Page 1

AAON

®

HA SERIES

HORIZONTAL DISCHARGE

COOLING UNITS

USERS

INFORMATION

MANUAL

MANUFACTURED IN THE U.S.A

1

Page 2

2

Page 3

AAON

TABLE OF CONTENTS

SECTION PAGE NUMBER

OWNER'S INFORMATION …………………………………………………………………………… 04

Unpacking

Setting the Unit

Electrical

Cooling

Low Ambient Operation …………………………………………………………………………05

Multiple Unit Operation

Condensate Piping

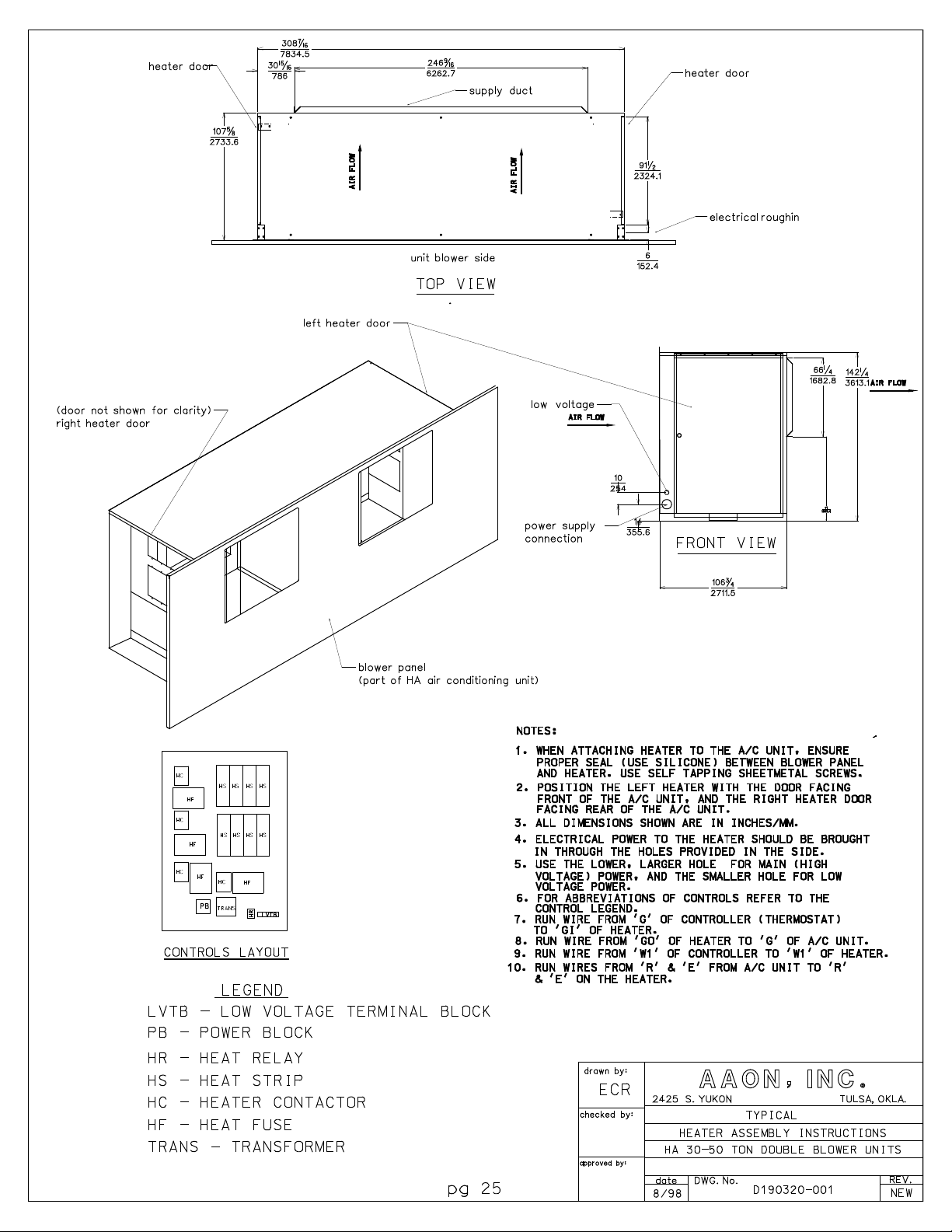

Electric Heat Option

Blower Information

Filter Installation / Replacement

SEQUENCE OF OPERATIONS ……………………………………………………………………… 06

Normal Operation

General Information

SERVICE, INSPECTIONS & MAINTENANCE …………………………………………………… 07

Cooling

Heating

Service

Replacement Parts

Cleaning

®

