Page 1

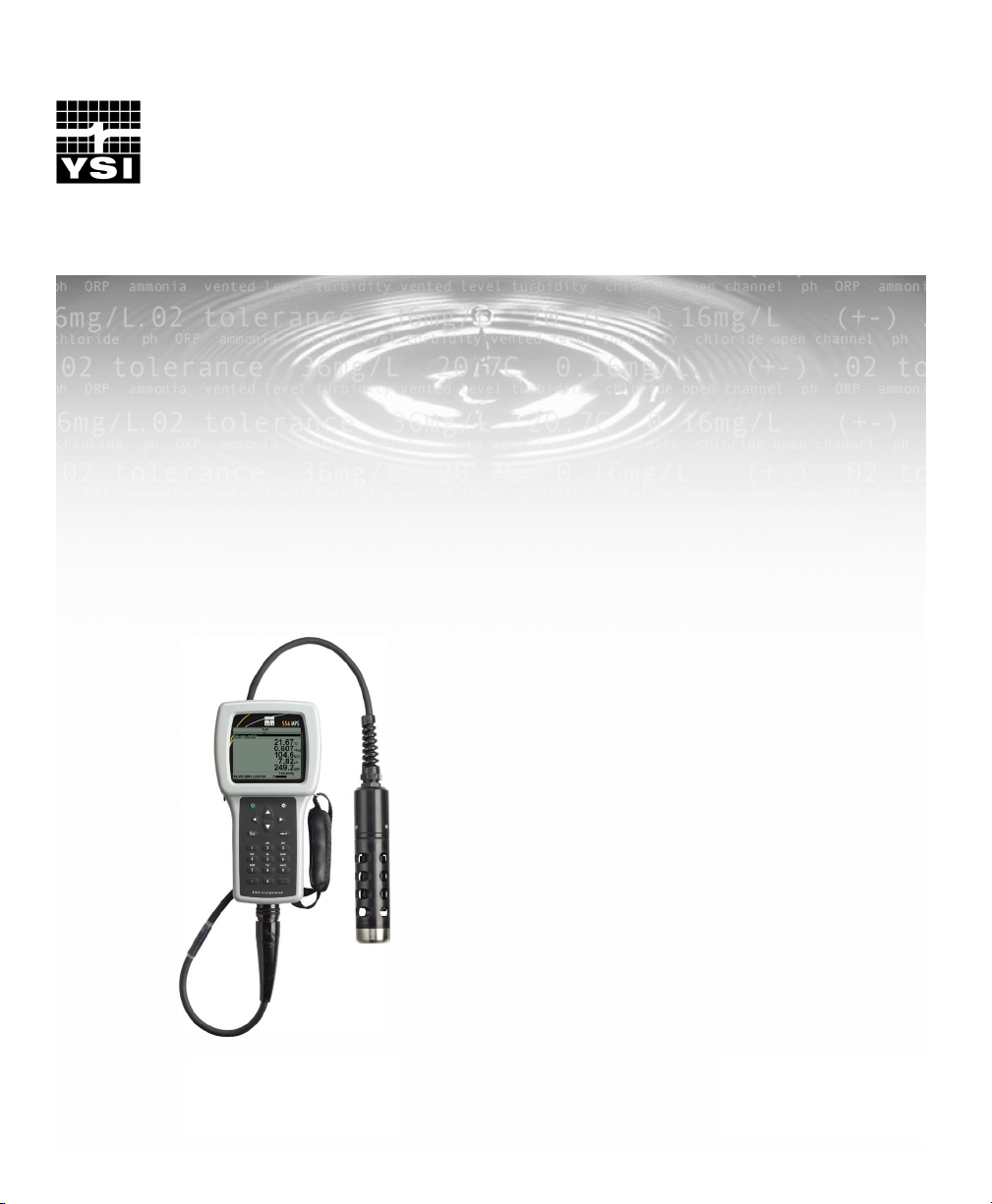

Y

YSI Environmental

Pure Data for a Healthy Planet.™

SI 556 MPS

Multi Probe System

Operations

Manual

Page 2

Page 3

Page 4

Page 5

Contents

1. Safety .........................................................................................................................1

1.1 General Safety Information ...............................................................................1

2. General Information ................................................................................................7

2.1 Description.........................................................................................................7

2.2 Unpacking the Instrument..................................................................................8

2.3 Features of the YSI 556 Multi-Probe System....................................................9

2.4 Batteries ...........................................................................................................10

2.5 Power On .........................................................................................................15

2.6 Setting Display Contrast..................................................................................15

2.7 Backlight..........................................................................................................16

2.8 General Screen Features ..................................................................................16

2.9 Keypad Use......................................................................................................17

2.10 Instrument Reset..............................................................................................18

2.11 Menu Flowchart...............................................................................................19

3. Probe Module..........................................................................................................21

3.1 Introduction......................................................................................................21

3.2 Unpacking the Probe Module ..........................................................................21

3.3 Features of the YSI 5563 Probe Module .........................................................22

3.4 Preparing the Probe Module............................................................................22

3.5 Transport/Calibration Cup...............................................................................26

3.6 Instrument/Cable Connection ..........................................................................27

4. Sensors.....................................................................................................................29

5. Report ......................................................................................................................33

6. Calibrate..................................................................................................................37

6.1 Getting Ready to Calibrate ..............................................................................37

6.2 Calibration Procedures.....................................................................................40

6.3 Return to Factory Settings ...............................................................................56

7. Run...........................................................................................................................59

7.1 Real-Time Data................................................................................................59

8. File............................................................................................................................61

8.1 Accessing the File Screen................................................................................61

8.2 Directory..........................................................................................................62

8.3 View File .........................................................................................................63

8.4 Upload to PC....................................................................................................64

8.5 File Memory ....................................................................................................69

YSI Incorporated YSI 556 MPS i

Page 6

Contents

8.6 Delete All Files................................................................................................ 70

9. Logging.................................................................................................................... 73

9.1 Accessing the Logging Setup Screen .............................................................. 73

9.2 Setting Logging Interval.................................................................................. 74

9.3 Storing Barometer Readings ........................................................................... 74

9.4 Creating a Site List.......................................................................................... 75

9.5 Editing a Site List............................................................................................ 79

9.6 Logging Data Without a Site List.................................................................... 81

9.7 Logging Data With a Site List......................................................................... 84

9.8 Adding Data to Existing Files ......................................................................... 85

10. System Setup........................................................................................................... 89

10.1 Accessing the System Setup Screen................................................................ 89

10.2 Date and Time Setup....................................................................................... 90

10.3 Data Filter........................................................................................................ 92

10.4 Shutoff Time.................................................................................................... 94

10.5 Comma Radix.................................................................................................. 95

10.6 ID..................................................................................................................... 95

10.7 GLP Filename.................................................................................................. 95

10.8 TDS Constant .................................................................................................. 96

10.9 Barometer Units .............................................................................................. 97

10.10 Calibrate Barometer .................................................................................... 98

11. Maintenance .........................................................................................................101

11.1 Sensor Care and Maintenance....................................................................... 101

11.2 Upgrading YSI 556 MPS Software............................................................... 107

12. Storage................................................................................................................... 111

12.1 General Recommendations for Short Term Storage...................................... 111

12.2 General Recommendations for Long Term Storage...................................... 111

13. Troubleshooting ...................................................................................................115

14. Appendix A YSI 556 MPS Specifications...........................................................119

14.1 Sensor Specifications .................................................................................... 119

14.2 Instrument Specifications .............................................................................. 120

15. Appendix B Instrument Accessories................................................................... 121

16. Appendix C Required Federal Communications Notice .................................. 123

17. Appendix D Health and Safety............................................................................125

18. Appendix E Customer Service............................................................................ 129

YSI 556 MPS YSI Incorporated

Page ii

Page 7

Contents

18.1 YSI Environmental Authorized Service Centers...........................................129

18.2 Cleaning Instructions.....................................................................................131

18.3 Packing Procedure .........................................................................................132

18.4 Cleaning Certificate.......................................................................................132

18.5 Warranty ........................................................................................................133

19. Appendix F Ferrite Bead Installation.................................................................135

20. Appendix G EcoWatch.........................................................................................137

20.1 Installing EcoWatch for Windows.................................................................137

20.2 EcoWatch Tutorial.........................................................................................139

21. Appendix H Calibration Record Information ...................................................151

21.1 Viewing the Calibration Record (.glp) File ...................................................151

21.2 Uploading the Calibration Record (.glp) File ................................................151

21.3 Understanding the Calibration Record (.glp) File..........................................151

YSI Incorporated YSI 556 MPS Page iii

Page 8

Contents

YSI 556 MPS YSI Incorporated

Page iv

Page 9

1. Safety

1.1 General Safety Information

Read all safety information in this manual carefully before using

the YSI 556 Multi-Probe System (MPS). Reagents that are used

to calibrate and check this instrument may be hazardous to your

health. Take a moment to review Appendix D Health and Safety.

WARNING

Warnings are used in this manual when misuse of the instrument

could result in death or serious injury to a person.

CAUTION

Cautions are used in this manual when misuse of the instrument

could result in mild or serious injury to a person and/or damage

to equipment.

IMPORTANT SAFETY INSTRUCTIONS!

SAVE THESE INSTRUCTIONS!

In essence, the most important safety rule for use of the YSI 556

MPS is to utilize the instrument ONLY for purposes documented

in this manual. This is particularly true of the YSI 6117

rechargeable battery pack that contains nickel metal hydride

(NiMH) batteries. The user should be certain to read all of the

safety precautions outlined below before using the instrument.

YSI 6117 Rechargeable Battery Pack Safety Information

Restrictions on Usage

1. Never dispose of the battery pack in a fire.

2. Do not attempt to disassemble the YSI 6117 battery pack.

3. Do not tamper with any of the electronic components or the

batteries within the battery pack. Tampering with either the

electronic circuitry or the batteries will result in the voiding

of the warranty and the compromising of the system

performance, but, more importantly, can cause safety

YSI Incorporated YSI 556 MPS Page 1

Page 10

Safety Section 1

hazards which result from overcharging such as overheating,

venting of gas, and loss of corrosive electrolyte.

4. Do not charge the battery pack outside the 0–40°C

temperature range.

5. Do not use or store the battery at high temperature, such as

in strong direct sunlight, in cars during hot weather, or

directly in front of heaters.

6. Do not expose the battery pack to water or allow the

terminals to become damp.

7. Avoid striking or dropping the battery pack. If the pack

appears to have sustained damage from these actions or

malfunctions after an impact or drop, the user should not

attempt to repair the unit. Instead, contact YSI Customer

Service. Refer to Appendix E Customer Service.

8. If the battery pack is removed from the YSI 556 MPS, do not

store it in pockets or packaging where metallic objects such

as keys can short between the positive and negative

terminals.

Precautions for Users with Small Children

Keep the battery pack out of reach of babies and small children.

Danger Notifications – Misuse creates a STRONG possibility of death

or serious injury.

FAILURE TO CAREFULLY OBSERVE THE

FOLLOWING PROCEDURES AND PRECAUTIONS CAN

RESULT IN LEAKAGE OF BATTERY FLUID, HEAT

GENERATION, BURSTING, AND SERIOUS PERSONAL

INJURY.

1. Never dispose of the battery pack in a fire or heat it.

2. Never allow the positive and negative terminals of the

battery pack to become shorted or connected with

electrically conductive materials. When the battery pack has

been removed from the YSI 556 MPS, store it in a heavy

plastic bag to prevent accidental shorting of the terminals.

YSI 556 MPS YSI Incorporated

Page 2

Page 11

Safety Section 1

3. Never disassemble the battery pack and do not tamper with

any of the electronic components or the batteries within the

battery pack. The battery pack is equipped with a variety of

safety features. Accidental deactivation of any of these

safety features can cause a serious hazard to the user.

4. The NiMH batteries in the battery pack contain a strong

alkaline solution (electrolyte). The alkaline solution is

extremely corrosive and will cause damage to skin or other

tissues. If any fluid from the battery pack comes in contact

with a user’s eyes, immediately flush with clean water and

consult a physician immediately. The alkaline solution can

damage eyes and lead to permanent loss of eyesight.

Warning Notifications – Misuse creates a possibility of death or serious

injury

1. Do not allow the battery pack to contact freshwater,

seawater, or other oxidizing reagents that might cause rust

and result in heat generation. If a battery becomes rusted, the

gas release vent may no longer operate and this failure can

result in bursting.

2. If electrolyte from the battery pack contacts the skin or

clothing, thoroughly wash the area immediately with clean

water. The battery fluid can irritate the skin.

Caution Notifications – Misuse creates a possibility of mild or serious

injury or damage to the equipment.

1. Do not strike or drop the battery pack. If any impact damage

to the battery pack is suspected, contact YSI Customer

Service. Refer to Appendix E Customer Service.

2. Store the battery pack out of reach of babies and small

children.

3. Store the battery pack between the temperatures of -20 and

30°C.

4. Before using the battery pack, be sure to read the operation

manual and all precautions carefully. Then store this

information carefully to use as a reference when the need

arises.

