Page 1

F1 Series

Indoor Air Handing Units

Installation, Operation

& Maintenance

QUALIFIED INSTALLER

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life.

Installation and service must be

performed by a trained, qualified

installer. A copy of this IOM should

be kept with the unit.

These instructions are addressed

primarily to the installer; however,

useful maintenance information is

included. This manual should be kept

with the unit for future reference.

NOTICE

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

Page 2

Page 3

Table of Contents

Safety .............................................................................................................................................. 6

F1 Base Model and Features Description ..................................................................................... 10

General Description ...................................................................................................................... 11

Codes and Ordinances ............................................................................................................... 11

Receiving Units ......................................................................................................................... 12

Before Beginning Installation ................................................................................................... 13

Storage ....................................................................................................................................... 13

Installation..................................................................................................................................... 14

General ...................................................................................................................................... 14

Service and Installation Clearance ............................................................................................ 14

Floor Mounted Units ................................................................................................................. 14

Suspended .................................................................................................................................. 14

Sealing ....................................................................................................................................... 15

Cooling Equipment ................................................................................................................... 15

Heating Equipment .................................................................................................................... 16

Field Wiring - MCA and MOP ................................................................................................. 16

Heat Pump ................................................................................................................................. 17

ECM Driven Fan ....................................................................................................................... 17

Reheat Coil Refrigerant Piping ................................................................................................. 18

Condensate Piping ..................................................................................................................... 20

Electrical .................................................................................................................................... 20

Thermostat ................................................................................................................................. 20

Filters ......................................................................................................................................... 20

Charging Refrigerant ................................................................................................................. 20

Evaporator Coil ......................................................................................................................... 22

Startup ........................................................................................................................................... 24

General ...................................................................................................................................... 24

Check-Out ................................................................................................................................. 24

Procedures ................................................................................................................................. 24

Electric Heat Section Procedures .............................................................................................. 25

Refrigerant Cooling Section Procedures ................................................................................... 25

Optional Equipment Procedures ................................................................................................ 25

Commissioning .......................................................................................................................... 26

Air Balancing ............................................................................................................................ 26

Water Balancing ........................................................................................................................ 26

Controls ..................................................................................................................................... 26

Operation and Maintenance .......................................................................................................... 26

General ...................................................................................................................................... 26

Maintenance Schedule ............................................................................................................... 26

Lubrication ................................................................................................................................ 27

Blower Assembly ...................................................................................................................... 27

Coils .......................................................................................................................................... 27

Heating ...................................................................................................................................... 27

Filters ......................................................................................................................................... 27

3

Page 4

Refrigerant Piping ..................................................................................................................... 28

Determining Refrigerant Line Size ........................................................................................... 29

Equivalent Line Length ............................................................................................................. 29

Predetermined Line Sizes .......................................................................................................... 32

Refrigerant Piping Diagrams ........................................................................................................ 35

Thermostat Installation and Wiring .............................................................................................. 43

F1 Series Startup Form ................................................................................................................. 53

Maintenance Log .......................................................................................................................... 56

Literature Change History............................................................................................................. 57

R58420 · Rev. B · 120509

(ACP 29902)

Page 5

Index of Table and Figures

Tables:

Table 1 - Electric Heat Minimum Circuit Ampacity .................................................................... 16

Table 2 - Electric Heat Maximum Overcurrent Protection ........................................................... 17

Table 3 - Factory Preset Air Flow................................................................................................. 17

Table 4 - Cooling Fan Speed Tap Settings ................................................................................... 17

Table 5 - Climate Settings ............................................................................................................. 18

Table 6 - Heating Fan Speed Tap Settings .................................................................................... 18

Table 7 - Acceptable Air-Cooled Refrigeration Circuit Values ................................................... 22

Table 8 - Predetermined Line Sizes for F1 and CB Series Matched Systems with Two Step R-

410A Scroll Compressors ............................................................................................................. 33

Figures:

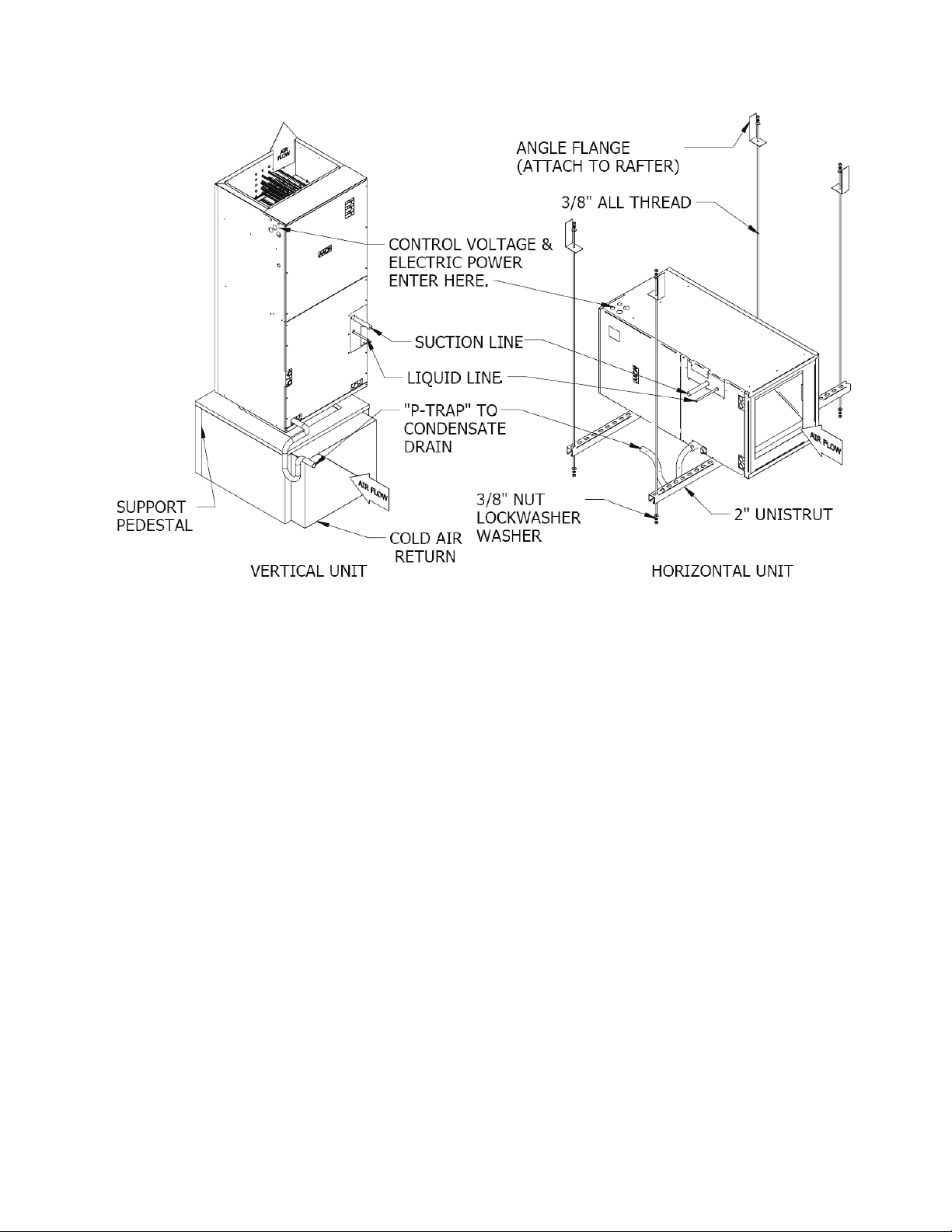

Figure 1 - Typical Vertical and Horizontal Unit Installation Methods ......................................... 15

Figure 2 - Example Configuration of ECM Fan Taps .................................................................. 17

Figure 3 - Riser Height Versus Total Equivalent Line Length for R-410A Split System

Applications with Two Step Scroll Compressor CB-024 through CB-060 units. ........................ 34

Figure 4 - Modulating Hot Gas Reheat Piping Diagram with Air Handling Unit above

Condensing Unit. .......................................................................................................................... 35

Figure 5 - Modulating Hot Gas Reheat Piping Diagram with Air Handling Unit below

Condensing Unit ........................................................................................................................... 36

Figure 6 - Modulating Hot Gas Reheat Piping Diagram with Air Handling Unit above

Condensing Unit with Optional Accumulator .............................................................................. 37

Figure 7 - Modulating Hot Gas Reheat Piping Diagram with Air Handling Unit below

Condensing Unit with Optional Accumulator .............................................................................. 38

Figure 8 - Heat Pump Piping Diagram with Indoor Unit above Outdoor Unit............................. 39

Figure 9 - Heat Pump Piping Diagram with Outdoor Unit above Indoor Unit ............................. 40

Figure 10 - Heat Pump Piping Diagram with Modulating Hot Gas Reheat and Indoor Unit above

Outdoor Unit ................................................................................................................................. 41

Figure 11 - Heat Pump Piping with Modulating Hot Gas Reheat and Outdoor Unit above Indoor

Unit ............................................................................................................................................... 42

Figure 12 - 2 Stage Cooling with Electric Heat ............................................................................ 43

Figure 13 - 2 Stage Cooling with Heat Pump and Electric Heat .................................................. 44

Figure 14 - 2 Stage Cooling and Electric Heat with Hot Gas Reheat and Humidistat ................. 45

