York PREDATOR BP 090, PREDATOR BP120 User Manual

INSTALLATION

MANUAL - 50 Hz

®

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . 5

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

NOMENCLATURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

See following pages for a complete Table of Contents.

SINGLE PACKAGE HEAT PUMP

HIGH EFFICIENCY

BP090 and 120

(7-1/2 and 10 TON)

NOTES, CAUTIONS AND WARNINGS

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. Notes

clarify or make the installation easier. Cautions

prevent equipment damage. Warnings are given to alert

installer that personal injury and/or equipment damage may

result if installation procedure is not handled properly.

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

BEGIN TO INSTALL YOUR UNIT.

SAVE THIS MANUAL

are intended to

are given to

66307-YIM-B-0606

TABLE OF CONTENTS

66307-YIM-B-0606

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . . . . . 5

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

REFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION SAFETY INFORMATION . . . . . . . . . . . .8

PRECEDING INSTALLATION . . . . . . . . . . . . . . . . . . . . . .8

LIMITATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

LOCATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . . . .10

CLEARANCES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

DUCT COVERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . .15

COMPRESSORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

THERMOSTAT WIRING . . . . . . . . . . . . . . . . . . . . . . . . .15

POWER AND CONTROL WIRING . . . . . . . . . . . . . . . . .15

POWER WIRING DETAIL . . . . . . . . . . . . . . . . . . . . . . . .16

FACTORY INSTALLED OPTIONS/

FIELD INSTALLED ACCESSORIES . . . . . . . . . . . . . . . .19

ELECTRIC HEAT ACCESSORY . . . . . . . . . . . . . . . . . . . . 19

ELECTRIC HEAT OPTION . . . . . . . . . . . . . . . . . . . . . . . . 19

MOTORIZED OUTDOOR DAMPER . . . . . . . . . . . . . . . . . 20

ECONOMIZER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

POWER EXHAUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

RAIN HOOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ECONOMIZER AND POWER EXHAUST SET

POINT ADJUSTMENTS AND INFORMATION . . . . . . . .20

MINIMUM POSITION ADJUSTMENT . . . . . . . . . . . . . . . . 20

ENTHALPY SET POINT ADJUSTMENT. . . . . . . . . . . . . . 20

POWER EXHAUST DAMPER SET POINT (WITH OR

WITHOUT POWER EXHAUST). . . . . . . . . . . . . . . . . . . . . 21

INDOOR AIR QUALITY AQ . . . . . . . . . . . . . . . . . . . . . . . . 21

PHASING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

BLOWER ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . .22

BELT TENSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AIR BALANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CHECKING AIR QUANTITY . . . . . . . . . . . . . . . . . . . . . . 30

METHOD ONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

METHOD TWO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SUPPLY AIR DRIVE ADJUSTMENT . . . . . . . . . . . . . . . 31

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SEQUENCE OF OPERATIONS OVERVIEW . . . . . . . . . 33

COOLING SEQUENCE OF OPERATION. . . . . . . . . . . . 33

CONTINUOUS BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . 33

INTERMITTENT BLOWER . . . . . . . . . . . . . . . . . . . . . . . . 33

NO OUTDOOR AIR OPTIONS . . . . . . . . . . . . . . . . . . . . . 33

ECONOMIZER WITH SINGLE ENTHALPY SENSOR . . . 33

ECONOMIZER WITH DUAL ENTHALPY SENSORS. . . . 34

ECONOMIZER (SINGLE OR DUAL) WITH POWER

EXHAUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

MOTORIZED OUTDOOR AIR DAMPERS . . . . . . . . . . . . 34

COOLING OPERATION ERRORS . . . . . . . . . . . . . . . . . 34

HIGH-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . 34

LOW-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . 34

FREEZESTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

LOW AMBIENT COOLING . . . . . . . . . . . . . . . . . . . . . . . . 34

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

COMPRESSOR PROTECTION . . . . . . . . . . . . . . . . . . . 35

FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

RESET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

HEATING SEQUENCE OF OPERATION. . . . . . . . . . . . 35

ELECTRIC HEAT OPERATION ERRORS . . . . . . . . . . . 36

TEMPERATURE LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

LIMIT SWITCH (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

RESET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ELECTRIC HEAT ANTICIPATOR SETPOINTS . . . . . . . 36

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PRESTART CHECK LIST. . . . . . . . . . . . . . . . . . . . . . . . 36

