Page 1

3M™ 4-Wall, Tripolarized Header

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

• Tripolarization to mating socket

•50 mil × 100 mil halves the connector length

• Latch and eject for rugged high performance

applications

• Available for thru hole or surface mount

attachment

• High temperature plastic

• Four-wall shroud provides contact protection

• Contacts: 20, 26, 36, 40, 50, 60, 68, 80 and 100

• RoHS* compliant version available (RB plating

suffix)

Physical

Electrical

Insulation

Material:

Flammability:

Color:

Contact

Material:

Plating

Underplating:

Wiping Area:

Solder Tails:

Terminal Finish Indicator:

Marking:

Current Rating:

Insulation Resistance:

Withstanding Voltage:

Date Modified: September 2, 2005

High Temperature Plastic (LCP)

UL 94V-0

Black (RoHS compliant) or Natural

Copper Alloy

100 µ″ [ 2.54 µm ] Nickel

30 µ″ [ 0.76 µm ] Gold

300 µ″ [7.6 µm ] Matte Tin (RoHS compliant) or Tin-Lead (see

ordering information)

e3 (ref JESD97)

3M Logo, Part Number and Orientation Triangle

0.5 A

> 1 × 109 Ω at 500 Vdc

500 Vrms at Sea Level

TS-0253-29

Sheet 1 of 7

Environmental

Temperature Rating:

Process Rating:

Moisture Sensitivity Level:

"RoHS compliant" means that the product or part does not contain any of the following substances in excess of the following maximum concentration values

in any homogeneous material, unless the substance is in an application that is exempt under RoHS: (a) 0.1% (by weight) for lead, mercury, hexavalent

chromium, polybrominated biphenyls or prolybromianted diphenyl ethers; or (b) 0.01% (by weight) for cadmium. Unless otherwise stated by 3M in writing,

UL File No.: E68080

3M

Interconnect Solutions

http://www.3M.com/interconnects/

* RoHS = Directive 2002/95/EC, Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment

-55°C to +105°C

Maximum

260°C (per J-STD-020C)

1 (per J-STD-020C)

this information represents 3M's knowledge and belief based upon information provided by third party suppliers to 3M.

3M is a trademark of 3M Company.

