Page 1

OPERATIONS MANUAL

Powe

r

!

O

K

B

e

i S

ta

p

e

lm

o

n

ta

g

e

A

u

fk

le

b

e

r

e

n

tf

e

r

n

e

n

u

n

d

K

o

n

t

a

k

tträ

g

e

r

m

o

n

tie

r

e

n

F

o

r

s

ta

c

k

m

o

u

n

tin

g

r

e

m

o

v

e

la

b

e

l

a

n

d

in

s

ta

ll c

o

n

ta

c

t

c

a

r

r

ie

r

ba76095d02 01/2013

MIQ/Blue PS Set

SET FOR WIRELESS DATA TRANSMISSION IN THE IQ SENSOR NET

Page 2

MIQ/Blue PS

CE conformity WTW herewith declares that the MIQ/Blue PS instrument is in compli-

ance with the basic requirements and other relevant regulations of the

directive 1999/5/EC.

The EC conformity declaration is available on request from WTW.

Copyright

© Weilheim 2013, WTW GmbH

Reprinting - even as excerpts - is only allowed with the explicit written

authorization of WTW GmbH, Weilheim.

Printed in Germany.

2 ba76095d02 01/2013

Page 3

MIQ/Blue PS Contents

MIQ/Blue PS - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 How to use this component operating manual . . . . . . . . 1-1

1.2 Features of the MIQ/Blue PS . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.1 General characteristics . . . . . . . . . . . . . . . . . . . 1-2

1.2.2 Instrument identification . . . . . . . . . . . . . . . . . . 1-3

1.2.3 Application examples . . . . . . . . . . . . . . . . . . . . 1-4

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 2-2

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Basic information on installation . . . . . . . . . . . . . . . . . . . 3-1

3.2.1 General information . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.3 Topology and terminator switch . . . . . . . . . . . . 3-3

3.3 Radio range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4 Installation in the IQ S

3.5 Electrical connections: General instructions . . . . . . . . 3-14

3.6 Connecting the voltage supply . . . . . . . . . . . . . . . . . . . 3-16

3.6.1 Connection to 100 ... 240 V AC . . . . . . . . . . . . 3-16

3.6.2 Connection to 24 V DC . . . . . . . . . . . . . . . . . . 3-20

3.7 Figure of the terminal strip . . . . . . . . . . . . . . . . . . . . . . 3-23

ENSORNET . . . . . . . . . . . . . . . . . 3-13

4 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

5 What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Check of the radio connection . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Error causes and remedies . . . . . . . . . . . . . . . . . . . . . . 5-2

ba76095e02 01/2013

6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1.1 Operation without line power supply unit . . . . . 6-1

6.1.2 Operation with line power supply unit . . . . . . . . 6-1

6.1.3 Electrical connections . . . . . . . . . . . . . . . . . . . . 6-3

0 - 1

Page 4

Contents MIQ/Blue PS

6.2 Radio transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3 Instrument safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

7 Appendix: Installation instructions for several radio

links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 Application example for several radio links . . . . . . . . . . .7-1

7.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

8 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

8.1 Ordering & Technical Support . . . . . . . . . . . . . . . . . . . .8-3

8.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

0 - 2

ba76095e02 01/2013

Page 5

MIQ/Blue PS Overview

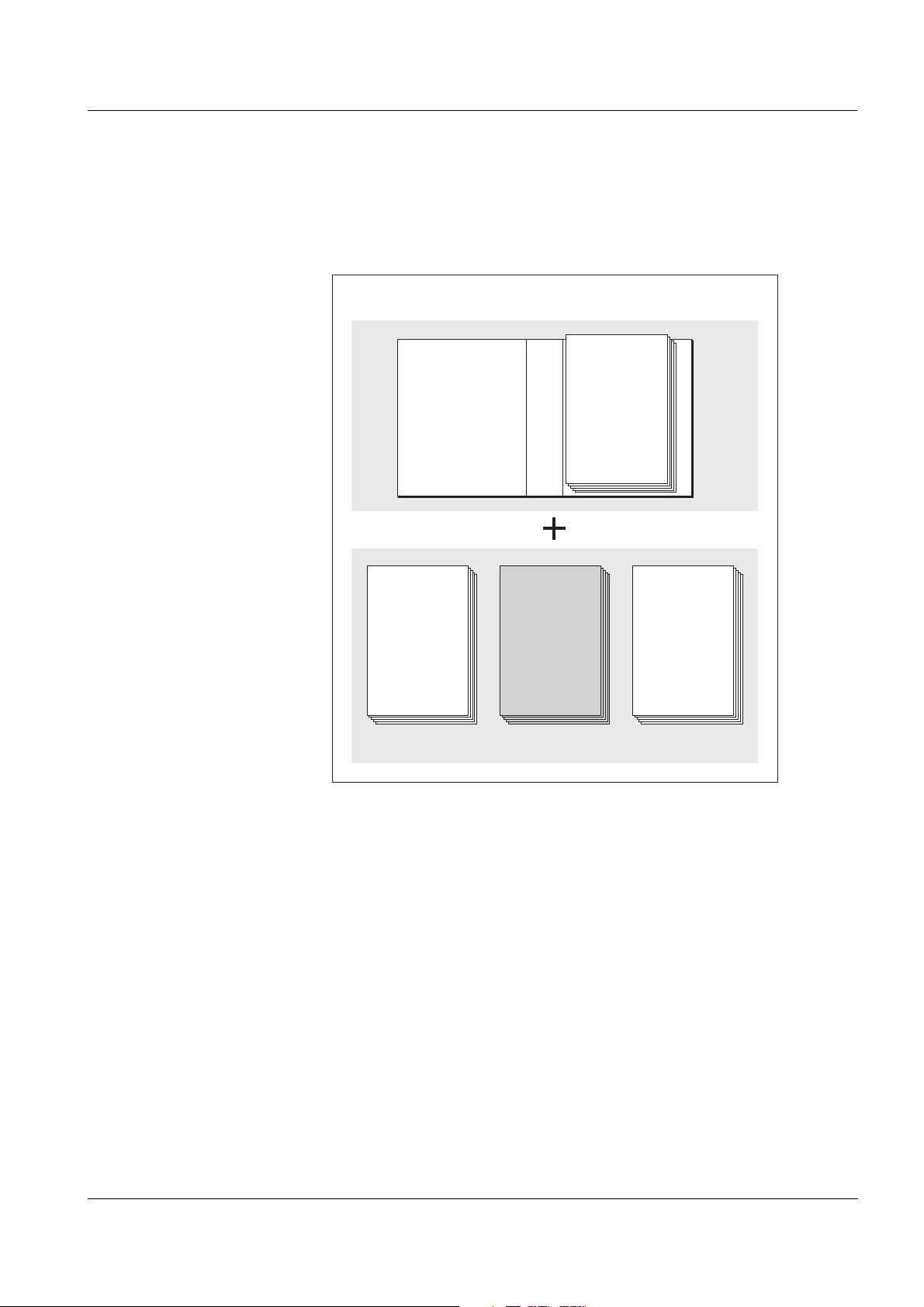

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

1Overview

1.1 How to use this component operating manual

Structure of the

IQ S

ENSORNET operating

manual

ba76095e02 01/2013

Fig. 1-1 Structure of the IQ SENSORNET operating manual.

The IQ SENSORNET operating manual has a modular structure like the

IQ S

ENSORNET system itself. It consists of a system operating manual

and the operating manuals of all the components used.

Please file this component operating manual into the ring binder of the

system operating manual.

1 - 1

Page 6

Overview MIQ/Blue PS

MIQ/Blue PS

Island 1 Island 2

(Power) (Power)

Radio

B

e

i

S

t

a

p

e

lm

o

n

ta

g

e

A

u

fk

le

b

e

r

e

n

tfe

r

n

e

n

u

n

d

K

o

n

t

a

k

tt

r

ä

g

e

r

m

on

tie

re

n

F

o

r

s

t

a

c

k

m

o

u

n

t

in

g

re

m

o

v

e

la

b

e

l

a

n

d

in

s

ta

ll

c

o

n

ta

c

t

c

a

r

r

ie

r

Powe

r

!

