Page 1

AAON Coil Products

CONDENSING UNITS

INSTALLATION

CA SERIES

AND

MANUFACTURED

IN THE U.S.A

OPERATION

MANUAL

!

▲

Scroll compressors will be damaged by

operation with the wrong rotation.

THE LOW PRESSURE SWITCH HAS BEEN

DISCONNECTED AFTER TESTING

The wiring must be reconnected and proper

rotation determined at the time of start-up by

a qualified service technician using suction

and discharge pressures gauges.

Any alteration should only be made at

the unit power connection.

WARNING

AT THE FACTORY.

1

Page 2

AAON Coil Products

SECTION PAGE NUMBER

INSTALLATION ……………………………………………………………………………3

General

Location

Service Clearance

Setting the Unit

Electrical

Thermostat

REFRIGERANT PIPING

General …………………………………………………………………………4

Interconnecting Piping

CHECKOUT PROCEDURE …………………………………………………………… 6

Cooling

Compressor Checkout Procedure ……………………………………… 7

SERVICE, TROUBLE SHOOTING & MAINTENANCE …………………………………8

General Instructions

Coil Information

TABLE OF CONTENTS

! IMPORTANT

▲

The Clean Air Act of 1990 bans the intentional

!

▲

Installation and service must be performed by

a qualified installer or service agency.

Owner should pay particular attention to the words: NOTE, CAUTION AND WARNING.

NOTES are intended to clarify or make the installation easier. CAUTIONS are given to prevent

equipment damage. WARNINGS are given to alert owner that personal injury and/or equipment

It is the intent of

However, in the interest of product improvement,

P84510-A

(ACP 27230)

CAUTION

damage may result if installation procedure is not handled properly.

AAON Coil Products, Inc.

and/or design of it's products without notice, obligation or liability.

© 1999

AAON Coil Products, Inc.

to provide accurate and current specification information.

AAON Coil Products, Inc.

, all rights reserved throughout the world.

venting of refrigerant (CFC's and HCFC's) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed.

Fines and/or incarceration may be levied for

non-compliance.

reserves the right to change pricing, specifications

2

Page 3

INSTALLATION

AAON Coil Products 'CA' Series units are designed for fast easy installation

GENERAL

All CA condensing units have lifting areas at the underside of the equipment to allow moving and placement

without physical damage. Arrange spreader bars,

blocking or other lifting devices to prevent any damage to the coils or cabinet of the condensing unit.

These condensing units may be placed on a roof or at

ground level since they are designed for exposure to

weather.

When roof mounted, a steel frame must be provided

that will support the unit above the roof itself.

When installed at ground level, a substantial base must

be provided that will not settle.

LOCATION

Airflow to and from the condensing unit must not be

restricted. Obstruction to air flow will result in decreased performance and efficiency. The installation

position must provide at least 3 feet of side clearance

for proper air flow into the coils. When units are

mounted adjacent to each other the clearance required between them would be 6 feet.

Condensing units should not be installed in an enclosure or pit that is deeper than the height of the unit.

When a recessed installation is used the side clearance requirement is doubled to 6 feet for the inlet air.

The CA 02 through CA 05 model sizes have a horizontal

airflow pattern. The discharge air side of one unit

should not be aligned with the intake of another. The

discharge air should be faced away from the adjacent building or structure.

The CA 08 through CA 25 models have a vertical air

discharge. There must be no obstruction above the

equipment that may deflect this air back to the inlet of

the condensing unit. Do not place the unit under an

overhang.

Condensing unit operation can also be affected by

wind. It is good practice to position the unit so its length

is parallel with the prevailing wind.

