Page 1

YSI Model 5239

Dissolved

Oxygen Probe

Instruction

Manual

Page 2

Page 3

NTRODUCTION

I

Table of Contents

........................................................................ 1

P

ROBE CONFIGURATION

S

YSTEM SPECIFICATIONS

T

EMPERATURE COMPENSATION

ROBE OPERATION

P

M

EMBRANE INSTALLATION

C

ALIBRATION

E

RRONEOUS READINGS

I

NTERFERENCES

A

S

RINCIPLES OF OPERATION

P

T

T

T

................................................................................... 6

CIDS

TORAGE

HE CLARK OXYGEN SENSOR

HE

HE FORMATION OF

.............................................................................. 6

DO R

EADINGS FROM THE CATHODE REDUCTION

................................................................. 2

....................................................................... 3

................................................................... 6

AgCl

....................................................... 1

...................................................... 1

........................................... 2

.................................................. 2

........................................................ 5

................................................... 7

.............................................. 7

......... 8

AT THE ANODE

............................ 8

T

HE FUNCTION OF THE ELECTROLYTE

AINTENANCE AND TROUBLESHOOTING

M

M

EMBRANE CAP LIFE

E

LECTRODE CLEANING

T

ROUBLE SHOOTING GUIDE

S

ERVICING

......................................................................... 13

........................................................ 10

...................................................... 11

............................................... 12

i

.................................. 9

............................ 10

Page 4

ARRANTY AND REPAIR

W

...................................................... 14

C

LEANING INSTRUCTIONS

P

ACKING INSTRUCTIONS

.................................................. 16

..................................................... 17

ii

Page 5

NTRODUCTION

I

The YSI Model 5239 probe is used for measuring dissolved

oxygen in the field. It is the first field probe that features cap

membranes for easy membrane replacement (YSI 5906

membrane caps). The probe is rugged, with the DO and

temperature sensors enclosed in a heavy duty probe guard. A

10, 25 or 50 foot cable is directly connected to the probe body

making it waterproof. A 5-pin MS connector at the end of the

cable makes the 5239 fully compatible with all YSI 50 series

DO meters retaining the accuracy of the system. The 5239 has

been optimized for YSI meters which have a micro-processor

for sampling and processing data, such as YSI Models 50B

and 52. The system specifications, when used with a YSI 50

Series DO meter, are as follows:

P

ROBE CONFIGURATION

• Cathode: Gold

• Anode: Silver

• Membrane: FEP Teflon

• Electrolyte: YSI standard probe solution (Half

saturated KCl)

• Polarizing voltage: -0.8 V vs. the potential of the Ag

anode/reference electrode

S

YSTEM SPECIFICATIONS

• Temperature range: -5° to 45° C

• Temperature accuracy: ±0.2° C

• Temperature response time: 30 sec for 95% of change.

1

Page 6

• DO range: 0 to 200 % air saturation or 0 to 20 mg/L.

• DO accuracy: ±2 % or ±0.2 mg/L whichever is greater.

• DO response time: 30 sec for 95% of change at 25°C.

T

EMPERATURE COMPENSATION

Temperature compensation of DO readings is provided by the

YSI DO meter. For best results, calibrate within ±5° C of the

sample temperature.

ROBE OPERATION

P

NOTE: The 5239 probe is shipped dry. A shipping membrane

was installed to protect the electrodes.

A new membrane cap

must be installed before first use.

