Page 1

YSI Environmental

Pure Data for a Healthy Planet.

®

YSI 5200

Recirculating System Monitor

Operations

Manual

Page 2

Page 3

Table of Contents

SECTION 1. SAFETY ........................................................................................................................3

1.1 GENERAL SAFETY INFORMATION................................................................................................3

SECTION 2. INTRODUCTION........................................................................................................5

SECTION 3. INSTALLATION .........................................................................................................9

3.1 UNPACKING AND INSPECTION .....................................................................................................9

3.2 SELECTING AN INSTALLATION LOCATION................................................................................. 10

3.3 INSTALLING THE COMPONENTS.................................................................................................12

3.4 MOUNT THE YSI 5200 RECIRCULATING SYSTEM MONITOR.....................................................13

3.5 INSTALLING THE 5562 OR 5561 PROBE ASSEMBLIES ................................................................17

3.6 WIRING THE SYSTEM.................................................................................................................20

3.7 COMMUNICATIONS METHOD.....................................................................................................23

3.8 GROUNDING INFORMATION.......................................................................................................26

3.9 SAFETY ISSUES .......................................................................................................................... 26

3.10 LIGHTNING AND SURGE PROTECTION ....................................................................................... 26

SECTION 4. PROBE MODULE .....................................................................................................27

4.1 UNPACKING THE PROBE MODULE .............................................................................................27

4.2 FEATURES OF THE YSI 5561 PROBE MODULE...........................................................................27

4.3 FEATURES OF THE YSI 5562 PROBE MODULE...........................................................................28

4.4 PREPARING THE YSI 5561 PROBE MODULE ..............................................................................28

4.5 PREPARING THE YSI 5562 PROBE MODULE ..............................................................................28

4.6 MEMBRANE CAP INSTALLATION ............................................................................................... 30

4.7 CALIBRATION/STORAGE CUP (5562 ONLY)...............................................................................31

4.8 INSTRUMENT/CABLE CONNECTION ...........................................................................................31

SECTION 5. OPERATION..............................................................................................................33

5.1 RUN SCREEN..............................................................................................................................33

5.2 MAIN MENU............................................................................................................................... 34

5.3 PARAMETERS MENU ..................................................................................................................35

5.4 DAILY CHECKS ..........................................................................................................................57

5.5 CONDUCTING A SYSTEM TEST................................................................................................... 58

SECTION 6. CALIBRATION .........................................................................................................60

6.1 GETTING READY TO CALIBRATE ............................................................................................... 60

6.2 CALIBRATION PROCEDURES ......................................................................................................62

SECTION 7. ALARM/PAGER........................................................................................................73

YSI Incorporated i 5200 Recirculating System Monitor

Page 4

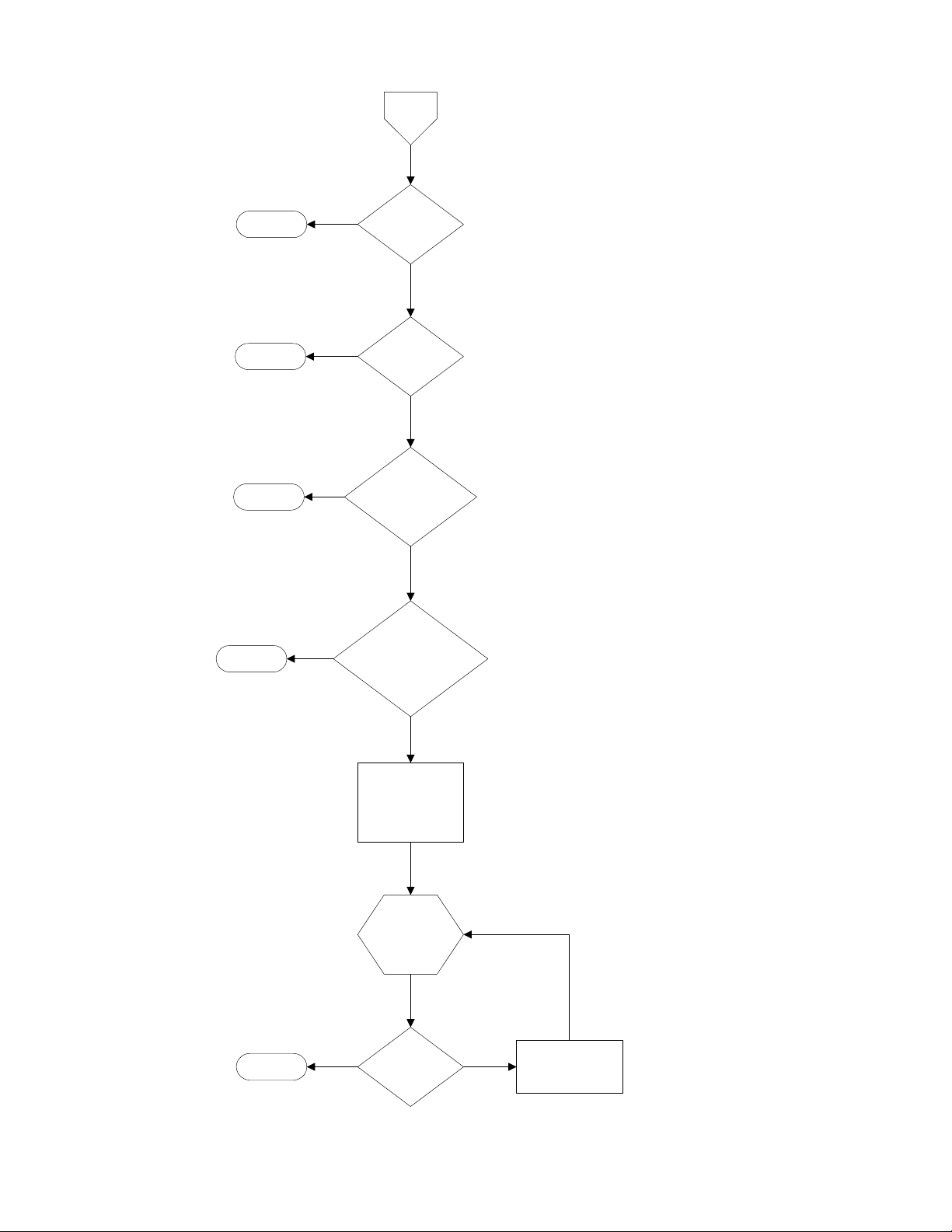

ALARM LOGIC FLOW CHARTS...................................................................................................73

7.1

7.2 GENERAL ALARM ......................................................................................................................77

SECTION 8. NETWORK.................................................................................................................78

8.1 RS485 NETWORK.......................................................................................................................78

8.2 AUXILIARY INPUTS WIRING ......................................................................................................79

SECTION 9. ADVANCED SETUP .................................................................................................82

9.1 SYSTEM MENU........................................................................................................................... 82

9.2 TIMERS MENU............................................................................................................................93

9.3 RELAY OUTPUT WIRING..........................................................................................................100

9.4 AUXILIARY SYSTEM ................................................................................................................102

SECTION 10. AQUAMANAGER SOFTWARE ...........................................................................106

SECTION 11. MAINTENANCE .....................................................................................................107

11.1 PROBE MAINTENANCE AT THE DEPLOYMENT SITE.................................................................107

11.2 CALIBRATION CHECKS ............................................................................................................ 108

11.3 RECOMMENDED QUALITY ASSURANCE PROTOCOL ................................................................108

11.4 SENSOR CARE AND MAINTENANCE .........................................................................................110

11.5 RECOMMENDED CLEANING OF THE 5200 MONITOR AND ACCESSORIES ................................. 114

SECTION 12. STORAGE.................................................................................................................115

12.1 SHORT TERM STORAGE ........................................................................................................... 115

12.2 LONG TERM STORAGE ............................................................................................................. 115

SECTION 13. TROUBLESHOOTING...........................................................................................117

SECTION 14. WARRANTY AND SERVICE INFORMATION .................................................120

SECTION 15. SYSTEM SPECIFICATIONS.................................................................................123

SECTION 16. FACTORY DEFAULT SETTINGS .......................................................................125

SECTION 17. INTERNATIONAL MODEM SUPPORT .............................................................133

SECTION 18. HEALTH AND SAFETY.........................................................................................134

SECTION 19. REQUIRED NOTICE..............................................................................................138

SECTION 20. ACCESSORIES........................................................................................................139

SECTION 21. SOLUBILITY AND PRESSURE/ALTITUDE TABLES .....................................140

SECTION 22. YSI CONDUCTIVITY CALIBRATION SOLUTION VALUES........................144

SECTION 23. DECLARATION OF CONFORMITY ..................................................................145

YSI Incorporated ii 5200 Recirculating System Monitor

Page 5

Section 1. Safety

1.1 General Safety Information

Read all safety information in this manual carefully before using the YSI 5200 Recirculating System

Monitor. Reagents that are used to calibrate and check this instrument may be hazardous to your health.

Take a moment to review Section 18 Health and Safety.

WARNING

Warnings are used in this manual when misuse of the instrument could result in death or serious injury to

a person.

CAUTION

Cautions are used in this manual when misuse of the instrument could result in mild or serious injury to a

person and/or damage to equipment.

IMPORTANT SAFETY INSTRUCTIONS!

Save these instructions for future reference!

The most important safety rule for use of the YSI 5200 is to utilize the instrument ONLY for purposes

documented in this manual. The user should be certain to read all of the safety precautions outlined below

before using the instrument.

WARNING: To avoid severe personal injury or damage to the equipment, installation, operation and

service should be performed by qualified personnel who are thoroughly familiar with the entire contents

of this manual.

WARNING: All wiring involving connections to mains power must be performed by a qualified licensed

electrician, and must conform to all locally applicable electrical codes. Any mains power circuit

connected within the 5200 enclosure must be protected by a Ground Fault Circuit Interrupt device. Do not

make connections while power is applied. Disconnect power before proceeding. See Section 3.6 Wiring

the System.

WARNING: The 5200 utilizes sensitive solid state devices that can be damaged by static shock.

Installers must observe accepted ESD, E

the 5200 I/O plate or damage may result. See Section 3.6 Wiring the System.

CAUTION: It is essential that all sensor wiring be run in a separate cable or conduit from power wiring.

See Section 3.6 Wiring the System.

CAUTION: The YSI 5579 power supply accessory is for indoor use only, and must be connected to the

5200 Monitor with a suitable waterproof extension cable if the 5200 Monitor is installed in a damp

location. See Section 3.6.1 DC Power Input Wiring.

WARNING: A UL Listed DC power supply is required for any installation which is connected to “mains

supply” or other power source which is “hazardous live” per UL 3101-1 section 3.5.2. See Section 3.6.1

DC Power Input Wiring.

lectro-Static Discharge, procedures while connecting cabling to

YSI Incorporated 3 5200 Recirculating System Monitor

Page 6

WARNING: A UL Listed slow-blow fuse with a maximum current rating of 1A must be connected in

series with the positive terminal of any power supply not provided by YSI. See Section 3.6.1 DC Power

Input Wiring.

CAUTION: Power supply voltage above 16.5VDC may permanently damage the 5200 Monitor. See

Section 3.6.1 DC Power Input Wiring.

CAUTION: The sensitivity and stability of the monitor will be impaired if the monitor is not grounded.

Do not

Grounding Information.

CAUTION: Do not ground the probe body. See Section 3.6 Wiring the System.

WARNING: Turn off all power and assure power “lockout” before servicing to avoid contact with

electrically powered circuits. See Section 3.6 Wiring the System.

CAUTION: Section 3.10 Lightning and Surge Protection or any other installation procedure cannot

protect against a direct lightning strike. YSI Incorporated cannot accept liability for damage due to

lightning or secondary surges.

apply power to the Monitor until all electrical connections are verified and secure. See Section 3.8

YSI Incorporated 4 5200 Recirculating System Monitor

Page 7

Section 2. Introduction

Congratulations on your purchase of a sophisticated, yet easy-to-use aquatic environment controller.

Designed with a powerful INTEL

Monitor/Controller includes the following features:

Ö Continuous monitoring of Dissolved Oxygen (DO), conductivity, salinity, temperature, pH and

Oxidation Reduction Potential (ORP).

Ö Menu-driven programming environment.

Ö 4 Relay outputs

Ö Aux. I/O system supporting 2 Inputs (1 Digital, 1 Analog/Digital)

Ö FLASH memory that makes upgrading your YSI 5200 Recirculating Monitor with new software

a simple task.

Ö Local audible alarm or optional remote dialup pager alarm capability.

Ö Parameter control capability for controlling peripheral equipment such as pumps, and lighting.

Ö Powerful data logging capability that stores up to 30-days of data.

Ö Communications ports supporting both direct and modem connectivity. RS232, TCP/IP

connectivity and a network communications port allowing multiple YSI 5200 Recirculating

Monitors to be connected via an RS485 network.

Ö Wide operating power range (7–16VDC) along with 12VDC battery backup capability.

™

Ö AquaManager

—Software that allows you to communicate with your YSI 5200 Recirculating

Monitor, perform advanced graphical analysis of current and historical data—from any

Windows 2000/XP PC.

™

microprocessor, your YSI 5200 Recirculating System

The YSI 5200 is constructed with only the highest quality components. All information gathered by the

controller is processed digitally. The YSI 5200 architecture includes Digital Signal Processing (DSP)

hardware and software that guarantees accurate and repeatable readings over the life of the YSI 5200.

Monitoring Capability

The YSI 5200 software provides for monitoring, control, and alarm capabilities. The five water quality

parameters monitored and controlled are:

Ö Dissolved Oxygen

Ö Conductivity

Ö Temperature

Ö pH

Ö ORP

In addition to the five parameters the YSI 5200 also provides two auxiliary inputs that can be configured

to provide 2 digital inputs or 1 digital input and 1 analog input for sampling a recorder output from

another instrument.

The probe is connected to the YSI 5200 through a waterproof connector (see Figure 4-10 Bottom

Connectors).

Ports for up to three non-metallic watertight compression or conduit fittings are located on the 5200

bottom panel and provide the means for connecting power, relay outputs and communications via the I/O

plate located within the 5200 Monitor. The 5200 Monitor is supplied with compression fittings; conduit

fittings are available as an accessory.