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . 37

POST START CHECK LIST . . . . . . . . . . . . . . . . . . . . . . 37

SUPERHEAT CHARGING METHOD . . . . . . . . . . . . . . . 37

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . 39

PREDATOR® FLASH CODES . . . . . . . . . . . . . . . . . . . . 39

COOLING TROUBLESHOOTING GUIDE. . . . . . . . . . . . 41

2 Unitary Products Group

66307-YIM-B-0606

LIST OF FIGURES

Fig. # Pg. #

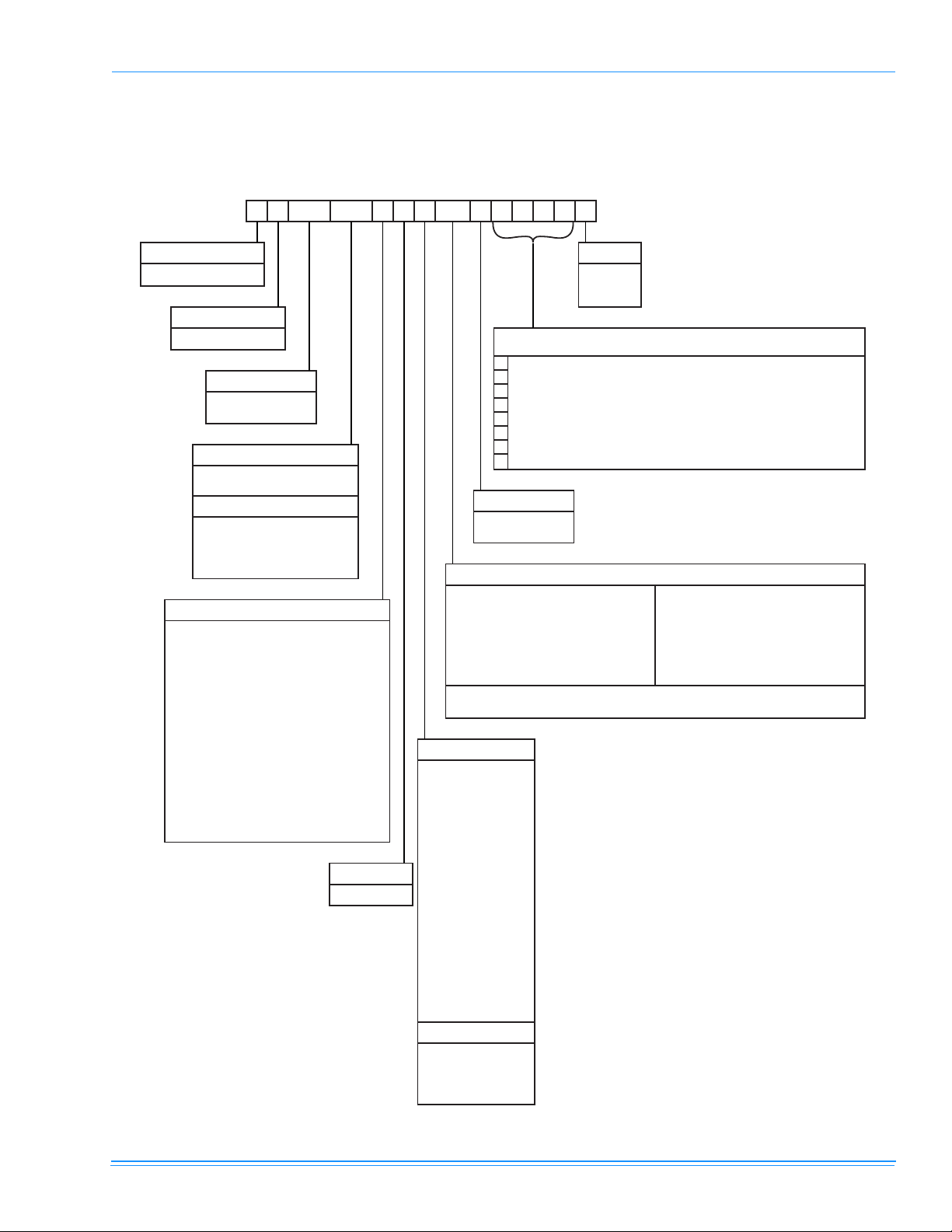

1 UNIT SHIPPING BRACKET . . . . . . . . . . . . . . . . . . . . . 8

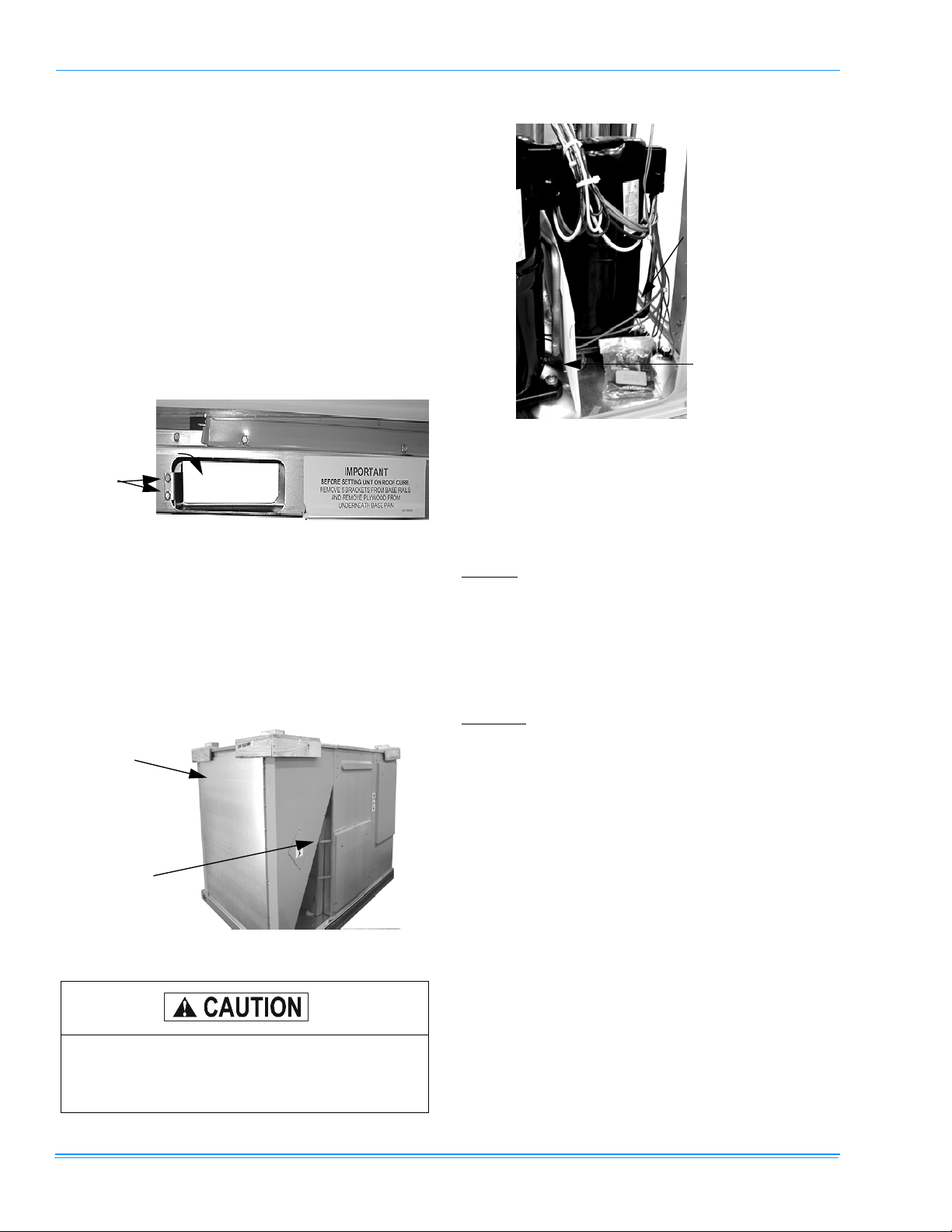

2 CONDENSER COIL COVERING . . . . . . . . . . . . . . . . . 8

3 COMPRESSOR SECTION . . . . . . . . . . . . . . . . . . . . . . 8

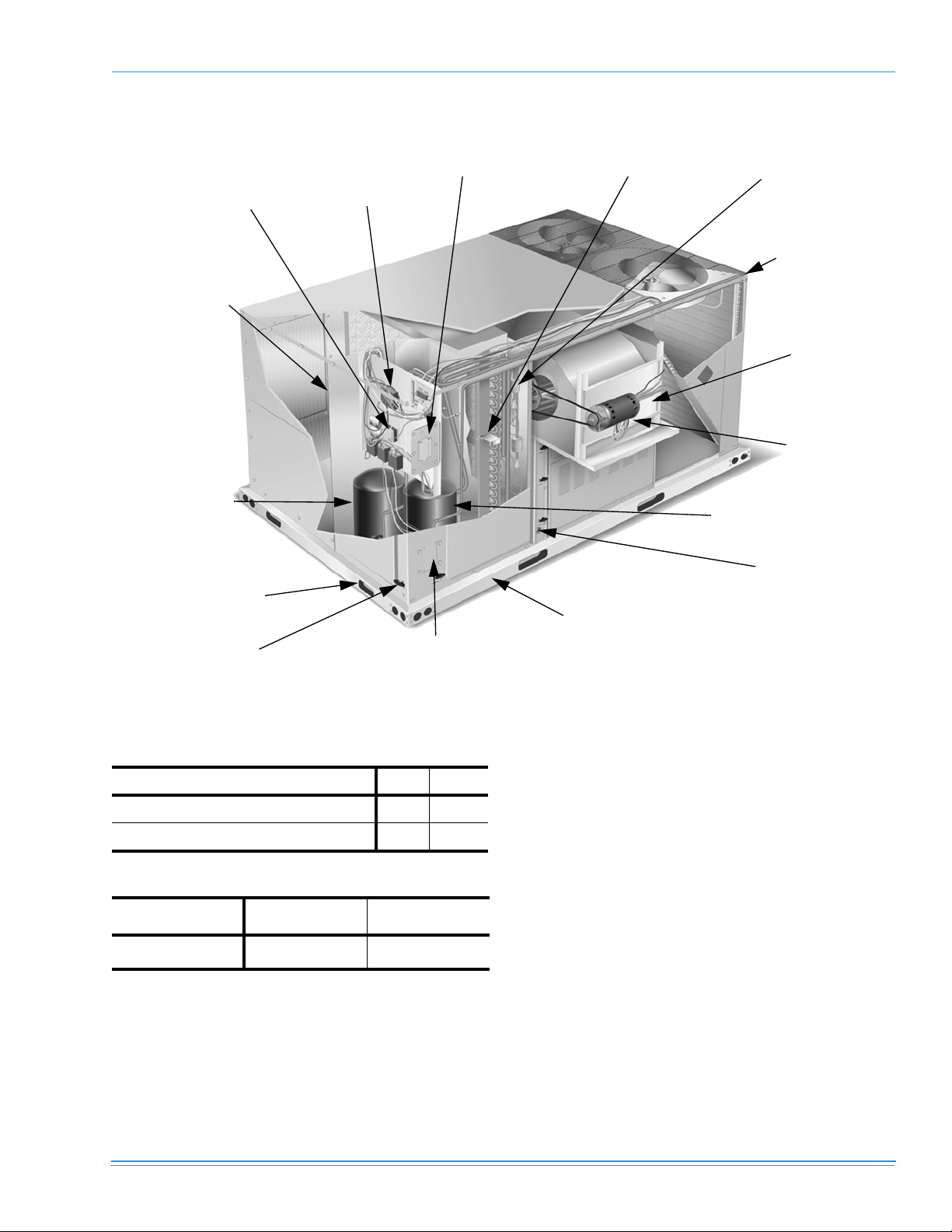

4 PREDATOR® COMPONENT LOCATION . . . . . . . . . . 9

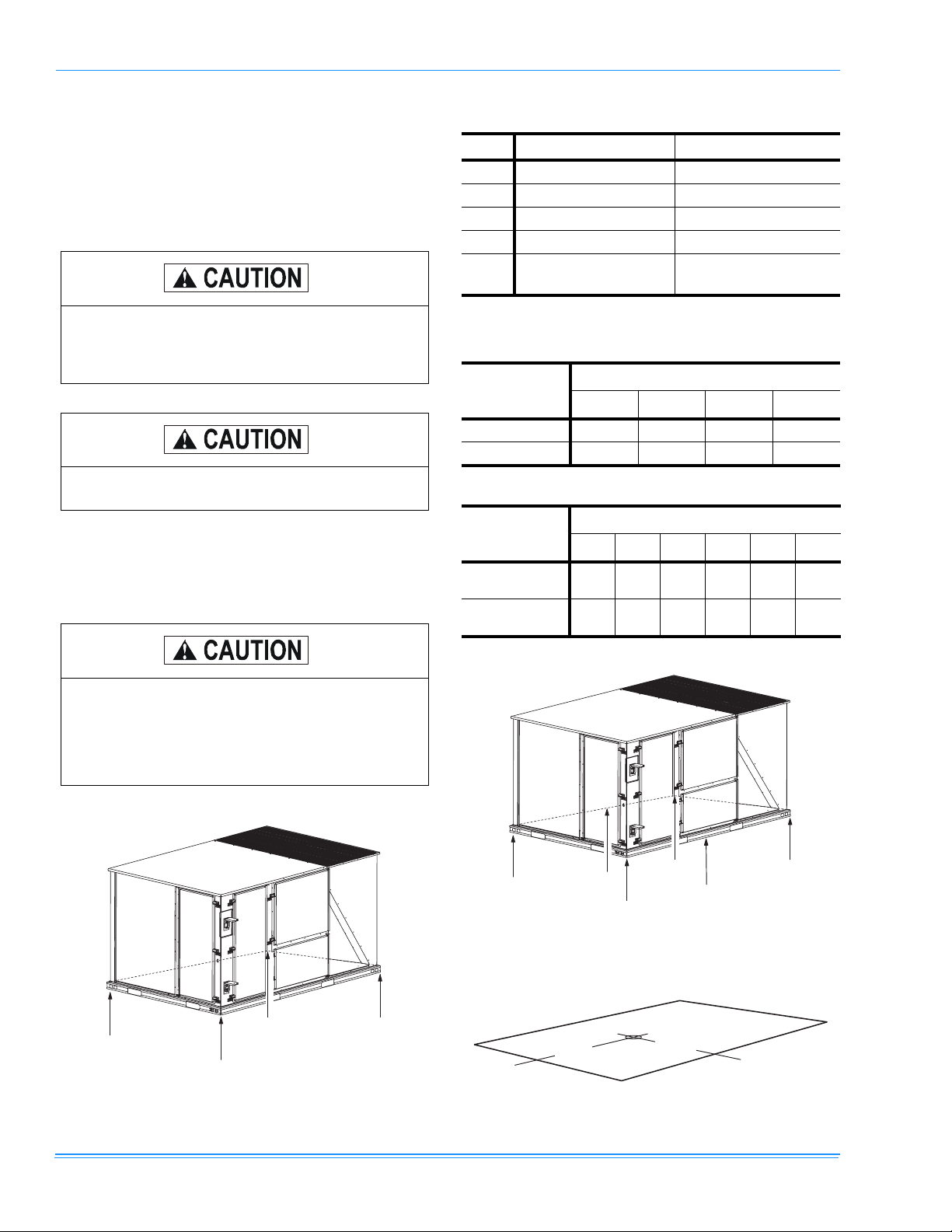

5 UNIT 4 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 UNIT 6 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 UNIT CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . 10

8 UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9 BOTTOM DUCT OPENINGS . . . . . . . . . . . . . . . . . . . 12

10 REAR DUCT DIMENSIONS . . . . . . . . . . . . . . . . . . . . 13

11 PREDATOR® ROOF CURB DIMENSIONS . . . . . . . . 14

12 SUNLINE™ TO PREDATOR® TRANSITION

