Page 1

___________________________________________________________________________

Infrastructure Installation Guide

Location Sensor

(including Locating Access Point)

Installation Guide

___________________________________________________________________________ 1

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 2

___________________________________________________________________________

_____________

____________

____________

Infrastructure Installation Guide

Typographical Conventions

Warnings call attention to a procedure or practice that could result in

personal injury if not correctly performed. Do not proceed until you fully

_____________

______________

Note

____________

understand and meet the required conditions.

Cautions call attention to an operation procedure or practice that could

damage the product, or degrade performance if not correctly performed. Do

not proceed until understanding and meeting these required conditions.

Notes provide information that can be helpful in understanding the operation

of the product.

___________________________________________________________________________ 2

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 3

___________________________________________________________________________

Infrastructure Installation Guide

Document Revision History

Revision Description of Changes Date Approved

PA6 Preliminary 1/20/02

___________________________________________________________________________ 3

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 4

___________________________________________________________________________

Infrastructure Installation Guide

Table of Contents Page

1 DOCUMENT O VERVIEW 6

2 PRODUCT DESCRIPTION AND FEATURES 6

3 PRODUCT SPECIFICATIONS 8

4 PARTS AND TOOLS 9

5 CONFIGURATION 13

6 ASSEMBLY INSTRUCTIONS 17

7 FCC INFORMATION 17

8 MOUNTING O VERVIEW 19

9 CABLING 23

10 LOCATION SENSOR INSTALLATION CHECKLIST 27

Table of Figures Page

FIGURE 1 ALL WEATHER OMNI ANTE NNA 11

FIGURE 2 INDOOR OFFICE OMNI ANTENNA 11

FIGURE 3 FLAT PANEL DIRECTIONAL ANTENNA 11

FIGURE 4 OPTIONAL HIGH GAIN ANTENNA 11

FIGURE 5 POWER SUPPLY 12

FIGURE 6 OUTDOOR P.S. HOUSING 12

FIGURE 7 RJ CABLE TOOL 13

FIGURE 8 FLUKE LAN CABLEMETER 13

FIGURE 9 LAP-4200 LABEL 15

___________________________________________________________________________ 4

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 5

___________________________________________________________________________

Infrastructure Installation Guide

FIGURE 10 WALL MOUNTING HOLE DIMENSIONS 21

FIGURE 11 LOCATION SENSOR CONNECTIONS 23

FIGURE 12 LOCATION SENSOR LED INDICATORSLED INDICATORS 33

___________________________________________________________________________ 5

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 6

___________________________________________________________________________

Infrastructure Installation Guide

1 DOCUMENT OVERVIEW

This document describes the physical installation and basic configuration of the

Location Sensor product. The site design is detailed in the D0406 Location Sensor

Placement Guide.

2 PRODUCT DESCRIPTION AND FEATURES

The Location Sensor receives the signals transmitted by the WhereTags, which are

attached to the tracked assets. The decoded tag information is time stamped and

routed to a PC for additional processing. The locate algorithm running on the PC

calculates the tag position based on the time stamps of multiple Location Sensors,

and reports that position to the database where it is displayed by Resource

Manager.

There are two separate Location Sensor models:

• LOS-4100 (802.3 Wired Ethernet)

• LAP-4200 (with 802.11b Wireless LAN Access Point, also known as a

Locating Access Point)

The difference between the two models is that the LAP-4200 contains an Access

Point, while the LOS-4100 does not. These units are identical in appearance; the

___________________________________________________________________________ 6

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 7

___________________________________________________________________________

Infrastructure Installation Guide

only way to distinguish them is by the model number on the housing. Note that

both units have a wired Ethernet port; the LAP-4200 has a can function as either a

client bridge or an access point.

Both units also include a low power transmitter which is used to distribute

configuration data, and timing signals to other Location Sensor units. This

transmitter has the same transmitter characteristics as a tag.

