Zebra® KR203

Kiosk Receipt Printer

Windows® CE

Software Integrator

P1028251-001 Rev. A

Guide

© 2011 ZIH Corp. The copyrights in this manua l and th e so f tware and/or firm ware in the

printer described therein are owned by ZIH Corp. Unauthorized reproduction of this

manual or the software and/or firmware in the printer may result in imprisonment of up to

one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject to

civil liability.

®

This product may contain ZPL

Equalizer

®

Circuit; E3®; and Monotype Imaging fonts. Software © ZIH Corp. All rights

, ZPL II®, and ZebraLink™ programs; Element Energy

reserved worldwide.

ZebraLink and all product names and numbers are trademarks, an d Zebra, the Zebra

logo, ZPL, ZPL II, Element Energy Equalizer Circuit, and E

3

Circuit are registered

trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders.

Proprietary Statement This man ual contains proprietary information of Zebra

Technologies Corporation and it s subsid iaries (“Zeb ra Technologies”). It is intended solely

for the information and use of parties operating and ma in taining the eq uipm en t de scr ibe d

herein. Such proprietary information may not be used, reproduced, or disclosed to any

other parties for any other purpose without the express, written pe rmission of Zebra

Technologies.

Product Improvements Continuous improvement of products is a policy of Zebra

Technologies. All specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies takes steps to ensure that its published

Engineering specifications and manuals are correct; however, errors do occur. Zebra

Technologies reserves the right to correct any such errors and disclaims liability resulting

therefrom.

Limitation of Liability In no event shall Zebra Technologies or anyone else involved in

the creation, production, or delivery of the accompanying produ ct (including hardwar e and

software) be liable for any damages whatsoever (including, without limitation,

consequential damages including loss of business profits, business interruption, or loss of

business information) arising out of the use of, the results of use of, or inability to use such

product, even if Zebra Technologies has been advised of the possibility of such damages.

Some jurisdictions do not allow the exclusion or limitation of incidental or conseque ntial

damages, so the above limitation or exclusion may not apply to you.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Who Should Use This Document. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How This Document Is Organized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Windows CE Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Windows CE Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Printer Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Port Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Print Spooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Status Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GetPrinterStatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Panel Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

KR203CPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Printer and Driver Parameter Setting and Maintenance . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Driver Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Update Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

UI Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Command Line Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Device Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Media Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Media Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Darkness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Max Print Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Media Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Top Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8/6/2010 KR203 Software Integrator Guide P1028248-001 Rev. A

ii

Contents

Bottom Margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cutter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Partial Cut Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Presenter Loop Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Eject Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Present Length Addition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Presenter Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clear Presenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

About. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting Black Mark Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Light Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Application LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Application User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Print Quality Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Media Sensing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Other Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Resetting the Factory Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Contact Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

KR203 Status codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Monitoring While Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Monitoring While Idle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

P1028248-001 Rev. A KR203 Software Integrator Guide 8/6/2010

Who Should Use This Document

This guide is intended for use by any person who need s to setup the KR203 printer for use

with a Windows CE device.

1

Introduction

How This Document Is Organized

The manual is set up as follows:

Introduction

Windows CE Driver Installation, updates, preferences, and properties.

Troubleshooting

Appendix A KR203 status codes.

Appendix B Programming samples

This manual will be updated from time to time as printer functions and features may be

added or amended. You will always find the latest edition on our web site (http://

www.zebra.com). If you require information for functions not found in this manual edition,

please contact Technical Support for your region or the Zebra partner the printer was

purchased from.

Contact information, document conventions.

Sta tu s light description, user interf ace, error handling,

and fixes to common printing problems.

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Introduction

2

Contacts

Contacts

Technical Support via the Internet is available 24 hours per day, 365 days per year.

Web Site: www.zebra.com

E-mail Back Technical Library:

• E-mail address: emb@zebra.com

• Subject line: Emaillist

Self Service Knowledge Base: www.zebra.com/knowledgebase

Online Case Registration: www.zebra.com/techrequest

Which Department

Do You Need?

