Page 1

3B SCIENTIFIC

®

PHYSICS

Franck-Hertz Tube with Hg Filling and Heating Chamber (230 V, 50/60 Hz)

Franck-Hertz Tube with Hg Filling and Heating Chamber (115 V, 50/60 Hz)

1006795 (230 V, 50/60 Hz)

1006794 (115 V, 50/60 Hz)

Instruction sheet

06/12 ALF

1. Safety instructions

The apparatus conforms to the safety regulations for

electrical test, control and laboratory equipment as

specified in DIN EN 61010 Part 1. Its protection classification is deemed to be class I. It is intended for use in dry

rooms suitable for electrical equipment or installations.

Safe operation of the equipment is guaranteed, provided it is used correctly. However, there is no guarantee of safety if the equipment is used in an improper or careless manner. If it is deemed that the

equipment can no longer be operated without risk

(e.g. visible damage has occurred), the equipment

should be switched off immediately and secured

against any inadvertent use.

In schools and training institutions, operation of the

apparatus is to be responsibly supervised by trained

personnel.

• Before putting the equipment into operation, con-

firm it is compatible with the local mains voltage.

• Before setting up or starting any experiments,

check the apparatus for any damage.

• In the event of any malfunction/defect or visible

damage, switch off the equipment immediately

and secure it against any inadvertent use.

• The instrument may only be connected to the

mains via a socket that has an earth connection.

• Only trained electricians are permitted to open

up the apparatus’ housing.

Beware: Risk of burns! The viewing windows and the

walls of the heating chamber can reach temperatures of up to 300° C during operation.

• Set up the heating chamber on a heat-resistant

surface.

• When the heating chamber is in operation, do

not attempt to touch or move the apparatus.

Only move or transport the equipment by using

the insulated handle.

• Allow the apparatus to cool before dismantling

the experiment.

Beware: There is always a risk that glass can break

and cause injury.

• Use all six knurled screws to affix the front plate

to the heating chamber.

• Do not subject the tube to any mechanical

stress. Do not put kinks in any connecting leads.

The Franck-Hertz tube contains mercury.

• If the glass breaks and mercury escapes, make

sure to observe safety regulations relating to the

handling of mercury.

1

Page 2

2. Description

The Franck-Hertz tube with its mercury filling is used

to demonstrate the quantised release of energy by

free electrons colliding with mercury atoms and to

determine that the excitation energy for the mercury

resonance line (6

1

S0 – 63P1) is 4.9 eV.

Franck-Hertz tube attached to front plate

The Franck-Hertz tube is a highly evacuated electron

tube containing mercury with its electrodes set up in

parallel planes. The electrodes consist of an indirectly

heated oxide cathode, an anode grid and a collector

electrode. In order to increase the likelihood of collisions, the distance between the anode and cathode

has been made large (8 mm) in comparison to the

mean free path in a mercury atmosphere (for a temperature of approx. 180°C). By contrast, the distance

between anode and collector is small. An earth ring is

located level with the anode grille to prevent disturbance due to background radiation. The tube is

mounted on the front plate of the heating chamber

and can be removed or exchanged. The front plate

also has ceramic-insulated sockets and a schematic

diagram of the tube. The Franck-Hertz tube is

mounted in such a way that the whole tube and its

connecting wires can all be maintained at constant

temperature. This is necessary because the density of

the mercury vapour is always determined at the coldest point of the tube. Leakage currents resulting from

radiation due to ion conduction in the hot glass walls

are prevented by a protective sintered alumina ring. A

fixed attenuating resistor (10 kΩ) is inserted between

the sockets for the accelerating voltage and for the

anode of the tube. This protects the tube in the event

of excessive voltage occurring due to arcing. The voltage drop across this resistor can be neglected when

measurements are being made.

Heating chamber

The heating chamber serves to establish the vapour

pressure inside the Franck-Hertz tube with its mercury

filling and helps you carry out experiments with a sodium fluorescence tube (1000913).

It consists of a powder-coated sheet steel casing with

two viewing windows. The front plate is attached via

six knurled screws. The chamber is heated via a tubular heating element in the chamber floor. Temperature measurement and regulation is carried via an

integrated micro-controller and a PT 100 thermocouple. A digital temperature display allows you to

read off the temperature set-point and the actual

temperature value. The “SET” button can be used to

toggle the display between ° Celsius and ° Fahrenheit. The “+/-” keys allow you to set the set-point for

the temperature in steps of 1 K. There is an opening

at the top with a spring clip for holding a thermometer and a thermally insulated carrying handle.

The apparatus 1006794 is for operation with a mains

voltage of 115 V (±10%), and the unit 1006795 is for

operation with a mains voltage of 230 V (±10%).

