Page 1

ZE511/ZE521

Industrial Print Engine

User Guide

P1117212-01EN

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

© 2021 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:zebra.com/linkoslegal

COPYRIGHTS:zebra.com/copyright

WARRANTY:zebra.com/warranty

END USER LICENSE AGREEMENT: zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

Publication Date

June 24, 2021

2

Page 3

Contents

Introduction ........................................................................................................................................... 7

Print Engine Orientation................................................................................................... 8

Print Engine Components ............................................................................................... 9

Control Panel ................................................................................................................. 10

Home Screen ................................................................................................................ 11

Print Status Tab...................................................................................................... 11

Printer Info Tab....................................................................................................... 12

Other Tabs.............................................................................................................. 13

Preparing to Print................................................................................................................................ 14

Ordering Supplies and Accessories............................................................................... 14

Label Software......................................................................................................... 14

Cables .................................................................................................................... 14

Media...................................................................................................................... 14

Ribbon .................................................................................................................... 15

Specifying the Media Handling Method.......................................................................... 16

Ribbon and Media Loading ........................................................................................... 17

Loading Ribbon ...................................................................................................... 17

Loading Media ........................................................................................................ 21

Calibrating the Ribbon and Media Sensors.................................................................... 26

Running the Print Wizard and Printing a Test Label ...................................................... 27

Printer Configuration and Adjustment ................................................................................................. 29

Changing Printer Settings .............................................................................................. 30

System Menu.......................................................................................................... 31

Connection Menu ................................................................................................... 38

Print Menu .............................................................................................................. 49

RFID Menu ............................................................................................................. 60

Storage Menu ......................................................................................................... 64

3

Page 4

Contents

Toggle Positioning and Printhead Pressure Adjustment................................................ 66

Changing the Toggle Position ................................................................................ 66

Adjusting the Printhead Pressure ........................................................................... 69

Routine Maintenance.......................................................................................................................... 72

Cleaning Schedule and Procedures............................................................................... 72

Cleaning the Exterior, the Media Compartment, and the Sensors................................ 73

Cleaning the Printhead and Rollers ............................................................................... 73

Removing Used Ribbon ................................................................................................. 77

Replacing Print Engine Components ............................................................................. 78

Ordering Replacement Parts .................................................................................. 78

Recycling Print Engine Components ...................................................................... 78

Storing the Print Engine ................................................................................................. 78

Lubrication...................................................................................................................... 78

Troubleshooting .................................................................................................................................. 79

Judging Barcode Quality................................................................................................ 80

Configuration Labels ...................................................................................................... 82

PAUSE Self-Test........................................................................................................... 83

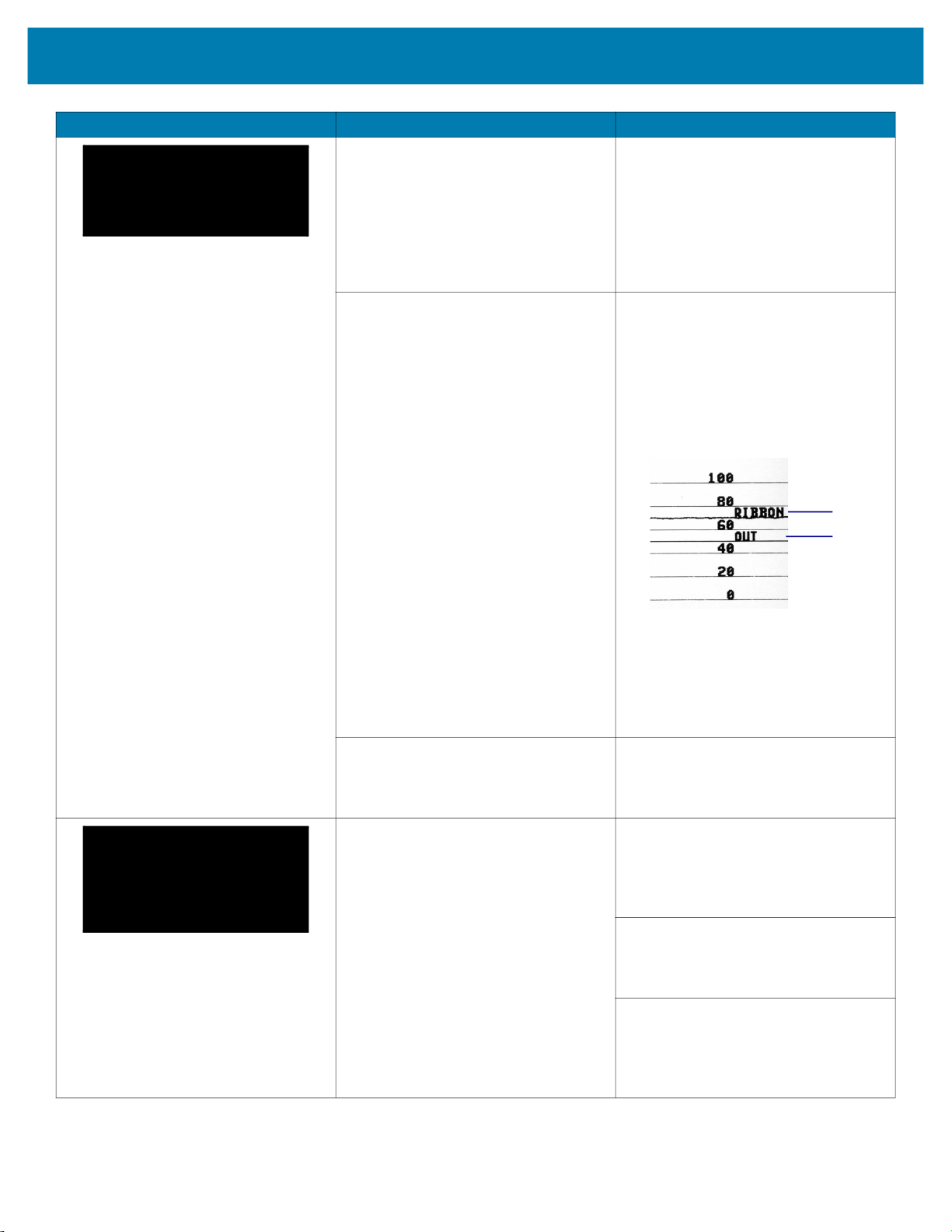

Printing and Interpreting a Sensor Profile ..................................................................... 84

Media Sensor Profile .............................................................................................. 84

Ribbon Sensor Profile............................................................................................. 85

Using Communication Diagnostics Mode ..................................................................... 86

Loading Defaults or Last Saved Values........................................................................ 87

Alert and Error States..................................................................................................... 88

Alerts and Error Messages ..................................................................................... 89

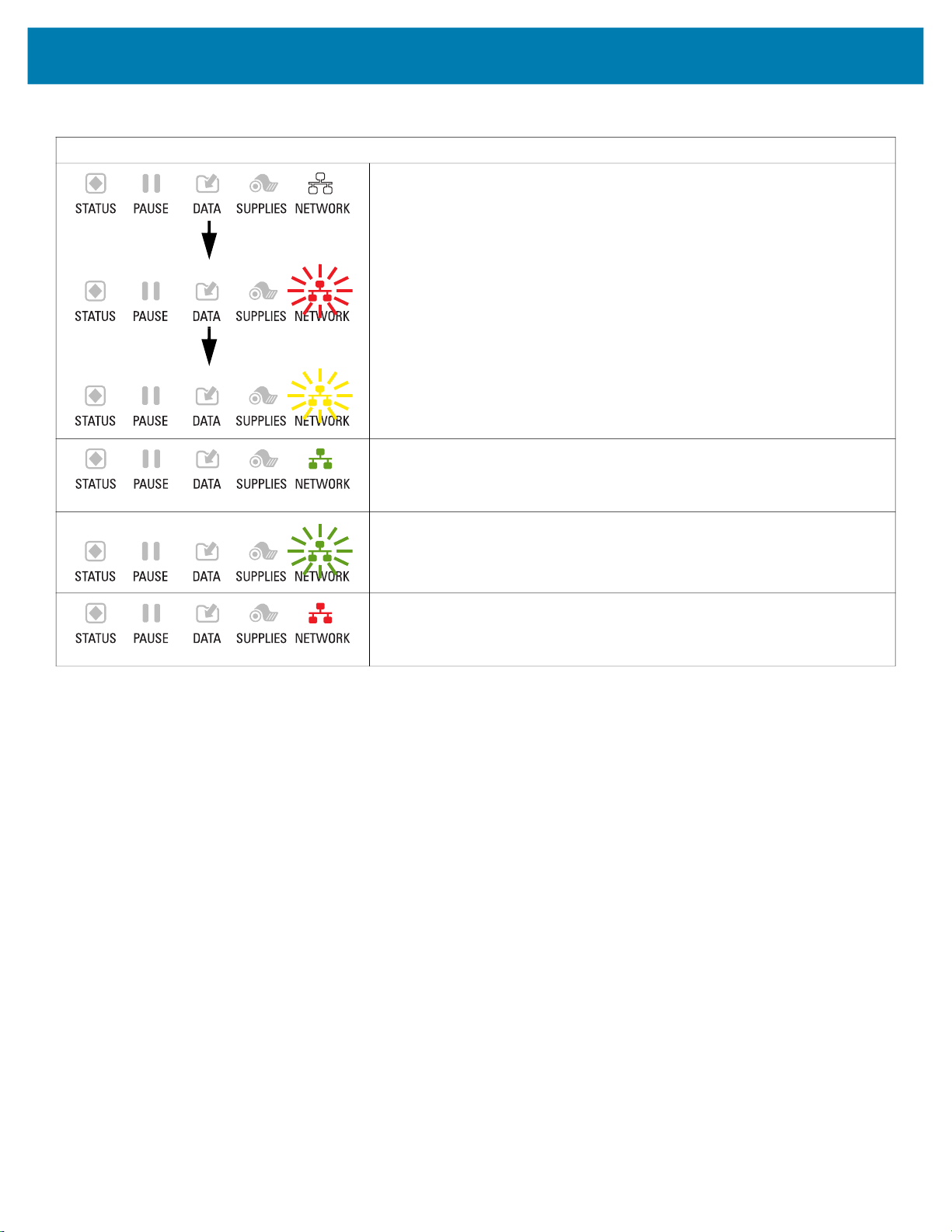

Indicator Lights ....................................................................................................... 93

