Page 1

TECHNICAL GUIDE

292454-YTG-B-0507

®

DESCRIPTION

YORK Sunline 2000™ units are convertible single package

air conditioners with a common cabinet and a common roof

curb for the 3, 4, 5 and 6 ton sizes. The units were designed

for light commercial and commercial applications. They can

easily be installed on a roof curb, slab, roof jack or frame.

SINGLE PACKAGE GAS/ELECTRIC UNITS

AND SINGLE PACKAGE

AIR CONDITIONERS

DM 036, 048, 060 & 072

3, 4, 5 & 6 NOMINAL TONS

10.0 SEER (3, 4, & 5 Ton), 9.0 EER (6 Ton)

All units include:

• Powder Paint finish that meets ASTM-B-117 1000 hour

salt spray standards

• Permanently lubricated motors

• Bottom or side air discharge configuration capability

(field convertible)

• Manufactured under the quality standards of ISO9001

®

• Simplicity

• Copper tube/aluminum fin coils

• Easy access to all components

• Rigging holes in base rails for lifting

• Fork lift slots on three sides

• Single point power connection

• Complete factory package - tested, charged and wired

• CSA agency listing on all units

WARRANTY

• Factory Limited Parts Warranty

• One-year parts warranty

Control Board

• A Five-year parts warranty on the compressor and

electric heat elements.

• Ten-year parts warranty on the gas-fired heat

exchangers.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

TABLE OF CONTENTS

292454-YTG-B-0507

DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . . 3

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FACTORY-INSTALLED OPTIONS . . . . . . . . . . . . . . 5

FIELD-INSTALLED ACCESSORIES. . . . . . . . . . . . . 7

GUIDE SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . 35

LIST OF FIGURES

Fig. # Pg. #

1 UNIT CUTAWAY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 TYPICAL FIELD POWER & CONTROL WIRING. . . . . 28

3 UNIT DIMENSIONS (3 - 6 TON COOLING

ONLY/ELECTRIC HEAT) FRONT VIEW . . . . . . . . . . .29

4 UNIT DIMENSIONS (3 - 6 TON COOLING/GAS HEAT)

FRONT VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5 UNIT WITH ECONOMIZER RAINHOOD . . . . . . . . . . .30

6 UNIT WITH FIXED OUTDOOR AIR/MOTORIZED

DAMPER RAINHOOD. . . . . . . . . . . . . . . . . . . . . . . . . .30

7 UNIT DIMENSIONS (REAR VIEW). . . . . . . . . . . . . . . .31

8 DISCONNECT/BLOWER ACCESS LOCATION. . . . . . 31

9 TYPICAL APPLICATIONS . . . . . . . . . . . . . . . . . . . . . .32

10 FOUR AND SIX POINT LOADING . . . . . . . . . . . . . . . .33

11 ROOF CURB DIMENSIONS. . . . . . . . . . . . . . . . . . . . .34

LIST OF TABLES

Tbl. # Pg. #

1 SOUND POWER RATING . . . . . . . . . . . . . . . . . . . . . . .8

2 CAPACITY RATINGS - (ARI 210/240) . . . . . . . . . . . . . . 8

3 GAS HEAT RATINGS. . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 2 STAGE GAS HEAT RATINGS. . . . . . . . . . . . . . . . . . .8

5 DM036 COOLING CAPACITIES (3 TON). . . . . . . . . . . .9

6 DM048 COOLING CAPACITIES (4 TON). . . . . . . . . . .10

Tbl. #

7 DM060 COOLING CAPACITIES (5 TON) . . . . . . . . . . 11

8 DM072 COOLING CAPACITIES (6 TON) . . . . . . . . . . 12

9 SUPPLY AIR BLOWER PERFORMANCE (3 TON

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . . 13

10 SUPPLY AIR BLOWER PERFORMANCE (4 TON

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . . 14

11 SUPPLY AIR BLOWER PERFORMANCE (5 TON

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . . 15

12 SUPPLY AIR BLOWER PERFORMANCE (6 TON

BELT DRIVE) - SIDE DUCT APPLICATION . . . . . . . . 16

13 SUPPLY AIR BLOWER PERFORMANCE (3 - 6 TON

DIRECT DRIVE) - SIDE DUCT APPLICATION. . . . . . 17

14 BELT DRIVE BLOWER MOTOR AND DRIVE DATA. . 17

15 STATIC RESISTANCES. . . . . . . . . . . . . . . . . . . . . . . . 18

16 ELECTRIC HEATER CFM LIMITATIONS . . . . . . . . . . 18

17 ELECTRICAL DATA - DM036-072 DIRECT DRIVE

W/O POWERED CONV. OUTLET . . . . . . . . . . . . . . . . 19

18 ELECTRICAL DATA - DM036-072 BELT DRIVE

W/O POWERED CONV. OUTLET . . . . . . . . . . . . . . . . 21

19 ELECTRICAL DATA -DM036-072 DIRECT DRIVE

W/POWERED CONV. OUTLET . . . . . . . . . . . . . . . . . . 23

20 ELECTRICAL DATA - DM036-072 BELT DRIVE

W/POWERED CONV. OUTLET . . . . . . . . . . . . . . . . . . 25

21 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

22 ELECTRIC HEAT CORRECTION FACTORS . . . . . . . 27

23 VOLTAGE LIMITATIONS. . . . . . . . . . . . . . . . . . . . . . . 27

24 UTILITIES ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

25 MINIMUM CLEARANCES . . . . . . . . . . . . . . . . . . . . . . 31

26 DM 4 AND 6 POINT LOADS WEIGHT

DISTRIBUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

27 CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . . . . . . 33

28 OPERATING WEIGHTS (LBS.) . . . . . . . . . . . . . . . . . . 34

Pg. #

2 Unitary Products Group

Page 3

292454-YTG-B-0507

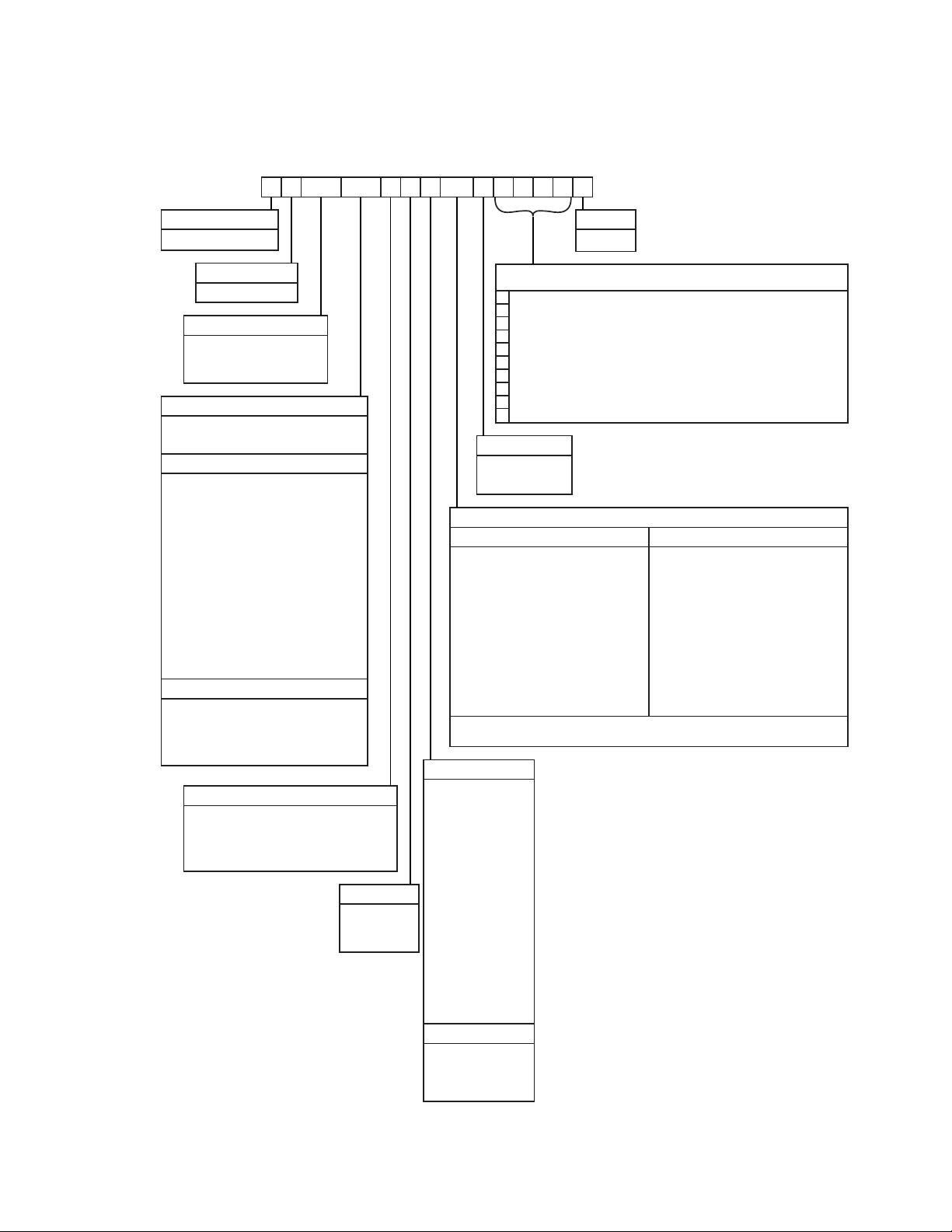

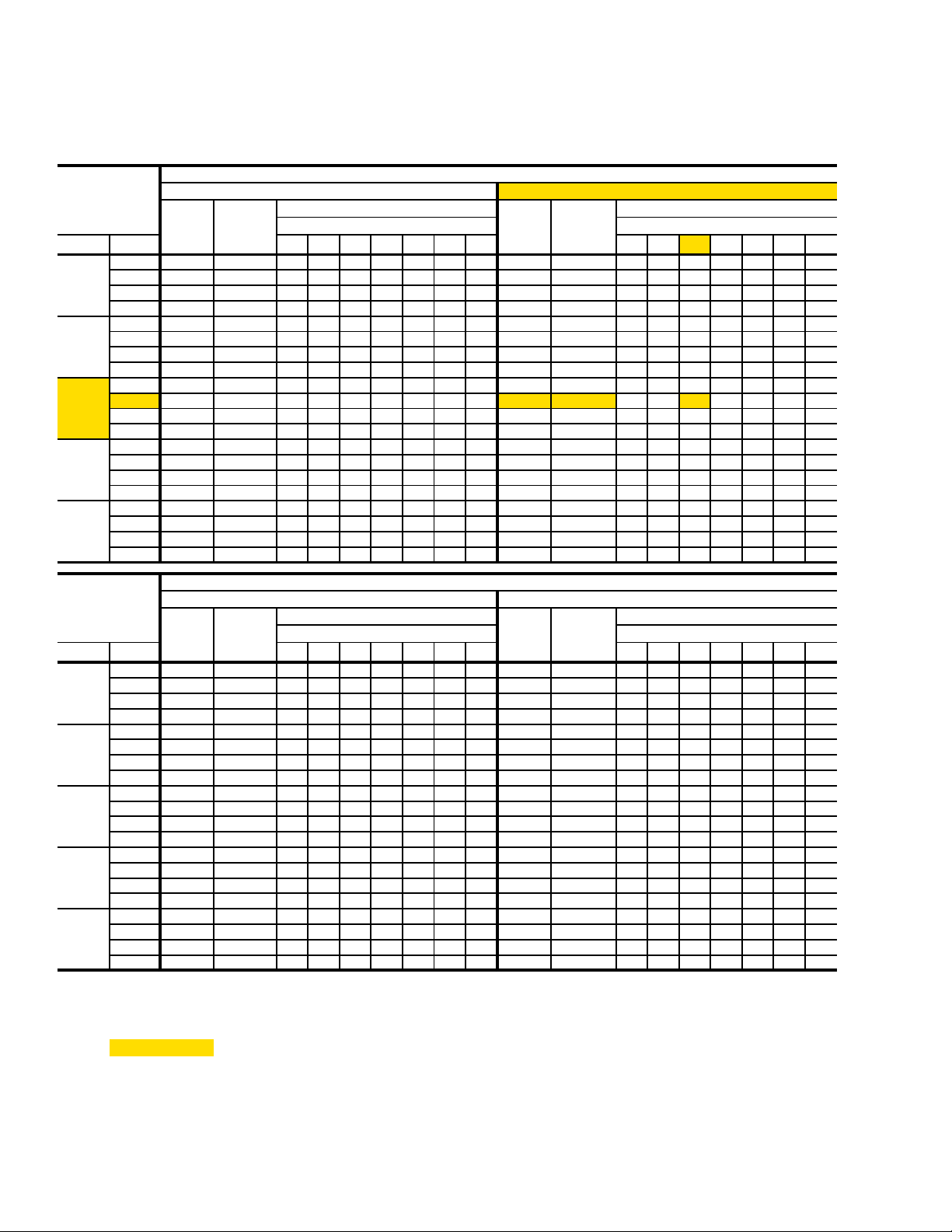

PRODUCT NOMENCLATURE

3-6 Ton Sunline Model Number Nomenclature

D M 048 N04 A 2 A AA 1 0 1 2 4 A

Product Category

D = A/C, Single Pkg., R-22

Product Identifier

M = 10.0 SEER A/C

Nominal Cooling Capacity

036 = 3.0 Ton

048 = 4.0 Ton

060 = 5.0 Ton

072 = 6.0 Ton

Heat Type and Nominal Heat Capacity

C00 = Cooling Only. Suitable for Field

Installed Electric Heat

Gas Heat Options

N04 = 40 MBH Output Aluminized Steel, 1 Stage (036)

