CoreBuilder™ 5000

®

Network Router Module

Installation Guide for

Token Ring

http://www.3com.com/

Document Number 17-00670-3

Published May 1997

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

Copyright © 3Com Corporation, 1997. All rights reserved. No part of this documentation may be

reproduced in any form or by any means, or used to make any derivative work (such as translation,

transformation, or adaptation) without permission from 3Com Corporation. Portions of this document are

reproduced in whole or part with permission from third parties.

3Com Corporation reserves the right to revise this documentation and to make changes in content from

time to time without obligation on the part of 3Com Corporation to provide notification of such revision or

change.

3Com Corporation provides this documentation without warranty of any kind, either implied or expressed,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

3Com may make improvements or changes in the products or programs described in this documentation at

any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described herein

are provided to you subject to the following restricted rights:

For units of the Department of Defense:

Restricted Rights Legend: Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c) (1) (ii) for Restricted Rights in Technical Data and Computer Software Clause at

48 C.F.R. 52.227-7013.

For civilian agencies:

Restricted Rights Legend: Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph

(a) through (d) of the Commercial Computer Software – Restricted Rights Clause at 48 C.F.R. 52.227-19

and the limitations set forth in the 3Com Corporation standard commercial agreement for the software.

Unpublished rights reserved under the copyright laws of the United States.

If there is any software on removable media described in this documentation, it is furnished under a license

agreement included with the product as a separate document, in the hardcopy documentation, or on the

removable media in a directory file named LICENSE.TXT. If you are unable to locate a copy, please contact

3Com and a copy will be sent to you.

Federal Communications Commission Notice

This equipment was tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case you must correct the interference

at your own expense.

Canadian Emissions Requirements

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

EMC Directive Compliance

This equipment was tested and conforms to the Council Directive 89/336/EEC for electromagnetic

compatibility. Conformity with this directive is based upon compliance with the following harmonized

standards:

EN 55022 – Limits and Methods of Measurement of Radio Interference

EN 50082-1 – Electromagnetic Compatibility Generic Immunity Standard: Residential, Commercial, and

Light Industry

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case you may be required to take adequate measures.

Compliance with this directive depends on the use of shielded cables.

Low Voltage Directive Compliance

This equipment was tested and conforms to the Council Directive 72/23/EEC for safety of electrical

equipment. Conformity with this directive is based upon compliance with the following harmonized

standard:

EN 60950 – Safety of Information Technology Equipment

ii

VCCI Class 1 Compliance

This equipment is in the 1st Class category (information equipment to be used in commercial or industrial

areas) and conforms to the standards set by the Voluntary Control Council for Interference by Information

Technology Equipment aimed at preventing radio interference in commercial or industrial areas.

Consequently, when the equipment is used in a residential area or in an adjacent area, radio interference

may be caused to radio and TV receivers, and so on.

Read the instructions for correct handling.

Fiber Cable Classification Notice

Use this equipment only with fiber cable classified by Underwriters Laboratories as to fire and smoke

characteristics in accordance with Section 770-2(b) and Section 725-2(b) of the National Electrical Code.

UK General Approval Statement

The CoreBuilder 5000 Integrated System Hub and ONline System Concentrator are manufactured to the

International Safety Standard EN 60950 and are approved in the U.K. under the General Approval Number

NS/G/12345/J/100003 for indirect connection to the public telecommunication network.

Trademarks

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com, Boundary Routing, CardFacts, EtherLink, LANplex, LANsentry, LinkBuilder, NETBuilder, NETBuilder II,

NetFacts, Parallel Tasking, SmartAgent, TokenDisk, TokenLink, Transcend, TriChannel, and ViewBuilder are

registered trademarks of 3Com Corporation.

3TECH, CELLplex, CoreBuilder, EtherDisk, EtherLink II, FDDILink, MultiProbe, NetProbe, and ONline are

trademarks of 3Com Corporation.

3ComFacts is a service mark of 3Com Corporation.

The 3Com Multichannel Architecture Communications System is registered under U.S. Patent

Number 5,301,303.

AT&T is a registered trademark of American Telephone and Telegraph Company.

Banyan and VINES are registered trademarks of Banyan Systems Inc.

CompuServe is a registered trademark of CompuServe, Inc.

DEC, DECnet, DELNI, POLYCENTER, VAX, VT100, VT220, and the Digital logo are trademarks of Digital

Equipment Corporation.

Hayes is a registered trademark of Hayes Microcomputer Products.

OpenView is a registered trademark of Hewlett-Packard Company.

Intel is a registered trademark of Intel Corporation.

AIX, IBM, and NetView are registered trademarks of International Business Machines Corporation.

Microsoft, MS-DOS, Windows, Windows 95, and Windows NT are registered trademarks of

Microsoft Corporation.

V30 is a trademark of NEC Corporation.

NetWare and Novell are registered trademarks of Novell, Incorporated.

IPX is a trademark of Novell, Incorporated.

OSF and OSF/Motif are registered trademarks of Open Software Foundation, Inc.

ONC, OpenWindows, Solaris, Solstice, Sun, Sun Microsystems, SunNet Manager, and SunOS are trademarks

of Sun Microsystems, Inc.

iii

SPARCstation is a trademark licensed exclusively to Sun Microsystems Inc.

OPEN LOOK is a registered trademark of Unix System Laboratories, Inc.

UNIX is a registered trademark of X/Open Company, Ltd. in the United States and other countries.

Other brand and product names may be registered trademarks or trademarks of their respective holders.