2.1 Scope of delivery

1 Franck-Hertz tube with mercury filling mounted

on front-plate

1 Heating chamber without front plate

1 Instruction sheet

1 Power switch 2 Operating display

3 “SET” button 4 Display

5 “+/-” buttons 6 Thermal insulation

7 Knurled screws 8 Front plate with Franck-

8 Hertz tube attached (not

8 shown)

9 Cathode socket 10 Tube filament socket

11 Anode socket 12 BNC socket for signal

12 output

13 Heating chamber 14 Spring clip for thermometer

15 Handle

3. Technical data

Franck-Hertz tube

Filament: 4 to 12 V AC/DC

Grid voltage: 0 to 70 V

Bias voltage: 1.5 V approx.

Operating temperature: 200° C approx.

Tube dimensions: 130 mm x 26 mm diam.

Weight: 380 g approx.

Heating chamber

Mains voltage: See back of case

Dimensions of front

opening: 230 x 160 mm² approx.

Heating power: 800 W (230 V, 50/60 Hz)

400 W (115 V, 50/60 Hz)

Maximum temperature: 300°C (230 V, 50/60 Hz)

250°C (115 V, 50/60 Hz)

Temperature constancy: ±1°C approx.

Dimensions: 335x180x165 mm³ approx.

Weight: 5.6 kg approx.

2

Page 3

4. Operation

The following equipment is also required to complete the experiment:

1 Power supply unit for F/H experiment (230 V, 50/60 Hz)

1012819

or

1 Power supply unit for F/H experiment (115 V, 50/60 Hz)

1012818

1 Analogue oscilloscope, 2x 30 MHz 1002727

1 HF Patch cord, 1 m 1002746

2 HF Patch cords, BNC/4 mm plug 1002748

Safety leads for experiments

• Place front plate of the open side of the heating

chamber and fix it in place with 6 knurled

screws.

• Turn off the heating chamber and the control

unit to begin with and turn all the knobs on the

control fully to the left.

• Do not apply a voltage to the tube when it is still

cold (the mercury inside may cause a short circuit).

• Connect terminals "A", "F" and "K" (refer to fig. 2).

• Connect terminal "E" of the Franck-Hertz tube to

the correct input on the control unit by means of

an BNC cable.

• Connect the “FH Signal U

control unit to the Y input of the oscilloscope

and terminal “U

• Turn on the heating chamber. Set a temperature

” to the X input.

X

-out” terminal of the

Y

of about 210° C and wait for the tube to warm

up (about 5 to 10 minutes).

• Turn on the control unit and the equipment

should enter ramp mode.

• Set a filament voltage of 6 - 7 V. The indirectly

heated cathode requires about 90 seconds to

warm up, once the voltage is applied.

• Set the minimum acceleration voltage to zero,

slowly increase the maximum acceleration voltage to 80 V.

• Do not, however, increase the accelerating volt-

age so much that self-discharge no longer occurs

inside the tube. Any ionisation due to collisions

will disrupt the curve.

• Set up the oscilloscope initially with settings of

x = 1 V/div and y = 1 V/div.

• Observe the emergence of the maxima in the

Franck-Hertz trace on the oscilloscope screen.

• Set up all the parameters, accelerating voltage,

cathode filament, bias voltage and amplitude so

that a trace with nicely delineated maxima and

minima is obtained.

The procedure as described so far is a general setting

procedure. Unavoidable differences resulting from

the manufacture of individual Frank-Hertz tubes

mean that the optimum parameters may differ from

tube to tube. The test report included with the tube

should give some idea of where good results may be

obtained for the tube in question.