M

EMBRANE INSTALLATION

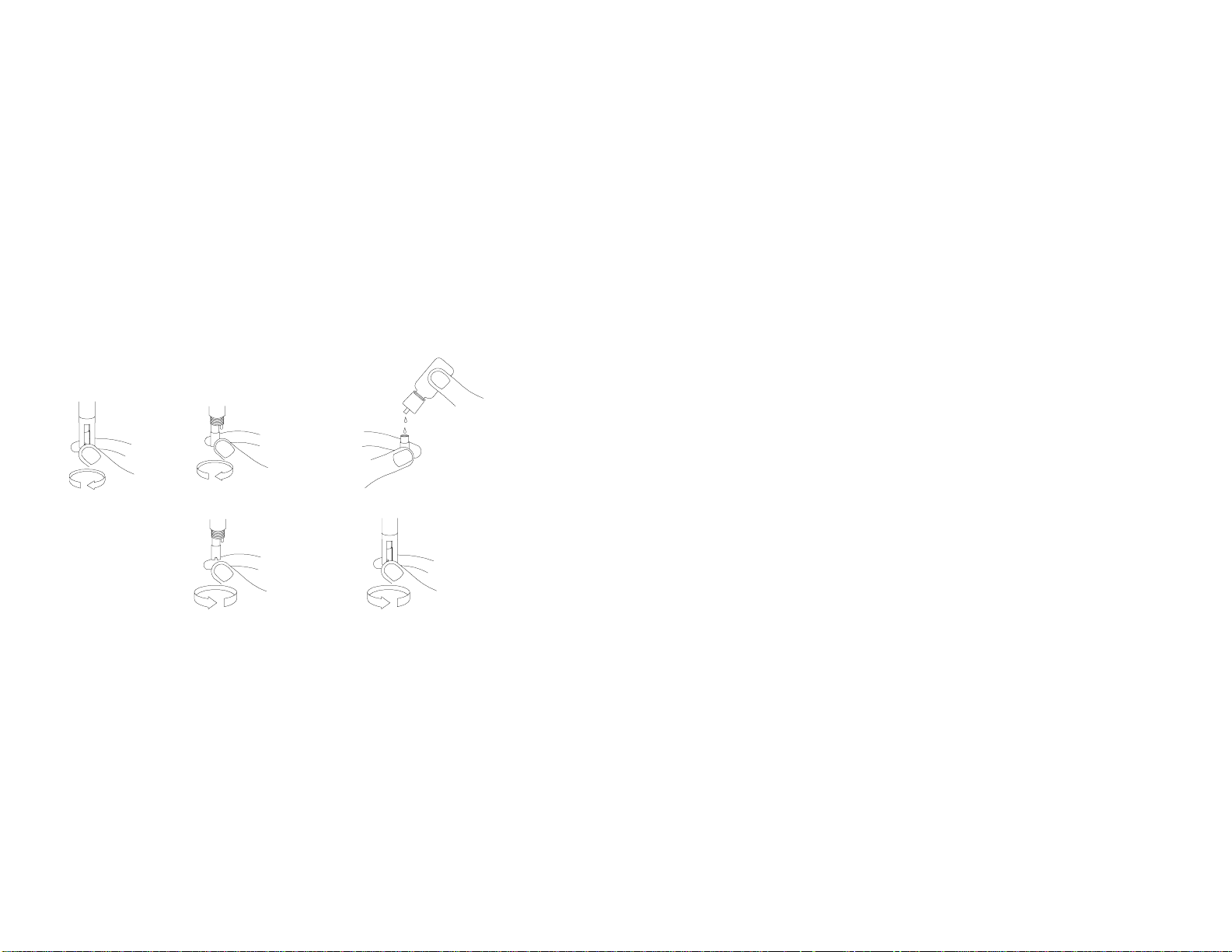

Follow the steps below to install a membrane cap:

1. Unscrew and remove the probe guard. See Figure 1.

2. Unscrew the old membrane cap and remove it from the

probe.

3. Thoroughly rinse the entire area of the silver anode,

gold cathode and threads with clean water (distilled or

deionized) to remove any dry crystals of the old

electrolyte.

4. Hold the membrane cap and fill it with 6 to 7 drops of

YSI standard electrolyte (KCl probe solution)

provided.

2

Page 7

5. Tap the bottom of the membrane cap with your finger a

few times (don’t touch the membrane) to shake loose

any trapped air bubbles.