Regional Headquarters

Technica l Sup port

For questions on the operation

of Zebra equipment and

software, please call your

distributor. For additional

assistance, contact us.

Please have your model and

serial numbers available.

Repair Service Department

For back-to-base service and

repair.

Techni cal Training

Department

For Zebra product training

courses.

Inquiry Department

For product literature and

distributor and dealer

information.

Customer Service

Department (US)

Internal Sales Department

(UK)

For printers, parts, media, and

ribbon, please call your

distributor or contact us.

Key:

T: Telephone

F: Facsimile

E: E-mail

The Americas

Zebra Technologies Inter national,

LLC

475 Half Day Road, Suite 500

Lincolnshire, IL 60069 USA

T: +1 847 634 6700

Toll-free +1 866 230 9494

F: +1 847 913 8766

T: +1 877 ASK ZEBRA (275 9327)

F: +1 847 913 2578

Hardware: ts1@zebra.com

Software: ts3@zebra.com

Kiosk Printers:

T: +1 866 322 5202

kiosksupport@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

F: +1 847 821 1797

E: repair@zebra.com

To request a repair in the U.S.,

go to www.zebra.com/repair

T: +1 847 793 6868

T: +1 847 793 6864

F: +1 847 913 2578

E: ttamerica@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

E: inquiry4@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

E: clientcare@zebra.com

.

Europe, Africa,

Middle East, India

Zebra Technologies Europe Limited

Dukes Meadow

Millboard Road

Bourne End

Buckinghamshire, SL8 5XF

United Kingdom

T: +44 (0) 1628 556000

F: +44 (0) 1628 556001

T: +44 (0) 1628 556039

F: +44 (0) 1628 556003

E: Tseurope@zebra.com

T: +44 (0) 1772 693069

F: +44 (0) 1772 693046

New requests: ukrma@zebra.com

Status updates:

repairupdate@zebra.com

T: +44 (0) 1628 556000

F: +44 (0) 1628 556001

E: Eurtraining@zebra.com

T: +44 (0) 1628 556037

F: +44 (0) 1628 556005

E: mseurope@zebra.com

T: +44 (0) 1628 556032

F: +44 (0) 1628 556001

E: cseurope@zebra.com

Asia Pacific

Zebra Technologies Asia Pacific

Pte. Ltd.

120 Robinson Road

#06-01 Parakou Building

Singapore 068913

T: + 65 6858 0722

F: +65 6885 0838

T: +65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

T: +65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

T: + 65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

E: China:

GCmarketing@zebra.com

All other areas:

AP ACChannelmarketing@zebra.co

m

T: +65 6858 0722

F: +65 6885 0836

E: China: order-csr@zebra.com

All other areas:

csasiapacific@zebra.com

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Document Conventions

The following conventions are used in this document to convey certain information:

Alternate Color – Cross-references contain links to othe r sections in this guide. If you are

viewing this guide online, click the blue text to jump to its location.

Note • Indicates information that emphasizes or supplements important points of the main

text.

Introduction

Document Conventions

3

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Introduction

4

Document Conventions

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Description

APPLICATION

GDI

DISPLAY DRIVER

PRINTER DRIVER

PORT MONITOR

USB

PORT

PRINTER

Windows CE Driver

2

Windows CE Driver

The following description applies to CE 5.0 and CE 6.0.

