Page 1

b/w Product Image

in Moment Style

Product Information

Version 3.2

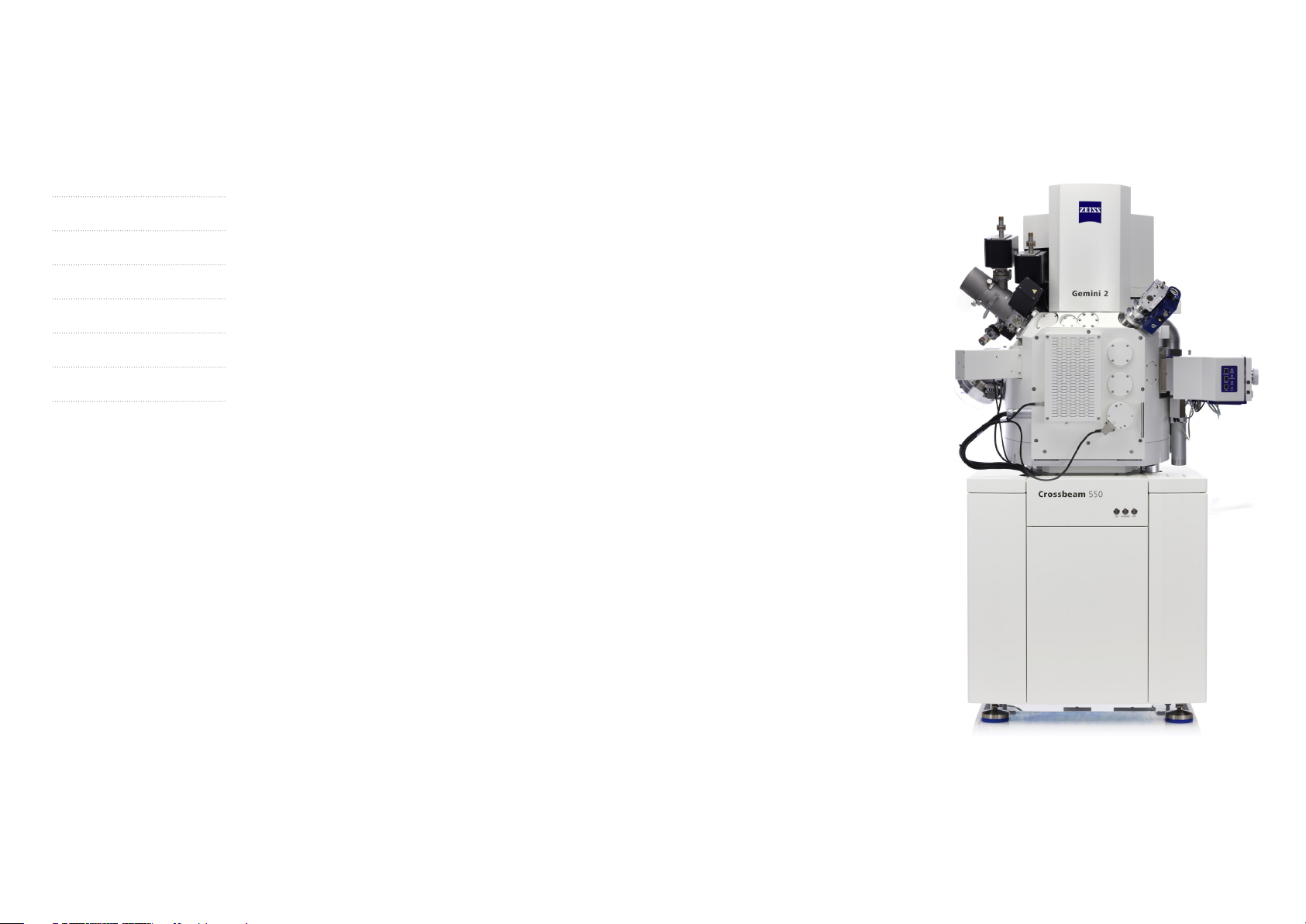

ZEISS Crossbeam Family

Your FIB-SEM for High Throughput 3D Analysis and

Sample Preparation

Page 2

Your FIB-SEM for High Throughput 3D Analysis and Sample Preparation

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

ZEISS Crossbeam combines the powerful imaging and analytical

performance of a field emission scanning electron microscope (FE-SEM)

column with the superior processing ability of a next-generation

focused ion beam (FIB).

Crossbeam gives your 3D work that dynamic edge, whether you are milling,

imaging or performing 3D analytics. Extract true sample information from your

SEM images using Gemini electron optics. The Ion-sculptor FIB column introduces

an altogether new way of FIB-processing. By minimizing sample damage you’ll

maximize sample quality—and perform experiments faster at the same time.

Customize your instrument to achieve both high quality and high throughput in TEM lamella preparation. Exploit the variable pressure capabilities

of Crossbeam 350. Or use Crossbeam 550 to prepare and characterize your

most demanding samples, choosing the chamber size that best suits your

samples.

You may be working on your own or in a multi-user facility, as an academic or

in an industrial lab. If you’ve set your sights on high impact results, Crossbeam’s

modular platform concept lets you upgrade your system as your needs grow.

2

Page 3

Simpler. More Intelligent. More Integrated.

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Maximize Sample Insights in Both 2D and 3D

Count on excellent images from any sample thanks to the Gemini electron optics of your ZEISS Crossbeam. You will

achieve high resolution and contrast while reaping the benefits of high signal-to-noise ratios, right down to very

low accelerating voltages. Prepare high quality samples, like TEM lamellae, using the FIB's low voltage perfor-

mance and characterize your samples comprehensively in 3D. Use a wide choice of detectors, including the

unique Inlens EsB (energy selective backscatter) detector for pure material contrast. Investigate non-conductive

specimens undisturbed by charging artifacts, offset either with local charge compensation while keeping

high vacuum in the chamber or with variable pressure available in Crossbeam 350.

Increase Your Sample Throughput

Combine Gemini optics with a new way of FIB machining: the superior low voltage performance of the Ion-

sculptor FIB column delivers fast and precise results while keeping amorphization damage on your sample

to a minimum. Use these advantages especially for the preparation of TEM lamellae – even challenging

samples. Benefit further from the FIB’s high current capability that saves time and achieves excellent

FIB profiles with up to 100 nA current—without compromising the ultimate FIB resolution.

Save even more time with automatically prepared batches of cross-sections or with any user-defined pattern.

And the benefits just keep on coming throughout your long-term experiments as optimized routines

enhance FIB source lifetime and stability.