6. Screw the membrane cap onto the probe moderately

tight. A small amount of electrolyte should overflow.

7. Rinse off the excess electrolyte with clean water.

8. Screw the probe guard onto the probe body.

9. Place the probe in the calibration bottle provided.

Verify that sponge in the bottle is wet.

Fill membrane cap

with 6-7 drops of

KCl solution.

Unscrew guard

Unscrew cap

Screw cap on

moderately tight

Screw guard on

moderately tight

Tap cap with finger

to remove bubbles.

Figure 1

C

ALIBRATION

Dissolved oxygen calibration must be done in an environment

with a known oxygen content. Three such environments will

be discussed here: calibration in air (water-saturated),

calibration in air-saturated water and calibration by Winkler

3

Page 8

titration. Choose the

Calibration in air is the simplest and most accurate method of

calibration.

which best fits your application.

one

• For

• For

• To calibrate

YSI recommends that the following procedure to calibrate the

5239 probe:

air calibration

humidity. To achieve this, place the probe in the plastic

calibration bottle (provided) with a wet sponge or paper

towel in the bottom.

air-saturated water calibration

volume of water (300 to 500 ml) by aerating for at least 15

minutes at a relatively constant temperature. Place the

probe in the aerated water and provide adequate stirring (at

least 1 foot per second) while calibrating.

to a Winkler-titrated sample

dissolved oxygen value of a sample by Winkler titration.

Place the probe in the sample and provide adequate stirring

(at least 1 foot per second) while calibrating.

1. Connect the 5239 probe to one of the YSI 50 series DO

meters.

2. Turn on the meter and wait for the probe to polarize

and the reading to stabilize. Depending on the

condition of the probe, the time for stabilization could

vary between 15 and 30 minutes. For a new probe with

clean electrodes and a properly installed membrane

cap, it usually takes 15 to 20 minutes. If the electrodes

are fouled or the membrane or electrolyte are not in

good condition, it may take longer to stabilize than

anticipated.

, place the probe in air at 100% relative

, air-saturate a

, determine the

4

Page 9

3. Check the membrane to make sure there are no water

beads attached to it. Wipe to remove the water beads

with a soft tissue if necessary.

NOTE: Make sure that the probe has been in the

calibration bottle for more than 2 minutes before

calibrating so that both the thermistor and DO

sensor are at the same temperature.

4. Calibrate the system according to the instructions in

the operations manual for the particular YSI 50 series

meter you are using. Be sure to take into consideration

the local barometric pressure and adjust to the proper

calibration value. All YSI 50 series DO meters have a

table on the back which relates barometric pressures to

%-air saturation values.

Checking the Probe Zero

The probe zero (background current) is checked by immersing

the probe in a sodium sulfite solution (0.08M or 3g

Na2SO3/300 ml), or in an inert gas (e.g. nitrogen, argon). The

meter should read less than 1% dissolved oxygen in either of

these environments. If it does not, change the membrane or

clean the probe.

E

RRONEOUS READINGS

Erratic readings will result from loose, wrinkled or fouled

membranes, or from bubbles larger than 1/8” in the electrolyte

solution. Erroneous readings may occur if the membrane is

coated with oxygen consuming bacteria or oxygen evolving

algae. Heavy residue may coat the membrane causing

incorrect readings. Frequent membrane changes will eliminate

this problem.

5

Page 10

I

NTERFERENCES

Hydrogen sulfide, sulfur dioxide, halogens, carbon monoxide,

chlorine, nitric oxide, and nitrous oxide can cause the probe to

give erroneous readings. If you suspect erroneous readings, it

may be necessary to determine if these are the cause.

A

CIDS

Avoid any environment that contains substances such as

concentrated acids, caustics, and strong solvents that may

attack the probe. Probe materials that may be damaged by

these substances include FEP Teflon, EPR rubber, ABS

plastic, and stainless steel.

