Page 1

PathBuilder

¨

WAN Access Switch Reference Guide

Release 2.02

®

S600

http://www.3com.com/

Part No.3C63917

010-11582-3005

Published July 1998

Page 2

©

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

3Com Corporation, 1998. All rights reserved. No part of this documentation may be reproduced in any

form or by any means or used to make any derivative work (such as translation, transformation, or

adaptation) without permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from

time to time without obligation on the part of 3Com Corporation to provide notification of such revision or

change.

3Com Corporation provides this documentation without warranty of any kind, either implied or expressed,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

3Com may make improvements or changes in the product(s) and/or the program(s) described in this

documentation at any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described herein

are provided to you subject to the following restricted rights:

For units of the Department of Defense:

Restricted Rights Legend: Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c) (1) (ii) for Restricted Rights in Technical Data and Computer Software Clause at 48

C.F.R. 52.227-7013. 3Com Corporation, 5400 Bayfront Plaza, Santa Clara, California 95052-8145.

For civilian agencies:

Restricted Rights Legend: Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph

(a) through (d) of the Commercial Computer Software - Restricted Rights Clause at 48 C.F.R. 52.227-19 and

the limitations set forth in 3Com Corporation’s standard commercial agreement for the software.

Unpublished rights reserved under the copyright laws of the United States.

If there is any software on removable media described in this documentation, it is furnished under a license

agreement included with the product as a separate document, in the hard copy documentation, or on the

removable media in a directory file named LICENSE.TXT. If you are unable to locate a copy, please contact

3Com and a copy will be provided to you.

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com and PathBuilder are trademarks of 3Com Corporation.

Other brand and product names may be registered trademarks or trademarks of their respective holders.

Page 3

C

ONTENTS

W

ARNING

Servicing ix

Rack Mounting ix

Power and Power Cords ix

EMI x

Safety Classification of Ports for Connection to Telecommunications Networks x

S

UPPLEMENTARY

Host Chassis/Module Compatibility and Creepage/Clearance Requirements xi

FCC Part 68 Statement xii

CE Notice xiii

BOUT

A

Introduction 15

How to Use This Guide 15

Conventions 16

Related Documentation 17

S

YSTEM

1

ATM Overview 19

Virtual Circuits 19

PathBuilder S600 with STX Overview 20

PathBuilder S600 STX Architecture 20

Key Features of the STX Module 21

Specifications 22

Options and Parts List 26

I

NFORMATION

THIS

G

D

ESCRIPTION

R

EGULATORY

UIDE

I

NFORMATION

2

I

NSTALLATION

Receiving and Inspecting the PathBuilder S600 29

Installation Overview 29

Step 1: Install the Shelf in the Rack 30

Step 2: Connect AC or DC Power 31

Step 3: (If needed) Install Additional Modules in the Shelf 32

Step 4: Connect I/O Cabling and Wiring 33

Site Requirements 30

Normal Start up Sequence 34

Page 4

Connecting a DS3 UNI Module 34

Connecting an E3 UNI Module 36

Connecting an OC3/STM-1 UNI Trunk/Port Module 37

Connecting a DS1/E1 UNI with IMA Module 37

Connecting an Ethernet Module 39

Connecting a CBR DSX or CBR E1 Port Module 41

Connecting a QSIM V.35/RS422/EIA530 Port Module 42

Connecting a HSIM Module 53

Connecting a DS1 Frame Access Module 53

Verifying CPU LEDs and Connecting the Office Alarm Connector 54

Connecting the Office Alarm Connector 55

Verifying STX LEDs and Connecting the Optional BITS Clock 56

Connecting the Optional BITS Clock (STX) 56

Step 5: Connect a Management Terminal 58

3

4

ETTING

G

Logging On 59

Using the Menus 61

Navigating through the Menus 61

Understanding the Menu Hierarchy 61

Using the Menus to Change Settings 62

Alarm Indicator 62

Performing Initial Configuration 63

Setting up Communication Parameters 63

Configuring In-band Management 70

Setting up a Password 72

Setting the Time and Date 73

P

ATH

System Module Overview 75

Management CPU Module 75

STX Module 76

ATM Module Overview 77

DS3 UNI Module Overview 78

E3 UNI Module Overview 78

OC3/STM-1 Module Overview 78

DS1/E1 Module Overview 78

Application Module Overview 78

Ethernet Module Overview 79

TARTED

S

Configuring the Local Host IP Address 65

Configuring Trap Clients 68

Configuring the Default Gateway 69

In-band Management via the 10Base-T Port on the Near-end MCPU Card 70

In-band Management via the Near-end Dual Ethernet Module 71

B

UILDER

SNMP MIB Standards Support 76

Priority Queuing 77

S600 M

ODULE

AND

A

PPLICATION

O

VERVIEW

Page 5

Ethernet Module Standards Support 79

Ethernet Module Operation 79

CBR DSX/E1 Module Overview 80

CBR DSX Module 80

CBR E1 Module 81

QSIM/HSIM/FAM Module Overview 82

Application Overview 83

Bridging 83

Filtering 84

Addressing 84

Virtual Circuits 84

Learning Bridge 85

Segmentation 86

Reassembly 87

Spanning Tree 87

Spanning Tree Operation 87

Spanning Tree Instances 88

CBR Application 88

Structured DS1 89

Dynamic Bandwidth Allocation (DS0 Signaling) 90

Unstructured DS1 91

Structured versus Unstructured Summary 93

Ethernet and Voice Application 93

Frame Application 96

DXI Mode 1A 97

Frame Relay Interworking Functions 100

HDLC/SDLC 101

ONFIGURING

C

5

PPLICATIONS

A

Viewing and Configuring System Information 103

Specifying General System Information 104

Managing the System Clock 105

Alarm Conditions that Cause Clock Source Failure 108

Viewing and Configuring RS-232 Parameters 108

Viewing the Firmware Version 110

Downloading New Firmware 110

Resetting the Interface Card 111

Viewing an Equipment List 111

Backing up and Restoring the Database and Code Image 112

Backing up the Database 112

Restoring the Database 112

Backing up the Code Image 113

Restoring the Code Image 113

PathBuilder S600 Configuration Overview 114

Configuring the PathBuilder S600 Shelf and the Application Modules 115

Setting Application Module Status 116

P

ATH

UILDER

B

S600 M

ODULES

, P

ORTS

AND

,

Page 6

Configuring the Shelf 116

Configuring the Management CPU 117

Viewing MCPU Configuration Information 118

Configuring Virtual Interfaces 118

Adding Virtual Interfaces 118

Viewing and/or Modifying Existing Virtual Interfaces 119

Deleting Virtual Interfaces 120

Configuring Input Shapers 121

Configuring the STX Module 122

Configuring the OC3/STM-1 UNI Module 123

Configuring the DS3 UNI Module 125

Configuring the E3 UNI Module 127

Configuring the DS1 (or E1) UNI with IMA Modules 128

Configuring the DS1/E1 UNI Ports 128

Activation/Deactivation Bit Error Rates 131

Configuring UNI and IMA Groups 132

Adding UNI Groups 132

Adding IMA Groups 134

Viewing and Modifying IMA and UNI Groups 135

Configuring Virtual Interfaces for IMA Groups 137

Deleting IMA and UNI Groups 137

Viewing IMA Link Status 137

Viewing IMA Group Status 140

Configuring the DS1 (or E1) UNI Card 142

Configuring the Ethernet Module 143

Configuring Ethernet Ports, Cards, Shapers and Virtual Interfaces 143

Configuring the Bridge 145

Configuring Source Protocol Filtering 147

Configuring Source Address Filtering 149

Configuring Destination Address Filtering 151

Viewing the List Forwarding Table 152

Constructing the Bridge Static Table 153

Enabling and Disabling the Spanning Tree 154

Configuring IP Over ATM 154

Configuring the CBR DSX (or E1) Modules 158

Configuring the QSIM/HSIM/FAM Modules 163

Configuring the QSIM/HSIM/FAM Ports 163

QSIM/HSIM/FAM Performance at Small Frame Sizes 165

Configuring the QSIM/HSIM/FAM Local Management Interface 167

Configuring the QSIM/HSIM/FAM Card 169

Configuring Virtual Circuits 170

Summary of Supported VPI/VCI Ranges and Number of Connections 171

Adding Virtual Circuits 172

Virtual Circuit Parameters 176

ATM Module Virtual Circuit Parameters 176

Ethernet Card Virtual Circuit Configuration Parameters 177

CBR Card Virtual Circuit Configuration Parameters 177

QSIM/HSIM/FAM Card Virtual Circuit Configuration Parameters 178

Page 7

Viewing Existing Virtual Circuits 182

Modifying a Virtual Circuit 185

Deleting a Virtual Circuit 186

Viewing Virtual Circuit Statistics 186

P

B

ATH

6

Managing System Alarms 187

Using Loopbacks 195

Viewing Statistics 200

UILDER

Viewing and Clearing Current Alarms 188

PathBuilder S600 Alarm Messages (STX) 189

Working with History Alarms 194

Viewing and Printing History Alarms 194

Clearing History Alarms 195

DS3 Loopbacks 196

E3 Loopbacks 197

OC3/STM-1 Loopbacks 198

CBR DSX Module Loopbacks 198

FAM Loopbacks 199

DS1/E1 UNI with IMA loopback 200

Card Statistics Overview 200

Performance Statistics Overview 200

ATM Statistics Overview 201

Virtual Circuit Statistics Overview 201

Viewing Card Statistics 202

Viewing DS3 Statistics 203

Viewing E3 Statistics 204

Viewing OC3/STM-1 Statistics 205

Viewing DS1 UNI and E1 UNI Statistics 207

Viewing Ethernet Statistics 209

Viewing CBR Statistics 212

Viewing QSIM/HSIM/FAM Statistics 213

Viewing Virtual Circuit Statistics 215

Viewing Virtual Circuit Statistics by Circuit 215

Conforming/Non-Conforming Cell Counters 217

Viewing Virtual Circuit Statistics by Port/Group 218

S600 D

IAGNOSTICS

AND

P

ERFORMANCE

M

ONITORING

A

T

Online Technical Services 221

Support from Your Network Supplier 222

Support from 3Com 223

Returning Products for Repair 224

ECHNICAL

World Wide Web Site 221

3Com FTP Site 221

3Com Bulletin Board Service 222

Access by Analog Modem 222

Access by Digital Modem 222

3ComFacts Automated Fax Service 222

UPPORT

S

Page 8

NDEX

I

OM

3C

ORPORATION

C

IMITED

L

ARRANTY

W

Page 9

1

2

3

4

W

ARNING

This section contains warning information for AC powered systems.

I

NFORMATION

Servicing

Rack Mounting

Service of this unit is to be performed by qualified service personnel only.

Service of certain components and subassemblies in this equipment is

accomplished by the replacement of Field Replaceable Units (FRUs). However,

safety agency approval requires that the servicing of other subassemblies within

this product be referred to 3Com’s service personnel.