N06 = 60 MBH Output Aluminized Steel, 1 Stage (048)

N08 = 80 MBH Output Aluminized Steel, 1 Stage

(036, 060, 072)

N10 = 100 MBH Output Aluminized Steel, 1 Stage

(048, 060, 072)

D06 = 60 MBH Output Aluminized Steel, 2 Stage

(036, 048, 060, 072)

D10 = 100 MBH Output Aluminized Steel, 2 Stage

(036*, 048, 060, 072)

S04 = 40 MBH Output Stainless Steel, 1 Stage (036)

S06 = 60 MBH Output Stainless Steel, 1 Stage (048)

S08 = 80 MBH Output Stainless Steel, 1 Stage

(036, 060, 072)

S10 = 100 MBH Output Stainless Steel, 1 Stage

(048, 060, 072)

T06 = 60 MBH Output Stainless Steel, 2 Stage

(036, 048, 060, 072)

T10 = 100 MBH Output Stainless Steel, 2 Stage

(036*, 048, 060, 072)

Electric Heat Options

E05 = 5 KW

E07 = 7 KW

E10 = 10 KW

E15 = 15 KW

E20 = 20 KW

E30 = 30 KW

*(D, T) 10 = 92 MBH Output on 036 Models

Airflow

A = Direct Drive

B = Direct Drive/Single Input Economizer

D = Direct Drive/Motorized Damper

N = Belt Drive

P = Belt Drive/Single Input Economizer

R = Belt Drive/Motorized Damper

Voltage

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

7 = 380/415-3-50

Product Style

A = Style A

These four digits will not be assigned until a quote is requested, or an order placed.

SS Drain Pan

CPC Controller, DFS, APS

Johnson Controller, DFS, APS

Honeywell Controller, DFS, APS

Novar Controller, DFS, APS

Simplicity IntelliComfort Controller

Simplicity IntelliComfort Controller w/ModLinc

2" Pleated filters

BAS Ready Economizer (2-10 V. D. C. Actuator without a Controller)

Any Combination of Additional Options that Don’t Have an Option Code Pre-assigned

Product Generation

1 = First Generation

2 = Second Generation

3 = Third Generation

Standard Cabinet

AA = None

AB = Phase Monitor

AC = Coil Guard

AD = Dirty Filter Switch

AE = Phase Monitor & Coil Guard

AF = Phase Monitor & Dirty Filter Switch

AG = Coil Guard & Dirty Filter Switch

AH = Phase Monitor, Coil Guard & Dirty Filter Switch

AS = Bottom Drain Connection

RC = Coil Guard & American Flag

TA = Technicoat Condenser Coil

TJ = Technicoat Evaporator Coil

TS = Technicoat Evaporator and Condenser Coil

ZZ = If desired option combination is not listed above, ZZ will be assigned and configuration options will be

located in digits 15-18.

Installation Options

A = No Options Installed

B=Option1

C=Option2

D = Options 1 & 2

E = Option 3

F = Option 4

G = Options 1 & 3

H = Options 1 & 4

J = Options 1, 2 & 3

K = Options 1, 2, & 4

L = Options 1,3 & 4

M = Options 1, 2, 3, & 4

N = Options 2 & 3

P = Options 2 & 4

Q = Options 2, 3, & 4

R = Options 3 & 4

S = Option 5

T = Options 1 & 5

U = Options 1, 3, & 5

V = Options 1, 4, & 5

W = Options 1, 3, 4, & 5

X = Options 3 & 5

Y = Options 4 & 5

Z = Options 3, 4 & 5

Options

1 = Disconnect

2 = Non-Pwr'd Conv. Outlet

3 = Smoke Detector S.A.

4 = Smoke Detector R.A.

5=Pwr'dConv.Outlet

Configuration Options (not required for all units)

Additional Options

Hinged Filter Door & Toolless Access Cabinet

BA = Hinged Filter Door & Toolless Access Panels

BA = Hinged Filter Door & Toolless Access Panels

BA = Hinged Filter Door & Toolless Access Panels

BB = Phase Monitor, Hinged Filter Door & Toolless

Access Panels

BC = Coil Guard, Hinged Filter Door & Toolless

Access Panels

BD = Dirty Filter Switch, Hinged Filter Door &

Toolless Access Panels

BE = Phase Monitor & Coil Guard, Hinged Filter

Door & Toolless Access Panels

BF = Phase Monitor & Dirty Filter Switch, Hinged

Filter Door & Toolless Access Panels

BG = Coil Guard & Dirty Filter Switch, Hinged Filter

Door & Toolless Access Panels

BH = Phase Monitor, Coil Guard & Dirty Filter Switch,

Hinged Filter Door & Toolless Access Panels

Unitary Products Group 3

Page 4

292454-YTG-B-0507

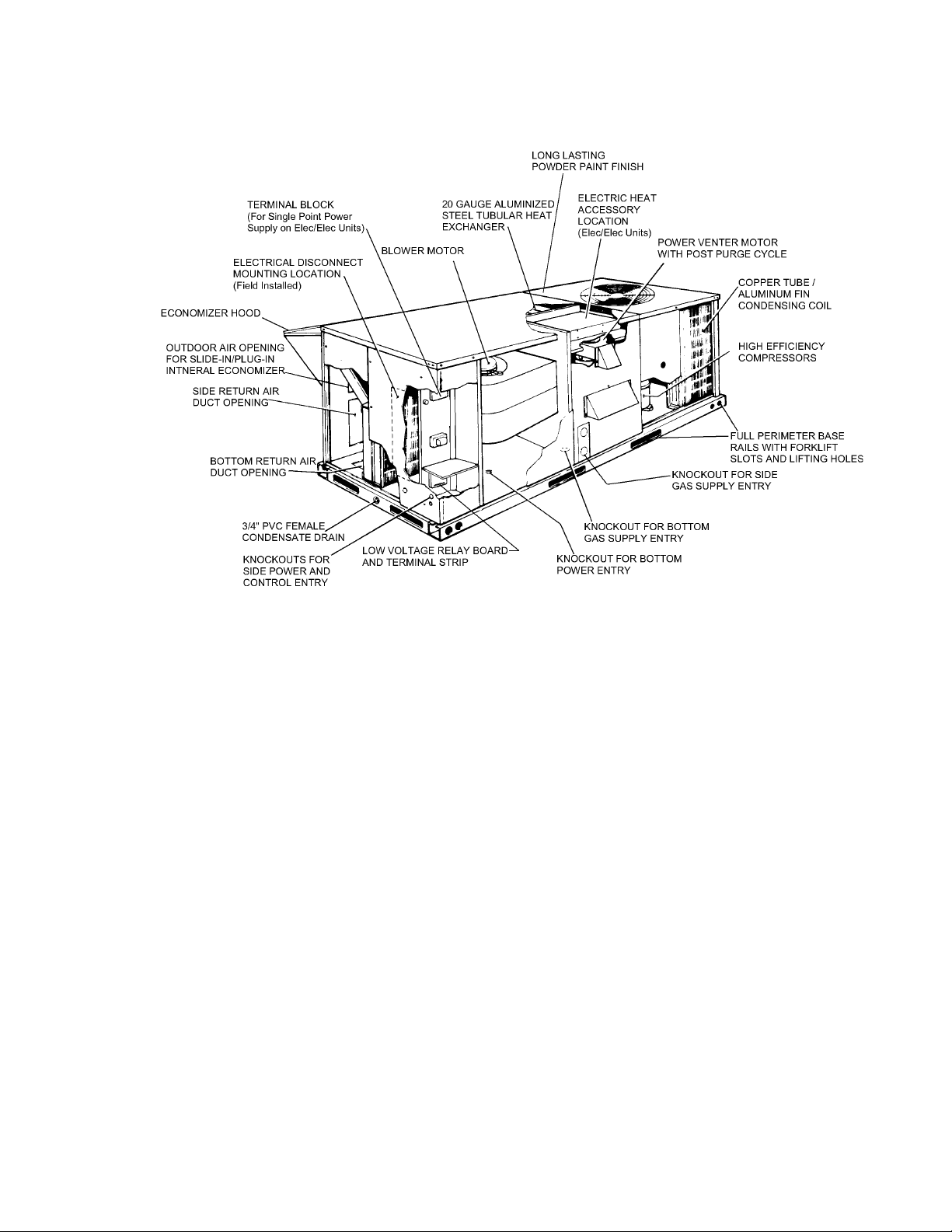

FEATURES

All models are available with a wide variety of factorymounted options such as stainless steel heat exchangers,

electric heaters, phase monitor, convenience outlet, dirty filter

switch, disconnect switch, smoke detectors, and coil guard

to make them suitable for almost every application.

All units are self-contained and assembled on full perimeter

base rails with forklift holes on three sides and holes for overhead rigging. Every unit is completely piped, wired, charged

and tested at the factory to simplify the field installation and to

provide years of dependable operation.

All models (including those with an economizer) are suitable for

either bottom or horizontal duct connections. For bottom duct,

remove the sheet metal panels from the supply and return air

openings through the base of the unit. For horizontal duct,

remove the supply and return air panels on the rear of the unit.

All models are available with these “factory mounted” outdoor

air damper options:

• Single enthalpy economizer

• Motorized outdoor air damper

Supply air blowers are equipped with either a direct drive or a

belt drive that can be adjusted to meet the exact requirements of the job.

All compressors are equipped with internal pressure relief.

Every refrigerant circuit includes a liquid line filter-drier, a high

pressure switch and a suction line with a freezestat and low

pressure/loss of charge switch to protect all system components.

®

• Simplicity

standardized a number of features previously available

only as options or by utilizing additional controls.

• Low Ambient - An integrated low-ambient control

• Anti-Short Cycle Protection - To aid compressor

• Fan Delays - Fan on and fan off delays are fully pro-

• Safety Monitoring - The control board monitors the

Controls - Simplicity® control boards have

allows all units to operate in the cooling mode down

to 0ºF outdoor ambient without additional assistance. Optionally , the control board can be programmed to lockout the compressors when the

outdoor air temperature is low or when free cooling

is available.

life, an anti-short cycle delay is incorporated into the

standard controls. Compressor reliability is further

ensured by programmable minimum run times. For

testing, the anti short cycle delay can be temporarily

overridden with the push of a button.

grammable and are independent of one another. All

units are programmed with default values based

upon their configuration of cooling and heat.

high and low-pressure switches, the freezestats, the

gas valve, if applicable, and the temperature limit

switch on gas heat units. The unit control board will

alarm on ignition failures, compressor lockouts and

repeated limit switch trips.

• Nuisance Trip Protection- To prevent nuisance

trouble calls, the control board uses a “three strikes,

you’re out” philosophy. The high and low-pressure

switches and the freezestats must trip three times

within two hours before the unit control board will

lock out the compressor.

• On Board Diagnostics - Each alarm will energize a

trouble light on the thermostat, if so equipped, and

flash an alarm code on the control board LED. Each

high and low-pressure switch alarm as well as each

freezestat alarm has its own flash code. The control

board saves the five most recent alarms in memory,

and these alarms can be reviewed at any time.

Alarms and programmed values are retained

through the loss of power.

All units have long lasting powder paint cabinets with 1000

hour salt spray test approval under ASTM-B117 procedures.

All models are CSA listed.

• Warranty - All models include a one-year limited parts

warranty on the complete unit. Compressors and electric

heater elements carry a five-year warranty. Gas heat

exchangers carry a 10-year parts warranty.

• Gas Heat Operation - All single phase models with gas

heat have minimum annual fuel utilizati on efficiency

(AFUE) of 80%. All three phase models with gas heat

have minimum steady state efficiency of 80%. Each section includes a durable heat exchanger with aluminized

steel or optional stainless steel tubes, a redundant gas

valve, spark ignition, power venting, an ignition module for

100% shut-off and all of the safety controls required to

meet the latest ANSI standards.

