Page 1

CoreBuilder™5000 Ethernet

®

Carrier Assembly and

Configuration Guide

http://www.3com.com/

Document Number 17-00721-3

Published April 1997

Page 2

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

Copyright © 3Com Corporation, 1997. All rights reserved. No part of this documentation may be

reproduced in any form or by any means, or used to make any derivative work (such as translation,

transformation, or adaptation) without permission from 3Com Corporation. Portions of this document are

reproduced in whole or part with permission from third parties.

3Com Corporation reserves the right to revise this documentation and to make changes in content from

time to time without obligation on the part of 3Com Corporation to provide notification of such revision or

change.

3Com Corporation provides this documentation without warranty of any kind, either implied or expressed,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

3Com may make improvements or changes in the products or programs described in this documentation at

any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described herein

are provided to you subject to the following restricted rights:

For units of the Department of Defense:

Restricted Rights Legend: Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c) (1) (ii) for Restricted Rights in Technical Data and Computer Software Clause at

48 C.F.R. 52.227-7013.

For civilian agencies:

Restricted Rights Legend: Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph

(a) through (d) of the Commercial Computer Software – Restricted Rights Clause at 48 C.F.R. 52.227-19

and the limitations set forth in the 3Com Corporation standard commercial agreement for the software.

Unpublished rights reserved under the copyright laws of the United States.

If there is any software on removable media described in this documentation, it is furnished under a license

agreement included with the product as a separate document, in the hardcopy documentation, or on the

removable media in a directory file named LICENSE.TXT. If you are unable to locate a copy, please contact

3Com and a copy will be sent to you.

Federal Communications Commission Notice

This equipment was tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case you must correct the interference

at your own expense.

Canadian Emissions Requirements

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

EMC Directive Compliance

This equipment was tested and conforms to the Council Directive 89/336/EEC for electromagnetic

compatibility. Conformity with this directive is based upon compliance with the following harmonized

standards:

EN 55022 – Limits and Methods of Measurement of Radio Interference

EN 50082-1 – Electromagnetic Compatibility Generic Immunity Standard: Residential, Commercial, and

Light Industry

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case you may be required to take adequate measures.

Compliance with this directive depends on the use of shielded cables.

Low Voltage Directive Compliance

This equipment was tested and conforms to the Council Directive 72/23/EEC for safety of electrical

equipment. Conformity with this directive is based upon compliance with the following harmonized

standard:

EN 60950 – Safety of Information Technology Equipment

ii

Page 3

VCCI Class 1 Compliance

This equipment is in the 1st Class category (information equipment to be used in commercial or industrial

areas) and conforms to the standards set by the Voluntary Control Council for Interference by Information

Technology Equipment aimed at preventing radio interference in commercial or industrial areas.

Consequently, when the equipment is used in a residential area or in an adjacent area, radio interference

may be caused to radio and TV receivers, and so on.

Read the instructions for correct handling.

Fiber Cable Classification Notice

Use this equipment only with fiber cable classified by Underwriters Laboratories as to fire and smoke

characteristics in accordance with Section 770-2(b) and Section 725-2(b) of the National Electrical Code.

UK General Approval Statement

The CoreBuilder 5000 Integrated System Hub and ONline System Concentrator are manufactured to the

International Safety Standard EN 60950 and are approved in the U.K. under the General Approval Number

NS/G/12345/J/100003 for indirect connection to the public telecommunication network.

Trademarks

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com, Boundary Routing, CardFacts, EtherLink, LANplex, LANsentry, LinkBuilder, NETBuilder, NETBuilder II,

NetFacts, Parallel Tasking, SmartAgent, TokenDisk, TokenLink, Transcend, TriChannel, and ViewBuilder are

registered trademarks of 3Com Corporation.

3TECH, CELLplex, CoreBuilder, EtherDisk, EtherLink II, FDDILink, MultiProbe, NetProbe, and ONline are

trademarks of 3Com Corporation.

3ComFacts is a service mark of 3Com Corporation.

The 3Com Multichannel Architecture Communications System is registered under U.S. Patent

Number 5,301,303.

AT&T is a registered trademark of American Telephone and Telegraph Company.

Banyan and VINES are registered trademarks of Banyan Systems Inc.

CompuServe is a registered trademark of CompuServe, Inc.

DEC, DECnet, DELNI, POLYCENTER, VAX, VT100, VT220, and the Digital logo are trademarks of Digital

Equipment Corporation.

Hayes is a registered trademark of Hayes Microcomputer Products.

OpenView is a registered trademark of Hewlett-Packard Company.

Intel is a registered trademark of Intel Corporation.

AIX, IBM, and NetView are registered trademarks of International Business Machines Corporation.

Microsoft, MS-DOS, Windows, Windows 95, and Windows NT are registered trademarks of

Microsoft Corporation.

V30 is a trademark of NEC Corporation.

NetWare and Novell are registered trademarks of Novell, Incorporated.

IPX is a trademark of Novell, Incorporated.

OSF and OSF/Motif are registered trademarks of Open Software Foundation, Inc.

ONC, OpenWindows, Solaris, Solstice, Sun, Sun Microsystems, SunNet Manager, and SunOS are trademarks

of Sun Microsystems, Inc.

iii

Page 4

SPARCstation is a trademark licensed exclusively to Sun Microsystems Inc.

OPEN LOOK is a registered trademark of Unix System Laboratories, Inc.

UNIX is a registered trademark of X/Open Company, Ltd. in the United States and other countries.

Other brand and product names may be registered trademarks or trademarks of their respective holders.