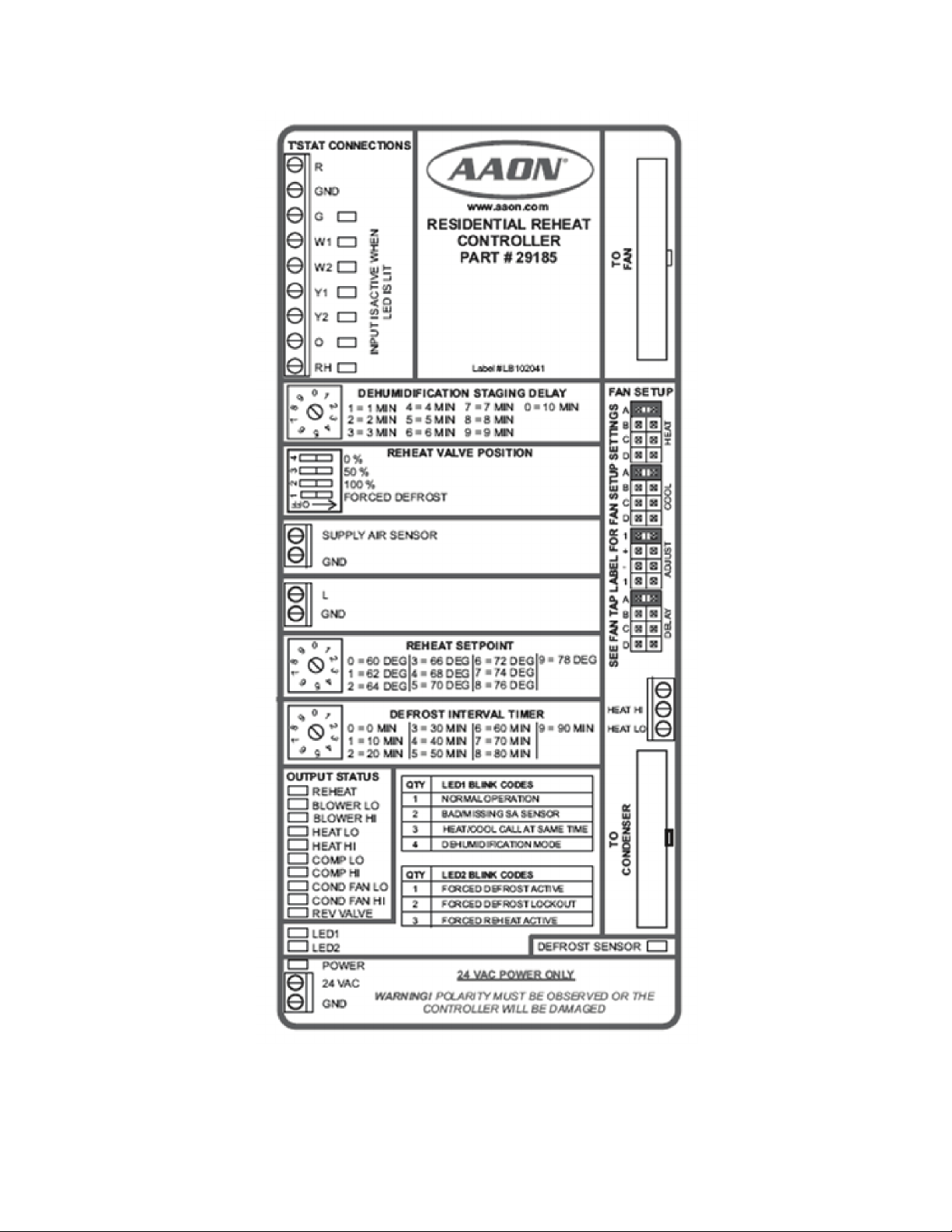

Figure 15 - Main Control Board for Units Equipped with Modulating Hot Gas Reheat .............. 46

Figure 16 - Field Wiring Connections for an F1 Series Air Handling Unit. ................................ 47

Figure 17 - 5kW Electric Heat ..................................................................................................... 48

Figure 18 - 10 kW Electric Heat .................................................................................................. 49

Figure 19 - 15 kW Electric Heat .................................................................................................. 50

Figure 20 - 20 kW Electric Heat ................................................................................................. 51

Figure 21 - 25 kW Electric Heat ................................................................................................. 52

5

Page 6

Safety

NOTE - Notes are intended to clarify the unit installation, operation and maintenance.

CAUTION - Caution statements are given to prevent actions that may result in

equipment damage, property damage, or personal injury.

WARNING - Warning statements are given to prevent actions that could result in

equipment damage, property damage, personal injury or death.

DANGER - Danger statements are given to prevent actions that will result in equipment

damage, property damage, severe personal injury or death.

Attention should be paid to the following statements:

ELECTRIC SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in dangerous

operation, serious injury, death or

property damage.

Improper servicing could result in

dangerous operation, serious injury,

death or property damage.

Before servicing, disconnect all

electrical power to the unit. More

than one disconnect may be

provided.

When servicing controls, label all

wires prior to disconnecting.

Reconnect wires correctly.

Verify proper operation after

servicing. Secure all doors with

key-lock or nut and bolt.

Electric shock hazard. Before

servicing, disconnect all electrical

power to the unit, including remote

disconnects, to avoid shock hazard

or injury from rotating parts. Follow

proper Lockout-Tagout procedures.

FIRE, EXPLOSION OR CARBON

MONOXIDE POISONING HAZARD

Failure to replace proper controls

could result in fire, explosion or

carbon monoxide poisoning. Failure

to follow safety warnings exactly

could result in serious injury, death or

property damage. Do not store or use

gasoline or other flammable vapors

and liquids in the vicinity of this

appliance.

6

Page 7

During installation, testing, servicing

and troubleshooting of the equipment

it may be necessary to work with live

electrical components. Only a

qualified licensed electrician or

individual properly trained in handling

live electrical components shall

perform these tasks.

Standard NFPA-70E, an OSHA

regulation requiring an Arc Flash

Boundary to be field established and

marked for identification of where

appropriate Personal Protective

Equipment (PPE) be worn, should be

followed.

GROUNDING REQUIRED

All field installed wiring must be

completed by qualified personnel.

Field installed wiring must comply

with NEC/CEC, local and state

electrical code requirements. Failure

to follow code requirements could

result in serious injury or death.

Provide proper unit ground in

accordance with these code

requirements.

To prevent injury or death lifting

equipment capacity shall exceed unit

weight by an adequate safety factor.

Always test-lift unit not more than 24

inches high to verify proper center of

gravity lift point to avoid unit damage,

UNIT HANDLING

injury or death.

ROTATING COMPONENTS

Unit contains fans with moving parts

that can cause serious injury. Do not

open door containing fans until the

power to the unit has been

disconnected and fan wheel has

stopped rotating.

Failure to properly drain and vent

coils when not in use during freezing

temperature may result in coil and

equipment damage.

Rotation must be checked on all

MOTORS AND COMPRESSORS of

3 phase units at startup by a qualified

service technician. Scroll

compressors are directional and can

be damaged if rotated in the wrong

direction. Compressor rotation must

be checked using suction and

discharge gauges. Fan motor rotation

should be checked for proper

operation. Alterations should only be

made at the unit power connection

7

Page 8

CAUTIO

CAUTIO

Do not use oxygen, acetylene or air

in place of refrigerant and dry

nitrogen for leak testing. A violent

explosion may result causing injury or

death.

WARNING

Always use a pressure regulator,

valves and gauges to control

incoming pressures when pressure

testing a system. Excessive pressure

may cause line ruptures, equipment

damage or an explosion which may

result in injury or death.

Do not work in a closed area where

refrigerant or nitrogen gases may be

leaking. A sufficient quantity of

vapors may be present and cause

injury or death.

Do not clean DX refrigerant coils with

hot water or steam. The use of hot

water or steam on refrigerant coils

will cause high pressure inside the

coil tubing and damage to the coil.

N

To prevent damage to the unit, do not

use acidic chemical coil cleaners. Do

not use alkaline chemical coil

cleaners with a pH value greater than

8.5, after mixing, without first using

an aluminum corrosion inhibitor in the

cleaning solution.

N

Some chemical coil cleaning

compounds are caustic or toxic. Use

these substances only in accordance

with the manufacturer’s usage

instructions. Failure to follow

instructions may result in equipment

damage, injury or death.

Risk of injury from hot parts –

Disconnect all power, close all

isolation valves and allow equipment

to cool before servicing equipment

with heating coils. Hot water will

circulated even after the power is off.

8

Page 9

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack by certain

chemicals. Polyolester (POE) oils

used with R-410A and other

refrigerants, even in trace amounts,

in a PVC or CPVC piping system will

result in stress cracking of the piping

and fittings and complete piping

system failure.

1. The unit is for indoor use only. See

General Information section for more

unit information.

2. Every unit has a unique equipment

nameplate with electrical, operational,

and unit clearance specifications.

Always refer to the unit nameplate for

specific ratings unique to the model you

have purchased.

3. READ THE ENTIRE INSTALLATION,

OPERATION AND MAINTENANCE

MANUAL. OTHER IMPORTANT

SAFETY PRECAUTIONS ARE

PROVIDED THROUGHOUT THIS

MANUAL.

4. Keep this manual and all literature

safeguarded near or on the unit.

9

Page 10

F1

Series and

Generation

F1 Base Model and Features Description

A

-

Rev.