For technical, sales or ordering information call

800-225-5373

Page 2

3M™ 4-Wall, Tripolarized Header

y

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

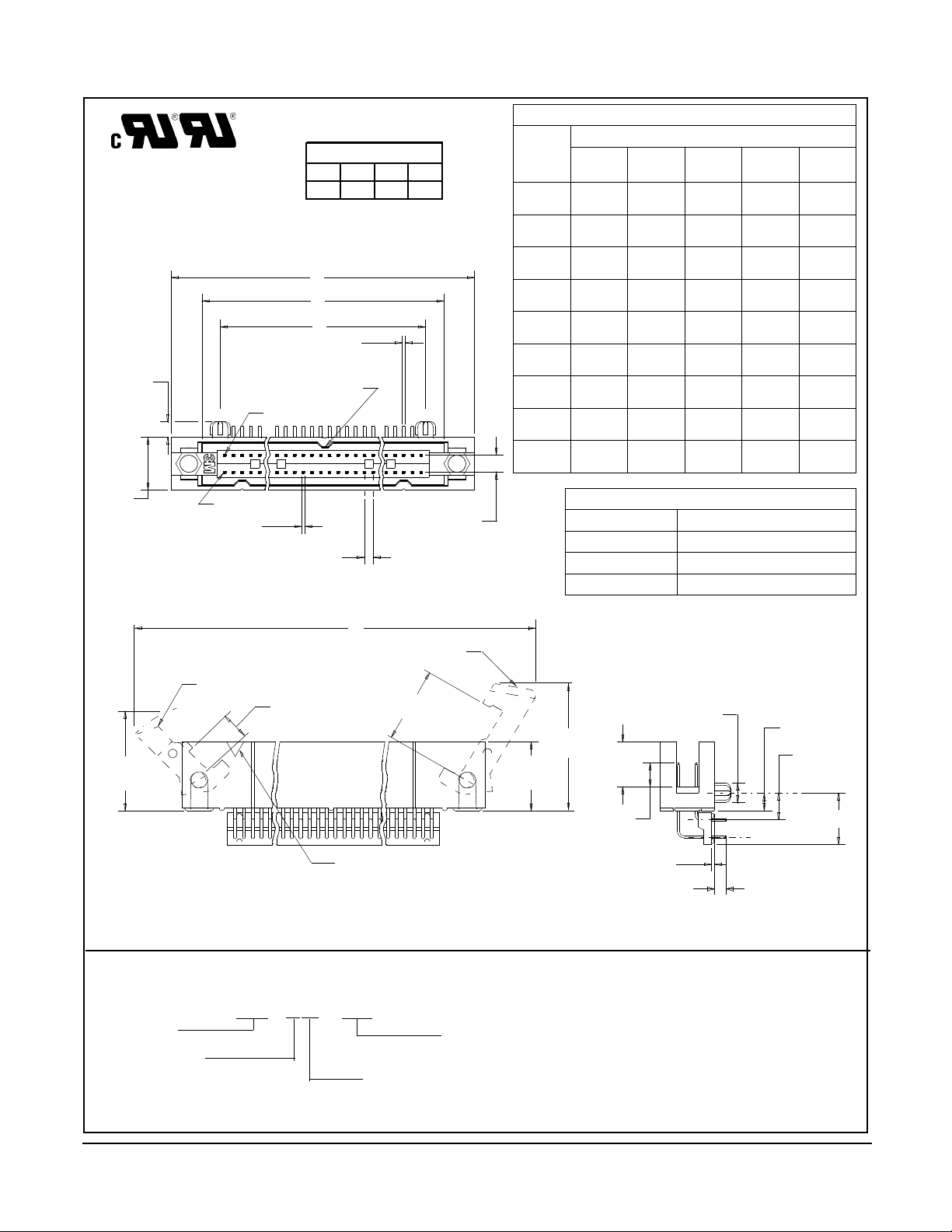

2X .092

[2.34]

.310

[7.87]

Position 1

.015 X .015

[0.38] X [0.38]

Tolerance Unless Noted

inch ±.1 ±.01 ±.005

[ ] Dimensions for Reference

A

B

C

.015 X .015

[0.38] X [0.38]

See Note 1

Position 2

.050 Typ

[1.27]

Inc h

[m m ]

.0 .00 .000

Onl

.100 Ref

[2.54]

Contact

Qty

020 1.060

026 1.210

036 1.460

040 1.560

050 1.810

060 2.060

068 2.260

080 2.560

100 3.060

[26.92]

[30.73]

[37.08]

[39.62]

[45.97]

[52.32]

[57.40]

[65.02]

[77.72]

PCB Thickness “F” Solder Tail Length ± .010

Table 1

Dimensions

A B C D Short

Ref

.722

[18.34]

.872

[22.15]

1.122

[28.50]

1.222

[31.04]

1.472

[37.39]

1.722

[43.74]

1.922

[48.82]

2.222

[56.44]

2.722

[69.14]

.500

[12.70]

.850

[16.51]

.900

[22.86]

1.000

[25.40]

1.250

[31.75]

1.500

[38.10]

1.700

[43.18]

2.000

[50.80]

2.500

[63.50]

1.671

[42.44]

1.817

[46.15]

2.070

[52.58]

2.170

[55.12]

2.421

[61.49]

2.671

[67.84]

2.870

[72.90]

3.178

[80.72]

3.676

[93.37]

Table 2

.062 [15.7] .090 [2.29]

.094 [2.39] .112 [2.79]

.125 [3.18] .143 [3.63]

D Long

Ref

1.842

[46.77]

1.987

[50.47]

2.274

[57.76]

2.365

[60.07]

2.609

[66.27]

2.872

[72.95]

3.083

[78.31]

3.370

[85.60]

3.875

[98.43]

D

Long Latch

Short Latch

.165 ± .010

[ 4.19 ]

.620 Ref

[ 15.75 ]

Notes:

1. This polarization bump does not exist on the 20 position header.

2. Recommended to be mated to the .050″ X .100″ Wiremount Socket 82XXX Series.

.440 ± .010

[11.18]

Position 1

Orientation Triangle

Ordering Information

81XXX-5X0X03-XX

Contact Quantity

(See Table 1)

Ejector/Latch System:

0 = None

5 = With Short Ejectors Installed

6= With Long Ejector Latches Installed

Contact Tail:

2 = Solder Tail for .062 [ 1.57 ] PC Board

3 = Solder Tail for .094 [ 2.39 ] PC Board

4 = Solder Tail for .125 [ .318 ] PC Board

Plating suffix:

blank = tin lead tails

RB = matte tin tails

(RoHS compliant)

.405

[10.29]

.828 Ref

[ 21.03 ]

.265

[6.73]

.140 ± .010

[3.56]

“F” (See Table 2)

.015

[0.38]

2X Ø.116

[2.95]

Ejector Latch

Long

3505-28 (natural)

3505-28B (black)

Short

3505-29 (natural)

3505-29B (black)

.105

[2.67]

.160 Ref

[4.06]

.306 Ref

[7.77]

TS-0253-29

Sheet 2 of 7

3M

Interconnect Solutions

http://www.3M.com/interconnects/

3M is a trademark of 3M Company.

For technical, sales or ordering information call

800-225-5373

Page 3

3M™ 4-Wall, Tripolarized Header

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

Ø.024 ± .003 Typ

[0.64]

.100 ± .002

[2.54]

.025 - .035

[0.64] - [0.89]

*Solder Thief Solder Pads required only on Solder side of PC Board.

.050 ± .002

[1.27]

.045 - .060

[1.14] - [1.52]

*Solder Thief Solder Pads

(See Note 2)

View A

E

.025 ± .002

[0.64]

Table 3

Ejector Latches Dimension E Min

None .575 [14.61]

Long 1.010 [25.65]

Short .885 [22.48]

C ± .002

2X Ø .109 ± .002

[2.77]

.050 ± .002 Typ

[1.27]

Tolerance Noncumulative

Position 2

Flow Solder

Direction

Position 1

Ø.024 ± .003 Typ

[0.64]

Recommended Mounting Hole Pattern

(Shown for mounting side of PC Board)

View A

.100 ± .002

[2.54]

.160 ± .002

[4.06]

.355 Max

[9.02]

.305 Min

[7.75]

Notes:

1. Recommended to process PC Boards through the solder bath such that the connector enters end first (two solder tails at a time).

This will help prevent solder bridging.

2. A Dummy or Solder Thief Solder Pad at the end of each row is recommended on the bottom or solder side of the PC.

Board in order to help prevent solder bridging on the end solder tails. The solder thiefs are only required on the end of the

rows which leave the solder bath last.

3. In order to facilitate flow soldering. It is recommended that ejector latches be installed after the soldering process.

3M

Interconnect Solutions

For technical, sales or ordering information call

3M is a trademark of 3M Company.

http://www.3M.com/interconnects/

TS-0253-29

Sheet 3 of 7

800-225-5373

Page 4

3M™ 4-Wall, Tripolarized Header

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

Table 1

Contact

Qty

A B C Short Ref C Long Ref D

020 1.060 [26.92] .722 [18.34] 1.671 [42.44] 1.842 [46.77] .860 [21.84]

026 1.210 [30.73] .872 [22.15] 1.817 [46.15] 1.987 [50.47] 1.010 [25.65]

036 1.460 [37.08] 1.122 [28.50] 2.070 [52.58] 2.274 [57.76] 1.260 [32.00]

040 1.560 [39.62] 1.222 [31.04] 2.170 [55.12] 2.365 [60.07] 1.360 [34.54]

050 1.810 [45.97] 1.472 [37.39] 2.421 [61.49] 2.609 [66.27] 1.610 [40.89]

060 2.060 [52.32] 1.722 [43.74] 2.671 [67.84] 2.872 [72.95] 1.860 [47.24]

068 2.260 [57.40] 1.922 [48.82] 2.870 [72.90] 3.083 [78.31] 2.060 [52.32]

080 2.560 [65.02] 2.222 [56.44] 3.178 [80.72] 3.370 [85.60] 2.360 [59.94]

100 3.060 [77.72] 2.722 [69.14] 3.676 [93.37] 3.875 [98.43] 2.860 [72.64]

.310

[7.87]

Position 2

Dimensions

A

B

See Note 1

Table 2

PCB Thickness "F" Solder Tail Length ± .010

.062 [15.7] .090 [2.29]

.094 [2.39] .112 [2.79]

.125 [3.18] .143 [3.63]

Position 1

.015 X .015

[ 0.38 ] X [ 0.38 ]

Ordering Information

Contact Quantity

(See Table 1)

Ejector/Latch System:

0 = None

5 = With Short Ejectors Installed

6 = With Long Ejector latches Installed

.100 Ref

[2.54]

.050 Typ

[1.27]

Header

81XXX-6X0X0X-XX

Board Mounting Options:

1 = None

3 = Press fit posts both ends

Contact Tail: (See Table 2)

2 = Solder Tail for .062 [ 1.57 ] PC Board

3 = Solder Tail for .094 [ 2.39 ] PC Board

4 = Solder Tail for .125 [ .318 ] PC Board

“F”

(See Table 2)

.100

[2.54]

Notes:

1. This polarization bump does not exist

on the 20 position header.