The trim enclosure and other mechanically secured plates serve as protection

barriers from potential hazardous internal areas. No attempt should be made to

troubleshoot internal components with these protective barriers removed

without first disconnecting the equipment from main power.

This equipment is for use only in complete equipment where the acceptability of

the combination is determined by the applicable safety agency in the country in

which it is installed. This includes UL in the U.S.A., CSA in Canada, and TUV in

Europe.

Conditions of Acceptability: When installed in the end-use equipment, the

following are among the considerations to be made.

The units shall be installed in compliance with enclosure, mounting, spacing,

casualty, and segregation requirements of the ultimate application.

These units have been judged on the basis of the required spacings of UL 1950

D3 deviations edition, CSA 22.2 No. 950-M89, and EN 60950 1988 through

TUV Rheinland, which would cover these components if submitted for

unrestricted listing or certification.

Complete testing should be performed in the end-use product.

Rack configurations with certain combinations of 3Com equipment installed in

racks with a height greater than 50” (127 cm) may require a counter-balance

weight, a stabilizer bar, or anti-tip legs to ensure rack stability in accordance

with safety agency regulations. See specific rack installation guidelines for 3Com

recommendations.

Power and Power

Cords

This equipment is not intended for use with IT power distribution systems

whose line to line voltage exceeds 250 VAC RMS defined by EN 60950 as

having no direct connection to earth. The PathBuilder S600 WAN Access Switch

will autoconfigure for 115 VAC or 220-240 VAC.

Page 10

HAPTER

C

: W

ARNING

x

NFORMATION

I

NORTH AMERICAN APPLICATIONS: Use a UL Listed and CSA Certified Cord Set

rated 6 amps, consisting of a minimum 18 AWG, Type SVT or SJT three

conductor cord maximum of 15 feet in length, with a NEMA 5-15P plug.

INTERNATIONAL APPLICATIONS: The power supply cords used with this

equipment should be harmonized with all local standards applicable in the

country in which it is installed.

Safety agency compliance requires this unit to be connected to branch circuits

with overcurrent protection

£ 20A for North American applications and £ 10A

for international applications.

The power supply cord must be disconnected when servicing all components or

subsystems.

EMI

Safety Classification

of Ports for

Connection to

Telecommunications

Networks

FCC - This equipment generates, uses, and can radiate radio frequency energy,

and if not installed and used in accordance with the instruction manual, may

cause interference to radio communications. It has been tested and found to

comply with the limits for a Class A computing device pursuant with Part 15 of

the FCC Rules, which are designed to provide reasonable protection against

such interference when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference, in which case

the user at his own expense will be required to take whatever measures may be

required to correct the interference. These tests were conducted with shielded

communications cables with metal connector hoods; the use of unshielded

cables may void this compliance.

Canada - This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Europe - This is a Class A product. In a domestic environment this product may

cause radio interference, in which case, the user may be required to take

adequate measures.

The following port types in the product range are classified according to the

Harmonized Europeans Standard EN41003, subclause 4.1.3, as follows:

E1/E3 - TNV normally operating within SELV limits (TNV-1)

1

Telecommunications Network Voltage (EN60950, subclause 1.2.8.8)

2

Safety Extra-Low Voltage (EN60950, subclause 1.2.8.5)

Page 11

S

UPPLEMENTARY

I

NFORMATION

This section provides information about host chassis/module compatibility and

creepage/clearance requirements. It also describes the compliance of the

PathBuilder

®

S600 with FCC and CE regulations.

R

EGULATORY

Host Chassis/Module

Compatibility and

Creepage/Clearance

Requirements

The installer of the E1 CBR and E3 UNI Module must ensure that the host

chassis and module are compatible and that the host chassis is capable of

providing adequate power to the module and any other auxiliary host apparatus.

The E1 CBR Module has the following input power requirements:

+5 vdc @ 3.6 Amps

The E3 UNI Module has the following input power requirements:

+5 vdc @ 3.0 Amps

Please contact 3Com for an up-to-date list of compatible host chassis.

In order to maintain the independent approval of this card, it must be installed

in such a way that with the exception of the connections to the host, when

other option cards are introduced which use or generate a hazardous voltage,

the minimum creepages and clearances specified in the table below are

maintained. A hazardous voltage is one which exceeds 42.2V peak AC or 60V

DC.

Voltage Used or Generated by Host

Clearance (mm)

2.0 2.4 (3.8) Up to 59 V

2.6 3.0 (4.8) Up to 125 V

4.0 5.0 (8.0) Up to 250 V

4.0 6.4 (10.0) Up to 300 V

For a host or other expansion card fitted in the

host, using or generating voltages greater than

300V (rms or dc), advice from a competent

telecommunications safety engineer must be

obtained before installation of this card.

Creepage (mm)

or Other Cards

rms

rms

rms

rms

Above 300 V

rms

or V

or V

or V

or V

or V

dc

dc

dc

dc

dc

If you have any doubt, seek advice from a component engineer before installing

other adapters into the best equipment.

The larger distance shown in brackets applies where the local environment

within the host is subject to conductive pollution or dry non-conductive

pollution which could become conductive due to condensation. Failure to

maintain these minimum distances would invalidate the approval.

Page 12

xii CHAPTER : SUPPLEMENTARY REGULATORY INFORMATION

Clearance (distance X in the figure below) is defined as the shortest distance

between two conductive parts, or between the conductive part and the bonding

surface of the equipment, measured through air.

Creepage (distance Y in the figure below) is defined as the shortest path

between two conductive parts, or between the conductive part and the bonding

surface of the equipment, measured along the surface of the insulation.

Y

X

Components

Interface Module Adjacent Card

Host Chassis

FCC Part 68 Statement This equipment complies with Part 68 of the Federal Communications

Commission (FCC) rules. On the product is a label that contains the FCC

registration number for this device. If requested, you must provide this

information to the telephone company.

This equipment is designed to be connected to the telephone network or

premises wiring using a compatible modular jack which is Part 68 compliant.

See installation instructions for details.

If this device causes harm to the telephone network, the telephone company

will notify you in advance that temporary discontinuance of service may be

required. The telephone company may request that you disconnect the

equipment until the problem is resolved.

The telephone company may make changes in its facilities, equipment,

operations, or procedures that could affect the operation of this equipment. If

this happens, the telephone company will provide advance notice in order for

you to make necessary modifications to maintain uninterrupted service.

If you experience trouble with this equipment or for repair or warranty

information, please follow the applicable procedures explained in the Technical

Support section of this manual (Appendix A).

Page 13

CE Notice Marking by the symbol CE indicates compliance of the equipment with the

EMC, Telecom and Low Voltage dIrectives of the European Community. Such

marking is indicative that this equipment meets or exceeds the following

technical standards.

EN55022—Limits and methods of measurement of radio interference

characteristics of information technology equipment.

EN50082-1—Electromagnetic compatibility - generic immunity standard part 1:

residential, commercial, and light industrial.

CTR 12—Connection of 2 Mbit/s Unstructured Leased Lines.

CTR13—Connection to 2 Mbit/s Structured Leased Lines.

EN 60950—Safety of Information Technology Equipment including Electrical

Business Equipment.

EN 41003—Particular safety requirements for electrical equipment to be

connected to Telecom networks.

WARNING: This customer equipment is to be installed and maintained by

service personnel as defined by AS/NZS 3260 clause 1.2.14.3. (Service

Personnel). Incorrect connection of connected equipment to the General

Purpose Outlet could result in a hazardous situation.

WARNING Safety requirements are not fulfilled unless the equipment is

connected to a wall socket outlet with protective earth contact.

Page 14

xiv CHAPTER : SUPPLEMENTARY REGULATORY INFORMATION

Page 15

ABOUT THIS GUIDE

About This Guide provides an overview of this guide, describes guide conventions,

tells you where to look for specific information and lists other publications that

may be useful.

Introduction This guide describes how to install and configure the PathBuilder S600 WAN

Access Switch (PathBuilder S600). It also provides an overview of the unit’s

modules and supported applications.

Audience Description This guide is intended for network administrators, system engineers, field

engineers, and other personnel responsible for installing, configuring, and

managing PathBuilder products.

If the information in the Release Notes shipped with your product differs from the

information in this guide, follow the Release Notes.

How to Use This Guide Table 1 shows where to find specific information in this guide.

Table 1 Where to Find Specific Information

If you are looking for... Turn to...

Descriptions of the features and benefits of the PathBuilder S600 Chapter 1

System specifications Chapter 1

Installation instructions Chapter 2

Information on how to get started using the PathBuilder S600 Chapter 3

Instructions for using the PathBuilder S600 menus Chapter 3

Information about the specific modules and applications you can use with

the PathBuilder S600

Instructions for configuring PathBuilder S600 modules, ports, and cards Chapter 5

Instructions for configuring virtual interfaces Chapter 5

Instructions for configuring shapers Chapter 5

Instructions for configuring virtual circuits Chapter 5

Instructions for configuring bridging applications Chapter 5

Information about managing system alarms and lists of the alarms

supported by each of the PathBuilder S600 modules

Information about setting up loopbacks and what loopbacks specific

modules support

Information on displaying statistics and lists of the types of statistics

available for specific modules

Technical support information Appendix A

Chapter 4

Chapter 6

Chapter 6

Chapter 6

Page 16

16 ABOUT THIS GUIDE

Conventions Table 2 and Table 3 list conventions that are used throughout this guide.

Table 2 Notice Icons

Icon Notice Type Alerts you to...

Information note Important features or instructions

Caution Risk of personal safety, system damage, or loss of data

Warning Risk of severe personal injury

Table 3 Text Conventions

Convention Description

Syntax The word “syntax” means you must evaluate the syntax provided and

Commands The word “command” means you must enter the command exactly as

Screen displays This typeface represents information as it appears on the screen.

The words “enter”

and “type”

[Key] names Key names appear in text in one of two ways:

Menu commands

and buttons

Words in italicized

type

Words in bold-face

type

supply the appropriate values. Placeholders for values you must supply

appear in angle brackets. Example:

Enable RIPIP by using the following syntax:

SETDefault !<port> -RIPIP CONTrol = Listen

In this example, you must supply a port number for <port>.

shown in text and press the Return or Enter key. Example:

To remove the IP address, enter the following command:

SETDefault !0 -IP NETaddr = 0.0.0.0

This guide always gives the full form of a command in uppercase and

lowercase letters. However, you can abbreviate commands by entering

only the uppercase letters and the appropriate value. Commands are

not case-sensitive.

When you see the word “enter” in this guide, you must type

something, and then press the Return or Enter key. Do not press the

Return or Enter key when an instruction simply says “type.”

n Referred to by their labels, such as “the Return key” or “the Escape

key”

n Written with brackets, such as [Return] or [Esc].

If you must press two or more keys simultaneously, the key names are

linked with a plus sign (+). Example:

Press [Ctrl]+[Alt]+[Del].

Menu commands or button names appear in italics. Example:

From the Help menu, select Contents.

Italics emphasize a point or denote new terms at the place where they

are defined in the text.

Bold text denotes key features.