ROOF CURBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fig. # Pg. #

13 SIDE PANELS WITH HOLE PLUGS . . . . . . . . . . . . . 14

14 RETURN DOWNFLOW PLENUM WITH PANEL . . . . 15

15 DISCHARGE PANEL IN PLACE . . . . . . . . . . . . . . . . 15

16 CONDENSATE DRAIN. . . . . . . . . . . . . . . . . . . . . . . . 15

17 ELECTRONIC THERMOSTAT FIELD WIRING . . . . . 16

18 FIELD WIRING 24 VOLT THERMOSTAT . . . . . . . . . 17

19 FIELD WIRING DISCONNECT. . . . . . . . . . . . . . . . . . 17

20 ENTHALPY SET POINT CHART . . . . . . . . . . . . . . . . 21

21 HONEYWELL ECONOMIZER CONTROL W7212. . . 22

22 BELT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 23

23 DRY COIL DELTA P. . . . . . . . . . . . . . . . . . . . . . . . . . 31

24 UNIT CONTROL BOARD. . . . . . . . . . . . . . . . . . . . . . 40

Unitary Products Group 3

LIST OF TABLES

66307-YIM-B-0606

Tbl. # Pg. #

1 UNIT TEMPERATURE LIMITATIONS . . . . . . . . . . . . . 9

2 UNIT VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . . . 9

3 UNIT WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 4 POINT LOAD WEIGHT . . . . . . . . . . . . . . . . . . . . . . 10

5 6 POINT LOAD WEIGHT . . . . . . . . . . . . . . . . . . . . . . 10

6 UNIT CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 CONTROL WIRE SIZES. . . . . . . . . . . . . . . . . . . . . . . 15