SERVICE CLEARANCE

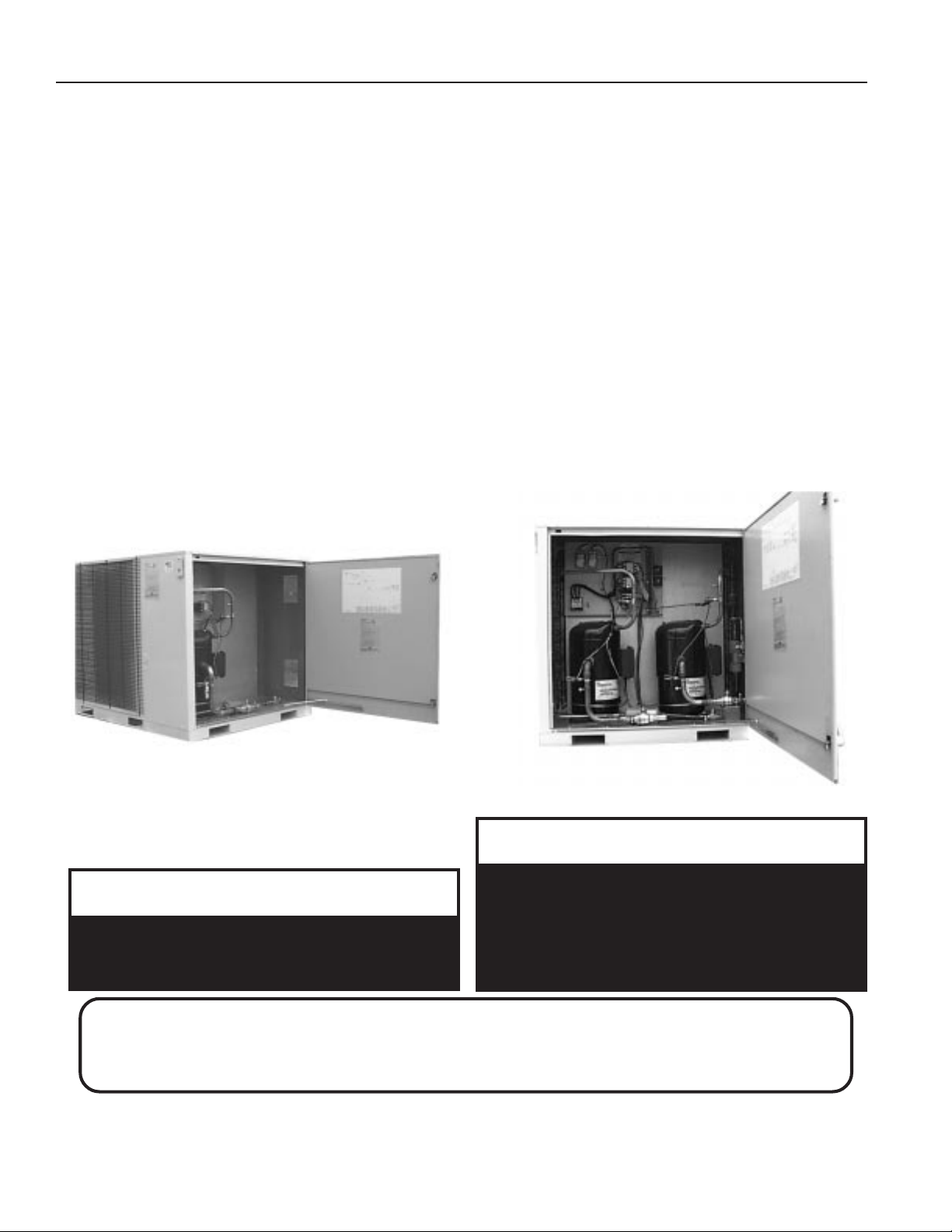

One end of the CA condensing unit contains the

access door that must be accessible for periodic

service. This area contains the compressor, controls,

safety devices, refrigerant service and shut-off valves.

It is recommended that a minimum of 4 feet be left free

at this end of the unit for proper and easier servicing.

SETTING THE UNIT

If cables or chains are used to hoist the unit, care

should be taken to prevent damage to the cabinet.

Hoist unit to a point directly above the pad, and lower

unit into the proper place. Unit may also be positioned

with a forktruck. Remove the harness used in hoisting.

Make sure the unit is properly seated and level.

ELECTRICAL

Check the unit data plate to make sure it agrees with

the power supply. Connect power to the unit according to the wiring diagram provided with the unit.

The power and control wiring may be brought in

through the holes provided at one corner of the unit.