Troubleshooting ............................................................................................................. 96

Printing or Print Quality Issues ............................................................................... 96

Ribbon Issues....................................................................................................... 100

RFID Issues.......................................................................................................... 102

Communications Issues ....................................................................................... 104

Miscellaneous Issues ........................................................................................... 105

Servicing the Printer..................................................................................................... 108

Shipping the Printer...................................................................................................... 108

Using USB Host Ports and Print Touch/NFC.................................................................................... 109

USB Host Ports............................................................................................................ 109

File Naming .......................................................................................................... 109

4

Page 5

Contents

Print Touch/Near Field Communication (NFC) ............................................................ 109

Related SGD Commands for Advanced Users........................................................... 110

Items Required for the Exercises................................................................................ 111

Exercises..................................................................................................................... 113

Exercise 1: Copying Files to a USB Flash Drive and Performing USB Mirror ...... 113

Exercise 2: Printing a Label Format from a USB Flash Drive............................... 114

Exercise 3: Copying Files to/from a USB Flash Drive .......................................... 115

Exercise 4: Entering Data for a Stored File with a USB Keyboard

and Printing a Label.............................................................................................. 116

Exercise 5: Entering Data for a Stored File with a Phone or Tablet

and Printing a Label .................................................................................................... 117

Specifications.................................................................................................................................... 119

General Specifications ................................................................................................. 119

Power Specifications................................................................................................... 120

Power Cord Specifications.......................................................................................... 121

Communication Interface Specifications..................................................................... 122

Standard Connections .......................................................................................... 122

Optional Connections ........................................................................................... 125

Wireless Specifications......................................................................................... 126

Printing Specifications................................................................................................. 127

Ribbon Specifications................................................................................................... 127

Media Specifications ................................................................................................... 128

Dimensions and Clearance Needs.............................................................................. 129

Front View (Right-Hand Print Engine Shown) ...................................................... 129

Rear View ............................................................................................................. 130

Top View—Electronics Enclosure Clearance ....................................................... 131

Side View—ZE511 Print Engine........................................................................... 132

Side View—ZE521 Print Engine........................................................................... 133

Print Engine Installation .................................................................................................................... 134

Requirements............................................................................................................... 134

Inspect the Contents of the Box................................................................................... 135

Install the Print Engine in an Applicator ...................................................................... 136

Applicator Interface Board Overview........................................................................... 137

Energy Star Effect on the Applicator Interface Board........................................... 138

Change the Applicator Interface Board Jumper Configuration ............................. 139

Applicator Interface Pin Configuration .................................................................. 142

Applicator Signals................................................................................................. 145

5

Page 6

Contents

Connecting the Printer to a Device ................................................................................................... 147

Connecting to a Phone or Tablet ................................................................................. 147

Connecting to a Windows-Based Computer ............................................................... 148

Installing and Running Zebra Setup Utilities......................................................... 148

Connecting a Computer to the Printer’s USB Port...................................................... 150

Connecting a Computer to the Printer’s Serial or Parallel Port.................................... 153

Connecting to Your Network through the Printer’s Ethernet Port................................ 160

Connecting the Printer to Your Wireless Network....................................................... 168

Glossary............................................................................................................................................ 174

6

Page 7

Introduction

This section provides a high-level overview of the printer and its components.

7

Page 8

Print Engine Orientation

The ZE511 and ZE521 print engines are available in a left-hand configuration (the print mechanism is on

the left) and a right-hand configuration (the print mechanism is on the right).

Left-hand (LH) print engine

Introduction

1

2

3

1

Power switch location

2

Control panel

3

Media cover

Right-hand (RH) print engine

1

2

3

8

Page 9

Print Engine Components

The following shows the components inside the media compartment of a right-hand (RH) print engine. A

left-hand (LH) unit contains a mirror image of these components. Familiarize yourself with these

components before continuing.

Introduction

1

2

12

11

1

Ribbon take-up spindle

2

Ribbon supply spindle

3

Printhead-release latch

4

Printhead assembly (shown open)

5

Peel bar

6

Platen roller

910 7

8

6

7

Peel roller assembly (hidden when closed)

8

Peel roller latch

9

Media guide

10

Pinch roller assembly

11

Lower guide post

12

Upper guide post

3

4

5

9

Page 10

Control Panel

All controls and indicators for the print engine are located on the control panel.

Introduction

1 2 4

5

6

7

1

Power switch Toggles the print engine on/off.

2

Display Shows the print engine’s operating status and allows the user to navigate

3

8

the menu system. For more information, see Home Screen on page 11.

3

NFC logo Used for the Print Touch feature. For more information, see Print

Touch/Near Field Communication (NFC) on page 109.

4

USB host ports Allows you to connect USB devices such as memory sticks, keyboards, or

handheld scanners to the printer. For more information, see USB Host

Ports on page 109.

5

PAUSE button Starts or stops print engine operation when pressed.

6

FEED button Forces the print engine to feed one blank label each time the button is

pressed.

7

CANCEL button Cancels print jobs when the print engine is paused.

8

Indicator lights Communicate the printer’s status. For more information, see Indicator

Lights on page 93.

10

Page 11

Home Screen

IMPORTANT: If the background color of the Home screen is yellow or red, the printer is in an alert or error

state and may need user intervention. For more information, see Alert and Error States on page 88.

Print Status Tab

The Print Status tab on the Home screen provides the current status (such as Idle). On this screen,

touching the left or right arrow rotates the image of the printer so that you can view it from any angle.

Introduction

NOTE: Depending on how your print engine is configured, the screens may display horizontally or

vertically. See System > Settings > Display Orientation on page 35 for options.

11

Page 12

Printer Info Tab

The Printer Info tab on the Home screen provides connectivity and firmware data. To scroll in a screen that

does not display everything at one time, such as the horizontal Printer Info screen, touch the screen and

drag upward.

Introduction

NOTE: Depending on how your print engine is configured, the screens may display horizontally or

vertically. See System > Settings > Display Orientation on page 35 for options.

12

Page 13

Other Tabs

The following tabs are available on the Home screen:

Menu

Allows you to access the user menus, where you can view or change the printer settings. See Changing

Printer Settings on page 30.

Wizards

Allows you to change printer settings by going through prompts. For more information about individual

parameters that are set by any of the wizards, see Changing Printer Settings on page 30.

IMPORTANT: When using the Wizards, do not send data to the print engine from the host. For best

results, use full-width media running the Print or Set All Wizards. If the media is shorter than an image to

be printed, the image may be truncated or print across multiple labels.

Introduction

Set All Wizard—runs all of the Wizards in sequence.

System—sets up non-print related operating system settings.

Connection—configures the printer’s connectivity options.

Print—configures key printing parameters and features. See

Running the Print Wizard and Printing a Test Label on

page 27.

RFID—sets up the RFID subsystem operations.

Shortcuts

Allows you to quickly access the most recent menu items and to save your favorites.The Print Station and

Calibrate menu items also appear in the shortcuts.

1. Touch the dark heart icon next to a menu item to save it to your list of favorites.

A red heart icon (1) indicates a saved item.

1

2. Access saved items by touching Favorites (1).

1

13

Page 14

Preparing to Print

Ordering Supplies and Accessories

The following required items do NOT come with the printer:

• Label design software

• Communication/network cables (such as USB, serial, parallel, wired Ethernet)

• Media

• Ribbon (if your printer has a thermal transfer option)

Label Design Software

Select and install the software that you will use to create label formats for your printer. One option is

ZebraDesigner, which you can download from zebra.com

Cables

.

Media

See Communication Interface Specifications on page 122 for more information.

For optimal printing quality and proper printer performance across our product line, Zebra strongly

recommends the use of Zebra Certified Supplies as part of the total solution. A wide range of paper,

polypropylene, polyester, and vinyl stock has been specifically engineered to enhance the printing

capabilities of the print engine and to prevent premature printhead wear. To purchase supplies, go to

zebra.com/supplies.

The Glossary on page 174 includes terms associated with media, such as black mark media, gap/notch

media, RFID media, fanfold media, and roll media. Use these terms to help determine which type of media

is best for your needs.

14

Page 15

Ribbon

Preparing to Print

Do I need to use ribbon? The media itself determines if you need to use ribbon. Thermal Transfer media

requires ribbon while Direct Thermal media does not.

How can I tell if media is Direct Thermal or Thermal Transfer? The easiest way is to scratch the surface

of the media rapidly with your fingernail. If a black mark appears where you scratched, the media is Direct

Thermal, and you do not need to use ribbon.

What kind of ribbon can I use? Ribbon can be wound with the coated side on the inside or outside. This

print engine can use either type. Contact your authorized Zebra reseller for ordering information.

Ink on the Outside Ink on the Inside

How can I tell which side of the ribbon is coated? Press a corner of the sticky side of a label to the outer

surface of the roll of ribbon, and then peel the label off of the ribbon. If ink particles adhere to the label, the

outer side of the roll is coated. Repeat this test with the inner surface if necessary to confirm the coated

surface.

An alternate method is to unroll a short length of ribbon, place the outer surface against a piece of paper,

and scratch the inner surface of the ribbon with your fingernail. Lift the ribbon and check for marks on the

paper. If the ribbon left a mark, the outer side is coated.

15

Page 16

Preparing to Print

Specifying the Media Handling Method

1. On the Home screen, touch Menu > Print > Image Adjust > Media Handling.

2. Select a media handling method that matches your media and setup.

Method Description

Tear Off The printer prints label formats as it receives them. The printer operator can

tear off the printed labels when the printer stops.

Peel Off The printer peels the label from the backing during printing and then pauses

until the label is removed.

Rewind The printer prints without pausing between labels. The media is wound onto a

core after printing.

Cutter The printer cuts between labels after each one is printed.

Delayed Cut The printer waits for a delayed cut ZPL command (

printed label.

Linerless Peel Not used. Reserved for future use.

