Page 1

User’s

Manual

30-CH Fast Digital

Thermometer Module

Yokogawa Electric Corporation

IM 707231-01E

1st Edition

Page 2

Foreword

Notes

Thank you for purchasing the WE7231 30-CH Fast Digital Thermometer Module, a PCbased measurement instrument for the WE7000.

This user’s manual contains useful information about the functions and operating

procedures of the WE7231 as well as precautions that should be observed during use.

This manual is written with the assumption that you will be using the WE7000 Control

Software that is included with the measuring station.

For general information about the WE7000, (primarily the operations of the measuring

station, the optical interface module, the optical interface card, and the WE7000 Control

Software) see the WE7000 User’s Manual (IM 707001-01E).

Manual Title Manual No.

WE7000 User’s Manual IM707001-01E

To ensure proper use of the instrument, please read this manual thoroughly before

beginning operation.

After reading the manual, keep it in a convenient location for quick reference in the event

a question arises.

• This manual was written for version 4.2.0.0 of the WE7000 Control Software and

module firmware version 3.05. The operating procedures and screen contents

described in this manual may differ from those in other versions of the software.

• The contents of this manual are subject to change without prior notice as a result of

improvements in the instrument’s performance and functions.

• Every effort has been made in the preparation of this manual to ensure the accuracy

of its contents. However, should you have any questions or find any errors, please

contact your nearest YOKOGAWA representative listed on the back cover of this

manual.

• Copying or reproduction of all or any part of the contents of this manual without the

permission of Yokogawa Electric Corporation is strictly prohibited.

Trademarks

• Microsoft, Windows, and Windows NT are trademarks or registered trademarks of

Microsoft Corporation in the United States and/or other countries.

• Adobe and Adobe Acrobat are trademarks of Adobe Systems incorporated.

• All other company and product names used in this manual are trademarks or

registered trademarks of their respective companies.

Revisions

1st Edition: November 2001

Disk No. WE16

1st Edition: Norbember 2001 (YK)

All Rights Reserved, Copyright © 2001 Yokogawa Electric Corporation

IM 707231-01E

1

Page 3

Checking the Contents of the Package

MODEL

NO.

Unpack the box and check the contents before operating the instrument. If some items

are missing or otherwise inconsistent with the contents description, please contact the

dealer from which you purchased them.

Measurement Module

Check that the model name given on the name plate matches the one on your order

form.

Model

Model Suffix Code Description

707231 WE7231 30-CH Fast Digital Thermometer Module

707231 /HE English help message

NO. (Instrument Number)

When contacting the dealer from which you purchased the instrument, please give them

the instrument number.

MODEL

NO.

Made in Japan

Accessories

The following standard accessories are supplied with the instrument. Make sure that all

items are present and undamaged.

One user’s manual (this document)

IM 707231-01E

Optional Accessories (Sold Separately)

Part Name Model Code Description

30-CH Scanner Box 707815 M4 screw terminal and 1 meter connecting cable

30-CH Scanner Box 707815/L3 M4 screw terminal and 3 meter connecting cable

Connecting cable

2

IM 707231-01E

Page 4

How to Use This Manual

Structure of the Manual

This manual consists of four chapters and an index as shown below.

Chapter Title Description

1 Functions Describes the system configuration and functions.

2 Hardware Preparation Explains how to install the module into the measuring

3Troubleshooting and Explains the procedures for troubleshooting and self-

Maintenance testing.

4 Specifications Outlines the specifications of the module.

Index An alphabetical index.

Conventions Used in This Manual

• Units

k Denotes 1000. (For example, 100 kHz)

K Denotes 1024. (For example, 720 KB)

• Boldface Characters

Characters set in boldface usually refer to items on-screen or on the instrument (such

as knobs, windows and buttons) with which the user interacts.

station, and how to connect the input.

• Symbols

The following symbols are used in this manual to alert you to important information.

This symbol is affixed to the instrument, and indicates that due to

possible danger to the user or instrument, the user’s manual should

be consulted. It is also printed on the corresponding reference

page in the user’s manual.

WARNING

CAUTION

Note

Describes precautions that should be observed to prevent injury or

death to the user.

Describes precautions that should be observed to prevent minor or

moderate injury to the user, or damage to the instrument.

Provides information that is important for proper operation of the

instrument.

IM 707231-01E

3

Page 5

4

IM 707231-01E

Page 6

Contents

Foreword .......................................................................................................................................... 1

Checking the Contents of the Package ............................................................................................. 2

How to Use This Manual...................................................................................................................... 3

Chapter 1 Functions

1.1 System Configuration and Block Diagram .............................................................................. 1-1

1.2 Operation Panel......................................................................................................................1-3

1.3 Setting Measurement Conditions............................................................................................ 1-5

1.4 Setting the Alarm ....................................................................................................................1-8

1.5 Waveform Display, Automatic Saving of Measured Data, File Conversion,

and Other Functions ............................................................................................................. 1-10

1.6 Name and Functions of Each Part........................................................................................ 1-11

Chapter 2 Hardware Preparation

2.1 Mounting Modules in the Measurement Station ..................................................................... 2-1

2.2 Connecting the 30-CH Scanner Box and the Input Signal Wire .............................................2-3

Chapter 3 Troubleshooting and Maintenance

3.1 Troubleshooting ......................................................................................................................3-1

3.2 Self Test ..................................................................................................................................3-2

3.3 Maintenance ...........................................................................................................................3-3

1

2

3

4

Index

Chapter 4 Specifications

4.1 Performance Specifications.................................................................................................... 4-1

4.2 Factory Default Settings ......................................................................................................... 4-4

4.3 General Specifications............................................................................................................4-5

4.4 Specifications for the 30-CH Scanner Box ............................................................................. 4-6

4.5 External Dimensions...............................................................................................................4-7

Index ................................................................................................................................ Index-1

