Page 1

3B SCIENTIFIC

Relativ-Drucksensor ± 100 hPa U11321

Bedienungsanleitung

03/08 Hh

®

PHYSICS

1. Sicherheitshinweise

• Um dauerhafte Beschädigungen des eingebau-

ten Halbleitersensors zu vermeiden, den maximalen Grenzdruck von 4000 hPa keinesfalls

überschreiten!

Nur für nicht-korrodierende Gase wie Luft, Helium

und Stickstoff geeignet!

• Das Sensorelement nicht mit Wasser in Berüh-

rung bringen!

2. Beschreibung

Relativ-Drucksensor mit einem Messbereich bis 100

hPa, geeignet zur Messung des Kolbendrucks (pVDiagramm) im Stirling-Motor nach Wilke U8440480.

Zweitor-Messverfahren des Sensors: Beide Anschlüsse sind mittels Schlauchwellen heraus geführt.

Die Sensorbox besitzt eine automatische Erkennung

durch das 3B NETlog

TM

.

3. Lieferumfang

1 Sensorbox

1 MiniDIN-Anschlusskabel 8-pin, 60 cm lang

1 Silikonschlauch, Øinnen 2 mm, 1 m lang

4. Technische Daten

Messbereich: ± 100 hPa

Sensortyp: Halbleitersensor

Genauigkeit: ± 1 %

Auflösung: ± 1 hPa

Anschlüsse: 2 Schlauchwellen

4,8 mm Ø

5. Bedienung

• Silikonschlauch auf die gewünschten Teilstück-

längen kürzen.

• Mit den Teilstücken die Druckverbindungen

zwischen Sensorbox und Stirling-Motor herstellen.

1

Page 2

• Wirkungsrichtung der Drücke beachten: „Posi-

tive“ und „Negative“ Schlauchwellenkennzeichnung!

• Beim Experiment die Elastizität des Schlauches

berücksichtigen – dies führt ggfs. zu einer geringen Verfälschung des Messwertes.

6. Anwendung

Messung der Druckdifferenz im Stirling-Motor

U8440840 und Auswertung in 3B NETlab

TM

.

7. Versuchsbeispiel

Aufnahme der Betriebsdruckwerte im rotierenden Stirling-Motor U8440840

Benötigte Geräte:

1 3B NETlog

1 3B NETlab

TM

U11300

TM

U11310

1 Relativ-Drucksensor ± 100 hPa U11321

1 Stirling-Motor nach Wilke U8440480

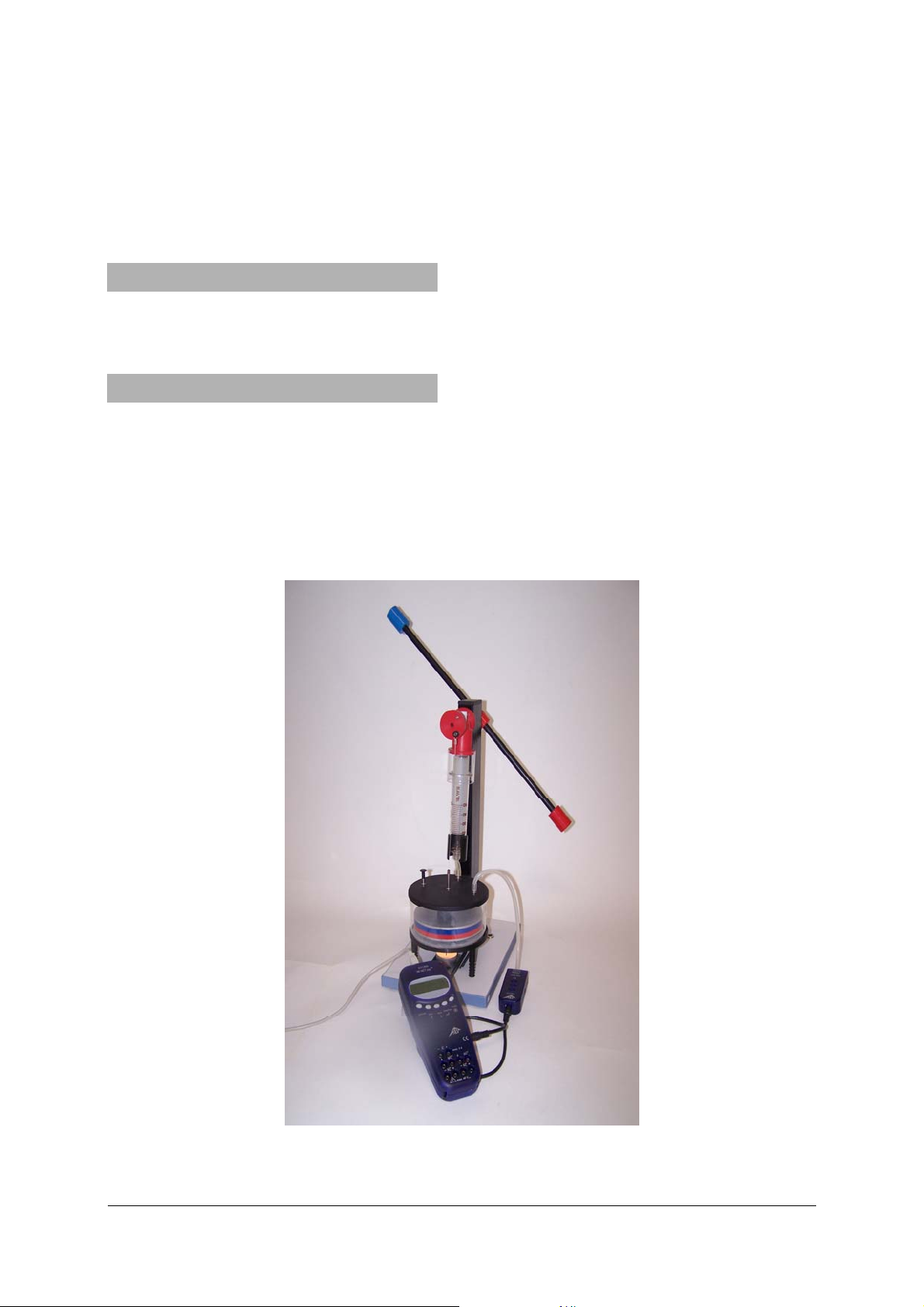

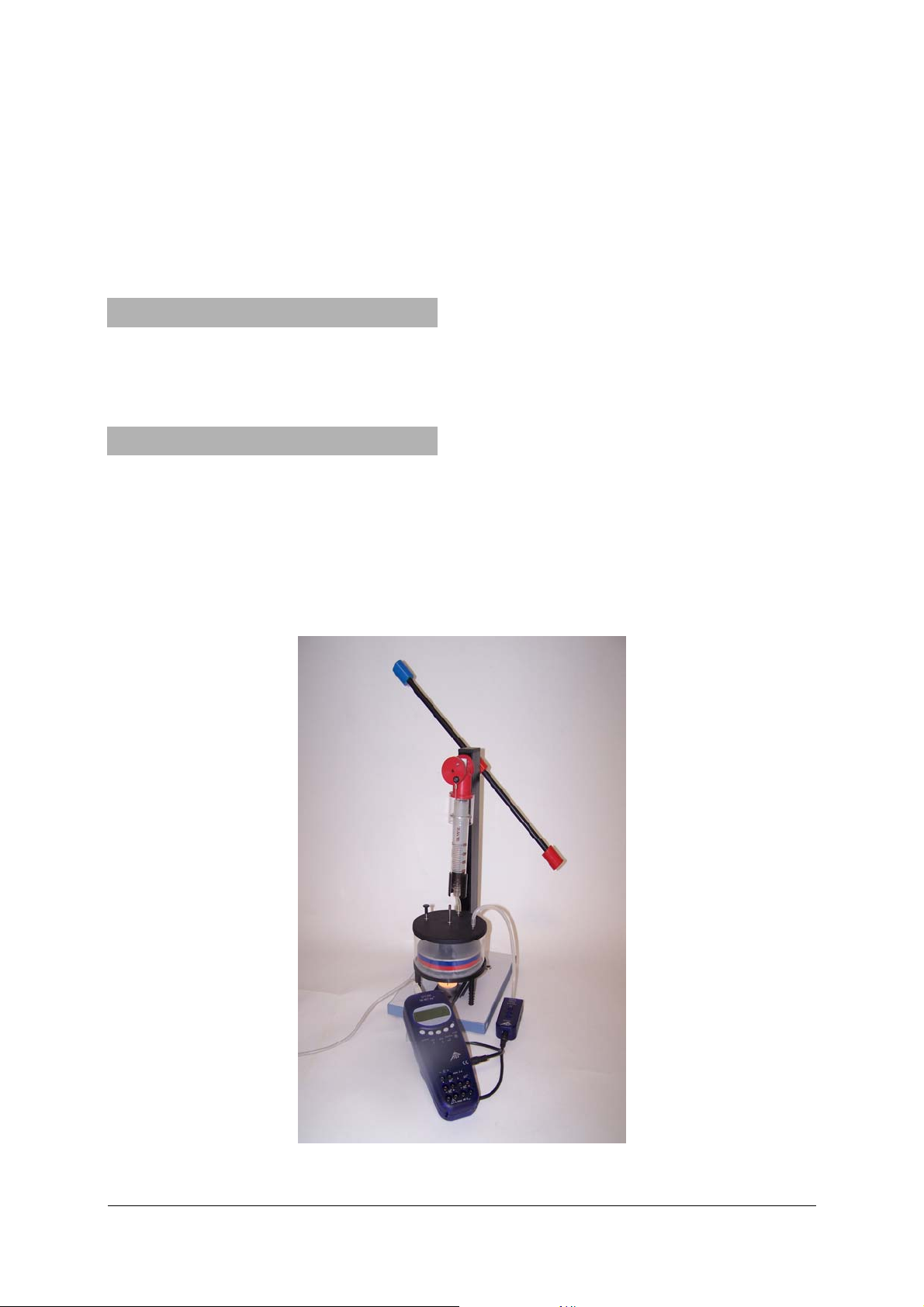

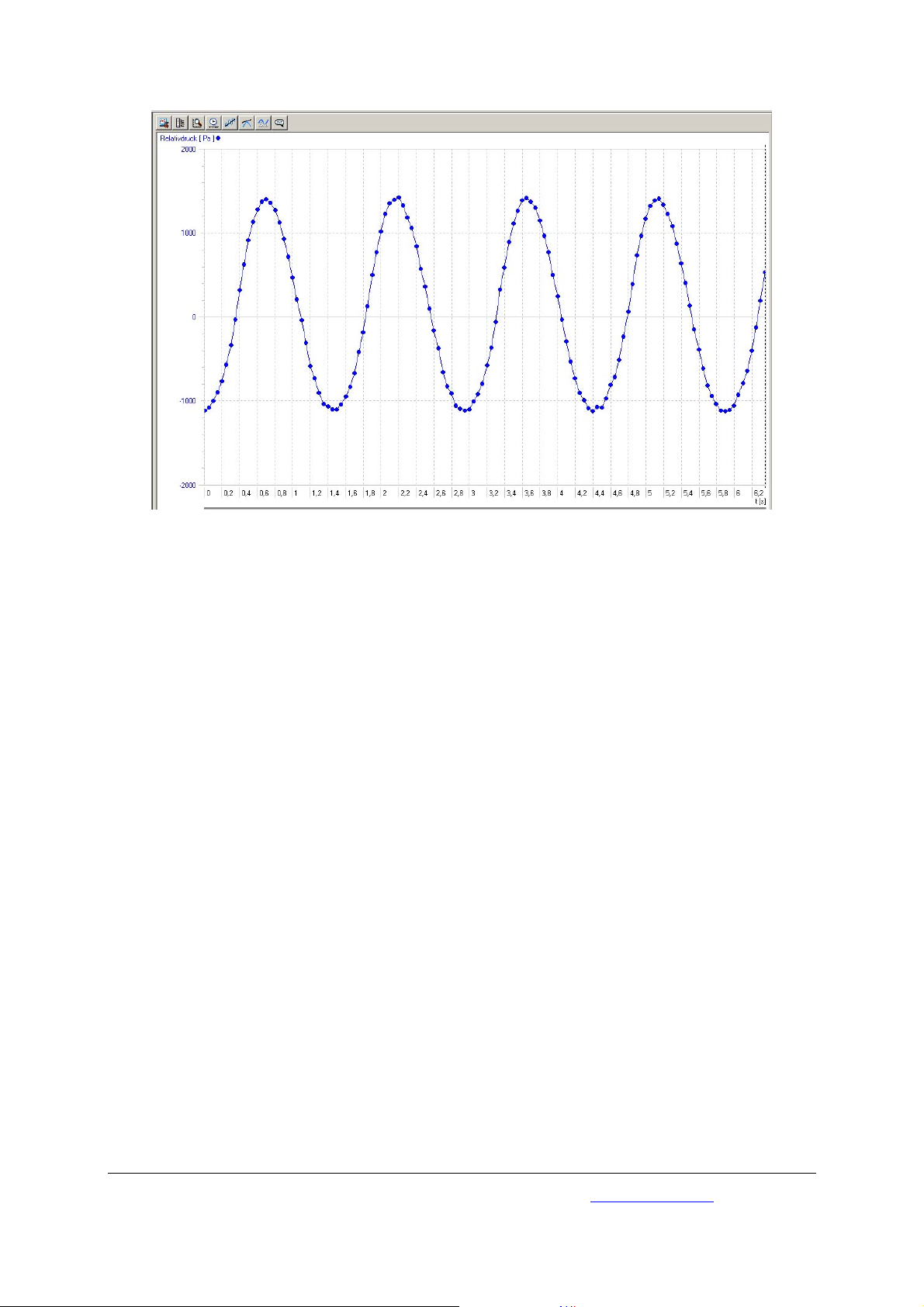

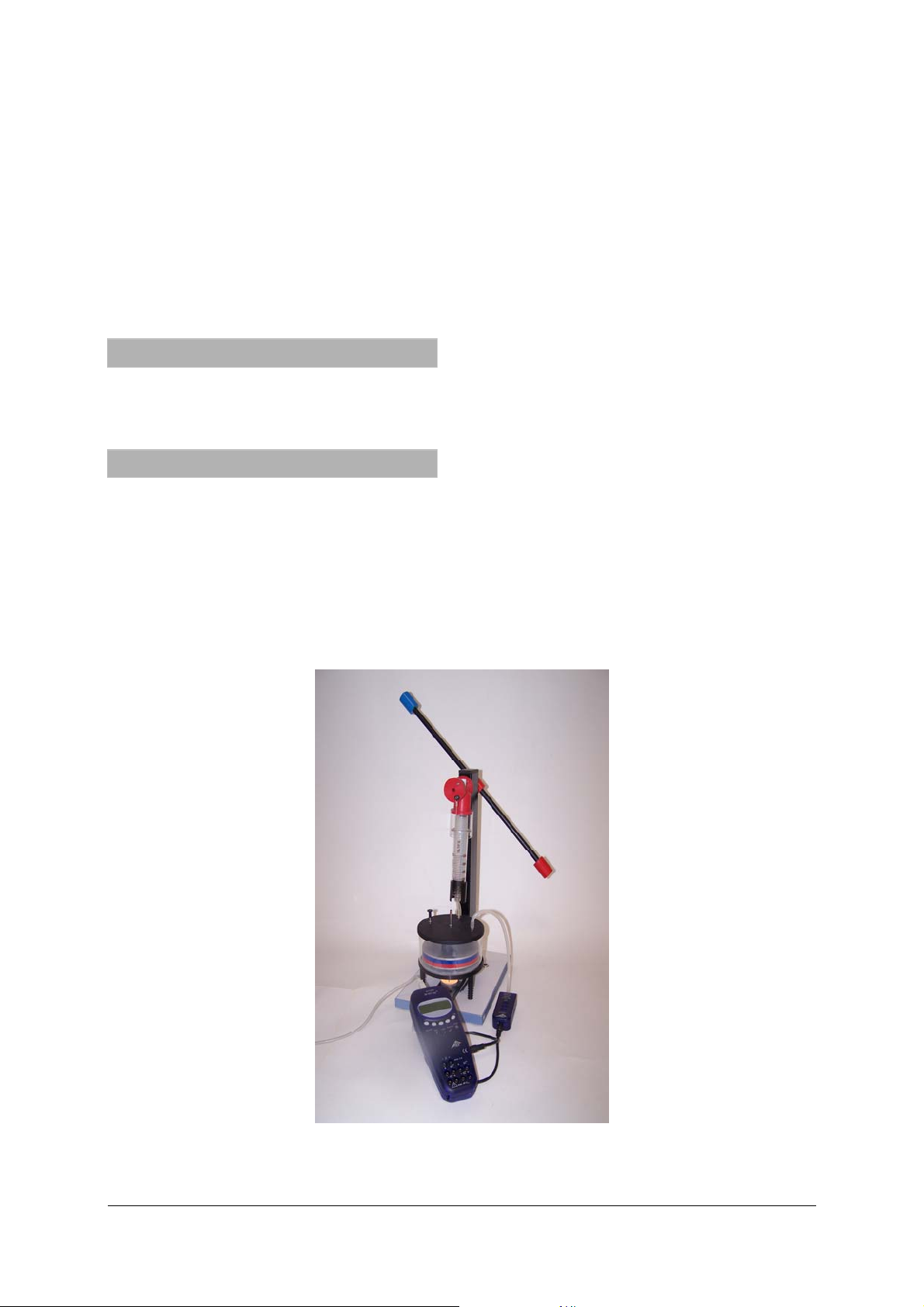

• Versuchsaufbau gemäß Fig. 1.

• Den Relativ-Drucksensor ± 100 hPa an das 3B

NETlog

TM

anschließen und die Sensorerkennung

abwarten.

• Mit einem Teilstück des Silikonschlauchs die

Druckverbindungen zwischen „positiver“

Schlauchwelle der Sensorbox und einer der

beiden Schlauchwellen des Stirling-Motors herstellen. Die beiden Schlauchwellen des Motors

sind gleichwertig.

• Motor anheizen und nach einigen Minuten

anwerfen.

• 3B NETlab

TM

-Anwendung (Template) zum Experiment mit dem Relativ-Drucksensor ± 100 hPa

öffnen.

• Druckwerte messen.