8 ELECTRICAL DATA - 7-1/2 TON HP . . . . . . . . . . . . . 18

9 ELECTRICAL DATA - 10 TON HP . . . . . . . . . . . . . . . 18

10 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

11 ELECTRIC HEAT MINIMUM SUPPLY AIR . . . . . . . . 20

12 SUPPLY AIR LIMITATIONS . . . . . . . . . . . . . . . . . . . . 22

13 BLOWER PERFORMANCE 7-1/2 TON

STANDARD MOTOR - SIDE DUCT (IMPERIAL) . . . . 24

14 BLOWER PERFORMANCE 7-1/2 TON

STANDARD MOTOR - SIDE DUCT (METRIC) . . . . . 24

15 BLOWER PERFORMANCE 7-1/2 TON

OPTIONAL MOTOR - SIDE DUCT (IMPERIAL). . . . . 24

16 BLOWER PERFORMANCE 7-1/2 TON

OPTIONAL MOTOR - SIDE DUCT (METRIC) . . . . . . 25

Tbl. #

20 BLOWER PERFORMANCE 10 TON

OPTIONAL MOTOR - SIDE DUCT (METRIC) . . . . . . 26

21 BLOWER PERFORMANCE 7-1/2 TON

STANDARD MOTOR - DOWNSHOT (IMPERIAL). . . 27

22 BLOWER PERFORMANCE 7-1/2 TON

STANDARD MOTOR - DOWNSHOT (METRIC) . . . . 27

23 BLOWER PERFORMANCE 7-1/2 TON

OPTIONAL MOTOR - DOWNSHOT (IMPERIAL) . . . 27

24 BLOWER PERFORMANCE 7-1/2 TON

OPTIONAL MOTOR - DOWNSHOT (METRIC) . . . . . 28

25 BLOWER PERFORMANCE 10 TON

STANDARD MOTOR - DOWNSHOT (IMPERIAL). . . 28

26 BLOWER PERFORMANCE 10 TON

STANDARD MOTOR - DOWNSHOT (METRIC). . . . 28

27 BLOWER PERFORMANCE 10 TON

OPTIONAL MOTOR - DOWNSHOT (IMPERIAL) . . . 29

28 BLOWER PERFORMANCE 10 TON OPTIONAL

MOTOR - DOWNSHOT (METRIC). . . . . . . . . . . . . . . 29

29 INDOOR BLOWER SPECIFICATIONS . . . . . . . . . . . 29

30 ADDITIONAL STATIC RESISTANCE - IMPERIAL . . 32

31 ADDITIONAL STATIC RESISTANCE - METRIC . . . . 32

32 MOTOR SHEAVE DATUM. . . . . . . . . . . . . . . . . . . . . 33

Pg. #

17 BLOWER PERFORMANCE 10 TON

STANDARD MOTOR - SIDE DUCT (IMPERIAL) . . . . 25

18 BLOWER PERFORMANCE 10 TON

STANDARD MOTOR - SIDE DUCT (METRIC) . . . . . 25

19 BLOWER PERFORMANCE 10 TON

OPTIONAL MOTOR - SIDE DUCT (IMPERIAL). . . . . 26

33 ELECTRIC HEAT LIMIT SETTING. . . . . . . . . . . . . . . 36

34 HEAT PUMP ANTICIPATOR SETPOINTS . . . . . . . . 36

35 SUPERHEAT CHARGING . . . . . . . . . . . . . . . . . . . . . 38

36 COOLING SUPERHEAT 7-1/2 TON . . . . . . . . . . . . . 38

37 COOLING SUPERHEAT 10 TON. . . . . . . . . . . . . . . . 39

38 UNIT CONTROL BOARD FLASH CODES. . . . . . . . . 40

4 Unitary Products Group

66307-YIM-B-0606

GENERAL

YORK® Predator® Heat Pump units are single package,

reverse cycle air conditioners designed for outdoor installation on a rooftop or slab and for non-residential use. These

units can be equipped with factory or field installed electric

heaters for heating applications.

These units are completely assembled on rigid, permanently

attached base rails. All piping, refrigerant charge, and electrical wiring is factory installed and tested. The units require

electric power and duct connections. The electric heaters

have nickel-chrome elements and utilize single-point power

connection.

SAFETY CONSIDERATIONS

Due to system pressure, moving parts, and electrical components, installation and servicing of air conditioning equipment

can be hazardous. Only qualified, trained service personnel

should install, repair, or service this equipment. Untrained

personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters.

Observe all precautions in the literature, labels, and tags

accompanying the equipment whenever working on air conditioning equipment. Be sure to follow all other applicable

safety precautions and codes including National Electric

Code, ANSI/NFPA No. 70 - latest edition U.S.A. and Canadian Electric Code, CSA C22.1 in Canada.

Wear safety glasses and work gloves. Use quenching cloth

and have a fire extinguisher available during brazing operations.

INSPECTION

As soon as a unit is received, it should be inspected for possible damage during transit. If damage i s evident , the extent of

the damage should be noted on the carrier’s freight bill. A

separate request for inspection by the carrier’s agent should

be made in writing.

This furnace is not to be used for temporary heating

of buildings or structures under construction.

Before performing service or maintenance operations on unit, turn off main power switch to unit. Electrical shock could cause personal injury. Improper

installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer

to this manual. For assistance or additional information consult a qualified installer, service agency or

the gas supplier.

Unitary Products Group 5

66307-YIM-B-0606

REFERENCE

Additional information is available in the following reference

forms:

• Technical Guide - 259336

• General Installation - 66307

• Pre-start & Post-start Check List

• Economizer Accessory Downflow Factory Installed

Downflow Field Installed

Horizontal Field Installed

• Motorized Outdoor Air Damper

• Manual Outdoor Air Damper (0-100%)

• Manual Outdoor Air Damper (0-35%)

• Electric Heater Accessory

• Unit Renewal Parts List

RENEWAL PARTS

Contact your local York® parts distribution center for authorized replacement parts.

3. For installation on combustible material an d may be

installed directly on combustible flooring or, in the U.S.,

on wood flooring or Class A, Class B or Class C roof covering materials.

This product must be installed in strict compliance

with the enclosed installation instructions and any

applicable local, state, and national codes including,

but not limited to, building, electrical, and mechan ical

codes.

Incorrect installation may create a condition where th e

operation of the product could cause personal injury

or property damage.

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. NOTES a re intended to

clarify or make the installation easier. CAUTIONS are given

to prevent equipment damage. WARNINGS are given to alert

installer that personal injury and/or equipment damage may

result if installation procedure is not handled properly.

APPROVALS

Design certified by CSA as follows:

1. For use as a cooling only unit, cooling unit with supplemental electric heat forced air furnace.

2. For outdoor installation only.

6 Unitary Products Group

66307-YIM-B-0606

NOMENCLATURE

B P 090 C00 A 7 A AA 3 0 1 2 4 A

7.5-10.0 Ton York® Model Number Nomenclature

Product Category

B = HP, Single Pkg., R-22

Product Identifier

P = 9.3-10.6 EER HP

Nominal Cooling Capacity

090 = 7.5 Ton

120 = 10.0 Ton

Heat Type and Nominal Heat Capacity

C00 = Cooling Only. No heat installed

Electric Heat Options

E09 = 9 KW

E18 = 18 KW

E24 = 24 KW

E36 = 36 KW

E54 = 54 KW

Airflow

A = Std. Motor

B = Std. Motor/Econo./Barometric Relief (Downflow

Only)

C = Std. Motor/Econo./Power Exhaust (Downflow Only)

D = Std. Motor/Motorized Damper (Downflow Only)

E = Std. Motor/Horizontal Economizer (No Baro.)

F = Std. Motor/Slab Econo./Power Exhaust

(Downflow Only)

G = Std. Motor/Slab Econo./Barometric Relief

(Downflow Only)

N = Hi Static Mtr.

P = Hi Static Mtr./Econo./Barometric Relief

(Downflow Only)

Q = Hi Static Mtr./Econo./Power Exhaust

(Downflow Only)

R = Hi Static Mtr./Motorized Damper (Downflow Only)

S = Hi Static Mtr./Horizontal Economizer (No Baro.)

T = Hi Static Mtr./Slab Econo./Power Exhaust

(Downflow Only)

U = Hi Static Mtr./Slab Econo./Barometric Relief

(Downflow only)

Voltage

7 = 380/415-3-50

Product Style

A = Style A

B = Style B

C = Style C

These four digits will not be assigned until a quote is requested, or an order placed.

