Page 1

The Name To Remember

In d I r e c t FI r e d cu s to m AIr HA n d l I ng un I ts

1,500 - 218,000 CFM

• Indirect Fired Burners

• 3 - Pass Stainless Steel Heat Exchanger

• 2 or 3 Deck Multizone Capability

• 0 - 100% Outside A i r O p e r a t i o n

• Indoor or Outdoor Operation

• Factory Wired & Tested

• Natural Gas, Liquid Propane or Oil Fired

Page 2

In d I r e c t FI r e d cu s to m AIr HA n d l I ng un I ts

AAON utilizes extensive product knowledge and state of the art manufacturing to continuously provide practical HVAC products to

the dynamic market place.

Functionality – AAON equipment is designed and manufactured to meet your particular specications. AAON custom products

provide superior features and your choice of premier options. Along with your choice of controls, AAON custom equipment is tailored

exactly to your job requirements.

Flexibility - AAON custom air handlers are optimally congured for individual applications. The custom market is differentiated

by higher quality construction and virtually unlimited choices in unit components, material, conguration, cabinet size and aspect

ratios.

Innovation - AAON sales, design and manufacturing engineers have extensive experience in the custom arena. As customers

demand for greater exibility and customization grows, AAON continues to develop innovative solutions to bring to the market. This

passion to provide inventive products for our customers has led AAON to make substantial investments in research, development,

engineering and manufacturing capability that have allowed AAON to revolutionize the HVAC market and deliver this standard of

excellence to you.

Superior Features

All natural gas and liquid propane burners are modulating;

•

#2 fuel oil burners are available as modulating or with

staged capacity control depending on burner capacity.

Gas and Electrical components operate down to -40°F

•

(-40° C) for worry free operation even at your coldest

operating point when operation is most important.

Heat Exchanger is capable of a 120°F temperature rise.

•

Hinged access doors for fan, lter, and coil sections provide

•

quick and easy access to key areas of the equipment. No need

to worry about removing panels to access the equipment.

The unit is fully factory wired and tested so that the unit

•

arrives to the jobsite ready for operation without costly

setup or troubleshooting.