BASE MODEL

SERIES AND GENERATION

F1

REVISION

A = Design Sequence

UNIT SIZE

024 = 24 MBtu/h (2 ton)

036 = 36 MBtu/h (3 ton)

048 = 48 MBtu/h (4 ton)

060 = 60 MBtu/h (5 ton)

VOLTAGE

1 = 208-230V/1Φ/60Hz

C = 115V/1Φ/60Hz

APPLICATION

V = Vertical Position (Up-flow)

M = Multi-Position (Up-flow or Horizontal)

HEATING

0 = No Heat

A = 5 kW

B = 10 kW

C = 15 kW

D = 20 kW

E = 25 kW

G = Hot Water Heating

H = Hot Water Heating - No Cooling

FEATURE 1: MOTORS

A = ECM - 1/2 hp

B = ECM - 3/4 hp

C = ECM - 1.0 hp

FEATURE 2: FILTERS

0 = Standard - 1” Fiberglass

060

-

Unit

Size

1

-

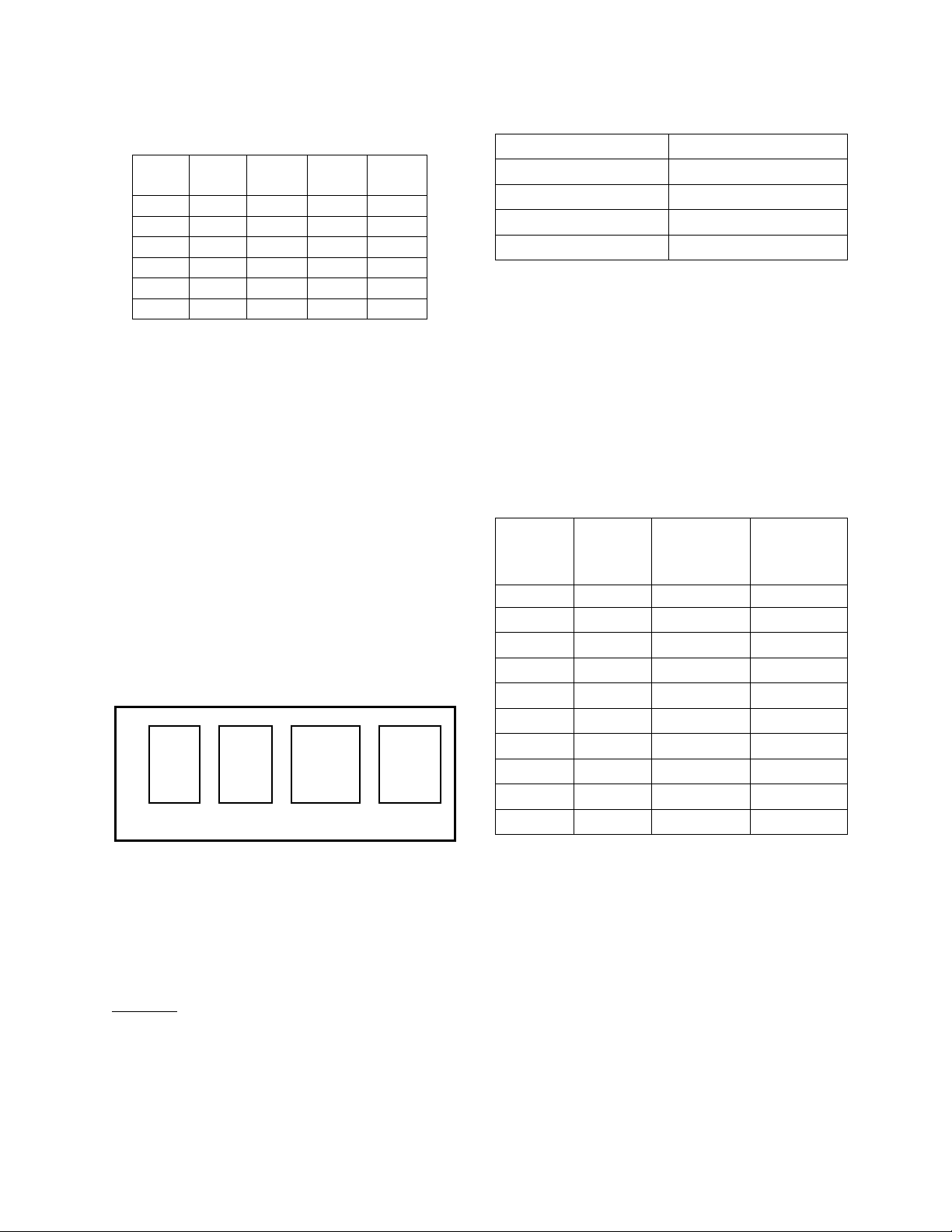

Voltage App. Heat Mtrs Filters Cntls Blank Refri. Blank Cabinet Special

M

-

C

-

C 0 0 0 C 000 0 0

:

FEATURE 3: CONTROLS

0 = Standard - Terminal Block

FEATURE 4: BLANK

0 = Standard

FEATURE 5: REFRIGERATION

0 = Standard - Split System Air Conditioner

C = Split System Heat Pump

D = Split System Air Conditioner + Modulating Hot

Gas Reheat

F = Split System Heat Pump + Modulating Hot Gas

Reheat

FEATURE 6: BLANK

0 = Standard

FEATURE 7: BLANK

0 = Standard

FEATURE 8: BLANK

0 = Standard

FEATURE 9: CABINET

0 = Standard - Embossed Galvanized Steel

A = Painted Cabinet Exterior

FEATURE 10: SPECIAL

0 = Standard

X = Special Price Authorization

10

Page 11

General Description

F1 Series air handling units are designed for

safe operation when installed, operated and

maintained within design specifications and

the instructions set forth in this manual. It is

necessary to follow these instructions to

avoid personal injury or damage to

equipment or property during equipment

installation, operation, start-up and

maintenance.

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life.

Installation and service must be

performed by a qualified installer. A

copy of this IOM should be kept with

the unit.

This equipment is protected by a

standard limited warranty under the

condition that initial startup and

maintenance is performed according

to the instructions set forth in this

manual. This manual should be read

in its entirety prior to installation and

before performing any service or

maintenance work.

These units must not be used as a

“construction heater” at anytime

during any phase of construction.

Very low return air temperatures,

harmful vapors, and misplacement of

the filters will damage the unit and its

efficiency.

Certification of Cooling Models

a. Certified for use with a residential

remote R-410A condensing unit with a

two-step compressor.

b. Certified for indoor installation only

Certification of Cooling and Reheat

Models

a. Certified for use with a residential

remote R-410A condensing unit with a

two-step compressor and hot gas

dehumidification capabilities.

b. Certified for indoor installation only

Certification of Electric Heat Models

a. Certified as an electric heating air

handling unit with a cooling coil.

b. Certified for indoor installation only.

Codes and Ordinances

F1 Series units have been tested and

certified, by ETL, in accordance with UL

Safety Standard 1995/CSA C22.2 No. 236.

System should be sized in accordance with

the American Society of Heating,

Refrigeration and Air Conditioning

Engineers Handbook.

Installation of F1 Series units must conform

to the ICC standards of the International

Mechanical Code, the International Building

Code, Installation of Air Conditioning and

Ventilating Systems Standard, NFPA 90A,

and local building, plumbing and waste

water codes. All appliances must be

electrically grounded in accordance with

local codes, or in the absence of local codes,

the current National Electric Code,

ANSI/NFPA 70 or the current Canadian

Electrical Code CSA C22.1.

Important: The United States

Environmental Protection Agency (EPA)

has issued various regulations regarding the

introduction and disposal of refrigerants in

11

Page 12

this unit. Failure to follow these regulations

CAUTIO

quip

may harm the environment and can lead to

the imposition of substantial fines. Because

regulations may vary due to passage of new

laws, AAON suggests a certified technician

perform any work done on this unit. Should

you have any questions please contact the

local office of the EPA.

WARNING

Do not, under any circumstances,

connect ductwork to any other heat

producing device such as fireplace

insert, stove, etc. Unauthorized use

of such devices may result in

property damage, fire, carbon

monoxide poisoning, explosion,

personal injury or death.

It is the responsibility of the installing

contractor to comply with codes,

ordinances, local and municipal

building laws, and manufacturer’s

instruction. Personal injury and/or

equipment damage may result if

proper procedures are not followed.

The Clean Air Act of 1990 bans the

intentional venting of refrigerant as of

July 1, 1992. Approved methods of

recovery, recycling, or reclaiming

must be followed.

N

Always wear hand and eye protection

when handling, installing, servicing,

or maintaining equipment. Sharp

edges, moving parts and fly debris

may cause personal injury and care

must be taken when working with

ment.

e

Any conflicting codes or regulations take

precedence over the information in this

manual. It is important that all installation

and service work be performed by qualified

professionals.

Receiving Units

All shipments are FOB from the factory. It

is the responsibility of the receiving party to

inspect the equipment upon arrival. Units

should be inspected for damage that may

have occurred in transit. Please do not refuse

shipments!

Check the unit model number,

specifications, electrical characteristics and

accessories to determine if they are correct.

In the event an incorrect unit is shipped, it

must be returned to the supplier and must

NOT be installed. The manufacturer

assumes no responsibility for installation of

incorrectly shipped units.

Do the following upon receipt:

1. Assure that freight carrier is in

compliance with Bill of Lading

instructions.

2. Inspect delivery before signing Bill of

Lading.

If damage is found or items are missing:

1. Note on Bill of Lading immediately.

2. Call carrier immediately to file a freight

claim and to schedule an inspection.

3. Photograph damage if possible.

12

Page 13

4. Do not move or discard damaged freight

packaging materials

5. After losses have been acknowledged by

the freight carrier, contact factory for a

repair or replacement part quote.

6. With permission of freight carrier, order

parts and/or make repairs.

7. Stay in contact with freight carrier to

ensure payment of your claim.

Nameplate should be checked to ensure the

correct model sizes and voltages have been

received to match the job requirements.

If repairs must be made to damaged goods,

then the factory should be notified before

any repair action is taken in order to protect

the warranty. Certain equipment alteration,

repair, and manipulation of equipment

without the manufacturer’s consent may

void the product warranty. Contact the

AAON Warranty Department for assistance

with handling damaged goods, repairs, and

freight claims: (903) 236-4403.

Note: Upon receipt check shipment for

items that ship loose such as filters,

thermostats and remote sensors. Consult

order and shipment documentation to

identify potential loose-shipped items.

Loose-shipped items may have been placed

inside unit cabinet for security.

Dependent upon the optional accessories

that were ordered, this equipment may

contain fragile components and delicate

electronics. Although the unit is constructed

of sturdy materials, avoid impacts and

handling methods that may damage internal

apparatus and structure of the unit. Take

care not to apply destructive force to coils,

coil and drain stub-outs, or other parts

protruding beyond the extents of the unit

casing. Always handle the unit by its

exterior casing and never by any of the

protruding parts.

Before Beginning Installation

Carefully read all instructions for the

installation prior to installing unit. Make

sure each step or procedure is understood

and any special considerations are taken into

account before starting installation.

Assemble all tools, hardware and supplies

needed to complete the installation.

Some items may need to be purchased

locally. After deciding where to install unit,

closely look the location over - both the

inside and outside of home. Note any

potential obstacles or problems that might be

encountered as noted in this manual. Choose

a more suitable location if necessary.

