Cub Cadet 2166 User Manual

OPERATOR’S MANUAL

2000 TRACTOR

2000 TRACTOR

Model Number 2166

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forestcovered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

CUB CADET LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 [www.cubcadet.com]

PRINTED IN U.S.A. |

FORM NO. 770-10282C |

|

(11/01) |

KOHLER CO.

FEDERAL AND CALIFORNIA EMISSION CONTROL SYSTEMS

LIMITED WARRANTY

SMALL OFF-ROAD EQUIPMENT ENGINES

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB), and Kohler Co. are pleased to explain the Federal and California Emission Control Systems Warranty on your small off-road equipment engine. For California, engines produced in 1995 and later must be designed, built and equipped to meet the state’s stringent anti-smog standards. In other states, 1997 and later model year engines must be designed, built and equipped, to meet the U.S. EPA regulations for small non-road engines. The engine must be free from defects in materials and workmanship which cause it to fail to conform with U.S. EPA standards for the first two years of engine use from the date of sale to the ultimate purchaser. Kohler Co. must warrant the emission control system on the engine for the period of time listed above, provided there has been no abuse, neglect or improper maintenance.

The emission control system may include parts such as the carburetor or fuel injection system, the ignition system, and catalytic converter. Also included are the hoses, belts and connectors and other emission related assemblies.

Where a warrantable condition exists, Kohler Co. will repair the engine at no cost, including diagnosis (if the diagnostic work is performed at an authorized dealer), parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

Engines produced in 1995 or later are warranted for two years in California. In other states, 1997 and later model year engines are warranted for two years. if any emission related part on the engine is defective, the part will be repaired or replaced by Kohler Co. free of charge.

OWNER’S WARRANTY RESPONSIBILITIES

(a)The engine owner is responsible for the performance of the required maintenance listed in the owner’s manual. Kohler Co. recommends that you retain all receipts covering maintenance on the engine. But Kohler Co. cannot deny warranty solely for the lack of receipts or for your failure to assure that all scheduled maintenance was performed.

(b)Be aware, however, that Kohler Co. may deny warranty coverage if the engine or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

(c)For warranty repairs, the engine must be presented to a Kohler Co. service center as soon as a problem exists. Call 1-800-544-2444, or access our web site at: www.kohlerengines.com, for the names of the nearest service centers. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding warranty rights and responsibilities, you should contact Kohler Co. at 1-920-457-4441 and ask for an Engine Service representative.

COVERAGE

Kohler Co. warrants to the ultimate purchaser and each subsequent purchaser that the engine will be designed, built and equipped, at the time of sale, to meet all applicable regulations. Kohler Co. also warrants to the initial purchaser and each subsequent purchaser, that the engine is free from defects in material and workmanship which cause the engine to fail to conform with applicable regulations for a period of two years.

Engines produced in 1995 or later are warranted for to years in California. For 1997 and later model years, EPA requires manufacturers to warrant engines for two years in all other states. These warranty periods will be begin on the date the engine is purchased by the initial purchaser. If any emission related part on the engine is defective, the part will be replaced by Kohler Co. at no cost to the owner. Kohler Co. is liable for damages to other engine components caused by the failure of a warranted part still under warranty.

Kohler Co. shall remedy warranty defects at any authorized Kohler Co. engine dealer or warranty station. Warranty repair work done at an authorized dealer or warranty station shall be free of charge to the owner if such work determines that a warranted part is defective.

Listed below are the parts covered by the Federal and California Emission Control Systems Warranty. Some parts listed below may require scheduled maintenance and are warranted up to the first scheduled replacement point for that part. The warranted parts are:

• Oxygen sensor (if equipped) |

• Intake manifold (if equipped) |

• Exhaust manifold (if equipped) |

• Catalytic muffler (if equipped) |

• Fuel metering valve (if equipped) |

• Spark advance module (if equipped) |

• Crankcase breather |

• Ignition module(s) with high tension lead |

• Gaseous fuel regulator (if equipped) |

• Electronic control unit (if equipped) |

• Carburetor or fuel injection system |

• Fuel lines (if equipped) |

•Air filter, fuel filter, and spark plugs (only to first scheduled replacement point)

LIMITATIONS

This Emission Control System Warranty shall not cover any of the following:

(a)repair or replacement required because of misuse or neglect, improper maintenance, repairs improperly performed or replacement not conforming to Kohler Co. specifications that adversely affect performance and/or durability and alterations or modifications not recommended or approved in writing by Kohler Co.,

(b)replacement of parts and other services and adjustments necessary for required maintenance at and after the first scheduled replacement point,

(c)consequential damages such as loss of time, inconvenience, loss of use of the engine or equipment, etc.,

(d)diagnosis and inspection fees that do not result in eligible warranty service being performed, and

(e)any add-on or modified part, or malfunction of authorized parts due to the use of add-on or modified parts.

MAINTENANCE AND REPAIRS REQUIREMENTS

The owner is responsible for the proper use and maintenance of the engine. Kohler Co. recommends that all receipts and records covering the performance of regular maintenance be retained in case questions arise. If the engine is resold during the warranty period, the maintenance records should be transferred to each subsequent owner. Kohler Co. reserves the right to deny warranty coverage if the engine has not been properly maintained; however, Kohler Co. may not deny warranty repairs solely because of the lack of repair maintenance or failure to keep maintenance records.

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repair must be performed by a Kohler authorized service center. Any replacement part or service that is equivalent in performance and durability may be used in non-warranty maintenance or repairs, and shall not reduce the warranty obligations of the engine manufacturer.

2

CONTENTS

Section |

|

Page |

Section |

|

Page |

|

Emission Control Systems Warranty ... |

2 |

VI |

Off-Season Storage ............................. |

45 |

|

Tractor and Deck Preparation.............. |

3 |

VII |

Mowing................................................. |

46 |

|

Safe Operation Practices..................... |

4 |

|

Optional Equipment and Accessories . |

47 |

|

Product Graphics ................................. |

7 |

|

Maintenance Chart............................... |

48 |

|

To The Owner...................................... |

8 |

|

Trouble Shooting.................................. |

49 |

|

Calling Service Information.................. |

8 |

|

Lubrication Table ................................. |

51 |

|

Recording Model & Serial Number ...... |

8 |

|

Lubrication Guide................................. |

52 |

I |

Controls and Indicators........................ |

9 |

|

Slope Gauge ........................................ |

55 |

II |

Operation ............................................. |

14 |

|

Specifications....................................... |

57 |

III |

Adjustments ......................................... |

18 |

|

Warranty — Commercial Use ............. |

58 |

IV |

Maintenance ........................................ |

23 |

|

Warranty — Residential Use ............... |

59 |

V |

Mower Deck......................................... |

33 |

|

Maintenance Parts Chart .................... |

60 |

TRACTOR AND DECK PREPARATION

1. ATTACHING THE CHUTE DEFLECTOR

For shipping purposes, the mulching plug has been installed in the mower deck. The mulching plug must be removed to install the chute deflector assembly.