IM 707231-01E

5

Page 7

Chapter 1 Functions

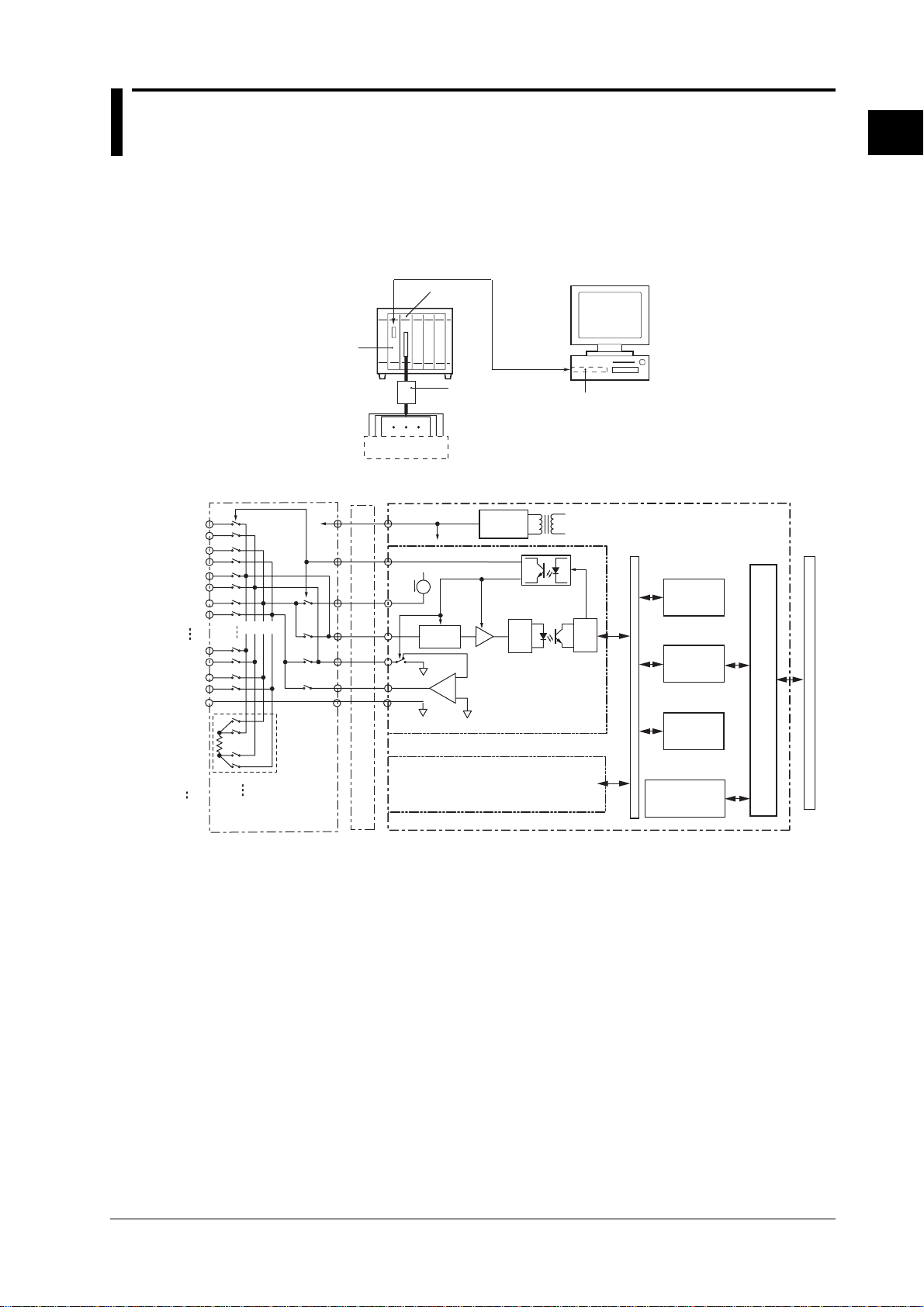

1.1 System Configuration and Block Diagram

System Configuration

The following is an example in which the 30-CH Fast Digital Thermometer WE7231 is

installed into the measuring station and the measuring station is connected to a PC with

the optical fiber cable.

1

Functions

Block Diagram

CH1

CH2

CH3

CH4

CH15

CH15c

G

Measuring station

Scan signal

RJC

Optical

interface

modules

Optical fiber cable

DUT

DC

Connecting cable

WE7231

30-CH Scanner

Box (sold separ

separately)

-

+

ATT

0/40dB

Amplifier

circuit

-

Voltage control circuit

+

Optical interface card

Power

supply

WE7231 30-CH Fast Digital

Thermometer Module

A/D

Acquisition

control circuit

Input signal processing

circuit for CH1-CH15

PC

Internal bus

CPU

32bits RISC

DPRAM

Memory

WE bus interface

CH16

CH30

CH30c

30-CH Scanner Box

Input signal processing

circuit for CH16-CH30

Module control

program

(flash memory)

WE bus

IM 707231-01E

1-1

Page 8

1.1 System Configuration and Block Diagram

Description of Operation

The 30-CH Scanner Box (sold separately) connects to the input connector of the 30-CH

Fast Digital Thermometer WE7231 using the connecting cable, and the devices under

measurement are connected to each terminal of the 30-CH Scanner Box. If the device

under measurement is a thermocouple or if you are measuring DC voltage, the input

terminals are connected using a 2-wire system. When measuring resistance or

resistance temperature detectors, a 4-wire system is used.

A scanning signal is sent through the connecting cable from the WE7231 to the 30-CH

Scanner Box, and the response from the device under measurement determines which

signals are selected for input to the WE7231.

With thermocouple or DC voltage input measurement, the input signal is modified in the

attenuator (A TT) and amplifier circuits then undergoes A/D conversion. When measuring

resistance such as in resistance temperature detectors, a constant current is given

through the connecting cable from the WE7231 to the device being measured, and in the

same manner as during thermocouple or DC voltage input measurement, the voltage

signal generated at both ends of the device being measured is input to the WE7231

where it undergoes A/D conversion. These converted digital signals are isolated in the

photocoupler and the digital data which represents the measured values is stored in

memory.

When measuring temperature, the reference junction temperature is measured using the

platinum resistance temperature detector inside the scanner box, and the CPU performs

reference junction compensation, or RJC, (this function can be turned ON/OFF) and

voltage-temperature conversion on the previously stored measurement data from the

thermocouple. These results are then re-stored. The data stored in memory can be

recalled from a PC through communications.

1-2

IM 707231-01E

Page 9

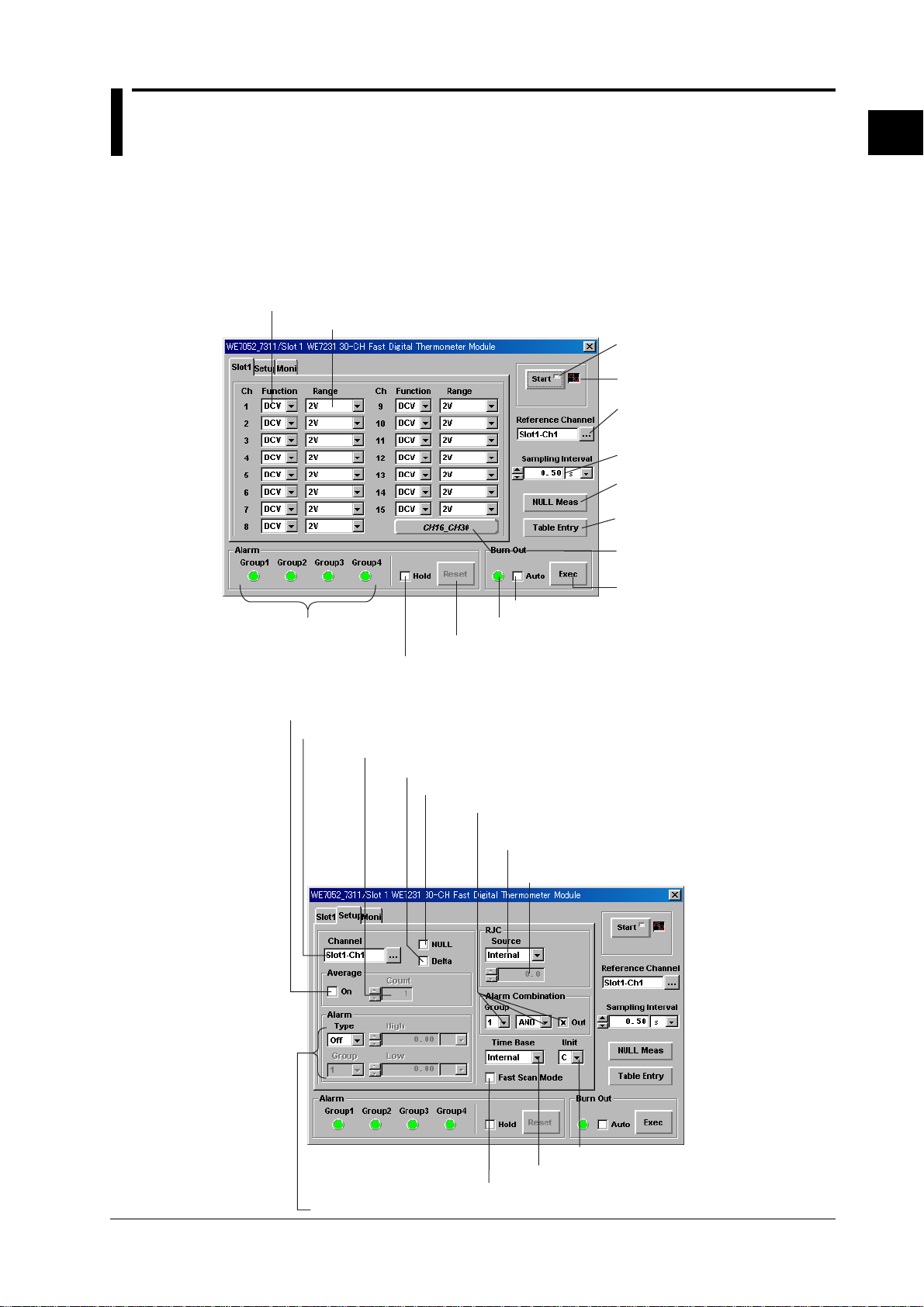

1.2 Operation Panel

The WE7000 Control Software installed in the PC is used to control the 30-CH Fast

Digital Thermometer WE7231. The WE7000 Control Software displays operation panels

similar to those shown in the figure below. This user’s manual does not explain the

operations of the operation panel or waveform monitor. For these operations, see the

WE7000 Control Software’s online help.