Storage

This equipment is not suitable for outdoor

use or storage. Never place this equipment

where it may be subjected to outdoor

conditions such as rain, snow, humidity,

extreme temperatures or corrosive

chemicals.

If installation will not occur immediately

following delivery, store equipment in a dry

protected area away from construction

traffic, and in the proper orientation as

marked on the packaging with all internal

packaging in place. Secure all loose-shipped

items.

Keep equipment free from debris, and

construction waste during installation.

Foreign materials may adversely affect unit

operation resulting in premature failures that

will not be covered by the manufacturer’s

warranty. Attach all service panels, and

cover all exposed equipment when work is

not being performed. Leave unit protected

from other construction until start-up is to

occur.

13

Page 14

CAUTIO

This unit must be stored indoors if

installation is not to occur

immediately following delivery.

Unprotected units could develop

corrosion if left exposed to the

environment. Damage resulting from

improper storage will not be covered

by the limited warranty.

N

Installation

AAON equipment has been designed for

quick and easy installation.

General

F1 Series air handling units are designed as

heating, cooling or combination units for

indoor installation only. They are designed

for R-410A refrigerant only. Flexible

connectors are required on all duct

connections to minimize air leaks.

Service and Installation Clearance

Before setting the air handling unit into

place, caution must be taken to provide

clearance for unit panels that must be

accessible for periodic service. These areas

contain the controls, safety devices,

refrigerant piping, shut-off valves and filter

access.

F1 series air handling units require a

minimum of 36 inches of service clearance

on the access panel side of the unit in order

to ensure room for removal, replacement, or

service of coils and other components if

necessary.

Note: An auxiliary (emergency) drain pan is

recommended for all applications where

there is a risk of water damage to

surrounding structure or furnishings. Refer

to local codes.

Floor Mounted Units

Make sure that the unit is level, and

mounted on a field-supplied platform with a

minimum height of 12” to allow for proper

fall on the condensate line. Other installation

provisions may be necessary according to

job specifications. F1 series air handling

units are designed for up flow and horizontal

applications only.

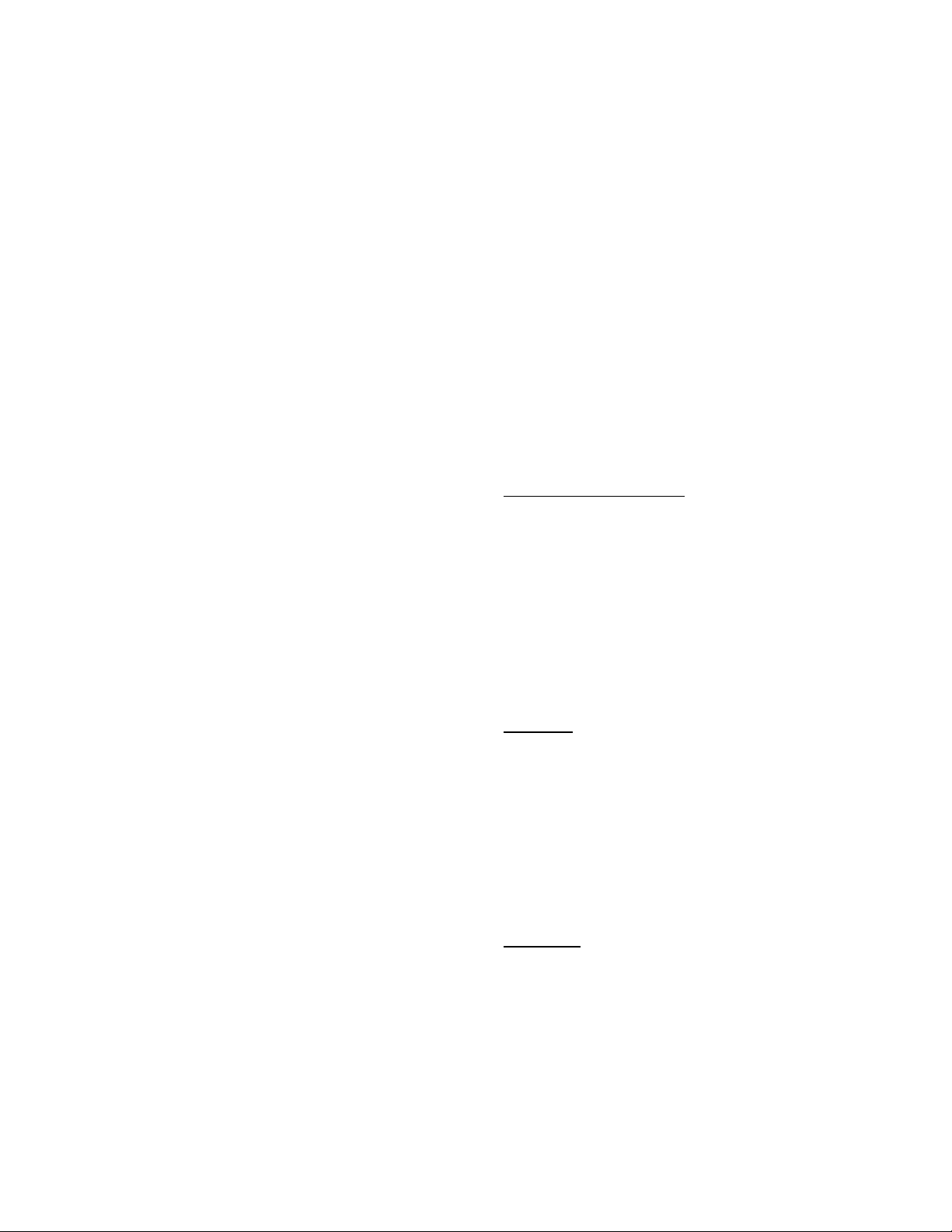

Suspended

The F1 series multi-position air handling

unit can be easily suspended for suspended

horizontal installations. The air handling

unit should be lifted into position,

supporting the entire unit from the bottom

throughout the lift. Suspend the air handling

unit as shown in the following Figure 1. An

auxiliary drain pan that covers the entire unit

would be required for above ceiling

installations.

The air handling unit must be installed level

and care should be taken to prevent damage

to the cabinet. Other installation provisions

may be necessary according to job

specifications and local code.

14

Page 15

Figure 1 - Typical Vertical and Horizontal Unit Installation Methods

Sealing

It is very important to keep outside air from

infiltrating the unit cabinet. Seal all piping

penetrations with Armaflex, Permagum, or

other suitable sealant. Also seal around drain

connections, electrical connections, and

other inlets where air may enter the cabinet.

This is especially important when the unit is

installed in an unconditioned area.

Cooling Equipment

Acceptable system design and installation

will include consideration as follows:

Piping from the condensing unit to the

indoor air handling unit is the responsibility

of the installing contractor.

Only clean “ACR” tubing should be used.

Piping should conform to generally accepted

practices and codes.

Care must be taken not to cross the circuits

on reheat systems.

Once piped, the interconnecting piping and

air handling unit MUST BE evacuated to

500 microns or less; leak checked and

condenser shutoff valves opened to allow

refrigerant flow to air handling unit. Charge

unit with R-410A refrigerant to the

recommended superheat/sub-cooling in the

Charging Refrigerant section of this manual.

Make sure air handling unit thermal

expansion valve bulb is mounted with

good thermal contact on the suction line

on a horizontal section, close to the

evaporator but outside the cabinet in the

4 or 8 o’clock position and well insulated.

Lines should be fastened and supported

according to local codes.

15

Page 16

Heating Equipment

Hot Water Heating:

Water supply lines must be insulated,

properly fastened, drained and supported

according to local code requirements.

Electric Heating:

Installing Electric Heat Strip into the

Unit:

1. Remove front control panel(s) of the unit

2. Remove screws and panel covering heat

strip compartment

3. Open the heat strip kit and remove

assembly from package

4. Install strip heat into opening and secure

with 4 (four) screws

5. Install breaker assembly on bracket and

secure with breaker with 4 (four) screws

6. Make sure that breaker is in the OFF

position

7. Connect all control wires per wiring

diagram included in the unit

8. Pull and install power wires per wiring

diagram and MCA, MOP information

herein and secure all wires firmly

9. Replace the front control panel(s) of the

unit

FIELD INSTALLED WIRES SHOULD BE

SINGLE STRAND WIRES. USE OF

ROMEX WIRES IS NOT ACCEPTABLE.

Heating is accomplished by passing

electrical current through a specified amount

of resistance heaters, which will produce the

required heat. The indoor blower motor will

energize at the same time as the heaters.

Wiring to the air handling unit must be done

in accordance with local electrical codes

and/or standards. Check specified electrical

rating and install with proper wire sizes.

Also refer to wiring diagrams included with

the unit for wire sizes and circuit breaker

recommendations.

Field Wiring - MCA and MOP

Minimum Circuit Ampacity (MCA) and

Maximum Overcurrent Protection (MOP)

are necessary to correctly connect field

wired equipment.

The calculations for the MCA and MOP are

based on requirements of NFPA 70, the

National Electrical Code (NEC) and CSA

C22.1, the Canadian Electrical Code (CEC).

The MCA is the minimum wire size needed

to prevent the wiring from overheating

during operating conditions for the life of

the product. The MOP is the maximum

allowable circuit breaker size that will

properly disconnect power to the equipment

under anticipated fault conditions.

