Page 1

3B SCIENTIFIC® PHYSICS

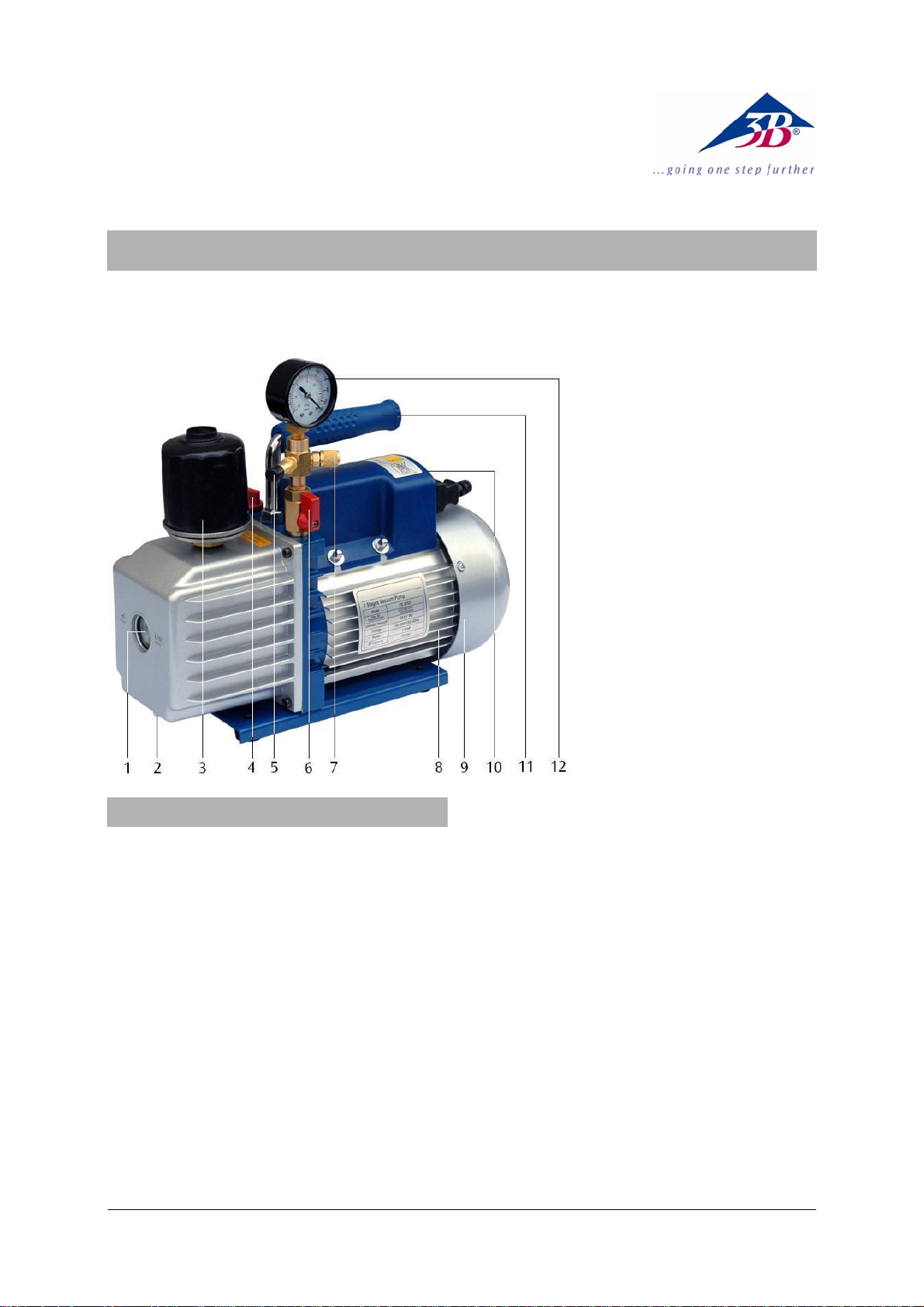

Rotary-Vane Vacuum Pump, Two-Stage 1003317

Instruction sheet

11/12 ALF

1 Oil sight glass

2 Oil drain cap

3 Exhaust filter

4 Oil fill cap

5 Hose nipple

6 Stopcock

7 Ventilation valve

8 Motor

9 Fan cover

10 Power switch and voltage

selector switch

11 Carrying handle

12 Manometer

1. Safety instructions

The rotary-vane pump 1003317 is in accordance

with the following applicable European directives

and standards:

89/336/EEC Electromagnetic Compatibility

73/23/EEC Low Voltage Directive

EMC: EN55014-1 (2000) + A2 (2002),

EN55014-2 (1997) + A1 (2001)

LVD: EN60034-1 (1998) + A11 (2002)

Safe operation of the pump is guaranteed, provided it is used correctly. However, there is no

guarantee of safety if the equipment is used in

an improper or careless manner.

The pump may only be used for its intended

use. Any other use is to be considered improper.

The manufacturer cannot be held responsible for

damages caused by improper use of the pump.

Under no circumstance must the pump be altered or tampered with.

In case of tempering the manufacturer declines

any responsibility for the functioning and safety

of the pump.

If it may be assumed for any reason that nonhazardous operation will not be possible (e.g. visible

damage), the pump should be switched off immediately and secured against any unintended use.

In schools and other educational institutions, the

operation of the pump must be supervised by

qualified personnel.

• Before setting up and using the pump for the

first time, read the manual carefully.

• Confirm that the voltage selector switch is

set to the local mains voltage.

• The pump may only be connected to the mains

via a socket that has an earth connection.

• The pump may only be opened/repaired by

qualified and trained personnel. Always disconnect the pump by pulling the mains plug before

proceeding to any of the mentioned operations.

1

Page 2

• In case of power failure during operation,

turn the pump off for safety reasons.

2. Description

The rotary-vane pump 1003317 must only be

used in vacuum experiments to depressurize

vacuum containers. It is not designed for commercial use.

The pump is a high performance, compact, twostage, oil-sealed rotary vane pump. It is protected against thermal overload and equipped

with an exhaust filter to reduce oil mist, a manometer and a

ventilation valve.

For reasons of transport the pump is delivered

with no oil in the reservoir. In the package you

should find a bottle of oil, sufficient for the first

filling.

The pump is equipped with a voltage selector

switch (refer to fig. 1), so that it can be operated

with mains voltages of 110 V or 230 V plus or

minus 10 %.

3. Technical data

Power supply: 110 – 120 V, 60 Hz

220 – 240 V, 50/60 Hz

Suction capacity: 100 l/min

Final pressure: 0.003 hPa

Motor power: 245 W

Oil capacity: 350 ml

Manometer: 0 – 1000 mbar

Hose nipple: 10 mm dia.

Di mensions: approx. 335x138x250 mm

3

Weight: approx. 11 kg

Ambient temperature: 5° – 40° C approx.

4. Operation

4.1 General information

• After unpacking, please place all parts of the

package (bags, boxes, polystyrene sides)

away from the reach of children.

• Check the presence of the data label on the

hosing. If the label is not present, do not use

the pump and inform the supplier.

• In case you need to send back the pump to

the distributer (e.g. repair) drain the oil.

• For the disposal of the oil adhere to the local

regulations.

4.2 Before operating the pump

• Place the pump horizontally on a stable

support.

• Do not connect the pump yet to the mains

voltage.

• Check that the voltage selector switch is set

to the local mains voltage and ensure that

the power switch is in the OFF position before connecting the pump to a power source.

• Remove the oil fill cap and add oil until it

shows at the bottom of the sight glass. Refer

to the technical data for the correct oil capacity of the pump.

• Screw back the oil fill cap, remove the cap

from the hose nipple and open the stopcock.

• Turn the motor switch to ON position.

• When the pump runs smoothly put the cap

back onto the hose nipple and close the

stopcock. This may take 2 to 30 seconds

depending on the ambient temperature.

• After the pump operates for approximately

one minute, check the sight glass for proper

oil level, which should be aligned with the

sight glass oil level line. Refill oil if necessary.

Note: Insufficient oil filling will result in poor vacuum performance. Excessive oil can result in

overflowing of oil from the exhaust fitting.

Fig. 1 A voltage selector switch, B power switch, C

socket

4.3 To shut off the pump after use

To prolong life span of the pump and a smooth

start-up, these procedures to shut off the pump

should be followed.