S

TORAGE

When the probe is not in use, store the probe in a humid

environment, such as the plastic calibration bottle (with a wet

sponge or paper towel inside) or a BOD bottle containing at

least 1 inch of water (remove probe guard first).

6

Page 11

RINCIPLES OF OPERATION

P

T

HE CLARK OXYGEN SENSOR

The 5239 probe is a Clark type polarographic (voltammetric)

dissolved oxygen sensor. The sensor is made of a silver anode

and a gold cathode (see Figure 2), and is separated from the

measured medium by a semi-permeable Teflon membrane.

The temperature sensing element (thermistor assembly) is

mounted next to the oxygen sensor vertically, providing

temperature readings for the DO system.

Temperature sensor

Anode (silver)

Cathode (gold)

Figure 2

The membrane selectively allows oxygen to permeate into the

sensor, but prevents most interfering molecules and fouling

materials from entering. Upon permeating through the

membrane, oxygen is reduced at the gold cathode. The current

resulting from this reduction is diffusion-limited and is

proportional to the partial pressure of oxygen in the sample.

The counter reaction is the oxidation of silver at the

7

Page 12

anode/reference electrode which completes the overall

electrolytic reaction in the chloride medium (KCl electrolyte)

behind the membrane. These reactions, at the cathode and the

anode, are as follows:

Cathode reaction: O

+ 2H2O + 4e- ==> 4OH

2

Anode reaction: Ag + Cl

T

DO R

HE

EADINGS FROM THE CATHODE REDUCTION

-

==> AgCl

-

The oxygen reduction current is sampled and processed, by the

meter, and displayed as either %-air saturation or mg/L. While

the parameter of %-air (partial pressure) is independent of

temperature and salinity, mg/L (solubility of oxygen) is a

function of temperature and salinity. For instance, the same %air reading (same partial pressure) would give a higher mg/L

reading at a lower temperature than at a higher temperature.

Also, the higher the salinity, the lower the solubility for the

same %-air reading at the same temperature.

T

HE FORMATION OF

AgCl

AT THE ANODE

While the oxygen reduction current passes through the internal

circuit to be reported as the DO reading, it also passes through

the anode oxidizing the silver and forming a thin layer of

silver chloride. This oxidation of silver at the chloride medium

provides a stable potential which the cathode potential is

referenced to (for instance, the polarization potential of the

cathode is -0.8 V versus the potential of the Ag/AgCl redox

couple at the silver anode). As more and more silver chloride

8

Page 13

(an insoluble solid and poor conductor of electricity)

accumulates at the anode, it begins to block the passage of

current in the electrolytic cell. The silver anode must be

cleaned periodically to prevent this thick layer of silver

chloride from reducing the sensitivity of the sensor.

T

HE FUNCTION OF THE ELECTROLYTE

There are two main functions for the electrolyte:

1. Supply the chloride (Cl-) to the anode/reference

electrode for the counter reaction of the oxygen

reduction at the cathode.

2. Provide the ionic conduction of electricity inside the

cell, especially in the thin layer between the gold

cathode and the membrane.

Under normal operating conditions, such as measuring oxygen

around 100 %-air (8.27 mg/L) at 25° C, the strength of the

chloride concentration should last up to 500 hours before the

chloride becomes a limiting factor in the operation of the

oxygen sensor. 500 hours translates into about 62.5 working

days at 8 hours per day operation.

9

Page 14

AINTENANCE AND TROUBLESHOOTING

M

M

EMBRANE CAP LIFE

If the probe is properly maintained, one membrane cap should

last two to four weeks depending on how often the probe is

used and the type of samples measured. Keep the probe in a

moist atmosphere as much as possible to avoid drying out the

electrolyte. Erratic readings will result from loose, wrinkled or

fouled membranes, or from bubbles larger than 1/8” in the

electrolyte solution. The following things are likely to cause

short membrane life:

1. The electrolyte has dried out because the membrane

cap was not tight or the probe was exposed to dry air

for a long time.