iv

Page 5

CONTENTS

HOW TO USE THIS GUIDE

Audience 1

Document Conventions 1

Related Documents 2

1 INTRODUCTION

Carrier and Engine Terminology 1-1

Carrier and Engine Architecture 1-2

2 INSTALLATION

Precautionary Procedures 2-1

Unpacking Procedures 2-2

Assembling the Module 2-3

Special Engine Requirements 2-3

Assembling the Module 2-4

Setting the Carrier DIP Switches 2-9

CoreBuilder 5000 Carrier DIP Switch Functions 2-10

Identifying the CoreBuilder 5000 Carrier DIP Switches 2-10

Enabling or Disabling NVRAM Configuration Settings 2-11

Assigning Backplane Networks to Carrier Ports 2-11

Setting the Carrier Jumpers 2-12

Identifying the CoreBuilder 5000 Carrier Jumpers 2-13

CoreBuilder 5000 Carrier Jumper Definitions 2-13

Disabling the Fast Reset Function 2-14

Installing the Module in a CoreBuilder 5000 Hub 2-14

Page 6

3 CONFIGURATION

Configuration Overview 3-1

3Com Management Agents 3-1

Using DIP Switch and Jumper Settings 3-1

Using Management Commands 3-2

Using the 3Com CoreBuilder 5000 Manager 3-2

Carrier Configuration Source Overview 3-2

Carrier Configuration Sources 3-2

DMM Settings 3-2

Carrier NVRAM Settings 3-3

Carrier DIP Switch Settings 3-3

Carrier Default Settings 3-3

Hot-Swap Installation 3-4

Determining the Carrier Configuration Source 3-5

Configuring the Carrier 3-5

Selecting a Network 3-5

Saving the Configuration 3-6

Showing Carrier Configuration and Status 3-6

Using the SHOW MODULE Command 3-6

Module Capabilities Field 3-8

Engine Status Field 3-9

Using the SHOW PORT Command 3-9

Resetting the Carrier and Engines 3-10

Using the Front Panel Reset Switches 3-10

Using the RESET MODULE Command 3-11

A SPECIFICATIONS

Electrical Specifications A-1

Environmental Specifications A-2

Mechanical Specifications A-2

vi

Page 7

B TECHNICAL SUPPORT

Online Technical Services B-1

World Wide Web Site B-2

3Com Bulletin Board Service B-2

Access by Analog Modem B-2

Access by Digital Modem B-2

3ComFacts Automated Fax Service B-3

3ComForum on CompuServe Online Service B-3

Support From Your Network Supplier B-4

Support From 3Com Corporation B-5

Returning Products for Repair B-6

Accessing the 3Com MIB B-6

Contacting 3Com Technical Publications B-7

INDEX

3COM CORPORATION LIMITED WARRANTY

vii

Page 8

Page 9

FIGURES

1-1 Carrier and Engine Architecture 1-2

2-1 CoreBuilder 5000 Carrier Engine Bays 2-4

2-2 Blank Faceplate in Engine Bay 2 2-5

2-3 Interface Connectors for CoreBuilder 5000 Carrier and Engine 2-6

2-4 Faceplates for CoreBuilder 5000 Carrier and Engine 2-7

2-5 Fastening the Engine to the CoreBuilder 5000 Carrier 2-8

2-6 Installing a Second Engine 2-9

2-7 CoreBuilder 5000 Carrier DIP Switch Location 2-10

2-8 CoreBuilder 5000 Carrier Jumpers 2-13

2-9 Setting CoreBuilder 5000 Carrier Jumpers 2-13

2-10 Installing a CoreBuilder 5000 Module 2-15

2-11 Opened and Closed Module Ejectors 2-16

ix

Page 10

Page 11

TABLES

2-1 NVRAM DIP Switch Settings (Unmanaged Hub) 2-11

2-2 Network Selection DIP Switch Settings 2-12

2-3 CoreBuilder 5000 Carrier Jumper Settings 2-13

3-1 Determining the Carrier Configuration Source 3-5

3-2 Module Capability Codes 3-8

3-3 Engine Status Values 3-9

A-1 Carrier Electrical Specifications A-1

A-2 Carrier Environmental Specifications A-2

A-3 Carrier Mechanical Specifications A-2

xi

Page 12

Page 13

HOW TO USE THIS GUIDE

This guide explains how to assemble and configure a 3Com

CoreBuilder

5000 module that uses the 3Com

CoreBuilder 5000

Ethernet Carrier (also referenced in this guide as the carrier) as a base.

Audience This guide is intended for the following people at your site:

■ Network manager or administrator

■ Hardware installer

Document

The following document conventions are used in this guide:

Conventions

Convention Indicates Example

Courier text User input In the Agent Information Form,

enter MIS in the New Contact field.

System output After pressing the Apply button, the

system displays the message

Transm itting da ta.

Bold text Keystroke Type your password and press

Enter.

Italics Text emphasis,

document titles

Ensure that you press the Apply

button after you add the new

search parameters.

Page 14

2 HOW TO USE THIS GUIDE

Icon Notice Type Alerts you to...

Information note Important features or instructions

Caution Risk of personal safety, system damage, or loss

of data

Warning Risk of severe personal injury

Related Documents The following 3Com documents provide additional information on

related 3Com products:

■ CoreBuilder 5000 Integrated System Hub Installation and

Operation Guide (Document Number 17-00362) – Provides

information on the installation, operation, and configuration of the

3Com CoreBuilder 5000 Integrated System Hub.

■ CoreBuilder 5000 Distributed Management Module User Guide

(Document Number 17-00370) – Provides information on the

operation of the CoreBuilder 5000 Distributed Management

Module.

■ CoreBuilder 5000 Distributed Management Module Commands

Guide (Document Number 17-00372) – Provides information on

using Distributed Management Module commands.

■ CoreBuilder 5000 Manager for UNIX User Guide

(Document Number 17-00320) – Provides information on the

operation of the CoreBuilder 5000 Manager for UNIX

™

.

Page 15

1

INTRODUCTION

The 3Com CoreBuilder™ 5000 Ethernet Carrier is a single-slot

CoreBuilder 5000 module that supports the installation of special

hardware components, known as engines, in the 3Com

CoreBuilder 5000 Integrated System Hub.

This chapter contains the following sections:

■ Carrier and Engine Terminology

■ Carrier and Engine Architecture

®

Carrier and Engine Terminology

This section defines terms used in this guide to describe product

components:

■ Carrier – Connects the engine to backplane networks in the

CoreBuilder 5000 hub and provides power to the engine. The carrier

provides no communication functions.

■ Engine – Mounts on the carrier and provides network

communication functions.

■ Interface Connector – Connects the carrier to the engine. Both the

carrier and the engine have an interface connector.

■ Module – Refers to the fully-assembled combination of carrier and

engine components.

Page 16

1-2 INTRODUCTION

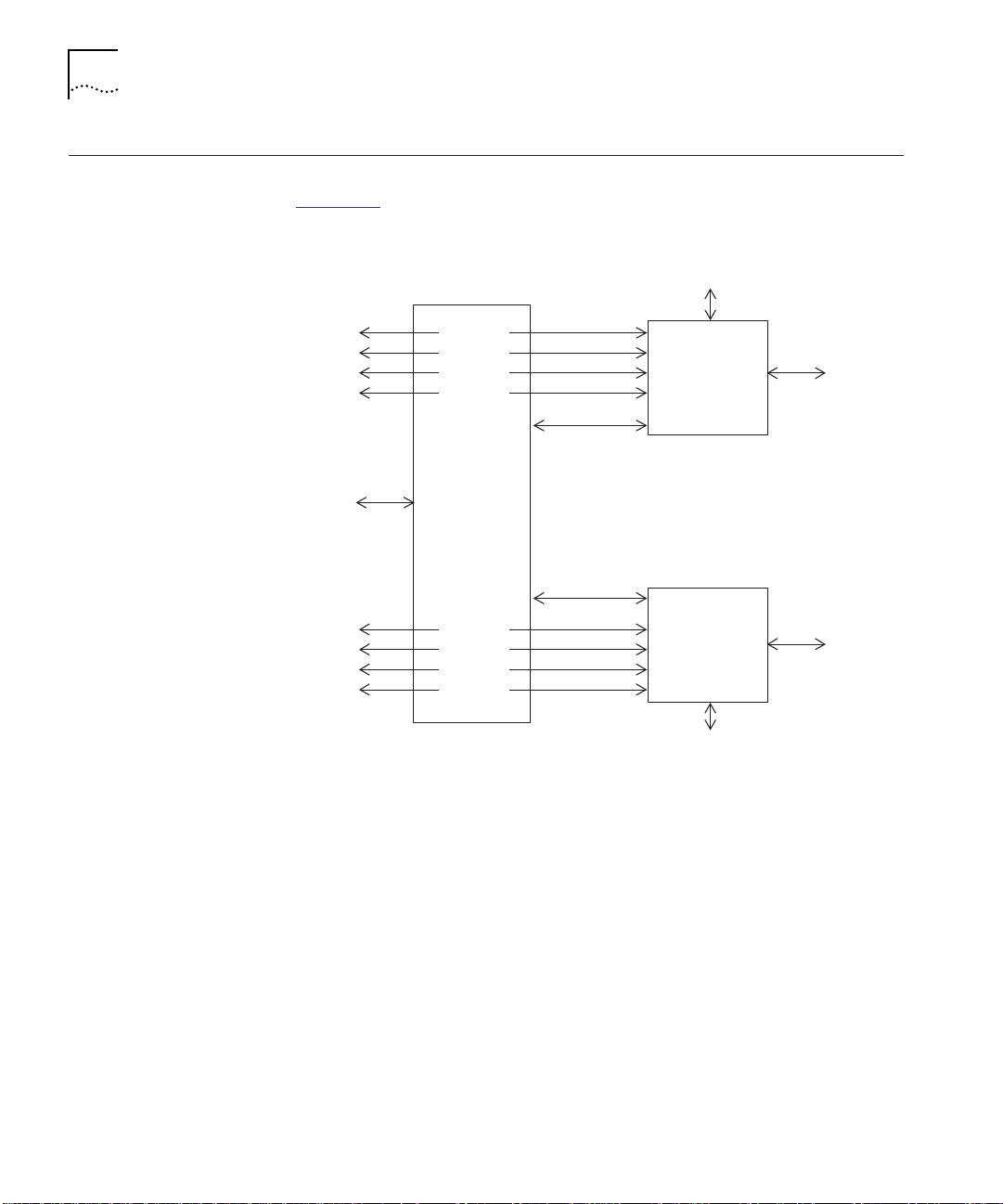

Carrier and Engine Architecture

This section provides an overview of the carrier and engine architecture.