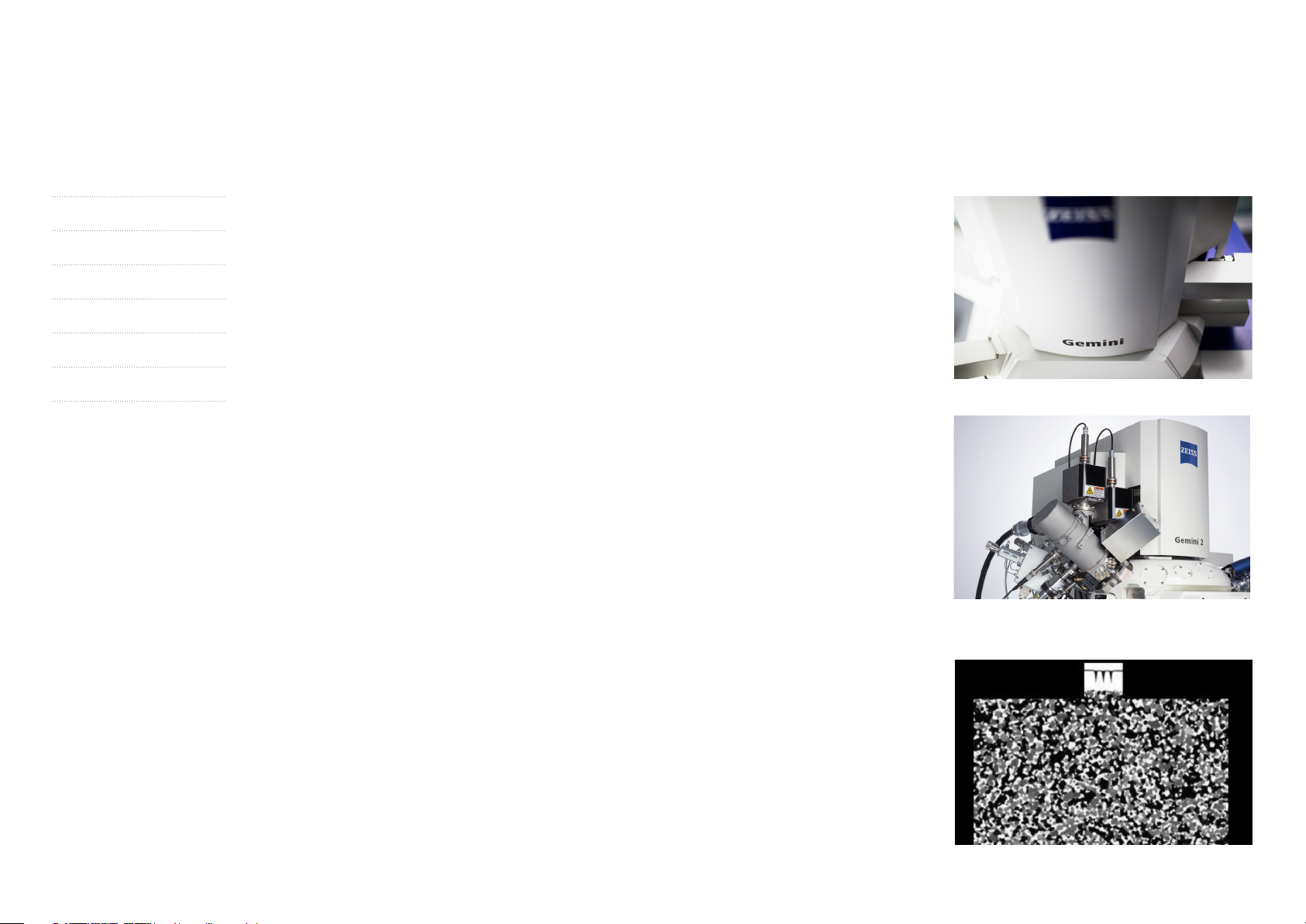

Count on excellent images thanks to Gemini electron optics.

Benefit from the superior low voltage performance of the

Ion-sculptor FIB-column, especially for TEM lamella preparation.

Experience Best 3D Resolution

Enjoy precise and reliable results in FIB-SEM tomography with best 3D resolution and leading isotropic voxel

size. The Inlens EsB detector lets you probe and image less than 3 nm in depth. Expand the capacity of your

Crossbeam with Atlas 5, our market-leading package for fast, precise tomography. You will save time by

collecting your serial section images while milling. You also have the advantage of trackable voxel sizes

and automated routines for active control of image quality. Meanwhile, Atlas 5’s new integrated Analytics

module enables 3D EDS and 3D EBSD analysis during tomography runs.

3D tomogram of a solid oxide fuel cell anode made of the heat

resistant composite material Nickel Samaria-doped ceria.

3

33

Page 4

Your Insight into the Technology Behind It

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

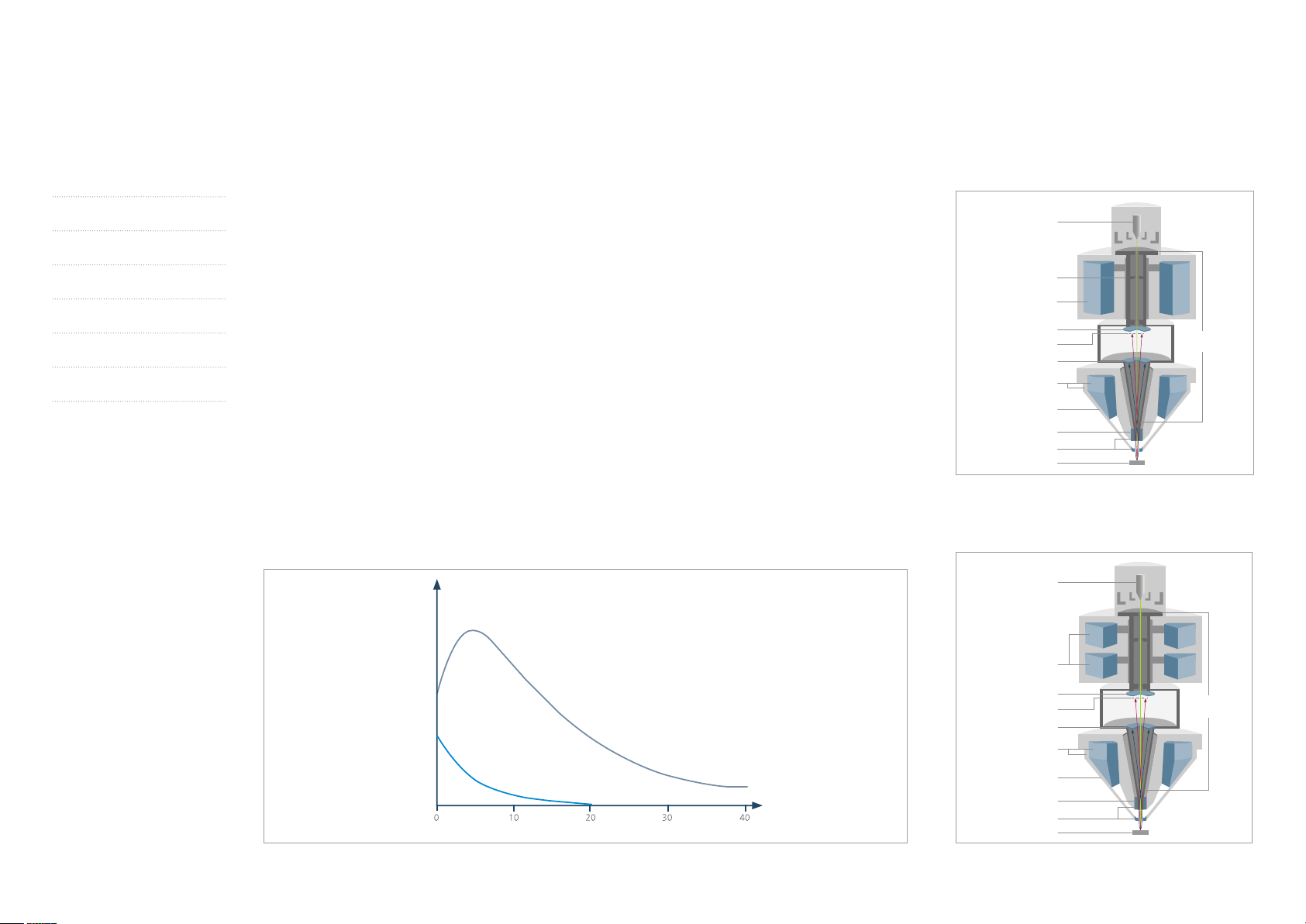

Profi t from Gemini Optics

Crossbeam’s FE-SEM column is based on Gemini

electron optics. You will appreciate the long-term

stability of your SEM alignment and the effortless

way it adjusts all system parameters such as probe

current and acceleration voltage. Unlike other

FE-SEMs, Gemini optics don’t expose your

specimen to a magnetic fi eld. This allows you

to achieve distortion-free, high resolution imaging

over large fi elds of view as well as to tilt the

specimen without infl uencing the electron optical

performance. Even magnetic samples can be

imaged easily.