2. The membrane was not properly installed. For

instance, wrinkles have formed after membrane

installation.

3. The probe was not properly rinsed with water after a

field measurement, allowing mud or algae to attach to

the membrane.

4. The membrane was damaged by an object, such as

reeds or small sticks in the water.

5. The probe has struck a hard object and the sensor or

membrane has been damaged.

10

Page 15

E

LECTRODE CLEANING

It is always a good practice to keep the probe in good

operating condition.

Silver Anode

After extended use, a thick layer of AgCl builds up on the

silver anode reducing the sensitivity of the sensor. The anode

must be cleaned to remove this layer and restore proper

performance. The cleaning can be chemical or mechanical:

•

Chemical cleaning:

Remove the membrane cap and

soak the entire anode section in a 14% ammonium

hydroxide solution for 2 to 3 minutes, followed by a

thorough rinsing with distilled or deionized water.

The anode should then be thoroughly wiped with a

wet paper towel to remove the residual layer from the

anode.

•

Mechanical cleaning:

Sand off the dark layer from

the silver anode with 400 grit wet/dry sandpaper.

Wrap the wet sandpaper around the anode and twist

the probe. Rinse the anode with clean water after

sanding, followed by wiping thoroughly with a wet

paper towel.

Gold Cathode

For correct probe operation, the gold cathode must be textured

properly. It can become tarnished or plated with silver after

extended use. The gold cathode can be cleaned by using the

adhesive backed sanding disc and tool provided in the YSI

5238 probe reconditioning Kit.

11

Page 16

Stick the disc to the sanding tool, then wet sand the gold with

a twisting motion about 3 times or until all silver deposits are

removed and the gold appears to have a matte finish. If the

cathode remains tarnished, return the probe for service.

Wipe the gold cathode thoroughly with a wet paper towel

before putting on a new membrane cap.

T

ROUBLE SHOOTING GUIDE

Below is a quick reference of symptoms with steps to follow

to cure these symptoms.

Symptoms Actions

Unable to calibrate • Extend the stabilization time from 15 min.

to 30 min. before calibrating

• Change membrane

• Check for loose or wrinkled membrane or

deposits between gold cathode and

membrane, especially after changing

membrane

• Clean probe (see instructions under

Electrode Cleaning)

12

Page 17

Symptoms Actions

Does not hold

calibration

• Allow sufficient time for temperature and

oxygen stabilization before calibration

• Check for water droplets on membrane

• Check membrane for a pinhole or split

• Change membrane

• Clean probe (see instructions under

Electrode Cleaning)

Unstable readings • Check membrane for a pinhole or split

• Allow 60 sec. for reading to stabilize

• Change membrane

• Clean probe (see instructions under

Electrode Cleaning)

Membrane cap is

tight

S

ERVICING

• Use pliers to loosen the cap (turn counter

clockwise while facing sensor tip)

The 5239 probe has only two replaceable parts (other than the

membrane cap), the probe guard and the 5-pin MS connector

on the end of the cable. The cable is permanently attached to

the probe and cannot be replaced.

YSI part number Description

110275 5-pin MS connector kit

059956 Probe guard

5238 Probe reconditioning kit

13

Page 18

ARRANTY AND REPAIR

W

YSI Model 5239 Dissolved Oxygen Probes are w arran t ed f or on e year from

date of purchase by the en d u s er again s t def ects in materials and

workmansh ip. Within th e warranty period, YSI will repair or replace, at its

sole discretion, free of charge, any product that YSI determines to be cov ered

by this warranty.

To exercise this warranty, write or call your local YSI representative, or

contact YSI Customer Service in Yellow Springs, Ohio. Send the produ ct an d

proof of purchase, tran sport at ion prepai d, to the Authorized Serv ice C en t er

selected by YSI. Repair or replacement will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted

for the balance of the ori g in al warranty period, or at l eas t 90 days from date

of repair or replacement.