TROUBLE SHOOTING ………………………………………………………………………………… 08

COMPRESSOR CHECKOUT PROCEDURE ……………………………………………………… 09

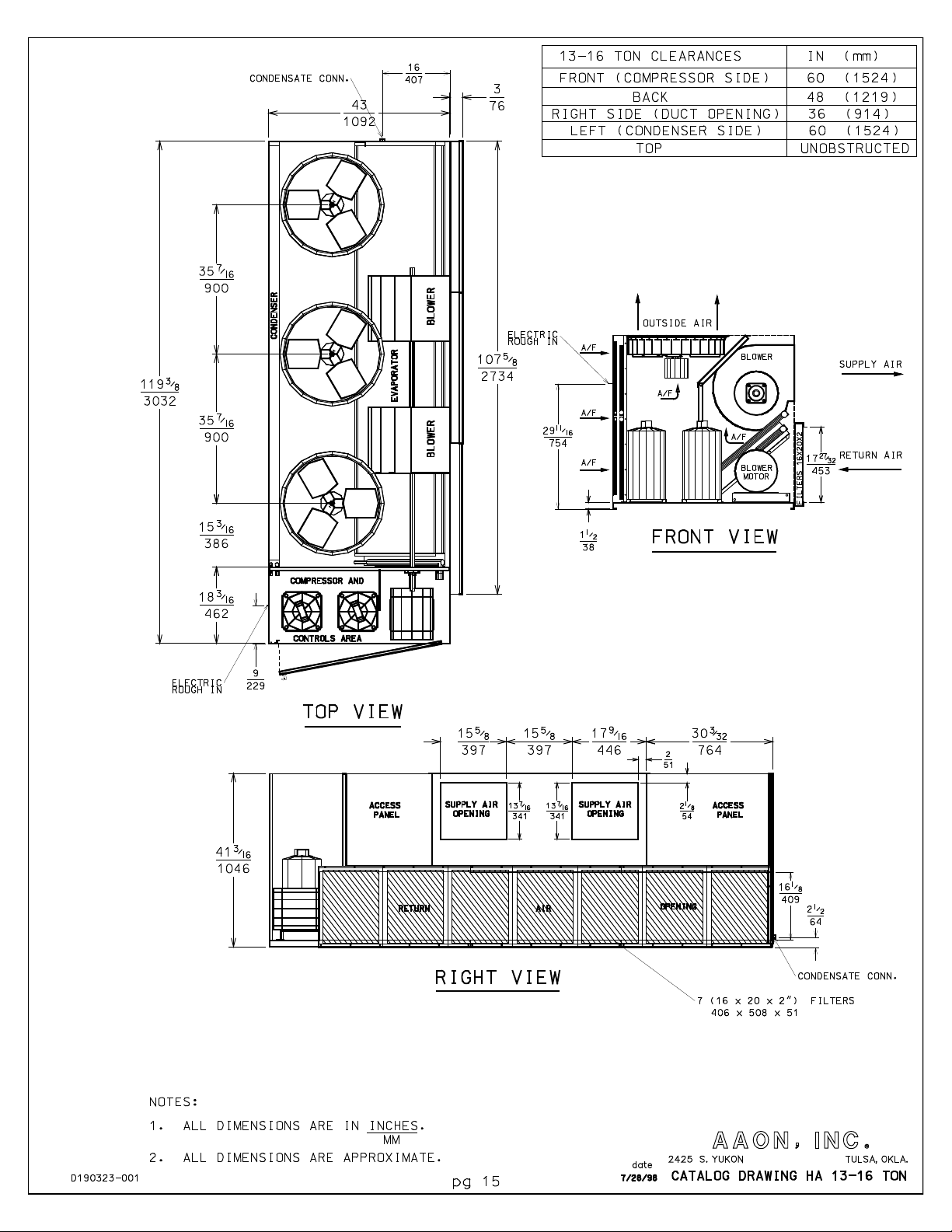

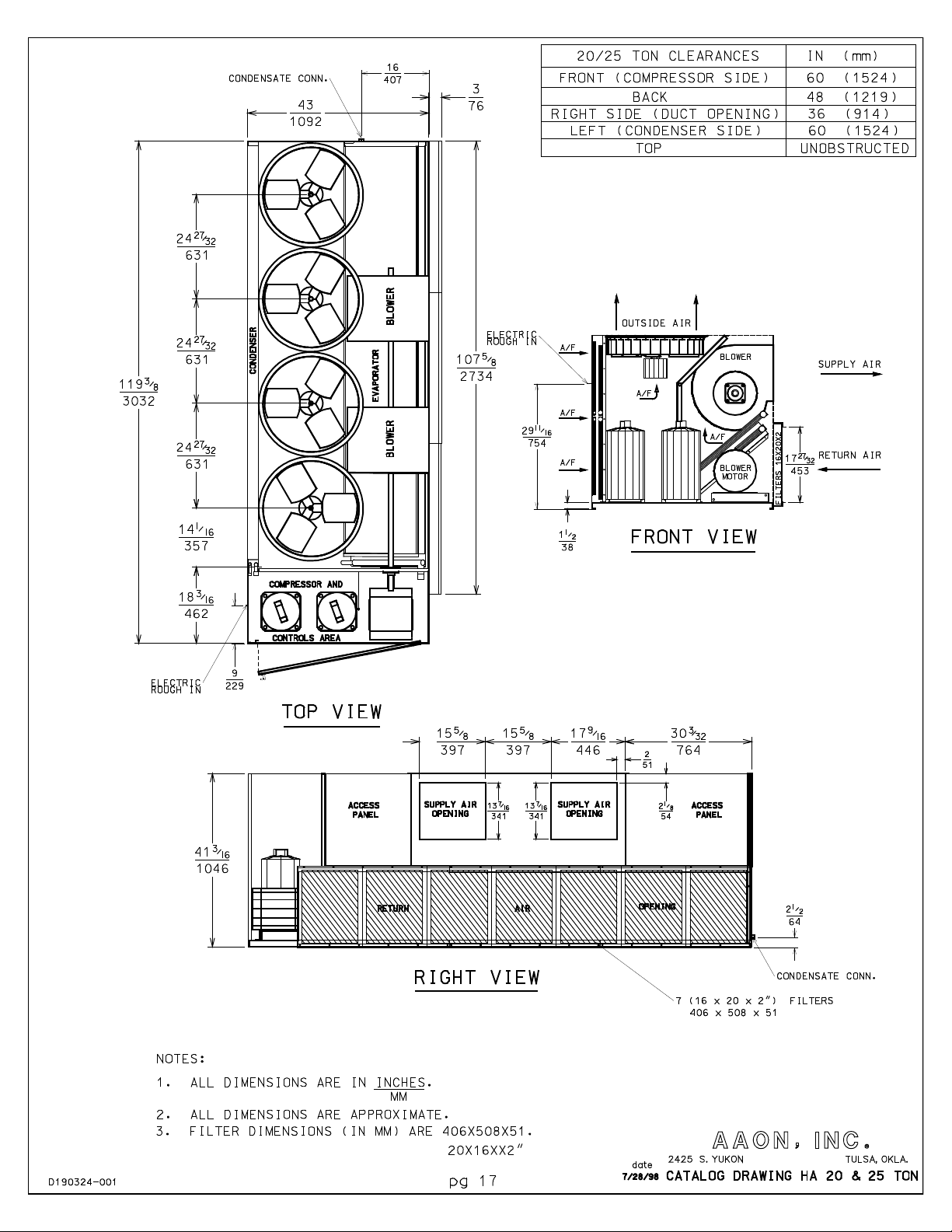

DIMENSIONAL DATA ………………………………………………………………………………… 11

!

▲

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury or loss of life.

Installation and service must be performed by

a qualified installer or service agency.

Owner should pay particular attention to the words: NOTE, CAUTION AND WARNING.

NOTES are intended to clarify or make the installation easier. CAUTIONS are given to prevent

equipment damage. WARNINGS are given to alert owner that personal injury and/or equipment

WARNING

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC's and HCFC's) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for noncompliance.

damage may result if installation procedure is not handled properly.

! IMPORTANT

▲

It is the intent of

AAON, Inc.

HA USERS • P92200 • 2000

AAON, Inc.

reserves the right to change pricing, specifications and/or design of it's products without notice, obligation or liablity.

to provide accurate and current specification information. However, in the interest of product improvement,

AAON

© 2000

&

AAONAIRE

AAON, Inc.

, all rights reserved throughout the world.

are registered trademarks of

3

AAON, Inc.

, Tulsa, OK.

Page 4

OWNER'S INFORMATION

The HA Series units are designed for fast, easy installation as a self-contained cooling unit for outdoor installation only.