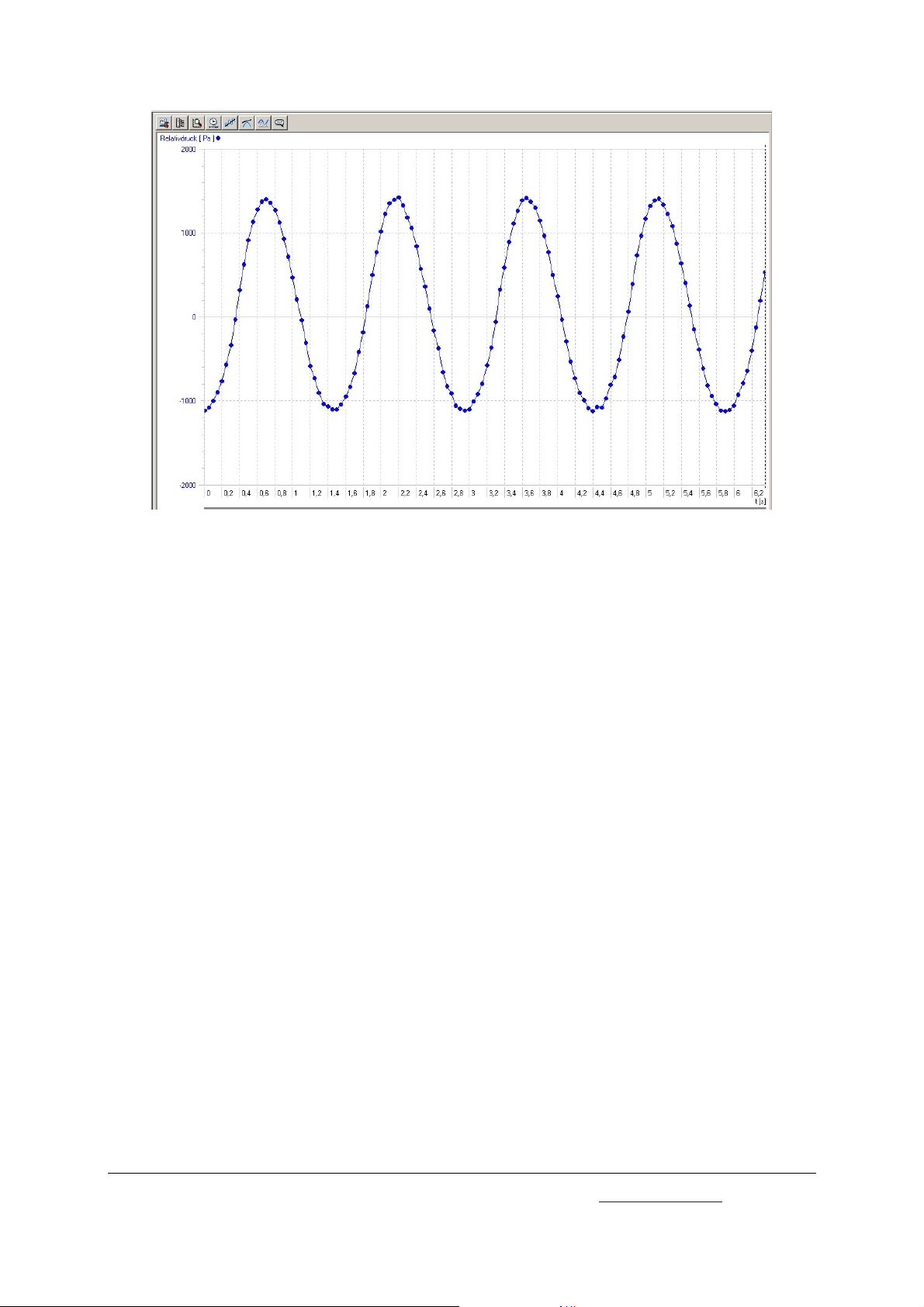

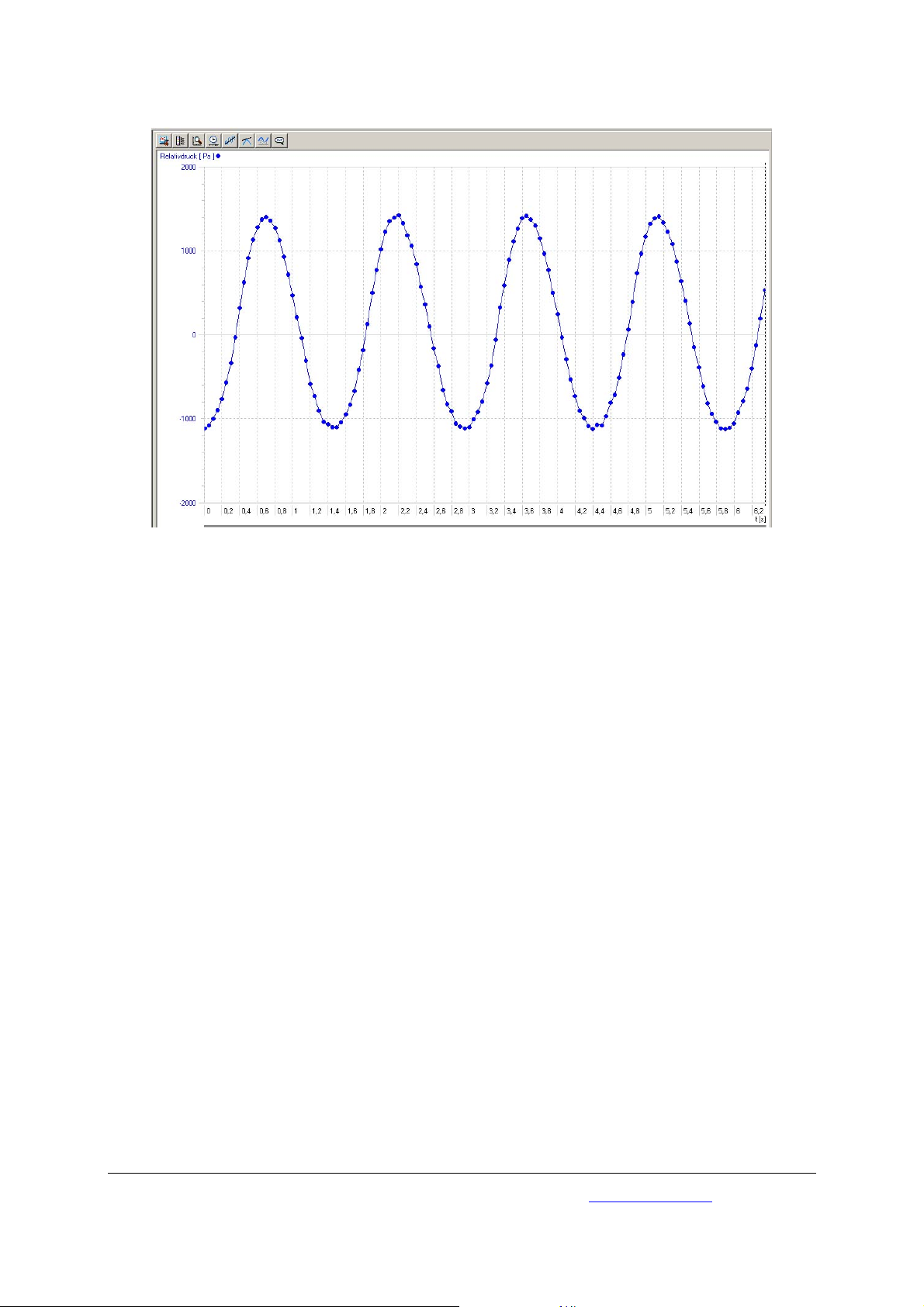

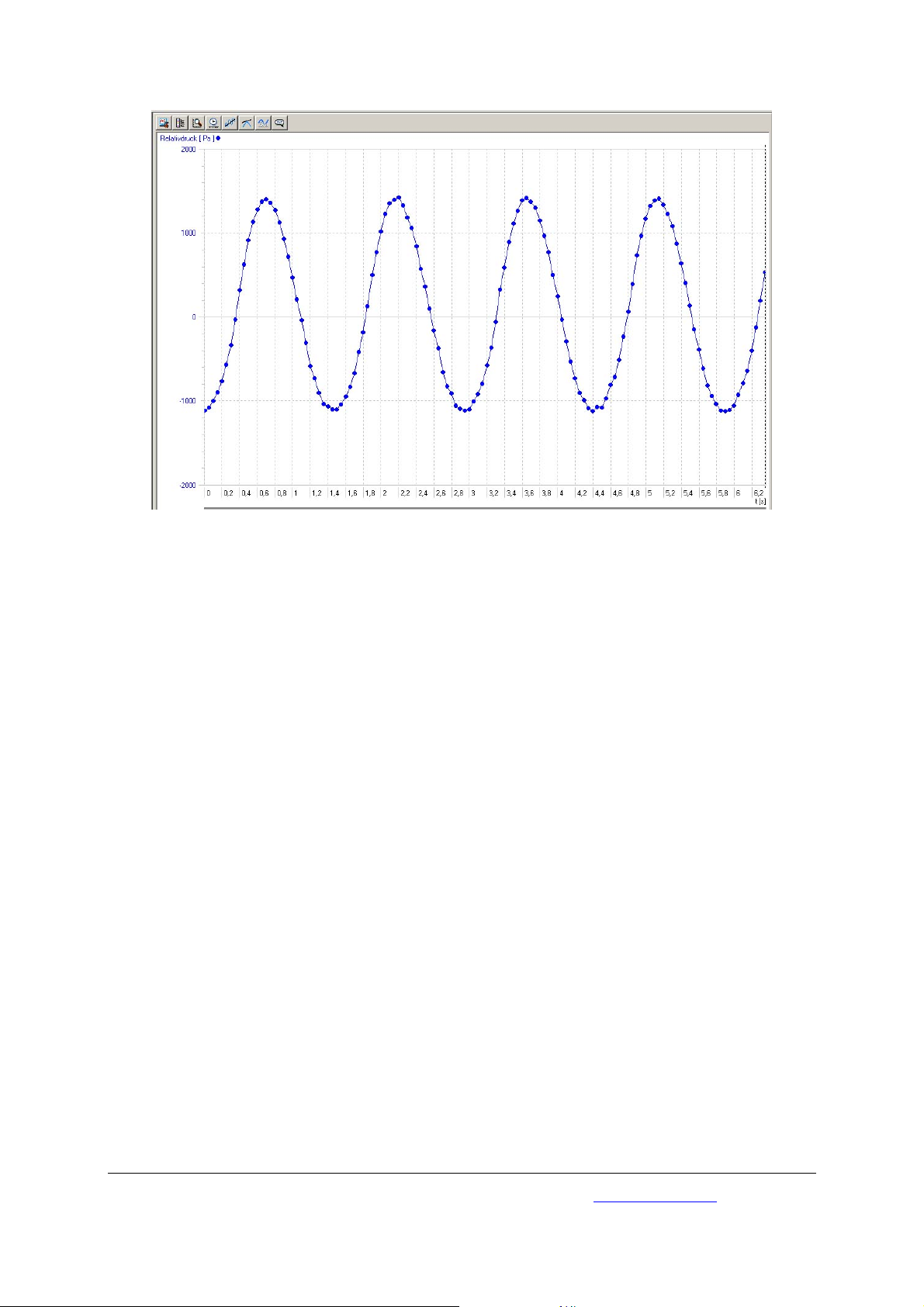

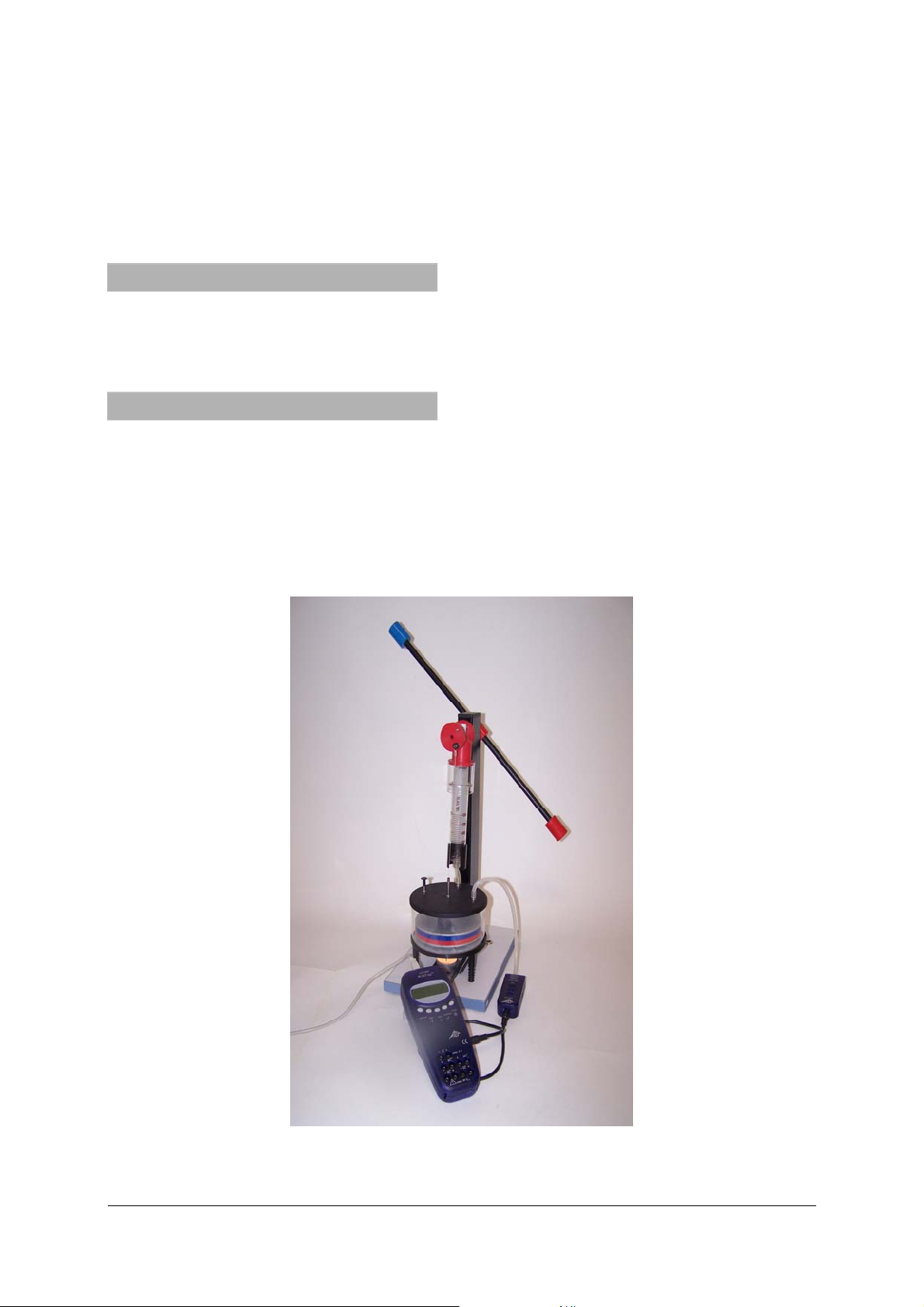

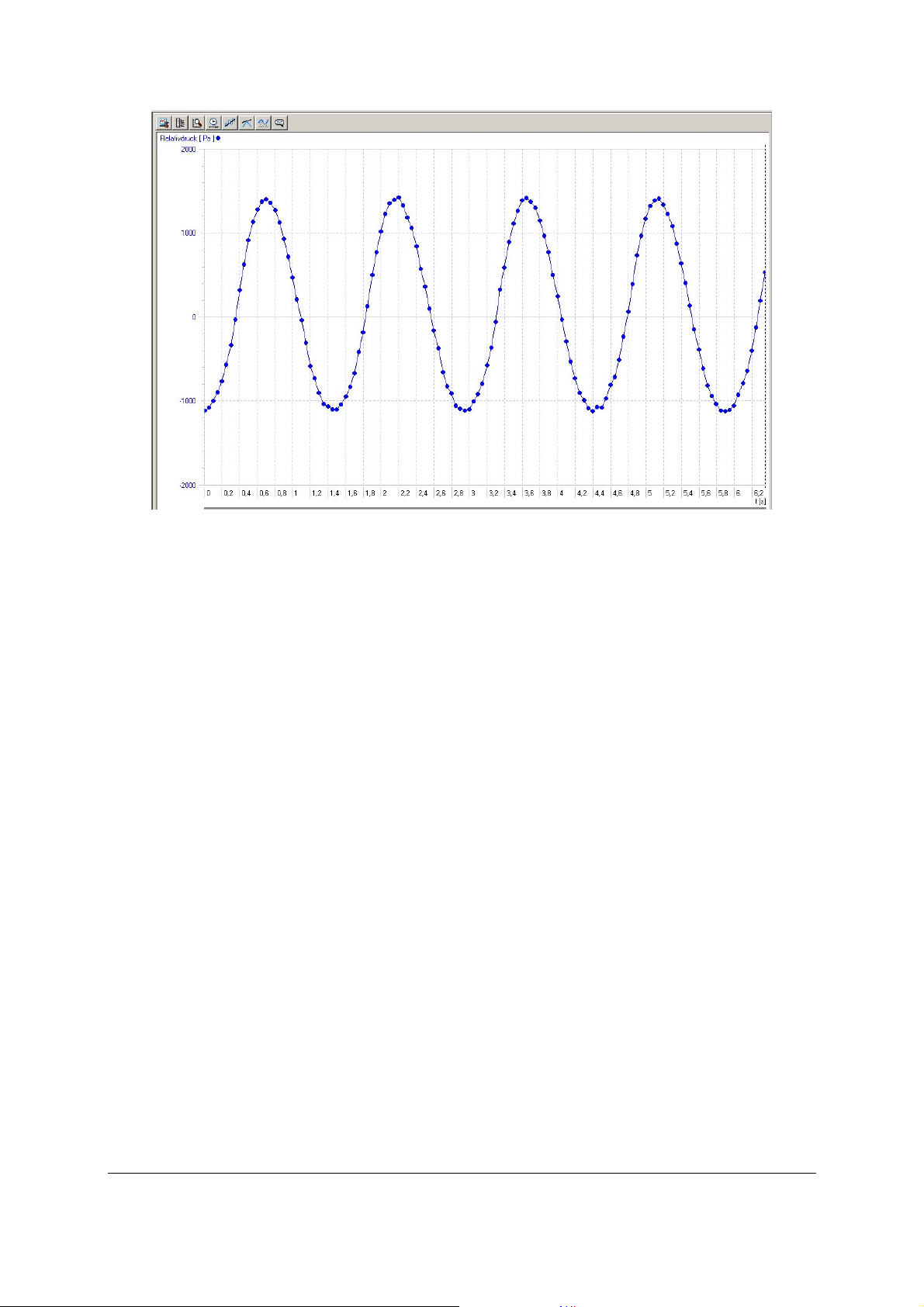

• Messkurve auswerten (Fig. 2).

Fig. 1 Versuchsaufbau zur Aufnahme der Betriebsdruckwerte im rotierenden Stirling-Motor nach Wilke

2

Page 3

Fig. 2 Druckverlauf im Stirling-Motor nach Wilke

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Deutschland • www.3bscientific.com

Technische Änderungen vorbehalten

© Copyright 2008 3B Scientific GmbH

Page 4

Page 5

3B SCIENTIFIC

Relative Pressure Sensor, ±100 hPa U11321

Instruction sheet

03/08 Hh

®

PHYSICS

1. Safety instructions

• To avoid permanent damage to the internal

semiconductor sensor, the maximum

permitted relative pressure of 4000 hPa must

never be exceeded.

Only suitable for use with non-corrosive gases such

as air, helium or nitrogen.

• Do not allow the sensor element to come into

contact with water.

2. Description

Relative pressure sensor with a measurement range

up to 100 hPa, suitable for measuring the pressure

