Page 1

User’s

Manual

VJ Series

Communication Functions

IM 77J01J11-01E

IM 77J01J11-01E

3rd Edition

Page 2

Blank Page

Page 3

<Toc> <Ind> <Rev>

Introduction

This instruction manual describes the communication functions of the VJ Series signal

conditioners and contains information on how to create communication programs.

Read the manual carefully to understand the communication functions of the VJ Series.

The VJ Series signal conditioners have the following communication protocols.

● PC link communication protocol

● MODBUS communication protocol

● Ladder communication protocol

Note that the VJ Series signal conditioner cannot communicate with a higher-level device

with a communication protocol other than these.

You are required to have background knowledge of the communication specifications of

higher-level devices, their communication hardware, language used for creating communication programs, and so on.

i

■ Intended Readers

This manual is intended for people familiar with the functions of the VJ Series signal conditioners, control engineers and personnel in charge of maintaining instrumentation and

control equipment.

■ Related Documents

The following instruction manuals all relate to the communication functions of the VJ series

signal conditioners. Read them as necessary.

● A variety of instruction manuals for VJ Series signal conditioners describing mounting,

wiring, and how to calibrate the signal conditioners.

All Rights Reserved Copyright © 1999, Yokogawa Electric Corporation

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 4

<Toc> <Ind> <Rev>

Documentation Conventions

■ Symbols

This manual uses the following symbols.

● Symbols Used in the Main Text

CAUTION

Draws attention to information that is essential for understanding the operation and/or

features of the product.

TIP

Gives additional information to complement the present topic.

See Also

ii

Gives reference locations for further information on the topic.

■ Description of Displays

(1) Some of the representations of product displays shown in this manual may be exag-

gerated, simplified, or partially omitted for reasons of convenience when explaining

them.

(2) Although, figures and illustrations representing the signal conditioner's displays may

differ from the real displays in regard to the position and/or indicated characters

(upper-case or lower-case, for example), the extent of difference does not impair a

correct understanding of the functions and the proper operations and monitoring of the

system.

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 5

<Toc> <Ind> <Rev>

Notices

■ Regarding This Instruction Manual

(1) This manual should be passed on to the end user. Keep the manual in a safe place.

(2) Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

(3) This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that

these functions are suited to the particular purpose of the user.

(4) Under absolutely no circumstance may the contents of this manual, in part or in whole,

be transcribed or copied without permission.

(5) The contents of this manual are subject to change without prior notice.

(6) Every effort has been made to ensure accuracy in the preparation of this manual.

Should any errors or omissions come to your attention however, please contact your

nearest Yokogawa representative or our sales office.

iii

■ Regarding Protection, Safety, and Prohibition Against Unauthorized

Modification

(1) In order to protect the product and the system controlled by it against damage and

ensure its safe use, be certain to strictly adhere to all of the instructions and precautions relating to safety contained in this document. Yokogawa does not guarantee

safety if products are not handled according to these instructions.

(2) The following safety symbols are used on the product and/or in this manual.

● Symbols Used on the Product and in This Manual

CAUTION

This symbol on the product indicates that the operator must refer to an explanation in

the instruction manual in order to avoid the risk of injury or death of personnel or

damage to the instrument. The manual describes how the operator should exercise

special care to avoid electric shock or other dangers that may result in injury or loss of

life.

Protective Grounding Terminal

This symbol indicates that the terminal must be connected to ground prior to operating

the equipment.

Functional Grounding Terminal

This symbol indicates that the terminal must be connected to ground prior to operating

the equipment.

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 6

<Toc> <Ind> <Rev>

■ Force Majeure

(1) Yokogawa does not make any warranties regarding the product except those men-

tioned in the WARRANTY that is provided separately.

(2) Yokogawa assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

(3) Be sure to use the spare parts approved by Yokogawa when replacing parts or

consumables.

(4) Modification of the product is strictly prohibited.

(5) Reverse engineering such as the disassembly or decompilation of software is strictly

prohibited.

(6) No portion of the software supplied by Yokogawa may be transferred, exchanged,

leased, or sublet for use by any third party without the prior permission of Yokogawa.

iv

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 7

<Int> <Ind> <Rev>

VJ Series Communication Functions

CONTENTS

Introduction........................................................................................................... i

Documentation Conventions ...............................................................................ii

Notices .................................................................................................................iii

1. Setup ....................................................................................................... 1-1

1.1 Setup Procedure ............................................................................................. 1-1

1.2 Notes on Setting Parameters ......................................................................... 1-2

2. Communication Specifications.............................................................. 2-1

2.1 RS-485 Communication Specifications ......................................................... 2-1

Toc-1

IM 77J01J11-01E 3rd Edition

3. PC Link Communication ........................................................................ 3-1

3.1 Overview.......................................................................................................... 3-1

3.1.1 Configuration of Command ............................................................... 3-2

3.1.2 Configuration of Response ............................................................... 3-3

3.1.3 Response Error Codes ..................................................................... 3-4

3.2 Commands ...................................................................................................... 3-5

3.2.1 List of Commands ............................................................................. 3-5

3.2.2 BRD Reading I Relays on a Bit-by-bit Basis ..................................... 3-6

3.2.3 BRR Reading I Relays on a Bit-by-bit Basis in a Random Order....... 3-7

3.2.4 BRS Specifying I Relays to be Monitored on a Bit-by-bit Basis ......... 3-8

3.2.5 BRM Monitoring I Relays on a Bit-by-bit Basis ................................. 3-9

3.2.6 WRD Reading D Registers/I Relays on a Word-by-word Basis....... 3-10

3.2.7 WRR Reading D Registers/I Relays on a Word-by-word Basis in a Random

Order ...............................................................................................3-11

3.2.8 WRS Specifying D Registers/I Relays to be Monitored on a Word-by-word

Basis .............................................................................................. 3-12

3.2.9 WRM Monitoring D Registers/I Relays on a Word-by-word Basis ... 3-13

3.2.10 INF Reading the Model, Presence/Absence of Options, and Revision3-14

3.3 Communication with Higher-level Devices ................................................. 3-15

3.3.1 Example of Communication Program Created Using Visual Basic .. 3-16

3.3.2 Communication with UT Link Module .............................................. 3-20

3.3.3 Communication with Graphic Panel ................................................ 3-21

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 8

<Int> <Ind> <Rev>

4. Ladder Communication.......................................................................... 4-1

5. MODBUS Communication...................................................................... 5-1

6. Functions and Usage of D Registers ..................................................... 6-1

Toc-2

4.1 Overview.......................................................................................................... 4-1

4.2 Commands/Responses at the PLC ................................................................ 4-2

4.2.1 Command/Response Component Elements ..................................... 4-2

4.2.2 Reading Parameters......................................................................... 4-3

4.2.3 Response Error Codes ..................................................................... 4-4

5.1 Overview.......................................................................................................... 5-1

5.1.1 Configuration of Message ................................................................. 5-2

5.1.2 Specifying D Registers...................................................................... 5-3

5.2 Function Codes ............................................................................................... 5-4

5.2.1 List of Function Codes ...................................................................... 5-4

5.2.2 Response Error Code[Response] ..................................................... 5-8

5.3 Example of Setting up Commercially Available SCADA Software ............... 5-9

6.1 Overview of D Registers ................................................................................. 6-1

6.2 Interpretation of D Register Map Table .......................................................... 6-1

6.3 D Register Map Table ...................................................................................... 6-2

6.3.1 Contents of D Registers .................................................................... 6-3

7. Functions and Usage of I Relays ........................................................... 7-1

7.1 Status............................................................................................................... 7-2

Appendix Table of ASCII Codes (Alphanumeric Codes) ............................App.-1

Revision Information ............................................................................................ i

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 9

<Toc> <Ind> <1. Setup >

1. Setup

This chapter describes the setup procedure required to use the communication

functions (PC link, Ladder, and MODBUS) and the communication parameters of the

VJ Series.

1.1 Setup Procedure

Set up the communication functions on the VJ Series as follows:

Set up the communication function parameters of the VJ Series. (See section 1.2.)

Connect a higher-level device and a VJ Series. (See the connection diagram below.)

Create communication programs for the higher-level device to perform communication.

010101E.EPS

Note: Refer to the documentation of each higher-level device when creating communication programs.

1-1

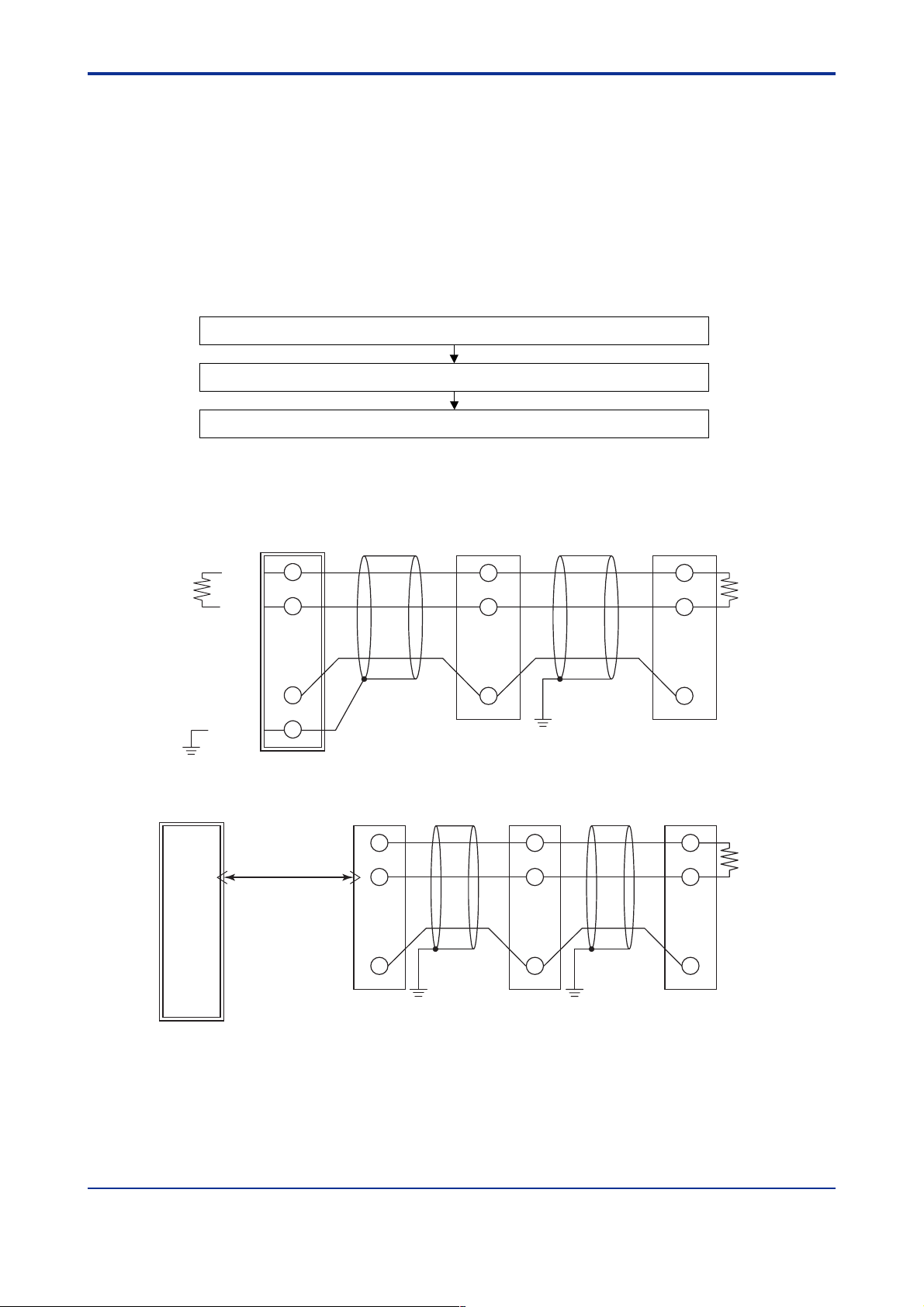

• Connection

Terminating resistor

220 Ω

1/4 W

Shielded

Grounding resistance of less than 100 Ω

PC or PLC

B (+)

A (-)

SG

RS-232C

(straight cable)

PLC

(RS-232C/RS-485 converter)

ML2

4

3

5

B (+)

A (-)

SG

VJ Series VJ Series

B (+)

A (-)

2

5

6

Grounding resistance of less than 100 Ω

VJ Series VJ Series

B (+)

2

A (-)

5

6

3rd Edition : Oct. 15, 2007-00

B (+)

A (-)

COMCOM

B (+)

A (-)

COMCOM

2

5

Terminating resistor

6

2

5

Terminating resistor

6

220 Ω

1/4 W

220 Ω

1/4 W

Grounding resistance

of less than 100 Ω

Grounding resistance

of less than 100 Ω

IM 77J01J11-01E

010102E.EPS

3rd Edition : Oct. 15, 2007-00

Page 10

<Toc> <Ind> <1. Setup >

1.2 Notes on Setting Parameters

This section describes the setting parameters for using the communication functions and their setting ranges.

