Page 1

User ’s

Manual

UV700G

UV Analyzer

(ORGANIC POLLUTANT MONITOR)

IM 12K01B02-01E

IM 12K01B02-01E

6th Edition

Page 2

INTRODUCTION

This manual describes the operation of the UV700G.

Be sure to read this manual before using the product to ensure proper and safe operation of the

instrument. Also safely store the manual so it is readily available whenever necessary.

Product specications and appearance, as well as the contents of this manual are subject to

change without notice.

n Warranty and Responsibility

Yokogawa warrants that the Product shall be free from defects in material and workmanship and

agrees to repair or replace free of charge, at Yokogawa’s option, any malfunctioned or damaged

Product attributable to Yokogawa’s responsibility for a period of one (1) year from the delivery

unless otherwise agreed with a written agreement. In any one of the following cases, none of the

warranties set forth herein shall be extended;

• Any malfunction or damage attributable to improper operation

• Any malfunction attributable to repair or modication by any person not authorized by

Yokogawa

• Any malfunction or damage attributable to the use in an environment not specied in this

manual

• Any malfunction or damage attributable to violation of the instructions in this manual or

operations in the manner not specied in this manual

• Any malfunction or damage attributable to any cause or causes beyond the reasonable

control of Yokogawa such as natural disasters

• Any deterioration in appearance attributable to corrosion, rust, and so on

• Replacement of consumables

YOKOGAWA SHALL NOT BE LIABLE FOR ANY DAMAGES RESULTING FROM ANY MAL-

FUNCTIONS OF THE PRODUCT, ANY ERASURE OF DATA, OR ANY OTHER USES OF THE

PRODUCT.

<INTRODUCTION>

i

Notes on Handling User’s Manuals

n

• Please hand over the user’s manuals to your end users so that they can keep the user’s

manuals on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to any

particular purpose but rather to describe the functional details of the product.

• No part of the user’s manuals may be transferred or reproduced without prior written consent from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product at

any time, without notice or obligation.

• If you have any questions, or you nd mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

Media No. IM 12K01B02-01E 6th Edition : Feb. 2021 (YK)

All Rights Reserved Copyright © 2007, Yokogawa Electric Corporation

IM 12K01B02-01E

Page 3

ii

<INTRODUCTION>

Safety Precautions

Safety,Protection,andModicationoftheProduct

n

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this user’s manual. We assume

no liability for safety if users fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specied in this user’s manual, the protection

provided by this instrument may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Modication of the product is strictly prohibited.

• The following safety symbols are used on the product as well as in this manual.

CAUTION

This symbol gives information essential for understanding the operations and functions.

NOTE

This symbol indicates information that complements the present topic.

Warning and Disclaimer

n

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor responsibility to any person or entity with respect to any direct or indirect loss or damage arising from

using the product or any defect of the product that YOKOGAWA can not predict in advance.

IM 12K01B02-01E

Page 4

After-sales Warranty

n Do not modify the product.

n During the warranty period, for repair under warranty consult the local sales representative

or service oce. Yokogawa will replace or repair any damaged parts. Before consulting for

repair under warranty, provide us with the model name and serial number and a description

of the problem. Any diagrams or data explaining the problem would also be appreciated.

• If we replace the product with a new one, we won’t provide you with a repair report.

• Yokogawa warrants the product for the period stated in the pre-purchase quotation Yokoga-

wa shall conduct dened warranty service based on its standard. When the customer site is

located outside of the service area, a fee for dispatching the maintenance engineer will be

charged to the customer.

• Returned goods that have been in contact with process uids must be decontaminated and

disinfected prior to shipment. Goods should carry a certicate to this eect, for the health

and safety of our employees. Material Safety Data sheets must be included for all components of the process to which the sensor have been exposed.

n In the following cases, customer will be charged repair fee regardless of warranty period.

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa

Electric did not supply.

• Failure due to improper or insucient maintenance by user.

• Failure due to modication, misuse or outside-of-specications operation which Yokogawa

does not authorize.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

n Yokogawa does not warrant conformance with the specic application at the user site.

Yokogawa will not bear direct/indirect responsibility for damage due to a specic application.

<INTRODUCTION>

iii

n Yokogawa Electric will not bear responsibility when the user congures the product into

systems or resells the product.

n Maintenance service and supplying repair parts will be covered for ve years after the pro-

duction ends. For repair for this product, please contact the nearest sales oce described in

this instruction manual.

IM 12K01B02-01E

Page 5

Blank Page

Page 6

<CONTENTS>

UV700G

UV Analyzer

(ORGANIC POLLUTANT MONITOR)

IM12K01B02-01E6thEdition

CONTENTS

INTRODUCTION .............................................................................................i

Safety Precautions .......................................................................................ii

After-sales Warranty ...................................................................................iii

1. Overview .................................................................................................... 1-1

1.1 Introduction ....................................................................................................... 1-1

1.2 Description of Parts .......................................................................................... 1-2

1.2.1 Unit ..................................................................................................... 1-2

1.2.2 Display ............................................................................................... 1-4

v

2. Specication ............................................................................................. 2-1

2.1 StandardSpecication ..................................................................................... 2-1

2.2 Characteristics .................................................................................................. 2-3

2.3 ModelandSuxCodes ................................................................................... 2-4

2.4 OverhaulParts ...................................................................................................2-4

2.5 ExternalDimensionsandFlowDiagrams ...................................................... 2-5

2.6 Connection Diagram ....................................................................................... 2-10

2.7 Measurement Principle .................................................................................. 2-11

3. Installation ................................................................................................. 3-1

3.1 Conditions for Installation ............................................................................... 3-1

3.2 InstallationMethod ...........................................................................................3-2

3.3 Pipingconguration ......................................................................................... 3-4

3.4 Wiring ................................................................................................................. 3-6

3.4.1 Grounding .......................................................................................... 3-6

3.4.2 Power Supply ..................................................................................... 3-6

3.4.3 Connecting Signal Lines .................................................................... 3-6

3.4.4 Connecting Detector to Converter ..................................................... 3-7

3.4.5 Connecting Float Switch Cable of Overow Tank to Converter ........ 3-7

4. Operation ................................................................................................... 4-1

4.1 Preparation for Operation ................................................................................ 4-1

4.2 Starting Operation ............................................................................................ 4-2

4.3 ShuttingDown ................................................................................................... 4-3

4.3.1 For Shut Down within 7 Days ............................................................. 4-3

4.3.2 For Shut Down over 7 Days ............................................................... 4-3

4.4 Restarting Operation ........................................................................................ 4-3

IM 12K01B02-01E

Page 7

vi

<CONTENTS>

4.4.1 For Shut Down within 7 Days ............................................................. 4-3

4.4.2 For Shut Down over 7 Days ............................................................... 4-3

5. Calibration ................................................................................................. 5-1

5.1 Calibration Pattern and its Cycle .................................................................... 5-1

5.2 Notes regarding Calibration ............................................................................ 5-2

5.3 Calibration Screen Display .............................................................................. 5-2

5.4 Calibration of UV/VIS ........................................................................................ 5-3

5.4.1 How to Prepare Calibration Solution.................................................. 5-3

5.4.2 Common Zero Calibration.................................................................. 5-6

5.4.3 Common Span Calibration ................................................................ 5-9

5.4.4 Individual (UV) Span Calibration ...................................................... 5-12

5.5 TURB (turbidity) Span Calibration ................................................................ 5-15

5.5.1 How to Prepare the Calibration Solution ......................................... 5-15

5.5.2 TURB (turbidity) Span Calibration ................................................... 5-16

6. Functions .................................................................................................. 6-1

6.1 MEAS. (Measurement) Screen ......................................................................... 6-1

6.2 TableofFunctions ............................................................................................ 6-1

6.3 Maintenance Screen Display ........................................................................... 6-2

6.4 Maintenance - Setting ....................................................................................... 6-3

6.4.1 Signal Allocation ................................................................................. 6-3

6.4.2 Signal Input Setting ............................................................................ 6-4

6.4.3 Output Setting .................................................................................... 6-5

6.4.4 Output Condition Setting .................................................................... 6-7

6.4.5 Time Adjustment ................................................................................ 6-7

6.4.6 LCD Setting ........................................................................................ 6-8

6.4.7 Touch Panel Adjustment .................................................................... 6-9

6.4.8 Maker Maintenance Mode ................................................................. 6-9

6.5 Maintenance - Measurement Setting ............................................................ 6-10

6.5.1 Measuring Range Setting for each Component .............................. 6-11

6.5.2 Setting of Decimal Place for each Component ................................ 6-12

6.5.3 Unit Setting for UV, VIS, and UV-αVIS ............................................. 6-12

6.5.4 Setting of Turbidity Correction Factor ..............................................6-13

6.5.5 Setting of COD Conversion Factor and Turbidity Correction Factor 6-14

6.5.6 Setting of MAX Alarm Value for COD and TURB (turbidity) ............ 6-15

6.5.7

6.5.8 Unit Setting for TURB (turbidity) ......................................................6-17

6.6 Maintenance - Action ...................................................................................... 6-17

6.6.1 Action ............................................................................................... 6-17

6.7 Maintenance-Check ...................................................................................... 6-18

6.7.1 Unit Information ................................................................................ 6-19

6.7.2 Individual ID Setting ......................................................................... 6-19

6.7.3 External Input/Output Check............................................................ 6-19

Setting of MIN Alarm Value for COD and TURB (turbidity) .................. 6-16

IM 12K01B02-01E

Page 8

<CONTENTS>

6.7.4 Check Analog Input .......................................................................... 6-20

6.7.5 Check Analog Output ....................................................................... 6-21

6.8 DataCheck ....................................................................................................... 6-21

6.8.1 Log Data Check ............................................................................... 6-22

6.8.2 Log Data Deletion ............................................................................ 6-23

6.8.3 Graph Display .................................................................................. 6-24

6.8.4 Calibration Report Check ................................................................. 6-25

6.8.5 Calibration Report Deletion .............................................................. 6-26

6.8.6 CF Card Transfer ............................................................................. 6-27

6.8.7 CF Card Initialization ........................................................................ 6-27

6.9 Alarm ................................................................................................................ 6-28

6.9.1 Alarm Check .................................................................................... 6-29

6.9.2 Alarm Stop ....................................................................................... 6-29

6.9.3 Alarm History Check ........................................................................ 6-30

6.9.4 Alarm History Deletion ..................................................................... 6-30

7. ExternalInputandOutput ....................................................................... 7-1

7.1 Terminal diagram of input and output ............................................................ 7-1

7.2 Analog Output ................................................................................................... 7-2