iv

CONTENTS

ABOUT THIS GUIDE

Introduction 1

Audience 1

How to Use This Guide 2

Conventions 2

Related Documents 4

3Com Documents 4

Reference Documents 4

1 INTRODUCTION

Router Module Overview 1-1

Router Functions 1-1

Module Architecture 1-2

Router Models 1-3

Typical Applications 1-4

Router Module Features 1-6

FDDI Support 1-6

WAN Support 1-6

Protocol Translation 1-7

Scalable Protocol Support 1-7

WAN Optimization 1-9

ATM Migration 1-9

Management Support 1-9

Distributed, Scalable Reliability 1-10

Hot Swap Capability 1-10

2 INSTALLING THE MODULE

Precautionary Procedures 2-1

Quick Installation 2-2

Unpacking Procedures 2-2

Preparing to Install the Router Module 2-4

Restoring Base Board Positions 2-4

Verifying CPU Board Positions 2-5

Installing the Router Module 2-5

Making NIM Connections 2-7

Making FDDI NIM Connections 2-7

Connecting the Multi-Mode, Dual Attachment Station NIM 2-7

Connecting the Multi-Mode, Single Attachment Station NIM 2-8

Connecting the Multi-Mode Optical Bypass Switch 2-9

Connecting the Single Mode, Dual Attachment Station NIM 2-10

Making Quad Serial NIM Connections 2-11

Making ATM NIM Connections 2-12

ATM Connector Types 2-12

ATM Distance Limitations 2-12

3 CONFIGURING THE MODULE

Configuration Overview 3-1

Attaching a Management Terminal 3-2

Connecting to the Console Port 3-2

Connecting to the Auxiliary Port 3-3

Configuring the Cisco NIM Connections 3-3

Configuring Cisco Parameters 3-3

Setting General Interface Parameters 3-4

Setting Token Ring Speed 3-4

Configuring 3Com Parameters 3-5

4 MONITORING OPERATION

Monitoring Router Module LEDs 4-1

Common Front Panel LEDs 4-2

FDDI NIM LEDs 4-6

Quad Serial NIM LEDs 4-7

ATM NIM LEDs 4-9

vi

Displaying the Router Module Configuration 4-10

Using the SHOW MODULE Command 4-11

Using the SHOW MODULE VERBOSE Command 4-11

Using the SHOW PORT Command 4-11

Using the SHOW PORT VERBOSE Command 4-12

Interpreting the SHOW PORT Status Field 4-13

5 TROUBLESHOOTING

Troubleshooting Startup Problems 5-1

Troubleshooting Network Connection Problems 5-2

Troubleshooting WAN Connection Problems 5-2

Correcting Operating Malfunctions 5-3

Recovering a Lost Password 5-4

A PRODUCT SPECIFICATIONS

General Specifications A-2

Electrical Specifications A-3

Environmental Specifications A-3

Mechanical Specifications A-3

B CABLING SPECIFICATIONS

Console and Auxiliary Port Cables B-1

Console Port Pinouts B-2

Auxiliary Port Pinouts B-2

Quad Serial NIM Cables B-3

EIA-530 DTE Synchronous Serial Cable Pinouts B-4

EIA-232 DTE and DCE Serial Cable Assembly and Pinouts (DB-25) B-5

EIA-449 DTE and DCE Serial Cable Assembly and Pinouts (DB-37) B-8

V.35 DTE and DCE Serial Cable

Assembly and Pinouts B-10

X.21 DTE and DCE Serial Cable Pinouts (DB-15) B-13

vii

C VIRTUAL CONFIGURATION REGISTER

VCR Tasks C-1

VCR Bit Definitions C-2

Boot Field C-2

Setting Boot Field Values C-3

Default Boot Filenames C-3

Break Function C-4

Internet Protocol Broadcast Address C-5

Engine Management Terminal Baud Rate C-5

Bootload Failure Response C-5

NVRAM Disable C-6

Changing VCR Settings C-6

Enabling Booting From Flash Memory C-7

D FDDI PRECAUTIONS

FDDI Laser Safety Information D-1

Processing D-2

E TECHNICAL SUPPORT

Online Technical Services E-1

World Wide Web Site E-2

3Com Bulletin Board Service E-2

Access by Analog Modem E-2

Access by Digital Modem E-2

3ComFacts Automated Fax Service E-3

3ComForum on CompuServe Online Service E-3

Support From Your Network Supplier E-4

Support From 3Com Corporation E-5

Returning Products for Repair E-6

Accessing the 3Com MIB E-6

Contacting 3Com Technical Publications E-7

INDEX

3COM CORPORATION LIMITED WARRANTY

viii

FIGURES

1-1 CoreBuilder 5000 Network Router Module 1-2

1-2 Quad Serial Network Router Module Typical Application 1-4

1-3 ATM OC3 Network Router Module Typical Application 1-4

1-4 Dual Attachment FDDI Network Router Module Typical Application 1-5

2-1 Locating the Spacing Clips 2-3

2-2 Base Board DIP Switch and Jumper Plug Positions 2-4

2-3 CPU Board Jumper Plug Positions 2-5

2-4 CoreBuilder 5000 Network Router Module in a CoreBuilder 5000

Integrated System Hub 2-6

2-5 Multi-Mode FDDI Network Interface Connector, MIC Type 2-7

2-6 Making Connections to the FDDI MM, DAS NIM 2-8

2-7 Making Connections to the FDDI MM, SAS NIM 2-8

2-8 Connecting the Multi-Mode Optical Bypass Switch 2-9

2-9 Making Connections to the FDDI SM, DAS NIM 2-10

2-10 Making Connections to the Quad Serial NIM 2-11

2-11 Making Connections to the ATM NIMs 2-12

4-1 Common Front Panel LEDs 4-2

4-2 FDDI NIM LEDs 4-6

4-3 Quad Serial NIM LEDs 4-7

4-4 ATM NIM LEDs 4-9

4-5 SHOW MODULE Command Information 4-11

4-6 SHOW MODULE VERBOSE Command Information 4-11

4-7 SHOW PORT Command Information 4-12

4-8 SHOW PORT VERBOSE Command Information 4-12

B-1 EIA-530 Cable Assembly B-4

B-2 EIA-232 Serial Cable Assembly B-5

B-3 EIA-449 Serial Cable Assembly B-8

B-4 V.35 Serial Cable Assembly B-10

B-5 X.21 Cable Assembly B-13

D-1 Required Class 1 Laser Product Label D-2

ix

TABLES

1 How to Use This Guide 2

2 Graphic Conventions 2

3 Text Conventions 3

1-1 Software Feature Sets 1-8

2-1 Quick Installation Steps 2-2

2-2 ATM Distance Limitations 2-13

4-1 Front Panel LED Definitions 4-3

4-2 Quad Serial NIM LED Definitions 4-8

4-3 ATM NIM LED Definitions 4-10

4-4 SHOW PORT Status Field Definitions 4-13

5-1 Troubleshooting Malfunctions 5-3

A-1 General Router Module Specifications A-2

A-2 Electrical Router Module Specifications A-3

A-3 Environmental Router Module Specifications A-3

A-4 Mechanical Router Module Specifications A-3

B-1 Console Port Pinout Specification B-2

B-2 Auxiliary Port Pinout Specification B-2

B-3 EIA-530 Cable Pinout Specifications B-4

B-4 EIA-232 DTE Cable Pinouts (DB-60 to DB-25) B-6

B-5 EIA-232 DCE Cable Pinouts (DB-60 to DB-25) B-7

B-6 EIA-449 DTE Cable Pinouts (DB-60 to DB-37) B-8

B-7 EIA-449 DCE Cable Pinouts (DB-60 to DB-37) B-9

B-8 V.35 DTE Cable Pinouts (DB-60 to Winchester-Type 34-Pin) B-11

B-9 V.35 DCE Cable Pinouts (DB-60 to Winchester-Type 34-Pin) B-12

B-10 X.21 DTE Cable Pinouts (DB-60 to DB-15) B-13

B-11 X.21 DCE Cable Pinouts (DB-60 to DB-15) B-14

C-1 Virtual Configuration Register Bit Values C-2

C-2 Boot Field Values (Configuration Register Bits 00 to 03) C-2

C-3 Default Boot Filenames C-4

C-4 Broadcast Address Destination Settings C-5

C-5 Engine Management Terminal Baud Rate Settings C-5

xi

ABOUT THIS GUIDE

Introduction This guide describes how to install, configure, and monitor the 3Com

CoreBuilder

If the information in the release notes shipped with your product differs

from the information in this guide, follow the release note instructions.

™

5000 Network Router Module.

Audience This guide is intended for the following people at your site:

■ Network manager or administrator

■ Trained hardware installer or service personnel

2 ABOUT THIS GUIDE

How to Use This Guide

Table 1 shows the location of specific information.

Table 1 How to Use This Guide

If you are looking for: Turn to:

General information about the router module Chapter 1

Description of the router module architecture

Typical applications of the router module

Features of the router module

Procedures for unpacking and preparing to install the router

module

Procedures for installing the router module

Procedures for making NIM connections

An overview of the router module configuration process Chapter 3

Procedures for attaching a management terminal

Procedures for configuring the Cisco NIM connections

Procedures for configuring Cisco parameters

Procedures for configuring 3Com parameters

Information for monitoring router module LEDs Chapter 4

Procedures for displaying the router module configuration

Information on troubleshooting the router module Chapter 5

Procedures for recovering a lost password

Module specifications, cable requirements, and other reference

information

Chapter 2

Appendices A-E

Conventions Table 2 and Ta b l e 3 list conventions used throughout this guide.

Table 2 Graphic Conventions

Icon Type Description

Information

Note

Caution Cautions alert you to personal safety risk, system

Warning Warnings alert you to the risk of severe personal

Information notes call attention to important features

or instructions.

damage, or loss of data.

injury.

Conventions 3

Table 3 Text Conventions

Convention Description

Enter vs. Type When the word enter is used in this guide, it means

type something, then press the Return or Enter key. Do

not press the Return or Enter key when instructed to

type.

Syntax vs. Command Syntax indicates that the general form of a command

syntax is provided. You must evaluate the syntax and

supply the appropriate port, path, value, address, or

string. For example:

Enable RIPIP by using the following syntax:

SETDef ault !<por t> -RIPIP CONTrol =

Listen

In this example, you must supply a port number for

!<port>.

Command indicates that all variables in the command

have been supplied and you can enter the command as

shown in text. For example:

Remove the IP address by entering the following

command:

SETDef ault !0 -IP NETaddr = 0. 0.0.0

For consistency and clarity, the full-form syntax (upperand lowercase letters) is provided. However, you can

enter the abbreviated form of a command by typing

only the uppercase portion and supplying the

appropriate port, path, address, value, and so on. You

can enter the command in either upper- or lowercase

letters at the prompt.

Text represented as

screen display

Text represented as

commands

Keys Specific keys are referred to in the text as Return key or

Italics Italics are used to denote new terms or emphasis.

This ty peface is used to represent displays that

appear on your terminal screen. For example:

NetL ogin :

This typeface is used to represent commands that

you enter. For example:

SETDef ault !0 -IP NETaddr = 0. 0.0.0

Escape key, or they may be shown as [Return] or [Esc].

If two or more keys are to be pressed simultaneously,

the keys are linked with a plus sign (+). For example:

Press [Ctrl]+[Alt]+[Del].

4 ABOUT THIS GUIDE

Related Documents This section provides information on supporting documentation,

including:

■ 3Com Documents

■ Reference Documents

3Com Documents The following documents provide additional information on 3Com

products:

CoreBuilder 5000 Integrated System Hub Installation and Operation

Guide – Provides information on the installation, operation, and

configuration of the CoreBuilder 5000 Integrated System Hub. This

guide also describes the principal features of the CoreBuilder 5000

Fault-Tolerant Controller Module.

CoreBuilder 5000 Distributed Management Module User Guide –

Provides information on the CoreBuilder 5000 Distributed

Management Module’s operation, installation, and configuration. This

guide also describes the software commands associated with the

Distributed Management Module.

CoreBuilder 5000 Distributed Management Module Commands Guide –

Describes each management command by providing details on

command format and use.

For a complete list of 3Com documents, contact your 3Com

representative.

Reference Documents The following documents supply related background information:

Case, J., Fedor, M., Scoffstall, M., and J. Davin, The Simple Network

Management Protocol, RFC 1157, University of Tennessee at Knoxville,

Performance Systems International and the MIT Laboratory for

Computer Science, May 1990.

Rose, M., and K. McCloghrie, Structure and Identification of

Management Information for TCP/IP-based Internets, RFC 1155,

Performance Systems International and Hughes LAN Systems,

May 1990.

1

INTRODUCTION

This chapter contains the following topics:

■ Router Module Overview

■ Router Module Features

Router Module Overview

The 3Com CoreBuilder™ 5000 Network Router Module is a

multiprotocol backplane router that operates in a 3Com

®

CoreBuilder 5000 Integrated System.

This section describes the following topics:

■ Router Functions

■ Module Architecture

■ Router Models

■ Typical Applications

Router Functions The CoreBuilder 5000 Network Router Module (referred to in this guide

as the router module) is designed to:

■ Provide the physical network interface to connect local- and

wide-area networks in multiprotocol environments

■ Run standard Cisco Systems

®

Internetworking Operating System®

(IOS) router software

■ Provide high-performance, fault-tolerant connectivity to backbone

networks for Token Ring local area networks (LANs) within the

CoreBuilder 5000 Integrated System

■ Deliver standards-based translation bridging and multiprotocol

routing capability

1-2 CHAPTER 1: INTRODUCTION

■ Internetwork Asynchronous Transfer Mode (ATM), Fiber Data

Distributed Interface (FDDI), or wide area network (WAN)

connections with four Token Ring backplane networks

■ Support the CoreBuilder 5000 Integrated System backplane for

connectivity to 4 of 10 CoreBuilder 5000 Token Ring backplane

networks

■ Act as the Simple Network Management Protocol (SNMP) agent for

in-band or out-of-band management by any SNMP-compliant

®

network management application or the 3Com Transcend

Enterprise Manager

Module Architecture The router module (Figure 1-1

CoreBuilder 5000 Integrated System.

Base board (integrated NIMs 2 and 3)

Faceplate

) occupies three slots in the

Networ k Int erfa ce Mo du le

(optional NIM 1)

CPU board

Figure 1-1 CoreBuilder 5000 Network Router Module

Router Module Overview 1-3

The base router module consists of a CoreBuilder 5000 14-inch base

board with an attached CPU board. Both the base board and the CPU

board plug directly into the CoreBuilder 5000 backplane.

The base router module provides four Token Ring backplane

connections (complex port connections), any one of which you can

connect to any one of 10 CoreBuilder 5000 backplane networks. The

Token Ring ports are equivalent to Cisco Systems IOS interface

connections.

You can connect only one Token Ring backplane connection to any one

CoreBuilder 5000 backplane network.

You can mount any one of multiple standard Cisco Systems Network

Interface Module (NIM) types on the base board to provide additional

routing connections (Cisco Systems NPM connections) for various

protocol types (see Figure 1-1

). Each NIM type requires a unique 3Com

faceplate.

Router Models The router module is available in the following configurations:

Base – Includes 4 Token Ring backplane connections.