UNPACKING

When received, the unit should be inspected and

checked for damage that might have occurred in transit.

If damage is found, it should be noted on the carrier's

Freight Bill. A request for inspection by the carrier's

agent should be made in writing at once.

Before lifting the unit, be sure that all shipping material

has been removed from the unit.

Once shipping material has been removed, check inside

the unit control compartment for the field installed "PTrap" condensate connector. Also check the inlet air

opening for the filter rails and filters that are shipped

loose with the unit for field installation.

SETTING THE UNIT

If cable or chains are used to hoist the unit, care should

be taken to prevent damage to the cabinet.

Secure hooks and cables at all lifting points / lugs

provided on the unit. Hoist the unit to a point directly

above the pad, and lower unit into place. Make sure unit

is properly seated on the pad.

ELECTRICAL

A complete set of unit specific wiring diagrams in both

ladder and point-to-point form are provided with the

unit.

Check the unit data plate to make sure it agrees with the

power supply. The power and control wiring may be

brought to the unit through a hole in the side of the unit.

Protect the branch circuit in accordance with code requirements and connect power to the unit according to

the wiring diagram provided with the unit. If the control

wires are to run inside the same conduit, use 600 volt

wire or as required by applicable code. The unit must be

electrically grounded in accordance with the National

Electric Code.

Power wiring is to the unit terminal block or compressor

contactor. All wiring beyond this point is done by the

manufacturer.

After connecting the control wiring to the unit, power

may now be applied to the unit. Be sure that the

evaporator blower and condenser fan(s) rotate in the

proper direction (this applies only to units having three

phase blower motor).