CAUTION

The details of VJ Series communication functions need to be the same as those of the

communication functions of the higher-level device to be connected. Check the communication parameters of the higher-level device first, then set up those of the VJ Series using

the Handy Terminal or setting tool (VJ77).

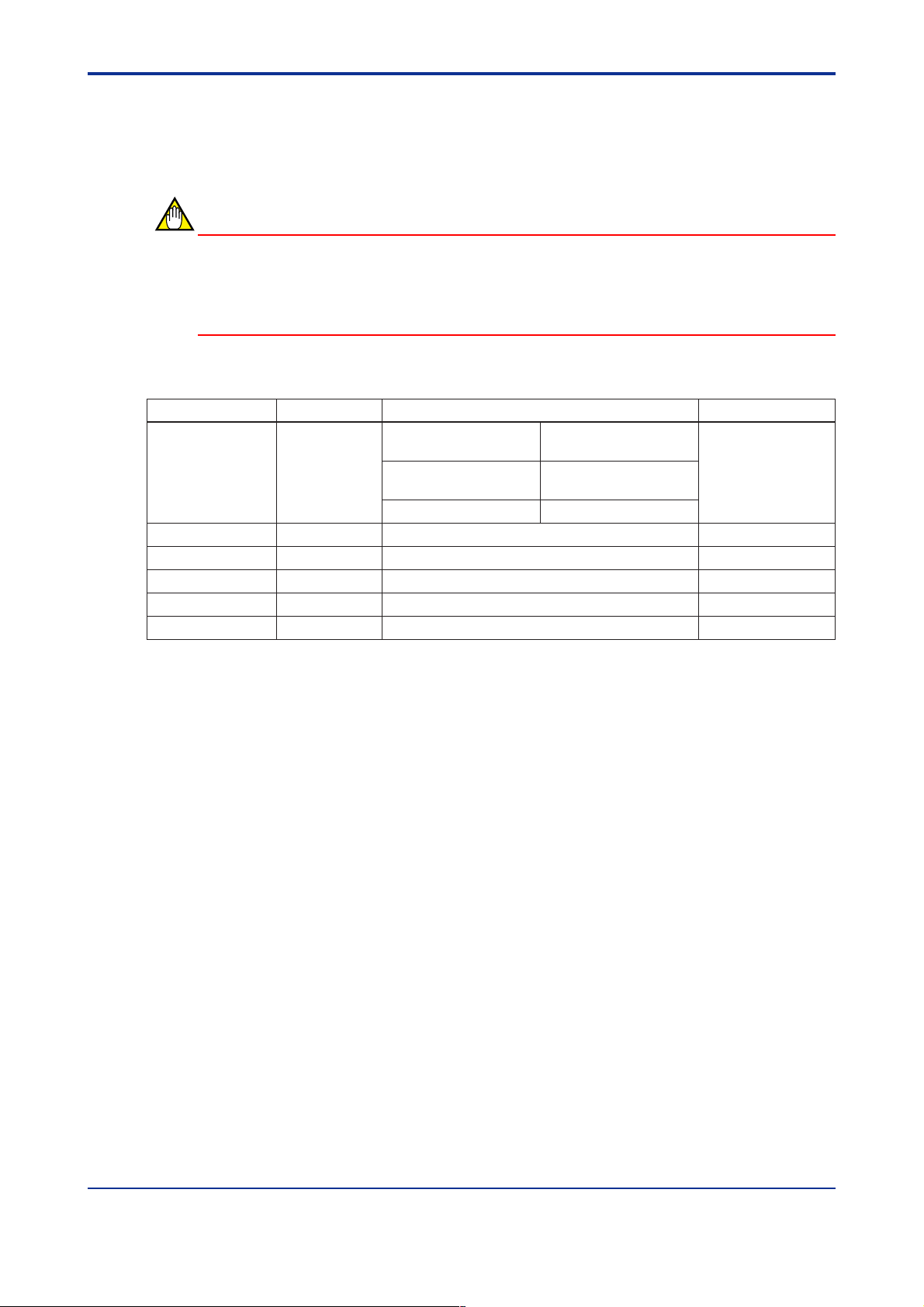

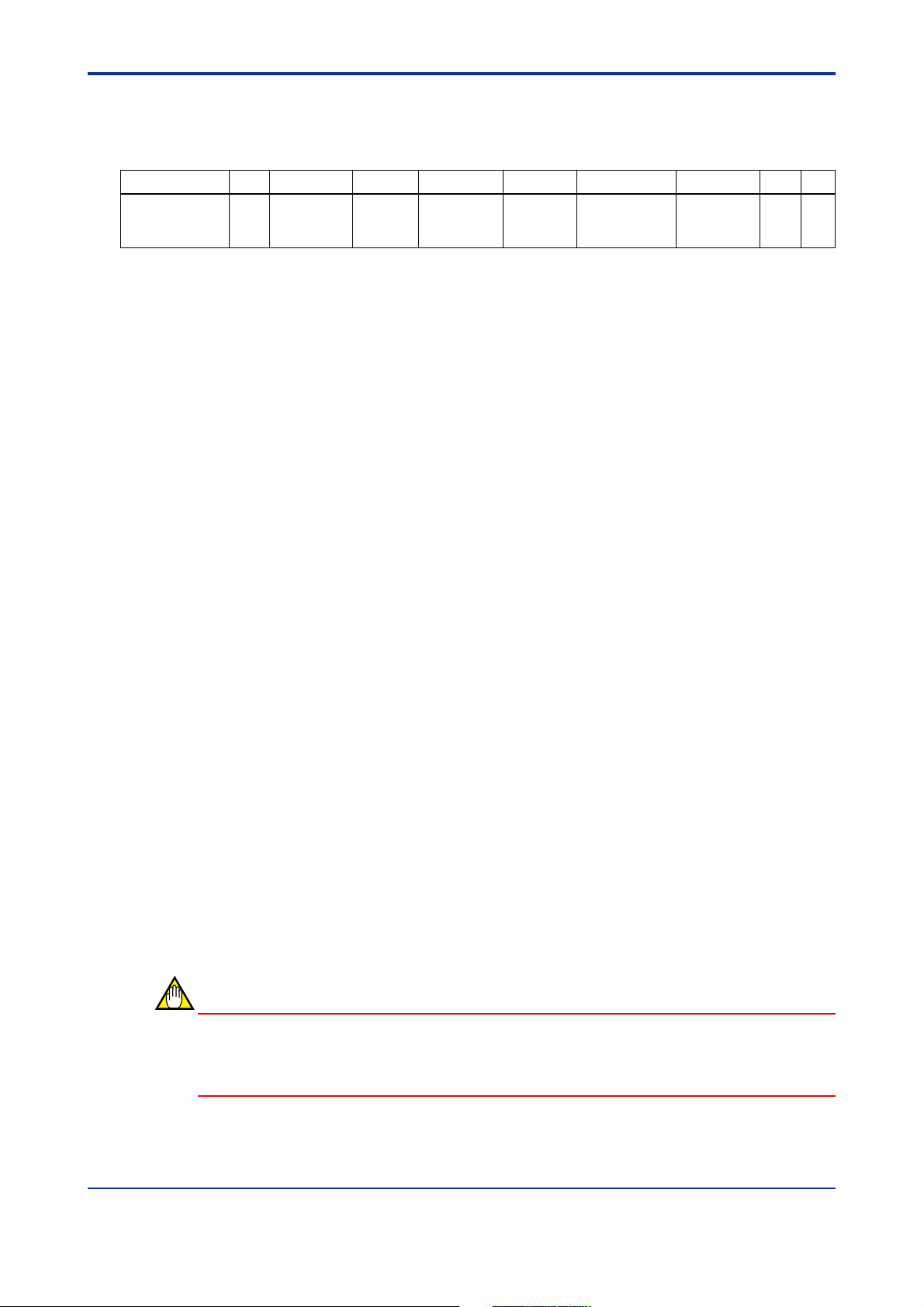

Table 1-1 Parameters to be Set for Communication Functions

1-2

Parameter Name

Protocol selection Without sum check

Address

Communication rate

Parity

Stop bit

Data length

*1: When "Ladder" is selected in protocol selection, it is fixed to "8."

When "ASCII mode" is selected for MODBUS communication, it is fixed to "7."

When "RTU mode" is selected, it is fixed to "8."

Symbol

PROTOCOL

ADDRESS

BAUD RATE

PARITY

STOP BIT

DATA LEN

Setting Range

PC link communication

With sum check

MODBUS communication ASCII mode

RTU mode

LadderLadder communication

1 to 99

1200, 2400, 4800, and 9600

NONE, EVEN, ODD

1, 2

7, 8 (*1)

PC link communication

without sum check

● Protocol selection (PROTOCOL)

Set the communication protocol identical to that of the higher-level device to be connected.

Default

1

9600

EVEN

1

8

010201E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 11

<Toc> <Ind> <1. Setup >

● Address number (ADDRESS)

Set the address number of the VJ Series itself. An address number of 1 to 99 may be

assigned in any order. However, there is a limitation - the number of VJ Series to be

connected to a single communication port is limited to 31.