FDDI MM, DAS – Multi-mode, dual attachment station/4 Token Ring

backplane connections.

FDDI MM, SAS – Multi-mode, single attachment station/4 Token Ring

backplane connections.

FDDI SM, DAS – Single mode, dual attachment station/4 Token Ring

backplane connections.

Quad Serial – 4 synchronous serial/4 Token Ring backplane

connections.

ATM OC3, MM – Multi-mode fiber optic cable (OC3)/4 Token Ring

backplane connections

ATM OC3, SM – Single mode fiber, optic cable (OC3)/4 Token Ring

backplane connections

1-4 CHAPTER 1: INTRODUCTION

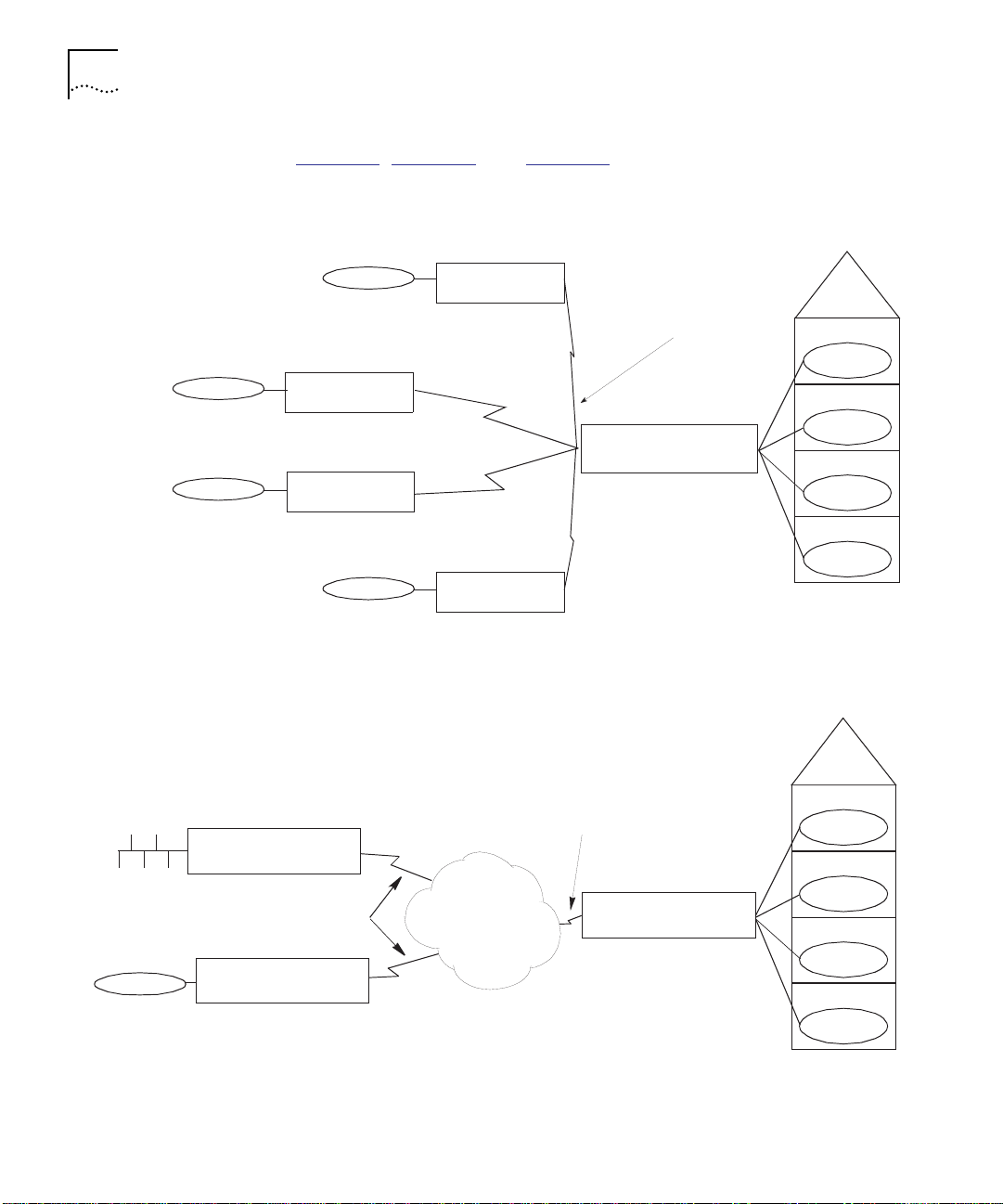

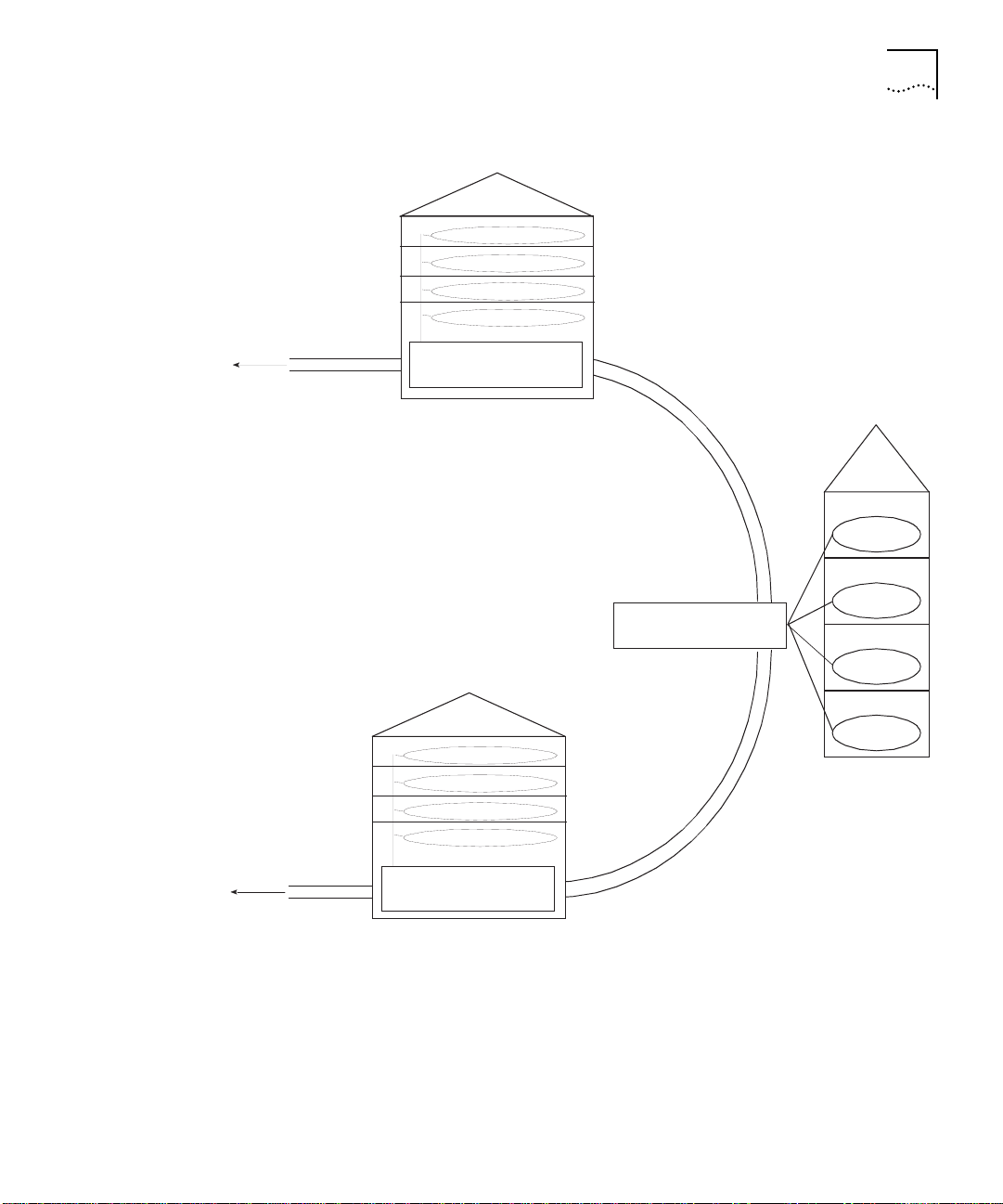

Typical Applications Figure 1-2, Figure 1-3, and Figure 1-4 show typical applications of the

Quad Serial, ATM OC3, and FDDI router modules.

Remote site C

Remote site D

Remote site B

3Com Edge

Router Module

3Co m Edge

Router Modu le

3Com Edge

Router Module

Remote site E

3Co m Edge

Router Module

Dedicated or dial-up

synchronous serial

connections

CoreBuilder 5000

Network Router Module

Figure 1-2 Quad Serial Network Router Module Typical Application

Local site A

Local site A

4th flo or

3rd floor

2nd flo or

1st floor

Ethernet

Token Ring

CoreBuilder 5 000

Network Router Module

ATM OC-3 MM

CoreBuilder 5000

Network Router Module

Figure 1-3 ATM OC3 Network Router Module Typical Application

ATM Service

ATM OC-3 MM

CoreBuilder 5000

Network Router Module

4th floor

3rd floor

2nd floor

1st floor

Build in g B

Router Module Overview 1-5

To other sites

To other sites

CoreBuild er 5000

Network Router Module

FDDI campus backbone

dual-attachment, multi-mode or single mode

Building C

CoreBuilder 5000

Networ k Rou ter Mod ul e

CoreBuilder 5000

Network Router Module

Buildin g A

4th floor

3rd floor

2nd floor

1st floor

Figure 1-4 Dual Attachment FDDI Network Router Module Typical Application

1-6 CHAPTER 1: INTRODUCTION

Router Module Features

FDDI Support The router module provides support for three FDDI configurations on

This section describes the following features of the router module:

■ FDDI Support

■ WAN Support

■ Protocol Translation

■ Scalable Protocol Support

■ WAN Optimization

■ ATM Migration

■ Management Support

■ Distributed, Scalable Reliability

■ Hot Swap Capability

the following two FDDI interfaces:

Multi-Mode Fiber – Can support distances of up to 2 km for both

Class A Dual Attachment Stations (DAS) and Class B Single

Attachment Stations (SAS).

Single Mode Fiber – Can support distances of up to 10 km for

Class A Dual Attachment Stations (DAS).