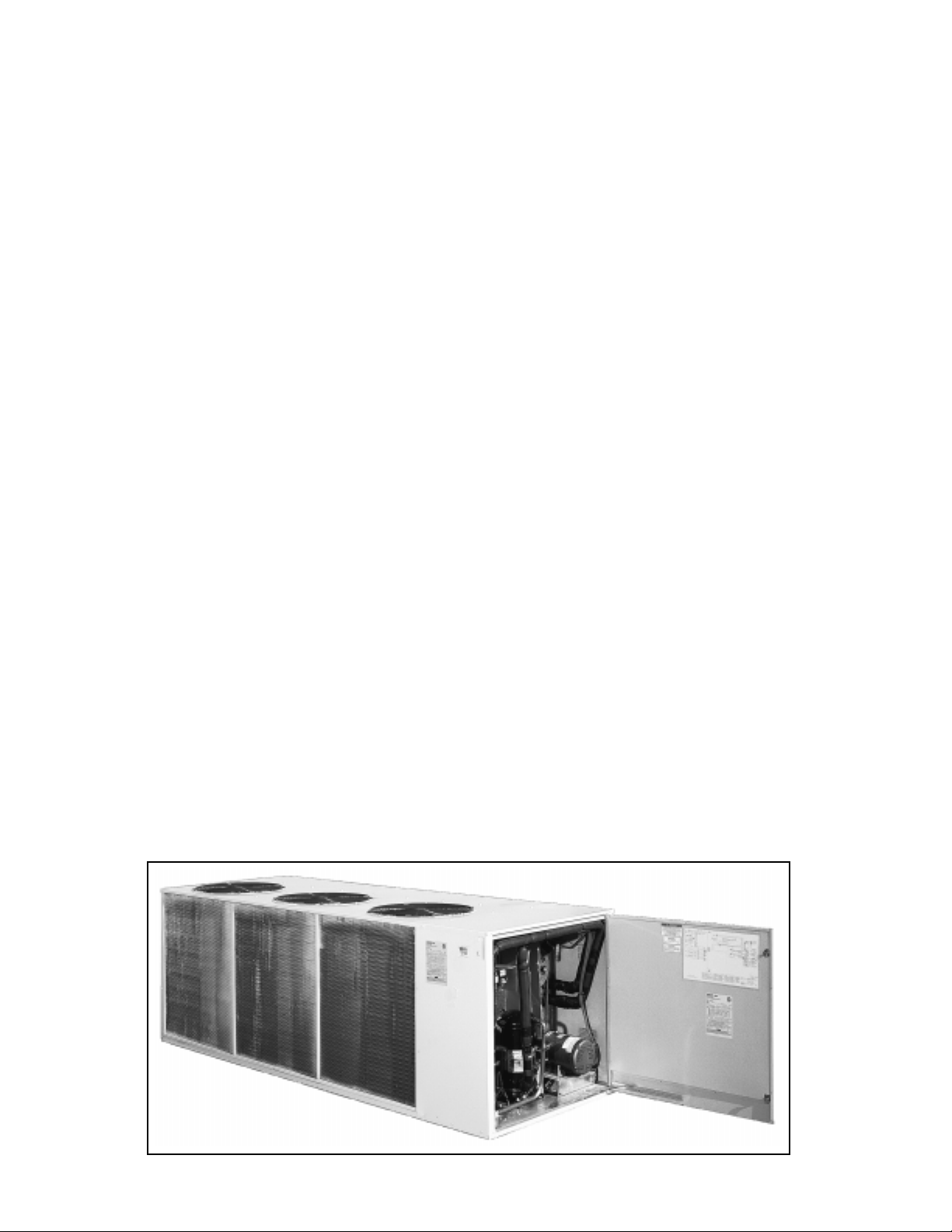

COOLING SECTION • DIRECT EXPANSION (DX)

All direct expansion refrigeration systems are factory

assembled, charged with refrigerant, tested and operated. On 13 - 25 ton units the refrigerant system includes

dual circuit evaporator and condenser coils providing

two stages of cooling. On 30 - 40 ton units the refrigeration system includes a four circuit evaporator coil and

two dual circuited condensor coils providing two or four

stages (optional) of cooling. These systems are provided

with liquid line filter driers, expansion valves and fully

hermetic compressors. Compressors are equipped with a

positive pressure forced lubrication system and crankcase heater. The air cooled condenser coil(s) is constructed of copper tubes with aluminum fins, the air is

pulled through with propeller fans. The evaporator coil

is draw through, made of copper tubes with aluminum

fins.

NOTE: Crankcase Heater Operation

Some units are equipped with a compressor crackcase

heater, which should be energized at least 24 hours prior

to setting the thermostat for cooling operation.

Never cut off the main power supply to the unit, except

for complete shutdown. When power is cut off from the

unit, any compressors using crankcase heaters cannot

prevent refrigerant migration. This means the compressor will cool down, and liquid refrigerant will accumulate in the compressor. Since the compressor is designed

to pump refrigerant gas, damage may occur when power

is restored.

If power must be cut off for more than an hour, turn the

thermostat system switch to "OFF", and leave it off until

the main power switch has been turned on again for at

least twenty four hours for units with compressor crankcase heaters. This will give the crankcase heater time to

clear any liquid accumulation out of the compressor

before it is required to run.

Always control the system from the thermostat, or control panel, never at the main power supply (except for

emergency or for complete shutdown of the system).

The refrigeration section of these appliances has been

found acceptable with applicable provisions of "ANSI /

UL 1995" and current "C.S.A. Standard C22.2" by E.T.L.

! CAUTION

▲

!

▲

W ARNING

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit to

OFF at disconnect switch(es). Unit may have

multiple power supplies.

Failure to observe the following instructions will

result in premature failure of your system, and

possible voiding of the warranty.

On three phase units the rototation must be

checked on ALL MOTORS AND COMPRESSORS.

SCROLL COMPRESSORS ARE DIRECTIONAL.

Rotation must be checked on start-up by a

qualified service technician using

suction and discharge gauges.

Scroll compressors will FAIL if run in the wrong

direction. Blower and condenser rotation

should be checked and only be altered if

necessary at the power connection.

4

Page 5

OWNER'S INFORMATION

During the cooling season, if the air flow is reduced due

to dirty air filters or any other reason, the cooling coils

will get too cold and will cause excessive liquid to return

to the compressor. As the liquid concentration builds up,

oil is washed out of the compressor, leaving it starved for

lubrication.

THE COMPRESSOR LIFE WILL BE SERIOUSLY

SHORTENED BY THIS REDUCED LUBRICATION,

AND THE PUMPING OF EXCESSIVE AMOUNTS OF

LIQUID OIL AND REFRIGERANT.

CAUTION: While the following incorrect operations

may not cause damage to the system, they will impair the

performance, and may cause the built-in safety devices

to cut the system off completely.

1. LOW AMBIENT OPERATION

The cooling section of a direct expansion (DX)

unit will not operate properly when the outdoor

temperature is below 55° degrees. Outside air

intake options are recommended if operation

below 55° degrees is expected.

2. MULTIPLE UNIT OPERATION

When several units are used in conditioning the

space, and part or all of them are combination

heating-cooling units, all systems thermostat

switches must be set at either heating or cooling

(or set at "off"). Do not leave part of the systems

switched to the opposite mode. All cooling only

units should be switched to "off" at the thermostat during the heating season.