The gas supply piping can be routed into the heating

compartment through a hole in the base pan of the unit

or through a knockout in the piping panel on the front of

the unit.

• Electric Heat Operation - All electric heat models are

wired for a single power source and include a bank of

nickel chromium elements mounted at the discharge of

the supply air blower to provide a high velocity and uniform distribution of air across the heating elements.

Every element is fully protected against excessive temperature by thermal limit switches.

The power supply wiring can be routed into the control

box through a threaded pipe connection (field supplied)

in the base pan of the unit or through a knockout in the

wiring panel on the side of the unit.

• BAS Controls - Y ork’s Sunline™ series unit s offer factory

mounted BAS controls such as Simplicity

®

INTELLI-

Comfort™, Novar, Honeywell, Johnson, and CPC.

4 Unitary Products Group

Page 5

292454-YTG-B-0507

FIGURE 1 - UNIT CUTAWAY

FACTORY-INSTALLED OPTIONS

• SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS - Includes a slide-in / plug-in damper assembly

with fully modulating spring-return motor actuator capable of introducing up to 100% outdoor air with nominal

1% leakage type dampers.

The enthalpy system contains one sensor that monitors

the outdoor air and determines when the air is cool

enough and dry enough to provide free cooling.

The rainhood is painted to match the basic unit and must

be field-assembled before installing.

• MOTORIZED OUTDOOR AIR INTAKE DAMPER -

Includes a slide-in / plug-in damper assembly with a 2position, spring return motor actuator which opens to a

pre-set position whenever the supply air blower is operating and will drive fully closed when the blower unit

shuts down.

The rain hood is painted to match the basic unit and

must be field assembled before installing.

• PHENOLIC COATED EVAPORATOR AND CON-

DENSER COILS - Special coating process that utilizes

TM

Technicoat 10-1

processes. Coating is applied by total

immersion of the complete coil for maximum protection.

• ELECTRIC HEATERS - Wired for single point power

supply. These nickel chromium heater elements are provided with limit and automatic reset capability to prevent

operation at excessive temperatures.

• FILTER OPTIONS - Standard units are shipped with 1”

throw-away filters installed. 2” pleated filters are offered

as a factory installed option.

• CONVENIENCE OUTLET - This 110 volt outlet can be

“powered” by the unit with a stepdown transformer or the

unit may be ordered with a “non-powered” convenience

outlet that can be wired in the field.

• DISCONNECT SWITCH - For gas heat units and cooling

units with electric heat, a HACR breaker sized to the unit

is provided. For cooling only units, a switch sized to the

largest electric heat available for the particular unit is

provided. Factory installed option only.

• BAS - Building Automation System Controls

Simplicity

®

INTELLI-Comfort™ CONTROL - The York®

Simplicity® INTELLI-Comfort™ control is factory

installed. It includes a supply air sensor, a return air sensor, and an outside air sensor . There are provisions for a

field installed dirty filter indicator switch, an air-proving

Unitary Products Group 5

Page 6

292454-YTG-B-0507

switch, an Outside Air Humidity sensor, a Return Air

Humidity sensor, an Inside IAQ sensor, and an Outside

Air IAQ sensor. Construction mode operation, 365-day

real time clock with 7 day programming plus holiday

scheduling is built-in. Two different modes of demand

ventilation are achieved through the INTELLI-Comfort™using CO2 sensors. It uses an inside CO2 sensor

to perform Demand Ventilation. It can also use an Outside CO2 sensor to perform Differential Demand Ventilation. It uses a Patented Comfort Ventilation algorithm to

provide comfortable ventilation air temperature. The patented economizer-loading algorithm will protect the

equipment when harsh operating conditions exist.

Humidity in the occupied space or return duct can be

monitored and controlled via humidity sensors and the

on-board connection for hot gas re-heat system. It uses

the INTELLI-Start™ algorithm to maximize energy savings by recovering the building from the Unoccupied Setpoints to the Occupied Setpoints just in time for the

Occupied Time Period to begin. The Simplicity

®

INTELLI-Comfort™ balances space temperature, ventilation air temperature, CO2 and humidity for ultimate

comfort.

®

• Simplicity

TROL - The York® Simplicity

INTELLI-Comfort™ with MOD LINK CON-

®

INTELLI-Comfort™ with

Mod Link control is factory installed. It includes all the

features of the INTELLI-Comfort™ control with an additional control to translate communications from MODBUS to the BACnet MSTP protocol.

• Novar® BAS CONTROL - The Novar® ETC-3 building

automation system controller is factory installed.

Includes supply air sensor, return air sensor, dirty filter

indicator switch, and air proving switch.

• JOHNSON CONTROLS BAS CONTROL - The Johnson

Control YK-UNT-1126 building automation system controller is factory installed. Includes supply air sensor,

return air sensor, dirty filter indicator switch, and air proving switch.

• CPC BAS CONTROL - The Computer Process Controls

Model 810-3060 ARTC Advanced Rooftop building automation system controller is factory installed. Includes

supply air sensor, return air sensor, dirty filter indicator

switch and air proving switch.

• HONEYWELL BAS CONTROL - The Honeywell

W7750C building automation system controller is factory

installed. Includes air supply sensor, return air sensor,

dirty filter indicator switch, and air proving switch.

• SMOKE DETECTORS - (supply air & return air) The

smoke detectors stop operation of the unit by interrupting

power to the control board if smoke is detected within the

air compartment.

Factory installed Smoke D etector s in the return ai r,

may be subjected to freezing temperatures during

“off” times due to outside air infiltration. These

smoke detectors have an operational limit of 32°F

to 131°F. Smoke detectors installed in areas that

could be outside those limitations will have to be

moved to prevent having false alarms.

• COIL GUARD - Customers can purchase a coil guard kit

to protect the condenser coil from damage. This is not a

hail guard kit.

• STAINLESS STEEL HEAT EXCHANGER - For applica-

tions in corrosive environments, this option provides a

full stainless steel heat exchanger assembly.

• STAINLESS STEEL DRAIN PAN - An optional rust-

proof stainless steel drain pan is available to provide

years of trouble-free operation in corrosive environments.

• BOTTOM DRAIN CONNECTION - An optional bottom

drain connection is available for inside the curb connections for applications in cold environments to reduce

freezing drain lines.

• PHASE MONITORS - Designed to prevent unit damage.

The phase monitor will shut the unit down in an out-ofphase condition.

• DIRTY FILTER SWITCH - This kit includes a differential

pressure switch that energizes the fault light on the unit

thermostat, indicating that there is an abnormally high

pressure drop across the filters. Factory installed option

or field installed accessory.

• HINGED FILTER DOOR/“TOOLLESS” BLOWER AND

ACCESS PANELS (not hinged) - This option allows for

easy access and maintenance.

NOTE:Knobs are shipped inside the unit to prevent ship-

ping damage. These must be field installed for

tool-less operation.

6 Unitary Products Group

Page 7

292454-YTG-B-0507

FIELD-INSTALLED ACCESSORIES

• SINGLE INPUT ELECTRONIC ENTHALPY ECONOMIZERS - Includes a slide-in / plug-in damper assembly

with fully modulating spring-return motor actuator capable of introducing up to 100% outdoor air with nominal

1% leakage type dampers.

The enthalpy system contains one sensor that monitors

the outdoor air and determines when the air is cool

enough and dry enough to provide free cooling.

The rainhood is painted to match the basic unit and must

be field-assembled before installing.

• MOTORIZED OUTDOOR AIR INTAKE DAMPER -

Includes a slide-in / plug-in damper assembly with a 2position, spring return motor actuator which opens to

some pre-set position whenever the supply air blower is

operating and will drive fully closed when the blower unit

shuts down.

The rain hood is painted to match the basic unit and

must be field assembled before installing.

• ELECTRIC HEA T ERS wired for single point power supply. These nickel chromium heater elements are provided with limit and automatic reset capability to prevent

operation at excessive temperatures.

• ROOF CURBS - Eight and fourteen-inch high roof curbs

provide a water-tight seal between the unit and the finished

roof. These full perimeter curbs meet the requirements of

the National Roofing Contractors Association (NRCA) and

are shipped knocked-down for field assembly.

Roof curbs are designed to fit inside the base rails of the

unit and include both a wood nailing strip and duct

hanger supports.

• HIGH ALTITUDE NATURAL GAS - Burner orifices and

pilot orifices are provided for proper furnace operation at

altitudes up to 6,000 feet.

• PROPANE - Burner orifices, pilot orifices and gas valve

parts are provided to convert a natural gas furnace to

propane.

• HIGH ALTITUDE PROPANE - Burner orifices and pilot

orifices are provided for proper furnace operation at altitudes up to 6,000 feet. This accessory supplements the

basic propane conversion kit.

• LOW NOX KIT- Required to reduce the emission of

nitrogen oxides below 40 nanograms per joule.

• POWER EXHAUST - Our single input economizer

options are available with power exhaust. Whenever the

outdoor air intake dampers are opened for free cooling,

the exhaust fan will be energized to prevent the conditioned space from being over-pressurized during economizer operation.

The power exhaust option can only be used on bottom duct configurations.

• BAROMETRIC RELIEF DAMPER - This damper accessory can be used to relieve internal building air pressure

on units with an economizer without power exhaust. This

accessory includes a rain hood, a bird screen and a fully

assembled damper. With bottom duct connections, the

damper should be mounted over the opening in the

return air panel. With horizontal ductwork, the accessory

should be mounted on the return air duct.

• ENTHALPY ACCESSORY CONTROL KIT - This kit

contains the required components to convert a single

enthalpy economizer to dual enthalpy.

• BURGLAR BARS - Mount in the supply and return

openings to prevent entry into the duct work.

• FLUE EXHAUST EXTENSION KIT - In locations with

wind or weather conditions which may interfere with

proper exhausting of furnace combustion products, this

kit can be installed to prevent the flue exhaust from

entering nearby fresh air intakes.

• CO

• COIL GUARD - Customers can purchase a coil guard kit

• HAIL GUARD -Hail Guard Kit is available to protect coils

• GAS PIPING KIT - This kit supplies all necessary fittings

SENSOR - Senses CO2 levels and automatically

2

overrides the economizer when levels rise above the

present limits.

to protect the condenser coil from damage. This is not a

hail guard kit.

from damage. This is a sloped hood that fits above the

outdoor coil.

and shut off valve.

Unitary Products Group 7

Page 8

292454-YTG-B-0507

TABLE 1: SOUND POWER RATING

UNIT

SIZE

CFM

ESP BLOWER

IWG SPEED KW 63 125 250 500 1,000 2,000 4,000 8,000

1

SOUND POWER (db 10

Octave Band Centerline Frequency (Hz)

-12

Watts)

SWL

dB(A)

dB(A)

@

10Ft.

036 1,200 0.6 LOW 0.60 84 84 74 67 69 62 57 52 74 41

048 1,600 0.55 HIGH 0.80 85 85 75 68 70 63 58 53 75 42

060 2,000 0.45 HIGH 1.00 86 86 76 69 71 64 59 54 76 43

072 2,2000.3HIGH1.3587877770726560557744

1. These values have been accessed using a model of sound propagation from a point source into the hemispheric\free field. The

dBA values provided are to be used for reference only. Calculation of dBA values cover matters of system design and the fan

manufacture has no way of knowing the details of each system. This constitutes and expectation to any specification or guarantee requiring a dBA value or sound data in any other form than sound power level ratings.

2. At a distance of 10 feet from the blower.

TABLE 2: CAPACITY RATINGS - (ARI 210/240)

MODEL MBH

DM036

DM048

DM060

DM072

36.0 9.1 10.0

47.4 9.0 10.0

59.0 9.1 10.0

72.0 9.0 -

1. 80/67°F Indoor and 95°F outdoor.

2. EER = Energy Efficiency Ratio at full load - the cooling

capacity in Btu’s per hour (Btuh) divided by the power

input in watts, expressed in Btuh per watt (Btuh/watt).

3. SEER = Seasonal Energy Efficiency Ratio.

EER

2

1

3

SEER

TABLE 3: GAS HEAT RATINGS

MODEL

DM036N04

DM036N08

DM048N06

DM048N10

DM060N08

DM060N10

DM072N08

DM072N10

MBH

INPUT

50

100

75

125

100

125

100

125

1

MBH

OUTPUT

40

80

60

100

80

100

80

100

AFUE

(%)

80.9

80.5

80.9

80.3

80.5

80.3

80.5

80.3

TEMP

RISE ºF

15 - 45

40 - 70

25 - 55

45 - 75

25 - 55

35 - 65

25 - 55

35 - 65

1. All units are single-stage heating.

2

TABLE 4: 2 STAGE GAS HEAT RATINGS

1

MODEL

DM036D06

DM036D10

DM048D06

DM048D10

DM060D06

DM060D10

DM072D06

DM072D10

1. Models are 3 Ø only.

MBH INPUT MBH OUTPUT STEADY STATE EFFICIENCY RISE

ST

1

STAGE 2ND STAGE 1ST STAGE 2ND STAGE 1ST STAGE 2ND STAGE MIN. MAX.