YSI Incorporated 5 5200 Recirculating System Monitor

Page 8

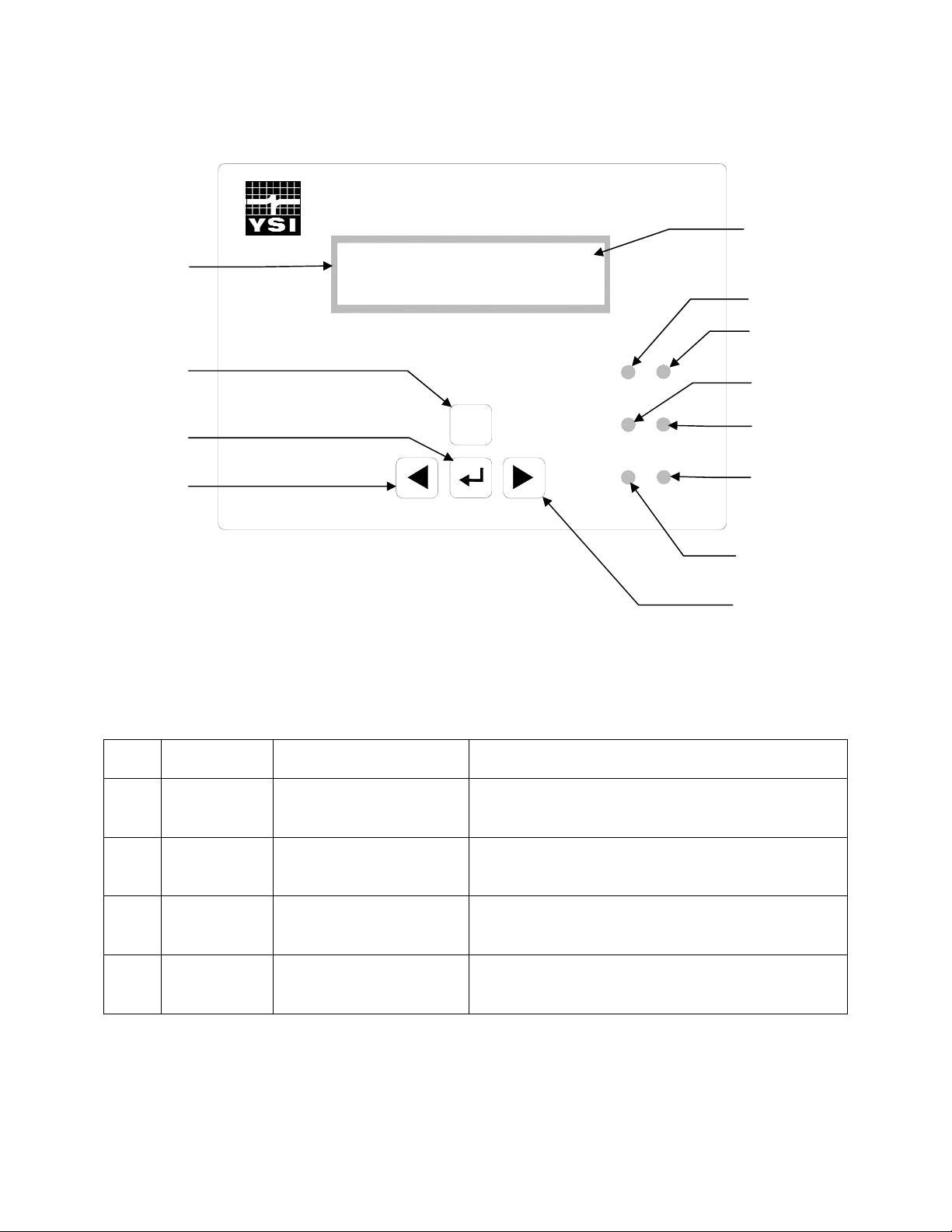

Front Panel

The front panel of the 5200 contains the display and keypad as shown in Figure 2-1 Front Panel.

Display

Escape key

Enter key

Left Arrow key

DO 6.57 mg/L H

Cond 7.63mS *

ESC

Figure 2-1 Front Panel

5200

Recirculating

System

Monitor

System

DO

Status

Temperature

Conductivity

pH

ORP

Hold indicator

DO LED

System Status

LED

Temperature LED

pH LED

ORP LED

Conductivity LED

Right Arrow key

The YSI 5200 is operated using tactile switches mounted behind the front overlay.

Key Name Main Display Function Menu Function

[ ]

Enter Enter main menu Pressing the Enter key confirms a selection and

advances the menu.

[ESC] Escape Hold display line Pressing the Escape key cancels a selection and

backs the system one menu level.

[f] Right Arrow Scroll display parameters

Scrolls right to the next selection.

forward

[e] Left Arrow Scroll display parameters

Scrolls left to the next selection.

backwards

YSI Incorporated 6 5200 Recirculating System Monitor

Page 9

Status Lights

The 6 status lights located on the front panel of the 5200 (see Figure 2-1 Front Panel) indicate whether a

system is operating within its preset limits or a control system has been activated.

Parameter Status Lights for Temperature, DO, pH, Conductivity and ORP are configured as follows:

OFF – parameter not enabled

GREEN – normal range

FLASHING GREEN – control mode (turns off when it crosses the original set point)

RED – alarm (turned off by pressing any key, except escape, and resolving the alarm condition)

The System Status LED is configured:

GREEN – normal operation

RED – battery back-up

Flash Memory Architecture

A key feature of the YSI 5200 is that it is designed using FLASH memory allowing software updates to

be easily accomplished. Refer to Section 9.1.5 Downloader (Upgrading Software) for instructions on

upgrading the software in the YSI 5200.

Powering the YSI 5200

Primary power for the YSI 5200 is either a wall mount power transformer providing 8.5 to 16 VDC at

700 mA or any power source providing voltage and current in the stated operating range. The YSI 5200

comes standard with a 12VDC 700 mA wall mount power supply. In addition, an optional 12VDC battery

backup input is available for powering the YSI 5200 should the primary power fail.

The YSI 5200 design incorporates FLASH Memory, RAM, and a battery backed-up real-time clock.

Should power be lost, none of the parameter setpoints or configuration data will be lost. However,

during a power failure, data in the data-log will be erased if no backup power is provided to the

unit.

Control Capability

The YSI 5200’s software gives it the capability for parameter control as well as monitoring. Using the 4

built in control relays, a wide variety of monitoring and control features can be automatically activated.

The sensors gather information and relay it to the YSI 5200 controller. The 5200 can directly control

devices through the four built-in relay outputs. Each device that the YSI 5200 controls, such as a heater or

chiller, can be programmed

Timing System

The timing control feature allows the YSI 5200 to control external devices such as a lighting system. The

timing system will support up to 4 independent control times per 24 hours. Each channel has one ON and

OFF time per 24-hour period.

Alarm System

The alarm system provides visual and audible notification in the event that a monitored parameter

exceeds the user defined range. Used in conjunction with the YSI 5201 modem (or a computer running

AquaManager software and equipped with a compatible modem), it provides remote alarm notification

YSI Incorporated 7 5200 Recirculating System Monitor

Page 10

via a digital pager. Used in conjunction with a computer running AquaManager Software, it provides

email alarm notification.

Feed Timer System

The Feed Timer System allows control and monitoring of feedings made by the 5200. Optional Parameter

control reduces the amount of food dispensed if the DO, temp or pH values are “out of range.” The

optional FCR (feed conversion ratio) feature automatically increases the daily amount of food dispensed.

YSI Incorporated 8 5200 Recirculating System Monitor

Page 11

Section 3. Installation

Installation includes the following sections:

Ö Unpacking and Inspection Ö Selecting an Installation Location Ö Installing the Components Ö Mount the YSI 5200 Recirculating System Monitor Ö Installing the 5562 or 5561 Probe Assemblies Ö Wiring the System Ö Communications Method Ö Grounding Information Ö Safety Issues Ö Lightning and Surge Protection

3.1 Unpacking and Inspection

Inspect the outside of the shipping carton for damage. If damage is detected, contact the carrier

immediately. Remove the instrument from the shipping container. Be careful not to discard any parts or

supplies. Confirm that all items on the packing list are present. Inspect all assemblies and components for

damage.

Save the original packing carton. Carriers typically require proof of damage due to mishandling. Also, if

it becomes necessary to return the monitor, you should pack the equipment in the same manner it was

received.

The following components are included with the purchase of the 5200 Monitor:

Ö 5200 Monitor

Ö 006515 Flange Mounting Kit

Ö 6506 Desiccant Kit

Ö 605226 Instruction Manual

Ö 605230 Compression Plugs, 2 each

Ö 605229 Compression Plugs, 2 each

Ö 655384 Dual Male RJ-45 Cable Assembly

Ö 655383 Adapter, DB-9 to RJ-45

Ö 655385 Inline Power Ferrite Assembly

Ö 655361 Ferrite Bead for Communication Port .390, .870, 1.272, 2 each

Ö 655365 Ferrite Bead for Relays, .500, 1.142, 1.280

Ö 605227UL 5579 (or 655478UL 5578) 12-Volt Power Supply

Ö 605223UL Pluggable Socket Connector for 12 VDC Power

Ö 605223UL Pluggable Socket Connector for RS-485, 4 Pole, with 120Ω termination resistor

Ö 065944UL Pluggable Socket Connector for Relays, 12 Pole

Ö 065942UL Pluggable Socket Connector for Auxiliary Inputs, 3 Pole

If any parts are damaged or missing, contact your factory representative or YSI immediately.

YSI Incorporated 9 5200 Recirculating System Monitor

Page 12

WARNING: To avoid severe personal injury or damage to the equipment, installation, operation and

Not

service should be performed by qualified personnel who are thoroughly familiar with the entire contents

of this manual.

3.2 Selecting an Installation Location

The 5200 monitor is an on-line continuous measurement tool that can be used to control various

operations and provide valuable insight into the facility’s operation. As with any instrument of this type,

proper installation is the first important step to ensure you are provided with reliable performance and

accurate data. Installation of the monitor and probe should be carefully planned in advance to obtain the

most effective and accurate utilization of the equipment.

3.2.1 Choosing a Probe Location

Probe location is determined by the necessity to obtain water quality readings which are representative of

the bulk flow stream. A suitable location should take a number of physical and chemical factors into

consideration. See Section 3.5 Installing the 5562 or 5561 Probe Assemblies.

Ö Standard probe cable lengths for the 5200 are 4, 10 and 20 meters. Consider the entire distance

required for cable routing when determining cable length requirements and mounting locations.

Ö The probe must be located in the flow stream where the sensors will remain submersed at all

times and level fluctuations will not expose them to the atmosphere.

Ö The probe must be placed in a well mixed, free-flowing area of the process stream. The flow

stream should be representative of the process being monitored/controlled. Placing the probe

midstream and mid-depth typically gives the most reliable results.