Choose between Two Columns:

• The Gemini VP column of Crossbeam 350 gives

you maximum sample fl exibility and multi-

purpose environments. With the optional

Variable Pressure (VP) you can perform in situ

experiments under excellent analytical condi-

tions, even with outgassing or charging samples.

• The Gemini II column of Crossbeam 550 has

a double condenser system that enables high

resolution, even at low voltage and high

current. It’s ideal for high resolution imaging

at high beam current and for fast analytics

• Simultaneous Inlens SE and Inlens EsB imaging

provides unique topographical and material

contrast. That means you will gain more

information in less time.

FE-Gun

Electromagnetic

aperture changer

Condenser

Inlens EsB detector

Filter grid

Inlens SE detector

Magnetic lens

Objective

Scan coils

Electrostatic lens

Specimen

ZEISS Crossbeam 350: Gemini colum with single condenser,

two Inlens detectors and VP capability.

FE-Gun

Beam

booster

Single-Pole Lens

Gemini lens

Magnetic fi eld strength (in arbitrary units)

WD (mm)

Magnetic fi eld leakage of the Gemini lens compared to a traditional single-pole lens design. The minimum magnetic fi eld on the sample

allows highest ion and electron beam performance on a tilted sample as well as high resolution imaging of magnetic materials.

Double condenser

Inlens EsB detector

Filter grid

Inlens SE detector

Magnetic lens

Objective

Scan coils

Electrostatic lens

Specimen

ZEISS Crossbeam 550: Gemini II column with double

condenser and two Inlens detectors.

Beam

booster

4

44

Page 5

Your Insight into the Technology Behind It

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

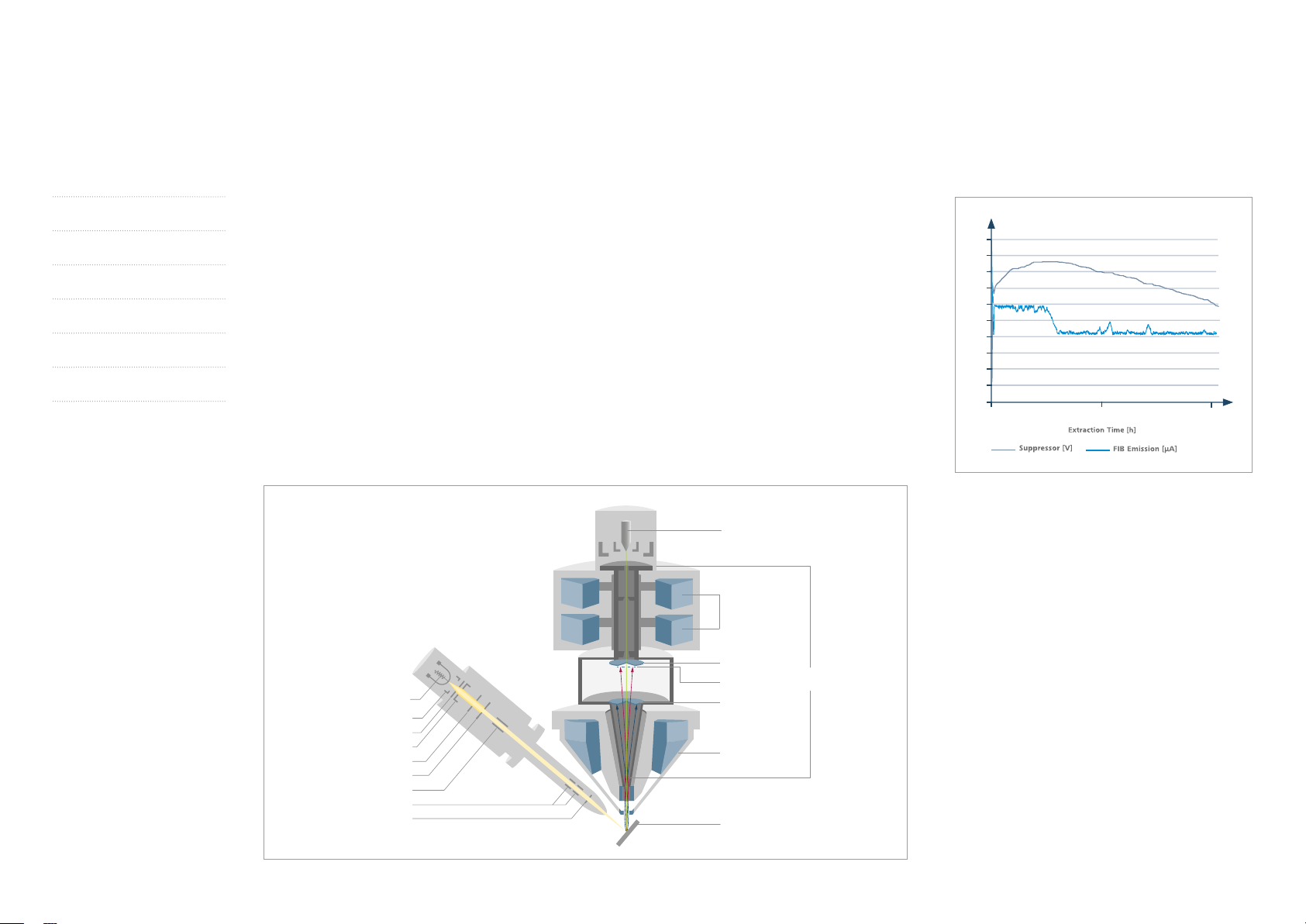

Discover a New Way of FIB-Machining – From Massive Ablation to Nanometer Precision

Maximize sample quality by using the low voltage capabilities of the Ion-sculptor FIB column. Minimizing

amorphization of delicate specimens will give you the best results after thinning or polishing—with the added

advantage of fast probe current exchanges to accelerate your FIB applications. Or opt for high current

performance and double the speed of your 3D FIB-SEM applications by working with the high gallium

ion beam currents. You’ll get precise and reproducible results with maximum stability during the acquisition

time. The column design gives you access to fi ve orders of magnitude in beam current, from 1 pA up to

100 nA. The larger beam currents of up to 100 nA allow fast and precise material removal and milling

processes. Meanwhile, at low currents you will achieve exceptionally high FIB resolution of less than 3 nm.

The gallium focused ion beam source – the so-called LMIS (liquid metal ion source) Ga source—is designed

for a typical lifetime larger than 3000 μAh when operating at a target emission current of 2 μA. For long-

term experiments, you have the bonus of the Crossbeam family’s automatic FIB emission recovery.

SEM column

FE-Gun

FIB column

Double condenser

2.50

2.40

2.30

2.20

2.10

2.00

1.90

1.80

FIB Emission Current [µA]

1.70

1.60

1.50

0

35

70

Regulation characteristic of Ga source emission current.

The suppressor voltage regulates the total emission current

between 1.9 µA and 2.1 µA.

2000

1800

1600

1400

1200

1000

800

600

400

200

Suppressor Voltage [V]

Ga-Reservoir

Suppressor

Extractor

Condenser

Differential Pumping Aperture

Beam Defining Apertures

Blanker Plates

Octopoles

Objective

ZEISS Crossbeam 550: FIB- and FE-SEM column arranged at an inclination angle of 54°.

