Page 1

BL Series

Outdoor Mechanical Rooms with Boilers and Pumps

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in serious injury,

death or property damage.

Be sure to read and understand the

installation, operation and service

instructions in this manual.

Improper installation, adjustment,

alteration, service or maintenance

can cause serious injury, death or

property damage.

A copy of this IOM should be kept

with the unit.

WARNING

Do not store gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch;

do not use any phone in your

building.

Leave the building immediately.

Immediately call you gas supplier

from a phone remote from the

building. Follow the gas supplier’s

instructions.

If you cannot reach your gas

supplier call the fire department.

Startup and service must be

performed by a Factory Trained

Service Technician.

WARNING

Installation, Operation,

& Maintenance

Page 2

Page 3

3

Table of Contents

Safety .............................................................................................................................................. 6

BL Base Model and Features Description ...................................................................................... 9

General Information ...................................................................................................................... 13

Codes and Ordinances ............................................................................................................... 13

Receiving Unit ........................................................................................................................... 13

Storage ....................................................................................................................................... 13

Outdoor Mechanical Room ....................................................................................................... 13

Wiring Diagrams ....................................................................................................................... 14

General Maintenance ................................................................................................................. 14

Boiler System ............................................................................................................................ 14

Boiler Primary/Secondary Pumping .......................................................................................... 14

Makeup Water ........................................................................................................................... 15

Compression/Expansion Tank ................................................................................................... 15

Pressure Relief Valve ................................................................................................................ 16

Automatic Air Vent ................................................................................................................... 16

Dual Pumps ............................................................................................................................... 16

Pressure Gauges and Thermometers ......................................................................................... 16

Pipe Insulation ........................................................................................................................... 17

Installation..................................................................................................................................... 17

Outdoor Mechanical Room Placement...................................................................................... 17

Curb and Steel Mount Installation ............................................................................................ 17

Lifting and Handling ................................................................................................................. 18

Water Connection ...................................................................................................................... 20

Gas Connection ......................................................................................................................... 20

Boiler Exhaust Connection ........................................................................................................ 20

Boiler Intake Connection .......................................................................................................... 22

Mounting Isolation .................................................................................................................... 22

Access Doors ............................................................................................................................. 22

Electrical .................................................................................................................................... 22

Startup ........................................................................................................................................... 24

Maintenance .................................................................................................................................. 25

General ...................................................................................................................................... 25

Lubrication ................................................................................................................................ 25

Service ....................................................................................................................................... 25

Replacement Parts ..................................................................................................................... 25

AAON Warranty, Service, and Parts Department ..................................................................... 25

Appendix - Water Piping Component Information ...................................................................... 26

Water Pressure Reducing Valve ................................................................................................ 26

Water Pressure Relief Valve ..................................................................................................... 28

Automatic Air Vent Valves ....................................................................................................... 28

Pumps - Installation and Operating Instructions ....................................................................... 30

Dual Pump Specific Information ............................................................................................... 35

Horizontal and Vertical Expansion Tanks ................................................................................ 41

Page 4

Suction Guides .......................................................................................................................... 42

Glycol Auto Fill Unit ................................................................................................................ 43

Flo-Trex Combination Valve .................................................................................................... 45

BL Series Startup Form ................................................................................................................ 50

Literature Change History............................................................................................................. 53

R53480 · Rev. A · 130725

4

Page 5

5

Index of Tables and Figures

Tables:

Table 1 - Service Clearances......................................................................................................... 17

Table 2 - Mounting Dimensions ................................................................................................... 18

Table 3 - Boiler Rated Input Capacity .......................................................................................... 20

Figures:

Figure 1 - Backflow Preventer ...................................................................................................... 15

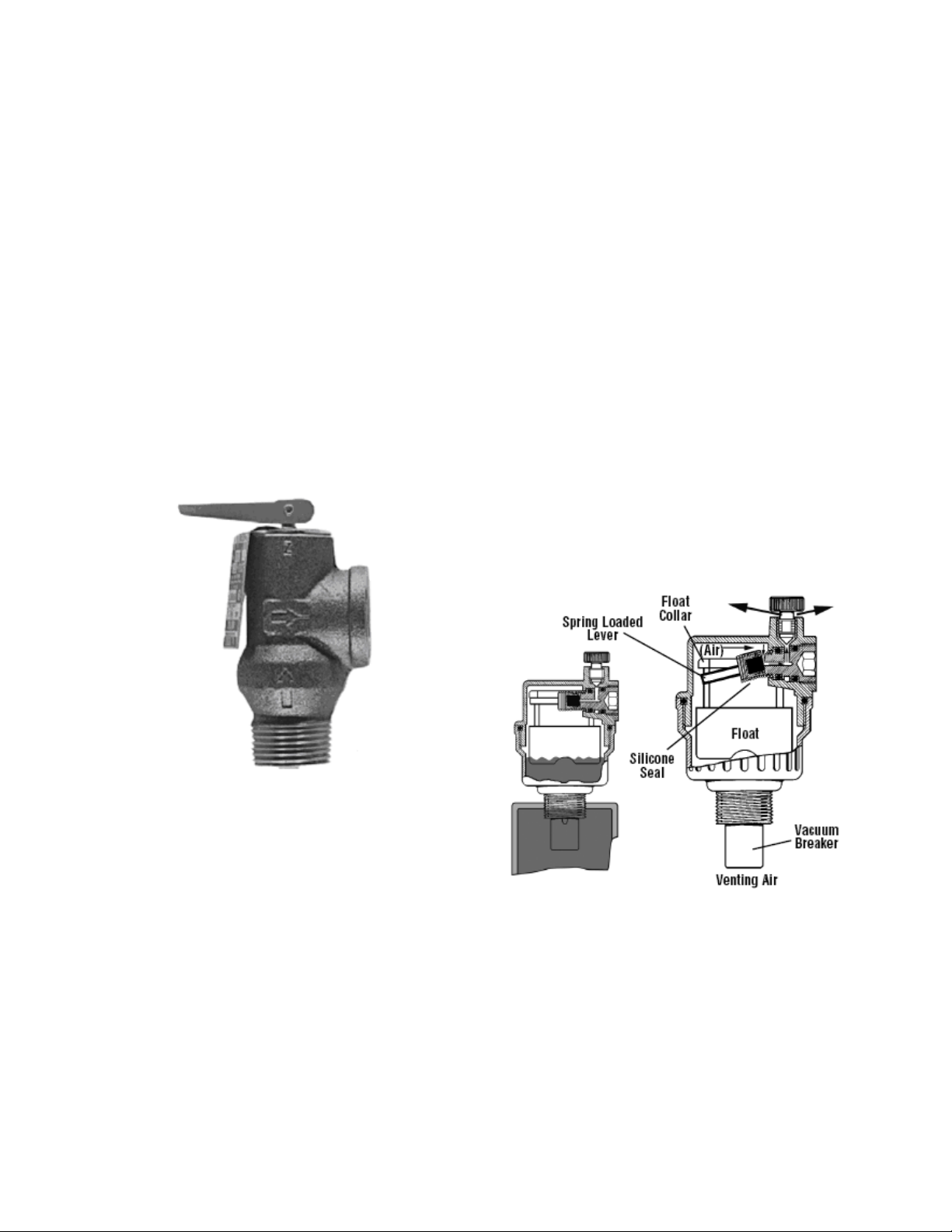

Figure 2 - Pressure Relief Valve ................................................................................................... 16

Figure 3 - Curb Mounting with Dimensions ................................................................................. 17

Figure 4 - Steel Mounting Rail with Dimensions ......................................................................... 18

Figure 5 - Marked Lifting Points .................................................................................................. 18

Figure 6 - BL, LL, RL, and CL Series Lifting Detail (General Configuration) ........................... 19

Figure 7 - Boiler Vent Shipping Covers ....................................................................................... 21

Figure 8 - Boiler Vent Components .............................................................................................. 21

Figure 9 - Correct Vent Pipe Connection ..................................................................................... 22

Figure 10 - Incorrect Vent Pipe Connection ................................................................................. 22

Figure 11 - Terminal Block ........................................................................................................... 23

Page 6

Safety

ELECTRIC SHOCK, FIRE OR

EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in dangerous

operation, serious injury, death or

property damage.

Improper servicing could result in

dangerous operation, serious injury,

death, or property damage.

Before servicing, disconnect all

electrical power to the furnace.

More than one disconnect may be

provided.

When servicing controls, label all

wires prior to disconnecting.

Reconnect wires correctly.

Verify proper operation after

servicing. Secure all doors with

key-lock or nut and bolt.

WARNING

WHAT TO DO IF YOU SMELL GAS

Do not try to turn on unit.

Shut off main gas supply.

Do not touch any electric switch.

Do not use any phone in the

building.

Never test for gas leaks with an

open flame.