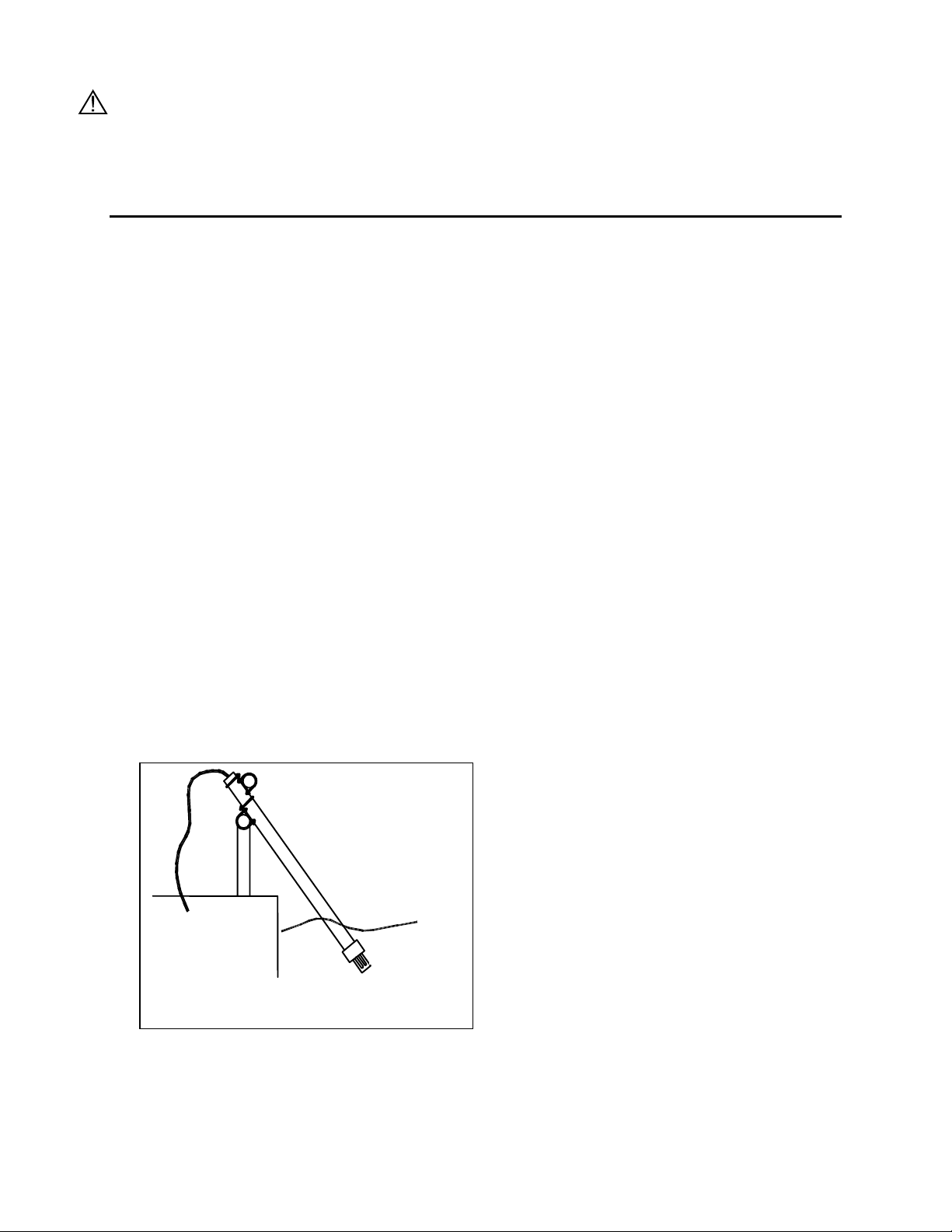

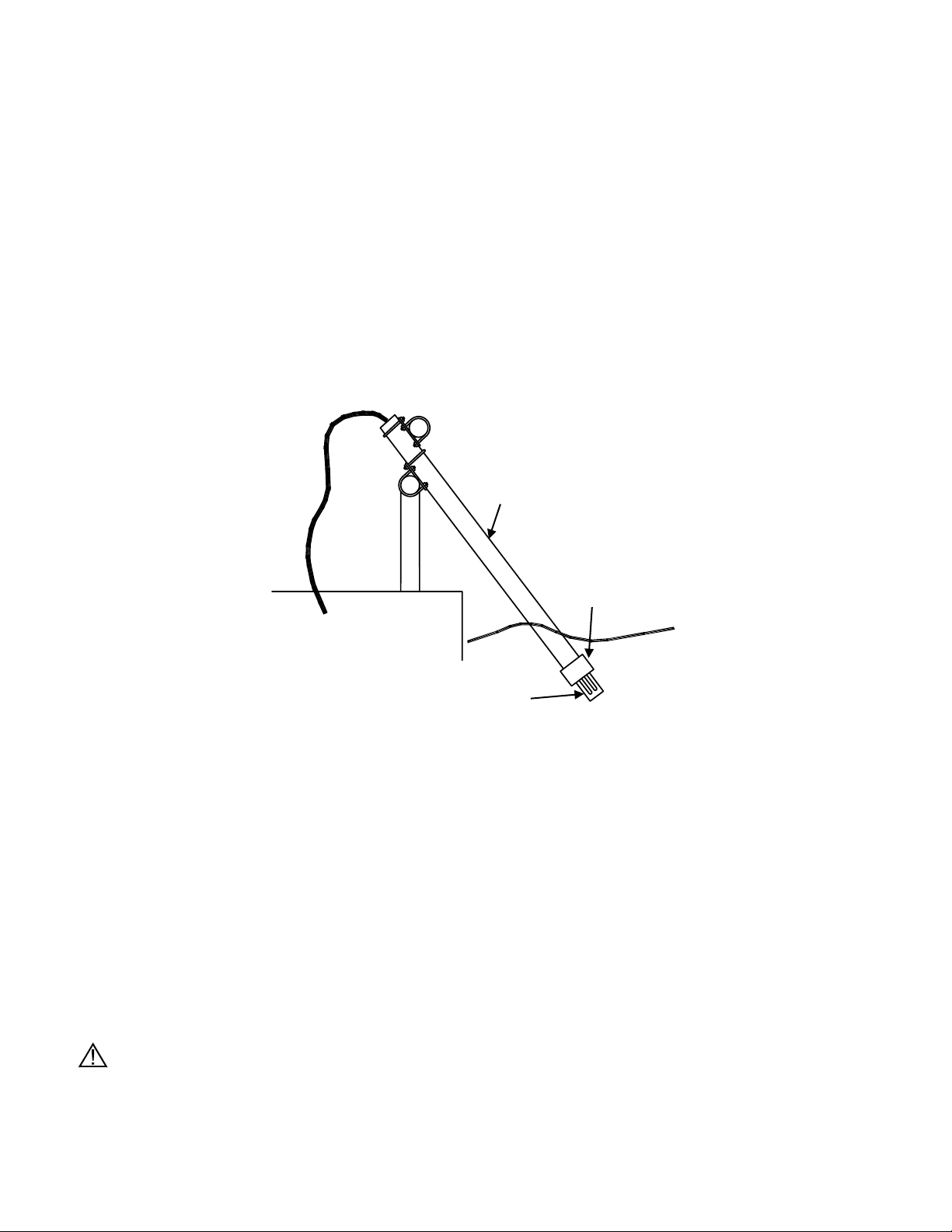

Ö Ideally, the probe should be placed at an angle within 45° of vertical and directed with the flow

direction (see Figure 3-1). This location will provide for the least stress on the support arm

holding the probe while minimizing the opportunity to collect debris. Placement against the flow

stream or perpendicular to the flow stream also provides accurate monitoring, but inspection and

cleaning may be required more frequently due to increased collection of debris.

Probe

to

scale.

drawn

Figure 3-1 Probe orientation (using rail mount kit)

The flow stream should be as free as possible of debris (e.g., algae) which could collect on the probe and

cause erroneous readings. See 3.5 Installing the 5562 or 5561 Probe Assemblies for flow requirements.

YSI Incorporated 10 5200 Recirculating System Monitor

Page 13

Note that this is an on-line device that is measuring actual conditions in real time. Composite sampling

N

for pH, for example, will not match on-line monitoring. Therefore, pH values recorded by the chart

recorder and/or plant control system connected to the 5200 Monitor cannot be averaged to equal the pH of

a composite sample.

3.2.2 Choosing a Monitor Location

The probe measures conditions in the flow stream and transmits a low voltage signal to the 5200 Monitor.

The probe is attached to a cable that is equipped with a “military grade” watertight connection to the

monitor.

Several options are available for mounting the 5200 Monitor. Easy to use, wall mount brackets (006515

Flange Mounting Kit) are provided with the 5200. If rail or panel mounting is desired, the 6509 Rail

Mount Kit and 6510 Panel Mount Kits are available as accessories.

NOTE: The 5200 Monitor is provided with a weatherproof enclosure that will withstand most

environmental conditions with no compromise to system performance. An optional Weather

Shield (YSI #6505) is available for added protection from the elements. When mounting the 5200

outdoors the 6505 Weather Shield should be used.

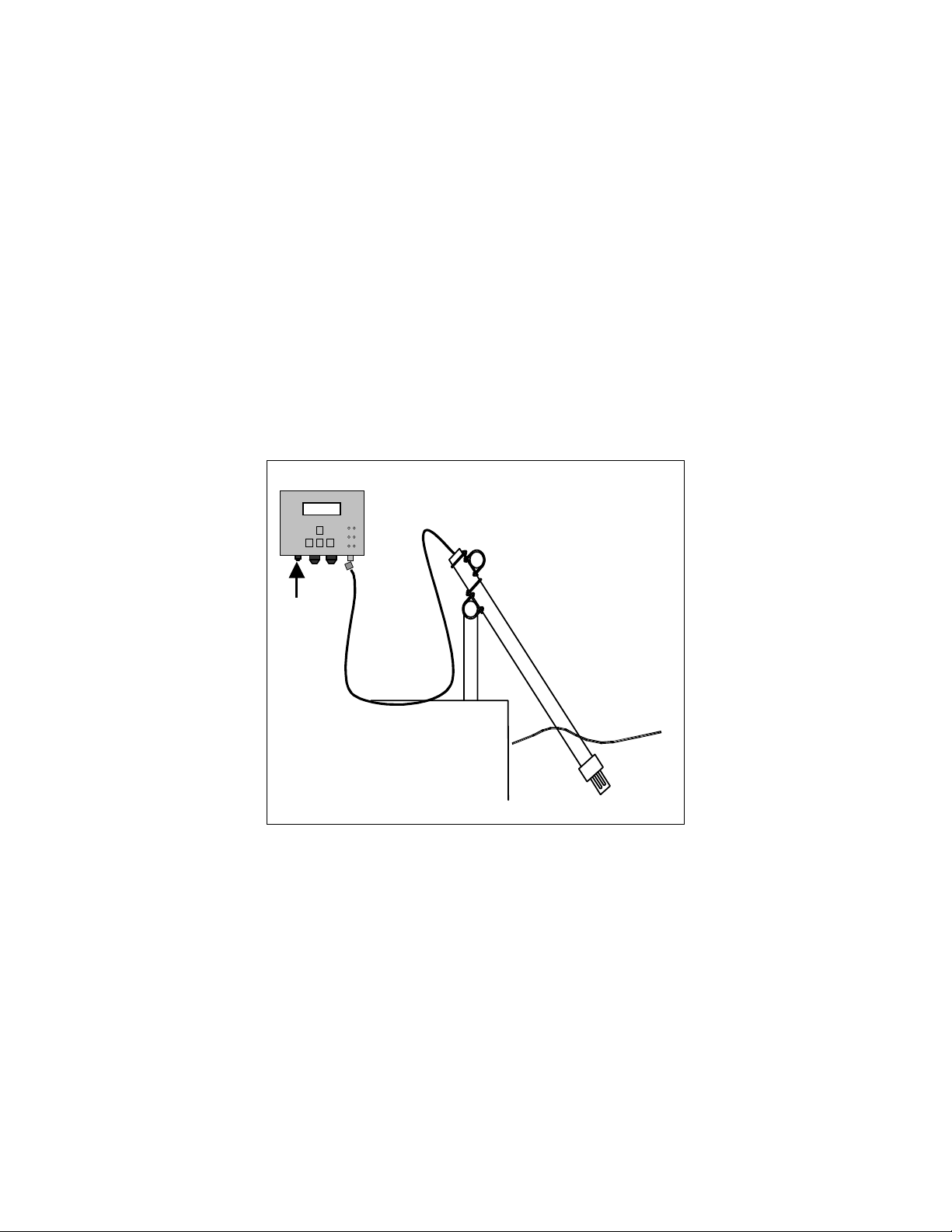

5200 Monitor

5200

Recirculating

DO 5.30 Mg/L

System

02/02/00 9:30PM

Monitor

ESC

↵

DC

Probe

ot drawn to scale.

Stream

Figure 3-2 Monitor and probe installed using 6511 probe rail mount kit

Locating the monitor close to the sample location has advantages since accuracy checks and calibration

can be more easily facilitated under this arrangement. For example, a recently calibrated, hand-held

dissolved oxygen meter can be placed next to the 5200’s probe and readings can be compared.

Probe cables for the 5200 Monitor are available in 4 (13.1 ft), 10 (32.8 ft) and 20 (65.6 ft) meter lengths.

The probe cable length determines the maximum distance the monitor can be mounted from the sample

being measured.

Location of the 5200 Monitor should be elevated and in a dry place above the potential flood level. The

unit should be easily accessible for an operator or technician.

Although the monitor is suitable for outdoor use, it should be located in an area where temperature

extremes, vibrations, electromagnetic and radio frequency interference are minimal. Select an installation

location that is at least two (2) feet from any high voltage conduit. Avoid mounting on severely vibrating

YSI Incorporated 11 5200 Recirculating System Monitor

Page 14

structures or near a high heat source, AC motor or transformer, radio transmitter or antenna. Be sure the

monitor can be fully opened and serviced at its installed location by maintenance personnel.

3.3 Installing the Components

There are three basic parts to installing the YSI 5200 Monitor, which are covered in the following

sections:

Ö Installing the YSI 5200 Monitor hardware and additional components

Ö Installing the probe assembly

Ö Wiring the 5200 Monitor

3.3.1 Sealants, Desiccants and Securing the Monitor

Since the 5200 Monitor will likely be subjected to environmental conditions that promote formation of

condensation, it is very important to follow the instructions below before securing the cover to your

unit(s). This will prevent damage to the electronic components within the Monitor and extend the life of

the monitoring system.

The 5200 Monitor is shipped with three compression fittings. The small compression fitting on the left

side of the bottom panel is to be used for the power supply wire. The two larger compression fitting are

supplied with solid plugs installed. These solid plugs should be left in place if no other electrical

connections are to be made to the 5200.

If electrical connections are required for control relays, PC connections or other devices, there are a

number of options to ensure a watertight installation to the 5200’s case.

1. Solid plugs, located in the 2 larger compression fitting, can be frozen (put in a freezer for 1 hour) and

then easily drilled to the required diameter. The drill bit diameter should be slightly smaller than the

wire diameter so that a watertight seal can be made.

2. Compression plugs with two different pre-sized holes are supplied with the 5200 Monitor. The hole

size in the plugs varies with the amount of torque applied to the compression nut. To install a predrilled plug, the solid plug can be “pushed out” of the compression fitting housing and the pre-drilled

plug installed.

3. Optional conduit fittings (YSI #065926) can be installed in place of the compression fittings. When

using conduit fittings, industrial encapsulant (YSI #065921 conduit sealer) must be used to prevent

moisture from entering the 5200 monitor. After all wiring and connections are complete, apply the

sealant to the conduit openings from the inside of the 5200 Monitor. Failure to use industrial

encapsulant may result in damage to the 5200 Monitor.

Also included with the 5200 Monitor is a desiccant pack, YSI #6506. Desiccant absorbs moisture

captured within the enclosure. After all wiring and connections are complete (just before the cover is to be

installed), place the desiccant pack inside the 5200 enclosure near the bottom right corner. Remove the

desiccant from its protective packet prior to installation.

Secure the monitor’s cover using four mounting screws. Note that the cover contains a captured rubber

gasket that provides weatherproofing. Make certain that the gasket is in place and not twisted or damaged.

Make certain that the large blue ribbon cable is not trapped in the gasket channel before inserting the

screws. When securing the screws, take care not to cross thread. The screws are stainless steel, and the

receiving threads are brass. Do not over-tighten!

CAUTION: Anytime the 5200 cover is removed, replace the desiccant pack with a new pack. Anytime

the 5200 front panel is removed, place it on top of the 5200 Monitor or secure it so that the blue ribbon

cable does not bear the weight of the cover.

YSI Incorporated 12 5200 Recirculating System Monitor

Page 15

3.3.2 Installation Check List

9 Determine optimum mounting location for the probe based on the parameters being measured and/or

controlled

9 Determine optimum mounting location for 5200 Monitor

9 Fabricate probe mounting plate if necessary

9 Mount the probe

9 Connect the probe to the monitor

9 Make wiring connections for relays

9 Make wiring connections for communication ports

9 Make wiring connections for DC power

9 Make ground wiring connections

9 Verify that all wiring connections are secure

9 Apply industrial encapsulant to conduit fittings-if applicable

9 Insert desiccant pack(s) into 5200 Monitor

9 Reinstall front cover to 5200

9 Recheck grounding and surge protection installations

9 Allow probe circuitry and sensors to warm up for several minutes

9 Calibrate the probes and program the monitor’s software

9 Place calibrated probe in mounting fixture

3.4 Mount the YSI 5200 Recirculating System Monitor

Several options are available for mounting the 5200 Monitor. Easy to use, wall mount brackets (6515

Flange Mounting Kit) are provided. If rail or panel mounting is desired, the 6509 Rail Mount Kit and

6510 Panel Mount Kits are available as accessories.

3.4.1 Wall Mounting Option

Although the monitor is designed for outdoor deployment, some operators may prefer the convenience of

reading the monitor under shelter, for example, inside a nearby building. Figure 3-4 shows this indoor

type of installation. Wall-mounting the 5200 Monitor is a simple process using the enclosed 006515

mounting hardware.