YSI Incorporated YSI 556 MPS Page 3

Page 12

Safety Section 1

YSI 616 Cigarette Lighter Charger Safety Information

1. This section contains important safety and operating

instructions for the YSI 556 MPS cigarette lighter battery

charger (YSI 616; RadioShack Number 270-1533E). BE

SURE TO SAVE THESE INSTRUCTIONS.

2. Before using the YSI 616 cigarette lighter charger, read all

instructions and cautionary markings on battery charger,

battery pack, and YSI 556 MPS.

3. Charge the YSI 6117 battery pack with the YSI 616 cigarette

lighter charger ONLY when the YSI 6117 is installed in the

YSI 556 MPS.

4. Do not expose charger to rain, moisture, or snow.

5. Use of an attachment not recommended or sold by the

battery charger manufacturer may result in a risk of fire,

electric shock, or injury to persons.

6. To reduce risk of damage to cigarette lighter and cord, pull

by cigarette lighter rather than cord when disconnecting

charger.

7. Make sure that the cord is located so that it will not be

stepped on, tripped over, or otherwise subjected to damage

or stress.

8. Do not operate charger with damaged cord or cigarette

lighter connector – replace it immediately.

9. Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way; contact YSI

Customer Service. Refer to Appendix E Customer Service.

10. Do not disassemble charger other than to change the fuse as

instructed. Replace the part or send it to YSI Product Service

if repair is required (refer to Appendix E Customer Service).

Incorrect reassembly may result in a risk of electric shock or

fire.

11. To reduce risk of electric shock, unplug charger before

attempting any maintenance or cleaning. Turning off

controls will not reduce this risk.

YSI 556 MPS YSI Incorporated

Page 4

Page 13

Safety Section 1

YSI 556 MPS Water Leakage Safety Information

The YSI 556 MPS has been tested and shown to comply with

IP67 criterion, i.e. submersion in 1 meter of water for 30 minutes

with no leakage into either the battery compartment or the main

case. However, if the instrument is submersed for periods of time

in excess of 30 minutes, leakage may occur with subsequent

damage to the batteries, the rechargeable battery pack circuitry,

and/or the electronics in the main case.

If leakage into the battery compartment is observed when using

alkaline C cells, remove batteries, dispose of batteries properly,

and dry the battery compartment completely, ideally using

compressed air. If corrosion is present on the battery terminals,

contact YSI Customer Service for instructions. Refer to

Appendix E Customer Service.

If leakage into the battery compartment is observed when using

the YSI 6117 rechargeable battery pack, remove the battery

assembly and set aside to dry. Return the battery pack to YSI

Product Service for evaluation of possible damage. Finally dry

the battery compartment completely, ideally using compressed

air. If corrosion is present on the battery terminals, contact YSI

Customer Service for instructions. Refer to Appendix E

Customer Service.

CAUTION: If water has contacted the rechargeable battery

pack, do not attempt to reuse it until it has been evaluated by YSI

Product Service (refer to Appendix E Customer Service). Failure

to follow this precaution can result in serious injury to the user.

If it is suspected that leakage into the main cavity of the case has

occurred, remove the batteries immediately and return the

instrument to YSI Product Service for damage assessment. Refer

to Appendix E Customer Service.

CAUTION: Under no circumstances should the user attempt to

open the main case.

YSI Incorporated YSI 556 MPS Page 5

Page 14

Safety Section 1

YSI 556 MPS YSI Incorporated

Page 6

Page 15

2. General Information

2.1 Description

The rugged and reliable YSI 556 MPS (Multi-Probe System)

combines the versatility of an easy-to-use, easy-to-read handheld

unit with all the functionality of a multi-parameter system.

Featuring a waterproof, impact-resistant case, the YSI 556 MPS

simultaneously measures dissolved oxygen, conductivity,

temperature, and optional pH and ORP. A simple cellular phone

style keypad and large display make the instrument easy to use.

The YSI 556 MPS is compatible with YSI EcoWatch

Windows

The YSI 556 MPS assists the user in conforming to Good

Laboratory Practice (GLP) standards which help ensure that

quality control/quality assurance methods are followed. Battery

life is displayed with a fuel gauge, and the user can choose

standard alkaline batteries or an optional rechargeable battery

pack.

The 1.5 MB memory can store more than 49,000 data sets. Other

options include a flow cell and barometer. The internal

barometer can be user-calibrated and displayed along with other

data, used in dissolved oxygen calibrations, and logged to

memory for tracking changes in barometric pressure.

TM

software.

TM

for

Features

• Waterproof - meets IP67 specifications

• Field-replaceable DO electrode module; pH and pH/ORP sensors

• Compatible with Ecowatch

software

• Assists with Good Laboratory Practice Standards (GLP)

• Choice of DO membrane material for different applications

• Easy-to-use, screw-on cap DO membranes

• User-upgradable software from YSI website

• Three-year warranty on the instrument; one-year on the probe

modules

• Available with 4,10, and 20 m cable lengths

• Stores over 49,000 data sets, time and date stamped

YSI Incorporated YSI 556 MPS Page 7

TM

for WindowsTM data analysis

Page 16

General Information Section 2

• Auto temperature compensating display contrast

• Optional barometer

• Optional rechargeable battery pack or standard alkaline batteries

2.2 Unpacking the Instrument

1. Remove the instrument from the shipping box. Note that the

probe module and sensors are shipped in a separate box and

will be unpacked later in Section 3.2 Unpacking the Probe

Module.

NOTE: Do not discard any parts or supplies.

2. Use the packing list to ensure all items are present.

3. Visually inspect all components for damage.

NOTE: If any parts are missing or damaged, contact your

YSI Service Center immediately. Refer to Appendix E

Customer Service or www.ysi.com.

YSI 556 MPS YSI Incorporated

Page 8

Page 17

General Information Section 2

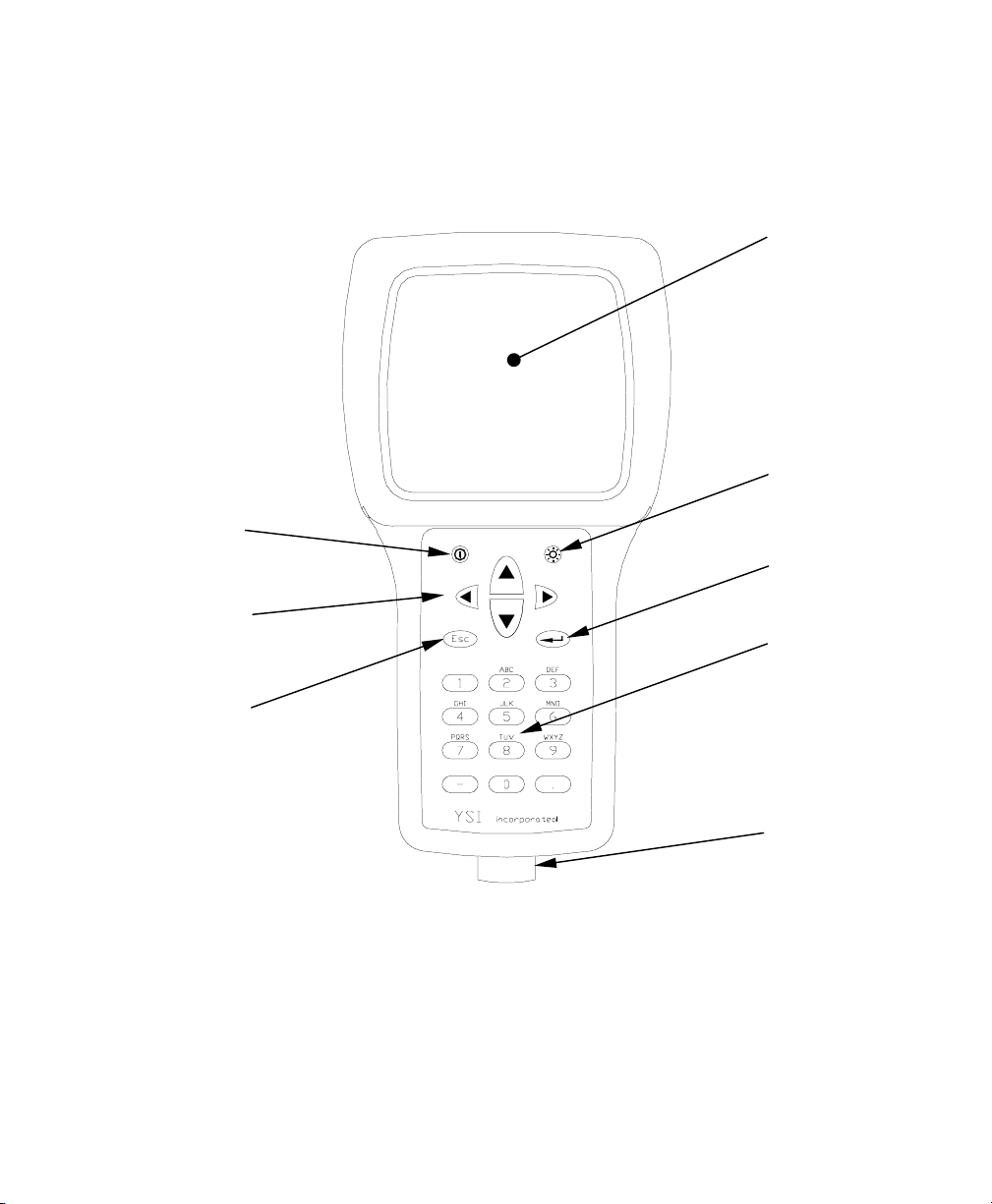

2.3 Features of the YSI 556 Multi-Probe System

On/Off Key

Arrow Keys

Escape Key

Display

Backlight

Key

Enter Key

Alpha/Numeric

Keys – Used to

enter letters and

numbers

Cable Connector

Figure 2.1 Front View of YSI 556 MPS

YSI Incorporated YSI 556 MPS Page 9

Page 18

General Information Section 2

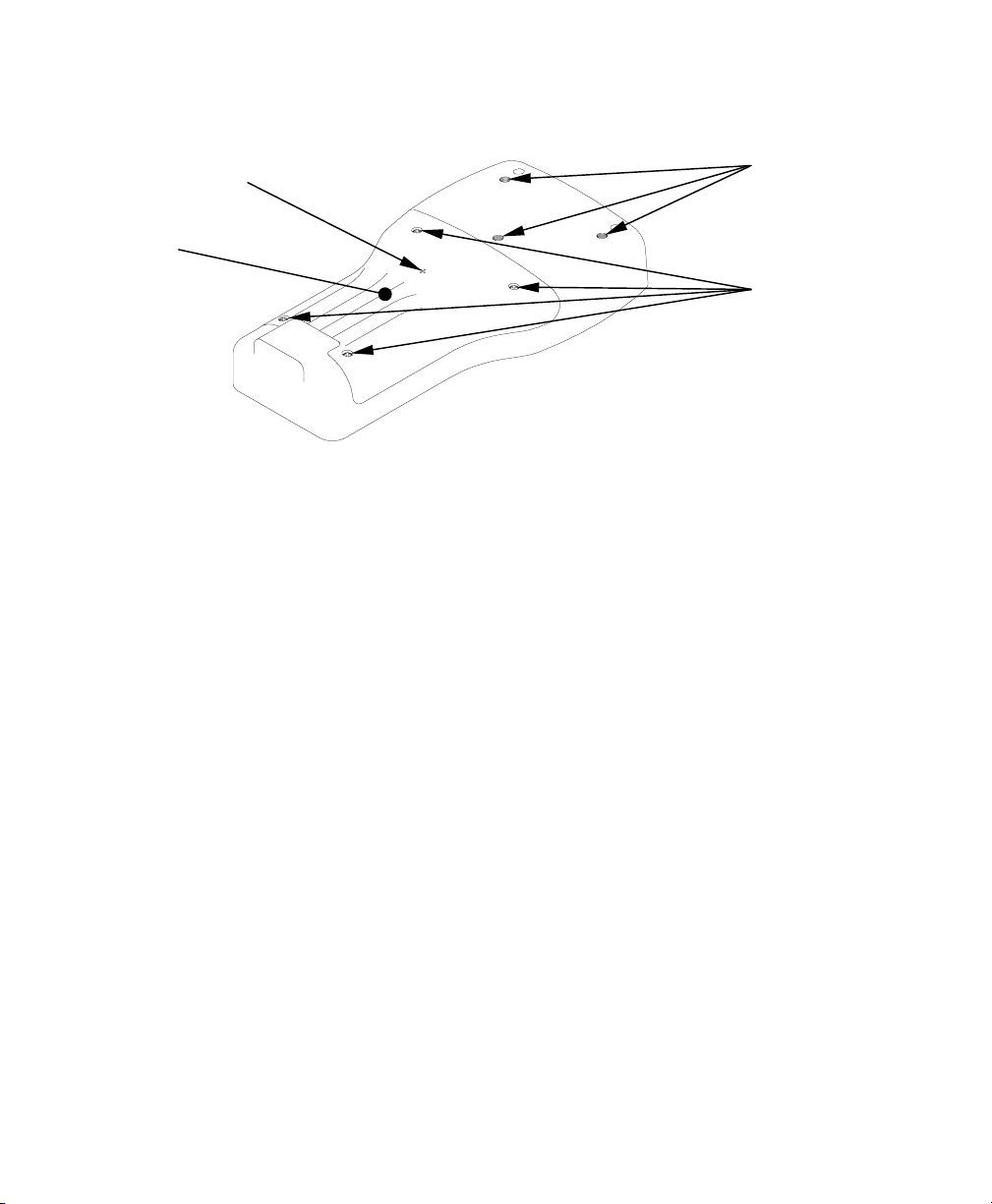

Accessory

Mounting

Holes

Barometer

Vent Patch

Lid

Battery Lid

Screws

Figure 2.2 Back View of YSI 556 MPS

2.4 Batteries

2.4.1 Battery Life

Standard Alkaline Batteries

With the standard battery configuration of 4 alkaline C cells, the

YSI 556 MPS will operate continuously for approximately 180

hours. Assuming a standard usage pattern when sampling of 3

hours of “on time” in a typical day, the alkaline cells will last

approximately 60 days.