WARNING

WARNING

Do not operate the mower deck, even with the mulching plug installed, unless the chute defelector has been properly installed.

1.Remove the wing nut, bell washer, and carriage bolt securing the mulching plug to the deck and withdraw the plug from the discharge opening of the deck.

HEX NUTS

BELL

BELL

WASHERS

|

CHUTE |

|

CARRIAGE |

DEFLECTOR |

|

|

||

BOLT |

HEX CAP |

|

|

||

|

SCREWS |

|

|

MULCHING |

|

WING NUT |

PLUG |

|

BELL |

||

|

||

|

WASHER |

2.Remove the hex cap screws, bell washers and hex nuts installed in the deck at the chute opening.

3.Positon the deflector assembly to align its hinge bracket holes with those of the deck. Install the hex cap screws from the underside of the deck and secure with the bell washers and hex nuts. Note: the crowned (rounded) surface of the washers go toward the hex nuts.

4.Refer to SECTION V-MOWER DECK when reinstalling the mulching plug.

2. CONNECT THE BATTERY

WARNING

WARNING

Battery posts, terminals and related accessories contain lead and lead compounds. Wash hands after handling.

The tractor is shipped with an activated sealed battery, with the positive battery cable factory connected. The negative cable must be connected.

Note: Make sure the ignition switch is in the "OFF" position before attaching the battery cables.

1.Pull the protective cap off the negative terminal of the battery, and remove the hex cap screw and nut from the free end of the negative battery cable.

2.Connect the negative battery cable (heavy black) and ground wire (green) to negative terminal (—) of the battery using the hex cap screw and nut.

3.Slide the black terninal cover over the negative terminal of the battery.

3

WARNING

WARNING

•The engine exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

•This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-covered, or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

•In the State of California, the above is required by law (Section 4442 of the California Public Resources Code). Other States may have similar laws. Federal laws apply to federal lands. A spark arrester muffler is available at your nearest engine authorized service center.

IMPORTANT |

SAFE OPERATION PRACTICES |

|

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR UNIT. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL—  HEED ITS WARNING.

HEED ITS WARNING.

Your lawn mower was built to be operated according to the rules for safe operation

in this manual. As with any type of power equipment, carelessness or error on the DANGER part of the operator can result in injury. This lawn mower is capable of amputating

hands and feet or throwing objects. Failure to observe the following safety instructions could result in serious injury or death.

I. GENERAL OPERATION

1.Read, understand and follow all instructions in the manual and on the machine before starting. Keep this manual in a safe place for future and regular reference and for ordering replacement parts

2.Only allow responsible individuals familiar with the instructions to operate the machine. Know the controls and how to stop the machine quickly.

3.Do not put hands or feet under the cutting deck or near rotating parts.

4.Clear the area of objects such as rocks, toys, wire, etc. which could be picked up and thrown by the blades. A small object may have been overlooked and could be accidentally thrown by the mower in any direction and cause injury to you or a bystander. To help avoid a thrown objects injury, keep children, animals, bystanders and helpers at least 75 feet from the mower while it is in operation. Always wear safety glasses with side shields or safety goggles during operation or while performing an adjustment or repair, to protect eyes from foreign objects. Stop the blades when crossing gravel drives, walks or roads.

5.Be sure the area is clear of other people before mowing. Stop machine if anyone enters the area.

6.Never carry passengers.

7.Disengage the blades before shifting into reverse and backing up. Always look down and behind before and while backing.

8.Be aware of the mower and attachment discharge direction and do not point it at anyone. Do not operate the mower without either the entire grass catcher or the chute guard in place.

9.Slow down before turning. Operate the machine smoothly. Avoid erratic operation and excessive speed.

10.Never leave a running machine unattended. Always turn off the blades, place the transmission in neutral, set the parking brake, stop the engine and remove key before dismounting.

11.Turn off blades when not mowing.

12.Stop the engine and wait until the blades come to a complete stop before (a) removing the grass catcher or unclogging chute, or (b) making any repairs, adjusting or removing any grass or debris.

4

13.Mow only in daylight or good artificial light.

14.Do not operate the machine while under the influence of alcohol or drugs.

15.Watch for traffic when operating near or crossing roadways.

16.Use extra care when loading or unloading the machine into a trailer or truck. This unit should not be driven up or down a ramp onto a trailer or truck under power, because the unit could tip over causing serious personal injury. The unit must be pushed manually on a ramp to load or unload properly.

17.Never make a cutting height adjustment while the engine is running if the operator must dismount to do so.

18.Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Do not wear loose fitting clothes or jewelry. They can be caught in moving parts. Never operate a unit in bare feet, sandals or sneakers.

19.Check overhead clearance carefully before driving under power lines, wires, bridges or low hanging tree branches, before entering or leaving buildings, or in any other situation where the operator may be struck or pulled from the unit, which could result in serious injury.

20.Disengage all attachment clutches, thoroughly depress the brake pedal and shift into neutral before attempting to start the engine.

21.Your mower is designed to cut normal residential grass of a height no more than 10”. Do not attempt to mow through unusually tall, dry grass (e.g. pasture) or piles of dry leaves. Debris may build up on the mower deck or contact the engine exhaust presenting a potential fire hazard.

22.Use only accessories approved for this machine by Cub Cadet. Read, understand and follow all instructions provided with the approved accessory.

II. SLOPE OPERATION

II. SLOPE OPERATION

Slopes are a major factor related to loss of control and tip-over accidents, which can result in severe injury or death. All slopes require extra caution. If you cannot back up the slope or if you feel uneasy on it, do not mow it.

