Page 1

CL SERIES

ROOFTOP CONDENSING UNITS

INSTALLATION, SERVICE

&

OWNER’S INFORMATION MANUAL

Page 2

TABLE OF CONTENTS

SECTION Page

GENERAL DESCRIPTION…………………………………………………………………………………………………

Unpacking…………………………………………………………………………………………………………..

OWNER’S INFORMATION………………………………………………………………………......................................

Wiring Diagrams……………………………………………………………………................................................

General Maintenance………………………………………………………………………………………………..

INSTALLATION…………………………………………………………………………….……………………………....

Lifting and Handling……………………………………….……………………………………………………….

Condenser Placement……………………………………………………………………………………………….

Compressor Compartment Exhaust Fan…………………………………………………………………………….

Mounting Isolation………………………………………………………………………………………………….

Access Doors……………………………………………………………………………………………………….

Low Ambient Operation…………………………………………………………………………………………….

LAC Valve…………………………………………………………………………………………………………..

OROA Valve………………………………………………………………………………………………………...

ORI/ORD Valves……………………………………………………………………………………………………

Condenser Flooding…………………………………………………………………………………………………

Electrical…………………………………………………………………………………………………………….

Refrigerant Piping Connection………………………………………………………………………………………

Evaporative-Cooled Condenser Field Piping Connections………………………………………………………….

STARTUP……………………………………………………………………………………………………………………

Pre Startup…………………………………………………………………………………………………………..

Startup………………………………………………………………………………………………………………

Axial Flow Fans…………………………………………………………………………………………………….

SERVICING & MAINTENANCE……………………………………………………………………………………….......

General ……………………………………………………………………………………………………………...

Compressors………………………………………………………………………………………………………...

Refrigerant Filter Driers……………………………………………………………………………………………..

Evaporator/Heat Exchanger…………………………………………………………………………….…………...

Charging Refrigerant ………………………………………………………………………………………………..

Checking Liquid Sub-Cooling………………………………………………………………………………………

Checking Evaporator Superheat…………………………………………………………………………………….

Adjusting Sub-cooling and Superheat Temperatures……………………………………………………………….

Special Charging Instructions……………………………………………………………………………………….

Lubrication……………………………………………………………….……………………………………...…..

Service Information…………………………………………………….……………………………………………

EVAPORATIVE-COOLED CONDENSER SECTION……………………………………………………………………...

General Information…………………………………………………………………………………………………

Pre Start-Up…………………………………………………………………………………………………………

Maintenance Recommendations…………………………………………………………………………………….

Water Quality………………………………………………………………………………………………………..

AIR-COOLED CONDENSER SECTION…………………………………………………………………………………...

REFRIGERANT PIPING FOR CL SERIES…………………………..………………………………….………..…….......

Equivalent Line Length…………………………………………………………………………………….……….

Liquid Line Sizing…………………………………………………………………...……………………………...

Suction Line Sizing……………………………………………………………………………………..…………...

Hot Gas Bypass Line Sizing..………………………………………………………………….………….………...

Predetermined Line Sizes…………………………………………………………………………………………...

TABLE RP-1 Predetermined Line sizes for Dual Circuit CL units with R-410A……………………….………….

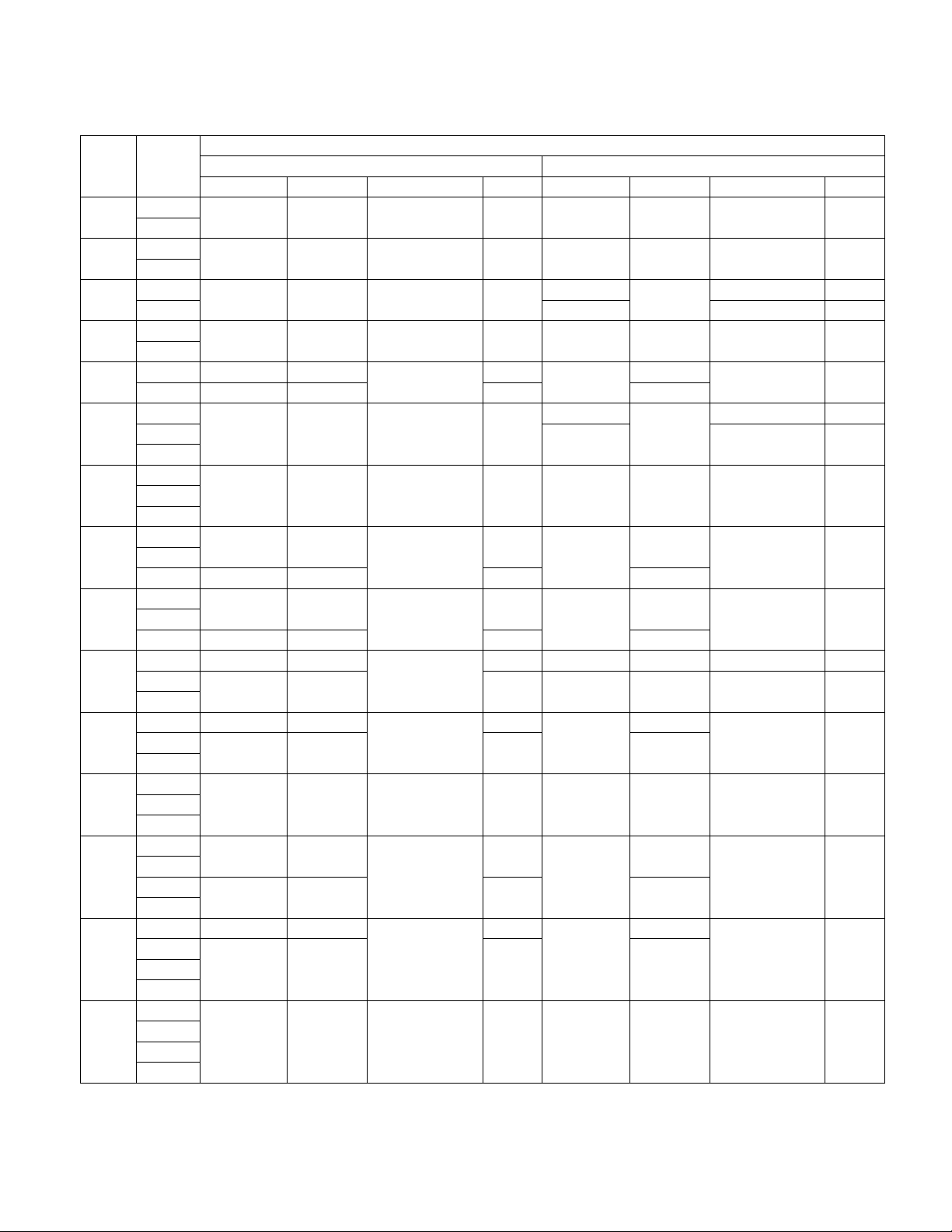

TABLE RP-2 Predetermined Line sizes for Dual Circuit CL units with R-22………………………….…………..

TABLE RP-3 Predetermined Line sizes for Single Circuit CL units with R-410A

TABLE RP-4 Predetermined Line sizes for Single Circuit CL units with R-22 ……………………….…………..

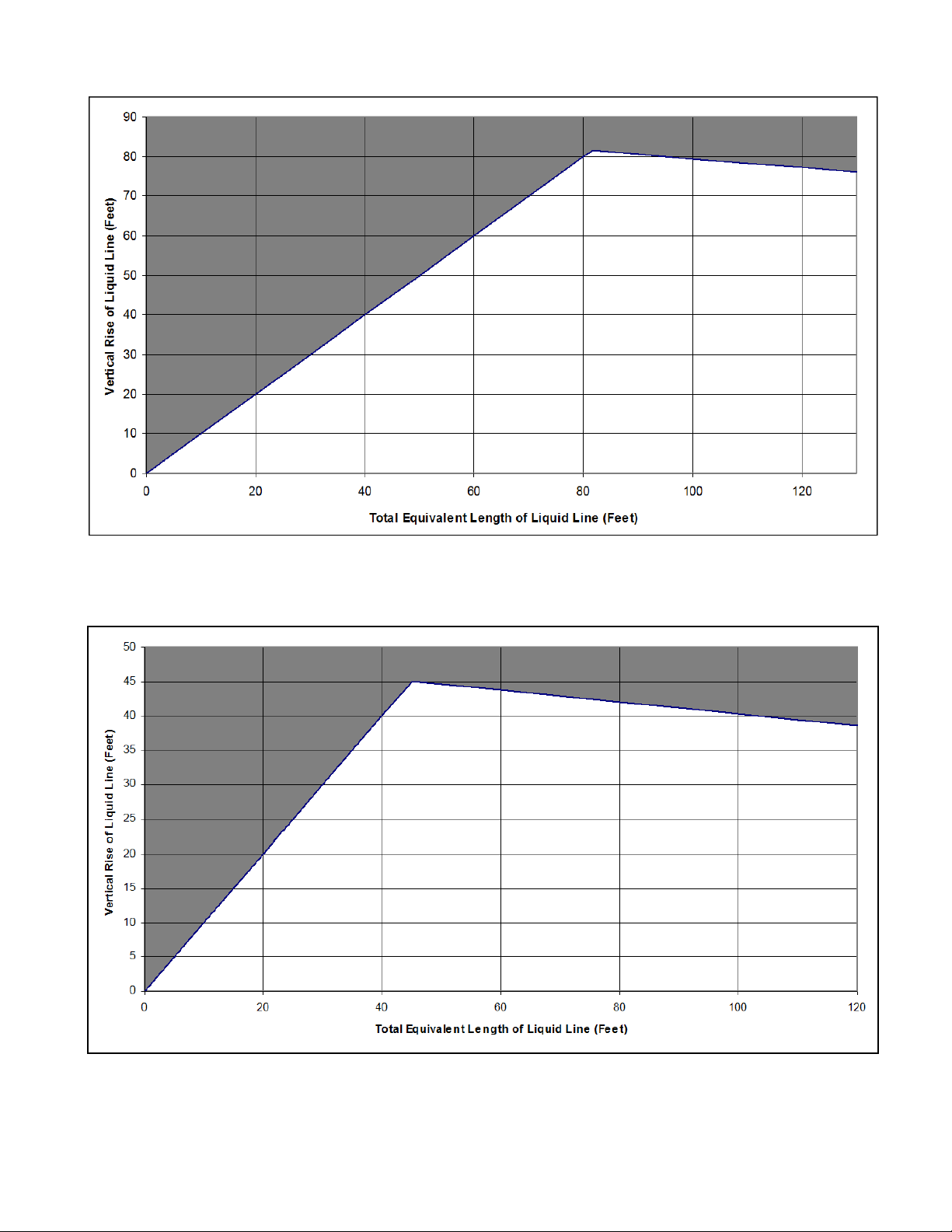

FIGURE RP-1 Riser height versus total equivalent line length Dual Circuit CL Units with R-410A .….…………

FIGURE RP-2 Riser height versus total equivalent line length Dual Circuit CL Units with R-22….. ….…………

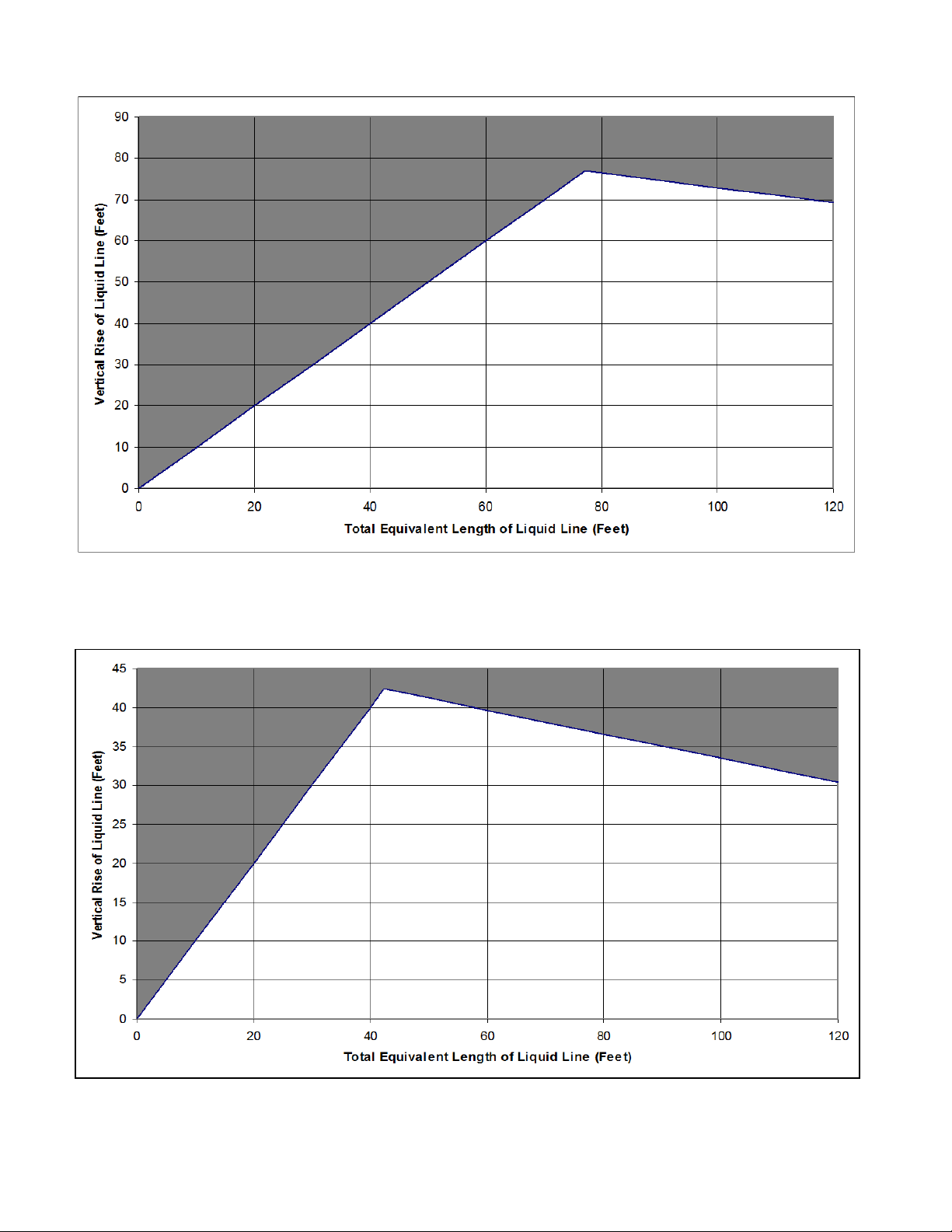

FIGURE RP-3 Riser height versus total equivalent line length Single Circuit CL Units with R-410A ……………

FIGURE RP-4 Riser height versus total equivalent line length Single Circuit CL Units with R-22… ……………