O

K

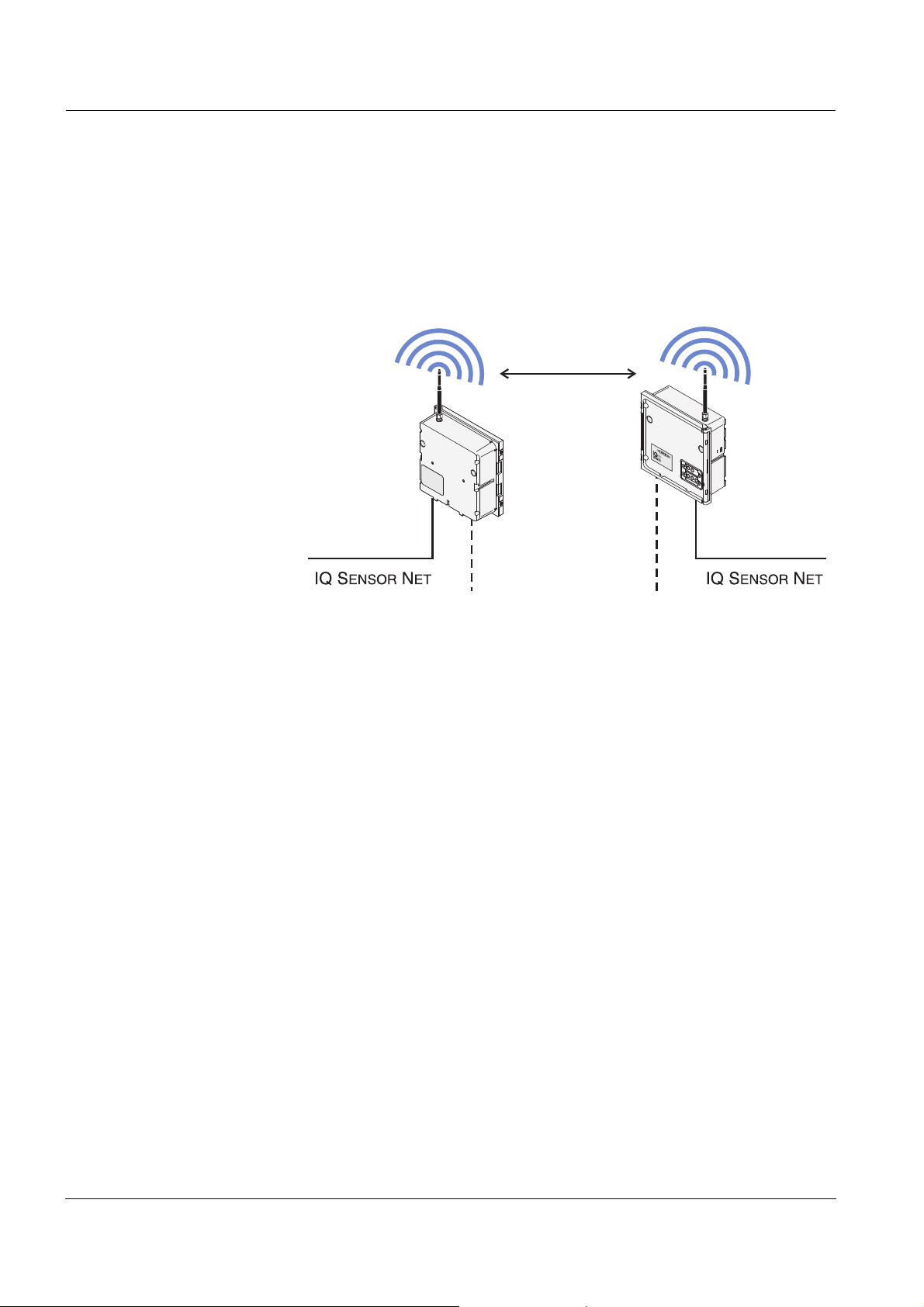

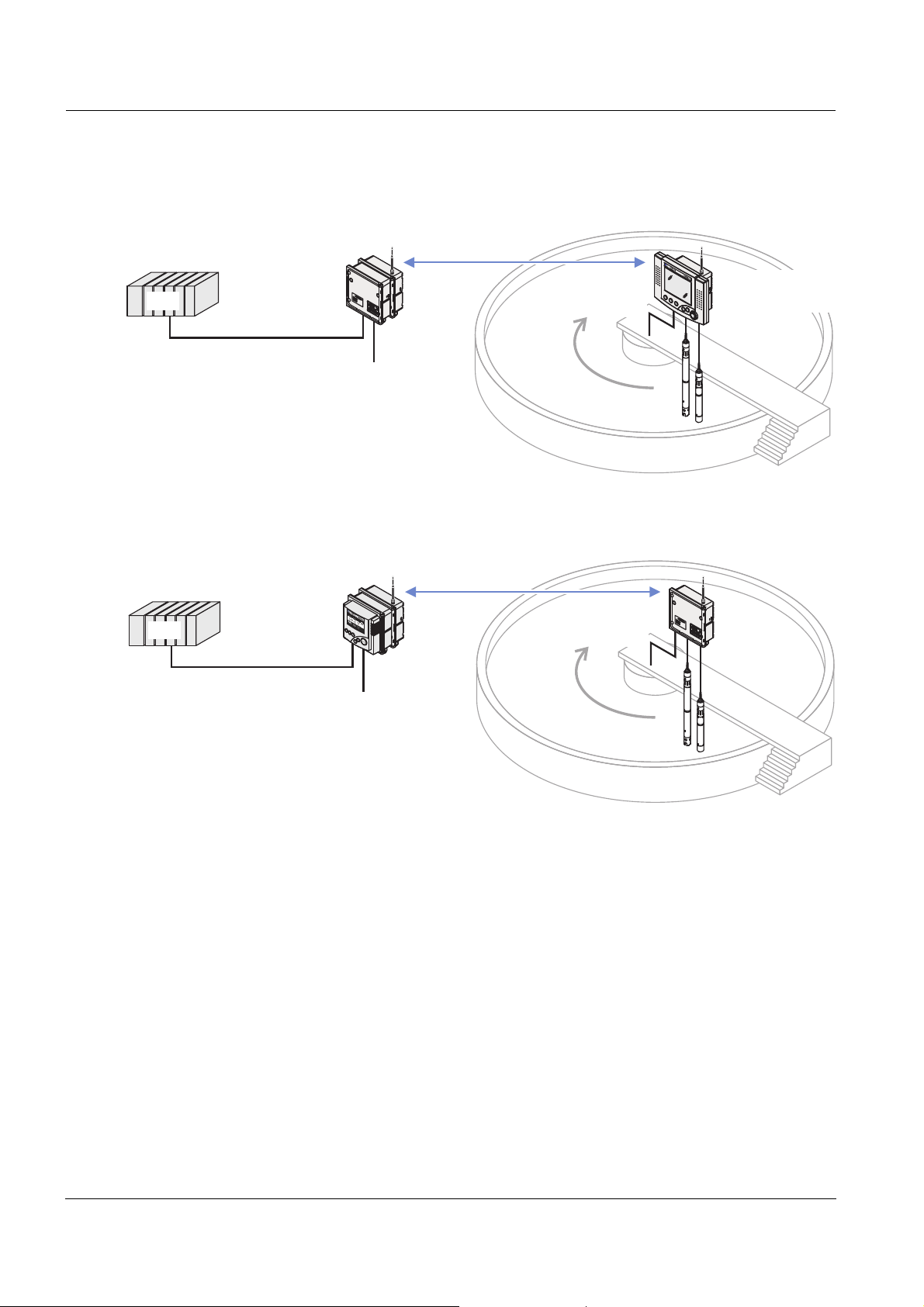

1.2 Features of the MIQ/Blue PS

1.2.1 General characteristics

With the aid of the MIQ/Blue PS SET you can replace an

IQ S

ENSORNET line section by a radio link. When doing so a new

IQ S

ENSORNET island is formed (Fig. 1-2):

Fig. 1-2 Structure of a radio link with the MIQ/Blue PS SET

Radio technology using Bluetooth modules features reliability and

insensitivity to foreign electromagnetic radiation. Transmission

between two MIQ/Blue PS modules of a set takes place in an encoded

form. In conjunction with the proprietary IQ S

ENSORNET record, the

transmission is thus tap-proof.

The antennas of the MIQ/Blue PS modules are omni-antennas without

directivity.

Power supply To supply an IQ S

ENSORNET island with power, a line power supply unit

is integrated in the MIQ/Blue PS. I can supply components with a total

power consumption of up to 7 watt, which is sufficient for most applications. The line power supply unit of the MIQ/Blue PS can be supplied

with line power or with 24 V. Thus, an island can also be supplied by a

battery or solar system.

Terminal strip The MIQ/Blue PS has the following electrical connections on the termi-

nal strip inside the enclosure:

1 x line power connection 100 ... 240 VAC, two-pole

1 x line power connection 24 VDC, two-pole

3 x SENSORNET connections

1 - 2

ba76095e02 01/2013

Page 7

MIQ/Blue PS Overview

Ser.-Nr.xxxxxxxxx

Power

!

OK

YSI

MIQ/

Blue PS

Netz/ Mains Ausgang/Output

100...240VAC 22 V DC

12W 7 W

50 / 60 Hz

Eingang/Input Ausgang/Output

24V DC 22V DC

24W 24W

SENSOR NET / Input

24V DC 0,6W

ID-Nr: XXXX

Master

This device contains

FCC ID:PVH090202S

IC:5325A-090202S

ID number of the module pair

Function:

Master or slave (here: master)