on the piston of the Wilke-type Stirling engine

U8440480 (for a pV diagram).

For two-port measurement using the sensor, hose

connections are provided for two inputs.

The sensor box is designed to be detected

automatically by the 3B NETlog

TM

unit.

3. Equipment supplied

1 Sensor box

1 MiniDIN 8-pin connector cable, 60 cm long

1 Silicone hose, internal diameter 2 mm, 1 m long

4. Technical data

Measurement range: ± 100 hPa

Sensor type: Semiconductor sensor

Accuracy: ± 1 %

Resolution: ± 1 hPa

Connections: 2 hose connections,

4.8 mm diameter

5. Instructions

• Cut the silicone hose into sections of the

required length.

• Using the lengths of hose, make the pressure

connections between the sensor box and the

Stirling engine.

1

Page 6

• Note the “positive” and “negative” labelling of

the hose connections - connect the hoses

correctly according to the effective direction of

the pressure.

• During the experiment, check that no elastic

expansion of the hose is occurring – this can

cause the pressure reading to be lower than

the correct value.

6. Application

Measurement of the pressure difference in the

Stirling engine U8440480, and analysis of the data

using 3B NETlab

TM

.

7. Sample experiment

Recording operating pressures in Stirling engine

U8440480 while it is in motion

Apparatus required:

1 3B NETlog

1 3B NETlab

TM

unit U11300

TM

program U11310

1 Relative pressure sensor, ±100 hPa U11321

1 Wilke-type Stirling engine U8440480

• Set up the experiment as shown in fig. 1.

• Connect the relative pressure sensor to the 3B

NETlog

TM

unit and wait for the sensor to be

detected.

• Use a suitable length of silicone hose to make

the pressure connection between the “positive”

hose connection of the sensor box and one of

the two hose connections of the Stirling

engine. The two hose connections of the

engine are identical in their function.

• Allow the engine to heat up and, after a few

minutes, set it running.

• Open the application program (template) for

the experiment with the ±100 hPa relative

pressure sensor on the 3B NETlab

• Measure the pressures.

• Evaluate the curve resulting from the

TM

unit.

measurements (fig. 2).