The FDDI interfaces also include a connector for attachment to an

external optical bypass unit. If the router module stops operating, the

optical bypass unit ensures that the FDDI signal bypasses that router.

The FDDI ring and other stations remain operational.

WAN Support The router module configured with a Quad Serial NIM provides four

synchronous serial ports to support backbone or redundant network

connections over the wide area network (WAN). The serial ports

support the following connection protocols:

■ V.35

■ EIA-232

■ EIA-449

■ RS-422

■ X.21

Router Module Features 1-7

Each serial port is capable of providing T1/E1 rate connectivity. Each

port operates in full duplex mode at speeds from 1,200 bits per

second (bps) to 2,048 Megabits per second (Mbps).

You can configure the synchronous serial ports to support IBM

®

Synchronous Data Link Control (SDLC) traffic using synchronous pass

through or Data Link Switching (DLSw).

Protocol Translation The router module protocol translation function allows you to extend

the life of your existing network devices. The router module allows

networks operating in dissimilar protocol environments to communicate

while managing up to 180 simultaneous sessions.

The router module supports the following bidirectional translations:

■ X.25 to TCP

■ X.25 to Local Area Transport (LAT)

■ X.25 to XRemote devices

■ LAT to TCP

■ LAT to TN3270 devices

Scalable Protocol

Support

Each router module type allows you to select a specific level of protocol

support to best match the needs of your application. Four Cisco IOS

router software feature sets offer an increasing level of protocol

support:

IP/IPX – The base feature set is used in applications requiring only

IP/IPX protocols.

Desktop – Provides additional LAN support for use in applications with

limited LAN protocol requirements.

Desktop plus IBM – Adds IBM support.

Enterprise – Adds top-level protocol support, including SNA

(Synchronous Network Architecture) integration.

1-8 CHAPTER 1: INTRODUCTION

Table 1-1 details the specific protocol support offered in each feature

set.

®

IPX

IP, Bridging,

LAN Extension,

Host Software,

Novell IPX,

DECnet

™

Appletalk

Phase 1 and 2

™

IV,

®

IP, Bridging, LAN

Extension, Host

Software, Novell IPX,

DECnet IV,

AppleTalk Phase 1

and 2

IP, Bridging, LAN

Extension, Host

Software, Novell IPX,

DECnet IV, AppleTalk

Phase 1 and 2, DECnet

V, XNS, Banyan

VINES

Table 1-1 Software Feature Sets

Feature

Category

Features Included in Each Feature Set

IP/IPX Desktop Desktop plus IBM Enterprise

LAN Support IP, Bridging,

LAN

Extension,

Host

Software,

Novell

Domain

IBM Support SRB/RSRB, SRT,

DLSW+, SNA &

NETBIOS

™

WAN

optimization (with

local

acknowledgment,

caching, and

filtering), SDLC

integration,

SDLC-to-LAN

conversion, SDLC

Transport (STUN),

Frame Relay SNA

Support (RFC 1490)

SRB/RSRB, SRT,

DLSW+, SNA &

NETBIOS WAN

optimization (with

local acknowledgment,

caching, and filtering),

SDLC integration,

SDLC-to-LAN

conversion, SDLC

Transport (STUN),

Frame Relay SNA

Support

(RFC 1490)TG/COS,

QLLC, DSPU

Concentration

Protocol

Translation

X.25-to-TCP,

X.25-to-LAT, and

X.25-to-XRemote;

LAT-to-TCP and

LAT-to-TN3279

(bidirectional)

IP Routing RIP, OSPF,

PIM, NHRP

RIP, OSPF, PIM,

NHRP, BGP,

EGP, IGRP

™

RIP, OSPF, PIM,

NHRP, BGP, EGP,

IGRP, Enhanced IGRP

RIP, OSPF, PIM, NHRP,

BGP, EGP, IGRP,

Enhanced IGRP, ES-IS,

IS-IS

WAN Services HDLC, PPP, X.25, Frame Relay, ISDN, SMDS, IPXWAN 2.0, ATM

WAN

Optimization

Header and link compression, X.25 packet payload compression,

dial-on-demand, dial backup, bandwidth-on-demand, custom and priority

queuing, access lists, access security, snapshot routing

Network

Autoinstall, SNMP, TELNET

Management

®

®

, OSI, Apollo®

Router Module Features 1-9

WAN Optimization The router module provides the following features to help limit network

operating costs by optimizing WAN network connections:

Dial-On-Demand Routing – A more economical alternative to a

second leased line as backup, a dial-on-demand backup dials up a

second line automatically if the primary WAN link fails.

Data Compression – The router module provides four types of data

compression for different network environments:

■ Link compression

■ X.25 packet payload compression

■ TCP/IP header compression

■ DEC

™

LAT compression

ATM Migration The router module can be upgraded to support your migration to an

ATM backbone (see Figure 1-3

).

Add an ATM network backbone by replacing your original router

module NIM, with one of two ATM NIM types:

Management

Support

■ OC-3, MM (Optical Carrier Type 3, Multi-Mode)

■ OC-3, SM (Optical Carrier Type 3, Single Mode)

Each ATM NIM type provides 155 Mbps backbone bandwidth.

The router module is shipped with a comprehensive Management

Information Base (MIB) for using Simple Network Management Protocol

(SNMP), the industry standard for network management.

You can monitor and control the router module from any SNMP-based

management station, including the 3Com Transcend Enterprise

Manager.

In addition, the router module is fully compatible with CiscoWorks

®

network management software from Cisco Systems.

TELNET capability provides for direct access in-band to the agent, and a

console port on the module provides for out-of-band management

capability.

1-10 CHAPTER 1: INTRODUCTION

Distributed, Scalable

Reliability

The router module operates in the CoreBuilder 5000 Integrated System

which is structured to eliminate any single point of failure.

The CoreBuilder 5000 hub provides redundancy for power supplies,

switched ports, controller modules, and the hub management module.

Automatic switching to the redundant components ensures

continuation of the specific function.

3Com fault-tolerant features are fully-scalable, allowing you to

implement and alter the degree of fault-tolerance you need as your

network grows.

Hot Swap Capability The router module features “hot swap” capability. You can swap the

router module in or out of (install or remove from) a powered-on

CoreBuilder 5000 hub.

2

INSTALLING THE MODULE

This chapter contains the following sections:

■ Precautionary Procedures

■ Quick Installation

■ Unpacking Procedures

■ Preparing to Install the Router Module

■ Installing the Router Module

■ Making NIM Connections

Precautionary Procedures

CAUTION: Electrostatic discharge (ESD) can damage static-sensitive

devices on circuit boards.

Follow these precautions when you unpack or handle the router

module:

■ Do not remove the board from its antistatic shielding bag until you

are ready to inspect or install it.

■ Handle the board by the faceplate only.

Use proper grounding techniques when you install the module,

including:

■ Using a footstrap and grounded static mat or wearing a grounded

static discharge wrist strap.

■ Touching the rack or other ground source just before you handle the

module.

2-2 CHAPTER 2: INSTALLING THE MODULE

Quick Installation Table 2-1 outlines the steps for quick installation of the

CoreBuilder

installing CoreBuilder 5000 modules, use this table as a checklist.

Otherwise, refer to the remainder of this chapter and to Chapters 3

and 4 to complete the installation.

.

Table 2-1 Quick Installation Steps

Step Procedure Section Title/Page Number

1 Unpack the module. Unpacking Procedures on

2 Prepare to install the module by verifying

3 Install the module into three contiguous

4 Connect the NIM cables. Making NIM Connections on

5 Attach a terminal to the console or auxiliary

6 Configure the NIM connections using Cisco

7 Configure the Cisco router interfaces using

8 Configure the Token Ring backplane

9 Monitor initial router module operation. Monitoring Router Module

™

5000 Network Router Module. If you are familiar with

DIP switch and jumper plug positions.

slots in the CoreBuilder 5000 Integrated

System Hub.

ports.

IOS router configuration commands.

Cisco IOS router configuration commands.

connections using DMM software.

page 2-2

Preparing to Install the Router

Module on page 2-4

Installing the Router Module

on page 2-5

page 2-7

Attaching a Management

Terminal on page 3-2

Configuring the Cisco NIM

Connections on page 3-3

Configuring Cisco

Parameters on page 3-3

Configuring 3Com

Parameters on page 3-5

LEDs on page 4-1

Unpacking Procedures

For information about potential problems, refer to the troubleshooting

techniques described in Chapter 5, Troubleshooting

.

To unpack the CoreBuilder 5000 Network Router Module:

1 Verify that the module is the model you ordered by checking the model

number listed on the side of the shipping carton.

The product model number listed on the box contains the prefix “3C9.”

Unpacking Procedures 2-3

2 Remove the module, in its antistatic bag, from the shipping carton.

3 Remove the module from the antistatic shielding bag and inspect it for

damage.

CAUTION: Always handle the module by the faceplate, being careful

not to touch the components. If the module appears to be damaged,

return it to the antistatic shielding bag, repack it in the shipping carton,

and contact your local supplier.

Keep the shipping carton and the antistatic shielding bag in which your

module was shipped so that you can repackage the module for storage

or shipment.