Figure 1-1

Backplane

network

conne cti ons

Carrier

management

interface

Backplane

network

connections

is an architectural block diagram.

Engine management

interface

Port 1

Port 2

Port 3

Port 4

Control

interface

CARRIER

Control

interface

Port 5

Port 6

Port 7

Port 8

ENGINE 1

ENGINE 2

Devices

Devices

Figure 1-1 Carrier and Engine Architecture

Engi ne management

interface

Page 17

Carrier and Engine Architecture 1-3

The following list summarizes important features of the carrier and

engine architecture:

■ The carrier provides four internal ports for use by each engine.

These ports independently connect to backplane networks on the

hub. Some engines may not use all four ports.

■ You manage the engine through the engine management interface,

which is accessible through a serial connector on the front panel of

the engine. You can also use in-band management if the engine

supports it. For details on the engine management interface, refer to

the documentation for the engine.

■ You manage the carrier through the command interface provided by

the 3Com CoreBuilder 5000 Distributed Management Module

(DMM) installed in the hub.

■ The control interface between the carrier and the engine provides

internal timing and low-level control functions. These functions are

not user-accessible.

Page 18

Page 19

2

INSTALLATION

This chapter describes the installation of the CoreBuilder™ 5000

Ethernet Carrier. It contains the following sections:

■ Precautionary Procedures

■ Unpacking Procedures

■ Assembling the Module

■ Setting the Carrier DIP Switches

■ Setting the Carrier Jumpers

■ Installing the Module in a CoreBuilder 5000 Hub

Precautionary Procedures

Electrostatic discharge (ESD) can damage static-sensitive devices on

circuit boards. Observe the following precautions when you handle the

carrier:

CAUTION: Do not remove the board from its antistatic shielding bag

until you are ready to inspect or install it.

Handle the board by the faceplate only.

Use one of the following proper grounding techniques whenever you

handle the carrier:

■ Use a foot strap and grounded mat or wear a grounded static

discharge wrist strap.

■ Touch the grounded rack or other source of ground just before you

handle the carrier.

Page 20

2-2 INSTALLATION

Unpacking Procedures

To unpack the CoreBuilder 5000 Ethernet Carrier:

1 Verify that you received the correct model by checking the model

number listed on the side of the shipping carton.

Note that the product model number printed on the shipping box

differs from the model number on the product. The model number on

the shipping box contains the prefix ’3C9’.

2 Remove the carrier, in its antistatic wrapping, from the shipping carton.

3 Remove the carrier from the antistatic wrapping and inspect for

damage.

Handle the carrier by the faceplate only, being careful not to touch the

circuitry. If the carrier appears to be damaged, return it to the antistatic

wrapping, repack it in the shipping carton, and contact your local

supplier.

4 Verify that the contents of the shipment are complete:

■ CoreBuilder 5000 Ethernet Carrier (one or two engines may

already be mounted on the carrier)

■ CoreBuilder 5000 Ethernet Carrier Assembly and Configuration

Guide

■ Release notes, if applicable

5 Store the shipping carton and antistatic wrapping so that you can

repackage the carrier for storage or shipment.

Page 21

Assembling the Module

Assembling the Module 2-3

Your supplier may deliver the engine and carrier fully assembled.

If so, skip this section and go to Setting the Carrier DIP Switches on

page 2-9.

This section describes how to assemble the module by mounting the

engine on the CoreBuilder 5000 Ethernet Carrier. This section contains

the following sections:

■ Special Engine Requirements

■ Assembling the Module

Special Engine

Requirements

Some engines may have unique assembly requirements. Before

attempting to assemble the module, consult the documentation for

the engine.

Page 22

2-4 INSTALLATION

Assembling the

Module

CAUTION: Observe antistatic precautions as described in Precautionary

Procedures on page 2-1.

To assemble the module:

1 Select the engine bay in which you plan to install the engine

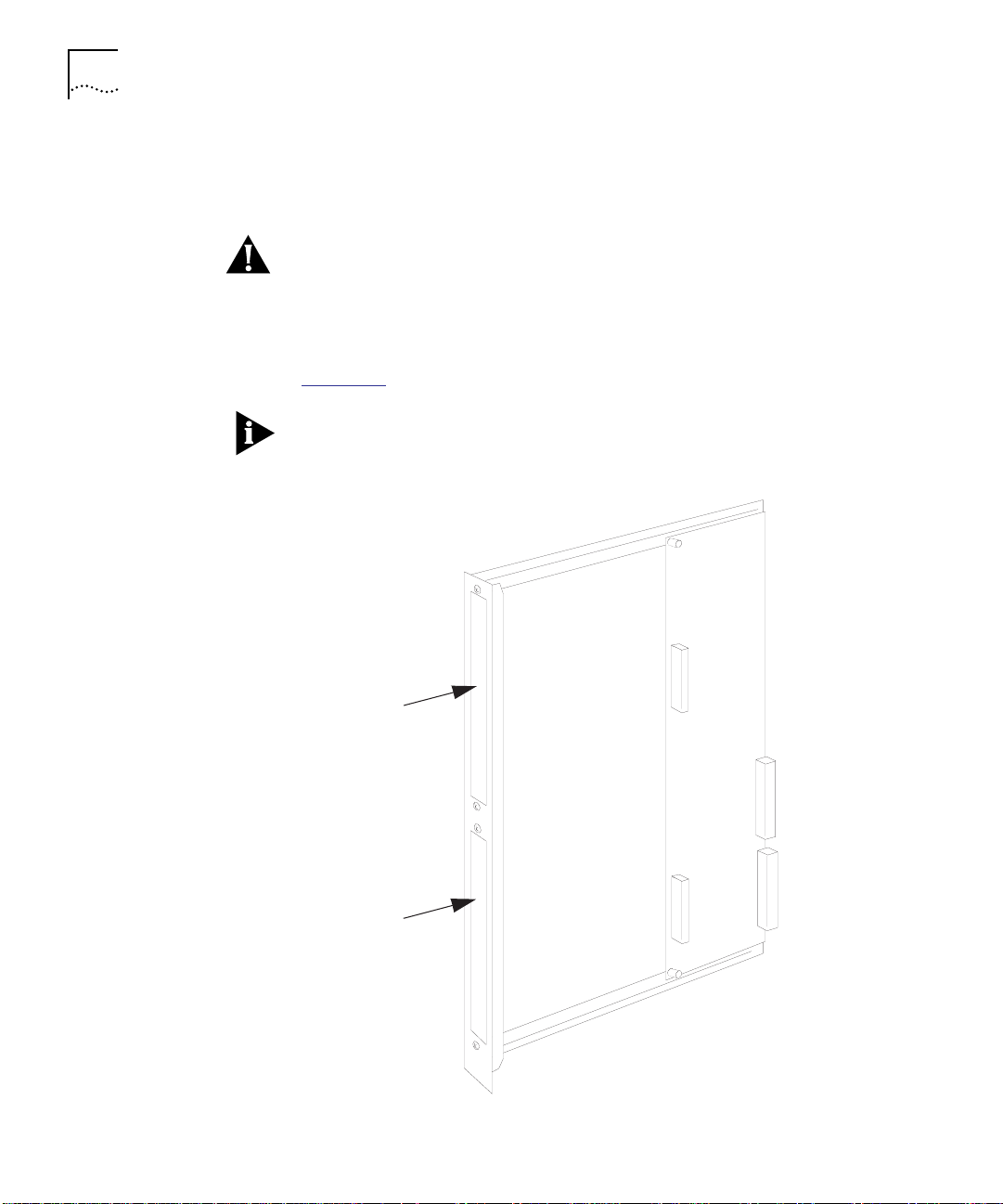

(Figure 2-1

).

You must use engine bay 1 if it is unoccupied. Use engine bay 2 only if

an engine is already installed in engine bay 1.