Basic Settings

Select the measurement function

Select the measuring range/type of thermocouple

Alarm occurrence

status indication

Select to put the alarm occurrence status indication on hold

1

Functions

Start/stop measurement

Turn the waveform monitor

ON and OFF

Select the reference channel

(for difference between channels

calculation)

Select the sampling interval

Execute NULL measurement

on channels set to use the null value

Display the Table Entry

window (see next page)

Display settings for

channels 16-30

Execute burn out detection

Select for automatic burn out detection

Burn out detection indicator

Click to release alarm occurrence status indication hold

Other Settings

Select to use the moving average as the measured values

Select the measurement channel

Set the number of samples for the moving average

Select to calculate the difference from the reference channel

Select to use the NULL value

Set alarm detection by group

Toggle the reference junction compensation (RJC)

between Internal and External

Input the reference junction temperature for

external reference junction compensation (RJC)

IM 707231-01E

Select the units of temperature

Select the time base

Select to enable fast scan mode

Set alarms for the measurement channels

1-3

Page 10

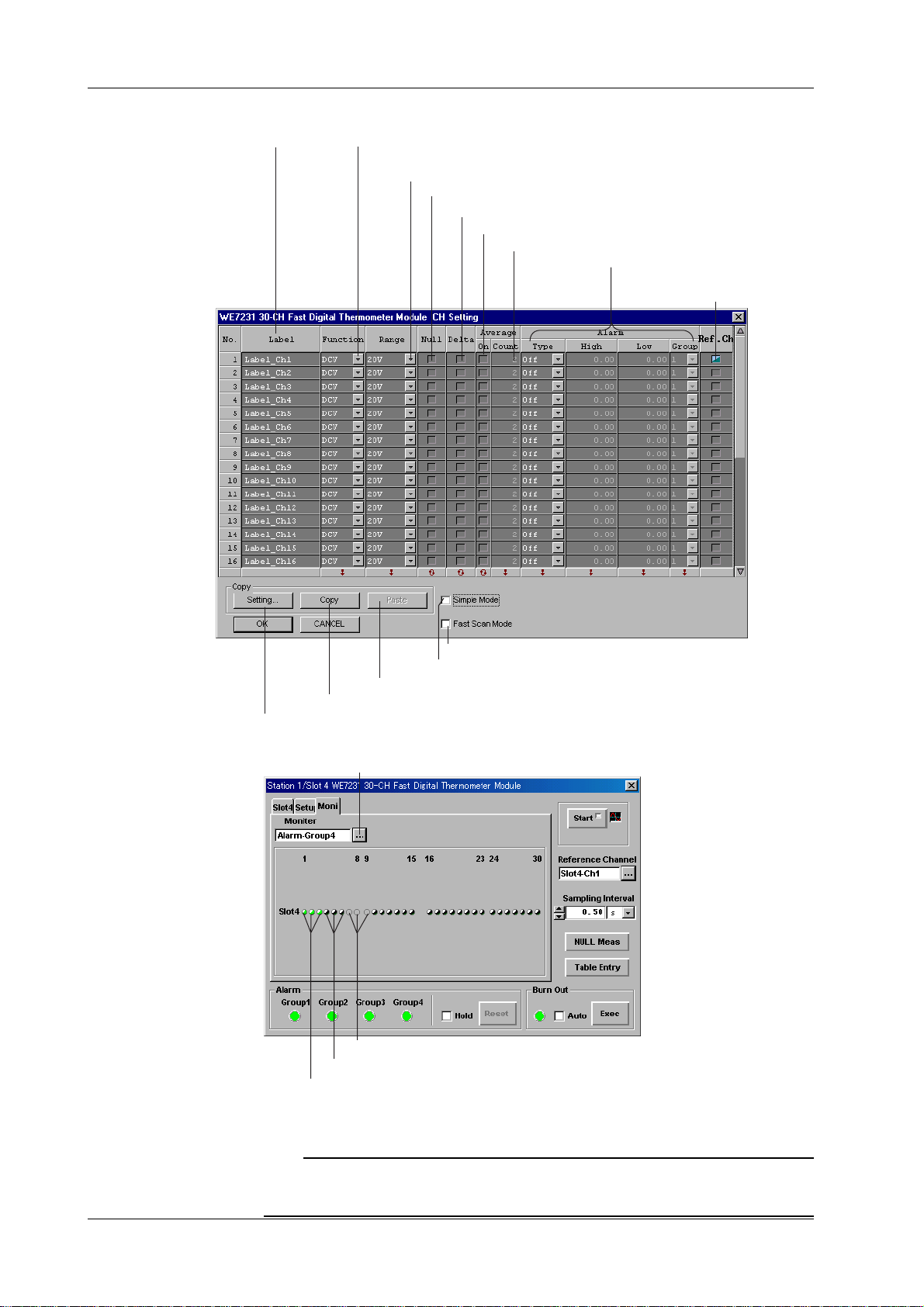

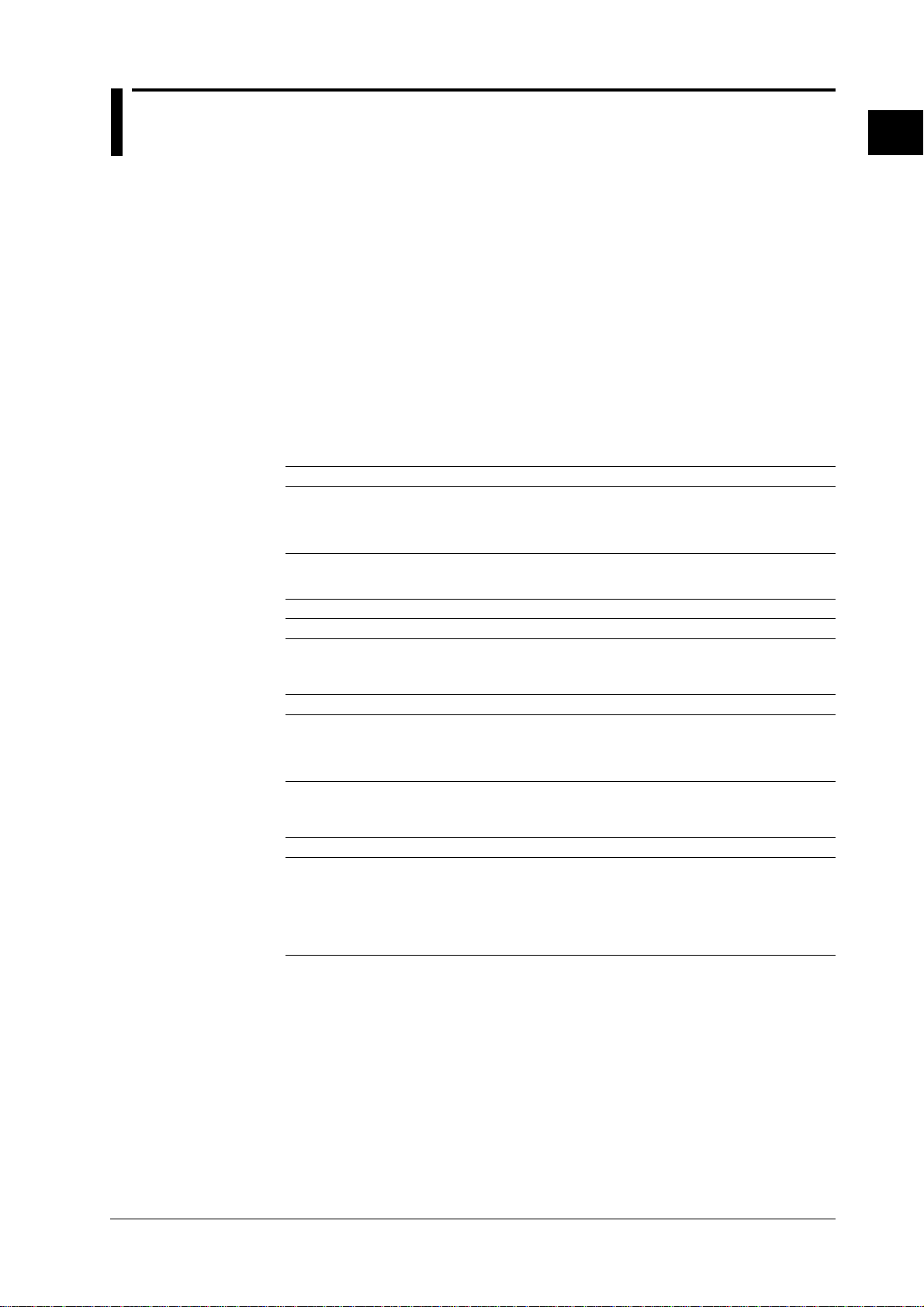

1.2 Operation Panel

Table Entry W indow

Select the Label

Select the measurement function

Select the type of thermocouple and resistance temperature

detector, and the measuring range

Select to use the NULL value

Select to calculate the difference from the reference channel

Select to average the measured values

Set the number of samples used for averaging

Enter the alarm output settings

Select the

reference channel

Select to enable fast scan mode

Select to hide alarm output and reference channel settings

Paste settings

Copy settings

Select items to be copied

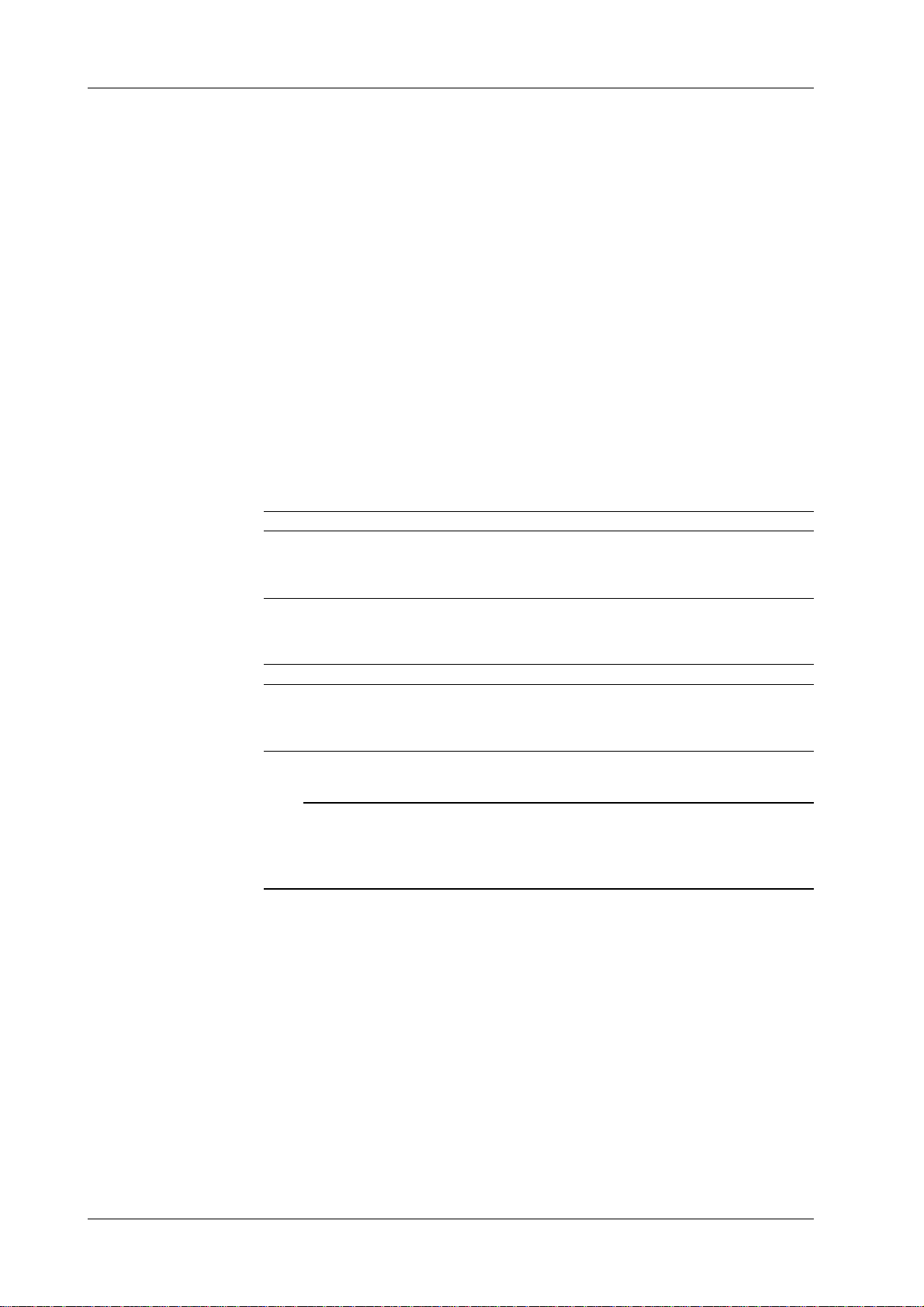

Displaying Alarm Status and Burn out by Channel

Select groups for alarm status display or burn out

Grey indicator: channels in the measured group currently not being measured

Black indicator: channels not set to output alarms

Green indicator: channels from the measured group set to output alarms

(When alarm occurs, color changes from green to red)

When displaying the Burn Out status, the indicators of the burned

out channels change from green to red.

Note

When an alarm occurs frequently, the alarm status display overloads processing resources and

may make it impossible to perform panel operations such as setting changes. If this happens,

turn the Monitor setting OFF.

1-4

IM 707231-01E

Page 11

1.3 Setting Measurement Conditions

Selecting the Measurement Function

Choose from TC (thermocouple), DCV (DC voltage), RTD (resistance temperature

detector), and OHM (resistance). RTD (resistance temperature detector) and OHM

(resistance) can only be selected for the odd-numbered channels between CH1 and

CH15, or the even-numbered channels between CH16 and CH30. Also, if at least one

channel among CH1-CH15 or CH16-CH30 is set to RTD (resistance temperature

detector) or OHM (resistance), measurement on the even-numbered channels from CH1