Page 17

Related Documentation 17

Related

Documentation

In addition to this guide, the following documentation may help you use the

PathBuilder S600.

PathBuilder S600 Release Notes—Provides configuration help and information

about new features and any known limitations and issues found in the release.

PathBuilder Switch Manager User Guide—Describes how to use PathBuilder

Switch Manager to configure and manage PathBuilder WAN access switches.

Using PathBuilder Switch Manager, you can configure shelf, device, and circuit

information; use a loopback panel to diagnose port cards; view line and interface

statistics; and perform administrative functions such as configuring trap

destinations and setting SNMP community strings.

Page 18

18 ABOUT THIS GUIDE

Page 19

1

(

)

{

SYSTEM DESCRIPTION

This chapter provides a brief overview of ATM (Asynchronous Transfer Mode)

technology, describes the PathBuilder

S600), and lists PathBuilder S600 system specifications. It includes the following

sections:

n ATM Overview

n PathBuilder S600 with STX Overview

n Specifications

n Options and Parts List

®

S600 WAN Access Switch (PathBuilder

ATM Overview ATM provides the means of simultaneously transferring a wide variety of services

with different protocols and bandwidth requirements such as voice, packet data,

and video between end users or user networks. It does so by segmenting the input

data streams into 53 byte cells, assigning the cells to virtual circuits set up in the

ATM network, multiplexing the cells for transmission according to the bandwidth

requirements of the individual data streams, and reassembling the cells into the

original data streams at the receiving end.

For more detail about how to apply the PathBuilder S600 to provide ATM WAN

access, see “Application Overview” in Chapter 4.

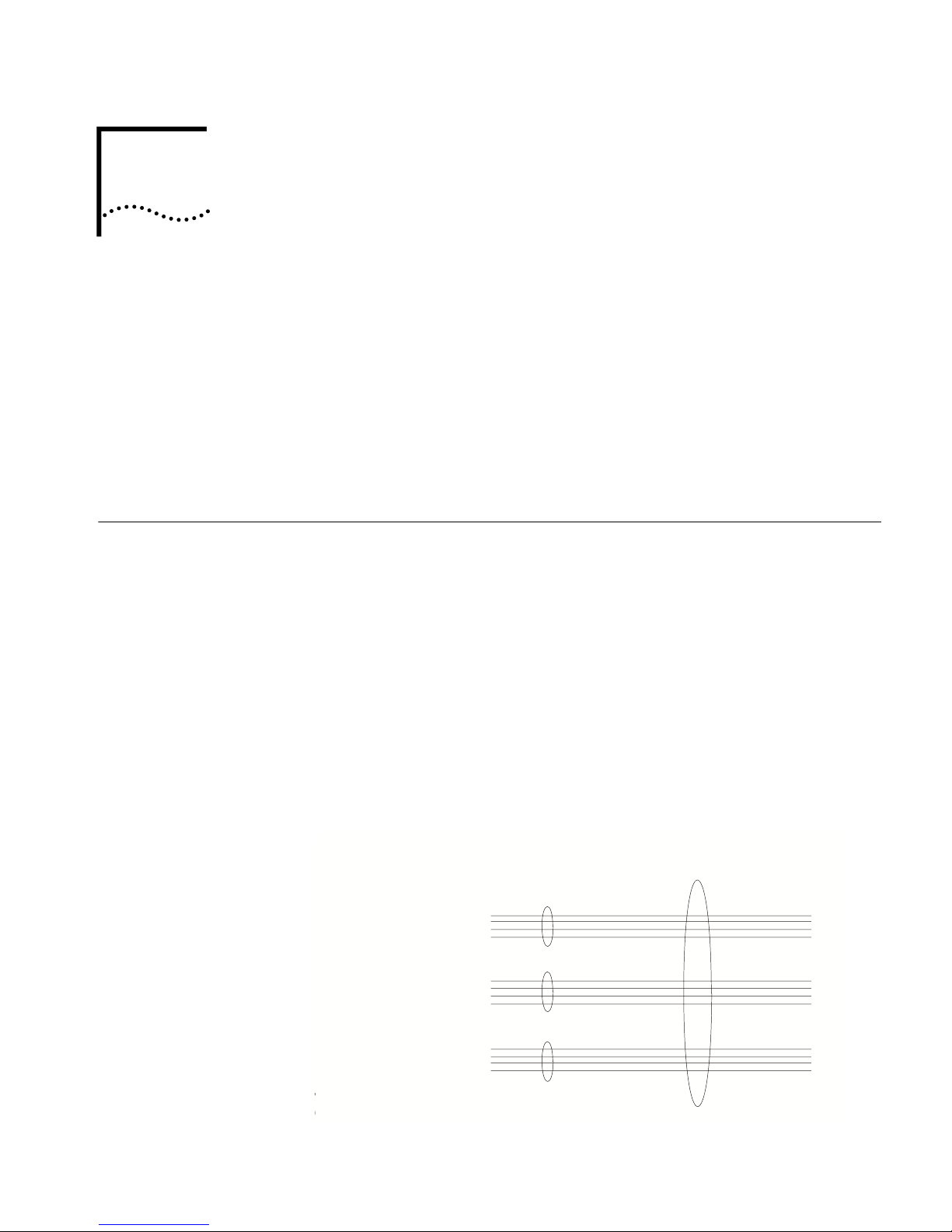

Virtual Circuits ATM networks are organized into virtual circuits or logical duplex paths between

two ATM unit ports, as shown in Figure 1.

Figure 1 Virtual Circuit Scheme

Virtual

Circuit

Virtual

Circuit

VCI 1 (Transmit)

{

VCI 1 (Receive)

VCIs

VCIs

VCI 1 (Transmit)

VCI 1

Receive

Transmission

Path

VPI 1

VPI 2

{

VPI 3

Transmission

Path

{

VPI 1

Page 20

20 CHAPTER 1: SYSTEM DESCRIPTION

Each transmission direction in a virtual circuit is referred to as a virtual channel.

Virtual channels are then grouped into virtual paths between two ports. The

channels and paths are assigned numbers: VPIs (Virtual Path Indicators) and VCIs

(Virtual Channel Indicators). Each ATM cell (a fixed-length unit of data over ATM)

is assigned to a virtual circuit by including the circuit's VPI/VCI in the cell's header.

This is then used to steer the cell through an ATM unit and the ATM network.

PathBuilder S600 with

STX Overview

PathBuilder S600 STX

Architecture

The PathBuilder S600 WAN access switch with Super Transport eXchange (STX)

provides enhanced switching and traffic management capabilities. It is designed to

concentrate, aggregate, and switch local ATM and legacy traffic over ATM

wide-area services for affordable ATM services access.

The PathBuilder S600 with STX requires software Release 2.0 or higher.

The modular architecture of the PathBuilder S600 with STX is designed to

accommodate a wide range of interfaces and support a comprehensive set of

applications. The core component of the unit is a 1.6 Gbps cell bus backplane

where all traffic is carried in the form of ATM cells. The PathBuilder S600 with STX

accommodates up to two power supplies (AC110/220 VAC and DC-48 VDC) in a

redundant configuration.

The overall design philosophy of the PathBuilder S600 with STX is to facilitate the

transfer of cells on and off the bus backplane with enhanced traffic management

and switching capabilities. All packet to cell segmentation and reassembly (SAR)

functions are performed on each of the application modules (Ethernet, Frame

Relay, and CBR), thereby ensuring efficient cell transfer through the system, (See

Figure 2.) Additional SAR power is added each time a non-ATM interface module

is added.

Figure 2 PathBuilder S600 with STX Cell Bus Architecture

10bt(2)

Ethernet

Because the STX module allows any-to-any port switching, there is no distinction

between port and trunk modules for the PathBuilder S600 with STX. Thus, the slot

assignments are as follows:

V.35(4), HSSI(1), T1(8)

Frame

Relay

STX MCPU

T1/E1, IMA(8), OC3/STM-1,

T1/E1(4/8)

CBR

10bt, RS232, SLIP

HSSI, DS3/E3

ATM

Page 21

PathBuilder S600 with STX Overview 21

n Slot 1 contains the Management CPU (MCPU). This slot is permanently

allocated. The MCPU manages the configuration database, network

management (via Text User Interface and SNMP) and software download

capabilities.

n Slot 2 contains the STX Module. This slot is permanently allocated.

n Slots 3-6 contain the application modules.

All modules are front-loading with a direct cable attachment on the front of each

card, and each module incorporates an RISC based processor (30 MIPs each) for

processing packets/cells, communication information, and statistics. The unit

accommodates up to 2 power supplies (AC 110/220 VAC & DC -48 VDC) in a

redundant configuration.

The S600 supports the following ATM and application modules:

n DS3 UNI module

n E3 UNI module

n OC3/STM-1 UNI module

n DS1 UNI with Inverse Multiplexing for ATM (IMA)

Key Features of the STX

Module

n E1 UNI with Inverse Multiplexing for ATM (IMA)

n Dual Ethernet module

n CBR (Constant Bit Rate) DSX module (4 port or 8 port)

n CBR (Constant Bit Rate) E1 module (4 port or 8 port)

n QSIM (Quad Serial Interface Module) (QSIM) - V.35/RS422/EIA530/X.21

n HSIM (HSSI Serial Interface Module)

n FAM (Frame Access Module) - DS1

The STX module includes a switching matrix that provides sophisticated traffic

management, priority queuing, and multicasting. Once an application module

SARs its traffic into ATM cells, the STX receives the cells and performs address

lookup for switching, queuing, traffic shaping, traffic policing, early packet

discard, and multicasting. The STX module provides the following functions to the

PathBuilder S600:

n Provides any-to-any port switching.

n Supports Deep buffers (192,000 cell buffers per module) for queuing.

n Introduces virtual interfaces (VIs)—logical UNI ports—and supports up to 24 VIs

per application module and up to 2 VIs for the MCPU module. The VIs provide

traffic shaping profiles.

n Provides priority queuing in which each VI can be assigned to specific VCs

n Supports per VC and/or per VP traffic shaping.

n Supports per VC traffic policing.

n Supports multicasting (up to 256 connections with 32 leaves).

n Includes a Bits timing clock.

n Supports per VC statistics.

n Allows a total of 8,000 connections per unit.

which then can be allocated to one of 4 queues.