Engine bay 1

Engine bay 2

Figure 2-1 CoreBuilder 5000 Carrier Engine Bays

Page 23

Assembling the Module 2-5

2 If you are installing an engine in engine bay 2, remove the two screws

that hold the blank faceplate in place (Figure 2-2

). Set the blank

faceplate and screws aside.

Screw

Blank faceplate

Screw

Figure 2-2 Blank Faceplate in Engine Bay 2

Page 24

2-6 INSTALLATION

3 Position the engine so that:

■ The interface connector on the engine inserts into the interface

connector on the carrier (Figure 2-3

■ The engine faceplate slides into place behind the carrier faceplate

(Figure 2-4

).

).

Slide the engine faceplate into place first, and then mate the

connectors.

Interface

connector

Interface

connector

Engine

Interface

connector

CoreBuilder 5000

carrier

Figure 2-3 Interface Connectors for CoreBuilder 5000 Carrier and Engine

Page 25

Carrier facepl ate

Engine faceplate

Assembling the Module 2-7

Figure 2-4 Faceplates for CoreBuilder 5000 Carrier and Engine

Page 26

2-8 INSTALLATION

4 As shown in Figure 2-5, use four screws and washers to fasten the

engine to:

■ The carrier standoffs (use the two screws and washers shipped

installed in the standoffs)

■ The carrier faceplate (use the two screws and washers packaged

with the engine)

Stando ff

Washer

Screw

Figure 2-5 Fastening the Engine to the CoreBuilder 5000 Carrier

Page 27

Setting the Carrier DIP Switches 2-9

If you are installing a second engine or an expansion card in the carrier,

first insert the outer front corner of the engine and then rotate the

inner front corner into place (Figure 2-6

). You must do this so that the

engine clears the ejector.

Ejector

Rotate en gine

in this direction

Setting the Carrier DIP Switches

Outer front corner of

engine

Figure 2-6 Installing a Second Engine

This section contains the following sections:

■ CoreBuilder 5000 Carrier DIP Switch Functions

■ Identifying the CoreBuilder 5000 Carrier DIP Switches

■ Enabling or Disabling NVRAM Configuration Settings

■ Assigning Backplane Networks to Carrier Ports

If you use a management module to manage your CoreBuilder 5000

hub, refer to Carrier Configuration Source Overview on page 3-2 before

setting the DIP switches.

Page 28

2-10 INSTALLATION

CoreBuilder 5000

Carrier DIP Switch

Functions

Identifying the

CoreBuilder 5000

Carrier DIP Switches

CoreBuilder 5000 Carrier DIP switches let you configure the following

functions:

■ NVRAM configuration settings

■ Backplane network assignments for carrier ports

Figure 2-7

locates and designates the CoreBuilder 5000 Carrier DIP

switches.

ONOFF

0

1

2

3

4

5

6

7

8

9

ENG 1

ENG 2

CH SEL 0

CH SEL 1

CH SEL 2

CH SEL 3

NV SEL

CH SEL 0

CH SEL 1

CH SEL 2

CH SEL 3

NV SEL

Figure 2-7 CoreBuilder 5000 Carrier DIP Switch Location

Page 29

Setting the Carrier DIP Switches 2-11

Enabling or

Disabling NVRAM

Configuration

Settings

Two NVRAM (labeled NV SEL) DIP switches control whether the

CoreBuilder 5000 Carrier uses configuration settings stored in NVRAM

(non-volatile memory) or DIP switches. Switch 4 provides the selection

for engine bay 1 and switch 9 provides the selection for engine bay 2.

In an unmanaged hub (a hub without a Distributed Management

Module (DMM) installed), the NVRAM DIP switch works as described in

Table 2-1

Table 2-1 NVRAM DIP Switch Settings (Unmanaged Hub)

NVRAM DIP

Switch

ON (enabled) The carrier uses configuration settings stored in its NVRAM. If

OFF (disabled) The carrier uses its DIP switch configuration settings.

.

Description

NVRAM does not contain settings, the carrier uses the following

configuration settings:

■ Ports 1 and 5 are assigned to the Isolated_1 network.

■ Ports 2 and 6 are assigned to the Isolated_2 network.

■ Ports 3 and 7 are assigned to the Isolated_3 network.

■ Ports 4 and 8 are assigned to the Isolated_4 network.

For instructions on using the NVRAM DIP switch in a managed hub

(DMM installed), refer to Carrier Configuration Source Overview on

page 3-2.

Assigning Backplane

Networks to Carrier

Ports

If the carrier is configured to use DIP switch settings, the network

selection DIP switch settings determine the backplane network

assignment for each port.

For information on configuring the carrier to use DIP switch settings:

■ In an unmanaged hub (no DMM installed), refer to Enabling or

Disabling NVRAM Configuration Settings on page 2-11.

■ In a managed hub (DMM installed), refer to Carrier Configuration

Source Overview on page 3-2.

Page 30

2-12 INSTALLATION

To select a network using DIP switches:

1 Set the switches according to Table 2-2

.

Table 2-2 Network Selection DIP Switch Settings

Network

Selection

Ethernet_1

(default)

Ethernet_2 OFF ON ON ON

Ethernet_3 ON OFF ON ON

Ethernet_4 OFF OFF ON ON

Ethernet_5 ON ON OFF ON

Ethernet_6 OFF ON OFF ON

Ethernet_7 ON OFF OFF ON

Ethernet_8 OFF OFF OFF ON

Isolate_1 ON ON ON OFF

Isolate_2 OFF ON ON OFF

Isolate_3 ON OFF ON OFF

Isolate_4 OFF OFF ON OFF

Switch combinations not listed in the Table 2-2

Switch Settings

CH SEL 0 CH SEL 1 CH SEL 2 CH SEL 3

ON ON ON ON

select Isolate_1.

Setting the Carrier Jumpers

This section describes how to use the CoreBuilder 5000 Carrier

jumpers. It contains the following sections:

■ Identifying the CoreBuilder 5000 Carrier DIP Switches

■ CoreBuilder 5000 Carrier Jumper Definitions

■ Disabling the Fast Reset Function

Page 31

Setting the Carrier Jumpers 2-13

Identifying the

CoreBuilder 5000

Carrier Jumpers

CoreBuilder 5000

Carrier Jumper

Definitions

Figure 2-8

locates and identifies the CoreBuilder 5000 Carrier jumpers.

ENG 1

FAST DIS

ENG 2

FAST DIS

P3

P4

Figure 2-8 CoreBuilder 5000 Carrier Jumpers

The CoreBuilder 5000 Carrier uses 2-pin jumpers, which can be

inserted or not inserted (Figure 2-9

).

Jumper pin

Not inserted (default)Inserted

Jumper

connector

Figure 2-9 Setting CoreBuilder 5000 Carrier Jumpers

Table 2-3 defines the CoreBuilder 5000 Carrier jumper settings.

Table 2-3 CoreBuilder 5000 Carrier Jumper Settings

Jumper Inserted Not Inserted

P3 (ENG 1 FAST DIS) Fast Reset disabled for

engine bay 1

P4 (ENG 2 FAST DIS) Fast Reset disabled for

engine bay 2

Fast Reset enabled for

engine bay 1 (default)

Fast Reset enabled for

engine bay 2 (default)

Page 32

2-14 INSTALLATION

Disabling the Fast

Reset Function

Installing the Module in a CoreBuilder 5000 Hub

The Fast Reset function restores clock synchronization to the engines if

a controller switchover occurs in the CoreBuilder 5000 hub.

■ If the engine supports Fast Reset, do not change the jumpers from

their default settings.

■ If the engine does not support Fast Reset, disable it. Disabling Fast

Reset causes a normal engine reset to occur during a controller

switchover.

To disable Fast Reset, insert the appropriate jumper (see Table 2-3

)

on the CoreBuilder 5000 Carrier.

You do not need to power down the CoreBuilder 5000 hub to install

or remove the module. You can insert the module while the hub is

operating (this is called a hot swap).

To install the module:

1 Use one of the following proper grounding techniques when you install

the module:

■ Properly ground yourself prior to handling the module.