to CH15 or the odd-numbered channels from CH16 to CH30 will no longer be possible.

Hence, you will not be able to enter measurement function settings on those channels.

Selecting the T ype of Thermocouple and Resistance Temperature Detector and the Range

The following is a breakdown by measurement function of the type, range, and

measurement range that can be selected.

Thermocouple (TC)

Type Measurement Range Resolution

K –200.0 to 1300.0°C 0.1°C

E –200.0 to 800.0°C 0.1°C

J –200.0 to 1100.0°C 0.1°C

T –200.0 to 400.0°C 0.1°C

1

Functions

NULL

IM 707231-01E

Resistance Temperature Detector (RTD)

Type Measurement Range Resolution*

Pt100 –200.0 to 650.0°C 0.01°C (0.1°C)

* The resolution in parentheses is for an integral time of 1 ms or 4 ms.

DC Voltage Input (DCV)

Range Measurement Range Resolution*

20 mV ±19.9999 mV 100 nV (1 µV)

200 mV ±199.999 mV 1 µV (10 µV)

2 V ±1.99999 V 10 µV (10 µV)

20 V ±19.9999 V 100 µV (1 mV)

*The resolution in parentheses is for an integral time of 1 ms or 4 ms.

Resistance (OHM)

Range Measurement Range Resolution*

20 OHM 0.0 to 19.9999 Ω 100 µΩ (1mΩ)

200 OHM 0.0 to 199.9999 Ω 1 µΩ (10 mΩ)

2 kOHM 0.0 to 1.99999 Ω 10 mΩ (100 mΩ)

20 kOHM 0.0 to 19.99999 kΩ 100 mΩ (1 Ω)

200 kOHM 0.0 to 199.99999 kΩ 1Ω (10 Ω)

2 MOHM 0.0 to 1.9999 MΩ 10 Ω (100Ω)

*The resolution in parentheses is for an integral time of 1 ms or 4 ms.

For each channel, you can set whether the null value is applied to measurement values.

When the NULL check box is selected, the measured value is equal to the actual value

minus the null value. Using the NULL value, the residual voltage can be cancelled, for

example when measuring in microvolts.

If the NULL check box is selected during measurement, the value measured immediately

thereafter is used as the null value. If the NULL check box is selected while

measurement is stopped, the value measured immediately after measurement starts is

used as the null value.

If you click the NULL Meas button, the null values of the channels whose NULL check

boxes are selected are measured again.

1-5

Page 12

1.3 Setting Measurement Conditions

Difference Computation of the Input Between Two Channels

You can assign a channel from other linked 30-CH Fast Digital Thermometer WE7231s

or equivalent modules as the reference channel, and calculate the difference against the

input of the reference channel, select the Delta check box of the channel on which to

calculate the difference.

The Moving Average of the Measured V alues

Select the On check box under Average to calculate the moving average of the

measured value. Select the average from 2 to 100.

Fast Scan Mode

If you select the Fast Scan Mode check box, only the odd-numbered channels from

groups 1 (CH1 to CH15) and 2 (CH16 to CH30) are available, thereby allowing a short

sampling interval.

When Fast Scan Mode is OFF (normal scan mode), all channels are enabled.

Sampling Interval

The sampling interval applies to all channels.

When using Internal Time Base

Normal Scan Fast Scan Integration time

0.10 to 0.19 s 0.06 to 0.11 s 1 ms

0.2 to 0.79 s 0.12 to 0.44 s 4 ms

0.8 to 3.49 s 0.45 to 1.99 s 16.7/20 ms*

3.50 s to 2.0 s to 100 ms

* The integration time is automatically switched depending on the frequency of the power supply.