7.3 Contact Input and Output ................................................................................. 7-3

7.3.1 Contact Output ................................................................................... 7-3

7.3.2 Contact Input ...................................................................................... 7-4

7.4 SavingDatatoaCFCard ................................................................................. 7-5

vii

8 Maintenance .............................................................................................. 8-1

8.1 Maintenance item .............................................................................................. 8-1

8.2 Maintenance of Detector .................................................................................. 8-2

8.2.1 Cleaning Method for Measuring Cell ................................................. 8-2

8.2.2 Replacement of Wiper Blade Rubber ................................................ 8-4

8.2.3 Replacement of Desiccant Agent and Seal Washers for Screws ......8-6

8.2.4 Replacement of Desiccant Agent in the Measuring Cell ................... 8-7

8.3 Cleaning of Sampling Unit ............................................................................. 8-11

8.3.1 Cleaning of Overow Tank and Measuring Tank ............................. 8-11

8.3.2 Removal of Inner Tank of Measuring Tank ...................................... 8-12

8.4 Accessories and spare parts ......................................................................... 8-13

9 Troubleshooting ....................................................................................... 9-1

9.1 Table of Status and Operation ......................................................................... 9-1

9.2 Table of alarm and Operation .......................................................................... 9-1

9.3 Alarm Occurrence Condition ........................................................................... 9-2

9.4 Causes and Measures for Alarm ..................................................................... 9-3

App.1 Overview ............................................................................................ App.1-1

App.1.1 Cautions ..................................................................................................... App.1-1

App.1.2 Composition .............................................................................................. App.1-1

IM 12K01B02-01E

Page 9

viii

<CONTENTS>

App.2 Installation ........................................................................................ App.2-1

App.2.1 Selecting an installation location ........................................................... App.2-1

App.2.2 Cautions for installation environment .................................................... App.2-1

App.2.2.1 Sample water condition ............................................................. App.2-1

App.2.2.2 Surrounding environment .......................................................... App.2-1

App.2.3 Installing UV700G .....................................................................................App.2-1

App.2.3.1 Positions of foundation bolts for pole stand ............................... App.2-1

App.2.3.2 Service and maintenance space ............................................... App.2-2

App.2.3.3 Figure of completed pole stand mount ...................................... App.2-2

App.2.3.4 Pole stand assembly .................................................................. App.2-3

App.2.3.5 Measuring tank assembly .......................................................... App.2-3

App.2.3.6 Overow tank assembly ............................................................. App.2-4

App.2.3.7 Converter assembly ................................................................... App.2-6

App.3 Piping ................................................................................................. App.3-1

App.3.1 Piping procedure ......................................................................................App.3-1

App.4 Wiring ................................................................................................. App.4-1

App.4.1 Wiring procedure ......................................................................................App.4-1

App.4.1.1 Earth connection ........................................................................ App.4-1

App.4.1.2 Power supply ............................................................................. App.4-1

App.4.1.3 Cable connection for detector .................................................... App.4-2

App.4.1.4 Float switch cable connection for overow tank ........................ App.4-2

App.4.1.5 Signal line connection ................................................................ App.4-2

Customer Maintenance Parts List ...................................... CMPL 12K01B02-01E

Revision Information ...............................................................................................i

IM 12K01B02-01E

Page 10

<1. Overview>

1. Overview

1.1 Introduction

GENERAL

Water pollution control laws and regulations require monitoring of wastewater quality to prevent

water pollution in lakes, rivers and enclosed bodies of water. Pollutant load is an index of

water quality standards and is dened as the product of the COD (chemical oxygen demand)

concentration and the wastewater volume. Certain entities are required to measure pollutant

loads and comply with the limits.

Among various methods for COD measurement, automatic ultraviolet absorption spectrometry is

the ideal choice on the whole since it provides high correlation between analyzer and laboratory

results, measurement continuity and maintainability.

The UV700G Ultraviolet (UV) analyzer is an instrument for continuous on-line measurement

using the same cell length modulation method as its predecessor UV400G.

It provides improved operability through a wide measuring range and touch screen interface, high

reliability and excellent maintainability.

1-1

FEATURES

• Graphic LCD with touch screen on the converter provides easy interactive operation.

• Detector uses the rotary cell length modulation method. Zero check is performed at the time

of minimum cell length, virtually eliminating zero drift.

• Continuous cell cleaning with unique wiper system, allowing long term, stable

measurement.

• Analyzer covers a wide measuring range:

from 0-0.1 Abs to 0-5.0 Abs.

• Flow-through cell type for easy maintenance.

• Data memory function for transferring data to a PC via an optional compact ash (CF) card.