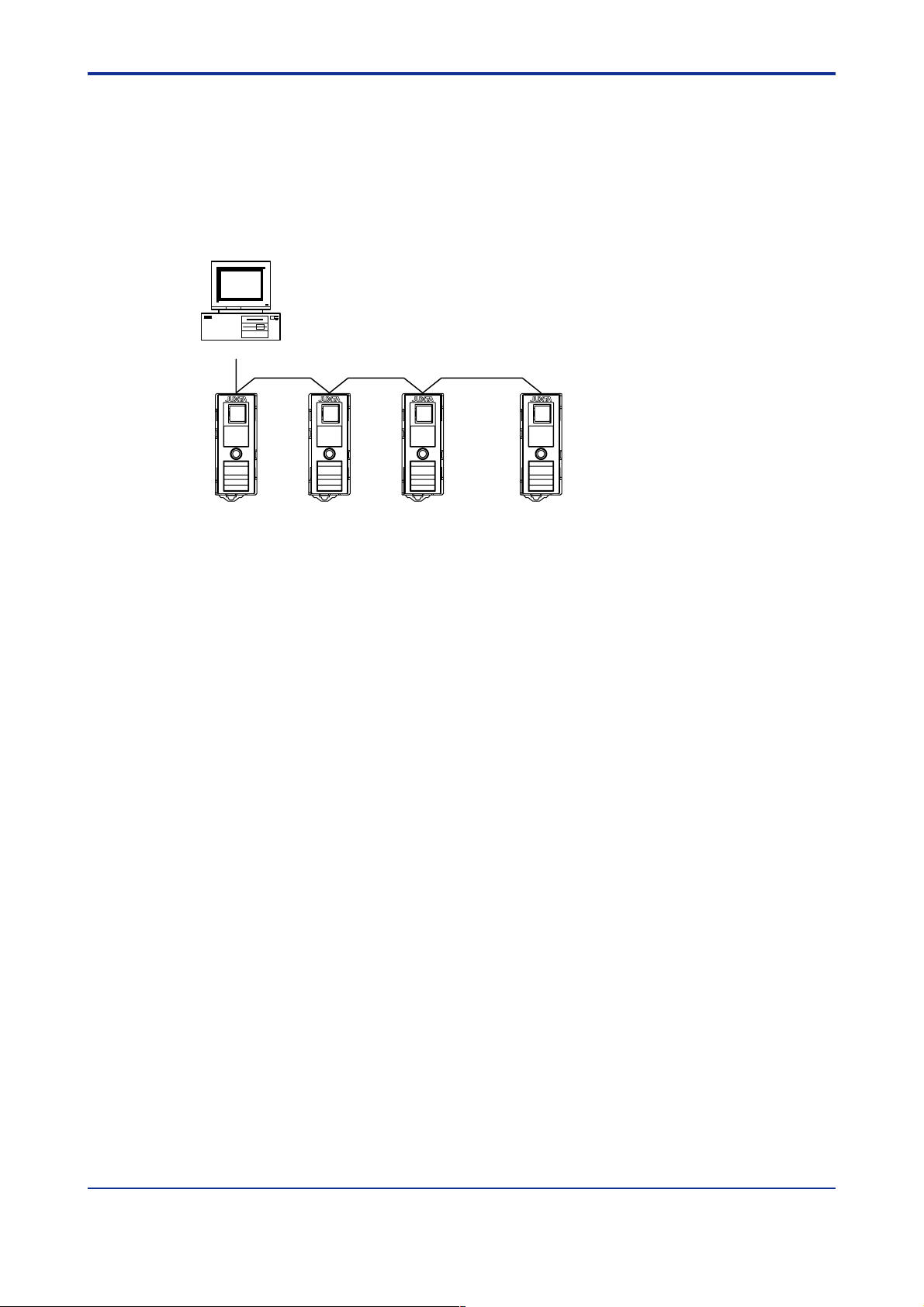

Example of connecting four VJ Series signal conditioners to a higher-level device by setting

address numbers of 1, 50, 10, and 20

1-3

PC

ADDRESS=1 ADDRESS=20ADDRESS=10ADDRESS=50

Maximum overall cable length of 1200 m

for a maximum of 31 substations

010202E.EPS

● Communication rate (BAUD RATE)

Set the communication rate identical to that of the higher-level device to be connected.

(Otherwise, proper communication cannot be achieved.) The unit of the communication

rate is bps (bits per second).

● Parity (PARITY)

Set the handling of parity to be carried out when data is sent or received. Set the parity bit

state identical to that of the higher-level device to be connected.

● Stop bit (STOP BIT)

Set the stop bit identical to that of the higher-level device to be connected.

● Data length (DATA LEN)

Set the data length identical to that of the higher-level device to be connected. (When

Ladder or MODBUS communication is chosen in protocol selection, the data length is

fixed.)

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 12

Blank Page

Page 13

<Toc> <Ind> <2. Communication Specifications >

2. Communication Specifications

The RS-485 communication interface has the PC link communication, Ladder communication, and MODBUS communication protocols.

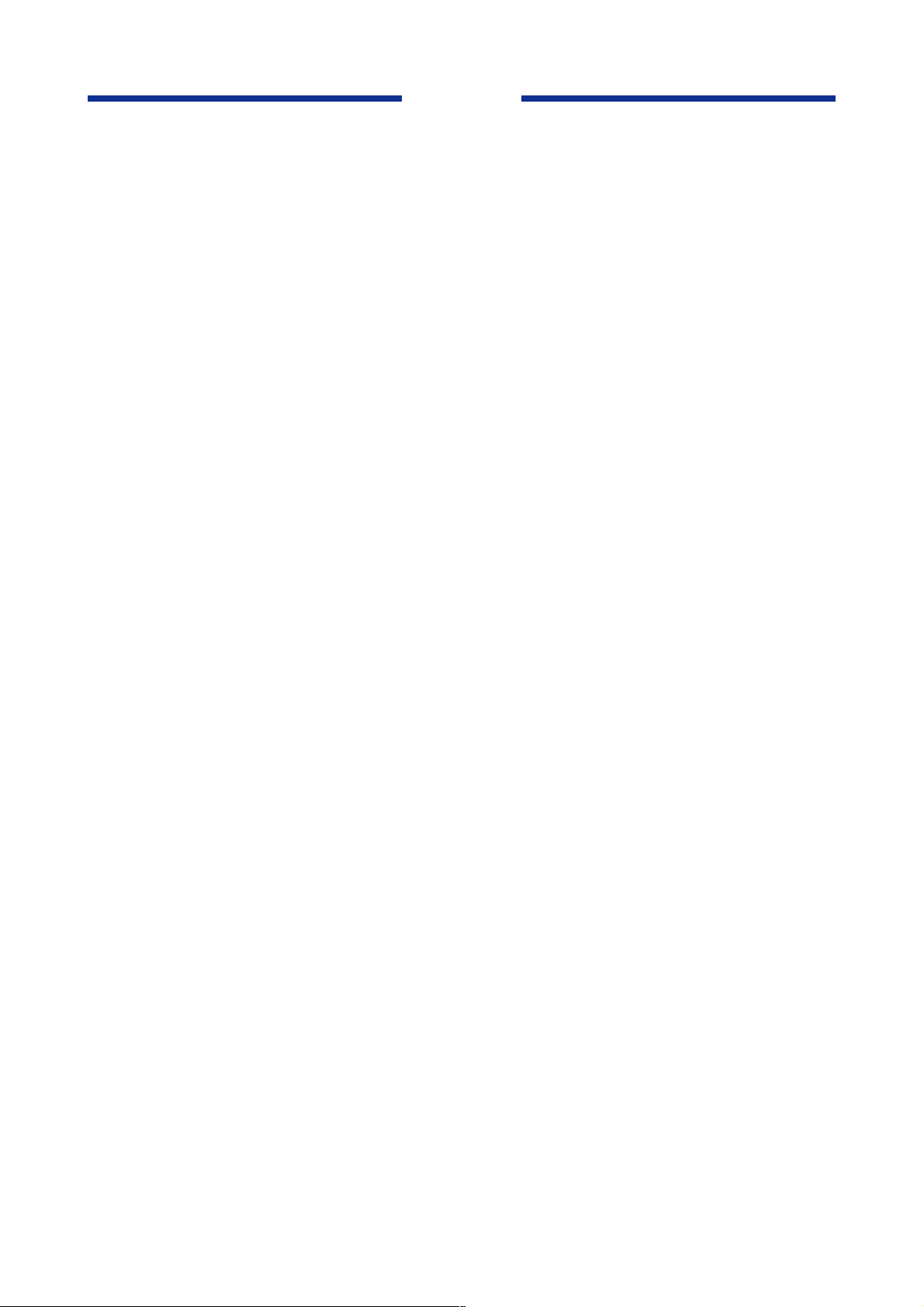

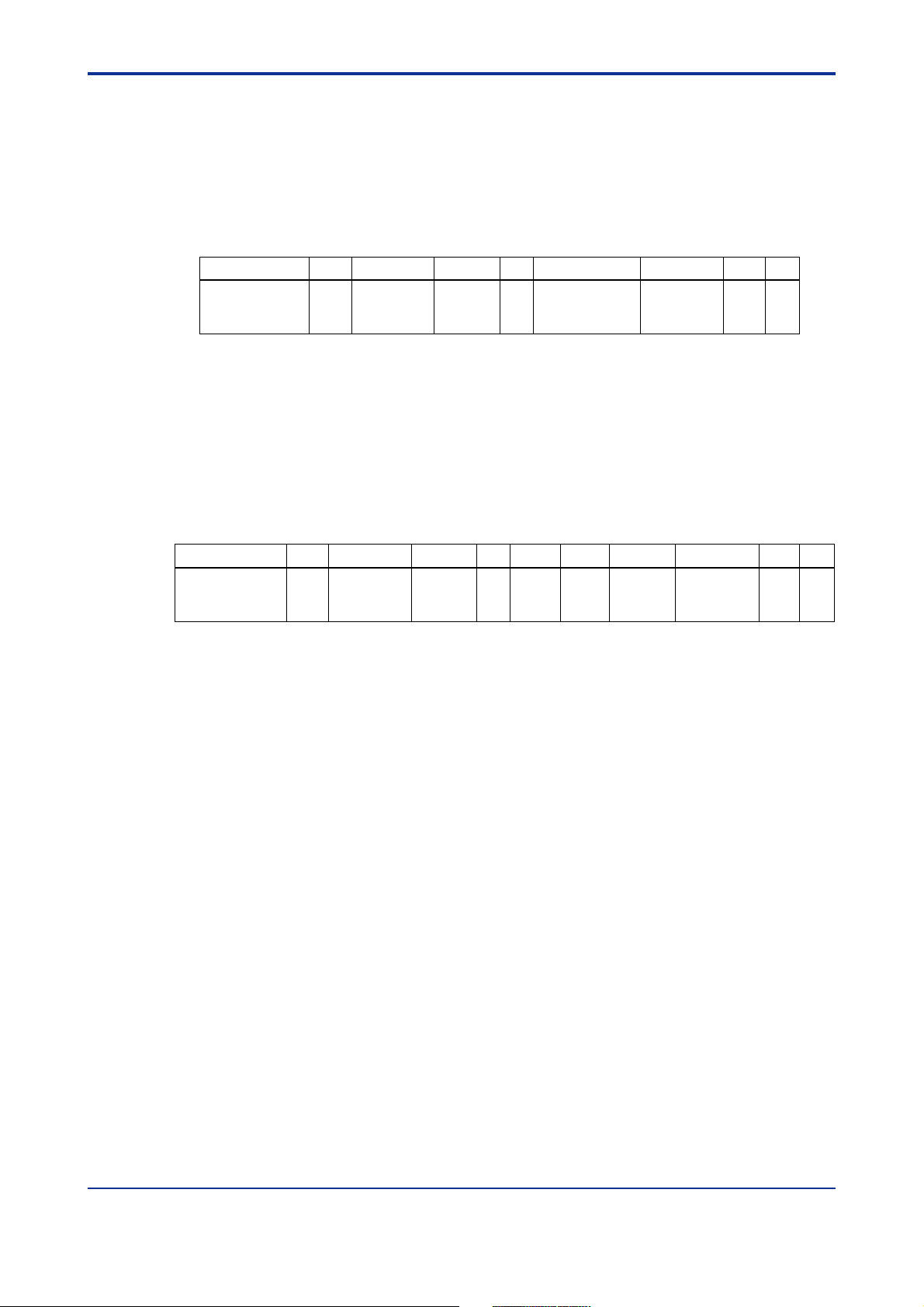

Table 2-1 VJ Series Communication Specifications

2-1

Communication Hardware

Terminal

Communication Protocol

Specifications

Maximum Communication Rate

2-wire RS-485 communication system

Terminal numbers: 2, 5, 6

PC link communication without sum check

PC link communication with sum check

MODBUS communication (ASCII mode)

MODBUS communication (RTU mode)

Ladder communication

9600 bps

020001E.EPS

Table 2-2 Types of Devices to be Connected

Devices to be Connected

PC

PC, graphic panels, and PLCs

(FA-M3’s UT link modules)

PLCs (sequencers) and FA-M3

ladder communication module

Communication Protocol

MODBUS communication

PC link communication

Ladder communication

Example of Connected Devices

General-purpose PC

General-purpose PC, FA-M3,

and GP Series

General-purpose PLCs

(sequencers)

2.1 RS-485 Communication Specifications

020002E.EPS

Table 2-3 RS-485 Communication Interface

Item

Standard EIA, RS-485, Compatible

Maximum number of devices to be connected 31

Communication system

Synchronization Asynchronous (start-stop)

Maximum communication distance 1200 m

Communication rate 1200, 2400, 4800, 9600

2-wire, half duplex

No protocolCommunication protocol

Specifications

020101E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 14

Blank Page

Page 15

<Toc> <Ind> <3. PC Link Communication >

3. PC Link Communication

3.1 Overview

The use of PC link communication enables the VJ Series to communicate with a

device such as a PC, graphic panel, or FA-M3's UT link module. Such a device can

be used in communication to read data from D registers or I relays, both of which are

internal registers of the VJ Series signal conditioners.