For your safety, use the slope gauge included as part of this manual to measure slopes before operating this unit on a sloped or hilly area. If the slope is greater than 15° as shown on the slope gauge, do not operate this unit on that area or serious injury could result.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, limbs, etc.

Watch for holes, ruts or bumps. Uneven terrain could overturn the machine. Tall grass can hide obstacles.

Use slow speed. Choose a low enough gear so that you will not have to stop or shift while on the slope. Always keep the machine in gear when going down slopes to take advantage of engine braking action.

Follow the manufacturer’s recommendations for wheel weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments. These can change the stability of the machine.

Keep all movement on the slopes slow and gradual. Do not make sudden changes in speed or direction. Rapid engagement or braking could cause the front of the machine to lift and rapidly flip over backwards, which could cause serious injury.

Avoid starting or stopping on a slope. If the tires lose traction, disengage the blades and proceed slowly straight down the slope.

DO NOT:

Do not turn on slopes unless necessary; then, turn slowly and gradually downhill, if possible.

Do not mow near drop-offs, ditches or embankments. The mower could suddenly turn over if a wheel is over the edge of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could cause sliding.

Do not try to stabilize the machine by putting your foot on the ground.

Do not use the grass catcher on steep slopes.

III. CHILDREN

Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the machine and the mowing activity. Never assume that children will remain where you last saw them.

1.Keep children out of the mowing area and in watchful care of an adult other than the operator.

2.Be alert and turn the machine off if children enter the area.

3.Before and when backing up, look behind and down for small children.

4.Never carry children, even with the blades off. Children may fall off and be seriously injured or may interfere with safe machine operation.

5

5.Never allow children under 14 years old to operate the machine. Children 14 years and over should only operate the machine under close parental supervision and proper instruction.

6.Use extra care when approaching blind corners, shrubs, trees or other objects that may obscure your vision of a child or other hazard.

7.Remove the key when the machine is left unattended to prevent unauthorized operation.

IV. SERVICE

IV. SERVICE

1.Use extreme care in handling gasoline and other fuels. They are extremely flammable and the vapors are explosive.

a.Use only an approved container.

b.Never remove fuel cap or add fuel with the engine running. Allow the engine to cool at least two minutes before refueling.

c.Replace the fuel cap securely and wipe off any spilled fuel before starting the engine as it may cause a fire or explosion.

d.Extinguish all cigarettes, cigars, pipes and other sources of ignition.

e.Never refuel the machine indoors because fuel vapors will accumulate in the area.

f.Never store the fuel container or machine inside where there is an open flame or spark, such as a gas hot water heater, space heater or furnace.

2.Never run a machine inside a closed area.

3.To reduce fire hazard, keep the machine free of grass, leaves or other debris build-up. Clean up oil or fuel spillage. Allow the machine to cool at least 5 minutes before storing.

4.Before cleaning, repairing or inspecting, make certain the blade and all moving parts have stopped. Disconnect the spark plug wire, and keep the wire away from the spark plug to prevent accidental starting.

5.Check the blade and engine mounting bolts at frequent intervals for proper tightness. Also visually inspect blades for damage (e.g., excessive wear, bent, cracked). Replace with blades which meet original equipment specifications.

6.Keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition.

7.Never tamper with safety devices. Check their proper operation regularly. Use all guards as instructed in this manual.

8.After striking a foreign object, stop the engine, remove the wire from the spark plug and thoroughly inspect the mower for any damage. Repair the damage before restarting and operating the mower.

9.Grass catcher components are subject to wear, damage and deterioration, which could expose moving parts or allow objects to be thrown. For your safety protection, frequently check the components and replace with manufacturer’s recommended parts when necessary.

10.Mower blades are sharp and can cut. Wrap the blades or wear gloves, and use extra caution when servicing blades.

11.Check brake operation frequently. Adjust and service as required.

12.Muffler, engine and belt guards become hot during operation and can cause a burn. Allow to cool down before touching.

13.Do not change the engine governor settings or overspeed the engine. Excessive engine speeds are dangerous.

14.Observe proper disposal laws and regulations. Improper disposal of fluids and materials can harm the environment and the ecology.

a.Prior to disposal, contact your local Environmental Protection Agency to determine the proper method for disposing of the waste. Recycling centers are established to properly dispose of materials in an environmentally safe fashion.

b.Use proper containers when draining fluids. Do not use food or beverage containers that may mislead someone into drinking from them. Properly dispose of the containers immediately following the draining of fluids.

c.DO NOT pour oil or other fluids into the ground, down a drain or into a stream, pond, lake, or other body of water. Observe Environmental Protection Agency regulations when disposing of oil, fuel, coolant, brake fluid, filters, batteries, tires and other harmful waste.

15.We do not recommend the use of a pressure washer or garden hose to clean your unit. They may cause damage to electrical components; spindles; pulleys; bearings; or the engine. The use of water will result in shortened life and reduce serviceability.

WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in this manual and on the machine.

6

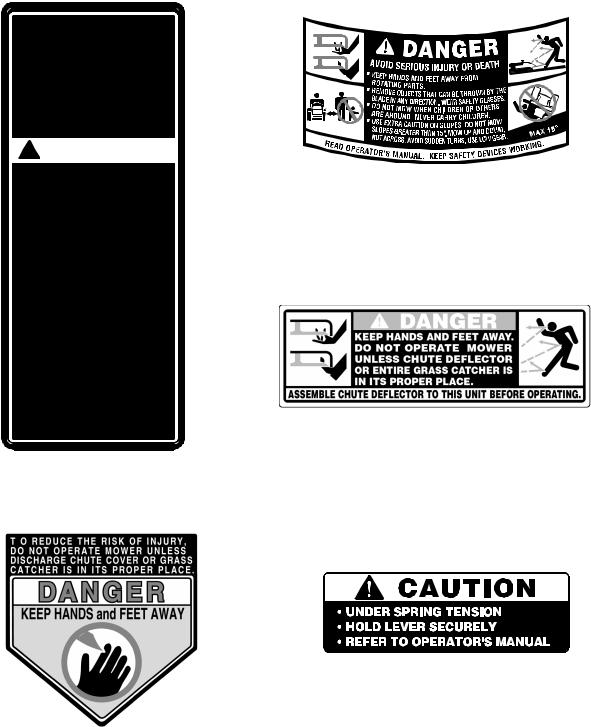

PRODUCT GRAPHICS

Keep product safety graphics (decals) clean. Replace any safety graphic that is damaged, destroyed, miss-

ing, painted over or can no longer be read. Replacement safety graphics are available through your dealer.