• Close the stopcock.

• Remove the hose from the hose nipple.

• Switch off the pump and open the stopcock for

a few seconds to relieve any vacuum inside

the pump.

• Place the cap on the hose nipple to prevent

any contamination or foreign particles from entering it.

2

Page 3

4.4 Maintenance

4.4.1 Vacuum pump oil

The condition and the type of oil used in any

high performance vacuum pump are extremely

important in determining the ultimate attainable

vacuum. It is recommended to use the high performance vacuum pump oil, which is specifically

blended to maintain maximum viscosity at normal running temperatures and to improve cold

weather start up.

4.4.2 Oil change

• Ensure that the pump is warmed up.

• Pull the mains plug.

• Remove the oil drain cap and drain the con-

taminated oil into a container. Take care not

lose the oil drain gasket.

• Dispose of the oil adhering to the local regu-

lations.

Oil can also be removed from the pump by

opening the stopcock and partially blocking the

exhaust with a cloth while the pump is running.

Do not operate the pump for more than 20 seconds using this method.

• When the drainage of oil completed, tilt the

pump forward to remove the residual oil.

• Screw in the oil drain cap.

• Remove the oil fill cap and fill the oil reser-

voir with new vacuum pump oil until oil is

seen at the bottom of the sight glass.

• Ensure that the stopcock is closed before

turning on the pump.

• Allow it to run for one minute before check-

ing the oil level.

• If the oil level is below the sight glass oil

level line, fill oil slowly (with the pump running) until the oil reaches the oil level line.

• Place back the oil fill cap, ensure the stopcock

is closed and the oil drain cap is closed tightly.

If the oil is badly contaminated with sludge that

forms during operation, you may use the following method to remove the oil from the pump

reservoir.

• Leave the pump running until it is warmed

up.

• While the pump is still running, remove the

oil drain cap. Take care not lose the oil drain

gasket.

• Restrict the exhaust slightly.

This will back-pressure the oil reservoir and

force out the sludge.

• Turn off the pump when the oil stops flowing.

• Repeat this procedure as required until the

contaminants are removed.

• Screw in the oil drain cap and refill the oil res-

ervoir to the proper oil level with clean vacuum

pump oil.

5. Troubleshooting guide

5.1 Failure to start

• Check if the voltage selector switch is in the

right position.

5.2 Oil leakage

• Ensure that that the oil is not a residual ac-

cumulation of spillage etc.

If leakage exists, the housing gasket or the shaft

seal may need to be replaced.

• Contact the distributor.

If leakage exists in the area of the oil drain plug,

• reseal the plug using a commercial pipe

thread sealer.

5.3 Failure to attain a good vacuum

• Ensure the vacuum gauge and all connec-

tions are in good condition and leak free.

• Confirm leakage by monitoring the vacuum

with the manometer while applying vacuum

pump oil at connections or suspected leak

points. The vacuum will improve briefly while

the oil is sealing the leak.

• Ensure the pump oil is clean.

A badly contaminated pump may require several

oil flushes.

• Ensure the oil is at the proper level.

For optimum pump operation, the oil must be

even with the oil level line on the sight glass

when the pump is running.

• Do not overfill as operating temperatures will

cause the oil to expand, which will appear at

a higher level than when the pump is not

running.

• To check the oil level, start the pump with

the stopcock closed.

• Check the oil level in the sight glass. Add oil

if necessary.

5.4 Automatic shut down

The pump is equipped with a thermal protection

function. If the ambient temperature is too hot,

the product may stop functioning.

• Do not to switch off the power supply imme-

diately.

If the pump does not re-start automatically after

3 minutes,

• cool the pump by lowering the ambient tempera-

ture to prolong the lifespan of the vacuum pump.

3

Page 4

6. Disposal

• The packaging should be disposed of at

local recycling points.

• Should you need to dispose of the equip-

ment itself, never throw it away in normal

domestic waste. Local regulations for the

disposal of electrical equipment will apply.

3B Scientific GmbH ▪ Rudorffweg 8 ▪ 21031 Hamburg ▪ Germany ▪ www.3bscientific.com

Subject to technical amendments

© Copyright 2012 3B Scientific GmbH

Loading...

Loading...