Page 1

User’s

Manual

Model UZ011

Analog Positioner

IM UZ011-01E

Please read through this User’s Manual before use for correct handling.

Please keep this User’s Manual for future reference.

1st Edition Aug. 2000 (MC)

2nd Edition June 2004 (YK)

IM UZ011-01E

Network Solutions Business Divisiion

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6793

1. CAUTIONARY NOTES FOR SAFE USE OF THE PRODUCT

This User’s Manual should be carefully read before installing and operating the product. The following symbol is used on the product and in

this manual to ensure safe use.

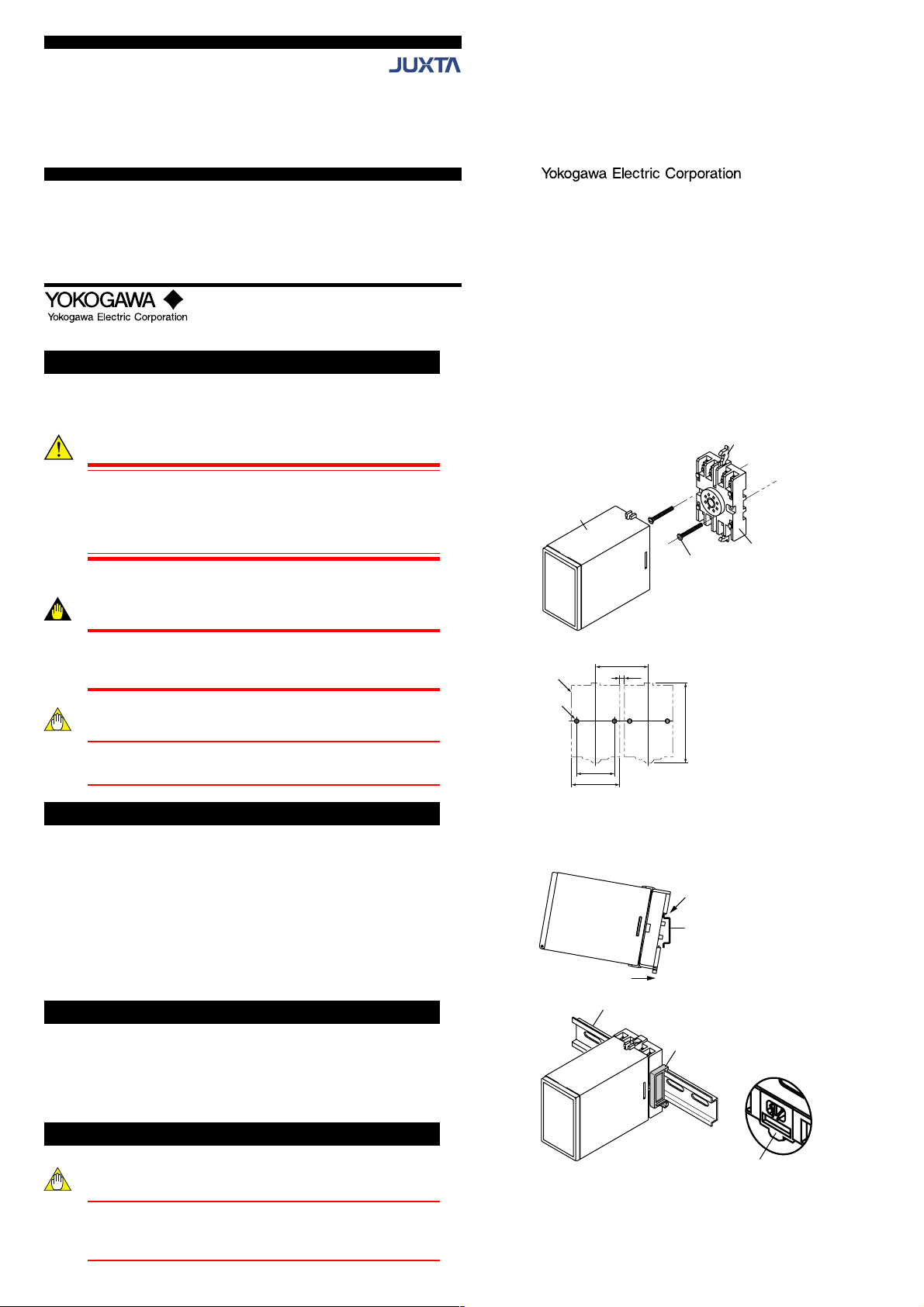

4.1 Wall Mounting

Remove the stoppers (top and bottom) from the product and pull out

the main unit from the socket. Fix the socket on the wall using two M4

screws. Next, insert the main unit into the socket and fasten the main

unit with the stoppers (top and bottom).

This symbol is displayed on the product when it is

necessary to refer to the User’s Manual for information on

personnel and instrument safety. This symbol is displayed

Main unit

in the User’s Manual to indicate precautions for avoiding

danger to the operator, such as an electric shock.

The following symbols are used only in this manual.

IMPORTANT

Indicates that operating the hardware or software in a

particular manner may cause damage or result in a system

failure.