IM 12K01B02-01E

Page 11

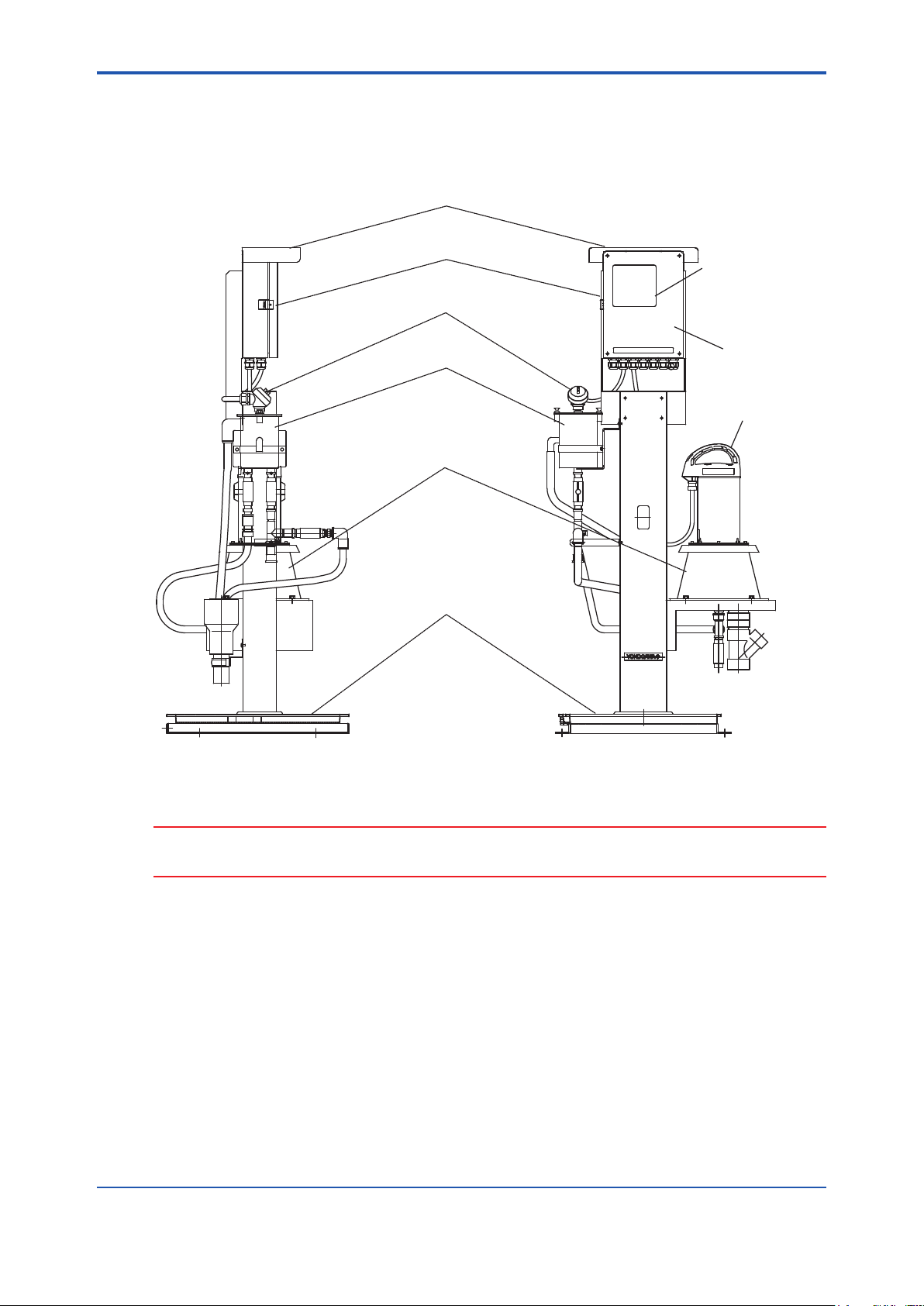

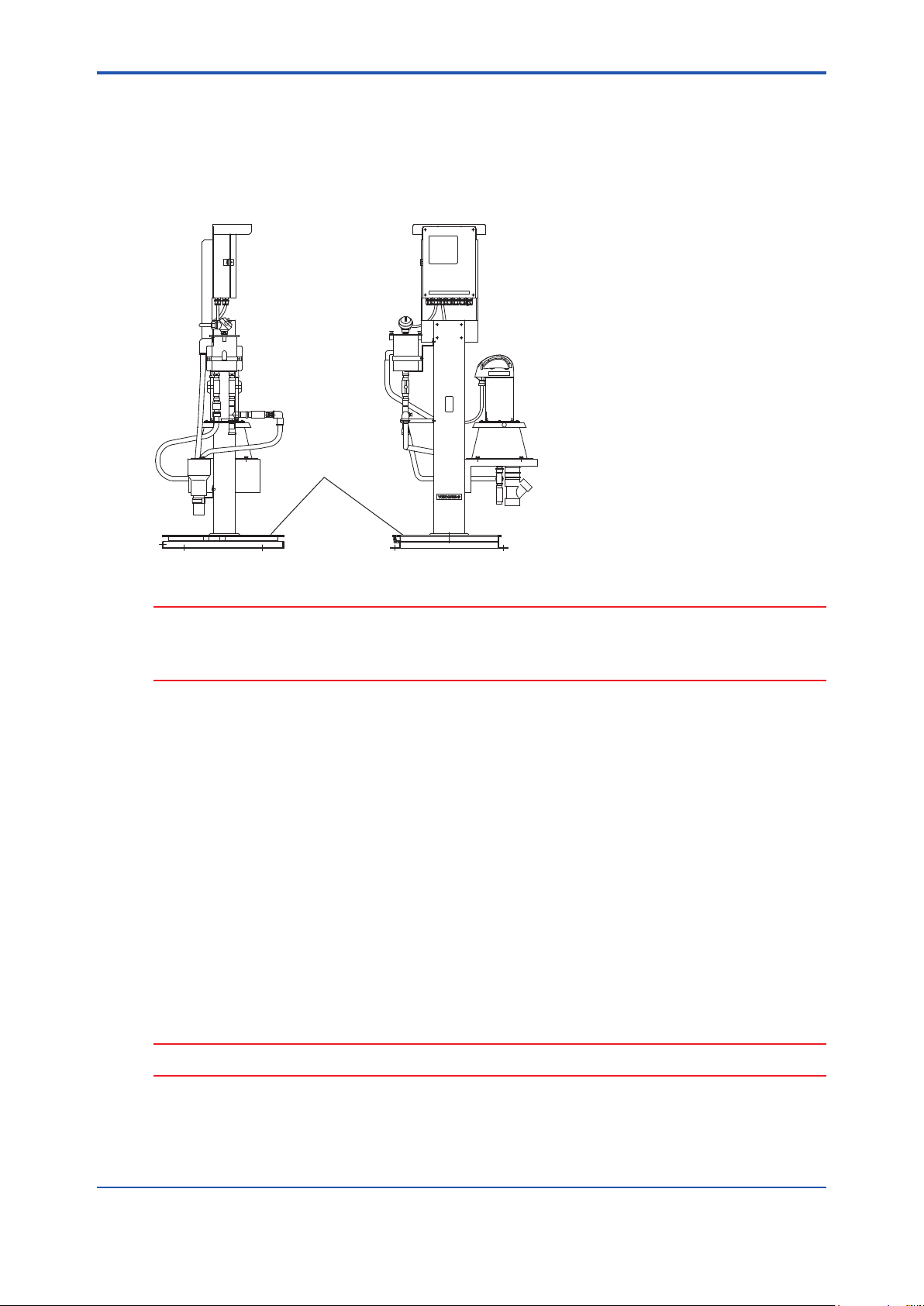

1.2 Description of Parts

1.2.1 Unit

Hood (optional)

Converter

Float Switch

<1. Overview>

1-2

Display

Left Side View

Overflow Tank

Measuring Tank

Base

Door

Detector

Front View

CAUTION

The stanchions illustrated are typical examples. Appearance and size may vary depending on the

specication.

IM 12K01B02-01E

Page 12

<1. Overview>

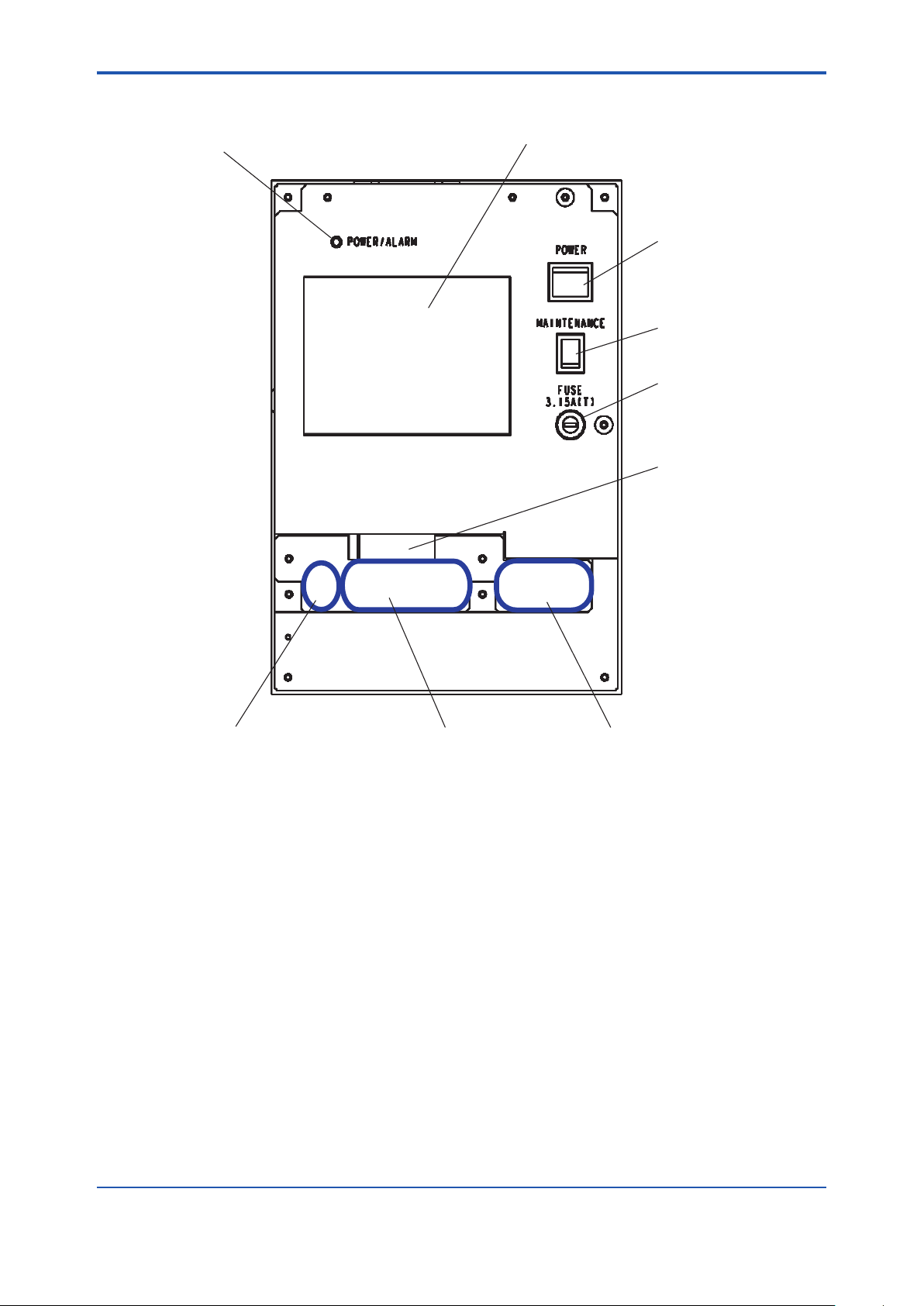

l Insideoftheconverter

1-3

Power / alarm LED

Display (Touch panel)

