Page 1

Instructions

SC & FC/PC3 Pull-Proof

Fiber Optic Connectors

Termination Procedures for

Single-mode and Multimode

Field-Mountable Connectors

using Epoxy

Issue 1, May 1993

Page 2

Contents:

A) Warnings, Recommendations and Overview................................................................................................ 3

B) Jacketed Cable Preparation.......................................................................................................................... 5

C) Mounting........................................................................................................................................................ 8

D) Scoring .......................................................................................................................................................... 12

E) Standard Polishing Process for Single-mode and Multimode Connectors (>30dB)..................................... 13

F) Polishing Process for Single-mode Connector Return Loss >40dB ............................................................. 16

G) Final Cleaning ............................................................................................................................................... 20

H) Mounting Unjacketed/900 ϑm Buffered Fiber ............................................................................................... 20

I) Connector Assembly and Installation............................................................................................................ 22

J) 3M SC and FC/PC3 Epoxy Field Termination Kits........................................................................................ 24

.972 in.

.068 in.

(1.73 mm)

.352 in.

(8.94 mm)

(24.7

mm)

.205 in.

(5.2 mm)

.283 in.

(7.19 mm)

.235 in.

(5.97 mm)

Ø .386 in.

(9.8 mm)

.289 in.

(7.34 mm)

.218 in.

(5.54 mm)

.266 in.

(6.75 mm)

Ø .0984 in.

(2.499 mm)

Ø .234 in.

(5.94 mm)

.154 in.

(3.9 mm)

Ø .094 in.

(2.499

mm)

Key-Shell

SC Connector

.925 in.

(23.5 mm)

FC/PC3

Connector

.925 in.

(23.5 mm)

.289 in.

(7.34 mm)

SC Connector

Crimp Ring Boot

1.97 in.

(50.0 mm)

BootCrimp Ring

1.66 in.

(15.0 mm)

2.27 in.

(57.7 mm)

FC/PC3 Connector

2

Page 3

SECTION A

Warnings, Recommendations and Overview

1. Most fibers can be mechanically stripped without the aid of chemicals or heat. If the fiber is not mechanically

strippable, contact 3M's Training Department or the cable manufacturer for their recommendations.

2. The recommended cleaning solvent for connectors and tools is isopropyl alcohol (reagent grade, 99% or

better). It may be purchased from laboratory supply companies. Isopropyl alcohol may also be used to clean

the lapping acetate and stripping tool when necessary. Do not use acetone for cleaning.

3. For safety reasons, no chemicals have been shipped with the 3M brand Field Termination Kit. We have,

however, included bottles for the alcohol and water.

Note: Carefully follow safety,health and disposal information on container label or Material Safety Data

Sheet for isopropyl alcohol being used.

4. Please contact the 3M Telecom Systems Training Department if you have any questions concerning

chemicals or procedures.

Warning: Do not view fiber ends if they are laser illuminated. Eye damage may result. Illuminate fiber

ends with white light only.

5. The connectors described in this manual have pre-radiused PC "domed" ferrule ends to ensure low

attenuation and the best reflection performance. All polishing should be done on the soft polishing pad

only, as described in this manual.

6. The 3M brand connectors with PC finishes are completely intermateable with flat finished connectors. PC to

flat terminations actually provide improved performance over flat to flat terminations. PC to PC terminations

as produced while using this manual, however, offer the best performance.

7. Safety glasses should be worn when working with optical fibers.

8. Appropriate containers of clean, dry, compressed air may be obtained from photographic supply stores. Do

not use types that leave a residue.

3

Page 4

SECTION A

Warnings, Recommendations and Overview

This manual is for terminating the following field mountable connectors:

Identification

SC Single-mode Product Number Housing (Color) Ferrule Collar Strain Relief Boot

125 ϑm 8305 Blue Black White

126 ϑm 8306 Blue Yellow White

127 ϑm 8307 Blue Silver White

SC Multimode

125 ϑm 6306 Beige Black Beige

FC Single-mode

125 ϑm 8202 Gray Black White

126 ϑm 8203 Gray Yellow White

127 ϑm 8204 Gray Silver White

FC Multimode

125 ϑm 6202 Beige Black Beige

Field Termination Kits

Field Termination Kit for SC & FC/PC3 Connectors (110V) 8350

Field Termination Kit for SC & FC/PC3 Connectors (220V) 8351

(See section J for kit listing)