2. Recommended to be mated to the

.050″ x .100″ 82XXX Series Socket.

Ejector Latch

Long

3505-28 (natural)

3505-28B (black)

Plating suffix:

blank = tin lead tails

RB = matte tin tails

(RoHS compliant)

Short

3505-29 (natural)

3505-29B (black)

.265 [6.73]

.140 ±

.010

TS-0253-29

Sheet 4 of 7

3M

Interconnect Solutions

http://www.3M.com/interconnects/

3M is a trademark of 3M Company.

For technical, sales or ordering information call

800-225-5373

Page 5

3M™ 4-Wall, Tripolarized Header

y

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

.100 ± .002

[2.54]

∅.025 ± .003

[0.64]

.025 - .035

[0.64] - [0.89]

*Solder Thief Solder Pads required only on

Solder side of PC Board.

.050 ± .002

[1.27]

.045 - .060

[1.14] - [1.52]

View A

E

2X .205 ± .003

[5.21]

.050 ± .002 Typ

[1.27]

Tolerance Noncumulative

*Solder Thief

Solder Pads

(See Note2)

D ± .002

Flow Solder

Direction

Table 3

Ejector/Latches Dimension E (Min)

None .215 [ 5.46 ]

Long .650 [16.51]

Short .525 [13.34]

.160 Min

[4.06]

.050 ± .003

[1.27]

.100 ± .002

[2.54]

VIEW A

View A

.100 ± .002

2X ∅ .109 ± .002

[2.77]

∅.025 ± .003 Typ

[0.64]

[2.54]

Recommended Mounting Hole Pattern

(Shown for mounting side of PC Board)

Notes:

1. Recommended to process PC Boards through the solder bath such that the connector enters end first (two solder tails at a time).

This will help prevent solder bridging.

.225 Min

[5.72]

Inc h

[mm]

Tolerance Unless Noted

.0 .00 .00 0

inc h ±.1 ±.01 ±.005

[ ] Dim e nsions for R efere nce

Onl

2. A Solder Thief Solder Pad (Dummy Pad) at the end of each row is recommended on the bottom or solder side of the PC

Board in order to help prevent solder bridging on the end solder tails. The Solder Thiefs are only required on the end of the

rows which leave the solder bath last.

3M

Interconnect Solutions

For technical, sales or ordering information call

3M is a trademark of 3M Company.

http://www.3M.com/interconnects/

TS-0253-29

Sheet 5 of 7

800-225-5373

Page 6

3M™ 4-Wall, Tripolarized Header

y

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

Table 1

.310

[7.87]

Position 1

.100 Ref

[2.54]

Position 2

See Note 1

[0.38] X [0.38]

.015 X ..015

Contact

Qty

A

020 1.060

B

026 1.210

036 1.460

040 1.560

050 1.810

060 2.060

068 2.260

.050 Typ

[1.27]

080 2.560

100 3.060

A B D Short

[26.92]

[30.73]

[37.08]

[39.62]

[45.97]

[52.32]

[57.40]

[65.02]

[77.72]

[18.34]

[22.15]

[28.50]

[31.04]

[37.39]

[43.74]

[48.82]

[56.44]

[69.14]

.722

.872

1.122

1.222

1.472

1.722

1.922

2.222

2.722

Dimensions

Ref

1.671

[42.44]

1.817

[46.15]

2.070

[52.58]

2.170

[55.12]

2.421

[61.49]

2.671

[67.84]

2.870

[72.90]

3.178

[80.72]

3.676

[93.37]

D Long

Ref

1.842

[46.77]

1.987

[50.47]

2.274

[57.76]

2.365

[60.07]

2.609

[66.27]

2.872

[72.95]

3.083

[78.31]