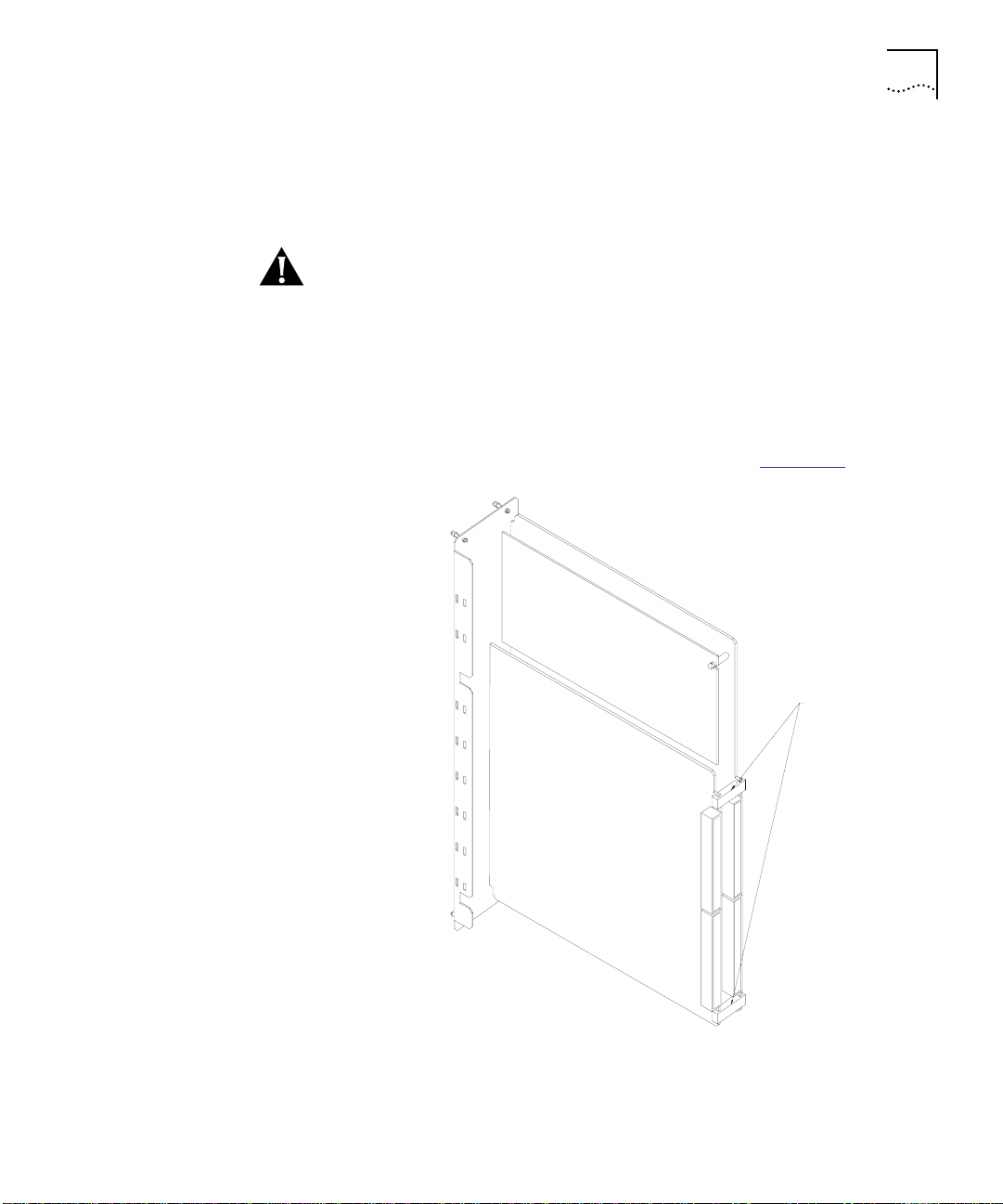

4 Remove the spacing clips from the router module (Figure 2-1

Spacing clips

).

Figure 2-1 Locating the Spacing Clips

2-4 CHAPTER 2: INSTALLING THE MODULE

CAUTION: The spacing clips on the CoreBuilder 5000 Network Router

Module are used only to protect the module during shipping. You must

manually remove the spacing clips before you install the module.

Failure to remove the spacing clips before installation could result in

damage to the CoreBuilder 5000 Integrated System Hub.

Preparing to Install the Router Module

Restoring Base

Board Positions

Plug inserted

in bottom

position

All DIP switch

positions on

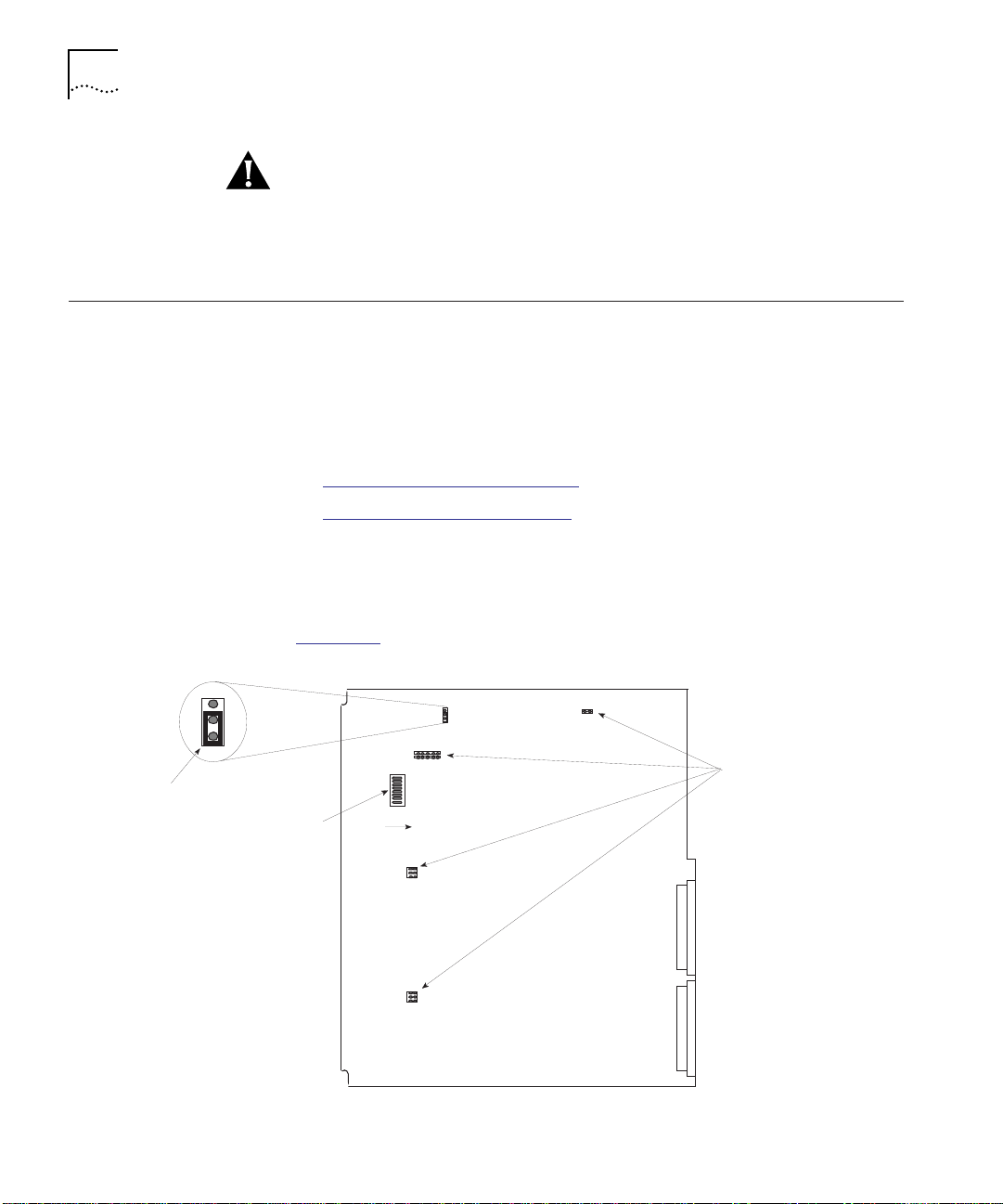

This section includes information to allow you to restore correct DIP

switch and jumper plug positions on the base and CPU boards if the

positions are inadvertently altered.

If you believe the default positions have been altered, refer to the

following sections:

■ Restoring Base Board Positions

■ Verifying CPU Board Positions

Do not attempt to configure the DIP switches and jumper plugs on the

base board. However, if you suspect that the DIP switch or jumper plug

positions have been altered, restore them to the positions shown in

Figure 2-2

.

.

Jumper plug

positions empty

On

Figure 2-2 Base Board DIP Switch and Jumper Plug Positions

Installing the Router Module 2-5

Verifying CPU Board

Positions

Do not attempt to configure the jumper plugs on the CPU board.

However, if you suspect that the jumper plug positions have been

altered, restore them to the positions shown in Figure 2-3

.

Plugs not inserted

Plug inserted in

bottom positi on

Figure 2-3 CPU Board Jumper Plug Positions

Plug inserted

.

Installing the Router Module

This section describes how to install the router module in the

CoreBuilder 5000 Integrated System Hub.

You do not need to power off the hub to install

or remove the router

module. You can insert the module while the hub is operating

(hot swap capability).

To install the router module:

1 Properly ground yourself prior to handling the module.

Put on a static wrist guard or touch a grounded static mat before you

handle the module.

2 Locate 3 adjacent open slots in the hub, or remove panels on the hub

to expose 3 slots for the router module.

2-6 CHAPTER 2: INSTALLING THE MODULE

3 Insert the router module into the board guides at the top and bottom

of the slot and slide it into the hub by pressing firmly at the top and

bottom of the faceplate. Make sure that the module ejectors are open

fully when you insert the module and that the connectors are

well-seated into the backplane of the hub. Figure 2-4

module being installed in a CoreBuilder 5000 Integrated System Hub.

Spring-lo aded screws

Ejector (opened)

CoreBuilder 5000 Network

Router Module

shows a router

Ejector

Spring-loaded screws

Figure 2-4 CoreBuilder 5000 Network Router Module in a CoreBuilder 5000

Integrated System Hub

To minimize electromagnetic interference, ensure that the slots adjacent

to the router module are occupied or have blank panels installed.

4 Push the module ejectors closed.

5 Using your fingers, tighten the spring-loaded screws on the front of the

router module faceplate (do not overtighten).

Making NIM Connections 2-7

Making NIM Connections

Making FDDI NIM

Connections

This section provides guidelines for making NIM (Network Interface

Module) network cable connections. This section describes the

following topics:

■ Making FDDI NIM Connections

■ Making Quad Serial NIM Connections

■ Making ATM NIM Connections

This section provides information on the following topics:

■ Connecting the Multi-Mode, Dual Attachment Station NIM

■ Connecting the Multi-Mode, Single Attachment Station NIM

■ Connecting the Multi-Mode Optical Bypass Switch

■ Connecting the Single Mode, Dual Attachment Station NIM

Connecting the Multi-Mode, Dual Attachment Station NIM

The Multi-Mode, Dual Attachment Station NIM (MM, DAS) connectors

are Fiber Distributed Data Interface (FDDI) standard physical sublayer

(PHY) connectors. The media interface connector (MIC) connects to

FDDI-standard 62.5/125 micron multi-mode fiber optic cable.

Figure 2-5

shows the MIC connector typically used for network and

chassis connections in multi-mode FDDI applications.