Features include:

• Outdoor weatherproof housing

• Wireless data transport capability

• Wireless Timing capability

There are three separate antenna options for the Location Sensor. In addition,

there is an optional high gain Wireless LAN Access Point directional antenna for

installati ons in which the standard antennas do not proved the range required to

communicate with the base access point. The available antennas are listed in

section 4 below.

___________________________________________________________________________ 7

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 8

___________________________________________________________________________

18 to 36

Infrastructure Installation Guide

3 PRODUCT SPECIFICATIONS

3.1 Mechanical

Size: 10.3 x 3.2 x 12.0

261 x 80 x 305

Weight: 8.0

3.6

in (HxDxW)

mm

Lbs

kg

3.2 Electrical

Voltage:

36 nominal

Current: 1.5 (max) Amps

Pwr Diss: 25 (max) Watts

AC Power1

1

With recommended power supply

100- 240 Vac

Vdc

3.3 Environmental

___________________________________________________________________________ 8

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Operating Temperature:

Storage Temperature:

-30 to +50

-40 to +70

Ingress Protection: 65 IP

ºC

Page 9

___________________________________________________________________________

Infrastructure Installation Guide

3.4 External Connections

Antenna: MCX (female)

DC Power: 2.5 ID/ 5.5 OD mm (female)

Opt. Access Point Antenna: RP-TNC (male)

Ethernet RJ45 (female)

Timing RJH (4 wire telephone handset, female)

4 PARTS AND TOOLS

The parts and tools indicated below are required to complete the installation of the

Location Sensor. Ordering information is supplied where applicable.

Part Model Number

• All Weather Omni Antenna1 (standard)

• Office Omni Antenna1 (indoor only)

• Flat PanelAntenna1 (directional indoor/

AK-210 (Figure 1)

AK-110 (Figure 2)

AK-120 (Figure 3)

outdoor)

• High Gain WLAN Antenna (optional)

• Power Supply

• Outdoor Power Supply enclosure

TBD (Figure 4)

PS-021 (Figure 5)

(Figure 6)

(outdoor use only)

___________________________________________________________________________ 9

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 10

___________________________________________________________________________

Infrastructure Installation Guide

Part Model Number

• Pole Mount Kit

• Wall Mount Bracket (to provide 12

inch (305 mm) spacing from metal

wall w/ AK-210 antenna

• Cat 5 network cable;

• Connector

• Timing cable (2 twisted pairs);

• Connector

• Network hub/ router/ switch

1

Choose 1 of the three antenna options

RM-410-00

RM-250-00

Belden: 1583A 006U1000

riser , 1585A 877U1000

Plenum, or equiv.

1624R Non-plenum, shielded;

1624P Plenum, shielded.

AMP 5-569278-X with load

bar, or AllenTel

AT8X8RCSC-24

Belden: 1588R-006U1000

riser, 1590A-8771000 plenum

Allen Tel AT4X4SC-2224

N/A

Recommended cable/connector/tool supplier Graybar (800) 766-7101

___________________________________________________________________________ 10

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 11

___________________________________________________________________________

Infrastructure Installation Guide

Figure 1 All weather omni antenna Figure 2 Indoor office omni antenna

Figure 3 Flat panel directional antenna Figure 4 Optional high gain antenna

___________________________________________________________________________ 11

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 12

___________________________________________________________________________

Infrastructure Installation Guide

Figure 5 Power supply Figure 6 Outdoor P.S. housing

Tools

• Computer to configure Location

Sensor, including

• Crossover Cat 5 (Ethernet) cable

• Null Modem serial cable (optional)

Available locally

Digi-Key: AE1034-ND DB9

M/F, or AE1033-ND F/F

• RJ Connector tool for RJ45 and RJH

• Fluke 620 LAN CableMeter

• Miscellaneous hand tools

Figure 7

Figure 8

Available locally

___________________________________________________________________________ 12

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 13

___________________________________________________________________________

____________

Infrastructure Installation Guide

Figure 7 RJ cable tool Figure 8 Fluke LAN CableMeter

Note

____________

5 CONFIGURATION

The Location Sensor (Location Access Point) must be configured prior to

operation. Configuration includes:

• Setting the Location Sensor configuration, including the IP address

• Setting the embedded Access Point configuration (LAP-4200 only),

including the Service Set Identifier (ESS ID), and IP address.