YSI Incorporated 13 5200 Recirculating System Monitor

Page 16

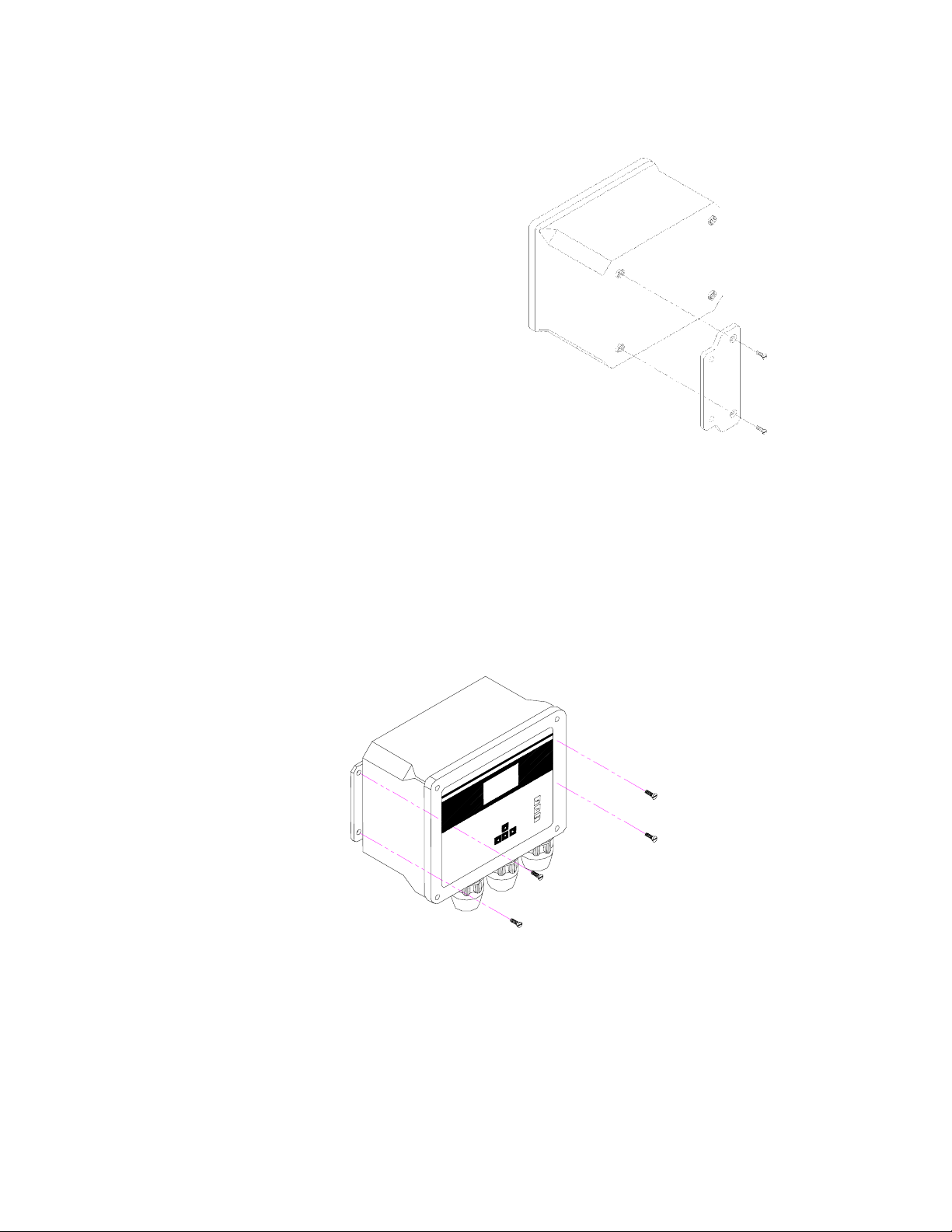

The following steps should be followed when wall

mounting the 5200 Monitor.

1. Loosely fasten the mounting brackets

(included) to the back of the 5200

Monitor with the mounting screws

provided as shown in Figure 3-3.

2. Tighten the screws, securing the brackets

to the Monitor.

3. Loosely fasten the 5200 Monitor to the

mounting surface with the mounting

screws provided as shown in Figure 3-4.

4. Tighten the screws, securing the Monitor

to the surface.

Figure 3-3 Attaching the Mounting Brackets

Figure 3-4 Securing the screws to the mounting surface

YSI Incorporated 14 5200 Recirculating System Monitor

Page 17

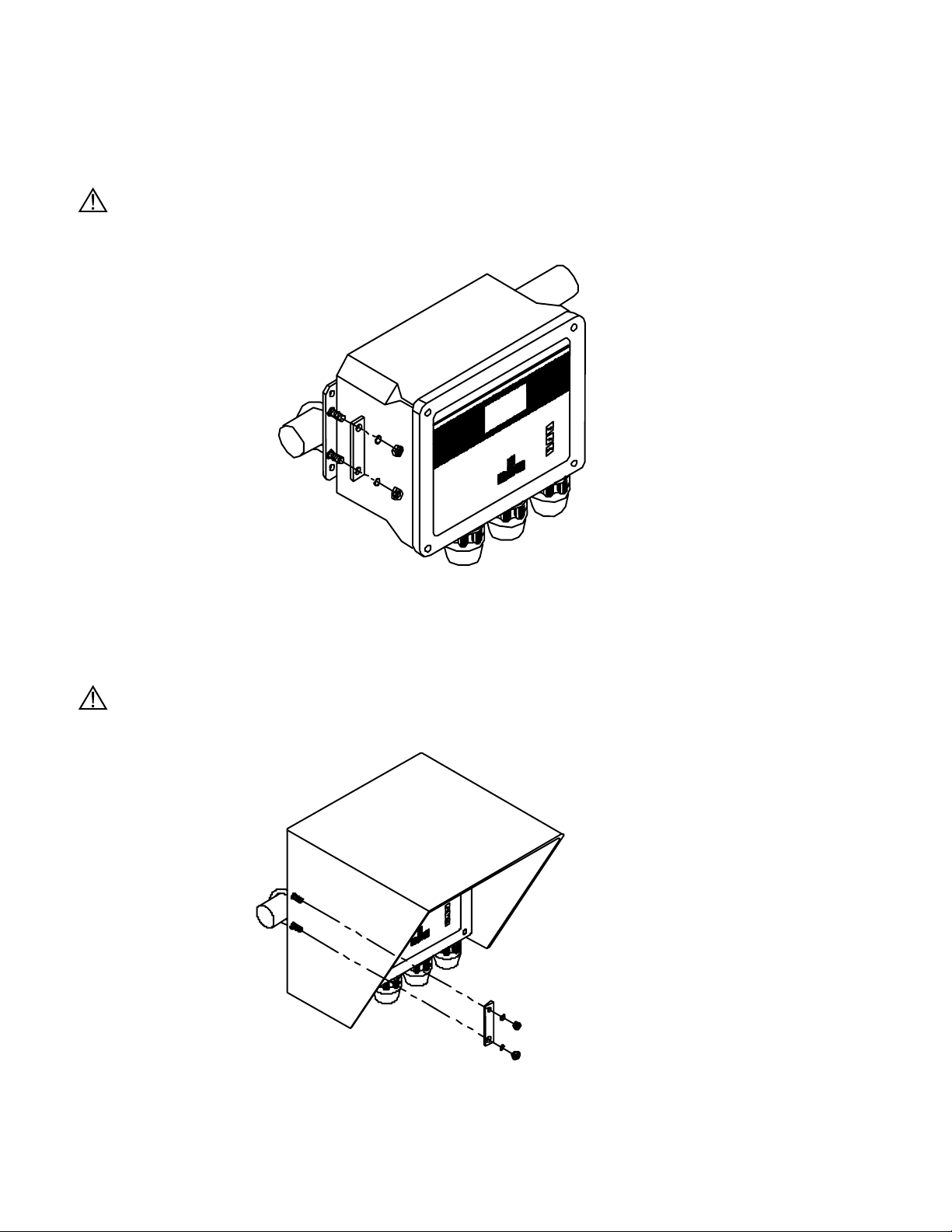

3.4.2 Optional 6509 – Rail Mount Kit

The 5200 Monitor can be easily mounted to pipe or handrail (1 to 1½ inch diameter) using the optional

6509 Rail Mount Kit. When using the 6509 Rail Mount Kit, the 006515 mounting flanges will have to be

modified by drilling two holes to accept the u-bolts. The predrilled metal plates can be used as a template.

CAUTION: The monitor should not be mounted on electrical conduit, a hot or vibrating pipe or structure,

or near a high heat source, an AC motor, transformer, radio transmitter or antenna.

3.4.3 Optional 6505 – Weather shield

The Weather Shield provides wall or optional rail mounting capability for the 5200 Monitor.

CAUTION: The monitor should not be mounted on electrical conduit, a hot or vibrating pipe or structure,

or near a high heat source, an AC motor, transformer, radio transmitter or antenna.

YSI Incorporated 15 5200 Recirculating System Monitor

Page 18

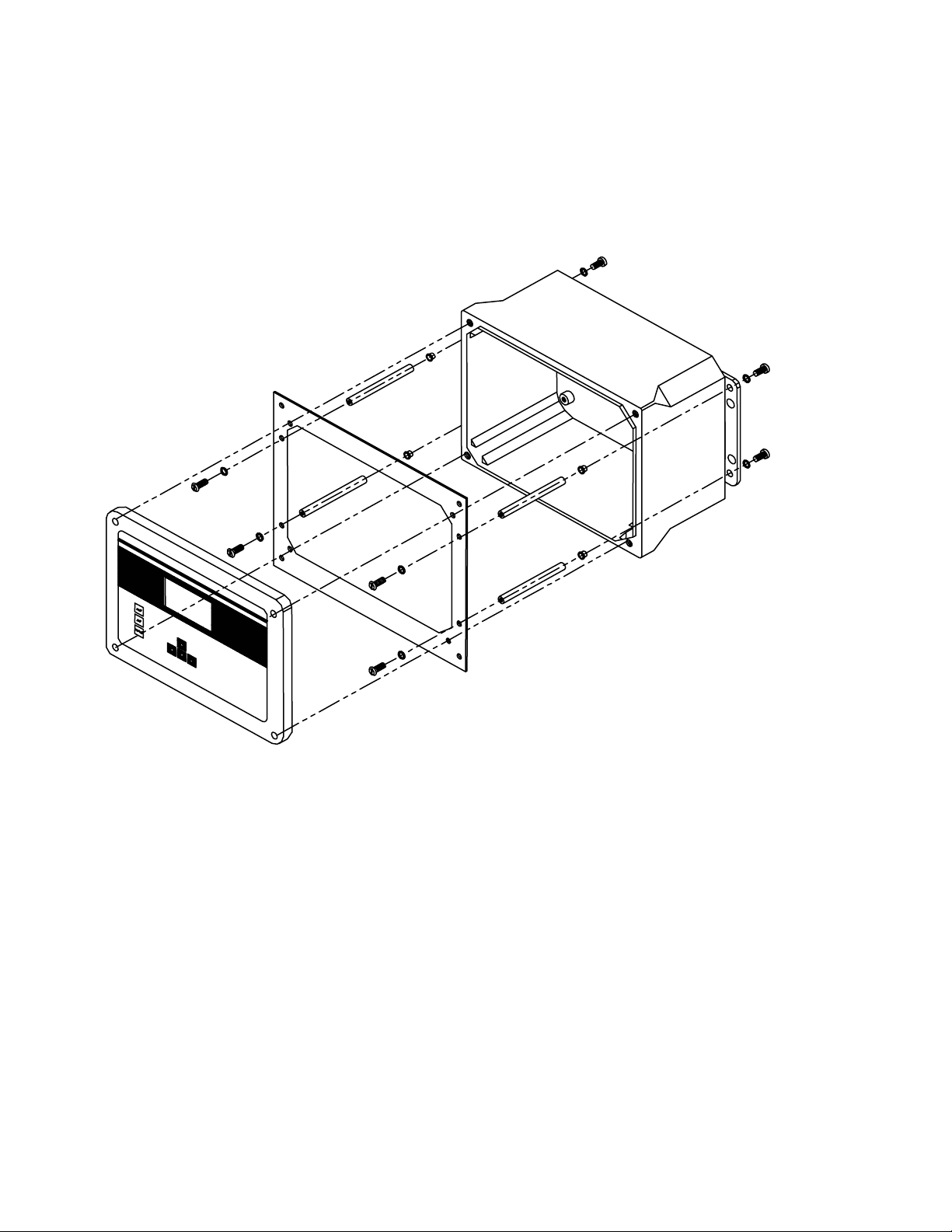

3.4.4 Optional 6510 – Panel Mount Kit

Panel mounting the 5200 Monitor is a simple process using the 6510 Panel Mount hardware and the

following tools; 5/32” Allen wrench, Philips screwdriver, and the necessary tools for cutting the mounting

hole in the control panel. The 5200 Monitor may be mounted in any panel with 9.5”L x 7.5”W space

available, and behind the panel depth of 5.5”.

YSI Incorporated 16 5200 Recirculating System Monitor

Page 19

3.5 Installing the 5562 or 5561 Probe Assemblies

CAUTION: Keep pH and ORP probe tips IN A MOIST ENVIRONMENT at all times.

After you have chosen suitable sites for the monitor and probe, proceed with the probe installation as

described below.

Avoid routing probe cabling near wiring associated with rotating machinery and/or equipment involving

electrical switching or regulation. In all cases, it is desirable to locate the probes away from sources of

electrical interference such as UV sterilizers, florescent lighting, ballasts, pumps, etc. Consider placing

probe cabling in grounded metallic conduit if unstable readings appear due to electromagnetic

interference.

The 5200 can be configured with either a 5562 multiprobe assembly (DO, Conductivity, Temperature,

and optional pH or pH/ORP sensors) or a 5561 DO/Temp probe assembly.

NOTES: When the 5200’s control functions are to be used, probe placement will be critical to the

operation of the system. Consequently, a professional should be consulted when designing the

system.

Water flow is important to the operation of the DO sensor. In addition, the mixing action provided

by water flow ensures that the area of sampled water is representative of the entire body of water.

Probe installation steps:

1. Select a suitable location for the probe assembly that allows for adequate water flow across the

DO sensor (approximately 0.5 ft/sec).

2. Select a method of securing the probe assembly.

3. Determine a method of routing and securing the cable.

In-Filter Location— A common place for probe location is in the filter. Installing probes in a filter or

sump requires that the probe be secured or hung in an area that will allow for adequate water flow across

the DO sensor (approximately .5 ft/sec).

In-Filter Location Using a Float—A float installation keeps probes at a constant depth, and is

economical to purchase or construct.

To construct a probe float, cut a hole (slightly smaller than the probe diameter) through a small piece of

Styrofoam. Insert the probe into the float so that the entire sensor guard protrudes through the Styrofoam

and the sensors are completely submerged.

In-Tank Location—Installing the probe assembly in a tank requires that the assembly be secured or

hung in an area that will allow for adequate water flow across the DO sensor (approximately 0.5 ft/sec). It

is preferred that the probe be secured so that the cable is not constantly flexed.

If using the 5562, the probe assembly can be secured using the 5205 Probe Mounting Kit or 6511 Probe

Rail Mount Kit. See Section 3.5.2 5205 and 6511 – Optional Probe Mount Kits for 5562 Probes. A

mounting kit is not available for the 5561 probe.

In-Line Location Using a Tee-Fitting—Although in-line probe placement is more time consuming and

requires some extra plumbing, it has been found to be a very effective and safe way to place probes. Inline placement gives accurate readings because water is moving across the probe tips at all times. It also

minimizes biological growth on the sensors.

IMPORTANT NOTE: When maintenance and/or calibration of the sensors is required, the probe

assembly will have to be removed from the in-line fitting. Take this into account when designing the

system. If water flow must be maintained during maintenance, by-pass plumbing will be required.

YSI Incorporated 17 5200 Recirculating System Monitor

Page 20

For this type of installation, the probe guard is removed and the probe is threaded into a tee-fitting using

the probe guard’s threads. All probes need to be placed into the flow stream. YSI does not provide tee

fittings for this type of installation.

Thread size for 5562 multiparameter probe assembly: 1.50-12 UNF 2A

Thread size for 5561 DO/Temp probe assembly: ¾-27 Class 2 thread

In–Line Location Using A Flow Cell (5562 Probe only) – The 5083 Flow Cell can be connected

anywhere in the pumping system where a water flow rate of 2–3 L/minute can be obtained. Maximum

pressure rating for the 5083 is 25 psi. A portion of water from a pump discharge line can be diverted

through the 5083 Flow Cell, or a method with a designated pump can be utilized.

3.5.2 5205 and 6511 – Optional Probe Mount Kits for 5562 Probes

NOTE: The 6511 kit includes Clamps for Rail Mounting. The 5205 Kit does not include mounting

hardware.