Linerless Rewind

Linerless Tear

Applicator The printer prints when it receives a signal from the applicator. Refer to the

Advanced User Information section of the Maintenance Manual for additional

information about the applicator interface.

Linerless Cut Not used. Reserved for future use.

Linerless Delayed Cut

Stream The printer prints a batch of labels with backfeed occurring only at the start

and end of the batch instead of between individual labels. This setting

increases label throughput in batch printing.

~JK) before it cuts the last

3. Touch the home icon to return to the Home screen.

16

Page 17

Ribbon and Media Loading

MEDIA SUPPLY

MEDIA BACKING

OPEN

SUPPLIES LOADING

PRESS

TO OPEN

WHEN OPEN

MEDIA BACKING

WHEN CLOSED

DETAIL VIEW

LABEL

www.zebra.com/ze511-info

Use the instructions in this section to load ribbon (if used) and media in a ZE511/ZE521 print engine.

NOTE: The majority of the graphics in this section show a right-hand (RH) unit with ribbon that is coated

with ink on the outside. Graphics for other options are included in some places for clarity.

Preparing to Print

Loading Ribbon

Ribbon is used with thermal transfer labels. For direct thermal labels, do not load ribbon in the print engine.

To determine if ribbon must be used with a particular media, see Do I need to use ribbon? on page 13. To

order Zebra Certified ribbon or media, visit zebra.com/supplies.

1. Determine which side of the ribbon is coated with ink (see How can I tell which side of the ribbon is

coated? on page 13), and then position the ribbon roll with the loose end unrolling in the direction

shown.

2. If necessary, update the ribbon ink side setting (see Print > Print Quality > Ribbon Tension on page 51).

LH (ink side out)

RH (ink side in)

RH (ink side out)

LH (ink side in)

17

Page 18

Open the media cover.

3.

Preparing to Print

4. Release the printhead assembly.

18

Page 19

Preparing to Print

Place the roll of ribbon on the ribbon supply spindle. Push the roll back as far as it will go.

5.

LH (ink side out) RH (ink side out)

LH (ink side in) RH (ink side in)

6. Place an empty ribbon core on the ribbon take-up spindle. Push the core back as far as it will go.

19

Page 20

Preparing to Print

CAUTION—HOT SURFACE: The printhead may be hot and could cause severe burns. Allow the

printhead to cool.

7. Thread the ribbon under the lower ribbon guide roller (1), under the printhead assembly (2), and then

over the upper ribbon guide roller (3).

3

1

2

LH (ink side out)

3

1

RH (ink side out)

1

1

3

2

3

2

LH (ink side in) RH (ink side in)

20

2

Page 21

Wind the ribbon around the core on the ribbon take-up spindle in the direction shown.

8.

Loading Media

1. Load media on the media supply reel of the applicator (refer to the applicator’s documentation for more

information).

2. Press the release button on the pinch roller assembly. Allow the assembly to pivot upward.

Preparing to Print

RHLH

3. Slide the media guide all the way out.

21

Page 22

Preparing to Print

Thread the media under the upper guide post (1), below the pinch roller assembly (2), and under the

4.

printhead assembly (3).

2

1

3

LH RH

5. Extend approximately 30 in. (75 cm) of media past the peel bar. Remove and discard the labels from

2

1

the liner on this exposed media.

3

6. Slide in the media guide until it just touches the edge of the media.

22

Page 23

Preparing to Print

Press down on the pinch roller assembly until it locks closed.

7.

8. Raise the peel roller latch so that the peel roller assembly pivots downward.

LH RH

9. Thread the liner around the peel bar (1) and through the peel roller assembly (2).

IMPORTANT: If the applicator has an air tube, route the liner between the air tube and the peel bar. Do not

thread the liner over the air tube.

LH RH

121 2

23

Page 24

Preparing to Print

Lock the printhead assembly.

10.

.

11. Rotate the peel roller assembly up until it locks into the closed position.

LH RH

12. Thread the liner around the take-up spindle of the applicator (refer to the applicator’s documentation for

more information).

24

Page 25

Close the media cover.

13.

Preparing to Print

14. If desired, perform the PAUSE Self-Test on page 83 to verify that your printer is able to print.

25

Page 26

Preparing to Print

Calibrating the Ribbon and Media Sensors

Use the procedure in this section to calibrate the printer, which adjusts the sensitivity of the media and

ribbon sensors.

IMPORTANT: Follow the calibration procedure exactly as presented.

To cancel the calibration process, press and hold CANCEL at any step in the procedure.

1. Touch Print > Sensors > Manual Calibration.

The printer prompts you to start calibration.

2. Touch Start Calibration.

3. Follow the steps in the calibration procedure.

4. When calibration is complete, press PAUSE to exit pause mode and enable printing.

26

Page 27

Preparing to Print

Running the Print Wizard and Printing a Test Label

The Print Wizard configures the printer, prints test labels, and adjusts print quality based on the results of

the test labels.

IMPORTANT: When using the Wizards, do not send data to the printer from the host.

For best results, use full-width media running the Print Wizard or Set All Wizard. If the media is smaller

than an image to be printed, the results may be truncated or print across multiple labels.

After you have completed the printer setup procedures and run the printer setup wizard, use this section to

print a test label. Printing this label allows you to see if your connection is working and if you need to adjust

any of the print settings.

1. On the Home screen, touch Wizards > Print > Start Print.

2. Follow the prompts to specify the following information:

• print type (Thermal Transfer or Direct Thermal)

• media type (Continuous, Gap/Notch, or Mark)

• label width

• media handling method (tear off, peel-off, rewind, cutter, delayed cut, linerless peel, linerless

rewind, linerless tear, or applicator)

After you have specified these, the wizard instructs you to load media and then to place a label over the

media sensor.

3. If you have not already done so, load media, and then touch the check mark.

4. At the prompt, close the printhead, and then touch the next check mark.

The printer calibrates and then asks if you would like to print a test label.

5. Follow the prompts until the printer completes auto calibration.

6. When asked to print a test label, touch the check mark.

A test label similar to this one prints. If your labels are smaller than the image, only a portion of the test

label prints.

27

Page 28

Preparing to Print

Examine the position of the label over the tear bar. If necessary, shift the position of the media over the

7.

tear-off bar after printing.

• If the space between labels falls on the tear bar, continue with the next step.

• If the space between labels does not fall directly on the tear bar, shift the position of the media over

the tear bar after printing. Lower numbers move the media into the printer by the specified number

of dots (the tear line moves closer to the edge of the label just printed). Higher numbers move the

media out of the printer (the tear line moves closer to the leading edge of the next label).

8. Examine the quality of the image on the test label. Is the quality of the barcode and text on the test label

acceptable? See Judging Barcode Quality on page 80 for assistance.

• If yes, touch the check mark, and then continue with step 13.

• If no, adjust the print quality manually by changing darkness and speed settings through the printer’s

menu system, or continue with this procedure to run the Print Quality Assistance wizard.

Print Quality Assistance Wizard

9. Touch Print Quality Assistance.

The printer prompts for the number of test labels to print. The more labels you choose to print, the more

choices that you will have available to decide on label quality. In general, if your test label from the

previous wizard was acceptable, a lower number of test labels in this step will probably suffice.

10. Select a number of test labels to print.

The printer prints the specified number of test labels and prompts you for the best test label.

11. Decide which test label is the best quality. See Judging Barcode Quality on page 80 for assistance. If

none of the labels are acceptable, use the arrow to back up a screen in the wizard, and select a larger

number of test labels.

12. In the list on the display, select the identifier for the test label with the best quality, and then touch the

check mark.

The printer changes the darkness and speed to the levels used on the best test label.

13. If necessary, see Printing or Print Quality Issues on page 96 to see what other issues may be affecting

your print quality.

The print setup procedure is complete.

28

Page 29

Printer Configuration and Adjustment

This section assists you with configuration of and adjustments to the print engine.

29

Page 30

Printer Configuration and Adjustment

Changing Printer Settings

You can view or change the printer settings in a number of ways. In this section, the user menus are

shown, and when other options for changing the same setting exist, they are included.

• User menus—See the following sections:

• System Menu on page 31

• Connection Menu on page 38

• Print Menu on page 49

• RFID Menu on page 60

• Storage Menu on page 64

• Control panel key(s)—Some actions can be initiated through control panel key combinations.

• ZPL and Set/Get/Do (SGD) commands—Many parameters can be set through these commands. See

the Zebra Programming Guide for ZPL, ZBI, Set-Get-Do, Mirror, and WML at zebra.com/manuals for

more information.

• Printer web pages—These are available when the printer has an active wired or wireless print server

connection. See the ZebraNet Wired and Wireless Print Servers User Guide at zebra.com/manuals for

more information.

30

Page 31

Printer Configuration and Adjustment

System Menu

System > Language

If necessary, change the language that the printer displays. This change

affects the words shown on the following:

• the Home screen

• the user menus

• error messages

• for some languages, the printer configuration label, the network

configuration label, and other labels that you can select to print

through the user menus

Accepted values:

English

Spanish

French

German

Italian

Norwegian

Portuguese

Swedish

Danish

Dutch

Related ZPL command(s):

SGD command used: display.language

Printer web page:

^KL

Finnish

Japanese

Korean

Simplified Chinese

Traditional Chinese

Russian

Polish

Czech

Romanian

View and Modify Printer Settings > General Setup > Language

31

Page 32

Printer Configuration and Adjustment

System > Program Language > Diagnostic Mode

Enabling this diagnostics tool causes the printer to output the

hexadecimal values for all data received by the printer. The hexadecimal

data is saved or printed based on the selection. For more information,

see Using Communication Diagnostics Mode on page 86.

Accepted values:

• Print

• E: Drive

• USB Host

• Off

System > Program Language > Virtual Device

If any Virtual Device apps are installed on your printer, you may view or

enable/disable them from this user menu. For more information about

Virtual Devices, go to the User Guide for the appropriate Virtual Device,

or contact your local reseller.

32

Page 33

Printer Configuration and Adjustment

System > Program Language > ZBI

Zebra Basic Interpreter (ZBI 2.0™) is a programming option that may be

installed on your printer. If you would like to acquire this option, contact

your Zebra reseller for more information.