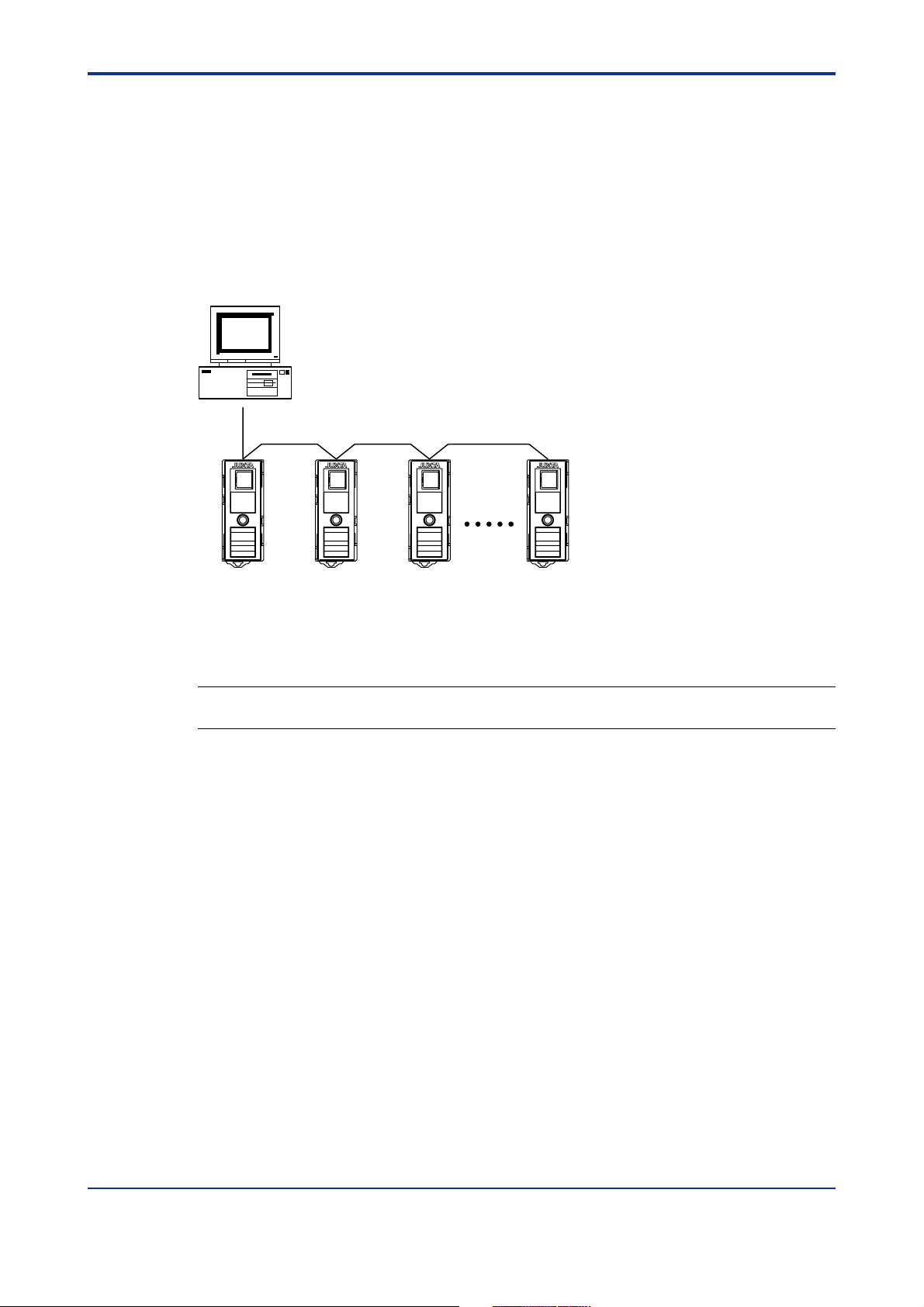

PC

Maximum overall cable length of 1200 m

for a maximum of 31 substations

3-1

030101E.EPS

Figure 3-1 Connection of Substations in PC Link Communication

Hereafter, PCs are generally called "higher-level devices."

See Also

Chapters 6 and 7 for information on the D registers and I relays.

In PC link communication, a higher-level device identifies each VJ Series signal conditioner

with a communication address of 1 to 99.

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 16

<Toc> <Ind> <3. PC Link Communication >

3.1.1 Configuration of Command

Commands sent from a higher-level device to VJ Series signal conditioners, consist of the

following elements.

3-2

Number of Bytes 12 2 1 3 211

Element STX Address

number

(ADDRESS)

(1) (2) (3) (4) (5) (7) (8) (9)(6)

CPU

number

01

Time to wait

for response

0

Command Data

Variable length

Checksum ETX CR

corresponding

to command

030102E.EPS

(1) STX (Start of Text)

This control code indicates the start of a command. The ASCII code is 02 in hexadecimal.

(2) Address Number (01 to 99)

Address numbers are used by the higher-level device to identify VJ Series signal

conditioners at the communication destination. (They are identification numbers

specific to the VJ Series signal conditioners.)

(3) CPU number

This number is fixed to “01”.

(4) Time to Wait for Response

This is fixed to “0”.

(5) Command (See subsection 3.2.1, “List of Commands”)

Specify a command to be issued from the higher-level device.

(6) Data Corresponding to Command

Specify an internal register (D register or I relay), number of data pieces, and others.

(7) Checksum

This converts the ASCII codes of texts between the character next to STX and the

character immediately before the checksum into hexadecimal values and adds them

byte by byte. It then fetches the single lowermost byte of the added results as the

checksum.

This column is required only for PC link communication with checksum. PC link

communication without checksum does not require this 2-byte space of ASCII code.

(8) ETX (End of Text)

This control code indicates the end of a command string. The ASCII code is “03” in

hexadecimal.

(9) CR (Carriage Return)

This control code indicates the end of a command. The ASCII code is “0D” in hexadecimal.

CAUTION

The control codes “STX”, “ETX”, and “CR” are essential for commands when you create a

communication program for PC link communication. Omission of any of them or incorrect

order of them results in communication failure.

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 17

<Toc> <Ind> <3. PC Link Communication >

3.1.2 Configuration of Response

Responses from the VJ Series with respect to a command sent from the higher-level

device consist of the elements shown below, which differ depending on the condition of

communication; normal or failure.

1) Normal Communication

When communication completes normally, the VJ Series returns a character string "OK"

and data corresponding to a command.

Number of Bytes Variable length12 22 211

Element STX Address

number

(ADDRESS)

CPU

number

01

2) In the Event of Failure

If communication does not complete normally, the VJ Series returns a character string "ER"

and error code (EC1 and EC2). (See subsection 3.1.3, “Response Error Code”.)

• No response is made in case of an error in address number specification or CPU

number specification.

• If a VJ Series cannot receive EXT in a command, response may not be made.

* As a countermeasure, provide a timeout process in the communication functions of the higher-level device or in

communication programs.

Number of Bytes 12 22223 211

Element STX ER EC1 EC2 Command Checksum ETX CRAddress

number

(ADDRESS)

CPU

number

01

OK Parameter data Checksum ETX CR

3-3

030105E.EPS

030106E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 18

<Toc> <Ind> <3. PC Link Communication >

3.1.3 Response Error Codes

See Also

3.1.2, “Configuration of Response”, for the structure of response in the event of error.

The error codes (EC1) and detailed error codes (EC2) of responses are as follows.

Table 3-1 List of Error Codes EC1

Error code Meaning Cause(s)

02

03

04

05

Command error

Device specification error

Out of setpoint range

Out of data count range

• No command exists.

• Command not executable

• No register number exists.

• Invalid specification of bit register (I relay) when it is used on a word basis

• Any character other than 0 or 1 is used for bit setting.

• A value other than 0000 to FFFF has been specified in word specification.

• The position of a start for a data load is out of the address range.

• The specification of the number of bits, words, etc. is out of the range of

use.

• The number of data specified and that of parameters for registers and

others are not consistent.

3-4

06 • An attempt was made to execute monitoring without specifying the

43 Internal buffer overflow

44 • The end-of-data or end-of-text character has not been received.

Monitor error

Sum error

Character reception timeout

monitor (BRS or WRS).

• An illegal parameter is set. 08 Parameter error

• The sum does not match the expected value. 42

• A data value greater than the specified was received.

Table 3-2 List of Detailed Error Codes EC2

Error Code (EC1)

03

04

05

08 Parameter error • An illegal parameter is set.

Meaning

Device specification error

Out of setpoint range

Out of data count range

Detailed Error Code (EC2)

Parameter number where error occurred (HEX)

This is the sequence number of a parameter that first resulted in an error

when counted from the leading parameter.

e.g.: Device name specification error

↓

[STX]01010BRR02I0001,D0001[ETX][CR]

Parameter numbers 1 2 3

[STX]0101ER0303BRR[ETX][CR]

For error codes other than those noted as EC1, there is no EC2 meaning.

030229E.EPS

030230E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 19

<Toc> <Ind> <3. PC Link Communication >

3.2 Commands

3.2.1 List of Commands

The following shows lists of commands available in PC link communication. Their details

are explained in the description of each command.

(1) Bit-basis Access Commands Dedicated to I Relays

Command Description Number of Bits to be Handled

BRD

BRR Bit-basis random read

BRS Specifies I relays to be monitored on a bit basis.

BRM

(2) Word-basis Access Commands

Bit-basis read

Bit-basis monitoring

1 to 256 bits

1 to 32 bits

1 to 32 bits

3-5

030201E.EPS

Command Description

WRD

WRR

WRS

WRM

Word-basis read

Word-basis random read

Specifies internal registers to be monitored on a word basis.

Word-basis monitoring

(3) Information Command

Command Description

INF Reads model, presence/absence of options, and revision.

Number of Words to be Handled

1 to 64 words

1 to 32 words

1 to 32 words

030202E.EPS

030203E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 20

<Toc> <Ind> <3. PC Link Communication >

3.2.2 BRD Reading I Relays on a Bit-by-bit Basis

● Function

Reads a sequence of contiguous ON/OFF statuses by the specified number of bits starting

at a specified I relay number.

• The number of bits to be read at a time is 1 to 256.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 12 2135 13 2 11

Command

Element

STX Address

number

(ADDRESS)

CPU

number

01

0 BRD ETX CRI relay

number

Comma

or space

Number

of bits

(n)

Checksum

3-6

Number of Bytes

Element

● Example:

Reading the status of alarm-1 of the VJ Series signal conditioner with communication

address-1.

The following command reads the status of alarm-1 (I0009) at communication address-1.

[Command]

[STX]01010BRDI0009,00199[ETX][CR]

The following response is returned with respect to the above command. (Alarm-1 is ON.)