Page 22

22 CHAPTER 1: SYSTEM DESCRIPTION

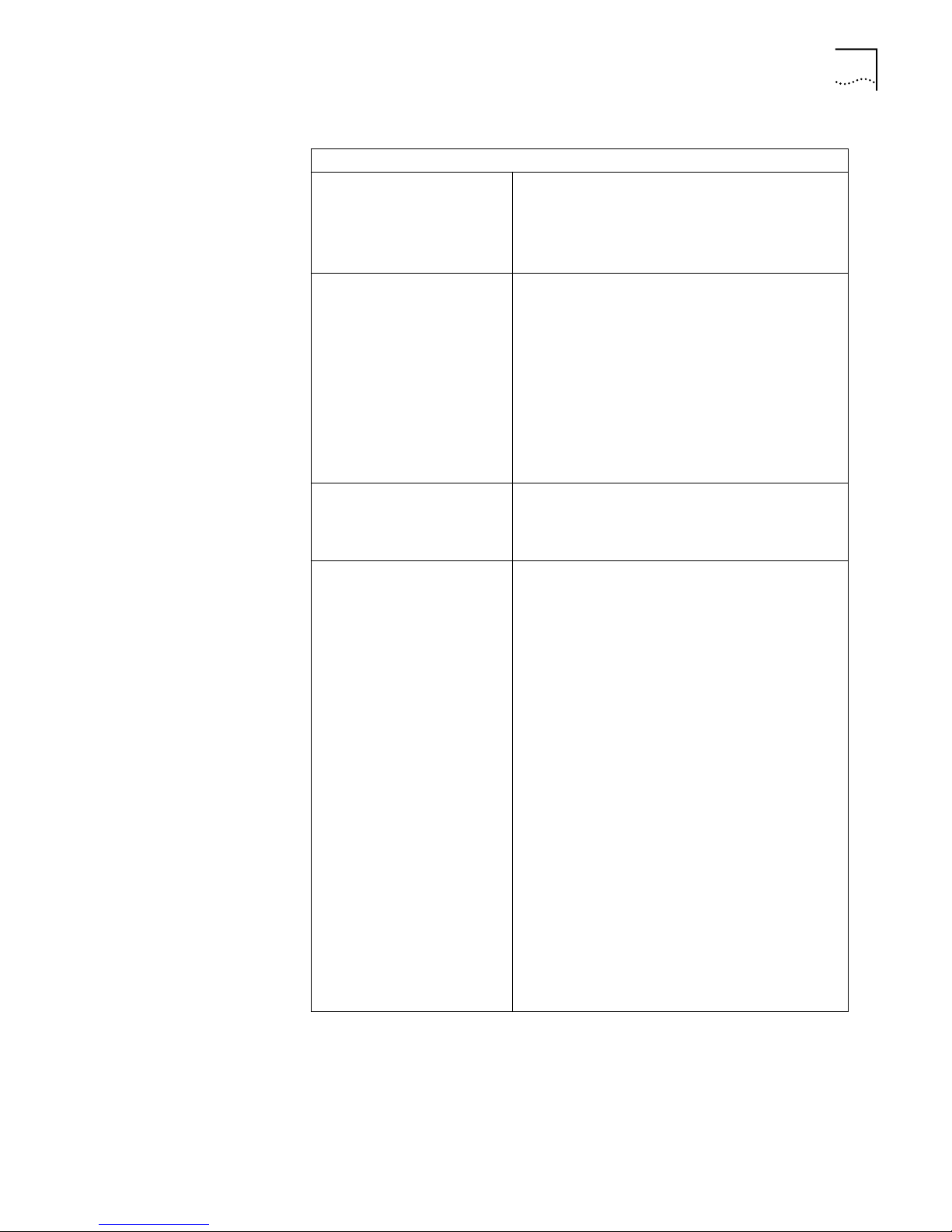

Specifications Table 4 lists complete specifications for the Pathbuilder S600. these specifications

are subject to change without notice.

Table 4 PathBuilder S600 Specifications

PLATFORM

Configuration 6 slots per shelf

Power Supplies 2 redundant and load sharing (1 required)

Power

Input

Consumption 175 watts

Environmental

Operating Temperature

Storage Temperature

Humidity

Altitude

Regulatory Compliance

Emissions

Safety UL listed (UL 1950 and 1459)

Physical Shelf Dimensions

Rack Mount Width

Rack Mount Spacing

Unit Weight (fully loaded)

Shipping Weight

(continued)

90 to 135 VAC, 50 to 60 Hz

180 to 265 VAC, 50 to 60 Hz

-44 to -52 VDC

0 to 45ºC

-40 to 70ºC

95% @ 40ºC (noncondensing)

14,000 ft. or 4,300 meters

FCC Part 15 rules for a Class A computing device

FCC Part 68

EN55022

EN50082-1

CTR 12

CTR 13

Austel TS-001

Austel AS 3260

VDE/TUV (EN 60950)

EN41003

CSA 22.2

Austel AS/NZS35-48

8.75” x 17” x 11” (H x W x D)

(22.3 cm x 43.2 cm x 27.9 cm)

19” (42.6 cm) or

23” (58.42 cm) optional

5 RMU

33 lbs (15 kg)

42 lbs (19 kg)

Page 23

Specifications 23

Table 4 PathBuilder S600 Specifications (continued)

MANAGEMENT

Management Functions On-board SNMP

In-band SNMP (See “Configuring In-band

Management” in Chapter 3 for details.)

Dual flash memory (image and configuration) TCP/IP

stack (TFTP, ping, Telnet)

SNMP Support GET/SET/TRAP

RFC 1213 (MIB II)

RFC 1406 (DS1/E1)

RFC 1407 (DS3/E3)

RFC 1493 (Bridge MIB)

RFC 1643 (Ethernet MIB)

RFC 1595 (SONET MIB)

ATM Forum CES MIB

Enterprise Specific MIB

Statistics Cells received, transmitted, and discarded (per port

and per VC)

Frames received, transmitted, and discarded (per port

and per VC)

Standards Compliance ATM Forum UNI 3.0, UNI 3.1

ATM Forum Circuit Emulation Service Interoperability

Specification V 2.0

ATM FORUM Inverse Multiplexing for ATM (IMA)

Specification Version 1.0

ANSI T1.107, 1988

ANSI T1.403

ANSI T1.107a, 1989

RFC 1483, 1490

RFC 826

RFC 1042

RFC 1577

IEEE 802.1

IEEE 802.3

AT&T PUB 54016

AT&T PUB 62411

ITU-T G.821

ITU-T G.703

ITU-T G.704

Frame Relay Forum Specifications 5 and 8

(continued)

Page 24

24 CHAPTER 1: SYSTEM DESCRIPTION

Table 4 PathBuilder S600 Specifications (continued)

ATM USER-TO-NETWORK INTERFACE (UNI) MODULES

Interfaces

T3 UNI

E3 UNI

OC-3 UNI

STM-1 UNI

ATM Framing

T3 UNI

E3 UNI

OC-3 UNI

STM-1 UNI

LBO

T3 UNI

E3 UNI

OC-3 UNI

Line Coding

T3 UNI

E3 UNI

OC-3 UNI

STM-1 UNI

Line Framing

T3 UNI

E3 UNI

OC-3 UNI

STM-1 UNI

Class of Service CBR, VBR, UBR-rt, VBR-nrt, UBR

Virtual Circuits Up to 8000 total per PathBuilder S600

(continued)

Single Mode

Multimode

Coax, BNC

Coax, BNC

MMF/SMF, SC

MMF/SMF, SC

HEC, PLCP

HEC

HEC

HEC

0-250, 250-450

0-250, 250-450

1300 Laser (SDX1155)

wavelength: 1261 nm-1360nm

TX (min) = -15 dBm

TX (max) = -8 dBm

RX (min = -30 dBm

RX (max) = -8 dBm

Reach: -15 km

1300 LED (HFBR-5205)

TX (min) = -19 dBm

TX (max) = -14 dBm

RX (min = -30 dBm

RX (max) = -14 dBm

Reach: -2 km

B3ZS

HDB3

CMI

CMI

M23 and C-BIT

G.751-PLCP / G.804 / G.832 for HEC

T1.105

G.709

Page 25

Specifications 25

Table 4 PathBuilder S600 Specifications (continued)

Traffic Shaping Bulk shaping

Per VC/VP shaping

Per VC shaping (Ethernet, FAM, QSIM, HSIM)

Traffic Policing Per VC

DS1/E1 UNI WITH INTEGRATED INVERSE MULTIPLEXING FOR ATM (IMA) MODULES

Number of Interfaces nx8,n = 1 to 8; software selectable for individual T1/E1

UNIs or as logical IMA group (>1 link)

Connector Type RJ-48 connectors

Integrated CSU Yes (for DS1)

Line Coding B8ZS for T1

HDB3 for E1

Line Framing ESF, SF (D4), or No Framing for T1

G. 703/704 for E1

ATM Framing HEC (ITU-T G.804), I.432

Payload Scrambling for E1

DS1/E1 INTERFACE CBR MODULE

Interface ATM Forum CES structured and unstructured (2.0)

Number of Interfaces 4 or 8

Connector Type RJ-48, 120 ohms balanced or 75 ohms unbalanced

ATM Encapsulation AAL1

Timing SRTS, adaptive, loop, internal

Cell Delay Variation Tolerance 24 msec (T1), 32 msec (E1)

Class of Service CBR

VPI/VCI Up to 192 per octal module

Up to 96 per quad module

Front Panel LEDs Power, in-service, fail, test, active

Port in-service, port alarm

ETHERNET LAN INTERFACE MODULE

Interfaces 2 Ethernet/IEEE 802.3

Packet Forwarding 14,800 pps simultaneously on each interface

Packet Protocols Learning bridge, 802.1d spanning tree, RFC 1577

forwarding, RFC 1483

Filtering MAC address, SAP, PID, user data field

Address Table Size 8192 entries (4096 per port)

ATM Protocols AAL5, RFC 1483

Class of Service VBR, UBR

VPI/VCI Up to 512 per module

Traffic Shaping Multiple levels with PCR, SCR, and MBS settings

(continued)

Page 26

26 CHAPTER 1: SYSTEM DESCRIPTION

Table 4 PathBuilder S600 Specifications (continued)

FRAME DATA MODULES

Interface Up to 8 T1 120 ohm (FAM)

4 V.35, RS-449, EIA530, X.21(QSIM)

1 HSSI (HSIM)

Speeds (line rate) T1/E1 56/64 Kbps to 1.5 Mbps

V.35, RS-422/449 up to 8 Mbps each,

HSSI @ 20 Mbps

Packet Protocols Frame Relay (service and network interworking), ATM

Clocking DTE or DCE

DTE SDU Up to 9232 octets

Class of Service VBR, UBR (AAL5)