CONDENSATE PIPING

The unit requires a drain trap to be connected to the

drain pan at the unit. If codes require a condensate drain

line, the line should be the same pipe size as the drain

nipple and should pitch downward toward drain.

The condensate drain pipe ("P" trap) is factory supplied

and is shipped loose in the control access compartment

for field installation. An air break should be used with

long runs of condensate lines.

Drain pans in any air conditioning equipment, even

when they have a built-in slope to the drain, will have

moisture present and will require periodic cleaning to

prevent any build up of algae of bacteria.

Cleaning of the drain pans will also prevent any

possible plugging of the drain lines and an overflow of the pan itself. All cleaning of the drain pans

and inside of the equipment should be done by

qualified personnel.

ELECTRIC HEATING (Optional)

The electric heat is available as an option.

Heating is accomplished by passing electrical current

through a specified amount of resistance heaters which

will produce the required heat. The indoor blower motor

will energize at the same time as the heaters.

When heat is called for, the cooling section in inoperable

except for the indoor blower motor.

The system is designed to heat or cool a given amount of

air each minute it operates. If this amount of air is

greatly reduced (approximately 1/3 during the heating

season), the heater coil will overheat, and may cut the

heater off entirely by action of the safety high temperature limit device.

BLOWER INFORMATION

DUE TO JOB SPECIFICATION REVISIONS, IT MAY

BE NECESSARY TO ADJUST OR CHANGE THE

SHEAVE OR PULLEY TO OBTAIN THE DESIRED

AIRFLOW AT THE TIME OF INSTALLATION.

START-UP TECHNICIAN MUST CHECK BLOWER

MOTOR AMPERAGE TO ENSURE THAT THE AMPERAGE LISTED ON THE MOTOR NAMEPLATE IS

NOT EXCEEDED.

Clean blower wheels are necessary to reduce electrical

use, maintain capacity and reduce stress on the unit.

FILTER INSTALLATION / REPLACEMENT

Filter rails and filters are shipped inside the unit for

field installation. Install filter rails and slide filters

into place before operation of the unit.

To replace filters, slide each filter out of filter rack and

inspect. Replace old filters with the size indicated on

each filter. Be sure arrow points towards the blower.

Filters should be checked every 30 days and replaced

or cleaned as necessary.

Do not permit the unit to be operated unless filters are

in place. Operation of the unit without filters will

result in a clogged evaporator coil.

IT IS IMPORTANT TO KEEP COILS,

BLOWER AND FIL TERS CLEAN !

!

▲

Before leaving installation, a complete

operating cycle should be observed

to verify that all components

are functioning properly.

CAUTION

5

Page 6

SEQUENCE OF OPERATIONS

NORMAL OPERATION

COOLING

Set the thermostat system switch to "COOL".

Set the thermostat fan switch to "AUTO" or "ON".

Set the thermostat temperature at the desired point.

HEATING

Set the thermostat system switch to "HEAT".

Set the thermostat fan switch to "AUTO" or "ON".

Set the thermostat temperature at the desired point.

AIR CIRCULATION

Set the thermostat system switch to "OFF".

Set the thermostat fan switch to "ON".

Do not change temperature setting.

With these settings, the air circulating blower will run

continuously but the air will not be heated or cooled.

SYSTEM OFF

Set the thermostat system switch to "OFF".

Set the thermostat fan switch to "AUTO".

Do not change temperature setting.

With these settings, the system is shut down, with the

exception of the control system power (24 volts), and the

crankcase heater of the compressor (about 60 watts).

DO NOT TURN OFF THE MAIN POWER SWITCH.

I. GENERAL INFORMATION

A. COOLING

1. Packaged Units

When the thermostat calls for cooling from the space, 'Y1'

makes 'R' to 'CC1' through the LPS (low pressure switch),

HPS (high pressure switch) and optional GOT (guarantee off timer).

On larger units 'CC3' is also made. If additional cooling

is required 'CC2' and 'CC4' are made through their

respective pressure switches and timers.

B. HEATING (Optional)

1. Electric

When the thermostat calls for heat 'W1' makes 'R' to the

heat relay. All N.O. contacts close, and all N.C. contacts

open. The heat relay makes 'R' to the first stage of

electric heat.

On a fault condition the main limit located in the supply

air or the auxiliary limit located in thesupply air fan

housing will remove power from all contactors.

If additional heating is required a second set of elements

can be turned on by 'W2'.