Use a gas detection soap solution

and check all gas connections

and shut off valves.

CAUTION

Attention should be paid to the following statements:

NOTE - Notes are intended to clarify the unit installation, operation and maintenance.

CAUTION - Caution statements are given to prevent actions that may result in

equipment damage, property damage, or personal injury.

WARNING - Warning statements are given to prevent actions that could result in

equipment damage, property damage, personal injury or death.

DANGER - Danger statements are given to prevent actions that will result in equipment

damage, property damage, severe personal injury or death.

QUALIFIED INSTALLER

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

A copy of this IOM should be kept

with the unit.

WARNING

6

Page 7

7

FIRE, EXPLOSION OR CARBON

MONOXIDE POISONING HAZARD

Failure to replace proper controls

could result in fire, explosion or

carbon monoxide poisoning. Failure

to follow safety warnings exactly

could result in serious injury, death or

property damage. Do not store or use

gasoline or other flammable vapors

and liquids in the vicinity of this

appliance.

Electric shock hazard. Before

servicing, shut off all electrical power

to the unit, including remote

disconnects, to avoid shock hazard

or injury from rotating parts. Follow

proper Lockout-Tagout procedures.

WARNING

VARIABLE FREQUENCY DRIVES

Do not leave VFDs unattended in

hand mode or manual bypass.

Damage to personnel or equipment

can occur if left unattended. When in

hand mode or manual bypass mode

VFDs will not respond to controls or

alarms.

WARNING

WARNING

During installation, testing, servicing,

and troubleshooting of the equipment

it may be necessary to work with live

electrical components. Only a

qualified licensed electrician or

individual properly trained in handling

live electrical components shall

perform these tasks.

Standard NFPA-70E, an OSHA

regulation requiring an Arc Flash

Boundary to be field established and

marked for identification of where

appropriate Personal Protective

Equipment (PPE) be worn, should be

followed.

WARNING

GROUNDING REQUIRED

All field installed wiring must be

completed by qualified personnel.

Field installed wiring must comply

with NEC/CEC, local and state

electrical code requirements. Failure

to follow code requirements could

result in serious injury or death.

Provide proper unit ground in

accordance with these code

requirements.

WARNING

Electric motor over-current protection

and overload protection may be a

function of the Variable Frequency

Drive to which the motors are wired.

Never defeat the VFD motor overload

feature. The overload ampere setting

must not exceed 115% of the electric

motors FLA rating as shown on the

motor nameplate.

CAUTION

Page 8

UNIT HANDLING

To prevent injury or death lifting

equipment capacity shall exceed unit

weight by an adequate safety factor.

Always test-lift unit not more than 24

inches high to verify proper center of

gravity lift point to avoid unit damage,

injury or death.

WARNING

Always use a pressure regulator,

valves and gauges to control

incoming pressures when pressure

testing a system. Excessive pressure

may cause line ruptures, equipment

damage or an explosion which may

result in injury or death.

WARNING

Door compartments containing

hazardous voltage or rotating parts

are equipped with door latches to

allow locks. Door latch are shipped

with nut and bolts requiring tooled

access. If you do not replace the

shipping hardware with a pad lock

always re-install the nut & bolt after

closing the door.

CAUTION

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack by certain

chemicals. Polyolester (POE) oils

used with R-410A and other

refrigerants, even in trace amounts,

in a PVC or CPVC piping system will

result in stress cracking of the piping

and fittings and complete piping

system failure.

CAUTION

8

1. Startup and service must be performed

by a Factory Trained Service

Technician.

2. The unit is for outdoor use only. See

General Information section for more

information.

3. Use only with type of the gas approved

for the boiler. Refer to the boiler rating

plate.

4. Provide adequate combustion ventilation

air to the boiler.

5. Every unit has a unique equipment

nameplate with electrical, operational,

and unit clearance specifications.

Always refer to the unit nameplate for

specific ratings unique to the model you

have purchased.

6. READ THE ENTIRE INSTALLATION,

OPERATION AND MAINTENANCE

MANUAL. OTHER IMPORTANT

SAFETY PRECAUTIONS ARE

PROVIDED THROUGHOUT THIS

MANUAL.

7. Keep this manual and all literature

safeguarded near or on the unit.

Page 9

9

BL Series Feature String Nomenclature

:

SIZE

VLT

CONFIGA1A2A3A4B1B2B31A1B1C1D2345A5B5C6A6B6C7891011121314A

14B1516171819202122

23

B

L

– 0 5 0 – 3 – 0 –

A

0 0 0 –A1A: 0 0 0 0 – 0C0 – 0 0 0 –

KCC–B

0 0 0 F

B

G

– 0

A–CAA

0 0 0 0 0

X

GEN

Model Options

Unit Feature Options

BASE MODEL

SERIES AND GENERATION

BL

UNIT SIZE

050 = 500 MBH Boiler Capacity

075 = 750 MBH Boiler Capacity

100 = 1,000 MBH Boiler Capacity

150 = 1,500 MBH Boiler Capacity

200 = 2,000 MBH Boiler Capacity

225 = 2,250 MBH Boiler Capacity

300 = 3,000 MBH Boiler Capacity

400 = 4,000 MBH Boiler Capacity

450 = 4,500 MBH Boiler Capacity

600 = 6,000 MBH Boiler Capacity

VOLTAGE

2 = 230V/3Φ/60Hz

3 = 460V/3Φ/60Hz

4 = 575V/3Φ/60Hz

8 = 208V/3Φ/60Hz

BLANK

0 = Standard

Model Option A: STYLE

A1: STYLE

0 = Standard - Narrow Cabinet

A = Wide Cabinet

A2, A3, A4: BLANK

000 = Standard

Model Option B: HEATING

B1: HEATING TYPE

A = Natural Gas Fired Boiler

B = Propane Fired Boiler

B2: BOILER QUANTITY

1 = 1 Boiler

2 = 2 Boilers

3 = 3 Boilers

4 = 4 Boilers

B3: BOILER HEATING CAPACITY

A = 500 MBH Modulating High Flow

B = 750 MBH Modulating High Flow

C = 1,000 MBH Modulating High Flow

D = 1,500 MBH Modulating High Flow

E = 500 MBH Modulating Low Flow

F = 750 MBH Modulating Low Flow

G = 1,000 MBH Modulating Low Flow

H = 1,500 MBH Modulating Low Flow

FEATURE 1: BLANK

1A, 1B, 1C, 1D: BLANK

0000 = Standard

FEATURE 2: BLANK

0 = Standard

FEATURE 3: BOILER ACCESSORIES

0 = Standard

A = Glycol Boiler

B = Thermometers and Pressure Gauges

C = Options A + C

Page 10

10

:

SIZE

VLT

CONFIGA1A2A3A4B1B2B31A1B1C1D2345A5B5C6A6B6C7891011121314A

14B1516171819202122

23

B

L

– 0 5 0 – 3 – 0 –

A

0 0 0 –A1A: 0 0 0 0 – 0C0 – 0 0 0 –

KCC–B

0 0 0 F

B

G

– 0

A–CAA

0 0 0 0 0

X

GEN

Model Options

Unit Feature Options

BL Series Feature String Nomenclature

FEATURE 4: BLANK

0 = Standard

FEATURE 5: BLANK

5A, 5B, 5C: BLANK

000 = Standard

FEATURE 6: BOILER PUMP

6A: BUILDING PUMP CONFIGURATION

0=Standard, No Boiler Pump

A = 1 Pump/Barrel - Std Eff, 1170 RPM

B = 2 Single Pumps/Barrel - Std Eff, 1170 RPM

C = dualArm Pump/Barrel - Std Eff, 1170 RPM

D = 1 Pump/Barrel - Prem Eff, 1170 RPM

E = 2 Single Pumps/Barrel - Prem Eff, 1170 RPM

F = dualArm Pump/Barrel - Premium Eff, 1170 RPM

G = 1 Pump/Barrel w/ VFD - 1170 RPM

H = 2 Single Pumps/Barrel w/ 2 VFDs - 1170 RPM

J = dualArm Pump/Barrel w/ 2 VFDs - 1170 RPM

K = 1 Pump/Barrel - Std Eff, 1760 RPM

L = 2 Single Pumps/Barrel - Std Eff, 1760 RPM

M = dualArm Pump/Barrel - Std Eff, 1760 RPM

N = 1 Pump/Barrel - Prem Eff, 1760 RPM

P = 2 Single Pumps/Barrel - Prem Eff, 1760 RPM

Q = dualArm Pump/Barrel - Prem Eff, 1760 RPM

R = 1 Pump/Barrel w/ VFD - 1760 RPM

S = 2 Single Pumps/Barrel w/ 2 VFDs - 1760 RPM

T = dualArm Pump/Barrel w/ 2 VFDs - 1760 RPM

Y = 1 Pump/Barrel - Prem Eff - 3520 RPM

Z = 2 Single Pumps/Barrel - Prem Eff, 3520 RPM

1 = dualArm Pump/Barrel - Prem Eff, 3520 RPM

2 = 1 Pump/Barrel w/ VFD - 3520 RPM

3 = 2 Single Pumps/Barrel w/ 2 VFDs - 3520 RPM

4 = dualArm Pump/Barrel w/ 2 VFDs - 3520 RPM

6B: BUILIDNG PUMP SIZE

0 = Standard, No Boiler Pump

A = Pump 4360 1.5B

B = Pump 4360 2B

C = Pump 4360 2D

D = Pump 4380 1.5x1.5x6

E = Pump 4380 2x2x6

F = Pump 4380/4382 3x3x6

G = Pump 4380/4382 4x4x6

H = Pump 4380 1.5x1.5x8

J = Pump 4380 2x2x8

K = Pump 4380/4382 3x3x8

L = Pump 4380/4382 4x4x8

M = Pump 4380 5x5x8

N = Pump 4380/4382 6x6x8

P = Pump 4380 2x2x10

Q = Pump 4380/4382 3x3x10

R = Pump 4380/4382 4x4x10

S = Pump 4380/4382 6x6x10

T = Pump 4380/4382 8x8x10

U = Pump 4380 4x4x11.5

V = Pump 4380 5x5x11.5

W = Pump 4380 6x6x11.5

Y = Pump 4380 8x8x11.5

Z = Pump 4380 4x4x13

1 = Pump 4380 6x6x13

2 = Pump 4380 8x8x13

3 = Pump 4382 6x6x6

4 = Pump 4382 8x8x8

5 = Pump 4360 3D

6C: BUILDING PUMP MOTOR

0 = Standard, No Building Pump

A = 0.50 hp

B = 0.75 hp

C = 1 hp

D = 1.5 hp

E = 2 hp

F = 3 hp

G = 5 hp

H = 7.5 hp

J = 10 hp

K = 15 hp

L = 20 hp

M = 25 hp

N = 30 hp

P = 40 hp

Q = 50 hp

R = 60 hp

S = 75 hp

Page 11

11

BL Series Feature String Nomenclature

:

SIZE

VLT

CONFIGA1A2A3A4B1B2B31A1B1C1D2345A5B5C6A6B6C7891011121314A

14B1516171819202122

23

B

L

– 0 5 0 – 3 – 0 –

A

0 0 0 –A1A: 0 0 0 0 – 0C0 – 0 0 0 –

KCC–B

0 0 0 F

B

G

– 0

A–CAA

0 0 0 0 0

X

GEN

Model Options

Unit Feature Options

FEATURE 7: SERVICE OPTIONS

0 = Standard

A = 115V Outlet, Factory Wired

B = 115V Outlet, Field Wired

FEATURE 8: BLANK

0 = Standard

FEATURE 9: BLANK

0 = Standard

FEATURE 10: POWER OPTIONS

0 = Standard Power Block

A = Power Switch (225 Amps)

B = Power Switch (400 Amps)

C = Power Switch (600 Amps)

D = Power Switch (800 Amps)

E = Power Switch (1200 Amps)

FEATURE 11: SAFETY OPTIONS

A = Standard, Boiler w/ UL/FM/CSD-1 Certification

B = Boiler w/ IRI Gas Train

C = Boiler w/ IRI Gas Train and Proof of Closure

D = Boiler w/ Low Water Cutoff

E = Options B + D

F = Options C + D

FEATURE 12: CONTROLS

0 = Standard

B = Phase and Brown Out Protection

FEATURE 13: SPECIAL CONTROLS

0 = MCS Controller

G = MCS Controller w/ Modem

P = w/ BACnet Connection

Q = w/ Modbus Connection

R = w/ N2 Connection

S = w/ LonTalk Connection

T = w/ Automated Logic Connection

U = w/ BACnet Connection and Modem

V = w/ Modbus Connection and Modem

W = w/ N2 Connection and Modem

Y = w/ LonTalk Connection and Modem

Z = w/ Automated Logic Connection and Modem

FEATURE 14: COMPRESSION TANK

14A: BLANK

0 = Standard

14B: BOILER COMPRESSION TANK

0 = Standard - No Compression Tank

A = AX-15V

B = AX-20V

C = AX-40V

D = AX-60V

E = AX-80V

F = AX-100V

G = AX-120V

H = AX-180V

J = AX-200V

K = AX-240V

L = AX-260V

M = AX-280V

N = 1000-L

P = 1200-L

Q = 1600-L

R = 2000-L

FEATURE 15: OPTION BOXES

0 = Standard

A = 2ft. Option Box

B = 4ft. Option Box

C = 6ft. Option Box

D = 8ft. Option Box

E = 10ft. Option Box

F = 12ft. Option Box

FEATURE 16: INTERIOR CABINET

OPTIONS

0 = Standard

A = Electric Vestibule Heating

Page 12

12

BL Series Feature String Nomenclature

:

SIZE

VLT

CONFIGA1A2A3A4B1B2B31A1B1C1D2345A5B5C6A6B6C7891011121314A

14B1516171819202122

23

B

L

– 0 5 0 – 3 – 0 –

A

0 0 0 –A1A: 0 0 0 0 – 0C0 – 0 0 0 –

KCC–B

0 0 0 F

B

G

– 0

A–CAA

0 0 0 0 0

X

GEN

Model Options

Unit Feature Options

FEATURE 17: EXTERIOR CABINET

OPTIONS

0 = Standard

A = Access Door Windows

FEATURE 18: CUSTOMER CODE

0 = Standard

FEATURE 19: CODE OPTIONS

0 = Standard - ETL U.S.A. Listing

A = MEA New York

H = ETL U.S.A. + Canada Listing

FEATURE 20: BLANK

0 = Standard

FEATURE 21: BLANK

0 = Standard

FEATURE 22: BLANK

0 = Standard

FEATURE 23: TYPE

B = Standard Paint

U = Special Price Authorization and Special Paint

X = Special Price Authorization w/ Standard Paint

Page 13

13

General Information

Sheet metal surfaces present sharp

edges and care must be taken when

working with equipment.

Failure to observe the following

instructions will result in premature

failure of your system and possible

voiding of the warranty.

WARNING

WARNING

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

WARNING

AAON BL Series boiler outdoor mechanical

rooms are complete self contained liquid

heating units. They are factory assembled,

wired, and run-tested.

Codes and Ordinances

System should be sized in accordance with

the American Society of Heating,

Refrigeration and Air Conditioning

Engineers Handbook.

Installation of BL Series units must conform

to the ICC standards of the International

Mechanical Code, the International Building

Code, and local building, plumbing and

waste water codes. All appliances must be

electrically grounded in accordance with

local codes, or in the absence of local codes,

the current National Electric Code,

ANSI/NFPA 70 or the current Canadian

Electrical Code CSA C22.1.

Receiving Unit

When received, the unit should be checked

for damage that might have occurred in

transit. If damage is found it should be noted

on the carrier’s Freight Bill. A request for

inspection by carrier’s agent should be made

in writing at once. Nameplate should be

checked to ensure the correct model sizes

and voltages have been received to match

the job requirements.

Storage

If installation will not occur immediately

following delivery, store equipment in a dry

protected area away from construction

traffic and in the proper orientation as

marked on the packaging with all internal

packaging in place. Secure all loose-shipped

items.

Outdoor Mechanical Room

Failure to observe the following instructions

will result in premature failure of your

system, and possible voiding of the

warranty.

Never turn off the main power supply to the

unit, except for complete shutdown.

Always control the system from the building

management system, or control panel, never

at the main power supply (except for

emergency or for complete shutdown of the

system).

Page 14

14

Wiring Diagrams

A complete set of unit specific wiring

diagrams in both ladder and point-to-point

form are laminated in plastic and located

inside the control compartment door.

General Maintenance

When the initial startup is made and on a

periodic schedule during operation, it is

necessary to perform routine service checks

on the performance of the boiler.

Boiler System

Boilers and pumping packages are factory

installed. The boiler system uses a

primary/secondary pumping package. There

can be 1-4 boilers in parallel and each boiler

has its own primary pump. The heating loop

must be designed to return at least 120°F

water to the boiler during normal operation.

Failure to return 120°F water to the boiler

will create condensation, which will reduce

the life of the heat exchanger and void the

boiler warranty. See unit submittal for unit

specific piping schematics. See the Thermal

Solutions Boiler “Installation, Operating,

and Service Instructions” that are included

with the unit for specific information about

the boiler.

Once the boiler is given a run signal, the

boiler secondary pump will be activated and

the controls package will stage boilers as

necessary to maintain the leaving water

temperature setpoint.

The controls package will also control the

speed of the secondary pump in the boiler

system to maintain differential pressure

across the pump.