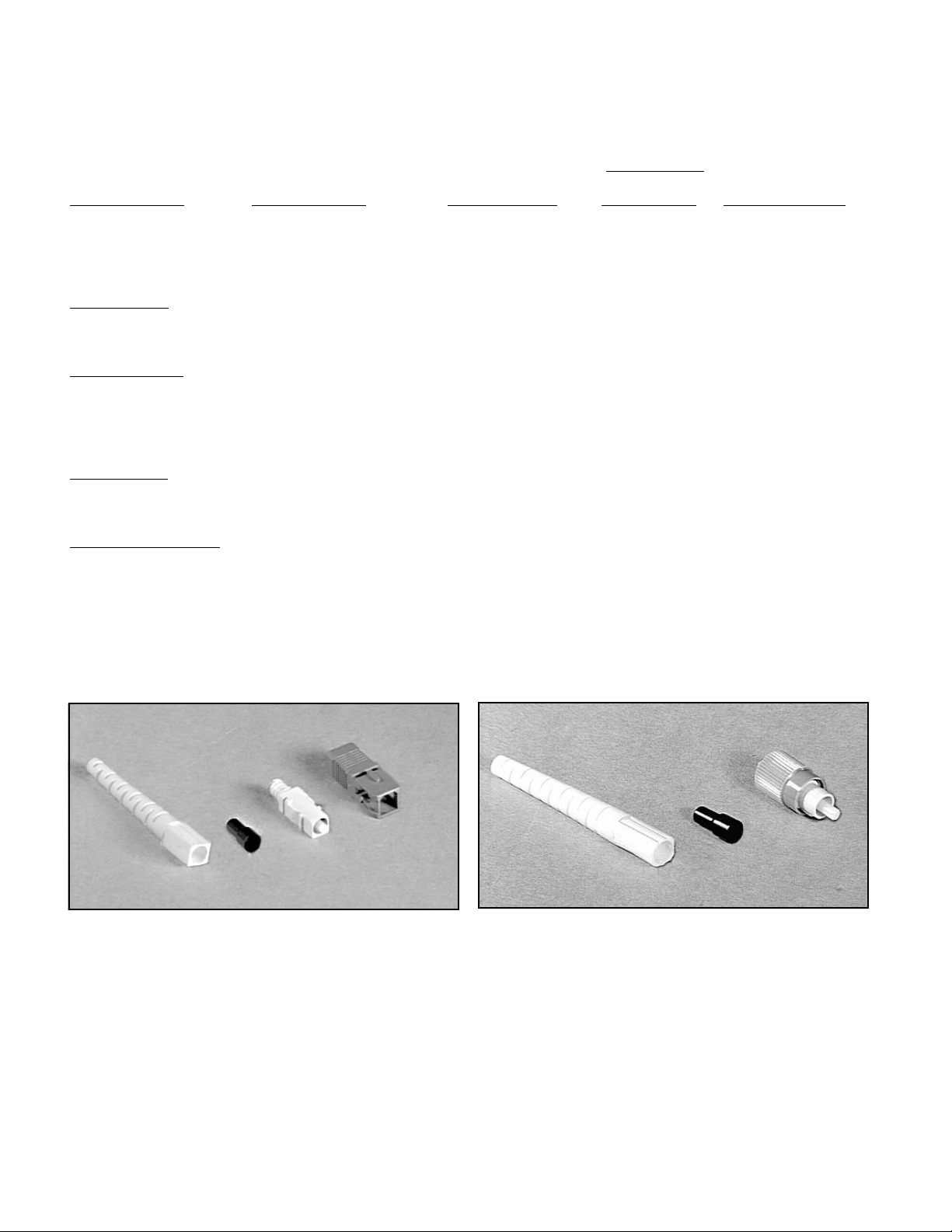

SC Connector FC/PC3

(A)

(C)

(B)

(D)

(A)

(A) - Strain Relief Boot

(B) - Crimp Ring

(C) - Connector

(D) - Housing

Connector

(C)

(B)

4

Page 5

SECTION B

Jacketed Cable Preparation

This section is for mounting the 3M brand SC and FC/PC3 fieldmountable connectors on 2.4 mm cable and 3.0 mm cable.

The process for mounting on 900 ϑm buffered fiber can be found in

Section H.

1. TURN THE OVEN ON

When the oven is heated to the proper temperature the heater

light will go off.

2. ASSEMBLE THE CURING STAND ACCORDING TO FIGURE B11

3. PREPARE CONTAINERS AS LABELED

a. Fill one bottle with isopropyl alcohol (reagent grade).

b. Fill one bottle with water.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data sheet for isopropyl

alcohol being used.

Fig. B1

4. PREPARE THE CRIMP TOOL

Included in the field termination kit is a crimp tool set. The package

includes a base tool and three die sets to be used as follows:

Die Marking Cavity Marking Application

BIC/ST .151 ST* Bayonet, FC-1 & Biconic

.213 TECS 200/230 connector

.178 Not used

SC / FC3 .120 2.4 mm Jacketed Cable

.137 3.0 mm Jacketed Cable

.190 Kevlar crimp

PPST (Push-Pull ST) .120 2.4 mm Jacketed Cable

.137 3.0 mm Jacketed Cable

.226 Kevlar crimp

Select the jaw labeled "SC/FC3." Secure the jaws loosely with the

thumb screws. Close the jaws to the fully closed position allowing

the jaws to align, then tighten the screws (Fig. B1).

5

Page 6

SECTION B

Jacketed Cable Preparation

5. SLIP THE STRAIN RELIEF BOOT AND THE CORRECT CRIMP

RING ONTO THE CABLE

DO NOT FORGET TO DO THIS STEP. The boot will not fit over a

mounted connector assembly so it is essential that it be slipped

onto the cable at this time. Slip the smaller diameter of the boot

onto the cable first.

Red crimp rings for 2.4 mm cable and black crimp rings for 3.0

mm cable are provided with each connector. Slide the appropriate

crimp ring onto the cable, small opening first (Fig. B2).

6. CUT AND REMOVE 1 3/16" (30 mm) OF THE CABLE'S OUTER

JACKET

Adjust the yellow handled stripper to cut the jacket and not the

Kevlar1.

Using the ruler supplied in the field kit, measure and mark the

cable 1 3/16" (30 mm) from the end of the jacket. Close the yellow

handled stripper on the cable until the outer jacket is cut (Fig. B3).

Remove the jacket with your fingers.

Fig. B2

Fig. B3

7. CUT AND FLARE THE STRENGTH MEMBERS

Gather the Kevlar and pull it off to one side giving it a slight twist.

Using the serrated scissors cut the Kevlar leaving about 5/16" (8

mm) sticking out of the outer jacket (Fig. B4). Slip the smaller

hole of the blue stripping collar over the buffer and flare out all of

the Kevlar evenly (Fig. B5). Reverse the collar and slide the

larger hole over the buffer and outer jacket. Push down gently

until the stripping collar folds the Kevlar back and seats.

8. HOLD THE CABLE SECURELY

Before stripping the buffer it is important to hold the cable in a

configuration which will prevent the buffered fiber from being

pulled out of the outer jacket.

Grasp the end of the outer jacket between your thumb and

forefinger. Wind the cable between your fingers (Fig.B6).

Squeezing with all fingers will clamp the buffered fiber in the outer

jacket (Fig. B6).

Fig. B4

Fig. B5

6

Fig. B6

Page 7

SECTION B

Jacketed Cable Preparation

9. BUFFER REMOVAL

With the modified No-Nik tool's arrow pointing in the direction of

the stripping, remove the fiber's buffer in small bites, about 3/16"

(5 mm).