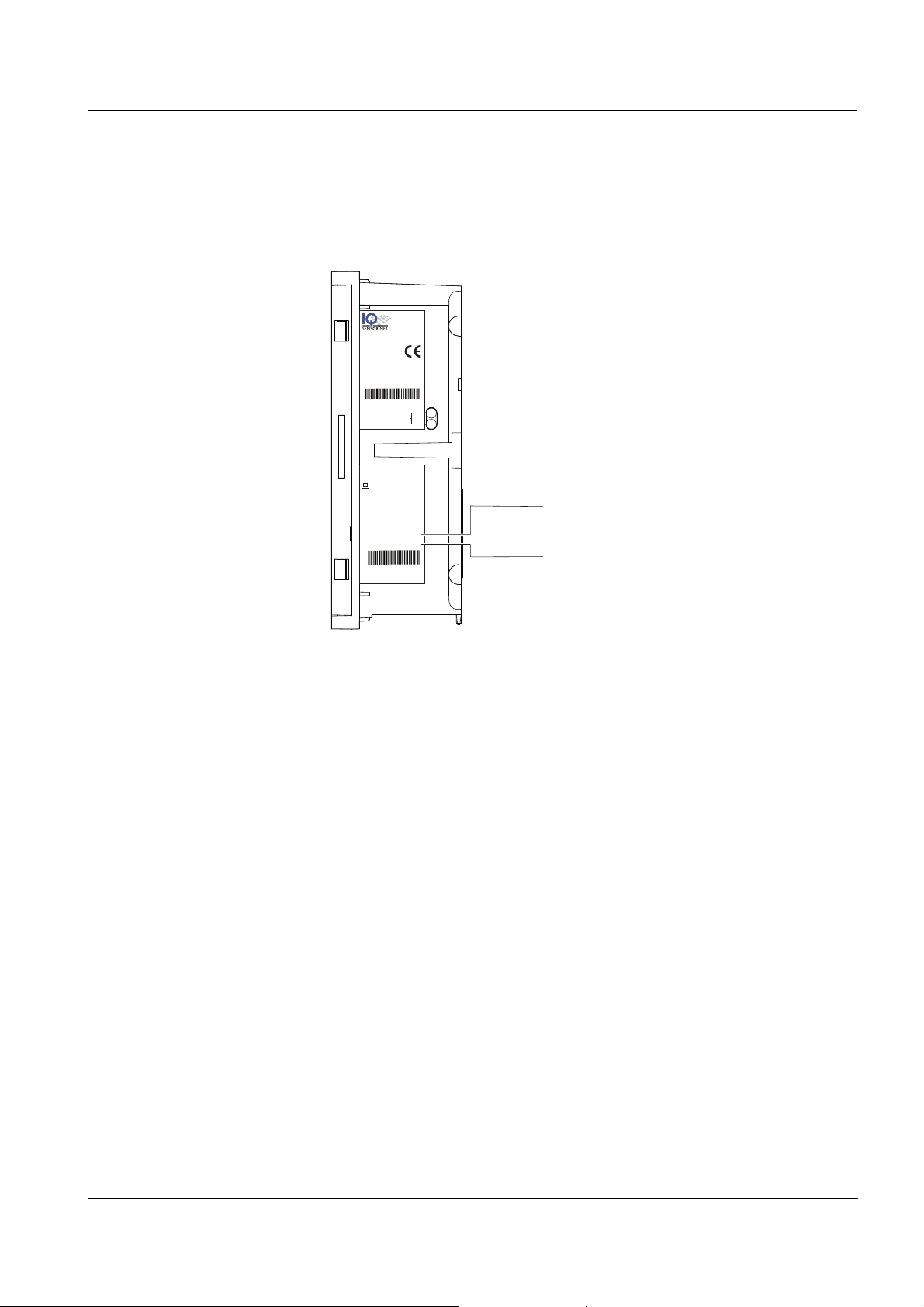

1.2.2 Instrument identification

The nameplate is on the side of the module enclosure. Among other, it

contains the following information (Fig. 1-3):

Fig. 1-3 Nameplate of the MIQ/Blue PS

ID number and encoding An MIQ/Blue PS SET consists of a module pair with the same ID num-

ber. Every module pair has its own coding of the radio transmission,

which is determined via the ID number. Any ID number is assigned only

once by YSI.This excludes the possibility of several module pairs having the same encoding and thus, of interferences by a module pair that

happens to have the same encoding. With several MIQ/Blue PS pairs,

the ID number enables to identify which pair communicates with each

other.

ba76095e02 01/2013

1 - 3

Page 8

Overview MIQ/Blue PS

0/4-20 mA

or field bus

MIQ/Blue PS

+MIQ/TC 2020

MIQ/Blue PS

PLC

Power

Power

Final sedimentation tank

Radio

PowerPower

!

O

K

OK

C

M

S

E

S

C

O

K

PowerPower

!

O

K

OK

Final sedimentation tank

0/4-20 mA

or field bus

MIQ/Blue PS

DIQ/S 182

PLC

Power

DIQ/S 182

PowerPower

!

O

K

OK

Power

Radio

MIQ/Blue PS

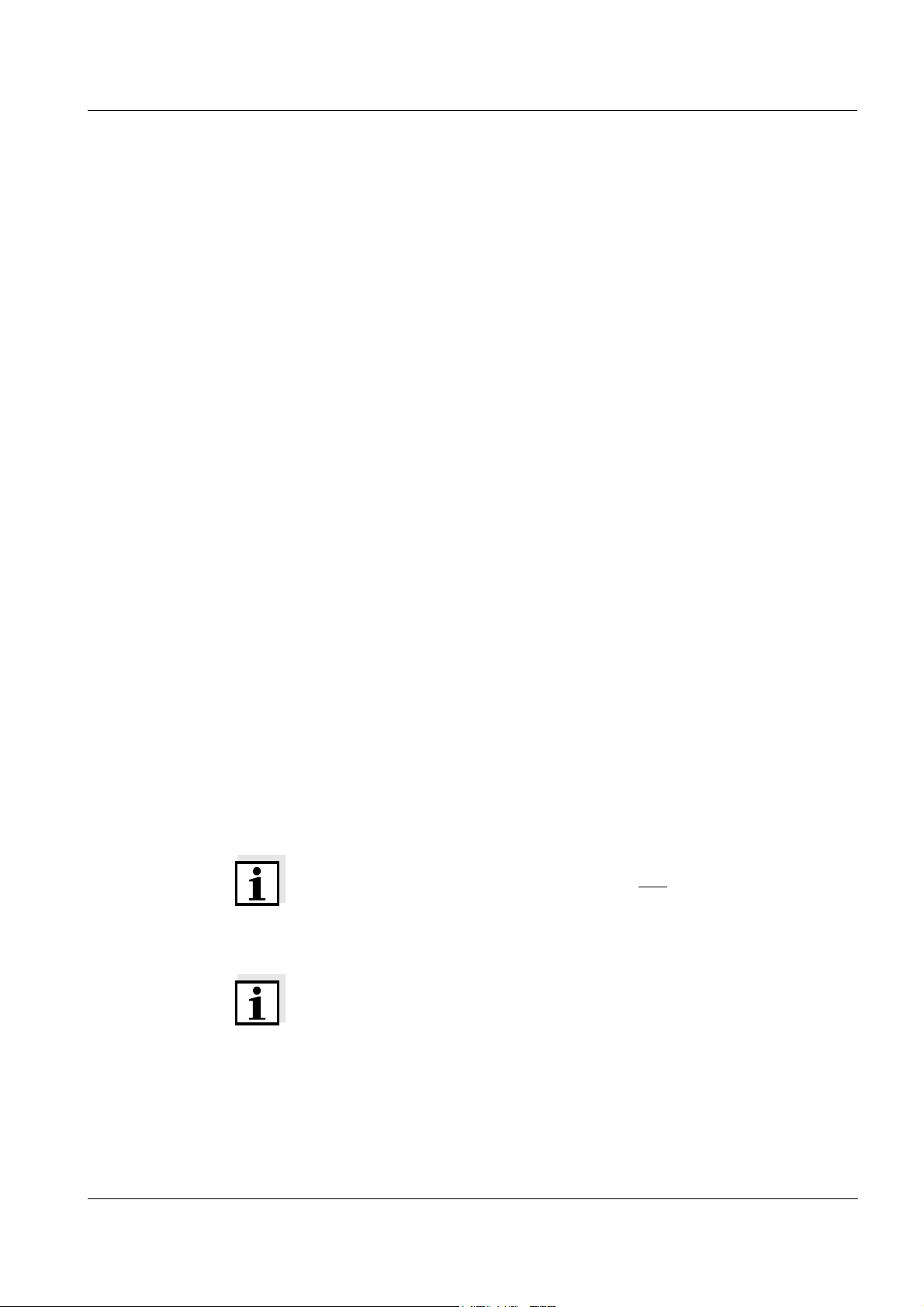

1.2.3 Application examples

Fig. 1-4 Example 1: Basin with rotating scraper bridge

1 - 4

Fig. 1-5 Example 2: Basin with rotating scraper bridge

ba76095e02 01/2013

Page 9

MIQ/Blue PS Safety instructions

2 Safety instructions

This component operating manual contains special instructions that

must be followed during the installation of the MIQ/Blue PS power supply module. Thus, it is essential to read this component operating manual before carrying out any work using this component. In addition to

this manual, the S

ing manual must be followed.

Always keep this component operating manual together with the system operating manual and all other component operating manuals in

the vicinity of the IQ S

AFETY chapter of the IQ SENSORNET system operat-

ENSORNET system.

Special user

qualifications

General safety

instructions

Other labels

The MIQ/Blue PS may only be connected to the line power supply by a

trained electrician.

Safety instructions in this operating manual are indicated by the warning symbol (triangle) in the left column. The signal word (e.g. "CAUTION") indicates the danger level:

Warning

indicates instructions that must be followed precisely in order to

prevent serious dangers to personnel.

Caution

indicates instructions that must be followed precisely in order to

avoid slight injuries to personnel or damage to the instrument or

the environment.

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. operating manuals.

ba76095e02 01/2013

2 - 1

Page 10

Safety instructions MIQ/Blue PS

2.1 Authorized use

Authorized use of the MIQ/Blue PS is its use as a radio module with

optional line power supply unit in the IQ S

ENSORNET.

Please observe the technical specifications according to

chapter 6 T

ECHNICAL DATA. Only operation according to the instructions

in this operating manual is authorized.

Any other use is considered to be unauthorized. Unauthorized use

invalidates any claims with regard to the guarantee.

2.2 General safety instructions

The MIQ/Blue PS is constructed and inspected according to the relevant guidelines and norms for electronic instruments (see

chapter 6 T

It left the factory in a safe and secure technical condition.

ECHNICAL DATA).

Function and opera-

tional safety

The failure-free function and operational safety of the MIQ/Blue PS is

only guaranteed if the generally applicable safety measures and the

special safety instructions in this operating manual are followed during

its use.

The failure-free function and operational safety of the MIQ/Blue PS is

only guaranteed under the environmental conditions that are specified

in chapter 6 T

ECHNICAL DATA.

Safe operation If safe operation is no longer possible, the MIQ/Blue PS must be taken

out of operation and secured against inadvertent operation.

Safe operation is no longer possible if the MIQ/Blue PS:

has been damaged in transport

has been stored under adverse conditions for a lengthy period of

time

is visibly damaged

no longer operates as described in this manual.

If you are in any doubt, contact the supplier of your MIQ/Blue PS.

2 - 2

ba76095e02 01/2013

Page 11

MIQ/Blue PS Installation

3 Installation

3.1 Scope of delivery

The scope of delivery of the MIQ/Blue PS module includes:

MIQ/Blue PS

Accessory set, including

– 4 x cable glands (clamping range 4.5-10 mm) with seals and blind

plugs

– 4x ISO blind nuts M4 with suitable socket head screws and plain

washers

– 2x countersunk screws M3x8 to close the module lid

(+ 2 spare ones)

– 1 x contact base with fixing screws

Accessories for range test with attenuator

(see section 3.3)

– 1 x SMA attenuator VAT 10 dB

– 2 x reverse SMA adapters for SMA attenuator

Operating manual.