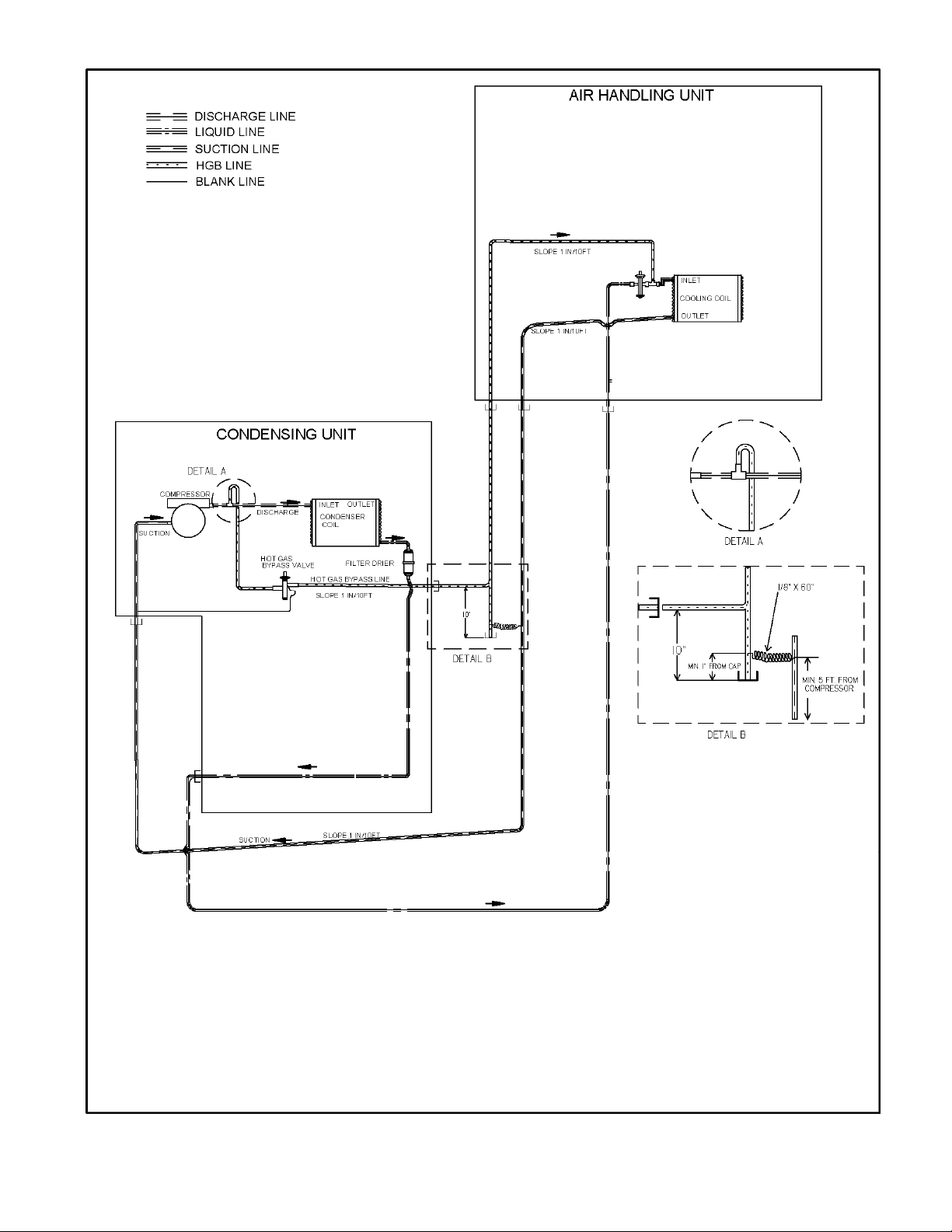

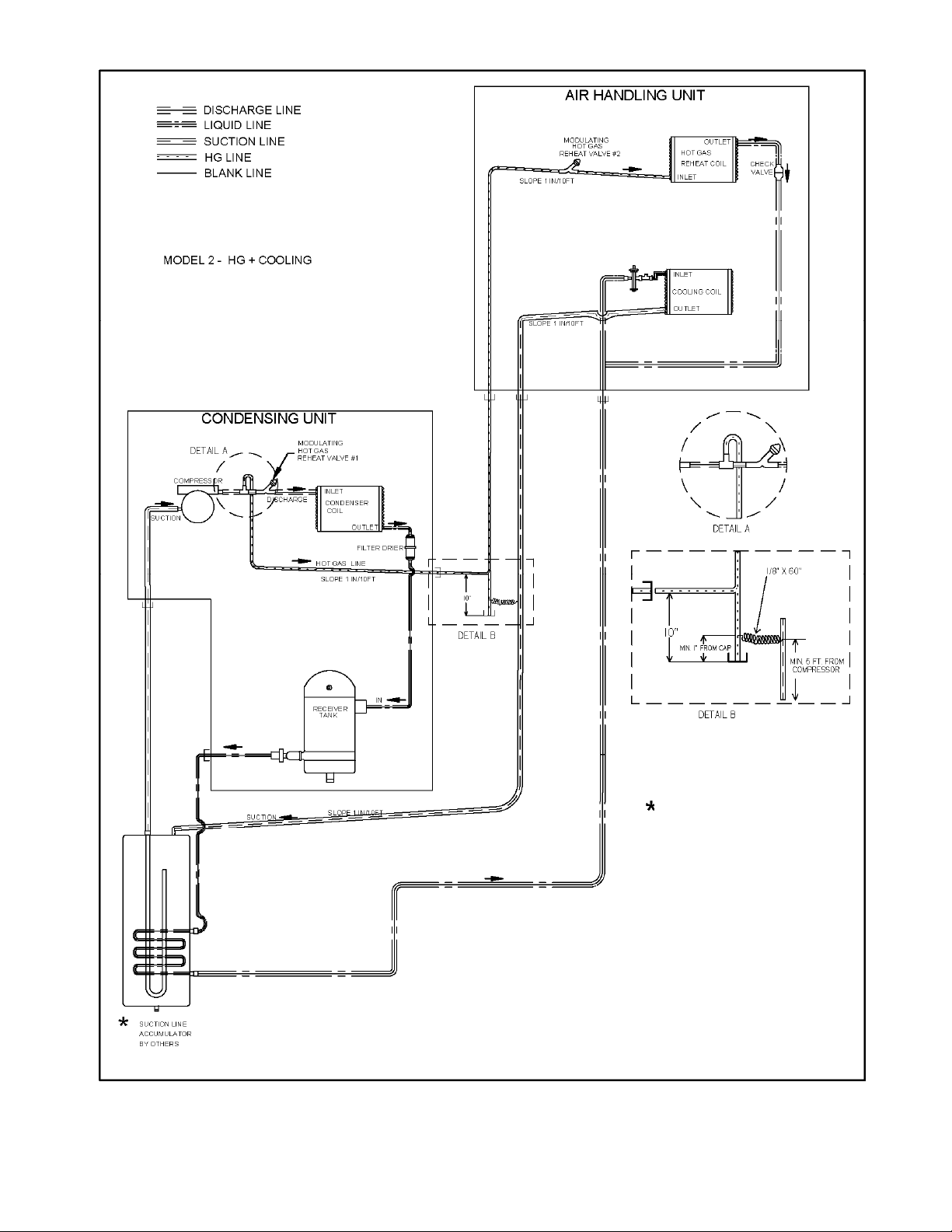

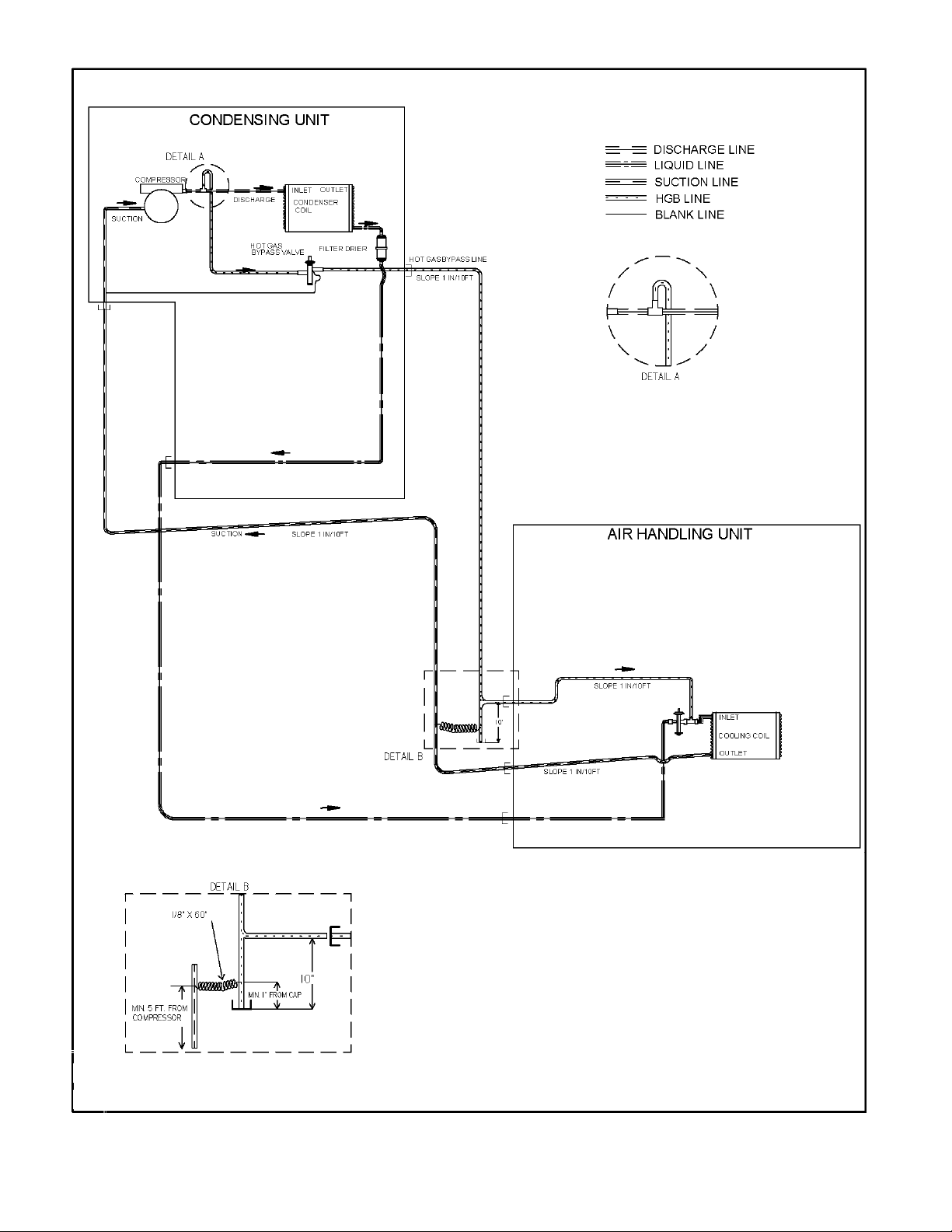

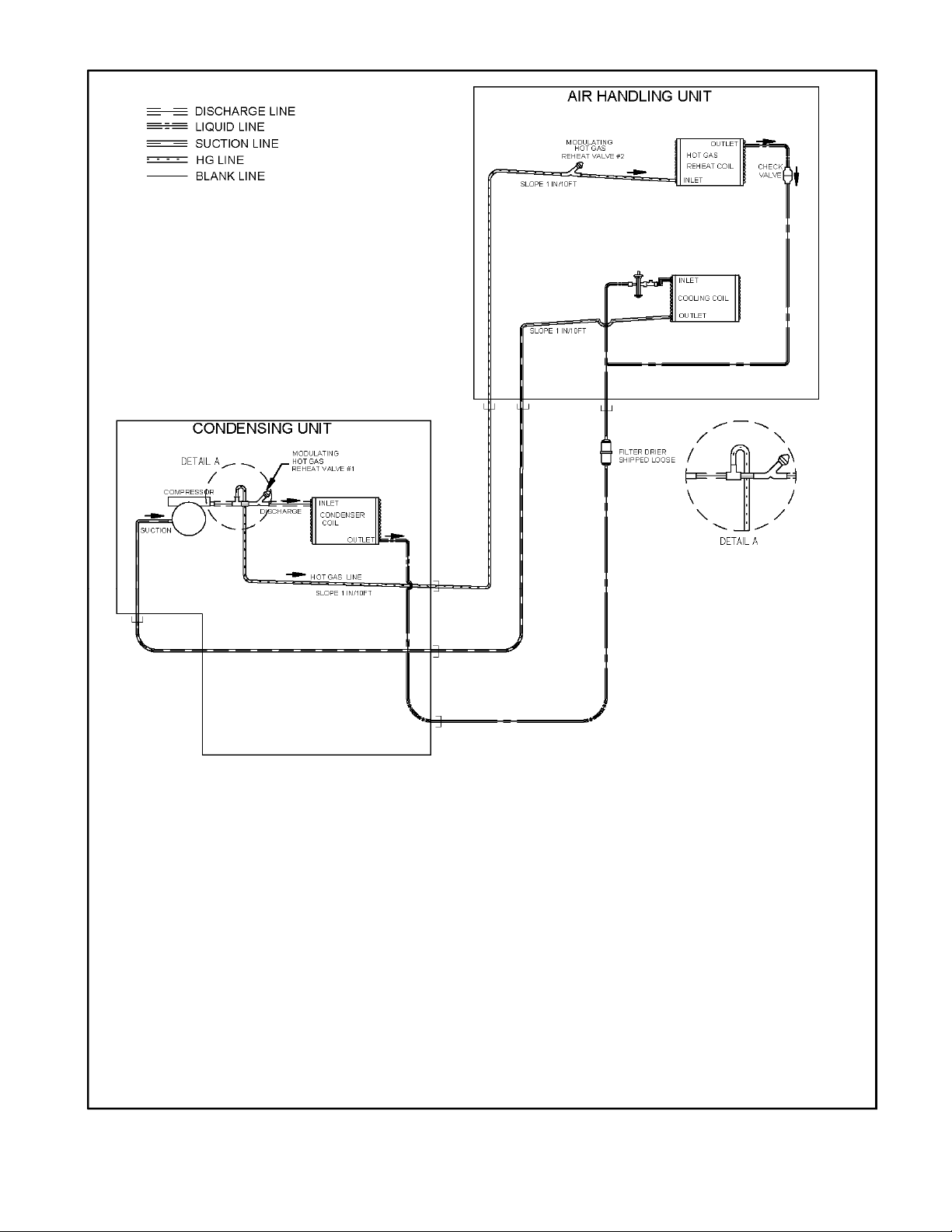

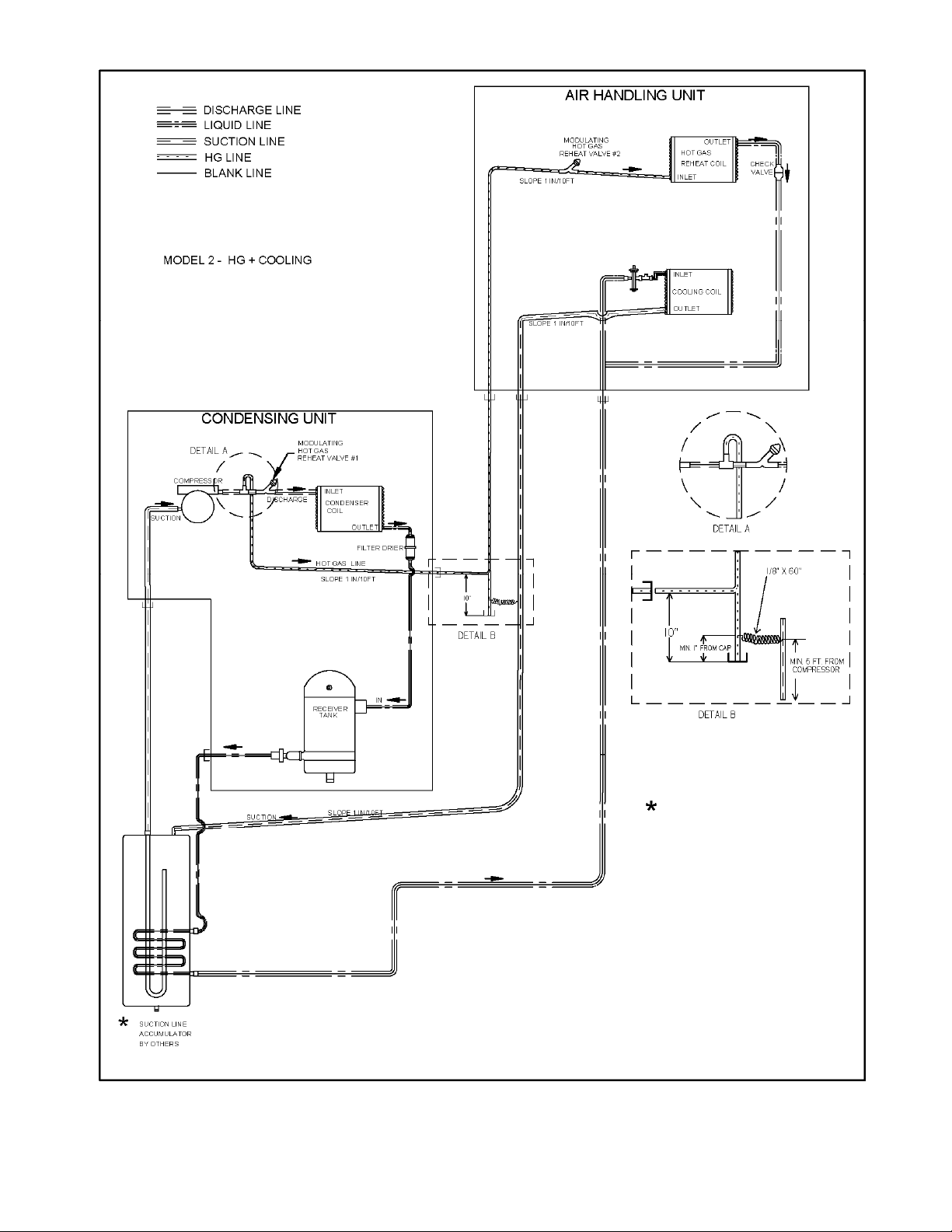

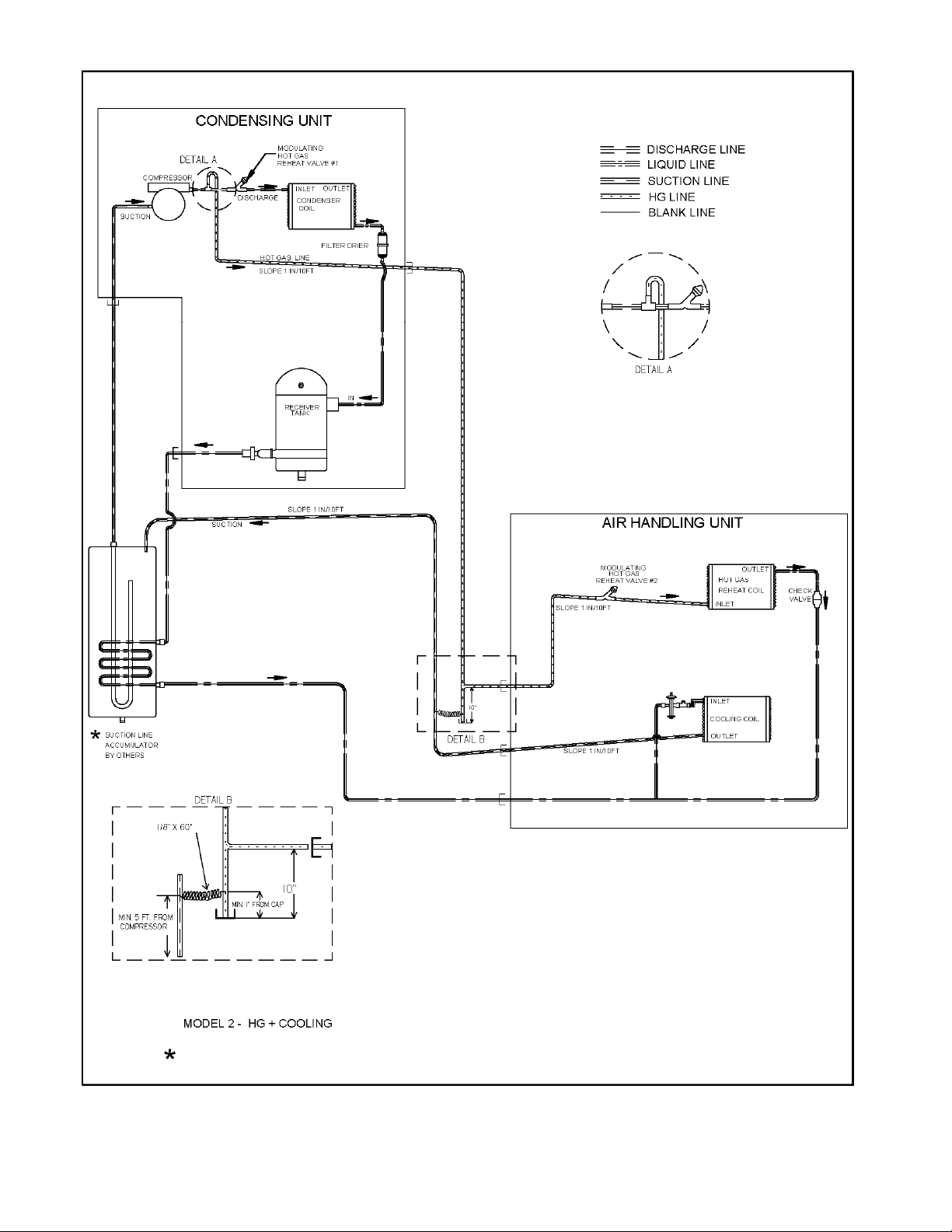

Hot Gas Bypass Line Routing Diagrams……………………………………………………………………………

CL SERIES STARTUP FORM……………………………………………………………………………………………… 41

2

………………….………..

04

04

04

04

05

05

05

05

05

05

05

05

06

07

07

08

09

09

09

11

11

11

11

13

13

13

13

13

14

14

14

15

15

15

15

16

16

17

20

21

21

21

22

22

23

23

24

26

27

28

28

29

29

30

30

31

Page 3

It is the intent of AAON, Inc. to provide accurate and current specification information. However, in the

interest of product improvement, AAON, Inc. reserves the right to change pricing, specifications, and/or

design of its products without notice, obligation or liability

© 2007 AAON, Inc., all rights reserved throughout the world.

AAON & AAONAIRE are registered trademarks of AAON, Inc., Tulsa, OK.

R10110 · Rev. B · 4-07

3

Page 4

GENERAL DESCRIPTION

All AAON 'CL Series' condensers are factory

assembled, wired, and charged with 15 lbs. of

refrigerant per system. Models are available for

air-cooled and evaporative-cooled applications.

Unpacking:

When received, the unit should be checked for

damage that might have occurred in transit. If

damage is found it should be noted on the

carrier’s Freight Bill. A request for inspection by

carrier’s agent should be made in writing at once.

Also, check the unit nameplate to ensure the

correct model size and voltage have been

received to match the job requirements.

to pump refrigerant gas, damage may occur when

power is restored.

• Before unit operation, the main power switch

must be turned on for at least twenty four hours

for units with compressor crankcase heaters. This

will give the crankcase heater time to clear any

liquid accumulation out of the compressor before

it is required to run.

• Always control the system from the thermostat,

or control panel, never at the main power supply

(except for emergency or for complete shutdown

of the system).

• Improper installation, adjustment, alteration,

service, or maintenance can cause property

damage, personal injury or loss of life.

Installation and service must be performed by a

qualified installer, service agency or if gas fired

units, the gas supplier. Refer to installation

instructions provided with the unit and this

manual.

• The compressors must be on a minimum of 4

minutes and off for a minimum of 5 minutes. The

cycle rate must be no more than 8 starts per hour.

OWNER'S INFORMATION

Warning:

• Failure to observe the following instructions

will result in premature failure of your system,

and possible voiding of the warranty.

• Never cut off the main power supply to the unit,

except for complete shutdown. When power is

cut off from the unit, any compressors using

crankcase heaters cannot prevent refrigerant

migration. This means the compressor will cool

down, and liquid refrigerant may accumulate in

the compressor. Since the compressor is designed

The compressor life will be seriously

shortened by reduced lubrication, and the

pumping of excessive amounts of liquid oil

and refrigerant.

Wiring Diagrams:

• A complete set of unit specific wiring diagrams

in both ladder and point-to-point form are

laminated in plastic and located inside the control

compartment door.

4

Page 5

OWNER'S INFORMATION cont.

General Maintenance:

When the initial startup is made and on a

periodic schedule during operation, it is

necessary to perform routine service checks on

the performance of the condenser. This includes

reading and recording suction pressures and

checking for normal sub-cooling and superheat.