STARTING INSTRUCTIONS

1.BE FAMILIAR WITH CONTROLS BEFORE STARTING ENGINE AND OPERATING.

2.SET CHOKE, MOVE THROTTLE TO MID POSITION AND DEPRESS BRAKE PEDAL.

3.TURN KEY TO THE START POSITION.

4.AFTER ENGINE STARTS OPEN CHOKE.

STOPPING INSTRUCTIONS

1.DISENGAGE PTO AND SET PARKING BRAKE.

2.MOVE THROTTLE CONTROL TO MID POSITION AND TURN KEY OFF.

!WARNING

•AVOID SERIOUS INJURY OR DEATH.

•READ OPERATORS MANUAL AND ALL WARNING LABELS BEFORE USING MACHINE.

•GO UP AND DOWN SLOPES, NOT ACROSS.

•AVOID SUDDEN TURNS.

•DO NOT OPERATE UNIT WHERE IT COULD SLIP OR TIP.

•IF MACHINE STOPS GOING UPHILL, STOP PTO AND BACK DOWN HILL SLOWLY.

•DO NOT MOW WHEN CHILDREN OR OTHERS ARE AROUND.

•NEVER CARRY CHILDREN.

•LOOK DOWN AND BEHIND BEFORE AND WHILE BACKING.

•KEEP SAFETY DEVICES [GUARDS, SHIELDS, AND SWITCHES] IN PLACE AND WORKING.

•REMOVE OBJECTS THAT COULD BE THROWN BY THE BLADES.

•KNOW LOCATION AND FUNCTION OF ALL CONTROLS.

•BE SURE THE BLADES AND THE ENGINE ARE STOPPED BEFORE PLACING HANDS OR FEET NEAR BLADES.

•BEFORE LEAVING OPERATOR'S POSITION, DISENGAGE PTO, ENGAGE BRAKE LOCK, SHUT OFF ENGINE AND REMOVE KEY.

GENERAL SAFETY INSTRUCTIONS WARNING – LOCATED ON RIGHT SIDE OF RUNNING BOARD

HANDS AND FEET SAFETY GRAPHIC– LOCATED ON DEFLECTOR CHUTE

SAFETY GRAPHIC – LOCATED ON LEFT SIDE OF MOWER DECK

DEFLECTOR and SAFETY GRAPHIC – LOCATED ON RIGHT SIDE OF DECK

SAFETY GRAPHIC – LOCATED ON LEFT SIDE OF DECK

7

TO THE OWNER

This Operator’s Manual is an important part of your new tractor. The information contained in this manual has been prepared in detail to help you better understand the features, correct operation, adjustments, and maintenance of your tractor. The performance and dependability of this tractor rely greatly on the manner in which it is operated and maintained. Therefore, it is recommended that all operators of the tractor carefully read this manual and fully understand its operation. Also keep the manual available for reference to ensure proper operation, and that maintenance procedures are performed as scheduled to assure the tractor’s optimal mechanical condition.

NOTE: All references to LEFT, RIGHT, FRONT, and REAR, unless specifically stated otherwise, indicate that relative position on the tractor when facing forward while seated in the operator’s seat.

CAUTION: DO NOT tow your Model 2166 tractor. Towing may damage the transmission. Place the tractor on a LEVEL SURFACE before pulling the transmission release lever to the disengaged position.

Your local authorized Cub Cadet dealer is interested in the performance you receive from your tractor, and with the maintenance needed to ensure the satisfactory operation of your tractor. The dealer has trained service personnel familiar with the latest servicing information, is equipped with the latest tools, and has a complete line of genuine Cub Cadet service parts which assure proper fit and high quality.

CALLING SERVICE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, and specifications.

If you have difficulties with the tractor and/or equipment; have any questions regarding the operation or maintenance of this equipment; or desire additional information not found in this manual, contact your nearest authorized Cub Cadet dealer. If you need assistance in locating a dealer in your area, contact the Customer Dealer Referral Line by calling:

1-877-282-8684

To obtain top performance and assure economical operation, the tractor should be inspected by your authorized dealer periodically or at least once a year, depending on its hours of use. Before calling your dealer, make sure that you have your model number(s) and manufacturing date available for the dealer.

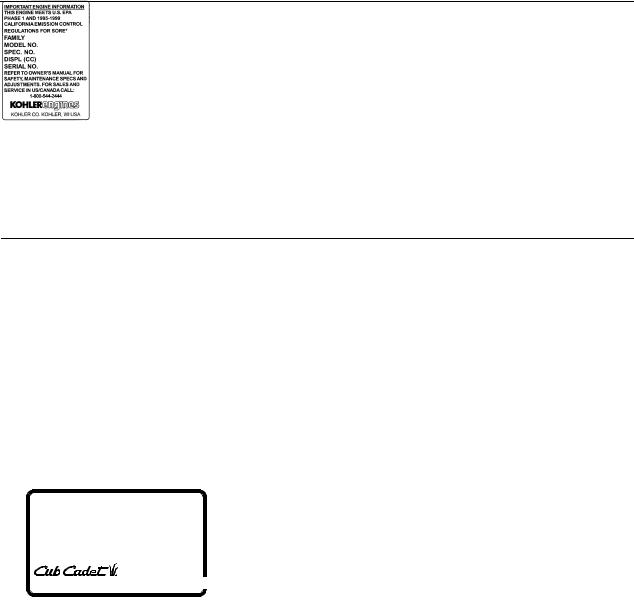

RECORDING MODEL AND SERIAL NUMBER INFORMATION

Product identification plates are provided for major components of your tractor. The numbers on these plates are important if your tractor should require dealer service, or if you need additional information on your tractor. Prior to using your tractor for the first time, record the numbers from the identification plates in the appropriate spaces provided below.

The chassis model plate, showing the factory model number and Mfg. Date (See Figure 1) can be found on the underside of the seat mounting base. Pivot the seat foward to locate the decal.

The engine serial number decal (See Figure 2) is located on the engine blower housing.