Optional Rechargeable Battery Pack

When fully charged, the optional rechargeable battery pack will

provide approximately 50 hours of battery life.

YSI 556 MPS YSI Incorporated

Page 10

Page 19

General Information Section 2

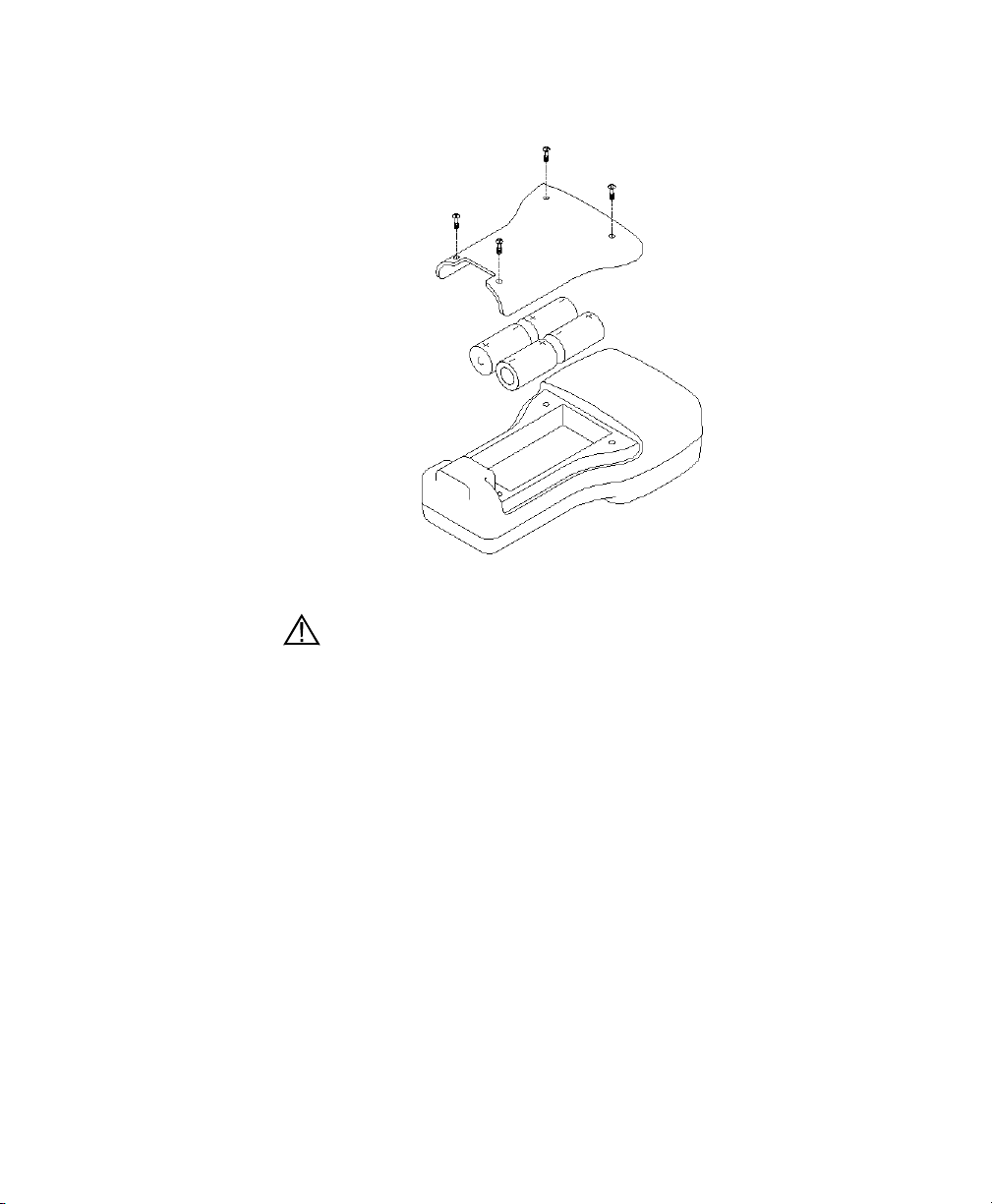

2.4.2 Inserting 4 C Batteries

Figure 2.3 Inserting C Cells

CAUTION: Install batteries properly to avoid damage to the

instrument.

1. Loosen the four screws in the battery lid on the back of the

instrument using any screwdriver.

2. Remove the battery lid.

3. Insert four C batteries between the clips following the

polarity (+ and -) labels on the bottom of the battery

compartment.

4. Check gasket for proper placement on the battery lid.

5. Replace the battery lid and tighten the 4 screws securely and

evenly.

NOTE: Do not over-tighten the screws.

YSI Incorporated YSI 556 MPS Page 11

Page 20

General Information Section 2

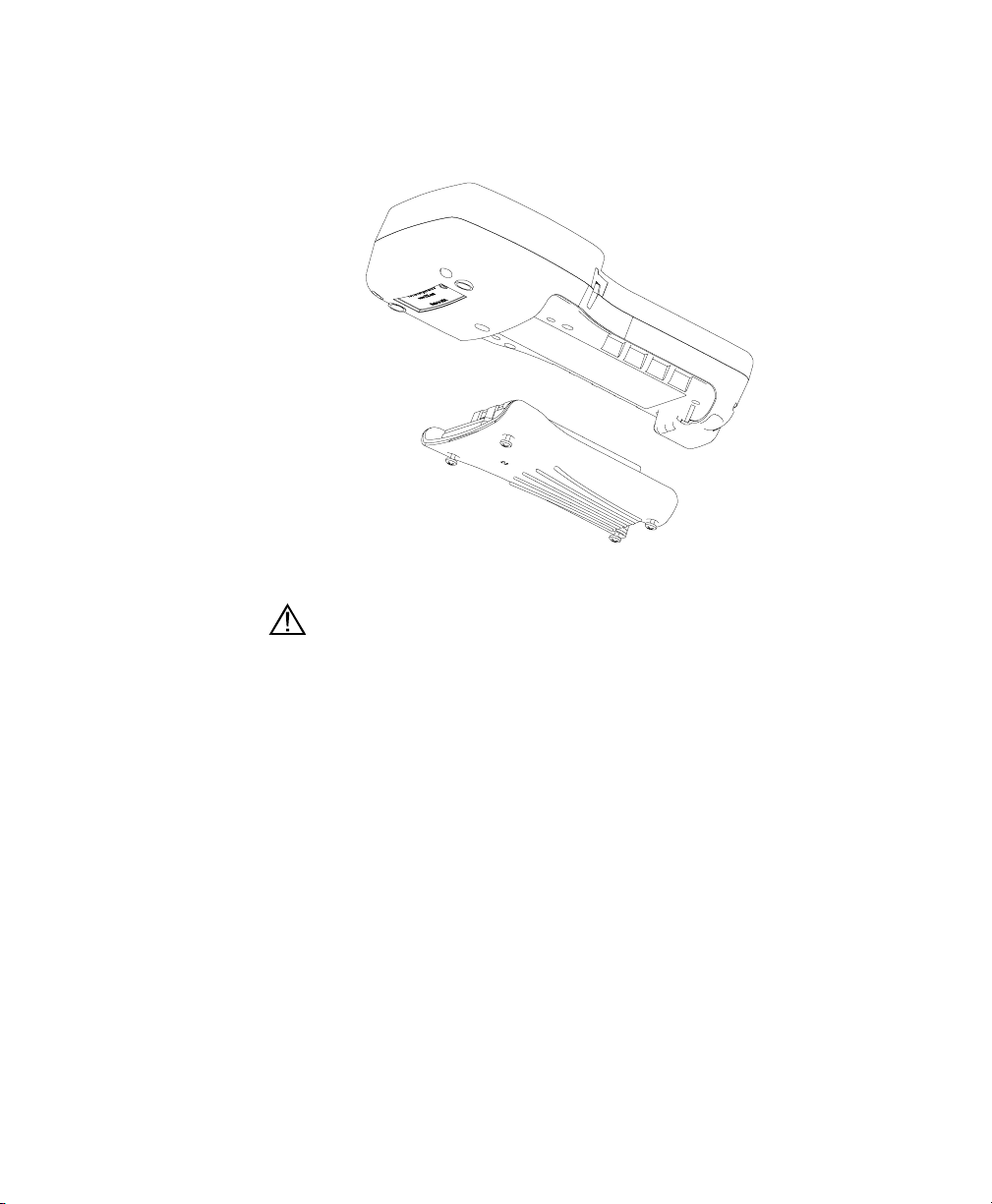

2.4.3 Inserting Optional Rechargeable Battery Pack

Figure 2.4 Inserting Battery Pack

CAUTION: Read all cautions and warnings that come with

the battery pack before using the battery pack.

1. Loosen the four screws in the battery lid on the back of the

instrument using any screwdriver.

2. Remove the C battery lid and store for future use. Remove C

batteries, if installed.

3. Check for proper placement of gasket on the rechargeable

battery pack and lid.

4. Install the rechargeable battery pack and lid and tighten the 4

screws securely and evenly.

NOTE: Do not over tighten the screws.

YSI 556 MPS YSI Incorporated

Page 12

Page 21

General Information Section 2

(

)

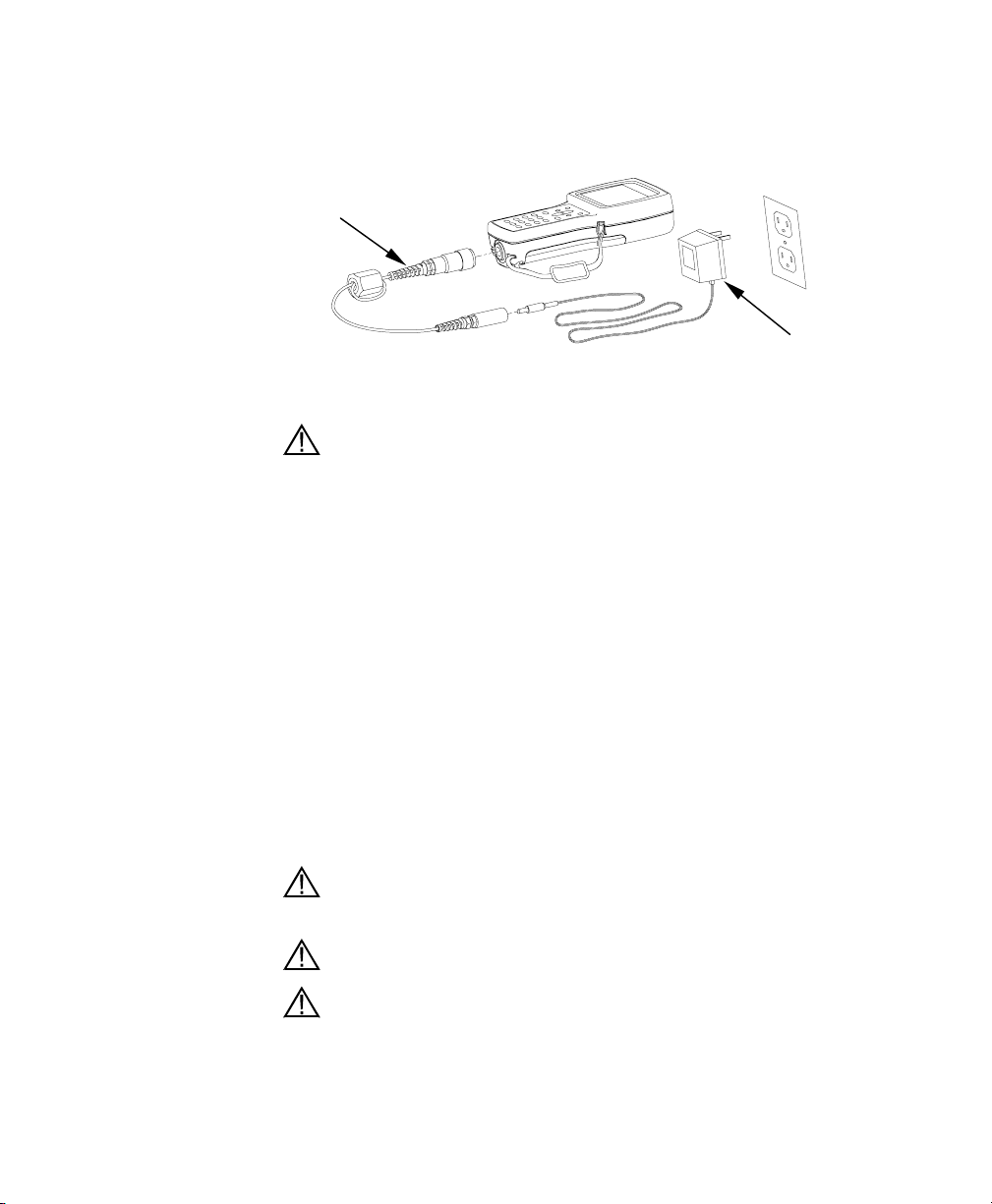

2.4.4 Charging the Optional Rechargeable Battery Pack

Charger adapter cable

(YSI 6119)

Wall power

supply

YSI 6114

Figure 2.5 Charging the Battery Pack

CAUTION: Do not use or store the battery pack at extreme

temperatures such as in strong direct sunlight, in cars during

hot weather or close to heaters.