<Mounting Dimensions>

Socket

2-ø4.5 or 2-M4

NOTE

Draws attention to essential information for understanding

the operations and/or functions of the product.

2.

CHECKING PRODUCT SPECIFICATIONS AND PACKAGED ITEMS

(1) Checking the Model and Product Specifications

Check that the model and specifications indicated on the nameplate

attached to the side face of the main unit are as ordered.

4.2 DIN Rail Mounting

Insert a DIN rail into the upper part of the DIN rail groove on the rear of

the socket, and then slide the slide lock at the lower part of the socket

upwards until the socket is fixed into position as shown below.

(2) Packaged Items

Check that the packing carton contains the following items:

● UZ011: 1

● Spacer (used for DIN rail mounting): 1

● External resistor, 1

● User’s Manual (this manual: IM 77J04A01-01E): 1 copy

(Shunt resistor used when 4 to 20mA DC input)

40±0.2

DIN rail

3. GENERAL

This UZ011 is a plug-in type Analog Positioner.

• Internal timer prevent frequent ON-OFF of motor valve.

•

Retransmission output can be used to monitor the motor position value.

• Feedback slide resistance : 100 ⍀ to 10 k⍀

• Easy adjustment operation, ⫾1% Setting Accuracy.

Pitch: 55 or more

5 or more

(51)

Push

Mounting

screws

(85)

Fit into here

DIN rail

Spacer

Stopper

Socket

Unit: mm

Note:

(1) More than 5 mm interval is

required for side-by-side

close mounting.

(2) Use the supplied spacer for

DIN rail mounting to keep 5

mm interval.

(Rear of the socket)

4. MOUNTING METHOD

NOTE

Insert/pull out the main unit into/from the socket vertically

to the face of socket. Otherwise the terminals are bent and

it may cause a bad contact.

Slide lock

4.3 Using a Duct

When using a wiring duct, install the duct at leaset 20 mm away from

the top and bottom faces of the main unit.

Page 2

5. INSTALLATION LOCATIONS

● Avoid the following environments for installation locations:

Areas with vibration, corrosive gases, dust, water, oil, solvents, direct sunlight, radiation, a strong electric field, and/or a strong

magnetic field

● If there is any risk of a surge being induced into the power line

and/or signal lines due to lightning or other factors, a dedicated

lightning arrester should be used as protection for both this unit

and a field-installed device.

6. EXTERNAL WIRING

WARNING

To avoid the risk of an electric shock, turn off the power

supply and use a tester or similar device to ensure that no

power is supplied to a cable to be connected, before carring

out wiring work.