Inlens EsB detector

Filter grid

Inlens SE detector

Objective

Specimen

Beam

booster

5

55

Page 6

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Customize Your Crossbeam with the Remote

Application Programming Interface

Innovative experiments will often require new

functionality beyond what is provided by the

operating software of your electron microscope.

That’s why the open programming interface of

Crossbeam is designed to allow access to almost

every microscope parameter. The remote API lets

you take complete control of electron and ion

optics, stage, vacuum system, detectors, scanning

and image acquisition from custom programs –

whether running on the system PC or on a

remote workstation.

ZEISS provides both documentation and code

examples in various programming languages –

plus technical support to make sure you get

the results you want. Quickly.

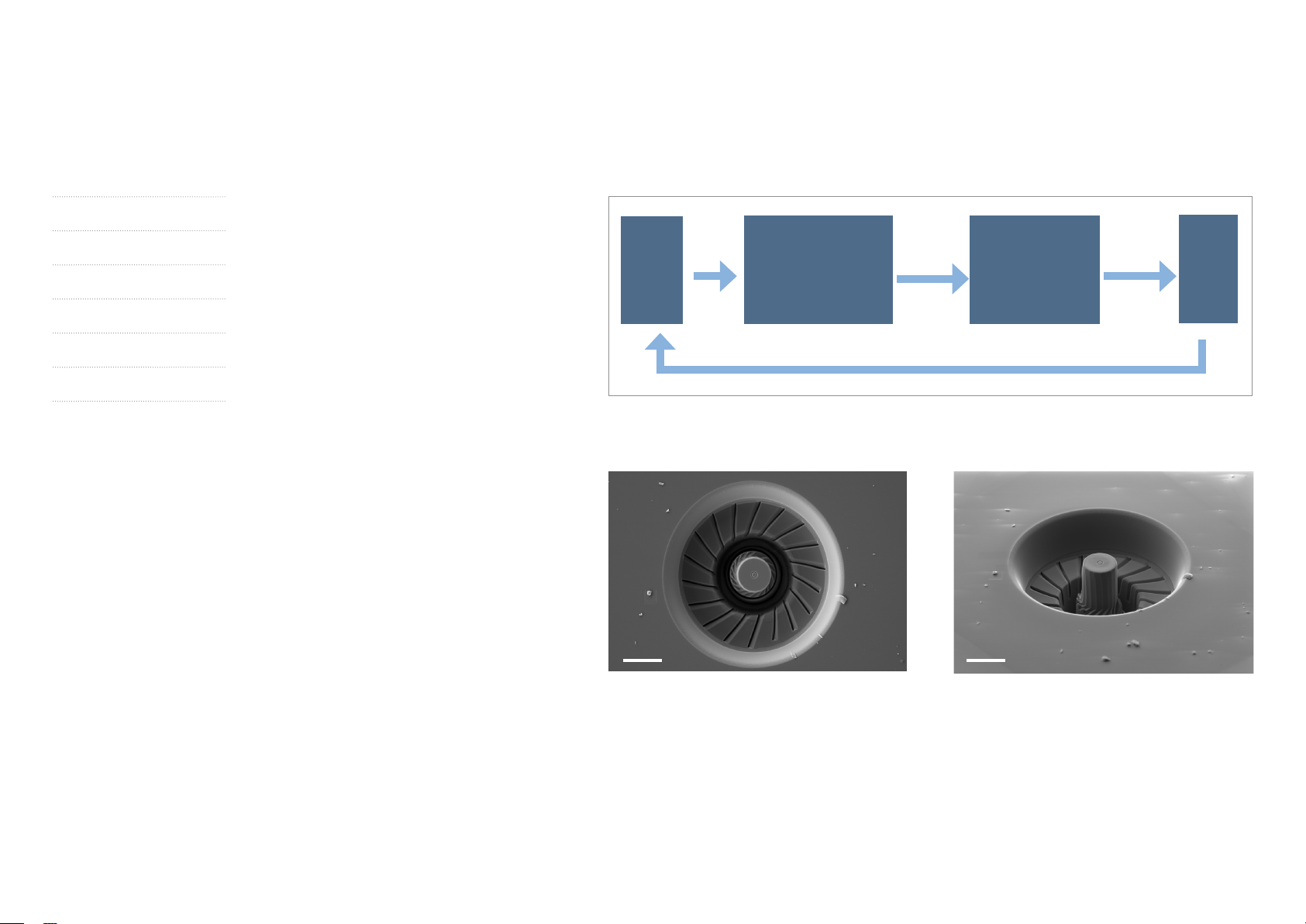

Rotate

sample

Rough repositioning

of sample using x, y

stage movement

Workflow for lathe milling, implemented in the custom application SmartLathe and using the API interface.

SEM drift

correction

Fine repositioning

of sample

10 µm 10 µm

FIB drift

correction

Start

milling

Pillar for compression testing after being machined using lathe milling: SEM top view (left), SEM side view (right).