1. Install the rechargeable battery pack into the instrument as

described in Section 2.4.3 Inserting Optional Rechargeable

Battery Pack.

2. Attach the charger adapter cable (YSI 6119) to the

instrument.

NOTE: Wall power supplies for use in countries outside the

US and Canada can be found in Appendix B Instrument

Accessories.

3. Insert the barrel connector of the wall power supply into the

barrel of the adapter cable.

CAUTION: Do not charge the battery pack continuously for

more than 48 hours.

CAUTION: Do not drop or expose to water.

CAUTION: Do not charge the battery pack at temperatures

below 0°°°°C or above 40°°°°C.

YSI Incorporated YSI 556 MPS Page 13

Page 22

General Information Section 2

4. Plug the wall power supply into an AC power outlet for

approximately 2 hours to obtain an 80% to 90% charge and

for 6 hours to get a full charge.

NOTE: The battery pack can be recharged whether the

instrument is on or off.

2.4.5 Storing the Battery Pack

Remove the battery pack from the instrument when the

instrument will not be used for extended periods of time to

prevent over discharge of the battery pack.

Store the battery pack in a heavy plastic bag to prevent

accidental shorting of the terminals. Store between –20 and

30°C.

2.4.6 Optional Cigarette Lighter Charger

CAUTION: Read all warnings and cautions that come with

the charger before using the charger.

CAUTION: Only use cigarette lighter charger when

rechargeable battery pack is inserted into instrument.

CAUTION: Do not mishandle cigarette lighter charger. Do

not expose to moisture.

1. Plug the barrel connector of the cigarette lighter charger into

the mating end of the YSI 6119 Charger Adapter Cable.

2. Attach the MS-19 end of the YSI 6119 Charger Adapter

Cable to the instrument.

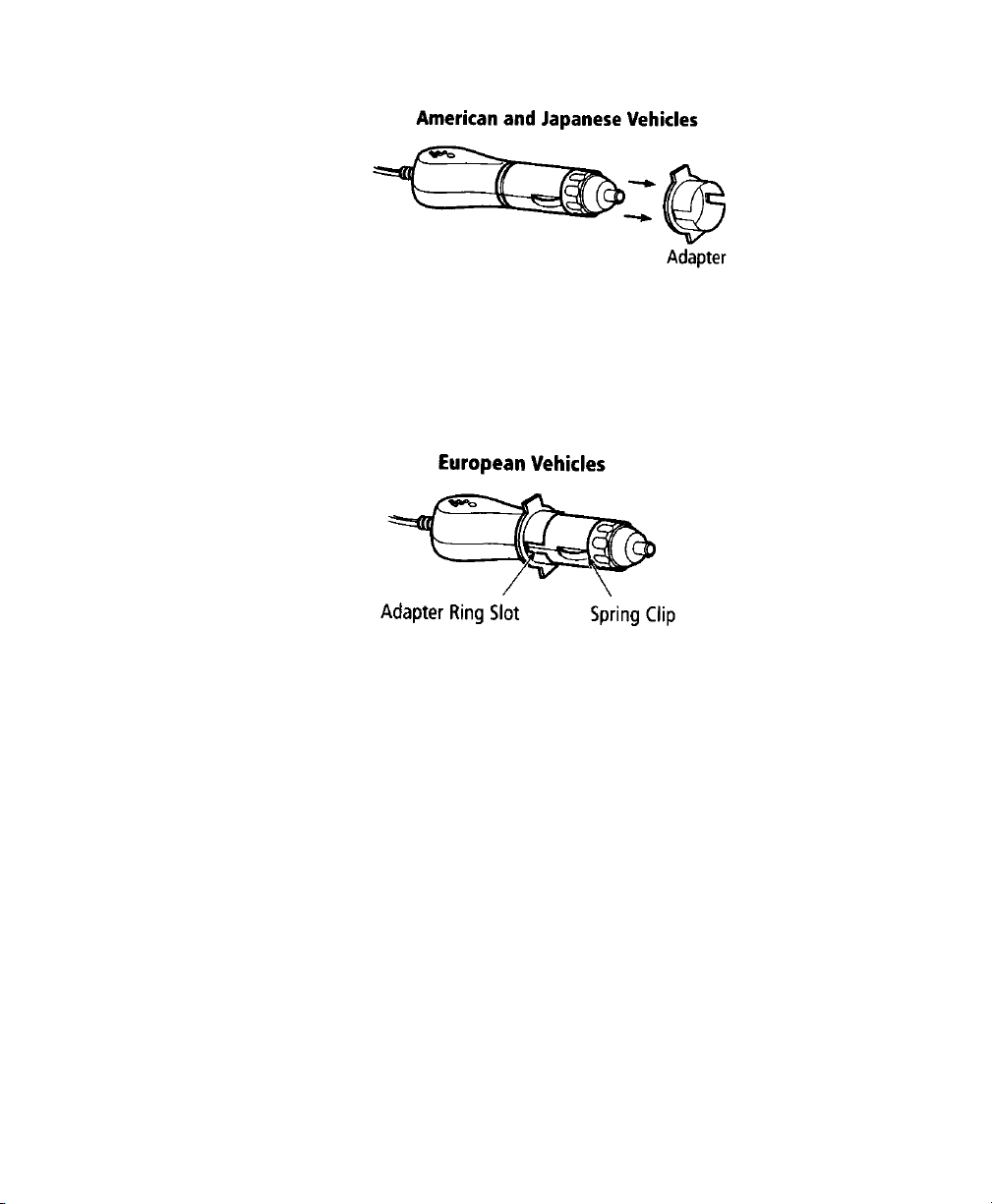

3. Make one of the following modifications to the other end of

the charger:

Slide the adapter ring off the plug to use the device with an

American or Japanese vehicle.

YSI 556 MPS YSI Incorporated

Page 14

Page 23

General Information Section 2

Figure 2.6 Charger Plug Adapter Use

Leave the adapter ring on the plug and position it so that the

slots on the adapter ring line up with the plug’s spring clips

to use the device on a European vehicle.

Figure 2.7 European Charger Plug Adapter Use

NOTE: If the charger stops working properly, refer to

Section 13 Troubleshooting.

2.5 Power On

Press and release the on/off button in the upper left corner of the

instrument keypad to turn the instrument on or off. See Figure

2.1 Front View of YSI 556 MPS.

2.6 Setting Display Contrast

The display contrast automatically compensates for temperature

changes. However, under extreme temperature conditions you

may wish to optimize the display by manual adjustment as

follows:

YSI Incorporated YSI 556 MPS Page 15

Page 24

General Information Section 2

1. Press and hold down the backlight key in the upper right

corner of the keypad and press the “up” arrow to increase

(darken) the contrast.

2. Press and hold down the backlight key in the upper right

corner of the keypad and press the “down” arrow to decrease

(lighten) the contrast.

2.7 Backlight

Press and release the backlight key in the upper right corner of

the keypad to turn the backlight on or off. See Figure 2.1 Front

View of YSI 556 MPS.

NOTE: The backlight turns off automatically after two minutes

of non-use.

