294.4 125 445.4

36 109.2 66 187.6 96 298.7 126 451.3

37 111.4 67 190.7 97 303.0 127 457.3

38 113.6 68 193.9 98 307.5 128 463.2

39 115.8 69 197.1 99 311.9 129 469.3

40 118.1 70 200.4 100 316.4 130 475.4

41 120.3 71 203.6 101 321.0 131 481.6

42 122.7 72 207.0 102 325.6 132 487.8

43 125.0 73 210.3 103 330.2 133 494.1

44 127.4 74 213.7 104 334.9 134 500.5

45 129.8 75 217.1 105 339.6 135 506.9

46 132.2 76 220.6 106 344.4 136 513.4

47 134.7 77 224.1 107 349.3 137 520.0

48 137.2 78 227.7 108 354.2 138 526.6

49 139.7 79 231.3 109 359.1 139 533.3

31

Page 32

)

AAON, Inc.

2425 S. Yukon

Tulsa, Oklahoma 74107

Tel 918-583-2266

Fax 918-583-6094

Download this manual,

and others from:

www.aaon.com

It is the intent of AAON to provide accurate and current specification information. However,

in the interest of product improvement, AAON, Inc. reserves the right to change pricing,

specifications, and/or design of its products without notice, obligation, or liability.

AAON is a registered trademark of AAON, Inc.

Effective June 2006

Supercedes December 2005

32

R33010 (06-06

Loading...

Loading...