Be sure to remove the stripped material from the tool after each

incremental cut. When stripping the last increment, the end of the

stripping collar should gently rest against the fiber guide inside of

the clearance hole of the No-Nik (Fig. B7). This will ensure the

correct

9/16" (14 mm) buffer length remaining.

10. CLEAN THE FIBER WITH ALCOHOL

With the collar still in place, moisten a lint free cloth with isopropyl

alcohol from the bottle and wipe the fiber clean (Fig. B8). Make

sure there is absolutely no buffer residue or dirt on the fiber by

holding it to a light and inspecting for a smooth shiny surface. If

necessary, wipe the fiber a second time to be sure that it is clean.

11. REMOVE THE STRIPPING COLLAR

Remove the stripping collar and position the cut Kevlar so that it is

evenly distributed around the buffer. At this time, verify the strip

length dimensions. It is very important that the exposed buffer

measures 9/16" (14 mm) from the end of the cut jacket as

shown in Fig. B9. (Figure not to scale). Confirm all dimensions

using the ruler provided (Fig. B10).

12. PROTECT PREPARED FIBERS

Clip the cable in the curing stand where the fiber end will not

touch anything (Fig. B11). When mounting more than one

connector, prepare all fiber ends before mixing the epoxy.

Fig. B7

Fig. B8

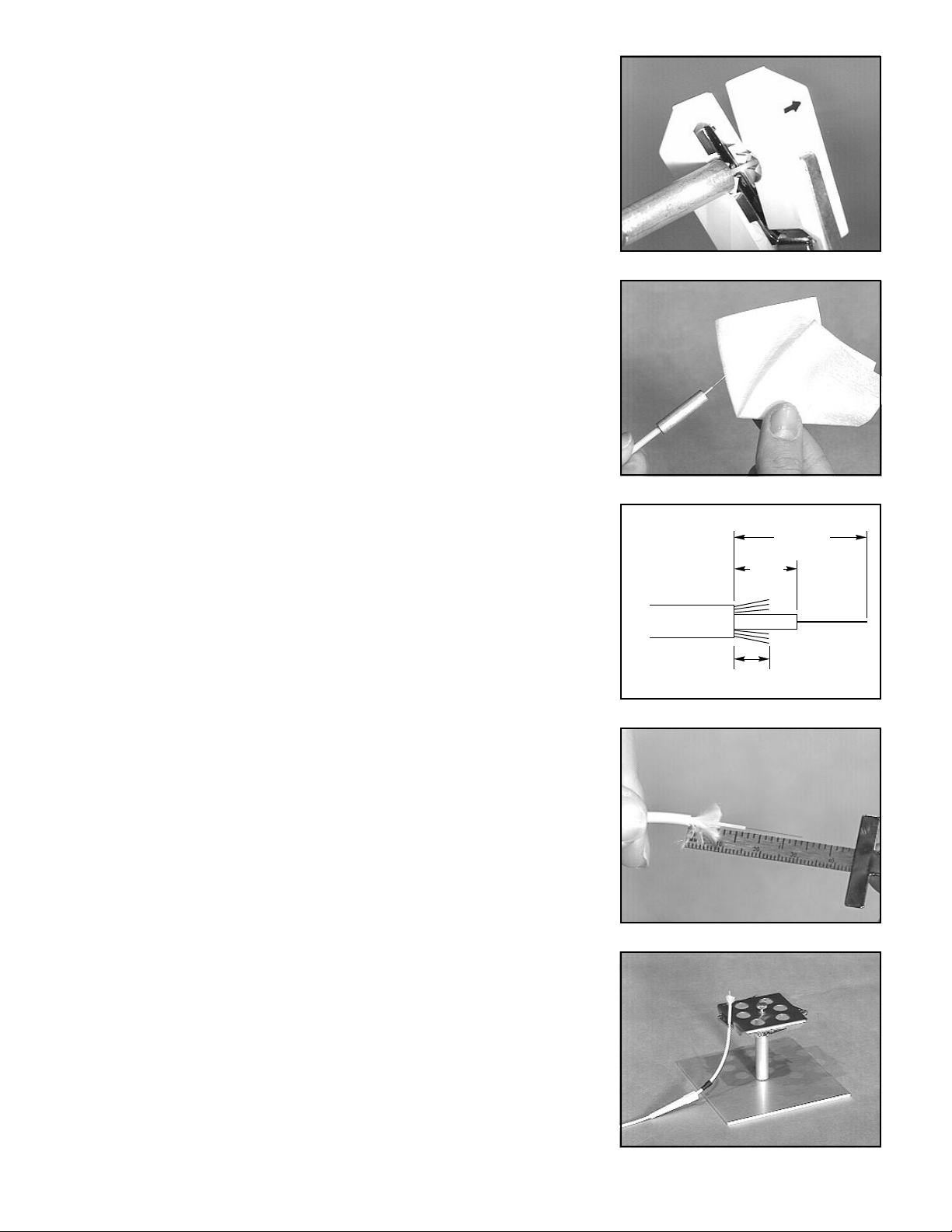

1 3/16"

(30 mm)

9/16"

(14 mm)

Outer Jacket

Kevlar

5/16" (8 mm)

Fig. B9

Fig. B10

Fig. B11

7

Page 8

SECTION C

Mounting

1. INSPECT THE CONNECTOR

Before mounting, hold the connector up to a light to ensure that

the capillary hole of the ceramic ferrule is clear. If the hole is

obstructed, blow it clear with air or use a piece of stainless steel

wire supplied with the kit. To clear simply insert a wire through the

back end of the connector so that the wire forces any debris

through the front end of the ceramic ferrule (Fig. C1).

2. MULTIMODE CONNECTOR MOUNTING

The 125 ϑm size connector will fit standard 125 ϑm multimode

fibers. Since dry fitting is therefore not necessary, advance to C3

in this section.

For 140 ϑm size fibers contact your local 3M sales representative.