Hood Model |

|

|

Factory Model No. |

|

Mfg. Date |

|

|||||||

Delivery Date |

|

|

Engine Model/Spec. No. |

|

|

Engine Serial No. |

|

||||||

XXXXXXXXXXX |

XXXXXXXXXX |

|

|

|

|

||||||||

Model Number |

Mfg. Date |

|

|

|

|

||||||||

|

|

|

|

|

CUB CADET LLC |

|

|

|

|

||||

|

|

|

|

|

P. O. BOX 361131 |

|

|

|

|

||||

www.cubcadet.com |

CLEVELAND, OH 44136 |

|

|

|

|

|

|

||||||

DEALER LOCATOR PHONE NUMBER: 877-282-8684 |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|||||||||

|

|

Figure 1 |

|

Figure 2 |

|||||||||

8

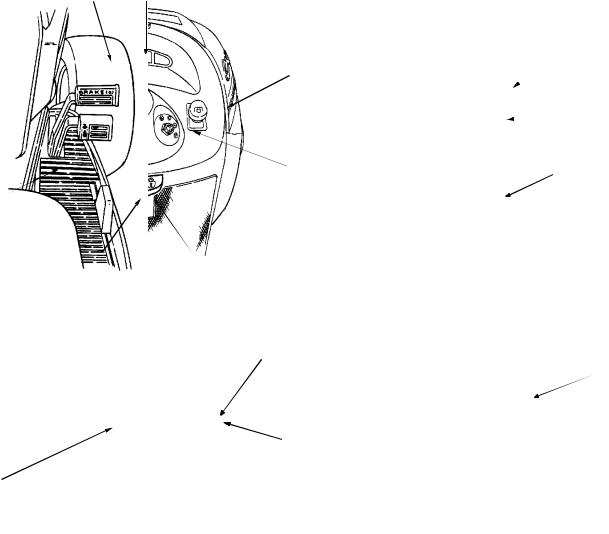

SECTION I. CONTROLS AND INDICATORS

Your Cub Cadet Tractor has been safety engineered. This section gives a brief description of the function and location of the various controls and indicators.

Thoroughly acquaint yourself with all the controls and indicators before attempting to start or operate the tractor.

A B

I

I

C

C

J

J

F

D  K

K

E

H  G

G

L

O

O

M

M

N

A. |

Low Oil Indicator |

I. |

Brake Pedal |

B. |

Hour Meter |

J. |

Forward Control Pedal |

C. |

Power Take-Off (PTO) Control Switch |

K. |

Reverse Control Pedal |

D. |

Ignition/Light Switch |

L. |

Lift Handle |

E. |

Throttle Control Lever |

M. |

Lift Height Indicator |

F. |

Choke Control |

N. |

Seat Adjustment Lever |

G. |

Brake Pedal Lock |

O. |

Transmission Release Lever |

H. |

Cruise Control Lever |

P. |

Fuses (Not Shown) |

|

|

Q. |

Safety Interlock Switches (Not Shown) |

Figure 3

9

A. LOW OIL INDICATOR

This indicator will illuminate when the engine oil level is low. If this indicator illuminates, stop the tractor immediately and check the engine oil level. If the oil level is within the operating range, but the light remains on, contact your Cub Cadet dealer.

CAUTION

CAUTION

Operating the tractor with low oil level or pressure could result in severe engine damage.

B. HOUR METER

The hour meter operates whenever the ignition key is in the “ON” position. Record the actual hours of tractor operation to ensure all maintenance procedures are completed according to the schedule in this manual.

C. POWER TAKE–OFF (PTO) CONTROL SWITCH

The power take-off control switch operates the front electric PTO clutch. Pull the switch knob to engage (“RUN”), or push the knob to disengage (“OFF”) the PTO clutch.

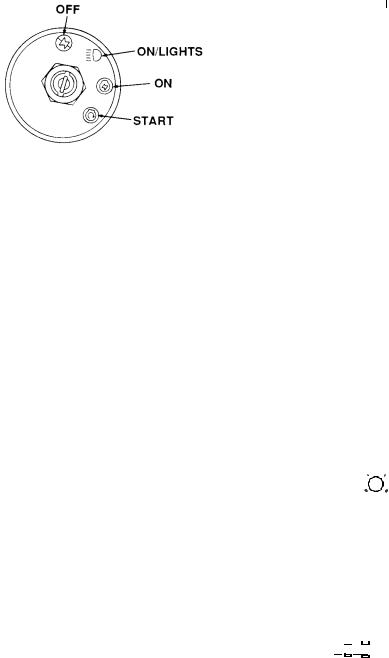

D. IGNITION/LIGHT SWITCH

WARNING

WARNING

To prevent accidental starting and/or battery discharge, remove the key from the ignition switch when the tractor is not in use.

The combination lights and ignition switch is a four position switch. (See Figure 4)

Figure 4

E. THROTTLE CONTROL LEVER

This lever controls the speed of the engine. When set in a given position, the control cable will maintain a uniform engine speed.

NOTE

NOTE

When using power take-off operated equipment, best performance is achieved with the throttle lever in the “FAST” position.

This symbol shows slow position.

This symbol shows fast position.

F. CHOKE CONTROL

The choke control is operated manually. Pull the knob out to ckoke the engine; push the knob in to open the choke.

G. BRAKE PEDAL LOCK

WARNING

WARNING

The hydrostatic transmission will not hold the tractor on a hill. Normal internal leakage in the transmission will allow the tractor to roll downhill. To avoid an accident and/or possible injury, engage the brake pedal lock.

The brake lock lever, located in the center of the dash panel below the steering wheel, is identified with the  P

P

symbol. Always engage the brake pedal lock when dismounting the tractor. To engage the brake pedal lock, depress the brake pedal and push down on the brake pedal lock lever. Hold the lever down while releasing the brake pedal. The lever should lock in the down position.

symbol. Always engage the brake pedal lock when dismounting the tractor. To engage the brake pedal lock, depress the brake pedal and push down on the brake pedal lock lever. Hold the lever down while releasing the brake pedal. The lever should lock in the down position.

H. CRUISE CONTROL LEVER

The cruise control lever, located in the center of the dash panel below the steering wheel, is identified with the

symbol. This lever can be used to maintain a desired “foot free” forward speed in areas where constant speed changes are not required. Refer to Section IIOPERATION for instructions on how to use this feature.

symbol. This lever can be used to maintain a desired “foot free” forward speed in areas where constant speed changes are not required. Refer to Section IIOPERATION for instructions on how to use this feature.