H1738

Figure 2-5 Multi-Mode FDDI Network Interface Connector, MIC Type

A dual attachment station requires two connections, one to the primary

ring and one to the secondary ring. On the FDDI MM, DAS NIM, the

PHY-A port is the left port and PHY-B is the right port.

Figure 2-6

shows how to connect a FDDI MM, DAS router module to

another Dual Attachment Station.

2-8 CHAPTER 2: INSTALLING THE MODULE

Figure 2-6 Making Connections to the FDDI MM, DAS NIM

To connect the FDDI MM, DAS NIM to another Dual Attachment

Station:

1 Connect PHY-A on the router module to PHY-B on the other DAS.

PHY-BPHY-A

PHY-B

Dual Attachment

Station (DAS)

PHY-A

2 Connect PHY-B on the router module to PHY-A on the other DAS.

Connecting the Multi-Mode, Single Attachment Station NIM

Connect the Single Attachment router module’s PHY-A port through a

concentrator to a Single Attachment ring (Figure 2-7

PHY-A

To concentrator

Figure 2-7 Making Connections to the FDDI MM, SAS NIM

).

Making NIM Connections 2-9

You can also connect the FDDI MM, SAS router module directly to

another device in a point-to-point configuration.

Connecting the Multi-Mode Optical Bypass Switch

The Multi-Mode FDDI router modules provide an optical bypass

capability that automatically drops the router module from the FDDI

ring if the module fails. Dropping the module from the ring ensures

that the ring remains available to the other stations.

To ring

Bypass operation

Figure 2-8

shows how to connect an optical bypass switch (not

included with the CoreBuilder 5000 Network Router Module) to the

FDDI MM, DAS NIM.

Optical bypass switch

Figure 2-8 Connecting the Multi-Mode Optical Bypass Switch

Optical bypass

interface cable

DIN

connector

To connect the FDDI MM, DAS NIM to an optical bypass switch:

1 Connect PHY-A on the router module to PHY-B on the optical bypass

switch.

2 Connect PHY-B on the router module to PHY-A on the optical bypass

switch.

3 Connect one end of the optical bypass interface cable to the 6-pin

Deutsche Industrie-Norm (DIN) connector on the optical bypass switch.

4 Connect the other end of the optical bypass interface cable to the

6-pin DIN connector on the router module.

2-10 CHAPTER 2: INSTALLING THE MODULE

Connecting the Single Mode, Dual Attachment Station NIM

A dual attachment, single mode module configuration requires two

connections: one to the primary ring and one to the secondary ring.

Figure 2-9

shows how to connect a FDDI SM, DAS router module to

another Dual Attachment Station.

FC connector type

To primary ring

To secondary ring

From primary ring

From secondary ring

Figure 2-9 Making Connections to the FDDI SM, DAS NIM

To connect the FDDI SM, DAS NIM to another Dual Attachment Station:

1 Connect one end of an FC connector cable to the PHY-A XMTR

connector on the router module.

2 Connect the other end of the FC connector cable to the primary ring

RCVR connector on the other DAS.

3 Connect one end of a second FC connector cable to the PHY-A RCVR

connector on the router module.

4 Connect the other end of the second FC connector cable to the

primary ring XMTR connector on the other DAS.

5 Connect one end of a third FC connector cable to the PHY-B XMTR

connector on the router module.

6 Connect the other end of the third FC connector cable to the

secondary ring RCVR connector on the other DAS.

7 Connect one end of a fourth FC connector cable to the PHY-B RCVR

connector on the router module.

8 Connect the other end of the fourth FC connector cable to the

secondary ring XMTR connector on the other DAS.

Making NIM Connections 2-11

Making Quad Serial

NIM Connections

The Quad Serial NIM has four synchronous serial ports with custom

DB-60 connectors.

When setting up your serial port connections, consider distance

limitations and potential electromagnetic interference (EMI) as defined

in the Electronics Industries Association (EIA) and Telecommunications

Industry Association (TIA) standards, such as standard EIA/TIA-232.

Figure 2-10

shows how to connect the Quad Serial NIM from any one

serial port on the router module to a modem or other communications

device.

Serial transmission cable

EIA/TIA-232, EIA/TIA-449, V.35,

X.21 or EIA-530 Connector

Modem or other

communications

device

Custom 60-pin

connector

Figure 2-10 Making Connections to the Quad Serial NIM

Be careful to insert the DB-60 connector correctly to prevent damage

to the connector pins.

To connect the Quad Serial NIM, attach each serial port from the

custom 60-pin connector to a modem or other DCE device using one

of the following standard device cable connectors:

■ EIA/TIA-232

■ EIA/TIA-449

■ EIA-530

■ V.35

■ X.21

2-12 CHAPTER 2: INSTALLING THE MODULE

Making ATM NIM

Connections

This section provides information on the following topics:

■ ATM Connector Types

■ ATM Distance Limitations

ATM Connector Types

Each ATM NIM type requires a specific connector (Figure 2-11

OC-3 MM NIM – Requires a multi-mode SC-type connector.

OC-3 SM NIM – Requires a single mode SC-type connector.

SC-type connector for

ATM OC-3 SM NIM

SC-type connector for

ATM OC-3 MM NIM

):

Figure 2-11 Making Connections to the ATM NIMs

ATM Distance Limitations

The SONET (Synchronous Optical Network) specification for fiber-optic

transmission defines two types of fiber:

■ single mode

■ multimode

Single-mode fiber is capable of higher bandwidth and greater cable run

distances than multimode fiber.

Making NIM Connections 2-13

The typical maximum distances for single-mode and multimode

transmissions, as defined by the SONET, are provided in Tab le 2 -2

you connect two optical devices at a distance greater than those

specified in Table 2-2

, significant signal loss could occur, making

transmission unreliable.

Table 2-2 ATM Distance Limitations

Fiber Type Maximum Distance Between Stations

Single mode Up to 9 miles (15 kilometers)

Multimode Up to 1.5 miles (3 kilometers)

. If

3

CONFIGURING THE MODULE

This chapter contains the following topics:

■ Configuration Overview

■ Attaching a Management Terminal

■ Configuring the Cisco NIM Connections

■ Configuring Cisco Parameters

■ Configuring 3Com Parameters

CAUTION: Throughout this chapter, Cisco nomenclature refers to the

four Token Ring backplane connections as interfaces 0, 1, 2, and 3.

3Com refers to the same four router connections as ports 1, 2, 3, and

4. For example, when configuring the router module, Cisco interface 0

is equivalent to 3Com port 1.

Configuration Overview

The following list is an overview of the procedures that are required

configure the router module. For more detail, refer to sections that

follow.

CAUTION: Failure to follow the configuration sequence specified in this

section could result in error messages at the router management

terminal during the configuration procedure. For best results, use the

procedure as outlined in the sections that follow.

To configure the router module:

1 Attach a Management Terminal – Attach a management terminal to

the console port of the router module.

2 Configure the Cisco NIM Connections – From the management

terminal, use Cisco router configuration commands to configure the

NIM (Network Interface Module) connections.

3-2 CHAPTER 3: CONFIGURING THE MODULE

3 Configure the Cisco Parameters – Use the management terminal to

configure the four Cisco router interfaces, including interface speed.

Attaching a Management Terminal

4 Configure the 3Com Parameters – Use the management terminal

that is connected to the 3Com

®

CoreBuilder 5000 Distributed

Management Module (DMM) to configure the four 3Com router ports,

including CoreBuilder

™

5000 backplane network speed.

Each of these steps is detailed in the sections that follow.

If you are using the router module in an unmanaged hub (one in which

a DMM module is not installed), upon power on, the router module

uses the last module configuration saved in NVRAM. To disable NVRAM

configuration, set DIP switch 5 to Off (see Figure 2-2

).

When you power on the router module with NVRAM configuration

disabled, the four Token Ring ports are set to isolated mode.

This section provides information on attaching a terminal to the console

or auxiliary ports of the router module for use as a Cisco management

terminal.

You must use the console port for initial router configuration. After you

configure the router, you can use the auxiliary port for an asynchronous

serial connection.

Connecting to the

Console Port

All router modules include an asynchronous router console port (female

DB-25 connector) wired as a data communications equipment (DCE)

device. The port requires a straight-through cable for connection to a

local terminal. The port uses the following default parameters:

■ 9600 baud

■ 8 data bits

■ No parity generated or checked

■ 2 stop bits

Configuring the Cisco NIM Connections 3-3

Connecting to the

Auxiliary Port

Configuring the Cisco NIM Connections

All router modules include a male DB-25 connector auxiliary port

(labeled AUX PORT DTE). The auxiliary port is a shared-memory data

terminal equipment (DTE) port to which you can attach an EIA/TIA-232

connector from a channel service unit/data service unit (CSU/DSU), a

modem, or protocol analyzer for network access.

Console and auxiliary port cabling requirements are provided in

Appendix B, Cabling Specifications

.

From the Cisco management terminal, use Cisco IOS routing

configuration commands to configure the FDDI or Quad Serial NIM

connections.

If you are configuring a base router module without a NIM installed

(Model Number 6701CS-NN), proceed to the next section Configuring

Cisco Parameters.

You may receive status messages referring to NIM 1, NIM 2, and NIM 3.

Cisco IOS makes the following NIM designations:

■ Optional NIM as NIM 1

■ Token Ring backplane interfaces 0 and 1 (3Com ports 1 and 2) as

NIM 2

Configuring Cisco Parameters

■ Token Ring backplane interfaces 2 and 3 (3Com ports 3 and 4) as

NIM 3

For detailed information on Cisco IOS routing configuration commands,

refer to the Cisco hardcopy documentation set

(Part Number 17-00138-MS) or to the Cisco documentation set on the

Cisco UniverCD

™

CD-ROM (Part Number 17-00138-CD).

This section outlines procedures for configuring Cisco parameters for

the four Token Ring interface connections on the router module using

Cisco IOS software management commands. The procedures include:

■ Setting General Interface Parameters

■ Setting Token Ring Speed

3-4 CHAPTER 3: CONFIGURING THE MODULE

Setting General

Interface Parameters

Setting Token Ring

Speed

Set any required general Cisco parameters for the four router

interfaces. Cisco Systems IOS software provides management

commands for configuring routing interface connections. Refer to the

Cisco hardcopy documentation set (Part Number 17-00138-MS) or to

the Cisco documentation set on the Cisco UniverCD CD-ROM

(Part Number 17-00138-CD).