SS Drain Pan

Honeywell Controller, DFS, APS

Simplicity IntelliComfort Controller

Simplicity IntelliComfort Controller w/ModLinc

2" Pleated filters

BAS Ready Unit with Belimo Economizer

Shipping Bag

Any Combination of Additional Options that Don’t Have an Option Code Pre-assigned

Product Generation

3 = Third Generation

4 = Fourth Generation

AA = None

AB = Phase Monitor

AC = Coil Guard

AD = Dirty Filter Switch

AE = Phase Monitor & Coil Guard

AF = Phase Monitor & Dirty Filter Switch

AG = Coil Guard & Dirty Filter Switch

AH = Phase Monitor, Coil Guard & Dirty Filter Switch

ZZ = If desired option combination is not listed above, ZZ will be assigned and configuration options will be

located in digits 15-18.

Installation Options

A = No Options Installed

B = Option 1

C=Option2

D=Options1&2

E = Option 3

F = Option 4

G = Options 1 & 3

H=Options1&4

J = Options 1, 2 & 3

K = Options 1, 2, & 4

L = Options 1,3 & 4

M = Options 1, 2, 3, & 4

N=Options2&3

P = Options 2 & 4

Q = Options 2, 3, & 4

R=Options3&4

S = Option 5

T=Options1&5

U=Options1,3,&5

V = Options 1, 4, & 5

W=Options1,3,4,&5

X=Options3&5

Y=Options4&5

Z = Options 3, 4 & 5

Configuration Options (not required for all units)

Additional Options

RC = Coil Guard, Shipping Bag & American Flag

TA = Technicoat Condenser Coil

TJ = Technicoat Evaporator Coil

TS = Technicoat Evaporator & Condenser Coils

Options

1 = Disconnect

2 = Non-Pwr'd Conv. Outlet

3 = Smoke Detector S.A.

4 = Smoke Detector R.A.

5=Pwr'dConv.Outlet

Unitary Products Group 7

INSTALLATION

INSTALLATION SAFETY INFORMATION

Read these instructions before continuing this appliance

installation. This is an outdoor combination heating and cooling unit. The installer must assure that these instructions are

made available to the consumer and with instructions to

retain them for future reference.

1. This equipment is not to be used for temporary heating

of buildings or structures under construction.

66307-YIM-B-0606

Toolless

Doorknobs

PRECEDING INSTALLATION

1. Remove the two screws holding the brackets in the front,

rear and compressor side fork-lift slots.

Bracket

Screws

Turn down

FIGURE 1 - UNIT SHIPPING BRACKET

2. Turn each bracket toward the ground and the protective

plywood covering will drop to the ground.

3. Remove the condenser coil external protective covering

prior to operation.

4. Remove the toolless doorknobs and instruction packet

prior to installation.

Condenser

Coil External

Protective

Covering

Installation

Instruction

Packet

FIGURE 3 - COMPRESSOR SECTION

LIMITATIONS

These units must be installed in accordance with the following:

In U.S.A.

1. National Electrical Code, ANSI/NFPA No. 70 - Latest

2. Local building codes

3. Local electric utility requirements

In Canada

1. Canadian Electri c al Code, CSA C22.1

2. Installation Codes, CSA - B149.1.

:

Edition

:

Barometric

Relief Hood in

Shipping Location (if included)

4. Other applicable local codes.

Refer to Tables 2 & 3 for unit application data.

If components are to be added to a unit to meet local codes,

they are to be installed at the dealer’s and/or customer’s

3. Local plumbing and waste water codes, and

FIGURE 2 - CONDENSER COIL COVERING

expense.

Size of unit for proposed installation should be based on heat

loss/heat gain calculation made according to the methods of

Air Conditioning Contractors of America (ACCA).

This product must be installed in strict compliance with

the enclosed installation instructions and any applicable local, state and national codes including, but not

This furnace is not to be used for temporary heating of buildings or structures under construction.

limited to, building, electrical, and mechanical codes.

8 Unitary Products Group

66307-YIM-B-0606

Terminal block for

hi-voltage connection

Second model nameplate inside hinged

access panel

Compressor #2

access (highefficiency compressor)

Base rails w/forklift slots (3 sides)

and lifting holes)

Tool-less door

latch

Simplicity™ Control

board w/screw connector for T-stat wiring and network

connection.

Disconnect location

(optional disconnect switch)

Side entry

power and control

wiring knockouts

Filter access (2” throw-away)

Compressor #1 access (highefficiency compressor)

Roof curbs in eight- and fourteen-inch

heights. Roof curbs for transitioning from

Y ork Sunline™ footprint to the BP Series

footprint are also available.

(field-installed accessory)

Filter drier (solid

core)

Slide-out drain pan

with steel 3/4” FPT

Condenser

section

Slideout motor

& blower

assembly for

easy access

adjustment &

service

Belt-drive

blower motor

connection

FIGURE 4 - PREDATOR® COMPONENT LOCATION

TABLE 1: UNIT TEMPERATURE LIMITATIONS

Temperature Min. Max.

Wet Bulb Temp °F (°C) of Air on Evap Coil 57 (14) 72 (22)

Dry Bulb Temp °F (°C) of Air on Cond Coil 0 (-18) 125 (52)

TABLE 2: UNIT VOLTAGE LIMITATIONS

Power Rating

380/415-3-50 342 456

*.

Utilization range “A” in accordance with ARI Standard

110.

*

Minimum Maximum

LOCATION

Use the following guidelines to select a suitable location for

these units:

1. Unit is designed for outdoor installation only.

2. Condenser coils must have an unlimited supply of air.

Where a choice of location is possible, position the unit

on either north or east side of building.

3. Suitable for mounting on roof curb.

4. For ground level installation, use a level concrete slab

with a minimum thickness of 4 inches (102 mm). The

length and width should be at least 6 inches (152 mm)

greater than the unit base rails. Do not tie slab to the

building foundation.

5. Roof structures must be able to support the weight of the

unit and its options/accessories. Unit must be installed

on a solid, level roof curb or appropriate angle iron

frame.

6. Maintain level tolerance to 1/2” (13 mm) across the entire

width and length of unit.

Unitary Products Group 9

66307-YIM-B-0606

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig

the unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreader bars, whose length

exceeds the largest dimension across the unit, MUST be

used across the top of the unit.

If a unit is to be installed on a roof curb other than a

YORK roof curb, gasketing must be applied to all

surfaces that come in contact with the unit underside.

Before lifting, make sure the unit weight is distributed equally on the rigging cables so it will lift evenly.

Units may be moved or lifted with a forklift. Slotted openings

in the base rails are provided for this purpose.

LENGTH OF FORKS MUST BE A MINIMUM OF 60 INCHES

(1524 mm).

TABLE 3: UNIT WEIGHTS

Model Shipping Weight lb. (kg)

BP090

BP120

Econ.

w/ PE

Elec.

Heat

*

*.

54kW heater.

1108 (503) 1103 (500)

1212 (550) 1207 (547)

85 (39) 84 (38)

150 (68) 148 (67)

49 (22) 49 (22)

Operating Weight

TABLE 4: 4 POINT LOAD WEIGHT

Model

BP090

BP120

ABCD

242 (109) 207 (94) 301 (137) 353 (160)

265 (120) 226 (103) 330 (150) 386 (175)

Location lbs. (kg)

TABLE 5: 6 POINT LOAD WEIGHT

Model

BP090

BP120

ABCDEF

166

(75)

181

(82)

Location lbs. (kg)

149

134

(68)

(61)

163

147

(80)

(67)

196

(89)

214

(97)

217

(98)

237

(108)

lb. (kg)

242

(110)

264

(120)

All panels must be secured in place when the unit is

lifted.