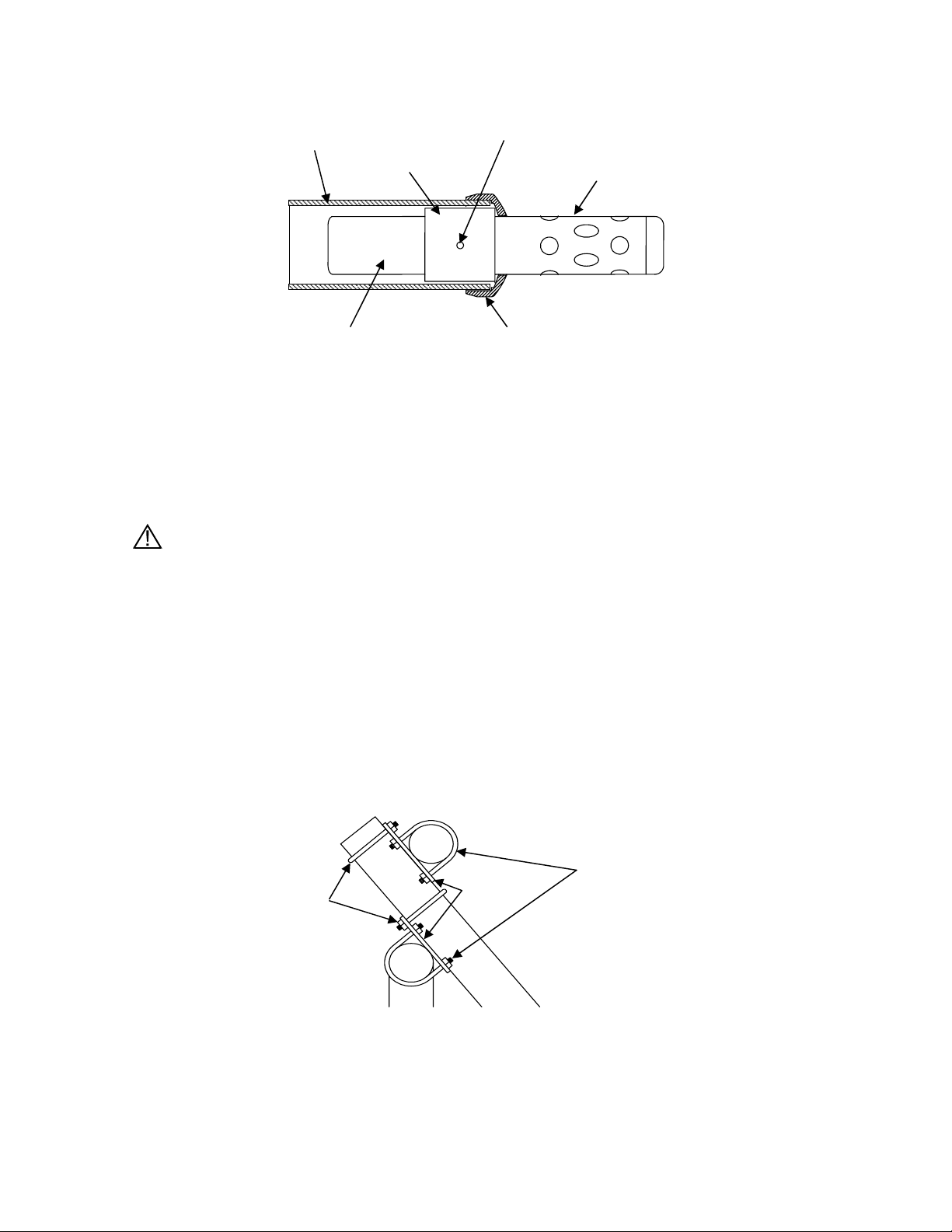

2” Schedule

40 PVC

Stop

Probe

Guard

Figure 3-5 Probe Mounting Kit

5205 and 6511 Probe Mount Kits allow a 5562 Probe to be deployed in a permanently mounted two-inch

schedule 40 PVC tube. The schedule 40 PVC is not included in the kit. Once installed, the probe is

deployed by gently sliding it down the tube, where it will rest on a stop cap at the end of the tube. The

sensors and probe guard will protrude through a hole in the stop cap at the end of the tube. See Figure 3-5.

When mounting to a 1–1½″ railing, the 6511 kit should be used. It includes brackets and u-bolts for rail

mounting and a stop cap and adaptor. See Figure 3-5.

When mounting to structures other than 1–1½″ railing, a 5205 kit should be used. When using the 5205

kit, the installer must develop a method of mounting the 2″ PVC tube to a permanent structure. The 5205

kit consists of a stop cap and adapter and does not include mounting hardware.

The 5205 and 6511 Kits should not be mounted on hot or vibrating pipes or structures, or near high heat

sources, AC motors or transformers, radio transmitters or antennas.

CAUTION: Do not mount on electrical conduit.

YSI Incorporated 18 5200 Recirculating System Monitor

Page 21

2” PVC Tube

Adapter

Set Screw

Probe Guard

5562 Probe Body

Stop Cap

Figure 3-6 Adapter Position

The following steps should be followed when mounting the 5205 or 6511 Probe Mount Kit.

1. With the 3 setscrews removed from the adapter, slide the adapter over the 5562 Probe. Align the

open screw holes directly over the 3 hex bolts located on the side of the 5562 Probe.

2. Insert the setscrews so that they seat into the head of the probe’s hex bolts.

CAUTION: Do not over-tighten the setscrews or damage to the probe body or adapter may

occur.

NOTE: The 5562 Probe Assembly can be deployed without the probe guard attached. When doing so,

application related precautions must be considered or system performance can be compromised.

Deployment without the guard is preferred as the effects of low water flow and fouling are

reduced, but exposed sensors or the DO membrane, can be damaged if not properly protected.

3. Attach the stop cap to the end of a PVC pipe using PVC cement, as per instructions on the cement

can label, ensuring that the stop cap is positioned straight and the pipe is fully inserted.

4. 5205 Only: Firmly mount PVC pipe to permanent structure. Skip to Step 9.

5. Loosely fasten two 1½” u-bolts on each mounting plate to the railing, orientated as shown in

Figure 3-7.

1.5” U-Bolts

2” U-Bolts

Mounting

Plates

Figure 3-7 6511 U-Bolt Mounting

6. Loosely attach the 2” u-bolts to the mounting plates, orientated as shown in Figure 3-7.

YSI Incorporated 19 5200 Recirculating System Monitor

Page 22

7. Slide the uncapped end of the PVC pipe up through the 2” u-bolts until there is approximately 1”

of the PVC pipe above the upper mounting plate, and tighten 2” u-bolts. Note: Do not over

tighten u-bolts or deformation of the PVC pipe may occur.

8. Tighten all remaining u-bolts to secure pipe.

9. Slowly slide the 5562 Probe/Adapter Assembly down the PVC pipe until it rests on the Stop Cap.

10. Connect the cable to the 5200 Monitor.

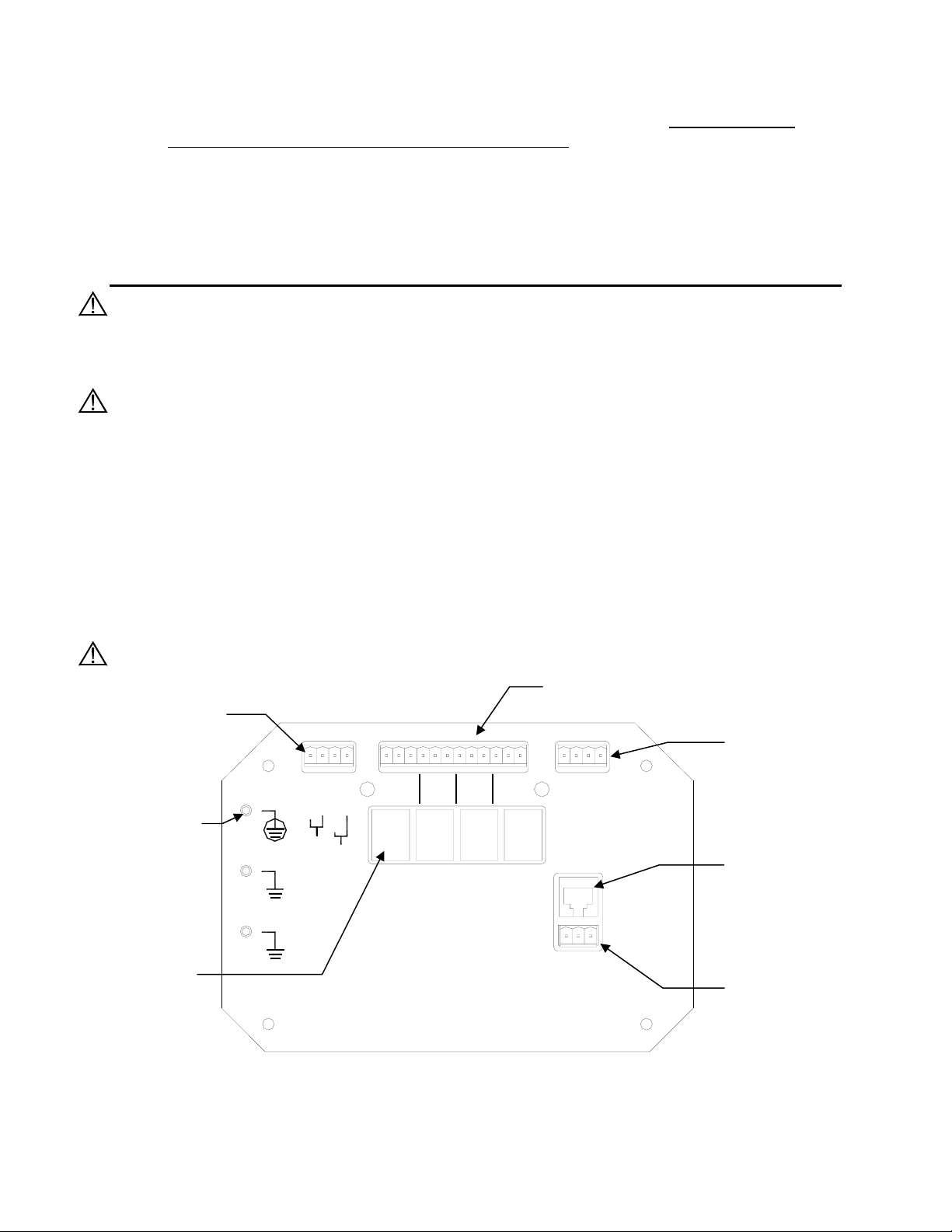

3.6 Wiring the System

WARNING: All wiring involving connections to mains power must be performed by a qualified licensed

electrician, and must conform to all locally applicable electrical codes. Any mains power circuit

connected within the YSI 5200 enclosure must be protected by a Ground Fault Circuit Interrupt device.

Do not make connections while power is applied. Disconnect power before proceeding.

WARNING: The 5200 utilizes sensitive solid-state devices that can be damaged by static shock.

Installers must observe accepted ESD (Electro-Static Discharge) procedures while connecting cabling to

the 5200 I/O plate or damage may result.

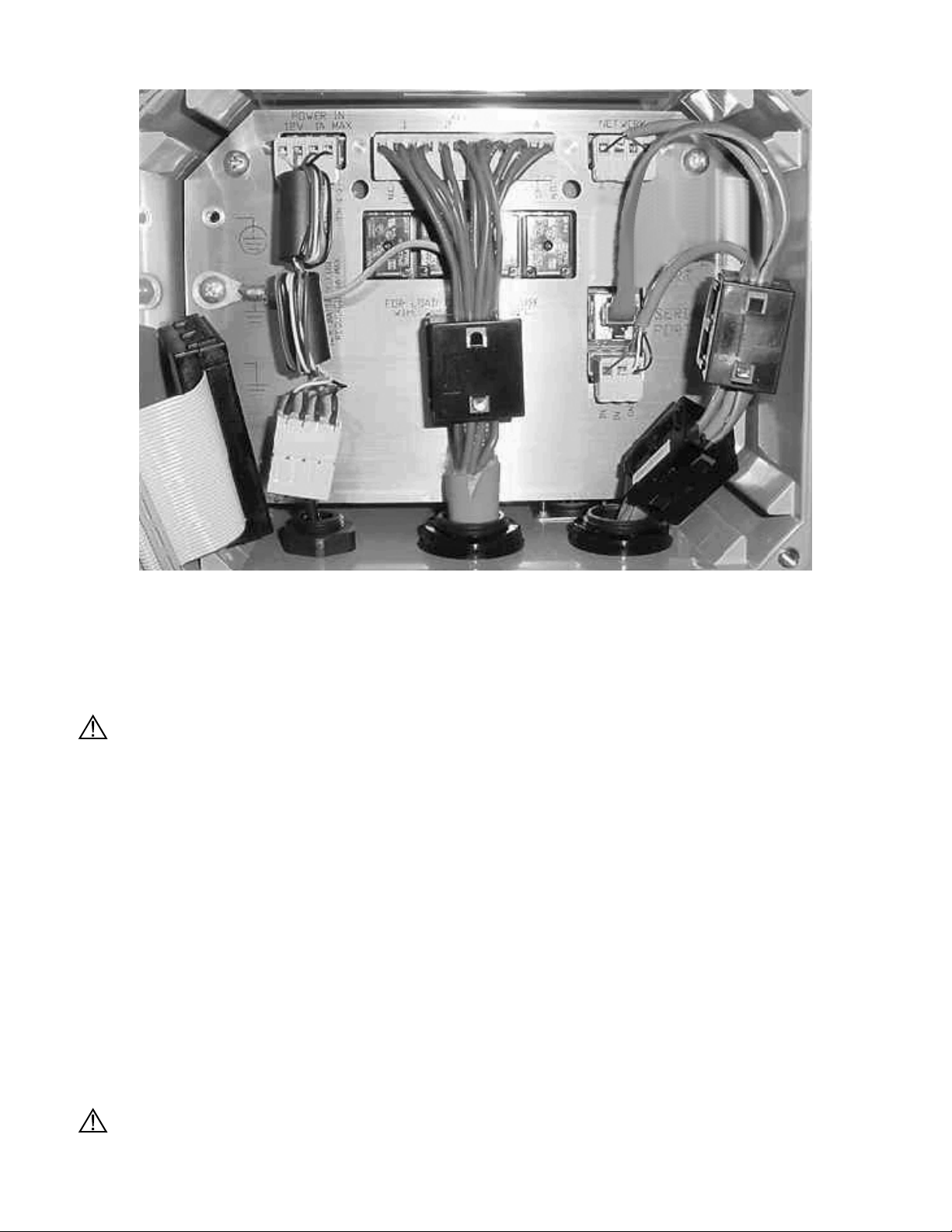

The 5200 Monitor has one MS-19 connector and three compression fittings in the bottom of the monitor

housing. The two larger compression fittings can be replaced with ¾ inch conduit fittings. From a front

view, the smaller compression fitting on the left is for 12-volt power. The opening on the right is for

communications and I/O wiring and the center opening is for relay wiring.