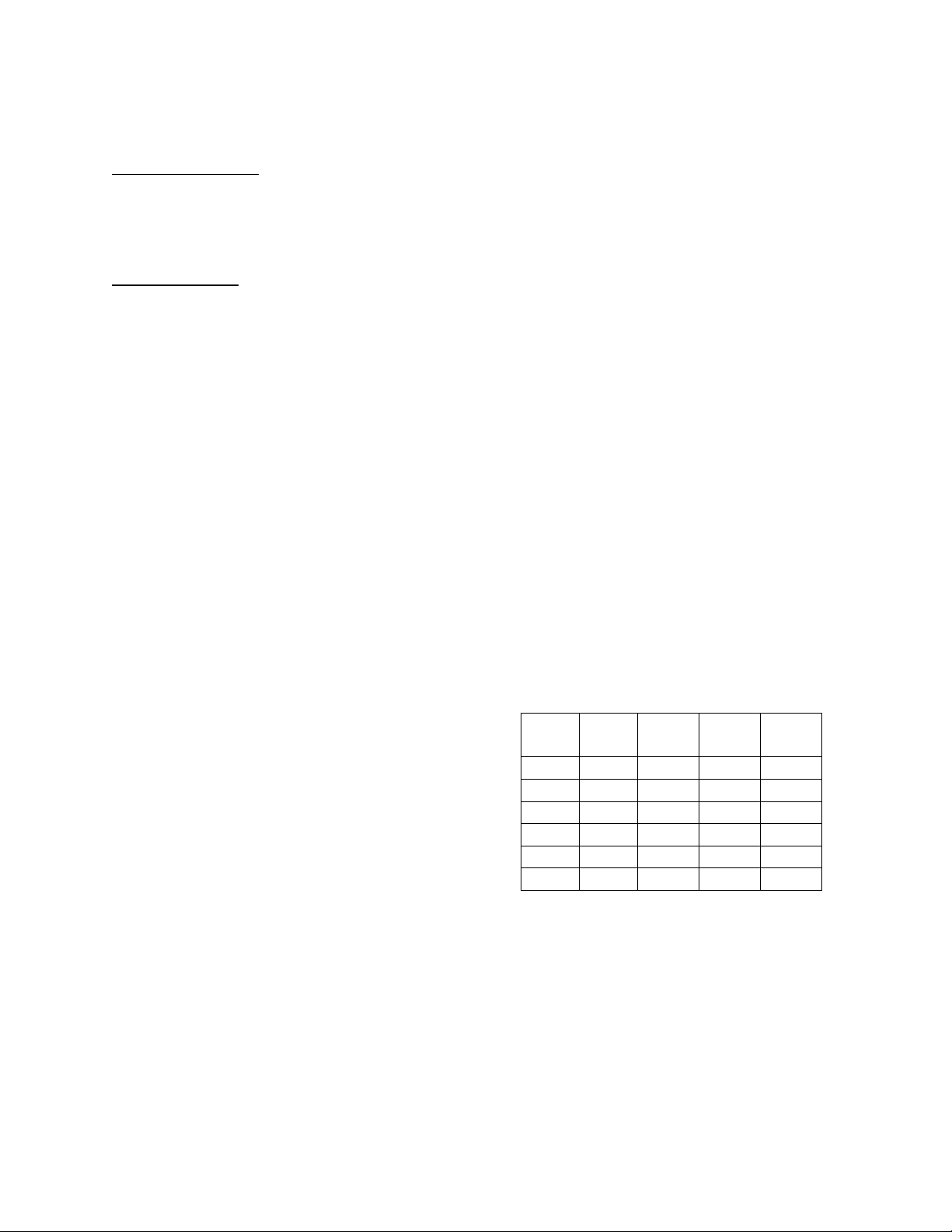

In the following tables, locate the kW of the

heater to be field installed, and then choose

the corresponding MCA and MOP values to

correctly size the wire gauge(s) and circuit

breaker(s), respectively.

Table 1 - Electric Heat Minimum Circuit

Ampacity

230V 208V

kW kW MCA MCA MCA

5 3.75 26.0

10 7.50 52.1

15 11.25 52.1 26.0

20 15.00 52.1 52.1

25 18.75 52.1 52.1 26.0

Overcurrent protection less than that

recommended on the unit's "Specification

Sheet" could result in unnecessary fuse

failure and service call. The manufacturer

bears no responsibility for damage caused to

the equipment as a result of not using the

recommended size for the protective devices

as listed on the unit's rating plate.

Line 1 Line 2 Line

3

16

Page 17

Table 2 - Electric Heat Maximum

A

A

A

Overcurrent Protection

230V 208V Line 1 Line 2 Line

3

kW kW MOP MOP MOP

5 3.75 30

10 7.50 60

15 11.25 60 30

20 15.00 60 60

25 18.75 60 60 30

Heat Pump

For heat pump equipped split system

configurations, the heat pump is the primary

heat source during a call for heat. During

operation at low ambient temperatures

where the heat pump alone cannot satisfy

the space temperature set point, electric

resistance heat elements are activated.

Below about 17°F, only the electric heat is

operable; the heat pump is not active.

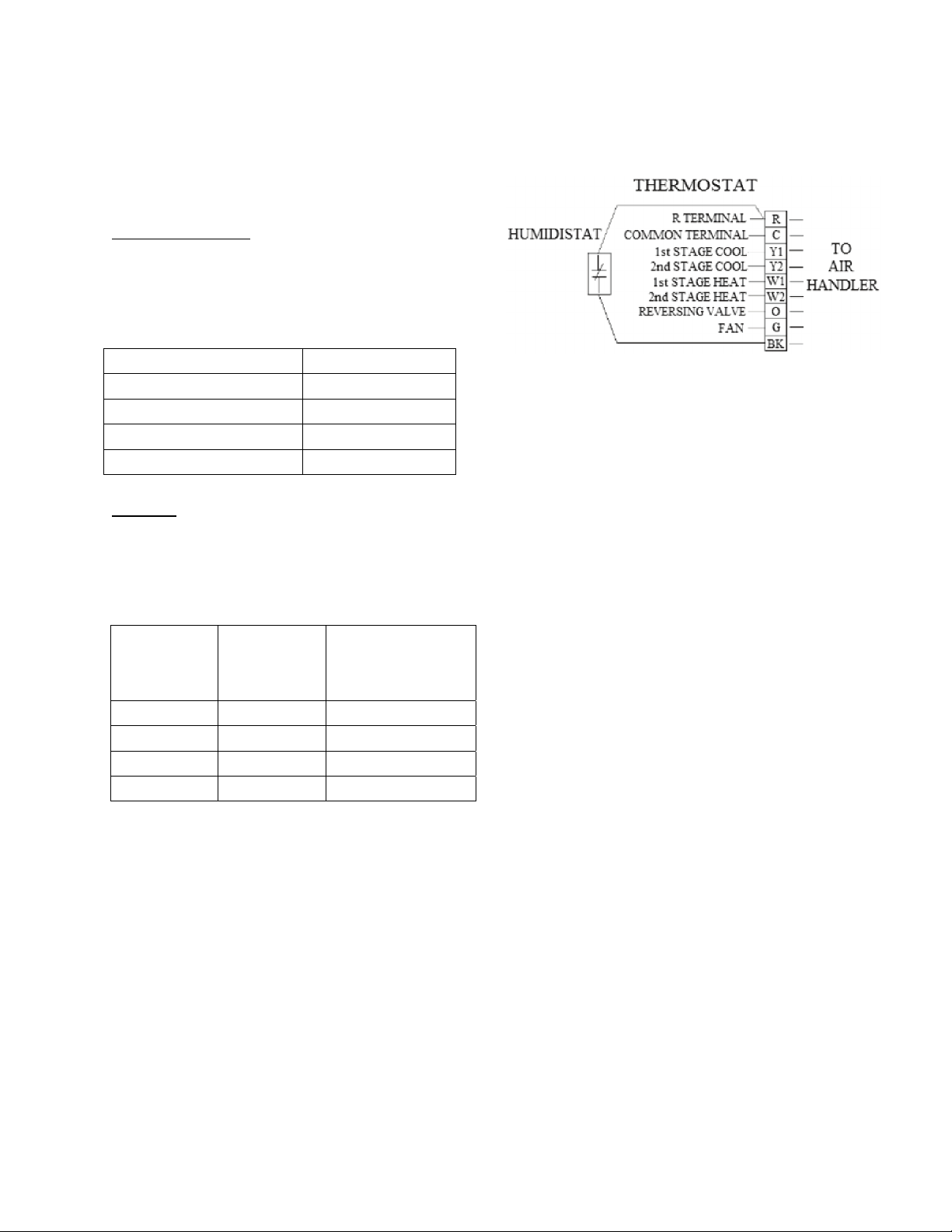

ECM Driven Fan

The Electrically Commutated Motor (ECM)

has selectable fan speeds as determined by

the configuration of four pins as shown in

FIGURE 2.

----

B

C

D

HEAT COOL ADJUST DELAY

- -

- -

- -

B

C

D

- -

- -

- -

----

1

- -

+

- -

-

----

1

- -

----

B

- -

C

- -

D

- -

Figure 2 - Example Configuration of ECM

Fan Taps

Adjust the taps as desired for cooling,

dehumidification, and heating according to

the following instructions.

Cooling:

Units are preprogrammed from the factory

for a rated airflow rate of 400 cfm per ton as

shown in Table 3.

Table 3 - Factory Preset Air Flow

Model Preset cfm

F1-060 2000

F1-048 1600

F1-036 1200

F1-024 800

* Maximum total static is 2.25” w.g.

The high speed for cooling may be selected

by setting the COOL and ADJUST fan

speed taps (shown in Figure 2). The setting

combinations are shown in Table 4.

Note: On the ADJUST tap, both of the ‘1’

selections have the same effect on motor

speed.

Table 4 - Cooling Fan Speed Tap Settings

F1-060/ F1-036/

F1-048 F1-024

(cfm) (cfm)

COOL

Tap

ADJUST

Tap

2000 1200 A 1

2000 1200 D 1

1840 1150 B +

1700 1020 A 1700 1020 D 1600 1000 B 1

1380 920 C +

1360 850 B 1200 800 C 1

1020 680 C -

A signal from the thermostat, showing a

need for dehumidification, will cause the

unit to slow the fan speed in order to allow

the air moving across the coil to get colder

thereby better dehumidifying the air. Fist

stage dehumidification has a low fan speed

of 67% of the selected max speed. Second

stage dehumidification has a fan speed of

45% of the selected max speed. NOTE: The

Modulating Hot Gas Reheat option must be

selected to have a second stage of

dehumidification.

17

Page 18

In this comfort cooling application of the

ECM fan motor, heat and cool taps, A & D

have the same effect on motor speed.

Humidity Control:

Adjust the DELAY tap for humidity control

that is suitable for the climate according to

Table 5.