Power switch

Maintenance switch

Fuse

CF card insertion slot

. CF CARD

Connectors for the detector Signal terminals

AC power terminals

IM 12K01B02-01E

Page 13

<1. Overview>

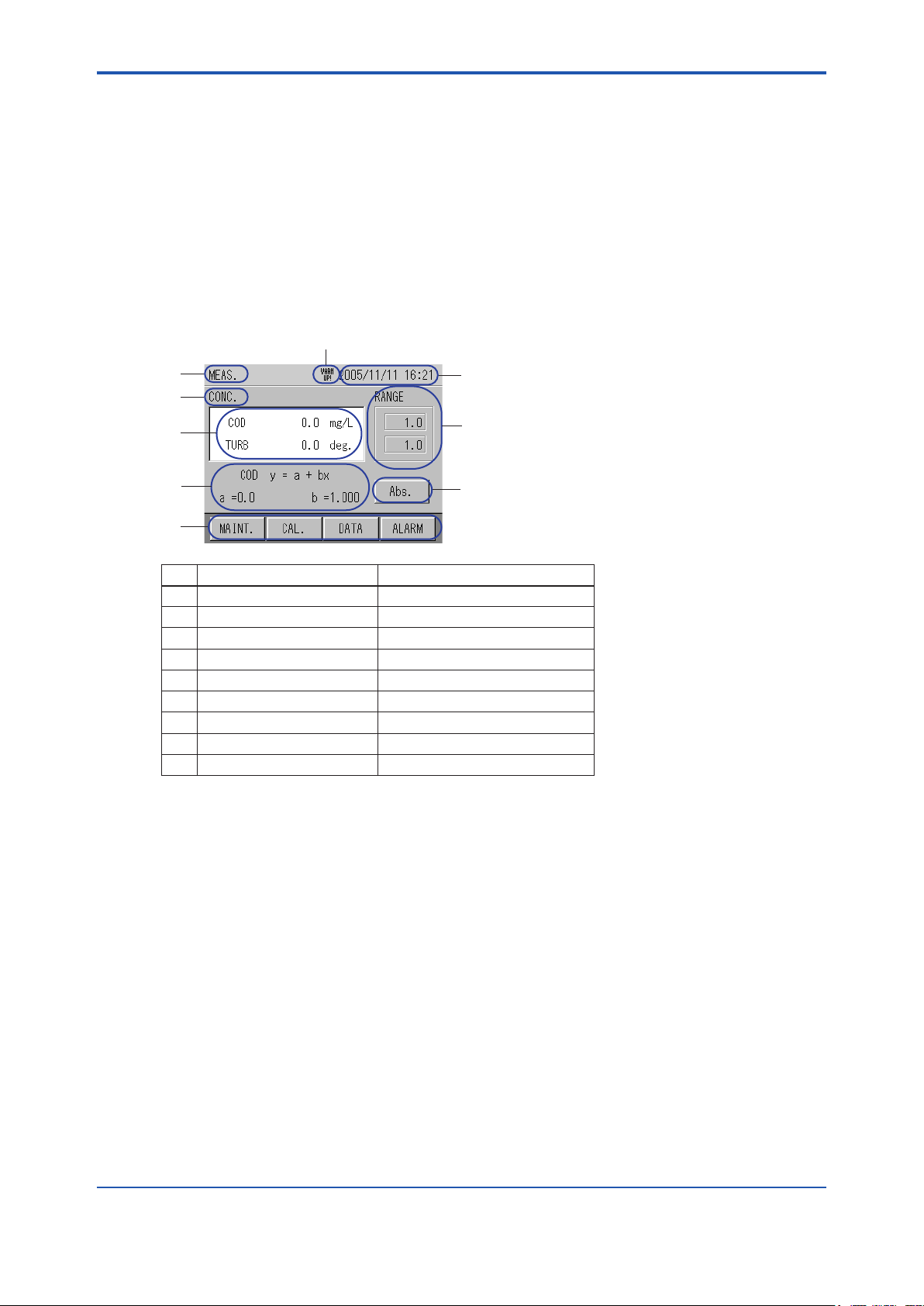

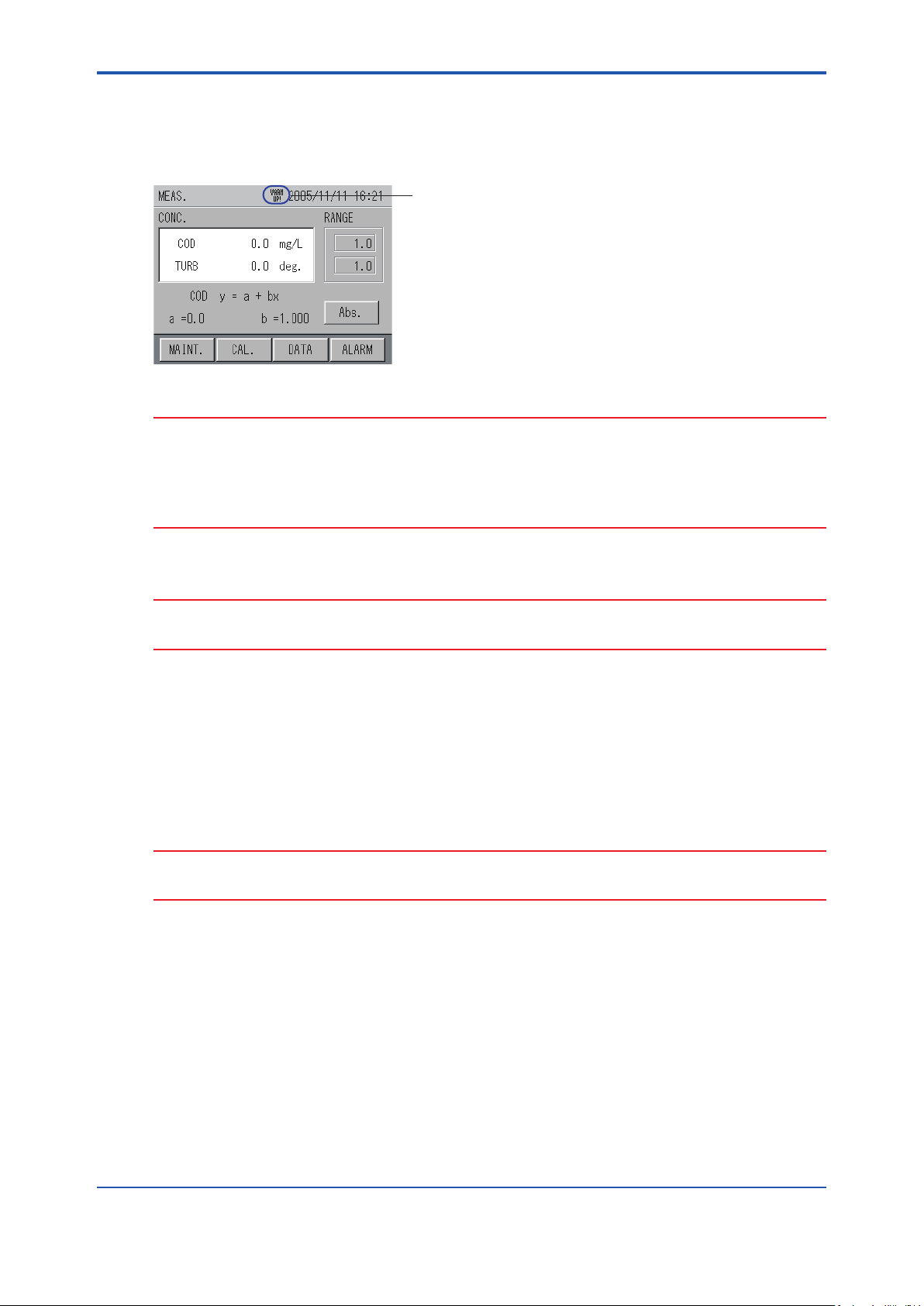

1.2.2 Display

This section describes the parameters shown on a typical display:

• The display is touch panel. Do not press buttons with wet hands, or a sharp object such as a

pen tip or a screwdriver.

• If no buttons are pressed for a certain period of time, the backlight turns OFF.

• If no buttons are pressed for about two hours on displays other than those for measurement,

data or alarm, the display turns to the measurement display.

l Exampleofdisplay-Displayingmeasurementreadings

The display shows measurement readings.

7

1-4

1

3

4

5

6

NO. Display exampleDescription

1

2

3

4

5

6

7

8

9

WARM UP!

2

8

9

MEAS., SETTING, LOG DATA, etc.Title of display

2004/01/30 09:57Clock

Abs, CONC, etc.Items to be measured

Instantaneous valuesReadings

Conversion factors for COD, etc.Conversion factor

MAINTENANCE, CAL, etc.Operation buttons

WARM UP!: Unit is being warmed up. Status of unit

RangeRange

Abs, CONC, etc.Switchable measurement items

When the power is turned ON, “WARM UP!” is displayed. This will disappear after one hour.

IM 12K01B02-01E

Page 14

<1. Overview>

l Exampleofdisplay-Displayingitemstobeselected

1

2

3

NO. Display exampleDescription

1

2

3

MAINTENANCE, SETTING, etc.Title of display

SETTING, MEAS. SETTING, etc.Selection keys

CLOSE etc. Switching keys

l Exampleofdisplay-Displayinghistoryandotherinformation

1

2

1-5

3

NO. Display exampleDescription

1

2

3

Alarm history, calibration report, etc.Title of display

Description of alarms, etc.Items to be displayed

–Data list

IM 12K01B02-01E

Page 15

Blank Page

Page 16

<2.Specication>

2. Specication

2.1 StandardSpecication

Measurement : Organic pollutants in wastewater.

Measurement method:

Dual optical path, dual wavelength, rotary cell length modulation method

Measurement wavelength:

Ultraviolet (UV): 253.7 nm

Visible light (VIS): 546.1 nm

Light source: Low pressure mercury-vapor lamp

Detector: Silicon photo cell, ow-through type

Measuring range (corrected for 10 mm cell)

UV/VIS absorbance 0-0.1 to 0-5.0 Abs

Display: Graphic LCD with touch screen,

320 240 dot, with backlight

Indication: UV absorbance, VIS absorbance, UV- VIS absorbance, COD

concentration, turbidity

Resolution: 0.0001 Abs (factory default) or 0.001 Abs

COD conversion: Conversion equation Y = a bX

where Y = COD concentration

X = absorbance (UV-VIS)

Turbidity conversion: Conversion equation Y = a bX

where Y = turbidity,

X = absorbance(VIS)

Analog output:

Number of outputs: 3

Functions: 3 functions selectable:

UV absorbance / VIS absorbance/ UV-VIS absorbance / COD

concentration / turbidity

Specications: 4-20 mA DC or 0-16 mA DC, isolated

(non-isolated between channels)

Contact output:

Number of outputs: 6

Functions:

2 functions xed:

Power o, maintenance status

4 functions selectable:

Total alarm / COD high alarm / turbidity high alarm / light souse

malfunction / no sample / cleaning motor error / analyzer error

Descriptions:

Power o:

Activated when power o occurs

Maintenance status:

Activated when instrument is in maintenance or calibration mode or

when MAINTENANCE switch is turned on

Total alarm:

Cleaning motor error, light source malfunction and / or analyzer error

2-1

IM 12K01B02-01E

Page 17

<2.Specication>

Specications: Voltage-free contact output, Form A

Contact rating: 0.3 A / 125 V AC, 1A / 30 V DC (resistive load), independent

common at each output

Contact input:

Number of inputs: 2

Functions: No sample oat switch, time adjustment

Specications: Voltage-free contact input (open collector can be connected), isolated

On resistance: 100 V max.

Open circuit voltage: 5.5 V DC

Short circuit current: 5 mA max.

Data memory: Measured data can be stored in converter and stored data transferred to

CF card.

Log interval: 1 min or 1 hour

Log time: On the hour every hour

Retention time: Approx. 10 days for 1 min interval

Approx. 1 year for 1 hour interval

Calibration method: Manual calibration using zero / span standard (calibration solution in

ampoule) (One touch calibration is available)

Cleaning method: Automatic, continuous wiper cleaning

Operating conditions:

Ambient temperature: 0 to 40 8C

Ambient humidity: 90% RH or less

Installation location: Flat, stable place not subject to severe vibration or shock. Allow pace for

maintenance. No dust, mist, corrosive gases are present. Atmospheric

pressure. Avoid exposure to direct sunlight. Good ventilation. Max.

altitude of 2000 m.

Sample conditions:

Temperature: 2 to 40 8C (non-freezing)

Pressure: 20 to 500 kPa

pH: 4 to 10

Flow rate: 2 to 20 L/min

Concentration of suspended solids:

200 mg/L or less

Note: Protection against freezing should be provided when needed.

Piping connection:

Analyzer with pole-base mount type (UV700G-A-A)

Sample inlet: Rp 1/2 female

Bypass outlet: Rc 1/2

Overow outlet 1: 13A nominal, elbow tting

Overow outlet 2: 20A nominal, elbow tting

Drain port: Rc 1/2

Discharge port: 50A nominal, tube tting

Analyzer with standard self-supporting type (UV700G-hB-A)

Sample inlet: Rp 1/2 female

Drain port: Rc 1/2

Discharge port 1: 50A nominal, tube tting

Discharge port 2: VP40 pipe

2-2

IM 12K01B02-01E

Page 18

<2.Specication>

Wiring:

Power wiring:

Size: 1.25 mm2 (AWG16) or larger

Connection: M4 screw terminal

Termination: Crimp terminal for M4 screw

Signal wiring:

Size: 0.08 to 1.5 mm2 (AWG28 to 16)

Connection: Pin terminal

Termination: Strip 7 mm of insulation o wire end

Dimensions (excluding projections):

Converter: 240(W) 3 104(D) 3 320(H) mm

Detector: 200(W) 3 180(D) 3 403(H) mm

Materials (main materials):

Wetted parts: SUS304, R-PVC, fused silica, polypropylene, chloroprene rubber,

titanium (when option code “/TN” is specied)

Stanchion

Material:

Pole-base mount type (UV700G-hA-A):

Iron

Standard self-supporting type (UV700G-hB-A):

Carbon steel plate

Finish:

Converter: Epoxy with modied melamine resin, baked, Munsell 5PB8/1 equivalent

Pole-base mount type (UV700G-hA-A):

Epoxy with modied melamine resin, baked, Munsell N1.0 equivalent

Standard self-supporting type (UV700G-hB-A):

Polyurethane resin, baked, Munsell 0.6GY3.1/2.0 equivalent

Construction: Outdoor installation (equivalent to IP54)

Weight:

Converter: Approx. 5.0 kg

Detector: Approx. 5.6 kg

Pole-base mount type:

Approx. 31 kg

Standard self-supporting type (including converter, detector, overow tank):

Approx. 47 kg

Power supply: 100 to 230 V AC 610%, 50/60 Hz

Grounding: JIS Class D grounding (100 V or less, φ1.6 mm copper wire)

Power consumption: 100 to 120 V AC, 45 VA max.

