Page 1

3B SCIENTIFIC

Relative Pressure Sensor, ±100 hPa U11321

Instruction sheet

03/08 Hh

®

PHYSICS

1. Safety instructions

• To avoid permanent damage to the internal

semiconductor sensor, the maximum

permitted relative pressure of 4000 hPa must

never be exceeded.

Only suitable for use with non-corrosive gases such

as air, helium or nitrogen.

• Do not allow the sensor element to come into

contact with water.

2. Description

Relative pressure sensor with a measurement range

up to 100 hPa, suitable for measuring the pressure

on the piston of the Wilke-type Stirling engine

U8440480 (for a pV diagram).

For two-port measurement using the sensor, hose

connections are provided for two inputs.

The sensor box is designed to be detected

automatically by the 3B NETlog

TM

unit.

3. Equipment supplied

1 Sensor box

1 MiniDIN 8-pin connector cable, 60 cm long

1 Silicone hose, internal diameter 2 mm, 1 m long

4. Technical data

Measurement range: ± 100 hPa

Sensor type: Semiconductor sensor

Accuracy: ± 1 %

Resolution: ± 1 hPa

Connections: 2 hose connections,

4.8 mm diameter

5. Instructions

• Cut the silicone hose into sections of the

required length.

• Using the lengths of hose, make the pressure

connections between the sensor box and the

Stirling engine.

1

Page 2

• Note the “positive” and “negative” labelling of

the hose connections - connect the hoses

correctly according to the effective direction of

the pressure.

• During the experiment, check that no elastic

expansion of the hose is occurring – this can

cause the pressure reading to be lower than

the correct value.

6. Application

Measurement of the pressure difference in the

Stirling engine U8440480, and analysis of the data

using 3B NETlab

TM

.

7. Sample experiment

Recording operating pressures in Stirling engine

U8440480 while it is in motion

Apparatus required:

1 3B NETlog

1 3B NETlab

TM

unit U11300

TM

program U11310

1 Relative pressure sensor, ±100 hPa U11321

1 Wilke-type Stirling engine U8440480

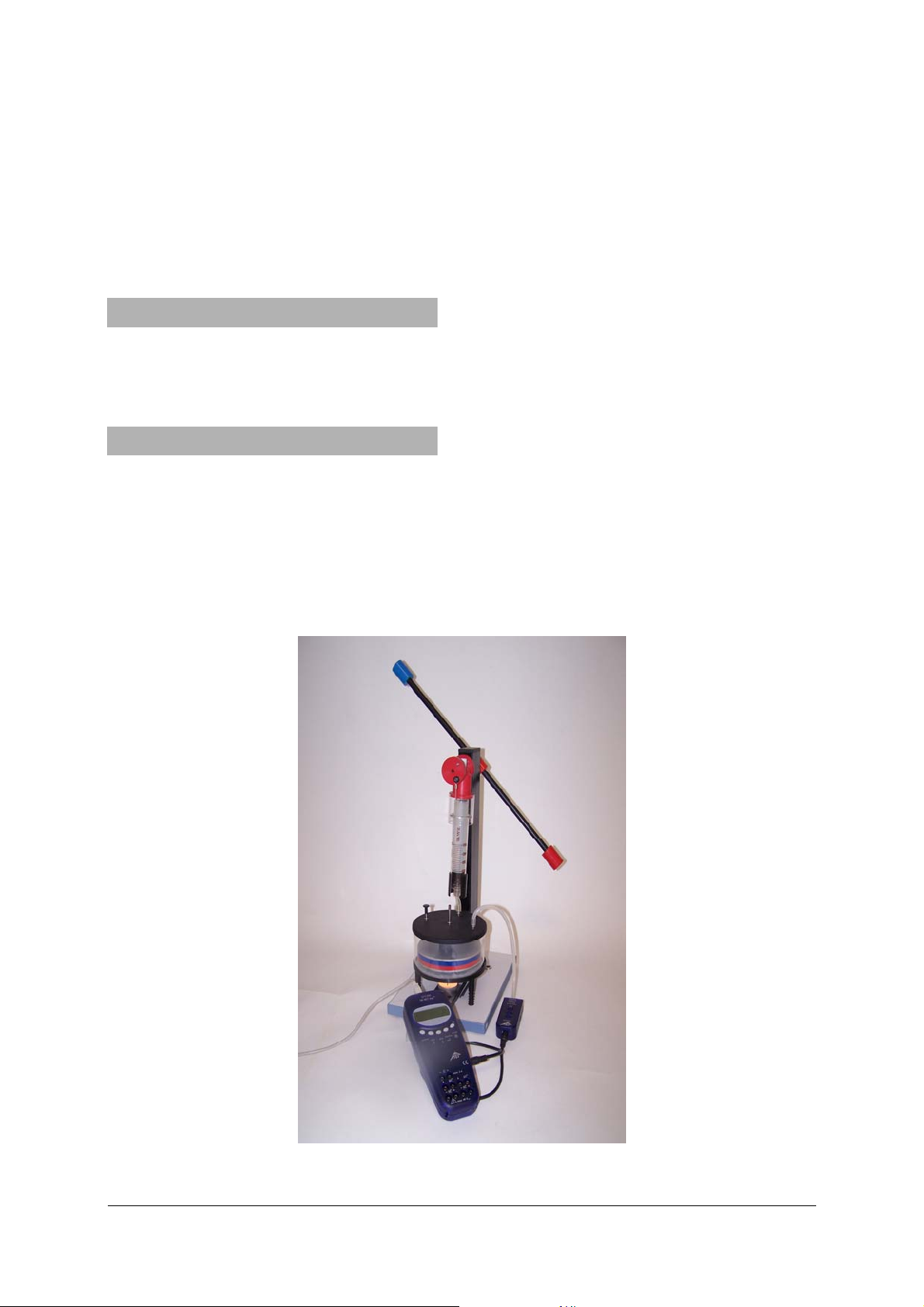

• Set up the experiment as shown in fig. 1.

• Connect the relative pressure sensor to the 3B

NETlog

TM

unit and wait for the sensor to be

detected.

• Use a suitable length of silicone hose to make

the pressure connection between the “positive”

hose connection of the sensor box and one of

the two hose connections of the Stirling

engine. The two hose connections of the

engine are identical in their function.

• Allow the engine to heat up and, after a few

minutes, set it running.

• Open the application program (template) for

the experiment with the ±100 hPa relative

pressure sensor on the 3B NETlab

• Measure the pressures.

• Evaluate the curve resulting from the

TM

unit.

measurements (fig. 2).

Fig. 1 Experiment set-up for recording operating pressures in the

2

Wilke-type Stirling engine while in motion

Page 3

Fig. 2 Trace of pressure in the

Wilke-type Stirling engine

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2008 3B Scientific GmbH

Page 4

Loading...

Loading...