VPI/VCI Up to 256 per module

Traffic Shaping Multiple levels per VC, with PCR, SCR, MBS setting

DXI, HDLC/SDLC pass through

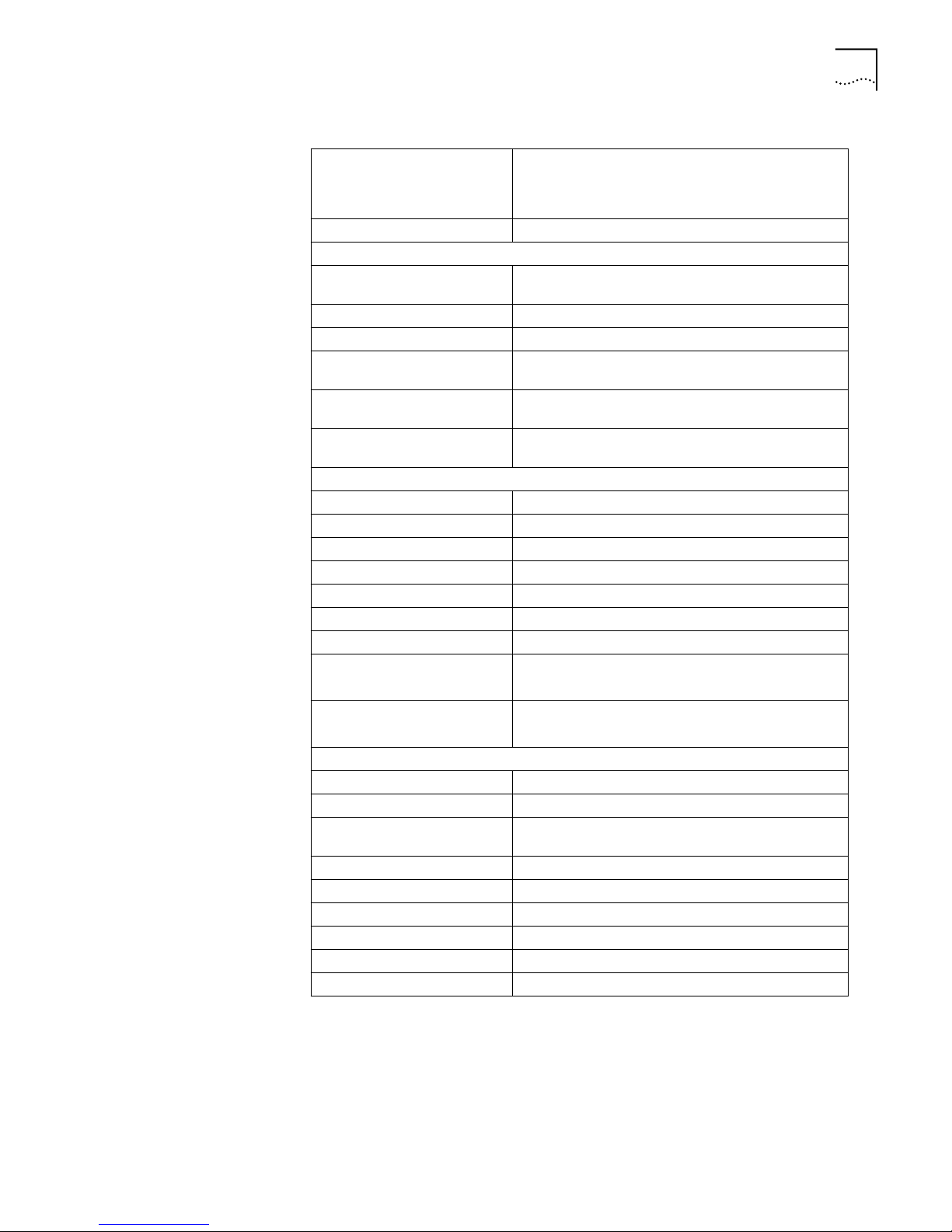

Options and Parts List Table 5 lists available PathBuilder S600 options including spare/redundant shelves,

port modules, trunk modules, system modules, and interface cables Contact

3Com or your VAR with the appropriate part number for ordering and pricing

information.

Table 5 Part Numbers and Description

Part Number Description

3C63119-AC-C PathBuilder S600 Base System STX (Chassis, MCPU, STX, One AC

3C63120-DC-C PathBuilder S600 Base System STX (Chassis, MCPU, STX, One DC

3C63101 Dual-Port Ethernet Modules (10BaseT) with bridging and RFC 1577

3C63103 Quad Serial Interface Module (4 Port V.35/RS449/RS530; DXI, Frame

3C63104 HSSI Serial Interface Module (Single HSSI; DXI, Frame Relay,

3C63105-4DSX 4-Port DSX CBR Module

3C63105-8DSX 8-Port DSX CBR Module

3C63105-4E1 4-Port E1 CBR Module

3C63105-8E1 8-Port E1 CBR Module

3C63106A-DS3 DS3 UNI Single Port or Trunk Module

3C63106A-E3 E3 UNI Single Port or Trunk Module

3C63107A-MMF OC3/STM-1 UNI Multi-Mode Port or Trunk Module

3C63114-8DS1 DS1 UNI - IMA (8 ports)

3C63114-8E1 E1 UNI - IMA (8 Ports)

3C63115-8DS1 DS1 FAM

3C63121-AC-C PathBuilder S600 (STX) System with one AC Power Supply

3C63122-DC-C PathBuilder S600 (STX) System with one DC Power Supply

3C63917 Additional PathBuilder S600 User Documentation

(continued)

Power Supply, Cover Panels, Rack Mount)

Power Supply, Cover Panels, Rack Mount)

Relay, SDLC/HDLC)

SDLC/HDLC)

Page 27

Options and Parts List 27

Table 5 Part Numbers and Description (continued)

Part Number Description

3C63108A MCPU System Controller Module

3C63116-STX STX Concentrator/Switching Module

3C63111A-AC Optional 110/220 AC Power Supply

3C63111A-DC Optional -48V DC Power Supply

3C63901-19RK Optional 19” Rack Mount Kit

3C63901-23RK Optional 23” Rack Mount Kit

3C63112 Spare Fan Assembly

3C63113-BPM Blank Panel For Module Slot(s)

CABLES

3C63911 Coax Cable; BNC to BNC - 8M/25Ft

3C63912 HSSI Cable; 50-Pin Male, Straight, to Male 50-Pin - 8M/25Ft

3C63915 RS232 Cable; RS232 DB9 Male, Crossover, to RS232 DB9 Female -

2M/6Ft

3C63902 DS1/E1 Cable; RJ48, Shielded Straight, to RJ48 - 8M/25Ft

3C63903 DS1/E1 Cable; RJ48, Shielded Crossover, to RJ48 - 8M/25Ft

3C63904 E1 Balun Adapter; RJ48 120 ohm to Coax 75 ohm - 2M/6Ft

3C63905 Fiber Cable; SC, Multimode, to SC 8M/25Ft

3C63906 Fiber Cable; SC, Multimode, to FC 8M/25Ft

3C63907 Fiber Cable; SC, Multimode, to ST 8M/25Ft

3C63908 Fiber Cable; SC, Singlemode, to SC 8M/25Ft

3C63909 Fiber Cable; SC, Singlemode, to FC 8M/25Ft

3C63910 Fiber Cable; SC, Singlemode, to ST 8M/25Ft

3C63913 V.35 Cable; HD 60-Pin Male to V.35 34-Pin Male, 2M/6Ft (Crossover

DTE)

3C63914 V.35 Cable; HD 60-Pin Male, Straight, to V.35 34-Pin Female, 2M/6Ft

3C63921 RS449 Cable; HD 60-Pin Male to RS449 Female (DCE), 2M/6Ft

3C63920 RS449 Cable; HD 60-Pin Male to RS449 Male (DTE), 2M/6Ft

3C63923 EIA530 Cable; HD 60-Pin Male to EIA530 Male (DTE), 2M/6Ft

3C63922 EIA530 Cable; HD 60-Pin Male to EIA530 Female (DCE), 2M/6Ft

3C63924 X.21 DTE Cable (HD 60-pin male straight to X.21 15-pin male)

3C63925 X.21 DCE Cable (HD 60-pin male straight to X.21 15-pin female)

3C63100-AC-C PathBuilder S600 Base System (Chassis, MCPU, CTX, One AC Power

Supply, Cover Panels, Rack Mount)

3C63100-DC-C PathBuilder S600 Base System (Chassis, MCPU, CTX, One DC Power

Supply, Cover Panels, Tabletop Mount)

3C63109-CTX CTX Concentrator Module

3C63110-AC PathBuilder S600 System (CTX) with one AC Power Supply

3C63110-DC PathBuilder S600 System (CTX) with One DC Power Supply

Page 28

28 CHAPTER 1: SYSTEM DESCRIPTION

Page 29

2

INSTALLATION

This chapter tells you how to mechanically and electrically install the PathBuilder®

S600 WAN Access Switch (PathBuilder S600) in your network. It contains the

following sections:

n Receiving and Inspecting the PathBuilder S600

n Installation Overview

n Step 1: Install the Shelf in the Rack

n Step 2: Connect AC or DC Power

n Step 3: (If needed) Install Additional Modules in the Shelf

n Step 4: Connect I/O Cabling and Wiring

n Step 5: Connect a Management Terminal

Before using the chapter for an actual installation, read through it at least once to

familiarize yourself with the overall process.

Receiving and

Inspecting the

PathBuilder S600

When you receive the PathBuilder S600, unpack it and inspect the unit for any

damage that might have occurred during shipment. Inventory the equipment

against the shipping notice.

Save the boxes and packing materials in the event there is damage or anything

needs to be reshipped at a future date. If anything is damaged or missing, contact

the shipper and 3Com immediately.

CAUTION: Many of the integrated circuits on the modules are sensitive to static

electricity. Do not remove the plug-in modules from their shelves without wearing

a properly grounded, antistatic, wrist strap.