Set the Token Ring speed of each router interface connection to match

the speed of the CoreBuilder 5000 backplane network to which it will

be connected.

To set the Token Ring speed of a router interface:

1 Use DMM at the CoreBuilder 5000 management station to ensure that

the router interface port is in isolated mode:

CB50 00> set po rt 7.1 network iso lated

Port 07 .01 networ k id set to I SOLATED.

2 At the router management terminal, set the configuration mode to

enable:

Rout er> e nable

3 Enter the required password:

Passwo rd: ****

4 Set the router management terminal to configuration mode:

Rout er# con fig termin al

Enter c onfigurat ion command s, one per line. End with

CNTL/Z.

Router (config)#

5 Specify the number of the Token Ring interface:

Router (co nfig )# in terface tokenrin g 0

Router (config-i f)#

6 Shut down the router interface:

Router (co nfig -i f)# shutdown

Router (config -if)#

7 Specify the ring speed of the router interface (in this example, 4 MBPS):

Router (co nfig -i f) # ring-speed 4

Router (config -if)#

Configuring 3Com Parameters 3-5

8 Remove the router interface from shutdown state:

Router (conf ig-i f)# no shutdown

Router (config -if)#

9 Exit from configuration mode:

Rout er(conf ig-i f)# ^Z

Rout er#

10 Save the interface configuration changes:

Rout er# w rite mem

Building configuration...

[OK]

Router#

At this point, the system may display a sequence of RESET messages on

the router management terminal. This a normal, temporary condition

that ends when the interface synchronizes to the new speed.

Configuring 3Com Parameters

This section outlines procedures for using DMM commands to

configure basic parameters for the 3Com router module.

Refer to the 3Com CoreBuilder 5000 Integrated System Hub Installation

and Operation Guide, Chapter 1, for a CoreBuilder 5000 backplane

architecture description and to the 3Com DMM Commands Guide for

detailed information on DMM configuration commands.

To configure the 3Com router module:

1 Set the Token Ring speed of the targeted four CoreBuilder 5000

backplane networks.

You must set the Token Ring speed of a backplane network to match

the Token Ring speed of the Cisco interface you intend to connect to

the backplane network.

In the following example, Token Ring backplane network 9 is set to 4

Mbps, the same speed at which the Cisco interface port was set.

CB50 00> s et network token_ring toke n_ring_9 r ing_speed

4mbps

Value set to 4 MBPS.

2 Connect each of the router ports to one of the 10 CoreBuilder 5000

backplane networks (or set the port to isolated mode).

3-6 CHAPTER 3: CONFIGURING THE MODULE

You cannot set more than one router port to any one backplane

network.

In the following example, 3Com router port 1 (Cisco interface 0) is set

to backplane network 9:

CB50 00> set port 7.1 network token_ring_9

Port 07 .01 networ k id set to T OKEN_RING _9.

At this point, the system may display a sequence of RESET messages at

the Cisco router management terminal. This is a normal, temporary

condition that ends when the interface successfully connects to the

backplane network.

3 Save the configuration:

CB50 00> save all

Failure to save configuration settings may result in loss of

configuration data.

4

MONITORING OPERATION

This chapter contains the following topics:

■ Monitoring Router Module LEDs

■ Displaying the Router Module Configuration

Monitoring Router Module LEDs

This section identifies the front panel LEDs of the CoreBuilder™5000

Network Router Module:

■ Common Front Panel LEDs

■ FDDI NIM LEDs

■ Quad Serial NIM LEDs

■ ATM NIM LEDs

4-2 CHAPTER 4: MONITORING OPERATION

Common Front Panel

LEDs

The front panel LEDs of the base model (without NIM) router module

are common to all router module models. Figure 4-1

common front panel LEDs. Table 4-1

describes the LEDs.

shows the

Figure 4-1 Common Front Panel LEDs

RESET is a recessed pushbutton that is used to reset the router module

under certain conditions. Refer to Chapter 5, Troubleshooting

, for

more information on using the RESET button.

Monitoring Router Module LEDs 4-3

.

Table 4-1 Front Panel LED Definitions

LED Description Definition

MOD STATUS Module Status ON – Indicates that 3Com router software is

loaded and the router module is

operational.

OFF – Indicates that 3Com router software

is not operational.

NIM PRES NIM Present ON – Indicates that an optional NIM is

installed on the router module.

OFF – Indicates that an optional NIM is not

installed on the router module.

SYS RUN System Run ON – Indicates that Cisco IOS router

software is loaded and operational.

OFF – Indicates that Cisco IOS router

software is not loaded and operational.

LEDS NIM NIM 1 Data

Present

ON – Indicates that data traffic is present

on one or more of the interfaces on the

optional NIM.

OFF – Indicates that data traffic is not

present on any interfaces on the optional

NIM.

LEDS DTR A, B NIM 2 (Dual

Token Ring A

and B) Data

Present

ON – Indicates that data traffic is present

on one or both of Cisco interfaces 0 and 1

(3Com ports 1 and 2).

OFF – Indicates that data traffic is present

on one or both of Cisco interfaces 0 and 1

(3Com ports 1 and 2).

LEDS DTR C, D NIM 3(Dual

Token Ring C

and D) Data

Present

ON – Indicates that data traffic is present

on one or both of Cisco interfaces 2 and 3

(3Com ports 3 and 4).

OFF – Indicates that data traffic is present

on one or both of Cisco interfaces 2 and 3

(3Com ports 3 and 4).

HLTH NIM NIM 1 Healthy ON – Indicates that optional NIM 1 is

operational and line protocol for the NIM

interfaces is up.

OFF – Indicates that the optional NIM 1 is

not operational.

HLTH DTR A, B NIM 2 (Dual

Token Ring A

and B) Healthy

ON – Indicates that Cisco interfaces 0 and 1

(3Com ports 1 and 2) are operational and

line protocol for the interfaces is up.

OFF – Indicates that Cisco interfaces 0 and

1 (3Com ports 1 and 2) are not operational.

4-4 CHAPTER 4: MONITORING OPERATION

Table 4-1 Front Panel LED Definitions (continued)

LED Description Definition

HLTH DTR C, D NIM 3 (Dual

16 MBPS A Port 1 (Cisco

16 MBPS B Port 2 (Cisco

16 MBPS C Port 3(Cisco

16 MBPS D Port 4 (Cisco

RING A IN Port 1 (Cisco

RING B IN Port 2 (Cisco

Token Ring A

and B) Healthy

interface 0) set

to 16 Mbps

interface 1) set

to 16 Mbps

interface 2) set

to 16 Mbps

interface 3) set

to 16 Mbps

interface 0) in

Ring

interface 1) in

Ring

ON – Indicates that Cisco interfaces 2 and 3

(3Com ports 3 and 4) are operational and

line protocol for the interfaces is up.

OFF – Indicates that Cisco interfaces 2 and

3 (3Com ports 3 and 4) are not operational.

ON – Indicates that port 1 (Cisco interface

0) is set to 16 Mbps.

OFF – Indicates that port 1 (Cisco interface

0) is set to 4 Mbps or is not initialized.

ON – Indicates that port 2 (Cisco interface

1) is set to 16 Mbps.

OFF – Indicates that port 2 (Cisco interface

1) is set to 4 Mbps or is not initialized.

ON – Indicates that port 3 (Cisco interface

2) is set to 16 Mbps.

OFF – Indicates that port 3 (Cisco interface

2) is set to 4 Mbps or is not initialized.

ON – Indicates that port 4 (Cisco interface

3) is set to 16 Mbps.

OFF – Indicates that port 4 (Cisco interface

3) is set to 4 Mbps or is not initialized.

ON – Indicates that port 1 (Cisco interface

0) is connected or connecting to its assigned

backplane network, or is set to isolated

mode.

OFF – Indicates that port 1(Cisco interface

0) is not connected to its assigned

backplane network.

ON – Indicates that port 2 (Cisco interface

1) is connected or connecting to its assigned

backplane network, or is set to isolated

mode.

OFF – Indicates that port 2 (Cisco interface

1) is not connected to its assigned

backplane network.

Monitoring Router Module LEDs 4-5

Table 4-1 Front Panel LED Definitions (continued)

LED Description Definition

RING C IN Port 3 (Cisco

interface 2) in

Ring

RING D IN Port 4 (Cisco

interface 3) in

Ring

ON – Indicates that port 3 (Cisco interface

2) is connected or connecting to its assigned

backplane network, or is set to isolated

mode.

OFF – Indicates that port 3 (Cisco interface

2) is not connected to its assigned

backplane network.

ON – Indicates that port 4 (Cisco interface

3) is connected or connecting to its assigned

backplane network, or is set to isolated

mode.

OFF – Indicates that port 4 (Cisco interface

3) is not connected to its assigned

backplane network.

4-6 CHAPTER 4: MONITORING OPERATION

FDDI NIM LEDs In addition to the common front panel LEDs, the three FDDI router

module models also have the LEDs shown in Figure 4-2

PHY-A

RING OP

PHY-B

RING OP

:

FDDI MM, DAS

Router Module

FDDI MM, SAS

Router Module

FDDI SM, DAS

Router M od ul e

Figure 4-2 FDDI NIM LEDs

The PHY-A RING OP LED lights when the router module PHY-A

attachment is connected in the FDDI A ring. The PHY-B RING OP LED

(Dual-Attachment FDDI NIMs only) lights when the PHY-B attachment

is connected in the FDDI B ring.

Monitoring Router Module LEDs 4-7

Quad Serial NIM

LEDs

The Quad Serial NIM router module model includes the additional LEDs

shown in Figure 4-3

P-3

P-2

P-1

P-0

.

LP

CN

TD

TC

RD

RC

LP

CN

TD

TC

RD

RC

LP

CN

TD

TC

RD

RC

LP

CN

TD

TC

RD

RC

Figure 4-3 Quad Serial NIM LEDs

4-8 CHAPTER 4: MONITORING OPERATION

Table 4-2 describes the Quad Serial NIM LEDs.

Table 4-2 Quad Serial NIM LED Definitions

LED Description Definition

LP Looped ON – Indicates that the port is set to a

CN Connected ON – Indicates that the port is in ready-state

TD Transmitted Data ON – Indicates that data is being

TC Transmitted Clock The clock supplied by the DCE device to

RD Received Data ON – Indicates that data is being received

RC Received Clock The clock supplied by the DCE device to

loopback state.