10

I.BRAKE PEDAL

The brake pedal is located at the front of the right running board above the forward control pedal. Press down to stop the tractor and disengage the cruise control. The brake pedal must be fully depressed to activate the safety interlock switch when starting the tractor.

J. FORWARD CONTROL PEDAL

The forward control pedal is located at the front of the right running board below the brake pedal. Slowly press down on the pedal to start moving forward. The forward ground speed of the tractor is directly affected by the distance the pedal is depressed.

K. REVERSE CONTROL PEDAL

WARNING

WARNING

Check behind the tractor to be sure the area is clear of people, pets or obstacles. Use a slower speed to maintain control of the tractor when traveling in reverse.

The reverse control pedal is located in the right front running board rearward of the the brake and forward control pedals. Press the pedal downward to move in reverse.

L. LIFT HANDLE

The lift handle is located in the left fender and is used to raise and lower equipment used with the tractor. The equipment can be set in any of six positions by depressing the top button on the handle, moving the handle to the desired position, then releasing the button. It may be necessary to push or pull slightly on the handle to depress the button. There is a lift assist spring which reduces the effort needed to lift attachments. To adjust spring tension refer to ADJUSTMENTS in Section III.

M. LIFT HEIGHT INDICATOR

The lift height indicator is located in the left fender and indicates the height of the deck attachment when installed.

N. SEAT ADJUSTMENT LEVER

The seat adjustment lever (see Figure 5) is used to move the seat forward or rearward into one of five positions. See ADJUSTING THE SEAT in Section III.

Figure 5

O. TRANSMISSION RELEASE LEVER

The transmission release lever is located at the back of the tractor in the rear drawbar. This lever disconnects the hydro transmission pump from the rear axle to allow the unit to be pushed a short distance by hand.

To disengage the transmission, pull back on the lever until its locking flange is visible outside the drawbar, then lift the lever up into the slot and release. To re-en- gage the transmission, pull back on the lever, drop out of the slot and release.

P. FUSES

The fuses are located under the hood between the indicator lamps and the hour meter (see Figure 6). Fuses are installed to protect the tractor’s electrical circuitry and components from damage caused by excessive amperage.

Figure 6

11

Q.SAFETY INTERLOCK SWITCHES

This tractor is equipped with a safety interlock system for the protection of the operator. If the interlock system should ever malfunction, do not operate the tractor. Contact your authorized Cub Cadet Dealer. The safety interlock system prevents the engine from cranking or starting unless the brake pedal is fully depressed, and the PTO switch is in the “OFF” position.

The safety interlock system will automatically shut off the engine if the operator leaves the seat before engaging the brake lock.

The safety interlock system will automatically shut off the engine if the operator leaves the seat with the PTO in the “RUN” position, regardless of whether the brake lock is engaged. The PTO switch must be moved to the “OFF” position to restart the engine.

The safety interlock system will automatically shut off the PTO if the reverse control pedal is depressed with the PTO in the “RUN” position. To re-engage the PTO, release the reverse control pedal, move the PTO switch to the “OFF” position, then again pull the switch to the “RUN” position.

FUEL TANK

The fuel tank is located under the rear fender. The filler cap is in the center/rear of the fender (see Figure 7).

Figure 7

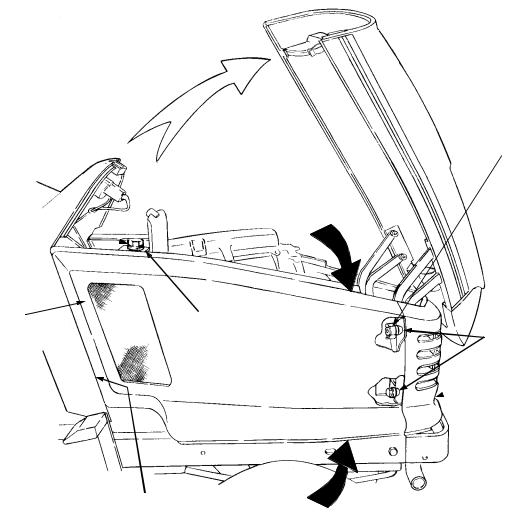

HOOD AND SIDE PANELS

The tractor hood is arranged to swing up and forward for easy access to the engine compartment (see Figure 8). Whenever engine maintenance is required, the side panels can be removed.

WARNING

WARNING

If the engine has been recently run, the engine, muffler and surrounding metal surfaces will be hot and can cause burns to the skin. Allow the tractor to cool and use caution when removing the side panels.

To remove either the right or left side panel, refer to Figure 8 and proceed as follows:

1.Engage the brake lock and raise the hood.

2.Loosen, but do not remove, the rear wing nut and upper front wing nut.

3.Grasp the side panel just behind the grille and pull outward to release the side panel from the tapered bushings on the grille.

4.Slide the side panel forward and out of the groove in the dash panel.

To install either the right or left side panel, refer to Figure 8 and proceed as follows:

1.Slide the rear of panel into the groove in the dash panel.

2.Position the notch of the rear side panel tab on the threads of the bulkhead rod, between the bulkhead and wing nut.

3.Press the slots of the front side panel flange onto the tapered retainers, between the retainers and the grille.

4.Tighten the rear and upper front wing nuts and close the hood.

12

UPPER FRONT

WING NUT

GRASP

REAR WING NUT

SIDE PANEL |

REAR TAB |

RETAINER WITH |

|

||

|

ON PANEL |

|

|

TAPERED GUIDE |

|

|

|

GRILLE

GRILLE

GROOVE IN |

GRASP |

DASH PANEL |

Figure 8

13

SECTION II. OPERATION

WARNING

WARNING

RECEIVE INSTRUCTION - Read the operator’s manual. Learn to operate this machine SAFELY. Don’t risk INJURY or DEATH.

1.Before starting the engine or beginning operation, be familiar with the controls. The operator must be seated, the PTO switch in the “OFF” position and the brake pedal fully depressed.

2.Keep all shields in place. Keep away from moving parts.

3.NO RIDERS! Keep all people and pets a safe distance away. Look behind to both sides before backing up.

4.DO NOT direct the mower discharge at people.

5.Avoid slopes. Tractors can be rolled over.

6.Before leaving the operator’s seat: Shut off the PTO, engage the brake pedal lock, shut off the engine and remove the ignition key. Wait for all movement to stop before servicing or cleaning.