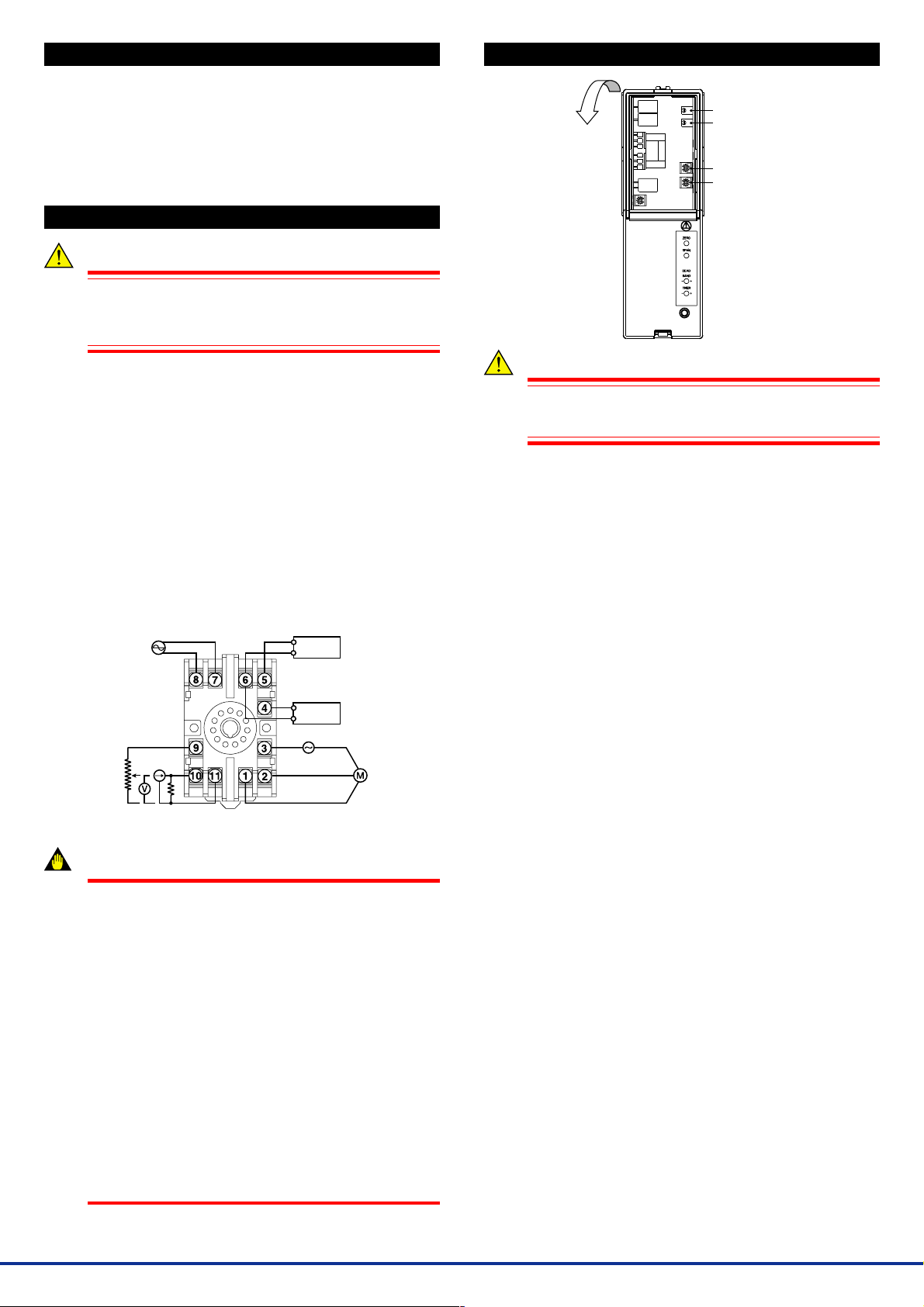

7. ADJUSTMENT

Open

the front panel

(cover)

Zero adjustment

Span adjustment

Dead band adjustment

Timer adjustment

Wiring should be connected to the terminals on the socket of the product. The terminals for external connections are of M3.5 screws. Use

crimp-on terminal lugs for connections to the terminals.

● Recommended cables: A nominal cross-sectional area of 0.5 mm

or thicker for signal cables, and that of 1.25 mm2 or thicker for

power cables.

(1) Position setpoint input signal's terminals are No.5 (⫹) and No.6 (⫺).

(2) Control output signal's terminals are No.1 (H), No.2 (L) and No.3

(COM).

(3) Position feedback input signal's terminals are ;

• When the slide-wire resistance is used: No.9 (100%), No.10

(CTR) and No.11 (0%).

• When analog signal (1 to 5V DC or 4 to 20mA DC) is used: No.10

(⫹) and No.11 (⫺).

(4) Power supply's terminals are No.7 (L⫹) and No.8 (N⫺).

(5) Retransmission output signal's terminals are No.4 (⫹) and No.6 (⫺).

Position setpoint

Power

supply

Position feed back

input

100%

CTR

L+

N-

0%

External resistor

(when 4 to 20mA DC input)

input

+

Control

unit

-

Retransmision

output

+

Monitor

-

COM

L Reverse(0%)

H Direct(100%)

Control

output

IMPORTANT

●

The power line and input/output signal lines should be

installed away from noise-generating sources. Other

wise accuracy cannot be guaranteed.

●

Use of the product ignoring the specifications may

cause overheating or damage. Before turning on the

power, ensure the following:

(a) Power supply voltage and input signal value applied

to the product should meet the required

specifications.

(b) The external wiring to the terminals and wiring to

ground are as specifications.

●

Do not operate the product in the presence of

flammable or explosive gases or vapors. To do so is

highly dangerous.

●

The product is sensitive to static electricity; exercise

care in operating it. Before you operate the product,

touch a nearby metal part to discharge static electricity.

●

Connect the external resistor (shunt resistor) when the

signal of the "Position setpoint input" or the "Feedback

input" is 4 to 20mA DC.

WARNING

2

To avoid electric shock, do NOT touch internal components

when adjusting the instrument with its front panel (cover)

removed.

The product starts running immediately when the power is turned on;

however, it needs 10 to 15 minutes of warm-up before it meets the

specified performance.

7.1 Zero and Span Adjustments

Perform the zero and span adjustments so that 0% and 100% retransmission outputs are obtained. (In general, 0% and 100% outputs are

valve fully-closed and fully-open, respectively.)

7.2 Deadband Adjustment

The deadband is the range (differential in an input signal) until the H

(direct) or L (reverse) relay turns on. Adjust the deadband in the range

from 1 to 20% if an undersired change (disturbance) or hunting adversely affects the operating points. This deadband is adjusted to a

maximum (20%) at the factory before shipment. Adjust the deadband

as narrow as possible (in an appropriate range to minimize outputting a

drive signal) by observing the control line status and stability of motordriven part operations.

7.3 Timer Adjustment

The timer-adjutment time is the time taken to enable the H or L relay

after it has been turned off. That is, it is the time during which a relay

output cannot be issued in order to prevent the motor from being overheated by frequently turning on and off the relays. Thus, there is a certain time until the motor can be restarted. Appropriately adjust the

timer-adjustment time between 1 and 30 seconds such that the relay

does not turn on and off too frequently. The timer-adjustment time is

adjusted to a minimum at the factory before shipment.

2

IM UZ011-01E 2nd Edition June 01,2004-00

Loading...

Loading...