Fig. 1 Experiment set-up for recording operating pressures in the

2

Wilke-type Stirling engine while in motion

Page 7

Fig. 2 Trace of pressure in the

Wilke-type Stirling engine

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2008 3B Scientific GmbH

Page 8

Page 9

3B SCIENTIFIC

Capteur de pression relative ± 100 hPa U11321

Instructions d'utilisation

03/08 Hh

®

PHYSICS

1. Consignes de sécurité

• Pour éviter des dommages durables du capteur

intégré à semi-conducteur, il est interdit de

dépasser la pression maximale de 4000 hPa !

Convient uniquement à des gaz non corrodants

comme l'air, l'hélium et l'azote !

• Ne mettez pas la sonde en contact avec de

l'eau !

2. Description

Le capteur de pression relative avec un calibre

jusqu'à 100 hPa convient à la mesure de la

pression du piston (diagramme pV) dans le moteur

Stirling transparent U10050.

Procédé de mesure à deux portes du capteur : les

deux connexions sont sorties via des embouts.

La boîte à capteur possède une détection

automatique par le 3B NETlog

3. Matériel fourni

1 boîte à capteur

1 câble de connexion mini-Din à 8 broches, 60 cm

de long

TM

.

1 flexible en silicone, Ø intérieur 2 mm, 1 m de

long

4. Caractéristiques techniques

Calibre : ± 100 hPa

Type de capteur : capteur à semi-conduc-

teur

Précision : ± 1 %

Résolution : ± 1 hPa

Connexions : 2 embouts, Ø 4,8 mm

5. Manipulation

• Raccourcissez le flexible en silicone aux

longueurs souhaitées.

• Avec ces segments, établissez les raccords de

pression entre la boîte à capteur et le moteur

Stirling.

• Observez le sens d'action des pressions :

identification « positive » et « négative » sur

l'embout !

• Au cours de l'expérience, tenez compte de

l'élasticité du flexible – la valeur de mesure

peut être légèrement faussée.

1

Page 10

6. Application

Mesure de la pression différentielle dans le moteur

Stirling U8440840 et évaluation sous 3B NETlab

TM

.

7. Exemple d'expérience

Enregistrement des valeurs de pression de

service dans le moteur Stirling U8440840 en

rotation

Matériel requis :

1 3B NETlog

1 3B NETlab

TM

U11300

TM

U11310

1 capteur de pression relative ± 100 hPa U11321

1 moteur Stirling d'après Wilke U8440840

• Montez l'expérience comme le montre la fig. 1.

• Branchez le capteur de pression relative

± 100 hPa à 3B NETlog

TM

et attendez que le

capteur soit reconnu.

• Avec un segment du flexible en silicone,

établissez les raccords de pression entre

l'embout serrage « positif » de la boîte à

capteur et l'un des deux embouts du moteur

Stirling. Les deux embouts du moteur sont

équivalents.

• Faites chauffer le moteur, puis mettez-le en

marche.

• Ouvrez l'application 3B NETlab

TM

(template)

pour réaliser l'expérience avec le capteur de

pression relative ± 100 hPa.

• Mesurez les valeurs de pression.

• Évaluez la courbe de mesure (fig. 2).

Fig. 1 Montage de l'expérience destiné à l'enregistrement des valeurs de pression de service dans le moteur Stirling d'après

Wilke en rotation

2

Page 11

Fig. 2 Courbe de pression dans le moteur Stirling d'après Wilke

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Allemagne • www.3bscientific.com

Sous réserve de modifications techniques

© Copyright 2008 3B Scientific GmbH

Page 12

Page 13

3B SCIENTIFIC

Sensore di pressione relativa ± 100 hPa U11321

Istruzioni per l'uso

03/08 Hh

®

PHYSICS

1. Norme di sicurezza

• Per evitare danni permanenti del sensore a

semiconduttore incorporato, non superare la

pressione di collasso massima di 4000 hPa!

Adatto solo per gas non corrosivi come aria, elio e

azoto!

• Non portare il sensore a contatto con acqua!

2. Descrizione

Sensore di pressione relativa con range di misura

fino a 1000 hPa adatto per la misurazione della

pressione dei pistoni (diagramma pV) nel motore

Stirling trasparente U10050.

Per misure a due porte con il sensore, i due

attacchi sono dotati di connessioni per tubo

flessibile.

La scatola del sensore viene riconosciuta

automaticamente da 3B NETlog

TM

.

3. Fornitura

1 scatola del sensore

1 cavo di collegamento Mini DIN a 8 pin, lungo 60

cm

1 tubo di silicone, Ø interno 2 mm, lungo 1 m

4. Dati tecnici

Range di misura: ± 100 hPa

Tipo sensore: sensore a semiconduttore

Precisione: ± 1 %

Risoluzione: ± 1 hPa

Attacchi: 2 connessioni per tubo

flessibile 4,8 mm Ø

5. Utilizzo

• Accorciare il tubo di silicone fino a ottenere i

segmenti della lunghezza desiderata.

• Con i segmenti ottenuti realizzare i

collegamenti a pressione tra la scatola del

sensore e il motore Stirling.

1

Page 14

• Rispettare la direzione di azione delle

pressioni: contrassegno “positivo” e “negativo”

delle connessioni per tubo flessibile.

• Durante l’esperimento tenere in

considerazione l’elasticità del tubo – potrebbe

provocare un’alterazione minima del valore

misurato.

6. Applicazione

Misurazione della differenza di pressione nel

motore Stirling U8440840 e valutazione in 3B

TM

NETlab

.

7. Esperimento di esempio

Registrazione dei valori della pressione di

esercizio nel motore Stirling rotante U8440840

Apparecchi necessari:

1 3B NETlog

1 3B NETlab

TM

U11300

TM

U11310

1 sensore di pressione relativa ±100 hPa U11321

1 motore Stirling del prof. Wilke U8440840

• Struttura di prova come da fig. 1.

• Collegare il sensore di pressione relativa

± 100 hPa a 3B NETlog

TM

e attendere il

riconoscimento del sensore.

• Con un segmento del tubo di silicone realizzare

i collegamenti a pressione tra l’albero flessibile

“positivo” della scatola del sensore e uno dei

due alberi flessibili del motore Stirling. I due

tubi flessibili del motore sono equivalenti.

• Accendere il motore e avviarlo dopo qualche

minuto.

• Aprire l'applicazione 3B NETlab

TM

(template)

per l'esperimento con il sensore di pressione

relativa ± 100 hPa.

• Misurare i valori di pressione.

• Analizzare la curva di misurazione (fig. 2).

Fig. 1 Struttura dell’esperimento per la registrazione dei valori della pressione di esercizio nel motore Stirling del prof. Wilke

rotante

2

Page 15

Fig. 2 Andamento della pressione nel motore Stirling del prof. Wilke

3B Scientific GmbH • Rudorffweg 8 • 21031 Amburgo • Germania • www.3bscientific.com

Con riserva di modifiche tecniche

© Copyright 2008 3B Scientific GmbH

Page 16

Page 17

3B SCIENTIFIC® PHYSICS

Sensor de presión relativa ± 100 hPa U11321

Istrucciones de uso

03/08 Hh

1. Advertencias de seguridad

• ¡ Para evitar daños permanentes del sensor de

semiconductor incorporado en la unidad no se

debe sobrepasar nunca la presión límite

máxima permitida de 4000 hPa !