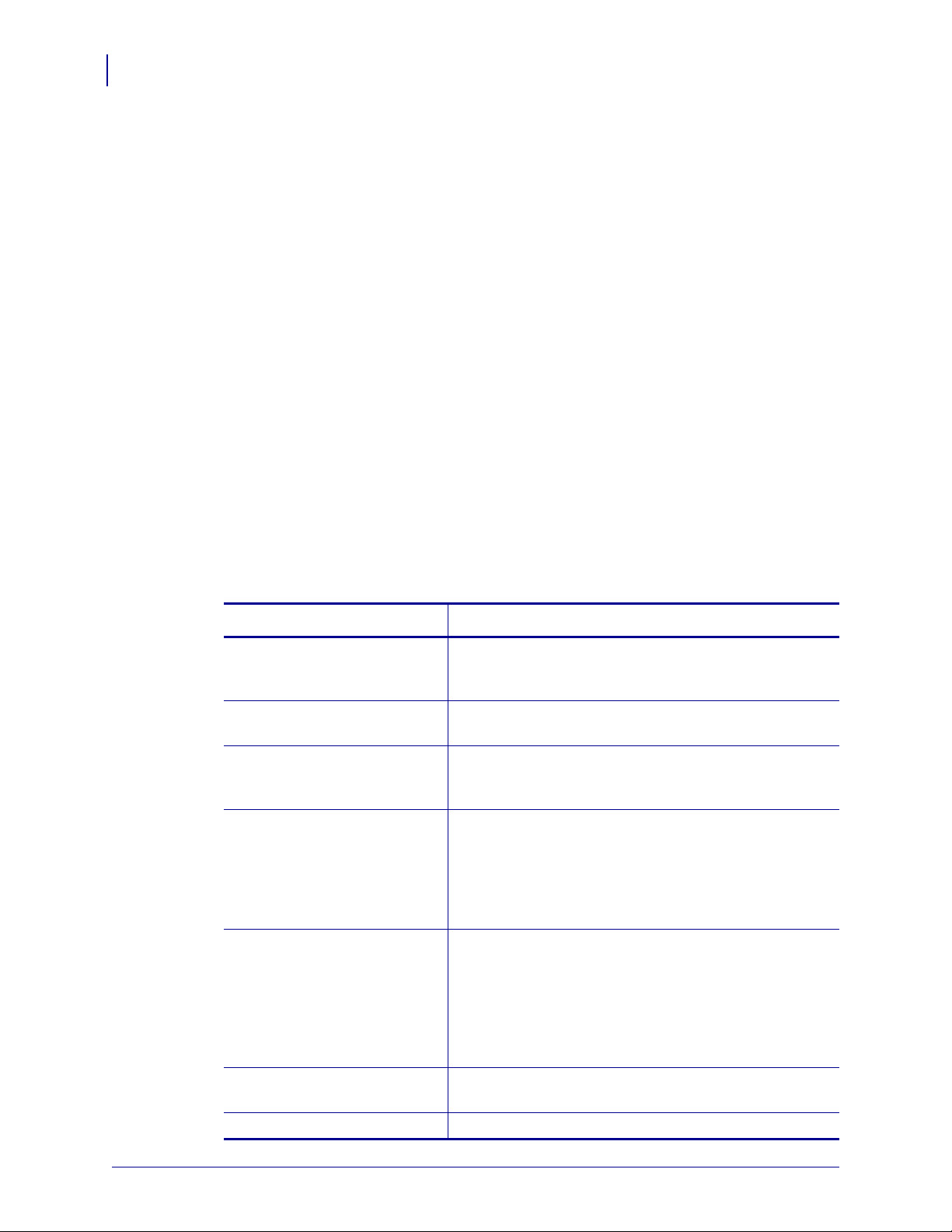

The illustration shows the relationship between the various system components involved

in printing.

Figure 2-1 • System Flowchart

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Windows CE Driver

6

Description

Printer Driver

The printer driver for the KR203 is named KR203.DLL. The Windows CE graphics device

interface (GDI) and display driver perform most of the work involved in printing. At the

beginning of the printing process, GDI creates a device context with attributes that are

retrieved from the printer driver during a call to DrvEnablePDEV. The display driver, not

the printer driver, is used to render subsequent drawing commands that are issued from

the application into the device context. Theref ore, some drawing functions that are pre sent

in a printer driver, such as DrvS tro kePath, are ne ver ca lled because the printer d river only

renders the document internally.