When using External Time Base

Normal Scan Fast Scan Integration time

0.15 to 0.24 s 0.10 to 0.14 s 1 ms

0.25 to 1.09 s 0.15 to 0.59 s 4 ms

1.10 to 3.69 s 0.60 to 2.09 s 16.7/20 ms*

3.7 s to 2.1 s to 100 ms

* The integration time is automatically switched depending on the frequency of the power supply.

Note

• If any channel uses the 200 kΩ or 2 MΩ range, an additional 0.8 s for normal scan or 0.4 s for

fast scan are added.

• If you change the sampling interval after starting measurement, the Time Since the Start of

Measurement display will not be accurate.

Reference Junction Compensation

To carry out reference junction compensation using the internal circuitry, select Internal

from the RJC Source list box. Select External for external reference junction

compensation. Set the reference junction temperature when performing external

reference junction compensation. This setting applies to all channels.

1-6

IM 707231-01E

Page 13

Burn Out

Time Base

1.3 Setting Measurement Conditions

This function is available only when TC (thermocouple) is selected as the measurement

function. When the Auto check box is selected, burn out is automatically detected during

measurement. If you click the Exec button, burn out detection is executed. This setting

applies to all channels.

When a burn out is detected in the thermocouple, the indicators displayed on the Moni

tab of the operation panel turn red and Burn Out appears in the measured value display .

Also, current flows to connected thermocouples during burn out detection.

Note

• When the sampling interval is set to one of the following values, the indicators are displayed at

every other channel. 1-0.14 s, 0.2-0.24 s, 0.8-1.14 s, 3.5-3.84 s.

• When burn out is automatically detected, the load on the PC can be large so updating of the

displayed waveform may be temporarily disabled.

You can select whether to sample the input signal with the sampling interval based on

the module’s internal clock, or to sample to the time base signal (CMNCLK) of the

measuring station (the BUSCLK setting). If you select BUSCLK, time base signals with

an interval shorter than the specified interval are ignored.

1

Functions

Units for T emperature Measurement

In the Unit box, select the units of temperature (C, K, or F) to be used by the module (or

all modules if more than one are linked) during temperature measurement.

IM 707231-01E

1-7

Page 14

1.4 Setting the Alarm

Alarm Type

Select the alarm type from the following choices.

Off: Do not detect alarms

Rise: Output when measured value changes from a value less than the specified upper

limit to a value greater than the specified upper limit.

Input signal

Alarm

High level

Fall: Output when a measured value changes from a value exceeding the specified

lower limit to a value less than the lower limit.

High: Output when a measured value is greater than or equal the specified upper limit.

Low: Output when a measured value is less than or equal the specified lower limit.

Input Signal

Alarm

Low level

In: Output when a measured value is between the specified upper and lower limits

(inclusive).

Out: Output when a measured value is less than the specified lower limit or greater

than the specified upper limit.

Input Signal

High level

Low level

1-8

Alarm

Group

You can divide the channels for which alarms were set into four groups. The alarm

occurrence status for each group is displayed in the operation panel, and can be output

to external devices by selecting the Out check box. You can assign any channel to any

group.

Combination

Select the condition under which alarms are output for each group.

OR: output alarm if any one channel in the group generates an alarm

AND: output alarm when all channels in the group generate an alarm

IM 707231-01E

Page 15

1.4 Setting the Alarm

Alarm Output

When the Out check box is selected, you can output the alarm occurrence status as a

bus trigger to the measuring station’s BUSTRG1 or BUSTRG2.

An alarm is output if any of the groups for which alarm output was specified generate an

alarm.

When an alarm occurs and the bus trigger signals are set to output from the WE7231 in

the Trigger Source/Time Base Source/Arming settings dialog box, if the alarm output

conditions are Rise/Fall when the conditions are met, the bus trigger signal is set to True

for approximately 1 µs. When the alarm output conditions are High, Low, In, or Out, the

bus trigger signal is True for as long as the conditions are met. For information about the

settings in the Trigger Source/Time Base Source Setting dialog box, see section 4.6,

“Setting the Trigger Source/Time Base Source/Arming” in the WE7000 User’s Manual (IM

707001-01E).

Example of Alarm Output

1

Functions

CH1 input

signal

Alarm

(type: High)

CH2 input

signal

Alarm

(type: Rise)

(When the combination is OR)

Event output

BUSTRG output

(When the combination is AND)

Event output

BUSTRG output

TRIG_HIGH

TRIG_LOW

TRIG_PULSE

TRIG_HIGH

TRIG_LOW

TRIG_PULSE

High level

High level

Alarm Status Indicator

The alarm occurrence status for each group is displayed according to the combination

setting. Also, when you select the group you wish to display under the Moni tab, the

button displaying the alarm status appears. You can confirm the alarm status of each

channel, and when an alarm occurs, the button color turns from green to red.

IM 707231-01E

Alarm Status Indicator Hold

When the Hold check box is selected, the alarm occurrence status indicator is held from

the point when an alarm occurs. If you click Reset, the hold is released.

1-9

Page 16

1.5 Waveform Display, Automatic Saving of

Measured Data, File Conversion, and Other

Functions

The following functions are common to all measurement modules controlled by the

WE7000 Control Software. For details, see the WE7000 User’s Manual (IM 70700101E).

Controlling the Timing of Measurement Start (Arming)

You can control the measurement start timing using the arming signal which is set in the

Trigger Source/T ime Base Source/Arming Setting dialog box. When the measurement

module is connected to the arming signal (ARM) bus in the Trigger Source/Time Base

Source/Arming Settings dialog box, the arming signal enters a wait state when the user

clicks the Start button in the operation panel, and measurement starts when the arming

signal becomes True. For information about the settings in the T rigger Source/Time Base

Source/Arming Setting dialog box, see section 4.6, “Setting the Trigger Source/Time

Base Source/Arming” in the WE7000 User’s Manual (IM 707001-01E).

Waveform Display

You can display measured data as a waveform on the WE7231. When measurement is

started on WE7231’s operation panel, waveforms are automatically displayed by default

in the WE7000 Control Software’s waveform monitor .

Automatic Saving

Besides saving the waveform data from those displayed in the waveform monitor,

measured data can also be automatically saved. You can select to save the data to one

file or by specifying the number of data points you may save to multiple files.

File Conversion

Saved measurement data can be converted from ASCII data in CSV format (*.csv) or

physical values in 32-bit floating point format (*.wvf, conforming the IEEE754-1985

standard).

Measured Data Scaling

Set two arbitrary points from the measured values (VP1, VP2) and the physical value

corresponding to those measured values (SP1, SP2). The scale conversion equation

(y=mx+b) is determined based on these four values. The measured values are

converted to physical values according to this equation, and can be displayed in a

waveform or saved as measurement data.

Physical

values

SP2

SP1

Y=ax + b

VP1

Measured values

VP2

1-10

IM 707231-01E

Page 17

1.6 Name and Functions of Each Part

Front Panel

Start indicator

Lights when

measurement starts

Input connector

Connector for the

scanner box

1

Functions

* See page 2-5 for the names and functions of each part of the 30-CH Scanner Box

(sold separately).

IM 707231-01E

1-11

Page 18

Chapter 2 Hardware Preparation

2.1 Mounting Modules in the Measurement Station

Preparation

Before shipping, a cover plate is affixed to each slot on the measuring station as shown

below. Confirm that there is no power being supplied to the measuring station, then

loosen the two attachment screws and remove the cover plate of the slot into which a

module will be installed. Please note that the left-most slot is reserved for

communications modules, and cannot be used for the WE7231.

* The example below shows the WE400 Measuring Station.

Dedicated slot for optical interface module

Available slot

Attachment screw

Cover plate

Attachment screw

2

Hardware Preparation

Installing the 30-CH Fast Digital Thermometer Module

WARNING

• Be sure to tightly fasten the upper and lower attachment screws. Connecting an

input cable without first tightening the screws may result in electric shock

because the protective grounding of the measuring station may be rendered

ineffective (depending on the power supply cord).

CAUTION

•To avoid damage to the instrument, turn OFF the standby power switch on the

measuring station when installing a measurement module.

• When inserting the module into the slot, be careful not to pinch your finger in the

release lever. Also, the module guide protrudes from inside the slot, so do not

insert your hand into the slot.

• Do not remove the cover plate from any slot unless a module will be mounted

into it. Doing so could cause problems, for example if the temperature rises. The

cover plate also suppresses the potentially damaging effects of magnetic waves.

IM 707231-01E

Insert the module along the guide rail of the slot from which you removed the cover plate.