SINGLE-MODE CONNECTOR FITTING

In order to achieve the lowest attenuation, it is important to dry fit

single-mode connectors onto individual fibers.

Single-mode connectors are available in three closely toleranced

ferrules sizes for mounting on single-mode fiber. Refer to page 4

for connector identification.

Fig. C1

Fig. C2

Select a 125 ϑm size connector. Line up the connector straight

with the fiber and thread it onto the fiber while slightly rotating the

connector between thumb and forefinger (Fig. C2). Do not try to

force the connector onto the fiber. If the ferrule is too tight, the

fiber will begin to buckle. If this is the case, carefully remove the

125 ϑm size and select a 126 ϑm size connector. Check to see

that the ferrule hole is clear and dry fit. If the 126 ϑm size is too

tight then a 127 ϑm connector should be used. If the connector

cannot be threaded onto the fiber, re-inspect the fiber and the

connector. Re-clean if necessary.

Note: At times when fitting connectors, a fiber particle may

become lodged in the ferrule. In order to clear the ferrule

it may be necessary to insert a stainless steel wire through

the front of the ferrule and push the fiber out through the

rear. Be sure to blow the connector clean after using the

wire.

Slide the correct size connector all the way onto the fiber until the

buffer bottoms against the ferrule. At this point, there should be

no more than 1/16" (2 mm) space between the end of the cable

and the back end of the connector (Fig. C3). After the fit is

confirmed, carefully remove the connector from the fiber and

place the fiber in the curing stand.

3. INSTALL THE LOAD ADAPTER ONTO THE CONNECTOR

After the connector has been fitted, insert it into the load adapter

(Fig. C4) and place the connector in the stand with its matching

fiber.

Fig. C3

Fig. C4

8

Page 9

SECTION C

Mounting

4. PREPARE THE SYRINGE AND EPOXY

Remove the plunger and protective cap from the syringe and

place both parts on a clean convenient surface along with the

dispensing tip. The epoxy supplied has been specifically

designed for use with fiber optic connectors and is packaged in

premeasured 2 gram bi-packs.

- Working time is 45 minutes.

- Cure time is 20 minutes, in 3M epoxy oven.

- Cure time is 18 hours at room temperature of 70ϖF (22ϖC).

- Shelf life is 9 months at 25ϖC. (Packages are dated).

(Refrigeration will prolong shelf life). If epoxy is stored at a

higher temperature, shelf life will be shortened.

- Each bi-pack will mount up to 30 connectors per mounter.

Bi-packs can be shared between 2 or 3 syringes, if desired.

Remove the separating bar by pulling the bi-pack ends. Mix the

two components together for one full minute by massaging the

package and rubbing it back and forth over the smooth edge of a

table (Fig. C5). Make sure that the epoxy is thoroughly mixed and

is a uniform blue color.

Fig. C5

Fig. C6

Note: Carefully follow safety, health and disposal information on

epoxy label or Material Safety Data Sheet.

5. LOAD THE SYRINGE WITH EPOXY

When thoroughly mixed, cut a small corner off of the package and

squeeze the contents into the syringe while holding the syringe

diagonally (Fig. C6).

Insert the plunger only about 3/8" (10 mm) and hold the syringe

pointing straight upward. After the epoxy settles on the plunger,

push in gently to expel any air through the tip of the syringe.

6. ATTACH THE EPOXY DISPENSING TIP

The mint green dispensing tips included in the field termination kit

are required for use with the 3M SC, FC3 and ST Push-Pull

connectors.

Push and twist-lock the dispensing tip onto the syringe body.

Depress the plunger and eject the epoxy until there are no air

pockets remaining.

7. INJECT EPOXY INTO THE CERAMIC FERRULE

Each time you inject a new connector, wipe the needle tip clean to

be sure that it is completely free of epoxy.

Fig. C7

Mint green color dispensing tip

stops and seals at this point, leaving

small reservoir of adhesive.

Epoxy

Bead

Buffer to contact ferrule.

Adhesive encapsulates

buffer in collar.

Fig. C7a

Insert the syringe tip into the back end of the connector until it

seats. Maintain pressure and slowly inject epoxy until a bead

appears on the end of the ceramic tip (Fig. C7 and Fig. C7a).

Continue to inject epoxy until the bead covers about one third of

the ferrule end face. Release the pressure on the plunger and

withdraw the needle straight back. DO NOT ALLOW EPOXY TO

FILL THE INSIDE OF THE CONNECTOR.

Note: Unlike other mounting procedures, do not place epoxy on

the fiber or in the back end of the connector.

9

Page 10

SECTION C

Mounting

8. THREAD THE CONNECTOR ONTO THE FIBER

Slide the crimp ring up the cable within 1/2" (13 mm) of the end of

the jacket. Hold the cable in one hand directly behind the crimp

ring and hold the connector in the other hand. Rest your hands

on the table or against each other and carefully thread the

connector straight onto the fiber. Slowly rotate the connector

between thumb and forefinger in order to ease the funneling of the

fiber into the guide hole of the ferrule (Fig. C8). Carefully observe

that the fiber is moving through the ferrule while threading the

connector. This ensures that the fiber hasn't broken during the

mounting process.

While rotating the connector, maintain a continuous light inward

pressure in order to assist entry alignment. Slowly slide the

connector onto the fiber until the buffer seats at the base of the

ferrule. The Kevlar must flare around the backbone of the

connector (Fig. C9).

Once the buffer is seated, do not pull on the fiber. Keeping the

fiber forward will ensure that the epoxy does not deposit anywhere

inside the body of the connector. Hold the connector in place and

carefully slide the crimp ring up over the Kevlar until the ring is

seated with the back end of the connector (Fig. C10).

9. CRIMP THE RING ONTO THE CONNECTOR BACKBONE.

Fig. C8

Fig. C9

Make sure that the crimp ring is fully seated over the back of the

connector. Hold the connector in place with your forefinger and

middle finger. Be sure that the crimp cavity marked .190

completely covers the upper portion of the ring and crimp the ring

to the connector, securing the Kevlar (Fig. C11).

