Page 1

3B SCIENTIFIC3B SCIENTIFIC

3B SCIENTIFIC®

3B SCIENTIFIC3B SCIENTIFIC

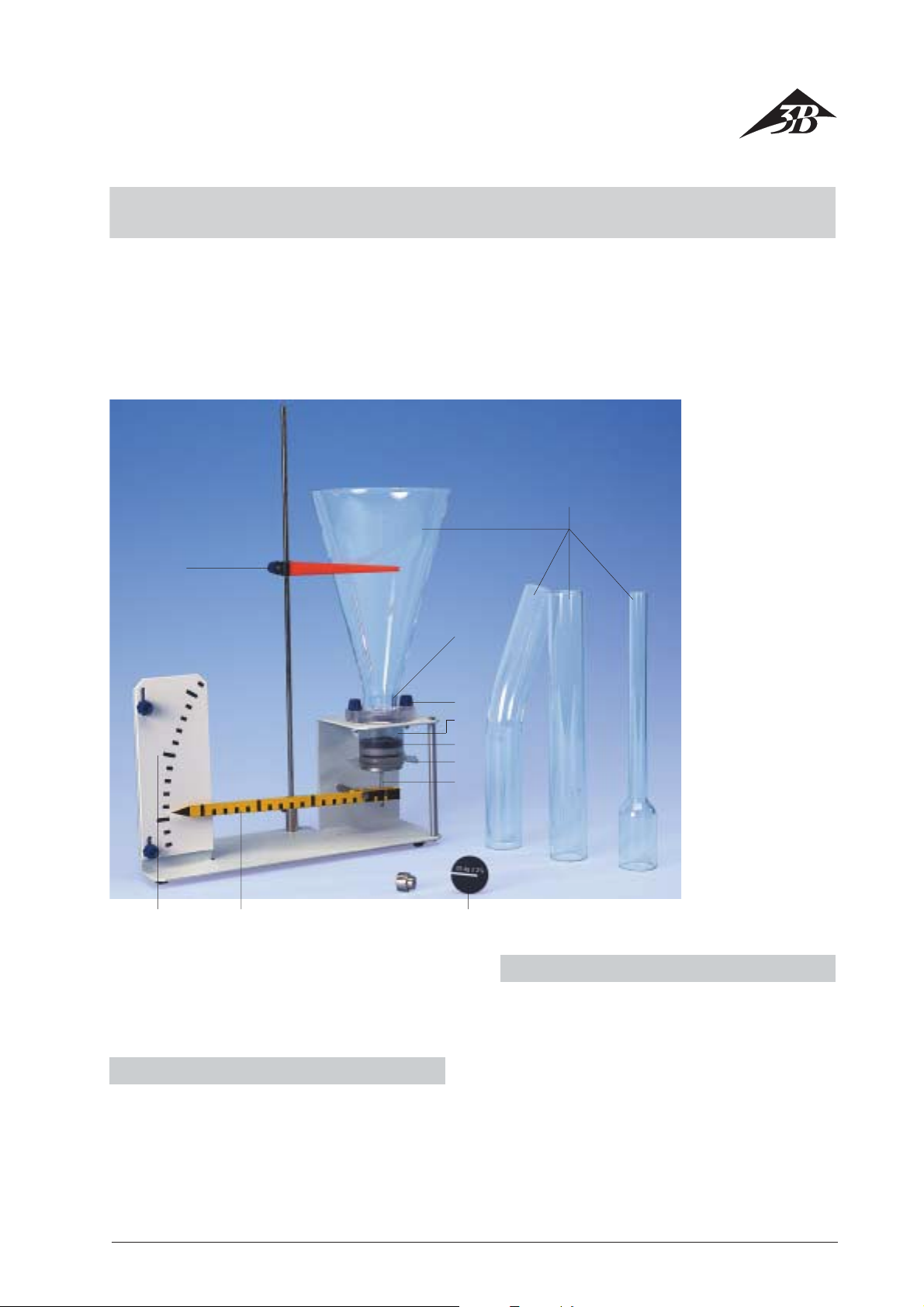

Pascal’s vane apparatus U15070

Instruction sheet

08/05 ALF

PHYSICSPHYSICS

PHYSICS

PHYSICSPHYSICS

®

... going one step further

1

bl

9

8

7

6

5

23 4

bm

1 Level indicator

2 Scale

3 Double-arm lever and scale

4 Slotted weight

5 Piston for transmitting

forces

6 Rubber diaphragm

7 Sealing rings

8 Acrylic tube

9 Locking screws for tube

nozzle

bl Outlet pipe at rear

bm Glass vessels

Pascal’s vane apparatus is used for demonstrating the

hydrostatic paradox and for quantitative measurements

of pressure at the bottom of a fluid column as a function

of its height.

1. Safety instructions

• Insert the glass vessels with care.

• Do not expose the glass vessels to any mechanical

stress. They could break.

• Only use liquids that will not corrode the rubber diaphragm and sealing rings. Coloured water is recommended.

2. Description, technical data

Pascal’s vane apparatus consists of a metal base plate,

on the right-hand side of which is mounted a bracket for

an acrylic plastic tube 8 with sealing rings 7 and a

rubber diaphragm 6 for supporting various glass vessels bm. The liquid in the glass vessels exerts a force on

the rubber diaphragm. The force is transmitted from the

diaphragm to the short arm of the lever 3 via a piston

5. The lever action means that the displacement due to