See the evaporative-cooled condenser and aircooled condenser sections in this manual for

specific details.

INSTALLATION

Lifting and Handling:

• If cables or chains are used to hoist the unit

they must be the same length and care should be

taken to prevent damage to the cabinet.

• Before lifting unit, be sure that all shipping

material has been removed from unit. Secure

hooks and cables at all lifting points/lugs

provided on the unit.

• Do not push, pull or lift the unit from anything

other than its base.

UNIT MUST BE RIGGED AT ALL

MARKED LIFTING POINTS (Typical)

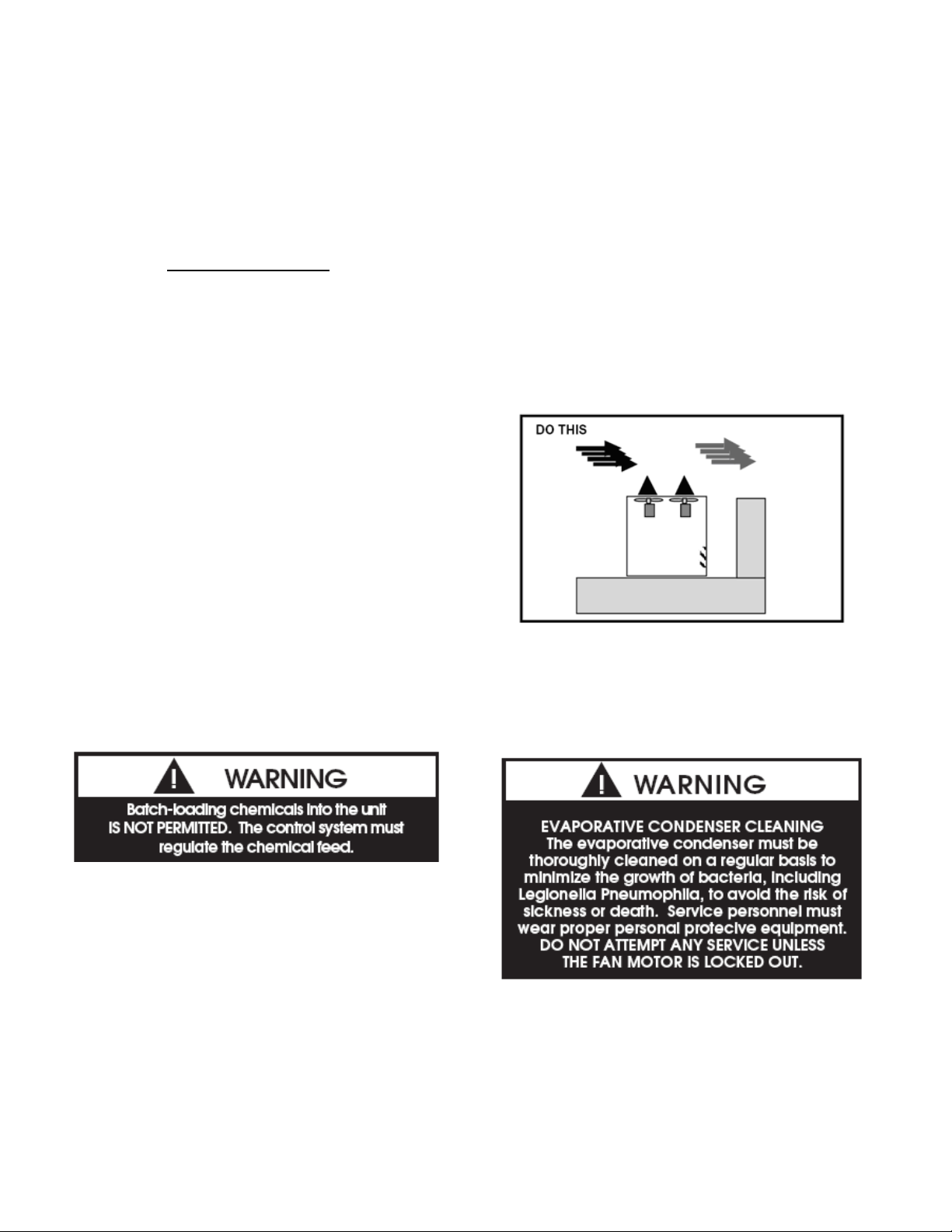

Condenser Placement:

• The AAON condenser is designed for outdoor

applications and mounting at ground level or on

a rooftop. It must be placed on a level and solid

foundation that has been prepared to support its

weight. When installed at ground level, a onepiece concrete slab should be used with footings

that extend below the frost line.

• With ground level installation, care must be

taken to protect the coil fins from damage due to

vandalism or other causes.

• The placement relative to the building air

intakes and other structures must be carefully

selected. Be sure to observe the dimensions that

are on the rating plate of the condenser for

operational and service clearances, which will

appear as follows:

Service Clearances

Location

Front - Vestibule Door Side 100" 142"

Back - Opposite of Front 100" 142"

Left Side - Condenser End 100" 100"

Right Side - Opposite of Left 100" 100"

Top UNOBSTRUCTED

Unit Size

045-135 134-230

• Condenser coils and fans must be free of any

obstructions in order to start and operate properly

with a correct amount of airflow.

• For proper unit operation, the immediate area

around condenser must remain free of debris that

may be drawn in and obstruct airflow in the

condensing section.

• Consideration must be given to obstruction

caused by snow accumulation when placing the

unit.

Compressor Compartment Exhaust Fan:

Prior to unit operation the compressor

compartment exhaust fan shipping support

MUST BE removed from the exterior of the unit.

The exhaust fan also requires the installation of

the exterior rain hood provided with the unit.

Mounting Isolation:

• For roof mounted applications or anytime

vibration transmission is a factor, vibration

isolators may be used.

Access Doors:

• A lockable access door is provided to the

compressor and electrical compartment.

• A light switch is on the wall of the compressor

control compartment.

Low Ambient Operation:

• The AAON low ambient (condenser floodback) system is used to operate a refrigerant

system below 25°F outside air temperature. As

the ambient temperature drops, the condenser

becomes more effective therefore lowering the

head pressure. When the head pressure gets too

5

Page 6

INSTALLATION cont.

low, there will be insufficient pressure to operate

the expansion valve properly. During low

ambient temperatures, it is difficult to start a

system because the refrigerant will migrate to the

cold part of the system (condenser) and make it

difficult for refrigerant to flow.

• The AAON low ambient system maintains

normal head pressure during periods of low

ambient by restricting liquid flow from the

condenser to the receiver, and at the same time

bypassing hot gas around the condenser to the

inlet of the receiver. This backs liquid

refrigerant up into the condenser reducing its

capacity that in turn increases the condensing

pressure. At the same time the bypassed hot gas

raises liquid pressure in the receiver, allowing

the system to operate properly.

• There are different types of low ambient control

used. The following describe the different

systems. Inspect the unit to determine the system

used.

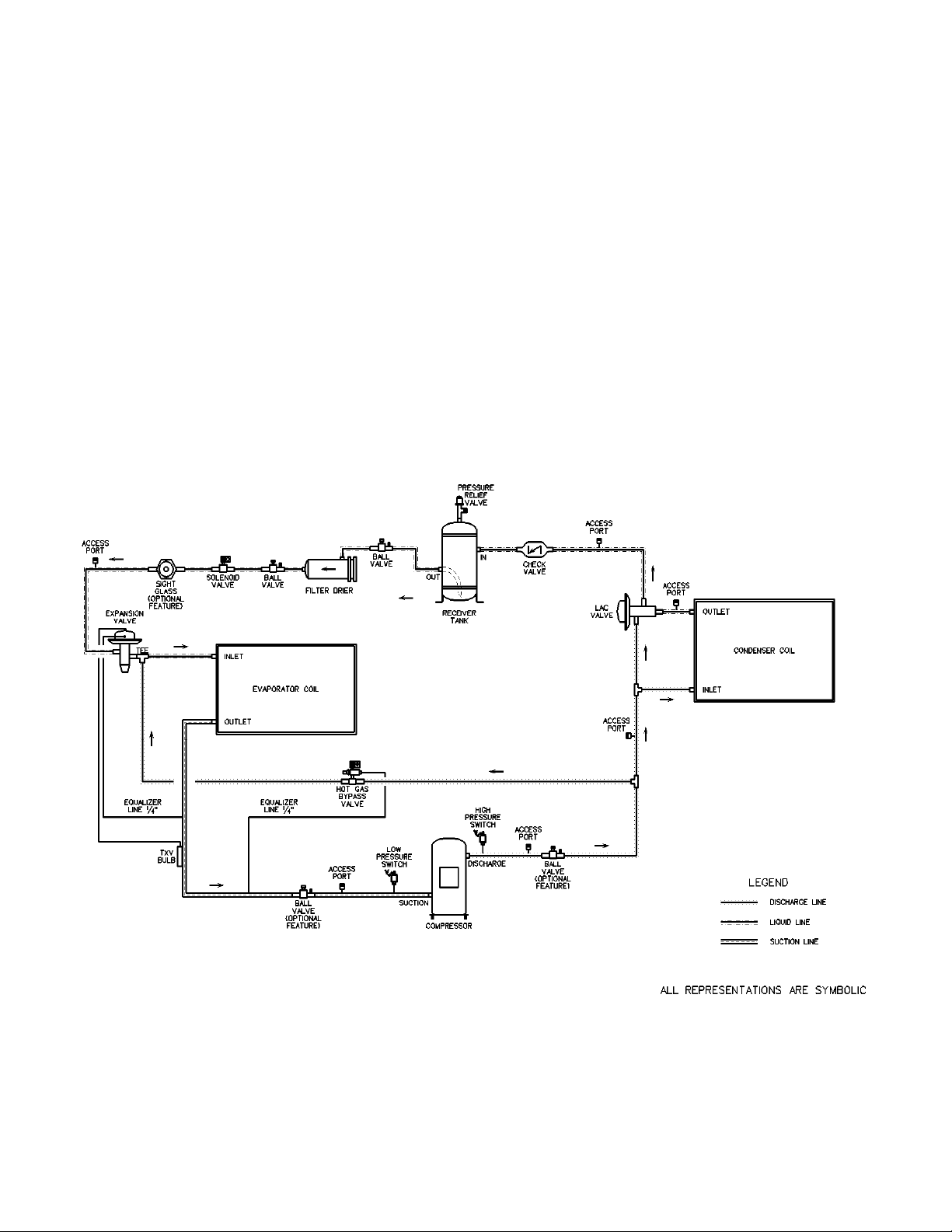

LAC Valve:

The LAC valve is a non-adjustable three way

valve that modulates to maintain receiver

pressure. As the receiver pressure drops below

the valve setting (180 psig for R-22 and 295 psig

for R-410A), the valve modulates to bypass

discharge gas around the condenser. The

discharge gas warms the liquid in the receiver

and raises the pressure to the valve setting. The

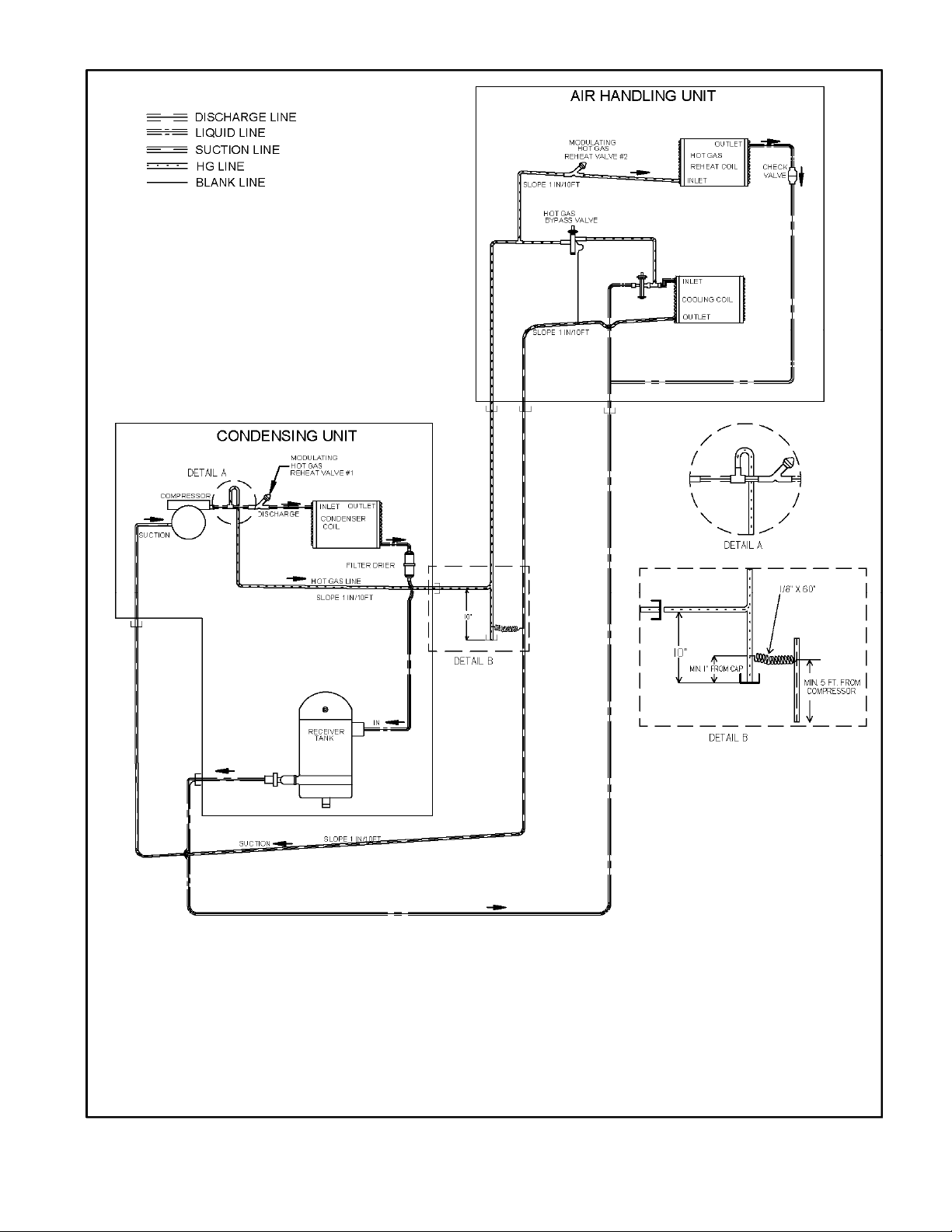

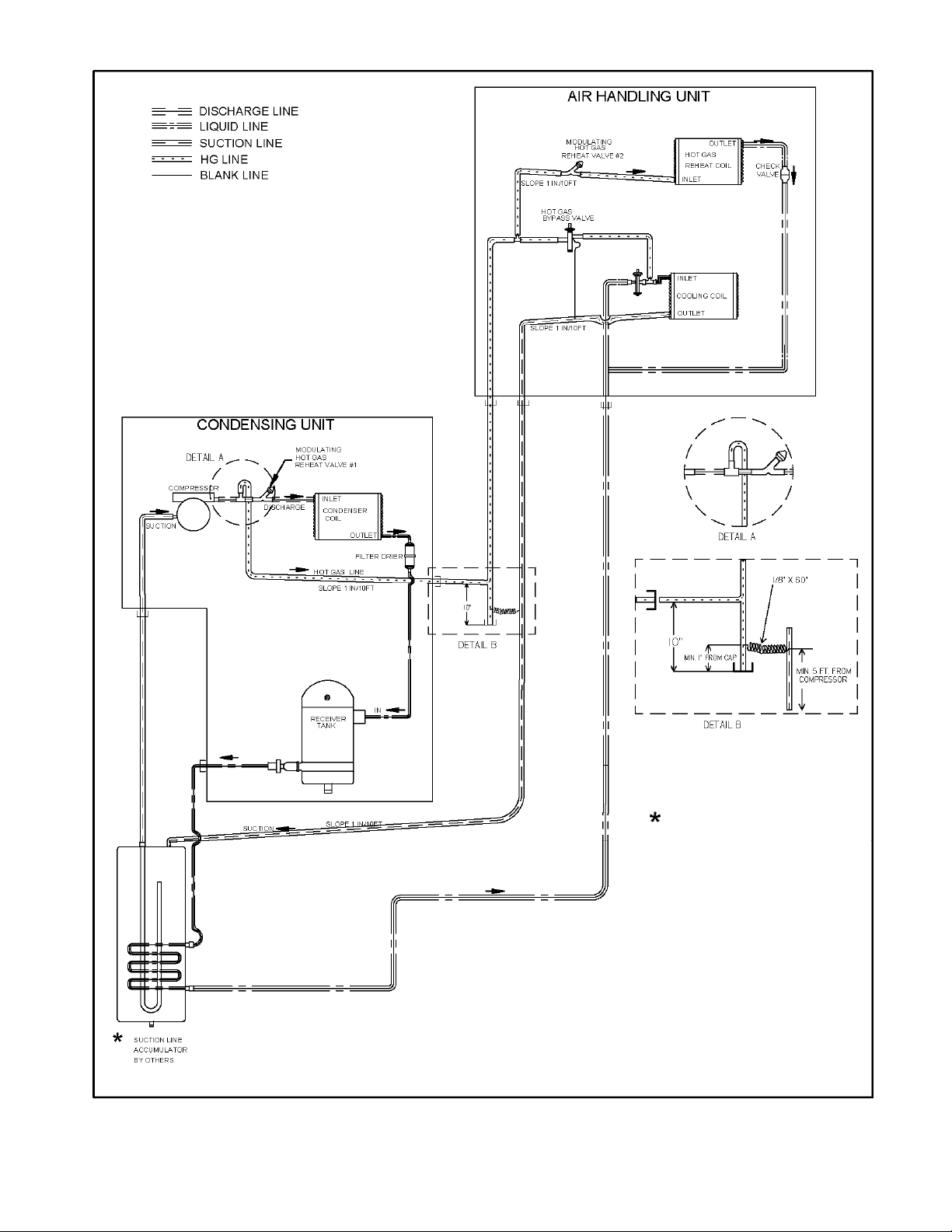

following schematic shows an example system

using the LAC valve.

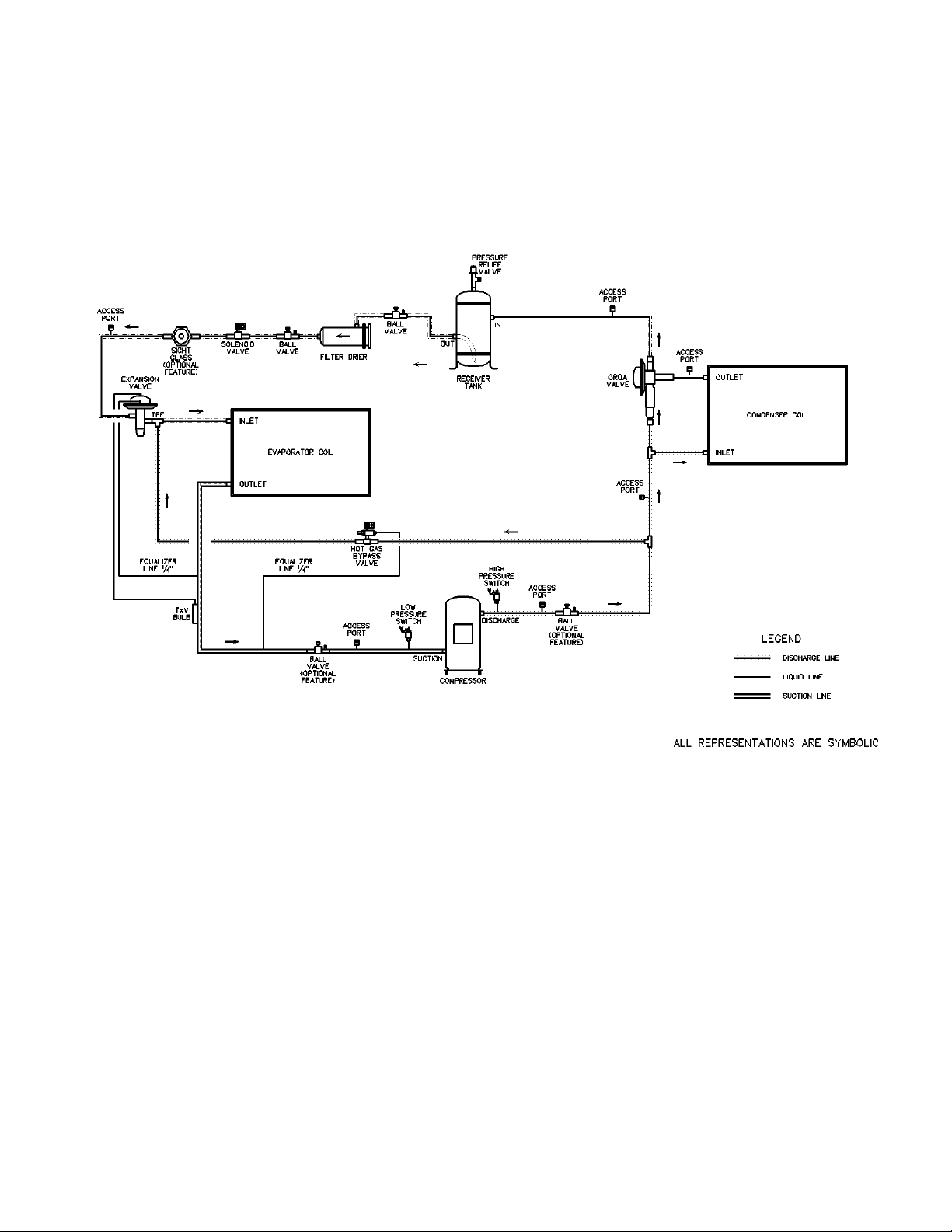

Piping Schematic of Example system using the LAC valve.

6

Page 7

INSTALLATION cont.

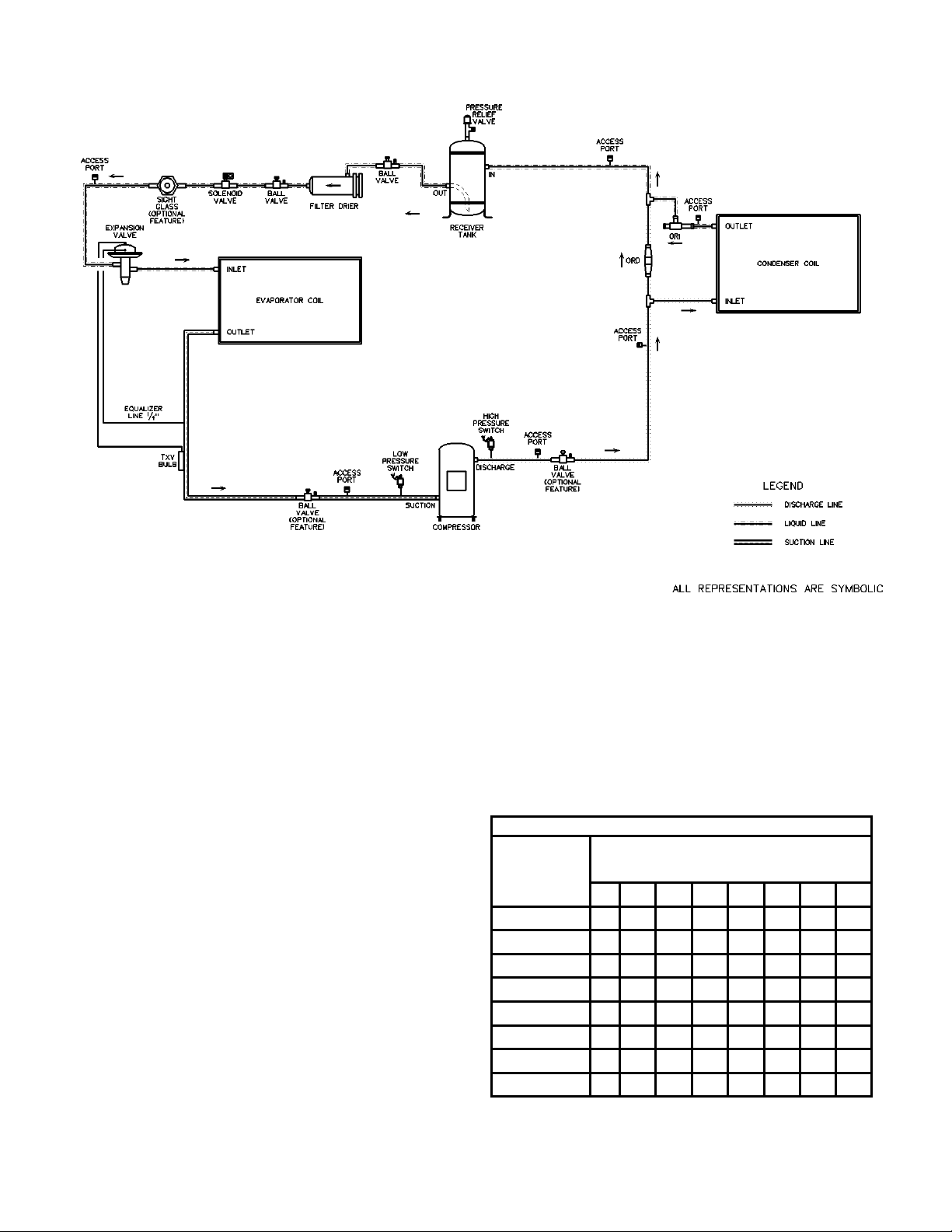

OROA Valve:

This system uses a nonadjustable head pressure

control valve that performs the function of

limiting the flow of liquid refrigerant from the

condenser and at the same time regulates the

flow of the hot gas around the condenser to the

receiver. The valve setpoint is 180 psig. This

valve is called an OROA valve (Open on Rise of

Outlet pressure). The following schematic

shows an example system using the OROA

valve.

Piping Schematic of Example system using the OROA valve.

ORI/ORD Valves:

This system uses a two-valve arrangement. The

head pressure control valve is an inlet pressure

regulating valve and responds to changes in

condensing pressure. This valve is located in the

discharge of the condenser and is called an ORI

valve (Open on Rise of Inlet pressure). As the

ambient temperature drops, the condenser

capacity increases and the condensing pressure

falls, causing the ORI to modulate toward the

closed position. The condenser bypass valve is a

pressure differential valve that responds to

changes in the pressure differential across the

valve. This valve is called an ORD valve (Open

on Rise of Differential pressure). As the ORI

starts to restrict liquid flow from the condenser, a

pressure differential is created across the ORD.

When the differential reaches the setpoint, the

ORD starts to open and bypass hot gas to the

liquid line. The ORI valve is adjustable from 65

to 225 psig (factory setting of 180 psig). The

ORD is not adjustable. On refrigeration systems

that are too large for a single ORI and ORD

valve, there will be two ORI and two ORD

valves in parallel. The schematic on the

following page shows an example system using

the ORI/ORD valves.

7

Page 8

INSTALLATION cont.

Piping Schematic of Example system using the ORI/ORD valve.

The pressure setting of the ORI valve determines

how well the system will operate. The proper

setting is a function of the specific system in

which is installed. Generally, the setting should

be equivalent to a condensing temperature of

90°F to 100°F or a receiver pressure equivalent

to a temperature of 80°F to 90°F. This means

that as the ambient temperature falls below 70°F,

the head pressure control valve will begin to

throttle. To adjust the ORI valve, remove the cap

and turn the adjustment screw with the proper

size hex wrench (1/4” for ORI-6 and 5/16” for

ORI-10). A clockwise rotation increases the

valve setting while a counter-clockwise rotation

decreases the setting. To obtain the desired

setting, a pressure gauge should be used at the

compressor discharge service valve so the effects

of any adjustment can be observed. Small

adjustments are recommended in order to allow

the system adequate time to stabilize after each

adjustment.

Condenser Flooding:

In order to maintain head pressure in the

refrigeration system, liquid refrigerant is backed

up in the condenser to reduce condenser surface.

The following chart shows the percentage that a

condenser must be flooded in order to function

properly at the given ambient temperature.