3.2 Basic information on installation

3.2.1 General information

The MIQ/Blue PS radio modules are preconfigured in pairs and ready

for installation. Installation consists only of the connection to the

IQ S

ENSORNET.

Note

This chapter describes the installation of one radio link in the

IQ S

ENSORNET system. If several radio links should be installed, the

instructions in the appendix of this operating manual have to be followed additionally.

Note

To prevent the radio transmission from being affected by water or snow

collecting on the antenna, we urgently recommend protecting any MIQ/

Blue PS radio modules against precipitation with the aid of a plastic

canopy (SSH/IQ).

ba76095e02 01/2013

3 - 1

Page 12

Installation MIQ/Blue PS

3.2.2 Power supply

The line power supply unit of the MIQ/Blue PS can be used for the

exclusive supply of an IQ S

power rating has to be made for each IQ S

ENSORNET island. In any case, a separate

ENSORNET island.

Power delivery

Compatibility with other

line power supply units

Example Problem:

24 V DC operation: 24 W

100 ... 240 V AC operation: 7 W

If the installation of further line power supply units should be necessary,

please note the following: If other power supply modules (e.g. MIQ/PS)

are installed on the IQ S

ENSORNET island, the line power supply unit of

the MIQ/Blue PS is automatically inactive. Connecting the MIQ/

Blue PS line power supply unit to a power supply remains ineffective

here. In this case, the MIQ/Blue PS is a consumer with a power consumption of 0.6 W in the power rating.

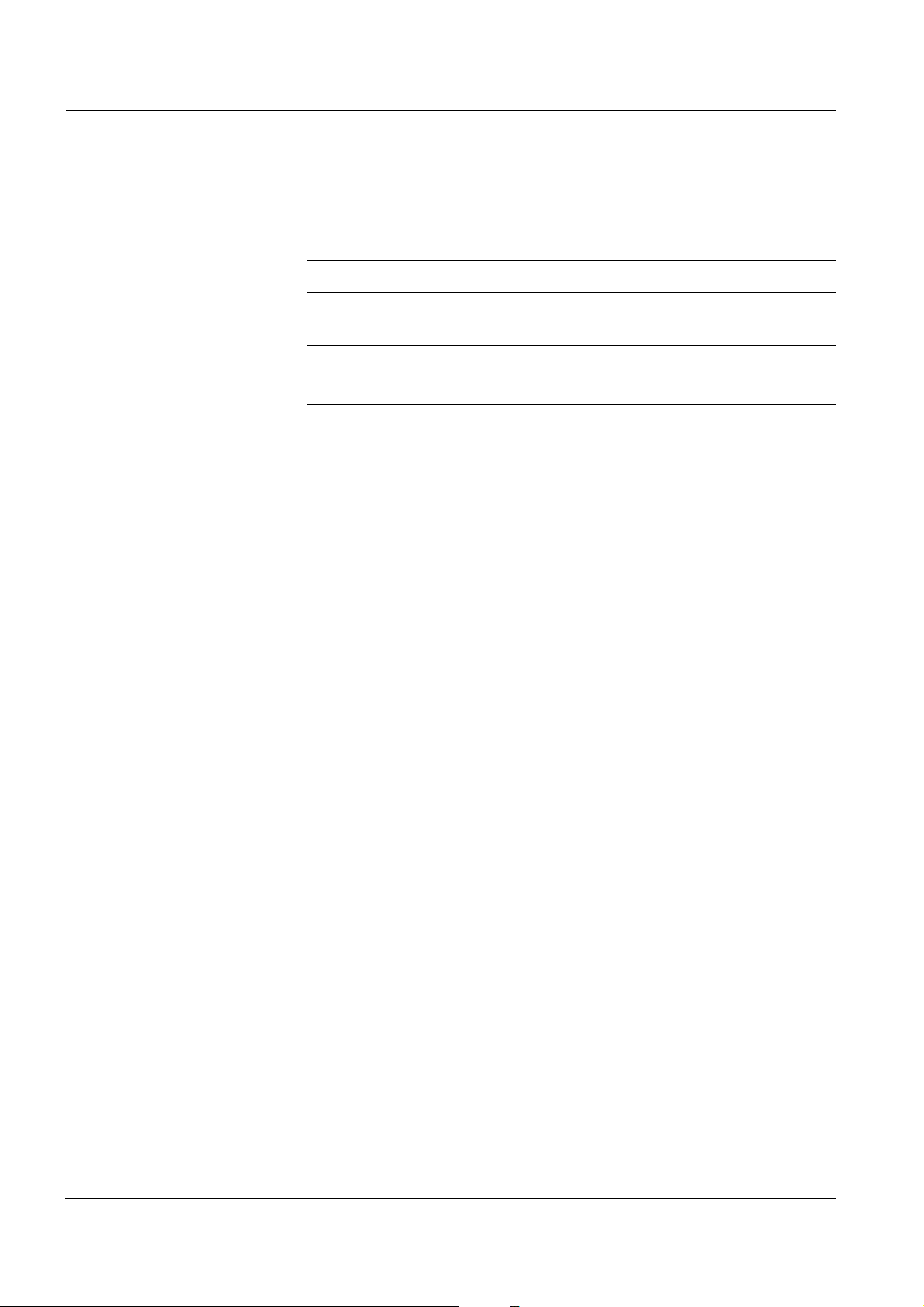

An IQ SENSORNET island should consist of the following compo-

nents plus the MIQ/Blue PS:

Component Power requirement

[W]

VisoTurb

ViSolid

SensoLyt

®

700 IQ 1.5

®

700 IQ 1.5

®

700 IQ 0.2

MIQ/CHV PLUS 1.0

MIQ/TC 2020 XT (docked from time to time) 3.0

In this example, the MIQ/Blue PS and the MIQ/CHV PLUS should

be mounted as a stack.

The IQ S

ENSORNET system should be supplied with 100 ...

240 V AC.

Solution/proceeding:

First it is assumed that the MIQ/Blue PS suffices for power supply.

It does not have to be taken into account as a consumer. In the worst

case, i. e. with a docked MIQ/TC 2020 XT, the power requirement of

all components is 7.2 W. Power losses in cables do not have to be

taken into account due to the stack mounting.

Power rating: The calculated power requirement is greater than the

maximum power delivery of the MIQ/Blue PS line power supply unit.

Therefore, an additional power supply module has to be installed

(e.g. MIQ/PS).

New power rating: The MIQ/Blue PS has to be counted as a con-

sumer as well. Therefore, the power consumption is now 7.8 W.

3 - 2

ba76095e02 01/2013

Page 13

MIQ/Blue PS Installation

X6 X5 X4

SENSORNET 2

RED

SHIELD

GREEN

X3 X2 X1

SENSORNET 1

RED

SHIELD

GREEN

ON

OFF

SN TERMINATOR

SN Terminator

With an MIQ/PS power supply module (18 W), there is still an

energy reserve of 10.2 W for any future extensions.

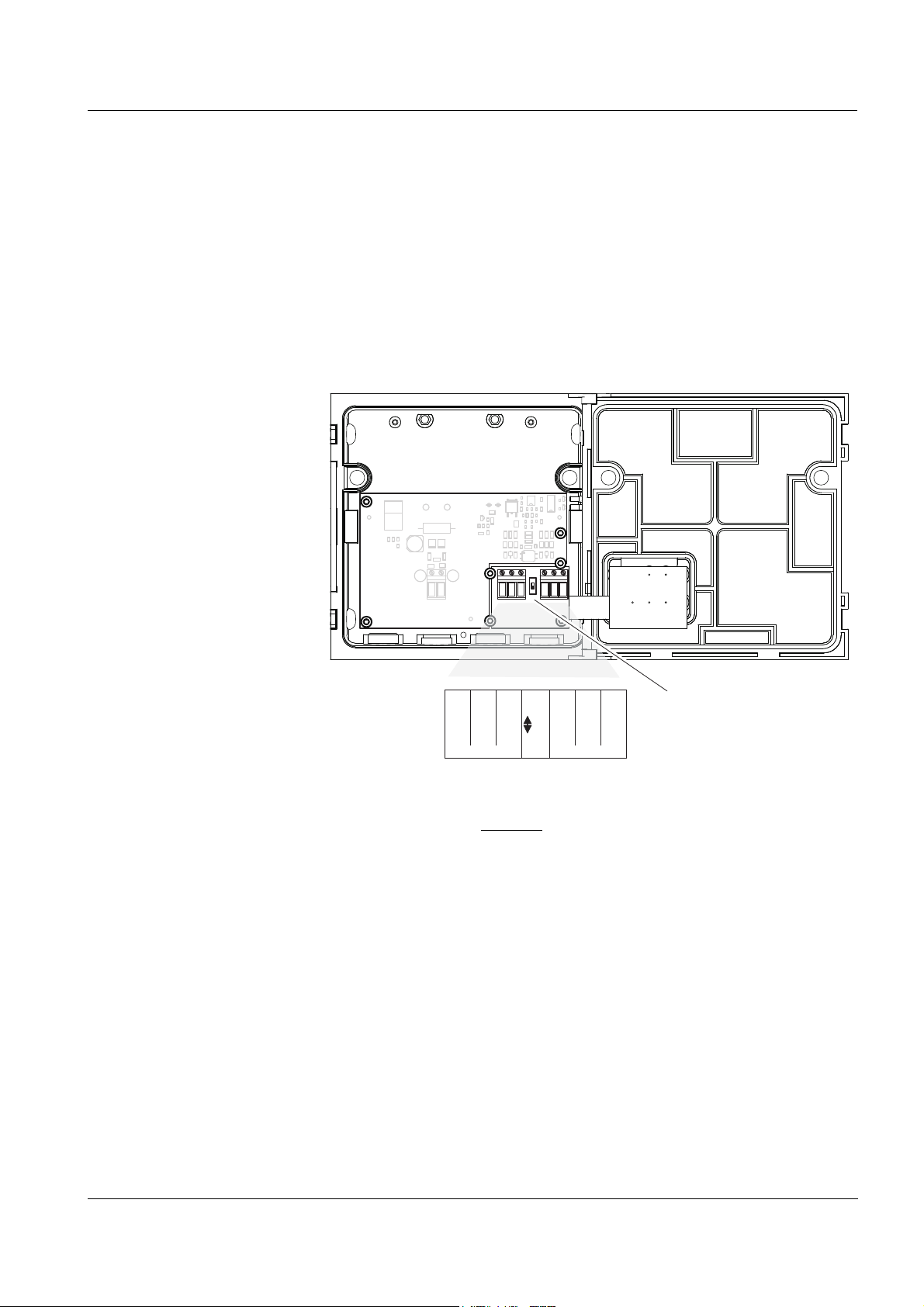

3.2.3 Topology and terminator switch

For failure-free operation, the terminator switches (terminating resistors) must always be set to ON on two MIQ modules of the

ENSORNET island. On which modules this is required results from

IQ S

the topology of the IQ S

ENSORNET island:

ba76095e02 01/2013

Fig. 3-1 Correct setting of the terminator switches

Main line (trunk

line)

Longest cable section with terminator switches at

its ends.