Table 5 - Climate Settings

CLIMATE DELAY Tap

Humid A

Sub-humid/Dry B

Semi-Arid C

Arid/Hyper-Arid D

Heating:

The fan speed for the heating cycle is

selected by adjusting the HEAT tap (see

FIGURE 2) according to TABLE 6.

Table 6 - Heating Fan Speed Tap Settings

F1-060/ F1-036/

HEAT Tap F1-048 F1-024

(cfm) (cfm)

1800 1000 A

1400 800 B

1200 600 C

1800 1000 D

ECM Fan Notes

1. Fan only = 50% of max speed

2. Dehumidifying speeds

i) First stage dehumidification =

67% of max speed

ii) Second stage dehumidification =

45% of max speed

3. Green Light will blink once per every

100 CFM

4. Dehumidification terminal is BK. There

must be a constant voltage to this

terminal, and when the voltage is

dropped then dehumidification mode

will begin.

Fan wiring notes:

1. If only one stage of cooling is used then

jumper Y1 and Y2.

2. If unit is not heat pump capable then

jumper O and Y1.

3. If no humidistat is used then jumper BK

and R.

4. When only one stage of heat is used

jumper W1 and W2.

Reheat Coil Refrigerant Piping

The reheat coil is shipped already

installed on the leaving air section of the

air handling unit. A liquid receiver is

shipped loose with the unit for field

installation. (See Refrigerant Piping Section

to determine acceptable refrigerant line

size.)

1. Run a hot gas line from the outdoor unit

and connect it to the inlet of the stub-out

on the reheat coil.

a. For vertical (up-flow) units. The

inlet connection is the left stub-out

when facing the front of the unit.

Connect the hot gas line from the

outdoor unit to the left stub-out.

Connect the check valve (shipped

loose) to the right stub-out in a

direction so that the refrigerant flow

is leaving the right side of the coil.

Be sure to not block access for

18

Page 19

service of the air handling unit with

the placement of the check valve.

b. For horizontal discharge units.

Connect the hot gas line from the

outdoor unit to the upper stub-out

connection of the reheat coil.

Connect the check valve (shipped

loose) to the lower stub-out in a

direction so that the refrigerant is

leaving the bottom side of the reheat

coil. Be sure to not block access for

service of the air handling unit with

the placement of the check valve.

2. After installing the check valve, mount

the receiver (shipped loose). The

receiver tank must be mounted

horizontally for proper operation. The

receiver may be mounted on the air

handling unit or at a convenient location

near the air handling unit. Be sure to not

block access for service of the air

handling unit with the placement of the

receiver.

3. After mounting the receiver, run a liquid

line from the discharge of the check

valve to the receiver tank through a tee

connection. Run a liquid line from the

condenser, through a check valve to the

other side of the tee. Note check valve in

condenser liquid line is not used on heat

pump models. (See Refrigerant Piping

Section to determine acceptable line

size, location of components and to see a

diagram depicting the finished line

piping.)

4. After installing the receiver tank, run a

liquid line from the receiver outlet to the

TXV. (See Refrigerant Piping Section to

determine acceptable line size and to see

a diagram depicting the finished line

piping.)

5. After completing the reheat and liquid

lines, run a Suction line from the

evaporator outlet to the outdoor unit

shutoff valve (See Refrigerant Piping

Section to determine acceptable line

size.)

6. After completing the refrigerant piping

installation, install the supply air

temperature sensor (shipped loose) 18”

from the leaving air outlet from the air

handling unit.

7. After installing the supply air

temperature sensor, check that the reheat

supply air temperature setpoint is

correctly set on the control board. This

temperature should be set to the desired

space temperature when the unit is in

cooling mode. If that temperature is

unknown at the time of installation, set

the setpoint to 72°F.

The reheat system provides for “neutral”

(neither hot nor cold) air to the space so that

the unit can dehumidify the air without over

cooling or over heating the space. The

desired leaving air temperature is set on the

control board in the unit. The factory

suggests a setpoint of 72°F for most

applications; however, the setpoint is

adjustable for more specific applications or

differing comfort levels. The setpoint should

be set for the desired temperature in the

space during cooling mode. During

dehumidification mode the cooling coil

operates and the modulating valve in the

reheat system meters the amount of hot

refrigerant being directed to the reheat coil

so that the cooled and dehumidified air is

reheated, to the setpoint provided on the

control board, to a room neutral temperature.

This temperature setpoint and method of

dehumidification allows for the home to be

dehumidified even when there is not a need

for cooling in the space.

Note: Systems with the modulating hot gas

reheat option will require refrigerant to be

field added because of the additional

refrigerant components and piping

associated with the system.

19

Page 20

Condensate Piping

A drain trap must be connected to the drain

pan at the unit. Condensate connections are

provided on each side of the unit.

Condensate piping should be installed

according to local codes. The line should be

the same pipe size as the drain nipple and

should pitch downward toward the building

drain.

All cooling coils must have drain pans

equipped with “P” traps to avoid pulling air

from outside the unit back through the drain

line. All drain connection ports are sealed.

Knock out only the connection port to be

used. The trap should be located in warm

ambient spaces. An additional drain pan

may be installed under the air handling unit,

and should include a separate drain line for

overflow from the primary drain. An air

break should be used with long runs of

condensate lines.

Drain pans in any air conditioning

equipment, even when they have a built-in

slope to the drain, will have moisture present

and will require periodic cleaning to prevent

any build-up of algae or bacteria. Cleaning

of the drain pans will also prevent any

possible plugging of the drain lines, and

overflow of the pan itself. Some means to

clean out the “P” trap should be provided.

Only qualified personnel should clean drain

pans, drain lines, or the insides of

equipment.

Electrical

Check the unit data plate to make sure it

agrees with the power supply. Connect

power to the unit according to the wiring

diagram provided with the unit.

The power and control wiring may be

brought in through the holes provided on the

unit. Protect the branch circuit in accordance

with code requirements. If the control wires,

are to run inside the same conduit, use 600volt wire or as required by applicable codes.

The units must be electrically grounded in

accordance with the National Electric Code,

ANSI / UL 1995 when installed if an

external source is utilized; in Canada use

current C.S.A. Standard C22.2, No. 236,

Canadian Electric Code Part 1.

Power wiring is to the unit terminal control

board. The manufacturer has done all wiring

beyond this point. Power can be applied to

the unit after the control wiring is connected,

and startup checks are complete.

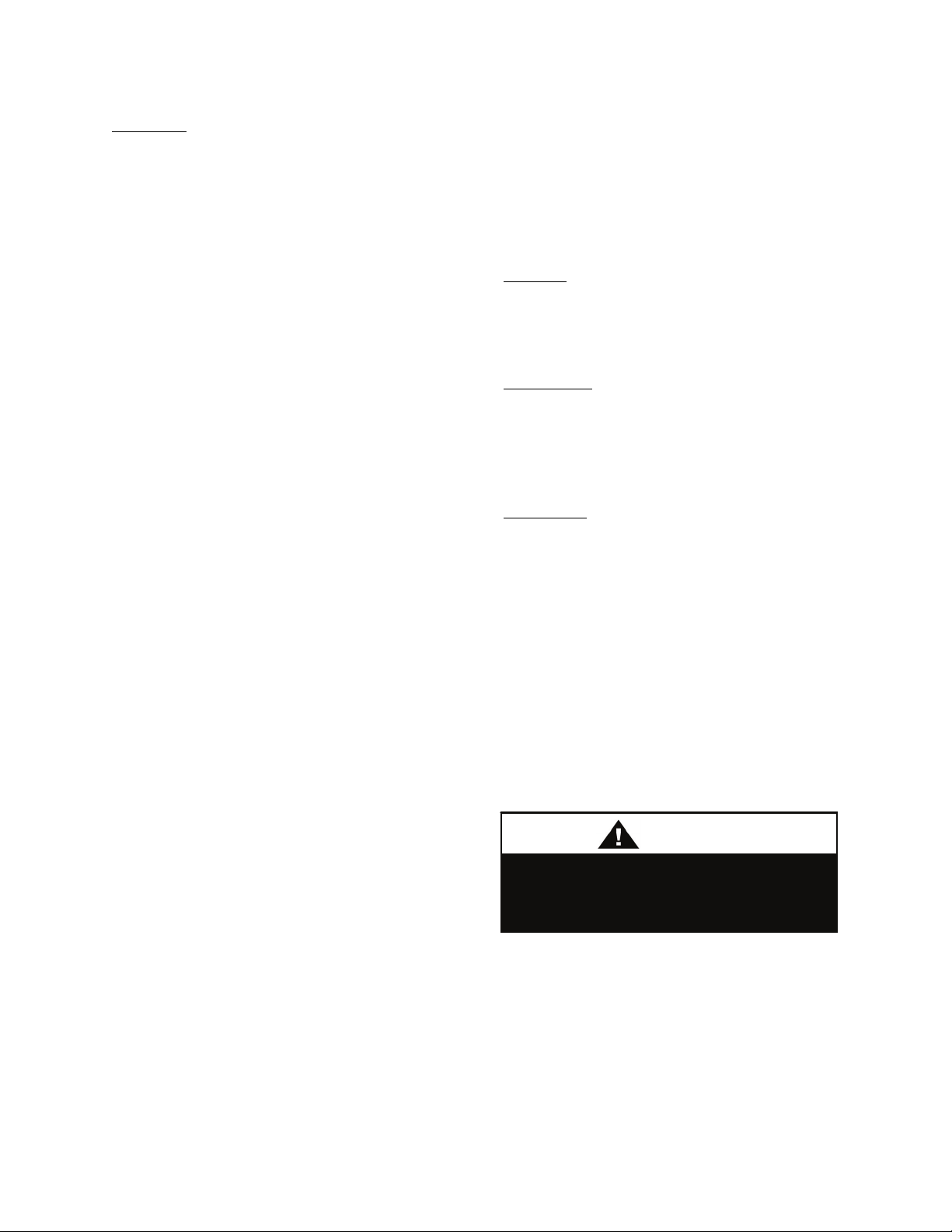

Thermostat

Units without the neutral air

dehumidification feature will operate with

most common thermostats. Units with the

neutral air dehumidification feature must use

thermostats with a normally closed (NC)

dehumidification option. The following stats

have been approved for usage with the

dehumidification feature.