2.8 General Screen Features

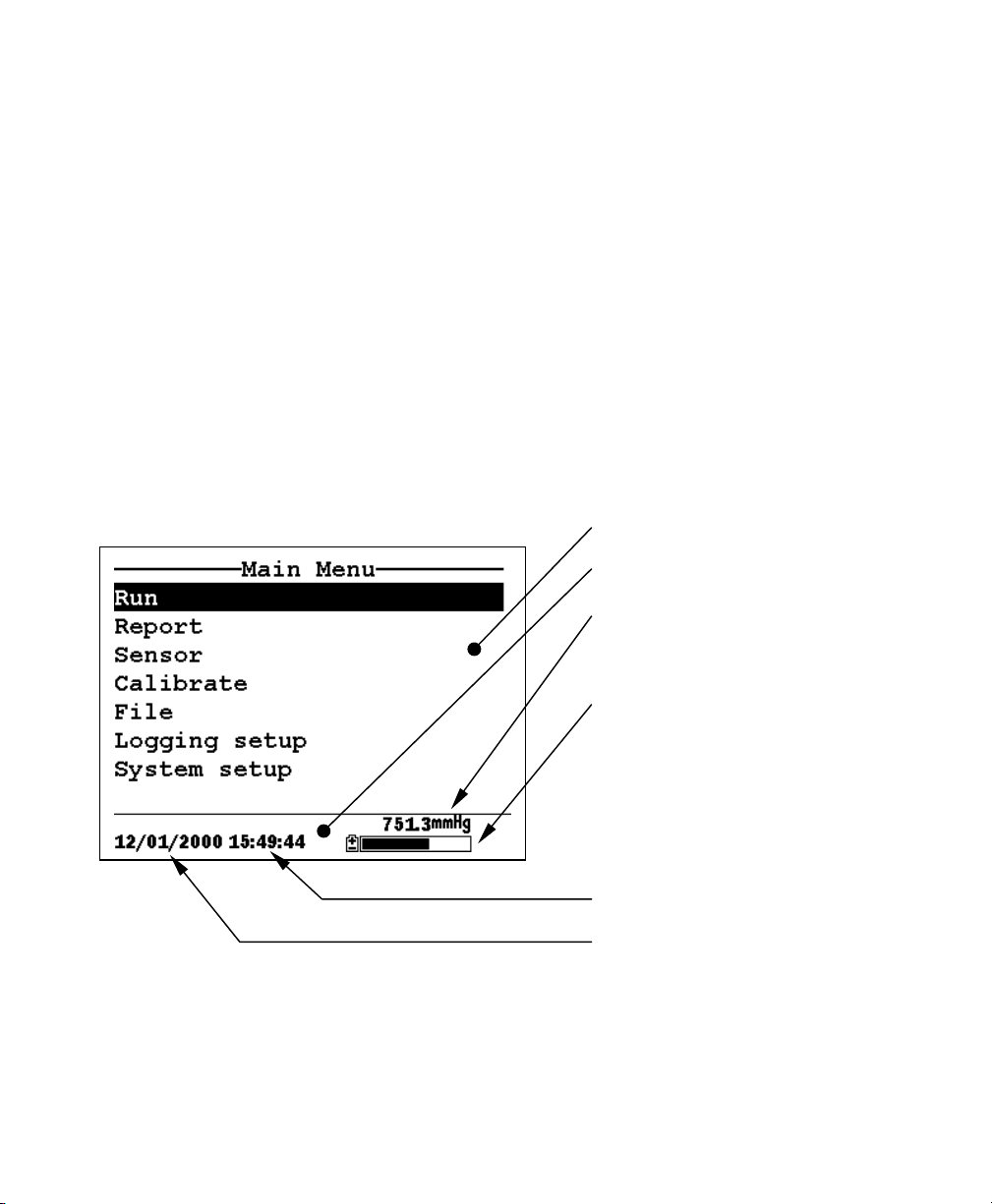

Figure 2.8 Main Menu Screen

Main Display

Status Bar

Barometer Reading (optional)–

Updated in real time, not

corrected to sea level

Battery Charge – NiMH

label indicates use of

optional rechargeable

battery pack, pulsing

indicates that battery is

charging, flashing indicates

batteries almost exhausted

Current Time

Current Date

YSI 556 MPS YSI Incorporated

Page 16

Page 25

General Information Section 2

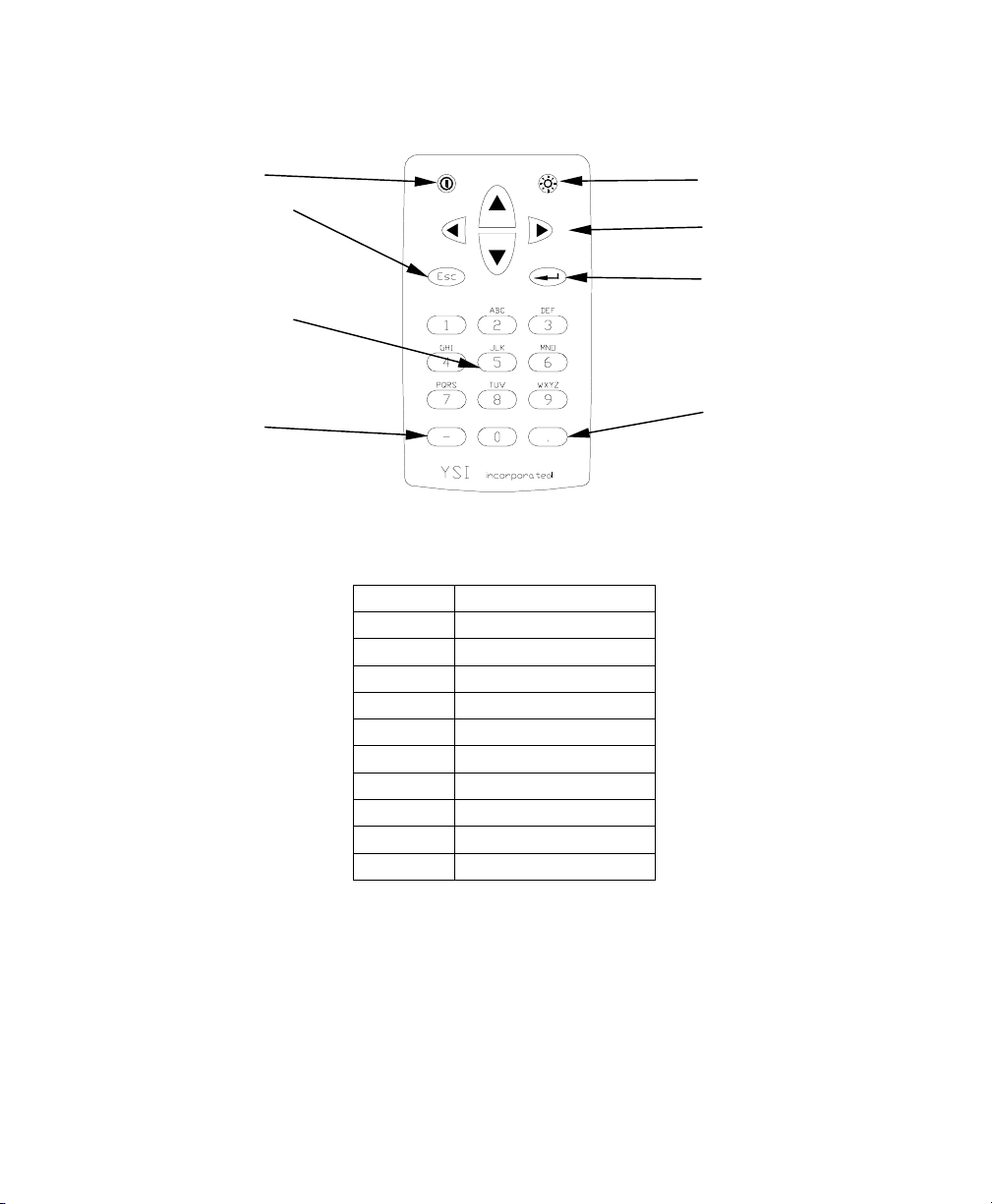

2.9 Keypad Use

On/Off Key

Escape Key – Use

to return to

previous position

in menu

Alpha/Numeric

Keys – Used to

enter letters and

numbers

Minus/Hyphen

(-) Key

Figure 2.9 Keypad Features

KEY LETTER/ NUMBER

1 1

2 ABC2abc3

3 DEF3def3

4 GHI4ghi4

5 JKL5jkl5

6 MNO6mno6

7 PQRS7pqrs7

8 TUV8tuv8

9 WXYZ9wxyz9

0 0

Backlight/Contrast

Arrows Keys

Enter Key

Period/Decimal

Point Key

Figure 2.10 Keypad Letters & Numbers

1. See Figure 2.10 Keypad Letters & Numbers and press the

appropriate key repeatedly until letter or number desired

appears in display.

NOTE: Press the key repeatedly in rapid succession to get to

the desired letter or number. If you pause for more than a

YSI Incorporated YSI 556 MPS Page 17

Page 26

General Information Section 2

second, the cursor automatically scrolls to the right to

prepare for the next input.

EXAMPLE 1: Press the 6 key once and release to display an

uppercase “M.”

EXAMPLE 2: Press the 6 key four times and release to

display the number “6.”

EXAMPLE 3: Press the 6 key five times and stop to display

a lowercase “m.”

2. Press the left arrow key to go back and reenter a number or

letter that needs to be changed.

3. Press the Enter key when your entry is complete.

NOTE: The instrument software permits only numeric

entries in many instances, such as when setting the clock or

entering calibration parameters.

2.10 Instrument Reset

The YSI 556 MPS is characterized by sophisticated software that

should provided trouble-free operation. However as with all

high-capability software packages, it is always possible that the

user will encounter circumstances in which the instrument does

not respond to keypad entry. If this occurs, the instrument

function can easily be restored by removing and then reapplying

battery power. Simply remove either your C-cells or

rechargeable battery pack from the battery compartment, wait 30

seconds and then replace the batteries. See Section 2.4 Batteries

for battery removal/reinstallation instructions.

YSI 556 MPS YSI Incorporated

Page 18

Page 27

General Information Section 2

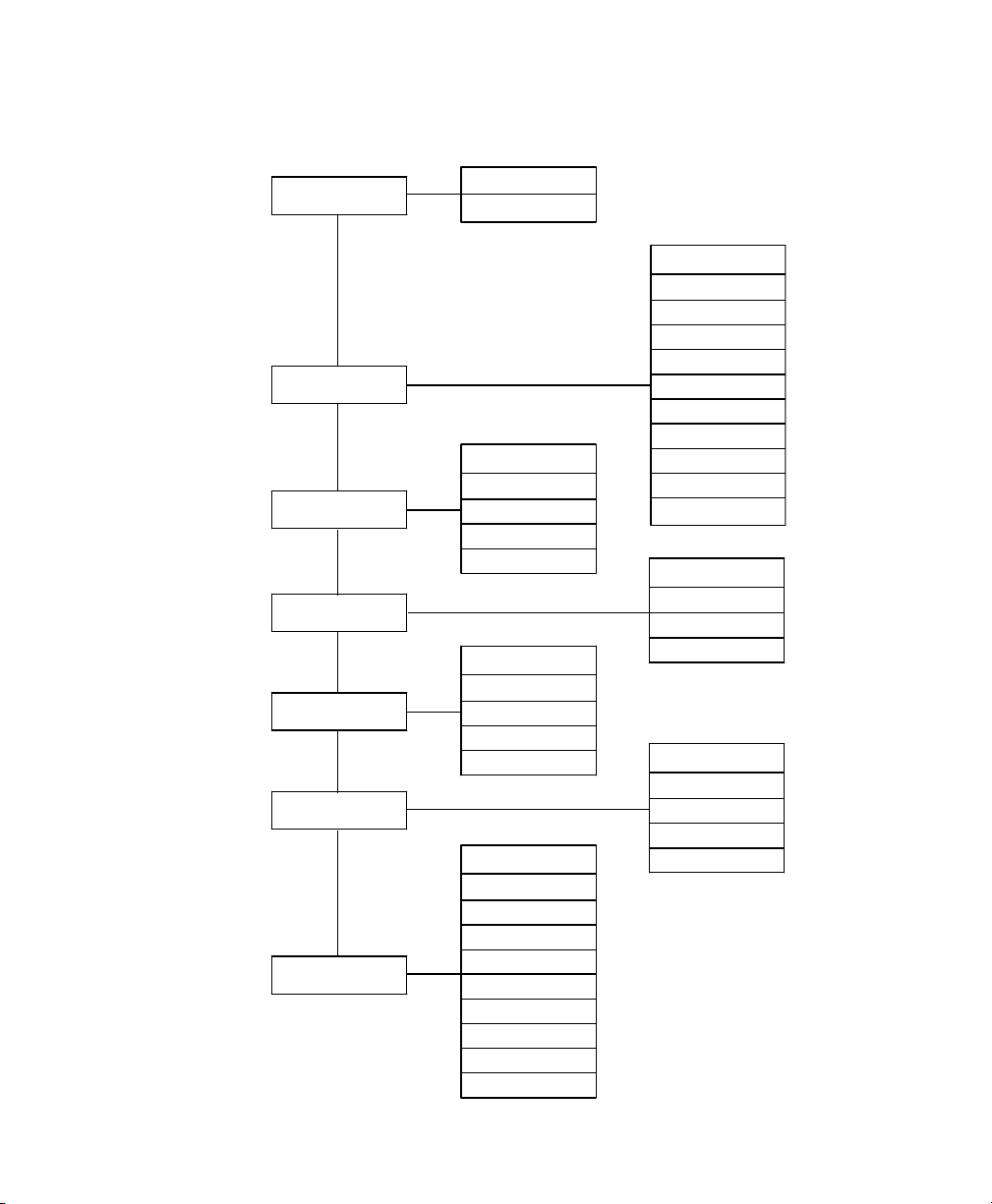

2.11 Menu Flowchart

Run

Report

Sensor

Calibrate

File

Logging Setup

System Setup

Log One Sample

Start Logging

Temperature

Conductivity

Dissolved Oxygen

pH

ORP

DIrectory

Upload to PC

View File

File Memory

Delete All Files

Ver sion

Date & Time

Data Filter

Shut Off Time

Comma Radix

ID

GLP Filename

TDS Constant

Barometer Units

Calibrate Barometer

Temperature

Specific Conductance

Conductivity

Resistivity

TDS

Salinity ppt

DO % saturation

DO mg/L

pH

pH mv

ORP mv

Conductivity

DO

pH

ORP

Interval

Use Site List

Store Barometer

Store Site Number

Edit Site List

YSI Incorporated YSI 556 MPS Page 19

Page 28

General Information Section 2

YSI 556 MPS YSI Incorporated

Page 20

Page 29

3. Probe Module

3.1 Introduction

The YSI 5563 Probe module is used for measuring dissolved

oxygen, temperature, conductivity, and optional pH and ORP.

The probe module is rugged, with the sensors enclosed in a

heavy duty probe sensor guard with attached sinking weight. A

4, 10 or 20 meter cable is directly connected to the probe module

body making it waterproof. An MS-19 connector at the end of

the cable makes the YSI 5563 fully compatible with the YSI 556

Multi-Probe System.

3.2 Unpacking the Probe Module

1. Remove the YSI 5563 Probe module from the shipping

boxes.

NOTE: Do not discard any parts or supplies.

2. Use the packing list to ensure all items are present.

3. Visually inspect all components for damage.

NOTE: If any parts are missing or damaged, contact your

YSI Service Center immediately. Refer to Appendix E

Customer Service or www.ysi.com.