Failure to configure the Location Sensor prior to operation may result in an

inoperative unit.

___________________________________________________________________________ 13

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 14

___________________________________________________________________________

Infrastructure Installation Guide

Both of these units are configured using:

• LPManager software via Ethernet (preferred),

• Telnet via Ethernet, or

• Hyperterminal (or any terminal emulation software) via serial port

For the LAP-4200, both the Location Sensor and the embedded Access Point must

be independently configured. That is, both units must have their IP addresses

correctly specified. The communication connection can be switched between the

Location Sensor and the Access Point by typing ctrl-w.

5.1 Location Sensor Configuration

Location Sensors communicate over an Ethernet interface using TCP/IP. Each

Location sensor must be configured with a unique IP address. The IP address of

each LS must be recoded and entered into the WhereNet site file, which contains

the configuration information for each LS, including its location.

Each Location Sensor is shipped with a label set containing one label (Figure 9)

with the bar coded MAC address of the Location Sensor (and of the Access Point

if so equipped) and three labels with the last six characters of the Location

Sensor’s MAC address in large type. Ensure that the label is correct by matching

the MAC address(es) on the loose label set with the MAC address(es) listed on the

back of the Location Sensor. Place the loose bar code label in the site design

___________________________________________________________________________ 14

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 15

___________________________________________________________________________

Last 6 LS

Access

Point

Label applied

factory

Location Sensor

Location Sensor

Infrastructure Installation Guide

document where indicated, and place one or more of the large type, six character

labels on the exterior of the Location Sensor in positions that are visible after

installation.

MAC digits

to unit from

Serial Number

MAC Address

MAC Address

Figure 9 LAP-4200 Label

Like other network equipment, the Location Sensor IP address(es) must be set to a

predetermined address. While there is no restriction to the IP address, it must

match the address in the Site file for that particular Location Sensor. The IP

address(es) can be static assigned, or dynamically assigned via DHCP. If assigned

though DHCP, the DHCP server must contain the MAC address and

corresponding IP address for each of the Location Sensors (and Access Points).

___________________________________________________________________________ 15

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 16

___________________________________________________________________________

____________

Infrastructure Installation Guide

The Location Sensors can be configured using either an automatic process or a

manual process:

Automatic Configuration

TBD

Manual Configuration

• Connect to the Location Sensor using LP Manager, Telnet or

______________

Hyperterminal.

• Confirm the unique MAC address for the Location Sensor.

• Select Set IP Address from the menu and set the IP address.

• Access the Access Point configuration by typing ctrl-w.

• Follow the menu prompts and set the IP address.

• Confirm communication to the Location Sensor by “pinging” the device(s)

using LP Manager.

The MAC address label must be clearly marked on the exterior of the

Location Sensor housing in a position visible after installation.

___________________________________________________________________________ 16

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 17

___________________________________________________________________________

____________

____________

Infrastructure Installation Guide

6 ASSEMBLY INSTRUCTIONS

The Outdoor Omni antenna must be mounted to the Location Sensor housing; the

Indoor Office Omni antenna and the Flat Panel Directional antennas are mounted

separately to the appropriate wall or ceiling. Follow the specific instructions

included with the antennas.

The left and right antenna must be correctly oriented per the site design.

______________

Note

____________

Inadvertently reversing the left and right antenna will result in a two foot

location error.

7 FCC INFORMATION

This equipment complies with Part 15 of the FCC Rules.

Any changes or modifications to WhereNet Corp. equipment not expressly

approved by WhereNet Corp. could void the user’s authority to operate the

equipment.

___________________________________________________________________________ 17

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 18

___________________________________________________________________________

Infrastructure Installation Guide

This equipment complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference

that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B

digital device pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential (and

commercial) installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the manufacturer's instruction manual, may

cause interference with radio communications. However, there is no guarantee

that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, you are encouraged to try to

correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

___________________________________________________________________________ 18

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 19

___________________________________________________________________________

____________

_____________

Infrastructure Installation Guide

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/ television technician for

assistance.