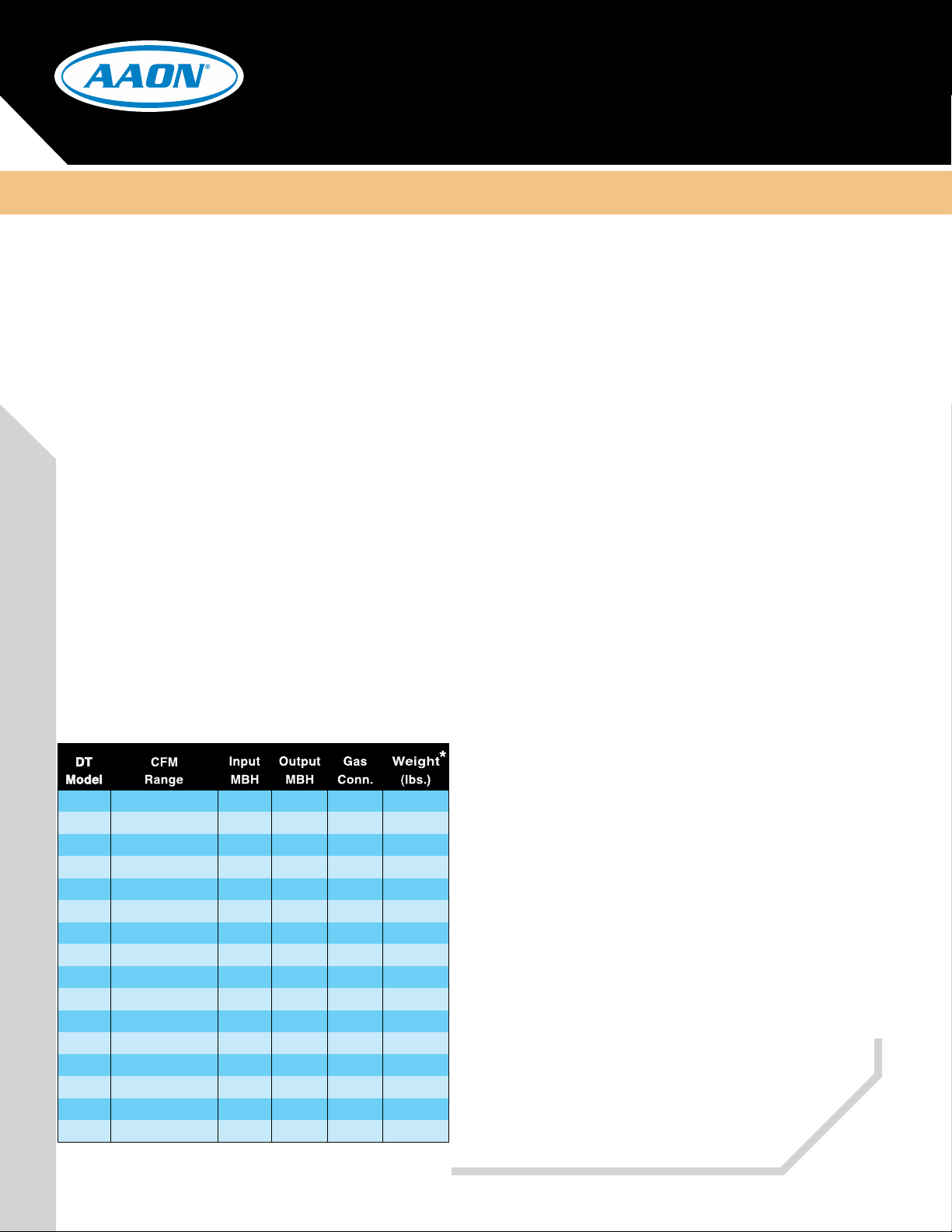

025 1,800 - 10,000 312 250 3/4” 1,200

030 2,350 - 12,000 375 300 3/4” 1,400

040 2,900 - 12,000 500 400 3/4” 1,400

050 3,600 - 17,000 652 500 3/4” 1,800

065 4,800 - 23,000 812 650 1” 2,300

075 5,400 - 24,000 937 750 1” 2,300

085 6,200 - 25,000 1,062 850 1 1/4” 3,600

100 7,500 - 36,000 1,250 1,000 1 1/4” 3,600

125 9,000 - 45,000 1,562 1,250 1 1/2” 5,200

150 11,000 - 54,000 1,875 1,500 1 1/2” 5,200

175 13,000 - 63,000 2,187 1,750 2” 6,500

200 15,000 - 72,000 2,500 2,000 2” 6,500

250 20,000 - 90,000 3,125 2,500 2” 11,500

300 22,000 - 109,000 3,750 3,000 2” 12,000

400 29,000 - 145,000 5,000 4,000 2 1/2” 13,000

600 43,000 - 218,000 7,500 6,000 2 1/2” 15,500

* Weight shown is for base model. Actual weight will depend on

options & materials selected.

Premier Options

Burner is rated and suitable for natural gas, propane or #2 fuel oil

•

operation.

Casing Options include 2” or 4” Double Wall construction to be sure the

•

conditioned air reaches the space and is not lost through the cabinet.

Factory installed condensing sections are available, allowing you to

•

create a completely customized packaged unit.

Factory mounted direct injection, electric, gas-to-steam humidiers and

•

dispersion tubes save installation time at the jobsite.

Factory or Field Mounted Controls can be provided to meet the

•

existing control architecture or designed to meet your needs for new

construction.

Factory provided service platform or walk-in service vestibule to allow

•

easy access to the equipment at the jobsite.

Fan Isolation options include 1” deection spring isolators, 2” deection

•

spring isolators, seismic or a concrete inertia base constructed of 6” iron

channel and isolated with 2” deection springs

Filter options include Pleated, Permanent Washable, Cartridge, Bag

•

and HEPA. These options are designed to meet even the most stringent

indoor air quality requirements.

Heat Exchanger material options include 304 and 321 to provide the

•

exibility in design needed for your application.

Liner Options for the interior cabinet include a solid galvanized steel liner

•

for improved indoor air quality and cleanability, a perforated galvanized

steel liner for elimination of operational noise or a solid stainless steel

liner for the ultimate in corrosion resistance.

R-410A environment friendly refrigerant.

•

Remote control panel with a summer-winter-off switch, burner on light,

•

alarm light, fan on light, discharge air temperature setting and LED

display and dirty lter indication light for unit monitoring without going to

the mechanical room or rooftop.