200 to 230 V AC, 60 VA max.

2-3

2.2 Characteristics

Linearity: 62% FS (65% FS for 2.6 to 5.0 Abs)

Repeatability: 62% FS (65% FS for 2.6 to 5.0 Abs)

Stability: 62% FS/24 h (65% FS/24 h for 2.6 to 5.0 Abs)

Response time: 90% within 1 min (sample ow rate at 5 L/min)

IM 12K01B02-01E

Page 19

<2.Specication>

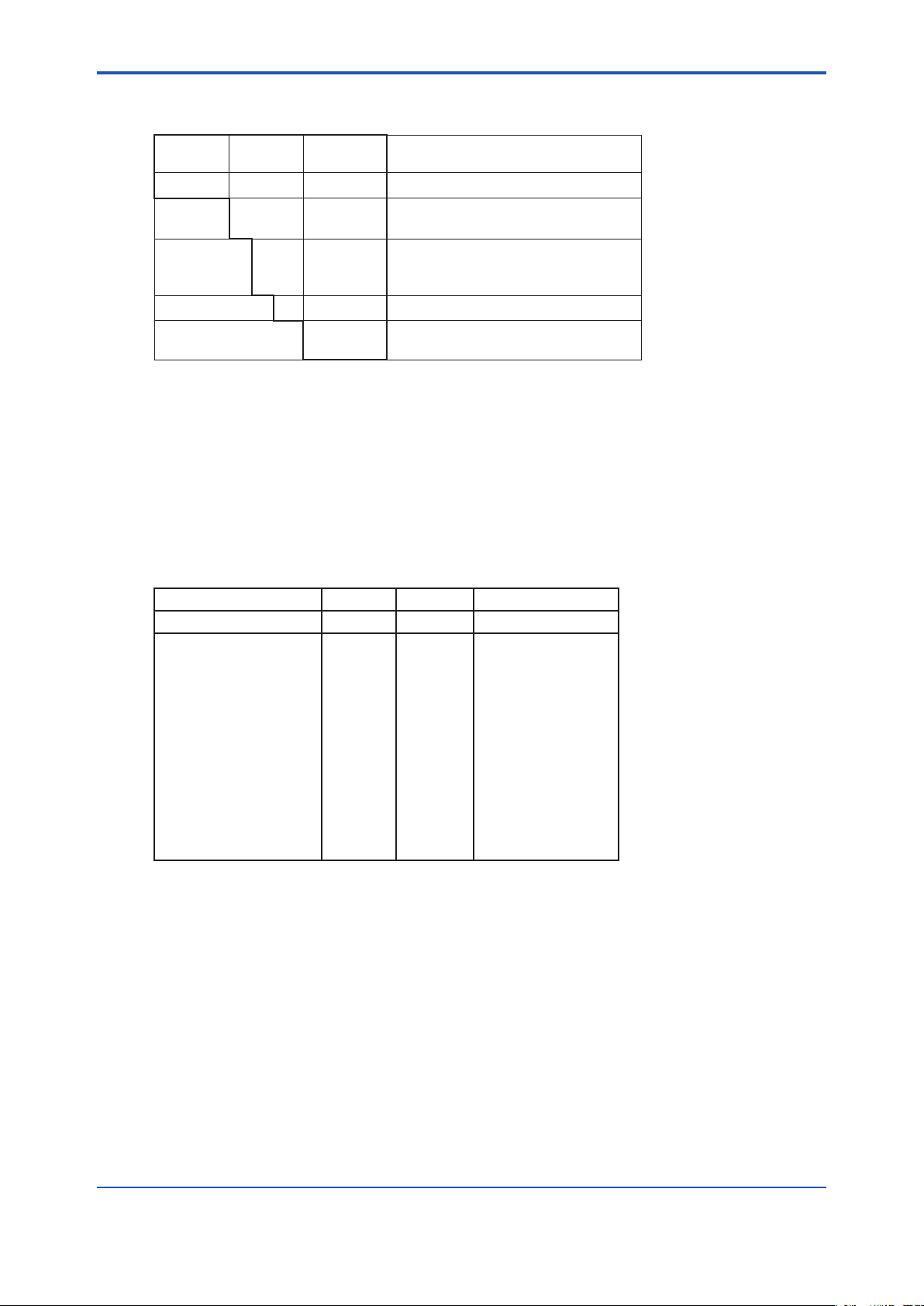

2.3 ModelandSuxCodes

2-4

Model

UV700G - - - - - - - - - - - - - - - - - - - -

Language

Stanchion

/

Option

*1: Should be selected when sample water contains seawater or chlorine.

Sux

Code

-J

-E

N

A

B

Option Code Description

UV analyzer (organic pollutant analyzer)

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

- - - - - - - - - - -

-A

/H

/TN

Japanese

English

Without stanchion

Pole-base mount type

Standard self-supporting type2

Always -A

Hood for sun protection

Titanium wetted parts*1

See “8.4 Accessories and spare parts” regarding Standard Accessories and Auxiliary parts.

2.4 OverhaulParts

For one year after delivery no parts are required to be replaced except wiper blade rubbers and

desiccants. To ensure reliable measurement with simple routine maintenance, it is recommended

that the instrument be overhauled every year by Yokogawa. The table below lists parts required

for overhaul.

Item P/N Qty Description

Inspection parts kit K9436CA 1 set

Contents:

V-ring A

Seal washer

Seal washer

Roller

Cell packing 2

Desiccant (cell)

Wiper blade rubber

Light source

Desiccant (detector)

Stepping motor

Blind cap

Case packing

Note: For yearly overhaul, it is recommended that an inspection parts kit (P/N K9436CA) be purchased.

The kit does not include calibration solutions, which should be purchased separately.

K9430EP

K9436CB

K9430ES

K9430EN

K9430ER

K9430EH

K9436CG

K9436FY

K9430EG

K9436GB

K9436GR

K9436GK

2 pcs/set

4 pcs/set

10 pieces

6 pieces

4 pcs/set

2 pcs/set

4 pcs/set

1 piece

5 pcs/set

1 piece

4 pcs/set

1 piece

Cell

Detector’s upper case

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Detector

Detector, case

Detector, case

IM 12K01B02-01E

Page 20

<2.Specication>

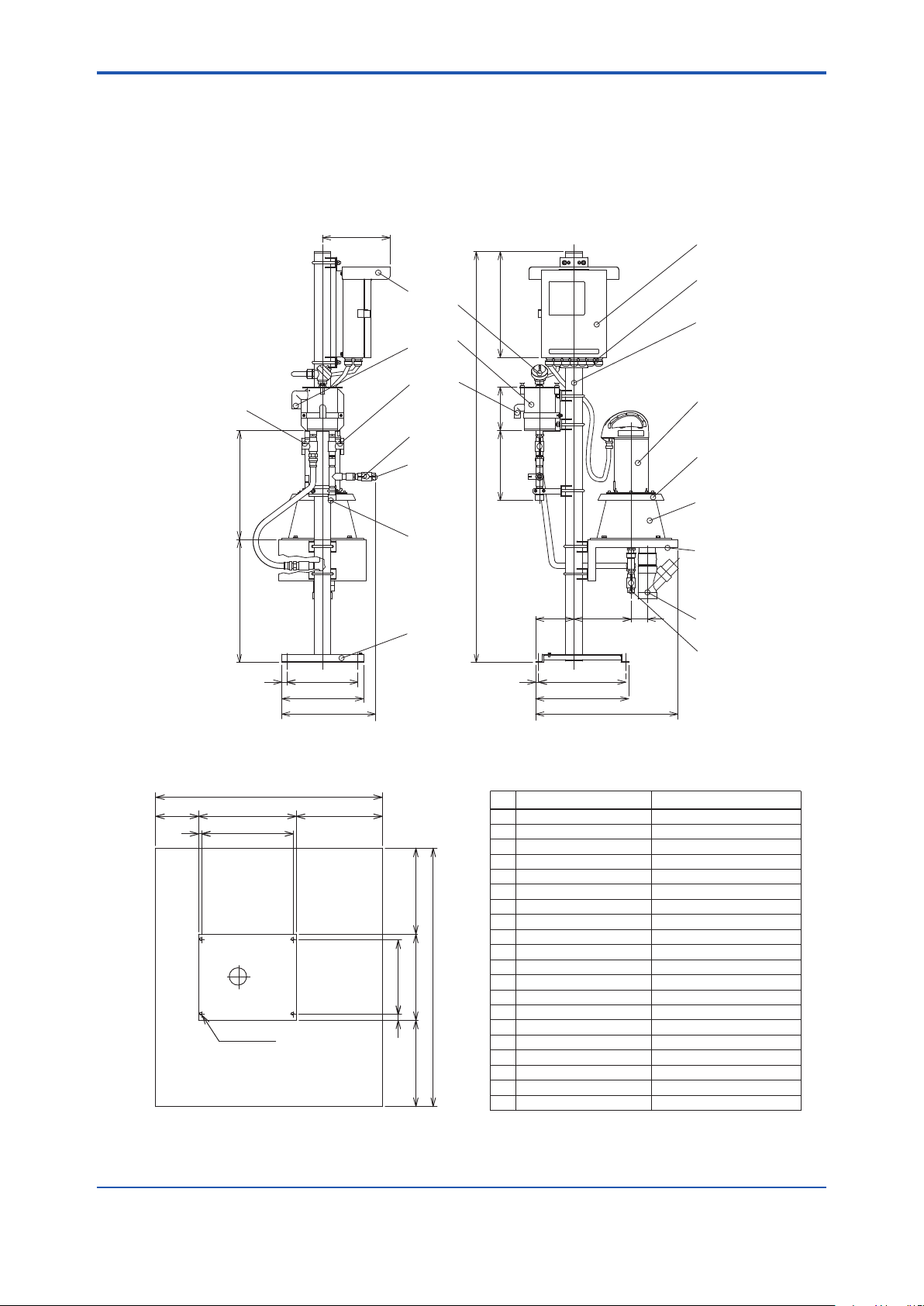

2.5 ExternalDimensionsandFlowDiagrams

1. UVAnalyzerwithpole-basemounttype,UV700G-A-A

n ExternalDimensions Unit: mm

2-5

18

400350-500

)(248

1

2

*

20

16

19

4

17

8

(390)

3

5

(160)(285)

9

10

(1506)

11

12

13

15

140

(209)

(60)

14

7

6

20

260

300

(345)

10

320

340

(520)

* Hood for sun protection is optionally available.

1840

340

32010

42-ø9

M8

Maintenance Area

Front

Basic Anchor Bolt Plan

(1000)500

300 (1000)1000

26020

2300

Weight: Approx. 31 kg

No.