■ Attach a static wrist guard to yourself or touch a grounded static

mat prior to handling the module.

2 To determine if the hub has enough power for the new module, enter

the SHOW POWER BUDGET command. Refer to Appendix A

for details

on power requirements for each of the specified wattages. For engine

power requirements, refer to the documentation for the engine.

Refer to the CoreBuilder 5000 Distributed Management Module

Commands Guide for information on the SHOW POWER BUDGET

command.

3 Locate an open slot in the hub. If necessary, remove a blank panel to

expose a slot.

Page 33

Installing the Module in a CoreBuilder 5000 Hub 2-15

4 Insert the module into the board guides at the top and bottom of the

slot and slide it into the hub by pressing firmly at a point slightly below

the center of the faceplate (Figure 2-10

).

Figure 2-10 Installing a CoreBuilder 5000 Module

Page 34

2-16 INSTALLATION

5 Close the ejectors (Figure 2-11).

Opened

ejector

Closed

eject or

Figure 2-11 Opened and Closed Module Ejectors

6 Using your fingers, tighten the spring-loaded screws on the front of the

carrier faceplate (do not overtighten).

Page 35

3

CONFIGURATION

This chapter describes how to configure the CoreBuilder 5000 Ethernet

Carrier. It contains the following sections:

■ Configuration Overview

■ Carrier Configuration Source Overview

■ Configuring the Carrier

■ Resetting the Carrier and Engines

To manage the engine, you must use engine management software.

For more information, refer to the documentation for the engine.

Configuration Overview

3Com Management

Agents

Using DIP Switch

and Jumper Settings

This section describes 3Com management agents and methods for

configuring the carrier. It contains the following sections:

■ 3Com Management Agents

■ Using DIP Switch and Jumper Settings

■ Using Management Commands

■ Using the 3Com CoreBuilder 5000 Manager

You can manage the carrier through SNMP (Simple Network

Management Protocol) or management commands if a local

management agent is available. Management agent services for the

carrier are provided by a 3Com CoreBuilder 5000 Distributed

Management Module (DMM) installed in the same hub as the carrier.

You can use DIP switches and jumpers on the carrier to perform certain

configuration functions. For information on using DIP switches and

jumpers, refer to Chapter 2

.

Page 36

3-2 CONFIGURATION

Using Management

Commands

Using the 3Com

CoreBuilder 5000

Manager

Carrier Configuration Source Overview

In this chapter, the section Configuring the Carrier on page 3-5

describes how to use management commands to make basic changes

to carrier configuration settings. For complete instructions on using

management commands to manage the carrier, refer to one of the

following:

■ CoreBuilder 5000 Distributed Management Module User Guide

(Document Number 17-00370)

■ CoreBuilder 5000 Management Module Commands Guide

(Document Number 17-00372)

The 3Com CoreBuilder 5000 Manager is an SNMP manager with a

graphical user interface. For instructions on using the CoreBuilder 5000

Manager to manage the carrier, refer to the CoreBuilder 5000 Manager

for UNIX User Guide (Document Number 17-00320).

This section describes the possible sources of carrier configuration

settings and the factors that determine which configuration source the

carrier uses. This section contains the following sections:

■ Carrier Configuration Sources

■ Hot-Swap Installation

Carrier

Configuration

Sources

■ Determining the Carrier Configuration Source

In a managed hub (hub with a DMM installed), the carrier obtains its

configuration settings from one of the following sources:

■ DMM settings

■ Carrier NVRAM settings

■ Carrier DIP switch settings

■ Carrier default settings

DMM Settings

The DMM can provide configuration settings to the carrier if you are

performing a hot-swap. For more information on hot-swapping, refer

to Hot-Swap Installation on page 3-4.

Page 37

Carrier Configuration Source Overview 3-3

Carrier NVRAM Settings

The carrier can store configuration settings in its NVRAM (Non-Volatile

Random Access Memory), which it can use when powering up in either

a managed or unmanaged hub. Two NVRAM DIP switches control

whether or not the carrier uses NVRAM settings. When the carrier is

shipped from the factory, its NVRAM contains no settings.

The carrier stores settings in NVRAM when either of the following

occurs:

■ You use a DMM configuration command or an SNMP manager to

change a carrier configuration setting. For example, if you use the

SET PORT NETWORK command to change a carrier port network

assignment, the carrier stores the new network assignment in its

NVRAM.

The carrier stores the new setting as soon as you issue the

command. The SAVE command does not affect the contents of

NVRAM.

■ The DMM sends settings to the carrier during a hot-swap. For a

definition of hot-swap, refer to Hot-Swap Installation on page 3-4.

For information on setting the NVRAM DIP switches, refer to Enabling

or Disabling NVRAM Configuration Settings on page 2-11.

Carrier DIP Switch Settings

The carrier contains a DIP switch that you can use to configure port

network assignments. For more information on DIP switch settings,

refer to Setting the Carrier DIP Switches on page 2-9.

Carrier Default Settings

In some cases the carrier uses default configuration settings contained

in its software. The carrier contains the following default settings for

port network assignment:

■ Ports 1 and 5 use Isolated_1

■ Ports 2 and 6 use Isolated_2

■ Ports 3 and 7 use Isolated_3

■ Ports 4 and 8 use Isolated_4

Page 38

3-4 CONFIGURATION

Hot-Swap Installation Whether or not you hot-swap the carrier affects which configuration

source the carrier uses.

Removing a carrier from the hub and installing an identical model

carrier in the same slot is a hot-swap. When you perform a hot-swap,

the DMM teaches the new carrier the configuration used by the old

carrier. The new carrier saves the settings in its NVRAM.

The DMM teaches the new carrier only if it has a saved configuration

for the old carrier installed in that slot. The DMM saves the

configuration when you do one of the following:

■ Issue the SAVE command.

■ Use SNMP to make the configuration changes to the carrier. The

DMM automatically saves the changes.

■ Reset or power-cycle the DMM. The DMM automatically learns and

saves the NVRAM configurations of all installed modules.

Swapping in a new carrier that contains a different engine from the old

carrier is still a hot-swap. Only the carrier models must be the same.

Page 39

Configuring the Carrier 3-5

Determining the

Carrier

Configuration Source

Table 3-1

shows how to determine the carrier configuration source.

Table 3-1 Determining the Carrier Configuration Source

Hot-swap?

DMM DIP

configuration

NVRAM DIP

*

Switch

Carrier

Configuration Source

Yes Disable ON or OFF DMM teaches the old

carrier configuration

settings to the new carrier.

Enable ON NVRAM settings

†

OFF DIP switch settings

No

‡

Disable ON NVRAM settings

2

OFF Default settings

Enable ON NVRAM settings

2

OFF DIP switch settings

* Use the SHOW DEVICE command to view the DIP configuration setting. Use the SET DEVICE

DIP_CONFIGURATION command to change the DIP configuration setting.

† If there are no settings stored in carrier NVRAM, the carrier uses default settings.

If the DMM detects a problem with the NVRAM configuration, it forces the carrier to use

default settings. For example, if you install the carrier with ports assigned to Ethernet_8 into

a CoreBuilder 5000 hub model that does not support Ethernet_8, the DMM forces the

carrier to use default settings. If the configuration problem is port-level, the DMM forces

only the affected ports to use default settings.

‡ The DMM must be fully initialized when you install the carrier module.

Configuring the Carrier

This section describes how to configure the carrier using network

management commands. It contains the following sections:

■ Selecting a Network

■ Saving the Configuration

■ Showing Carrier Configuration and Status

Selecting a Network The engine connects to the backplane through backplane ports on the

carrier. The carrier provides a total of eight backplane ports. Engine 1

uses ports 1 to 4 and Engine 2 uses ports 5 to 8. Depending on the

engine architecture, the engine may not use all of the ports.

Page 40

3-6 CONFIGURATION

You can assign a carrier module port to:

■ One of eight Ethernet backplane networks

■ One of four Isolated backplane networks

For details on backplane networks, refer to the CoreBuilder 5000

Integrated System Hub Installation and Operation Guide.