Next, crimp the smaller diameter of the crimp ring to retain the

cable's jacket. Use cavity .137 for 3.0 mm and .120 for 2.4 mm.

Be careful not to pinch the cable between the jaws.

10. EXAMINE THE EPOXY BEAD

The correct epoxy bead height at the fiber should be between 2 to

4 fiber diameters (0.10" to 0.020") above the ceramic tip. If this is

not the case, additional epoxy must be applied around the fiber

base to build the bead to the proper height. A short piece of

buffered fiber with about 1/4" (6 mm) of exposed fiber makes a

good applicator.

To apply: Carefully deposit epoxy on the end of the ferrule

through the opening in the load adapter using a short piece of

buffered fiber .

Important: The outside diameter of the ceramic ferrule must be

free of epoxy. Excess epoxy will adhere the load

adapter to the ferrule during the curing process.

Fig. C10

Fig. C11

10

Page 11

SECTION C

Mounting

11. SECURE THE STRAIN RELIEF BOOT

Use the syringe to apply two dabs of epoxy onto the larger half of

the crimp ring (Fig. C12). While holding the load adapter, slide the

boot up over the crimp ring and rotate it to evenly distribute the

epoxy.

The boot should cover only the crimp ring, not the plastic body of

the connector.

Note: Be sure to wipe away any excess epoxy using a dry lint-free

cloth.

For SC Connectors

Be sure to align the key on the boot with the flat, smooth side of

the connector (Fig. C13). Attach an alignment clip over the boot

and connector body to hold the boot in alignment while the epoxy

cures . The back of the alignment clip should cover the key on the

boot

(Fig. C14). (If the clips spread with use, pinch them closed while

warm.)

12. EPOXY CURING

When the oven is heated to the proper temperature, the heater

light will go off. Place the connector and load adapter into one of

the oven's ports (Fig. C15). After 20 minutes, remove the

connector from the oven and place it in the curing stand to cool.

Note: Do not score the fiber before the epoxy is cool and hard.

Note: Heat curing this epoxy in the 3M oven is required in order

to meet the Bellcore temperature requirement of +85ϖC as

outlined in TR-NWT-000326 Issue 3. If compliance to this

specification is not necessary, the 3M epoxy can also be

cured overnight at room temperature.

Fig. C12

Fig. C13

Fig. C14

11

Fig. C15

Page 12

SECTION D

Scoring

1. CAREFULLY REMOVE THE LOAD ADAPTER

2. SCORE THE FIBER

Hold the connector in a vertical position with the fiber pointing

upward. Score the fiber by drawing the scoring blade lightly

against the fiber, just above the epoxy bead (Fig. D1). The fiber

should merely be touched and not severed.

3. DETACH THE SCORED FIBER

Using your fingers, carefully remove the fiber by pulling straight up

from the ferrule. If the fiber is too short, use the scoring tool to

gently press against the fiber from the scored side until it breaks

along the score mark.

Note: Be sure to dispose of all fiber ends per company practice.

If the fiber should break off accidentally without the benefit

of proper scoring, polishing should still be attempted.

Fig. D1

4. CHECK THE FIBER END

Check the quality of the score using the jeweler's loupe. The fiber

should not protrude from the epoxy bead more than one fiber

diameter (Fig. D2). If the fiber is longer than one diameter,

proceed as follows: Hold the connector in one hand and a sheet

of brown

5 ϑm acetate in the other. Using small circular strokes, shorten

the fiber to an acceptable length (Fig. D3).

Fig. D2

Fig. D3

12

Page 13

SECTION E

Standard Polishing Process for Single-mode and

Multimode Connectors (>30dB)

Note: See Section F to achieve >40 dB Return Loss.

1. PREPARE THE 5 ϑm POLISHING SURFACE

Clean the surface of the soft polishing pad with a lint-free cloth

dampened with isopropyl alcohol. Blow clean both sides of a

sheet of brown 5 ϑm lapping acetate. Place the acetate shiny

side down onto the soft pad.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

2. PREPARE THE POLISHING JIG AND CONNECTOR

Wipe the polishing surface of the jig with a lint-free cloth

moistened with isopropyl alcohol. Blow the entire jig clean with

compressed air. Clean the connector with compressed air only,

since wiping it may break the fiber.

Wear Indicator

(3 Places)

Fig. E1

Note: The polishing jig used in these procedures is designed

with three "wear indicators" on its polishing surface (Fig.

E1). Each indicator is 0.002" deep. As polishing is done,

the surface of the jig will be worn away. Uniform pressure

across the jig's surface during polishing will result in the

areas surrounding the "indicators" to wear evenly. Nonuniform pressure will result in one or two indicators

disappearing, thereby requiring the jig to be replaced.

13

Page 14

SECTION E

Standard Polishing Process for Single-mode and

Multimode Connectors

3. PERFORM THE 5 ϑm FINISH

While holding the polishing jig in your hand, insert the connector

so that the ferrule end does not protrude past the bottom of the

polishing jig. This is to ensure that the extended fiber from the

ferrule will not be broken off below the epoxy level upon initial

contact with the lapping film.

Note: The ferrule must be inserted straight into the jig hole. If

the ferrule tip is wiggled upon entering the composite jig,

the composite jig may be damaged.

Note: If the connector does not fit easily into the jig, examine the

sides of the ceramic ferrule for epoxy. Any excess epoxy

can be removed with a razor blade.

While holding both the connector and the polishing jig in one

hand, slowly place the jig on the lapping film and begin to polish in

a figure 8 motion without applying pressure on the connector (Fig.

E2). Light scratch marks should begin to appear on the acetate

surface.

Fig. E2

Fig. E3

Continue to polish until the fiber is flush with the epoxy bead

(approximately 6 figure 8's) (Fig. E3). Once the fiber is supported

by the epoxy bead, begin applying light pressure on the connector

while polishing in a figure 8 motion. Continue to polish on the 5

ϑm acetate until a thin layer of light blue color epoxy remains on

the ceramic tip (Fig. E4). Stop when the outer edges of the epoxy

layer start to break up and feather. This can be seen using the 7X

jewelers loupe.