The terminator switches must be set to On at both

ends.

If all MIQ modules are located at one point, i. e. in

a module stack, the length of the main line is zero

(star-shaped wiring).

Branch line All lines branching from the main line.

Branch lines can be branched further.

3 - 3

Page 14

Installation MIQ/Blue PS

L1

= 150 m

L4 = 200 m

L2 = 200 m L3 = 300 m

Special features with

certain configurations

Example of determining

the main line

If, except in the MIQ/Blue PS, no other terminator switch is available

on the IQ S

ENSORNET island, it must be set to ON. In addition, a ter-

minating resistor (included in the scope of delivery) must be connected to one of the three SENSORNET connectors. For more

details, see page 3-6.

If a DIQ/S 182 Universal Transmitter is on the IQ S

all

terminator switches on the IQ SENSORNET island must be set to

ENSORNET island,

ON.

The following figure shows the main line L made up of the partial

lengths L1, L2 and L3 as the cable section L4 is shorter than L3:

Length of the main line = L1 + L2 + L3

3 - 4

Fig. 3-2 Example of determining the length of the main line

ba76095e02 01/2013

Page 15

MIQ/Blue PS Installation

X6 X5 X4

SENSORNET 2

RED

SHIELD

GREEN

X3 X2 X1

SENSORNET 1

RED

SHIELD

GREEN

ON

OFF

SN TERMINATOR

SN Terminator

Terminator switch Terminator switches are located in each MIQ module between the two

SENSORNET connections on the right of the terminal strip (designation "SN TERMINATOR").

Fig. 3-3 Terminator switch

ba76095e02 01/2013

3 - 5

Page 16

Installation MIQ/Blue PS

6

8

7

9

2

1

3

5

4

SN terminator

switch ON

additional terminating resistor

X13

X12

100...

240V AC

MAINS

L1

N

X11

X10

24V DC

INPUT

POWER

SENSORNET 2

SENSORNET 1

ON

OFF

X6

RED

RED

SN TERMINATOR

SHIELD

GREEN

SHIELD

GREEN

X5

X4

X3

X2

X1

SENSORNET 3

X8

X9

X7

RED

SHIELD

GREEN

+

-

RRR

connection selectable

Additional terminating

resistor on the MIQ/

Blue PS

An additional terminating resistor is only required if, except in the MIQ/

Blue PS, no other terminator switch is available on the IQ S

ENSORNET

island. The terminating resistor is connected to one of the three SENSORNET connectors (Fig. 3-4). The terminating resistor must bridge

the two outside terminals of the SENSORNET connector. The SENSORNET connector can still be used to connect a sensor.

Fig. 3-4 MIQ/Blue PS with additional terminating resistor

3 - 6

ba76095e02 01/2013

Page 17

MIQ/Blue PS Installation

ON

Power

PowerPower

!

O

K

OK

C

M

S

E

S

C

O

K

PowerPower

!

O

K

OK

PowerPower

!

O

K

OK

PowerPower

!

O

K

OK

Power

DIQ/S 182

PowerPower

!

O

K

O

K

Power

ON+R

R = additional terminating resistor

OFF

OFF

ON+R

ON

ON OFF

ON

PowerPower

!

O

K

OK

PowerPower

!

O

K

OK

Examples of the correct

setting of the terminator

switches

The figure on the following page demonstrates with several examples

of IQ S

ENSORNET islands how the terminator switches and terminating

resistors are correctly set.

Fig. 3-5 Terminator switches and terminating resistors

ba76095e02 01/2013

3 - 7

Page 18

Installation MIQ/Blue PS

Radio (maximum distance)

PowerPower

!

OKOK

PowerPower

!

OKOK

MIQ/Blue PS

MIQ/Blue PS

3.3 Radio range

The range of a radio link with MIQ/Blue PS SET in the free field is up to

100 m with installation and testing according to this chapter (see

chapter 6 T

As with any other radio technology, the following points have to be

observed when installing the MIQ/Blue PS SET:

All materials (even window glass) in the radio link reduce the range.

Therefore, keep the radio link free of barriers (even temporary

ones). Both MIQ/Blue PS modules should be in permanent "visual

contact" through the air. Take into account that there may be shorttime events such as trucks driving by that interrupt the radio link.

Water, snow and ice on the antenna will reduce the range. When it

is installed in the free field, protect the MIQ/Blue PS against water,

snow and ice. Use the plastic canopy SSH/IQ for this.

Canopies made out of metal or PVC reduce the range!

ECHNICAL DATA).

A high location of the MIQ/Blue PS increases the range. If neces-

Fig. 3-6 Height of the location for the MIQ/Blue PS module

Install the MIQ/Blue PS where the mentioned requirements are best

sary, install the MIQ/Blue PS higher over ground.

available and establish the connection to the IQ S

ENSORNET island

with the aid of the SNCIQ cable. Do not in any case use an antenna

extension cable to improve the position of the antenna alone.

Antenna extension cables cause range losses.

3 - 8

Mount the MIQ/Blue PS outside of a building on a pole and run the

SNCIQ cable through the wall to the next MIQ module.

ba76095e02 01/2013

Page 19

MIQ/Blue PS Installation

Antenna

extension

PowerPower

!

OK

PowerPower

!

OK

PowerPower

!

OK

PowerPower

!

OK

Power

!

OKO

K

Po

we

r

Po

wer

!

OK

Po

we

r

Po

wer

!

OK

PowerPower

!

OK

PowerPower

!

OK

SNCIQ

Example: IQ SENSORNET

island in a building.

Fig. 3-7 Installation of the MIQ/Blue PS

Note

When installing several radio links:

Follow the "Master" or "Slave" labeling of the individual MIQ/Blue PS

modules. The labeling of a MIQ/Blue PS module is on the name plate

(see section 1.2.2):

Mount every MIQ/Blue PS master with a maximum distance to the

next master (at least 50 m).

ba76095e02 01/2013

Mount every MIQ/Blue PS slave with a minimum distance of 2 m to

the next slave.

3 - 9

Page 20

Installation MIQ/Blue PS

Master 1

Po

w

e

r

Po

w

e

r

!

OKOK

Radio

Po

we

r

Po

we

r

!

OKO

K

Master 2

Pow

e

r

Pow

er

!

OKO

K

Radio

Po

w

e

r

Po

w

e

r

!

OKOK

Antenna distance at least !50 mMaster - Master:

Slave 2

Slave 1

Master 1

P

o

we

r

P

o

we

r

!

OKOK

P

ow

e

r

P

ow

e

r

!

OKO

K

P

o

w

e

r

P

o

w

e

r

!

OKO

K

Po

we

r

Po

we

r

!

OKOK

Slave 2

Slave 1

PowerPowe

r

!

OKOK

Master 3

P

o

we

r

P

o

we

r

!

OKOK

Po

w

e

r

Po

w

er

!

OKO

K

Master 4

Pow

e

r

Pow

e

r

!

OKOK

Slave 4

Slave 3

Radio

Radio

Radio

Radio

Antenna distance Master - Master: at least !50 m

Master 2

Master 1

PowerPower

!

OKOK

P

o

w

e

r

P

o

w

er

!

OKO

K

Master 2

Po

w

e

r

Po

w

er

!

OKO

K

P

o

w

e

r

P

o

w

er

!

OKOK

Po

we

r

Po

wer

!

OKO

K

Master 3

PowerPower

!

OKOK

P

o

w

e

r

P

o

w

er

!

OKOK

Master 4

Po

w

e

r

Po

w

e

r

!

OKOK

Radio

Radio

Radio

Radio

Slave 3Slave 2Slave 1 Slave 4

Antenna distance Master - Master: at least !50 m

Maximum distance of

the MIQ/Blue PS

masters (examples)

Fig. 3-8 Example 1: Maximum distance of the MIQ/Blue PS masters

Fig. 3-9 Example 2: Maximum distance of the MIQ/Blue PS masters

3 - 10

Fig. 3-10 Example 3: Maximum distance of the MIQ/Blue PS masters

ba76095e02 01/2013

Page 21

MIQ/Blue PS Installation

Note

If it is not possible to keep the minimum distances of the MIQ/Blue PS

masters, you can reduce interferences of the radio communication by

shielding the modules against one another (e.g. by using directional

antennas with side-lobe suppression in conjunction with attenuators). If

necessary, contact a radio technology specialist.

Note

If high gain antennas in order to increase the range are used, the

requirements of the directive 1995/5/EC will not be met.