7.Do not fill the fuel tank when the engine is running or while the engine is hot. Tighten the fuel cap securely.

BEFORE OPERATING YOUR TRACTOR

1.Before you operate the tractor, study this manual carefully. It has been prepared to help you operate and maintain your tractor with utmost efficiency.

2.Familiarize yourself with the operations of all the instruments and controls.

3.This engine is certified to operate on unleaded gasoline. For best results, fill the fuel tank with only clean, fresh, unleaded gasoline with a pump sticker octane rating of 87 or higher. In countries using the Research method, it should be 90 octane minimum.

Unleaded gasoline is recommended because it leaves less combustion chamber deposits. Leaded gasoline may be used in areas where unleaded is not available and exhaust emissions are not regulated. Be aware however, that the cylinder head may require more frequent service.

Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by volume) is an approved fuel. Other gasoline/alcohol blends are not approved.

Methyl Tertiary Butyl Ether (MTBE) and unleaded gasoline blends (up to a maximum of 15% MTBE by volume) are approved fuels. Other gasoline/ ether blends are not approved.

4.Check the engine and transmission oil levels.

5.Clean the air cleaner element if necessary.

6.Check the tire inflation pressures.

7.Adjust the seat for operator’s maximum comfort, visibility and for maintaining complete control of the tractor.

8.Remove the side panels and clean any accumulated grass and debris from the engine air inlet screen. Also clean the dash air intake screen, grille and side panels to ensure adequate cooling.

9.Refer to the various sections of the Owner’s Manual for additional information.

STARTING THE ENGINE

WARNING

WARNING

For personal safety, the operator must be sitting in the tractor seat when starting the engine.

WARNING

WARNING

This unit is equipped with a safety inerlock system designed for the protection of the operator. Do not operate the tractor if any part of the interlock system is malfunctioning. Periodically check the functions of the interlock system for proper operation as described below:

•The safety interlock system prevents the engine from cranking or starting unless the brake pedal is fully depressed and the PTO clutch engagement switch is in the “OFF” position.

14

•The safety interlock system will automatically shut off the engine if the operator leaves the seat before engaging the brake pedal lock.

•The safety interlock system will automatically disengage the PTO if the reverse control pedal is pressed down with the PTO in the “RUN” position. To re-engage the PTO, release the reverse control pedal, move the PTO switch into the “OFF” position and then engage the PTO while seated.

•The safety interlock system will automatically shut off the tractor engine if the operator leaves the seat with the PTO in the “RUN” position.

1.Operator must be sitting in the tractor seat.

2.Pull choke control knob to full choke position. Less choking may be necessary due to variations in temperature, grade of fuel, etc. Little or no choking will be needed when the engine is warm.

3.Place the throttle midway between the “SLOW” and “FAST” position.

4.Place the PTO switch in the “OFF” position.

5.Fully depress the brake pedal.

6.Turn the ignition key clockwise to the “START” position and release it as soon as the engine starts; however, do not crank the engine continuously for more than 10 seconds at a time. If the engine does not start within this time, turn the key “OFF” and wait a minute to allow the engine’s starter motor to cool, then try again.

7.After the engine starts, slowly release the brake pedal. As the engine warms up, gradually push the choke control knob all the way in. Do not use the choke to enrich the fuel mixture, except as necessary to start the engine.

STOPPING THE ENGINE

CAUTION

CAUTION

Remove the key from the ignition switch to prevent accidental starting or battery discharge if the equipment is left unattended.

Place the PTO switch in the “OFF” position. Move the throttle control lever between the “MID” and “FAST” positions. Wait a moment to allow the engine speed to stabilize, then turn the ignition key to the “OFF” position. Remove the key from the ignition switch.

TRACTOR BREAK-IN PROCEDURE

CAUTION

CAUTION

Never operate a new engine immediately under full load. Break it in carefully as shown in the table below.

COLD WEATHER STARTING

WARNING

WARNING

Engine exhaust gases are dangerous. Do not run the engine in a confined area such as a storage building any longer than is necessary. Immediately move the tractor outdoors.

WARNING

WARNING

For personal safety, the operator must be sitting in the tractor seat before starting the tractor.

When starting the engine at temperatures near or below freezing, ensure the correct viscosity motor oil is used in the engine and the battery is fully charged. Start the engine as follows:

1.Pull the choke all the way out to full choke position.

2.Move the throttle control lever to midway between the “SLOW” and “FAST” position.

3.Place the PTO switch in the “OFF” position.

4.Fully depress the brake pedal.

15

5.Turn the ingnition key to the “START” position and hold until the engine starts; however, do not crank the engine continuously for more than 10 seconds at a time. Once the engine starts, gradually adjust the choke as needed to keep the engine running until warmed up, then push the choke control all the way in.

NOTE

NOTE

If the engine fails to start after several attempts, the engine may become flooded. If this happens, wait a minute to allow the starter motor to cool. Move the throttle control to the “SLOW” position, push the choke in all the way and momentarily crank the engine to help clear the cylinders. With the throttle control in the “SLOW” position and the choke all the way in, turn the ignition key to the “START” position while slowly pulling the choke out to a position that will allow the engine to start. Gradually adjust the choke as needed to keep the engine running until warmed up, then push the choke control all the way in.

DRIVING THE TRACTOR

CAUTION

CAUTION

Avoid sudden starts, excessive speed and sudden stops.

CAUTION

CAUTION

Do not leave the seat of the tractor without disengaging the PTO, depressing the brake pedal and engaging the brake pedal lock. If leaving the tractor unattended, also turn the ignition key off and remove the key.

NOTE

NOTE

When using power take-off operated equipment, best performance is achieved with the throttle lever in the “FAST” position.

1.Depress the brake pedal to release the brake pedal lock and let the pedal up. Move the throttle lever to the position where the engine operates best for the load to be handled.

2.Driving with forward or reverse pedals.

CAUTION

CAUTION

Do not use the forward or reverse control pedals to change the direction of travel when the tractor is in motion. Use the brake pedal to bring the tractor to a stop before depressing either the forward or reverse control pedal.

a.To move forward, slowly depress the forward control pedal until the desired speed is achieved.

b.To move in reverse, check that the area behind is clear then fully depress the reverse control pedal.

3.Using the cruise control lever.