Note: Until familiar with the process from this point, inspect the

remaining epoxy after each single figure 8 until a thin

feathered edge remains. DO NOT REMOVE ALL EPOXY

WITH THE 5 ϑm ACETATE.

Note: The 5 ϑm lapping acetate can be cleaned with isopropyl

alcohol and blown dry for reuse. The sheet can be used to

polish 2 to 4 connectors.

Fig. E4

14

Page 15

SECTION E

Standard Polishing Process for Single-mode and

Multimode Connectors

4. PREPARE TO PERFORM THE 1 ϑm FINISH

Using an isopropyl alcohol dampened lint-free cloth, clean the

ferrule, the polishing jig, and the 5 ϑm lapping acetate. Blow all

pieces dry with compressed air.

Clean a sheet of the green 1 ϑm lapping acetate and place it shiny

side down directly on top of the 5 ϑm acetate which remains on

the polishing pad. Place three to four drops of water on the 1 ϑm

acetate (Fig. E5).

5. PERFORMING THE 1 ϑm FINISH

Insert the ferrule into the jig and lower it gently on to the

moistened green 1 ϑm acetate.

Lightly polish until all the epoxy is removed (15 to 20 figure 8's).

Inspect with the jewelers loupe (Fig. E6).

Do not overuse the 1 ϑm lapping acetate. Always attempt to

polish on fresh areas of the acetate. After the entire surface of the

acetate has been used it can be cleaned with isopropyl alcohol

and reused to polish several more connectors and then discarded.

If deep scratches appear on the fiber, discard the 1 ϑm acetate at

that time.

6. FINAL INSPECTION

After polishing, remove the connector from the polishing jig, clean

the ferrule and insert it into the fiber view scope (Fig. E7). The

fiber should be free of epoxy and scratches and be flush with the

domed end of the ceramic ferrule (Fig. E8). If scratches or epoxy

are present (Fig. E9) clean the 1 ϑm acetate surface and repeat

step 5 with frequent inspections.

Fig. E5

Fig. E6

Fig. E7

15

Fig. E8

Fig. E9

Page 16

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

This process will need to be used for single-mode finishes with a

reflection requirement of 40dB or better. This specification is outlined in

Bellcore TR-NWT-00326 Issue 3.

1. PREPARE THE POLISHING SURFACE

Wear Indicator

(3 Places)

Clean the surface of the soft polishing pad with a lint-free cloth

moistened with isopropyl alcohol. Blow clean both sides of a

sheet of brown 5 ϑm lapping acetate. Place the acetate shiny

side down onto the soft pad.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

2. PREPARE THE POLISHING JIG

Wipe the polishing surface of the composite jig with a lint-free

cloth moistened with isopropyl alcohol. Blow the entire jig clean

with compressed air.

Note: The polishing jig used in these procedures is designed

with three "wear indicators" on its polishing surface (Fig.

F1). Each indicator is 0.002" deep. As polishing is done,

the surface of the jig will be worn away. Uniform pressure

across the jig's surface during polishing will result in the

areas surrounding the "indicators" to wear.

Note: The composite polishing jig must be used when following

the >40dB process. The stainless steel jig, which is

available separately, can be used with the standard

polishing process only.

Fig. F1

Fig. F2

3. CHECK THE FERRULE HOLE IN THE POLISHING TOOL

In order to achieve greater than -40dB reflection on single-mode

connectors, it is extremely important that the polishing tool

accurately holds the ceramic ferrule radius on center during the

polishing procedure. This is accomplished by the squareness and

tight dimensional clearance of the polishing jig.

Periodically, check the ferrule hole in the jig using the NO/GO

gauge pin provided in the Field Termination Kit. The NO/GO pin

should not even start into the hole if the polishing jig is within

tolerance. To check the ferrule hole, gently insert the gauge pin

through the hole on the top of the polishing tool (Fig. F2). DO

NOT TRY TO FORCE THE PIN THROUGH THE OPENING. If

the pin does not pass through the hole, continue to use the tool to

polish single-mode connectors. If the pin does pass through the

opening of the tool, the tool has worn and should be used for

multimode finishes only.

16

Page 17

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

4. PERFORM THE 5 ϑm FINISH

While holding the polishing jig in your hand, insert the connector

so that the ferrule end does not protrude past the bottom of the

polishing jig. This is to ensure that the extended fiber from the

ferrule will not be broken off below the epoxy level upon initial

contact to the lapping film.

Note: The ferrule must be inserted straight into the jig hole. If

the ferrule tip is wiggled upon entering, the composite jig

may be damaged.

Note: If the connector does not fit easily into the jig, examine the

sides of the ceramic ferrule for epoxy. Any excess epoxy

can be removed with a razor blade.

While holding both the connector and the polishing jig in one

hand, slowly place the jig on the lapping film and begin to polish in

a figure 8 motion without applying pressure on the connector (Fig.

F3). Light scratch marks should begin to appear on the acetate

surface.

Fig. F3

Fig. F4

Continue to polish until the fiber is flush with the epoxy bead

(approximately 6 figure 8's) (Fig. F4). Once the fiber is supported

by the epoxy bead, begin applying light pressure on the connector

while polishing in a figure 8 motion. Continue to polish on the 5

ϑm acetate until a thin layer of light blue color epoxy remains on

the ceramic tip (Fig. F5). Stop when the outer edges of the epoxy

layer start to break up and feather. This can be seen using the 7X

jewelers loupe.

Note: Until familiar with the process from this point, inspect the

remaining epoxy after each single figure 8 until a thin

feathered edge remains. DO NOT REMOVE ALL OF THE

EPOXY WITH THE 5 ϑm ACETATE.

Note: The 5 ϑm lapping acetate can be cleaned with isopropyl

alcohol and blown dry for reuse. The sheet can be used to

polish 2 to 4 connectors.