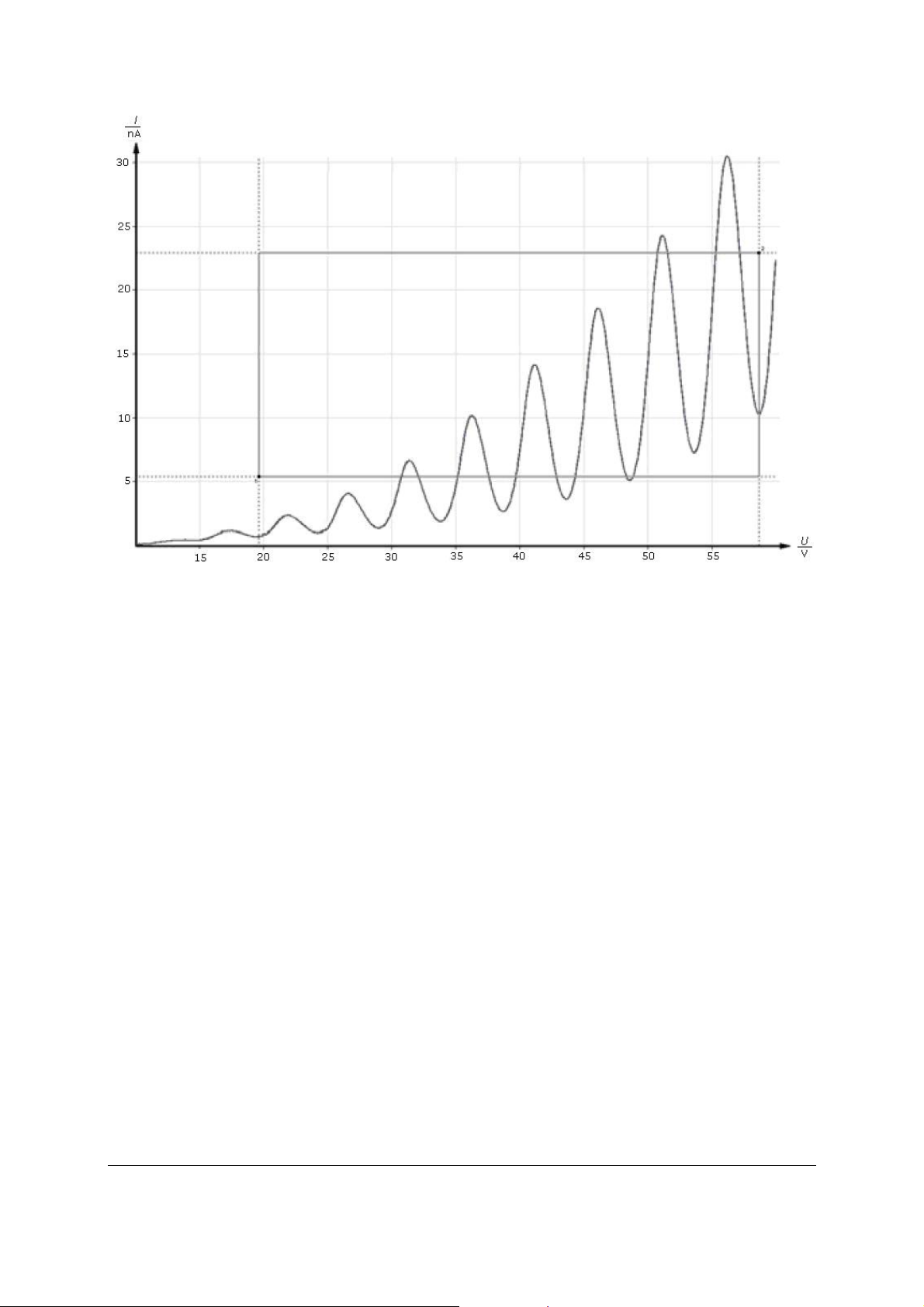

The collector current displays regularly recurring,

equidistant maxima and minima that are independent of the accelerating voltage. The interval between

these peaks is 4.9 V. A contact potential of 2 V exists

between the anode and cathode of the tube, which is

why the first maximum only appears in the region of

7 V. The first maxima will be more obvious when the

temperature of the heating chamber is lower.

Evaluation of the Franck-Hertz curve:

To fully evaluate the Franck-Hertz curve, a digital

voltmeter is needed. This does not require that the

current of the electron beam be determined precisely. The oscilloscope screen should show the trace

of a Franck-Hertz curve featuring very clear maxima

and minima.

• Connect a digital voltmeter between the signal

output (U

• Press the “Man/Ramp” button and the display

) and the ground socket (refer to fig. 3).

X

will show “Man” to indicate manual mode.

• Turn the accelerating voltage knob all the way to

the left (UA = 0 V).

The display will show the accelerating voltages in

steps of 0.5 V. In order to obtain better test results, a

digital voltmeter can be connected between sockets

"A" and "K" in order to obtain a more accurate

measure of the accelerating voltage.

Note: The accelerating voltage is reduced by a factor

of 10 at the signal output (U

however, measures the full accelerating voltage

). The digital voltmeter,

X

between sockets “A” and “K”.

By gradually increasing the accelerating voltage at a

constant rate, the precise position of the maxima

and minima can be determined with the aid of the

digital voltmeter.

5. Care and maintenance

• Before cleaning the equipment, disconnect it

from its power supply.

• Use a soft, damp cloth to clean it.

6. Disposal

• The packaging should be

disposed of at local recycling points.

• Should you need to dis-

pose of the equipment itself, never throw it away

in normal domestic waste.

Local regulations for the

disposal of electrical

equipment will apply.

• If Frank-Hertz tubes are to

be disposed of, local regulations applying to the

disposal of mercury must

be followed.

3

Page 4

Fig. 1 Schematic of set up for measuring the Franck-Hertz curve for mercury (C cathode, G grid, A collector electrode)

E

A

F

FK

K

GA

+

-

Fig. 2: Experiment set-up for Franck-Hertz tube with Hg filling

E

E

X

Y

A

F

FK

K

GA

E

+

-

Fig. 3 Experiment set-up for Franck-Hertz tube with 2 digital voltmeters

4

X

Y

Page 5

Fig. 4 Franck-Hertz curve

Elwe Didactic GmbH • Steinfelsstr. 5 • 08248 Klingenthal • Germany • www.elwedidactic.com

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2012 3B Scientific GmbH

Page 6

Loading...

Loading...