Page 1

3B SCIENTIFIC® PHYSICS

U10300 Optical bench, triangular profile, 1 m

U10301 Optical bench, triangular profile, 2 m

U10302 Optical bench, triangular profile, 0.5 m

U10304 Set of supports for the optical bench

U10305 Swivel joint

6/03 ALF

Instruction sheet

®

The optical bench and its accessories are used in experiments with optical components for research and

demonstrations where the highest degree of precision

is required for adjustment of axes and distance measurement. The swivel joint permits experiment configurations where the beam path is deflected.

1. Description, technical data

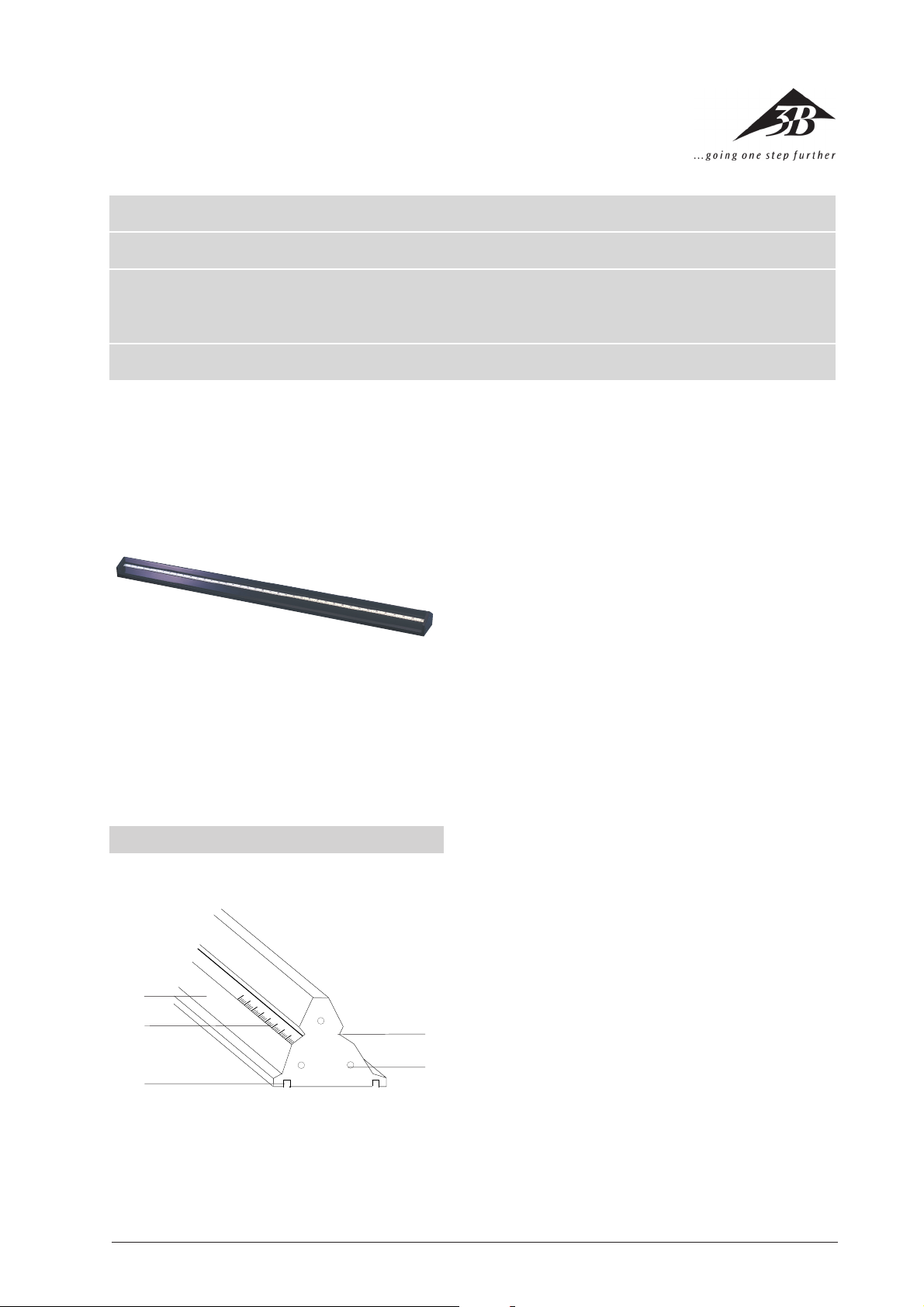

1.1 Optical benches

1

2

5

4

3

Abb. 1: 1 Rail 2 Scale

3 Groove for mounting 4 Drill hole for attaching the

the rail feet swivel joint

5 Groove for the tightening of the optical rider

The optical bench made of triangular-profile, black

anodised aluminium is tilt-proof, deformation- and

torsion-proof as well as anti-slip. A continuous scale in

cm/mm division is attached to both sides. Two grooves

on the supporting surface are available for optional

mounting on two rail supports or one support and a

single-point support. There are three drill holes at the

front end for fastening the end plate or the swivel joint.