45 75 35.8 60.8 79.4 81.1 35 70 790

69 115 55.2 92 80.0 80.2 55 90 950

45 75 35.7 60.8 79.4 81.1 25 70 790

75 125 60.4 100.6 80.5 80.5 45 75 1230

45 75 35.8 60.8 79.4 81.1 35 70 1010

75 125 60.4 100.6 80.5 80.5 45 75 1230

45 75 35.8 60.8 79.4 81.1 35 70 1230

75 125 60.4 100.6 80.5 80.5 45 75 1230

MINIMUM HEATING

AIRFLOW (CFM)

8 Unitary Products Group

Page 9

292454-YTG-B-0507

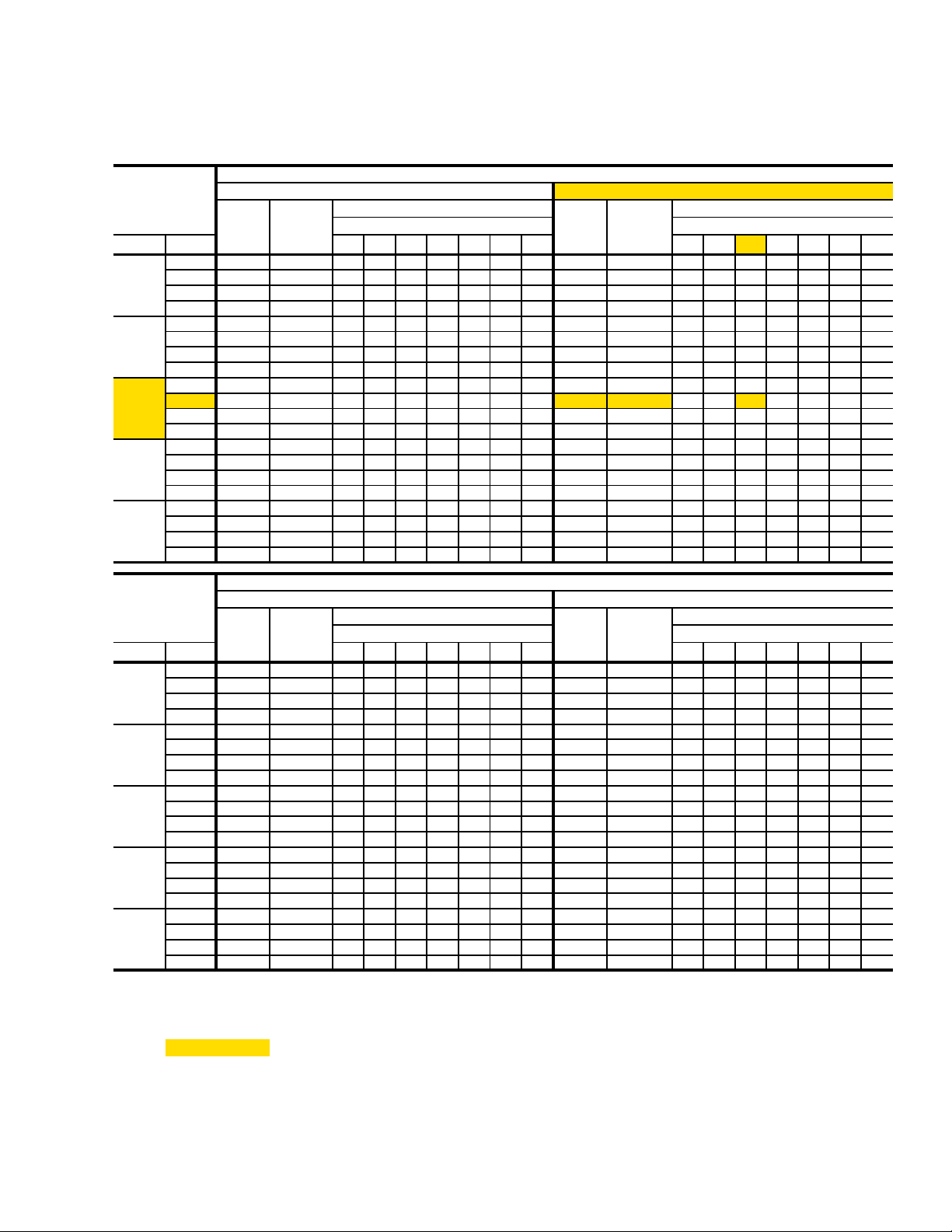

TABLE 5: DM036 COOLING CAPACITIES (3 TON)

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

85°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1

72 45 3.1 35 30 26 21 17 - - 43 3.3 35 30 26 21 17 - -

1750

67 43 3.0 43 38 34 29 25 20 16 41 3.3 41 38 34 29 25 21 16

62 39 3.0 39 39 39 34 30 25 21 36 3.3 36 36 36 32 27 23 18

57 40 2.9 40 40 40 35 31 26 22 38 3.2 38 38 38 33 29 24 20

72 44 3.1 31 28 24 20 16 - - 42 3.3 31 27 23 20 16 - -

1475

67 41 3.0 39 35 31 27 23 19 16 39 3.3 37 35 31 27 23 19 15

62 38 3.0 38 38 37 33 29 25 21 36 3.3 36 36 35 31 27 23 19

57 39 2.9 39 39 39 35 31 27 23 37 3.2 37 37 36 32 28 25 21

72 42 3.1 28 25 22 18 15 - - 41 3.3 28 24 21 18 14 - -

1200

67 40 3.0 35 32 28 25 22 18 15 38 3.2 34 31 28 25 21 18 15

62 36 3.0 36 36 35 31 28 25 21 35 3.3 35 35 34 30 27 24 20

57 37 2.9 37 37 37 34 31 27 24 36 3.2 36 36 35 32 28 25 22

72 41 3.1 26 23 20 17 14 - - 39 3.2 26 23 20 17 14 - -

1050

67 38 3.0 32 30 27 24 21 18 15 37 3.2 32 29 26 23 20 17 14

62 35 3.0 35 35 33 30 27 24 21 33 3.2 33 33 31 28 25 22 20

57 36 2.9 36 36 35 32 29 26 23 34 3.2 34 34 32 30 27 24 21

72 39 3.1 24 21 19 16 14 - - 38 3.2 23 21 18 16 13 - -

900

67 37 3.0 30 27 25 22 20 17 15 36 3.2 29 26 24 21 19 16 14

62 34 3.0 34 33 30 28 25 23 20 32 3.2 32 31 29 26 24 21 19

57 34 2.9 34 34 33 30 27 25 22 33 3.1 33 33 30 27 25 22 20

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

SENSIBLE CAPACITY

1

72 41 3.7 34 29 25 20 16 - - 39 4.1 33 28 24 19 15 - -

1750

67 38 3.7 38 37 33 28 24 19 15 36 4.0 36 36 32 27 23 18 14

62 34 3.7 34 34 34 30 25 21 16 32 4.0 32 32 32 27 23 18 14

57 35 3.6 35 35 35 31 26 22 17 33 4.0 33 33 33 28 24 19 15

72 40 3.7 30 26 23 19 15 - - 38 4.1 30 26 22 18 14 - -

1475

67 37 3.6 36 34 30 26 22 18 14 35 4.0 34 33 29 25 21 17 13

62 33 3.7 33 33 33 29 25 21 17 31 4.0 31 31 31 27 23 19 15

57 34 3.6 34 34 34 30 26 22 18 32 4.0 32 32 32 28 24 20 16

72 39 3.7 27 24 20 17 14 - - 37 4.1 26 23 20 16 13 - -

1200

67 36 3.6 34 30 27 24 20 17 14 34 4.0 33 30 26 23 20 16 13

62 32 3.6 32 32 32 29 25 22 19 30 4.0 30 30 30 27 24 20 17

57 33 3.6 33 33 33 29 26 23 19 31 3.9 31 31 31 27 24 21 17

72 37 3.6 25 22 19 16 13 - - 36 4.1 24 21 18 15 12 - -

1050

67 35 3.6 31 28 25 22 19 16 13 32 4.0 30 27 24 21 18 15 12

62 31 3.6 31 31 29 27 24 21 18 29 4.0 29 29 28 25 22 19 16

57 32 3.5 32 32 30 27 24 21 18 30 3.9 30 29 28 25 22 19 16

72 36 3.6 22 20 17 15 12 - - 34 4.0 21 19 16 14 11 - -

900

67 33 3.6 28 25 23 20 18 15 13 31 4.0 27 24 22 19 17 14 11

62 30 3.6 30 29 27 24 22 19 17 28 4.0 28 28 25 22 20 17 15

57 31 3.5 31 30 28 25 22 20 17 28 3.9 28 28 25 23 20 17 15

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

Unitary Products Group 9

Page 10

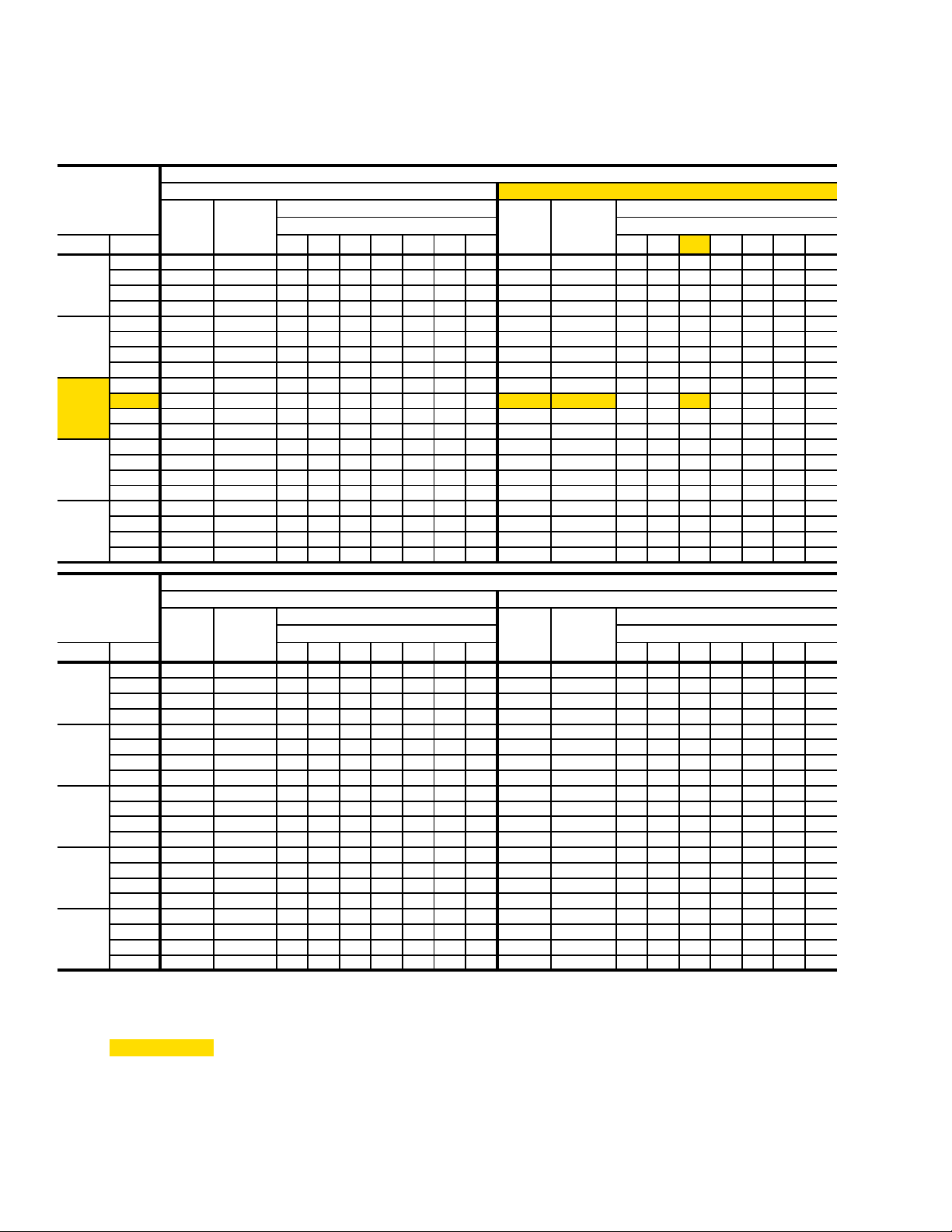

TABLE 6: DM048 COOLING CAPACITIES (4 TON)