The condenser coils should be protected from rigging cable damage with plywood or other suitable

material.

L E F T

A

D

F R O N T

FIGURE 5 - UNIT 4 POINT LOAD

L E F T

A

B

F

C

F R O N T

D

E

FIGURE 6 - UNIT 6 POINT LOAD

N O T E :

( x x x ) i n d i c a t e s

d i m e n s i o n s i n

CB

m i l l i m e t e r s

L E F T

4 1 "

( 1 0 4 0 )

2 4 "

( 6 1 0 )

F R O N T

FIGURE 7 - UNIT CENTER OF GRAVITY

10 Unitary Products Group

66307-YIM-B-0606

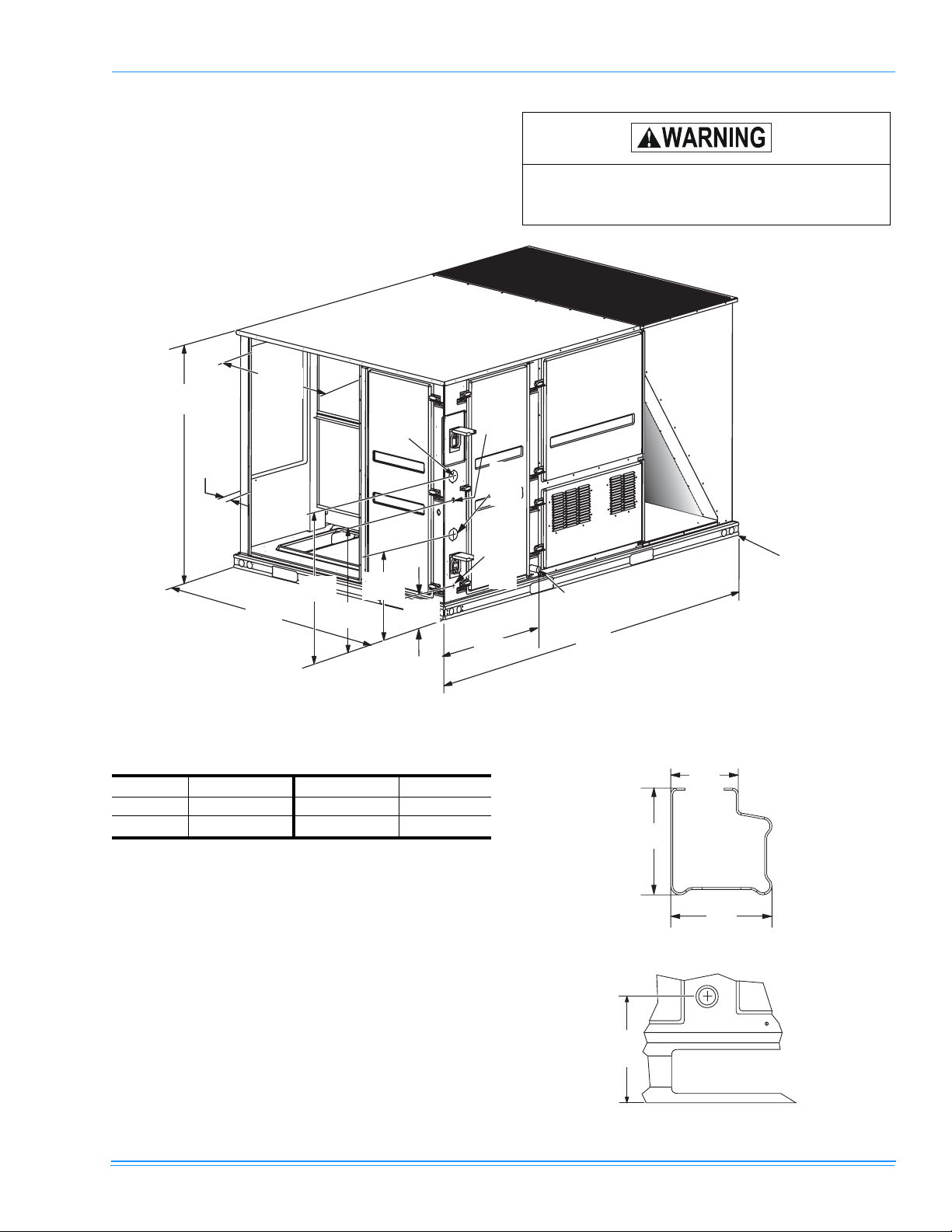

A

CLEARANCES

All units require particular clearances for proper operation

and service. Refer to Table 6 for clearances required for construction, servicing, and proper unit operation.

3 0 - 1 1 / 3 2

5 0 - 3 / 4

( 1 2 9 0 )

4 - 1 / 4

( 1 1 0 )

( 7 7 0 )

P o w e r

E n t r y

Ø 2 - 1 / 2

( 6 5 )

C o n t r o l

E n t r y

Ø 7 / 8

( 2 2 )

P o w e r

E n t r y

Ø 2 - 1 / 2

( 6 5 )

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet, combustion

air inlet or vent outlets.

3 0 - 3 / 1 6

( 7 6 5 )

2 4 - 3 / 1 6

( 6 1 5 )

L E F T

5 9

( 1 5 0 0 )

FIGURE 8 - UNIT DIMENSIONS

TABLE 6: UNIT CLEARANCES

†

Top

Front

‡

Rear

*.

In inches and millimeters, in.(mm).

†.

Units must be installed outdoors. Overhanging structure or

72 (1830)

36 (915)

36 (915)

shrubs should not obstruct condenser air discharge outlet.

‡.

To remove the slide-out drain pan, a rear clearance of 60”

(1525 mm) is required. If space is unavailable, the drain pan

can be removed through the front by separating the corner

wall.

**.

Units may be installed on combustible floors.

Right

Left

Bottom

C o n v e n i e n c e

P o w e r

1 7 - 3 / 1 6

( 4 3 5 )

6 - 3 / 1 6

( 1 5 5 )

O u t l e t

2 7

( 6 8 5 )

E n t r y

Ø 7 / 8

( 2 2 )

F R O N T

F o r D r a i n

D i m e n s i o n s

S e e D e t a i l B

8 9

( 2 2 6 0 )

F o r B a s e r a i l

D i m e n s i o n s

S e e D e t a i l

N O T E : ( x x x ) i n d i c a t e s d i m e n s i o n s

g i v e n i n m i l l i m e t e r s

*

12 (305)

36 (915)

**

0 (0)

DETAIL A

3 - 3 / 4

( 9 5 )

2 - 3 / 8

( 6 0 )

3 - 9 / 1 6

( 9 0 )

DETAIL B

NOTE: A one-inch clearance must be provided between

any combustible material and the supply ductwork

for a distance of 3 feet from the unit .