66

6

Page 7

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

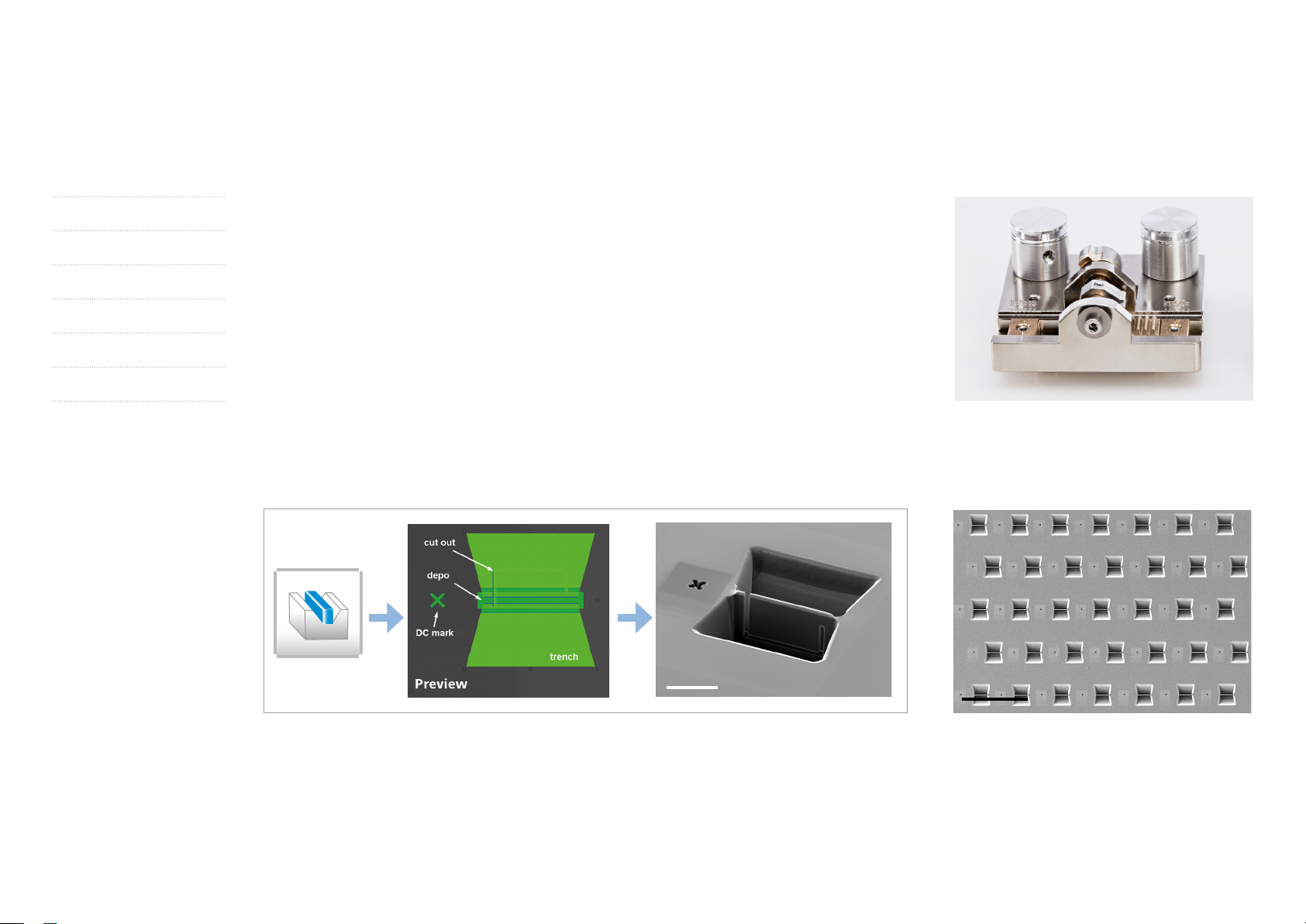

It’s Easy to Create TEM Lamellae

Simply use Automatic Sample Preparation (ASP)

for your TEM sample: it includes all necessary

steps and it’s ready for lift out.

How it Works

• Click on the TEM sample icon.

• Draw a line to defi ne the location of

the lamella on your sample.

• Trigger execution.

Prepare Batches of TEM Lamellae –

Automatically

• Execute a batch of TEM samples at

predefi ned sites without supervision.

How it Works

• Defi ne location of single TEM lamella and

transfer to process list.

• Repeat step 1 as often as required or

perform copy & paste in sample mode.

• Execute process list.

2

sample holder. Use the patented X²-preparation method

X

to prepare ultra-thin, stable TEM lamellae and obtain a

homogeneous thickness of less than 10 nm without causing

sample damage.

10 µm

Illustration of the simple three-step workfl ow for TEM sample preparation (depo stands for deposition, DC for drift correction)

20 µm

Array of TEM lamellae prepared automatically.

7

77

Page 8

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

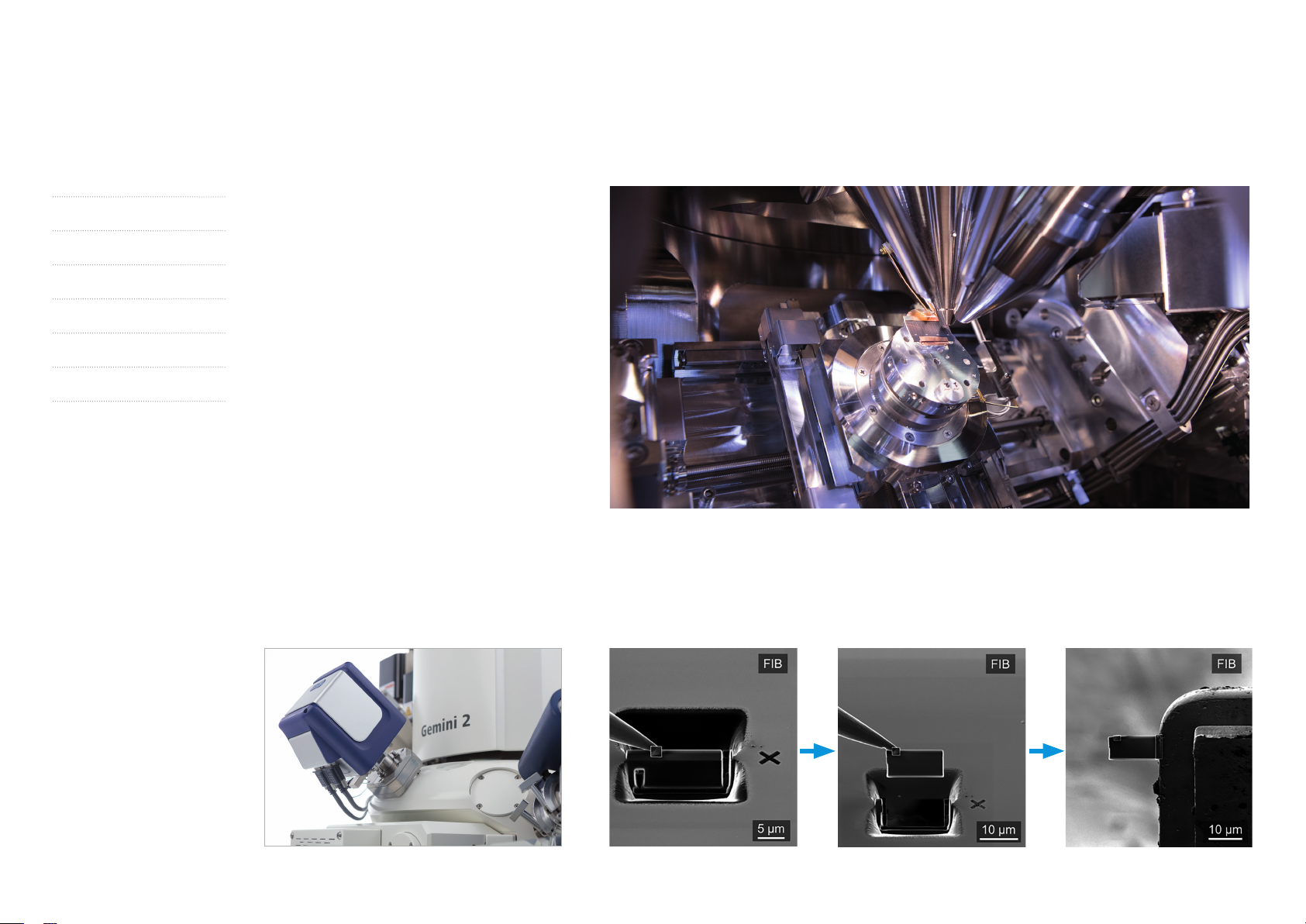

Select Your Micromanipulator for

TEM Lamella Lift-out

When starting a TEM lamella preparation work-

flow find your region of interest quickly with

the help of the super-eucentric 6-axis stage and

always stay at eucentricity when tilting the sample

no matter which working distance. Prepare your

sample and eventually utilize a micromanipulator

for the next steps in the workflow.

It's quick and easy to lift out a prepared TEM

lamella from the bulk. Select a micromanipulator

that is targeted to your needs in flexibility, free-

dom of operation and ease-of-use in control.

Attach your lamella to a grid for final thinning

and low kV polishing.

Find your region of interest quickly with the help of the super-eucentric 6-axis stage and always stay at eucentricity when tilting the

sample. Prepare your sample. Lift out your TEM lamella, eventually.

The micromanipulator of your choice will be configured to

enable optimized workflows.

Attach the needle of the micromanipulator to the lamella, lift it out of the bulk and attach it to the TEM-grid for further investigation in

transmission mode. (from left to right)

8

88

Page 9

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Keep Control During TEM Lamella Thinning

The final polishing step is crucial, as it defines the

quality of your TEM lamella. When you aim to

reach a desired thickness, the SEM allows live

monitoring of the thinning. During imaging, the

`split mode` gives you the benefit of having the

signals of several detectors available in parallel.

Use the SE signal to judge lamella thickness and

obtain reproducible end thickness. At the same

time, the Inlens SE signal helps you control

surface quality.

SE2InLens

SmartEPD is an optional software module that

allows you to determine the thickness of your

TEM lamella quantitatively and thus stop the

thinning process at your pre-defined endpoint,

this time using the Inlens EsB detector.