292454-YTG-B-0507

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

85°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1

72 60 4.1 44 39 33 28 23 - - 60 4.5 44 39 33 28 23 - -

2000

67 55 4.1 53 48 42 37 32 26 21 52 4.5 52 47 42 36 31 25 20

62 51 4.0 51 51 51 45 40 34 29 48 4.4 48 48 48 42 37 32 26

57 49 3.9 49 49 49 44 39 33 28 47 4.3 47 47 47 42 36 31 26

72 58 4.1 41 36 31 26 21 - - 57 4.5 41 36 31 26 21 - -

1800

67 53 4.1 49 45 40 35 30 25 20 50 4.5 49 44 39 34 29 24 19

62 49 4.0 49 49 48 43 38 33 28 46 4.4 46 46 46 41 36 31 26

57 47 3.9 47 47 47 43 38 33 28 45 4.3 45 45 45 40 36 31 26

72 56 4.1 38 34 29 25 20 - - 55 4.6 38 33 29 24 20 - -

1600

67 51 4.1 46 41 37 32 28 24 19 48 4.5 45 40 36 31 27 23 18

62 47 4.0 47 47 45 41 36 32 27 44 4.4 44 44 44 40 35 31 26

57 46 3.9 46 46 46 41 37 32 28 44 4.4 44 44 44 39 35 30 26

72 54 4.1 35 31 27 23 19 - - 53 4.5 35 31 27 23 19 - -

1400

67 49 4.1 42 38 34 30 26 22 19 47 4.5 41 38 34 30 26 22 18

62 45 4.0 45 45 42 38 34 30 26 43 4.4 43 43 41 37 33 29 25

57 44 3.9 44 44 43 39 35 31 27 42 4.3 42 42 41 37 33 29 25

72 52 4.1 32 29 25 22 18 - - 51 4.5 32 28 25 21 18 - -

1200

67 47 4.1 39 35 32 28 25 21 18 45 4.4 38 35 31 28 24 21 17

62 43 4.0 43 43 39 36 32 29 25 41 4.3 41 41 38 35 31 28 24

57 42 3.9 42 42 39 36 32 29 25 41 4.3 41 41 38 34 31 27 24

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

SENSIBLE CAPACITY

1

72 56 5.1 42 37 31 26 21 - - 53 5.6 40 35 29 24 19 - -

2000

67 49 5.0 49 46 40 35 29 24 19 46 5.5 46 44 39 33 28 23 17

62 45 4.9 45 45 45 39 34 28 23 41 5.4 41 41 41 36 30 25 20

57 44 4.9 44 44 44 39 33 28 22 41 5.4 41 41 41 35 30 25 19

72 55 5.0 39 34 29 24 20 - - 52 5.5 38 33 28 23 18 - -

1800

67 48 5.0 47 43 38 33 28 23 18 45 5.4 45 42 37 32 27 22 17

62 43 4.9 43 43 43 38 33 28 23 40 5.4 40 40 40 35 30 26 21

57 43 4.9 43 43 43 38 33 28 23 40 5.4 40 40 40 35 30 25 20

72 53 5.0 36 32 28 23 19 - - 51 5.5 35 31 26 22 17 - -

1600

67 46 4.9 44 40 35 31 26 22 17 44 5.4 44 39 35 30 26 21 17

62 42 4.9 42 42 42 37 33 28 24 39 5.3 39 39 39 35 30 26 21

57 41 4.8 41 41 41 37 32 28 23 39 5.3 39 39 39 34 30 25 21

72 51 5.0 33 29 26 22 18 - - 48 5.5 32 28 24 20 16 - -

1400

67 44 4.9 41 37 33 29 25 21 17 42 5.3 40 36 32 28 24 20 16

62 40 4.8 40 40 39 35 31 27 23 37 5.3 37 37 36 32 28 24 20

57 40 4.8 40 40 38 34 30 26 22 37 5.3 37 37 36 32 28 24 20

72 49 4.9 30 27 23 20 16 - - 46 5.4 29 26 22 19 15 - -

1200

67 42 4.9 37 34 30 27 23 20 16 39 5.3 36 33 29 26 22 19 15

62 38 4.8 38 38 36 32 29 25 22 35 5.3 35 35 33 29 26 22 19

57 38 4.8 38 38 35 32 28 25 21 35 5.3 35 35 33 29 26 22 19

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

10 Unitary Products Group

Page 11

292454-YTG-B-0507

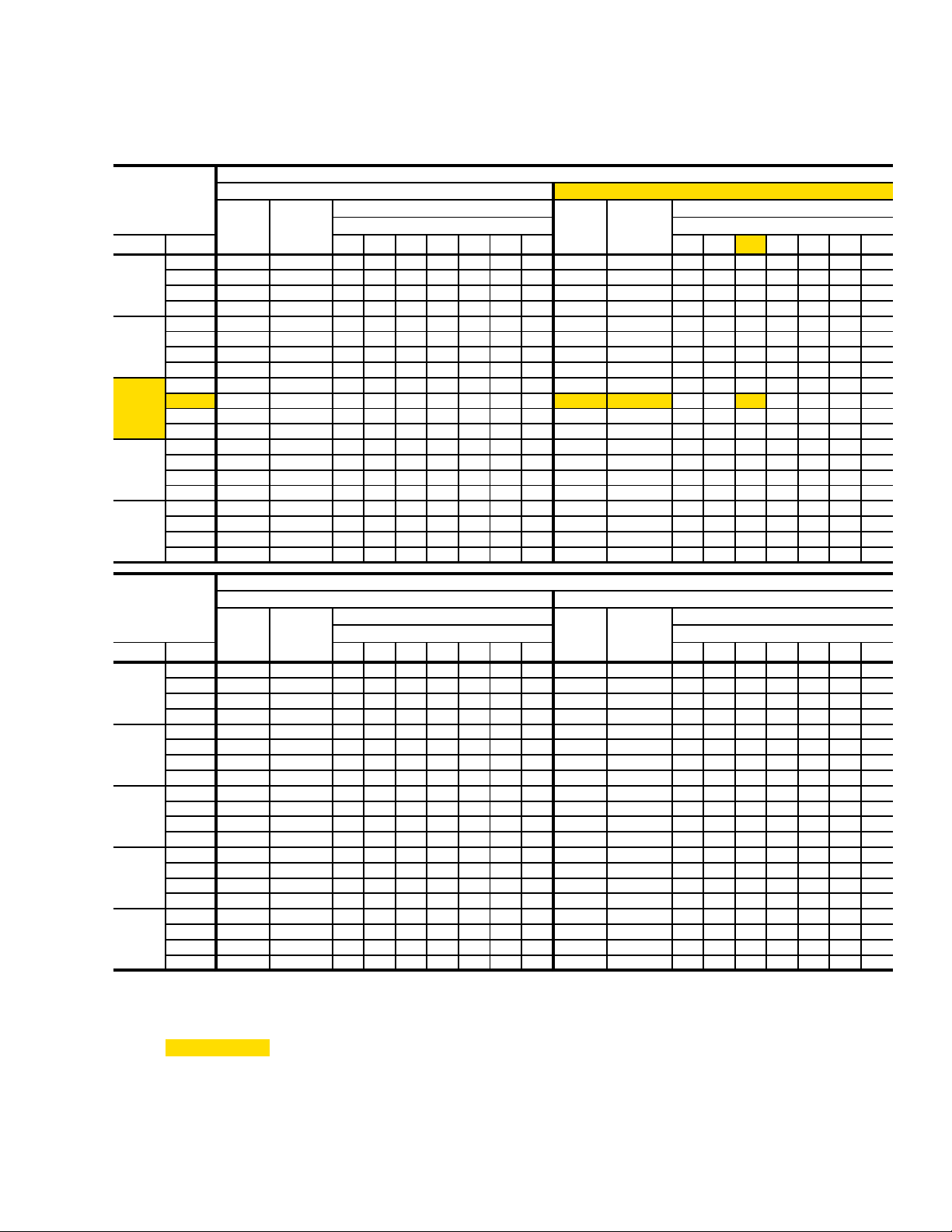

TABLE 7: DM060 COOLING CAPACITIES (5 TON)

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

85°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1

72 68 4.9 50 44 38 32 25 - - 65 5.6 50 43 37 31 24 - -

2500

67 62 4.8 62 56 50 43 37 31 24 60 5.3 60 54 48 42 35 29 23

62 57 4.7 57 57 57 51 44 38 32 53 5.3 53 53 53 47 41 34 28

57 55 4.7 55 55 55 48 42 36 29 51 5.4 51 51 51 44 38 32 25

72 67 4.9 48 42 36 30 24 - - 65 5.4 47 41 35 29 23 - -

2250

67 62 4.8 59 53 47 41 35 30 24 59 5.2 57 51 45 40 34 28 22

62 56 4.7 56 56 56 50 45 39 33 53 5.2 53 53 53 47 41 35 29

57 54 4.7 54 54 54 48 42 36 31 50 5.3 50 50 50 44 39 33 27

72 66 4.9 45 39 34 29 23 - - 64 5.3 44 39 33 28 22 - -

2000

67 61 4.8 55 50 44 39 34 28 23 58 5.1 54 48 43 38 32 27 22

62 55 4.7 55 55 55 50 45 39 34 52 5.1 52 52 52 47 42 36 31

57 53 4.6 53 53 53 48 42 37 32 50 5.2 50 50 50 44 39 34 28

72 63 4.8 41 36 31 27 22 - - 61 5.4 40 35 31 26 21 - -

1750

67 58 4.7 51 46 41 36 32 27 22 56 5.1 49 44 39 35 30 25 21

62 53 4.6 53 53 51 47 42 37 32 50 5.2 50 50 48 43 39 34 29

57 51 4.6 51 51 49 44 40 35 30 47 5.2 47 47 46 41 36 32 27

72 60 4.8 37 33 29 25 21 - - 58 5.4 36 32 28 24 20 - -

1500

67 56 4.7 46 42 38 34 30 26 21 53 5.2 44 40 36 32 28 24 20

62 51 4.6 51 51 47 43 39 35 31 47 5.2 47 47 44 40 36 32 27

57 49 4.6 49 49 45 41 37 33 29 45 5.3 45 45 42 38 34 29 25

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

SENSIBLE CAPACITY

1

72 61 6.1 48 41 35 29 22 - - 57 6.7 46 39 33 27 20 - -

2500

67 55 5.9 55 52 46 39 33 27 20 50 6.6 50 50 43 37 31 24 18

62 49 5.9 49 49 49 42 36 30 23 44 6.5 44 44 44 38 31 25 19

57 47 5.9 47 47 47 40 34 28 21 42 6.5 42 42 42 36 30 23 17

72 61 6.0 45 39 33 28 22 - - 57 6.6 43 38 32 26 20 - -

2250

67 54 5.9 53 49 44 38 32 26 20 50 6.5 50 47 42 36 30 24 18

62 48 5.8 48 48 48 42 37 31 25 44 6.4 44 44 44 38 32 26 20

57 46 5.8 46 46 46 40 35 29 23 42 6.4 42 42 42 36 31 25 19

72 60 6.0 42 37 32 26 21 - - 57 6.6 41 36 30 25 20 - -

2000

67 54 5.8 52 47 41 36 31 25 20 50 6.5 50 45 40 34 29 24 18

62 48 5.7 48 48 48 43 37 32 27 44 6.4 44 44 44 38 33 28 22

57 46 5.8 46 46 46 41 35 30 25 42 6.3 42 42 42 37 32 26 21

72 57 6.0 38 34 29 24 19 - - 53 6.5 37 32 27 23 18 - -

1750

67 51 5.8 47 42 38 33 28 24 19 46 6.4 45 41 36 31 26 22 17

62 45 5.7 45 45 44 39 34 30 25 41 6.3 41 41 39 35 30 25 21

57 43 5.8 43 43 42 37 32 28 23 39 6.3 39 39 38 33 29 24 19

72 54 6.0 34 30 26 22 18 - - 49 6.5 33 28 24 20 16 - -

1500

67 48 5.8 42 38 34 30 26 22 18 43 6.4 40 36 32 28 24 20 16

62 43 5.7 43 43 39 35 31 27 23 38 6.3 38 38 35 31 27 23 19

57 41 5.8 41 41 38 34 30 26 21 37 6.2 37 37 34 30 26 22 18

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

Unitary Products Group 11

Page 12

TABLE 8: DM072 COOLING CAPACITIES (6 TON)