Boiler Primary/Secondary Pumping

Water enters the unit through the return

water piping, and then travels through a

suction guide with strainer. The end of the

suction guide is removable for strainer

access. The strainer assembly is composed

of two parts, the operational strainer, and the

startup strainer, (located inside the

operational strainer) which is to be removed

24 hours after startup.

The pump is installed after the suction

guide, and before a combination valve (FloTrex). This combination valve acts as

isolation valve, check valve, and flow

balancing valve. The boiler is placed after

the combination valve in the water circuit.

The primary/secondary pumping package

provides variable flow to the system. It

consists of a constant flow pump for the

boiler, and a variable flow pump for the

building. The controls package senses

differential pressure across the pump with

pressure transducers installed at the suction

and discharge, and varies the speed of the

pump using a VFD in order to maintain a

given differential pressure across the pump.

The primary/secondary pumping package is

essentially composed of two piping loops

coupled together. The primary loop has a

constant flow rate in order to maintain water

temperature through the boiler, and the

secondary, variable flow loop, provides

water to the building. The two loops are

coupled via a water line that compensates

for excess flow in either loop. As the flow in

the secondary loop decreases below the flow

in the primary, excess flow bypasses the

building loop and circulates through the

primary loop. On the other hand, as the flow

in the secondary loop increases above the

primary loop, excess flow bypasses the

boiler and circulates through the bypass

water line.

The secondary pump includes suction guide,

combination valve, and isolation valve with

the addition of an air separator to remove

any air that is entrapped in the water.

Page 15

15

See appendix for additional information on

the installation, operation and maintenance

of pumps.

Makeup Water

A city makeup water connection is provided

to replace water that is lost from the system.

Glycol units require a glycol feeder

(optional factory installed or field installed)

to replace fluid that is lost in the system.

Water should not be added to glycol

applications as this would dilute the glycol

concentration and thereby increase the

freezing temperature of the fluid.

The makeup water connection is provided

with a backflow preventer that has isolation

valves on the inlet and outlet for service.

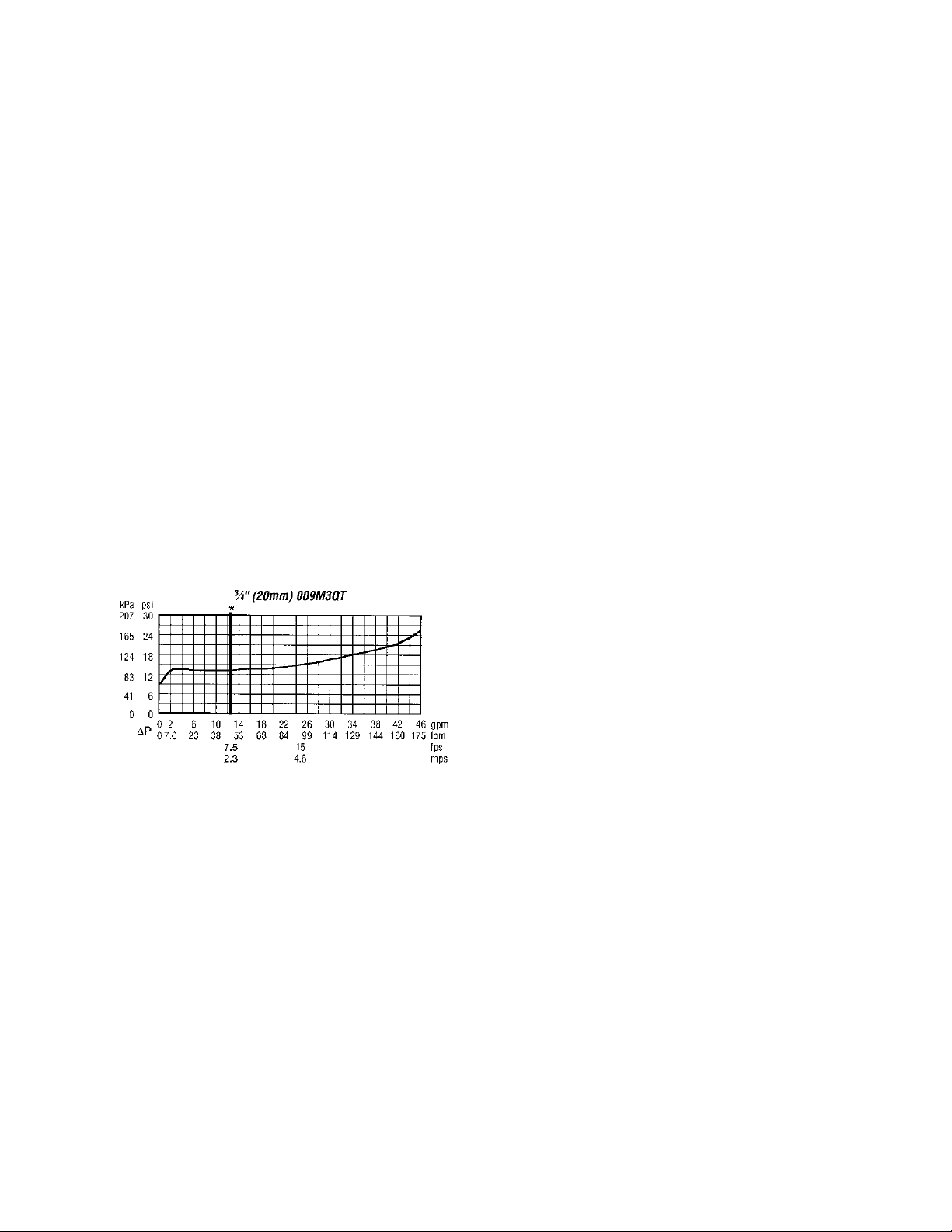

Figure 1 shows the pressure drop versus

flow rate for the backflow preventer.

Figure 1 - Backflow Preventer

There is a pressure-reducing valve after the

backflow preventer. This valve reduces the

city water pressure to maintain the operating

pressure of the system. This valve is

adjustable from 10-35 psig with a factory

setting of 30 psig. The system pressure

varies with the height of the system. The

pressure-reducing valve setting should be set

so that the pressure at the high point in the

system is high enough to vent air from the

system (usually 4 psig). There should be air

vents at all parts in the system where air

could be trapped. If the pressure is not high

enough throughout the system, flashing

could occur in the piping or the pump could

cavitate. There is an isolation valve on the

inlet and outlet of the pressure-reducing

valve for service.

The pressure reducing valve fills the system

at a reduced rate. There is a bypass around

the pressure reducing valve for the initial fill

of the system to increase the initial fill

speed. After the initial system fill, this valve

should be closed.

Compression/Expansion Tank

As the water temperature in the system

increases, the volume that water displaces

increases. In order to compensate for these

expansion forces, a compression or

expansion tank must be used. The factory

installed tank option includes a prepressurized diaphragm compression tank

that is preset for 12 psig.

The factory pre-charge pressure may need to

be field adjusted. The tank must be precharged to system design fill pressure before

placing into operation. Remove the pipe

plug covering the valve enclosure. Check

and adjust the charge pressure by adding or

releasing air.

If the system has been filled, the tank must

be isolated from the system and the tank

emptied before charging. This ensures that

all fluid has exited the diaphragm area and

proper charging will occur.

If the pre-charge adjustment is necessary, oil

and water free compressed air or nitrogen

gas may be used. Check the pre-charge

using an accurate pressure gauge at the

charging valve and adjust as required. Check

the air valve for leakage. If evident, replace

the Schrader valve core. Do not depend on

the valve cap to seal the leak. After making

sure the air charge is correct, replace the

Page 16

16

pipe plug over the charging valve for

protection.

Purge air from system before placing tank

into operation. All models have system

water contained behind the diaphragm.

It is recommended that the pre-charge be

checked annually to ensure proper system

protection and long life for the vessel.

Pressure Relief Valve

Required pressure relief valve is installed in

the unit. This valve is set at 125 psig. Figure

2 shows inlet pressure versus capacity for

this pressure relief valve. See appendix for

additional information.

Figure 2 - Pressure Relief Valve

Automatic Air Vent

There is an automatic air vent installed at the

high point of the system inside the pumping

package compartment. The air vent valve

must be in the proper position for operation.

Ensure that the small vent cap is loosened

two turns from the closed position, allowing

air to be vented from the system. It is

advisable to leave the cap on to prevent

impurities from entering the valve. See

appendix for additional information.

Dual Pumps

When redundant pumping is required,

factory installed dual pumps or two single

pumps can be ordered. A dual pump is a

pump with two independent motors and

pumps in a single casing. This dual pump

has a swing split-flapper valve in the

discharge port to prevent liquid recirculation

when only one pump is operating. Isolation

valves in the casing allow one pump to be

isolated and removed for service while the

other pump is still operating.