Cooling Coils.

•

Heat Recovery, plate, wheel, heatpipe, run-around coils.

•

Page 3

Applications

High-rise Residential

•

Clean Rooms

•

Commercial office buildings

•

Educational buildings

•

Food processing facilities

•

Grocery Stores

•

Hospitals

•

Manufacturing plants

•

Pharmaceutical rms

•

Performance

Because of the AAON custom air

handler’s performance exibility, it

has been successfully applied in a

number of different applications.

Whether your specic need is,

Multizone

•

VAV units

•

Unique footprint or selectable

•

air tunnel dimensions

Special humidication /

•

dehumidication

Ultra quiet operation

•

Energy recovery capabilities

•

Make-up air capabilities

•

Factory mounted options

•

Indirect Fired Heater

Indirect-red heaters do not discharge

•

combustion products into the heated

space

Highly efcient 3-pass heat

•

exchanger design

Uniform temperature distribution

•

extends heat exchanger life

Constructed to provide outdoor, as

•

well as 100% recirculated air

Standard Stainless Steel construction

•

Fans

AAON can provide many types of fans

to meet exact design requirements and

are always individually selected to match

external static, sound efciency and

space design criteria.

Housed airfoil

•

Housed backward inclined

•

Housed forward curve

•

Airfoil plenum

•

Vane axial

•

Prop exhaust

•

All fans can be provided with open drip

proof (ODP) or totally enclosed fan

cooled (TEFC) motors.

Variable frequency drives

•

Fan isolation options:

Rubber-in-shear isolators

•

1” or 2” deection spring isolators

•

Seismic

•

Concrete inertia bases islolated with 2”

•

deection springs

Coils

ARI Certied 1/2” and 5/8” coils.

Low pressure drop and high

•

performance

Aluminum or copper ns

•

Galvanized or stainless steel casing

•

Intertwined, face-split or condensing

•

unit matched circuiting

Special coatings for highly corrosive

•

environments

Controls

Control exibility provides solutions

for stand alone operation or building

automation system integration.

Factory wired to terminal strip for

•

controls by others

Pre-engineered factory mounted

•

commisioned controls

Customer specied factory mounted

•

controls

Interconnected or networked

•

Integrated into open protocol

•

environments

Page 4

AAO N E nvi ron men tal ly Friendly HVA C P rod uct Fa mil y

Customer Commitment – AAON encourages environmentally responsible design by incorporating many

energy saving features into our superior heating and cooling products. In addition to energy efciency, AAON

also offers environmentally friendly R-410A refrigerant capability in all our cooling and heat pump equipment. As

countries throughout the world phase out CFC and HCFC refrigerants, R-410A is becoming the global standard

and AAON is leading the way!

Rooftop Units

2 - 5 Tons

26 - 70 Tons

45 - 230 Tons

Outdoor Air Handling Units

2 - 30 Tons

Condensing Units

2 - 5 Tons

7.5 - 40 Tons

45 - 230 Tons

Indoor Air Handling Units

Air-Cooled or

Evaporative-Cooled Chiller

35 - 365 Tons

Boiler

500 - 6,000 MBH

Custom Indoor or Outdoor

Air Handling Units

800 - 2,000 CFM

10,400 - 28,000 CFM

18,000 - 68,000 CFM

R51020 • 070130

800 - 12,000 CFM

It is the intent of AAON to provide accurate up-to-date specication data. However, in the interest of ongoing product improvement, AAON, Inc.

reserves the right to change specications and/or design of any product without notice, obligation, or liability.

2425 South Yukon Avenue • Tulsa, OK 74107 • 918-583-2266 • Fax 918-583-6094 • www.aaon.com

AAON® products are covered by one or more of the following U.S. patents:

5,738,167; 5,826,641; 5,839,505; 6,715,312; 6,792,767, 6,802,543, 6,929,452.

AAON and AAONAIRE are registered trademarks of AAON, Inc.

D-PAC and AAONEcat32 are trademarks of AAON, Inc.

Heatow and AAON Suite are trademarks of AAON Coil Products, Inc.

1,000 - 16,000 CFM

17,000 - 52,000 CFM

1,500 - 218,000 CFM

800 - 10,000 CFM

1,000 - 100,000+ CFM

1,000 - 120,000+ CFM

Loading...

Loading...