Even more benefits come your way with the

2

- Holder, which is built to enable the prepara-

x

tion of ultra-thin lamellae. This is a big help when

dealing with challenging samples that show

intrinsic stress, for example, heterogeneous

materials or polymers that would otherwise bend.

5 µm

Keep full control during lamella thinning. Use SmartEPD to determine the lamella thickness and endpoint

of polishing quantitatively.

Use the patented X² preparation method to prepare ultra-thin,

stable TEM lamellae and obtain a homogenous thickness of less

than 10 nm without causing sample damage.

9

99

Page 10

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

ZEISS Atlas 5 – Master Your Multi-scale

Challenge

Use Atlas 5’s sample-centric correlative environ-

ment to create comprehensive multi-scale, multi-

modal images. This powerful yet intuitive hard-

ware and software package extends the capacity

of your Crossbeam. With its efficient navigation

you can correlate images from any source.

For example, use X-ray volume data from your

ZEISS X-ray microscope to target buried features

of interest and analyze them in your Crossbeam.

Take full advantage of Atlas 5’s high throughput

and automated large area imaging. Unique work-

flows will help you gain a deeper understanding

of your sample. The modular structure lets you

tailor Atlas 5 to your everyday needs in materials

or life sciences research.

Recommended Modules for your Crossbeam

• NPVE Advanced (Advanced Nanopatterning

& Visualization Engine): Perform nano-

patterning with full control over patterning

geometry and parameters.

• 3D Tomography: Turn your Crossbeam into

a precise 3D FIB-SEM tomography acquisition

engine with automated sample preparation.

Automatically acquire 3D image data with

up to several thousand images and a voxel

resolution below 10 nm isotropic voxel size

in 3D. Unique sample-tracking technology

gives you the benefit of consistent slice

thickness over long acquisitions. Meanwhile,

robust autofocus and auto-stigmation

algorithms keep all of your images sharp.

• Analytics: Add 3D EDS / 3D EBSD analytics to

high resolution FIB-SEM tomography acquisi-

tion. Specify imaging and mapping condi-

tions independently.Use the advanced acqui-

sition engine to automatically switch

between analysis and imaging conditions

during acquisition. Flexible visualization

allows you to simultaneously view SEM

images and process elemental maps.

Tomography data of a lead free solder containing Cu and Ag

particles in an Sn matrix. SEM images (top) and EDS maps

(bottom) were acquired at the same sample site at 1.8 kV and

6 kV, respectively, with a ZEISS FIB-SEM and Atlas 5 Analytics.

Courtesy of: M. Cantoni, EPFL Lausanne, Switzerland.

10

10

10

Page 11

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Fastmill – Speed Up Your Material Removal

Milling speed depends on a multitude of factors: target material, lattice orientation, ion current, milling

geometry and so on. For a given material, your scanning strategy has the biggest impact on the material

removal rate. During milling, sample topography changes are based on the precise milling strategy. This

change, in turn, affects the milling rate.

Two milling styles are commonly distinguished: line and frame milling. In the first, the ion dose is delivered

line by line in a single pass. In the latter, the entire frame is milled multiple times until the total dose is

delivered. The local change of the sample surface in line milling dynamically alters the milling conditions –

an effect that can be exploited to speed up material removal.

While line milling is potentially faster, redeposition fills up most of the trench and hence restricts the view-

able cross-section. Targeting a specific cross-section depth requires experimentation and can be cumber-

some. With Fastmill, a newly-introduced scanning strategy, milling speed is enhanced by optimally exploiting

the angle-dependent sputtering effect. Fastmill enables up to 40 % faster milling than regular line milling.

You need only activate one checkbox in the regular cross-sectioning or TEM prep workflow wizards.

20 µm

Comparison of milling strategies in silicon. Material removal

with convential milling (left) takes 10 min 54 sec whereas

with Fastmill the same amount of material is removed in 7 min

21 sec (right).

1111

11

Page 12

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

ToF-SIMS enables High Throughput in

3D Analysis

Secondary Ion Mass Spectroscopy (SIMS) is an

established means of analyzing surfaces that

gives you excellent sensitivity and mass resolution,

along with the ability to differentiate between

isotopes. Adding ToF-SIMS (time of flight

secondary ion mass spectrometry) to your

Crossbeam brings unique analytical capabilities

to the FIB-SEM.

You will Benefit from:

• parallel detection of atomic and molecular

ions down to the ppm level

• analysis of light elements, e.g. lithium

• analysis of isotopes

• analytical mapping and depth profiling

• better than 35 nm lateral resolution,

20 nm depth resolution

• post-mortem retrieval of any signal from

the ROI

Secondary Ions

Primary

Ion Beam

Working principle of SIMS: The Ga focused ion beam (blue)

removes material from the top few nm of the sample surface.

Different sputtered ion species (light and dark grey) are

collected and transferred to the ToF-SIMS detector.

Top: Al (27 amu) map of a calibrated BAM L200 sample. The

FOV is 2 μm. Bottom: Line profile for the area within the green

frame. Lines with a width and separation of 33.75 nm can be

resolved clearly (arrows).

SIMS spectrum of boron doped silicon. The peaks at 10 and

11 amu correspond to the two isotopes of boron. The

concentration of

10

B is below 4.2 ppm.

2 µm

Left: SEM image of the cross section of an AlAs GaAs multilayer

system. The AlAs layers are 10 nm thick. Right: Corresponding

SIMS depth profile showing the aluminum signal at 27 amu for

the top 11 layers.

12

1212

Page 13

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Gemini’s Novel Optics – Profit from Surface Sensitive Imaging

High resolution imaging at low landing energy has become standard in SEM applications. It is not only

required for beam sensitive samples and for non-conductive materials, it is also applied for gaining true

surface information without undesirable background signal from deeper sample layers.

SEM imaging performance of the Gemini optics is optimized dramatically at low and very low voltages

through the introduction of a novel optical design. It includes a high resolution gun mode which results

in the reduction of the primary beam energy width by 30 %. And that is finally responsible for the advances

in resolution.

Additionally, a two-step deceleration modus, the so-called Tandem decel, is introduced with the novel

optical design of Gemini columns. The electron optical column of ZEISS FE-SEMs have an integrated beam

deceleration by design using the beam booster technology. Now, an additional external sample biasing

further improves low voltage resolution and contrast. A high negative bias voltage is applied to the sample,

which decelerates the electrons of the primary electron beam, thus effectively reducing landing energy:

E

landing

= E

primary

-E

bias

.

The Tandem decel mode can be used in two different application modes: one for contrast enhancement

by applying a variable negative bias voltage between 50 V and 100 V and the second enables low voltage

resolution improvement by applying a negative bias voltage of 4 different fixed values of 1 kV, 2 kV,

3 kV or 5 kV.

Inlens SE detector

Magnetic lens

Objective

Scan coils

Electrostatic lens

Specimen

Sample biasing applies a voltage of up to 5 kV, using the

optional feature Tandem decel, and improves imaging with

the Gemini lens at low voltages even further.

500 nm500 nm

Brain tissue sample, showing numerous nerves that are surrounded by layers of special molecules for insulation, the myelin sheaths.

Imaged at 1 kV without (left) and with Tandem decel (right). With the bias activated the myelin sheaths are clearly visible. Sample

courtesy of: M. Cantoni, EPFL Lausanne, CH.

Tandem decel sample holder for 9 single specimens.

1313

13

Page 14

Expand Your Possibilities

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Make the most of your Crossbeam

Start smart, without that time-consuming search

for the region of interest on your sample: take

advantage of the optional navigation camera

on the airlock. Locate specimens or specific

sites, even in color. The integrated user interface

makes it easy to navigate to your ROI. Select the

large airlock and handle wafers of up to 8-inch

diameter with fast sample transfer times.