5 - 3 / 8

( 1 3 5 )

Unitary Products Group 11

66307-YIM-B-0606

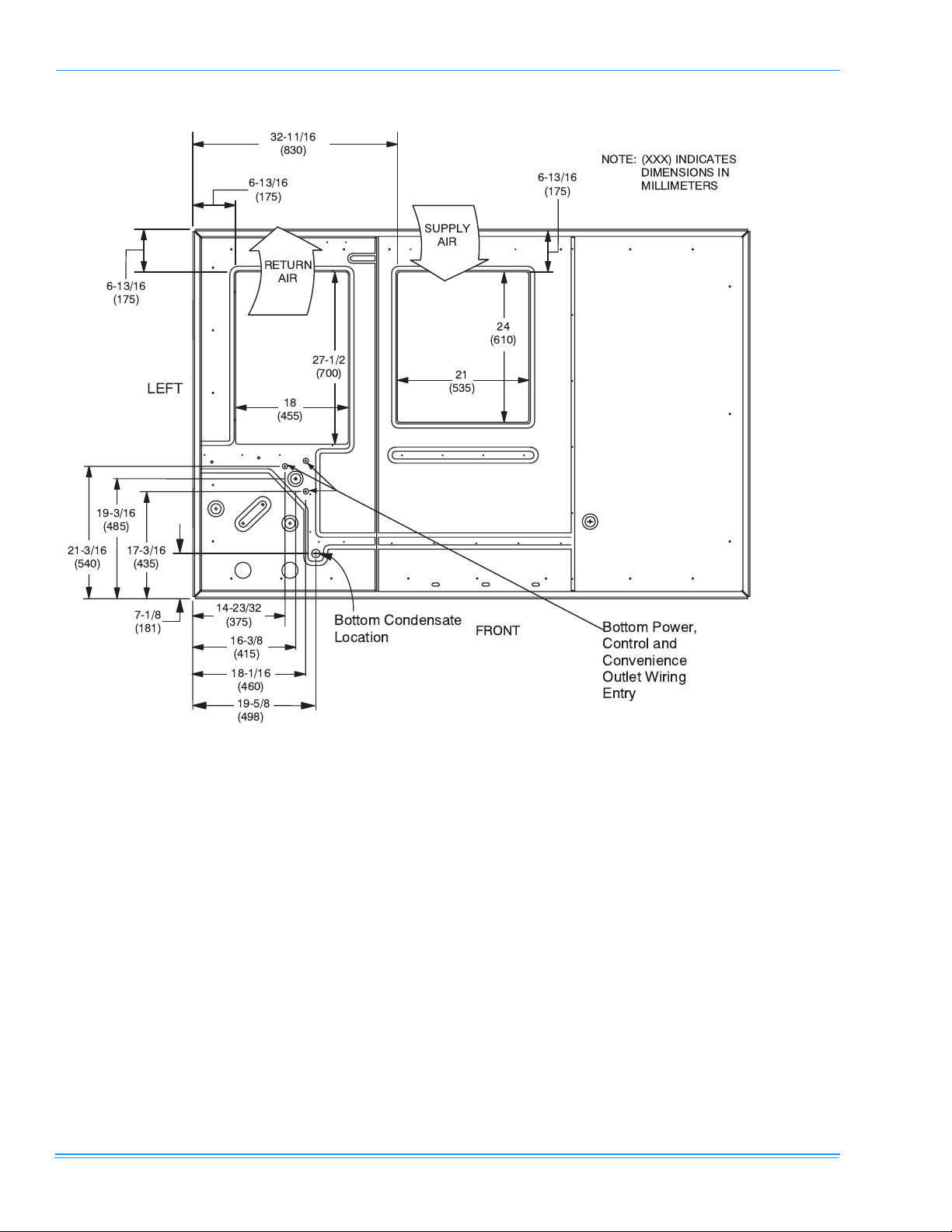

.

32-11/16

6-13/16

(175)

LEFT

(830)

6-13/16

(175)

RETURN

AIR

(455)

18

27-1/2

(700)

6-13/16

(175)

SUPPLY

AIR

24

(610)

21

(535)

(XXX)INDICATES

NOTE:

DIMENSIONSIN

MILLIMETERS

19-3/16

(485)

21-3/16

(540)

17-3/16

(435)

7-1/8

(181)

14-23/32

(375)

16-3/8

(415)

18-1/16

(460)

19-5/8

(498)

BottomCondensate

Location

FIGURE 9 - BOTTOM DUCT OPENINGS (FROM ABOVE)

FRONT

BottomPower,

Controland

Convenience

OutletWiring

Entry

12 Unitary Products Group

66307-YIM-B-0606

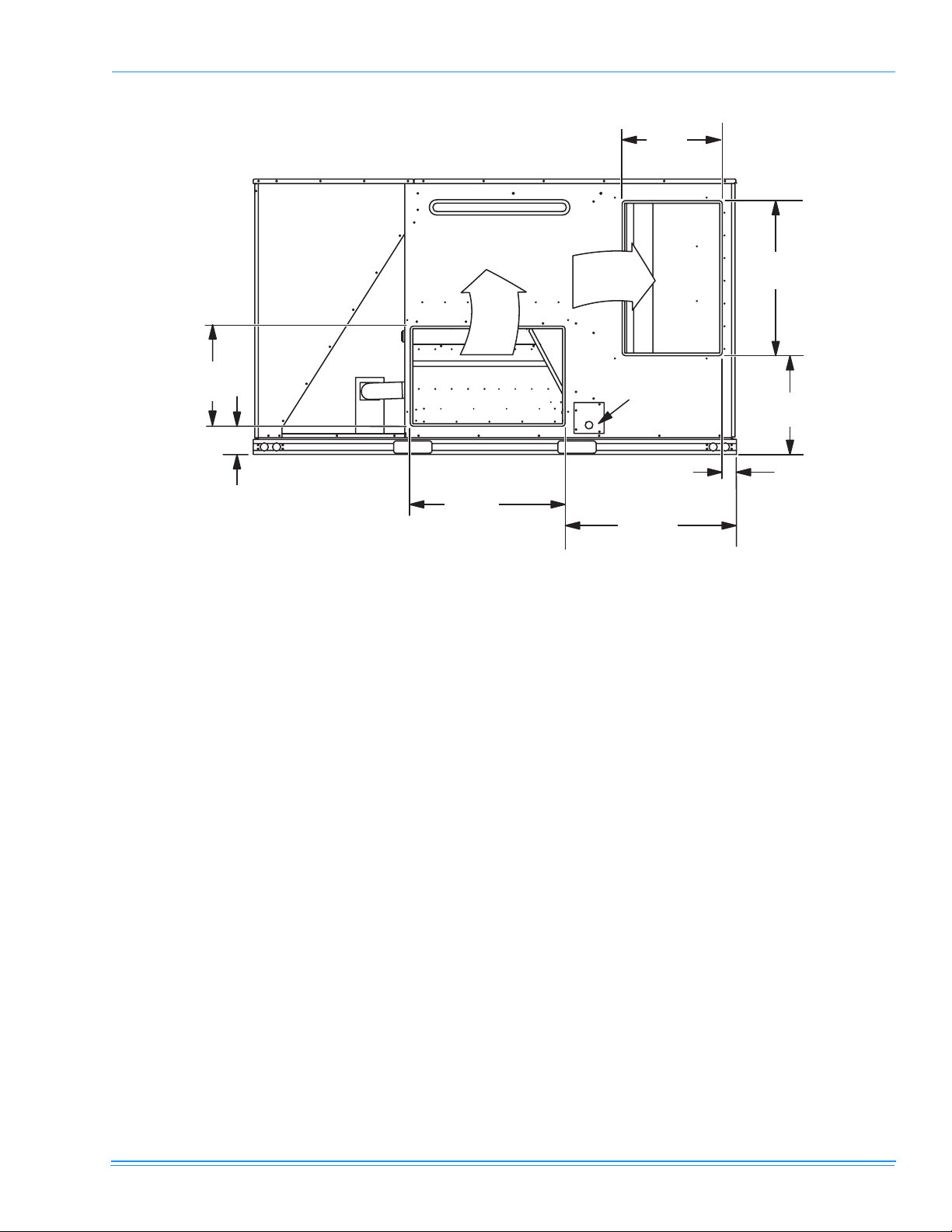

1 8 - 1 / 4

( 4 6 5 )

S u p p l y

1 8 - 1 / 4

( 4 6 5 )

5 - 5 / 3 2

( 1 3 0 )

2 8 - 1 / 4

( 7 2 0 )

N O T E : ( X X X ) i n d i c a t e s m i l l i m e t e r s

FIGURE 10 - REAR DUCT DIMENSIONS

DUCTWORK

Ductwork should be designed and sized according to the

methods in Manual D of the Air Conditioning Contractors of

America (ACCA) or as recommended by any other recognized authority such as ASHRAE or SMACNA.