To assign the carrier module ports to a network using the network

management software, use the following command:

Saving the

Configuration

Showing Carrier

Configuration and

Status

SET PORT {

slot.port

} NETWORK {ethernet_1 ... ethernet_8}

{isolated_1 ... isolated_4}

For example, the following command sets port 1 in the carrier installed

in slot 3 to ethernet_2:

CB50 00> set po rt 3.1 network eth ernet_2

Port 03 .01 networ k id set to E THERNET_2

To save configuration changes, use the SAVE command. For example,

the following command saves all configuration changes:

CB50 00> save all

Failure to save module settings may result in the loss of configuration

data.

Use the following commands to show carrier configuration and status:

■ SHOW MODULE

■ SHOW PORT

Using the SHOW MODULE Command

The SHOW MODULE command displays information about a particular

module.

The syntax for the SHOW MODULE command is:

SHOW MODULE {

slot .sub sl ot

{all} {no_v er bo se}

} { ve rbos e}

Page 41

Configuring the Carrier 3-7

The following command uses the verbose option to display detailed

information on the carrier installed in slot 3:

CB50 00> show m odule 3.al l verbose

Slot Module Version Networ k General Inform ation

----- - --------- ----- ----- -- ------- ------ -- ----------- ------

03.01 6102M -SDEK 1. 00 PER_PORT 2109 R-RA

6102M-SDEK: CB5000 ON deck Ethe rnet Carr ier Module

Boot Versio n: 1.00

ENGINE 1 Mod el Number: 2109R-RA

Descri ption: LAN Acc ess

Expans ion Module Model Num ber:

Software Version: v5.04

Boot Versio n: v3.91

IP Defa ult Gatewa y: 155.10 2.2.1

Mailbo x Version: 1.00

No. Bac kplane Ports: 1

No. Fro nt Ports: 8

Engine Status: OK

NVRAM D ip Switch State: ENABLE D

Module Capabilit ies IPCFG;

ENGINE 2 Mod el Number: NOT INS TALLED

Description:

Expansion Module Model Number:

Software Version:

Boot Version:

IP Default G ateway: 0.0.0.0

Mailbox Ver sion: 0.00.0

No. Bac kplane Ports: 4

No. Fro nt Ports: 0

Engine Status: NOT INS TALLED

NVRAM D ip Switch State: DISABL ED

Module Capabilit ies NONE

If an output field is not applicable, it is left blank. In the example

above, no engine is installed in engine bay 2. Therefore, several fields

are blank in the section that describes engine 2.

Page 42

3-8 CONFIGURATION

Module Capabilities Field

The Module Capabilities field in the SHOW MODULE command output

contains a list of module capability codes. The codes describe optional

module capabilities that the installed engine supports. Module

capabilities are interactions that can occur through the interface

between the engine and the carrier.

Module capability codes indicate engine capabilities only.

Corresponding carrier management functions may not be available.

Also, module capability codes do not indicate engine functions that

are available through the engine management interface.

Table 3-2

Table 3-2 Module Capability Codes

Code Capability Description

ADSTAT Administrative State

IPCFG IP Configuration

MACCFG MAC Configuration

NETCFG Network Configuration

OPSTAT Operational Status

SANITY Heartbeat Check Engine supports echo requests and

SPDCFG Speed Configuration

defines the possible module capability codes.

Notification

Notification

Notification

Notification

Notification

Notification

Engine can report module and port

administrative states. Administrative

state refers to whether a module or

port is enabled or disabled.

Engine can report IP address changes.

Engine can report MAC address

changes.

Engine can accept notification of

backplane configuration changes.

Engine can report module and port

status information.

responses to support a heartbeat

mechanism.

Engine can accept notification of

speed changes.

Page 43

Configuring the Carrier 3-9

Engine Status Field

The Engine Status field in the SHOW MODULE command output

contains a value that describes current engine status. Table 3-3

describes the engine status values.

Table 3-3 Engine Status Values

Value Description

FATAL ERROR The engine reported a fatal error condition. Check

engine status using the engine management

interface.

INITIALIZING Carrier is waiting for installed engine to finish

initializing.

MAILBOX TIME-OUT A timeout failure occurred during communication on

the control interface between the carrier and engine.

Check engine status using the engine management

interface.

NOT INSTALLED No engine installed.

OKAY Engine has finished initializing and has communicated

its personality to the carrier.

TRANSIENT ERROR The engine reported a transient error condition.

Check engine status using the engine management

interface.

Using the SHOW PORT Command

The SHOW PORT command displays information on a single port or all

ports.

The syntax for the SHOW PORT command is:

SHOW PORT {

slot.port

{

slot

.all} {no_v erbose}

} {verbose}

Page 44

3-10 CONFIGURATION

CB50 00> show p ort 3.all verbose

Port Di splay for Module 6102M -SDEK :

Port Mode Status Netwo rk Gener al Inform ation

----- ------- ------------------- --------------- -------------------

03.01 L OGICAL OKAY ETHERNET_1 2109R -RA

Port Connec tor: BAC KPLANE

IP Addr ess: 155.1 04.15.40

Subnetwork Mask: ff.ff.ff.00

Statio n Address: 00- c0-2c-ff-fb-00

Dip Net work Setti ng: ETHERNE T_1

The following command displays information for port 1 on the carrier

installed in slot 3:

The command does not display data for unused ports. In the example

above, the engine uses only one of the four available backplane ports.

Therefore, the command displays information for one port only.

Resetting the Carrier and Engines

Using the Front Panel

Reset Switches

You can reset the carrier and installed engines using either of the

following methods:

■ Front panel reset switches

■ RESET MODULE command

To reset the carrier and installed engines, you can use the reset switch

provided on the engine faceplate.

■ To reset a single engine, press the reset switch for that engine and

hold it in for less than 3 seconds.

■ To reset all installed engines and the carrier, press the reset switch

on the engine and hold it in for longer than 3 seconds. If two

engines are installed, you can use either reset switch.

Page 45

Resetting the Carrier and Engines 3-11

Using the RESET

MODULE Command

To reset the carrier and installed engines, you can use the RESET

MODULE command.

The syntax for the RESET MODULE command is:

RESET MODUL E {s

lot.

1} {engine_1}

{engine_2}

{all}

engine_1 – Resets engine 1 only.

engine_2 – Resets engine 2 only.

all – Resets the carrier and all installed engines.

For example, the following command resets the carrier and all engines:

CB50 00> reset module 3.1 all

Resett ing module 3.1: all

Page 46

Page 47

A

SPECIFICATIONS

This appendix lists specifications for the CoreBuilder™ 5000 Ethernet

Carrier. This appendix contains the following sections:

■ Electrical Specifications

■ Environmental Specifications

■ Mechanical Specifications

Specifications listed in this appendix do not account for installed

engines.

Electrical Specifications

Table A-1 Carrier Electrical Specifications

Power

Requirements

Fuse Requirements 1 A @ +2 V

4 mA @ +2 V

800 mA @ +5 V

22 mA @ –5 V

15 A @ +5 V

1 A @ –5 V

3 A @ +12 V

2 A @ –12 V

Page 48

A-2 SPECIFICATIONS

Environmental Specifications

Mechanical Specifications

Table A-2 Carrier Environmental Specifications

Operating

Temperature

Storage

Temperature

Humidity Less than 95%, noncondensing

BTUs/hr 14.1 BTUs/hr

Table A-3 Carrier Mechanical Specifications

Dimensions 1.0" W x 14.37" H x 10.275" L

Weight 1.0 lb.

0 to 50 °C (32 to 122 °F)

–10 to 66 °C (14 to 151 °F)

Page 49

B

TECHNICAL SUPPORT

3Com provides access to technical support information through a

variety of services. This appendix describes these services.

Information contained in this appendix is correct at time of publication.

For the very latest, access 3Com Corporation’s World Wide Web site as

described below.