NIGHT AND VACANT WEEKEND OPERATION

If it is desired to reduce the operating time during the

night, and during periods when the space is unused,

it is recommended that the temperature setting be

raised about five degrees during these periods of the

cooling season, and lowered about ten degrees during

the heating season.

6

Page 7

SERVICING, TROUBLE SHOOTING, INSPECTIONS & MAINTENANCE

SERVICE

!

▲

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit to

OFF at disconnect switch(es). Unit may have

multiple power supplies.

COOLING

1.

2. Set thermostat in cooling mode and place the

"fan" switch to on. Check blower for correct operating

direction, amperage and voltage.

Check compressor(s) operation. Check the amperage

and compare to the nameplate data (check amperage

load side of the compressor contactor).

BLOWER

Inspect blower and blower section to keep free of dust or

debris. To clean the blower, turn the thermostat and the

power to the "OFF" position. Clean the assembly, check

the bearings for looseness, inspect the belt condition and

tightness, check screws for tightness, rotate blower

wheel and inspect for noise or roughness in the bearings.

HEATING • ELECTRIC (IF APPLICABLE)

1. Set thermostat in the heat mode.

2. Set thermostat to call for heat to engage all

electric heat strips. Check blower for proper rotation

and voltage.

3. Measure the amperage and voltage. Compare

them to the nameplate data.

LUBRICATION

All original blower motors and bearings are furnished

with an orginal factory charge of lubrication. Some

applications will require that bearings be re-lubricated

periodically. The schedule will depend on the operating

duty, temperature variations or other severe atmospheric

conditions.

Bearings should be re-lubricated when at normal operating temperatures, but not running. Rotate the fan

shaft by hand and add only enough grease to purge the

seals. DO NOT OVERLUBRICATE.

Recommended greases are:

Main Power Switches are on and power is to the unit.

W ARNING

SHELL OIL - DOLIUM R

CHEVRON OIL - SRI No. 2

TEXACO INC. - PREMIUM RB

In the event the unit is not functioning correctly and a

service company is required, a company with service

technicians qualified and experienced in electric heating and air conditioning be permitted to service the

systems in order to keep warranties in effect. The

service tech may call the factory if assistance is required.

BEFORE CALLING, HE SHOULD HAVE THE MODEL

AND SERIAL NUMBER OF THE UNIT AVAILABLE

FOR THE CUSTOMER SERVICE DEPARTMENT TO

HELP ANSWER QUESTIONS REGARDING THE

UNIT.

AAON, Inc.

Phone: 918-583-2266

Fax: 918-382-6364

Customer Service Department

UNIT REPLACEMENT PARTS

Replacement parts for AAON equipment may be obtained from AAON. When ordering parts, always reference the unit model number, serial number and part

number.

ALWAYS USE AAON SPECIFIED PARTS

COMMON CAUSES OF REDUCED AIR FLOW

A. DIRTY FILTERS - Filters must be inspected and

replaced on a regular basis. It is strongly recommended

that the media be replaced monthly. Clean filters are

your best insurance against premature system breakdown. Do not permit the unit to be operated unless the

filters are in place. Operation of the unit without filters

will result in a clogged evaporator coil - a very expensive

service job to correct.

B. OBSTRUCTION TO AIR FLOW - Supply and

return air grilles must be kept clear so air can be freely

discharged and drawn from the system.

CLEANING

Inspect unit interior at the beginning of each heating

and cooling season and as operating conditions require.

COILS

Evaporator coil(s) should be inspected and cleaned annually to ensure there is no obstruction to air flow.

Condenser coil(s) should be inspected monthly. Clean

condenser coils annually and as required by location or

outdoor air conditions.

!

▲

All of the items listed under the service, trouble

shooting, inspections and maintenance section of

this manual should be performed once a year.