When redundant pumping is required with

high flow rates, two independent pumps

may be installed in parallel. Each pump will

have its own suction guide/strainer,

combination valve, and isolation valves.

The controls package will activate the pump

when the unit is given a run command. If the

controls do not recognize flow in 60

seconds, the second pump will be activated

and an alarm signal will be generated. If the

second pump does not activate, the cooling

will be locked out. See appendix for

additional information.

Pressure Gauges and Thermometers

Pressure gauges and thermometers are

available as a factory installed option.

Thermometers are installed on the inlet and

outlet of the unit. One pressure gauge is

installed at each pump. This pressure gauge

is connected in three places to the water

piping before the suction guide/strainer,

after the suction guide and before the pump,

and after the pump. There is also a needle

valve at each of these points to isolate the

pressure. To measure the pressure at any

given point, open the needle valve at that

point and close the other two needle valves.

One gauge is used so that the calibration of

the pressure gauge is irrelevant in the

calculation of the differential pressure.

Page 17

17

Pipe Insulation

Location

All Sizes

Front

100”

Back

100”

Ends

100”

Top

Unobstructed

All roofing work should be performed

by competent roofing contractors to

avoid any possible leakage.

CAUTION

The water piping and components on units

with pumping packages are not insulated at

the factory. Insulation should be installed on

the water piping after the system has been

checked for leaks.

Installation

Outdoor Mechanical Room Placement

The AAON BL Series is designed for

outdoor applications and mounting at

ground level or on a rooftop. It must be

placed on a level and solid foundation that

has been prepared to support its weight.

Table 1 - Service Clearances

Units require rail support along all four sides

of the unit base.

When installed at ground level, a one-piece

concrete slab should be used with footings

that extend below the frost line.

If unit is elevated a field supplied catwalk is

recommended to allow access to unit service

doors.

This unit ships with a curb gasket that is

1¼” wide and 1½” tall. It is recommended

that this or another similar gasket be used

between the curb and the unit to reduce

vibration from the unit to the building.

Consideration must be given to obstruction

caused by snow accumulation when placing

the unit.

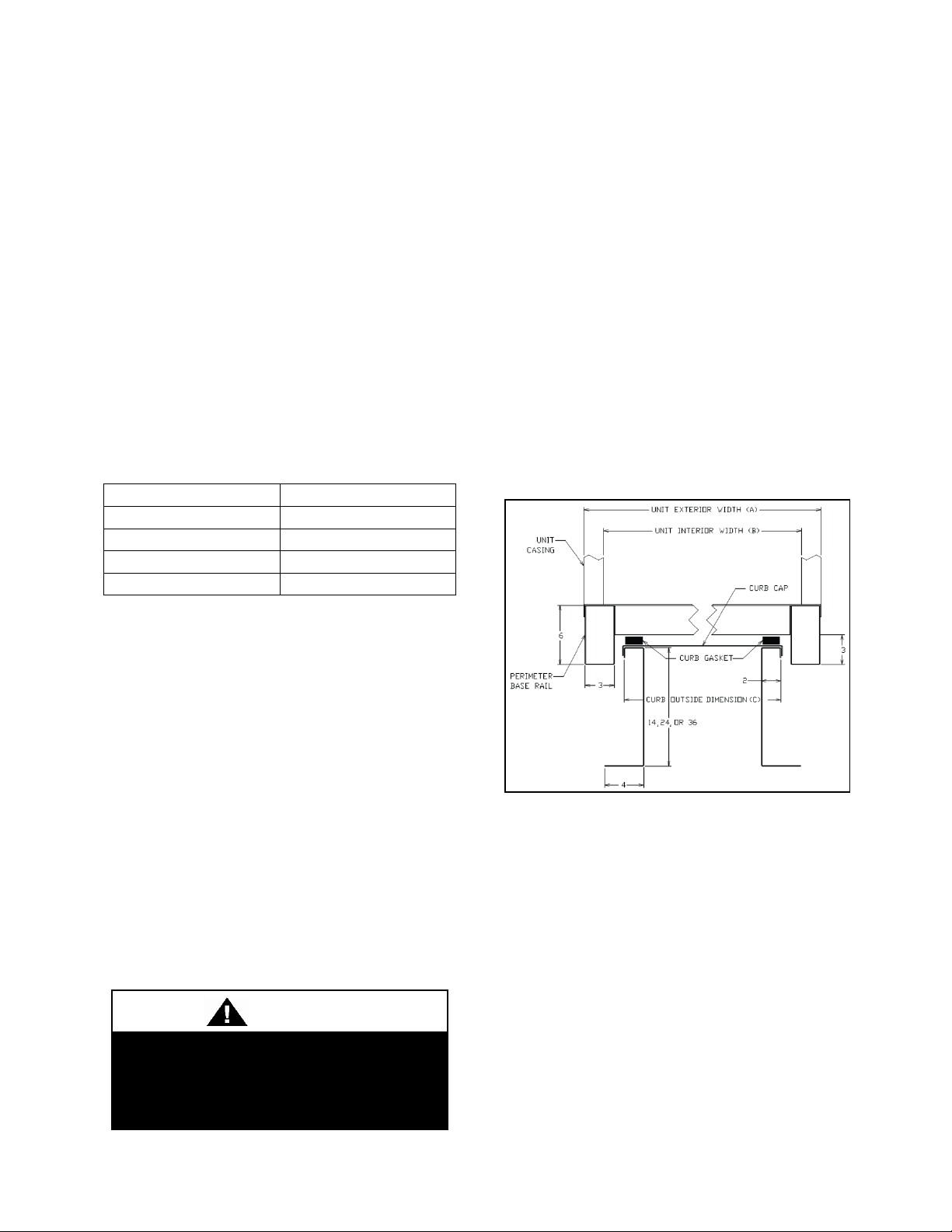

Curb and Steel Mount Installation

Make openings in the roof decking large

enough to allow for water piping, electrical,

and gas penetrations and workspace only.

Do not make openings larger than necessary.

Set the curb to coincide with the openings.

Make sure curb is level.

Unit specific curb drawing is included with

job submittal. See SMACNA Architectural

Sheet Metal Manual for curb installation

details.

Figure 3 - Curb Mounting with Dimensions

Page 18

18

Cabinet

Style

A B C

D

Standard

Narrow

100”

96”

92”

97”

Wide

142”

138”

134”

139”

Do not push, pull or lift the unit from

anything other than its base.

Figure 4 - Steel Mounting Rail with

Dimensions

Table 2 - Mounting Dimensions

Lifting and Handling

If cables or chains are used to hoist the unit

they must be the same length and care

should be taken to prevent damage to the

cabinet.

Before lifting unit, be sure that all shipping

material has been removed from unit.

Secure hooks and cables at all lifting points/

lugs provided on the unit.

Hoist unit to a point directly above the curb

or mounting rail. Be sure that the gasket

material has been applied to the curb or

mounting rail.

Carefully lower and align unit with utility

and duct openings. Lower the unit until the

unit skirt fits around the curb. Make sure the

unit is properly seated on the curb and is

level.

Figure 5 - Marked Lifting Points

NOTE: UNIT MUST BE RIGGED AT ALL

MARKED LIFTING POINTS

Page 19

19

Figure 6 - BL, LL, RL, and CL Series Lifting Detail (General Configuration)

Lifting slot locations are unit specific.

Unit must be rigged at all marked lifting points.

Page 20

20

Water Connection

Boiler Size

Rated Capacity (CFH)*

Natural

LP/Propane

500 MBH

500

200

750 MBH

750

300

1000 MBH

1000

400

1500 MBH

1500

600

Boilers must be operated only with

liquid flowing through boiler.

WARNING

PVC (Polyvinyl Chloride) and CPVC

(Chlorinated Polyvinyl Chloride) are

vulnerable to attack by certain

chemicals. Polyolester (POE) oils

used with R-410A and other

refrigerants, even in trace amounts,

in a PVC or CPVC piping system will

result in stress cracking of the piping

and fittings and complete piping

system failure.

CAUTION

Connect the supply and return water lines.

The connection size is listed on the unit

rating sheet, along with the designed

volumetric flow rate. The maximum

operating pressure for AAON BL Series

units is 125 psi.

Gas Connection

Size the gas piping to supply the unit with

proper pressure when all gas consuming

devices in the building connected to the

same gas system are operating. The

maximum gas train inlet pressure for all

boiler sizes is 5 psig. The minimum gas train

inlet pressure for the 500 MBH boiler is 5

inches of water column, and for all other

boilers, 7 inches of water column.

Carefully consider all current and future gas

usage. Table 3 details the input rate for each

boiler unit.

Gas connection sizes are listed on the unit

rating sheet.

Table 3 - Boiler Rated Input Capacity

*Note: Rating is for sea level conditions.