¡ Solamente apropiado para gases no corrosivos

como aire, helio y nitrógeno !

• ¡ El elemento de sensor no se debe poner en

contacto con el agua !

2. Descripción

Sensor de presión relativa con un alcance de medida de hasta 100 hPa, apropiado para la medición

de la presión de émbolo (Diagrama pV) en el motor

de Stirling según Wilke U8440480.

Procedimiento de medida de dos puertas del

sensor: Ambas conexiones hacia afuera se han

sacado por medio de husillos de manguera.

La caja de sensor tiene un reconocimiento automático por medio del 3B NETlog

TM

.

3. Volumen de entrega

1 Caja de sensor

1 Cable de conexión MiniDIN de 8 pines, de 60 cm

de largo

1 Manguera de silicona, Ø-interno 2 mm, 1 m de

largo

4. Datos técnicos

Alcance de medida: ± 100 hPa

Tipo de sensor: Semiconductor

Exactitud: ± 1 %

Resolución: ± 1 hPa

Contactos: 2 Husillos de manguera,

4,8 mm Ø

5. Manejo

• Se acorta la manguera a las longitudes parcia-

les deseadas.

• Con las mangueras acortadas se realizan las

conexiones de presión entre el motor de

Stirling y la caja de sensor.

1

Page 18

• Tenga en cuenta las direcciones de acción de

las presiones:Marcas de los husillos de manguera ¡“Positive“ y “Negative“!

• Al experimentar tenga en cuenta la elasticidad

de la manguera, puede ser que esto conduzca

a una alteración del valor de medida.

6. Aplicación

Medición de diferencias de presión en el motor de

Stirling según Wilke U8440480 y evaluación a continuación con el 3B NETlab

TM

.

7. Ejemplo de experimentación

Registro de los valores de presión de trabajo en

el motor de Stirling U8440480 en rotación

Aparatos necesarios:

1 3B NETlog

1 3B NETlab

TM

U11300

TM

U11310

1 Sensor de presión relativa ± 100 hPa U11321

1 Motor de Stirling según Wilke U8440480

• Montaje de experimentación de acuerdo con

fig. 1.

• El sensor de presión relativa ± 100 hPa se

conecta con el 3B NETlog

TM

y se espera a que se

realice el reconocimiento del sensor.

• Con un trozo de la manguera de silicona se

realizan las conexiones de presión entre el

husillo “positivo“ de la caja de sensor y uno de

los dos husillos de manguera del motor de

Stirling. Los dos husillos del motor son equivalentes.

• Se calienta el motor y después de unos minu-

tos se pone en marcha.

• Se abre la aplicación de 3B NETlab

TM

(Templete)

para la experimentación con el sensor de

presión relativa ± 100 hPa.

• Se miden los valores de presión.

• Se evalua la curva de medida (fig. 2).

Fig. 1 Montaje de experimentación para el registro de los valores de presión de trabajo de un motor de Stirling según

Wilke en rotación

2

Page 19

Fig. 2 Curso de la presión en el motor de Stirling según Wilke

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburgo • Alemania • www.3bscientific.com

Se reservan las modificaciones técnicas

© Copyright 2007 3B Scientific GmbH

Page 20

Page 21

3B SCIENTIFIC

Sensor de pressão relativa ±100 hPa U11321

Instruções de operação

03/08 Hh

®

PHYSICS

1. Indicações de segurança

• A fim de evitar danos permanentes no sensor

de semi-monitoramento, a pressão limite

máxima não deverá ser ultrapassada acima de

4000 hPa !

Este equipamento é adequado somente para gases

não corrosivos como ar, hélio e nitrogênio!

• Evitar o contato de água com o elemento

componente do sensor!

2. Descrição

Sensor de pressão relativa com alcance de área de

medição até 100 hPa, adequado para medições da

pressão da coronha (pV-Diagrama) no motor de

Stirling segundo Wilke U8440480.

Segundo procedimento de medição do sensor:

Ambas as conexões são levadas ao exterior pela

mangueira.

A caixa de sensor possui um reconhecimento

automático através de 3B NETlog

TM

.

3. Volume de fornecimento

1 Caixa de sensor

1 Mini cabo de conexão DIN 8-pin, 60 cm de

comprimento

1 Mangueira de silicone, Øinterno 2 mm, 1 m de

comprimento

4. Dados técnicos

Área de medição: ± 100 hPa

Tipo de sensor: Sensor de semi-

monitoramento

Precisão: ± 1 %

Resolução: ± 1 hPa

Conexões: 2 conexões de

mangueiras 4,8 mm Ø

5. Operação

• Encurtar a mangueira de silicone para os

pedaços de comprimento desejado.

1

Page 22

• Proceder a conexão utilizando os pedaços

previamente ajustados entre a caixa de sensor

e o motor Stirling.

• Observar a direção de efeito da pressão: Fazer

a respectiva marcação da mangueira „Positiva“

e „Negativa“!

• Durante a experiência considerar a elasticidade

da mangueira – porque esta eventualmente

leva a um resultado de medição com um

mínimo desvio.

6. Utilizaçõe

Medição da diferença de pressão no motor Stirling

U8440480 e avaliação em 3B NETlab

TM

.

7. Exemplo de experiência

Aceitação dos valores de pressão de

funcionamento no motor Stirling U8440480 em

rotação

Equipamentos utilizados:

1 3B NETlog

1 3B NETlab

TM

U11300

TM

U11310

1 Sensor de pressão relativa ±100 hPa U11321

1 Motor Stirling, segundo Wilke U8440480

• Montagem da experiência segundo fig. 1.

• Conectar o sensor de pressão de relativa ±100

hPa no 3B NETlog

TM

e aguardar o

reconhecimento do sensor.

• Proceder a conexão com um pedaço da

mangueira de silicone previamente ajustado

da conexão de pressão entre a mangueira

„positiva“ da caixa de sensor e uma das duas

mangueiras do motor Stirling. Ambas as

mangueiras do motor são de valor igual.

• Aquecer o motor e após alguns minutos colocá-

lo em funcionamento.

• 3B NETlab

TM

-abrir a placa (Template) para a

experiência com o sensor de pressão de

relativa ±100 hPa.

• Fazer a medição do valor de pressão.

• Fazer a avaliação da curva de medição (fig. 2).

Fig. 1 Montagem da experiência para aceitação dos valores de pressão de funcionamento do motor Stirling segundo Wilke

em rotação

2

Page 23

Fig. 2 Ação da pressão no motor Stirling segundo Wilke

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburgo • Alemanha • www.3bscientific.com

Sob reserva de alterações técnicas

© Copyright 2008 3B Scientific GmbH

Page 24

Loading...

Loading...