Range test with

attenuator

To test the quality of the radio link, carry out the following test with a

defined signal attenuation:

Note

If a canopy is used, the MIQ/Blue PS has to be mounted lower on the

canopy for the duration of the range test. If necessary, use the lower

boreholes in the plastic canopy (SSH/IQ) for this.

1 Unscrew the antenna from on of the two MIQ/Blue PS mod-

ules. For the test, insert the attenuator with both adapters

between the antenna connector of the module enclosure and

the antenna.

2 Test the radio link with the attenuator under the most unfavor-

able conditions such as with installation on rotating scraper

bridges and the utmost distance of both MIQ/Blue PS modules.

If the test is successful with signal attenuation, faultless operation should also be possible under unfavorable conditions

(e.g. fog, heavy rainfall, snow).

3 To terminate the test operation, remove the attenuator and

mount the antenna directly on the MIQ/Blue PS again.

ba76095e02 01/2013

4 If you had mounted the MIQ/Blue PS lower on the canopy for

the test:

Mount the MIQ/Blue PS higher on the canopy again.

3 - 11

Page 22

Installation MIQ/Blue PS

Radio link check list:

1 Is there direct visual contact between the antennas of both

MIQ/Blue PS modules at any time (e.g. with installation on

moving scraper bridges)?

2 Is the radio link free from permanent disturbances? Examples:

– Obstacles (such as buildings, windows, etc.)

– Shielding (such as a metal or PVC canopy)

3 Is the radio link free from temporary disturbances? Examples:

– Regular temporary disturbances (e.g. center support or

mounting stand, with installation on a moving scraper

bridge)

– Irregular temporary disturbances (e.g. vehicles or persons

crossing the radio link)

4 Are the antennas of the MIQ/Blue PS modules free of water,

snow, ice?

5 When using a canopy:

Is the SSH/IQ plastic canopy used

(no metal or PVC canopy)?

6 Are the antennas in the original condition (e.g. no antenna ex-

tension cable)?

7 Was the range test carried out with attenuator?

8 With installation on a moving scraper bridge:

Was the range test carried out for a complete rotation of the

scraper bridge?

9 Is the distance between 2 MIQ/Blue PS masters (for several ra-

dio links) at least 50 m?

10 Is the distance between 2 MIQ/Blue PS slaveS (for several ra-

dio links) at least 2 m?

Radio link check list For safe operation of a radio link, check the system with the following

check list.

The following checklist supports you when planning, projecting and

installing a radio link with the MIQ/Blue PS radio modules.

For smooth operation, you should be able to answer all questions with

"Yes".

Note

Interferences are possible also with short radio links if the radio signal

is reflected by walls that are outside the direct radio link. Due to reflections, radio signals may reach the receiver alleviated or several times.

In this case, changing the location of a MIQ/Blue PS module only

slightly can improve the transmission.

3 - 12

ba76095e02 01/2013

Page 23

MIQ/Blue PS Installation

3.4 Installation in the IQ SENSORNET

The IQ SENSORNET provides a number of options for integrating the

MIQ/Blue PS mechanically and electrically in the system (stacked

mounting, distributed mounting, etc.). The individual types of installation are described in detail in the I

operating manual.

Note

If there are several power supply modules in the IQ S

helpful if all the power supply modules are connected to a single power

supply. As a result, the system can be easily switched on and off from

a single location.

NSTALLATION chapter of the system

ENSORNET, it is

ba76095e02 01/2013

3 - 13

Page 24

Installation MIQ/Blue PS

Sealing ring 20 x 15 x 1 mm

Cable gland M16

Blind plug

Sealing ring 20 x 15 x 1 mm

Extension piece M16/M20

Sealing ring 24 x 19 x 2 mm

Cable gland M20

3.5 Electrical connections: General instructions

Cable glands All electric cables are fed into the enclosure of the MIQ/Blue PS from

below through prepared openings. Cable glands with different clamping

ranges are provided with the MIQ/Blue PS to provide sealing between

the cable and enclosure as well as for strain relief. Select the suitable

cable gland for the respective cable diameter:

Small, clamping range 4.5 to 10 mm. This cable gland is suitable for

all IQ S

ENSOR NET cables.

Large, clamping range 7 to 13 mm. This cable gland is required for

cable sheaths with an outer diameter of more than 10 mm and is

screwed into the enclosure via an extension piece.

Note

If necessary, you can order additional large cable glands as a set of 4

pieces (model EW/1, order number 480 051).

3 - 14

ba76095e02 01/2013

Page 25

MIQ/Blue PS Installation

General installation

instructions

Observe the following points when attaching connecting wires to the

terminal strip:

Shorten all the wires to be used to the length required for the instal-

lation

Always fit all the ends of the wires with wire end sleeves before con-

necting them to the terminal strip

Any wires that are not used and project into the enclosure must be

cut off as closely as possible to the cable gland.

In each of the remaining free openings, screw in a small cable gland

with sealing ring and close them with a blind plug.

Warning

No free wires must be allowed to project into the enclosure. Otherwise, there is a danger that areas safe to contact could come

into contact with dangerous voltages. This could result in life

threatening electric shock when working with the IQ S

Always cut off any wires that are not in use as closely as possible

to the cable gland.

ENSORNET.

ba76095e02 01/2013

3 - 15

Page 26

Installation MIQ/Blue PS

3.6 Connecting the voltage supply

The following two sections need only be observed if the IQ SENSORNET

island should be supplied with power by the MIQ/Blue PS.

3.6.1 Connection to 100 ... 240 V AC

Warning

If the power supply is connected incorrectly, it may represent a

danger to life from electric shock. Pay attention to the following

points during installation:

The MIQ/Blue PS may only be connected by a trained electri-

cian.

The connection of the MIQ/Blue PS to the power supply may

only be carried out when it is not carrying any voltage.

The power supply must fulfill the specifications given on the

nameplate and in chapter 6 T

When installed in a building, a switch or power switch must be

provided as an interrupt facility for the MIQ/Blue PS.

The interrupt facility must

– be installed in the vicinity of the MIQ/Blue PS, easily acces-

sible by the user, and

ECHNICAL DATA.

– be labeled as an interrupt facility for the MIQ/Blue PS.

After it has been installed, the MIQ/Blue PS may only be opened

if the mains voltage has been switched off beforehand.

Materials required Wire end sleeves, suitable for the power line, with suitable crimping

tool

1 x cable gland, suitable for the cable diameter (see section 3.5 on

page 3-14).

Tools Cable stripping knife

Wire stripper

Phillips screw driver

Small screw driver.

3 - 16

ba76095e02 01/2013

Page 27

MIQ/Blue PS Installation

ca. 45 mm

L

N

cut protective conducter here

Preparing the power

cable

1 Cut off the cable to the required length.

2 Strip the cable insulation for approx. 45 mm.

3 Bare the wires of phases L and N and fit them with wire end

sleeves.

4 If present, cut off the protective ground wire at the end of the

cable sheath.

Fig. 3-11 Prepared power cable.

Caution

The ground wire must not project into the enclosure. Otherwise,

malfunctions could occur.

ba76095e02 01/2013

3 - 17

Page 28

Installation MIQ/Blue PS

1

3

2

L

N

4

Connecting the power

line

5 Open the enclosure.

Fig. 3-12 Inserting the supply line.

6 Screw a cable gland (pos. 1 in Fig. 3-12) with sealing ring (pos.

2) into the enclosure below the power supply connection.

7 Loosen the coupling ring (pos. 3).

8 Feed the power line through the cable gland into the enclosure.

When doing so bend the flexible divider (pos. 4) to the right.

3 - 18

ba76095e02 01/2013

Page 29

MIQ/Blue PS Installation

3

NL

Terminal

labeling:

X13

X12

100...

240V AC

NETZ/MAINS

L1

N

Fig. 3-13 Line power connection.

Note

The complete assignment of the terminal strip is shown in section 3.7.

9 Connect phases L and N to the terminal strip. Make sure that

the cable assignment agrees with the specification on the terminal label under the terminal strip.

10 Tighten the coupling ring (pos. 3).

Warning

No free wires must be allowed to project into the enclosure. Otherwise, there is a danger that areas safe to contact could come

into contact with dangerous voltages. Always cut off any wires

that are not in use as closely as possible to the cable gland.

11 Close the enclosure.

ba76095e02 01/2013

3 - 19

Page 30

Installation MIQ/Blue PS

3.6.2 Connection to 24 V DC

Warning

If the 24 V DC supply is connected incorrectly, it may represent a

danger to life from electric shock. Pay attention to the following

points during installation:

The MIQ/Blue PS may only be connected by a trained electri-

cian.

The 24 V DC supply must meet the specifications quoted on the

nameplate and in chapter 6 T

age SELV).

The connection of the MIQ/Blue PS to the power supply may

only be carried out when it is not carrying any voltage.

When installed in a building, a switch or power switch must be

provided as an interrupt facility for the MIQ/Blue PS.

The interrupt facility must

– be installed in the vicinity of the MIQ/Blue PS, easily acces-

sible by the user, and

ECHNICAL DATA (protective low volt-

– be labeled as an interrupt facility for the MIQ/Blue PS.

Note

Battery systems should be protected against total discharge. The MIQ/

Blue PS has no integrated deep discharge protection.

Materials required Wire end sleeves, suitable for the 24 V AC/DC feed line, with suit-

able crimping tool

1 x cable gland, suitable for the cable diameter (see section 3.5 on

page 3-14).

Tools Cable stripping knife

Wire stripper

Phillips screw driver

Small screw driver.

Preparing the 24 V DC

line

1 Cut off the cable to the required length.

2 Strip the cable insulation for approx. 45 mm.

3 Bare the wires 1 and 2 and fit them with wire end sleeves.

3 - 20

ba76095e02 01/2013

Page 31

MIQ/Blue PS Installation

ca. 45 mm

wire 1

wire 2

1

3

2

4

-

+

Fig. 3-14 Prepared 24 V DC line.

Connecting the 24 V DC

line

4 Open the enclosure.

ba76095e02 01/2013

Fig. 3-15 Inserting the 24 V DC line.