Because it can be configured with two chamber

sizes, Crossbeam 550 guarantees a high level of

flexibility. The large chamber lets you customize

your Crossbeam with a wider range of imaging,

analytical and sample modification capabilities.

Opt for a multi-channel gas injection system

(GIS) to inject up to five different gases or

configure your Crossbeam with up to two

single GIS systems.

The large chamber offers you the possibility of

configuring three pneumatically-driven accessories

simultaneously, e.g. an aSTEM (annular scanning

transmission electron microscopy) detector, an

annular backscatter detector and a local charge

compensation.

The navigation camera on the airlock helps you find your region

of interest quickly and easily.

Crossbeam equipped with two Uni-GIS units, both configured

for optimal access angles to achieve optimal depositions.

Take high resolution images in transmission mode with the

STEM detector and exploit all contrast mechanisms from

brightfield to high angular annular darkfield.

14

1414

Page 15

Tailored Precisely to Your Applications

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Typical Applications, Typical Samples Task ZEISS Crossbeam Offers

Cross-sectioning Acquire high resolution images of cross-sections to obtain sub-surface

information.

FIB-SEM Tomography Perform serial cross-sectioning to image and reconstruct volumes of

your sample.

FIB-SEM Tomography in Life Sciences Acquire high resolution images of your cross-section or perform large

volume tomography for morphological analysis.

3D Analytics Study the chemical and crystallographic microstructure of your sample. Crossbeam is the perfect tool for 3D EDS and 3D EBSD analysis of your sample. Different

TEM Sample Preparation Prepare thin lamellae for their analysis in TEM or STEM. Crossbeam offers a complete solution for preparing TEM lamellae, even for batches. Profit

Nanopatterning Create new structures or modify existing structures by FIB (or SEM)

and different gases.

Surface sensitive analysis of batteries or

polymers

Characterize the composition of the first few atom layers of solid surfaces. Adding the ToF-SIMS spectrometer lets you analyze trace elements such as lithium, detect

Crossbeam offers a wide range of detectors for a comprehensive characterization of your

sample. Up to four detector signals can be acquired simultaneously to get more information

at the same time. The Gemini lens design does not expose your sample to a magnetic field.

It allows distortion free imaging of large fields of view. Coupled with image frame store resolutions of up to 50 k × 40 k pixel your Crossbeam is ideal for large area mapping applications.

The Inlens EsB detector provides excellent material contrasts and allows surface sensitive

imaging because it reduces the information depth to only a few nanometers. When used

during milling with the focused ion beam, it speeds up long-term experiments. Intelligent

software solutions enable long and unattended tomography runs for reliable and precise

results in the shortest time.

Precisely target, image and reconstruct the volume of interest to get 3D information from

your biological samples.

packages are provided for fully automated acquisition of the 3D datasets.

from the low voltage performance of the Ion-sculptor FIB column in gaining high quality

lamella and avoid amorphization of delicate specimens. Use a simple three-step workflow

to get started and wait for automatic execution. For preparing high quality lamellae, use the

patented X

that gives you accurate information about the thickness of your lamella.

Perform FIB patterning tasks with full SEM control in real time. Just choose and draw the

shapes you want to create on your FIB image, set up the parameters and start patterning.

The system’s user-friendly software helps inexperienced users to achieve great results.

For most advanced fabrication tasks, the software allows you to access all relevant SEM,

FIB or GIS parameters to tailor the best FIB patterning strategy at single object level.

You can plan and create your FIB exposure work offline.

isotopes, and perform elemental mapping and depth profiling with a lateral analytical

resolution down to 35 nm.

2

sample holder during final thinning. Profit from an endpoint detection software

15

Page 16

ZEISS Crossbeam at Work

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Nanopatterning SEM Imaging

100 nm

Live imaging while milling a spiral: SE signal (left), Inlens SE (right).

Alumina nanospheres imaged at 1 kV and FIB-SEM coincidence

point with Tandem decel exemplifies high resolution, surface

sensitive imaging of challenging samples.

Cross-sectioning and 3D Analysis

10 µm

cathode material of a lithium ion battery. Close-up of cross-section shows surface information on an Inlens SE image and unique, pure materials contrast with an Inlens

LiMn

2O4

EsB image. The distribution of lanthanum (red) and manganese (green) is derived from an EDS map (from left to right).

2 µm2 µm

16

Page 17

ZEISS Crossbeam at Work

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Nanopatterning

20 µm

Nanofluidics channels fabricated by FIB in a silicon master stamp (left). Detail: meander-shaped channel (center). Inlets and outlets have a funnel shape (right). Courtesy of: I. Fernández-Cuesta,

INF Hamburg, Germany.

10 µm

1 µm

Milling

10 µm

Trenches milled in high entropy alloy, dimensions

25 µm × 15 µm, milling time 3 minutes for 65 nA box (right)

and 11 minutes for 30 nA box (left).

10 µm

Trench milled in silicon, dimensions 100 × 30 × 25 µm³,

milling time 10 minutes using 100 nA FIB current.

10 µm

Pillar for compression testing after being machined using lathe

milling.

17

Page 18

ZEISS Crossbeam at Work

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

TEM Sample Preparation Preparation of Sample Batches

10 µm

Lamella of a copper sample ready for lift out, fabricated with

automatic sample preparation, prepared and imaged by FIB.

2 µm

Ion-sculptor 5kV image of a lamella of poly-crystalline silicon.

High imaging quality at low voltages allows precise thinning of

the central region of the lamella.

STEM

50 µm

Array of compression testing pillars in high entropy alloy,

machined fully automatically.

1 nm

Silicon in <110> orientation, STEM image of a FIB lamella in a

TEM. <110> silicon dumbbells and a twin boundary are clearly

visible. The TEM lamella was prepared with the lon-sculptor

FIB of ZEISS Crossbeam 550 with low kV thinning.

Image Courtesy of: C. Downing, CRANN Institute, Trinity

College, Dublin, Ireland. Nion UltraSTEM 200.

200 nm

Chromium carbides at the grain boundary of thermally-affected

X2CrNi18-10 steel: STEM BF in a FIB-SEM (left), EDS chromium

map (right).

50 µm

Array of TEM lamellae fabricated with automated preparation.

18

Page 19

ZEISS Crossbeam at Work

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

FIB – Tomography in Life Sciences

Cell Biology – HeLa Cells Cell Biology – Algae Neuroscience – Brain Sections

Click here to view this video

Investigation of different cell compartments in single cells.

Individual HeLa cells were grown in culture dishes, chemicallyfi xed and resin-embedded in EPON. Voxel size 5 × 5 × 8 nm,

Inlens EsB detection, 1400 sections. 3D visualization with

Dragonfl y Pro, ORS. Courtesy: A. Steyer and Y. Schwab, EMBL,

Heidelberg, DE.

3D reconstruction of a vitrifi ed Emiliania huxleyi coccolithophore

obtained from a cryo-FIB-SEM image series. The 3D reconstruction

shows the immature coccolith (in yellowish), a coccolith in statu

nascendi (blue) and lipid bodies (red). Courtesy: L. Bertinetti,

Max-Planck Institute of Colloids and Interfaces, Potsdam, DE and

A. Scheffel, Max-Planck Institute Plant Physiology, Potsdam, DE.

Large area milling and imaging of a brain section with the

3D module of ZEISS Atlas 5. High current allows fast milling and

imaging of large fi elds of view up to 150 μm in width. The

depicted brain image has a fi eld of view of 75 μm in width and

was milled with a beam current of 20 nA. Courtesy: C. Genoud,

FMI Basel, CH.