Robertshaw Honeywell

9825i2

Filters

Open filter access bracket and slide correct

filter in with arrow pointing towards the

blower in the direction of airflow.

Replacement filters are 20” x 20” x 1”.

Charging Refrigerant

The unit comes with full charge based on a

25-foot line set. Charging a system in the

field must be based on determination of

liquid sub-cooling and evaporator superheat.

On a system with a thermostatic expansion

valve, liquid sub-cooling is more

representative of the charge than evaporator

superheat but both measurements must be

taken.

VisionPRO®IAQ

20

Page 21

The Clean Air Act of 1990 bans the

intentional venting of refrigerant as of

July 1, 1992. Approved methods of

recovery, recycling, or reclaiming

must be followed.

Before Charging

The unit being charged must be at or near

full load conditions before adjusting the

charge.

Units equipped with hot gas reheat must

have the hot gas reheat valves closed to get

the proper charge.

Units equipped with hot gas reheat must be

charged with the hot gas valve closed while

the unit is in cooling mode.

After adding or removing charge the system

must be allowed to stabilize, typically 10-15

minutes, before making any other

adjustments.

The type of unit and options determine the

ranges for liquid sub-cooling and evaporator

superheat. Refer to Table 7 when

determining the proper sub-cooling.

The vertical rise of the liquid line must be

known in order to adjust the sub-cooling

range for proper charge.

Checking Liquid Sub-cooling

1. Measure the temperature of the liquid

line as it leaves the condenser coil.

2. Read the gauge pressure reading of the

liquid line close to the point where the

temperature was taken. You must use liquid

line pressure, as it will vary from discharge

pressure due to condenser coil pressure

drop.

3. Convert the pressure obtained in Step 2 to

a saturated temperature using the

appropriate refrigerant temperature-pressure

chart.

4. Subtract the measured liquid line

temperature in Step 1 from the saturated

temperature in Step 3 to determine the liquid

sub-cooling.

5. Compare calculated sub-cooling to

TABLE 7 for the appropriate unit type and

options.

Checking Evaporator Superheat

1. Measure the temperature of the suction

line close to the compressor.

2. Read gauge pressure at the suction line

close to the compressor.

3. Convert the pressure obtained in Step 2 to

a saturated temperature using the

appropriate refrigerant temperature-pressure

chart.

4. Subtract the saturated temperature in Step

3 from the measured suction line

temperature in Step 1 to determine the

evaporator superheat.

5. Compare calculated superheat to TABLE

7 for the appropriate unit type and options.

Adjusting Sub-cooling and Superheat

Temperatures

The system is overcharged if:

1. the sub-cooling temperature is too high

and

2. the evaporator is fully loaded (low loads

on the evaporator result in increased subcooling) and

3. the evaporator superheat is within the

temperature range as shown in TABLE 7

(high superheat results in increased subcooling)

21

Page 22

Table 7 - Acceptable Air-Cooled

Refrigeration Circuit Values

Sub-cooling

with Hot

Gas Reheat

(°F)

Air-

Cooled

Condenser

Sub-

cooling

(°F)

12-18* 8-15** 15-22*

Superheat

(°F)

* Sub-cooling must be increased by 2°F per

20 feet of vertical liquid line rise for R410A

** Superheat will increase with long suction

line runs.

Correct an overcharged system by reducing

the amount of refrigerant in the system to

lower the sub-cooling.

Refrigerant overcharging leads to

excess refrigerant in the condenser

coils resulting in elevated compressor

discharge pressure.

DO NOT OVERCHARGE!

The system is undercharged if:

1. The superheat is too high and

2. The sub-cooling is too low.

Correct an undercharged system by adding

refrigerant to the system to reduce superheat

and raise sub-cooling.

If the sub-cooling is correct and the

superheat is too high, the TXV may need

adjustment to correct the superheat.

Elevation Limitations

See Table 8 for rise and run limitations. All

lengths listed are in equivalent feet. An

equivalent foot of the line includes the

pressure drop of all valves, components,

fittings and other pipes in the sections.

Evaporator Coil

Evaporator coils are shipped under

high pressure. Use extreme care and

follow the installation instructions

provided with the evaporator coil to

avoid personal injury.

The indoor coil is pressurized. The copper

caps must be punctured to permit a gradual

escape of the pressure prior to unsweating

those caps. Immediately couple the tubing to

the indoor unit to avoid exposing the coils to

moisture. A properly sized filter drier is

furnished in the condenser. When making

solder connections, make sure dry nitrogen

flows through the lines, when heating the

copper, to prevent oxidization inside of the

copper.

22

Page 23

°F

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

PSIG

78.3

80.0

81.8

83.6

85.4

87.2

89.1

91.0

92.9

94.9

96.8

98.8

100.9

102.9

105.0

107.1

109.2

111.4

113.6

115.8

118.1

120.3

122.7

125.0

127.4

129.8

132.2

Table 8 - R-410A Refrigerant Temperature-Pressure Chart

°F

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

PSIG

134.7

137.2

139.7

142.2

144.8

147.4

150.1

152.8

155.5

158.2

161.0

163.8

166.7

169.6

172.5

175.4

178.4

181.5

184.5

187.6

190.7

193.9

197.1

200.4

203.6

207.0

210.3

°F

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

PSIG

213.7

217.1

220.6

224.1

227.7

231.3

234.9

238.6

242.3

246.0

249.8

253.7

257.5

261.4

265.4

269.4

273.5

277.6

281.7

285.9

290.1

294.4

298.7

303.0

307.5

311.9

316.4

°F

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

PSIG

321.0

325.6

330.2

334.9

339.6

344.4

349.3

354.2

359.1

364.1

369.1

374.2

379.4

384.6

389.9

395.2

400.5

405.9

411.4

416.9

422.5

428.2

433.9

439.6

445.4

451.3

457.3

°F

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

PSIG

463.2

469.3

475.4

481.6

487.8

494.1

500.5

506.9

513.4

520.0

526.6

533.3

540.1

547.0

553.9

560.9

567.9

575.1

582.3

589.6

596.9

604.4

611.9

23

Page 24

Startup

General

ONLY QUALIFIED, AUTHORIZED

PERSONNEL SHOULD POWER ON, OR

STARTUP THIS EQUIPMENT.

Before starting up the equipment, building

construction should be complete, and startup personnel should:

Have a working knowledge of general

HVAC and mechanical commissioning

procedures and practices.

Be familiar with unit functions, features,

optional unit accessories, and all control

sequences.

Have appropriate literature on hand for

consultation.

Equipment operation during

construction is not recommended.

Construction site pollution can affect

unit operation, and seriously degrade

performance. Operation during

construction will void all

manufacturers’ warranties.

Before the structure is occupied, the

installation, and/or startup personnel must

take three essential steps:

1. Check-Out

2. Start-Up

3. Commissioning

Check-Out

Equipment should be thoroughly checked

for loose wiring, a free spinning blower

wheel and well fitting access panels. Air

handling units should not be operated

without proper ductwork and access panels

installed, except as required during start-up

and air balancing.

1. Check all electrical connections to be

sure they are tight.

2. Open all access panels, and remove all

shipping screws, or restraints.

3. Clean out any debris that may be

present.

4. Check wheel alignment, and tightness of

fan drives.

5. Check bearing locking collars if

provided and fan wheel set screws for

tightness.

6. Turn fan wheels to assure free rotation.

7. Ensure electrical supply matches the unit

nameplate.

8. Ensure condensate lines are correctly

connected.

9. Check local codes for any special

provisions.

10. Replace and/or close all access panels.

Procedures

Note: Failure to adhere to the following

start-up procedures will void all

manufacturer warranties.

Install gauges, voltmeter and ammeter

before start-up. Observe refrigerant

pressures during initial operation. Note, and

determine the cause of any excessive sound

or vibration. Follow start-up procedures

outlined below to start each piece of

equipment.

Note: Completed factory test sheets are in

the equipment literature packet shipped

inside the unit. Factory run-test readings

recorded on the test sheets may be helpful to

reference during start-up.

24

Page 25

Do not alter factory wiring. Deviation

from the supplied wiring diagram will

void all warranties, and may result in

equipment damage or personal

injury. Contact the factory with wiring

discrepancies.

Electric Heat Section Procedures

1. Perform final visual inspection.

Check all equipment ductwork and

piping to verify that all work is

complete. Improperly installed

equipment or ductwork can affect

readings.

2. Ensure that there is no construction

debris in the unit.

3. Check the unit for external damage.

4. Note all accessories installed.

5. Install a filter of the proper size and

type.

6. Check all terminal blocks, fuses, fuse

blocks, and contactors for

correctness.

7. Check all high and low voltage

wiring connections for correctness,

and tightness.

8. Check unit for correct incoming

voltage per the data plate.

9. Turn the power on.

10. Turn on the first stage of heating

Check amp draw of each element of each

stage.

Ensure blower started with electric heat.

Check for temperature rise across heating

section while all stages are on.

If temperature rise is within range, turn all

heating calls off.

Check to see that fan stops.

Refrigerant Cooling Section Procedures

1. Perform final visual inspection. Check

all equipment, ductwork and piping to

verify that all work is complete, and

equipment is properly installed and

mounted. Improperly installed

equipment or ductwork can affect

readings.

2. Perform condensing unit start-up checks

in addition to these air handling unit

checks according to the unit

manufacturer’s instructions.

3. Ensure that there is no construction

debris in the unit.

4. Check the unit for external damage.

5. Install filter of the proper size and type.

6. Ensure that drain P-trap is installed.

7. Check all terminal blocks, fuses, fuse

blocks, disconnect box, and contactors

for correctness.

8. Check all high and low voltage wiring

connections for tightness. Check unit for

correct incoming voltage per the data

plate.

9. Check the security of the locking system

on all blower bearings.

10. Turn the power on.

11. Check and record ambient temperature.

12. Check for guaranteed off timers (GOT),

and/or time delay relays (TDR).