5. PREPARE TO PERFORM THE 1.5 ϑm FINISH

Using an isopropyl alcohol dampened lint-free cloth, clean the

ferrule and the polishing jig. Blow both parts dry with compressed

air.

Clean a sheet of the 1.5 ϑm diamond lapping acetate and place it

shiny side down directly onto the clean polishing pad.

Fig. F5

17

Page 18

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

6. PERFORM THE 1.5 ϑm FINISH

Insert the ferrule into the jig and lower it gently onto the 1.5 ϑm

acetate.

Using medium pressure (equivalent to 1 lb of force), perform four

figure 8 strokes. Rotate the ferrule in the jig 180ϖ (Fig. F6) and

perform another four figure 8's. Continue to follow this sequence

rotating 180ϖ every 4 strokes until 6 sets of 4 figure 8's (24 total)

have been performed.

Note: Without rotating the ferrule the radius center may drift.

Rotating effectively eliminates this.

Clean the ferrule with a lint-free cloth moistened with isopropyl

alcohol and inspect the fiber using the 100X view scope. The

fiber should be completely smooth and all the epoxy removed as

in Fig. F7. If epoxy remains or scratches or rough edges are

present on the fiber as in Fig. F8, perform a few more figure 8

strokes on each 180ϖ orientation.

Note: If all of the epoxy was removed from the fiber during the

first step of polishing, the fiber surface may be heavily

scratched and pitted. If this is the case, perform another

set of figure 8's on each 180ϖ orientation and inspect again.

Note: The 1.5 ϑm diamond film can be cleaned with isopropyl

alcohol and blown dry for reuse. The sheet can be used to

polish up to 15 connectors.

Fig. F6

Fig. F7

Fig. F8

18

Page 19

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

7. PREPARE TO PERFORM THE FINAL POLISH

Using an isopropyl alcohol dampened lint-free cloth, clean the

ferrule and the polishing jig.

Clean a sheet of the final polishing film and place it shiny side

down onto the clean polishing pad. Section the film into four (4)

quarters. Mark the section 1, 2, 3 and 4. Place a few drops of

water on section 1 of the film (Fig. F9).

8. PERFORM THE FINAL POLISH

Insert the ferrule into the jig and lower it gently onto the moistened

polishing film.

Using the same medium pressure as in step 6, perform small

circles in a spirograph pattern as shown in (Fig. F10). Perform 25

circular strokes. Wipe the ferrule dry with a lint-free cloth and

inspect the ferrule end using the 100X microscope. The fiber

should be completely smooth and free of any scratches (Fig. F11).

If scratches are present in the fiber, perform an additional 3 to 5

strokes on an unused area of the film and inspect again. If

necessary a final lapping of 3 to 5 strokes can be performed.

Note: The final polishing film can be used to polish up to 4

ferrule ends. Be sure to use a fresh area of the polishing

film each time a new connector is to be polished.

Fig. F9

Fig. F10

Fig. F11

19

Page 20

SECTION G

Final Cleaning

1. BLOW THE DUST CAP WITH COMPRESSED AIR

2. WIPE THE CERAMIC FERRULE WITH AN ISOPROPYL

ALCOHOL DAMPENED LINT-FREE CLOTH (Fig. G1)

Be sure to wipe the entire length of the ferrule and the ferrule tip.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

3. BLOW THE FERRULE WITH THE COMPRESSED AIR

4. IMMEDIATELY COVER THE FERRULE WITH THE DUST CAP

SECTION H

Mounting Unjacketed/900

Note: General instructions for preparation for mounting may be

found in Section B steps 1 - 4.

1. SLIP THE STRAIN RELIEF BOOT ONTO THE BUFFERED

FIBER, SMALL END FIRST (Fig. H1)

2. PLACE THE CRIMP RING ONTO THE STRAIN RELIEF TUBE

Measure and mark the clear strain relief tube 3/16" (5 mm) from

its end. Slide the smaller diameter of the black 3.0 mm crimp ring

onto the tube until the end of the ring aligns with the mark on the

tube (Fig. H2).

3. PLACE THE CLEAR TUBE WITH THE CRIMP RING ONTO THE

BUFFERED FIBER (Fig. H3)

m Buffered Fiber

Fig. G1

Fig. H1

Fig. H2

The larger diameter of the crimp ring MUST be towards the end of

the fiber.

4. REMOVE 3/4" (19 mm) OF BUFFER USING THE NO-NIK TOOL

(Fig. H4)

(Refer to Section B, step 9).

5. CLEAN THE FIBER WITH ISOPROPYL ALCOHOL

(See Section B, step 10).

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

6. CONTINUE WITH STEPS C1 - C7

20

Fig. H3

Fig. H4

Page 21

SECTION H

Mounting Unjacketed/900

7. THREAD THE CONNECTOR ONTO THE FIBER

Slide the strain relief tube with the crimp ring within 1/2" (13 mm)

of the buffer. While holding the fiber directly behind the strain

relief tube, slowly thread the connector straight onto the fiber until

the buffer seats at the base of the ferrule (Fig. H5). While holding

the connector in place, slide the strain relief tube and the crimp

ring up the buffer until the crimp ring is seated on the back end of

the connector. The mark on the clear tube MUST align with the

end of the crimp ring before crimping the ring to the connector

and tube (Fig. H6).

8. CRIMP THE RING TO THE CONNECTOR AND TUBE

While holding the connector and strain relief tube in place, crimp

the upper portion of the ring to the back end of the connector

using the cavity marked .190 in the crimp tool (Fig. H7).

Reposition the connector to the center cavity .137, securing the

ring to the tube.

9. CONTINUE WITH TERMINATION PROCEDURE FOR

JACKETED CABLE, SECTION C10-12 AND SECTIONS D

THROUGH G

m Buffered Fiber

Note: After placing the connector in the curing oven, gently

push down on the buffered fiber to be sure that it is

seated.