To comply with FCC RF exposure requirements, no one may remain within

_____________

______________

20 cm of the antenna.

8 MOUNTING OVERVIEW

The site design specifies the location of the Location Sensor(s) to provide

optimum system performance. It is critical that the Location Sensor is mounted in

a position which provides good RF visibility to the tracked assets. Thus the

Location Sensor must be mounted exactly in the position specified in the site

design document.

Failure to mount the Location Sensor in the exact position specified in the site

design will result in erroneous or non-locates of the tracked assets.

___________________________________________________________________________ 19

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 20

___________________________________________________________________________

Infrastructure Installation Guide

The Location Sensor can be mounted to a wall using the integral keyhole mounting

slots. An attachment hole is also provided to accept a 3/8 in (10 mm) threaded

rod. A pole mount hardware kit is available separately.

8.1 Wall Mount

The Location Sensor may be mounted directly against a non-metallic wall using

the standard AK-210 All Weather Omni-directional antennas. For a metallic wall,

Location Sensor must be mounted 12 inches (305 mm) away from the wall for the

antennas to operate properly. Alternately, the AK-120 Flat Panel antennas may

utilized as they may be mounted directly to a metallic wall.

The Location Sensor can be mounted to a wall using the four key hole mounting

slots per the following instructions:

• Determine the preferred screw/ anchor type (not supplied) for the particular

wall material. The Location Sensor requires a #6 or 3.5 mm mounting

screw.

• Mark and drill holes in the wall to match the keyholes on the Location

Sensor (Figure 10).

• Mount the Location Sensor and securely tighten the screws.

___________________________________________________________________________ 20

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 21

___________________________________________________________________________

7.88i

n

_____________

Infrastructure Installation Guide

200.2 mm

9.22 in

234.2 mm

_____________

Figure 10 Wall mounting hole dimensions

If the Location Sensor is in a position in which it could be ripped off the wall

by industrial equipment, it should be secured to the building infrastructure

with a safety cable through the 3/8 inch (10 mm) hole in the housing.

___________________________________________________________________________ 21

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 22

___________________________________________________________________________

Infrastructure Installation Guide

8.2 3/8ths Threaded Rod

The Location Sensor can be hung via a 3/8 inch (10 mm) threaded rod per the

following instructions. The required supports, threaded rod, nuts, etc., are not

included.

• Cut the threaded rod to the desired length and install it directly above the

desired Location Sensor position.

• Thread one nut up 2 inches (50 mm) from the bottom of the threaded rod.

• Place the Location Sensor onto the threaded rod and install the second nut.

• Tighten the upper nut down on top of the Location Sensor housing.

8.3 Pole Mount

The required pole mount kit, catalog number RM-410-00, must be ordered

separately. The Location Sensor can be mounted to a pole per the following

instructions:

TBD

___________________________________________________________________________ 22

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 23

___________________________________________________________________________

Infrastructure Installation Guide

9 CABLING

Figure 11 below shows the connections which must be made to the Location

Sensor in normal operation. The connector types and recommended cable types

are detailed in section 4 above.

Power

Left Right

Antenna

Ethernet

Timing

Serial

Figure 11 Location Sensor connections

9.1 Power

The customer must provide 120 Vac power to the specified Location Sensor

position. The Location Sensor utilizes an external power supply to convert 120

Vac to the required +18 to 36 Vdc. The recommended power supply has a 6 foot

(2 m) AC cable and a 6 foot (2 m) dc cable. The electrician should verify that the

AC power is available within 3 feet (1 m) of the position of the Location Sensor.

___________________________________________________________________________ 23

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 24

___________________________________________________________________________

_____________

____________

Infrastructure Installation Guide

This allows a 9 foot (3 m) “service loop” margin if the Location Sensor position

must be readjusted after the AC power is installed.