For additional information regarding the gas

piping connection, see the Thermal

Solutions Boiler “Installation, Operating,

and Service Instructions” that are included

with the unit.

Boiler Exhaust Connection

In addition to gas connection installation,

each boiler requires installation of the

exhaust vent piping and inlet vent hood. The

exhaust panel with chimney cutout is

removed for shipping, and replaced with a

shipping cover.

Remove the shipping cover and attach the

exhaust panel shipped with the unit. When

the exhaust panel is securely fastened with

sheet metal screws, locate the exhaust piping

that is also shipped along with the unit. The

exhaust piping that must be attached to the

internal exhaust vent piping includes the

vent length, 90 degree elbow and rain cap.

Examine all components prior to

installation. The female end of each vent

pipe component incorporates a sealing

gasket and a mechanical locking band.

Page 21

21

Figure 7 - Boiler Vent Shipping Covers

Failure to follow proper joint

connection procedure may result in

carbon monoxide gas poisoning due

to flue gas leakage.

WARNING

Intake and exhaust covers are in place for

shipping. These must be removed and

external intake/exhaust components must be

installed prior to boiler operation.

Figure 8 - Boiler Vent Components

Gaskets must be in proper position or flue

gases could leak.

Page 22

22

Securely fasten the vent pipe joints

according to the following procedure.

1. Insert the male end into the female

section. Push the units together and turn

them until the bead of the male end is

seated against the flared end of the

female section. This creates the

necessary airtight seal. Align the seams

on the vent lengths and orient them

upward in all horizontal applications.

2. Tighten the locking band with a nut

driver until snug plus 1/4 turn.

Before proceeding, recheck all joints and

ensure that all male sections extend to the

top of the flared female end and all clamps

are tightened.

Figure 9 - Correct Vent Pipe Connection

Stop bead on male end must be pushed

directly against the flared end of the female

end. When checking the inside of the joint,

the gasket is fully covered and out of sight.

Figure 10 - Incorrect Vent Pipe Connection

Boiler Intake Connection

Remove the intake shipping cover. The

round collar on the back of the intake vent

passes through the cabinet wall and slides

over the crimped end of the air intake pipe

inside the unit. This joint should be secured

with aluminum foil tape. The outer flange of

the wall vent is fastened to the outer wall of

the cabinet using sheet metal screws.

Mounting Isolation

For roof mounted applications or anytime

vibration transmission is a factor, vibration

isolators may be used.

Access Doors

Lockable access door is provided to the

electrical and control compartment. A

separate access door is also provided to the

boiler and pumping package compartment.

A light switch is on the wall of the control

compartment.

Electrical

The single point electrical power

connections are made in the electrical

control compartment.

The microprocessor control furnished with

the unit is supplied with its own power

supply factory wired to the main power of

the outdoor mechanical room.

Page 23

23

Verify the unit nameplate voltage agrees

Electric shock hazard. Before

attempting to perform any installation,

service, or maintenance, shut off all

electrical power to the unit at the

disconnect switches. Unit may have

multiple power supplies. Failure to

disconnect power could result in

dangerous operation, serious injury,

death or property damage.

WARNING

with the power supply. Connect power and

control field wiring as shown on the unit

specific wiring diagram provided with the

unit.

Size supply conductors based on the unit

MCA rating. Supply conductors must be

rated a minimum of 167°F (75°C).

Route power and control wiring, separately,

through the utility entry. Do not run power

and signal wires in the same conduit.

Protect the branch circuit in accordance with

code requirements. The unit must be

electrically grounded in accordance with

local codes, or in the absence of local codes,

the current National Electric Code,

ANSI/NFPA 70 or the current Canadian

Electrical Code CSA C22.1.

Power wiring is to the unit terminal block or

main disconnect. All wiring beyond this

point has been done by the manufacturer and

cannot be modified without effecting the

unit's agency/safety certification.

Figure 11 - Terminal Block

Startup technician must check motor

amperage to ensure that the amperage listed

on the motor nameplate is not exceeded.

Motor overload protection may be a function

of the variable frequency drive and must not

be bypassed.

Note: All units are factory wired for

208/230V, 460V, or 575V. If unit is to be

connected to a 208V supply, the transformer

must be rewired to 208V service. For 208V

service interchange the yellow and red

conductor on the low voltage control

transformer.

Red-Black for 208V

Yellow-Black for 230V

Wire control signals to the unit’s low

voltage terminal block located in the

controls compartment.

If any factory installed wiring must be

replaced, use a minimum 221°F (105°C)

type AWM insulated conductors.

Page 24

24

Startup

Electric shock hazard. Shut off all

electrical power to the unit to avoid

shock hazard or injury from rotating

parts.

WARNING

Improper installation, adjustment,

alteration, service or maintenance

can cause property damage,

personal injury or loss of life. Startup

and service must be performed by a

Factory Trained Service Technician.

WARNING

Rotation must be checked on all

MOTORS of three phase units. All

motors, to include and not be limited

to pump motors motors, should all be

checked by a qualified service

technician at startup and any wiring

alteration should only be made at the

unit power connection.

CAUTION

Before completing installation, a

complete operating cycle should be

observed to verify that all

components are functioning properly.

CAUTION

(See back of the manual for startup form)

Before the startup of the boiler be sure that

the following items have been checked.

1. Verify that electrical power is available

to the unit.

2. Verify that any remote stop/start device

connected to the boiler controller is

requesting the boiler to start.

3. Verify that liquid flow is present through

the boiler from the building.

4. There should be a building load of at

least 25% of the boiler capacity in order

to properly check operation.

5. With the main power switch off, review

the MCS Controller Manual provided

with the boiler. Understand the keypad

functions, how to set the leaving water

temperature setpoint and how to initiate

the Run State.

Use the general check list at the top of the

startup form to make a last check that all the

components are in place, water flow is

present, and the power supply is energized.

Using the controller keypad, individually set

the outputs in “Manual On” to confirm relay

closure.

Cycle on all the boilers to confirm that all

are operating within tolerance.

While performing the check, use the startup

form to record observations of boiler amps

When all is running properly, place the

controller in the Run mode and observe the

system until it reaches a steady state of

operation.

Note: For more information on

programming the controller refer to the

MCS Controller manual provided with the

boiler.

Page 25

25

Maintenance

General

Qualified technicians must perform routine

service checks and maintenance.

Lubrication

All original motors and bearings are

furnished with an original factory charge of

lubrication. Certain applications require

bearings be re-lubricated periodically. The

schedule will vary depending on operating

duty, temperature variations, or severe

atmospheric conditions.

Bearings should be re-lubricated at normal

operating temperatures, but not when

running. Rotate the motor shaft by hand and

add only enough grease to purge the seals.

DO NOT OVERLUBRICATE.

Service

If the unit will not operate correctly and a

service company is required, only a

company with service technicians qualified

and experienced in both boilers and

pumping systems are permitted to service

the systems to keep warranties in effect. If

assistance is required, the service technician

must contact AAON.

Replacement Parts

Parts for AAON equipment may be obtained

from AAON at www.aaonparts.com. When

ordering parts, reference the unit serial

number and part number.

AAON Warranty, Service, and Parts Department

2424 S. Yukon Ave.

Tulsa, OK 74107

Ph: 918-583-2266

Fax: 918-382-6364

www.aaon.com

Note: Before calling, technician should have

model and serial number of the unit

available for the service department to help

answer questions regarding the unit.

Page 26

26

Appendix - Water Piping Component Information

Water Pressure Reducing Valve

Water Pressure Reducing Valves are

designed to reduce incoming water pressure

to protect plumbing system components and

reduce water consumption.

Overview

Standard construction includes Z3 sealed

spring cage and corrosion resistant adjusting

cage screws for outdoor/waterworks pit

installations.

Integral stainless steel strainer

Replaceable seat module

Bronze body construction

Serviceable in line

High temperature resistant reinforced

diaphragm for hot water

Low pressure range 10-35psi (69-241

kPa)

Materials

Body: Bronze

Seat: Replaceable stainless steel

Integral Strainer: Stainless steel

Diaphragm: Reinforced EPDM

Valve Disc: EPDM

Standards

Meets requirements of ASSE Standard

1003; (ANSI A112.26.2); CSA Standard

B356; Southern Standard Plumbing Code

and listed by IAPMO.

Teflon® is a registered trademark of E.I.

Dupont de Nemours & Company.

Page 27

27

Capacity

Maintenance Instructions

To clean strainer remove the bottom plug

and pull out strainer.

Adjustment

To adjust pressure setting, loosen the lock

nut and turn the adjusting bolt clockwise to

increase pressure, counter clockwise to

decrease pressure.

Dimensions-Weights:

Note: Use a pressure gauge downstream to

adjust and verify the pressure setting.