Fig. H5

Fig. H6

Fig. H7

21

Page 22

SECTION I

Connector Assembly and Installation

1. CONNECTOR ASSEMBL Y

Once the SC connector has been mounted and polished, the

housing can be installed onto the body.

A. Standard Density Applications

While holding the connector firmly by the boot, align the

chamfers on both the connector and housing and snap into

place (Fig. I1). A positive click will be heard when the housing

is fully engaged.

B. High Density Applications

This application does not require the housing to be placed onto

the connector body. The high density coupling is used without

the sliding housing.

2. CONNECTOR COUPLING CLEANING

Only one connection should be made at a time and the dust caps

should not be removed until immediately prior to mating.

A. Clean the ceramic ferrule of the connector with an isopropyl

alcohol dampened lint-free cloth (Fig. I2) and immediately blow

with compressed air.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

B. Insert an isopropyl alcohol dampened pipe cleaner into the

coupling to remove any foreign particles (Fig. I3). Blow with

compressed air.

3. SC CONNECTOR - STANDARD DENSITY MATING

Fig. I1

Fig. I2

Fig. I3

Installation

A. Hold the connector by the housing. Align the key on the

connector housing with the slot of the coupling (Fig. I4) and

push into place with a positive click. (The white line or slot in

the housing will not be visible when fully latched).

B. Uncap, clean and install the second connector as described

above.

Removal

A. To release the connector from the coupling, pull back on the

connector housing.

B. Cover connector and coupling ends with dust caps when not

being used.

22

Fig. I4

Page 23

SECTION I

Connector Assembly and Installation

4. SC CONNECTOR - HIGH DENSITY MATING

Installation

A. Clean the connector and coupling as described above.

B. Hold the connector by the boot.

C.Align the connector chamfers with the coupling (Fig. I5) and

push into place.

Removal

Note: This connector requires a tool to remove it from a

coupling.

A. Depress the buttons on the tool to raise pulling fingers.

B. Position tool prongs over connector and insert into the

coupling.

C.Release the buttons on the tool to engage the fingers and pull

firmly back to release the connector.

Fig. I5

Fig. I6

5. FC/PC3 CONNECTOR - MATING

Installation

A. Clean the connector and coupling as described above.

B. Engage the key in the slot while holding the connector by the

boot (Fig. I6). Make sure that the key remains engaged while

tightening the threaded nut.

Removal

A. To release the connector from the coupling, unscrew the

connector and cover all parts with dust caps.

23

Page 24

SECTION J

3M brand SC and FC/PC3 Epoxy Field Termination Kits

DESCRIPTION QTY PRODUCT #

3M brand SC and FC/PC3 Epoxy Field Termination Kit (110V) 1 8350

3M brand SC and FC/PC3 Epoxy Field Termination Kit (220V) 1 8351

KIT COMPONENTS QTY PART #

Scissors 1 80-6104-4754-4

Cable Stripper 1 80-6104-4314-7

Modified No-Nik Stripper (175 m) 1 80-6104-5332-8

Scribe - blade 1 80-6106-2590-9

Fiber View Scope with Adapter 1 80-6104-4344-4

Lint Free Cloths (Pkg.) 1 80-6104-4324-6

Ferrule Connector Polishing Jig 2 78-8073-7527-0

Alcohol Bottle 1 80-6104-4329-5

Water Bottle 1 80-6104-5334-4

Pipe Cleaners (Pkg.) 1 80-6104-4349-3

Jewelers Loupe (7X) 1 80-6104-4353-5

Pocket Ruler 1 80-6104-5337-7

Crimp Tool 1 78-8073-8169-0

Stripping Collar SC and FC/PC3 4 78-8073-8168-2

Manual 1 34-7033-9144-0

Dispensing Tips 25 78-8073-7596-5

Syringes 25 80-6104-4347-7

Curing Stand 1 80-6104-4334-5

Polishing Pad 1 80-6104-5375-7

5um Acetate (Pkg.) 1 80-6104-4346-9

1um Acetate (Pkg.) 1 80-6104-4323-8

1.5um Diamond Acetate (Pkg.) 1 78-8073-8167-4

SM Final Polish Acetate (Pkg.) 1 78-8073-8166-6

Cleaning Wires 12/vial 1 80-6104-4345-1

Epoxy (8692) 10 80-6107-7202-4

SC and FC/PC3 Load Adapters 6 78-8073-8165-8

Curing Oven, 110V (8350 Kit) 1 80-6104-4351-9

Curing Oven, 220V (8351 Kit) 1 80-6104-4354-3

Pin Gauge, Jig 1 78-8073-7965-2

Alignment clips (pkg) 1 78-8073-8179-9

"Kevlar" is a trademark of DuPont Co. "ST" is a trademark of AT&T.

Important Notice

All statements, technical information and recommendations related to the Seller's products are based on information believed

to be reliable, but the accuracy or completeness thereof is not guaranteed. Before utilizing the product, the user should

determine the suitability of the product for its intended use. The user assumes all risks and liability whatsoever in connection

with such use.

Any statements or recommendations of the Seller which are not contained in the Seller's current publications shall have no

force or effect unless contained in an agreement signed by an authorized officer of the Seller. The statements contained

herein are made in lieu of all warranties, express or implied, including but not limited to the implied warranties of

merchantability and fitness for a particular purpose which warranties are hereby expressly disclaimed.

SELLER SHALL NOT BE LIABLE TO THE USER OR ANY OTHER PERSON UNDER ANY LEGAL THEORY, INCLUDING

BUT NOT LIMITED TO NEGLIGENCE OR STRICT LIABILITY, FOR ANY INJURY OR FOR ANY DIRECT OR

CONSEQUENTIAL DAMAGES SUSTAINED OR INCURRED BY REASON OF THE USE OF ANY OF THE SELLER'S

PRODUCTS THAT WERE DEFECTIVE.

34-7033-9144-0

© 1993 3M

Litho in U.S.A.

3M Telecom Systems Group

6801 River Place Blvd.

Austin, TX 78726-9000

800/426-8688

Loading...

Loading...