Push the module until it clicks into the connector. Be careful not to get your fingers

caught in the ejection lever while inserting the module. When the module is securely

inserted, fasten the module attachment screws (tightening torque: 0.6 to 0.7 N-m).

To remove the module, loosen the module attachment screws and pull the ejection lever

from the inside to the outside. This will force the module out of the slot.

See illustration on the next page.

2-1

Page 19

2.1 Mounting Modules in the Measurement Station

Module attachment

screw

Module attachment screw

Note

When synchronization of the measurements of multiple input signals is desired (linking the

modules), install the multiple digital thermometer modules in adjacent slots.

• When removing the module

Ejection lever

2-2

IM 707231-01E

Page 20

2.2 Connecting the 30-CH Scanner Box and the Input Signal Wire

You cannot connect the input signal wires directly to the 30-CH Fast Digital Thermometer

Module WE7231. To connect the input signal wires, you need the 30-CH Scanner Box

(model 707815, sold separately).

Connecting the 30-CH Scanner Box to the Input Signal Wire

WARNING

• There is a danger of electric shock between the input terminals since they only

have functional isolation. Functional isolation means isolation that removes the

effect of noise from the electric potential difference occurring between 2 points,

and is intended to satisfy measurement specifications rather than to provide

protection from electric shock.

• The guard terminal is common within groups (CH1-CH15 and CH16-CH30).

Also the guard terminal is connected to the L terminal of the measurement

channel inside the module. If the potential of the L terminal at each channel

differs, the module or connected device may be damaged so don’t use the guard

terminal.

2

Hardware Preparation

CAUTION

• Do not apply a voltage exceeding the following levels, as it may damage the

module.

Maximum allowable input range: 30 VACrms, 42.4 Vpeak or ±60 VDC between

H and L.

(Overvoltage category: CA T I and II)

Maximum noise across channels: 60 VACrms or ±100 VDC

• Do not apply the voltage exceeding 60 V ACrms or ±100 VDC between input

channels, as it may damage the module and 30-CH Scanner Box.

• Remove the 30-CH Scanner Box from the module when connecting the signal

wires to avoid damaging the module.

• Do not apply voltage between the L terminal and guard terminal (terminal with

the G signal) as this may result in damage to the module and any connected

devices. The guard terminal is connected to the circuit common inside the

module. When measuring voltage, the guard terminal and L terminal form a

direct connection since the L terminal is connected to the circuit common. Also,

when measuring resistance, L terminal is the standard for the circuit common.

Note

• When performing internal reference junction compensation on the thermocouple input, consider

the following suggestions for stabilizing the temperature at the terminal section.

• Make sure the terminal cover is in place.

• Keep the temperature constant in the area where the instrument is operating.

• Do not use thick wires (a cross sectional area of 0.5 mm2 or more) that have large radiation

effects.

• Place the 30-CH Scanner Box at a sufficient distance from the point of measurement so that

the heat from the point of measurement will be conducted through the wiring rather than to

the 30-CH Scanner Box.

•To prevent noise, you can use the functional grounding terminal on the side of the 30-CH

Scanner Box to ground the guard terminal or L terminal (see next page).

IM 707231-01E

2-3

Page 21

2.2 Connecting the 30-CH Scanner Box and the Input Signal Wire

• Thermocouple/V oltage Measurement

Connects to the H and L terminals of channels 1-30 using a 2 wire system. Each H

and L terminal of channel 15C and 30C is a dedicated input terminal for resistance

temperature detector/resistance measurement. Don’t connect these when measuring

thermocouple/voltage.

• Resistance T emperature Detector/Resistance Measurement

Connect using a 4 wire system. When the measurement function is set to RTD

(resistance temperature detector) or OHM (resistance), measurement is performed on

the input signal voltages from the odd-numbered channels between CH1 and CH15, or

the even-numbered channels between CH16 and CH30. The next-numbered channel

becomes the current output terminal of the voltage measurement channel. For

example, if channel 1’s H and L terminals are the voltage input terminals, then channel

2’s H and L terminals are the current output terminals. The each H and L terminal of

channel 15 or 30 become current output terminals.

i

CH2’s H terminal

CH1’s H terminal

V

CH1’s L terminal

CH2’s L terminal

Mixing 2 and 4 Wire Systems

The terminals on the scanner box are divided into groups 1 and 2, and you can specify a

2 or 4 wire system for each group. Even for one channel, when you select measurement

with a 4 wire system (resistance temperature detector/resistance measurement), you can

only measure the odd-numbered channels from group 1 or even-numbered channels

from group 2. However you can mix 2 and 4 wire systems; for example if you measure a

resistance temperature detector or resistance with a 2 wire system on CH1, you can

have a 4 wire system such as the thermocouple or voltage on CH3.

Group 1: CH1-CH15, Group 2: CH16-CH30

2-4

IM 707231-01E

Page 22

2.2 Connecting the 30-CH Scanner Box and the Input Signal Wire

Attaching and Removing the Terminal Cover

Unscrew the two attachment screws in the upper part of the 30-CH Scanner Box and

remove the cover as shown in the diagram below. After connecting all of the input signal

wires to the input terminals, fasten the input signal wire with the cable clamp, re-attach

the terminal cover, and tighten the terminal cover attachment screws. Use crimp-on lugs

to ensure the connection to the input terminal is secure, and if it’s not necessary to use

the cable clamp, you can remove the clamp to widen the opening, and allow thicker

wiring. When connecting to all input terminals, the maximum allowable cross-sectional

area per cable (due to the restriction on the area of the cover opening) is the following.

With a cable clamp: 2 mm

Terminal cover attachment screws (2)

2

, without a cable clamp: 19 mm

2

Terminal

cover

2

Hardware Preparation

Cable attachment

screw

Cable clamp

Cable clamp

attachment screw

Functional ground terminal

Example of terminal arrangement

M4 screw for each terminal

Connector

BETWEEN H AND L

TERMINAL 30VACrms,

42.4Vpeek OR 60VAC

BETWEEN L TERMINALS

Guard terminal

L terminal (1)

H terminal (1)

L terminal (15)

H terminal (15)

L terminal (15C)

H terminal (15C)

Guard terminal

AND CASE 150V MAX

CAT

G

L

116

H

L

217

H

(1C) (16C)

L

318

H

L

419

H

(3C) (18C)

L

520

H

L

621

H

(5C) (20C)

L

722

H

L

823

H

(7C) (22C)

L

924

H

L

10 25

H

(9C) (24C)

L

11 26

H

L

12 27

H

(11C) (26C)

L

13 28

H

L

14 29

H

(13C) (28C)

L

15 30

H

L

(15C)

G

G

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

(30C)

LH

G

Guard terminal

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H terminal (16)

L terminal (16)

H terminal (30)

L terminal (30)

H terminal (30C)

L terminal (30C)

Guard terminal

IM 707231-01E

Functional ground terminal

Cable clamp

2-5

Page 23

2.2 Connecting the 30-CH Scanner Box and the Input Signal Wire

Connecting to a Module

CAUTION

•Turn OFF the standby power switch on the measuring station when connecting a

module to the 30-CH Scanner Box.

As in the diagram below, use the cable that came with the 30-CH Scanner Box between

the scanner box and the module input connector.

Connection Cable

(Accessory for the 30-CH Scanner Box)

30-CH Scanner Box

2-6

IM 707231-01E

Page 24

Chapter 3 Troubleshooting and Maintenance

3.1 Troubleshooting

• If servicing is required, or if the instrument is not operating correctly after performing

the corrective actions listed below, contact your nearest YOKOGAWA dealer as listed

on the back cover of this manual.

•To verify that the module is operating correctly , perform the self test described on the

next page.

Problem Possible Causes/Corrective Actions Reference Page

Module does not operate. Check that the module is installed correctly into the station. 2-1, *

Also, install the module into another slot, and check whether it will

operate there. If it operates in the other slot, the measuring station is

likely to have malfunctioned.

If the module is installed correctly and does not operate, the fuse might

have melted, the connector might be bad, or the IC may have

malfunctioned.

In any case, contact your nearest YOKOGAW A dealer to have it repaired.

Waveform data cannot be Check that the input signal wires are connected properly. 2-3 to 2-6

acquired. Also check the connection between the 30-CH Scanner Box and

the module.

Noise enters the input signal If the signal line and the AC power supply line are close to each other, 2-3

move them apart. Also make sure that the signal line is away from the

noise source.