292454-YTG-B-0507

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

85°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

95°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F

1

72 80 5.7 63 55 47 40 32 - - 77 6.3 63 55 47 40 32 - -

2700

67 80 5.7 76 68 60 53 45 37 30 77 6.3 75 68 60 53 45 37 30

62 70 5.5 70 70 70 62 55 47 39 71 6.3 71 71 71 63 56 48 40

57 68 5.6 68 68 68 60 52 45 37 71 6.3 71 71 71 63 56 48 40

72 82 5.7 60 53 46 38 31 - - 76 6.3 60 53 46 39 31 - -

2550

67 82 5.7 73 65 58 51 43 36 29 76 6.3 73 66 58 51 44 36 29

62 71 5.5 71 71 70 62 55 48 41 70 6.3 70 70 69 62 55 48 40

57 69 5.6 69 69 69 62 55 47 40 70 6.3 70 70 70 62 55 48 40

72 83 5.7 58 51 44 37 30 - - 75 6.3 58 51 44 37 30 - -

2400

67 83 5.7 70 63 56 49 42 35 28 75 6.3 70 64 57 50 43 36 29

62 73 5.5 73 73 70 63 56 49 42 69 6.3 69 69 68 61 54 47 40

57 71 5.6 71 71 71 64 57 50 43 69 6.3 69 69 68 61 54 47 40

72 79 5.7 54 48 41 35 29 - - 73 6.3 53 47 41 35 29 - -

2100

67 79 5.7 65 59 53 47 40 34 28 73 6.3 65 59 52 46 40 34 28

62 69 5.5 69 69 66 60 54 47 41 67 6.3 67 66 63 57 51 45 38

57 67 5.6 67 67 67 61 54 48 42 67 6.3 67 66 63 57 51 45 39

72 74 5.6 50 44 39 34 28 - - 71 6.3 49 43 38 33 27 - -

1800

67 74 5.6 60 55 50 44 39 34 28 71 6.3 59 54 48 43 38 32 27

62 65 5.4 65 65 62 57 51 46 41 65 6.2 65 63 58 53 47 42 37

57 63 5.5 63 63 63 58 52 47 42 65 6.3 65 63 58 53 47 42 37

AIR ON

EVAPORATOR

COIL

CFM WB °F 86 83 80 77 74 71 68 86 83 80 77 74 71 68

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

105°F 115°F

SENSIBLE CAPACITY

ENTERING DRY BULB, °F ENTERING DRY BULB, °F

TEMPERATURE OF AIR ON CONDENSER COIL

1

TOTAL

CAP.

MBH

1

POWER

INPUT

2

kW

SENSIBLE CAPACITY

1

72 76 7.1 61 53 45 38 30 - - 75 7.9 59 51 43 36 28 - -

2700

67 71 7.1 70 66 58 50 43 35 27 65 7.8 65 64 56 48 41 33 25

62 64 7.0 64 64 64 56 49 41 34 57 7.8 57 57 57 50 42 34 27

57 64 7.0 64 64 64 56 49 41 34 57 7.7 57 57 57 50 42 34 27

72 76 7.1 59 51 44 37 29 - - 76 7.9 57 49 42 35 27 - -

2550

67 71 7.1 69 64 56 49 42 34 27 66 7.9 66 61 54 47 40 32 25

62 64 7.0 64 64 64 56 49 42 35 58 7.8 58 58 58 51 43 36 29

57 64 7.0 64 64 64 56 49 42 34 58 7.7 58 58 58 50 43 36 29

72 75 7.1 56 49 43 36 29 - - 76 8.0 55 48 41 34 27 - -

2400

67 70 7.1 68 61 54 48 41 34 27 66 7.9 66 59 52 45 38 32 25

62 64 7.0 64 64 63 56 49 42 35 59 7.8 59 59 59 52 45 38 31

57 64 7.0 64 64 63 56 49 42 35 59 7.7 59 59 58 51 44 37 30

72 73 7.1 52 45 39 33 27 - - 73 7.9 50 44 37 31 25 - -

2100

67 68 7.1 63 56 50 44 38 32 26 63 7.8 61 54 48 42 36 30 24

62 61 7.0 61 61 58 52 46 40 34 56 7.7 56 56 54 48 42 35 29

57 61 7.0 61 61 58 52 46 40 34 56 7.7 56 56 53 47 41 35 29

72 70 7.1 47 41 36 31 25 - - 69 7.8 45 40 34 29 23 - -

1800

67 65 7.0 57 51 46 41 35 30 25 60 7.8 55 49 44 39 33 28 23

62 59 7.0 59 58 54 48 43 38 32 53 7.7 53 53 49 44 39 33 28

57 59 6.9 59 58 53 48 43 37 32 53 7.6 53 53 49 44 38 33 27

1. These capacities are gross ratings. For net capacity, determine the kW of the supply air blower motor from the SUPPLY AIR BLOWER PERFORMANCE

Table, multiply this value by 3.415 MBH/kW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2. These ratings include the compressor and the condenser fan motors but not the supply air blower motor. The total condenser fan motor power input

is 0.36kW. Refer to the SUPPLY AIR BLOWER PERFORMANCE Table for the kW of the supply air blower motor.

NOMINAL RATING

12 Unitary Products Group

Page 13

292454-YTG-B-0507

pp

T ABLE 9: SUPPLY AIR BLOWER PERFORMANCE (3 TON BELT DRIVE) - SIDE DUCT APPLICATION

UNIT

TONNAGE

1,2

3

UNIT

TONNAGE

1, 2

3

AIR

FLOW

CFM

0.20 0.30 0.40 0.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

3

0.60 0.70 0.80

1700 835 705 880 745 923 795 969 860 1013 970 ----

1600 811 655 854 695 898 740 942 790 986 840 1029 900 - -

1500 782 610 827 650 871 685 917 730 960 775 1003 825 1046 905

1400 - - 798 595 844 640 889 680 932 720 975 765 1018 790

1300 ----816590862635907675951715995750

1200 ------834585881630927665970705

1100 ------809550855590900625942665

1000 ------782510829545872858919625

900--------797500843540890580

AIR

FLOW

CFM

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

3

1700 --------------

1600 --------------

1500 --------------

1400 1055 875 ------------

1300 1036 780 1066 850 ----------

1200 1011 735 1047 765 1075 800 --------

1100 987 690 1028 720 1060 750 1084 775 ------

1000 963 655 1005 680 1040 695 1068 715 1089 735 ----

900 936 615 980 645 1020 660 1050 670 1053 680 1090 690 - -

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table

for resistance values on a

lications other than gas / electric units with side duct airflows.

Unitary Products Group 13

Page 14

TABLE 10: SUPPLY AIR BLOWER PERFORMANCE (4 TON BELT DRIVE) - SIDE DUCT APPLICATION

292454-YTG-B-0507

UNIT

TONNAGE

1, 2

4

UNIT

TONNAGE

1, 2

4

AIR

FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.20 0.30 0.40 0.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

0.60 0.70 0.80

2000 843 860 880 925 919 1005 956 1065 993 1145 1030 1195 1067 1235

1900 817 775 854 850 893 920 930 995 970 1065 1008 1125 1046 1170

1800 790 700 828 760 867 840 906 905 944 980 985 1040 1025 1100

1700 - - 802 670 840 745 881 815 920 900 961 970 1001 1030

1600 ----818665858740898820940890980950

1500 ------842695882755922835962895

1400 ------833650867705904765942820

1300 --------858665893725932785

1200 --------847640880680916730

AIR

FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

2000 1103 1270 ------------

1900 1085 1210 ------------

1800 1064 1145 1102 1180 ----------

1700 1040 1075 1081 1115 1121 1140 --------

1600 1020 1005 1060 1050 1100 1085 --------

1500 1003 945 1044 995 1086 1035 --------

1400 982 880 1024 920 1067 965 1107 1000 ------

1300 970 835 1010 870 1053 920 1099 960 ------

1200 953 780 992 815 1034 855 1080 905 ------

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table for

resistance values on applications other than gas / electric units with side duct airflows.

14 Unitary Products Group

Page 15

292454-YTG-B-0507

T ABLE 11: SUPPLY AIR BLOWER PERFORMANCE (5 TON BELT DRIVE) - SIDE DUCT APPLICATION

UNIT

ONNAGE

1, 2

5

UNIT

ONNAGE

1, 2

5

AIR FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.20 0.30 0.40 0.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

0.60 0.70 0.80

2500 1059 1560 1077 1590 1095 1630 1114 1650 1134 1660 1158 1685 1181 1720

2400 1032 1405 1054 1470 1074 1525 1094 1560 1116 1595 1140 1620 1167 1640

2300 1005 1260 1024 1275 1049 1370 1069 1440 1090 1475 1116 1505 1142 1535

2200 980 1160 1002 1170 1022 1190 1044 1250 1066 1350 1090 1410 1117 1440

2100 930 1060 957 1070 983 1080 1010 1100 1039 1160 1064 1260 1092 1340

2000 877 950 908 975 941 1000 976 1020 1009 1050 1040 1100 1070 1225

1900 ----8948859409409809801014 1020 1047 1095

1800 ----8558159038609509059889401022 970

1700 ------8848159258509648801001 910

1600 ------864770908805948835987870

1500 --------882740926780965830

AIR FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

2500 --------------

2400 1193 1665 ------------

2300 1170 1580 1202 1620 ----------

2200 1148 1480 1180 1530 ----------

2100 1121 1385 1155 1425 1190 1475 --------

2000 1100 1285 1133 1340 1169 1385 1205 1445 ------

1900 1079 1180 1110 1240 1143 1280 1178 1330 1222 1375 ----

1800 1058 1060 1090 1135 1122 1190 1158 1240 1196 1295 ----

1700 1035 960 1071 1030 1103 1100 1134 1140 1164 1175 1197 1205 - -

1600 1020 900 1056 965 1088 1035 1118 1065 1145 1105 1170 1130 1198 1150

1500 1004 860 1038 880 1070 925 1101 980 1130 1045 1158 1075 1184 1110

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table for

resistance values on applications other than gas / electric units with side duct airflows.

Unitary Products Group 15

Page 16

TABLE 12: SUPPLY AIR BLOWER PERFORMANCE (6 TON BELT DRIVE) - SIDE DUCT APPLICATION

292454-YTG-B-0507

UNIT

TONNAGE

1, 2

6

UNIT

TONNAGE

1, 2

6

AIR

FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.20 0.30 0.40 0.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

0.60 0.70 0.80

3200 1150 2325 1182 2425 1212 2525 --------

3000 1100 2010 1129 2090 1157 2150 1185 2225 1215 2290 1242 2360 - -

2800 1045 1700 1074 1780 1102 1850 1131 1940 1160 2025 1190 2075 1217 2130

2600 985 1425 1015 1475 1045 1540 1075 1630 1103 1715 1135 1760 1163 1825

2400 930 1240 958 1300 990 1350 1020 1400 1051 1430 1081 1490 1111 1600

2200 - - 905 1070 933 1160 965 1210 997 1250 1028 1285 1060 1325

2000 ------9191025 950 1100 982 1130 1014 1160

1800 --------9099259391005 968 1030

AIR

FLOW

CFM

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS RPM WATTS

3

3200 --------------

3000 --------------

2800 1245 2190 ------------

2600 1193 1920 1222 1990 1250 2060 --------

2400 1142 1675 1173 1730 1205 1800 1234 1885 ------

2200 1090 1380 1124 1450 1155 1550 1186 1640 1217 1710 1249 1775 - -

2000 1045 1175 1077 1200 1109 1275 1140 1360 1170 1460 1205 1545 1235 1600

1800 998 1050 1028 1060 1058 1060 1087 1075 1118 1150 1148 1250 1176 1360

1. 230/460/575 Volts

2. For 208 Volts multiply values by 0.95.

3. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCE Table for

resistance values on applications other than gas / electric units with side duct airflows.

16 Unitary Products Group

Page 17

292454-YTG-B-0507

TABLE 13: SUPPLY AIR BLOWER PERFORMANCE (3 - 6 TON DIRECT DRIVE) - SIDE DUCT APPLICATION

UNIT

TONNAGE

1

3

1

4

1

5

1

6

UNIT

TONNAGE)

1

3

1

4

1

5

1

6

MOTOR SPEED

HI

MED

LOW

HI

MED

LOW

HI

MED

LOW

HI

MOTOR SPEED

HI

MED

LOW

HI

MED

LOW

HI

MED

LOW

HI

CFM WATTS CFM WATTS CFM WATTS CFM WATTS CFM WATTS

----1699 825 1650 785 1570 755

1684 800 1631 780 1582 750 1524 720 1410 690

1487 710 1464 690 1421 670 1367 650 1315 620

1996 960 1933 936 1868 910 1795 880 1722 845

1804 838 1765 810 1714 785 1650 765 1589 735

1681 760 1640 738 1604 715 1541 695 1490 670

2400 1155 2338 1125 2274 1095 2167 1045 2096 1010

2290 1105 2214 1065 2145 1030 2071 990 1990 950

2150 1020 2100 990 2029 950 1965 910 1905 880

2461 1480 2402 1440 2361 1395 2260 1350 2178 1305

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

0.70

CFM WATTS CFM WATTS CFM WATTS CFM WATTS

1430 725 1360 700 1280 680 1180 655

1324 650 1260 630 1185 610 1100 590

1246 605 1185 590 1110 570 1020 545

1635 820 1544 790 1419 765 1300 740

1508 705 1407 675 1306 645 1195 625

1416 645 1337 620 1230 595 1120 575

1990 980 1887 945 1771 905 1629 855

1911 920 1828 885 1724 835 1604 798

1816 838 1724 800 1644 770 1531 710

2101 1260 2000 1205 1914 1155 1830 1110

AVAILABLE EXTERNAL STATIC PRESSURE-IWG

2

0.900.80 1.00

1. Side Duct application (230/460/575 Volts)

2. Includes allowances for a wet evaporator coil, 1” filters, and the heat exchangers. Refer to STATIC RESISTANCES Table for resistance

values.