PERCENTAGE OF CONDENSER TO BE FLOODED

Ambient

Temperature

(

°F)

70°

60°

50°

40°

30°

20°

0°

-20°

Evaporating Temperature (

0° 10° 20° 30° 35° 40° 45° 50°

40 24 0 0 0 0 0 0

60 47 33 17 26 20 10 4

70 60 50 38 45 40 33 28

76 68 60 50 56 52 46 42

80 73 66 59 64 60 55 51

86 77 72 65 69 66 62 59

87 83 78 73 76 73 70 68

91 87 82 77 80 79 76 73

°F)

8

Page 9

INSTALLATION cont.

During higher ambient temperatures the entire

condenser is required to condense refrigerant.

During these higher ambient temperatures, a

receiver tank is used to contain the refrigerant

that was required to flood the condenser during

low ambient operation. The receiver must be

sized to contain all of the flooded volume

otherwise there will be high head pressures

during higher ambient conditions.

Electrical:

• The single point electrical power connections

are made in the electrical control compartment.

• Check the unit data plate voltage to make sure

it agrees with the power supply. Connect power

to the unit according to the wiring diagram

provided with the unit.

• The power and control wiring may be brought

up through the utility entry. Protect the branch

circuit in accordance with code requirements.

Control wires and power should not be run inside

the same conduit. The unit must be electrically

grounded in accordance with the current National

Electric Code.

• Power wiring is to the unit terminal block or

main disconnect. All wiring beyond this point

has been done by the manufacturer and cannot be

modified without effecting the unit's

agency/safety certification.

Note: Startup technician must check motor

amperage to ensure that the amperage listed

on the motor nameplate is not exceeded.

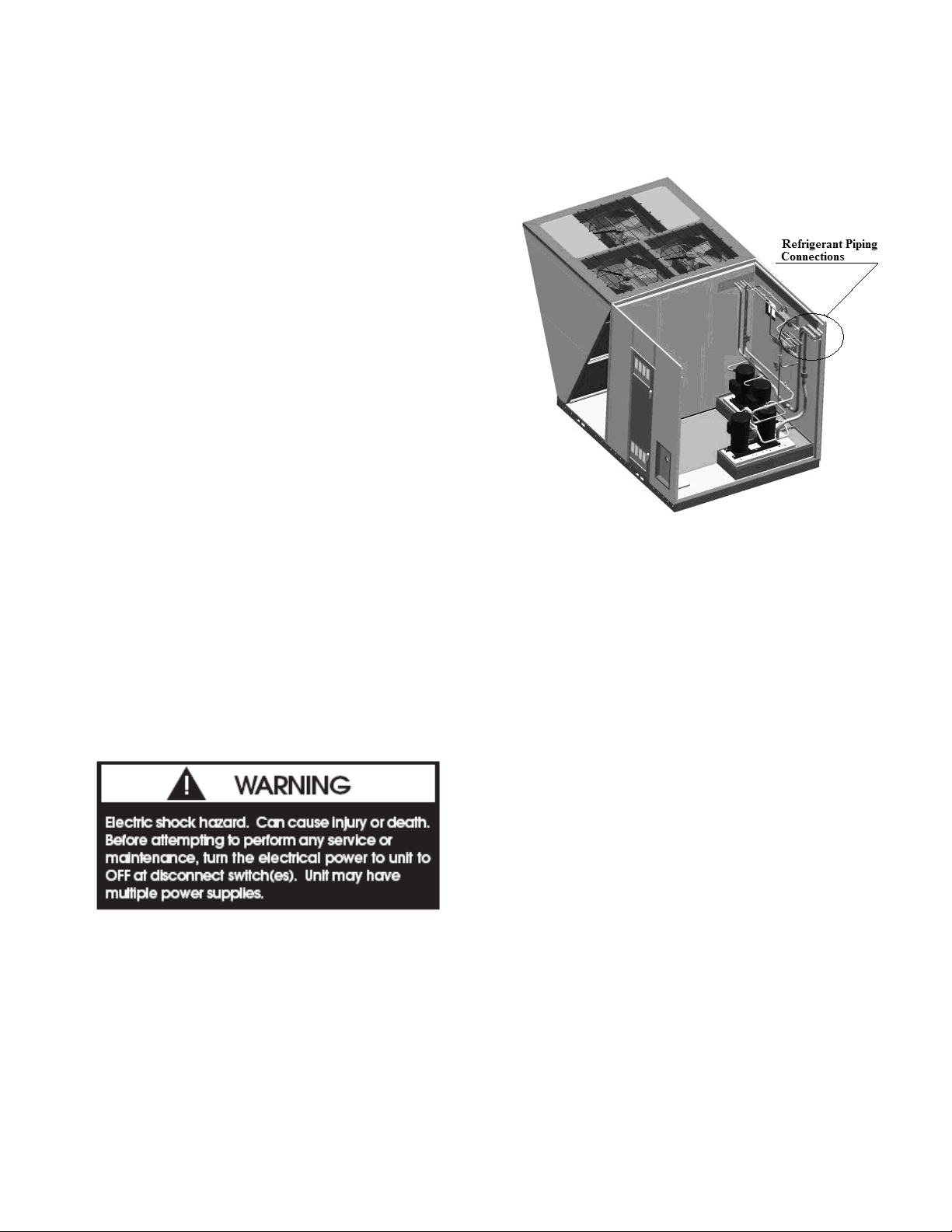

Refrigerant Piping Connections

• CL condensing unit refrigerant piping

connections are located in the upper corner of the

service vestibule side of the unit (opposite the

condenser section) as shown in the figure.

• The piping connections are protected with a

shipping cover that must be removed prior to

copper connection and installation.

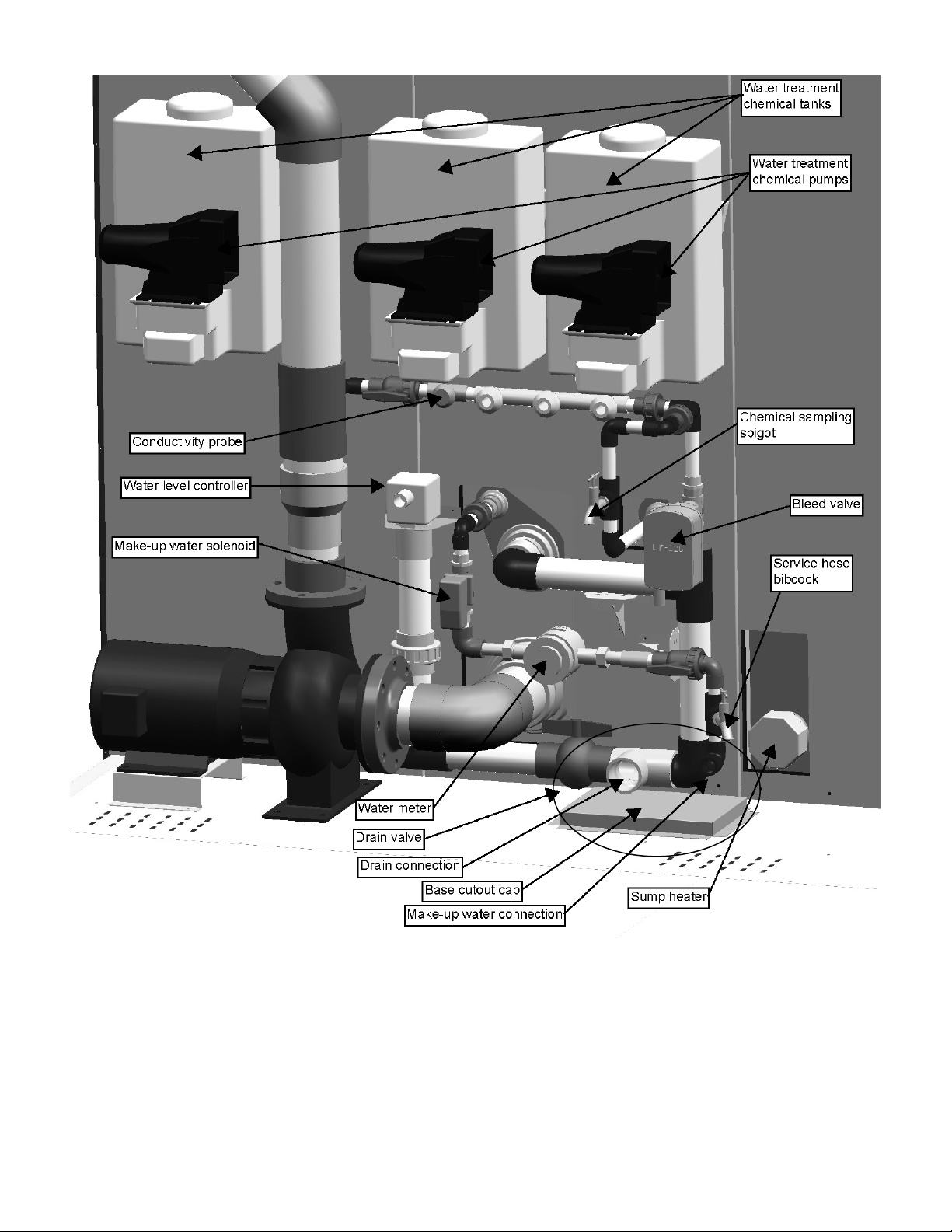

Evaporative-cooled Condenser Field Piping

Connections:

• There are two field water connections that must

be made for the evaporative-cooled condenser.

There is a ¾” PVC socket city make-up water

connection and a 2” PVC socket drain

connection (as shown on the next page). This

drain should connect to a sanitary sewer or other

code permitted drain. These connections can go

through the base or the wall of the unit.

• There is a cutout in the base with a cap that is

1” tall and the cap is sealed to the unit base to

prevent any leaks in the unit from penetrating

into the building. Any piping through the base

should go through a field cutout in this cap. The

pipes must be sealed to the cap once the piping is

complete to prevent any leaks in the unit from

penetrating into the building.

• A field cutout must be made in the wall if the

evaporative-cooled condenser piping is to go

through the unit wall. This cutout must be

sealed once the piping is installed to prevent

water from leaking into the unit.

9

Page 10

Diagram of Evaporative-cooled condenser Section including field water connections and base cutout

tap

10

Page 11

STARTUP

Pre-Startup:

After the installation and immediately before the

startup of the condenser be sure that these items

have been checked.

1. Verify that electrical power is available to the

unit.

2. Verify that any remote stop/start device is

requesting the condenser to start.

While performing the Startup, use the

Condensing Startup Form at the back of this

booklet to record motor amps and any other

comments.

Startup:

• Use the General Check List at the top of the

Startup Form to make a last check that all the

components are in place and the power supply is

energized.

Note: Condensing fan operation should start

with the first compressor.

• Cycle through all the compressors to confirm

that all are operating within tolerance.

• When unit is running, observe the system for a

complete operation cycle to verify that all

systems are functioning properly.

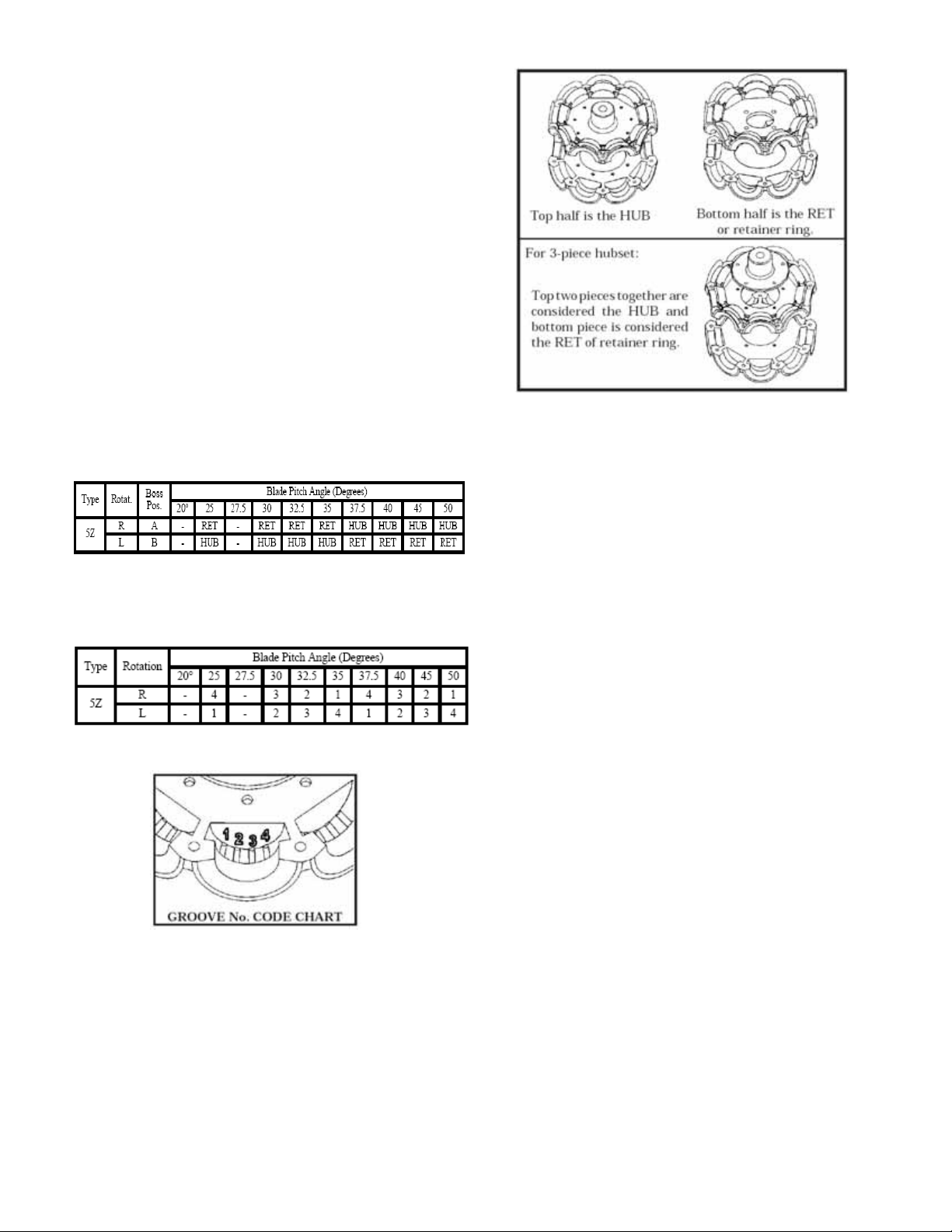

Axial Flow Fans:

Multi-Wing Z Series Aluminum Fan Blade

Pitch Angle Setting Instructions:

Before You Begin, to maintain balance of fan:

• Mark the hub castings across a joint, so the fan

hub can be reassembled in the same orientation.

• Mark the location of any balancing weight.

Balancing weight will be on the outer bolt circle,

in the form of washers, and/or longer bolts, or an

additional balancing nut.

• Number the blades and blade sockets, so that

they are replaced into their original position.

• If possible, note the location of the pitch setting

pin in the blade socket, and whether pin is

located in the Hub or Retainer half of the fan.

Step 1. Determine Boss Location Code: “A” or

“B” The boss is the center section of the hub

through which the fan is mounted to the shaft,

and typically contains either setscrews or a

center-tapered hole where the bushing inserts.

Select boss location A or B:

A is the boss on air inlet, including AS

configurations.

B is the boss on air discharge, including BS.

For flange mounted fans, use boss location A for

R rotation fans, and boss location B for L

rotation fans.

• While performing the check, use the Condenser

Startup Form to record observations of amps and

refrigerant pressures.

• When all is running properly, place the

controller in the Run mode and observe the

system until it reaches a steady state of operation.

11

Page 12

STARTUP cont.

Step 2. Find Blade Pitch Angle:

( 20, 25, 27.5, 30, 32.5, 35, 37.5, 40, 45 or 50 )

• Carefully disassemble fan on flat surface and

note in which groove the pin is located. Refer to

groove number code diagram.

• Using diagrams in step 5, determine if the pin

was in the hub (HUB) or retainer side (RET) of

fan.

• Using table in step 4, find the possible blade

pitch.

• Using table in step 3, select your blade angle

based on whether your pin was in the HUB or

RET.

Step 3. Determine Hub/Retainer Code: “HUB”

or “RET”

Step 4. - Determine Groove Number: 1 or 2 or 3

or 4

Step 5. Final Assembly

Definition of HUB and RET for purposes of

instructions. For 2-piece hubset:

Using the HUB or RET code found in Step 3:

• If code is HUB, place the hub down on work

surface first (one or two pieces, depending on

above).

• If code is RET, place one retainer ring only

down on the work surface first. (A weighted

coffee can could be used to elevate the fan from

the work surface).

• Using the groove number, place the locking pin

in the groove number that was found in Step 4.

Insert Blades:

• Place the blade over the pin in the hub/retainer

blade socket, so that the pin also fits into the

appropriate pitch angle groove in the blade.

• Repeat for all blades.

• Assemble hub set together, aligning the match

marks that were made.