Protect the branch circuit in accordance with code

requirements. If the control wires are to run inside the

same conduit, use 600 volt wire or as required by

applicable codes. The unit must be electrically

grounded in accordance with the National Electric

Code, ANSI / NFPA No. 70-1984 when installed if an

external source is utilized, in Canada use current C.S.A.

Standard C22.1 Canadian Electric Code Part 1.

Power wiring is to the unit terminal block or compressor

contactor. All wiring beyond this point has been done

by the manufacturer.

Connect the control wiring and apply power to the unit.

CHECK COMPRESSOR FOR PROPER ROTATION BY STARTING UNIT ONLY AFTER CONNECTING PRESSURE GAUGES

TO SUCTION AND DISCHARGE.

THE COMPRESSOR WILL BE DESTROYED IF RUN IN THE

WRONG DIRECTION.

NOTE: All units are factory wired for 230, 380, 415, 460

or 575 volt.

THERMOSTAT

Low voltage room thermostat should be located on an

inside wall 4 to 5 feet above the floor where it will not

be subjected to drafts, sun exposure or heat from

electrical fixtures or appliances. Follow manufacturer's

instructions enclosed with thermostat for general installation procedure.

! IMPORTANT

▲

Three phase Scroll Compressors are directional

and start-up must be performed by a qualified

service technician using suction and discharge

gauges.

!

▲

WARNING

Electric shock hazard. Can cause injury or death.

Before attempting to perform any service or

maintenance, turn the electrical power to unit to

OFF at disconnect switch(es). Unit may have

multiple power supplies.

3

Page 4

REFRIGERANT PIPING

GENERAL

All refrigeration systems are factory assembled, including a holding charge of R-22, and tested. On 13 - 25 ton

units the refrigerant system includes dual condenser

coils providing two stage cooling. These systems are

provided with liquid line filter driers and fully hermetic

compressors. Compressors are equipped with a positive pressure forced lubrication system and crankcase

heater. The air cooled condenser coil(s) is constructed

of copper tubes with aluminum fins (copper fins optional), the air is pulled through with steel propeller

fans.

All CA Condensing units have factory furnished liquid

and suction line shutoff valves. The pipe sizes must be

selected to meet the actual installation conditions

and not simply based on the connection sizes at the

evaporator and/or condensing unit.

The refrigeration section of these appliances has been

listed by E.T.L. as meeting the applicable provisions of

UL 1995, CAN/CSA C22.2, No. 236-Second Edition.

NOTE: Crankcase Heater Operation

The 8 through 25 ton sizes are equipped with a crankcase heater, which should be energized at least 24

hours prior to setting the thermostat for cooling operation with the compressor.

This section is not intended to provide all the information required by the designer or installer of the refrigerant piping between the condensing units and the low

side components. The appropriate sections of the

ASHRAE Guide and the ASME standards should be

used for final information.

! IMPORTANT

▲

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC's and HCFC's) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed.

Fines and/or incarceration may be levied for

non-compliance.

• once piped, the interconnecting piping and air

handler MUST BE evacuated to 50 microns or less;

leak checked and charged with R22 refrigerant.

• open the shut off valves.

• run unit, check rotation of compressors using

refrigerant gauges.

• check super heat and subcooling; subcooling

should be 10-13°F, evaporator superheat should

be 10-15 °F. Also check the compressor discharge

line superheat. It should be at least 60°F.

• make sure airhandler thermal expansion valve

bulb is mounted with good thermal contact on

the correct suction line on a horizontal section,

close to the evaporator in the 4 or 8 o'clock

position and insulated.

• the suction line should be insulated for its entire

length.

SUCTION LINE

The suction line pipe size should be selected to have

a maximum pressure drop of 3 PSI for the equivalent

length of piping that is used. This corresponds to

approximately 2°F with R22.

The piping between the condenser and low side must

assure:

• minimum pressure drop

• continuous oil return

• prevention of liquid refrigerant slugging or carryover.

Acceptable system design and installation will include

consideration as follows:

Interconnecting Piping Summary

• piping from the condensing unit to the indoor air

handler is the responsibility of the installing contractor.

• only clean "ACR" tubing should be used.