Developmental Biology – C.elegans Microbiology – Trypanosoma

Understanding the morphology of a whole organism in 3D with

the highest resolution and reliability. The data set shows a

large 3D volume of C.elegans consisting of 10.080 z-sections

at 5 x 5 x 8 nm pixel size. The nematode was high pressure

frozen and freeze-substituted in EPON. Even the smallest

structures inside the worm can be identifi ed very easily.

Courtesy: A. Steyer and Y. Schwab, EMBL Heidelberg, DE; and

S. Markert and C. Stigloher, University of Wuerzburg, DE.

Ultrastructural investigation of the parasite Trypanosoma brucei.

The cells are high pressure frozen and freeze-substituted in

EPON. Acquisition of 800 z-sections which corresponds to ~ 8 μm

thickness in z; pixel size in x/y is 5 nm. Sample courtesy:

S. Vaughan, Oxford Brookes University, Research Group

’Cell biology of Trypanosomes’, UK.

19

Page 20

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Your Flexible Choice of Components

Available Options

1. Focused Ion Beam (FIB) column

2. Electron fl ood gun allows ion beam

preparation of non-conductive samples

3. Local charge compensation allows SEM

imaging and analysis of non-conductive

samples

4. Retractable ToF-SIMS spectrometer for

parallel mass detection with excellent spatial

resolution

5. Multichannel Gas Injection system (GIS) for

up to 5 precursor materials on a single fl ange

6. Uni-GIS for high angle sample access,

two systems confi gurable

7. Manipulators for sample handling and

probing

8. Annular STEM for high resolution transmission

imaging or aBSD4 detector for high effi ciency

and angle selective material characterization

9. Inlens EsB detector for high resolution without

topographic artifacts and unique material

contrast

10. Airlock solution (80 mm or 200 mm sample size)

for fast and effi cient sample transfer and fast

pumping times with integrated navigation camera

Further Options

• SESI detector for secondary electron

and secondary ion imaging

• Atlas 5 for advanced tomography,

patterning and EDS and EBSD analytics in 3D

• Plasma cleaner

• Electrostatic beam blanker for SEM

• Laser ablation upgrade

• Tandem decel for enhanced resolution and

contrast at low voltages for suitable samples

(Crossbeam 550 only).

• Analytic detectors: EDS, WDS, EBSD

• 34 inch, 21:9, ultra-wide screen monitor

20

Page 21

Technical Specifications

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

ZEISS Crossbeam 350 ZEISS Crossbeam 550

SEM Schottky Emitter Schottky Emitter

1.7 nm @ 1 kV 1.4 nm@ 1 kV

1.2 nm@ 1 kV with Tandem decel

1.6 nm @200 V with Tandem decel

0.9 nm @ 15 kV 0.7 nm @ 15 kV

0.7 nm @ 30 kV (STEM mode) 0.6 nm @ 30 kV (STEM mode)

2.3 nm @ 1 kV (WD 5 mm) 1.8 nm @ 1 kV (WD 5 mm)

1.3 nm @ 1 kV with Tandem decel (WD 5 mm)

1.1 nm @ 15kV (WD 5 mm) 0.9 nm @ 15kV (WD 5 mm)

2.3 nm @20 kV & 10 nA (WD 5 mm) 2.3 nm @20 kV & 10 nA (WD 5mm)

Beam current: 5 pA – 100 nA Beam current: 10 pA – 100 nA

FIB

Detectors Inlens SE, Inlens EsB, VPSE (Variable pressure secondary electron detector),

Chamber Size and Ports Standard with 18 configurable ports Standard with 18 configurable ports Large with 22 configurable ports

Stage X /Y = 100 mm X/Y = 100 mm X / Y = 153 mm

Charge Control Flood Gun Flood Gun

Gases Uni-GIS: Pt, C, SiO

LMIS: Lifetime: 3000 μAh LMIS: Lifetime: 3000 μAh

Resolution: 3 nm @ 30 kV (statistical method) Resolution: 3 nm @ 30 kV (statistical method)

Resolution: 120 nm @ 1 kV & 10 pA (optional) Resolution: 120 nm @ 1 kV & 10 pA

SESI (secondary electron secondary ion), aSTEM (scanning transmission electron),

aBSD (backscatter detector)

Z = 50 mm, Z‘ = 13 mm Z = 50 mm, Z‘ = 13 mm Z = 50 mm, Z‘ = 20 mm

T = –4° to 70°, R = 360° T = –4° to 70°, R = 360° T = –15° to 70°, R = 360°

Local Charge Compensation Local Charge Compensation

Variable Pressure –

, W, H2O Uni-GIS: Pt, C, SiOx, W, H2O

x

Multi-GIS: Pt, C, W, Au, H

O, SiOX, XeF

2

2

Inlens SE, Inlens EsB, ETD (Everhard-Thornley detector), SESI (secondary electron,

secondary ion), aSTEM (scanning transmission electron), aBSD (backscatter detector),

CL (cathodoluminescence)

Multi-GIS: Pt, C, W, Au, H2O, SiOX, XeF

2

21

Page 22

Technical Specifications

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

ZEISS Crossbeam 350 ZEISS Crossbeam 550

Store Resolution 32 k × 24 k (up to 50 k × 40 k with optional Atlas 5 3D Tomography module) 32 k × 24 k (up to 50 k × 40 k with optional Atlas 5 3D Tomography module)

Analytic Options EDS, EBSD, WDS, SIMS, others on request EDS, EBSD, WDS, SIMS, others on request

Advantages Maximum sample variety due to variable pressure mode, wide range of in situ

experiments.

Retractable ToF-SIMS spectrometer

Detection limit: < 4,2 ppm boron in silicon

Lateral resolution: < 35 nm

Mass/charge range: 1-500 Th

Mass resolution: m/Δm > 500 FWTM

Depth resolution: < 20nm AlAs/GaAs multilayer system

High throughput in analytics and imaging, high resolution under all conditions.

22

Page 23

Count on Service in the True Sense of the Word

› In Brief

› The Advantages

› The Applications

› The System

› Technology and Details

› Service

Because the ZEISS microscope system is one of your most important tools, we make sure it is always ready

to perform. What’s more, we’ll see to it that you are employing all the options that get the best from

your microscope. You can choose from a range of service products, each delivered by highly qualified

ZEISS specialists who will support you long beyond the purchase of your system. Our aim is to enable you

to experience those special moments that inspire your work.

Repair. Maintain. Optimize.

Attain maximum uptime with your microscope. A ZEISS Protect Service Agreement lets you budget for

operating costs, all the while reducing costly downtime and achieving the best results through the improved

performance of your system. Choose from service agreements designed to give you a range of options and

control levels. We’ll work with you to select the service program that addresses your system needs and

usage requirements, in line with your organization’s standard practices.

Our service on-demand also brings you distinct advantages. ZEISS service staff will analyze issues at hand

and resolve them – whether using remote maintenance software or working on site.

Enhance Your Microscope System.

Your ZEISS microscope system is designed for a variety of updates: open interfaces allow you to maintain

a high technological level at all times. As a result you’ll work more efficiently now, while extending the

productive lifetime of your microscope as new update possibilities come on stream.

Profit from the optimized performance of your microscope

system with services from ZEISS – now and for years to come.

>> www.zeiss.com/microservice

23

Page 24

Carl Zeiss Microscopy GmbH

07745 Jena, Germany

microscopy@zeiss.com

www.zeiss.com/crossbeam

Not for therapeutic use, treatment or medical diagnostic evidence. Not all products are available in every country. Contact your local ZEISS representative for more information.

EN_42_011_091 | CZ 05-2019 | Design, scope of delivery, and technical progress subject to change without notice. | © Carl Zeiss Microscopy GmbH

Loading...

Loading...