If ZBI programs have been downloaded to your printer, you may select

one to run using this menu item. If no program exists on your printer,

NONE is listed.

When ZBI programs have been downloaded but none are running, the

printer lists all available programs. To run one of them, touch Run

(highlighted in white) under the program name.

After a program is running, only that program is listed. Touch Stop

(highlighted in white) to end the program.

SGD command used:

System > Settings > Display Time Format

Select the time format used by the printer.

Accepted values:

• 12-Hour

• 24-Hour

System > Settings > Password Level

Select the level of password protection for user menu items.

Accepted values:

• Selected

• All

• None

zbi.key (identifies if the ZBI 2.0 option is enabled or disabled on the printer)

Related ZPL command(s):

^KP (to change the printer password)

33

Page 34

Printer Configuration and Adjustment

System > Settings > Set Password

Set a new printer password for menu items protected by the previous

parameter. The default printer password is

Accepted values: Numerals 0–9

Related ZPL command(s):

^KP

System > Settings > Power Up Action

Set the action for the printer to take during the power-up sequence.

Accepted values:

• CALIBRATE—Adjusts sensor levels and thresholds, determines

the label length, and feeds the media to the next web.

• FEED—Feeds the labels to the first registration point.

1234.

• LENGTH—Determines the label length using current sensor

values, and feeds the media to the next web.

• NO MOTION—Tells the printer not to move the media. You must

manually ensure that the web is positioned correctly, or press

FEED to position the next web.

• SHORT CAL—Sets the media and web thresholds without adjusting sensor gain, determines the label length, and

feeds the media to the next web.

Related ZPL command(s):

SGD command used:

^MF

ezpl.power_up_action

Printer web page:

View and Modify Printer Settings > Calibration

34

Page 35

Printer Configuration and Adjustment

System > Settings > Head Close Action

Set the action for the printer to take when you close the printhead.

Accepted values:

• CALIBRATE—Adjusts sensor levels and thresholds, determines

the label length, and feeds the media to the next web.

• FEED—Feeds the labels to the first registration point.

• LENGTH—Determines the label length using current sensor

values, and feeds the media to the next web.

• NO MOTION—Tells the printer not to move the media. You must

manually ensure that the web is positioned correctly, or press

FEED to position the next web.

• SHORT CAL—Sets the media and web thresholds without adjusting sensor gain, determines the label length, and

feeds the media to the next web.

Related ZPL command(s):

SGD command used:

^MF

ezpl.head_close_action

Printer web page:

View and Modify Printer Settings > Calibration

System > Settings > Display Orientation

Select the angle at which the control panel displays.

Accepted values:

• 0—Horizontal display (default)

• 90—Vertical display, rotated right

• 180—Horizontal display, upside-down

• 270—Vertical display, rotated left

SGD command used:

display.orientation

System > Settings > Screen Calibration

Touch each crosshair to calibrate the screen.

35

Page 36

Printer Configuration and Adjustment

System > Settings > Restore Defaults

Restore specific printer, print server, and network settings back to the

factory defaults. Use care when loading defaults because you will need

to reload all settings that you changed manually.

Accepted values:

• PRINTER—Restores all printer settings other than the network

settings back to the factory defaults.

• NETWORK—Reinitializes the printer’s wired or wireless print

server. With a wireless print server, the printer also reassociates

with your wireless network.

• LAST SAVED—Loads settings from the last permanent save.

Related ZPL command(s):

• PRINTER—

• NETWORK— ^JUN

• LAST SAVED— ^JUR

Control panel key(s):

• PRINTER—Hold FEED + PAUSE during printer power-up to reset the printer parameters to factory values.

• NETWORK—Hold CANCEL + PAUSE during printer power-up to reset the network parameters to factory values.

• LAST SAVED—N/A

Printer web page:

• PRINTER—View and Modify Printer Settings > Restore Default Configuration

• NETWORK—Print Server Settings > Reset Print Server

• LAST SAVED—View and Modify Printer Settings > Restore Saved Configuration

^JUF

36

Page 37

Printer Configuration and Adjustment

System > Settings > Print: System Settings

Prints a printer configuration label. The following is a sample label.

Related ZPL command(s):

Control panel key(s):

Do one of the following:*

• Hold CANCEL during printer power-up. (Formerly called a CANCEL self-test.)

• Hold FEED + CANCEL for 2 seconds when the printer is in the Ready state.

Printer web page:

View and Modify Printer Settings > Print Listings on Label *

* Prints a printer configuration label and a network configuration label.

~WC

37

Page 38

Printer Configuration and Adjustment

System > Energy Saving > Energy Star

When Energy Star mode is enabled, the printer goes into a “sleep” mode

after a timeout period, thereby lowering power consumption. Press any

button on the control panel to bring the printer back to an active state.

Accepted values:

• ON

• OFF

SGD command used:

•

power.energy_star.enable

•

power.energy_star_timeout

(to set the amount of idle time before Energy Star is invoked)

Connection Menu

Connection > Networks > Reset Network

IMPORTANT: You must reset the print server to allow changes to the network settings to take effect.

This option resets the wired or wireless print server and saves any

changes that you made to any network settings.

Related ZPL command(s):

SGD command used:

Printer web page:

Print Server Settings > Reset Print Server

Connection > Networks > Primary Network

View or modify whether the wired or wireless print server is considered

primary. You may select which one is primary.

Accepted values:

• Wired

• Wi-Fi

Related ZPL command(s):

SGD command used:

~WR

device.reset

^NC

ip.primary_network

38

Page 39

Printer Configuration and Adjustment

Connection > Networks > IP Port

This printer setting refers to the internal wired print servers port number

that the TCP print service is listening on. Normal TCP communications

from the host should be directed to this port.

SGD command used:

•

internal_wired.ip.port

•

wlan.ip.port

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > TCP/IP Settings

Connection > Networks > IP Alternate Port

NOTE: Print servers supporting this command monitor both the primary port and the alternate port for connections

at the same time.

This command sets the port number of the alternate TCP port.

SGD command used:

•

internal_wired.ip.port_alternate

•

wlan.ip.port_alternate

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > TCP/IP Settings

39

Page 40

Printer Configuration and Adjustment

Connection > Networks > Print: Network Info

Prints the settings for any print server or Bluetooth device that is

installed. The following is a sample label.

Related ZPL command(s):

Control panel key(s):

Do one of the following:*

• Hold CANCEL during printer power-up. (Formerly called a CANCEL self-test.)

• Hold FEED + CANCEL for 2 seconds when the printer is in the Ready state.

Printer web page:

View and Modify Printer Settings > Print Listings on Label *

* Prints a printer configuration label and a network configuration label.

~WL

40

Page 41

Printer Configuration and Adjustment

Connection > Networks > Visibility Agent

When the printer is connected to a wired or wireless network, it attempts

to connect to Zebra’s Asset Visibility Service via the Cloud-based Zebra

Printer Connector using an encrypted, certificate-authenticated web

socket connection. The printer sends Discovery Data and Settings and

Alerts Data. Data printed via any label formats is NOT transmitted.

To opt out of this feature, disable this setting. For more information, see

the “Opting Out of the Asset Visibility Agent” application note at

zebra.com.

Accepted values:

• On

• Off

SGD command used:

weblink.zebra_connector.enable

Printer web page:

View and Modify Printer Settings > Network Configuration > Cloud Connect Settings

Connection > Wired > Wired IP Protocol

IMPORTANT: You must reset the print server to allow changes to the network settings to take effect. See

Connection > Networks > Reset Network on page 38.

This parameter indicates if the user (permanent) or the server (dynamic)

selects the wired print server’s IP address. When a dynamic option is

chosen, this parameter tells the method(s) by which this print server

receives the IP address from the server.

Accepted values:

• ALL

• GLEANING ONLY

• RARP

• BOOTP

• DHCP

• DHCP & BOOTP

• PERMANENT

Related ZPL command(s):

SGD command used:

^ND

internal_wired.ip.protocol

Printer web page:

View and Modify Printer Settings > Network Communications Setup > TCP/IP Settings

41

Page 42

Printer Configuration and Adjustment

Connection > Wired > Wired IP Address

NOTE: To save changes to this setting, set Connection > Wired > Wired IP Protocol on page 41 to PERMANENT,

and then reset the print server (see Connection > Networks > Reset Network on page 38).

View and, if necessary, change the printer’s wired IP address.

Accepted values: 000 to 255 for each field

Related ZPL command(s):

^ND

SGD command used:

internal_wired.ip.addr

Printer web page:

View and Modify Printer Settings > Network Communications Setup

> TCP/IP Settings

Connection > Wired > Wired Subnet

NOTE: To save changes to this setting, set Connection > Wired > Wired IP Protocol on page 41 to PERMANENT,

and then reset the print server (see Connection > Networks > Reset Network on page 38).

View and, if necessary, change the wired subnet mask.

Accepted values: 000 to 255 for each field

Related ZPL command(s):

SGD command used:

^ND

internal_wired.ip.netmask

Printer web page:

View and Modify Printer Settings > Network Communications Setup

> TCP/IP Settings

Connection > Wired > Wired Gateway

NOTE: To save changes to this setting, set Connection > Wired > Wired IP Protocol on page 41 to PERMANENT,

and then reset the print server (see Connection > Networks > Reset Network on page 38).

View and, if necessary, change the default wired gateway.

Accepted values: 000 to 255 for each field

Related ZPL command(s):

SGD command used:

^ND

internal_wired.ip.gateway

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > TCP/IP Settings

42

Page 43

Printer Configuration and Adjustment

Connection > Wired > Wired Mac Address

View the Media Access Control (MAC) address of the wired print server.

This value cannot be modified.

SGD command used:

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > TCP/IP Settings

Connection > Wi-Fi > Wi-Fi IP Protocol

IMPORTANT: You must reset the print server to allow changes to the network settings to take effect. See

Connection > Networks > Reset Network on page 38.

This parameter indicates if the user (permanent) or the server (dynamic)

selects the wireless print server’s IP address. When a dynamic option is

chosen, this parameter tells the method(s) by which this print server

receives the IP address from the server.