YSI Incorporated YSI 556 MPS Page 21

Page 30

Probe Module Section 3

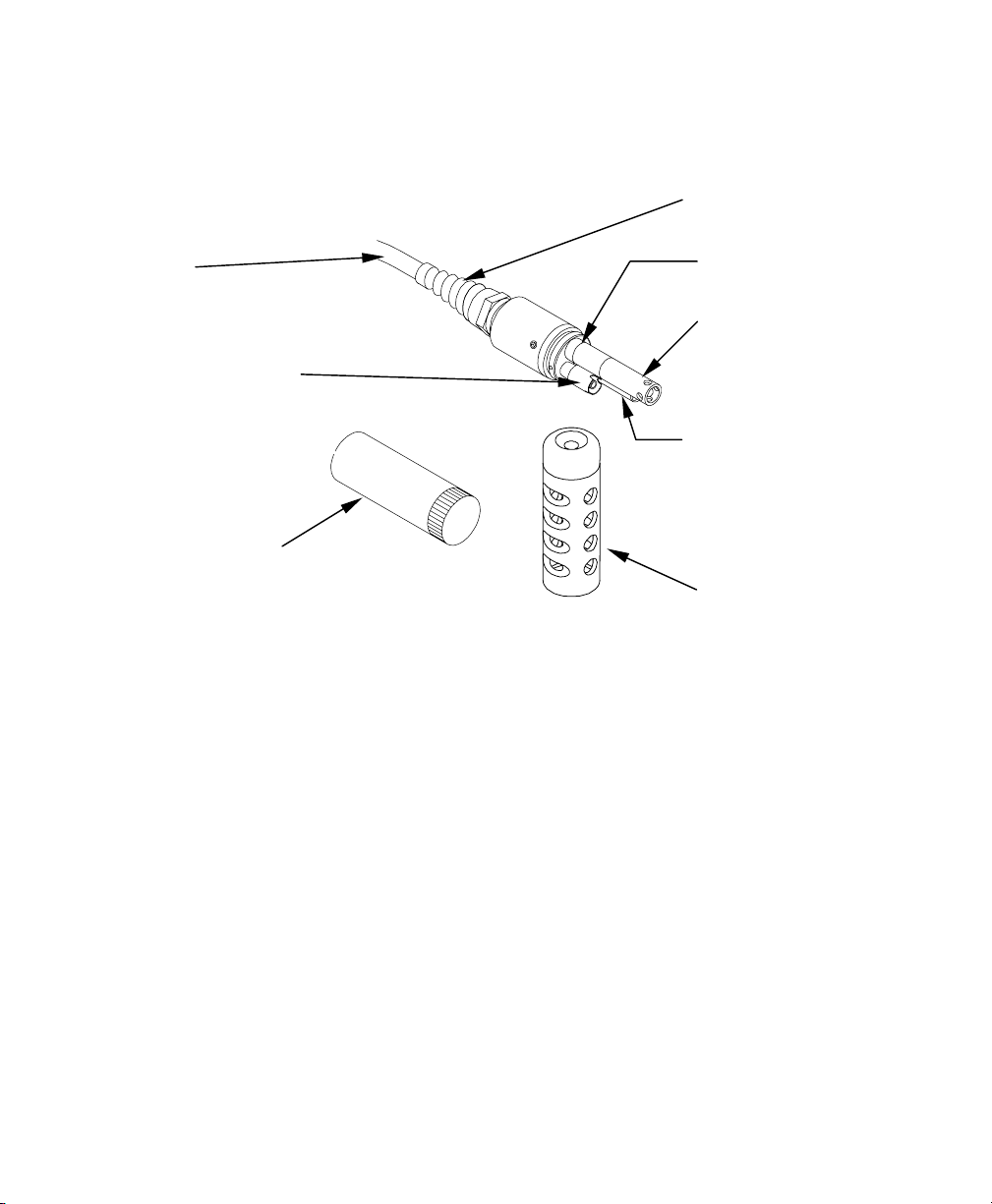

3.3 Features of the YSI 5563 Probe Module

Cable

Dissolved Oxygen

(DO) Probe

Transport/

Calibration Cup

Figure 3.1 Probe Module

3.4 Preparing the Probe Module

To prepare the probe module for calibration and operation, you

need to install the sensors into the connectors on the probe

module bulkhead. In addition to sensor installation, you need to

install a new DO membrane cap.

Strain Relief

Metal Probe

Connector Nut

pH/ORP Probe

Conductivity/

Temperature

Probe

Probe Sensor Guard

3.4.1 Sensor Installation

Whenever you install, remove or replace a sensor, it is extremely

important that the entire probe module and all sensors be

thoroughly dried prior to the removal of a sensor or a sensor port

plug. This will prevent water from entering the port. Once you

remove a sensor or plug, examine the connector inside the probe

module sensor port. If any moisture is present, use compressed

air to completely dry the connector. If the connector is corroded,

return the probe module to your dealer or directly to YSI

Customer Service. Refer to Appendix E Customer Service.

YSI 556 MPS YSI Incorporated

Page 22

Page 31

Probe Module Section 3

t

Conductivity/Temperature and pH, pH/ORP Sensor Installation

1. Unscrew and remove the probe sensor guard.

2. Using the sensor installation tool supplied in the YSI 5511

maintenance kit, unscrew and remove the sensor port plugs.

Figure 3.2 Port Plug Removal

3. Locate the port with the connector that corresponds to the

sensor that is to be installed.

Oxygen por

Figure 3.3 Sensor Port Identification

pH or pH/ORP port

Conductivity/Temperature

port

4. Apply a thin coat of o-ring lubricant (supplied in the YSI

5511 maintenance kit) to the o-rings on the connector side of

the sensor (see Figure 3.4 O-Ring Lubrication).

YSI Incorporated YSI 556 MPS Page 23

Page 32

Probe Module Section 3

O-Rings

Sensor nut

Figure 3.4 O-Ring Lubrication

CAUTION: Make sure that there are NO contaminants between

the O-ring and the sensor. Contaminants that are present under

the O-ring may cause the O-ring to leak.

5. Be sure the probe module sensor port is free of moisture and

then insert the sensor into the correct port. Gently rotate the

sensor until the two connectors align.

6. With connectors aligned, screw down the sensor nut using

the sensor installation tool.

Figure 3.5 Sensor Installation

CAUTION: Do not cross thread the sensor nut. Tighten the nut

until it is flush with the face of the probe module bulkhead. Do

not over tighten.

YSI 556 MPS YSI Incorporated

Page 24

Figure 3.6 Bulkhead Seating

Page 33

Probe Module Section 3

7. Repeat steps 3-6 for any other sensors.

8. Replace the probe sensor guard.

Dissolved Oxygen Sensor Installation

The YSI 5563 comes with the DO sensor already installed. Refer

to Section 11.1.2 DO Sensor Replacement for instructions on

installing the YSI 558 Replaceable DO Module Kit.

3.4.2 Membrane Cap Selection

The YSI 5563 is shipped with a YSI 5909 kit that contains

membrane caps made with 2 mil polyethylene (PE), a material

which should be ideal for most field applications of the 556.

However, YSI also offers membrane caps made with two other

materials (1 mil polyethylene and 1 mil Teflon) which some

users may also prefer. All membranes available for the

556/5563 system provide comparable accuracy if used properly.

The difference between the two thicknesses of PE is found in the

trade-off of flow dependence and response time as described

below. Teflon is offered because some users may prefer to

continue using the traditional membrane material used by YSI.

To avoid confusion, the membrane caps are color coded as

described below and can be ordered in kits as noted:

1 mil Teflon – Black Caps (Kit = YSI 5906)

1 mil Polyethylene (PE) – Yellow Caps (Kit = YSI 5908)

2 mil Polyethylene (PE) – Blue Caps (Kit = YSI 5909)

The 1 mil Teflon caps will offer traditional, reliable performance

for most dissolved oxygen applications. The 1 mil PE caps will

provide a significantly faster dissolved oxygen response (as long

as your 556 Data Filter is set correctly as described below in

Sections 10.2 and 10.3.1)) while also giving readings which are

significantly less flow dependent than the 1 mil Teflon caps.

Finally, 2 mil PE caps will show a large reduction in flow

dependence over 1 mil Teflon while not significantly increasing

the response time. Generally, one of the PE caps is likely to

provide better performance for your application.

IMPORTANT: No matter which type of membrane cap you

select, you will also have to confirm your selection in the 556

YSI Incorporated YSI 556 MPS Page 25

Page 34

Probe Module Section 3

software from the Sensor menu as described in Section 4

Sensors.

3.4.3 Membrane Cap Installation

NOTE: The YSI 5563 DO sensor (already installed in the probe

module) was shipped dry. A shipping membrane was installed to

protect the electrode. A new membrane cap must be installed

before the first use.

1. Unscrew and remove the probe sensor guard.

2. Unscrew, remove, and discard the old membrane cap.

3. Thoroughly rinse the sensor tip with distilled water.

4. Prepare the electrolyte according to the directions on the

electrolyte solution bottle.

5. Hold the new membrane cap and fill it at least 1/2 full with

the electrolyte solution.

6. Screw the membrane cap onto the sensor moderately tight. A

small amount of electrolyte should overflow.

CAUTION: Do not touch the membrane surface.

7. Screw the probe sensor guard on moderately tight.

3.5 Transport/Calibration Cup

The YSI 5563 Probe module has been supplied with a

convenient transport/calibration cup. This cup is an ideal

container for calibration of the different sensors, minimizing the

amount of solution needed. Refer to Section 6 Calibrate.

YSI 556 MPS YSI Incorporated

Page 26

Page 35

Probe Module Section 3

3.5.1 Transport/Calibration Cup Installation

1. Remove probe sensor guard, if already installed.

2. Ensure that an o-ring is installed in the o-ring groove on the

threaded end of the probe module body.

3. Screw the transport/calibration cup on the threaded end of

the probe module and securely tighten.

NOTE: Do not overtighten as this could cause damage to

the threaded portions.

Figure 3.7 Transport/Calibration Cup Installation

3.6 Instrument/Cable Connection

Attach the cable to the instrument as follows:

1. Line up the pins and guides on the cable with the holes and

indentations on the cable connector at the bottom of the YSI

556 instrument. See Figure 2.1 Front View of YSI 556 MPS.

2. Holding the cable firmly against the cable connector, turn

the locking mechanism clockwise until it snaps into place.

Remove the cable from the instrument by turning the cable

connector counterclockwise until the cable disengages from the

instrument.

O-ring

YSI Incorporated YSI 556 MPS Page 27

Page 36

Probe Module Section 3

YSI 556 MPS YSI Incorporated

Page 28

Page 37

4. Sensors

The Sensors Enabled screen allows the user to enable or disable

each of the sensors and select which membrane material will be

used for the dissolved oxygen sensor. Disabled sensors will not

be displayed on the screen in real time or logged to files.

1. Press the On/off key to display the run screen.

2. Press the Escape key to display the main menu screen.

Figure 4.1 Main Menu Screen

3. Use the arrow keys to highlight the Sensor selection.

4. Press the Enter key to display the sensors enabled screen.

Enabled sensor

Disabled sensor

Figure 4.2 Sensors Enabled Screen Before DO Membrane Selection

YSI Incorporated YSI 556 MPS Page 29

Page 38

Sensors Section 4

A black dot to the left of a sensor indicates that sensor is

enabled. Sensors with an empty circle are disabled.

Highlight the “DO None” entry as shown above and press Enter

to display the membrane choice screen. Consult Section 3.4.2

Membrane Cap Selection for information on the advantages of

each type of membrane material. Blue membrane caps using 2

mil polyethylene (PE) were shipped with your YSI 5563 and are

likely to be the best choice for most 556 field applications.

Figure 4.3 Membrane Selection Screen

Highlight the desired membrane choice – in this case, 2 mil PE -and press Enter to activate your selection with a dot to the left of

the screen. Then press Escape to return to the Sensor menu that

now shows your DO membrane selection.

Figure 4.4 Sensors Enabled Screen After DO Membrane Selection

YSI 556 MPS YSI Incorporated

Page 30

Page 39

Sensors Section 4

NOTE: The Temperature sensor cannot be disabled. Most

other sensors require temperature compensation for accurate

readings. In addition, the conductivity sensor must be

activated in order to obtain accurate dissolved oxygen mg/L

readings.

5. Use the arrow keys to highlight the sensor you want to

change, then press the Enter key to enable or disable it.

6. Repeat step 5 for each sensor you want to change.

7. Press the Escape key to return to the main menu screen.

YSI Incorporated YSI 556 MPS Page 31

Page 40

Sensors Section 4

YSI 556 MPS YSI Incorporated

Page 32

Page 41

r

y

N

d

y

5. Report

The Report Setup screen allows the user to select which sample

parameters and units the YSI 556 MPS will display on the

screen. It does NOT determine which parameters are logged to

memory. Refer to Section 4 Sensors.

1. Press the On/off key to display the run screen.

2. Press the Escape key to display the main menu screen.

Figure 5.1 Main Menu

3. Use the arrow keys to highlight the Report selection.

4. Press the Enter key to display the report setup screen.

Selected fo

displa

OT selecte

for displa

Figure 5.2 Report Setup Screen

YSI Incorporated YSI 556 MPS Page 33

Page 42

Report Section 5

NOTE: A black dot to the left of a parameter indicates that

parameter is selected for display. Parameters with an empty

circle will not be displayed.

NOTE: You may have to scroll down past the bottom of the

screen to see all the parameters.

5. Use the arrow keys to highlight the parameter you want to

change, then press the Enter key. If you can't find the

parameter you want, even after scrolling down past the

bottom of the screen, the sensor used for that parameter is

disabled. Refer to Section 4 Sensors.

6. If you selected Temperature, Specific Conductivity,

Conductivity, Resistance or Total Dissolved Solids, the

Units screen will appear.

Figure 5.3 Units Screen

7. Use the arrow keys to select the units desired, then press the

Enter key to return to the report setup screen.

If you selected Salinity, Dissolved Oxygen %, Dissolved

Oxygen mg/L, pH, pH mv or ORP mv, the selection dot will

simply toggle on or off.

8. Repeat steps 5 and 6 for each parameter you want to change.

YSI 556 MPS YSI Incorporated

Page 34

Page 43

Report Section 5

NOTE: All parameters may be enabled at the same time.

Figure 5.4 All Parameters Displayed

9. Press the Escape key to return to the Main menu screen.

YSI Incorporated YSI 556 MPS Page 35

Page 44

Report Section 5

YSI 556 MPS YSI Incorporated

Page 36

Page 45

6. Calibrate

All of the sensors, except temperature, require periodic

calibration to assure high performance. You will find specific

calibration procedures for all sensors that require calibration in

the following sections. If a sensor listed is not installed in your

probe module, skip that section and proceed to the next sensor

until the calibration is complete.

CAUTION: Reagents that are used to calibrate and check this

instrument may be hazardous to your health. Take a moment to

review Appendix D Health and Safety. Some calibration standard

solutions may require special handling.

6.1 Getting Ready to Calibrate

6.1.1 Containers Needed to Calibrate the Probe Module

The transport/calibration cup that comes with your probe module

serves as a calibration chamber for all calibrations and

minimizes the volume of calibration reagents required.