This appendix describes:

■ Online Technical Services

■ Support From Your Network Supplier

■ Support From 3Com Corporation

■ Returning Products for Repair

■ Accessing the 3Com MIB

Online Technical Services

■ Contacting 3Com Technical Publications

3Com offers worldwide product support 24 hours a day, 7 days a

week, through the following online systems:

■ World Wide Web Site

■ 3Com Bulletin Board Service

■ 3ComFacts Automated Fax Service

■ 3ComForum on CompuServe Online Service

Page 50

B-2 TECHNICAL SUPPORT

World Wide Web Site Access the latest networking information on 3Com Corporation’s World

Wide Web site by entering our URL into your Internet browser:

http ://ww w. 3Com .c om/

This service features news and information about 3Com products,

customer service and support, 3Com Corporation’s latest news releases,

NetAge Magazine, and more.

3Com Bulletin Board

Service

3ComBBS contains patches, software, and drivers for all 3Com

products, as well as technical articles. This service is available through

modem or ISDN 24 hours a day, 7 days a week.

Access by Analog Modem

To reach the service by modem, set your modem to 8 data bits,

no parity, and 1 stop bit. Call the telephone number nearest you:

Country Data Rate Telephone Number

Australia up to 14400 bps 61 2 9955 2073

Brazil up to 14400 bps 55 11 547 9666

France up to 14400 bps 33 1 6986 6954

Germany up to 28800 bps 4989 62732 188

Hong Kong up to 14400 bps 852 2537 5608

Italy (fee required) up to 14400 bps 39 2 27300680

Japan up to 14400 bps 81 3 3345 7266

Mexico up to 28800 bps 52 5 520 7853

P. R. of China up to 14400 bps 86 10 684 92351

Singapore up to 14400 bps 65 534 5693

Taiwan up to 14400 bps 886 2 377 5840

U.K. up to 28800 bps 44 1442 438278

U.S.A. up to 28800 bps 1 408 980 8204

Access by Digital Modem

ISDN users can call 3ComBBS using a digital modem for fast access up

to 56 Kbps. To access 3ComBBS using ISDN, use the following number:

408 654 2703

Page 51

Online Technical Services B-3

3ComFacts

Automated Fax

Service

3Com Corporation’s interactive fax service, 3ComFacts

SM

, provides data

sheets, technical articles, diagrams, and troubleshooting instructions on

3Com products 24 hours a day, 7 days a week.

Call 3ComFacts using your Touch-Tone telephone using one of these

international access numbers:

Country Telephone Number

Hong Kong 852 2537 5610

U.K. 44 1442 278279

U.S.A. 1 408 727 7021

Local access numbers are available within the following countries:

Telephone

Country

Australia 1 800 123853 Netherlands 06 0228049

Belgium 0800 71279 Norway 800 11062

Denmark 800 17319 Portugal 0505 442 607

Finland 98 001 4444 Russia (Moscow only) 956 0815

France 05 90 81 58 Spain 900 964 445

Germany 0130 81 80 63 Sweden 020 792954

Italy 1678 99085 U.K. 0800 626403

Number

Country

Telephone

Number

3ComForum on

CompuServe Online

Service

3ComForum is a CompuServe-based service containing patches,

software, drivers, and technical articles about 3Com products, as well

as a messaging section for peer support. To use 3ComForum, you

need a CompuServe

®

account.

To use 3ComForum:

1 Log on to CompuServe.

2 Ty pe

go threecom

3 Press Return to view the 3ComForum main menu.

Page 52

B-4 TECHNICAL SUPPORT

Support From Your Network Supplier

If additional assistance is required, contact your network supplier.

Several suppliers are authorized 3Com service partners who are

qualified to provide a variety of services, including network planning,

installation, hardware maintenance, application training, and support

services.

If you contact your network supplier for assistance, have the following

information ready:

■ Diagnostic error messages

■ A list of system hardware and software, including revision levels

■ Details about recent configuration changes, if applicable

If you are unable to contact your network supplier, refer to the

following section on how to contact 3Com.

Page 53

Support From 3Com Corporation B-5

Support From 3Com Corporation

If you are unable to receive support from your network supplier,

technical support contracts are available from 3Com.

Contact your local 3Com sales office to locate your authorized service

provider using one of the following numbers:

Regional Sales Office Telephone Number Regional Sales Office Telephone Number

3Com Corporation

U.S.A.

3Com ANZA

East

West

3Com Asia Limited

China

Hong Kong

India

Indonesia

Korea

Malaysia

Singapore

Taiwan

Thailand

3Com Benelux B.V.

Belgium

Netherlands

3Com Canada

Calgary

Montreal

Ottawa

Toronto

Vancouver

3Com France

3Com GmbH

Austria

Czech and Slovak Republics

Germany

Hungary

Poland

Switzerland

800 NET 3Com or

1 408 764 5000

61 2 9937 5000

61 3 9866 8022

86 10 68492 568 (Beijing)

86 21 6374 0220 Ext 6115

(Shanghai)

852 2501 1111

91 11 644 3974

62 21 523 9181

82 2 319 4711

60 3 732 7910

65 538 9368

886 2 377 5850

662 231 8151 4

32 725 0202

31 30 6029700

403 265 3266

514 683 3266

613 566 7055

416 498 3266

604 434 3266

33 1 69 86 68 00

43 1 5134323

42 2 21845 800

49 30 3498790 (Berlin)

49 89 627320 (Munich)

36 1 250 83 41

48 22 6451351

41 31 996 14 14

3Com Ireland

3Com Japan

3Com Latin America

Argentina

Brazil

Chile

Colombia

Mexico

Peru

Venezuela

3Com Mediterraneo

Italy

3Com Middle East

3Com Nordic AB

Denmark

Finland

Norway

Sweden

3Com Russia

3Com South Africa

3Com UK Limited

353 1 820 7077

81 3 3345 7251

54 1 312 3266

55 11 546 0869

56 2 633 9242

57 1 629 4110

52 5 520 7841

51 1 221 5399

58 2 953 8122

39 2 253011 (Milan)

39 6 5279941 (Rome)

971 4 349049

45 39 27 85 00

358 0 435 420 67

47 22 18 40 03

46 8 632 56 00

007 095 2580940

27 11 807 4397

44 131 2478558 (Edinburgh)

44 161 8737717 (Manchester)

44 1628 897000 (Marlow)

Page 54

B-6 TECHNICAL SUPPORT

Returning Products for Repair

Accessing the

3Com MIB

Before you send a product directly to 3Com for repair, you must first

obtain a Return Materials Authorization (RMA) number. Products sent

to 3Com without RMA numbers are returned to the sender unopened,

at the sender’s expense.

To obtain an RMA number, call or fax:

Country Telephone Number Fax Number

U.S.A. and Canada 1 800 876 3266, option 2 408 764 7120

Latin America 1 408 326 7801 408 764 7120

Europe, South Africa and

Middle East

Outside Europe, U.S.A.,

and Canada

44 1442 438125 44 1442 435822

1 408 326 7804 1 408 764 7120

The 3Com Management Information Base (MIB) describes commands

that enable you to manage 3Com SNMP-based products. The MIB is

available over the Internet on an anonymous FTP server. Updates to

these MIBs are released as new 3Com products are introduced.

To access Internet versions:

1 FTP to

ftp.3com.com (151.104.9.65).

2 Enter the login name anonymous .

3 Enter your full Internet e-mail address as the password

(for example,

4 Change to the /pub/mibs directory using the command

jdoe@company.com).

cd/pub/mibs.

5 Read the readisd.txt file to determine the MIB or MIBs you need to

manage your 3Com products.

6 To view the 3Com MIB, OID, or schema entries, enter the

■ To pause the display, press Ctrl+S.

■ To continue the display, press Ctrl+Q.

ls command.

7 Copy the MIB, OID, or schema files to your current directory using the

appropriate command (for example,

8 Exit the FTP session using the

quit command.

get isd.mib).

Page 55

Contacting 3Com Technical Publications B-7

Contacting 3Com Technical Publications

02/06/97

If you have comments or questions on 3Com Technical Publications

documents, contact the Technical Publications group by fax at

(508) 229-1551.