[Response]

1 2 2 2111 1 2 1 1

STX Address

number

(ADDRESS)

The response is “0” when the status is OFF or “1” when ON.

number

dn: reads data of the specified number of bits (n=1 to 256)

dn=0(OFF)

dn=1(ON)

CPU

01

OK d1 d2 d3 ETX CRResponse

• • •

• • • dn Checksum

030206E.EPS

[STX]0101OK18D[ETX][CR]

Alarm has been ON since "1" was returned.

030207E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 21

<Toc> <Ind> <3. PC Link Communication >

3.2.3 BRR Reading I Relays on a Bit-by-bit Basis in a Random Order

● Function

Reads the ON/OFF statuses of I relays by the specified number of bits in a random order.

• The number of bits to be read at a time is 1 to 32.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 1 2 213 2 5 1 5 1

Command

Element

Command (continued)

STX Address

number

(ADDRESS)

CPU

number

01

0 BRR Number

of bits

(n)

I relay

number 1

Comma

or space

I relay

number 2

Comma

or space

3-7

• • •

• • • I relay

Number of Bytes • • • 112 2211 2 11

Response

Element

5211

number n

Checksum ETX CR

STX Address

number

(ADDRESS)

The response is “0” when the status is OFF or “1” when ON.

dn: reads data of the specified number of bits (n=1 to 32)

dn=0(OFF)

dn=1(ON)

CPU

number

01

OK d1 d2 CR• • • dn Checksum ETX

030209E.EPS

● Example:

Reading the statuses of alarms-1 and -2 of the VJ Series signal conditioner with communication address-1

The following command reads the statuses of alarm-1 (

communication address-1.

[Command]

[STX]01010BRR02I0009,I001082[ETX][CR]

I0009) and alarm-2 (I0010) at

With respect to the above command, the ON and OFF responses are returned for alarms-1

and -2 respectively.

[Response]

[STX]0101OK10BD[ETX][CR]

Alarm-1 has been ON.

030210E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 22

<Toc> <Ind> <3. PC Link Communication >

3.2.4 BRS Specifying I Relays to be Monitored on a Bit-by-bit Basis

● Function

Specifies the numbers of I relays to be monitored on a bit-by-bit basis. Note that this

command simply specifies I relays. Actual monitoring is performed by the BRM command

after the I relay numbers are specified.

When the volume of data is large and you wish to increase the communication rate, it is

effective to use a combination of the BRS and BRM commands rather than just the BRR

command.

When the power is turned OFF, the register numbers specified will be erased.

• The number of registers to be specified at a time is 1 to 32.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

3-8

Number of Bytes 1221325151

Command

Element

Command (continued)

• • •

• • • I relay

Response

Element

STX Address

5211

number n

number

(ADDRESS)

Checksum ETX CR

12 22 2 11Number of Bytes

STX Address

number

(ADDRESS)

number

number

CPU

01

CPU

01

BRS Comma

0 Number

OK Checksum ETX CR

of bits

(n)

I relay

number 1

or space

I relay

number 2

Comma

or space

030212E.EPS

● Example:

Specifying that the burnout and alarms-1 and -2 of the VJ Series signal conditioner with

communication address-1 are to be monitored

The following command specifies that the statuses of burnout (I0004), alarm-1 (I0009), and

alarm-2 (

(This command simply specifies the registers to be monitored.)

I0010) at communication address-1 are to be monitored.

[Command]

[STX]01010BRS03I0004,I0009,I0010BD[ETX][CR]

OK is returned in response to the above command.

[Response]

[STX]0101OK5C[ETX][CR]

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 23

<Toc> <Ind> <3. PC Link Communication >

3.2.5 BRM Monitoring I Relays on a Bit-by-bit Basis

● Function

Reads the ON/OFF statuses of I relays that have been specified in advance by the BRS

command.

• Before executing this command, the BRS command must always be executed to

specify which I relays are to be monitored. If no relay has been specified, error code

06 is generated.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 12 213 2 11

Command

Element

STX 0 BRM ETX CRAddress

number

(ADDRESS)

CPU

number

01

Checksum

3-9

Number of Bytes 12 22111 1 2 11

Response

Element

STX OK d1 d2 d3 ETX CRAddress

number

(ADDRESS)

The response is “0” when the status is OFF or “1” when ON.

dn: registers data of the number of bits specified by the BRS command (n=1 to 32)

dn=0(OFF)

dn=1(ON)

CPU

number

01

• • •

• • • dn Checksum

030213E.EPS

● Example:

When the burnout and alarms-1 and -2 of the VJ Series signal conditioner with communication address-1 have been specified to be monitored:

The following command monitors the statuses of burnout (

alarm-2 (

I0010) at communication address-1.

(This command reads the statuses of the I relays specified by the BRS command.)

[Command]

[STX]01010BRMA3[ETX][CR]

I0004) and alarm-1 (I0009) and

With respect to the above command, the ON and OFF statuses of the I relays are returned

as responses.

[Response]

[STX]0101OK000EC[ETX][CR]

All are in OFF statuses.

030214E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 24

<Toc> <Ind> <3. PC Link Communication >

3.2.6 WRD Reading D Registers/I Relays on a Word-by-word Basis

● Function

Reads a sequence of contiguous register information starting at the specified register

number on a word-by-word basis, by the specified number of words.

• The number of words to be read at a time is 1 to 64.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 1 2 213 5 1 2211

Command

Element

STX Address

number

(ADDRESS)

CPU

number

01

Register

number

Comma

or space

Number

of words

(n)

Checksum0 WRD ETX CR

3-10

Number of Bytes • • •12 2244 4 2 11

Response

Element

STX OK dddd1 dddd2 ETXAddress

number

(ADDRESS)

The response is returned in a 4-digit character string (0000 to FFFF) in a hexadecimal pattern.

CPU

number

01

Reads data of the specified number of words

ddddn is a character string in a hexadecimal pattern.

n=1 to 64

• • • ddddn Checksum

CR

030215E.EPS

● Example:

Reading the output value of the VJ Series signal conditioner with communication address-1.

The following command reads the output value (

[Command]

[STX]01010WRDD0008,0178[ETX][CR]

With respect to the above command, the output value 500 (01F4 (HEX)) is returned as

response (50.0% is expressed as 500).

[Response]

D0008) at communication address-1.

[STX]0101OK01F437[ETX][CR]

500 in decimal (output is 50.0%)

030231E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 25

<Toc> <Ind> <3. PC Link Communication >

3.2.7 WRR Reading D Registers/I Relays on a Word-by-word Basis in a Random Order

● Function

Reads the statuses of specified registers on a word-by-word basis in a random order.

• The number of words to be read at a time is 1 to 32.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 1221325151

Command

Element

Command (continued)

STX Address

number

(ADDRESS)

CPU

number

01

0 WRR Number

of words

(n)

Register

number 1

Comma

or space

Register

number 2

3-11

Comma

or space

• • •

Response

Element

5211

Register

number n

1 2 224 4 4 2 11Number of Bytes

STX Address

number

(ADDRESS)

The response is returned in a 4-digit character string (0000 to FFFF) in a hexadecimal pattern.

ETX CR• • • Checksum

OK dddd1 dddd2 ETX CR• • • ddddn Checksum

CPU

number

01

Reads data of the specified number of words

ddddn is a character string in a hexadecimal pattern.

n=1 to 32

• • •

● Example:

Reading the input and output values of the VJ Series signal conditioner with communication address-1

The following command reads the input value (

munication address-1.

[Command]

[STX]01010WRR02D0004,D00088F[ETX][CR]

D0004) and output value (D0008) at com-

030217E.EPS

With respect to the above command, the input value 500 (01F4 (HEX)) and output value

500 (

01F4 (HEX)) are returned as responses (50.0% is expressed as 500).

[Response]

[STX]0101OK01F401F4FC[ETX][CR]

500 in decimal

(input is 50.0 %)

500 in decimal

(output is 50.0 %)

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 26

<Toc> <Ind> <3. PC Link Communication >

3-12

3.2.8 WRS Specifying D Registers/I Relays to be Monitored on a Word-by-word Basis

● Function

Specifies the numbers of registers to be monitored on a word-by-word basis. Note that this

command simply specifies registers. Actual monitoring is performed by the WRM command after the register numbers are specified.

When the volume of data is large and you wish to increase the communication rate, it is

effective to use a combination of the WRS and WRM commands rather than just the WRR

command.

When the power is turned OFF, the register numbers specified will be erased.

• The number of words to be specified at a time is 1 to 32.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 12 213 2 5 1 5 1

Command

Element

Command (continued)

• • •

Element

STX Address

5211

Register

number n

number

(ADDRESS)

12 22 2 11Number of Bytes

STX Address

number

(ADDRESS)

CPU

number

01

ETX CR• • • Checksum

CPU

number

01

0 WRS

OK Checksum

Number

of words

Register

number 1

(n)

ETX CRResponse

Comma

or space

Register

number 2

Comma

or space

030221E.EPS

● Example:

Specifying the input value (%) and output value (%) of the VJ Series signal conditioner with

communication address-1 are to be monitored

The following command specifies that the input value (

communication address-1 are to be monitored.

(This command simply specifies the registers to be monitored.)

D0004) and output value (D0008) at

[Command]

[STX]01010WRS02D0004,D000890[ETX][CR]

CPU number: 01 D register numbers

030222E.EPS

OK is returned as a response to the above command.

[Response]

[STX]0101OK5C[ETX][CR]

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 27

<Toc> <Ind> <3. PC Link Communication >

3-13

3.2.9 WRM Monitoring D Registers/I Relays on a Word-by-word Basis

● Function

Reads the information of registers that have been specified in advance by the WRS command.

• Before executing this command, the WRS command must always be executed to

specify which registers are to be monitored. If no register has been specified, error

code 06 is generated.

• For the format of response in the event of failure, see subsection 3.1.2.

• The command shown below includes the checksum function. When performing

communication without a checksum, do not include the 2-byte checksum command

element in the command.

● Command/Response (for normal operation)

Number of Bytes 12 213 2 11

Command

Element

STX Address

number

(ADDRESS)

CPU

number

01

Checksum0 WRM ETX CR

Number of Bytes

Response

Element

12 2244 4 2 11

STX OK dddd1 dddd2 ETX CRAddress

number

(ADDRESS)

The response is returned in a 4-digit character string (0000 to FFFF) in a hexadecimal pattern.

CPU

number

01

Reads data of the number of words specified by the WRS command

ddddn is a character string in a hexadecimal pattern.

n=1 to 32

• • •

• • • ddddn Checksum

● Example:

When the input value (%) and output value (%) of the VJ Series signal conditioner with

communication address-1 have been specified to be monitored:

The following command monitors the input value (D0004) and output value (D0008) at

communication address-1.

(This command reads the registers specified by the WRS command.)

[Command]

[STX]01010WRME8[ETX][CR]

CPU number: 01

With respect to the above command, the input value 500 (01F4 (HEX)) and output value

500 (

01F4 (HEX)) are returned as responses (50.0% is expressed as 500).

030223E.EPS

[Response]

[STX]0101OK01F401F412[ETX][CR]

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 28

<Toc> <Ind> <3. PC Link Communication >

3-14

3.2.10 INF Reading the Model, Presence/Absence of Options, and Revision

● Function

Returns the model number of a VJ Series signal conditioner, whether any options are

included, and the version and revision numbers.

• For the format of response in the event of failure, see subsection 3.1.2.

● Command/Response (for normal operation)

Number of Bytes 12 2 1 31 2 11

Command

Element

Number of Bytes 12228844

Response

Element

STX Address

number

(ADDRESS)

Address

STX Start register

number

(ADDRESS)

CPU

number

01

CPU

number

01

time (0)

OK 䊐䊐䊐䊐䊐䊐䊐䊐

INF 6 ETX CR

(Note 1)

ChecksumResponse

Version

Revision

(Note 2)

specified for

readout

refreshing *

Number of

registers

specified for

readout

refreshing *

Response (continued)

44211

Number of

specified

for readout

refreshing *

The * mark indicates fields the FA-M3 UT link module refers to.