Accepted values:

internal_wired.mac_addr

• ALL

• GLEANING ONLY

• RARP

• BOOTP

• DHCP

• DHCP & BOOTP

• PERMANENT

Related ZPL command(s):

SGD command used:

^ND

wlan.ip.protocol

Printer web page:

View and Modify Printer Settings > Network Communications Setup > Wireless Setup

43

Page 44

Printer Configuration and Adjustment

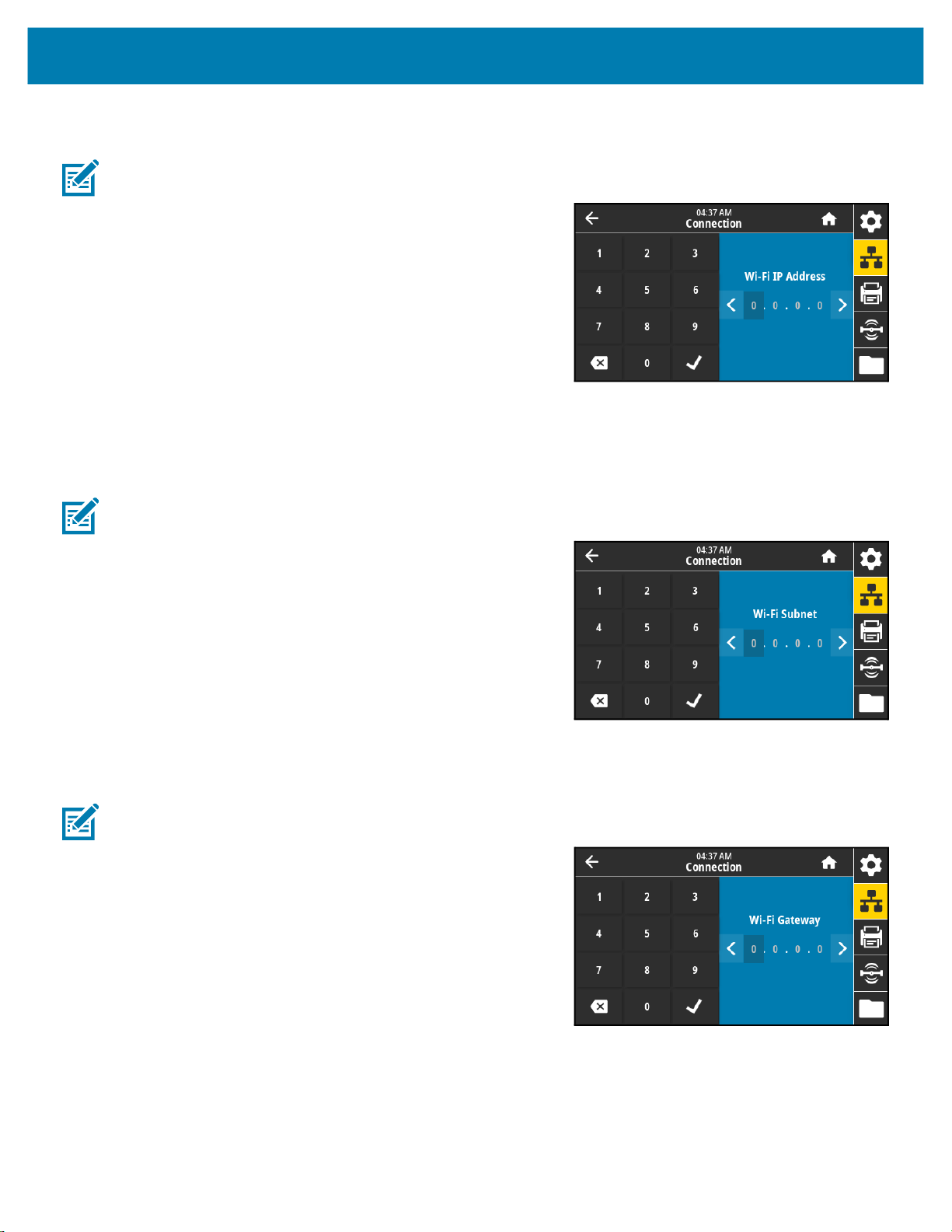

Connection > Wi-Fi > Wi-Fi IP Address

NOTE: To save changes to this setting, set Connection > Wired > Wired IP Protocol on page 41 to PERMANENT,

and then reset the print server (see Connection > Networks > Reset Network on page 38).

View and, if necessary, change the printer’s wireless IP address.

Accepted values: 000 to 255 for each field

Related ZPL command(s):

SGD command used:

•

ip.addr

•

wlan.ip.addr

Printer web page:

View and Modify Printer Settings > Network Communications Setup > Wireless Setup

Connection > Wi-Fi > Wi-Fi Subnet

NOTE: To save changes to this setting, set Connection > Wired > Wired IP Protocol on page 41 to PERMANENT,

and then reset the print server (see Connection > Networks > Reset Network on page 38).

^ND

View and, if necessary, change the wireless subnet mask.

Accepted values: 000 to 255 for each field

Related ZPL command(s):

SGD command used:

^ND

wlan.ip.netmask

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > Wireless Setup

Connection > Wi-Fi > Wi-Fi Gateway

NOTE: To save changes to this setting, set Connection > Wired > Wired IP Protocol on page 41 to PERMANENT,

and then reset the print server (see Connection > Networks > Reset Network on page 38).

View and, if necessary, change the default wireless gateway.

Accepted values: 000 to 255 for each field

Related ZPL command(s):

SGD command used:

^ND

wlan.ip.gateway

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > Wireless Setup

44

Page 45

Printer Configuration and Adjustment

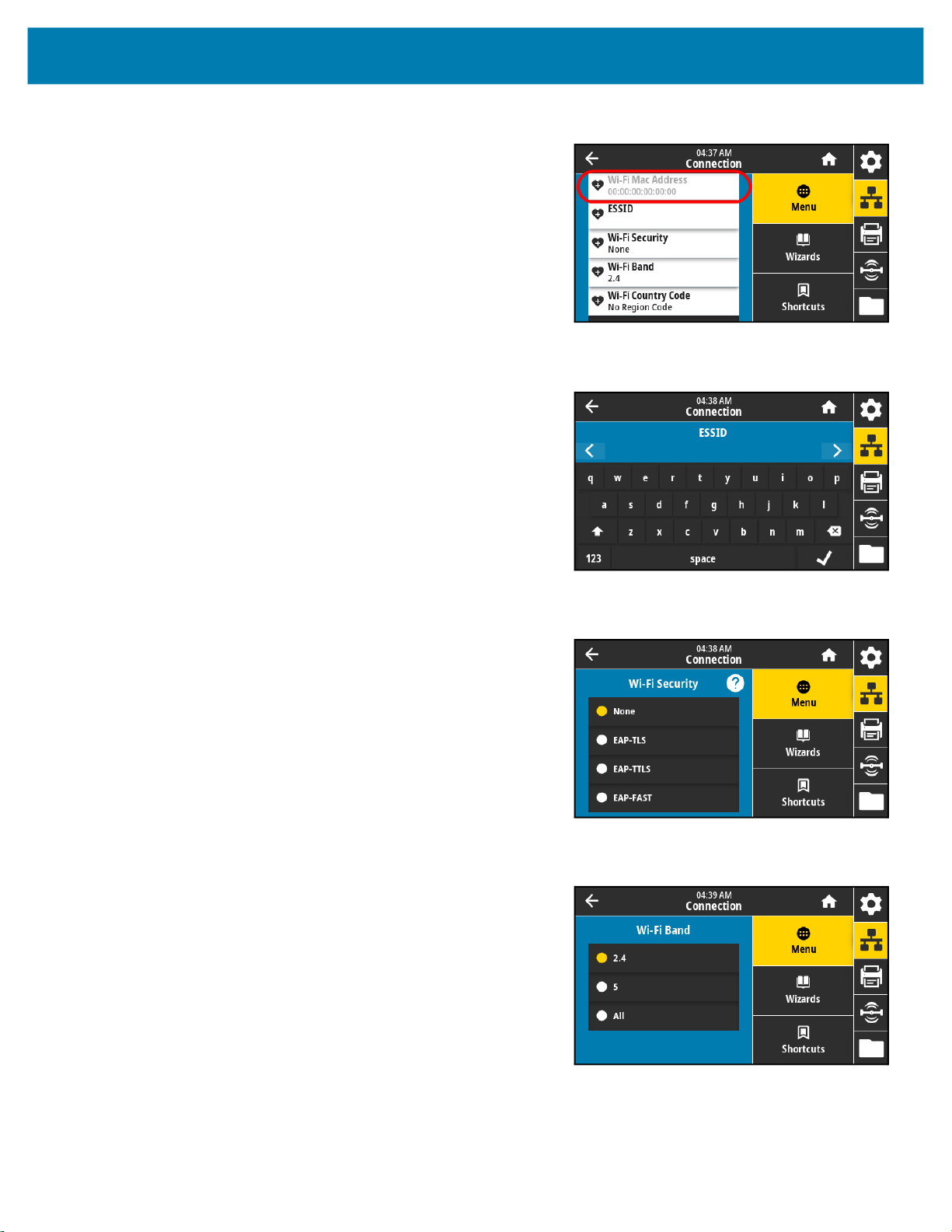

Connection > Wi-Fi > Wi-Fi Mac Address

View the Media Access Control (MAC) address of the wireless print

server. This value cannot be modified.

SGD command used:

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > Wireless Setup

Connection > Wi-Fi > ESSID

The Extended Service Set Identification (ESSID) is an identifier for your

wireless network. Specify the ESSID for the current wireless

configuration.

Accepted values: 32-character alphanumeric string (default 125)

SGD command used:

wlan.mac_addr

wlan.essid

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > Wireless Setup

Connection > Wi-Fi > Wi-Fi Security

Select the security type being used on your wireless network.

Related ZPL command(s):

SGD command used:

^WX

wlan.security

Printer web page:

View and Modify Printer Settings >

Network Communications Setup > Wireless Encryption Setup

Connection > Wi-Fi > Wi-Fi Band

Set a preferred band to connect with via Wi-Fi.