5 Screw a cable gland (pos. 1 in Fig. 3-15) with sealing ring (pos.

2) into the enclosure below the 24 V DC connection.

6 Loosen the coupling ring (pos. 3).

7 Feed the 24 V DC line through the cable gland into the enclo-

sure. When doing so bend the flexible divider (pos. 4) to the

left.

3 - 21

Page 32

Installation MIQ/Blue PS

3

Terminal

labeling:

X11

X10

24V DC

EINGANG

INPUT

POWER

+

-

Fig. 3-16 Line power connection.

Note

The complete assignment of the terminal strip is shown in section 3.7.

8 Connect wires 1 and 2 to the terminal strip. Make sure that the

cable assignment agrees with the specification on the terminal

label under the terminal strip.

9 Tighten the coupling ring (pos. 3).

Warning

No free wires must be allowed to project into the enclosure. Otherwise there is the danger of short circuits that can cause a fire.

Always cut off any wires that are not in use as closely as possible

to the cable gland.

10 Close the enclosure.

3 - 22

ba76095e02 01/2013

Page 33

MIQ/Blue PS Installation

X13

X12

100...

240V AC

NETZ/MAINS

L1

N

X11

X10

24V DC

INPUT

POWER

SENSORNET 2

SENSORNET 1

ON

OFF

X6

RED

RED

SN TERMINATO R

SHIELD

GREEN

SHIELD

GREEN

X5

X4

X3

X2

X1

SENSORNET 3

X8

X9

X7

RED

SHIELD

GREEN

+

-

3.7 Figure of the terminal strip

Fig. 3-17 MIQ/Blue PS terminal strip

ba76095e02 01/2013

3 - 23

Page 34

Installation MIQ/Blue PS

3 - 24

ba76095e02 01/2013

Page 35

MIQ/Blue PS Maintenance and cleaning

4 Maintenance and cleaning

4.1 Maintenance

The MIQ/Blue PS requires no special maintenance. The general maintenance of IQ S

IQ S

ENSORNET system operating manual.

4.2 Cleaning

The cleaning of IQ SENSORNET components is described in the

IQ S

ENSORNET system operating manual.

ENSORNET components is described in the

ba76095e02 01/2013

4 - 1

Page 36

Maintenance and cleaning MIQ/Blue PS

4 - 2

ba76095e02 01/2013

Page 37

MIQ/Blue PS What to do if ...

6

8

7

9

2

1

3

5

4

Status LED

Radio boards

5 What to do if ...

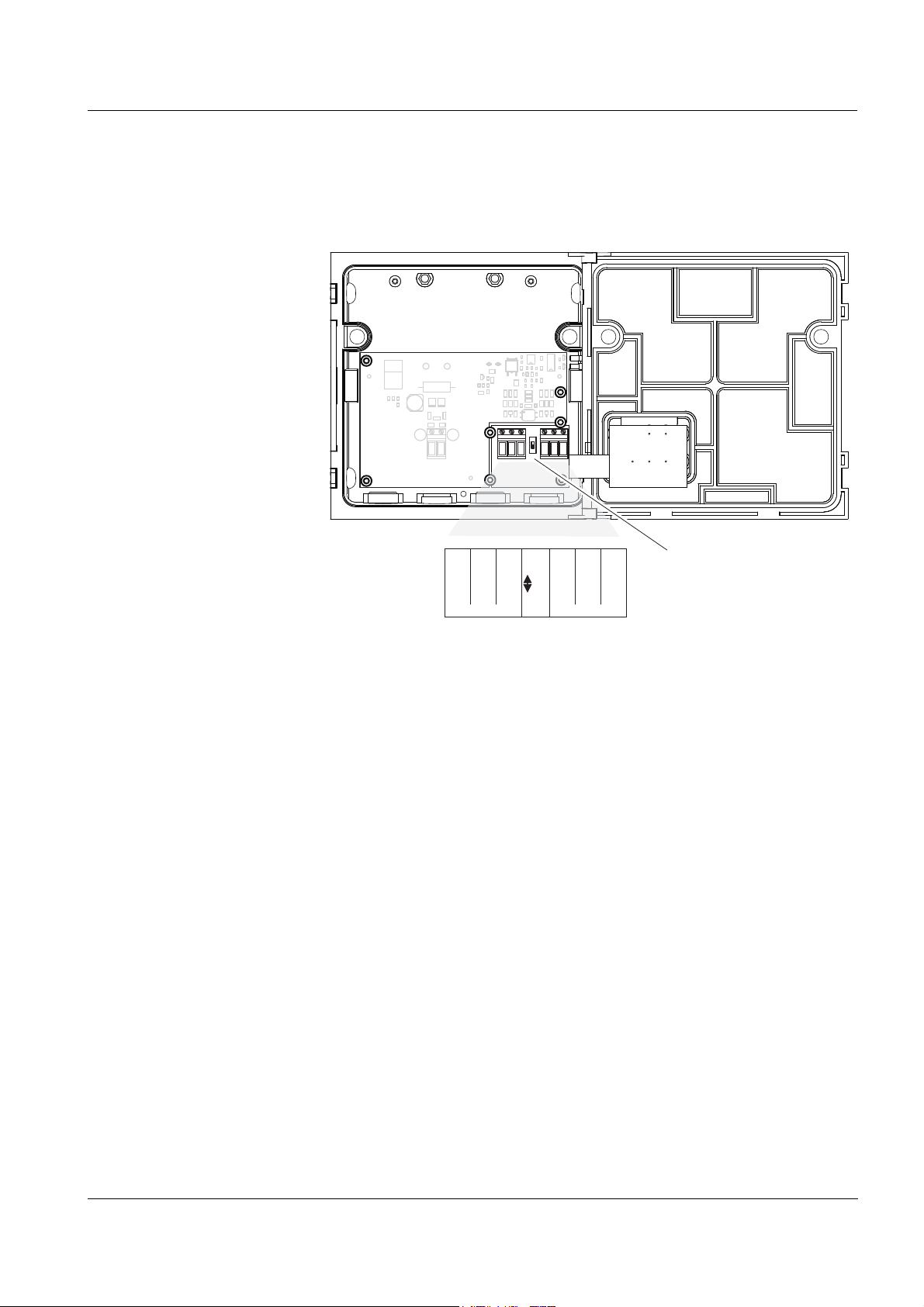

5.1 Check of the radio connection

A yellow LED inside of both MIQ/Blue PS modules indicates the status

of the radio connection:

LED state Connection status

Permanently on Connection OK, no data transmission activity

Flickering Connection OK, data transmission active

Permanently off No connection

The status LED is located at the top edge of the rear radio board:

ba76095e02 01/2013

Fig. 5-1 Status LED radio connection

5 - 1

Page 38

What to do if ... MIQ/Blue PS

5.2 Error causes and remedies

Already established

radio connection does

no longer work

Range insufficient

Cause Remedy

– Obstacle in the radio link – Remove the obstacle

– Range at the limit – see following point, R

INSUFFICIENT

– Moisture on antenna surface – Wipe the antenna dry

– Use a canopy

– The radio link is not active

despite the display on the radio

PCB (status LED permanently

– Switch on and after 5 sec-

onds off again both MIQ/

Blue PS modules

on)

Cause Remedy

– Obstacle in the radio link – Remove the obstacle

– Mount the MIQ/Blue PS in a

higher position (e.g. on a

pole)

– Make sure there is "visual

contact" between the MIQ/

Blue PS modules

ANGE

– MIQ/Blue PS too close to the

ground

– Mount the MIQ/Blue PS in a

higher position (e.g. on a

pole)

– Shielding by metal canopy – Use plastic canopy SSH/IQ

5 - 2

ba76095e02 01/2013

Page 39

MIQ/Blue PS Technical data

6 Technical data

Note

General technical data on MIQ modules are given in the T

DATA chapter of the IQ SENSORNET system operating manual.

6.1 Electrical data

6.1.1 Operation without line power supply unit

Nominal voltage Max. 24 V DC via the IQ SENSORNET (for

details, see chapter T

IQ S

Power consumption 0.6 W

ENSORNET system operating manual).

ECHNICAL DATA of the

ECHNICAL

100 ... 240 V AC

operation

6.1.2 Operation with line power supply unit

Supply Nominal voltage:100 ... 240 V AC ± 10 %

Frequency: 50/60 Hz

according to DIN IEC 60038

Line power connection:2 pin, N and L

Line cross-section of mains connection:

Europe: 1.5 ... 4.0 mm

USA: AWG 14 ... 12

Fuse rating on the operator side: max. 16 A

Power consumption Approx. 12 W

Output voltage Max. 24 VDC via the IQ S

details, see chapter T

IQ S

ENSORNET system operating manual).

ENSORNET (for

ECHNICAL DATA of the

2

ba76095e02 01/2013

6 - 1

Page 40

Technical data MIQ/Blue PS

40 50 6020 300-30 -20 -10 10

0

1

2

3

4

5

6

7

8

Power output [W]

Ambient temperature [°C]

Admissible ambient temperature -20 … +55 °C

Power output Up to 47 °C (117 °F) ambient temperature

7 W; over 47 °C (117 °F) the power delivery

is reduced linearly to 4.4 W at 55 °C

(131 °F):

24 V DC operation

Protective class II

Overvoltage

II

category

Supply Input:23 ... 26.5 V DC / max. 1 A

protective low voltage

SELV (Safety

Extra Low Voltage)

Ripple:

<5%

Connection:2 pin

Line cross-section of connections:

Europe:1.5 ... 4.0 mm

2

USA:AWG 14 ... 12

Fuse rating on the operator side: max. 16 A

Power consumption Max. 24 W

6 - 2

Output voltage Max. 24 VDC via the IQ S

details, see chapter T

IQ S

ENSORNET system operating manual).

ENSORNET (for

ECHNICAL DATA of the

Power output Max. 24 W

ba76095e02 01/2013

Page 41

MIQ/Blue PS Technical data

X13

X12

100...