Troubleshooting

High System Pressure

If the downstream system pressure is higher

than the set pressure under no flow

conditions, the cause could be thermal

expansion, pressure creep or dirt/debris on

the seat. Thermal expansion occurs

whenever water is heated in a closed system.

The system is closed when supply pressure

exceeds 150 psi, or a check valve or

backflow preventer is installed in the supply

piping. To determine if this is the result of

thermal expansion, try briefly opening the

cold water tap. If the increased pressure is

caused by thermal expansion, the pressure

will immediately be relieved and the system

will return to the set pressure.

Page 28

28

Water Pressure Relief Valve

Overview

ASME Rated, Design Certified and Listed

by C.S.A.

Used for protection against excessive

pressure on domestic storage tanks or

tankless water heaters, the pressure relief

valve has no temperature relieving element.

Standard setting, 125 psi Size 3⁄4" x 3⁄4"

(20mm x 20mm).

ASME construction and is tested, listed and

certified by the National Board of Boiler and

Pressure Vessel Inspectors.

seals and prevents any water from escaping

from the system.

The float vent can also operate as an antivacuum device since it will permit air to

enter the system when it must be drained. It

can also be installed to permit the separation

and dispersal of air while fluid is actually

circulating in the system.

Overview

Body and cover are brass construction.

Air vent with silicone rubber seal.

Impurities do not usually affect function

as maximum float line of water is always

lower than the valve seal.

Float is high temperature resistant

polyethylene.

Suitable for use with glycol systems.

Can be disassembled for inspection and

cleaning.

ANSI Z21.22 “Relief Valves for Hot Water

Supply Systems.”

DESIGN CERTIFIED and listed by C.S.A.

Automatic Air Vent Valves

Automatic Air Vent Valves provide

automatic air venting for hot or cold water

distribution systems. These vents purge air

that may be in the water system.

The vent valve utilizes a float to actuate the

valve plug which is located at the top of the

valve. Once the air is displaced and the

system pressure is sustained, the valve plug

Page 29

29

Operating Range

Minimum working pressure: 1.45psi (10

kPa)

Maximum working pressure: 150psi (10

bars)

Temperature Range: 33°F – 240°F (5°C –

116°C)

Performance:

The figure below shows the installation of

the vent valve for the venting of air while

the fluid is circulating in the system and the

required increase in pipe size in order to

obtain proper separation of air from water.

Performance curve details the quantity of air

vented by the “Float Vent” according to the

pressure in the system.

Note: In order to get the best results in

venting air from risers, use connecting pipes

of at least 1⁄2" diameter between the “Float

Vent” valves and installation.

Installation

When the air vent valve is installed as

shown, the air will not be vented while the

fluid is circulating in the system, but it can

vent when the system is shut off.

The valve should be mounted only in a

vertical position as its operation is based on

the vertical movement of the float.

While the air vent valve is in operation, back

off the small vent cap two turns. This is the

proper operating setting which will allow air

to be vented from the system. It is advisable

to leave the cap on to prevent impurities

from entering the valve.

Page 30

30

No Installation of this equipment

should take place unless this

document has been read and

understood.

CAUTION

Dimensions – Weights:

Maintenance

No maintenance is normally necessary.

However, if the FV-4M1 is disassembled for

inspection or cleaning it is important that

when re-assembling to ensure that the spring

loaded lever properly engages under the

float collar

Pumps - Installation and Operating Instructions

Introduction

This document contains specific information

regarding the safe installation, operating and

maintenance of Vertical In-Line pumps and

should be read and understood by installing,

operating and maintenance personnel. The

equipment supplied has been designed and

constructed to be safe and without risk to

health and safety when properly installed,

operated and maintained. The instructions

following must be strictly adhered to. If

clarification is needed on any point please

contact Armstrong quoting the equipment

serial number.

Page 31

31

Where under normal operating conditions

the limit of 68°C/155°F (Restricted Zone)

for normal touch, or 80°C/176°F

(Unrestricted Zone) for unintentional touch,

may be experienced, steps should be taken

to minimize contact or warn operators/users

that normal operating conditions will be

exceeded. In certain cases where the

temperature of the pumped liquid exceeds

the above stated temperature levels, pump

casing temperatures may exceed

100°C/212°F and not withstanding pump

insulation techniques appropriate measures

must be taken to minimize risk for operating

personnel.

Storage

Pumps removed from service and stored,

must be properly prepared to prevent

excessive rusting. Pump port protection

plates must not be removed until the pump is

ready to connect to the piping. Rotate the

shaft periodically (At least monthly) to keep

rotating element free and bearings fully

functional.

For long term storage, the pump must be

placed in a vertical position in a dry

environment. Internal rusting can be

prevented by removing the plugs at the top

and bottom of the casing and drain or air

blow out all water to prevent rust buildup or

the possibility of freezing. Be sure to

reinstall the plugs when the unit is made

operational. Rust-proofing or packing the

casing with moisture absorbing material and

covering the flanges is acceptable. When

returning to service be sure to remove the

drying agent from the pump.

Handling Large VIL Units

One effective way of lifting a large pumping

unit is to place lifting hooks through the

motor lifting rings or straps around the

upper part of the motor. The pump and

motor unit will free-stand on the casing ribs.

Remove the coupling guard and place (2)

lifting straps through the pump/motor

pedestal, one on each side of the motor shaft

and secure to the lifting device.

With the straps in place, using a spacer bar if

necessary to protect the motor fan cover, the

whole assembly can now be lifted securely.

Note: Handling, transportation and

installation of this equipment should only

undertaken by trained personnel with proper

use of lifting equipment.

Remove coupling guard and place lifting

straps on each side of coupling, use spacer

bar if necessary to protect motor fan cover.

Vertical Inline Pump Lifting Strap

Positioning

Note: All split-coupled pumps contain a

tapped hole in the motor bracket above the

discharge flange for draining the well. Pipe

this drain hole to a floor drain to avoid

overflow of the cavity caused by collecting

chilled water condensate or from seal

failure.

Page 32

32

Pump Piping - General

Do not run pumps with discharge

valve closed or under very low flow

conditions.

Use Caution. Piping may carry high

temperature fluid.

Discharge valve only is to be used to

throttle pump flow.

CAUTION

CAUTION

CAUTION

The discharge valve only is to be used to

throttle pump flow, not the suction valve.

Care must be taken in the suction line layout

and installation, as it is usually the major

source of concern in centrifugal pump

applications

Alignment

Alignment is unnecessary on close-coupled

pumps as there is no shaft coupling.

Split-coupled units are accurately aligned at

the factory prior to being shipped and do not

need re-aligning when installed.

Operation

Starting Pump

Ensure that the pump turns freely by hand,

or with some mechanical help such as a

strap and lever on larger pumps. Ensure that

all protective guarding is securely fixed in

position.

The pump must be fully primed on startup.

Fill the pump casing with liquid and rotate

the shaft by hand to remove any air trapped

in the impeller. On split coupled units, any

air trapped in the casing as the system is

filled must be removed by the manual air

vent in the seal flush line. Close-coupled

units are fitted with seal flush/vent lines

piped to the pump suction area. When these

units operate residual air is drawn out of the

pump towards the suction piping.

“Bump” or energize the motor momentarily

and check that the rotation corresponds with

the directional arrow on the pump casing. To

reverse rotation of a three phase motor,

interchange any two power leads.

Start the pump with the discharge valve

closed and the suction valve open, and then

gradually open the discharge valve when the

motor is at operating speed. The discharge

valve may be cracked” or open slightly at

start up to help eliminate trapped air.

When stopping the pump: Close the

discharge valve and de-energize the motor.

DO NOT run the pump against a closed

discharge valve for an extended period of

time. (A few minutes maximum)

Star-Delta motor starters should be fitted

with electronic/mechanical interlocks that

have a timed period of no more than 40

milliseconds before switching from star

(Starting) to delta (Run) connection yet

allow the motor to reach full star (Starting)

speed before switching to delta (Run).

Should the pump be noisy or vibrate on

start-up a common reason is overstated

system head. Check this by calculating the

pump operating head by deducting the

suction pressure gauge value from the

discharge gauge reading. Convert the result

Page 33

33

into the units of the pump head as stated on

Check rotation arrow prior to

operating the unit.

CAUTION

Electric shock hazard. Before

attempting to perform any service or

maintenance on pumping unit,

disconnect power source to the

driver, LOCK IT OFF and tag with the

reason.

WARNING

the pump nameplate and compare the

values. Should the actual pump operating

head be significantly less than the nameplate

head value it is typically permissible to

throttle the discharge isolation valve until

the actual operating head is equal to the

nameplate value.

Any noise or vibration usually disappears.

The system designer or operator should be

made aware of this soon as some adjustment

may be required to the pump impeller

diameter or drive settings, if applicable, to

make the pump suitable for the system as

installed.