1

2 Wiring port

3 Pole

4 Overflow tank

5 Detector

6 Drain port (V-4)

7 Discharge port 50A nominal, tube fitting

8 Ball valve (V-1)

9 Ball valve (V-2)

10

11

12

13

14

15

16

17

18

19

20

Item Description

Converter

Rc 1/2

Bypass outlet Rc 1/2

Blind plate

Measuring tank

Sample inlet Rp 1/2 female

Detector table

Base

Overflow outlet 2 20A nominal, elbow fitting

Overflow outlet 1 13A nominal, elbow fitting

Ball valve (V-3)

Float switch

OptionalHood for sun protection

IM 12K01B02-01E

Page 21

<2.Specication>

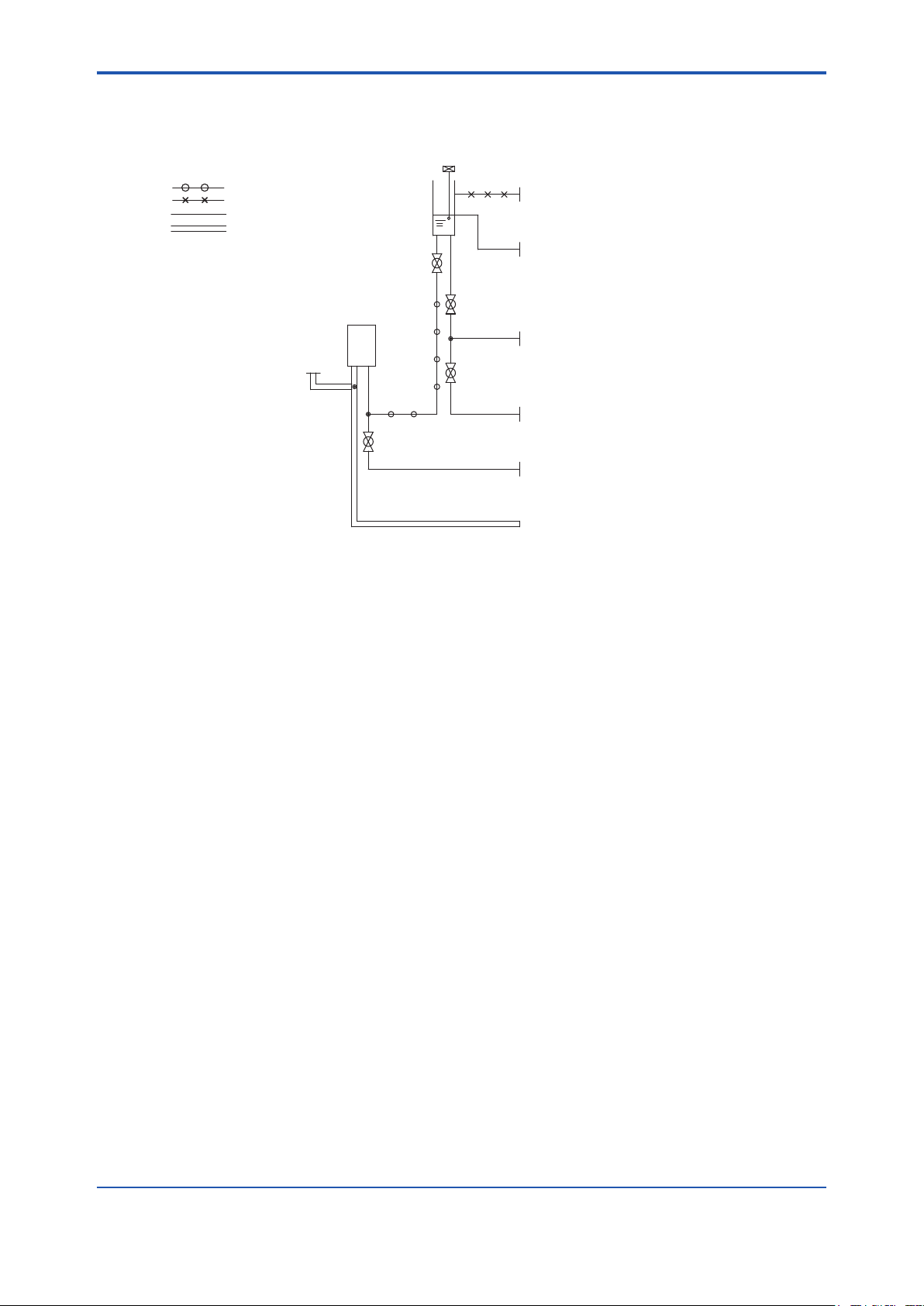

n FlowDiagram

Overflow Tank

Float Switch

Piping Material

ø22/ø15 soft tube

VP20 rigid PVC pipe

VP13 rigid PVC pipe

VP50 rigid PVC pipe

V-3

Overflow Outlet 2

20A nominal, elbow fitting

Overflow Outlet 1

13A nominal, elbow fitting

2-6

Measuring Tank

Vent to Atmosphere

V-1

Sample Inlet

Rp 1/2 female

V-2

Bypass Outlet

Rc 1/2

V-4

Drain Port

Rc 1/2

Discharge Port

50A nominal, tube fitting

Note: Drain piping should be installed so that back pressure does not develop.

IM 12K01B02-01E

Page 22

<2.Specication>

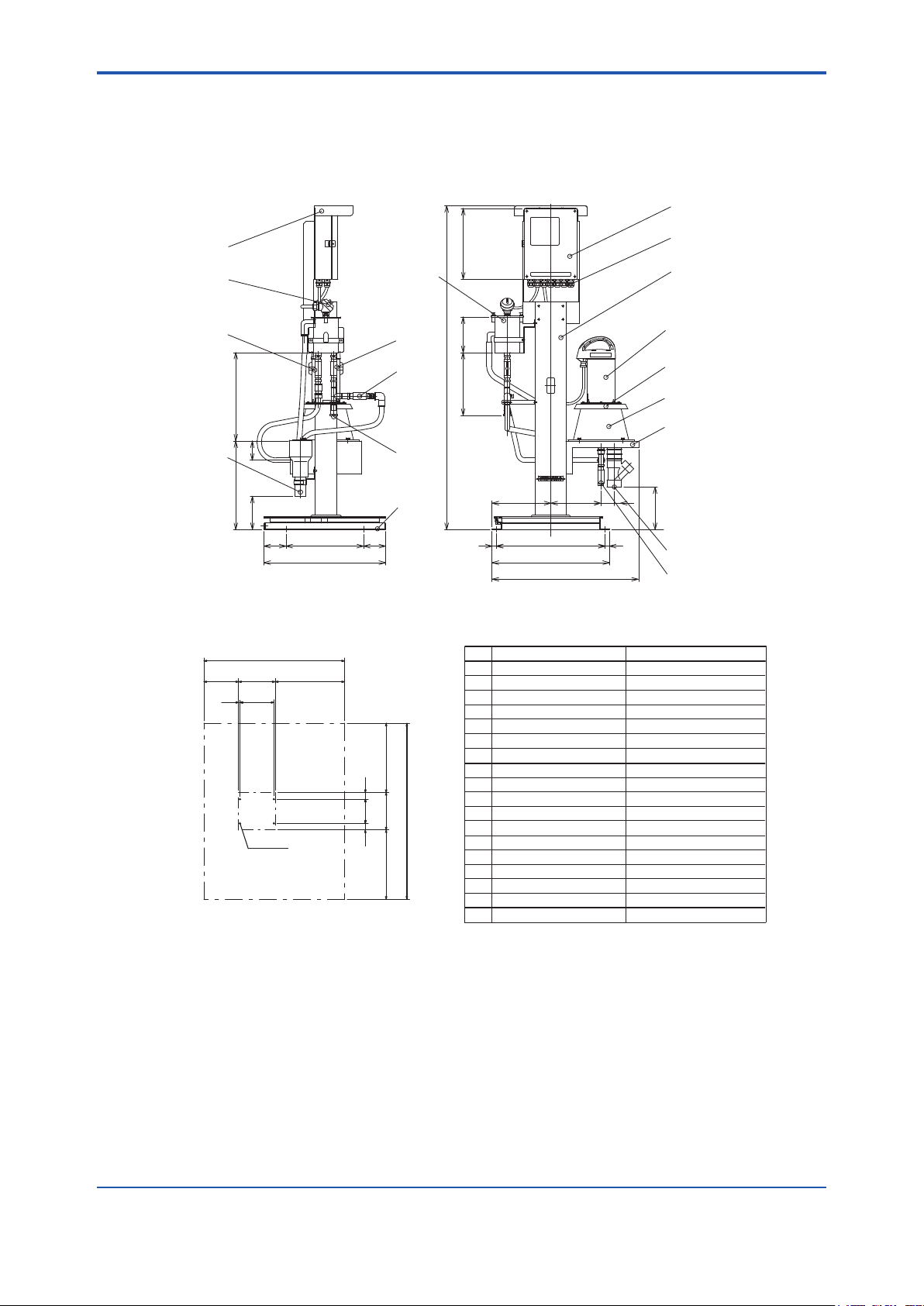

2. UVAnalyzerwithstandardself-supportingtype,UV700G-B-A

n ExternalDimensions Unit: mm

1

2-7

*

18

17

9

8

10

400

87

16

400

150

100

350 (100)

550

13

15

* Hood for sun protection is optionally available.

2030

530 (1000)500

49020

350 9595

540 (1000)1000

2540

2–ø15

4

Front

Maintenance Area

320

4

(160)

1464

(285)

(240)

(265)

49020

530

(60)

665

Weight: Approx. 47 kg

No.