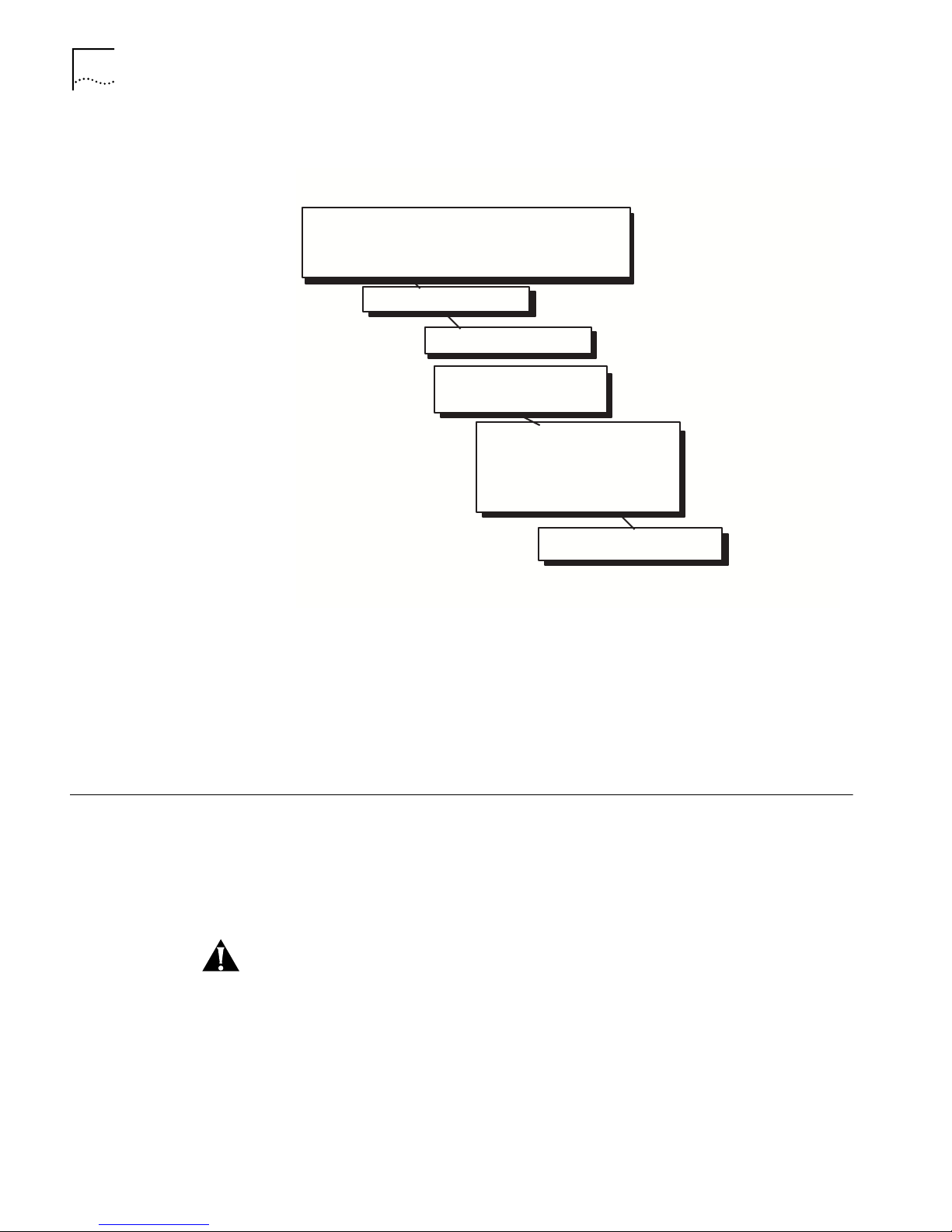

Installation Overview Figure 3 summarizes the overall installation procedure for the PathBuilder S600.

For details about each step in the overall procedure, see the following sections.

Page 30

30 CHAPTER 2: INSTALLATION

Figure 3 General Installation Procedure

Prepare the Site:

Verify Clearances Around the Shelf Site

Fabricate and Run Cabling and Wiring

Prepare AC or DC Power Run (Install Fuse and Alarm Panel)

Step 1

Install the Shelf in the Rack

Step 2

Step 3

Connect AC or DC Power

(If needed) Install Additional

Modules in the Shelf and

Monitor Front-Panel LEDs

Connect I/O Cabling and Wiring:

Step 4

Network Ports

Trunk Ports

Local Terminal

Office Alarms

BITS clock

Step 5

Connect a VT100 Terminal for

Local Management Access

Site Requirements n Be within the maximum distances to the port and trunk connections, as well as

the NMS terminal

n Have interconnect cabling and wiring ready and labeled

n Have a dedicated source of switched and fused AC power.

Step 1: Install the

Shelf in the Rack

n Provide clearance for making all connections and performing maintenance.

In a normal rack mount configuration the PathBuilder S600 shelf is 8.75" x 17.25"

x 11" including cables. Since the equipment is cooled with two internal fans,

clearance at the top is not needed. Convection cooled equipment should not be

mounted directly under the shelf but a least one rack unit below it. See Figure 4

for details. If the PathBuilder S600 is mounted in an enclosure, plan on enough

clearance at the front for cable and wiring service loops.

CAUTION: Many of the integrated circuits on the modules are sensitive to static

electricity. Do not handle the plug-in modules without wearing a properly

grounded, antistatic, wrist strap. When removing the modules from the shelf,

place them printed-circuit side down on a nonconducting, static-free, flat surface.

Page 31

Step 2: Connect AC or DC Power 31

To install the shelf in the rack, follow these steps:

1 Adjust the mounting ears, if necessary, for 19" installation. See Figure 4.

Figure 4 Rack Mounting Ear Configurations

19”

PathBuilder S600

5 Rows 8.75”

Caution: Weight

25 lbs

(Two People are

!

Recommended.)

Step 2: Connect AC or

DC Power

2 Support the shelf in its mounting place and attach the mounting hardware.

Since the unit weighs approximately 25 pounds, we recommend that two people

perform this step.

You make the input AC/DC power connections at the front of the PathBuilder

S600 shelf. Table 6 lists the specifications for the AC/DC Source.

Table 6 AC/DC Source Specifications

Input Power

Requirements

Power Consumption 200 Watts, Typical

Maximum Current 2.0 A @ 11v

90-264 VAC, 50-60Hz, Standard Grounded

Outlet for all PathBuilder S600s

Requirements

-42 to -52 VDC, Optional

14 AWG wire, Belden type 19364

1.0A @ 220V

3Com recommends that AC/DC power and office alarms be connected through a

Fuse and Alarm Panel mounted above the PathBuilder S600.

Page 32

32 CHAPTER 2: INSTALLATION

To make AC/DC power connections, follow these steps:

1 Plug the power supply modules directly into the backplane of the shelf. Their low

voltage DC outputs are bussed across the backplane to the other modules. Make

sure that the power supply modules and the fan tray are in the shelf and that they

are fully seated in their backplane connectors. (See Figure 5.)

The PathBuilder S600 supports dual redundant power supplies, but only one

Power Supply Module is required for operation.

Figure 5 Shelf Fill for AC/DC Power Application

Fan tray Power supply modules

AC

PathBuilder S600

Power

Input

DC

+

GND

-

CAUTION: Before servicing the unit and handling AC/DC power leads, disconnect

all power supply cords. Always have a partner close by who is familiar with first aid

for electrical shock.

WARNING: DC Units are to be installed only in Restricted Access Areas (dedicated

equipment rooms, equipment closets, etc.) in accordance with Articles 110-16 or

110-17, and 110-18 of the National Electrical Code, ANSI/NFDA No.70.

2 Turn off the AC/DC power source and connect the AC/DC leads to the front of the

shelf. Dress the leads to the rack leaving a service loop.

3 Turn on the AC/DC power and verify that the POWER indicators on both Power

Supply Modules are on and that the fans are running.

Step 3: (If needed)

Install Additional

Modules in the Shelf

The PathBuilder S600 ships with the factory-ordered modules installed. If you have

ordered additional modules, install them as described in this section; otherwise,

proceed to “Step 4: Connect I/O Cabling and Wiring” for instructions on how to

connect the factory-installed modules and verify front panel indicators.

n Install the Management CPU module in slot 1.

n Install the STX module in slot 2. (requires software release 2.00 or higher)

Page 33

Step 4: Connect I/O Cabling and Wiring 33

n Install any one of the following application modules in slot 3-6:

n DS3 UNI

n E3 UNI

n OC3/STM-1 UNI

n DS1 UNI with IMA

n E1 UNI with IMA

n Ethernet

n CBR DSX

n CBR-E1

n QSIM (Quad Serial Interface Module)

n HSIM (HSSI Module)

n FAM (Frame Access Module)

Step 4: Connect I/O

Cabling and Wiring

This section tells you how to connect I/O cabling and wiring once the modules are

installed in the shelf and describes the common and module-specific front panel

LEDs. Figure 6 shows an example of a PathBuilder S600 configuration with all of

the associated cabling connected.

Figure 6 Sample Full System Configuration

PathBuilder S600

Slot 6

Slot 5

Slot 4

DS3

Line

CSU or

CPE

Network

Management

Station

VT100 Terminal

Initial

Management

Connection to

Add an IP

Address for LAN

Management

T1 Timing

Source

Local

Alarm

System

Page 34

34 CHAPTER 2: INSTALLATION

Normal Start up

Sequence

All modules feature a set of five common system LEDs on the left side of the

module. When you install and connect a module, the common LED sequence

shown in Figure 7 occurs.

Power (PWR)—Indicates power from the power supply is good.

In Service (INS)—Indicates that the corresponding card is available for

transmission.

Fail—Indicates a sub-system failure.

Test—Indicates that a diagnostic is active.

Active (ACTV)—Indicates that the card is in service and active.

For descriptions of the LEDs specific to each module, see the following sections.

Figure 7 Common LED Sequence

PathBuilder S600

Connecting a DS3 UNI

Module

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Slot 1

Power Inservice Fail Test

1.

2.

3.

Upon Power Up

Power On Tests Completed

Connect the DS3 UNI module to a DS3 repeater using the female BNC connectors.

Figure 8 shows a trunk module connection. The maximum coax run is 450 feet.

The transmitter in the DS3 UNI Module includes selectable LBO (Line Build-Out) to

adjust the output signal to cable runs of 0-255 or 225-450 feet. Select the LBO

during card configuration from the local terminal or NMS. See “Configuring the

DS3 UNI Module” in Chapter 5, for details.

Page 35

Figure 8 DS3 UNI Module Connection

PathBuilder S600

Step 4: Connect I/O Cabling and Wiring 35

Slot 6

Slot 5

Slot 4

RX

In

TX Out

TX In

DS3 Service

DS3

CSU or CPE

TX Out

75 ohm coax

0-225 ft or 225-450 ft

Once you have connected the module, verify the front-panel indicator sequence

illustrated in Figure 9. The DS3 UNI module features the following front panel

indicators in addition to the common system LEDs:

LOS (RED)—Powers up in the “off” state and illuminates when a LOS (Loss of

Signal) condition is detected on the incoming DS3. The LOS LED is off if a signal is

present. It reflects the LOS state of the DS3 in real time (no integration of the state

is needed).

A LOS condition sometimes occurs when the DS3 cell encapsulation (PLCP or

Clear) is set incorrectly. For details about setting DS3 cell encapsulation, see

“Configuring the DS3 UNI Module” in Chapter 5.

LOF (RED)—Powers up in the “off” state and illuminates when a LOF (Loss of

Frame) condition is detected on the incoming DS3. The LOF LED is off when the

signal is in frame. It reflects the LOF state of the DS3 in real time (no integration of

the state is needed).

LOCD (RED)—Powers up in the “off” state and illuminates when a LOCD (Loss of

Cell Delineation) condition is detected on the incoming DS3 under HEC (Header

Error Control) framing. The LOCD LED is off when delineations are obtained. It

reflects the LOCD state of the DS3 in real time (no integration of the state is

needed).

Page 36

36 CHAPTER 2: INSTALLATION

Figure 9 DS3 UNI Module LEDs

PathBuilder S600

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Slot 1

Connecting an E3 UNI

Module

1.

2.

3.

Inservice Fail Test Active

Power

LOS

LOF LOCD

Power Up

Diagnostic Running

Power On Test Complete

Good DS3 / E3 / OC3-STM-1

Good ATM Cell Delineation

Connect the E3 UNI module to an E3 repeater using the female BNC connectors,

as shown in Figure 10. The maximum coax run is 1200 feet.

Figure 10 E3 UNI Module Connection

PathBuilder S600

Slot 6

Slot 5

Slot 4

E3

Service

TX Out

TX In

RX

In

E3

r PE

TX Out

75 ohm coax

Page 37

Step 4: Connect I/O Cabling and Wiring 37

Once you have connected the module, verify the front-panel indicator sequence.