Check rotation arrow prior to operating the

unit. The rotation of all Vertical In-Line

units is “clockwise” when viewed from the

drive end. (Looking from on top of / behind

the motor)

General Care

Vertical In-Line pumps are built to operate

without periodic maintenance, other than

motor lubrication on larger units. A

systematic inspection made at regular

intervals, will ensure years of trouble-free

operation, giving special attention to the

following:

Keep unit clean.

Keep moisture, refuse, dust or other

loose particles away from the pump and

ventilating openings of the motor.

Avoid operating the unit in overheated

surroundings (Above 100ºF/40ºC).

Any possibility of the unit starting while

being serviced must be eliminated.

If mechanical seal environmental

accessories are installed, ensure water is

flowing through the sight flow indicator and

that filter cartridges are replaced as

recommended.

Lubrication

Pump

Lubrication is not required. There are no

bearings in the pump that need external

lubrication service.

Large Series split-coupled units are installed

with a shaft bushing located beneath the

impeller that is lubricated from the pump

discharge. This bearing is field removable

for service on the 20x20x19 size without

disturbing the motor or other major pump

components.

Motor

Follow the lubrication procedures

recommended by the motor manufacturer.

Many small and medium sized motors are

permanently lubricated and need no added

lubrication. Generally if there are grease

fittings evident the motor needs periodic

lubrication, and if there are no grease fittings

evident, no periodic lubrication is required.

Page 34

34

Check the lubrication instructions supplied

Double Check Prior to Startup

CAUTION

with the motor for the particular frame size

indicated on the motor nameplate.

Mechanical Seal

Mechanical seals require no special

attention. The mechanical seal is fitted with

a flush line. The seal is flushed from

discharge of the pump casing on splitcoupled pumps and is flushed/vented to the

suction on close coupled pumps.

The split-coupled pump is flushed from the

pump discharge because the mechanical seal

chamber is isolated from the liquid in the

pump by a throttle bushing. Because the seal

chamber is isolated, seal environmental

controls such as filters and separators, when

installed in the split-coupled flush line are

very effective, as only the seal chamber

needs cleansing, and will prolong seal life in

HVAC systems.

Do not run the pump unless properly filled

with water as the mechanical seals need a

film of liquid between the faces for proper

operation.

Mechanical seals may ‘weep’ slightly at

start-up. Allow the pump to continue

operating for several hours and the

mechanical seal to ‘seat’ properly prior to

calling for service personnel.

System Cleanliness

Before starting the pump the system must be

thoroughly cleaned, flushed and drained and

replenished with clean liquid.

Welding slag and other foreign materials,

“Stop Leak” and cleaning compounds and

improper or excessive water treatment are

all detrimental to the pump internals and

sealing arrangement.

Proper operation cannot be guaranteed if the

above conditions are not adhered to.

Note

Particular care must be taken to check the

following before the pump is put into

operation:

1. Pump primed?

2. Rotation OK?

3. Lubrication OK?

4. Pipe work properly supported?

5. Voltage supply OK?

6. Overload protection OK?

7. Is the system clean?

8. Is the area around the pump clean?

Warranty

Does not cover any damages to the

equipment resulting from failure to observe

the above precautions.

Page 35

35

Noise Levels

Estimated Pumping Unit Sound Power Level, Decibels, A-Weighted, at 1 m (3 ft.) from unit.

Vibration Levels

Vertical In-Line pumps are designed to meet vibration levels set by Hydraulic Institute Standard

HI Pump Vibration 9.6.4. Standard levels are as detailed below:

Dual Pump Specific Information

Dual Pump Flapper Valve Operating

Instructions

This unit is fitted with internal valves to

allow isolation of one pump for service and

to automatically prevent recirculation of the

flow when only one pump is running.

Procedure for Parallel or Stand-By

Pumping

Discharge and suction valve stems should be

locked in the center position. This is

indicated by both locking handles in the

vertical position and the center pin of the

locking arms (4) locked by the handles. This

procedure allows the discharge flapper

valves to pivot freely and locks the suction

valve firmly in the center position.

Procedure for Isolation of One Side

1. Stop the pump to be serviced.

2. Close and lock the suction and discharge

valves: as per instructions below.

3. Ensure seal flush line interconnection

valve is closed and drain the isolated

casing.

4. Service isolated pump as required.

Procedure for Starting the Pump after

Servicing

1. Ensure serviced pump is fully re-

assembled including all seal flush lines

and drain plugs.

Page 36

36

2. Fill the dry casing with system fluid by

opening the seal flush line

interconnecting valve and the air vent

fitting.

3. Allow the pressure to equalize in the two

casings, if necessary, by opening seal

flush line interconnected valve.

4. Unlock the discharge valve as per

instructions below.

5. Unlock the suction valve as per

instructions below.

NOTE: Keep hands and tools away from

locked suction valve arm, as the differential

pressure may cause the arm to rotate quickly

with force when unlocked.

6. Close the seal flush line interconnect

valve and restart pump.

Valve Operation - Refer to following 3”, 4”

& 6” valve illustration and the 8” valve

illustration.

Discharge Valve

This valve performs the dual function of

automatically sealing the discharge of the

inactive pump when one pump is running

and can manually be closed and locked to

isolate one pump for service.

Automatic Flapper Operation

In the flapper mode the two halves of the

discharge valve are free to pivot

independently under normal operating

conditions. The locking handle (3) should be

secured with the set screw (11) in the

vertical position with the center pin of the

locking arm (4) trapped by the locking

handle (3).

Manual Valve Locking

The locking feature of this valve is to ensure

a positive seal (leak proof) of the discharge

port on the pump to be serviced.

Note: Ensure the pump to be isolated is not

operating before attempting to release the

locking mechanism. Failure to do so may

result in injury to the operator and/or

damage to the pump.

Locking

1. Loosen discharge side set screw (11) to

release the locking handle (3).

2. Rotate the discharge side locking handle

(3) so that the handle points toward the

pump to be serviced and secure in the

horizontal position, using set screw (11).

This releases the discharge locking arm

(4).

3. Rotate discharge valve shaft (16)

towards the pump to be isolated. The

orientation of the shaft is indicated by

the center pin on the locking arm (4).

4. Raise the locking handle (3) so that the

cam on the base of the handle forces the

pin of the locking arm (4) towards the

pump to be isolated. The locking handle

(3) should be raised to between 45

degrees and the vertical position.

5. Tighten set screw (11) to lock the

locking handle (3) in position.

This handle should not be rotated past the

vertical position.

Note: Ensure the isolated pump is not

operating before attempting to release the

locking mechanism. Failure to do so may

result in injury to the operator and/or

damage the pump.

Unlocking:

1. Open the interconnecting valve on the

seal flush line to pressurize the serviced

pump and vent air through bleeder valve

on series 4302.

2. Close these valves once the pressure is

equalized and air removed.

Page 37

37

3. Loosen set screw (11) and lower locking

Care should be taken when

performing procedures 3 and 4. Read

instructions carefully.

WARNING

handle (3) to the horizontal position,

secure with set screw (11).

4. Rotate valve to center position so that

the center pin of the locking arm (4)

locates in the recess on the locking

handle (3).

5. Loosen set screw (11) and raise locking

arm (3) to the vertical position, locking

the center pin in the locking arm recess,

secure with set screw (11).

Suction Valve

Manual Operation

The suction side valve is designed for use as

a manually operated isolation valve. This

valve is not designed to automatically pivot

as the discharge flappers do.

Locking

1. Loosen suction side set screw (11) to

release the locking handle (3).

2. Rotate the suction side locking handle

(3) so that the handle points towards the

pump to be serviced and secure in the

horizontal position, using set screw (11).

This releases the suction locking arm

(4).

Note: The locking handle (3) should only be

rotated towards the pump stopped for

service. The suction valve is designed to

prevent the locking handle (1) from rotating

towards the running pump, as the suction of

the running pump could cause the valve to

slam shut with sufficient force to injure the

operator and/or cause damage to the pump.

Do not attempt to circumvent this safety

feature.

3. Rotate the suction valve towards the

pump to be isolated. The orientation of

the shaft is indicated by the center pin on

the locking arm (4).

4. Loosen set screw (11) and raise the

locking handle (3) so that the cam on the

base on the handle forces the pin of the

locking arm (4) towards the pump to be

isolated. The locking handle (3) should

be raised to between 45 degrees and the

vertical position.

This handle should not be rotated past the

vertical position.

5. Tighten set screw (11) to secure the

locking handle (3) in position.

Page 38

38

Care should be taken when

performing procedures 3 and 4. Read

instructions carefully.

WARNING

Unlocking:

1. Open the interconnecting valve on the

seal flush line to pressurize the serviced

pump and vent air through bleeder valve

on series 4302. Close these valves once

the pressure is equalized and air

removed.