W ARNING

7

Page 8

SERVICING, TROUBLE SHOOTING, INSPECTIONS & MAINTENANCE

TROUBLE

SYSTEM OFF

CONDENSER FAN WILL NOT RUN

EVAPORATOR BLOWER WILL NOT RUN

COMPRESSOR SHORT CYCLES

COOLING PACKAGE

1. Check power at lineside of contactor(s).

2. Thermostat not set for cooling.

3. High pressure control tripped.

4. Low pressure switch open (loss of charge).

1. Overload thermal protector open in motor.

2. Motor run capacitor open or shorted.

3. Motor failed.

4. Fan or shaft stuck.

1. Overload thermal protector open in motor.

2. Relay not closing.

3. Motor failed.

4. Capacitor shorted or open (PSC motors only).

5. Stuck shaft or blower wheel.

1. Check for low refrigeration charge.

2. Compressor overload setting.

3. Ambient temperature too low.

4. Filters dirty or air flow restricted.

5. Evaporator blower not running.

POSSIBLE CAUSE

FAN MOTOR RUNS HOT AND CUTS OUT

COMPRESSOR WILL NOT START

BLOWER DOES NOT DELIVER AIR

ELECTRIC HEATING

SYSTEM OFF

EVAPORATOR MOTOR WILL NOT RUN

BLOWER DOESN'T DELIVER AIR

1. Line voltage too high.

1. Line voltage too low.

2. Limit switches are open.

3. Overload or pressure control tripped.

1. Blower running backwards.

2. Dirty filters.

3. Duct obstruction.

4. Belts loose.

1. Check power at line side of contactor(s).

2. Thermostat not set for heating.

1. Overload relay tripped.

2. Heater Relay not energized.

3. Blower Contactor not energized.

4. Capacitor shorted or open (PSC motors only).

1. Blower running backwards.

2. Dirty air filters.

3. Dirty coils.

4. Duct obstruction.

5. Belts loose.

BLOWER COMES ON, BUT LITTLE OR NO

HEAT

1. One or more heater contactors are open.

2. Limit switches are open.

3. Heater relay open.

4. Heat strips burned out.

8

Page 9

COMPRESSOR CHECKOUT PROCEDURE

CONTROL PANEL NOT SET FOR COOLING

NO POWER TO

CONTACTOR

COMPRESSOR

WON'T RUN

POWER TO CONTACTOR

ALL 3 LEGS

POWER TO

UNIT

NO POWER TO

UNIT

CONTACTOR

OPEN

CONTACTOR

CLOSED

CHECK UNIT FUSES

AND WINDING

CHECK CIRCUIT BREAKER AT

POWER DISTRIBUTION PANEL

NO 24 VOLT POWER

TO HOLDING COIL

POWER TO HOLDING COIL

COMPRESSOR

HUMS

COMPRESSOR

DOESN'T HUM

MOTOR WINDING OPEN

COMPRESSOR

NO POWER TO

COMPRESSOR

HOLDING COIL BURNED OUT

STUCK COMPRESSOR

GROUNDED WINDING

POWER TO

ALL 3 LEGS

OVERLOAD OPEN

COMPRESSOR LOW AMBIENT LOCKOUT OPEN

REVERSE LEADS

REPLACE

COMPRESSOR

MOTOR

WINDING OPEN

INTERNAL

THERMOSTAT NOT CALLING FOR COOLING

LO PRESSURE SWITCH OPEN

HI PRESSURE SWITCH OPEN

(TEMPERATURE OUTSIDE BELOW 55 DEG.)

TRANSFORMER OPEN

BROKEN OR LOOSE CONTROL

REPLACE CONTACTOR

COMPRESSOR RUNS

COMPRESSOR

DOESN'T RUN

REPLACE

COMPRESSOR

IF COMPRESSOR DOME IS HOT,

IT MAY BE LOCKED OUT ON

INTERNAL OVERLOAD.

WAIT FOR RESET, IT COULD TAKE

AS LONG AS 2 HOURS.

REPLACE LEADSBROKEN LEADS

REPLACE

COMPRESSOR

COMPRESSOR RUNS

OR

COMPRESSOR CYCLES

(Poor Cooling)

CHECK COMPRESSOR

ROTATIONAL

DIRECTION

HIGH HEAD

PRESSURE

LOW HEAD

HIGH SUCTION

PRESSURE

LOW

SUCTION

PRESSURE

LOW AIR (CONDENSER)

OVERCHARGE OF REFRIGERANT

AIR IN SYSTEM

DIRTY CONDENSER COIL

DEFECTIVE COMPRESSOR VALVES

LOW AIR (EVAPORATOR)

LOW REFRIGERANT CHARGE

RESTRICTED FEEDER TUBE

BAD EXPANSION VALVE POWER ELEMENT

9

REPLACE COMPRESSOR

CHECK FILTERS,

OR DIRTY EVAPORATOR COIL

OR LOOSE BELT

Page 10

NOTES:

10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

®

AAON

HA COOLING UNITS

•

USERS

INFORMATION

MANUAL

P92200 • HA Users • 2000

AAON, Inc.

2425 South Yukon

Tulsa, Oklahoma U.S.A. 74107

ph: (918) 583-2266 • fax: (918) 583-6094

12

Loading...

Loading...