Instead of the transport/calibration cup, you may use laboratory

glassware to perform calibrations. If you do not use the

transport/calibration cup that is designed for the probe module,

you are cautioned to do the following:

Perform all calibrations with the Probe Sensor Guard

installed. This protects the sensors from possible physical

damage.

Use a ring stand and clamp to secure the probe module body

to prevent the module from falling over. Most laboratory

glassware has convex bottoms.

Ensure that all sensors are immersed in calibration solutions.

Many of the calibrations factor in readings from other

sensors (e.g., temperature sensor). The top vent hole of the

conductivity sensor must also be immersed during some

calibrations.

YSI Incorporated YSI 556 MPS Page 37

Page 46

Section 6 Calibrate

6.1.2 Calibration Tips

1. If you use the Transport/Calibration Cup for dissolved

oxygen (DO) calibration, make certain to loosen the seal to

allow pressure equilibration before calibration. The DO

calibration is a water-saturated air calibration.

2. The key to successful calibration is to ensure that the sensors

are completely submersed when calibration values are

entered. Use recommended volumes when performing

calibrations.

3. For maximum accuracy, use a small amount of previously

used calibration solution to pre-rinse the probe module. You

may wish to save old calibration standards for this purpose.

4. Fill a bucket with ambient temperature water to rinse the

probe module between calibration solutions.

5. Have several clean, absorbent paper towels or cotton cloths

available to dry the probe module between rinses and

calibration solutions. Shake the excess rinse water off of the

probe module, especially when the probe sensor guard is

installed. Dry off the outside of the probe module and probe

sensor guard. Making sure that the probe module is dry

reduces carry-over contamination of calibrator solutions and

increases the accuracy of the calibration.

6. If you are using laboratory glassware for calibration, you do

not need to remove the probe sensor guard to rinse and dry

the sensors between calibration solutions. The inaccuracy

resulting from simply rinsing the sensor compartment and

drying the outside of the guard is minimal.

7. If you are using laboratory glassware, remove the stainless

steel weight from the bottom of the probe sensor guard by

turning the weight counterclockwise. When the weight is

removed, the calibration solutions have access to the sensors

without displacing a lot of fluid. This also reduces the

amount of liquid that is carried between calibrations.

8. Make certain that port plugs are installed in all ports where

sensors are not installed. It is extremely important to keep

these electrical connectors dry.

YSI 556 MPS YSI Incorporated

Page 38

Page 47

Calibrate Section 6

6.1.3 Recommended Volumes

Follow these instructions to use the transport/calibration cup for

calibration procedures.

Ensure that an o-ring is installed in the o-ring groove of the

transport/calibration cup bottom cap, and that the bottom cap

is securely tightened.

NOTE: Do not over-tighten as this could cause damage to

the threaded portions.

Remove the probe sensor guard, if it is installed.

Remove the o-ring, if installed, from the probe module and

inspect the installed o-ring on the probe module for obvious

defects and, if necessary, replace it with the extra o-ring

supplied.

Some calibrations can be accomplished with the probe

module upright or upside down. A separate clamp and stand,

such as a ring stand, is required to support the probe module

in the inverted position.

To calibrate, follow the procedures in the next section,

Calibration Procedures. The approximate volumes of the

reagents are specified below for both the upright and upside

down orientations.

When using the Transport/Calibration Cup for dissolved

oxygen % saturation calibration, make certain that the vessel

is vented to the atmosphere by loosening the bottom cap or

cup assembly and that approximately 1/8” of water is present

in the cup.

Sensor to Calibrate Upright Upside Down

Conductivity 55ml 55ml

pH/ORP 30ml 60ml

Table 6.1 Calibration Volumes

YSI Incorporated YSI 556 MPS Page 39

Page 48

Section 6 Calibrate

6.2 Calibration Procedures

6.2.1 Accessing the Calibrate Screen

1. Press the On/off key to display the run screen.

2. Press the Escape key to display the main menu screen.

3. Use the arrow keys to highlight the Calibrate selection.

Figure 6.1 Main Menu

4. Press the Enter key. The Calibrate screen is displayed.

YSI 556 MPS YSI Incorporated

Page 40

Figure 6.2 Calibrate Screen

Page 49

Calibrate Section 6

6.2.2 Conductivity Calibration

This procedure calibrates specific conductance (recommended),

conductivity and salinity. Calibrating any one option

automatically calibrates the other two.

1. Go to the calibrate screen as described in Section 6.2.1

Accessing the Calibrate Screen.

2. Use the arrow keys to highlight the Conductivity selection.

See Figure 6.2 Calibrate Screen.

3. Press Enter. The Conductivity Calibration Selection Screen

is displayed.

Figure 6.3 Conductivity Calibration Selection Screen

4. Use the arrow keys to highlight the Specific Conductance

selection.

5. Press Enter. The Conductivity Calibration Entry Screen is

displayed.

YSI Incorporated YSI 556 MPS Page 41

Page 50

Section 6 Calibrate

Figure 6.4 Conductivity Calibration Entry Screen

6. Place the correct amount of conductivity standard (see Table

6.1 Calibration Volumes) into a clean, dry or pre-rinsed

transport/calibration cup.

WARNING: Calibration reagents may be hazardous to

your health. See Appendix D Health and Safety for more

information.

NOTE: For maximum accuracy, the conductivity standard

you choose should be within the same conductivity range as

the samples you are preparing to measure. However, we do

not recommend using standards less than 1 mS/cm. For

example:

For fresh water use a 1 mS/cm conductivity standard.

For brackish water use a 10 mS/cm conductivity

standard.

For seawater use a 50 mS/cm conductivity standard.

NOTE: Before proceeding, ensure that the sensor is as dry

as possible. Ideally, rinse the conductivity sensor with a

small amount of standard that can be discarded. Be certain

that you avoid cross-contamination of solutions. Make

certain that there are no salt deposits around the oxygen and

pH/ORP sensors, particularly if you are employing standards

of low conductivity.

YSI 556 MPS YSI Incorporated

Page 42

Page 51

Calibrate Section 6

7. Carefully immerse the sensor end of the probe module into

the solution.

8. Gently rotate and/or move the probe module up and down to

remove any bubbles from the conductivity cell.

NOTE: The sensor must be completely immersed past its

vent hole. Using the recommended volumes from Table 6.1

Calibration Volumes, should ensure that the vent hole is

covered.

9. Screw the transport/calibration cup on the threaded end of

the probe module and securely tighten.

NOTE: Do not overtighten as this could cause damage to

the threaded portions.

10. Use the keypad to enter the calibration value of the standard

you are using.

NOTE: Be sure to enter the value in mS/cm at 25°°°°C.

11. Press Enter. The Conductivity Calibration Screen is

displayed.

Figure 6.5 Conductivity Calibration Screen

12. Allow at least one minute for temperature equilibration

before proceeding. The current values of all enabled sensors

YSI Incorporated YSI 556 MPS Page 43

Page 52

Section 6 Calibrate

will appear on the screen and will change with time as they

stabilize.

13. Observe the reading under Specific Conductance. When the

reading shows no significant change for approximately 30

seconds, press Enter. The screen will indicate that the

calibration has been accepted and prompt you to press Enter

again to Continue.

Figure 6.6 Calibrated

14. Press Enter. This returns you to the Conductivity Calibrate

Selection Screen, See Figure 6.3 Conductivity Calibration

Selection Screen.

15. Press Escape to return to the calibrate menu. See Figure 6.2

Calibrate Screen.

16. Rinse the probe module and sensors in tap or purified water

and dry.

6.2.3 Dissolved Oxygen Calibration

This procedure calibrates dissolved oxygen. Calibrating any one

option (% or mg/L) automatically calibrates the other.

1. Go to the calibrate screen as described in Section 6.2.1

Accessing the Calibrate Screen.

YSI 556 MPS YSI Incorporated

Page 44

Page 53

Calibrate Section 6

NOTE: The instrument must be on for at least 20 minutes to

polarize the DO sensor before calibrating.

2. Use the arrow keys to highlight the Dissolved Oxygen

selection. See Figure 6.2 Calibrate Screen.

3. Press Enter. The dissolved oxygen calibration screen is

displayed.

Figure 6.7 DO Calibration Screen

DO Calibration in % Saturation

1. Use the arrow keys to highlight the DO% selection.

2. Press Enter. The DO Barometric Pressure Entry Screen is

displayed.

Figure 6.8 DO Barometric Pressure Entry Screen

YSI Incorporated YSI 556 MPS Page 45

Page 54

Section 6 Calibrate

3. Place approximately 3 mm (1/8 inch) of water in the bottom

of the transport/calibration cup.

4. Place the probe module into the transport/calibration cup.

NOTE: Make sure that the DO and temperature sensors are

not immersed in the water.

5. Engage only 1 or 2 threads of the transport/calibration cup to

ensure the DO sensor is vented to the atmosphere.

6. Use the keypad to enter the current local barometric

pressure.

NOTE: If the unit has the optional barometer, no entry is

required.

NOTE: Barometer readings that appear in meteorological

reports are generally corrected to sea level and must be

uncorrected before use (refer to Section 10.10 Calibrate

Barometer, Step 2).

7. Press Enter. The DO% saturation calibration screen is

displayed.

Figure 6.9 DO Sat Calibration Screen

8. Allow approximately ten minutes for the air in the

transport/calibration cup to become water saturated and for

YSI 556 MPS YSI Incorporated

Page 46

Page 55

Calibrate Section 6

the temperature to equilibrate before proceeding. The current

values of all enabled sensors will appear on the screen and

will change with time as they stabilize.

9. Observe the reading under DO %. When the reading shows

no significant change for approximately 30 seconds, press

Enter. The screen will indicate that the calibration has been

accepted and prompt you to press Enter again to Continue.

See Figure 6.6 Calibrated.

10. Press Enter. This returns you to the DO calibration screen,

See Figure 6.7 DO Calibration Screen.

11. Press Escape to return to the calibrate menu. See Figure 6.2

Calibrate Screen.

12. Rinse the probe module and sensors in tap or purified water

and dry.

DO Calibration in mg/L

DO calibration in mg/L is carried out in a water sample which

has a known concentration of dissolved oxygen (usually

determined by a Winkler titration).

1. Go to the DO calibrate screen as described in Section 6.2.3

Dissolved Oxygen Calibration, steps 1 through 3.

2. Use the arrow keys to highlight the DO mg/L selection.

3. Press Enter. The DO mg/L Entry Screen is displayed.

YSI Incorporated YSI 556 MPS Page 47

Page 56

Section 6 Calibrate

Figure 6.10 DO mg/L Entry Screen

4. Place the probe module in water with a known DO

concentration.

NOTE: Be sure to completely immerse all the sensors.

5. Use the keypad to enter the known DO concentration of the

water.

6. Press Enter. The Dissolved Oxygen mg/L Calibration

Screen is displayed.

Figure 6.11 DO mg/L Calibration Screen

YSI 556 MPS YSI Incorporated

Page 48

Page 57

Calibrate Section 6

7. Stir the water with a stir bar, or by rapidly moving the probe

module, to provide fresh sample to the DO sensor.

8. Allow at least one minute for temperature equilibration

before proceeding. The current values of all enabled sensors

will appear on the screen and will change with time as they

stabilize.

9. Observe the DO mg/L reading, when the reading is stable

(shows no significant change for approximately 30 seconds),

press Enter. The screen will indicate that the calibration has

been accepted and prompt you to press Enter again to

Continue.

10. Press Enter. This returns you to the DO calibration screen.

See Figure 6.7 DO Calibration Screen.

11. Press Escape to return to the calibrate menu. See Figure 6.2

Calibrate Screen.

12. Rinse the probe module and sensors in tap or purified water

and dry.

6.2.4 pH Calibration

1. Go to the calibrate screen as described in Section 6.2.1

Accessing the Calibrate Screen.

2. Use the arrow keys to highlight the pH selection. See Figure

6.2 Calibrate Screen.

3. Press Enter. The pH calibration screen is displayed.

YSI Incorporated YSI 556 MPS Page 49

Page 58

Section 6 Calibrate

Figure 6.12 pH Calibration Screen

Select the 1-point option only if you are adjusting a previous

calibration. If a 2-point or 3-point calibration has been

performed previously, you can adjust the calibration by

carrying out a one point calibration. The procedure for this

calibration is the same as for a 2-point calibration, but the

software will prompt you to select only one pH buffer.

Select the 2-point option to calibrate the pH sensor using

only two calibration standards. Use this option if the media

being monitored is known to be either basic or acidic. For

example, if the pH of a pond is known to vary between 5.5

and 7, a two-point calibration with pH 7 and pH 4 buffers is

sufficient. A three point calibration with an additional pH 10

buffer will not increase the accuracy of this measurement

since the pH is not within this higher range.

Select the 3-point option to calibrate the pH sensor using

three calibration solutions. In this procedure, the pH sensor

is calibrated with a pH 7 buffer and two additional buffers.