Note 1: Model and input and output information of the VJ Series

Model information:

VJU7: Universal temperature converter

VJA7: Distributor

VJH7: Isolator

Note 2: Version number and revision number

registers

specified

for readout

refreshing *

Checksum

ETX CRStart register

Space

Output-2 signal:

P: RS-485 communication

Output-1 signals:

A: Analog output

1: Pulse output

Z: Those other than the above

Input signals:

T: Thermocouple

M: mV

R: RTD

H: Isolator

A: Distributor

030226E.EPS

Revision number of downloaded data

ROM version number

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 29

<Toc> <Ind> <3. PC Link Communication >

3.3 Communication with Higher-level Devices

Higher-level devices are those capable of using the PC link communication protocol.

As an example of a communication program, the Basic program created using

Microsoft Visual Basic is given in subsection 3.3.1. Further, communications with

an FA-M3's UT link module or graphic panel can be achieved without creating a

complex program. Examples of communication with them are given in subsections

3.3.2 and 3.3.3.

3-15

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 30

<Toc> <Ind> <3. PC Link Communication >

3-16

3.3.1 Example of Communication Program Created Using Visual Basic

This subsection shows a sample program created using Microsoft Visual Basic 6.0.

Operation verification environment: PC/AT compatible machine + Windows NT 4.0

(SP4), Windows 95

PC/AT is a product of International Business Machine Corp.

Visual Basic is a registered trademark of Microsoft Corporation.

See Also

MSDN and commercially available documentation for information on Visual Basic programming.

The sample program reads the contents of D register D0002 using the PC link communication protocol. When you press the Command button, the commands sent and responses

received will be displayed in a form. If no response is received, a timeout will occur.

030301E.EPS

'==========================================================

' Program name: Sample

'

' RS-485 communication program for VJ series

'

'============================= YOKOGAWA Electric Corporation ===

'

'Definition of public variables

Public fSend As Boolean 'Sending flag

Public strSend As String 'Character string sent

Public strBuf1 As String 'Character (1 byte) received

Public strReceive As String 'Character string received

'When the Command button is pressed,

Private Sub Command1_Click()

strSend = "01010WRDD0002,01" 'Character string to be sent

'[stx]01010WRDD0003,01[etx][cr]

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 31

<Toc> <Ind> <3. PC Link Communication >

Label1.Caption = "[stx]" + strSend + "[etx][cr]"

Label2.Caption = ""

MSComm1.PortOpen = True 'Open port

Timer1.Enabled = True 'Start timer for detecting timeout

Command1.Enabled = False 'Disable the Command button temporarily

fSend = True 'Set sending flag

'Send

MSComm1.Output = Chr(&H2) + strSend + Chr(&H3) + Chr(&HD)

'Send with stx, etx, and cr added

Do 'Loop until sending flag becomes false

If DoEvents() = 0 Then '

End If '

Loop Until fSend = False '

Timer1.Enabled = False 'Stop Timer 1

MSComm1.PortOpen = False 'Close port

3-17

Label2.Caption = strReceive 'Display received character string in Label 2

Command1.Enabled = True 'Enable the Command button

End Sub

--------------------------------------------------------------------------------

'At start of program

Private Sub Form_Load()

Form1.Caption = "Communication Sample"

'Set up timer for detecting timeout

Timer1.Enabled = False

Timer1.Interval = 2000

'Regard as being 2 seconds

'Initialize MSComm control

MSComm1.CommPort = 1 'COM1

MSComm1.InputLen = 1 'Size of receiving buffer

MSComm1.InputMode = comInputModeText 'Receiving mode

MSComm1.RThreshold = 1 'MSComm1_OnComm interrupt processing starts

'each time 1 byte is received

MSComm1.Settings = "9600,e,8,1" 'Communication conditions: 9600 bps; Parity,

'even; Data length, 8 bits; Stop bit, 1 bit

'Command button control

Command1.Caption = "Send"

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 32

<Toc> <Ind> <3. PC Link Communication >

'Initialize label control that displays character strings sent and received

Label1.Caption = ""

Label2.Caption = ""

End Sub

--------------------------------------------------------------------------------

'This processing starts each time 1 byte is received

Private Sub MSComm1_OnComm()

Dim strBuf0 As String

Select Case MSComm1.CommEvent

Case comEvReceive

strBuf0 = MSComm1.Input '

Select Case strBuf0 'Case classification based on 1 byte received

Case Chr(2) 'When it is stx

strBuf1 = "[stx]"

Case Chr(3) 'When it is etx

strBuf1 = strBuf1 & "[etx]"

Case Chr(13) 'When it is cr

strBuf1 = strBuf1 & "[cr]"

'This is provided as a measure against the fact that a command sent may

'be seen as response depending on a combination with communication

'converter.

3-18

If strBuf1 = Label1.Caption Then

strBuf1 = ""

Else

strReceive = strBuf1 'Completion of character string received

fSend = False 'When it is not stx, etx, or cr

End If

Case Else 'stx,etx,crÇ≈ǻǢÇ∆Ç´

strBuf1 = strBuf1 & strBuf0

End Select

Case Else

End Select

End Sub

--------------------------------------------------------------------------------

'Timeout

Private Sub Timer1_Timer()

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 33

<Toc> <Ind> <3. PC Link Communication >

strReceive = "Time Out!"

fSend = False 'Receiving is regarded as being ended

End Sub

3-19

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 34

<Toc> <Ind> <3. PC Link Communication >

3.3.2 Communication with UT Link Module

Communication with FA-M3 is achieved by simply connecting the VJ Series to a UT

link module using the PC link communication protocol. Set the communication

conditions of the VJ Series signal conditioners identical to those of the UT link

module.

Model of UT link module: F3LC51-2N

FA-M3

Maximum overall cable length of 1200 m

for a maximum of 31 substations

030401E.EPS

The UT link module function has the following three modes, which allow you to communicate with FA-M3 without being aware of it. For more information, see the optionally available "UT Link Module Instruction Manual (IM 34M6H25-01E)."

3-20

1. Automatic mode

This mode enables the instruments' fixed devices (those that cannot be specified by

the user) to be constantly refreshed by reading from and/or writing to them. The fixed

devices are D0001 to D0015, and the read areas cannot be written to.

2. Customize mode (constant access)

This mode reads and refreshes the instrument's devices (those that can be specified

by the user).

See Also

The devices mentioned here are D registers and I relays. For more information on D registers and I

relays, see Chapters 6 and 7.

3. Command Action

This mode allows access to be made as necessary.

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 35

<Toc> <Ind> <3. PC Link Communication >

3.3.3 Communication with Graphic Panel

Communication with a graphic panel is achieved using the PC link communication

protocol. Set the communication conditions of the VJ Series signal conditioners

identical to those of the graphic panel.

Graphic panel

Maximum overall cable length of 1200 m

for a maximum of 31 substations

030501E.EPS

For more information, refer to the instruction manual of the graphic panel to be connected.

3-21

Model Name Remarks

Yokogawa Electric TOP75T Touch operation panel (large) 10-inch

TOP72S

Digital’s

Pro-face

Note 1: For Digital's graphic panels, contact Digital Corp. directly.

Note 2: The system data area should be assigned to D0065.

*1: Display devices differ depending on the model.

GP-70 Series Graphic operation panel

GP-J Series High-speed graphic operation panel

GP-230 Series Medium-size graphic operation panel

GP-430 Series High-speed, advanced graphic operation

GP-530 Series

Touch operation panel (medium) 5-inch

panels

TFT color LCD

STN color LCD

(*1)

030502E.EPS

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 36

Blank Page

Page 37

<Toc> <Ind> <4. Ladder Communication >

4. Ladder Communication

4.1 Overview

Communication with a sequencer (PLC) is achieved using a ladder program. Specifying the register numbers of D registers of the VJ Series signal conditioners in the

ladder program allows the registers to be read using the BCD codes (0 to 9).

Ladder communication module

FA-M3

Maximum overall cable length of 1200 m

for a maximum of 31 substations

4-1

040101E.EPS

Figure 4-1 Example of Connection for Ladder Communication

● Connecting the VJ Series to a PLC of another company

When the VJ Series signal conditioners are connected to a PLC manufactured by

Mitsubishi Electric (MELSEC-A series), you can use the no-handshaking mode of the

computer link unit.

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 38

<Toc> <Ind> <4. Ladder Communication >

4.2 Commands/Responses at the PLC

The PLC sends commands and receives responses to commands. The commands

and responses that can be used are as follows.

4.2.1 Command/Response Component Elements

Commands sent from the PLC to the VJ Series signal conditioners are configured as

shown below.

Number of Bytes 11 221111

Number of BCD Digits 22 1 4422111

Command/Response

Element

Address

number

(ADDRESS)

CPU

number

01

Parameter

number

5th

0 +/-0 Data

digit

4-2

CR

(0D)LF(0A)

Variable only for responses.

A maximum of 64 data items

(1) Address number (01 to 99)

Numbers used by the PLC to identify the VJ Series signal conditioners at the communication destination. (They are identification number specific to individual VJ Series

signal conditioners.)

(2) CPU number

This number is fixed to “01”.

(3) Parameter number

This is 4-digit BCD data of a D register number, not including "D." No I-relays can be

specified.

See Also

Chapter 6 for more information on D registers.

(4) 0

This is fixed to "0."

(5) 0

040201E.EPS

This is fixed to "0" for commands, while it is 5th digit of read data for responses.

(6) 0

This is fixed to "0."

(7) +/-

This is fixed to "0" for commands, while it is 0: positive data (+) or 1: negative data (-)

for responses.

(8) Data

This is data to be read for commands, while it is the number of read data for responses.

(9) CR and LF

These are the control codes indicating the end of a command. The corresponding

control character strings are CR, which is 0D in hexadecimal in ASCII code, and LF,

which is 0A in hexadecimal in ASCII code.

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 39

<Toc> <Ind> <4. Ladder Communication >

4.2.2 Reading Parameters

Parameters from the PLC are read in the VJ Series signal conditioners in the following

configuration. (The maximum number of data items to be read is 64.)

Number of Bytes 11 221111

Number of BCD Digits 22 1 4422111

Command Element Address

number

(ADDRESS)

CPU

number

01

Parameter

number

0 0 00 Number of

read data

(n)

CR

(0D)LF(0A)

4-3

Number of Bytes 112

Number of BCD Digits 224

Parameter

Response Element Address

number

(ADDRESS)

CPU

number

01

• • •

• • •

number

1422111

5th

digit

Data of parameter no. (n)

● Example of reading the output value (D register 0008) of the VJ Series

signal conditioner with communication address-1

[Command]

01010008000000010D0A

The output value 500 (BCD code) is returned as a response to the above command (50.0%

is expressed as 500).

211

14111

5th

0 +/-0 dddd1

digit

Data of parameter no. (a) Data of parameter no. (b)

21111

0 +/-0 ddddn

CR

(0D)LF(0A)

14111

5th

0 +/-0 dddd2

digit

211

040204E.EPS

[Response]

010100080000005000D0A

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 40

<Toc> <Ind> <4. Ladder Communication >

4.2.3 Response Error Codes

Data that the master station (PLC) will receive in the event of an error and the description of

errors are given in the table below.

0101/0103/0000/0001/CR/LF

Read data

0, 5th digit, 0, and +/-

Parameter number

Address number and CPU number

040206E.EPS

Note: Slashes (/) in the following send and receive data examples are used for explanatory purposes only, and are not part of

the actual data string.