• condensing units are provided with in-line shutoff

valves on both the liquid and suction lines. These

should remained closed until the system is ready

for start-up.

• piping should conform to generally accepted

practices and codes.

• care must be taken not to cross the circuits on

multiple circuit systems.

Any vertical suction risers should be checked to confirm that oil will be returned to the compressor. (Use

the following tables for pipe sizing information).

All suction lines must be pitched in the direction of flow

and supported to maintain their position.

Fully insulated piping must be used between the

evaporator and the condensing unit. A suction accumulator is not included as part of the CA condensing

unit and must be field furnished and installed if required by job conditions.

R22 SUCTION LINE CAPACITY

Pressure Loss = 3 PSI (2°F) at 40°F saturated suction

LINE SIZE - inches MAX. TONS / COMPRESSOR

5/8" 1.1

7/8" 2.9

1 1/8" 5.8

1 3/8" 10.1

1 5/8" 16.0

NOTE: Pressure loss, PSI/100 feet of equivalent line length

due to line friction. (Corresponding change in R22 saturation temperature.)

4

Page 5

LIQUID LINE

The liquid line pipe size should be selected to have a

maximum pressure drop of 6 PSI which corresponds to

approximately 2°F with R22.

The CA condensing units have a built in filter drier. The

units do not include a liquid line solenoid valve and this

must be field furnished and installed if required by job

conditions.

(OPTIONAL) HOT GAS LINE

The hot gas bypass option is a system that maintains

evaporator pressure at or above a minimum value.

This will prevent the coil from freezing and also keep

the velocity of the refrigerant gas sufficiently high for

proper oil return to the compressor when the cooling

is at light load conditions.

Pressure drop in the hot gas line is normally designed

not to exceed the equivalent of a 2°F change in

saturation temperature. The recommended sizing

table below is based on a 1°F change in saturation

temperature.

Hot gas bypass lines must be insulated to minimize

heat loss and condensation of gas inside the piping

and to prevent injury from high temperature surfaces.

R22 LIQUID LINE CAPACITY

Pressure Loss = 3 PSI (1°F) at 100°F liquid

MINIMUM TONS CAPACITY

To Carry Oil Up a Suction Riser at 40°F saturated suction

LINE SIZE - inches Min. TONS / COMPRESSOR

3/4" 0.8

7/8" 1.1

1 1/8" 1.8

1 3/8" 2.9

1 5/8" 4.0

2 1/8" 7.2

FITTING LOSSES

In Equivalent Feet of Straight Copper Tubing

Line

Size - in.

90°

Std.

90°

LongRad

90°

Street

45°

Std.

45°

Street

180°

Std.

1/2" 1.4 0.9 2.3 0.7 1.1 2.3

5/8" 1.6 1.0 2.5 0.8 1.3 2.5

7/8" 2.0 1.4 3.2 0.9 1.6 3.2

1 1/8" 2.6 1.7 4.1 1.3 2.1 4.1

1 3/8" 3.3 2.3 5.6 1.7 3.0 5.6

1 5/8" 4.0 2.6 6.3 2.1 3.4 6.3

2 1/8" 5.0 3.3 8.2 2.6 4.5 8.2

NOTE: The equivalent feet for a piping system must include

the equivalent length of straight tubing for all the fittings, as

well as, any valves that are added to the system.

LINE SIZE - inches MAX. TONS / COMPRESSOR

1/2" 3.6

5/8" 6.7

7/8" 18.2

NOTE: Pressure loss, PSI/100 feet of equivalent line length

due to line friction. (Corresponding change in R22 saturation temperature.)

R22 HOT GAS BYPASS LINE CAPACITY

Pressure Loss = 3 PSI (1°F) at 40°F saturated suction

LINE SIZE - inches TONS / COMPRESSOR

1/2" 0.85

5/8" 1.6

7/8" 4.2

1 1/8" 8.5

1 3/8" 14.8

NOTE: Pressure loss, PSI/100 feet of equivalent line length

due to line friction. (Corresponding change in R22 saturation temperature.)

WEIGHT OF REFRIGERANT 22

In Type L Copper Tubing (Pounds / 100 Feet)

Line Size - in.