The startup LED sequence and module-specific LEDs for the E3 UNI module are the

same as those for the D3 UNI module. See “Connecting a DS3 UNI Module”

above, for details.

Connecting an

OC3/STM-1 UNI

Trunk/Port Module

Connect the OC3/STM-1 UNI module using the Internal SC type connector. As

shown in Figure 11, the OC3-STM-1 UNI module supports two types of fiber optic

cable.

n Use multi-mode cable to generate UNI traffic over a port interface.

n Use single-mode cable to generate UNI traffic over a trunk interface.

Figure 11 OC3/STM-1 UNI Module Connection

PathBuilder S600

Slot 6

Slot 5

Slot 4

Connecting a DS1/E1

UNI with IMA Module

ATM

OC3 UNI Multi Mode Port

OC3 UNI Single Mode Trunk

Once you have connected the module, verify the front-panel indicator sequence.

The startup LED sequence and module-specific LEDs for the OC3/STM-1 UNI

module are the same as those for the D3 UNI module. See “Connecting a DS3 UNI

Module” earlier in this chapter, for details.

Connect the DS1 UNI with IMA module or the E1 UNI with IMA module using the

RJ-48 connectors (with integrated CSU for the DS1 module, with no CSU for the

E1 module), as shown in Figure 12.

If you are using a G703 coax physical connection to connect the E1 line to the

interface, you must use the E1 Balun Adapter (part number 3C63904) for proper

resistance.

Page 38

38 CHAPTER 2: INSTALLATION

Figure 12 DS1/E1 UNI with IMA Module Connection

PathBuilder S600

Slot 6

Slot 5

Slot 4

DS1/E1

ATM

n x T1 or E1

PathBuilder S600

PathBuilder S600

Once you have connected the module, verify the front-panel indicators. As shown

in Figure 13, the DS1/E1 UNI with IMA module features eight pairs of port

indicator LEDs in addition to the common system front panel indicators—each pair

corresponds to one of the eight RJ48 interfaces on the DS1/E1 UNI module.

Figure 13 DS1/E1 UNI LEDs

n The green indicator light illuminates to show that the port is in service.

n The red indicator light illuminates to show that the port is not in service.

Page 39

Step 4: Connect I/O Cabling and Wiring 39

Slot 6

Slot 5

Slot 4

PathBuilder S600

LAN

Connecting an Ethernet

Module

Connect an Ethernet module to the LAN directly or through a hub, as shown in

Figure 14, Table 7 lists the RJ48 connector pinouts.

Table 7 Ethernet Module Connector Pinouts

PIN 1 TX+

PIN 2 TX-)

PIN 3 RX+

PIN 4

PIN 5

PIN 6 RXPIN 7

PIN 8

The cable runs from the PathBuilder S600 Ethernet ports to the Ethernet LAN

connections must be no longer than 100 meters in compliance with EIA/TIA

standards for 10BaseT. The cable lengths should include service loops at the ends

and the complete cable route distances.

Figure 14 Ethernet Module Connection

Once you have connected the module, verify the front panel indicator sequence.

As shown in Figure 15, the Ethernet module has the following front panel

indicators in addition to the common system LEDs.

TX Port 1 (GREEN)—This is a transmit (to the cable) activity indicator. For each

frame sent to the cable, the LED is momentarily flashed.

Page 40

40 CHAPTER 2: INSTALLATION

RX Port 1 (GREEN)—This is a Receive (from the cable) activity indicator. For each

frame received from the cable, the LED will momentarily flash.

Link Port1 (GREEN)—This LED will illuminate when properly connected to the

Ethernet cable, otherwise it will be off.

TX Port 2 (GREEN)—This is a transmit (to the cable) activity indicator. For each

frame sent to the cable, the LED is momentarily flashed.

RX Port2 (GREEN)—This is a Receive (from the cable) activity indicator. For each

frame received from the cable, the LED will momentarily flash.

Link Port 2 (GREEN)—This LED will illuminate when properly connected to the

Ethernet cable, otherwise it will be off.

FWD (GREEN)—This is a bridging activity detector. For each frame bridged the

LED will momentarily flash.

ATM (GREEN)—This is an ATM traffic indicator. The use of this function will be

defined later.

Figure 15 Ethernet Module LEDs

PathBuilder S600

Common System

Power Inservice Fail Test

1.

2.

Fwd

ATM

Tx Rx Link Tx Rx Link

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Slot 1

Power Up

Power On Test

Complete

Bridge

Data If

Blinking

Blinks

With

Data

Should Be On When Properly

Connected To 10BASE-T

Page 41

Step 4: Connect I/O Cabling and Wiring 41

Connecting a CBR DSX

or CBR E1 Port Module

Connect a CBR DSX or CBR E1 module using the RJ48 DSX interface for T1 traffic.

Table 8 describes the CBR DSXE1 connector pinouts.

Table 8 CBR DSX/E1 Connector Pinouts

PIN 1 RX (ring)

PIN 2 RX tip

PIN 3 NC

PIN 4 TX ring

PIN 5 TX tip

PIN 6 NC

PIN 7 NC

PIN 8 NC

If you are using a G703 coax physical connection to connect the CBR E1 line to the

interface, you must use the E1 Balun Adapter (part number 3C63904) for proper

resistance.

The CBR DSX module supports LBOs (LIne Build Outs) to CSU of up to 655 feet.

You must configure the LBO via the local terminal or NMS. See “Configuring the

CBR DSX (or E1) Modules” in Chapter 5, for details. You can typically make

connections locally to DTE equipment without DSU/CSUs, as long as the

equipment supports a direct T1 interface and can recover T1 signal. See Figure 16.

Figure 16 CBR DSX/E1 Module Connections

Channel

Bank

PBX

CSU

CBR DSX

or

E1 CBR

LBO

655 Ft.

PathBuilder S600

DS1 Structured for DS0

Drop and Insert or

Unstructured for DS1

Tunneling

You can make connections from the CBR E1 module locally to DTE equipment as

long as the equipment supports a direct E1 interface and can recover an E1 signal.

Once you have connected the CBR DSX or CBR E1 module, verify the front panel

indicator sequence illustrated in Figure 17.

Page 42

42 CHAPTER 2: INSTALLATION

Figure 17 CBR Module LEDs

Common System

Power Inservice Fail Test Active

1.

2.

3.

Port is

Out of

Service

Port is in

Service

Port Has OOF

or LOS

Condition

(Out of

Service)

Port is in

Service with

OOF or LOS

Condition

As shown in Figure 18, the CBR DSX/E1 module features eight pairs of port

indicator LEDs in addition to the common system front panel indicators—each pair

corresponds to one of the eight ports on the CBR DSX module.

n The green indicator light illuminates to show that the port has been placed in

service.

n The red indicator light illuminates to show an OOF or LOS condition on the

port.

Figure 18 CBR DSX LEDs

Install in Slot 4 - 6

18

PWR

INS

Connecting a QSIM

V.35/RS422/EIA530 Port

Module

The QSIM (Quad Serial Interface Module) provides the following cabling options:

n DTE/DCE V.35

n DTE/DCE EIA530

n DTE/DCE RS-422

n DTE/DCE X.21

FAIL

16 Port Indicator Lights

TEST

ACTV

Page 43

Step 4: Connect I/O Cabling and Wiring 43

To connect the QSIM, attach the appropriate cable to one of the four ports using

the 60-pin amphenol connector, as shown in Figure 19.

Figure 19 QSIM Connection

PathBuilder S600

Slot 6

Slot 5

Slot 4

Slot 3

V.35

EIA530

RS-422

Router

Table 9, Table 10, Table 11, Table 12, Table 13, Table 14, Table 15, Table 17, and

Table 16 describe the connector pinouts

Page 44

44 CHAPTER 2: INSTALLATION

Table 9 V.35 DTE Cable (60-pin Male to 34-pin Male; Part # 3C63913)

Signal Name

Pin # on 60 Pin

Conn

Pin # on V.35 Conn

Direction (For

QSIM)

Frame GND 46 A

Circuit GND 45 B

RTS 42 C Out

CTS 35 D In

DSR 34 E In

DCD 33 F In

DTR 43 H Out

LL (not used) 44 K Out

SD+ 18 P Out

SD- 17 S Out

RD+ 28 R In

RD- 27 T In

SCTE+ 20 U Out

SCTE- 19 W Out

SCR+ 26 V In

SCR- 25 X In

SCT+ 24 Y In

SCT- 23 AA In

Shorting GR 1 48, 49

Shorting GR 2 50, 51, 52

Shorting GR 3 53, 54, 55, 56

Page 45

Step 4: Connect I/O Cabling and Wiring 45

Table 10 V.35 DCE Cable Pinouts (60-pin Make to 34-pin Female; Part # 3C63914)

Signal Name

Pin # on 60 Pin

Conn

Pin # on V.35 Conn

Direction (For

QSIM)

Frame GND 46 A

Circuit GND 45 B

RTS 35 C In

CTS 42 D Out

DSR 43 E Out

DCD 44 F Out

DTR 34 H In

LL (not used) 33 K In

SD+ 28 P In

SD- 27 S In

RD+ 18 R Out

RD- 17 T Out

SCTE+ 26 U In

SCTE- 25 W In

SCR+ 22 V Out

SCR- 21 X Out

SCT+ 20 Y Out

SCT- 19 AA Out

Shorting GR 1 48, 49

Shorting GR 2 50, 51,

Shorting GR 3 53, 54, 55, 56

Page 46

46 CHAPTER 2: INSTALLATION

Table 11 RS-422/449 DTE Cable Pinouts (60-pin Male to RS-449 male; Part # 3C63920)

Signal Name

Pin # on 60 Pin

Conn

Pin # on V.35 Conn

Direction (For

QSIM)

Frame GND 46 1

Circuit GND 15, 16, 45 19, 20, 37

RTS 9, 10 7, 25 Out

CTS 1, 2 9, 27 In

DSR 3, 4 11, 29 In

DCD (not used, see

5, 6 13, 31 In

DCE cable)

DTR 7, 8 12, 30 Out

LL (not used) 44 10 Out

SD+ 11 4 Out

SD- 12 22 Out

RD+ 28 6 In

RD- 27 24 In

SCTE+ 13 17 Out

SCTE- 14 35 Out

SCR+ 26 8 In

SCR- 25 26 In

SCT+ 24 5 In

SCT- 23 23 In

Shorting GR 1 48, 49

Shorting GR 2 51, 52,

Page 47

Step 4: Connect I/O Cabling and Wiring 47

Table 12 RS422/449 DCE Cable Pinouts (60-pin Make to RS-449 Female; Part # 3C63921)

Signal Name

Pin # on 60 Pin

Conn

Pin # on V.35 Conn

Direction (For

QSIM)