Page 56

Page 57

INDEX

Numerics

3Com Bulletin Board Service (3ComBBS) B-2

3Com sales offices B-5

3Com URL B-2

3ComFacts B-3

3ComForum B-3

A

Audience of Manual 1

B

bulletin board service B-2

C

CompuServe B-3

Contents, package 2-2

CoreBuilder 5000 Hub

hot swap capabilities

2-14

D

DIP Switch

setting

2-9

E

Edge Router Module

installing

Electrical specifications A-1

Electro-static discharge

precautionary procedures

Environmental specifications A-2

2-14

2-1

F

fax service. See 3ComFacts

FCC notice

ii

I

Installation

hot swap capabilities

installing the module 2-14 to 2-16

module 2-15, 2-16

2-14

M

Mechanical specifications A-2

Media module

procedures for handling

MIBs

3Com

B-6

2-1

Page 58

2 INDEX

N

Network Management Commands

Set Port Network

Network Selection 3-5

network supplier support B-4

3-6

O

Online technical services B-1

P

Package contents 2-2

R

returning products for repair B-6

S

Selecting a Network 3-6

using network management 3-6

Set Port Network Command 3-6

Shipment contents 2-2

Show Module Command 3-6

Show Port Command 3-9

Simple Network Management Protocol (SNMP)

commands

SNMP. See Simple Network Management Protocol

B-6

U

Unpacking Procedures 2-2

URL B-2

W

World Wide Web B-2

WWW B-2

T

technical support B-1

3Com URL B-2

bulletin board service B-2

fax service B-3

network suppliers B-4

product repair B-6

using CompuServe B-3

Page 59

3Com Corporation LIMITED WARRANTY

For purposes of this warranty, the CoreBuilder 5000 Ethernet Carrier is considered an Internetworking product.

HARDWARE 3Com warrants its hardware products to be free from defects in workmanship and materials, under

SOFTWARE 3Com warrants that the software programs licensed from it will perform in substantial conformance to the

normal use and service, for the following lengths of time from the date of purchase from 3Com or its

Authorized Reseller:

Internetworking products 1 year

Network adapters Lifetime

Ethernet stackable hubs and Unmanaged Ethernet fixed port repeaters Lifetime*

*Power supply and fans in the stackable hubs and unmanaged repeaters 1 year

Other hardware products 1 year

Spare parts and spares kits 90 days

If a product does not operate as warranted above during the applicable warranty period, 3Com shall, at

its option and expense, repair the defective product or part, deliver to Customer an equivalent product or

part to replace the defective item, or refund to Customer the purchase price paid for the defective

product. All products that are replaced will become the property of 3Com. Replacement products may be

new or reconditioned. Any replaced or repaired product or part has a 90-day warranty or the remainder of

the initial warranty period, whichever is longer.

3Com shall not be responsible for any software, firmware, information, or memory data of Customer

contained in, stored on, or integrated with any products returned to 3Com for repair, whether under

warranty or not.

program specifications therefor for a period of 90 days from the date of purchase from 3Com or its

Authorized Reseller. 3Com warrants the media containing software against failure during the warranty

period. No updates are provided. 3Com’s sole obligation with respect to this express warranty shall be (at

3Com’s discretion) to refund the purchase price paid by Customer for any defective software products, or

to replace any defective media with software which substantially conforms to 3Com’s applicable published

specifications. Customer assumes responsibility for the selection of the appropriate applications program

and associated reference materials. 3Com makes no warranty or representation that its software products

will work in combination with any hardware or applications software products provided by third parties,

that the operation of the software products will be uninterrupted or error free, or that all defects in the

software products will be corrected. For any third-party products listed in the 3Com software product

documentation or specifications as being compatible, 3Com will make reasonable efforts to provide

compatibility, except where the noncompatibility is caused by a “bug” or defect in the third party’s

product.

(1 year if not registered)

STANDARD WARRANTY

S

ERVICE

WARRANTIES EXCLUSIVE IF A 3COM PRODUCT DOES NOT OPERATE AS WARRANTED ABOVE, CUSTOMER’S SOLE REMEDY FOR

Standard warranty service for hardware products may be obtained by delivering the defective product,

accompanied by a copy of the dated proof of purchase, to 3Com’s Corporate Service Center or to an

Authorized 3Com Service Center during the applicable warranty period. Standard warranty service for

software products may be obtained by telephoning 3Com’s Corporate Service Center or an Authorized

3Com Service Center, within the warranty period. Products returned to 3Com’s Corporate Service Center

must be pre-authorized by 3Com with a Return Material Authorization (RMA) number marked on the

outside of the package, and sent prepaid, insured, and packaged appropriately for safe shipment. The

repaired or replaced item will be shipped to Customer, at 3Com’s expense, not later than 30 days after

receipt of the defective product by 3Com.

BREACH OF THAT WARRANTY SHALL BE REPAIR, REPLACEMENT, OR REFUND OF THE PURCHASE PRICE

PAID, AT 3COM’S OPTION. TO THE FULL EXTENT ALLOWED BY LAW, THE FOREGOING WARRANTIES AND

REMEDIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES, TERMS, OR CONDITIONS,

EXPRESS OR IMPLIED, EITHER IN FACT OR BY OPERATION OF LAW, STATUTORY OR OTHERWISE,

INCLUDING WARRANTIES, TERMS, OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, AND SATISFACTORY QUALITY. 3COM NEITHER ASSUMES NOR AUTHORIZES ANY OTHER

PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH THE SALE, INSTALLATION,

MAINTENANCE, OR USE OF ITS PRODUCTS.

Page 60

3COM SHALL NOT BE LIABLE UNDER THIS WARRANTY IF ITS TESTING AND EXAMINATION DISCLOSE

THAT THE ALLEGED DEFECT IN THE PRODUCT DOES NOT EXIST OR WAS CAUSED BY CUSTOMER’S OR

ANY THIRD PERSON’S MISUSE, NEGLECT, IMPROPER INSTALLATION OR TESTING, UNAUTHORIZED

ATTEMPTS TO REPAIR OR MODIFY, OR ANY OTHER CAUSE BEYOND THE RANGE OF THE INTENDED USE,

OR BY ACCIDENT, FIRE, LIGHTNING, OR OTHER HAZARD.

LIMITATION OF LIABILITY TO THE FULL EXTENT ALLOWED BY LAW, 3COM ALSO EXCLUDES FOR ITSELF AND ITS SUPPLIERS ANY

LIABILITY, WHETHER BASED IN CONTRACT OR TORT (INCLUDING NEGLIGENCE), FOR INCIDENTAL,

CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE DAMAGES OF ANY KIND, OR FOR LOSS OF REVENUE

OR PROFITS, LOSS OF BUSINESS, LOSS OF INFORMATION OR DATA, OR OTHER FINANCIAL LOSS ARISING

OUT OF OR IN CONNECTION WITH THE SALE, INSTALLATION, MAINTENANCE, USE, PERFORMANCE,

FAILURE, OR INTERRUPTION OF ITS PRODUCTS, EVEN IF 3COM OR ITS AUTHORIZED RESELLER HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, AND LIMITS ITS LIABILITY TO REPAIR, REPLACEMENT,

OR REFUND OF THE PURCHASE PRICE PAID, AT 3COM’S OPTION. THIS DISCLAIMER OF LIABILITY FOR

DAMAGES WILL NOT BE AFFECTED IF ANY REMEDY PROVIDED HEREIN SHALL FAIL OF ITS ESSENTIAL

PURPOSE.

Some countries, states, or provinces do not allow the exclusion or limitation of implied warranties or the

limitation of incidental or consequential damages for certain products supplied to consumers, so the above

limitations and exclusions may be limited in their application to you. This warranty gives you specific legal

rights which may vary depending on local law.

GOVERNING LAW This Limited Warranty shall be governed by the laws of the state of California.

3Com Corporation, 5400 Bayfront Plaza, Santa Clara, CA 95052-8145 (408) 764-5000

10/20/96

Loading...

Loading...