The 3-point calibration method assures maximum accuracy

when the pH of the media to be monitored cannot be

anticipated. The procedure for this calibration is the same as

for a 2-point calibration, but the software will prompt you to

select a third pH buffer.

4. Use the arrow keys to highlight the 2-point selection.

5. Press Enter. The pH Entry Screen is displayed.

YSI 556 MPS YSI Incorporated

Page 50

Page 59

Calibrate Section 6

Figure 6.13 pH Entry Screen

6. Place the correct amount (see Table 6.1 Calibration

Volumes) of pH buffer into a clean, dry or pre-rinsed

transport/calibration cup.

WARNING: Calibration reagents may be hazardous to your

health. See Appendix D Health and Safety for more

information.

NOTE: For maximum accuracy, the pH buffers you choose

should be within the same pH range as the water you are

preparing to sample.

NOTE: Before proceeding, ensure that the sensor is as dry

as possible. Ideally, rinse the pH sensor with a small amount

of buffer that can be discarded. Be certain that you avoid

cross-contamination of buffers with other solutions.

7. Carefully immerse the sensor end of the probe module into

the solution.

8. Gently rotate and/or move the probe module up and down to

remove any bubbles from the pH sensor.

NOTE: The sensor must be completely immersed. Using the

recommended volumes from Table 6.1 Calibration Volumes,

should ensure that the sensor is covered.

YSI Incorporated YSI 556 MPS Page 51

Page 60

Section 6 Calibrate

9. Screw the transport/calibration cup on the threaded end of

the probe module and securely tighten.

NOTE: Do not overtighten as this could cause damage to

the threaded portions.

10. Use the keypad to enter the calibration value of the buffer

you are using at the current temperature.

NOTE: pH vs. temperature values are printed on the labels

of all YSI pH buffers.

11. Press Enter. The pH calibration screen is displayed.

Figure 6.14 pH Calibration Screen

12. Allow at least one minute for temperature equilibration

before proceeding. The current values of all enabled sensors

will appear on the screen and will change with time as they

stabilize.

13. Observe the reading under pH, when the reading shows no

significant change for approximately 30 seconds, press

Enter. The screen will indicate that the calibration has been

accepted and prompt you to press Enter again to Continue.

14. Press Enter. This returns you to the Specified pH

Calibration Screen, See Figure 6.13 pH Entry Screen.

YSI 556 MPS YSI Incorporated

Page 52

Page 61

Calibrate Section 6

15. Rinse the probe module, transport/calibration cup and

sensors in tap or purified water and dry.

16. Repeat steps 6 through 13 above using a second pH buffer.

17. Press Enter. This returns you to the pH Calibration Screen,

See Figure 6.12 pH Calibration Screen.

18. Press Escape to return to the calibrate menu. See Figure 6.2

Calibrate Screen.

19. Rinse the probe module and sensors in tap or purified water

and dry.

6.2.5 ORP Calibration

1. Go to the calibrate screen as described in Section 6.2.1

Accessing the Calibrate Screen.

2. Use the arrow keys to highlight the ORP selection. See

Figure 6.2 Calibrate Screen.

3. Press Enter. The ORP calibration screen is displayed.

Figure 6.15 Specified ORP Calibration Screen

4. Place the correct amount (see Table 6.1 Calibration

Volumes) of a known ORP solution (we recommend Zobell

solution) into a clean, dry or pre-rinsed transport/calibration

cup.

YSI Incorporated YSI 556 MPS Page 53

Page 62

Section 6 Calibrate

WARNING: Calibration reagents may be hazardous to your

health. See Appendix D Health and Safety for more

information.

NOTE: Before proceeding, ensure that the sensor is as dry

as possible. Ideally, rinse the ORP sensor with a small

amount of solution that can be discarded. Be certain that you

avoid cross-contamination with other solutions.

5. Carefully immerse the sensor end of the probe module into

the solution.

6. Gently rotate and/or move the probe module up and down to

remove any bubbles from the ORP sensor.

NOTE: The sensor must be completely immersed. Using the

recommended volumes from Table 6.1 Calibration Volumes

should ensure that the sensor is covered.

7. Screw the transport/calibration cup on the threaded end of

the probe module and securely tighten.

NOTE: Do not overtighten as this could cause damage to

the threaded portions.

8. Use the keypad to enter the correct value of the calibration

solution you are using at the current temperature. Refer to

Table 6.2 Zobel Solution Values.

Temperature °C Zobell Solution Value, mV

-5 270.0

0 263.5

5 257.0

10 250.5

15 244.0

20 237.5

25 231.0

30 224.5

35 218.0

40 211.5

45 205.0

50 198.5

Table 6.2 Zobel Solution Values

YSI 556 MPS YSI Incorporated

Page 54

Page 63

Calibrate Section 6

9. Press Enter. The ORP calibration screen is displayed.

Figure 6.16 ORP Calibration Screen

10. Allow at least one minute for temperature equilibration

before proceeding. The current values of all enabled sensors

will appear on the screen and will change with time as they

stabilize.

NOTE: Verify that the temperature reading matches the

value you used in Table 6.2 Zobel Solution Values.

11. Observe the reading under ORP, when the reading shows no

significant change for approximately 30 seconds, press

Enter. The screen will indicate that the calibration has been

accepted and prompt you to press Enter again to Continue.

12. Press Enter. This returns you to the Calibrate Screen. See

Figure 6.2 Calibrate Screen.

13. Rinse the probe module and sensors in tap or purified water

and dry.

YSI Incorporated YSI 556 MPS Page 55

Page 64

Section 6 Calibrate

6.3 Return to Factory Settings

1. Go to the calibrate screen as described in Section 6.2.1

Accessing the Calibrate Screen.

2. Use the arrow keys to highlight the Conductivity selection.

See Figure 6.2 Calibrate Screen.

NOTE: We will use the Conductivity sensor as an example;

however, this process will work for any sensor.

3. Press Enter. The Conductivity Calibration Selection Screen

is displayed. See Figure 6.3 Conductivity Calibration

Selection Screen.

4. Use the arrow keys to highlight the Specific Conductance

selection.

5. Press Enter. The Conductivity Calibration Entry Screen is

displayed. See Figure 6.4 Conductivity Calibration Entry

Screen.

6. Press and hold the Enter key down and press the Escape

key.

Figure 6.17 ORP Calibration Screen

7. Use the arrow keys to highlight the YES selection.

YSI 556 MPS YSI Incorporated

Page 56

Page 65

Calibrate Section 6

CAUTION: This returns a sensor to the factory settings. For

example, in selecting to return specific conductance to the

factory setting, salinity and conductivity will automatically

return to their factory settings.

8. Press Enter. This returns you to the Conductivity Calibrate

Selection Screen, See Figure 6.3 Conductivity Calibration

Selection Screen.

9. Press Escape to return to the calibrate menu. See Figure 6.2

Calibrate Screen.

YSI Incorporated YSI 556 MPS Page 57

Page 66

Section 6 Calibrate

YSI 556 MPS YSI Incorporated

Page 58

Page 67

7. Run

The Run screen displays data from the sensors in real-time and

allows the user to log sample data to memory for later analysis.

Refer to Section 9 Logging for details on logging sample data.

7.1 Real-Time Data

NOTE: Before measuring samples you must prepare the probe

module (refer to Section 3.4 Preparing the Probe Module),

attach the probe module to the instrument (refer to Section 3.6

Instrument/Cable Connection) and calibrate the sensors (refer to

Section 6 Calibrate).

1. Press the On/off key.

OR select Run from the main menu to display the run screen.

Figure 7.1 Run Screen

2. Make sure the probe sensor guard is installed.

3. Place the probe module in the sample. Be sure to completely

immerse all the sensors.

4. Rapidly move the probe module through the sample to

provide fresh sample to the DO sensor.

5. Watch the readings on the display until they are stable.

YSI Incorporated YSI 556 MPS Page 59

Page 68

Section 7 Run

6. Refer to Section 9 Logging for instructions on logging

sample data.

YSI 556 MPS YSI Incorporated

Page 60

Page 69

8. File

The File menu allows the user to view, upload or delete sample

data and calibration record files stored in the YSI 556 MPS.

8.1 Accessing the File Screen

1. Press the On/off key to display the run screen.

2. Press the Escape key to display the main menu screen.

Figure 8.1 Main Menu Screen

3. Use the arrow keys to highlight the File selection.

4. Press the Enter key. The file screen is displayed.

Figure 8.2 File Screen

YSI Incorporated YSI 556 MPS Page 61

Page 70

Section 8 File

8.2 Directory

1. Go to the file screen as described in Section 8.1 Accessing

the File Screen.

2. Use the arrow keys to highlight the Directory selection. See

Figure 8.2 File Screen.

3. Press the Enter key. The file list screen is displayed.

NOTE: Files are listed in the order in which they are logged

to memory. Sample Data files have the file extension .dat,

while Calibration Record files have the file extension .glp.

Figure 8.3 File List Screen

4. Use the arrow keys to highlight a file.

5. Press the Enter key. The file details screen is displayed.

YSI 556 MPS YSI Incorporated

Page 62

Page 71

File Section 8

Figure 8.4 File Details Screen

6. Press the Enter key to view the file data. Refer to Section

8.3 View File for details.

7. Press the Escape key repeatedly to return to the main menu

screen.

8.3 View File

1. Go to the file screen as described in Section 8.1 Accessing

the File Screen. See Figure 8.2 File Screen.

2. Use the arrow keys to highlight the View file selection.

3. Press the Enter key. A list of files is displayed. See Figure

8.3 File List Screen.

4. Use the arrow keys to highlight an individual file.

NOTE: You may have to scroll down to see all the files.

5. Press the Enter key. The file data is displayed with the file

name at the top of the display.

NOTE: If no file name was specified, the data is stored

under the default name NONAME1.dat.

YSI Incorporated YSI 556 MPS Page 63

Page 72

Section 8 File

Figure 8.5 File Data Screen

6. Use the arrow keys to scroll horizontally and/or vertically to

view all the data.

7. Press the Escape key repeatedly to return to the main menu

screen.

8.4 Upload to PC

EcoWatch for Windows must be used as the PC software

interface to the YSI 556 MPS. Refer to Appendix G EcoWatch

for more information. EcoWatch for Windows is available at no

cost via a download from the YSI Web Site (www.ysi.com) or

by contacting YSI Customer Support. Refer to Appendix E

Customer Service.

8.4.1 Upload Setup

1. Disconnect the YSI 5563 Probe Module from the YSI 556

MPS instrument.

2. Connect the YSI 556 MPS to a serial (Comm) port of your

computer via the 655173 PC Interface cable as shown in the

following diagram:

YSI 556 MPS YSI Incorporated

Page 64

Page 73

File Section 8

t

556 MPS

Computer with

EcoWatch for

Windows

Installed

655173 PC

Interface Cable

DE-9 PC Serial Por

Figure 8.6 Computer/Instrument Interface

3. Open EcoWatch for Windows on your computer.

NOTE: See Appendix G EcoWatch for installation

instructions.

4. Click on the sonde/probe icon

in the upper toolbar.

5. Set the Comm port number to match the port the YSI 556

MPS is connected to. After this setup procedure, the

following screen will be present on your PC monitor:

YSI Incorporated YSI 556 MPS Page 65

Page 74

Section 8 File

8.4.2 Uploading a .DAT File

1. Setup the instrument as described in Section 8.4.1 Upload

Setup.

2. Go to the YSI 556 MPS file screen as described in Section

8.1 Accessing the File Screen.

3. Use the arrow keys to highlight the Upload to PC selection.

See Figure 8.2 File Screen.

4. Press the Enter key. The file list screen is displayed. See

Figure 8.3 File List Screen.

5. Use the arrow keys to highlight the DAT file that you wish

to transfer and press Enter, both the YSI 556 MPS and PC

displays show the progress of the file transfer.

YSI 556 MPS YSI Incorporated

Page 66

Page 75

File Section 8

w

Figure 8.7 File Transfer Progress Screen

NOTE: After transfer, the file will be located in the

C:\ECOWWIN\DATA folder of your PC, designated with a

.DAT extension.

6. After the file transfer is complete, close the terminal window

(small window on the PC) by clicking on the “X” at its upper

right corner.

Click on X to

close windo

YSI Incorporated YSI 556 MPS Page 67

Page 76

Section 8 File

7. Press the Escape key on the YSI 556 MPS repeatedly to

return to the main menu screen.

8.4.3 Uploading a Calibration Record (.glp) File

For more information on the calibration record, Refer to

Appendix H Calibration Record Information.

1. Setup up the instrument as described in Section 8.4.1 Upload

Setup.

2. Go to the YSI 556 MPS file screen as described in Section

8.1 Accessing the File Screen.

3. Use the arrow keys to highlight the Upload to PC selection.

See Figure 8.2 File Screen.

4. Press the Enter key. The file list screen is displayed. See

Figure 8.3 File List Screen.

5. Use the arrow keys to highlight the calibration record file

that you wish to transfer and press Enter.

6. You will then be given a choice of uploading the file in three

formats; Binary, Comma & “” Delimited, and ASCII

Text.

NOTE: The binary format is reserved for future YSI

software packages.