Accepted values:

• 2.4

• 5

• All

SGD command used:

wlan.band_preference

Printer web page:

View and Modify Printer Settings > Network Communications Setup > Wireless Setup

45

Page 46

Printer Configuration and Adjustment

Connection > Wi-Fi > Wi-Fi Country Code

IMPORTANT: The list of country codes is specific to each printer and depends on the printer model and its

wireless radio configuration. The list is subject to change, addition, or deletion with any firmware update, at any

time, without notice.

The country code defines the regulatory country for which the wireless

radio is currently configured.

To determine the country codes available on your printer, issue the

! U1 getvar "wlan" command to return all commands related to Wi-Fi

settings. Locate the

view the country codes available for your printer.

SGD command used:

Connection > Bluetooth > Bluetooth

Select if Bluetooth is enabled.

Accepted values:

wlan.country.code command in the results and

wlan.country_code

• On—Enables the Bluetooth radio.

• Off—Disables the Bluetooth radio.

SGD command used:

bluetooth.enable

Connection > Bluetooth > Bluetooth Discovery

Select if the printer is “Discoverable” for Bluetooth device pairing.

Accepted values:

• On—Enables Bluetooth discoverable mode.

• Off—Disables Bluetooth discoverable mode.

SGD command used:

bluetooth.discoverable

46

Page 47

Printer Configuration and Adjustment

Connection > Bluetooth > Friendly Name

This command sets the friendly name, which is used during service

discovery. For changes to take effect, you must power cycle the printer

or issue the

Reset Network on page 38).

If you do not set a friendly name, this setting defaults to the printer serial

number.

Accepted values: 17-character text string

SGD command used:

Connection > Bluetooth > Minimum Security Mode

This printer setting defines the minimum level of security that the printer

requires for a Bluetooth connection. Connections attempting to use a

lower level are refused.

Accepted values: 1–4

SGD command used:

device.reset command (see Connection > Networks >

bluetooth.friendly_name

bluetooth.minimum_security_mode

Connection > Bluetooth > Specification Version

This parameter displays the Bluetooth library version number.

SGD command used:

bluetooth.version

Connection > Bluetooth > MAC Address

This parameter displays the Bluetooth device address.

SGD command used:

bluetooth.address

47

Page 48

Printer Configuration and Adjustment

Connection > Bluetooth > Bluetooth Auth. PIN

Set the PIN used when Bluetooth authentication is enabled (Bluetooth

2.0 and earlier).

SGD command used:

•

bluetooth.bluetooth_pin (to set the PIN)

•

bluetooth.authentication (to enable authentication)

Connection > Bluetooth > Bluetooth Bonding

Select if the printer should retain details from previously completed

Bluetooth pairings.

Accepted values:

• On—Enables Bluetooth bonding so that the information is

retained.

• Off—Disables Bluetooth bonding.

SGD command used:

bluetooth.bonding

48

Page 49

Printer Configuration and Adjustment

Print Menu

Print > Print Quality > Darkness

Set the print darkness to the lowest setting that provides good print

quality. If you set the darkness too high, the label image may print

unclearly, barcodes may not scan correctly, the ribbon may burn

through, or the printhead may wear prematurely.

Accepted values: 0.0 to 30.0

Related ZPL command(s):

•

^MD

•

~SD

SGD command used:

Printer web page:

View and Modify Printer Settings > General Setup > Darkness

Print > Print Quality > Print Speed

Select the speed, in inches per second (ips), for printing a label. Slower

print speeds typically yield better print quality.

Accepted values:

• ZE511 203 dpi = 2 to 18

• ZE511 300 dpi = 2 to 14

• ZE511 600 dpi = 2 to 6

• ZE521 203 dpi = 2 to 14

• ZE521 300 dpi = 2 to 12

Related ZPL command(s):

SGD command used:

Printer web page:

View and Modify Printer Settings > General Setup > Print Speed

print.tone

^PR

media.speed

49

Page 50

Printer Configuration and Adjustment

Print > Print Quality > Print Type

Specify if the printer needs to use ribbon for printing. If you need

assistance, see Do I need to use ribbon? on page 13.

Accepted values:

• Thermal Transfer—Uses ribbon and thermal transfer media.

• Direct Thermal—Uses direct thermal media and no ribbon.

Related ZPL command(s):

SGD command used:

^MT

ezpl.print_method

Printer web page:

View and Modify Printer Settings > Media Setup > Print Method

Print > Print Quality > Ribbon Ink Side

Select whether your ribbon is coated on the inside or the outside. To

determine which side of the ribbon is coated, see How can I tell which

side of the ribbon is coated? on page 13.

Accepted values:

• Ink Side Out

• Ink Side In

SGD command used:

ribbon.coating

50

Page 51

Printer Configuration and Adjustment

Print > Print Quality > Ribbon Tension

Select the ribbon tension setting that is appropriate for the width or type

of media being printed. High can be used for most media. The correct

setting is determined by a combination of the ribbon width and the

ribbon length. If necessary, use a lower value for narrow media or for

glossy media.

Ribbon Width

76 to 127 mm

(3 to 5 in.)

102 to 152 mm

(4 to 6 in.)

127 to 180 mm

(5 to 7.1 in.)

Accepted values:

• Low

• Medium

• High

Related ZPL command(s):

300 Meters 450 Meters 600 Meters

Low Low Low

Low Low or Medium Low or Medium

Low or Medium Medium Medium

Ribbon Length

or High

^JW

51

Page 52

Printer Configuration and Adjustment

Print > Print Quality > Media Type

Select the type of media that you are using.

Accepted values:

• Continuous—With continuous media, you must include a label length

in your label format (

• Gap/Notch—With gap/notch media, you may need to adjust the

position of the transmissive media sensor, which finds “start of label”

indicators, such as notches or holes in the media or interlabel gaps.

On the pinch roller assembly (1), slide the sensor position indicator

(2) to move the sensor.

1

2

^LL if you are using ZPL).

• If the media uses interlabel gaps, position the sensor approximately at the center of the media width.

• If the media has notches or holes between labels, align the sensor with the notch or hole in the media.

• Mark—Some types of media have black marks printed on the underside of the media liner, which act as “start of label”

indicators. The reflective media sensor senses these black marks. The position of this sensor is not adjustable. If you

use this type of media, refer to Media Specifications on page 128 for information about black mark requirements.

Related ZPL command(s):

SGD command used:

^MN

ezpl.media_type

Printer web page:

View and Modify Printer Settings > Media Setup > Media Type

52

Page 53

Printer Configuration and Adjustment

Print > Print Quality > Label Length (Dots)

For continuous media, specify the length of the labels being used, in

dots. For non-continuous media, this value is determined during media

calibration and cannot be modified.

Accepted values: 1 to 32000, (in dots) not to exceed the maximum label

length

Related ZPL command(s):

^LL

SGD command used:

zpl.label_length

Print > Print Quality > Label Width (Dots)

NOTE: Setting the width too narrow can result in portions of a label format not being printed on the media. Setting

the width too wide wastes formatting memory and can cause the printer to print off of the label and onto the platen

roller. This setting can affect the horizontal position of the label format if the image was inverted using the

ZPL II command.

Specify the width of the labels being used, in dots. The default value is

the maximum width for the printer, based on the printhead dpi (dots per

inch) value.

Accepted values:

• ZE511 203 dpi = 0002 to 832

• ZE511 300 dpi = 0002 to 1228

• ZE511 600 dpi = 0002 to 2456

• ZE521 203 dpi = 0002 to 1344

• ZE521 300 dpi = 0002 to 1984

Related ZPL command(s):

^PW

^POI

SGD command used:

ezpl.print_width

Printer web page:

View and Modify Printer Settings > Media Setup > Print Width

53

Page 54

Printer Configuration and Adjustment

Print > Image Adjust > Media Handling

Select a media handling method that is compatible with the options

available on your printer. See the Zebra Programming Guide at

zebra.com/manuals for more information.

Accepted values:

Tear Off, Peel Off, Rewind, Cutter, Delayed Cut, Linerless Peel,

Linerless Rewind, Linerless Tear, Applicator, Linerless Cut, Linerless

Delayed Cut, Stream

Related ZPL command(s):

SGD command used:

^MM

ezpl.print_mode

Printer web page:

View and Modify Printer Settings > General Setup > Print Mode

Print > Image Adjust > Tear Line Offset

If necessary, shift the position of the media over the tear-off bar after

printing.

• Lower numbers move the media into the printer by the specified

number of dots (the tear line moves closer to the edge of the label

just printed).

• Higher numbers move the media out of the printer (the tear line

moves closer to the leading edge of the next label).

Accepted values: –120 to +120

Related ZPL command(s):

~TA

SGD command used: ezpl.tear_off

Printer web page:

View and Modify Printer Settings > General Setup > Tear Off

54

Page 55

Printer Configuration and Adjustment

Print > Image Adjust > Horizontal Label Offset

If necessary, shift the position of the image horizontally on the label.

• Negative numbers move the left edge of the image toward the left

edge of the label by the number of dots selected.

• Positive numbers move the edge of the image toward the right edge

of the label.

Accepted values: –9999 to 9999

Related ZPL command(s):

^LS

SGD command used:

zpl.left_position

Printer web page:

View and Modify Printer Settings > Advanced Setup > Left Position

Print > Image Adjust > Vertical Label Offset

If necessary, shift the position of the image vertically on the label.

• Lower numbers move the image higher on the label (toward the

printhead).

• Higher numbers move the image farther down on the label (away

from the printhead) by the specified number of dots.

Accepted values: –120 to +120

Related ZPL command(s):

^LT

Printer web page:

View and Modify Printer Settings > General Setup > Label Top

55

Page 56

Printer Configuration and Adjustment

Print > Image Adjust > Invert Label

When this option is enabled, the image prints inverted on the media.

Accepted values:

• On

• Off

SGD command used: print.invert_label

Print > Sensors > Calibrate

This option adjusts sensor levels and thresholds, determines the label

length, and feeds the media to the next web. This option is disabled

when Media Type is set to Continuous and Head Close Action is set to

Calibrate.

Printer web page: Calibration cannot be initiated through the web pages.