U10300 1 m Weight: approx. 3.5 kg

U10301 2 m Weight: approx. 7 kg

U10302 0.5 m Weight: approx. 1.75 kg

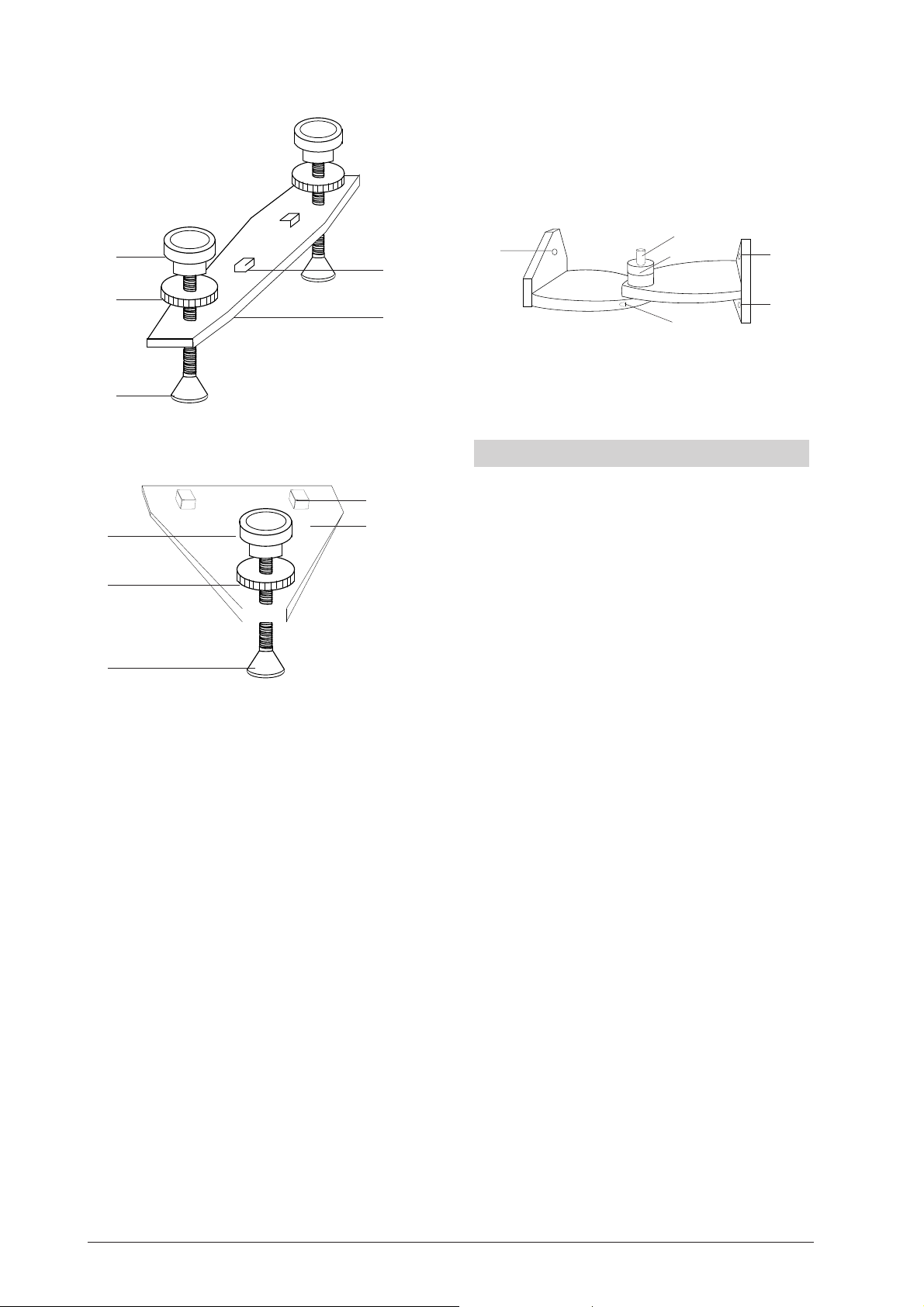

1.2 Set of supports for the optical bench

This set consists of two rail supports and a single-point

support made of black anodised aluminium. It allows

for height adjustment of the optical bench in a fourpoint or three-point support configuration.

Length of the supports: 270 mm

3

Page 2

Rotational angle: ± 90°

Protractor: ±180°

Scale division: 1°

Sleeve height: 60 mm

Span width for shaft: 10 mm up to 14 mm

1

5

2

4

3

Fig. 2.1 Rail supports

5

1

4

2

3

Fig. 2.2 Single-point support

1 Adjustment screw to adjust the height

2 Grub-screw to secure the height

3 Stand base

4 Rail support

5 Square-socket screw to fasten the rail foot into the groove

1.3 Swivel joint

The swivel joint consists of black anodised aluminium

and can be swivelled around an angle of 90° in both

directions. A protractor has been included to set the

angle. In the rotational axis there is a sleeve to mount

optical components.

1

2

1

1

1

Figure 3

1

Drilled screw holes for fastening to the optical bench

2

Mount for protractor and sleeve

2. Operation

2.1 Assembly of the rail supports

• Insert the square-socket screws into the guide

groove under the profile rail and fasten by tightening them.

• Adjust the height using the adjustment screw.

• Use the grub-screw to secure the settings.

2.2 Assembly of the swivel joint

• Take off the front plate by loosening the three fastening screws.

• Place the swivel joint on the rail and secure it by

tightening the three screws.

• Connect the swivel joint to the second rail in like

fashion.

2.3 Recommended rider and assembly aids

• For the assembly of elements in the optical axis:

Optical rider (U10310 to U10312 and U10315 to

U10317)

Double rider (U10340 to U10342)

• To tilt element out of the optical axis:

Tilting rider (U10330)

• To slide elements perpendicular to the optical

bench axis: sliding rider (U10320)

• To position elements adjacent to the optical axis:

Extension arm (U10331)

2

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Deutschland • www.3bscientific.com • Technical amendments are possible

4

Loading...

Loading...