2

0.600.20 0.30 0.40 0.50

TABLE 14: BELT DRIVE BLOWER MOTOR AND DRIVE DATA

BELT

(NOTCHED)

PITCH

LENGTH

(IN.)

QTY.

MODEL

SIZE

BLOWER

RANGE

(RPM)

1

MOTOR

HP FRAME

ADJUSTABLE MOTOR PULLEY FIXED BLOWER PULLEY

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIGNATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

3 TON 790/1120 1 1/2 56 1VL40 2.7-3.7 2.4-3.4 5/8 AK61 5.9 5.7 1 A36 37.3 1

4 TON 790/1120 1 1/2 56 1VL40 2.7-3.7 2.4-3.4 5/8 AK61 5.9 5.7 1 A36 37.3 1

5 TON 850/1220 1 1/2 56 1VL40 2.7-3.7 2.4-3.4 5/8 AK56 5.4 5.2 1 A36 37.3 1

6 TON 900/1250 1 1/2 56 1VL44 3.1-4.1 2.8-3.8 7/8 AK56 5.4 5.2 1 A36 37.3 1

1. All motors have solid bases and are in herently p rot ected. t hese mot ors ca n be selecte d t o operat e into t heir service f acto r becau se t hey are locat ed

in the moving air, upstream of any heating device.

Unitary Products Group 17

Page 18

TABLE 15: STATIC RESISTANCES

RESISTANCE, IWG

DESCRIPTION

ECONOMIZER

ELECTRIC

HEATERS

BOTTOM DUCT CONNECTIONS

1. Deduct these resistance values from the available external static pressure shown in SUPPLY AIR BLOWER PERFORMANCE Tables.

2. Add these resistance values to the available static resistance values on SUPPLY AIR BLOWER PERFORMANCE Tables.

3. The pressure through the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air

duct system is less than 0.25 IWG, the unit will deliver less CFM during full economizer operation.

1

COOLING ONLY

1 3

7-15KW 0.04 0.05 0.06 0.07 0.08 0.10 0.12 0.14 0.16 0.19 0.22

20-30KW 0.06 0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23 0.26

2

1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

0.07 0.08 0.09 0.11 0.13 0.15 0.17 0.20 0.23 0.26 0.30

1

0.06 0.07 0.08 0.09 0.10 0.11 0.12 0.14 0.16 0.19 0.22

0.08 0.10 0.12 0.14 0.16 0.18 0.20 0.23 0.26 0.29 0.32

CFM

TABLE 16: ELECTRIC HEATER CFM LIMITATIONS

MINIMUM SUPPLY AIR CFM

UNITMODEL SIZE NOMINAL

TONS

3

4

5

6

VOLTAGE

HEATER SIZE NOMINAL KW

5 7 10 15 20 30

208/230-3-60 1100 1100 1200 1200 1300 -

460-3-60 - 1100 1200 1200 1300 575-3-60 - - 1200 1200 1300 -

208/230-3-60 1300 1300 1300 1300 1300 -

460-3-60 - 1300 1300 1300 1300 575-3-60 - - 1300 1300 1400 -

208/230-3-60 1600 1600 1600 1600 1600 1600

460-3-60 - 1600 1600 1600 1600 1600

575-3-60 - 1600 1600 1600 1600 1800

208/230-3-60 1800 1800 1800 1800 1800 1800

460-3-60 - 1800 1800 1800 1800 1800

575-3-60 - - 1800 1800 1800 1800

292454-YTG-B-0507

18 Unitary Products Group

Page 19

292454-YTG-B-0507

TABLE 17: ELECTRICAL DATA - DM036-072 DIRECT DRIVE W/O POWERED CONV. OUTLET

MODEL

TONNAGE

DM036

(3.0)

DM048

(4.0)

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 8.7 72.0 1.3 4.4 0.0

230-3-60 8.7 72.0 1.3 4.4 0.0

460-3-60 4.9 45.0 0.8 2.2 0.0

575-3-60 3.9 36.0 0.8 2.2 0.0

208-3-60 14.1 105.0 1.3 5.0 0.0

230-3-60 14.1 105.0 1.3 5.0 0.0

460-3-60 7.1 55.0 0.8 2.2 0.0

575-3-60 5.8 44.0 0.8 2.2 0.0

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 16.6 20

2CE04510525

2CE04510725

HEATER KWHEATER

2

4.0 11.1 19.4 25

2

5.6 15.5 24.9 25

2CE04511025 8.0 22.2 33.3 35

2CE04511525 11.9 33.0 46.8 50

2CE04512025 15.9 44.1 60.7 70

None -- -- 16.6 20

2CE04510525

2CE04510725

2

5.3 12.7 21.4 25

2

7.5 18.0 28.1 30

2CE04511025 10.6 25.5 37.4 40

2CE04511525 15.9 38.2 53.3 60

2CE04512025 21.2 51.0 69.2 70

None -- -- 9.1 15

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

6.8 8.2 13.0 15

2

10.1 12.1 17.9 20

2

13.6 16.4 23.2 25

2

19.5 23.5 32.1 35

None -- -- 7.3 15

2CE04511058 10.6 10.2 14.9 15

2CE04511558 15.9 15.3 21.3 25

2CE04512058 21.2 20.4 27.7 30

None -- -- 23.9 30

2CE04510525

2CE04510725

2

4 11.1 23.9 30

2

5.6 15.5 25.7 35

2CE04511025 8 22.2 34 35

2CE04511525 11.9 33.0 47.5 50

2CE04512025 15.9 44.1 61.4 70

None -- -- 23.9 30

2CE04510525

2CE04510725

2

5.3 12.7 23.9 30

2

7.5 18.0 28.8 35

2CE04511025 10.6 25.5 38.1 40

2CE04511525 15.9 38.2 54.1 60

2CE04512025 21.2 51.0 70 70

None -- -- 11.9 15

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

6.8 8.2 13 15

2

10.1 12.1 17.9 20

2

13.6 16.4 23.2 25

2

19.5 23.5 32.1 35

None -- -- 9.7 15

2CE04511058 10.6 10.2 14.9 15

2CE04511558 15.9 15.3 21.3 25

2CE04512058 21.2 20.4 27.7 30

AMPS

MIN.

CIRCUIT

AMPACITY

(AMPS)

MAX. FUSE/

1

BRKR

SIZE

(AMPS)

Unitary Products Group 19

Page 20

TABLE 17: ELECTRICAL DATA - DM036-072 DIRECT DRIVE W/O POWERED CONV. OUTLET (CONT.)

MODEL

TONNAGE

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 16.0 125.0 1.3 6.6 0.0

230-3-60 16.0 125.0 1.3 6.6 0.0

DM060

(5.0)

460-3-60 8.0 66.5 0.8 3.3 0.0

575-3-60 6.4 50.0 0.8 3.3 0.0

208-3-60 18.9 146.0 1.3 6.8 0.0

230-3-60 18.9 146.0 1.3 6.8 0.0

DM072

(6.0)

460-3-60 9.5 73.0 0.8 3.6 0.0

575-3-60 7.6 58.4 0.8 3.6 0.0

1. HACR T ype per NEC.

2. These electric heaters do not include a fuse box. If a fuse box is required to meet a local code (i.e. Chicago), the fuse block

accessories 2FB04700825 and 2FB04700846 are available for field installation.

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 27.9 35

2CE04510525

2CE04510725

HEATER KWHEATER

AMPS

2

4 11.1 27.9 35

2

5.6 15.5 27.9 35

2CE04511025 8 22.2 36 40

2CE04511525 11.9 33.0 49.5 50

2CE04512025 15.9 44.1 63.4 70

2CE04513025 22.2 61.6 85.3 90

None -- -- 27.9 35

2CE04510525

2CE04510725

2

5.3 12.7 27.9 35

2

7.5 18.0 30.8 40

2CE04511025 10.6 25.5 40.1 45

2CE04511525 15.9 38.2 56.1 60

2CE04512025 21.2 51.0 72 80

2CE04513025 29.6 71.2 97.3 100

None -- -- 14.1 20

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2CE04513046

2

6.8 8.2 14.3 20

2

10.1 12.1 19.3 20

2

13.6 16.4 24.6 25

2

19.5 23.5 33.4 35

2

28.8 34.6 47.4 50

None -- -- 11.3 15

2CE04511058 10.6 10.2 16 20

2CE04511558 15.9 15.3 22.4 25

2CE04512058 21.2 20.4 28.8 30

2CE04513058 30.4 29.3 39.9 40

None -- -- 31.7 40

2

2CE04510525

2CE04510725

4 11.1 31.7 40

2

5.6 15.5 31.7 40

2CE04511025 8 22.2 36.3 50

2CE04511525 11.9 33.0 49.8 50

2CE04512025 15.9 44.1 63.7 70

2CE04513025 22.2 61.6 85.5 90

None -- -- 31.7 40

2CE04510525

2CE04510725

2

5.3 12.7 31.7 40

2

7.5 18.0 31.7 40

2CE04511025 10.6 25.5 40.4 50

2CE04511525 15.9 38.2 56.3 60

2CE04512025 21.2 51.0 72.2 80

2CE04513025 29.6 71.2 97.5 100

None -- -- 16.3 25

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2CE04513046

2

6.8 8.2 16.3 25

2

10.1 12.1 19.7 25

2

13.6 16.4 24.9 25

2

19.5 23.5 33.8 35

2

28.8 34.6 47.8 50

None -- -- 13 15

2CE04511058 10.6 10.2 16.3 20

2CE04511558 15.9 15.3 22.7 25

2CE04512058 21.2 20.4 29.1 30

2CE04513058 30.4 29.3 40.2 40

292454-YTG-B-0507

MIN.

CIRCUIT

AMPACITY

(AMPS)

MAX. FUSE/

1

BRKR

SIZE

(AMPS)

20 Unitary Products Group

Page 21

292454-YTG-B-0507

TABLE 18: ELECTRICAL DATA - DM036-072 BELT DRIVE W/O POWERED CONV. OUTLET

MODEL

TONNAGE

DM036

(3.0)

DM048

(4.0)

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 8.7 72.0 1.3 5.2 0.0

230-3-60 8.7 72.0 1.3 5.2 0.0

460-3-60 4.9 45.0 0.8 2.6 0.0

575-3-60 3.9 36.0 0.8 2.0 0.0

208-3-60 14.1 105.0 1.3 5.2 0.0

230-3-60 14.1 105.0 1.3 5.2 0.0

460-3-60 7.1 55.0 0.8 2.6 0.0

575-3-60 5.8 44.0 0.8 2.0 0.0

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 17.4 25

2CE04510525

2CE04510725

HEATER KWHEATER

2

4.0 11.1 20.4 25

2

5.6 15.5 25.9 30

2CE04511025 8.0 22.2 34.3 35

2CE04511525 11.9 33.0 47.8 50

2CE04512025 15.9 44.1 61.7 70

None -- -- 17.4 25

2CE04510525

2CE04510725

2

5.3 12.7 22.4 25

2

7.5 18.0 29.1 30

2CE04511025 10.6 25.5 38.4 40

2CE04511525 15.9 38.2 54.3 60

2CE04512025 21.2 51.0 70.2 80

None -- -- 9.5 15

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

6.8 8.2 13.5 15

2

10.1 12.1 18.4 20

2

13.6 16.4 23.7 25

2

19.5 23.5 32.6 35

None -- -- 7.5 15

2CE04511058 10.6 10.2 15.2 20

2CE04511558 15.9 15.3 21.6 25

2CE04512058 21.2 20.4 28.0 30

None -- -- 24.1 35

2CE04510525

2CE04510725

2

4 11.1 24.1 35

2

5.6 15.5 25.9 35

2CE04511025 8 22.2 34.3 35

2CE04511525 11.9 33.0 47.8 50

2CE04512025 15.9 44.1 61.7 70

None -- -- 24.1 35

2CE04510525

2CE04510725

2

5.3 12.7 24.1 35

2

7.5 18.0 29.1 35

2CE04511025 10.6 25.5 38.4 40

2CE04511525 15.9 38.2 54.3 60

2CE04512025 21.2 51.0 70.2 80

None -- -- 12.3 15

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

6.8 8.2 13.5 15

2

10.1 12.1 18.4 20

2

13.6 16.4 23.7 25

2

19.5 23.5 32.6 35

None -- -- 9.9 15

2CE04511058 10.6 10.2 15.2 20

2CE04511558 15.9 15.3 21.6 25

2CE04512058 21.2 20.4 28 30

AMPS

MIN.