NOTE

NOTE

The cruise control feature can only be operated in the forward direction.

a.Slowly depress the forward control pedal until the desired speed is achieved.

b.Lightly push the cruise control lever downward as far as possible and hold in this position.

c.While continuing to hold the cruise lever down, lift your foot from the forward control pedal (you should feel the cruise latch engage).

d.If properly engaged, the cruise lever and forward control pedal should lock in the down position, and the tractor will maintain the same forward speed.

e.Disengage the cruise control using one of the following methods:

•Depress the brake pedal to disengage the cruise control and stop the tractor.

•Lightly depress the forward control pedal.

•Lift the cruise control lever upward.

NOTE

NOTE

Although not recommended, depressing the reverse pedal will also disengage the cruise control.

f.To change to the reverse direction when operating with cruise control, depress the brake pedal to disengage the cruise control and stop the tractor; then depress the reverse control pedal.

16

DRIVING ON SLOPES

Refer to the SLOPE GAUGE on page 55 to help determine slopes where you may not operate safely.

WARNING

WARNING

Do not mow on inclines with a slope in excess of 15 degrees (a rise of approximately 2-1/2 feet every 10 feet). The tractor could overturn and cause serious injury.

WARNING

WARNING

Operate the tractor up and down slopes, never across slopes. Always drive up or down the face of a slope. Do not drive so that the tractor may tip over sideways .

Before operating the tractor on any slope, walk the slope to look for possible hazards such as rocks. mounds, ruts, stumps or other surface irregularities which could cause the tractor to be upset.

Back the tractor with implement up the steepest portion of each slope you intend to work. If the tractor cannot negotiate the slope in reverse, the slope is too steep to be worked.

Avoid turns when driving on a slope. If a turn must be made, turn down the slope. Turning up a slope greatly increases the chance of a roll over.

Avoid stopping when driving up a slope. If it is necessary to stop while driving up a slope, start up smoothly and carefully to reduce the possibility of flipping the tractor over backward.

STOPPING THE TRACTOR

CAUTION

CAUTION

Always engage the brake pedal lock, push the PTO switch to the “OFF” position, lower the equipment and shut off the engine before dismounting. Never try to start the engine while standing on the ground.

Fully depress the brake pedal to bring the tractor to a complete stop (and disengage the cruise control), engage the brake pedal lock, disengage the PTO, turn the ignition switch to “OFF’” and remove the key from the switch before dismounting.

OPERATING THE POWER TAKE-OFF (PTO) CLUTCH

Before operating the new clutch under load (mowing grass, etc.), perform the following break-in procedure:

1.Start and run the engine a few minutes to warm up.

2.With the mowing deck, snow thrower, etc. installed and the engine running at approximately 50% throttle, engage and disengage the clutch at ten second intervals (ten seconds ON-ten seconds OFF) five times. The engine choke may have to be pulled out slightly to accomplish this.

3.Increase the engine speed to 75% throttle and again engage and disengage the PTO clutch at ten second intervals five times.

4.Make certain the PTO is disengaged and stop the engine.

Operate the PTO clutch as follows:

1.Move the throttle control lever to approximately the mid throttle position.

2.Pull the PTO switch to the “RUN” position.

3.Advance the throttle lever to the operating speed (full engine speed).

4.The operator must remain in the tractor seat at all times. If the operator should leave the seat without turning off the power take-off switch, the tractor’s engine will shut off.

5.The PTO clutch cannot be operated when the tractor is driving in the reverse direction. The PTO switch must in the “OFF” position when the reverse control pedal is depressed, or the PTO clutch will automatically disengage. To re-engage the PTO clutch, release the reverse control pedal, move the PTO switch to the “OFF” position, then again pull the switch to the “RUN” position.

DRAWBAR

Drawbar type equipment must be hitched to the tractor only at the hitch hole in the drawbar (See Figure 9).

Figure 9

17

SECTION III. ADJUSTMENTS

This section contains adjustment information for the Model 2166 tractor. Adjustment information for the 42inch deck is located in Section V – Mower Deck beginning on page 33.

ADJUSTING THE SEAT

WARNING

WARNING

Do not adjust the seat when the tractor is moving. Adjusting the seat while the tractor is moving could cause the operator to lose control of the tractor.

Before starting the tractor, adjust the seat forward or rearward to the most comfortable driving position. To reposition the seat, move the seat adjustment lever (see Figure 10) upward and slide the seat forward or rearward. Release the adjustment lever when the seat is comfortably positioned. Gently rock the seat forward and rearward once to be sure the seat is locked in place.

Figure 10

ADJUSTING THE BRAKES

During normal operation of this tractor, the brakes are subject to wear and will need periodic examination and adjustment.

To check the brake adjustment, position the tractor on a firm and level surface. Stop the tractor engine and remove the ignition key. Pull and lock the transmission release lever in the “TRANSMISSION RELEASED” position. Perform the following checks:

1.Engage the brake pedal lock. If the tractor can be pushed forward or rearward, the braking force must be increased.

2.Release the brake pedal lock. If the tractor cannot be pushed forward or rearward, the braking force must be decreased.

To adjust the braking force, refer to Figure 11 and proceed as follows:

1.Place the tractor on a level surface with the brake pedal lock disengaged. Stop the tractor engine and remove the ignition key.

2.While working from the underside of the tractor, facing the threaded end of the rod, remove the hairpin cotter from the brake rod adjustment ferrule. Remove the ferrule from the brake cam.

To increase the braking force—

Turn the ferrule clockwise (inward) one full turn at a time until the ferrule can be inserted into the brake cam while applying a minimal tension on the spring.

To decrease the braking force—

Turn the ferrule counterclockwise (outward) one full turn at a time until the ferrule can be inserted into the brake cam while applying a minimal tension on the spring.

3.Turn the ferrule counterclockwise (outward) one full turn to release the slight spring tension, then insert the ferrule into the brake cam and secure with the hairpin cotter.

BRAKE |

ADJUSTMENT |

|

CAM |

||

FERRULE |

||

|

HAIRPIN

COTTER

COTTER

BRAKE ROD

SPRING

Figure 11. Viewed from top (fender off).

Recheck the brake adjustment to ensure proper brake operation before operating the tractor. If brake rod adjustment does not correct the problem, see your authorized Cub Cadet dealer.

18

Loading...

Loading...