Limitation of Warranty

This Warranty does not appl y to any YSI product damage or failure cau s ed

by (i) failure to install, operate or us e th e produ ct in accordan ce with YSI’s

written instructions, (ii) abuse or misuse of the product, (iii) failure to

maintain the product in accordance with YSI’ s written instructions or

standard industry procedure, (iv) any i mproper repairs to the product, (v) use

by you of defective or improper components or parts in se rv ic in g or repai ri n g

the product, or (vi) modi f i cati on of the product in any way not ex pres sl y

authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

YSI’s LIABILITY UNDER THIS WARRANTY IS LIMITED TO

REPAIR OR REPLACEMENT OF THE PRODUCT, AND THIS SHALL

BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY DEFECTIVE

PRODUCT COVERED BY THIS WARRANTY. IN NO EVENT

SHALL YSI BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING

FROM ANY DEFECTIVE PRODUCT COVERED BY THIS

WARRANTY.

14

Page 19

YSI Authorized Service Centers

For the nearest authroized service center contact:

YSI Technical Support • 1725 Brannum Lane • Yellow Springs, OH • 45387

Phone: +1 937 767-7241 • Fax: 937 767-9353 • environmental@ysi.com • www.ysi.com

15

Page 20

C

LEANING INSTRUCTIONS

NOTE: Before they can be serviced, equipment exposed to

biological, radioactive, or toxic materials must be cleaned

and disinfected.

Biological contamination is presumed for

any instrument, probe, or other device that has been used with

body fluids or tissues, or with waste water. Radioactive

contamination is presumed for any instrument, probe or other

device that has been used near any radioactive source.

If an instrument, probe, or other part is returned or presented

for service without a Cleaning Certificate, and if in our

opinion it represents a potential biological or radioactive

hazard, our service personnel reserve the right to withhold

service until appropriate cleaning, decontamination, and

certification has been completed. We will contact the sender

for instructions as to the disposition of the equipment.

Disposition costs will be the responsibility of the sender.

When service is required, either at the user's facility or at YSI,

the following steps must be taken to insure the safety of our

service personnel.

In a manner appropriate to each device, decontaminate all

1.

exposed surfaces, including any containers. 70% isopropyl

alcohol or a solution of 1/4 cup bleach to 1 gallon tap

water are suitable for most disinfecting. Instruments used

with waste water may be disinfected with .5% Lysol if this

is more convenient to the user.

The user shall take normal precautions to prevent

2.

radioactive contamination and must use appropriate

decontamination procedures should exposure occur.

16

Page 21

If exposure has occurred, the customer must certify that

3.

decontamination has been accomplished and that no

radioactivity is detectable by survey equipment.

Any product being returned to the YSI Repair Center,

4.

should be packed securely to prevent damage.

Cleaning must be completed and certified on any product

5.

before returning it to YSI.

P

ACKING INSTRUCTIONS

Clean and decontaminate items to insure the safety of the

1.

handler.

Complete and include the Cleaning Certificate.

2.

Place the product in a plastic bag to keep out dirt and

3.

packing material.

Use a large carton, preferably the original, and surround

4.

the product completely with packing material.

Insure for the replacement value of the product.

5.

17

Page 22

Cleaning Certificate

Organization ________________________________

Department _________________________________

Address ___________________________________

City _______________ State ______ Zip ________

Country __________________

Model No. of Device ______ Lot Number _________

Contaminant (if known) _____________________

Cleaning Agent(s) used _____________________

Radioactive Decontamination Certified?

(Answer only if there has been radioactive exposure)

___ Yes ___ No

Cleaning Certified By _________________________

Name Date

18

Page 23

1725 Brannum Lane

Yellow Springs, Ohio 45387 USA 052395 - Web

937 767-7241 • 800 765-4974 A52395B

Fax 937 767-9353 September 99

Environmental@YSI.com • www.YSI.com

1997 YSI Incorporated

Loading...

Loading...