OFF – Indicates that the port is set to normal

mode.

(DSR, DTR, DCD, RTS, CTS signals) to

exchange data.

OFF – Indicates that the port is not in

ready-state to exchange data.

transmitted over the serial link from the DTE

device. The router module port can be set

to operate as DTE or DCE.

OFF – Indicates that data is not being

transmitted by the DTE device.

synchronize transmitted data.

over the serial link by the DCE device. Each

router module port can be set to operate as

DTE or DCE.

OFF – Indicates that data is not being

received by the DCE device.

synchronize received data.

Monitoring Router Module LEDs 4-9

ATM NIM LEDs The ATM MM and ATM SM router modules include the additional LEDs

shown in Figure 4-4

.

Figure 4-4 ATM NIM LEDs

4-10 CHAPTER 4: MONITORING OPERATION

Table 4-3 describes the ATM NIM LEDs.

Table 4-3 ATM NIM LED Definitions

LED Description Definition

Busy ATM NIM Busy ON – Indicates that the NIM is not available

Ready ATM NIM Ready ON – Indicates that the NIM is ready to

RX Cells Received Cells ON – Indicates that the ATM NIM is receiving

Rx Alarm Receive Alarm ON – Indicates that the receive signal is lost

to receive data cells.

OFF – Indicates that the NIM is available for

data cells.

receive data cells.

OFF – Indicates that the NIM is not ready to

receive ATM cells.

a a data cell. This LED flickers during normal

operation.

OFF – Indicates that the ATM NIM is not

receiving a data cell.

or that a remote alarm has been received by

the ATM NIM.

OFF – Indicates that the receive signal is not

lost and that a remote alarm has not been

received.

Displaying the Router Module Configuration

To display information about router module configuration and status,

use the following DMM commands.

■ SHOW MODULE

■ SHOW MODULE VERBOSE

■ SHOW PORT

■ SHOW PORT VERBOSE

Displaying the Router Module Configuration 4-11

A

Using the SHOW

MODULE Command

Slot Module Version Network General Information

----- --------- ------ ------- ----- -------- - ---------- --------

07.01 6704R-TCS v1.00.0 PER_PORT Module up

Using the SHOW

MODULE VERBOSE

Command

Slot Module Versi on Ne twork Gener al Informa tion

----- - --------- ----- ----- -- ------------- --- --------- -------

07.01 6704R-TCS v1.00.0 PER_PORT Module up

Use the SHOW MODULE command to display summary information

about the router module:

CB50 00> s how module 7.1

This command displays the summary information shown in Figure 4-5.

Figure 4-5 SHOW MODULE Command Information

Use the SHOW MODULE VERBOSE command to display detailed

information about the router module:

CB50 00> s how module 7.1 ver bose

This command displays the detailed information shown in Figure 4-6.

6704R- TCS: CB500 0 Token Ring Back bone Rout er Module

Boot Ve rsion: v1.00

Native Software V ersion: 10.30

Native Boot Software V ersion: v5.20

Number Simple Por ts: 1

Networ k Interfac e Module Typ e: FDDI- SINGLE-MO DE-DUAL-AT T

Using the SHOW

PORT Command

Figure 4-6 SHOW MODULE VERBOSE Command Information

Use the SHOW PORT command to display summary information about

any of the four router module ports:

CB50 00> show port 7.2

4-12 CHAPTER 4: MONITORING OPERATION

This command displays the summary information shown in Figure 4-7.

Port Mo de Sta tus Netwo rk Genera l Informat ion

----- ------ -- ------ -------- ----- ---- -------- ---- --------------- ------

07.02 L OGICAL OKAY TOKEN _RING_2

Figure 4-7 SHOW PORT Command Information

Using the SHOW

PORT VERBOSE

Use the SHOW PORT VERBOSE command to display detailed

information about any one of the four router module ports:

Command

CB50 00> s how port 7.2 verbose

This command displays the detailed information shown in Figure 4-8.

Port Di splay for Module 6704R -TCS :

Port Mo de Stat us Network General Informat ion

----- - ------- -- -------- --------- -- -------- ------ -- --------------------

07.02 L OGICAL OKAY TOKEN_R ING_2

Port Co nnector: BACKP LANE

IP Address: 151.104.12.1

Subnetwork Mask: ff.ff.00.00

Default Gateway: 0.0.0.0

Station Address: 08-00-8f-00-00-01

Speed: 16 MBPS

Figure 4-8 SHOW PORT VERBOSE Command Information

The Speed field in Figure 4-8 identifies the speed for the Cisco interface

that corresponds to the 3Com port.

Displaying the Router Module Configuration 4-13

Interpreting the

SHOW PORT Status

Field

The SHOW PORT and SHOW PORT VERBOSE commands provide

standard DMM command configuration information with the exception

of the Status field. DMM SHOW PORT Status field definitions are

unique for the CoreBuilder 5000 Network Router Module. Table 4-4

lists the Status field definitions for ports on the CoreBuilder 5000

Network Router Module.

Table 4-4 SHOW PORT Status Field Definitions

Status Field Indication Definitions

NOT INSERTED The port is set to isolated mode.

CONNECTING The port is attempting to connect with the backplane

network.

OKAY The port is connected normally to the backplane

network.

SPEED MISMATCH The speed of the port (as set for the corresponding

LOST LOCK The 3Com port has lost synchronization with the

Cisco interface) does not match the speed of the

backplane network to which it is assigned.

corresponding Cisco interface.

5

TROUBLESHOOTING

Troubleshooting Startup Problems

This chapter provides hardware troubleshooting information to use if

the CoreBuilder

correctly. After reviewing the information in this chapter, if you cannot

correct the problem, contact your 3Com representative for further

assistance.

For IOS software-related troubleshooting information, refer to the

appropriate Cisco Systems manual. For information on interpreting

router module LEDs, refer to Chapter 4, Monitoring Operation.

This chapter contains the following sections:

■ Troubleshooting Startup Problems

■ Troubleshooting Network Connection Problems

■ Troubleshooting WAN Connection Problems

■ Correcting Operating Malfunctions

■ Recovering a Lost Password

This section describes how to troubleshoot startup problems on the

CoreBuilder 5000 Network Router Module.

™

5000 Network Router Module fails to operate

When you first install the router module in the hub, the Cisco Systems

router software runs a full set of hardware diagnostic tests. If the router

module fails diagnostics, the MOD STATUS LED does not turn off. This

indicates a problem with the router module hardware or software.

Refer to the appropriate Cisco Systems troubleshooting documentation

for corrective action.

5-2 CHAPTER 5: TROUBLESHOOTING

Troubleshooting Network Connection Problems

Troubleshooting WAN Connection Problems

If the CoreBuilder 5000 Network Router Module does not appear to be

routing traffic properly on the network, it may indicate that there is no

connection to the network. Perform the following troubleshooting

actions:

■ From the 3Com management interface (for example,

CoreBuilder 5000 Distributed Management Module), verify that the

router module backplane port is set to the appropriate backplane

network (channel).

■ Use the DMM SHOW PORT command and check the Status field for

the port. Refer to Using the SHOW PORT VERBOSE Command

on

page 4-12.

■ Use the ping utility to confirm there is network connectivity.

■ Verify that your router configuration is valid. Refer to the Cisco

Systems Troubleshooting Internetworking Systems guide for more

information.

If you suspect that the CoreBuilder 5000 Network Router Module has

lost WAN connectivity, perform the following troubleshooting actions:

■ Verify that you have the correct cable for your configuration. Refer

to Appendix B, Cabling Specifications, for lists of approved cables,

cable specifications, and pinouts.

■ If you are using a:

DCE cable – Verify that a clock rate is defined in the router WAN

interface configuration.

DTE cable – Verify that no clock rate is defined in the router WAN

interface configuration.

■ Verify that your router configuration is valid. Refer to the Cisco

Systems Troubleshooting Internetworking Systems guide for more

information.

Correcting Operating Malfunctions 5-3

Correcting Operating Malfunctions

Table 5-1 Troubleshooting Malfunctions

Table 5-1 lists the symptoms, possible causes and corrective actions of

operating malfunctions for the CoreBuilder 5000 Network Router

Module.

.

Symptom Possible Cause Corrective Action

Module does not

power up

Module is not fitted

correctly against

backplane.

To ensure that the module is fitted correctly,

remove the module from the slots and replace it

in the slots.

Place the module in different slots in the hub.

Power mode is not

Ensure that power mode is enabled for the slot.

enabled for slot.

The hub is not

receiving electrical

power.

Check that the hub is receiving power.

Test for power at the wall outlet by plugging in

another device.

If the wall outlet is not receiving power, select

another outlet on a different circuit.

Attached terminal does

not operate

The terminal is

malfunctioning.

Follow the troubleshooting procedures

recommended by the terminal manufacturer.

Cables are unattached. Make sure that the cable connections at both

ends are secure.

Cables are not the

correct type.

Make sure that the cable attached to the

terminal conforms to the specification. Refer to

Appendix B for cabling specifications.

The console is

configured incorrectly.

Check the console port configuration.

Note: You can use TELNET to verify port

configurations.

Refer to the Cisco Systems Router Products

Configuration and Reference documents for

more information. Verify that the port is

configured as:

■ 8-bit data

■ No parity

■ 2 stop bits

■ 9600 baud rate

■ Flow control parameters set to Xon and Xoff

5-4 CHAPTER 5: TROUBLESHOOTING

Table 5-1 Troubleshooting Malfunctions (continued)

Symptom Possible Cause Corrective Action

The terminal fails to

respond to commands

entered at the keyboard

The terminal is not

receiving commands.

The keyboard cable is

attached incorrectly.

Cables are not the

correct type.

The console port is

malfunctioning.

Power off the terminal, wait 30 seconds, and

then power on again.

If the terminal still does not respond to

commands, power off the terminal and

disconnect the keyboard cable. Then re-attach

the keyboard cable and power on the terminal.

Make sure that the cable attached to the

terminal conforms to the specification. Refer to

Appendix B

Check the state of the LEDs on the front of the

module. If the LEDs indicate a problem, contact

your supplier for assistance.

for cabling specifications.

Recovering a Lost Password

To recover a lost password:

1 Attach an ASCII terminal to the router module console port.

2 Configure the terminal to operate at 9600 baud, 8 data bits, no parity,

2 stop bits.