LIQUID AT 100°F

SUCTION AT 40°F

3/8" 4.3 .065

1/2" 7.9 .120

5/8" 12.7 .195

7/8" 26.4 .405

1 1/8" 45.0 .690

1 3/8" 68.6 1.05

1 5/8" - - - 1.49

2 1/8" - - - 2.58

WIRING DIAGRAMS

A complete set of unit wiring diagrams is provided and

located inside the control compartment door.

HEATING SYSTEMS

(optional as part of indoor air handler)

When heat is called for, the cooling section is inoperable except for the indoor blower motor. Actual heating is accomplished by an indoor air handling unit with

heating capabilities.

5

Page 6

CHECK OUT PROCEDURES

CAUTION:

Before leaving installation, a complete operating cycle should be observed to

see that all components are functioning properly.

COOLING

1. Main Power Switch(es) is / are on and power is to the unit.

2. Put the thermostat in cooling mode and place the "fan" switch to on.

Check to see if air handler blower is running in the correct direction and at the

nameplate amperage.

3. TURN COOLING ON - Check to see that the compressor is operating.

Check the amperage draw and compare to the nameplate

(check amperage at the load side of the compressor contactor).

TROUBLE

POSSIBLE CAUSE

COOLING PACKAGE

1. Check power at line side of contactor(s).

2. Thermostat not set for cooling.

SYSTEM OFF

CONDENSER FAN WILL NOT RUN

3. High pressure control tripped.

4. Low pressure switch open (loss of charge).

5. Low pressure switch open (clogged filters).

1. Overload thermal protector open in motor.

2. Motor run capacitor open or shorted.

3. Fan or shaft stuck.

EVAPORATOR BLOWER WILL NOT RUN

COMPRESSOR SHORT CYCLES

FAN MOTOR RUNS HOT AND CUTS OUT

COMPRESSOR WILL NOT START

BLOWER DOES NOT DELIVER AIR

1. Overload thermal protector open in motor.

2. Relay not closing.

3. Capacitor shorted or open (PSC motors only).

4. Stuck shaft or blower wheel.

1. Check for low refrigeration charge.

2. Compressor overload opening.

3. Ambient temperature too low.

4. Thermostat in supply air stream.

5. Filters dirty or air flow restricted.

6. Evaporator blower not running.

1. Line voltage too high.

1. Line voltage too low.

2. Limit switches are open.

3. Overload or pressure control tripped.

1. Blower running backwards (3 phase only).

2. Dirty filters.

3. Duct obstruction.

6

Page 7

COMPRESSOR CHECKOUT PROCEDURE

CONTROL PANEL NOT SET FOR COOLING

NO POWER TO

CONTACTOR

COMPRESSOR

WON'T RUN

POWER TO CONTACTOR

ALL 3 LEGS

COMPRESSOR

CHECKOUT

PROCEDURE

POWER TO

UNIT

NO POWER TO

UNIT

CONTACTOR

OPEN

CONTACTOR

CLOSED

CHECK UNIT FUSES

AND WINDING

CHECK CIRCUIT BREAKER AT

POWER DISTRIBUTION PANEL

NO 24 VOLT POWER

TO HOLDING COIL

POWER TO HOLDING COIL

COMPRESSOR

HUMS

COMPRESSOR

DOESN'T HUM

MOTOR WINDING OPEN

COMPRESSOR

NO POWER TO

COMPRESSOR

HOLDING COIL BURNED OUT

STUCK COMPRESSOR

GROUNDED WINDING

POWER TO

ALL 3 LEGS

COMPRESSOR LOW AMBIENT LOCKOUT OPEN

REVERSE LEADS

REPLACE

COMPRESSOR

MOTOR

WINDING OPEN

INTERNAL

OVERLOAD OPEN

THERMOSTAT NOT CALLING FOR COOLING

LO PRESSURE SWITCH OPEN

HI PRESSURE SWITCH OPEN

(TEMPERATURE OUTSIDE BELOW 55 DEG.)