13. Start the first step cooling circuit, and

blower circuit.

Optional Equipment Procedures

If Modulating Hot Gas Reheat is equipped,

additional installation steps are required.

1. Field installed piping is required.

2. The field supplied thermostat and

humidistat must be wired to the reheat

control as shown in the unit wiring diagram.

25

Page 26

3. Verify that the condenser hot gas valve

and reheat hot gas valve are wired as shown

in the wiring diagram.

4. Verify that the Modulating Hot Gas

Reheat system is working properly. Run for

five minutes in the reheat mode and verify

that the temperature of the supply air stream

matches the reheat temperature set point.

Commissioning

Air Balancing

High performance systems commonly have

complex air distribution and fan systems.

Unqualified personnel should not attempt to

adjust fan operation, or air circulation, as all

systems have unique operating

characteristics. Professional air balance

specialists should be employed to establish

actual operating conditions, and to configure

the air delivery system for optimal

performance.

Water Balancing

A hydronic specialist with a complete

working knowledge of water systems,

controls and operation must be employed to

properly balance the entire system.

Unqualified personnel should not attempt to

manipulate temperatures, pressures, or flow

rates, as all systems have unique operating

characteristics, and improper balancing can

result in undesirable noises and operation.

Controls

A variety of controls and electrical

accessories may be provided with the

equipment.

Identify the controls on each unit by

consulting appropriate submittal or order

documents, and operate according to the

control manufacturer’s instructions. If you

cannot locate installation, operation or

maintenance information for the specific

controls, then contact your sales

representative, or the control manufacturer

for assistance.

Operation and Maintenance

General

Immediately following unit startup, the air

conditioning system requires a maintenance

schedule to assure continued successful

operation. A maintenance program similar to

the example given below should be

scheduled for routine maintenance of this

equipment in order to provide efficient and

reliable operation for the owner.

Maintenance Schedule

One week after start-up:

Check refrigerant charge. Evacuate and

repair if leaking.

Check filters for cleanliness. Measure

pressure loss if applicable. Replace if

necessary.

Check cycling of compressors, fans and

valves. Correct unusual cycling.

Monthly:

Check cleanliness of filters, and replace if

necessary.

Check cooling coil drain pan to assure

proper drainage or correct.

Inspect evaporator and condenser coils.

Clean if dirty or obstructed in any way.

Quarterly:

Check operation of heating and cooling

sections.

Check inlet and outlet air temperatures.

Determine cause for abnormal changes.

26

Page 27

Annually:

Clean the condenser and evaporator coils

with steam or a non-corrosive cleaner.

Clean the drain line, “P” trap and condensate

pan.

Check refrigerant pressures and

temperatures every spring and correct

unusual readings.

Check heating section every fall. Check all

electrical connections for tightness and

check heater elements for indications of

overheating. Determine cause and replace

elements if necessary.

Inspect and clean unit interior at the

beginning of each heating and cooling

season and as operating conditions require.

Lubrication

All original motors and bearings are

furnished with factory lubrication. They

require no lubrication.

Blower Assembly

F1 air handling units are equipped with

highly efficient forward curved fans. The

blower wheel should be inspected

periodically and cleaned of dust and debris.

Clean blower wheels reduce electrical use,

maintain capacity and reduce stress on the

unit.

To inspect and clean the blower, set

thermostat to the “OFF” position. Turn the

electrical power to the unit to the “OFF”

position at the disconnect switch. Check set

screw for tightness.

Coils

Coils should be inspected and cleaned

annually to ensure there is no obstruction to

airflow. Dirty evaporator coils will

eventually freeze up, and often result in a

time consuming and expensive service call.

Clean filters will help to prevent dirt from

accumulating on the evaporator. The

evaporator should be cleaned annually with

a non-corrosive coil cleaning solution.

Heating

Electric:

Set thermostat in the heat mode; call for heat

to engage all electric heat strips. Verify that

electric heat operates correctly.

Heat Pump:

Set thermostat in the heat mode; call for heat

to engage the three-way valve and turn the

heat pump mode on. Verify that the heat

pump operates correctly.

Hot Water:

Set thermostat in the heat mode; call for hot

water valve to open. Verify that hot water

valve opens with call for heat.

Filters

Open filter access door. Slide filters away

from unit and inspect. Replace dirty filters

with 20” x 20” x 1” filters.

Ensure that the arrow points toward the

blower in the direction of airflow. Filters

should be checked every 30 days and

replaced or cleaned as necessary.

Equipment should never be operation

without filters.

Permanent type filters may be vacuumed

and/or washed but should not be reinstalled

until thoroughly dry. Most air filters are

marked to indicate the direction of airflow,

and this should be carefully noted when they

are being installed.

27

Page 28

Never flip a dirty filter to allow airflow

in the opposite direction.

The blower and motor bearings are

permanently lubricated and do not require

additional lubrication. It is recommended

that the owner have available at least one set

of replacement fuses of the size supplied

with the original equipment.

Important: Keep coils, fans and filters

clean.

Service

In the event the unit is not functioning

correctly and a service company is required,

only a company with service technicians

qualified and experienced in both heating

and air conditioning should be permitted to

service the systems in order to keep

warranties in effect. The service tech may

call the sales representative if assistance is

required.

Note: Service technician must provide the

model and serial number of the unit in all

correspondence with AAON.

To order parts from the AAON parts

store online go to www.aaonparts.com.

Refrigerant Piping

(See back of the manual for refrigerant

piping diagrams.)

This section is for information only

and is not intended to provide all

details required by the designer or

installer of the refrigerant piping

between the condenser or

condensing unit and the air handling

unit. AAON is not responsible for

interconnecting refrigerant piping.

Consult ASHRAE Handbook –

Refrigeration and ASME Standards.

General

Piping from the condensing unit to the air

handling unit is the responsibility of the

installing contractor.

Use only clean type “ACR” copper tubing

that has been joined with high temperature

brazing alloy.

The pipe sizes must be selected to meet the

actual installation conditions and not simply

based on the connection sizes at the

evaporator and/or condensing unit.

Condensing units are provided with in-line

shutoff valves on both the liquid and suction

lines. These should remain closed until the

system is ready for start-up after piping and

vacuuming.

Piping should conform to generally accepted

practices and codes.

Upon completion of piping connection, the

interconnecting piping and air handling unit

MUST BE evacuated to 500 microns or less;

leak checked and charged with R-410A

refrigerant.

28

Page 29

Determining Refrigerant Line Size

Line sizes must be selected to meet

actual installation conditions, not

simply based on the connection sizes

at the condensing unit or air handling

unit.

The piping between the condenser and low

side must assure:

1. Minimum pressure drop, and

2. Continuous oil return, and

3. Prevention of liquid refrigerant slugging,

or carryover

Minimizing the refrigerant line size is

favorable from an economic perspective,

reducing installation costs, and reducing the

potential for leakage. However, as pipe

diameters narrow, pressure-reducing

frictional forces increase.

Excessive suction line pressure drop causes

loss of compressor capacity and increased

power usage resulting in reduced system

efficiency. Excessive pressure drops in the

liquid line can cause the liquid refrigerant to

flash, resulting in faulty expansion valve

operation and improper system performance.

In order to operate efficiently and cost

effectively, while avoiding malfunction,

refrigeration systems must be designed to

minimize both cost and pressure loss.

The pipe sizes must be selected to meet

the actual installation conditions, and not

simply based on the connection sizes at

the evaporator and/or condensing unit.

Equivalent Line Length

All line lengths discussed in this manual,

unless specifically stated otherwise, are

Equivalent Line Lengths.

The frictional

pressure drop through valves, fittings and

accessories is determined by establishing the

equivalent length of straight pipe of the

same diameter. Always use equivalent line

lengths when calculating pressure drop.

Special piping provisions must be taken

when lines are run underground, up vertical

risers, or in excessively long line runs.

Liquid Line Sizing

When sizing the liquid line, it is important to

minimize the refrigerant charge to reduce

installation costs and improve system

reliability. This can be achieved by

minimizing the liquid line diameter.

However, reducing the pipe diameter will

increase the velocity of the liquid

refrigerant, which increases the frictional

pressure drop in the liquid line, and causes

other undesirable effects such as noise.

Maintaining the pressure in the liquid line is

critical to ensuring sufficient saturation

temperature, avoiding flashing upstream of

the TXV, and maintaining system

efficiency. Pressure losses through the liquid

line due to frictional contact, installed

accessories and vertical risers are inevitable.

Maintaining adequate sub-cooling at the

condenser to overcome these losses is the

only method to ensure that liquid refrigerant

reaches the TXV.

Liquid refrigerant traveling upwards in a

riser will lose head pressure. If the

evaporator section is below the condenser,

and the liquid line does not include risers,

the gravitational force will increase the

pressure of the liquid refrigerant. This will

allow the refrigerant to withstand greater

frictional losses without the occurrence of

flashing prior to the TXV.

A moisture-indicating sight glass may be

installed in the liquid line by special order to

indicate the occurrence of premature

flashing or moisture in the line. The sight

29

Page 30

glass should not be used to determine if the

CAUTIO

system is properly charged. Use

temperature and pressure measurements

to determine liquid sub-cooling, not the

sight glass.

Liquid Line Routing

Care should be taken with vertical risers.

When the system is shut down, gravity will

pull liquid down the vertical column, and

back to the condenser when it is below the

evaporator. This could potentially result in

compressor flooding. A check valve can be

installed in the liquid line where the liquid

column rises above the condenser to prevent

this. The liquid line is typically pitched

along with the suction line, or hot gas line,

in the direction of the compressor to

minimize the complexity of the

configuration.

Liquid Line Insulation

When the liquid line is routed through

regions where temperature losses are

expected, no insulation is required, as this

may provide additional sub-cooling to the

refrigerant. When routing the liquid line

through high temperature areas, insulation of

the line is appropriate to avoid loss of subcooling through heat gain.

Liquid Line Guidelines

In order to ensure liquid at the TXV,

frictional losses must not exceed available

sub-cooling. A commonly used guideline to

consider is a system design with pressure