The printer driver converts the bitmap dat a from a GDI bitmap format into the for mat that is

recognized by the printer. This can include such operations as color reduction to the color

space of the printer , dat a compression, and d ata conversion in to the format that is used by

the printer – a format sometimes known as a page-description la ngu age (PDL) . Then, th e

printer driver calls the port monitor to send the rendered image to the printer.

Only a small number of the graphics driver functions defined for printer drivers are

required in printer drivers for Windows CE. Printer drivers are required to implement only

those graphics driver functions that are necessary for gathering printe r m etrics, setting up

the printer, starting and ending print jobs, and preparing content for printing.

The following table shows the functions implemented in the driver:

T able 2-1 • Driver Functions

Function Description

DrvCopyBits Translates between device-managed raster surfa ces

and graphics device interface (GDI) standard format

bitmaps.

DrvDisablePDEV Used by MGDI to notify a driver that the specified

PDEV structure is no longer needed.

DrvDisableSurface Used by the GDI to notify a driver that the surface

created by the DrvEnableSurface function for the

current device is no longer needed.

DrvEnableDriver Specifies the initial driver entry point exported by the

driver DLL for devices that link directly to GWES, such

as display drivers and printer drivers. It fills a

DRVENABLEDATA structure with the driver version

number and calling addresses of functions supported

by the driver

DrvEnablePDEV Enables a device context for drawing and returns

device metrics for the target printer or display device in

a GDIINFO structure. Printer drivers call a display

driver's DrvEnablePDEV function to create and

initialize the device context, and then substitute the

printer's device metrics before returning the device

context to the GDI for bitmap rendering.

DrvEnableSurface Sets up a surface to be drawn on and associates it with

a specified PDEV.

DrvEndDoc Called by the GDI to finish or abort a print job.

P1028251-001 Rev. A KR203 Windows CE Software Integrator Guide 3/1/2011

Windows CE Driver

Description

T able 2-1 • Driver Functions

Function Description

DrvGetModes Lists the modes supported by a specified device.

DrvStartDoc Called by the GDI to start a print job.

DrvStartPage Called by the GDI to start printing the next page of a

print job.

GetPrinterInfo Obt ains information about printers, such as the name

of the printer or whether the printer can print in color.

PrinterClose Closes a printer handle previously opened by a call to

the PrinterOpen function.

PrinterOpen Opens a specified printer port and return s a handle to

the printer.

PrinterSend Sends a block of data to a printer.

ReportPrinterS tatus Returns the st atus of a pr inter or printing operation that

is in progress.

GetPrinterSt atus Returns a specific KR203 status.

7

Note • The table includes links to descriptions of the driver functions.

Port Monitor

The port monitor for the KR203 is called KRPort.DLL. Printing is supported over universal

serial bus (USB) port only. The printing architecture provides application programming

interfaces (APIs) that are exposed by the Graphics, Windowing, and Events Subsystem

(GWES) to communicate with the printer driver. The printer driver communicates with the

port driver that sends the print data over the supported bus. Therefor e, the pr inter driver i s

independent of the bus and the corresponding bus driver.

Print Spooling

No separate printer spooler component exist s in Windows CE, unlike the desktop ver sions

of the Windows OS. With Windows CE, spooling or background printing is implemented in

the printer driver itself. However, because print spooling typically consumes a lot of

memory, limited memory might be a problem. A practical print spooler usually has to

implement a complicated compression scheme to store spooled documents before

printing.

Status Monitoring

In order to allow applications to get status from the printer, there are two functions

implemented: 1) the default ReportPrinterStatus function described in the MSDN

documentation, and; 2) a new function GetPrinterStatus that returns the actual printer

status (see Table 2-2, Printer Status Codes on page 8).

3/1/2011 KR203 Windows CE Software Integrator Guide P1028251-001 Rev. A

Loading...

Loading...