1 Converter

2 Wiring port

3 Stanchion

4

5 Detector

6 Drain port (V-4)

7 Discharge port 1

8 Ball valve (V-1)

9 Ball valve (V-2)

10

11 Blind plate

12 Measuring tank

13 Sample inlet Rp 1/2 female

14 Detector table

15 Base

16

17

18

Item Description

Overflow tank

Ball valve (V-3)

Float switch

Hood for sun protection

2

3

5

11

12

14

(192)

(20)

7

6

Rc 1/2

50A nominal, tube fitting

VP40 pipeDischarge port 2

Optional

IM 12K01B02-01E

Page 23

<2.Specication>

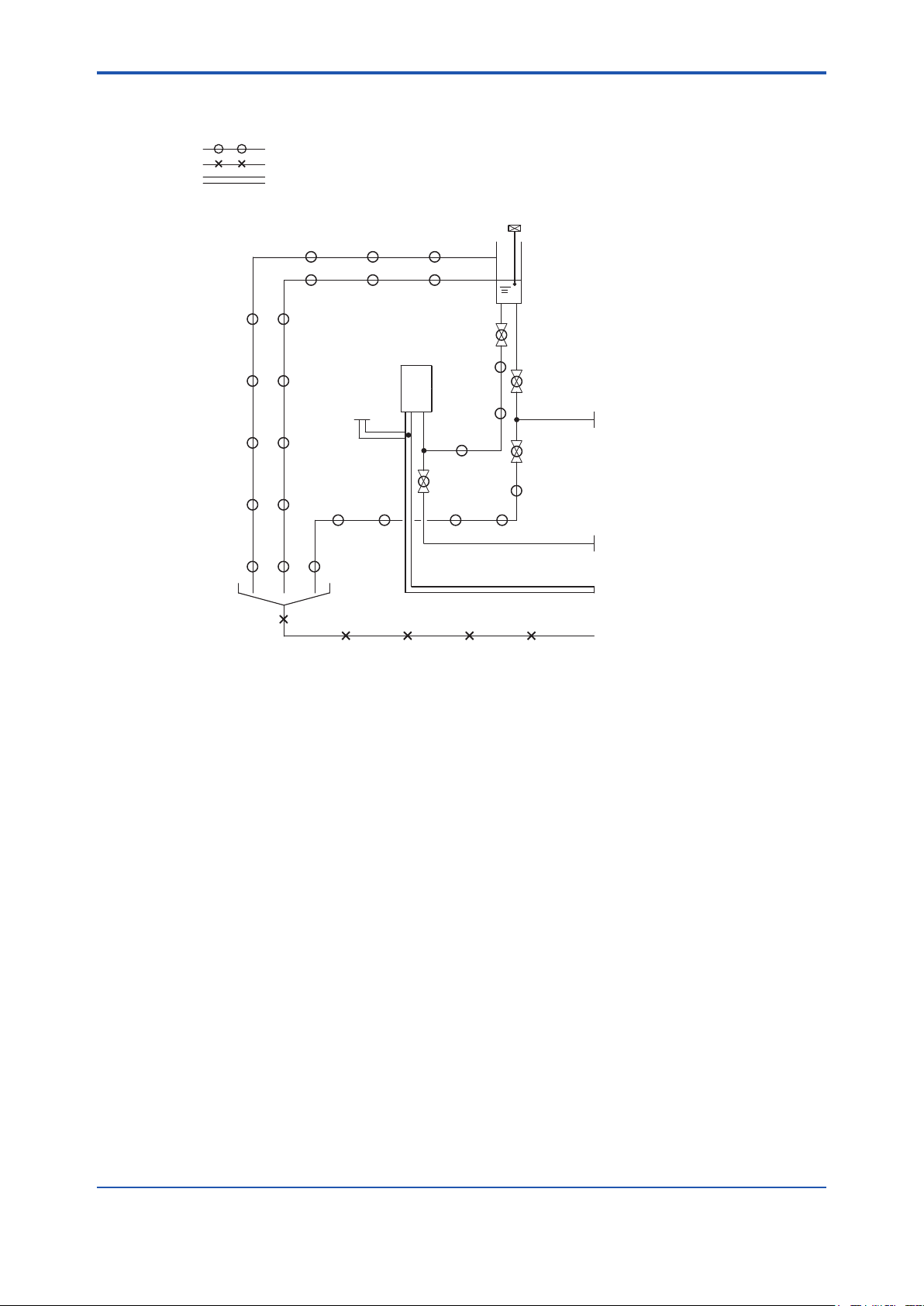

n FlowDiagram

Piping Material

ø22/ø15 soft tube

VP40 rigid PVC pipe

VP50 rigid PVC pipe

Float Switch

Overflow Tank

V-3

Measuring Tank

V-1

2-8

Vent to Atmosphere

Sample Inlet

Rp 1/2 female

V-2

V-4

Drain Port

Rc 1/2

Discharge Port 1

50A nominal, tube fitting

Discharge Port 2

VP40 pipe

Note: Drain piping should be installed so that back pressure does not develop.

IM 12K01B02-01E

Page 24

<2.Specication>

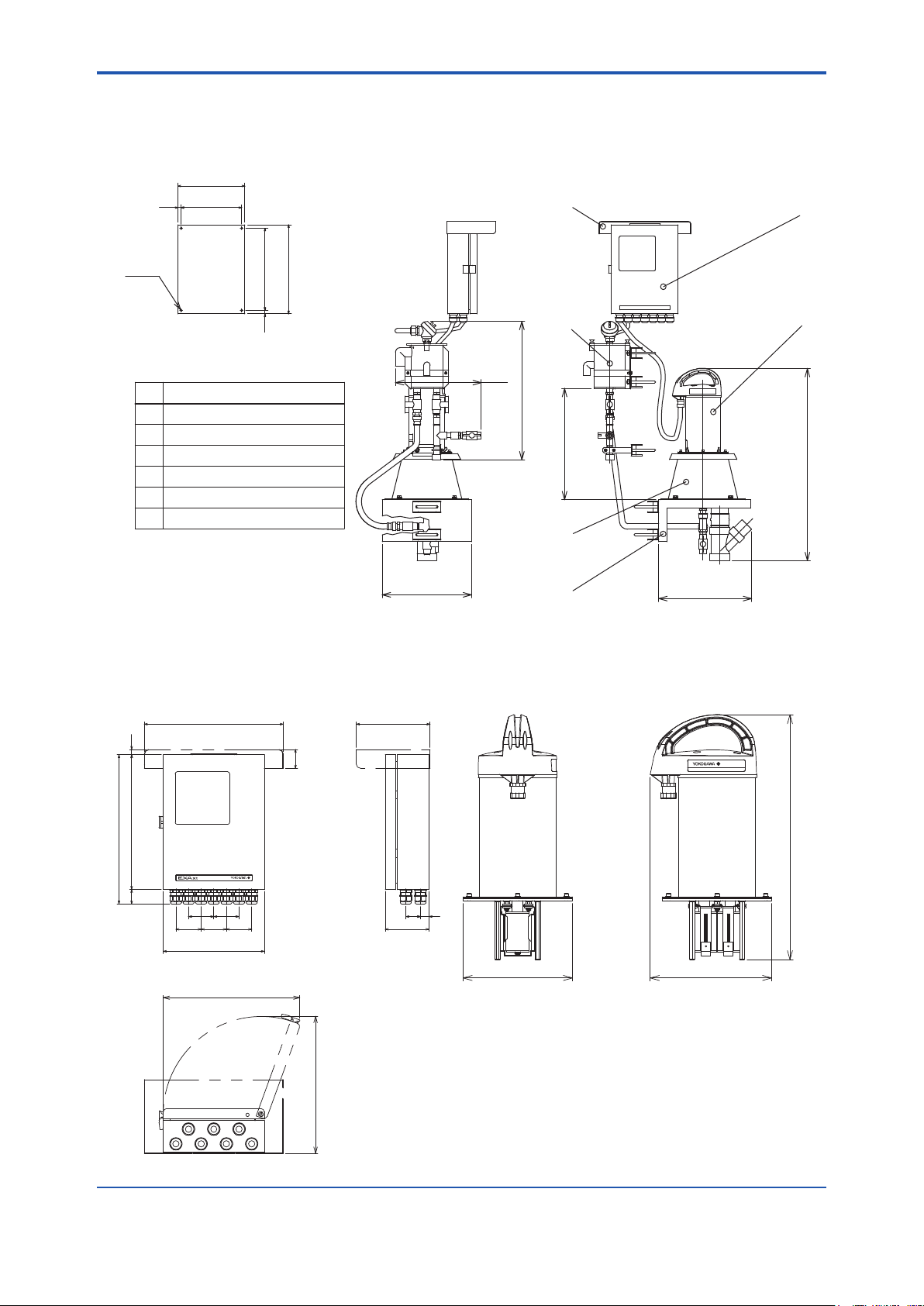

3. UVAnalyzerwithoutstanchion,UV700G-N-A

n ExternalDimensions

240

21511.5

6

2-9

1

4-M6

Converter

Rear

29512.5

320

Converter Mounting Dimensions

No. Item

1 Converter

2

Detector

3

Measuring tank

4

Detector table

5

Overflow tank

Hood for sun protection(optional)

6

Pipes, fittings, and U-bolts are included

with shipment.

320

When "UV700G-N-A" is specified, each assembly will be

delivered without a stanchion and converter brackets that are

provided when "UV700G-A-A" is specified. Hood for sun

protection is optionally available.

Converter

330

12.5

45

175

5

(307.5)

(500)

Head ≥400

3

4

Detector

2

(690)

(333)

UV700GULTRA VIOLET ANALYZER

320

354.5

(34.5)