See the following web page for settings that are set during sensor

calibration:

View and Modify Printer Settings > Calibration

Print > Sensors > Manual Calibration

This option adjusts the sensitivity of the media and ribbon sensors,

adjusts sensor levels and thresholds, determines the label length, and

feeds the media to the next web.

Related ZPL command(s):

SGD command used:

Control panel key(s):

Hold PAUSE + FEED + CANCEL for 2 seconds to initiate calibration.

Printer web page: Calibration cannot be initiated through the web pages.

See the following web page for settings that are set during sensor calibration:

View and Modify Printer Settings > Calibration

~JC

ezpl.manual_calibration

56

Page 57

Printer Configuration and Adjustment

Print > Sensors > Label Sensor

IMPORTANT: This value is set during sensor calibration. Do not change these settings unless you are told to do

so by Zebra Technical Support or by an authorized service technician.

Set the sensitivity of the label sensor.

Accepted values: 0 to 255

SGD command used:

Printer web page:

View and Modify Printer Settings > Calibration

Print > Sensors > Sensor Type

Select the media sensor that is appropriate for the media that you are

using. The reflective sensor typically is used only for black mark media.

The transmissive sensor typically is used for other media types.

Accepted values:

ezpl.label_sensor

• Transmissive

• Reflective

Related ZPL command(s):

SGD command used:

^JS

device.sensor_select

Printer web page:

View and Modify Printer Settings > Media Setup

Print > Sensors > Print: Sensor Profile

Shows the sensor settings compared to actual sensor readings. To

interpret the results, see Printing and Interpreting a Sensor Profile on

page 84.

Related ZPL command(s):

~JG

Control panel key(s):

Hold FEED + CANCEL during printer power-up.

Printer web page:

View and Modify Printer Settings > Print Listings on Label

57

Page 58

Printer Configuration and Adjustment

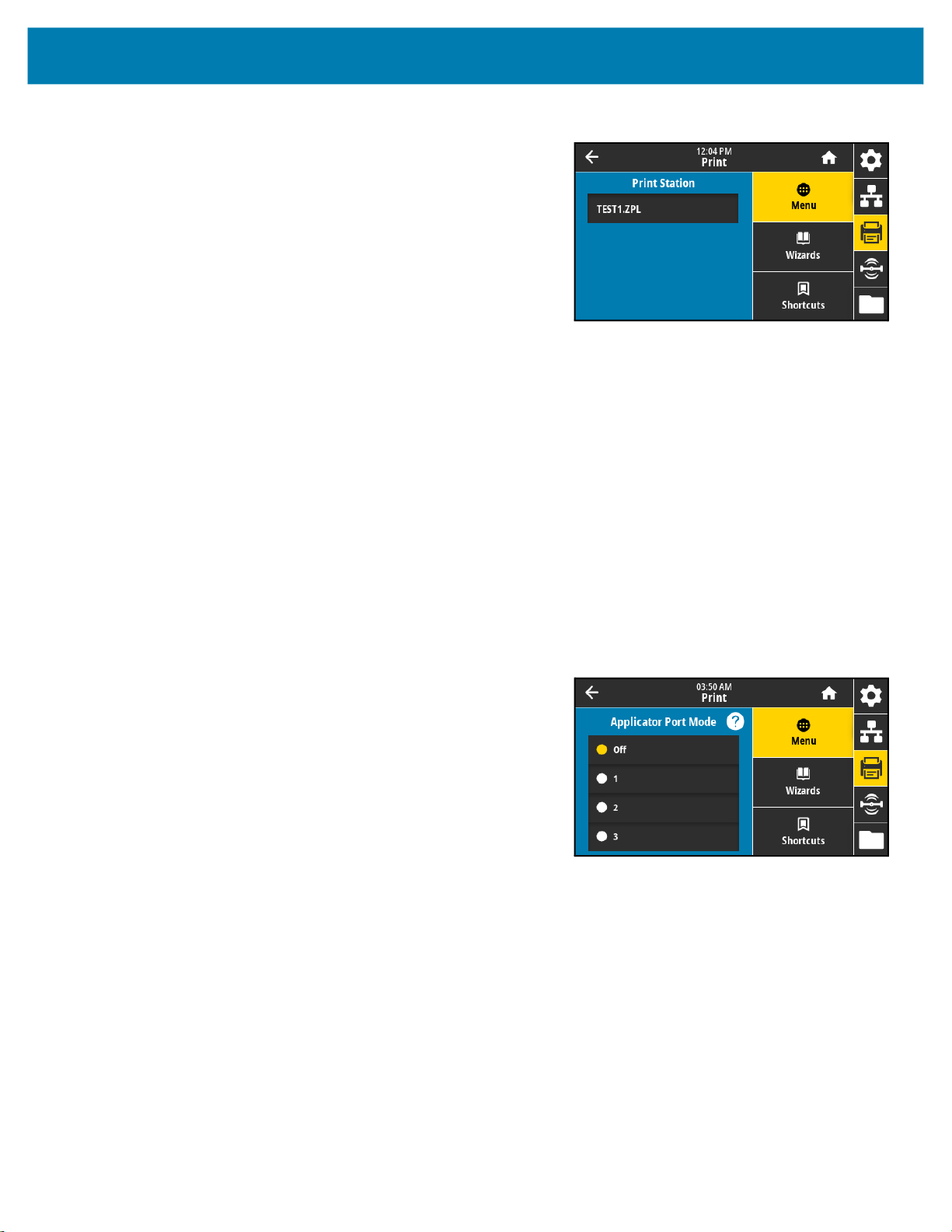

Print > Print Station

Use this menu item to fill in variable fields in a label format and print the

label using a Human Input Device (HID), such as a USB keyboard,

scale, or barcode scanner. A suitable label format must be stored on the

E: drive of the printer to use this option. See the exercises in Using USB

Host Ports and Print Touch/NFC on page 109 for an exercise using this

capability.

When you plug an HID into one of the printer’s USB host ports, use this

user menu to select a form on the printer’s E: drive. After you have been

prompted to fill in each variable

the desired quantity of labels to print.

For more information about using the

Programming Guide at zebra.com/manuals.

* This menu item can be used only if a USB device is connected to a USB host port on the printer.

SGD command used:

•

usb.host.keyboard_input (must be set to ON)

•

usb.host.template_list

field on the form, you can specify

^FN

^FN command or the SGD commands related to this feature, see the Zebra

•

usb.host.fn_field_list

•

usb.host.fn_field_data

•

usb.host.fn_last_field

•

usb.host.template_print_amount

Print > Applicator > Applicator Port Mode

Controls the way in which the applicator port’s “End Print” signal

functions.

Accepted values:

• Off

• 1 = End Print signal normally high, and low only when the printer

is moving the label forward.

• 2 = End Print signal normally low, and high only when the printer

is moving the label forward.

• 3 = End Print signal normally high, and low for 20 ms when a label

has been printed and positioned.

• 4 = End Print signal normally low, and high for 20 ms when a label has been printed and positioned.

Related ZPL command(s):

^JJ

SGD command used:

device.applicator.end_print

58

Page 59

Printer Configuration and Adjustment

Print > Applicator > Start Print Mode

Determines if the applicator port’s “Start Print” signal is in level mode or

pulse mode.

Accepted values:

• Pulse Mode—Start Print signal must be deasserted before it can

be asserted for the next label.

• Level Mode—Start Print signal does not need to be deasserted to

print the next label. As long as the Start Print signal is low and a

label is formatted, a label prints.

Related ZPL command(s):

SGD command used:

^JJ

device.applicator.start_print

Print > Applicator > Error on Pause

Determines how applicator port errors are treated by the printer.

Enabling this feature also causes the “Service Required” pin to be

asserted.

Accepted values:

• Enabled

• Disabled

SGD command used:

device.applicator.error_on_pause

Printer web page:

View and Modify Printer Settings > Advanced Setup > Error on Pause

Print > Applicator > Applicator Reprint

Specifies if a high or low value is required for an applicator to reprint a

label.

Enables or disables the

~PR command, which when enabled reprints the

last printed label. It also enables the Reprint button on the Home screen.

Related ZPL command(s):

•

^JJ

•

~PR

SGD command used:

device.applicator.reprint

59

Page 60

Printer Configuration and Adjustment

RFID Menu

RFID > RFID Status

Display the status of the RFID subsystem of the printer.

Related ZPL command(s):

SGD command used: rfid.error.response

RFID > RFID Test

During the RFID test, the printer attempts to read and write to a

transponder. No printer movement occurs with this test.

1. Position the RFID label with its transponder over the RFID antenna

array.

^HL or ~HL

2. Touch Start.

The results of the test are shown below the Start button.

SGD command used:

rfid.tag.test.execute

RFID > RFID Calibrate

NOTE: Before running this command, load the printer with RFID media, calibrate your printer, close the printhead,

and feed at least one label to make sure that tag calibration begins from the correct position.

Leave all transponders before and after the tag that is being calibrated. This allows the printer to determine RFID

settings which do not encode the adjacent tag. Allow a portion of media to extend out the front of the printer to

allow for backfeed during the tag calibration procedure.

Initiate tag calibration for RFID media. (Not the same as media and

ribbon calibration.) During the process, the printer moves the media,

calibrates the RFID tag position, and determines the optimal settings for

the RFID media being used. These settings include the programming

position, the antenna element to use, and the read/write power level to

use. See the RFID Programming Guide 3 for more information.

Related ZPL command(s):

SGD command used:

rfid.tag.test.content and

^HR

rfid.tag.calibrate

60

Page 61

Printer Configuration and Adjustment

RFID > Read Power

If the desired read power is not achieved through RFID tag calibration, a

value may be specified.

Accepted values: 0 to 30

Related ZPL command(s):

^RW

SGD command used:

rfid.reader_1.power.read

Printer web page:

View and Modify Printer Settings > RFID Setup > RFID READ PWR

RFID > Write Power

If the desired write power is not achieved through RFID tag calibration, a

value may be specified.

Accepted values: 0 to 30

Related ZPL command(s):

SGD command used:

^RW

rfid.reader_1.power.write

Printer web page:

View and Modify Printer Settings > RFID Setup > RFID WRITE PWR

RFID > RFID Antenna

If the desired antenna is not achieved through RFID tag calibration, a

value may be specified.