NOTE: The 5200 Monitor is supplied with components necessary to make reliable electrical connections.

When received, pluggable sockets are installed in the power, relay, RS485 and auxiliary ports.

These sockets are to be unplugged prior to making electrical connections and reinstalled after

connections are made.

CAUTION: It is essential that all sensor wiring be run in a separate cable or conduit from power wiring.

Relay Outputs

12VDC Primary

and Back-up

Power

Connector

Connect to

POWER IN

12V, 1A MAX

COM (-)--

MAIN (+)--

BACKUP (+)--

RELAYS

123

4

NETWORK

RS485 5200

Network Connector

R(-)--

N.C.--

N.C.--

N.C.--

N.O.--

N.O.--

COM--

COM (-)--

COM--

N.C.--

N.O.--

COM--

COM--

T(-)--

N.O.--

R(+)--

T(+)--

earth ground

RS232 and

Control Relays

(4) soldered to

PCB

YSI MODEL 5579

FOR LOAD CONNECTIONS USE

WIRE SUITABLE FOR 90°C

REQUIRED, 1A MAX

12V BATTERY FUSE

IN 1 --

IN 2 --

GND--

SERIAL IP

PORT

TCP/IP Serial

Connector

(RJ-45)

Aux. Analog and

Digital Input

Connector

Figure 3-8 I/O Plate

YSI Incorporated 20 5200 Recirculating System Monitor

Page 23

Figure 3-9 Placement of Ferrites and Pluggable Sockets

3.6.1 DC Power Input Wiring

12VDC power for the 5200 Monitor may be supplied by the YSI 5578/5579 power supply accessory

provided with the unit, or by a 12VDC source supplied by the user.

CAUTION: The YSI 5578/5579 power supply accessory is for indoor use only, and must be connected to

the 5200 Monitor with a suitable waterproof extension cable if the 5200 Monitor is installed in a damp

location.

For outdoor or damp locations, the YSI 5578/5579 power supply may also be installed in a NEMA 4X

enclosure adjacent to the 5200.

3.6.2 Installing the 5578/5579 Power Supply

When using the 5579 power supply it should be wired as follows: (see Figure 3-9)

• Connect the Inline Power Ferrite Assembly, YSI# 655385, to the I/O plate power connector. Failure

to do so could cause catastrophic monitor failure.

• Route the 5578/5579 power supply wire through the small compression fitting and into the case.

• Connect the 5578/5579 wires to the 4-pole 605223UL Pluggable Socket Connector so that the white

wire goes to Main (+) and black wire to Common (-).

• Connect the 4-pole 605223UL Pluggable Socket Connector to Inline Power Ferrite Assembly.

• Tighten compression fitting. See Section 3.3.1 Sealants, Desiccants and Securing the Monitor.

WARNING: A UL Listed DC power supply is required for any installation which is connected to “mains

YSI Incorporated 21 5200 Recirculating System Monitor

Page 24

supply” or other power source which is “hazardous live” per UL 3101-1 Section 3.5.2.

The 5200 Monitor may be powered by any regulated 8.5–16.5 VDC source that can provide

approximately 800mA of current and is isolated from mains supply by double or reinforced insulation.

(An unregulated supply may also be acceptable if the peak output voltage does not exceed 16.5VDC.)

WARNING: A UL Listed slow-blow fuse with a maximum current rating of 1A must be connected in

series with the positive terminal of any power supply not provided by YSI.

CAUTION: Power supply voltage above 16.5VDC may permanently damage the 5200 Monitor.

When the front panel of the 5200 Monitor is removed, take care not to drop the cover since it is not

hinged to the Monitor.

CAUTION: The sensitivity and stability of the monitor will be impaired if the monitor is not grounded.

Do not apply power to the Monitor until all electrical connections are verified and secure. Connect earth

ground to the 5200 I/O plate (see Figure 3-8 I/O Plate).

3.6.3 Back-up Power

WARNING: A UL Listed slow-blow fuse with a maximum current rating of 1A must be connected in

series with the positive terminal of the back-up supply.

The 5200 Monitor will automatically switch to auxiliary battery back-up operation if primary voltage

drops below 8.5 VDC, providing back-up power is connected. For proper back-up power operation, use

the YSI 5578/5579 Power Supply as the primary power source. Use of a different primary power supply

may prevent proper switching to back-up power.

WARNING: A UL Listed DC power supply is required for any installation which is connected to “mains

supply” or other power source which is “hazardous live” per UL 3101-1 Section 3.5.2.

The auxiliary power source is user supplied and can come from a variety of choices including lead acid or

gel cell external batteries. The 5200 will not charge batteries, so quality assurance maintenance

procedures must be established if batteries are used as the back-up power source.

Input power requirements for back-up operation are the same as primary power, 8.5–16.5 VDC at

approximately 800mA. With no primary power, when the back-up voltage falls below 7.0 volts the 5200

will cease to operate properly.

Connecting back-up power to the 5200 Monitor

Refer to Figure 3-9.

• If necessary, disconnect power to the 5200 Monitor

• Route the back-up supply wire through the compression fitting and into the case. See Section 3.3.1

Sealants, Desiccants and Securing the Monitor.

• Connect the back-up wires to the 4-pole 605223UL Pluggable Socket Connector so that the positive

wire goes to the Back-up (+) terminal and the negative wire goes to the Common (-) terminal.

• Connect the 4-pole 605223UL Pluggable Socket Connector to Inline Power Ferrite Assembly. Failure

to do so could cause catastrophic monitor failure.

• Connect the Inline Power Ferrite Assembly to the I/O plate power connector.

IMPORTANT: After completing system installation, test back-up power by removing main power while

all control/alarm relays are energized. At cold temperatures, logged data may be lost due

to temporary power loss when switching to battery backup power.

YSI Incorporated 22 5200 Recirculating System Monitor

Page 25

CAUTION: The sensitivity and stability of the monitor will be impaired if the monitor is not grounded.

Do not apply power to the Monitor until all electrical connections are verified and secure.

3.7 Communications Method

The 5200 has three methods of communication:

Ö RS232 TCP/IP Serial Port—to directly connect with a computer or network

Ö Modem—to communicate with a computer or pager via phone line

Ö RS485 Network—to directly connect with other 5200s

3.7.1 RS232 and TCP/IP Port

RS232 serial and TCP/IP communications are made through the TCP/IP port. This port can be

permanently connected to a PC or network for continuous monitoring applications, or to the 5201 Modem

sending alarm messages via phone. The RS232/TCP/IP port uses a standard RJ-45 connector.

Two snap on ferrite assemblies, YSI# 655361, are included with the 5200 Monitor. Wires being

connected to the communication port need to be routed through the ferrites as shown in Figure 3-9.

Failure to do so could cause catastrophic monitor failure.

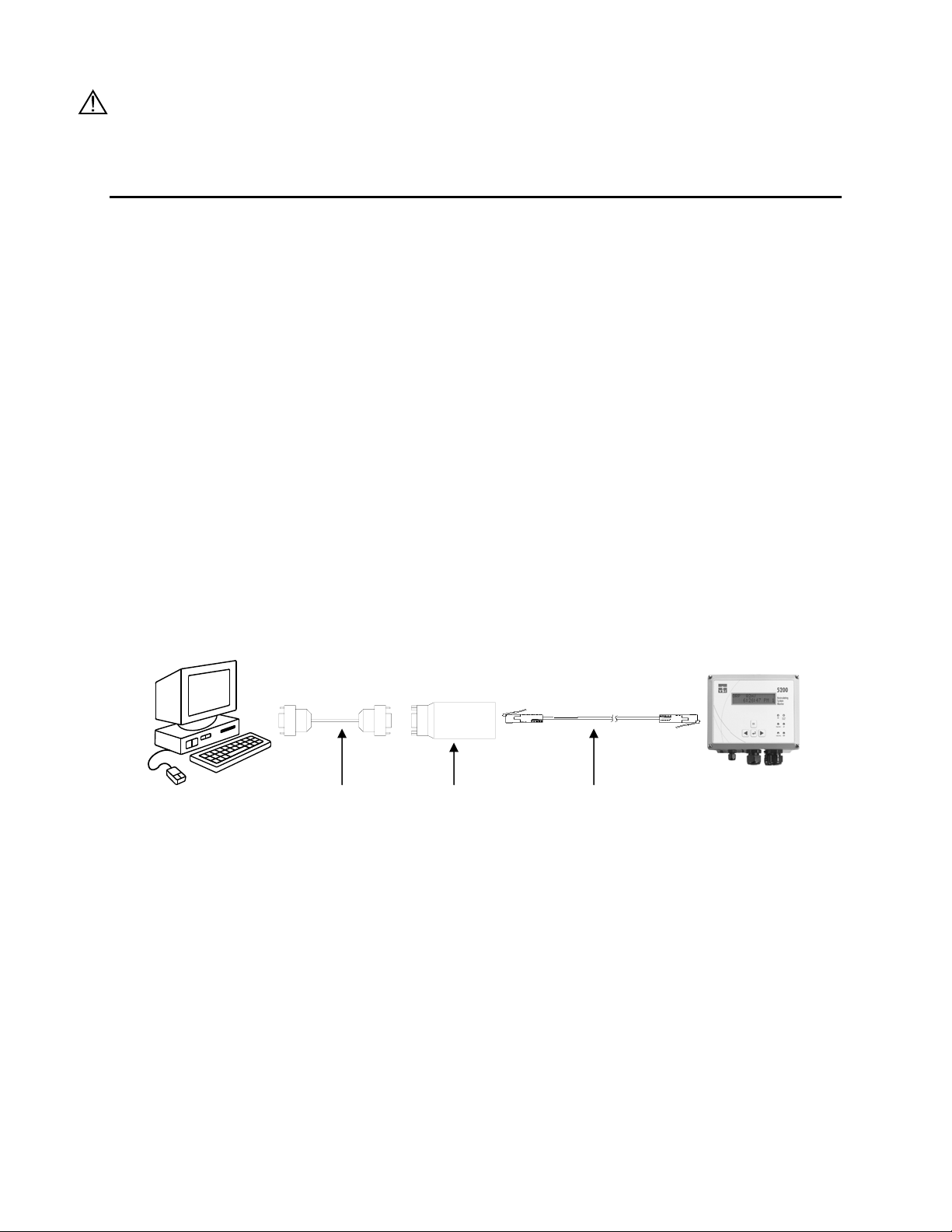

RS232 PC Connection

When connecting the 5200 via the serial port to a PC for continuous operation, use an inline RS232 OptoIsolator device (YSI# 5285 or equivalent) to prevent ground loops. Failure to use this device may cause

incorrect DO, pH, ORP and conductivity data to be displayed and logged. Mount the isolator as close to

the PC as possible or in an area where it is protected from moisture.

Computer DB9 RS232

Serial Cable

YSI 5285

Opto-Isolator

RJ-45 Straight-through

Cat 5 network cable

5200 Monitor

RS232 Serial Connection to a PC

When making RS232 cable runs greater than 100 feet (30.5 meters), use an RS232 Line

Extender/Booster. Not using this device may cause communication failures. Mount the booster in an area

where it is protected from moisture.

When temporarily connecting the 5200 to a PC, a “Straight-Pinned” Dual Male RJ-45 cable and a DB-9

to RJ-45 Adapter (YSI# 655383) wired as in the chart below are required.

YSI Incorporated 23 5200 Recirculating System Monitor

Page 26

Wiring Diagram for DB-9 to RJ-45 Adapter

Wire color internal to

Signal name (from 5200) RJ-45 pin #

adapter (may change

DB-9 pin #

based on supplier)

TX (232TXD) 4 Red 3

RX (232RXD) 5 Green 2

Common (DGND) 6 Yellow 5

CTS (232CTS) 7 Brown 8

DTR (232DTR) 8 Gray 4

Supplied with the 5200 are a YSI# 655384 Straight-pinned Cat 5 EIA568 compliant network patch cable

and pre-wired YSI# 655383 RJ-45 to DB-9 Adapter. The supplied cable and adapter are only intended to

be used for software upgrades or downloading data. Do not use this cable for long-term installation as the

compression fitting cannot form a proper seal. See Section 3.3.1 Sealants, Desiccants and Securing the

Monitor.

Bulk cable for permanent installations must be round (to allow the compression fitting to seal) and should

be purchased locally. A crimping tool will be required to install RJ-45 connectors to each end of the

cable.

IMPORTANT: 1. The connector that is to connect inside the case should be crimped after the cable is

run through the compression fitting.

2. Round cable must be used so a watertight seal at the compression can be achieved.

TCP/IP LAN Connection

An Ethernet serial server is required to connect the 5200 to a LAN. The serial server must be assigned a

static IP address.

LAN

Ethernet

network

RJ-45 Straight-through

Cat 5 network cable

Ethernet Serial

Server

DB9 to RJ-45

adapter

RJ-45 Straight-through

Cat 5 network cable

5200 Monitor

TCP/IP Connection to a LAN

Additional RS232 TCP/IP Wiring Information

The 5200 uses a symmetrical EIA-232 data terminal equipment (DTE) pinout on the RJ-45 serial port.

Table 3-1 lists the pinouts of the RJ-45 ports used for EIA-232 serial communications.

YSI Incorporated 24 5200 Recirculating System Monitor

Page 27

RJ-45 Pin

Number

1 DCD I NC P Signals module that remote device is

2 RTS O NC P Flow control, to enable remote device to

3 SG

4 TXD O P P Serial data out, from YSI-5200 to remote

5 RXD I P P Serial data in, from remote device to YSI-

6 SG

7 CTS I NC P Flow control, to enable YSI-5200 to send

8 DTR O NC P Signals remote device that YSI-5200 is

RS232

Name

Direction RS232 TCP/IP Signal Function

attached and powered on

send data

P P Signal return (NOT chassis ground)

device

5200

P P Signal return (NOT chassis ground)

data on TXD

attached and powered on

Table 3-1

To connect the 5200 to an EIA-232 device, it needs to be determined if the device connector wiring

follows the standard for data terminal equipment (DTE) or for data communication equipment (DCE). In

general, modems are wired as DCE devices and all other devices are wired as DTE; however, some

equipment manufacturers may deviate from the standard. In most cases, you use "straight through" RJ-45

cable. If you use "crossover" RJ-45 cable, the RJ-45 pins will be reversed.

3.7.2 5201 Modem

The YSI 5201 Modem is available only for use within the United States. For modem support outside the

US, an external modem registered for use within the local country is required. See Section 17

International Modem Support.

The YSI 5201 Modem mounts inside the 5200 case and connects to the RS232/TCP/IP Port. Refer to the

5201 Modem Installation Instructions, included with the modem, for details.

CAUTION: The phone line entering the 5200 case must be #26 AWG wire and must be sealed where it

enters the case or the instrument may be seriously damaged.

CAUTION: The ground wire from the 5201 Modem must be connected to the ground screw on the 5200

I/O plate.

3.7.3 RS485 Network

Connecting 5200s via the RS485 network is described in 8.1 RS485 Network.