For outdoor installations the power supply must be installed within a suitable

waterproof housing. Follow local and national building codes.

_____________

9.2 Timing

______________

For most indoor and some outdoor applications the Location Sensor requires at

least one timing cable to be connected to other nearby Location Sensor units. The

site design document will specify which Location Sensors will be connected

together. Each of the three timing ports on the Location Sensor is an identical bidirectional link. The cable and connector types are specified in section 4 above.

For a reliable system operation, the jacket of the timing cable must be

securely crimped inside the RJH connector. Standard eight conductor cat 5

cable is too large for crimping in the 4 wire connector; the recommended 4

wire cable must be utilized to ensure a proper crimp.

___________________________________________________________________________ 24

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 25

___________________________________________________________________________

____________

Infrastructure Installation Guide

The following rules must be applied when connecting timing cables between the

Location Sensors:

• Do not connect the timing cable from one Location Sensor back to the

same Location Sensor.

• Do not connect two timing cables between the same two Location Sensors.

• The maximum timing cable length is 1000 feet (310 m).

Install the Location Sensor timing cables from one unit to the next, as specified in

the site design document, using the specified 2 pair Cat 3 cable and RJH

______________

(telephone handset) connectors.

Incorrect routing of the timing cables between the Location Sensors may

result in decreased location accuracy.

9.3 Ethernet

The Location Sensor utilizes standard 10/100 802.3 Ethernet connectivity via cat 5

cables. The Location Sensor must be wired to a nearby hub, which is in turn

connected to the network containing the database cpu. The maximum Ethernet

cable run is 328 feet (100 m). If additional distance is required, hubs, repeaters,

and fiber (with 10baseT converters) can be used to extend the distance. Refer to

IEEE guidelines for Ethernet cabling.

___________________________________________________________________________ 25

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 26

___________________________________________________________________________

____________

Infrastructure Installation Guide

______________

Do not exceed the maximum Ethernet cabling length of 328 ft (100 m).

9.4 Access Point Antenna Cabling (Optional)

In many installations, the Access Point antenna must have omni directional RF

coverage to support communication from nearby 802.11 wireless terminals. Thus,

in the standard configuration the Access Point shares the same antennas as the

Location Sensor.

However, in some installations the distance between the Location Sensor and the

receiving Access Point is beyond the maximum **TBD** range supported by the

omni directional antennas. In that case the optional high gain antenna must be

utilized to permit the embedded Access Point to communicate with the receiving

Access Point. The high gain Access Point antenna will increase the

communication range to approximately 2000 feet (620 m) (US Only), at a bit rate

of 1 MB/s, when used in conjunction with a receiving omni directional antenna.

The range in Europe will be less due to regulatory output power restrictions.

___________________________________________________________________________ 26

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 27

___________________________________________________________________________

____________

Infrastructure Installation Guide

The use of the optional high gain Access Point antenna will reduce the

wireless LAN coverage range for hand held terminals in areas of the site to

______________

the side of and behind the high gain antenna due to the directivity of the

antenna.

To install the optional high gain Access Point antenna follow the following

instructions:

TBD

10 LOCATION SENSOR INSTALLATION

CHECKLIST

___________________________________________________________________________ 27

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

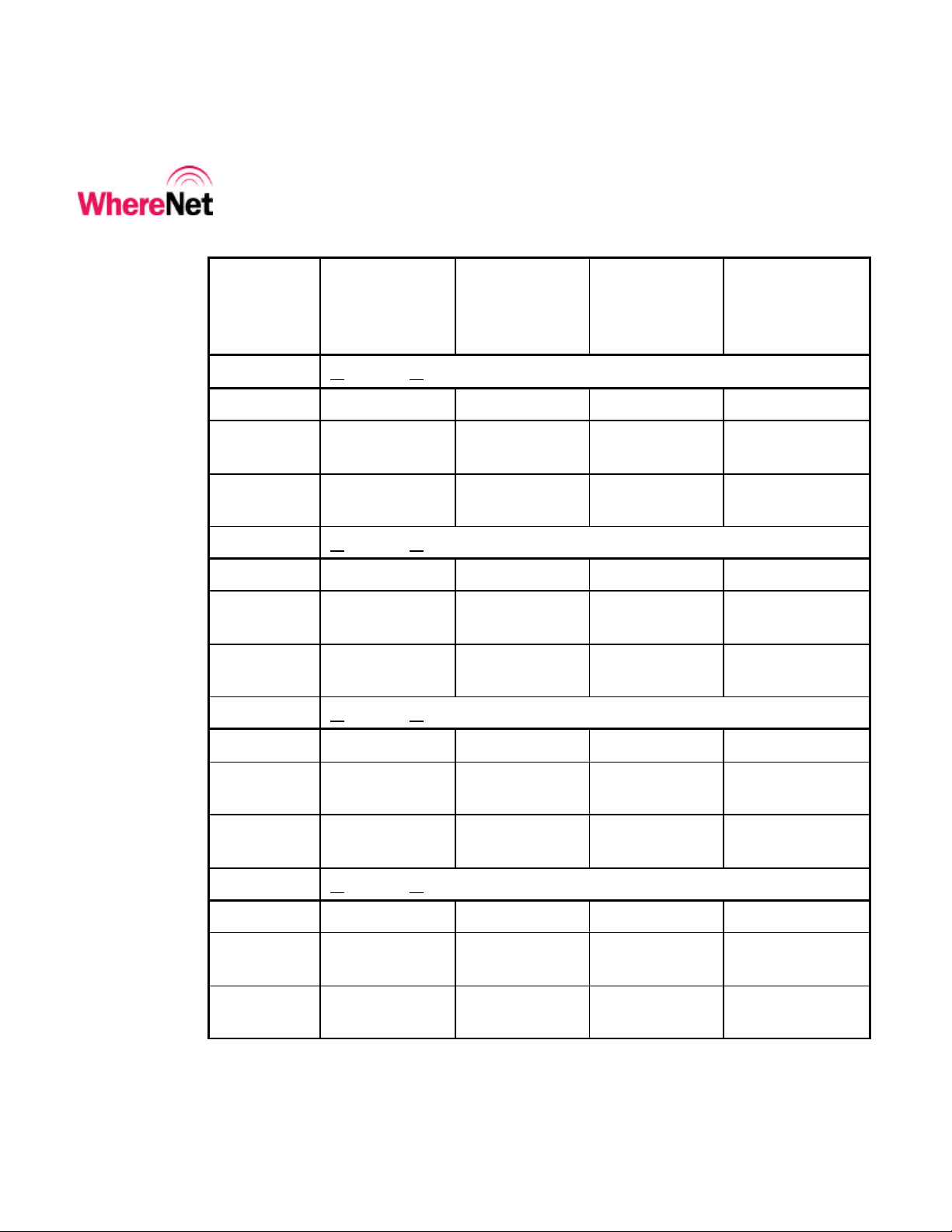

10.1 Location Sensor Installation Verification

The installation of each Location Sensor must be verified by the Account Manager

to ensure that it was correctly installed at the location specified in the Site Design

document. The Account Manager should also record the MAC and IP addresses of

each Location Sensor. After verifying these items the Account Manager should

initial and date the table at the end of this section.

Page 28

___________________________________________________________________________

Infrastructure Installation Guide

q Location Sensor mounted within +/-1 foot (0.3 m) of position specified in

Site Design document. After measuring the installed position,

documenting it on the following form, and comparing it to the position

specified in the Site Design document, the Account Manager should place

an “X” in the installed position accepted/rejected line for each Location

Sensor on site.

q MAC and IP addresses recorded in document below. One or more MAC

label (s) placed on the Location Sensor in a position visible from ground.

q Location Sensor mounted properly with cylindrical antennas pointing down

a minimum of 12” (0.3 m) from metal walls.

q Ethernet, power, timing (if required), and antennas cables properly

connected.

LS Site

Design ID

Number

Reference

point desc.