A closed return duct system should be used. This will not

preclude use of economizers or outdoor fresh air intake. The

supply and return air duct connections at the unit should be

made with flexible joints to minimize noise.

The supply and return air duct systems should be designed

for the CFM and static pressure requirements of the job. They

should NOT be sized to match the dimensions of the duct

connections on the unit.

Refer to Figure 9 for bottom air duct openings. Refer to Figure 10 for rear air duct openings.

R e t u r n

A i r

2 8 - 1 / 4

( 7 2 0 )

A i r

P a t c h P l a t e

F o r S l i d e - O u t

D r a i n P a n

1 8 - 1 / 1 6

( 4 6 0 )

2 - 3 1 / 3 2

( 7 5 )

3 1 - 1 1 / 1 6

( 8 0 5 )

DUCT COVERS

Units are shipped with the side duct openings covered and a

covering over the bottom of the unit. For bottom duct application, no duct cover changes are necessary. For side duct

application, remove the side duct covers and install over the

bottom duct openings. The panels removed from the side

duct connections are designed to be reused by securing each

panel to its respective downflow opening. But keep in mind

that the supply panel is installed with the painted surface UP,

facing the heat exchanger, while the return panel is installed

with the painted surface DOWN, facing the downflow duct

opening. The supply panel is secured with the bracket

(already in place from the factory) and two screws. It’s a snug

fit for the panel when sliding it between the heat exchanger

and unit bottom, but there is room. The return panel is

secured with four screws.

Unitary Products Group 13

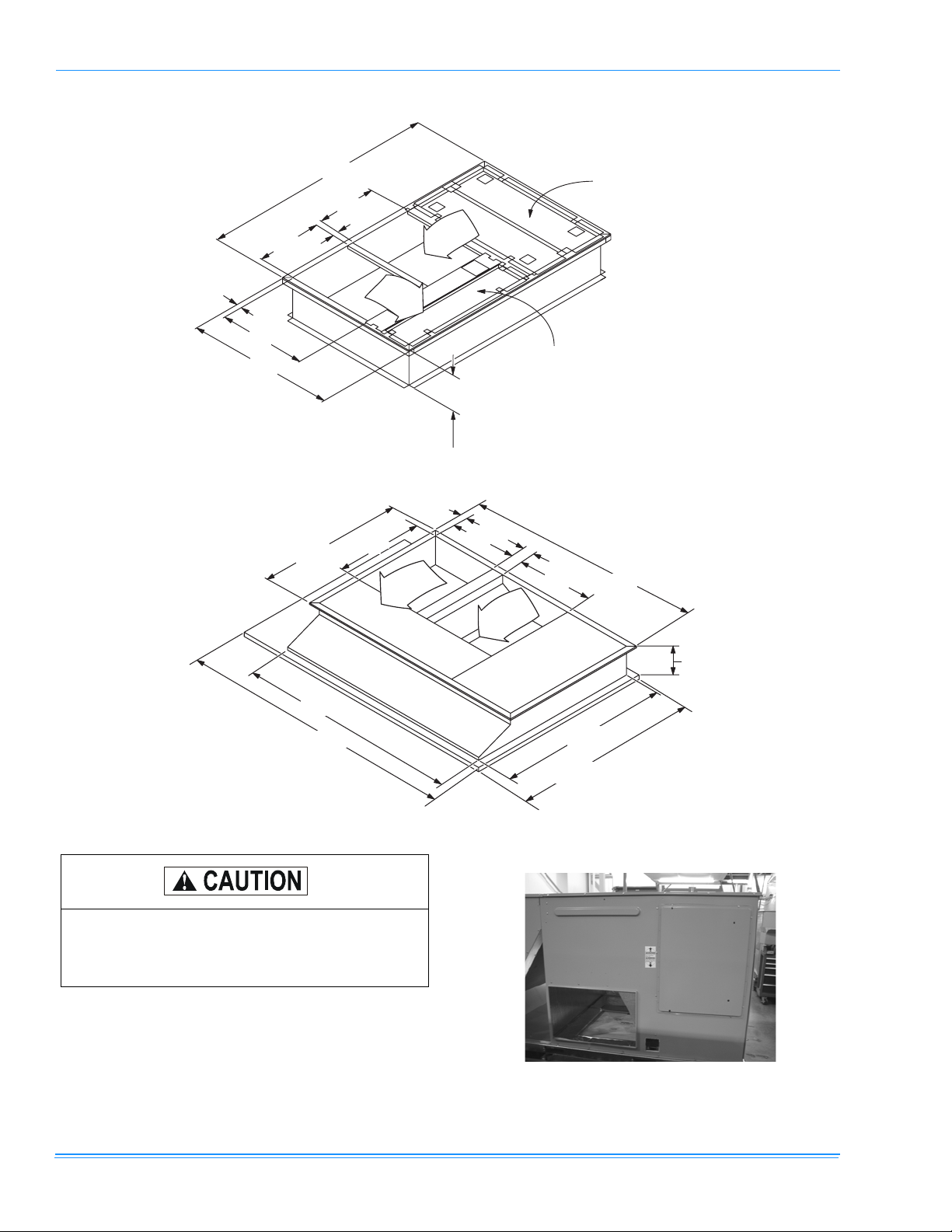

2 0

)

( 5 1 0 )

( 1 5 0 )

66307-YIM-B-0606

R I G H T

8 0 - 5 / 8

( 2 0 5 0 )

2 0

( 5 1 0 )

6

S U P P L Y

I N S U L A T E D D E C K U N D E R

C O N D E N S E R S E C T I

O N

2 T Y P .

( 5 0 )

3 0

( 7 6 0 )

5 0 - 1 / 2

( 1 2 8 5 )

N O T E :

R E T U R N

( X X X ) I N D I C A T E S

D I M E N S I O N S I N

M I L L I M E T E R S

FIGURE 11 - PREDATOR® ROOF CURB DIMENSIONS

2 T Y P

( 5 0 )

3 0 - 1 / 2

F R O N T

5 0 - 1 / 2

( 1 2 8 5 )

7 6 - 5 / 8

( 1 9 4 5 )

9 4

( 2 3 9 0 )

( 7 7 5 )

R E T U R N

( 2 0 5 )

I N S U L A T E D D E C K U N D E R

C O M P R E S S O R S E C T I O N

1 4

8

O R

( 3 5 5 )

2 3

( 5 8 5 )

S U P P L Y

F R O N T

( 1 0 0 )

2 6

( 6 6 0 )

4

6 4 - 1 / 4

( 1 6 3 0 )

5 9 - 1 / 4

( 1 5 0 5 )

8 0 - 5 / 8

( 2 0 5 0 )

R I G H T

( 2 5 5

1 0

FIGURE 12 - SUNLINE™ TO PREDATOR® TRANSITION ROOF CURBS

When fastening ductwork to side duct flanges on

unit, insert screws through duct flanges only. DO

NOT insert screws through casing. Outdoor ductwork must be insulated and water-proofed.

FIGURE 13 - SIDE PANELS WITH HOLE PLUGS

14 Unitary Products Group

Note orientation. Panel is “insulation” side up.

Loading...

Loading...