Table 4-2 List of Error Codes

4-4

Description of error

A non-existing parameter was set. 0101/0129/0000/0001/CR/LF 0101/0103/0000/FFFF/CR/LF

was used in item other than address.

* Note that this excludes LF (0A).

address.

Address was different from that of a VJ

Series signal conditioner.

* Examples at the right show addresses not existing.

incorrect.

* Command length is 10 bytes including CR and LF.

* Timeout is 2 seconds.

Buffer overflowed

* Buffer overflow occurs if data exceeds 367 bytes.

Example of data sent

by master station

0101/0123/0000/000B/CR/LF

0101/0123/000B/0000/CR/LF

0101/0123/0B00/0000/CR/LF

0101/012B/0000/0000/CR/LF

0101/0123/0000/000A/CR/LF

0101/0123/000A/0000/CR/LF

0101/0123/0A00/0000/CR/LF

0101/010A/0000/0000/CR/LF

0103/0123/0000/0000/CR/LF

0001/0123/0000/0000/CR/LF

3301/0123/0000/0000/CR/LF

0101/0123/0000/00/CR/LF

0101/0123/0/CR/LF

0101/0/CR/LF

0101/012 No responseA timeout occurred during communication.

–

–Framing error or parity error occurred. No response

0101/FFFF/FFFF/FFFF/CR/LFA character other than a BCD code (0 to 9)

No responseLF code (0A) is used in an item other than

No response

No responseCommand length (length of send data) is

No response

Data received

by master station

FFFF is returned.

040207E.EPS

CAUTION

If a parameter not existing in the D register table is read, an error will not occur. In this

case, "0" will be returned instead.

IM 77J01J11-01E

3rd Edition : Oct. 15, 2007-00

Page 41

<Toc> <Ind> <5. MODBUS Communication >

5. MODBUS Communication

5.1 Overview

The use of MODBUS communication allows the VJ Series signal conditioners to

communicate with a PC. In this communication, a PC reads data from D registers,

internal registers of the VJ Series.

Hereafter, PCs are generally called "higher-level devices."

PC

Maximum overall cable length of 1200 m

for a maximum of 31 substations

5-1

050101E.EPS

Figure 5-1 Example of Connection for MODBUS Communication

See Also

Chapter 6 for information on the D registers.

For MODBUS communication with the VJ Series, we provide the ASCII mode and RTU

mode (binary system) for the transmission mode.

Table 5-1 ASCII and RTU Modes

Item ASCII Mode RTU Mode

Number of data bits 7 bits (ASCII) 8 bits (binary)

Message start mark

Message end mark

Message length (*1)

Data time intervals 1 second or less 24 bit time or less (*2)

Error detection

*1: When message length in the RTU mode is assumed to be "N"

*2: For a communication rate of 9600 bps, 1⫼9600⫻24 seconds or less applies.

: (colon) Not necessary

CR+LF Not necessary

2N+1 N

Longitudinal redundancy check: LRC Cyclic redundancy check: CRC-16

050102E.EPS

In MODBUS communication, a higher-level device identifies each VJ Series signal conditioner with a communication address of 1 to 99.

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 42

<Toc> <Ind> <5. MODBUS Communication >

5.1.1 Configuration of Message

Messages sent from the higher-level device to the VJ Series consist of the following elements.

5-2

Element Address

Number of bytes in RTU mode None

Number of bytes in ASCII mode 22

Message Mark

None

1224n

(1) (3) (4) (5)(2) (6)

Number

(ADDRESS)

1 1 2n 2

Function CodeStart of

Data Error Check End of

Message Mark

050103E.EPS

(1) Start of Message Mark

This mark indicates the start of a message. Note that only ASCII mode requires a

colon (:).

(2) Address Number (1 to 99)

Address numbers are used by the higher-level device to identify the VJ Series signal

conditioners at the communication destination. (These numbers are identification

numbers specific to individual VJ Series, which are expressed in a hexadecimal in the

message.)

(3) Function Code (See subsection 5.2.1, “List of Function Codes”)

This element specifies a command (function code) from the higher-level device.

(4) Data

This element specifies D register numbers, the number of D registers, parameter

values, or others in accordance with the function code. (It is expressed in a hexadecimal in the message.)

(5) Error Check

In RTU mode Carried out by the cyclic redundancy check (CRC-16) system.

In ASCII mode Carried out by the longitudinal redundancy check (LRC) system.

(6) End of Message Mark

This mark indicates the end of a message. Note that only ASCII mode requires CR +

LF.

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 43

<Toc> <Ind> <5. MODBUS Communication >

5.1.2 Specifying D Registers

Specification of D registers using commercially available SCADA or other software

and specification of D registers for messages used in a customer-created communication program are different. Take note of this.

1) When using commercially available SCADA or other software, specify a "reference

number" in which "D," the first character of a D register number, is replaced by "4."

2) For a customer-created communication program, specify a value in hexadecimal that

is obtained by subtracting 40001 from a reference number.

Example: Specifying a value (alarm 1 (D0014))

1) For messages when using commercially available SCADA or other software, specify

the reference number "40014."

2) For messages in the customer-created communication program, specify "000D," the

hexadecimal number of value 13 obtained by subtracting 40001 from the reference

number.

5-3

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 44

<Toc> <Ind> <5. MODBUS Communication >

5.2 Function Codes

5.2.1 List of Function Codes

Function codes are command words used by the higher-level device to obtain the D register information of the VJ Series signal conditioners.

Table 5-2 List of Function Codes

5-4

Code Number

03 Reads data from multiple

D registers.

Performs a loop back test.08 See subsection 5.2.2, “Function Codes”.

Function Description

Capable of reading data from a maximum of 64 successive

D registers between D0001 and D0128.

050201E.EPS

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 45

<Toc> <Ind> <5. MODBUS Communication >

03 Reads data from multiple D registers.

● Function

This function code reads the contents of successive D registers by the specified number of

them starting at a specified D register number.

• The maximum number of D registers to be read at a time is 64.

• For the format of responses in the event of failure, see subsection 5.2.2.

● Message (for normal operation)

5-5

Element Start of

Number of bytes in RTU mode

Number of bytes in ASCII mode

Message (continued)

Error

Check

End of Message

Mark (CR+LF)

2

22

None

Message Mark

(:)

None 11 2

Address

Number

(ADDRESS)

Function

Code (03)

D-Register

Start Number

4122

Number of

D Registers

2

4

050204E.EPS

● Response (for normal operation)

Element Start of

Number of bytes in RTU mode None 1112• • •

Response (continued)

Contents of

D-Register

Error

Check

Message Mark

(:)

12 224Number of bytes in ASCII mode • • •

End of Message

Mark (CR+LF)

None22

224

Address

Number

(ADDRESS)

Function

Code (03)

Byte

Count

Contents of

D-Register

050205E.EPS

• • •

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 46

<Toc> <Ind> <5. MODBUS Communication >

● Example:

Reading the statuses of alarms-1 and -2 from the VJ Series signal conditioner with communication address 1.

The following message reads two successive D registers starting at alarm-1 (D0014) and

communication address 1 in the ASCII mode.

[Message]

: 0103000D0002ED[CR][LF]

Start of message mark

"01": communication address 1, "03": function code 03, "000D": D-register address 0014,

"0002": number of D registers 2, and "ED": error check

Note: Numbers in quotation marks are hexadecimal.

The following response is returned with respect to the above message.

[Response]

: 01030400010000F7[CR][LF]

Alarm-1 is ON. Alarm-2 is OFF.

5-6

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 47

<Toc> <Ind> <5. MODBUS Communication >

08 Performs a loop back test.

● Function

This function code is used to check the connection for communication.

• For the format of responses in the event of failure, see subsection 5.2.2.

• The element marked with * is "00" (fixed).

• Any value can be selected to send data.

● Message (for normal operation)

5-7

Element Function

Number of bytes in RTU mode

Number of bytes in ASCII mode

Message (continued)

Error

Check

End of Message

Mark (CR+LF)

None2

22

Start of

Message Mark

(:)

● Response (for normal operation)

Element Function

Number of bytes in RTU mode

Number of bytes in ASCII mode

Response (continued)

Error

Check

End of Message

Mark (CR+LF)

None2

22

Start of

Message Mark

(:)

Address

Number

(ADDRESS)

Address

Number

(ADDRESS)

Code (08)

Code (08)

00*

0000

211None

4221

00

0000

211None

4221

Send Data

(any)

2

4

050216E.EPS

Same as

send data

2

4

050217E.EPS

● Example:

Sending data "1234h" in hexadecimal to the VJ Series signal conditioner with communication address 1 to check connection for communication.

The following message sends "1234" (hexadecimal) to communication address 1 in the

ASCII mode.

[Message]

: 010800001234B1[CR][LF]

Start of message mark

When connection for communication is normal, the response whose configuration is the

same as that of the message is returned with respect to the above message.

[Response]

: 010800001234B1[CR][LF]

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 48

<Toc> <Ind> <5. MODBUS Communication >

5.2.2 Response Error Code[Response]

● Message Format in the Event of Error

If there are any inconsistencies other than communication errors in a message, a VJ Series

signal conditioner does nothing, but returns the following message.

5-8

Element Function Code

Number of bytes in RTU mode

Number of bytes in ASCII mode 2

*1: The function code contains a function code (hexadecimal number) + number 80 (hexadecimal number).

Address

Number

(ADDRESS)

1

2

(*1)

1

2

Error Code Error Check [CR] [LF]

1

2

● Response Error Codes

Table 5-3 List of Error Codes

Error Code Meaning Description

01

02 D-register number error

03 D-register count error

Function code error

No function code exists.

D-register number out of the range has

been specified.

Number of D registers has been specified,

being out of the range.

● Even when a message is sent, no response returns if:

• Retransmission error (overrun, framing, parity, LRC, or CRC-16 error) was detected.

• Address in an instructed message is incorrect.

2

None

2

050220E.EPS

050221E.EPS

• Interval between data composing a message was 2 seconds or more.

• CRC-16 or LRC values are incorrect.

Note: As a countermeasure, provide a timeout process in the communication functions of a higher-level device or in the

communication program.

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 49

<Toc> <Ind> <5. MODBUS Communication >

5.3 Example of Setting up Commercially Available SCADA Software

The MODBUS protocol is widely supported by commercially available SCADA and

other software. This section shows examples of settings when using WonderWare's

SCADA software, or “InTouch”, and MODBUS DDE Server.

See Also

The documentation of each software for more information on DDE and SCADA software.

The following setting shows an example of providing a DDE integer-type tag variable called

"INPUT1" and reading data from D0002 of VJU7 (TC, type K).

● Example of MODBUS DDE setting

This setting uses "N01" as the topic name.

5-9

050301E.EPS

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 50

<Toc> <Ind> <5. MODBUS Communication >

● Example of setting the tag variable of InTouch

In setting "DDE Access Name (D)..." for definition of the tag variable, define the DDE

application/server name to be used and the DDE topic name. For the topic name, enter

"N01" which was defined in the MODBUS DDE.

For the item name, enter value "40002," obtained by replacing D-register number "D0002"

with the MODBUS reference number. "S" indicates that read data is handled with a sign

assigned to it.

5-10

050302J.EPS

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 51

<Toc> <Ind> <6. Functions and Usage of D Registers >

6. Functions and Usage of D Registers

6.1 Overview of D Registers

This section describes the functions and usage of D registers.

The D registers store the input and output values, statuses, and others that are

handled by the VJ Series signal conditioners. By connecting VJ Series signal conditioners to higher-level equipment capable of PC link communication, Ladder communication, or MODBUS communication, you can readily use these internal data

items by reading from or writing to the D registers.