• Replace any balancing weight to its original

position.

• To finish, tighten the bolts in a cross pattern to

5 to 6 ft-lbs of torque.

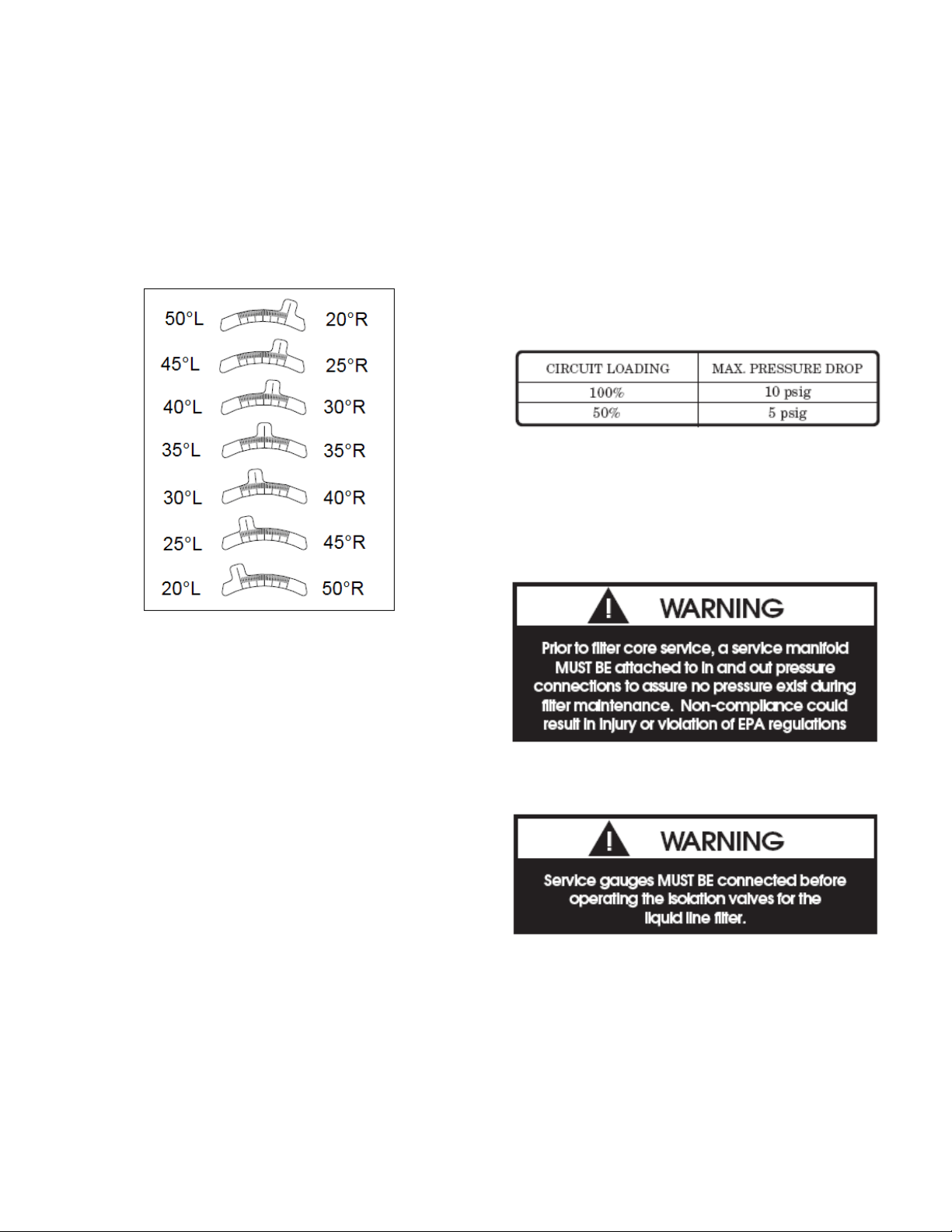

Multi-Wing W Series Black Glass Reinforced

Polypropylene Fan Blade Pitch Angle Setting

Instructions:

Step 1. Note original position of retaining plates,

center boss and all hardware including additional

hardware used for balancing.

Step 2. Remove all the bolts and nuts.

12

Page 13

STARTUP cont.

Step 3. Determine blade rotation – on the

concave side of the blade is a blade marking

showing 6WR, 6WL, 7WL, 7WR, or 9WR. The

“L” and “R” denote the rotation of the blade.

Step 4. Replace the pitch insert in the blade root

with an insert of the desired pitch.

Compressors:

The scroll compressors are fully hermetic and

require no maintenance except keeping the shell

clean.

Refrigerant Filter Driers:

Each refrigerant circuit contains a replaceable

core filter drier. Replacement is recommended

when there is excessive pressure drop across the

assembly or moisture is indicated in a liquid line

sight glass.

The filter driers are provided with pressure taps

and shutoff valves for isolation when changing

the core. For safety purposes a service manifold

must be attached prior to filter maintenance.

Step 5. Replace blades to their original location.

Step 6. Replace all nuts, bolts, and washers on

the fan hub.

Step 7. Replace retaining plates and center boss

to original location.

Step 8. Tighten nuts and bolts to 14 ft-lbs of

torque.

SERVICING AND MAINTENANCE

General:

• Qualified technicians must perform routine

service checks and maintenance. This includes

reading and recording the condensing and

suction pressures and checking for normal subcooling and superheat (see charging information

beginning on page 14).

• Air-cooled and evaporative-cooled condenser

units require different maintenance

schedules/procedures. Unit specific instructions

for both types are included in this manual.

Evaporator/Heat Exchangers:

Normally no maintenance or service work will be

required for a matching direct expansion

evaporator with a thermal expansion valve to

regulate refrigerant.

13

Page 14

SERVICING AND MAINTENANCE

cont.

Charging Refrigerant:

• Charging a system in the field must be based on

determination of liquid sub-cooling and

evaporator superheat. On a system with a

thermostatic expansion valve liquid sub-cooling

is more representative of the charge than

evaporator superheat but both measurements

must be taken.

Before Charging:

• Refer to the Unit Nameplate to determine the

proper refrigerant to charge the system with.

• The unit being charged must be at or near full

load conditions before adjusting the charge.

• Units equipped with hot gas bypass must have

the hot gas bypass valve closed to get the proper

charge.

• Units equipped with hot gas reheat must be

charged with the hot gas valve closed while the

unit is in cooling mode.

• After adding or removing charge the system

must be allowed to stabilize, typically 10-15

minutes, before making any other adjustments.

• The type of unit and options determine the

ranges for liquid sub-cooling and evaporator

superheat. Refer to Table 1 when determining

the proper sub-cooling.

• The vertical rise of the liquid line must be

known in order to adjust the sub-cooling range

for proper charge.

• Units equipped with low ambient (0°F) option

see special charging instructions at the end of the

charging instructions.

Checking Liquid Sub-cooling:

1. Measure the temperature of the liquid line as

it leaves the condenser coil.

2. Read the gauge pressure reading of the liquid

line close to the point where the temperature was

taken. You must use liquid line pressure as it

will vary from discharge pressure due to

condenser coil pressure drop.

3. Convert the pressure obtained in Step 2 to a

saturated temperature using the appropriate

refrigerant temperature-pressure chart.

4. Subtract the measured liquid line temperature

in Step 1 from the saturated temperature in Step

3 to determine the liquid sub-cooling.

5. Compare calculated sub-cooling to TABLE 1.

for the appropriate unit type and options.

Checking Evaporator Superheat:

1. Measure the temperature of the suction line

close to the compressor.

2. Read gauge pressure at the suction line close

to the compressor.

3. Convert the pressure obtained in Step 2 to a

saturated temperature using the appropriate

refrigerant temperature-pressure chart.

4. Subtract the saturated temperature in Step 3

from the measured suction line temperature in

Step 1 to determine the evaporator superheat.

5. Compare calculated superheat to TABLE 1 for

the appropriate unit type and options.

TABLE 1

Sub-cooling

W/Hot Gas

Reheat (°F)

Air Cooled

Condenser

Evaporative

Cooled

Condenser

Water

Cooled

Condenser

Sub-

cooling

(°F)

12-18* 8-15** 15-22*

6-10* 8-15** 8-12*

6-10* 8-15** 8-12*

Superheat

(°F)

* Sub-cooling must be increased by 3°F per 20

feet of vertical liquid line rise for R-22 and 2°F

for R-410A

** Superheat will increase with long suction line

runs.

14

Page 15

SERVICING AND MAINTENANCE

cont.

Adjusting Sub-cooling and Superheat

Temperatures:

The system is overcharged if:

1. the sub-cooling temperature is too high and

2. the evaporator is fully loaded (low loads on

the evaporator result in increased sub-cooling)

and

3. the evaporator superheat is within the

temperature range as shown in TABLE 1 (high

superheat results in increased sub-cooling)

Correct an overcharged system by reducing the

amount of refrigerant in the system to lower the

sub-cooling.

The system is undercharged if:

1. the superheat is too high and

2. the sub-cooling is too low

• Correct an undercharged system by adding

refrigerant to the system to reduce superheat and

raise sub-cooling.

• If the sub-cooling is correct and the superheat is

too high, the TXV may need adjustment to

correct the superheat.

Special Charging Instructions:

• For units equipped with low ambient refrigerant

flood back option being charged in the summer

when the ambient temperature is warm:

Once enough charge has been added to get the

evaporator superheat and sub-cooling values to

the correct setting more charge must be added.

Add approximately 80% of the receiver tank

volume to the charge to help fill the receiver

tank. The additional charge is required for the

system when running in cold ambient conditions.

• For units equipped with low ambient refrigerant

flood back option being charged in the winter

when the ambient temperature is cold:

1. Once enough charge has been added to get the

evaporator superheat and sub-cooling values to

the correct setting more charge may need to be

added. If the ambient temperature is 0°F no

more charge is required. If the ambient

temperature is around 40°F add approximately

40% of the receiver tank volume.

2. The unit will have to be checked for proper

operation once the ambient temperature is above

80°F.

Lubrication:

• All original motors and bearings are furnished

with an original factory charge of lubrication.

Certain applications require bearings be relubricated periodically. The schedule will vary

depending on operating duty, temperature

changes, or severe atmospheric conditions.

• Bearings should be re-lubricated at normal

operating temperatures, but not when running.

Rotate the fan shaft by hand and add only enough

grease to purge the seals. DO NOT

OVERLUBRICATE.

Service Information:

If the unit will not operate correctly and a service

company is required, only a company with

service technicians qualified and experienced in

both condensing units and air conditioning are

permitted to service the systems to keep

warranties in effect. If assistance is required, the

service technician must contact AAON.

Note: Service technician must provide the

model and serial number of the unit in all

correspondence with AAON.

Replacement parts for AAON equipment may be

obtained from AAON. When ordering parts,

always reference the unit model number, serial

number and part number.

15

Page 16

AAON, Inc.

www.aaon.com

Customer Service Department

2425 South Yukon Ave • Tulsa, OK 74107

Phone: 918-583-2266 • Fax: 918-382-6364

ALWAYS USE AAON SPECIFIED PARTS

To order parts from the AAON Parts store

online go to www.aaonparts.com.

EVAPORATIVE-COOLED

CONDENSER

• Evaporative cooling equipment rejects heat by

evaporating a portion of the recirculated water

spray and discharging it from the unit with the

hot, saturated air. As the spray water evaporates,

it leaves behind the mineral content and

impurities of the supply water. If these residuals

are not purged from the water distribution

system, they will become concentrated and lead

to scaling, corrosion, sludge build-up and

biological fouling.

• A water treatment monitoring and control

system has been furnished with this unit. Be sure

to read the complete manual that has been

furnished. All water treatment is a combination

of bleed water and chemical treatment for proper

control of the residuals and to prevent any

biological contamination.

may form solutions and deposits harmful to the

products and personnel.

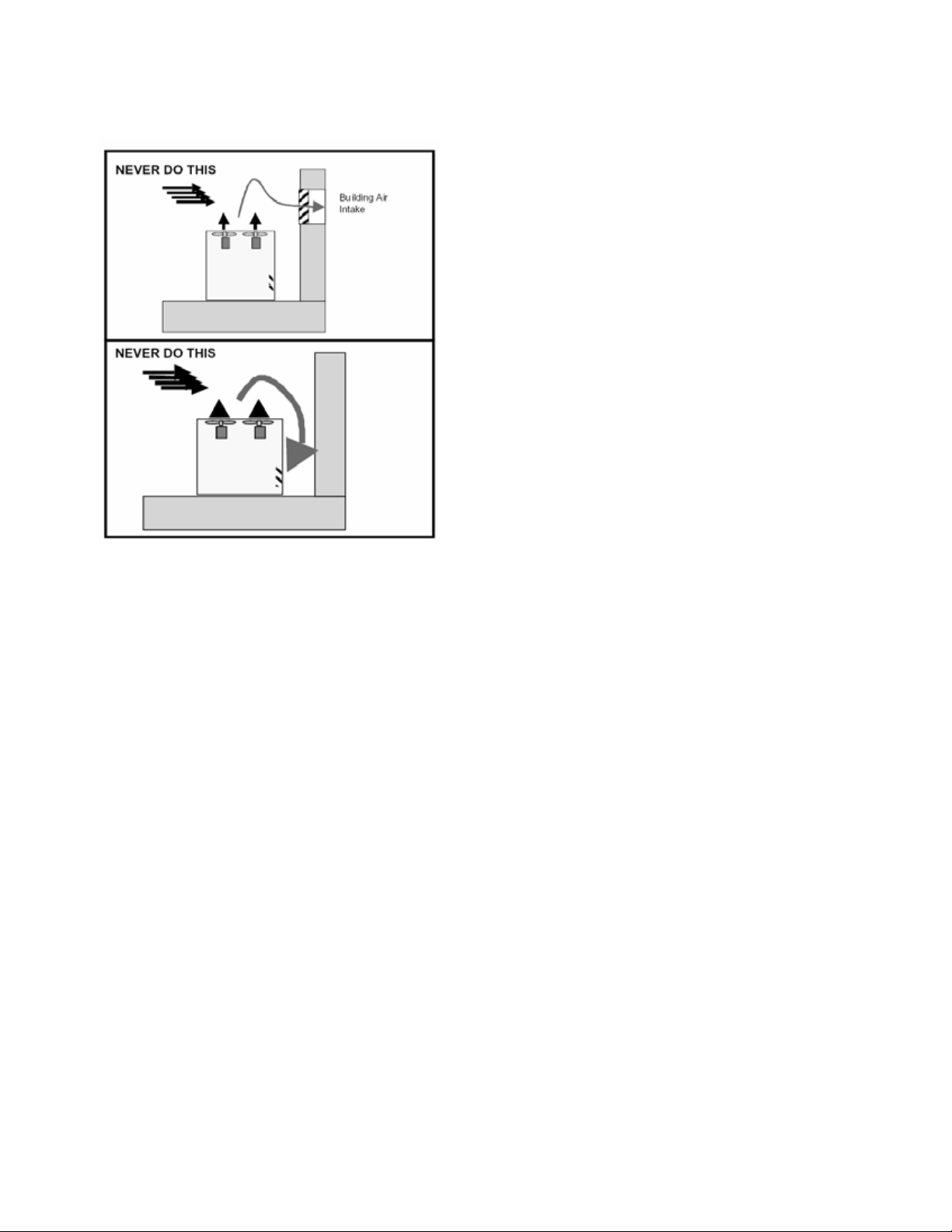

Safety:

The recirculating water system contains chemical

additives for water quality control and biological

contaminants removed from the air by the

washing action of the water. Personnel exposed

to the saturated effluent, drift, or direct contact

should use proper precaution. Proper location of

the evaporative-cooled condenser requires good

judgment to prevent the air discharge from

entering fresh air intakes or to avoid allowing

contaminated building exhaust from entering the

condenser.

Follow local and national codes in locating the

evaporative-cooled condenser but as minimum

the evaporative-cooled condenser sump must be

15 feet from the nearest intake.

GENERAL INFORMATION

Severe Service:

The following recommended maintenance

procedures are basic requirements for normal

operating environments. For severe operating

conditions, the frequency of inspection and

service should be increased. Air containing

industrial and chemical fumes, salt, dust, or other

airborne contaminates and particulates will be

absorbed by the recirculating water system and

16

Page 17

EVAPORATIVE-COOLED

CONDENSER cont.

Performance:

Improper location of the evaporative-cooled

condenser may seriously degrade the capacity of

the equipment. Make sure the equipment is

located such that discharge air from the

condenser does not enter the condenser air inlet.

Warranties:

Please refer to the limitation of warranties in

effect at the time of purchase.

Condenser Tube Inspection:

The coil is leak tested at 450 P.S.I.G. before

shipment. AAON will not be responsible for loss

of refrigerant. It is the responsibility of the

installer to verify that the system is sealed before

charging with refrigerant. If the unit is operated

during low ambient temperature conditions,

freeze protection for the recirculating water

system must be provided.