TRANSFORMER OPEN

BROKEN OR LOOSE CONTROL

REPLACE CONTACTOR

COMPRESSOR RUNS

COMPRESSOR

DOESN'T RUN

REPLACE

COMPRESSOR

IF COMPRESSOR DOME IS HOT,

IT MAY BE LOCKED OUT ON

INTERNAL OVERLOAD.

WAIT FOR RESET, IT COULD TAKE

AS LONG AS 2 HOURS.

REPLACE LEADSBROKEN LEADS

REPLACE

COMPRESSOR

COMPRESSOR RUNS

COMPRESSOR CYCLES

OR

(Poor Cooling)

HIGH HEAD

PRESSURE

LOW HEAD

HIGH SUCTION

PRESSURE

LOW

SUCTION

PRESSURE

LOW AIR (CONDENSER)

OVERCHARGE OF REFRIGERANT

AIR IN SYSTEM

DIRTY CONDENSER COIL

DEFECTIVE COMPRESSOR VALVES

LOW AIR (EVAPORATOR)

LOW REFRIGERANT CHARGE

RESTRICTED FEEDER TUBE

BAD EXPANSION VALVE POWER ELEMENT

7

REPLACE COMPRESSOR

CHECK FILTERS,

OR DIRTY EVAPORATOR COIL

OR LOOSE BELT

Page 8

SERVICING, TROUBLE SHOOTING AND MAINTENANCE

In the event the unit cannot be made to function

correctly, it is strongly recommended that only servicemen who are well qualified and experienced in

heating and air conditioning be permitted to service

the systems.

GENERAL LUBRICATING INSTRUCTIONS

All original condensing unit motors and fan bearings

REQUIRE NO LUBRICATION.

COIL INFORMATION

The condenser coil(s) MUST BE KEPT CLEAN.

This will reduce electrical use, maintain capacity and

reduce stress on the unit.

Before attempting to clean the coils; set thermostat to

the "OFF" position; turn the electrical power to the unit

to the "OFF" position at the disconnect switch. The

condenser coil can be thoroughly cleaned by washing from the inside out with water and a coil cleaner

and can be brushed on the outside by a broom. If coil

is extremely dirty with clogged fins, a serviceman who

specializes in coil cleaning should be called.

DO NOT BEND OR DAMAGE FINS.

If the unit has been off for over an hour, restore power

to the unit and wait two hours before turning the

thermostat on.

The inside (evaporator) coil can be inspected at the

air handler by removing the filters and observing the

cleanliness of the coil from the filter side.

If dirty, have an experienced serviceman clean by

washing from the blower side toward the filter side.

AIR HANDLER - FILTER INFORMATION

Install new filters with size indicated on the filters or as

indicated by installation instructions before running

the air handler. Be sure filters are installed in the correct

direction with respect to the air flow.

FILTERS SHOULD BE CHECKED EVERY 30 DAYS AND REPLACED OR CLEANED AS NECESSARY.

Do not permit the unit to be operated unless the filters

are in place. Operation of the unit without filters will

result in a clogged evaporator coil - a very expensive

service job to correct.

AIR HANDLER - BLOWER INFORMATION

CLEAN BLOWER WHEELS are necessary to reduce electrical use, maintain capacity and reduce stress on the

unit. To inspect and clean the blower; set thermostat

to the "OFF" position; turn the electrical power to the

unit to the "OFF" position at the disconnect switch.

Clean the assembly, check the bearings for looseness,

inspect the belt condition and tightness, check screws

for tightness, rotate blower wheel while listening close

to each bearing and with a finger on the bearing to

check for noise or roughness in the bearing, which

indicates a failing bearing. Replace blower deck, turn

on the power to the unit, if the unit has been off over

on hour do not turn the thermostat on for two or more

hours after turning on disconnect.

OBSTRUCTION TO AIR FLOW

Supply and return air grilles must be kept clear so air

can be freely drawn into and discharged from the

system.

AAON Coil Products

P84510 • (Rev A) 11-98 (ACP 27230)

CA COOLING UNITS

•

INSTALLATION

AND

OPERATION MANUAL

AAON Coil Products, Inc.

203 Gum Springs Road

Longview, Texas U.S.A 75602

ph: 903-236-4403 • fax: 903-236-4463

8

Loading...

Loading...