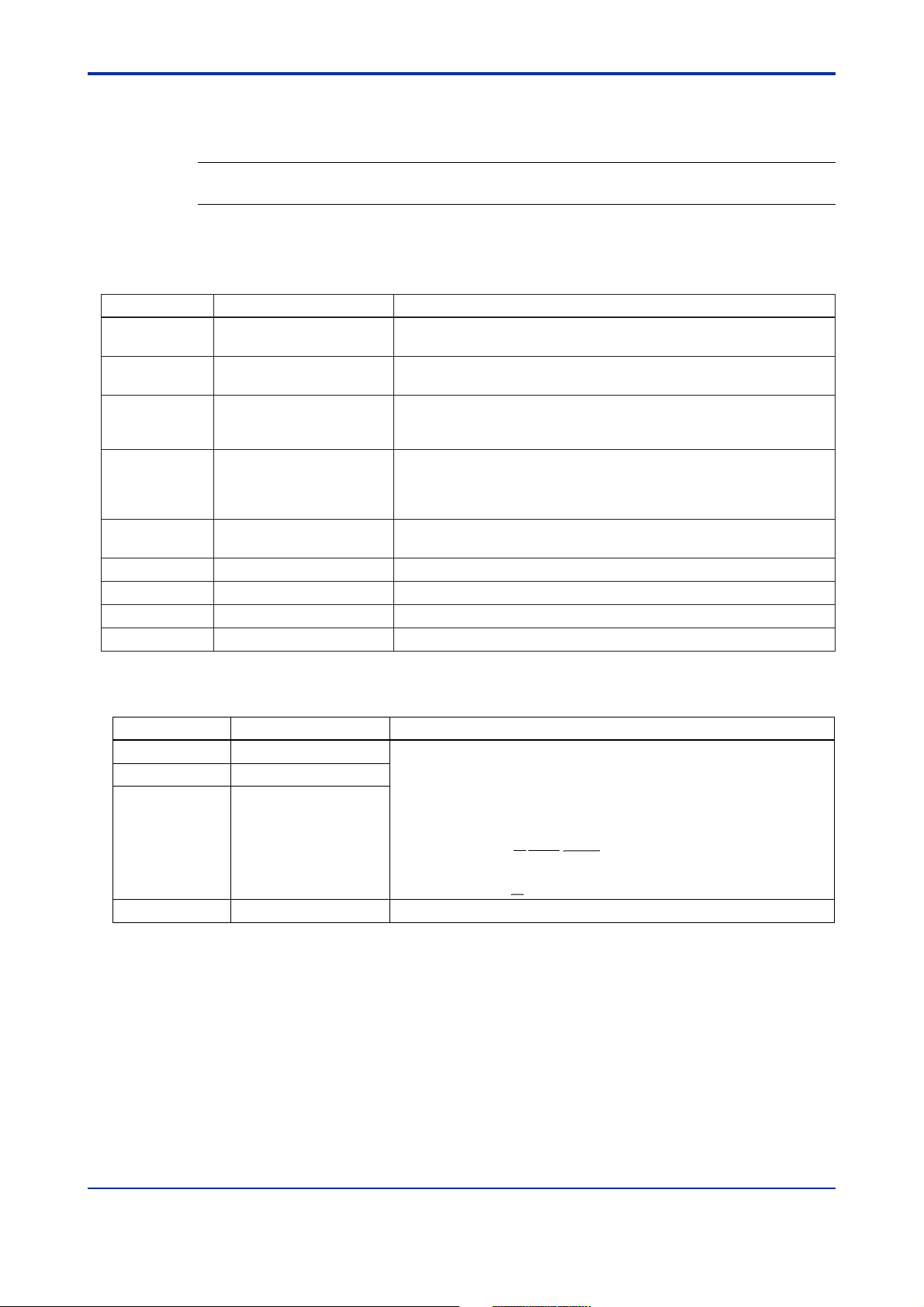

6.2 Interpretation of D Register Map Table

This section explains how to interpret the "D Register Map" table. In the example

shown below, the number in the leftmost column denotes the register number "1."

The five-digit number in the column on the immediate right of the leftmost column

represents the reference number for MODBUS communication "2." The number in

the column third from left is the register number (hexadecimal) for the MODBUS

communication program "3."

6-1

Name of D Register Map

D-Reg No. Ref No. H No. Description

D0001 40001 0000

(1) D register number

(2) Reference number (for MODBUS communication)

(3) Hex number (for MODBUS communication)

Status

060201E.EPS

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 52

<Toc> <Ind> <6. Functions and Usage of D Registers >

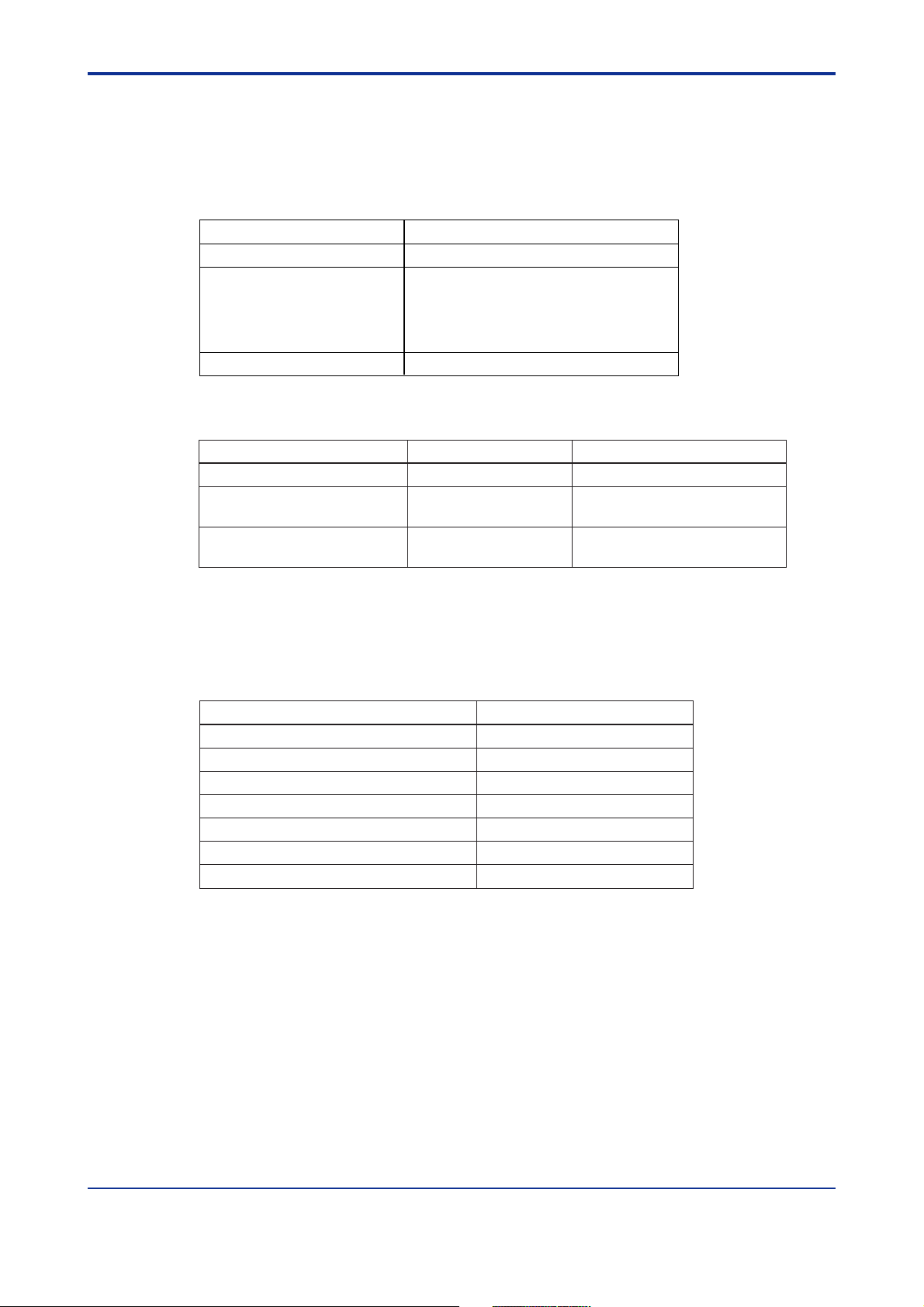

6.3 D Register Map Table

D-Register Data Area

D-Reg No. Ref No. H No.

D0001 40001 0000 Status

D0002 40002 0001 Input value (engineering unit)

D0003 40003 0002 Input value (engineering unit),

number of digits below decimal point

D0004 40004 0003 Input value (ratio of input to span, %)

D0008 40008 0007 Output value (%)

D0014 40014 000D Alarm-1 status

D0015 40015 000E Alarm-2 status

D0041 to D0044 40041 to 40044 0028 to 002B Revision

D0045 to D0048 40045 to 40048 002C to 002F Revision of menu table

D0049 to D0052 40049 to 40052 0030 to 0033 Tag No. 1

D0053 to D0056 40053 to 40056 0034 to 0037 Tag No. 2

D0057 to D0060 40057 to 40060 0038 to 003B Comment 1

D0061 to D0064 40061 to 40064 003C to 003F Comment 2

User area (*1) 40065 to 40128 0040 to 007FD0065 to D0128

*1: The user area applies when a graphic panel manufactured by Digital Corp. is used. The system data area must be

assigned to D0065.

Description

060401E.EPS

6-2

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 53

<Toc> <Ind> <6. Functions and Usage of D Registers >

6.3.1 Contents of D Registers

● D0001: Bit configuration of status

The D0001 register represents errors and parameter data by a combination of bits in the

register.

In the table below, if any of the events shown occurs, the corresponding bit is set to "1."

The bit remains set to "0" if the event has not occurred yet. Note that blank fields indicate

bits not used, which are in "0."

Bit Event

0 EEP error

1 EEP sum error

2 Low-cut status

3 AD off-scale (burnout)

4 Communication error

5

6 History of power failures

7 RJC error

8 "1" if alarm 1 is on, or "0" if off

9 "1" if alarm 2 is on, or "0" if off

10 Status of contact input

11 Status of contact output

12 Overflow of computation cycle

13 Computation overflow

14

15

6-3

IM 77J01J11-01E 3rd Edition : Oct. 15, 2007-00

Page 54

<Toc> <Ind> <6. Functions and Usage of D Registers >

● D0002, D0003: INPUT1_L, INPUT1_H (input value: engineering unit)

D0002 shows a numeric value and D0003 shows the number of digits below the decimal

point.

6-4

Input Units

mA, mV, V

⬚C, K

Number of digits

belowdecimal point

2

1

060301E.EPS

● D0004: input value (ratio of input value to input span is indicated as a

percentage)

● D0008: output value (percentage indication)

Example 1: When the input value (engineering unit) is 680.0 °C for VJU7 (universal

temperature converter), thermocouple input, and type K (input range: 0 to

1000°C):

Contents of D registers Internal value

D0002: input value (engineering unit)

D0003: input value (engineering unit),

number of digits below decimal point

D0004: input value (%) 02A8 (=680)

D0008: output value (%) 02A8 (=680)

1A90 (=6800)

0001 (=1)

680.0 (⬚C)

68.0 (%)

68.0 (%)

060302E.EPS

Example 2: Representation of negative values

When the input value (engineering unit) is -10.5 °C in the same conditions

as above:

Contents of D registers Internal value

D0002: input value (engineering unit)

D0003: input value (engineering unit),

number of digits below decimal point

D0004: input value (%) FFF5 (= -11)

D0008: output value (%) FFF5 (= -11)

FF97 (= -105)

0001 (=1)

-10.5 (⬚C)

-1.1 (%)

-1.1 (%)

060303E.EPS

● D0014, D0015: Alarms 1 and 2 ("1" when on or "0" when off)

● D0041 to D0064: Revision, revision of menu table, tag number 1,

tag number 2, comment 1, and comment 2

One D register indicates two letters in the ASCII code.