the force can be seen enlarged at the end of the long

arm. This displacement is indicated on a large scale and

acts as a measure of the force. The height of the scale can

be adjusted. By moving a slotted weight 4 along the

3

Page 2

long arm of the lever, the apparatus can be balanced to

match the force acting on the short arm. Four glass vessels of different shapes bm but with the same base area

and height are available for experiments. A level indicator 1 can be used to show the filling level of the glass

vessels. An outlet pipe bl at the rear of the acrylic tube

allows a hose pipe to be connected for draining liquid.

Height of vessels: 220 mm

Diameter of base: 22 mm

Total height: 350 mm

Base plate dimensions: 260 mm x 100 mm

Length of lever arms: 20 mm, 175 mm

Outlet tube: 8 mm Ø

Mass of slotted weight: 20.4 g

Weight: 0.8 kg

3. Operation

• Set up the Pascal’s vane apparatus on a high enough

surface that liquid can drain away via the drainage

hose into a beaker .

• On the movable scale, mark the balanced position of

the lever with no force acting (and no slotted weight).

• Place a glass vessel into the Pascal’s vane apparatus

so that the outlet is sealed off.

• Pour some of the liquid being used for the experiment into the glass vessel and mark the filling level

with the help of the level indicator.

• Balance the lever with the aid the slotted weight.