Change to a shielded signal wire if you are not already using one. 2-3

Measured values are not correct. Check that the ambient temperature and humidity are within the 4-5

allowed ranges. If you did not allow a warm-up time of 30 minutes,

try measuring again after the warm-up time has passed.

Check to see that the input signal level is not exceeding the 4-1, 4-2

measurement range.

Temperature measurement is not Check that the RJC setting is correct. 1-3, 1-5

correct. Check whether the thermocouple type and polarity are set properly.

Check to see that the thermocouple is not burnt out after clicking the

Exec button under Burn Out.

Check whether the terminal cover for the 30-CH Scanner Box is 2-5

attached.

Check to see that there is no draft in the area where the instrument is

located that might cause significant changes in temperature.

Check to see that the two types of thermocouple wires are not too far

apart, the tip is not touching a metal object, and that the thermocouple

is being handled properly .

Check to see that the input signal level from the object being measured

is within the measurement range.

The displayed waveform does not Check whether the measurement has been started on the operation 1-3

get updated. panel.

Check whether the sampling interval is set properly on the operation 1-6

panel.

The waveform is not displayed. Check whether measurement has been started on the operation panel. 1-3

If the time base setting is BUSCLK, check to see that the time base 1-6, *

source is set properly in the Trigger Source/Time Base Source/Arming

Setting dialog box of the WE7000 Control Software.

Check to see that the input signal level from the object being measured

is within the measurement range.

The waveform monitor is not Check that the waveform monitor ON/OFF button located to the right of 1-3

displayed. the Start button on the operation panel is turned ON.

* See the WE7000 User’s Manual (IM707001-01E).

3

Troubleshooting and Maintenance

IM 707231-01E

3-1

Page 25

3.2 Self Test

If you believe that the module is not operating correctly, perform the self test according to

the following steps.

Executing the Self T est

1. In the WE7000 Control Software, select System > Self T est .

2. In the Self Test dialog box, select the station name and slot number of the module to

be tested, and click the Execute button.

“Executing” is displayed in the Result box.

→

Verifying Test Results

If a value other than 0 is displayed in the Result box of the Self Test dialog box, the

module is probably malfunctioning. Contact your nearest YOKOGAW A representative as

listed on the back cover of this manual.

3-2

IM 707231-01E

Page 26

3.3 Maintenance

Maintenance of Parts

There are no parts in this module that require periodic replacement.

Calibration

We recommend that you calibrate the measurement module once a year to assure its

measurement accuracy.

Contact your nearest YOKOGAW A representative as listed on the back cover of this

manual for calibration.

3

Troubleshooting and Maintenance

IM 707231-01E

3-3

Page 27

Chapter 4 Specifications

4.1 Performance Specifications

Input Signal

Thermocouple: K, E, J, T (2 wire system)

DC voltage: 20 mV, 200 mV, 2 V , 20 V (2 wire system)

Resistance temperature detector: Pt100 (4 wire system)

Resistance: 20 Ω, 200 Ω, 2 kΩ, 20 kΩ, 200 kΩ, 2 MΩ (4 wire

system)

Number of input channels

With only 2 wire systems connected: 30, with only 4 wire systems connected: 16

Groups: Group 1 (CH1-CH15), Group 2 (CH16-CH30)

Possible to specify wiring (2 wire system/4 wire system) for each group.

Input format

Floating unbalance input, isolated between input and ground

Input terminal type

Multi-pole square connector (to connect the 30-CH Scanner Box, sold separately)

4

Specifications

Measurement Mode

Sampling interval

Normal Scan: all channels (30 channels total)

Fast Scan: odd channels from group 1, and even channels from group 2 (16

channels total)

Internal time base

Normal scan: 0.10 s to 60 min (0.9 s or more if any channel uses the 200 kΩ/2 MΩ

range)

Fast Scan: 0.06 s to 60 min (0.46 s or more if any channel uses the 200 kΩ/2 MΩ

range)

Normal Scan Fast Scan Integration time

0.10 to 0.19 s 0.06 to 0.11 s 1 ms

0.2 to 0.79 s 0.12 to 0.44 s 4 ms

0.8 to 3.49 s 0.45 to 1.99 s 16.7/20 ms

3.5 s to 2.0 s to 100 ms

If any channel uses the 200 kΩ or 2 MΩ range, an additional 0.8 s and 0.4 s are added during

normal scan and fast scan. Can be specified in units of 0.01 s for the 0.06 s to 60.0 s range and

60.0 s to 60.0 min range.

External Time Base

Normal Scan: 0.15 s to 60 min (0.95 s or more if any channel uses the 200 kΩ/2 MΩ

range)

Fast Scan: 0.1 s to 60 min (0.5 s or more if any channel uses the 200 kΩ/2 MΩ

range)

IM 707231-01E

Normal Scan Fast Scan Integration time

0.15 to 0.24 s 0.10 to 0.14 s 1 ms

0.25 to 1.09 s 0.15 to 0.59 s 4 ms

1.10 to 3.69 s 0.60 to 2.09 s 16.7/20 ms

3.7 s to 2.1 s to 100 ms

If any channel uses the 200 kΩ or 2 MΩ range, an additional 0.8 s and 0.4 s are added during

normal scan and fast scan. Can be specified in units of 0.01 s for the 0.06 s to 60.0 s range and

60.0 s to 60.0 min range.

4-1

Page 28

4.1 Performance Specifications

Measurement Range and Resolution

TC Input

Type Measurement Range Resolution

K –200.0 to 1300.0°C 0.1°C

E –200.0 to 800.0°C 0.1°C

J –200.0 to 1100.0°C 0.1°C

T –200.0 to 400.0°C 0.1°C

Units: °C, K or °F can be selected.

Reference junction compensation: internal or external can be selected.

Burn out: auto or manual detect can be selected.

Resistance temperature detector (4 wire system)

Range Measurement Range Resolution Measured Current

Pt100 –200 to 650°C 0.01 (0.1)°C1 mA

The resolution in the parentheses is for an integration time of 1 ms or 4 ms.

DC voltage

Range Maximum display Resolution

20 mV 19.9999(19.999) 100 nV (1 µV)

200 mV 199.999(199.99) 1 µV (10 µV)

2 V 1.99999(1.9999) 10 µV (10 µV)

20V 19.9999(19.999) 100 µV (1 mV)

The resolution in the parentheses is for an integration time of 1 ms or 4 ms.

Accuracy

Resistance (4 wire system)

Range Maximum display Resolution Measured Current

20 Ω 19.9999(19.999) 100 µΩ (1 mΩ)1 mA

200 Ω 199.999(199.99) 1 mΩ (10 mΩ)1 mA

2 kΩ 1.99999(1.9999) 10 mΩ (100 mΩ)1 mA

20 kΩ 19.9999(19.999) 100 mΩ (1 Ω) 100 µA

200 kΩ 199.999(199.99) 1 Ω (10 Ω) 10 µA

2 MΩ 1.99999(1.9999) 10 Ω (100Ω)1 µA

Open terminal voltage: 10 V max.

The resolution in the parentheses is for an integration time of 1 or 4 ms.

Thermocouple ±(% of reading +°C)

Gain error (%) Offset error °C (for every integration time)

Range Measurement Range 100 ms 16.7/20 ms 4 ms 1 ms

K –200≤t<–100°C 0.035 0.5 0.6 2 3.0

–100≤t<1300°C 0.035 0.3 0.4 1 1.5

E –200≤t<–100°C 0.035 0.3 0.4 1.5 2.0

–100≤t<800°C 0.035 0.2 0.3 1.0 1.5

J –200≤t<–100°C 0.035 0.4 0.5 2.0 2.5

–100≤t<1100°C 0.035 0.2 0.3 2.0 1.5

T –200≤t<–100°C 0.035 0.5 0.6 2.5 3.5

–100≤t<400°C 0.035 0.3 0.4 1.5 2.0

Resistance temperature detector ±(% of reading +°C)

Gain error (%) Offset error °C (for every integration time)

Range Measurement Range 100 ms 16.7/20 ms 4 ms 1 ms

Pt100 –200≤t<200°C0 0.3 0.3 0.4 0.5

200≤t<650°C 0.1 0.1 0.1 0.2 0.3

4-2

IM 707231-01E

Page 29

4.1 Performance Specifications

DC voltage ±(% of reading + digit)

Range Gain error (%) 100 ms 16.7/20 ms 4 ms 1 ms

20 mV 0.03 60 80 30 50

200 mV 0.025 8 10 4 8

2 V 0.02 5 7 3 6

20 V 0.035 5 7 3 6

Offset error (digit) (for every integration time)

Resistance ±(% of reading + digit)

Range Gain error (%) 100 ms 16.7/20 ms 4 ms 1 ms

20 Ω 0.04 60 80 30 50

200 Ω 0.04 8 10 4 8

2 kΩ 0.035 6 8 3 6

20 kΩ 0.035 6 8 3 6

200 kΩ 0.035 6 8 3 6

2 MΩ 0.3 20 25 40 60

Reference Junction Compensation Accuracy

1°C (the value not including the noise component when the temperature of the 30-CH

Scanner Box is balanced).