Frame GND 46 1

Circuit GND 15, 16, 30 19, 20, 37

RTS 1, 2 7, 25 In

CTS 9, 10 9, 27 Out

DSR 7, 8 11, 29 Out

DCD 5, 6 13, 31 Out

DTR 3, 4 12, 30 In

LL (not used) 29 10 In

SD+ 28 4 In

SD- 27 22 In

RD+ 11 6 Out

RD- 12 24 Out

SCTE+ 26 17 In

SCTE- 25 35 In

SCR+ 24 8 Out

SCR- 23 26 Out

SCT+ 13 5 Out

SCT- 14 23 Out

Shorting GR 1 48, 49

Page 48

48 CHAPTER 2: INSTALLATION

Table 13 EIA530 DTE Cable Pinouts (60-pin Male to EIA530 Male; Part # 3C63923)

Signal Name

Pin # on 60 Pin

Conn

Pin # on V.35 Conn

Direction (For

QSIM)

Frame GND 46 1

Circuit GND 45 7

RTS 9, 10 4, 19 Out

CTS 1, 2 5, 13 In

DSR 3, 4 6, 22 In

DCD (not used, see

5, 6 8, 10 In

DCE cable)

DTR 7, 8 20, 23 Out

LL (not used) 44 18 Out

SD+ 11 2 Out

SD- 12 14 Out

RD+ 28 3 In

RD- 27 16 In

SCTE+ 13 24 Out

SCTE- 14 11 Out

SCR+ 26 17 In

SCR- 25 9 In

SCT+ 24 15 In

SCT- 23 12 In

Shorting GR 1 47, 48, 49

Shorting GR 2 51, 52,

Page 49

Step 4: Connect I/O Cabling and Wiring 49

Table 14 EIA530 DCE Cable Pinouts (60-pin Male to EIA530 Female; Part # 3C63922)

Signal Name

Pin # on 60 Pin

Conn

Pin # on V.35 Conn

Direction (For

QSIM)

Frame GND 46 1

Circuit GND 45 7

RTS 1, 2 4, 19 In

CTS 9, 10 5, 13 Out

DSR 7, 8 6, 22 Out

DCD (not used, see

5, 6 8, 10 Out

DCE cable)

DTR 3, 4 20, 23 In

LL (not used) 29 18 In

SD+ 28 2 In

SD- 27 14 In

RD+ 11 3 Out

RD- 12 16 Out

SCTE+ 26 24 In

SCTE- 25 11 In

SCR+ 24 17 Out

SCR- 23 9 Out

SCT+ 13 15 Out

SCT- 14 12 Out

Shorting GR 1 47, 48, 49

Page 50

50 CHAPTER 2: INSTALLATION

Table 15 HSSI straight DTE to DCE cable (50-pin Male to 50-pin Male; Part # 3C63912)

Signal Name Pin # on DCE Pin # on DTE Direction (For DTE)

Circuit GND 1, 7, 13, 19, 25,

26, 32, 38, 44,

1, 7, 13, 19, 25, 26, 32,

38, 44, 50

50

TA 8, 33 8,33 Out

CA 3, 28 3, 28 In

LA 10, 35 10, 35 In

LB 12, 37 12, 37 In

LC 5, 30 5, 30 Out

SD 11, 36 11, 36 Out

RD 4, 29 4, 29 In

TT 9, 34 9, 34 Out

RT 2, 27 2, 27 In

ST 6, 31 6, 31 In

ST DTE 14, 39 14, 39 Out

Ancillary to DTE

(not used)

20, 21, 22, 23,

24, 45, 46, 47,

20, 21, 22, 23, 24, 45,

46, 47, 48, 49

In

48, 49

Ancillary to DCE

(not used)

15, 16, 17, 18,

40, 41, 42, 43

15, 16, 17, 18, 40, 41,

42, 43

Out

Page 51

Step 4: Connect I/O Cabling and Wiring 51

Table 16 X.21 DTE cable (60 pin Male to 15-pin Male; Part # 3C63924)

Signal Name

Pin # on

60 PIN CONN

Pin # on DB15 CONN

Direction

(For QSIM)

Frame GND 46 1

Circuit GND 15 8

RTS 1, 2 3, 10 In

CTS 9, 10 5, 12 Out

DSR Out

DCD (in order to keep

Out

cable compatible with

Cisco, DCD should be

tristated when in DTE

mode.

DTR In

LL (not used) In

SD+ 28 2 In

SD- 27 9 In

RD+ 11 4 Out

RD- 12 11 Out

SCTE+ In

SCTE-1 In

SCR+ (in order to keep

24 6 Out

cable compatible with

Cisco, SCR+ & - should

be tristated when in

DTE mode, double

term, double buffer)

SCR- 23 13 Out

SCT+ Out

SCT- Out

Shorting GR 1 47, 48

Page 52

52 CHAPTER 2: INSTALLATION

Table 17 X.21 DCE Cable Pinouts (60-pin Male to 15-pin Female; Part # 3C63925)

Signal Name

Pin # on

60 PIN CONN

Pin # on DB15 CONN

Direction

(For QSIM)

Frame GND 46 1

Circuit GND 15 8

RTS 9, 10 3, 10 Out

CTS 1, 2 5, 12 In

DSR In

DCD (not used, see

In

DCE cable note)

DTR Out

LL (not used) Out

SD+ 11 2 Out

SD- 12 9 Out

RD+ 28 4 In

RD- 27 11 In

SCTE+ Out

SCTE- Out

SCR+ 26, 24 6 In

SCR- 25, 23 13 In

SCT+ In

SCT- In

Shorting GR 1 47, 48

Shorting GR 2 51, 52

Once you have connected the QSIM, verify the front panel indicators. As shown in

Figure 20, in addition to the common system front panel indicators, each port has

a pair of LEDs to the left of the port.

Figure 20 QSIM LEDs

Install in Slot 4 - 6

INS

PWR

FAIL

PWR = Power On

INS = Inservice

ENBL

CLK

TEST

PORT 4

PORT 3 PORT 2 PORT 1

60-Pin

Amphenol

Connector

ENBL—Illuminates when the port is in service.

CLK—Illuminates when clocking is in service.

Page 53

Step 4: Connect I/O Cabling and Wiring 53

Connecting a HSIM

Module

PWR

PWR = Power On

INS = Inservice

Connect a HSIM module using a HSSI SCSI-II 50-pin cable, as shown in Figure 21.

Once you have connected the HSIM module, verify the front panel indicators. As

shown in Figure 21, the HSIM module has two front panel indicators in addition to

the common system LEDs:

Inservice—Indicates that the HSIM card is active.

Not Used—Indicates that the HSIM card is not in use.

Figure 21 HSIM Connection and LEDs

Install in Slot 4 - 6

One HSSI

50 Pin SCSI-II

HSSI

INS

FAIL

TEST

Inservice

Not

Used

Connecting a DS1 Frame

Access Module

Router

Connect a Frame Access Module (FAM) using up to eight RJ48 interfaces for T1

traffic, as shown in Figure 22.

Once you have connected the FAM, verify the front panel indicator sequence

illustrated in Figure 22.

The FAM features eight pairs of port indicator LEDs in addition to the common

system front panel indicators—each pair corresponds to one of the eight ports on

the FAM.

Inservice—Indicates that the FAM card is active.

Not Used—Indicates that the FAM card is not in use.

Page 54

54 CHAPTER 2: INSTALLATION

Figure 22 FAM LEDs

Router

Verifying CPU LEDs and

Connecting the Office

Alarm Connector

PWR

INS

FAIL

TEST

ACTV

Inservice

Not Used

Common System

Power Inservice Fail

1.

2.

3.

n x 64K

Power Up/Or Failure

Test Diagnostics

Frame Relay

8 RJ 48 Interfaces

Normal Mode

The Management CPU module requires no external connections, but you must

verify the front panel indicator sequence illustrated in Figure 23.

In addition to the common front panel indicators, the Management CPU module

features the following LEDs:

Critical—Indicates a critical alarm.

Major—Indicates a major alarm.

Minor—Indicates a minor alarm.

ACO—Alarm Cut off; illuminates when you push the ACO button. ACO is

generally used in conjunction with an external alarm. When certain alarms are

generated, the external alarm rings. Pushing the ACO button cuts off the external

alarm and illuminates the ACO LED.

Page 55

Figure 23 Management CPU LEDs

PathBuilder S600

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Common System CPU LEDs

Inservice Fail Test Active Critical Major Minor ACO

Power

1.

2.

Step 4: Connect I/O Cabling and Wiring 55

Power Up

Power On Test

Complete

Connecting the Office Alarm Connector

Figure 24 shows the office alarm connector on the Management CPU. The

PathBuilder S600 supports Alarm In and Alarm Out functions.

Figure 24 Office Alarm Connector

Major Alarm

External

Alarm

2

1

Ground

Normally Open

46

3

5

Major Alarm

Closure Enable

Minor Alarm

Normally Open

Minor Alarm

Closure Enable

Connect the alarm equipment to the appropriate pins, as determined by the type

of alarm equipment you are using. For example, if the alarm equipment you are

using requires OPEN state when there is no alarm and CLOSE state when the alarm

is activated, you would connect to Pin 4 and Pin 5.

Page 56

56 CHAPTER 2: INSTALLATION

Verifying STX LEDs and

Connecting the Optional

BITS Clock

The STX module requires no external connections, but you must verify the front

panel indicator sequence illustrated in Figure 25.

Figure 25 STX Module LEDs

PathBuilder S600

Power Inservice Fail Test Active

1.

2.

3.

Upon Power Up

Power On Tests Completed

Connecting the Optional BITS Clock (STX)

The PathBuilder S600 can receive or transmit a Bipolar Timing Source (BITS) clock

through the STX module. It offers the following options for the clock setting:

n T1 CSU

n DSX 0-133 feet

n DSX 133-266 feet

n DSX 266-399 feet

n DSX 399-533 feet

n DSX 533-655 feet

If desired, you can connect a BITS clock to the clock signal input or output port

located on the STX module using an RJ48 connector, as shown in Figure 26.

Page 57

Step 4: Connect I/O Cabling and Wiring 57

Figure 26 BITS Clock Connection (STX Module)

PathBuilder S600

Slot 6

Slot 5

Slot 4

1.544 Mbps

All Ones

RJ48 PIN 1 - Receive Ring

RJ48 PIN 2 - Receive Tip

1.544 Mbps

All Ones

RJ48 PIN 4 -Transmit Tip

RJ48 PIN 5 - Transmit Ring

Table 18 and Table 19 list the connector pinouts for the input and output

connectors.

Table 18 STX Module BITS Clock Input Connector Pinouts

PIN 1 Receive Ring

PIN 2 Receive Tip

PIN 3

PIN 4 Transmit Tip

PIN 5 Transmit Ring

PIN 6

PIN 7

PIN 8

Table 19 STX Module BITS Clock Output Connector Pinouts

PIN 1 Receive Ring

PIN 2 Receive Tip

PIN 3

PIN 4 Transmit Tip

PIN 5 Transmit Ring

PIN 6

PIN 7

PIN 8

This feature is currently available for North American, DSI, Standard carrier signals.

Page 58

58 CHAPTER 2: INSTALLATION

Step 5: Connect a

Management Terminal

In order to configure application connections and an IP address for SNMP support,

you must connect a management terminal to the PathBuilder S600. To do this, you