3.370

[85.60]

3.875

[98.43]

tape &

suffix reel

WD

WE

WF

WG

WH

Short Latch

Position 1

Orientation

Triangle

.620 Ref

[15.75]

.092

[2.34]

Notes:

1. This polarization bump does not exist on the 20 position header.

2. Recommended to be mated to the .050″ X .100″ 82XXX Series Wiremount Socket.

Optional Single Press

Fit Post Mount/Alignment

Feature

∅.116

[2.95]

Ordering Information

D

.165 ± .010

[4.19]

.440 ± .010

[11.18]

Header

Long Latch

Optional Metal

Clip Retention

81XXX-6X0C0X-XX-XX

Contact Quantity

(See Table 1)

Ejector/Latch System:

0 = None

5 = With Short Ejectors Installed

6 = With Long Ejector Latches Installed

Board Mounting Options:

1 = None

4 = Press Fit Post Mount at Position 1 end

7 = Metal retention clips

8 = #1 end press fit post & metal retention clips

.015

[0.38]

.080

[2.03]

Packaging Options:

Blank = Trays

WX = Tape & Reel Package

(see table)

Plating suffix:

blank = tin lead tails

RB = matte tin tails

(RoHS compliant)

.405

[10.29]

.828 Ref

[21.03]

.346 ± .010

[8.79]

.140 ± .010

[3.56]

.265

[6.73]

To lera nce Unless N ote d

[ ] Dimensions for Reference

Inch

[mm]

.0 .00 .0 0 0

inch ±.1 ±.01 ±.005

Onl

Ejector Latch

Long

3505-28 (natural)

3505-28B (black)

Short

3505-29 (natural)

3505-29B (black)

TS-0253-98

Sheet 6 of 7

3M

Interconnect Solutions

http://www.3M.com/interconnects/

3M is a trademark of 3M Company.