Freeze Protection:

In order to prevent water temperatures from

dropping below 50°F, this unit is equipped with a

variable frequency drive (VFD) on the fan

motors when the refrigeration system is

operating.

Recirculating Water System:

Electric sump heaters are available to keep the

sump water from freezing when the refrigeration

system is not operating. An electric resistance

heater is supplied in the vestibule when sump

heaters are selected.

Note: The condenser should not be operated

with the fan on and the pump cycled on and

off to maintain head pressure control under

any conditions. The unit is equipped with a

water temperature controller which varies fan

speed to maintain sump water temperature.

This unit is not equipped with a compressor

discharge pressure controller for fan speed

modulation and therefore can not be operated

without water flow.

PRE START-UP

Do not start the evaporative-cooled condenser or

compressors without installation of proper water

treatment chemicals. Contact your local water

treatment expert for correct selection of water

treatment chemical, adjustment of chemical feed

and bleed rates.

Cleanliness:

Dirt and debris may accumulate in the sump

during shipping and storage. The sump should be

cleaned prior to start-up to prevent clogging the

water distribution system. Any surfaces that

show contamination should be cleaned ONLY

with a commercial stainless steel cleaner to

restore the initial appearance. The inlet screens

should be inspected for foreign material.

Pump Operation:

Before initial start of the pump, check as follows:

1. Be sure that pump operates in the direction

indicated by the arrow on the pump casing.

Check rotation each time motor leads have been

disconnected.

2. Check all connections of motor and starting

device with wiring diagram. Check voltage,

phase and frequency of line circuit with motor

name plate.

3. Check suction and discharge piping and

pressure gauges for proper operation.

17

Page 18

EVAPORATIVE-COOLED

CONDENSER cont.

4. Turn rotating element by hand to assure that it

rotates freely.

Running:

Periodically inspect pump while running, but

especially after initial start-up and after repairs.

1. Check pump and piping for leaks. Repair

immediately.

2. Record pressure gauge readings for future

reference.

3. Record voltage, amperage per phase, and kW.

Condenser Fan Motors:

• The direct-drive condenser motors on AAON

evaporative-cooled condensers are 1200-rpm

premium efficiency motors controlled by a VFD.

These motors are totally enclosed air over motors

with weep holes in the bottom end bell so that

any condensation can drain out of the motor.

• The motors have a small electric resistance

heater installed inside the casing to keep the

motors warm when they are deactivated. The

heaters are designed to keep the interior of the

motor 10°F warmer than the surrounding

ambient temperature. This prevents condensation

from forming inside the motor.

• Ensure that fan is tightly mounted to the motor

shaft and the motor mounting bolts are aligned

and secure.

Water Make-up Valve:

• The sump water level is controlled by a set of

conductivity probes at different levels in the

sump. This water level controller is located in

the vestibule behind the condenser pump. There

are four conductivity probes in this controller.

There is a reference probe (shown as “ref” on the

wiring diagram). This probe is one of the two

longest probes. The other long probe is the low

water level probe (shown as “lo” on the wiring

diagram). The medium length probe is for the

medium water level (shown as “med” on the

wiring diagram). The short probe is for the high

water level (shown as “hi” on the wiring

diagram). There is a solenoid valve in the makeup water line that is activated by the water level

controller. The water level controller determines

the level of water in the sump based on

conductivity between two probes. If the

controller sees conductivity between two probes,

it knows that water is at least at the level of that

probe.

• If the water in the sump is below the low probe,

it will not allow the condenser pump or the sump

heater to operate. It will activate the make-up

water solenoid to try to fill the sump assuming

water is flowing to the unit. Once water is above

the low probe, it will allow the condenser pump

and sump heater (if ordered and the ambient

temperature is below 40°F) to operate. The

make-up water solenoid will remain activated

until water gets to the high water level. The

make-up water solenoid will deactivate until

water gets to the medium water level. In normal

operation, the water level should swing between

the medium and high water levels. The

maximum high water level should be 1” below

the overflow drain which occurs after the makeup water valve shuts off when the water level

reaches the high level probe.

• Make-up water supply pressure should be

maintained between 15 and 60 psig for proper

operation of the valve. The make-up water valve

assembly should be inspected monthly and

adjusted as required. Replace the valve seat if

leakage occurs when the valve is in the closed

position.

18

Page 19

EVAPORATIVE-COOLED

CONDENSER cont.

Water Treatment System:

• All AAON evaporative-cooled condensers

come equipped with a water treatment system

that should be maintained by a local water

treatment professional trained in the water

treatment of evaporative condensers. This

system consists of a controller, three chemical

pumps and storage tanks, a conductivity sensor, a

motorized ball valve for water bleed, and a water

meter.

• One chemical pump and tank is typically used

for a descaling chemical to prevent scale from

forming in the condenser. The other two pumps

and tanks are typically used for two different

biocides (to kill any microorganisms that could

grow in the condenser). Two biocides are used

to prevent organisms from becoming resistant to

one chemical.

• The mineral content of the water must be

controlled. All make-up water has minerals in it.

As water is evaporated from the condenser, these

minerals remain. As the mineral content of the

water increases, the conductivity of the water

increases. The water treatment controller

monitors this conductivity. As the water

conductivity rises above set point, the controller

will open a motorized ball valve on the discharge

side of the condenser pump and dumps water

into the condenser drain until conductivity is

lowered. While the motorized ball valve is

opened, the controller will not disperse

chemicals.

• The chemicals are dispersed by the water

treatment controller based on the scheduled input

by the water treatment professional. (See the

separate manual for the water treatment controls

for specific programming information.)

• The water meter measures the quantity of

make-up water used by the condenser.

• Any water treatment program must be

compatible with stainless steel, copper,

aluminum, ABS plastic and PVC. Batch feed

processes should never be used as concentrated

chemicals can cause corrosion. Never use

hydrochloric acid (muratic acid) as it will

corrode stainless steel.

Sequence of Operation:

• On a call for cooling, the condenser pump is

activated. A pressure switch in the pump

discharge is bypassed for six seconds by a time

delay relay in order for the pump to establish

recirculating water flow. If flow is not proven

within the six seconds, the pressure switch opens,

breaking the safety circuit, thereby shutting down

the entire system. This pressure switch is set to

close at 3 psi and open at 1 psi.

• A Johnson Controls S350C measures the water

temperature in the pump discharge line. If the

sump water temperature exceeds 105°F, the

cooling system will be shut down thereby

preventing damage to the evaporative condenser.

• If a fault occurs in the evaporative condenser

fan motor VFD, normally closed fault terminals

on the VFD will interrupt the safety circuit,

thereby shutting down the system.

• If the VFD does fault and cannot be reset, there

is a VFD bypass switch mounted near the VFD.

This switch has four positions—line, off, drive,

and test. The “line” position will bypass the

VFD, sending power to the motor. In this

position, the condenser fans will run at full

speed. The “off” position will not allow power

to pass through the switch. This functions as a

disconnect switch. The “drive” position runs

power through the VFD. This is the normal

operation for the switch. The “test” position

routes power to the VFD but not to the motor.

This is useful for running tests on the VFD

without sending power to the motor.

• A Johnson Controls A350P controls the VFD

speed. This device sends a 0-10 VDC signal to

the VFD. This controller is set to maintain a

sump temperature of 70°F. On a rise in sump

temperature, the controller increases the voltage

to the VFD, increasing the speed of the

condenser fans. Conversely, on a drop in sump

temperature, the controller will decrease the

voltage to the VFD, decreasing the speed of the

condenser fans.

• An outside air thermostat does not allow the

condenser to operate when the ambient

temperature is below 35°F.

19

Page 20

EVAPORATIVE-COOLED

CONDENSER cont.

MAINTENANCE RECOMMENDATIONS

Pump Maintenance:

• Cleaning - Remove oil, dust, water, and

chemicals from exterior of motor and pump.

Keep motor air inlet and outlet open. Blow out

interior of open motors with clean compressed

air at low pressure.

• Labeled Motors - It is imperative for repair of a

motor with Underwriters’ Laboratories label that

original clearances be held; that all plugs, screws,

other hardware be fastened securely, and that

parts replacements be exact duplicates or

approved equals. Violation of any of the above

invalidates Underwriters’ Label.

Fan Motor Maintenance:

Same as pump maintenance

Access Doors:

If scale deposits or water is found around the

access doors, adjust door for tightness. Adjust as

necessary until leaking stops when door is

closed.

Bearings - Lubrication:

Every 6 months or after a prolonged shut down.

Use waterproof, lithium based grease. Below

32°F - Esso Exxon or Beacon 325. Above 32°F –

Mobil Mobilox EP2, Shell Alvania EP2 or

Texaco RB2.

Recommended Monthly Inspection:

1. Clean sump section interior. Dirt and other

impurities which have accumulated in the sump

should be removed from the sump area. Shut off

make-up water ball valve and open the drain

connection for flushing of the sump.

2. Clean dirt out of sump using a water hose (not

a pressure washer).

3. Clean sump suction strainer.

4. Check water operating level. Adjust float as

required.

5. Inspect fan motor(s) and water circulation

pump(s) and lubricate per the lubrication

nameplate or manufacture’s recommendations.

6. Inspect axial fans and eliminators removing

any debris which may have accumulated during

operation.

7. Inspect the water distribution system to insure

that nozzles and spray orifices are functioning

correctly. The inspection should be made with

the circulation pump on and fans off.

Mist Eliminators:

The mist eliminators must be correctly

positioned when they are replaced during

cleaning or service.

Air Inlet:

Inspect the air inlet louvers and mist eliminators

into the condenser section on a monthly basis to

remove any paper, leaves or other debris that

may block the airflow.

Stainless Steel Base Pan:

The base pan under the tube bundles is stainless

steel and may sometimes become tarnished due

to contamination. These surfaces should be

inspected yearly to ensure they remain clean of

any contamination that may result in damage.

Any surfaces that show contamination should be

cleaned ONLY with a commercial stainless steel

cleaner to restore the initial appearance.

Propeller Fans and Motors:

The fans are directly mounted on the motor

shafts and the assemblies require minimal

maintenance except to assurance they are clear of

dirt or debris that would impede the airflow.

Recommended Annual Inspection:

In addition to the above maintenance activities, a

general inspection of the unit surface should be

completed at least once a year. Remove spray

header and flush out.

Cleaning:

Mechanical cleaning, including pressure

washing, should never be performed as surfaces

and seals could be damaged. Chemical cleaning

that is safe for stainless steel, copper, aluminum,

ABS plastic and PVC is the only acceptable

means of cleaning the evaporative condenser. A

proper water treatment program should reduce

cleaning needs.

20

Page 21

EVAPORATIVE-COOLED

CONDENSER cont.

WATER QUALITY

Recirculating Water Quality Guidelines:

• Cycles of concentration (the ratio of dissolved

solids in recirculated water to dissolved solids in

make-up), should be determined and monitored

frequently by a competent water treatment

expert.

• To limit cycles of concentration to maintain the

above guideline, it is necessary to “bleed” a

certain portion of the recirculated water. This is

achieved automatically with a solenoid valve

actuated by a conductivity meter set at the

desired conductivity corresponding to the desired

cycles of concentration. It should be noted that

these are guidelines and even though these

individual values are met, under certain

conditions the water quality can be aggressive.

For example, water with very low alkalinity and

levels of chlorides and sulfates approaching

maximum recommended levels can be corrosive.

Mechanical Cleaning:

Do not attempt to mechanically clean the copper

tubing in the evaporative-cooled condenser. Do

not use wire brushes or any other mechanical

device on the copper tubing. Severe damage may

result. Contact your water treatment expert for

recommendations on chemical cleaning

procedures.

Parts:

Contact your local AAON Representative for

factory authorized parts. Orders must include the

Serial Number from the product nameplate OR

visit www.aaonparts.com for more information.

AIR-COOLED CONDENSER

• The air-cooled condenser section rejects heat by

passing outdoor air over the fin tube coils for

cooling of the hot refrigerant gas from the

compressors. The heated air will discharge from

the top of the section through the axial flow fans.

• The condenser coils should be inspected yearly

to ensure unrestricted airflow. If the installation

has a large amount of airborne dust or other

material, the condenser coils should be cleaned

with a water spray in a direction opposite to

airflow. Care must be taken to prevent bending

of the aluminum fins on the copper tube.

REFRIGERANT PIPING FOR THE

CL SERIES

Note: This section is for information only and

is not intended to provide all details required

by the designer or installer of the refrigerant

piping between the condensing unit and air

handling equipment. AAON Inc. is not

responsible for interconnecting refrigerant

piping. Consult ASHRAE Handbook 2006 –

Refrigeration and ASME Standards.

General:

• Use only clean type L copper tubing (type K for

underground) that has been joined with high

temperature brazing alloy.

• All AAON CL condensing units have factory

furnished liquid and suction line shutoff valves.

Determining Refrigerant Line size:

The piping between the condenser and low side

must assure:

1. Minimum pressure drop, and

2. Continuous oil return, and

3. Prevention of liquid refrigerant slugging, or

carryover

• Minimizing the refrigerant line size is favorable

from an economic perspective, reducing

installation costs, and reducing the potential for

leakage. However, as pipe diameters narrow,

pressure-reducing frictional forces increase.

21

Page 22

REFRIGERANT PIPING cont.

• Excessive suction line pressure drop causes loss

of compressor capacity and increased power

usage resulting in reduced system efficiency.

Excessive pressure drops in the liquid line can

cause the liquid refrigerant to flash, resulting in

faulty expansion valve operation and improper

system performance. In order to operate

efficiently and cost effectively, while avoiding

malfunction, refrigeration systems must be

designed to minimize both cost and pressure loss.

The pipe sizes must be selected to meet the

actual installation conditions, and not simply

based on the connection sizes at the

evaporator and/or condensing unit. Refer to

TABLES RP-1 through RP-4 for connection

size information.

Equivalent Line Length:

All line lengths discussed in this manual, unless

specifically stated otherwise, are Equivalent Line

Lengths. The frictional pressure drop through

valves, fittings, and accessories is determined by

establishing the equivalent length of straight pipe

of the same diameter. Always use equivalent

line lengths when calculating pressure drop.

Special piping provisions must be taken when

lines are run underground, up vertical risers, or in

excessively long line runs.

Liquid line sizing:

• When sizing the liquid line, it is important to

minimize the refrigerant charge to reduce

installation costs and improve system reliability.

This can be achieved by minimizing the liquid

line diameter. However, reducing the pipe

diameter will increase the velocity of the liquid

refrigerant which increases the frictional pressure

drop in the liquid line, and causes other

undesirable effects such as noise. Maintaining

the pressure in the liquid line is critical to

ensuring sufficient saturation temperature,

avoiding flashing upstream of the TXV, and

maintaining system efficiency. Pressure losses

through the liquid line due to frictional contact,

installed accessories, and vertical risers are

inevitable. Maintaining adequate sub-cooling at

the condenser to overcome these losses is the

only method to ensure that liquid refrigerant

reaches the TXV.

• Liquid risers decrease head pressure. If the

evaporator section is below the condenser, and

the liquid line does not include risers, the

gravitational force will increase the pressure of

the liquid refrigerant. This will allow the

refrigerant to withstand greater frictional losses

without the occurrence of flashing prior to the

TXV.

• A moisture indicating sight glass may be

factory installed in the liquid line to indicate the

occurrence of premature flashing or moisture in

the line. The sight glass should not be used to

determine if the system is properly charged. Use

temperature and pressure measurements to

determine liquid sub-cooling, not the sight

glass.

Liquid Line Routing:

Care should be taken with vertical risers. When

the system is shut down, gravity will pull liquid

down the vertical column, and back to the

condenser when it is below the evaporator. This

could potentially result in compressor flooding.

A check valve can be installed in the liquid line

where the liquid column rises above the

condenser to prevent this. The liquid line is

typically pitched along with the

suction line, or hot gas line, to minimize the

complexity of the configuration.

Liquid Line Insulation:

When the liquid line is routed through regions

where temperature losses are expected, no

insulation is required, as this may provide

additional sub-cooling to the refrigerant. When

routing the liquid line through high temperature

areas, insulation of the line is appropriate to

avoid loss of sub-cooling.

Liquid Line Guidelines:

• In order to ensure liquid at the TXV, frictional

losses must not exceed available sub-cooling. A

commonly used guideline to consider is a system

design with pressure losses due to friction

through the line not to exceed a corresponding 12°F change in saturation temperature.

22

Page 23

REFRIGERANT PIPING cont.

• If the velocity of refrigerant in the liquid line is

too great, it could cause excessive noise or piping

erosion. The recommended maximum velocities

for liquid lines are 100 fpm from the condenser

to a receiver tank to discourage fluid backup, and

300 fpm from receiver tank to the evaporator to

minimize valve induced liquid hammer.

Liquid Line Accessories:

Liquid line accessories including sight glasses

and filter driers are available and factory

installed. The total length equivalent of pressure

losses through valves, elbows and fittings must

be considered when adding additional

components in the field. It is a good practice to

utilize the fewest elbows that will allow the

mating units to be successfully joined.

Suction Line Sizing:

The suction line is more critical than the liquid

line from a design and construction standpoint.