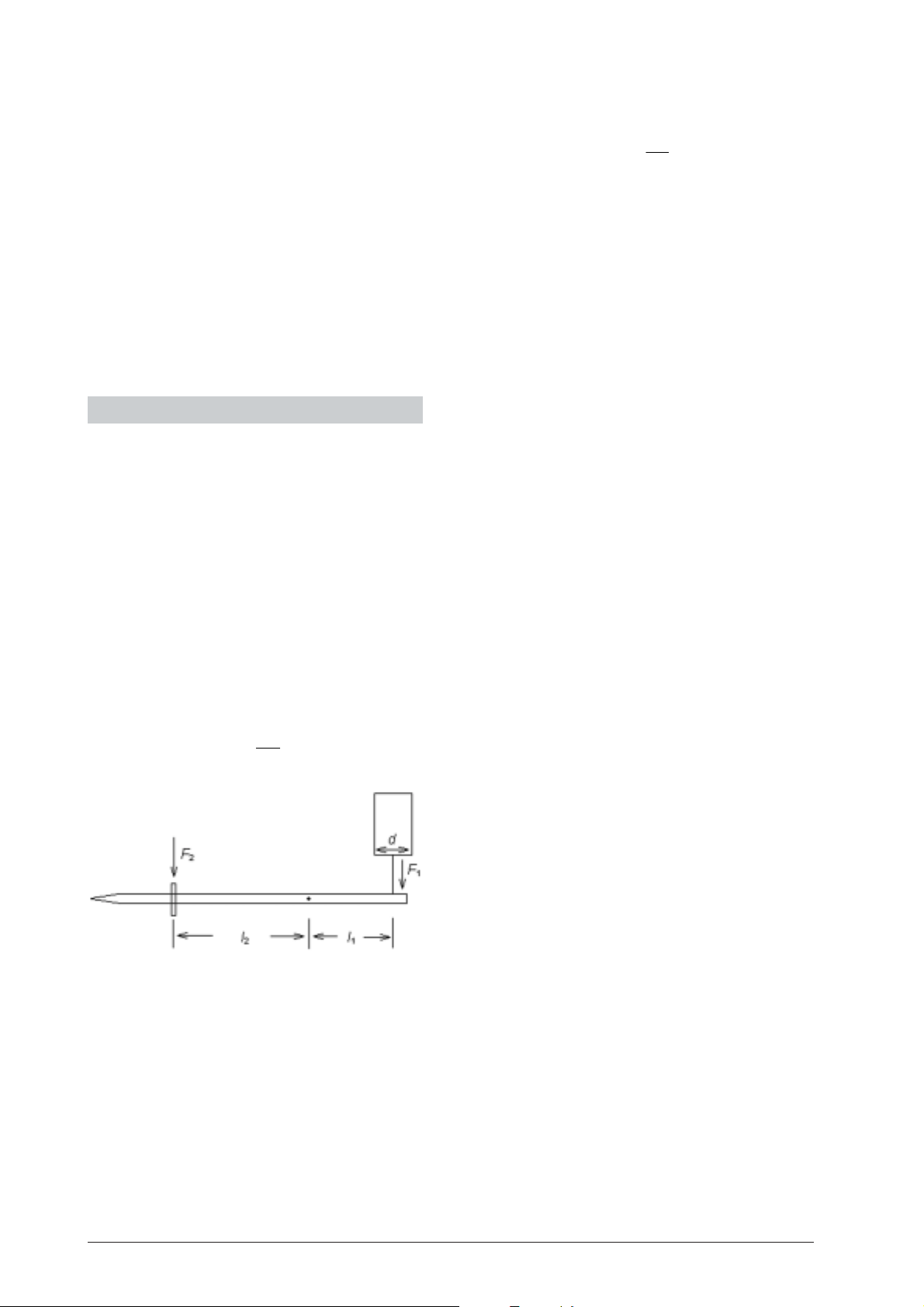

• In order to determine the pressure at the bottom of

the tube, first calculate the force F1 exerted by the

liquid column on the diaphragm by multiplying the

weight of the balancing mass F2 by the ratio of the

lengths of the lever arm l1 and l2.

IF

22

=

F

1

I

1

• The pressure at the bottom of the tube is given by:

F

1

=

P

2

π

r

where r is the radius of the effective base surface of

the vessel. (Measure the diameter of the tube d = 2r

using vernier callipers

• Lift up the glass vessel enough for the liquid to drain

through the outlet and into a beaker .

• Thoroughly dry the apparatus to ensure that the tube

does not get dirty due to residual liquid.

3.1 Replacing rubber diaphragm and seals

• In order to replace the rubber diaphragm and the

seals, undo the screws 9 and pull out the acrylic

tube 8 from above.

• Unscrew the bottom, i.e. the diaphragm holder, then

remove the plastic ring and the damaged diaphragm.

• Secure the new diaphragm with the plastic ring. Make

sure the membrane is slightly slack. If it is too taut

experimental results may be in error .

• Screw the acrylic tube into the apparatus again.

If liquid starts to leak from glass vessels, even though

they are correctly inserted, then the seals need to be

replaced, as follows:

• Remove the acrylic tube 8 and unscrew the bottom, i.e. the diaphragm holder.

• Grip the lips of the seals and pull them out.

• Firmly press new sealing rings into the groove.

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com • Technical specifications subject to change

4

Loading...

Loading...