CIRCUIT

AMPACITY

(AMPS)

MAX. FUSE/

1

BRKR

SIZE

(AMPS)

Unitary Products Group 21

Page 22

TABLE 18: ELECTRICAL DATA - DM036-072 BELT DRIVE W/O POWERED CONV. OUTLET (CONT.)

MODEL

TONNAGE

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 16.0 125.0 1.3 5.2 0.0

230-3-60 16.0 125.0 1.3 5.2 0.0

DM060

(5.0)

460-3-60 8.0 66.5 0.8 2.6 0.0

575-3-60 6.4 50.0 0.8 2.0 0.0

208-3-60 18.9 146.0 1.3 5.0 0.0

230-3-60 18.9 146.0 1.3 5.0 0.0

DM072

(6.0)

460-3-60 9.5 73.0 0.8 2.5 0.0

575-3-60 7.6 58.4 0.8 2.0 0.0

1. HACR T ype per NEC.

2. These electric heaters do not include a fuse box. If a fuse box is required to meet a local code (i.e. Chicago), the fuse block

accessories 2FB04700825 and 2FB04700846 are available for field installation.

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 26.5 35

2CE04510525

2CE04510725

HEATER KWHEATER

AMPS

2

4 11.1 26.5 35

2

5.6 15.5 26.5 35

2CE04511025 8 22.2 34.3 40

2CE04511525 11.9 33.0 47.8 50

2CE04512025 15.9 44.1 61.7 70

2CE04513025 22.2 61.6 83.5 90

None -- -- 26.5 35

2CE04510525

2CE04510725

2

5.3 12.7 26.5 35

2

7.5 18.0 29.1 40

2CE04511025 10.6 25.5 38.4 40

2CE04511525 15.9 38.2 54.3 60

2CE04512025 21.2 51.0 70.2 80

2CE04513025 29.6 71.2 95.5 100

None -- -- 13.4 20

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2CE04513046

2

6.8 8.2 13.5 20

2

10.1 12.1 18.4 20

2

13.6 16.4 23.7 25

2

19.5 23.5 32.6 35

2

28.8 34.6 46.6 50

None -- -- 10.6 15

2CE04511058 10.6 10.2 15.2 20

2CE04511558 15.9 15.3 21.6 25

2CE04512058 21.2 20.4 28 30

2CE04513058 30.4 29.3 39.1 40

None -- -- 29.9 40

2

2CE04510525

2CE04510725

4 11.1 29.9 40

2

5.6 15.5 29.9 40

2CE04511025 8 22.2 34 45

2CE04511525 11.9 33.0 47.5 50

2CE04512025 15.9 44.1 61.4 70

2CE04513025 22.2 61.6 83.3 90

None -- -- 29.9 40

2CE04510525

2CE04510725

2

5.3 12.7 29.9 40

2

7.5 18.0 29.9 40

2CE04511025 10.6 25.5 38.1 45

2CE04511525 15.9 38.2 54.1 60

2CE04512025 21.2 51.0 70 70

2CE04513025 29.6 71.2 95.3 100

None -- -- 15.2 20

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2CE04513046

2

6.8 8.2 15.2 20

2

10.1 12.1 18.3 20

2

13.6 16.4 23.6 25

2

19.5 23.5 32.4 35

2

28.8 34.6 46.4 50

None -- -- 12.1 15

2CE04511058 10.6 10.2 15.2 20

2CE04511558 15.9 15.3 21.6 25

2CE04512058 21.2 20.4 28 30

2CE04513058 30.4 29.3 39.1 40

292454-YTG-B-0507

MIN.

CIRCUIT

AMPACITY

(AMPS)

MAX. FUSE/

1

BRKR

SIZE

(AMPS)

22 Unitary Products Group

Page 23

292454-YTG-B-0507

TABLE 19: ELECTRICAL DATA -DM036-072 DIRECT DRIVE W/POWERED CONV. OUTLET

MODEL

TONNAGE

DM036

(3.0)

DM048

(4.0)

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 8.7 72.0 1.3 4.4 10.0

230-3-60 8.7 72.0 1.3 4.4 10.0

460-3-60 4.9 45.0 0.8 2.2 5.0

575-3-60 3.9 36.0 0.8 2.2 4.0

208-3-60 14.1 105.0 1.3 5.0 10.0

230-3-60 14.1 105.0 1.3 5.0 10.0

460-3-60 7.1 55.0 0.8 2.2 5.0

575-3-60 5.8 44.0 0.8 2.2 4.0

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 26.9 35

2CE04510525

2CE04510725

HEATER KWHEATER

2

4.0 11.1 31.9 35

2

5.6 15.5 37.4 40

2CE04511025 8.0 22.2 45.8 50

2CE04511525 11.9 33.0 59.3 60

2CE04512025 15.9 44.1 73.2 80

None -- -- 26.9 35

2CE04510525

2CE04510725

2

5.3 12.7 33.9 35

2

7.5 18.0 40.6 45

2CE04511025 10.6 25.5 49.9 50

2CE04511525 15.9 38.2 65.8 70

2CE04512025 21.2 51.0 81.7 90

None -- -- 14.2 15

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

6.8 8.2 19.2 20

2

10.1 12.1 24.2 25

2

13.6 16.4 29.4 30

2

19.5 23.5 38.3 40

None -- -- 11.3 15

2CE04511058 10.6 10.2 19.9 20

2CE04511558 15.9 15.3 26.3 30

2CE04512058 21.2 20.4 32.7 35

None -- -- 33.9 45

2CE04510525

2CE04510725

2

4 11.1 33.9 45

2

5.6 15.5 38.2 45

2CE04511025 8 22.2 46.5 50

2CE04511525 11.9 33.0 60 70

2CE04512025 15.9 44.1 73.9 80

None -- -- 33.9 45

2CE04510525

2CE04510725

2

5.3 12.7 34.7 45

2

7.5 18.0 41.3 45

2CE04511025 10.6 25.5 50.6 60

2CE04511525 15.9 38.2 66.6 70

2CE04512025 21.2 51.0 82.5 90

None -- -- 16.9 20

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

6.8 8.2 19.2 20

2

10.1 12.1 24.2 25

2

13.6 16.4 29.4 30

2

19.5 23.5 38.3 40

None -- -- 13.7 15

2CE04511058 10.6 10.2 19.9 20

2CE04511558 15.9 15.3 26.3 30

2CE04512058 21.2 20.4 32.7 35

AMPS

MIN.

CIRCUIT

AMPACITY

(AMPS)

MAX. FUSE/

1

BRKR

SIZE

(AMPS)

Unitary Products Group 23

Page 24

TABLE 19: ELECTRICAL DATA -DM036-072 DIRECT DRIVE W/POWERED CONV. OUTLET (CONT.)

MODEL

TONNAGE

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 16.0 125.0 1.3 6.6 10.0

230-3-60 16.0 125.0 1.3 6.6 10.0

DM060

(5.0)

460-3-60 8.0 66.5 0.8 3.3 5.0

575-3-60 6.4 50.0 0.8 3.3 4.0

208-3-60 18.9 146.0 1.3 6.8 10.0

230-3-60 18.9 146.0 1.3 6.8 10.0

DM072

(6.0)

460-3-60 9.5 73.0 0.8 3.6 5.0

575-3-60 7.6 58.4 0.8 3.6 4.0

1. HACR T ype per NEC.

2. These electric heaters do not include a fuse box. If a fuse box is required to meet a local code (i.e. Chicago), the fuse block

accessories 2FB04700825 and 2FB04700846 are available for field installation.

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 37.9 50

2CE04510525

2CE04510725

HEATER KWHEATER

AMPS

2

4 11.1 37.9 50

2

5.6 15.5 40.2 50

2CE04511025 8 22.2 48.5 50

2CE04511525 11.9 33.0 62 70

2CE04512025 15.9 44.1 75.9 80

2CE04513025 22.2 61.6 97.8 100

None -- -- 37.9 50

2CE04510525

2CE04510725

2

5.3 12.7 37.9 50

2

7.5 18.0 43.3 50

2CE04511025 10.6 25.5 52.6 60

2CE04511525 15.9 38.2 68.6 70

2CE04512025 21.2 51.0 84.5 90

2CE04513025 29.6 71.2 109.8 110

None -- -- 19.1 25

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2CE04513046

2

6.8 8.2 20.6 25

2

10.1 12.1 25.6 30

2

13.6 16.4 30.8 35

2

19.5 23.5 39.7 40

2

28.8 34.6 53.7 60

None -- -- 15.3 20

2CE04511058 10.6 10.2 21 25

2CE04511558 15.9 15.3 27.4 30

2CE04512058 21.2 20.4 33.8 35

2CE04513058 30.4 29.3 44.9 45

None -- -- 41.7 60

2

2CE04510525

2CE04510725

4 11.1 41.7 60

2

5.6 15.5 41.7 60

2CE04511025 8 22.2 48.8 60

2CE04511525 11.9 33.0 62.3 70

2CE04512025 15.9 44.1 76.2 80

2CE04513025 22.2 61.6 98 100

None -- -- 41.7 60

2CE04510525

2CE04510725

2

5.3 12.7 41.7 60

2

7.5 18.0 43.6 60

2CE04511025 10.6 25.5 52.9 60

2CE04511525 15.9 38.2 68.8 70

2CE04512025 21.2 51.0 84.7 90

2CE04513025 29.6 71.2 110 125

None -- -- 21.3 30

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2CE04513046

2

6.8 8.2 21.3 30

2

10.1 12.1 25.9 30

2

13.6 16.4 31.2 35

2

19.5 23.5 40.1 45

2

28.8 34.6 54.1 60

None -- -- 17 20

2CE04511058 10.6 10.2 21.3 25

2CE04511558 15.9 15.3 27.7 30

2CE04512058 21.2 20.4 34.1 35

2CE04513058 30.4 29.3 45.2 45

292454-YTG-B-0507

MIN.

CIRCUIT

AMPACITY

(AMPS)

MAX. FUSE/

1

BRKR

SIZE

(AMPS)

24 Unitary Products Group

Page 25

292454-YTG-B-0507

TABLE 20: ELECTRICAL DATA - DM036-072 BELT DRIVE W/POWERED CONV. OUTLET

MODEL

TONNAGE

DM036

(3.0)

DM048

(4.0)

VOLTAGE

COMPRESSORS

RLA

EACH

LRA

EACH

OD FAN

MOTOR

FLA

208-3-60 8.7 72.0 1.3 5.2 10.0

230-3-60 8.7 72.0 1.3 5.2 10.0

460-3-60 4.9 45.0 0.8 2.6 5.0

575-3-60 3.9 36.0 0.8 2.0 4.0

208-3-60 14.1 105.0 1.3 5.2 10.0

230-3-60 14.1 105.0 1.3 5.2 10.0

460-3-60 7.1 55.0 0.8 2.6 5.0

575-3-60 5.8 44.0 0.8 2.0 4.0

ID

BLOWER

MOTOR

FLA

CONV

OUTLET

FLA

ELECTRIC HEATER

MODEL NO.

None -- -- 27.7 35

2CE04510525

2CE04510725

HEATER KWHEATER

2

2

2CE04511025 8.0 22.2 46.8 50

2CE04511525 11.9 33.0 60.3 70

2CE04512025 15.9 44.1 74.2 80

None -- -- 27.7 35

2CE04510525

2CE04510725

2

2

2CE04511025 10.6 25.5 50.9 60

2CE04511525 15.9 38.2 66.8 70

2CE04512025 21.2 51.0 82.7 90

None -- -- 14.6 15

2CE04510746

2CE04511046

2CE04511546

2CE04512046

2

2

2

2

None -- -- 11.5 15

2CE04511058 10.6 10.2 20.2 25

2CE04511558 15.9 15.3 26.6 30

2CE04512058 21.2 20.4 33.0 35

None -- -- 34.1 45

2CE04510525

2CE04510725

2

2

2CE04511025 8 22.2 46.8 50