YSI Incorporated 25 5200 Recirculating System Monitor

Page 28

3.8 Grounding Information

This section contains important installation information regarding grounding of the 5200 Monitor.

Connect earth ground to the 5200 I/O panel as described below in 3.9 Safety ISSUES.

The probe is powered by the 5200 Monitor and will be operated with a “floating” ground reference. This

requires that the probe not be individually grounded. Grounding the probe individually will cause a

“ground loop”; i.e. one conductor of the probe output grounded common to both the probe and the

monitor. Grounding the probe will cause significant performance problems with the sensors and likely

result in erroneous readings.

CAUTION: Do not ground the probe body.

All tanks should be electrically grounded via a ground probe.

3.9 Safety Issues

The electrical system must be grounded via the I/O plate to avoid possible electrical shock or damage to

the equipment (see Figure 3-8 I/O Plate).

WARNING: Turn off all power and assure power “lockout” before servicing to avoid contact with

electrically powered circuits.

To avoid possible electrical shock, do not touch other circuit components when making adjustments to the

5200 Monitor circuit board. Disconnect external power to the unit before connecting or disconnecting

wiring.

3.10 Lightning and Surge Protection

Surge protectors are strongly recommended to protect from secondary surges and lightning on outdoor

installations.

Surge suppression devices should be located on the AC line supplying power to the 5200 Monitor and any

signal lines connecting the 5200 Monitor.

AC line voltage surge suppressors protect field equipment on any AC line to ground from damage due to

electrical transients induced in the interconnecting power lines from lightning discharges and other high

voltage surges. The unit should include noise filtering, common mode and normal mode suppression and

nanosecond reaction time. Surge suppressors should be internally fused to remove the load if the unit is

overloaded or the internal protection fails.

Signal line suppressors protect low voltage signals and relay outputs from damage due to electrical

transients induced in the signal lines from lightning discharges or nearby electrical devices. Signal line

suppressors should be installed at each end of an analog loop. Relay outputs should be protected at the

receiver end. Signal line suppressors should consist of a three-element gas tube followed by metal oxide

varistors and suppressor diodes. The protective elements should be matched such that high-energy surge

voltages trigger the gas surge arrester, while low energy or surge voltages affect the MOV’s and

suppressor diodes.

Lightning protection devices should be located as close to the monitor as possible and wired in

accordance with the National Electric Code in approved watertight enclosures.

CAUTION: This or any other installation procedure cannot protect against a direct lightning strike. YSI

Incorporated cannot accept liability for damage due to lightning or secondary surges.

YSI Incorporated 26 5200 Recirculating System Monitor

Page 29

Section 4. Probe Module

Probe Module covers the following:

Ö Unpacking the Probe Module Ö Features of the YSI 5561 Probe Module Ö Features of the YSI 5562 Probe Module Ö Preparing the YSI 5561 Probe Module Ö Preparing the YSI 5562 Probe Module Ö Membrane Cap Installation Ö Calibration/Storage Cup (5562 only) Ö Instrument/Cable Connection

Two different probe modules are available for the YSI 5200 Recirculating Monitor. The YSI 5561 Probe

module is used for measuring dissolved oxygen and temperature only, while the YSI 5562 Probe module

is used for measuring dissolved oxygen, temperature, conductivity, and optional pH or pH/ORP. A 4, 10

or 20 meter cable is directly connected to the probe module body making it waterproof.

4.1 Unpacking the Probe Module

1. Remove the Probe module from the shipping box(es).

NOTE: Do not discard any parts or supplies.

2. Use the packing list to ensure all items are present.

3. Visually inspect all components for damage.

NOTE: If any parts are missing or damaged, contact your YSI Service Center immediately. Refer

to Section 14 WARRANTY AND SERVICE INFORMATION or www.ysi.com/environmental.

4.2 Features of the YSI 5561 Probe Module

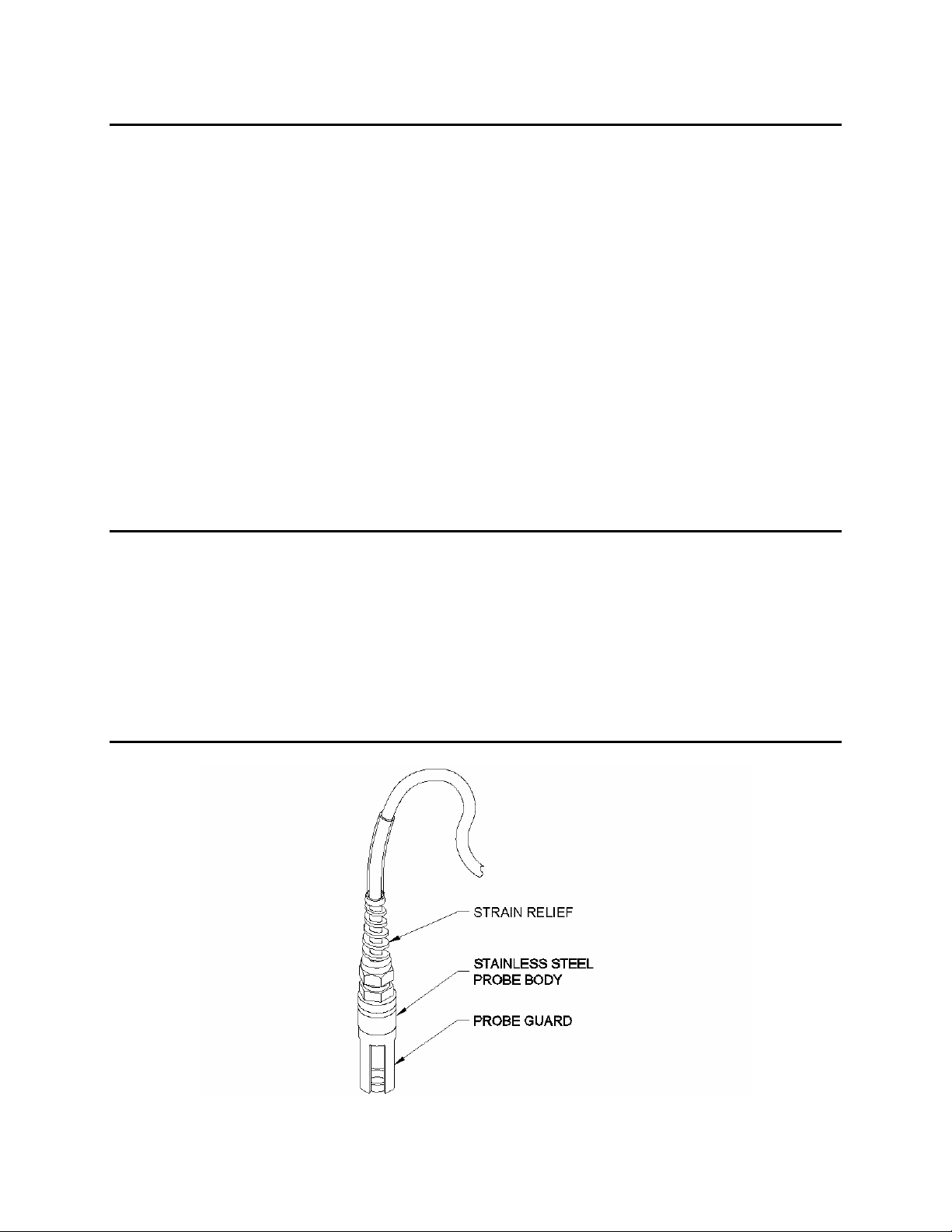

Figure 4-1 5561 Probe Module

YSI Incorporated 27 5200 Recirculating System Monitor

Page 30

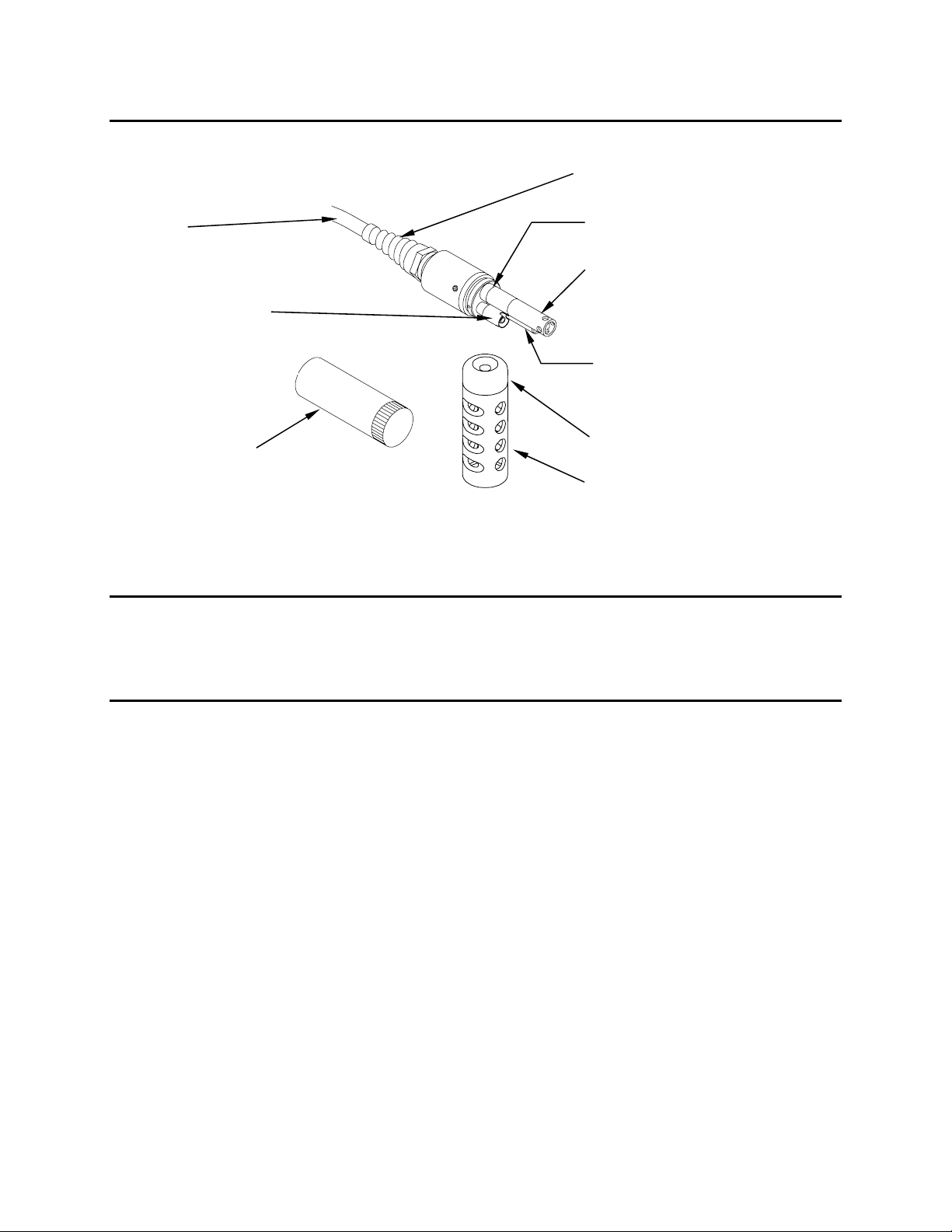

4.3 Features of the YSI 5562 Probe Module

Cable

Dissolved Oxygen

(DO) Probe

Calibration/

Storage Cup

Figure 4-2 5562 Probe Module

Strain Relief

Metal Probe

Connector Nut

pH/ORP Probe

Conductivity/Temperature

Probe

Detachable Weight

Probe Sensor Guard

4.4 Preparing the YSI 5561 Probe Module

To prepare the YSI 5561 Probe Module for calibration and operation, you need to install a new DO

membrane cap. Refer to Section 4.6 Membrane Cap Installation for details.

4.5 Preparing the YSI 5562 Probe Module

To prepare the YSI 5562 Probe Module for calibration and operation, you need to install the sensors into

the connectors on the probe module bulkhead. In addition to sensor installation, you need to install a new

DO membrane cap.

4.5.1 Sensor Installation

Whenever you install, remove or replace a sensor, it is extremely important that the entire probe module

and all sensors be thoroughly dried prior to the removal of a sensor or a sensor port plug. This will

prevent water from entering the port. Once you remove a sensor or plug, examine the connector inside the

probe module sensor port. If any moisture is present, use compressed air to completely dry the connector.

If the connector is corroded, return the probe module to your dealer or directly to YSI Customer Service.

Refer to Section 14 Warranty and Service Information.

Conductivity/Temperature and pH, pH/ORP Sensor Installation

1. Unscrew and remove the probe sensor guard.

2. Using the sensor installation tool supplied in the YSI 5511 maintenance kit, unscrew and remove

the sensor port plugs.

YSI Incorporated 28 5200 Recirculating System Monitor

Page 31

port

Figure 4-3 Port Plug Removal

3. Locate the port with the connector that corresponds to the sensor that is to be installed. The

number of pins is specific for each probe type.

pH or pH/ORP port

Oxygen port

Conductivity/Temperature

Figure 4-4 Sensor Port Identification

4. Apply a thin coat of o-ring lubricant (supplied in the YSI 5511 maintenance kit) to the o-rings on

the connector side of the sensor (see Figure 4-5 O-Ring Lubrication).

O-Rings

Sensor nut

Figure 4-5 O-Ring Lubrication

CAUTION: Make sure that there are NO contaminants between the O-ring and the sensor.

Contaminants that are present under the O-ring may cause the O-ring to leak.

5. Be sure the probe module sensor port is free of moisture and then insert the sensor into the correct

port. Gently rotate the sensor until the two connectors align.

6. With connectors aligned, screw down the sensor nut by hand, and then tighten using the sensor

installation tool.

Figure 4-6 Sensor Inst a llation

YSI Incorporated 29 5200 Recirculating System Monitor

Page 32

CAUTION: Do not cross thread the sensor nut. Tighten the nut until it is flush with the face of

the probe module bulkhead. Do not over tighten.

Figure 4-7 Bulkhead Seating

7. Repeat steps 3-6 for any other sensors.

8. Replace the probe sensor guard.

Dissolved Oxygen Sensor Installation

The YSI 5562 comes with the DO sensor already installed. Refer to Section 11.4.2 DO Sensor

Replacement for instructions on installing the YSI 558 Replaceable DO Module Kit.

4.6 Membrane Cap Installation

NOTE: The DO sensor was shipped dry. A shipping membrane cap was installed to protect the electrode.

A new membrane cap must be installed before the first use.

1. Unscrew and remove the probe sensor guard.

2. Unscrew, remove, and discard the old membrane cap.

3. Thoroughly rinse the sensor tip with distilled water.

4. Install a gasket from the 5204 Teflon or 5909 PE Membrane Kit onto the DO sensor.

Membrane Cap

Gasket

DO Sensor

Probe Body

Figure 4-8 Gasket Installation

Gasket Installed

5. Seat the gasket all the way down against the probe body. A small pair of tweezers may aid in the

installation.