240V AC

NETZ/MAINS

L1

N

X11

X10

24V DC

EINGANG

INPUT

POWER

SENSORNET 2

SENSORNET 1

ON

EIN

OFF

AUS

X6

ROT

RED

ROT

RED

SN TERMINATO R

SCHIRM

SHIELD

GRÜN

GREEN

SCHIRM

SHIELD

GRÜN

GREEN

X5

X4

X3

X2

X1

SENSORNET 3

X8

X9

X7

ROT

RED

SCHIRM

SHIELD

GRÜN

GREEN

+

-

6.1.3 Electrical connections

Terminal strip inside the

enclosure

Terminals

Cable glands

Terminal type Screw-type terminal strip, accessible by

opening the lid

Terminal ranges Solid wires:

0.2 ... 4.0 mm

2

AWG 24 ... 12

2

Suitable for cable diam-

Flexible wires:

0.2 ... 2.5 mm

4.5 ... 10 mm or 7 ... 13 mm

eter

6.2 Radio transmission

Radio frequency 2.402 ... 2.480 GHz

Transmitting power max. 20 dBm or 100 mW

Bridgeable distance max. 100 m (328 ft)

The specified maximum range applies if the

radio link was installed and tested according

to this operating manual (see section 3.3).

6.3 Instrument safety

Used directives and

standards

ba76095e02 01/2013

In addition to the standards listed in the IQ SENSORNET system operating manual, the MIQ/Blue PS is based on the following directives and

standards:

Data radio – EEC directive 1999/5/EC

(R&TTE directive)

– EN 300 328-2

6 - 3

Page 42

Technical data MIQ/Blue PS

6 - 4

ba76095e02 01/2013

Page 43

MIQ/Blue PS Appendix: Installation instructions for several radio links

7 Appendix: Installation instructions for

several radio links

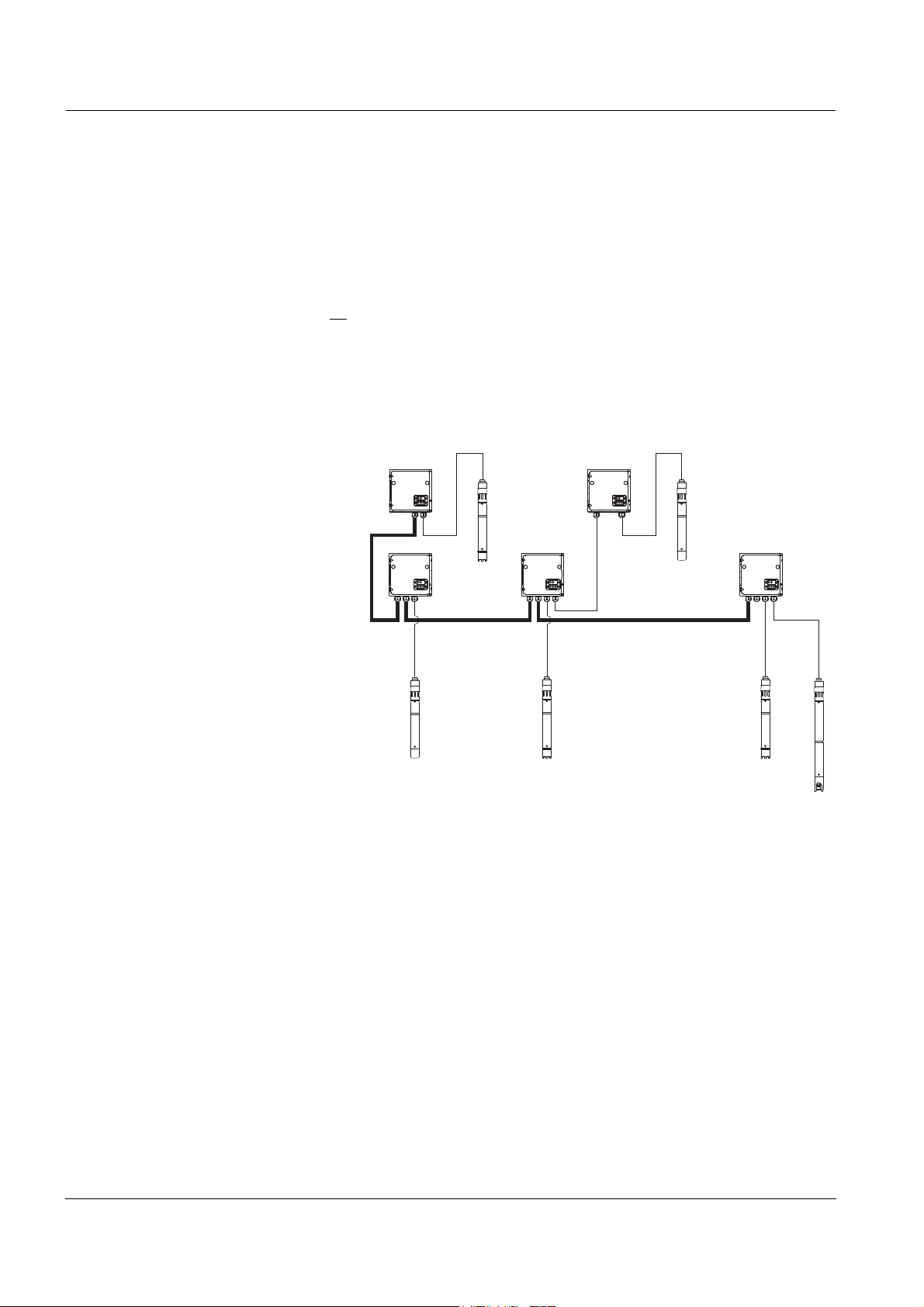

7.1 General information

If no further 2,4 GHz radio links ("Pico nets", e. g. Bluetooth or WLan

devices) of other manufacturers operate in the same radio area, 10

MIQ/Blue PS SETs can be operated at a plant at the same time.

The appendix describes the special features that have to be taken into

account when several radio links should be established in an

IQ S

ENSORNET system.

7.2 Application example for several radio links

ba76095e02 01/2013

Fig. 7-1 Example 3: Star-shaped structure - controller in the center

7 - 1

Page 44

Appendix: Installation instructions for several radio links MIQ/Blue PS

7.3 Power supply

Several MIQ/Blue PS

modules on an

IQ S

ENSORNET island

Compatibility with other

line power supply units

Example Problem:

If several MIQ/Blue PS modules are positioned on one IQ S

ENSORNET

island, only one of them can take over the power supply. All other MIQ/

Blue PS modules count as consumers in the power rating (power

requirement 0.6 W). Accordingly, only one MIQ/Blue PS module has to

be connected to the power supply.

If other power supply modules (e.g. MIQ/PS) are installed on the

IQ S

ENSORNET island, the line power supply units of all MIQ/Blue PS

modules are automatically inactive. Connecting the MIQ/Blue PS line

power supply units to a power supply remains ineffective here. In this

case, all MIQ/Blue PS modules are consumers with a power consumption of 0.6 W each in the power rating.

An IQ SENSORNET island should consist of the following compo-

nents plus two MIQ/Blue PS modules:

Component Power requirement

[W]

VisoTurb

ViSolid

SensoLyt

®

700 IQ 1.5

®

700 IQ 1.5

®

700 IQ 0.2

MIQ/CHV PLUS 1.0

MIQ/TC 2020 XT (docked from time to time) 3.0

In this example, both MIQ/Blue PS modules and the MIQ/CHV

PLUS should be mounted as a stack.

The IQ S

ENSORNET system should be supplied with 100 ...

240 V AC.

Solution/proceeding:

An MIQ/Blue PS module counts as a consumer with 0.6 W. In the

worst case, i. e. with a docked MIQ/TC 2020 XT, the power requirement of all components is 7.8 W. Power losses in cables do not have

to be taken into account due to the stack mounting.

Power rating: The calculated power requirement is greater than the

maximum power delivery of the MIQ/Blue PS line power supply unit.

Therefore, an additional power supply module has to be installed

(e.g. MIQ/PS).

New power rating: The second MIQ/Blue PS module has to be taken

into account as a consumer as well. Therefore, the power consumption is now 8.4 W. With an MIQ/PS power supply module (18 W),

there is still an energy reserve of 9.6 W for any future extensions.

7 - 2

ba76095e02 01/2013

Page 45

MIQ/Blue PS Contact Information

8 Contact Information

8.1 Ordering & Technical Support

Telephone

Fax

: (937) 767-9353 (orders)

Email

Mail: YSI Incorporated

Internet

When placing an order please have the following information available:

YSI account number (if available) Name and Phone Number

Model number or brief description Billing and shipping address

Quantity Purchase Order or Credit Card

: (800) 897-4151

(937) 767-7241

Monday through Friday, 8:00 AM to 5:00 PM ET

(937) 767-1058 (technical support)

: environmental@ysi.com

1725 Brannum Lane

Yellow Springs, OH 45387

USA

: www.ysi.com

ba76095e02 01/2013

8.2 Service Information

YSI has authorized service centers throughout the United States and

Internationally. For the nearest service center information, please visit

www.ysi.com

directly at 800-897-4151.

When returning a product for service, include the Product Return form

with cleaning certification. The form must be completely filled out for an

YSI Service Center to accept the instrument for service. The Product

Return form may be downloaded at www.ysi.com

‘Support‘ tab.

and click ‘Support’ or contact YSI Technical Support

and clicking on the

3

Page 46

Contact Information MIQ/Blue PS

4

ba76095e02 01/2013

Page 47

Page 48

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We're 12,500 people unified in a common purpose: creating innovative solutions

to meet our world's water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem |' m|zīlə

YSI

1725 Brannum Lane

Yellow Springs, OH 45387

Tel: +1 937-767-7241; 800-765-4974

Fax: +1 937-767-1058

Email: environmental@ysi.com

Web: www.ysi.com

©Xylem Inc

Loading...

Loading...