Temperature coefficient

• In the 20 V range: ±(accuracy/5)/°C

• Other ranges: ±(accuracy/10)/°C

However, at 5 to 18°C or 20 to 40°C

Computaion

The calculations below can be turned ON/OFF for each channel.

• Difference

Difference from the reference channel. When modules are linked, the difference can

be computed across modules. However, difference cannot be computed between two

different measurement functions.

•NULL

Sets the NULL value for each channel.

• Moving Average

100 samples maximum. Can be specified for each channel.

Offset error (digit) (for every integration time)

4

Specifications

Alarm Output

IM 707231-01E

Can output trigger signals to the internal bus (BUSTRG1/BUSTRG2) of the measuring

station on the AND/OR condition of the alarm detection result specified by high, low, in,

out, rising, or falling of each channel.

4-3

Page 30

4.2 Factory Default Settings

Function (measurement function): TC

Range (measurement range): T ype T

Reference Channel: CH 1 on the module

Sampling Interval: 0.80 s

Burn Out (Auto Detect): Off

Alarm Hold: Off

Channel: CH 1 on the module

NULL (use NULL value): Off

Delta (difference measurement): Off

Averaging: Off

Type (alarm type): Off

RJC Source (internal/external switch for the reference junction compensation): Internal

Alarm Combination: AND

Out (alarm output): On

Time Base: Internal

Unit (units of temperature measurement): °C

Fast Scan Mode: Off

Monitor (group selection of alarm status for each channel/burn out status display): Off

4-4

IM 707231-01E

Page 31

4.3 General Specifications

Safety Standards

Complies with CSA C222 No. 1010.1 and EN61010-1, conforms to JIS C1010-1

Standard Operating Conditions

Ambient T emperature: 23±5°C

Ambient Humidity: 50±10% RH

After the warm-up time has passed.

Warm-up Time

At least 1 hour

Operating Condition

Same as those of the measuring station

Storage Condition

Temperature: –20 to 60°C

Humidity: 20 to 80% RH (no condensation)

Maximum Allowable Input Range

30 VACrms, 42.4 Vpeak or ±60 VDC

(Overvoltage category: CA T I and II)

Maximum Common Mode V oltage

150 V rms or ±150 VDC between ground and L terminal

Maximum Noise between Channels

60 VACrms, 84.8 Vpeak or ±100 VDC

Input Resistance

1 GΩ or more (except, 10 MΩ ±1% for the 20 V range)

Allowable Signal Resistance

1 kΩ or lower (when using thermocouple or resistance temperature detector)

Normal Mode Rejection Ratio

Approximately 60 dB

(at an integration time of 16.7 ms or longer, 50/60 Hz ±0.1%)

Common Mode Rejection Ratio

Approx. 120 dB or more.

(at an integration time of 16.7 ms or longer, 50/60 Hz ±0.1%, and unbalanced input Rs=1

kΩ)

Withstand V oltage

1500 VAC at 60 Hz between ground and L terminal for one minute

Power Consumption

7.0 VA (typical value* at 100 V/50 Hz when connected to the 30-CH Scanner Box (model:

707815))

External Dimensions

Approx. 33(W) × 243(H) × 232(D) mm (projections excluded)

Weight

Approx. 0.8 kg

Number of Used Slots

1

Standard Accessories

User’s manual (1)

Optional Accessories

707815 30-CH Scanner Box (cable length: 1 m)

707815/L3 30-CH Scanner Box (cable length: 3 m)

4

Specifications

* The typical value is a typical or average value. It is not strictly guaranteed.

IM 707231-01E

4-5

Page 32

4.4 Specifications for the 30-CH Scanner Box

Number of Input Channels

30

Input Format

Isolation between input and ground

Functional isolation between the Input channels*.

* Functional isolation means insulation that removes the effect of noise from the electric potential

difference occurring between 2 points, and is intended to satisfy measurement specifications

rather than to provide protection from electric shock.

Input T erminal type

M4 Screw

The maximum allowable cross-sectional area per one cable (due to the restriction on

the area of the cover opening) when connecting to all input terminals.

When using the cable clamp: 2 mm

Without the cable clamp: 19 mm

Operating Conditions

Temperature: 5 to 40°C

Humidity: 20-80% RH (except maximum wet-bulb temperature of 29°C, no

condensation)

Maximum Allowable Input Voltage

30 VACrms, 42.4 Vpeak or ±60 VDC between H and L terminals (overvoltage category:

CAT I and II).

Maximum Noise between Channels

60 VACrms, ±100 VDC.

Insulation Withstand Voltage

Between voltage input terminals and case: 60 Hz 1500 V ACrms for one minute

Insulation Resistance

Between input terminal and ground: 10 MΩ (500 VDC) or more

Modules that can be Connected

707231 (WE7231 30-CH Fast Digital Thermometer Module)

Weight

Approx. 1.3 kg

External Dimensions

Approx. 123(W) × 76(H) × 305(D) mm (projections excluded)

2

2

4-6

IM 707231-01E

Page 33

4.5 External Dimensions

WE7231 30-CH Fast Digital Thermometer Module

33

START

242.4

30-CH,FAST

30-CH Scanner Box (Model 707815)

Main Unit

Units: mm

227 4.5

4

Specifications

132 305

Connecting cable

707815: 1 m

707815/L3: 3 m

106.5 59.5

If not specified, the tolerance is ±3%. However, if less than 10 mm, the tolerance is ±0.3

mm.

IM 707231-01E

4-7

Page 34

Index

Index

Symbols

*.csv ................................................................................. 1-10

*.wvf ................................................................................. 1-10

2 wire system ..................................................................... 2-4

30-CH Scanner Box ...........................................................2-3

4 wire system ............................................................. 2-4, 2-4

A

AND ................................................................................... 1-8

Alarm.................................................................................. 1-8

Alarm Type......................................................................... 1-8

Arming.............................................................................. 1-10

Automatic Saving ............................................................. 1-10

Average.............................................................................. 1-6

B

Burn Out............................................................................. 1-7

C

Combination ....................................................................... 1-8

Contents of the Package....................................................... 2

Controlling the Timing of Measurement Start................... 1-10

D

DC Voltage Input................................................................ 1-5

DCV ................................................................................... 1-5

Delta................................................................................... 1-6

Difference Computation ..................................................... 1-6

E

External .............................................................................. 1-6

F

Fall ..................................................................................... 1-8

Fast Scan Mode ................................................................. 1-6

File Conversion ................................................................ 1-10

Front Panel ...................................................................... 1-11

Function ............................................................................. 1-5

M

Measurement Function ...................................................... 1-5

Model .................................................................................... 2

Moving Average ................................................................. 1-6

N

NO......................................................................................... 2

NULL .................................................................................. 1-5

O

OHM................................................................................... 1-5

OR...................................................................................... 1-8

On ...................................................................................... 1-6

Out ..................................................................................... 1-8

R

RTD .................................................................................... 1-5

Range ................................................................................ 1-5

Reference Junction Compensation .................................... 1-6

Reset.................................................................................. 1-9

Resistance ......................................................................... 1-5

Resistance Temperature Detector...................................... 1-5

Rise .................................................................................... 1-8

reference channel .............................................................. 1-6

S

START.............................................................................. 1-11

Sampling Interval ............................................................... 1-6

Scaling ............................................................................. 1-10

Self Test ............................................................................. 3-2

System Configuration......................................................... 1-1

T

TC ...................................................................................... 1-5

Thermocouple .................................................................... 1-5

Time Base .......................................................................... 1-7

Troubleshooting ................................................................. 3-1

Type ................................................................................... 1-8

terminal arrangement ......................................................... 2-5

Index

Index

G

Group ................................................................................. 1-8

H

High.................................................................................... 1-8

Hold.................................................................................... 1-9

I

In ........................................................................................1-8

Input Connector ............................................................... 1-11

Internal ............................................................................... 1-6

L

Low .................................................................................... 1-8

IM 707231-01E

U

Unit..................................................................................... 1-7

Units for Temperature Measurement.................................. 1-7

Index-1

Loading...

Loading...