Accepted values:

A1, A2, A3, A4, A5, A6, A7

B1, B2, B3, B4, B5, B6, B7

Related ZPL command(s):

SGD command used:

^RW

rfid.reader_1.antenna_port

Printer web page:

View and Modify Printer Settings > RFID Setup > RFID ANTENNA

61

Page 62

Printer Configuration and Adjustment

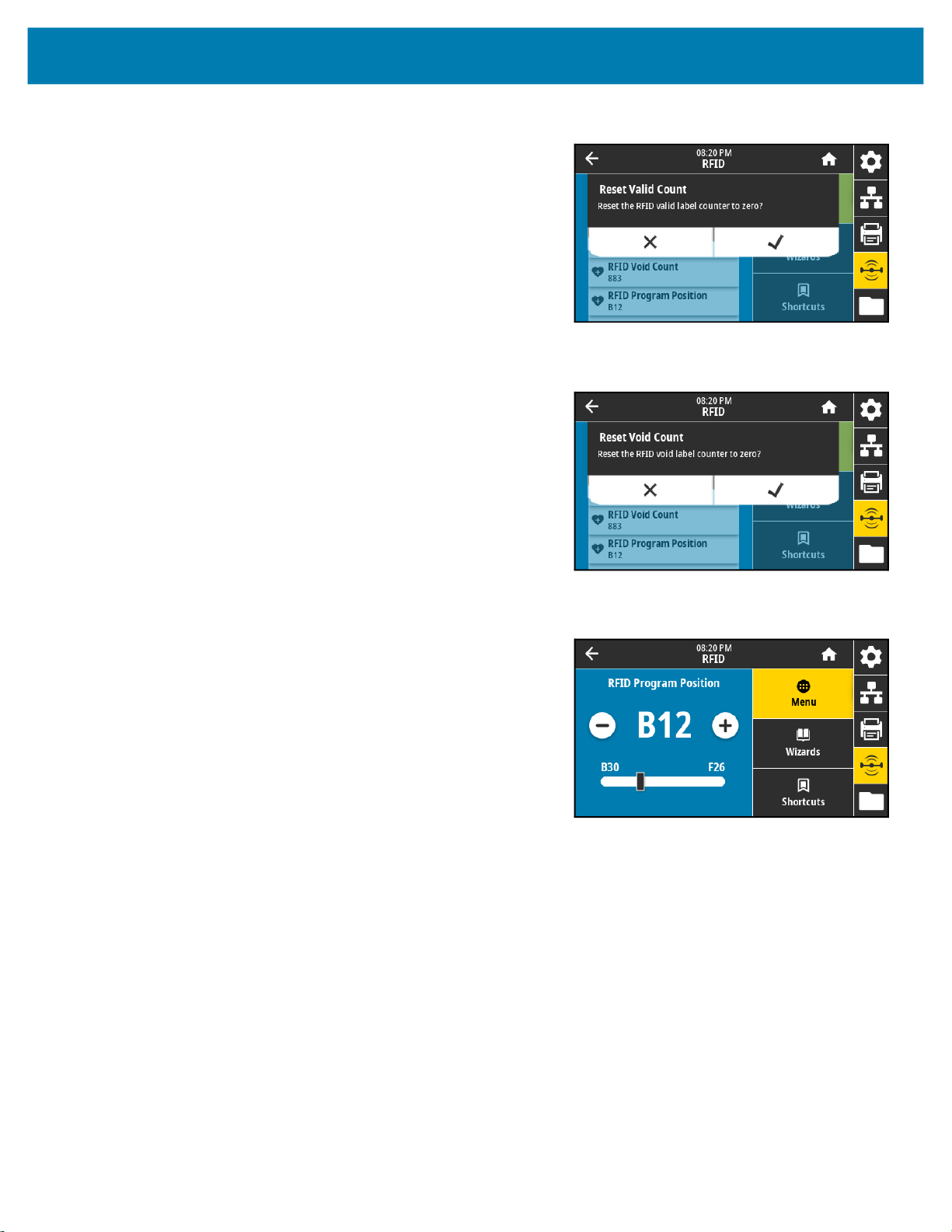

RFID > RFID Valid Count

Resets the RFID valid label counter to zero.

Related ZPL command(s):

SGD command used:

odometer.rfid.valid_resettable

RFID > RFID Void Count

Resets the RFID void label counter to zero.

Related ZPL command(s):

SGD command used:

odometer.rfid.void_resettable

~RO

~RO

RFID > RFID Program Position

If the desired programming position (read/write position) is not achieved

through RFID tag calibration, a value may be specified.

Accepted values:

• F0 to Fxxx (where xxx is the label length in millimeters or 999,

whichever is less)—The printer feeds the label forward for the

specified distance and then begins programming.

• B0 to B30—The printer backfeeds the label for the specified

distance and then begins programming. To account for the

backfeed, allow empty media liner to extend out of the front of the

printer when using a backward programming position.

Related ZPL command(s):

SGD command used:

^RS

rfid.position.program

Printer web page:

View and Modify Printer Settings > RFID Setup > PROGRAM POSITION

62

Page 63

Printer Configuration and Adjustment

RFID > Read RFID Data

Read and return the specified tag data from the RFID tag located over

the RFID antenna. No printer movement occurs while tag data is being

read. The printhead can be open or closed.

1. Position the RFID label with its transponder over the RFID antenna.

2. Touch Read RFID Data.

The results of the test are shown on the display.

Related ZPL command(s):

^RF

SGD command used:

•

rfid.tag.read.content

•

rfid.tag.read.execute

RFID > RFID Country Code

sets the RFID reader country code. The country code is restricted based

on the region code assigned to the reader and, in some instances,

cannot be modified. Only the countries available for your region are

listed.

SGD command used:

rfid.country_code

63

Page 64

Printer Configuration and Adjustment

Storage Menu

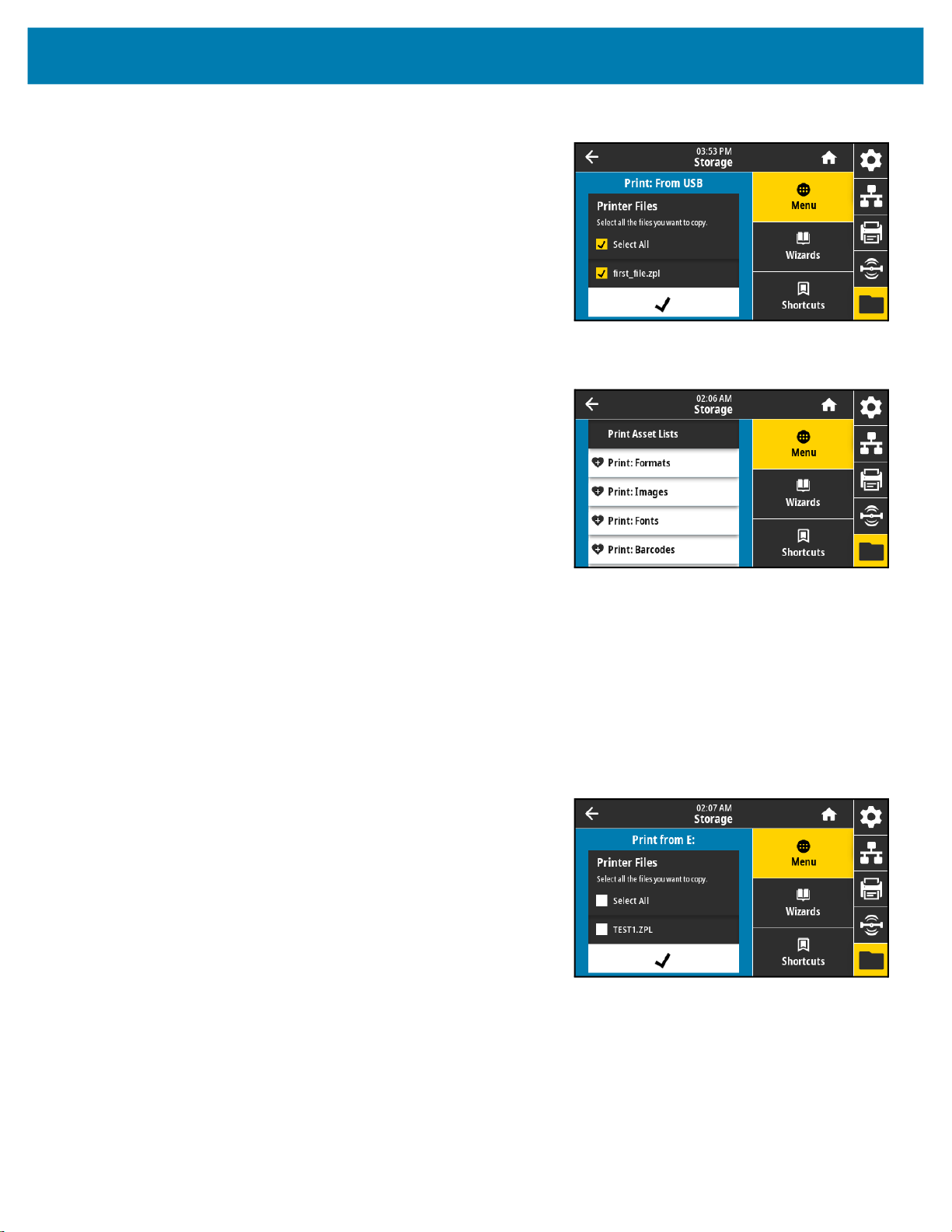

Storage > USB > Copy: Files to USB

Select files from the printer to store on a USB Flash drive.

1. Insert a USB flash drive into the printer’s USB host port.

The printer lists available files.

2. Touch the box next to the desired files. Select All is also available.

3. Touch the check mark to copy the selected files.

SGD command used:

Storage > USB > Copy: Files to Printer

Select files to copy to the printer from a USB Flash drive.

1. Insert a USB flash drive into the printer’s USB host port.

The printer lists available files.

2. Touch the box next to the desired files. Select All is also available.

3. Touch the check mark to copy the selected files.

SGD command used:

Storage > USB > Copy: Configuration to USB

Use this function to copy the printer’s configuration information to a USB