(e.g., column

E12)

Distance and

bearing from

reference point

in X direction

Distance and

bearing from

reference point

in Y direction

1. MAC address: IP address:

Specified in

Site Design

Actual

installed

Height above

floor level Z/

Direction LEDs

are facing

___________________________________________________________________________ 28

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 29

___________________________________________________________________________

Infrastructure Installation Guide

LS Site

Design ID

Number

Reference

point desc.

(e.g., column

E12)

Distance and

bearing from

reference point

in X direction

Distance and

bearing from

reference point

in Y direction

Accept Reject installed position specified above

2. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

3. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

Height above

floor level Z/

Direction LEDs

are facing

4. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

5. MAC address: IP address:

Specified in

Site Design

Actual

installed

___________________________________________________________________________ 29

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 30

___________________________________________________________________________

Infrastructure Installation Guide

LS Site

Design ID

Number

Reference

point desc.

(e.g., column

E12)

Distance and

bearing from

reference point

in X direction

Distance and

bearing from

reference point

in Y direction

Accept Reject installed position specified above

6. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

7. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

Height above

floor level Z/

Direction LEDs

are facing

8. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

9. MAC address: IP address:

Specified in

Site Design

Actual

installed

___________________________________________________________________________ 30

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 31

___________________________________________________________________________

Infrastructure Installation Guide

LS Site

Design ID

Number

Reference

point desc.

(e.g., column

E12)

Distance and

bearing from

reference point

in X direction

Distance and

bearing from

reference point

in Y direction

Accept Reject installed position specified above

10. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

11. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

Height above

floor level Z/

Direction LEDs

are facing

12. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

13. MAC address: IP address:

Specified in

Site Design

Actual

installed

___________________________________________________________________________ 31

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 32

___________________________________________________________________________

Infrastructure Installation Guide

LS Site

Design ID

Number

Reference

point desc.

(e.g., column

E12)

Distance and

bearing from

reference point

in X direction

Distance and

bearing from

reference point

in Y direction

Accept Reject installed position specified above

14. MAC address: IP address:

Specified in

Site Design

Actual

installed

Accept Reject installed position specified above

Section Signoff

Initial Date Comments/ Exceptions

Height above

floor level Z/

Direction LEDs

are facing

10.2 Location Sensor Operational Verification

Prior to optimizing locate performance, the operation of the Location Sensor must

be verified. The checklist below specifies the verification of the configuration and

basic operation.

___________________________________________________________________________ 32

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 33

___________________________________________________________________________

Infrastructure Installation Guide

Location Sensor

Power/

WLAN

Health

Tag

Reception

Ethernet

Outdoor

Omni

Antenna

Figure 12 Location Sensor LED indicatorsLED indicators

q Verify that each Location Sensor is operational by verifying that the left

Power/ Health LED is illuminated green.

q For wired 802.3 Location Sensors, verify that the Ethernet LED is blinking

green.

q Verify that the RX detects LED is blinking green.

q For wireless 802.11b Location Sensors, verify that the WLAN activity

LED is blinking green.

___________________________________________________________________________ 33

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Page 34

___________________________________________________________________________

Infrastructure Installation Guide

q Confirm that the site LS channel assignment is correct by running “display

locate” from the LP Manager tool with a tag placed directly under each LS.

Verify that the nearest LS, as indicated by a “0” in the display locate

report, is that LS nearest the tag.

q Verify that detects are received on the channel by using either LP Manager

Detect History, or WT LPHealth APC detects when a tag is placed at a

distance from each LA equivalent to the maximum required range from

that LA. Typical tag to LA range is 1000 ft (305 m) (Unobstructed/

outdoor), 350 ft (107 m) Minimally Obstructed (indoor office/ light

commercial), 250 feet (76 m) Significantly Obstructed (heavy industrial).

Section Signoff

Initial Date Comments/ Exceptions

___________________________________________________________________________ 34

Location Sensor Installation Guide D0405 rev PA6

Copyright WhereNet, Corp. 2001

WhereNet Confidential

Loading...

Loading...