More care must be taken to ensure that adequate

velocity is achieved to return oil to the

compressor at minimum loading conditions.

However, reducing the piping diameter to

increase the velocity at minimal load can result

in excessive pressure losses, capacity reduction,

and noise at full load.

Suction Line Routing:

• Pitch the suction line in the direction of flow

(about 1 ft. per 100 ft of length) to maintain oil

flow towards the compressor, and keep it from

flooding back into the evaporator. Crankcase

heaters are provided to keep any condensed

refrigerant that collects in the compressor from

causing damage or wear. Make sure to provide

support to maintain suction line positioning, and

insulate completely between the evaporator and

condensing unit.

• It is important to consider part load operation

when sizing suction lines. At minimum capacity,

refrigerant velocity may not be adequate to return

oil up the vertical riser. Decreasing the diameter

of the vertical riser will increase the velocity, but

also the frictional loss. A double suction riser

can be applied in this situation. The double

suction riser is designed to return oil at minimum

load while not incurring excessive frictional

losses at full load. The double suction riser

consists of a small diameter riser in parallel with

a larger diameter riser, and a trap at the base of

the large riser. At minimum capacity, refrigerant

velocity is not sufficient to carry oil up both

risers, and it collects in the trap, effectively

closing off the larger diameter riser, and

diverting refrigerant up the small riser where

velocity of the refrigerant is sufficient to

maintain oil flow. At full load, the mass flow

clears the trap of oil, and refrigerant is carried

through both risers. The smaller diameter pipe

should be sized to return oil at minimum load,

while the larger diameter pipe should be sized for

acceptable pressure drop at full load.

Suction Line Insulation:

The entire suction line should be insulated. This

prevents condensation from forming on the line,

and reduces any potential loss in capacity

associated with heat gain placing additional load

on the system.

Suction Line Guidelines:

• For proper performance, suction line velocities

less than a 4000 fpm maximum are

recommended. The minimum velocity required

to return oil is dependent on the pipe diameter,

however a general guideline of 1000 fpm

minimum may be applied.

• In a fashion similar to the liquid line, a common

guideline to consider is a system design with

pressure losses due to friction through the line

not to exceed a corresponding 1-2°F change in

saturation temperature.

• At points where small pipe size can be used to

provide sufficient velocity to return oil in vertical

risers at part loads, greater pressure losses are

incurred at full loads. This can be compensated

for by over sizing the horizontal and vertical

drop sections. This will however require

additional refrigerant charge.

Suction Line Accessories:

If the job requirements specify suction

accumulators, they must be separately purchased

and installed.

23

Page 24

REFRIGERANT PIPING cont.

Hot Gas Bypass Line:

• Hot Gas Bypass is available for use with DX

systems that may experience low suction

pressure during the operating cycle. This may be

due to varying load conditions associated with

VAV applications or units supplying a large

percentage of outside air. The system is

designed to divert refrigerant from the

compressor discharge to the low pressure side of

the system in order to keep the evaporator from

freezing and to maintain adequate refrigerant

velocity for oil return at minimum load.

• Hot discharge gas is redirected to the

evaporator inlet via an auxiliary side connector

(ASC) to false load the evaporator when reduced

suction pressure is sensed. Field piping between

the condensing unit and the evaporator is

required.

See figures RP-5 through RP-10 for hot gas

bypass piping configurations.

Hot Gas Bypass Piping Considerations for

Evaporator Above Condensing Unit:

• Pitch the hot gas bypass line downward in the

direction of refrigerant flow, toward the

evaporator.

• When installing hot gas bypass risers, a drain

leg must be provided at the lowest point in the

system. The drain leg must be vertical, its

diameter should be the same as the diameter of

the riser, and it should be 1 foot long. Install a

sight glass in the drain leg for observation. Run

an oil return line, using 1/8 inch capillary tube, 5

feet in length, from the drain leg to the suction

line. Connect the oil return line below the sight

glass, 1 inch

• HGBP valves are adjustable. Factory HGBP

valve settings will be sufficient for most

applications, but may require slight adjustments

for some make up air or other process cooling

applications.

• Insulate the entire length of the HGBP line with

a minimum 1 inch thick Armaflex insulation.

• Refer to figure RP-5 for piping diagram

Hot Gas Bypass Piping Considerations for

Evaporator Below Condensing Unit:

above the bottom of the drain leg.

• The line must slope downward from the hot gas

bypass valve toward the evaporator.

• Refer to figure RP-6 for piping diagram

Hot Gas Bypass Line Guidelines:

• Choose a small size line to ensure oil return,

and minimize refrigerant charge.

• Maintain velocities below a maximum of 4000

fpm. A general minimum velocity guideline to

use is approximately 1000 fpm.

Hot Gas Reheat:

• The AAON modulating hot gas reheat system

diverts hot discharge gas from the condenser to

the air handling unit to supply the reheat coil

and/or the hot gas bypass valve. Size this line as

a discharge line.

• Discharge lines should be sized to ensure

adequate velocity of refrigerant to ensure oil

return, avoid excessive noise associated with

velocities that are too high, and to minimize

efficiency losses associated with friction.

• Pitch the hot gas line in the direction of flow for

oil return.

• Insulate the entire length of the hot gas line

with a minimum 1 inch thick Armaflex

insulation.

• Refer to figures RP-7 through RP-10 for piping

diagrams.

Hot Gas Reheat Guidelines:

• Maintain velocities below a maximum of 3500

fpm. A general minimum velocity guideline is

2000 fpm.

Predetermined Line Sizes:

• To aid in line sizing and selection, AAON has

predetermined line sizes for comfort cooling

applications.

• In order to generate this information, the

following cycle assumptions are made:

Saturated suction temperature = 50°F, Saturated

condensing temperature = 125°F, Sub-cooling =

10°F, Superheat = 15°F.

• The liquid lines have been chosen to maintain

velocities between 100 and 350 fpm. The

suction line diameters are selected to limit

velocities to a 4000 fpm maximum, while a

minimum velocity restriction is imposed by the

ability to entrain oil up vertical suction risers

24

Page 25

REFRIGERANT PIPING cont.

(ASHRAE Handbook 2006 - Refrigeration p.

2.19). Hot gas bypass pipe diameters are

selected to maintain velocity below a maximum

4000 fpm, while a minimum criteria guarantees

oil return up vertical rise sections, as with the

suction line (ASHRAE Handbook 2006 –

Refrigeration p. 2.20).

• Acceptable pressure loss criteria are applied to

each of the lines: The total equivalent length of

the liquid line available is determined such that

3°F of liquid sub-cooling remain at the TXV.

This includes the pressure losses in horizontal

and vertical sections, accessories, elbows, etc.

Recall that the available sub-cooling for the cycle

is assumed as 10°F. To maintain at least 3°F subcooling as a factor of safety to avoid flashing at

the TXV, we consider a maximum pressure loss

equivalent to a 7°F change in saturation

temperature. Pressure losses in the suction line

are not to exceed 2°F. When sizing the hot gas

bypass line we consider a maximum acceptable

pressure loss in the hot gas bypass line with R-22

to be 20 psi, 30 psi with R-410A refrigerant.

When to use predetermined line sizing:

The line sizes presented are not the only

acceptable pipe diameters, they are however

appropriate for general comfort cooling

applications, and satisfy common job

requirements. Examine the conditions,

assumptions, and constraints used in the

generation of the predetermined pipe diameters

to ensure that this method is applicable to a

particular case. Do not assume that these line

sizes are appropriate for every case. Consult

ASHRAE Handbook – Refrigeration 2006 for

generally accepted system practices.

How to use predetermined line sizing:

First, read the previous section entitled (When to

use predetermined line sizing) to decide if this

method is applicable.

Second, determine the refrigerant being used,

AAON offers CL products with R-410A and R-

22 refrigerants, and the line sizes are not

identical for both.

Next, determine whether the product is operating

with single, or dual circuited compressors.

Locate the appropriate table of line sizes:

TABLE RP-1: Dual Circuited R-410A

condensers

TABLE RP-2: Dual Circuited R-22 condensers

TABLE RP-3: Single Circuited R-410A

condensers

TABLE RP-4: Single Circuited R-22 condensers

Locate the Model number in the table. For each

model, the circuits are listed, along with the pipe

diameters of the connection sizes, and the

diameters of the predetermined line size.

A figure accompanies each table.

FIGURE RP-1: Dual circuited R-410A

condensers

FIGURE RP-2: Dual circuited R-22 condensers

FIGURE RP-3: Single circuited R-410A

condensers

FIGURE RP-4 Single circuited R-22 condensers

Examine the appropriate figure to determine the

acceptable line dimensions. The figure is shown

as total available riser height versus total

equivalent line length for the liquid line. This

curve identifies a region of acceptable piping

configuration when the predetermined line sizes

are selected for any model in the table. A piping

configuration above the curve falls outside the

assumptions used to determine the line size and

will result in a loss of sub-cooling, and additional

pressure losses in the suction and hot gas bypass

lines. The total equivalent line length definition

includes the height of vertical rise, pressure drop

through elbows and accessories, and horizontal

line length, so elbows, accessories and vertical

rise must be considered when determining

horizontal length available from the total

equivalent line length.

This figure is presented in terms of the liquid

line, but it assumes that the line lengths for the

suction and hot gas bypass are similar, as these

lines will commonly be routed together to

minimize the space and cost required for split

system installation.

25

Page 26

REFRIGERANT PIPING cont.

TABLE RP-1 Predetermined Line sizes for Dual Circuit CL units with R-410A

Tons System

45

60

70

75

95

100

110

125

134

135

155

170

190

210

230

1

2

1

2

1

2 1-1/8 in. 1-3/8 in. 7/8 in. 1-3/8 in.

1

2

1 1-5/8 in.

2 2-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-3/8 in.

1

2

3

1

3

1

3 2-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in.

1

3 2-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in.

1 1-5/8 in. 7/8 in.

2

3

1 1-5/8 in.

3

1

3

1

2

3

4

1 1-5/8 in.

2

3

4

1

2

3

4

Suction Line Liquid Line Hot Gas Bypass Reheat Suction Line Liquid Line Hot Gas Bypass Reheat

1-3/8 in. 7/8 in. 7/8 in. 7/8 in. 1-5/8 in. 7/8 in. 3/4 in. 1-1/8 in.

1-5/8 in. 7/8 in. 7/8 in. 1-1/8 in. 2-1/8 in. 1-1/8 in. 3/4 in. 1-1/8 in.

1-5/8 in.

1-5/8 in. 1-1/8 in. 7/8 in. 1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in. 1-3/8 in.

1-5/8 in.

1-5/8 in. 1-1/8 in. 7/8 in. 1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in. 1-3/8 in. 2

1-5/8 in.

1-5/8 in.

2-1/8 in. 1-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-3/8 in.

2-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in.

2-1/8 in. 1-1/8 in. 7/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-3/8 in. 2

1-5/8 in. 1-1/8 in.

2-1/8 in. 1-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in.

2-1/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in.

2-1/8 in. 1-1/8 in. 7/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-3/8 in.

Connection Size Predetermined Line Size

7/8 in.

1-1/8 in. 7/8 in.

7/8 in.

1-1/8 in. 1-3/8 in. 7/8 in. 1-3/8 in.

1-1/8 in. 7/8 in.

1-1/8 in. 7/8 in.

1-1/8 in. 7/8 in.

1-1/8 in. 7/8 in.

7/8 in.

7/8 in.

7/8 in.

7/8 in.

R-410A

1-1/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in. 1-3/8 in.

1-1/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

1-1/8 in. 2-1/8 in. 1-1/8 in. 3/4 in. 1-1/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

2-1/8 in. 1-1/8 in.

2-1/8 in. 1-1/8 in.

3/4 in. 1-1/8 in.

3/4 in. 1-1/8 in.

1-3/8 in. 2

1-3/8 in. 2

1-3/8 in. 2

1-3/8 in.

1-3/8 in.

26

Page 27

REFRIGERANT PIPING cont.

TABLE RP-2 Predetermined Line sizes for Dual Circuit CL units with R-22

Tons System

45

60

70

75

95

100

110

125

134

135

155

170

190

210

230

1

2

1

2

1

2 2-5/8 in. 1-1/8 in. 1-5/8 in.

1

2

1 2-1/8 in. 7/8 in.

2 2-5/8 in. 1-3/8 in. 1-5/8 in. 1-3/8 in.

1

2

3

1

3

1

3 2-5/8 in. 1-3/8 in. 1-5/8 in. 1-3/8 in.

1

3 2-5/8 in. 1-3/8 in. 1-5/8 in. 1-3/8 in.

1 2-1/8 in. 7/8 in.

2

3

1 2-1/8 in. 7/8 in.

3

1

3

1

2

3

4

1 2-1/8 in. 7/8 in.

2

3

4

1

2

3

4

Suction Line Liquid Line Hot Gas Bypass Reheat Suction Line Liquid Line Hot Gas Bypass Reheat

1-3/8 in. 5/8 in. 7/8 in. 7/8 in. 2-1/8 in. 7/8 in. 7/8 in. 1-1/8 in.

2-1/8 in. 7/8 in. 7/8 in. 1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in. 1-3/8 in.

2-1/8 in. 7/8 in. 7/8 in. 1-3/8 in.

2-1/8 in. 7/8 in. 7/8 in. 1-3/8 in. 2-5/8 in. 1-1/8 in. 1-1/8 in. 1-5/8 in.

2-1/8 in. 7/8 in. 7/8 in. 1-3/8 in.

2-1/8 in. 7/8 in. 7/8 in. 1-3/8 in. 2-5/8 in. 1-1/8 in. 1-1/8 in. 1-5/8 in. 2

2-1/8 in. 7/8 in.

2-1/8 in. 7/8 in.

2-5/8 in. 1-3/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-5/8 in.

2-5/8 in. 1-3/8 in. 1-5/8 in. 1-3/8 in.

2-5/8 in. 1-3/8 in. 7/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-5/8 in. 2

2-1/8 in. 7/8 in.

2-5/8 in. 1-3/8 in. 1-5/8 in. 1-3/8 in.

2-5/8 in. 1-3/8 in. 1-5/8 in. 1-3/8 in.

2-5/8 in. 1-3/8 in. 7/8 in. 1-5/8 in. 2-5/8 in. 1-3/8 in. 1-1/8 in. 1-5/8 in.

Connection Size Predetermined Line Size

7/8 in.

7/8 in.

7/8 in.

7/8 in.

7/8 in.

7/8 in.

7/8 in.

R-22

2-1/8 in.

1-3/8 in.

1-3/8 in.

1-3/8 in.

1-3/8 in. 2-1/8 in. 1-1/8 in. 7/8 in. 1-3/8 in.

1-3/8 in.

1-3/8 in.

1-3/8 in.

2-5/8 in.

2-1/8 in.

2-5/8 in. 1-1/8 in. 1-5/8 in.

2-5/8 in.

2-5/8 in.

2-5/8 in.

2-5/8 in.

2-5/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

1-1/8 in.

7/8 in. 1-3/8 in.

1-1/8 in. 1-5/8 in.

7/8 in. 1-3/8 in.

1-1/8 in. 1-5/8 in. 2

1-1/8 in. 1-5/8 in. 2

1-1/8 in. 1-5/8 in. 2

1-1/8 in. 1-5/8 in.

1-1/8 in. 1-5/8 in.

27

Page 28

REFRIGERANT PIPING cont.

TABLE RP-3 Predetermined Line sizes for Single Circuit CL units with R-410A

Tons System

Suction Line Liquid Line Hot Gas Bypass Reheat Suction Line Liquid Line Hot Gas Bypass Reheat

1

45

60

70

75

95

2

3

4

1

2

3

4

1 1-3/8 in.

2 1-5/8 in. 1-5/8 in. 7/8 in. 1-1/8 in.

3 1-3/8 in. 1-3/8 in. 3/4 in. 7/8 in.

4 1-5/8 in. 1-5/8 in. 7/8 in. 1-1/8 in.

1

2

3

4

1

2 7/8 in. 1-1/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

3 5/8 in. 7/8 in. 1-5/8 in. 7/8 in. 3/4 in.

4 7/8 in. 1-1/8 in. 2-1/8 in. 1-1/8 in. 7/8 in.

TABLE RP-4 Predetermined Line sizes for Single Circuit CL units with R-22

Tons System

Suction Line Liquid Line Hot Gas Bypass Reheat Suction Line Liquid Line Hot Gas Bypass Reheat

1

45

60

70

75

95

2

3

4

1

2

3

4

1

2 2-1/8 in.

3 1-5/8 in.

4 2-1/8 in.

1

2

3

4

1 1-3/8 in. 5/8 in.

2 2-1/8 in. 7/8 in. 1-3/8 in. 1-1/8 in. 1-1/8 in. 1-3/8 in.

3 1-3/8 in. 5/8 in. 7/8 in. 3/4 in. 7/8 in. 1-1/8 in.

4 2-1/8 in. 7/8 in. 1-3/8 in. 1-1/8 in. 1-1/8 in. 1-3/8 in.