For technical, sales or ordering information call

800-225-5373

Page 7

3M™ 4-Wall, Tripolarized Header

.050″ × .100″ Latch/Ejector, PTH & SMT Straight, PTH Right Angle 810 Series

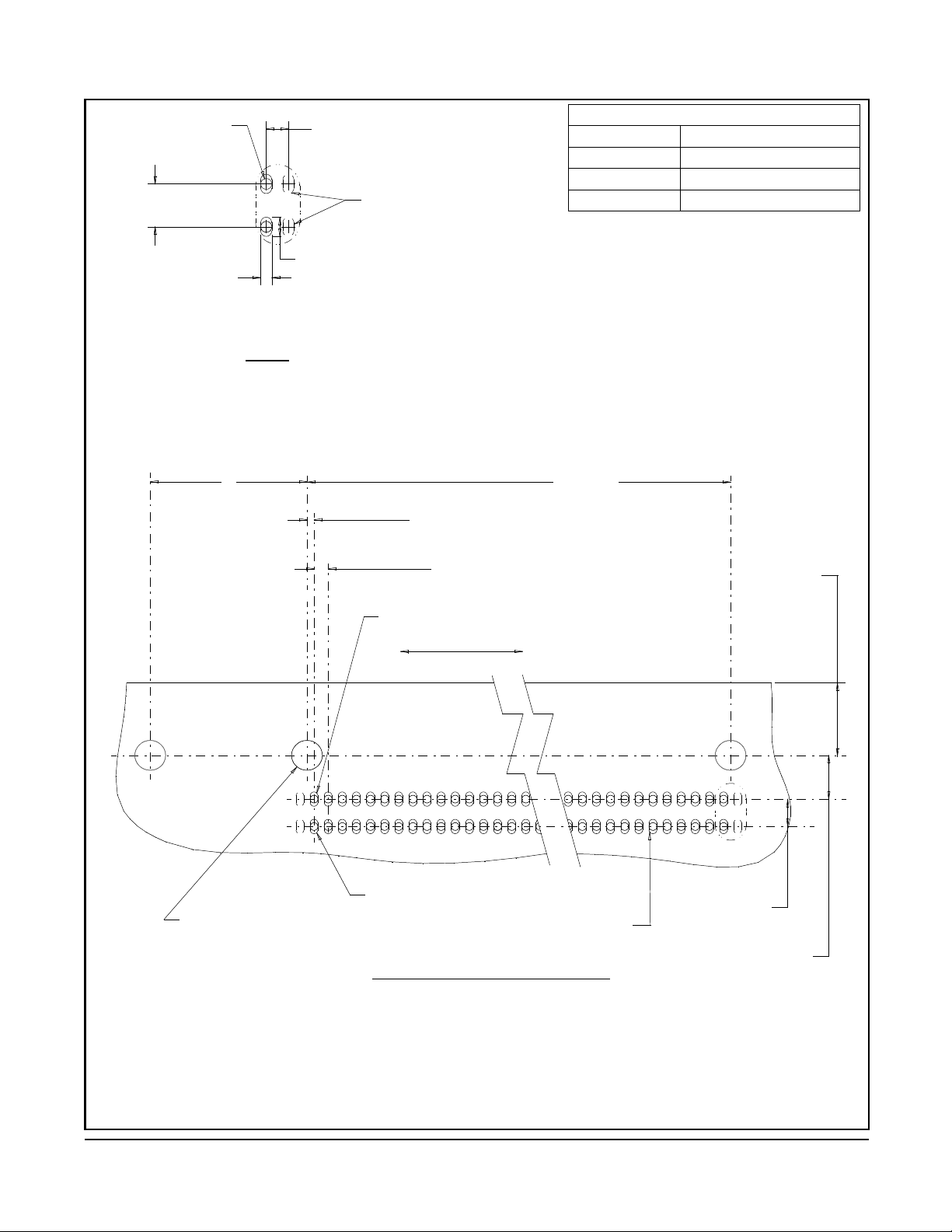

Ejector Latches Dimensions

H Min

No .775 [19.69]

Short 1.085 [27.56]

Long 1.21 [30.73]

No. of Positions Dimensions

F G

∅ .042 ± .003 Typ (Plated thru hole)

[1.07]

Typ, Full R

Detail A

Optional plated thru hole

for metal clip retention

∅.065 ± .002 Typ

[1.65]

20 .450 [11.43] N/A

26 .600 [15.24] N/A

36 .850 [21.59] N/A

40 .950 [24.13] N/A

50 1.200 [30.48] .025 [6.35]

60 1.450 [36.83] 0.000

68 1.650 [41.91] 0.000

80 1.950 [49.53] 0.000

100 2.450 [62.23] 0.000

.158 ± .002

[3.96]

.220 ± .003

[5.59]

Optional Drilled Hole

for Plastic Post

∅.109 ± .002

[2.77]

See Detail A

.110 ± .002

[2.79]

Position 2

.205 ± .003

[5.21]

C

L

F

C

L

.050 ± .002 Typ

[1.27]

Tolerance Noncumulative

.029 ± .001

[0.74]

Position 1

H

.280

[7.11]

C

L

G

C

L

2X .075 ± .002

[1.09]

.376

[9.55]

Recommended Mounting Hole Pattern

(Shown for mounting side of PC Board)

3M

Interconnect Solutions

http://www.3M.com/interconnects/

TS-0253-29

Sheet 7 of 7

3M is a trademark of 3M Company.

For technical, sales or ordering information call

800-225-5373

Page 8

Important Notice

All statements, technical information, and recommendations

related to 3M’s products are based on information believed to be

reliable, but the accuracy or completeness is not guaranteed.

Before using this product, you must evaluate it and determine if it

is suitable for your intended application. You assume all risks and

liability associated with such use. Any statements related to the

product which are not contained in 3M’s current publications, or

any contrary statements contained on your purchase order shall

have no force or effect unless expressly agreed upon, in writing,

by an authorized officer of 3M.

3

Electronics

6801 River Place Blvd.

Austin, TX 78726-9000

800/328-1368

www.3M.com/electronics

Warranty; Limited Remedy; Limited Liability.

This product will be free from defects in material and manufacture

for a period of 90 days from the time of purchase. 3M MAKES

NO OTHER WARRANTIES INCLUDING, BUT NOT LIMITED

TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. If this product is

defective within the warranty period stated above, your exclusive

remedy shall be, at 3M’s option, to replace or repair the 3M

product or refund the purchase price of the 3M product.

where prohibited by law, 3M will not be liable for any indirect,

special, incidental or consequential loss or damage arising

from this 3M product, regardless of the legal theory asserted.

Minimum 10%

Post-Consumer Fiber

Printed in USA.

© 3M 2005

Except

Loading...

Loading...