6. Prepare the electrolyte according to the directions on the electrolyte solution bottle.

7. Hold the new membrane cap and fill it at least 1/2 full with the electrolyte solution.

YSI Incorporated 30 5200 Recirculating System Monitor

Page 33

CAUTION: Do not touch the membrane surface.

8. Screw the membrane cap onto the sensor moderately tight. A small amount of electrolyte should

overflow.

9. IMPORTANT: To prevent the formation of a bulge in the membrane (which can slow sensor

response), partially unscrew the membrane cap then retighten.

10. Screw the probe sensor guard on moderately tight.

4.7 Calibration/Storage Cup (5562 only)

The YSI 5562 Probe module is supplied with a convenient calibration/storage cup. This cup is an ideal

container for calibration of the different sensors, minimizing the amount of solution needed. Refer to

Section 6 Calibration.

4.7.1 Calibration/Storage Cup Installation

1. Remove probe sensor guard, if already installed.

2. Ensure that an o-ring is installed in the o-ring groove on the threaded end of the probe module

body.

3. Screw the calibration/storage cup on the threaded end of the probe module and securely tighten.

NOTE: Do not over tighten as this could cause damage to the threaded portions.

Figure 4-9 Calibration/Storage Cup Installation

O-ring

4.8 Instrument/Cable Connection

Attach the probe cable to the instrument as follows:

1. Line up the pins and guides on the cable with the holes and indentations on the cable connector at

the bottom of the YSI 5200 instrument.

YSI Incorporated 31 5200 Recirculating System Monitor

Page 34

r

Figure 4-10 Bottom Connectors

2. Holding the cable firmly against the cable connector, turn the locking mechanism clockwise until

it snaps into place.

3. Remove the cable from the instrument by turning the cable connector counterclockwise until the

cable disengages from the instrument.

Probe

Connecto

YSI Incorporated 32 5200 Recirculating System Monitor

Page 35

Section 5. Operation

p

ppt

Operation covers the basic set up and operation of the 5200 Recirculating Monitor including:

Ö Run Screen Ö Main Menu Ö Parameters Menu Ö Daily Checks Ö System Test

See Section 9 Advanced Setup for more advanced set up options.

In the Parameters menu section, Temperature is explained in step-by-step detail as an example. Once

familiar with the temperature set up procedure, other parameters can be set up in a similar manner.

5.1 Run Screen

The initial 5200 display is the Run screen.

DO 8.31 mg/L

Temp 18.5 °C

The current values of enabled parameters are displayed (two at a time in a rotating fashion) on the Run

Screen. The speed with which the display automatically rotates through these values can be changed (see

Section 9.1.4 Display, Display Speed). The parameters may also be manually rotated by pressing the [e]

or [f] arrow key. Press the [

display. An H will appear to the right of the parameter indicating Hold mode. Press the [

hold the 2

through all parameters.

nd

displayed parameter. Press the [ESC] key again to return to the normal display that rotates

ESC] key to hold the currently shown parameter on the top line of the

ESC] key again to

DO 7.15 mg/L H

Hold indicator

Temp 18.5 °C

Any messages will also appear on the Run Screen. As systems are activated or alarms are triggered the

display provides up to date status on the system being managed. Up to 16 events are saved and displayed

in sequence. Figure 3.2 shows the Run screen.

DO 7.11 mg/L

Tem

18.5°C

Current readings and any

messages rotate through the

display. (Order may vary)

pH 7.32

ORP 270 mV

Cond. 24.0ms*

Sal. 10.4

YSI Incorporated 33 5200 Recirculating System Monitor

Page 36

Cond 24.0mS *

Sal. 10.4ppt

The status LEDs show the current status of each parameter as follows:

OFF – parameter not enabled

GREEN – normal range

FLASHING GREEN – control mode (turns off when it crosses the original set point)

RED – alarm (turned off by pressing any key, except escape, and resolving the alarm condition)

Indicates temperature

compensation

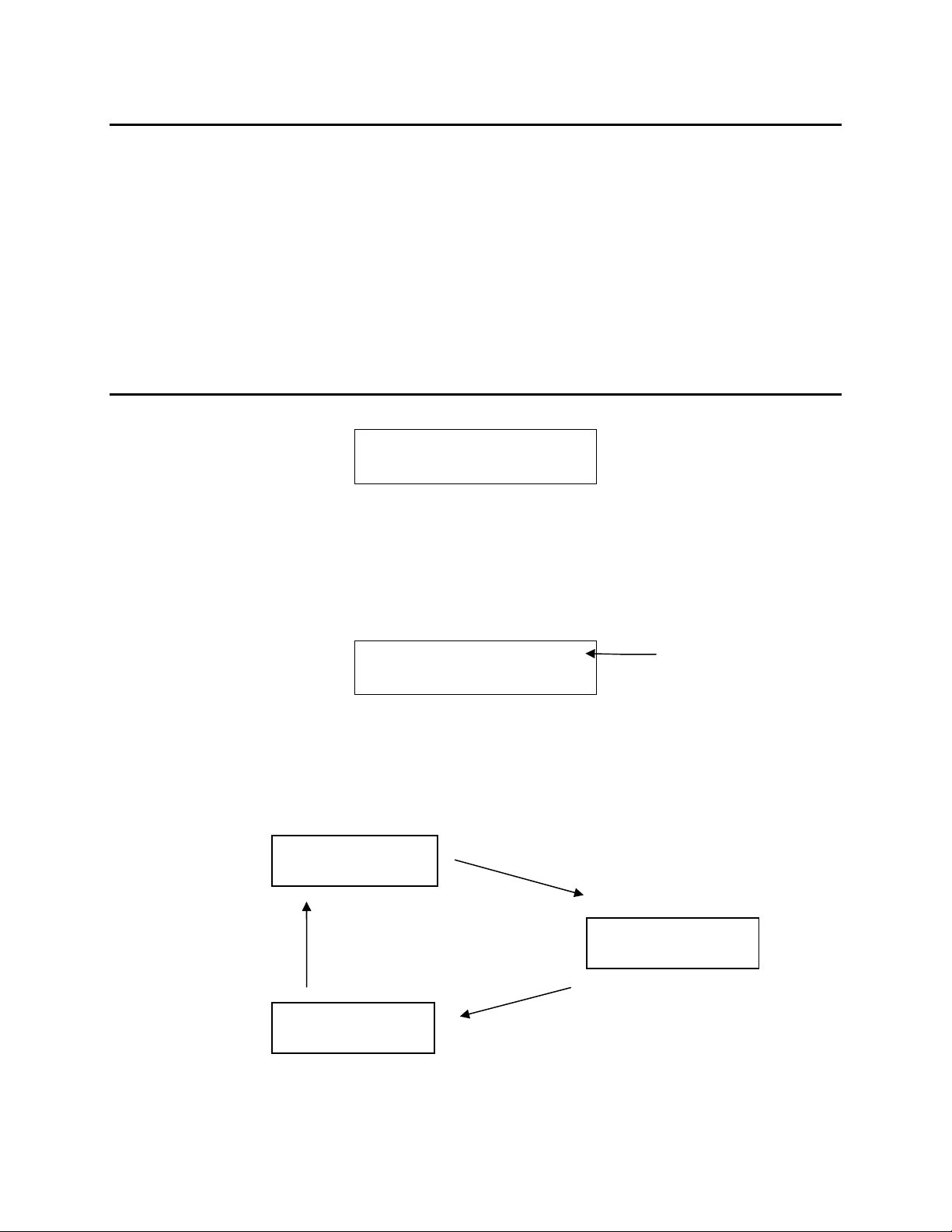

5.2 Main Menu

Run Screen

Serv ic e HoldSystem Menu Parameter Menu Timer Menu

Figure 5-1 Main Menu

From the Run screen, press the Enter [

] key to enter the Main menu.

Service Hold

Enter to Select

NOTE: Service Hold is the first selection in the Main menu. It allows you to perform service operations

(clean probes, provide tank maintenance etc.) without breaching any alarms or set points. See

Section 9.2.2 Service Hold.

Press the [e] or [f] key to rotate through the Main menu selections.

Parameters

Enter to Select

The menus are displayed in the order indicated in Figure 5-1, starting with Service Hold. You can cycle

through the menus as many times as you desire in either direction using the arrow keys.

NOTE: Entering the menus automatically turns off all 4 internal control relays.

YSI Incorporated 34 5200 Recirculating System Monitor

Page 37

5.3 Parameters Menu

The Parameters Menu allows you to enter the menu for specific measurement parameters. In addition to

establishing Set Points, Control Points and Alarms, the Parameters menu also enables the user to perform

calibrations (refer to Section 6 Calibration for calibration routines). The majority of the day-to-day

operations of the YSI 5200 will be accessed through this menu.

The options in this menu include:

Ö DO System

Ö pH System

Ö ORP System

Ö Temperature System

Ö Conductivity System

Ö Salinity System

Ö Auxiliary System

Param e ters Me nu

Salanity DO Menu ORP MenuCond Menu Temp MenupH MenuAUX Menu

Enable System

(Yes/N o)

Save Changes

Figure 5-2 Parameters Menu

5.3.1 Entering Setpoint and Range Values

Various Set Points and ranges must be established for each of the five monitoring parameters that are

enabled: conductivity, temperature, pH, ORP and DO.

Ö The optimal Set Point value.

Ö The control range, or High and Low Set Points.

Ö The alarm range.

YSI Incorporated 35 5200 Recirculating System Monitor

Page 38

Low

Alarm

ON

Low

Control

ON

Acceptable

Operating

Range

Hi

Control

ON

High

Alarm

ON

Low

Alarm

Setpoint

Low

Control

Setpoint

ON

Optimal

Setpoint

Value

High

Control

Setpoint

ON

High

Alarm

Setpoint

Figure 5-3 Setpoints and Ranges

When these values are entered, the system will operate as illustrated in Figure 5-3. As long as the water

quality parameters remain within the acceptable operating range, no control or alarm will be activated. If,

however, a parameter rises above or falls below the acceptable operating range, the YSI 5200 will activate

the appropriate control device. The control device remains in operation until the parameter returns to the

Set Point value.

As you enter a Set Point value, the YSI 5200 may prompt you if there are problems with the set up. If the

High or Low value breaches the optimal Set Point, you will see an Autofix question displayed that will

automatically adjust your High or Low value to a value ±0.1 or ±0.01 to the high or low side of your

optimal Set Point depending on the parameter of interest. For example, pH will be adjusted to the

hundredths place while DO will be adjusted to the tenths place.

If you had your optimal Set Point at 8.0 mg/L for DO and the Low range at 7.8 and the High range at 8.2

and you changed your optimal Set Point to 7.7 then attempted to escape without resetting the High and

Low ranges, you would see the following displayed:

Setpoint Errors.

Auto Fix? YES

If you choose YES, the Low range Set Point would automatically be adjusted to 7.6, but the High range

Set Point would remain 8.2 because it did not get breached.

IMPORTANT: For Controlling Applications, it is highly recommended that you use Alarms and verify

all Set Point, Alarm and Control Range settings.

This product has been designed and tested to provide trouble free service. However, as with all

microprocessor based products, there is potential for failure which could cause loss of control functions.

Proper QC procedures can reduce the potential for failure. See 11.3 Recommended Quality Assurance

Protocol.

The default set point and alarm values loaded during factory configuration are shown below.

YSI Incorporated 36 5200 Recirculating System Monitor

Page 39

Parameter Set Point High Set

ORP +400 mV +425 mV --- +375 mV --- +435 mV +300 mV

Temperature 25oC or 77oF 26oC or

pH 7.00 7.50 --- 6.50 --- 8.00 6.00

Specific Conductance

(range dependent;

0-200 us, 0-2000 us,

0-20 ms, 0-200 ms)

Dissolved Oxygen 8.3 mg/L 8.5 mg/L 8.7 mg/L 8.1 mg/L 7.9 mg/L 8.9 mg/L 7.7 mg/L

(0-200 us)

160.0 us

(0-2000 us)

1600 us

(0-20 ms)

16.00 ms

(0-200 ms)

160.0 ms

Point #1

o

78.8

F

(0-200 us)

180.0 us

(0-2000 us)

1800 us

(0-20 ms)

18.00 ms

(0-200 ms)

130.0 ms

High Set

Point #2

--- 24

--- (0-200 us)

Low Set

Point #1

o

C or

o

75.2

F

140.0 us

(0-2000 us)

1400 us

(0-20 ms)

14.00 ms

(0-200 ms)

140.0 ms

Low Set

Point #2

--- 26.5

--- (0-200 us)

High Alarm Low Alarm

o

C or

o

79.7

F

190.0 us

(0-2000 us)

1900 us

(0-20 ms)

19.00 ms

(0-200 ms)

190.0 ms

o

C or

23.5

o

74.3

F

(0-200 us)

130.0 us

(0-2000 us)

1300 us

(0-20 ms)

13.00 ms

(0-200 ms)

130.0 ms

5.3.2 Temperature System

Temperature is explained in step-by-step detail as an example. Once you are familiar with the temperature

set up procedure, other parameters can be set up in a similar manner.

From the Parameters menu, press the [e] or [f] key until the Temp System option appears.

Temp System

Enter to Select

Press the Enter [ ] key to enter the Temp System menu.

Temp System

ENABLED? Yes

If the Temperature System is disabled (as indicated by No appearing on the display), press the [e] or [f]

key to select Yes.

Temp System

ENABLED? Yes

Press the Enter [ ] key to confirm that the option is Enabled and enter the Temp System menu.

Set Point Menu

Enter to Select

Temperature System menu selections are shown below.

YSI Incorporated 37 5200 Recirculating System Monitor

Page 40

Temp Menu

Enabled

Yes

NO

Set Point

Range Low

Range High

Alarm Low

Alarm High

0-45 C

From 0.0 to 0.1

below Set Point

From Set Point +

0.1 to Max

From 0.0 to 0.1

below Range Low

From Range High

+ 0.1 to Max

Control MenuSet Point MenuSetup Menu

Range Low

Range High

Alarm Low

Alarm High

Alarm System

Select

Relay

Select

Relay

Select

Relay

Select

Relay

Enable System

F

C

Accept

Accept

(Yes/No)

Figure 5-4 Temperature Menu

Set Point Menu

From the Temp System menu, press the [e] or [f] key until the Set Point Menu option appears.

YSI Incorporated 38 5200 Recirculating System Monitor

Page 41

Set Point Menu

Enter to Select

Press the Enter [ ] key.

Enter to Select

SetPoint

Set Point Menu selections for Temperature are SetPoint, Range Low, Range High, Alarm Low and Alarm

High.

SetPoint

The Temperature Set Point defines the optimum Temperature that you wish the YSI 5200 to maintain in

the aquatic environment. This determines the control range for heating and chilling devices. See Section

5.3.1 Entering Setpoint and Range Values for an overview of control functions.

From the Set Point menu (with the SetPoint option displayed), press the Enter [

] key.

SetPoint

077.0°F

Using the [e], [f] and Enter [ ] keys, enter the Temp Set Point value.

NOTE: The previous value entered will be displayed.

SetPoint

069.0°F