ULTRA VIOLET

UV

ANALYZER

6060

60 6060

240

Maintenance Area ≥500

104

Converter Dimensions

Maintenance Area ≥500

Weight: Approx. 5.0 kg

403±5

20

35

200±3180

Detector Dimensions

Weight: Approx. 5.6 kg

IM 12K01B02-01E

Page 25

<2.Specication>

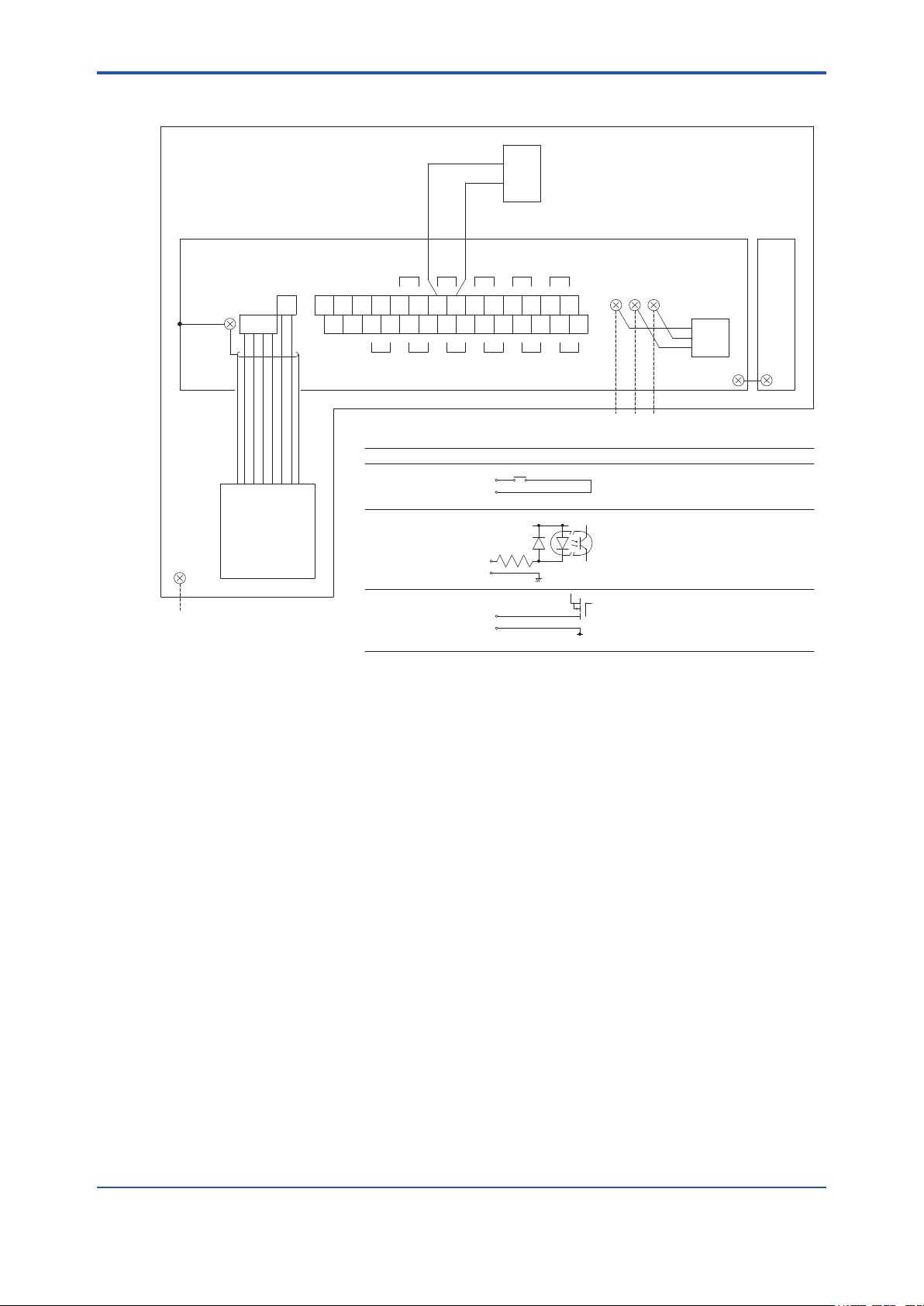

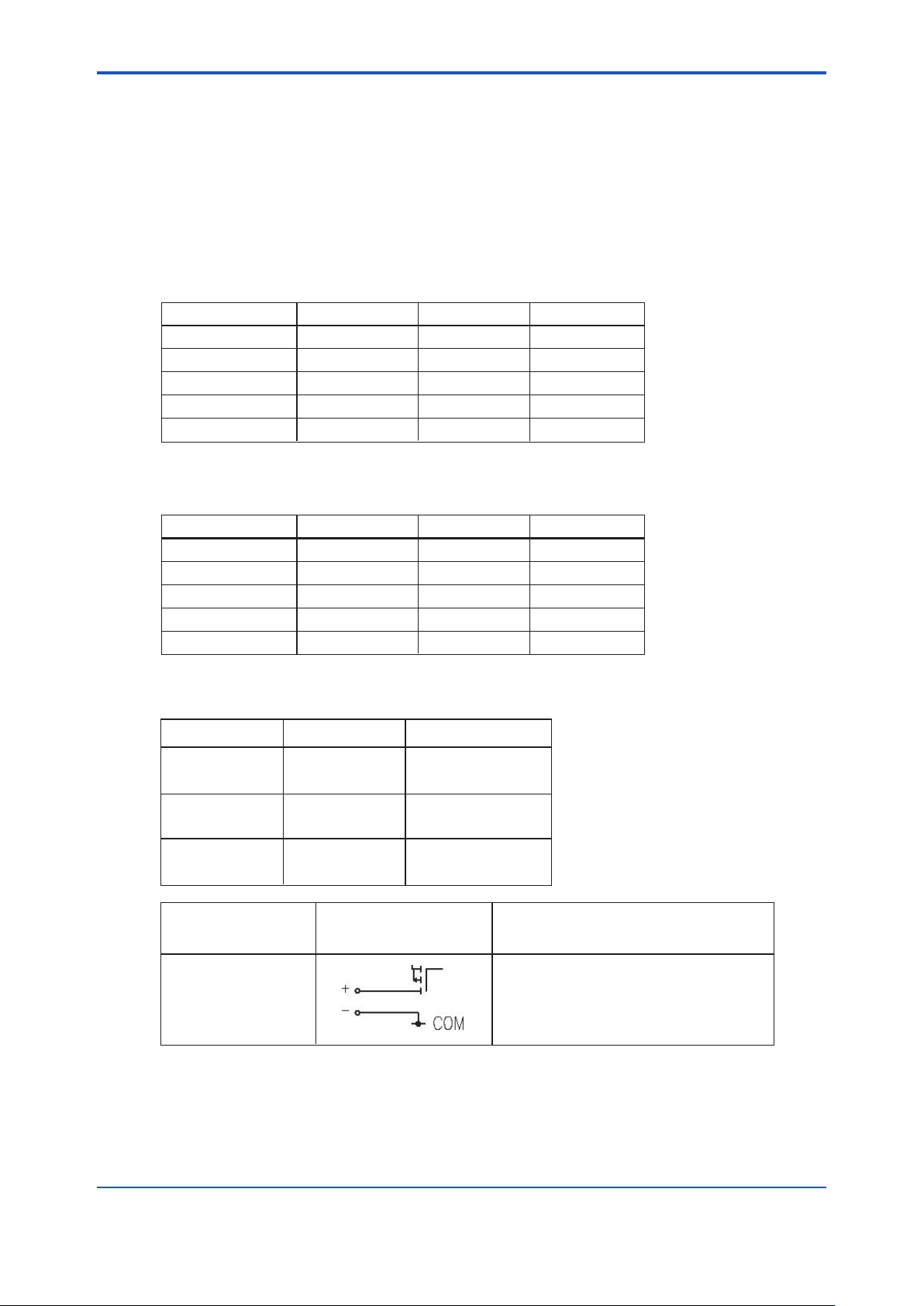

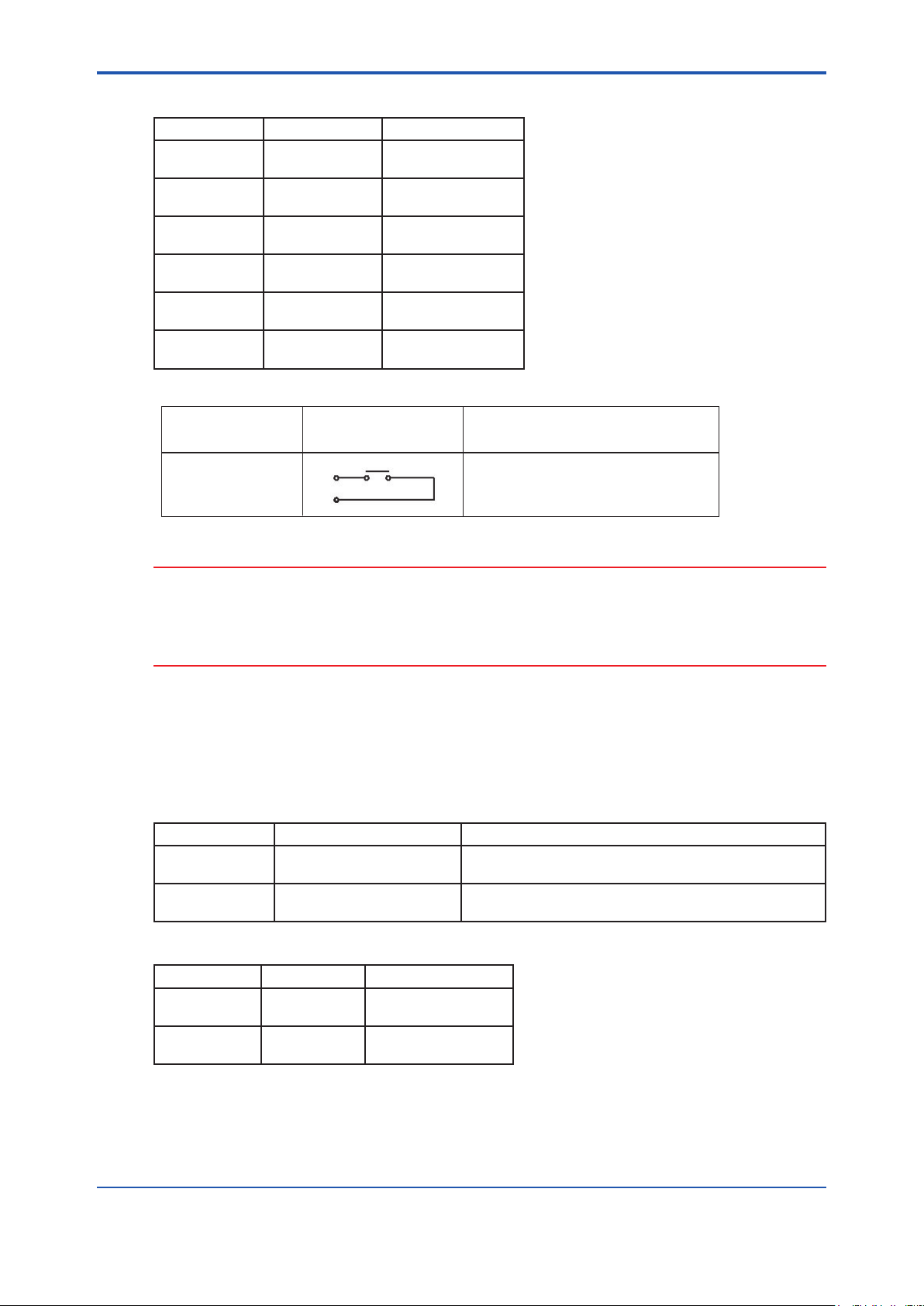

0-16/4-20 mA DC

Current signal output

Isolated input (shared common)

Load resistance 600 V max.

Voltage free contact signal input

Isolated input (shared negative)

On resistance: 100 V max.

Open circuit voltage: 5.5 V DC

Short circuit current: 5 mA max.

Contact rating:

0.3 A/125 V AC, 1A/30 V DC (resistive load)

Voltage free contact signal output

SpecificationI/O Circuit

Analog signal output

Contact signal input

Contact signal output

Signal Type

2

1

COM

Photocoupler

15V

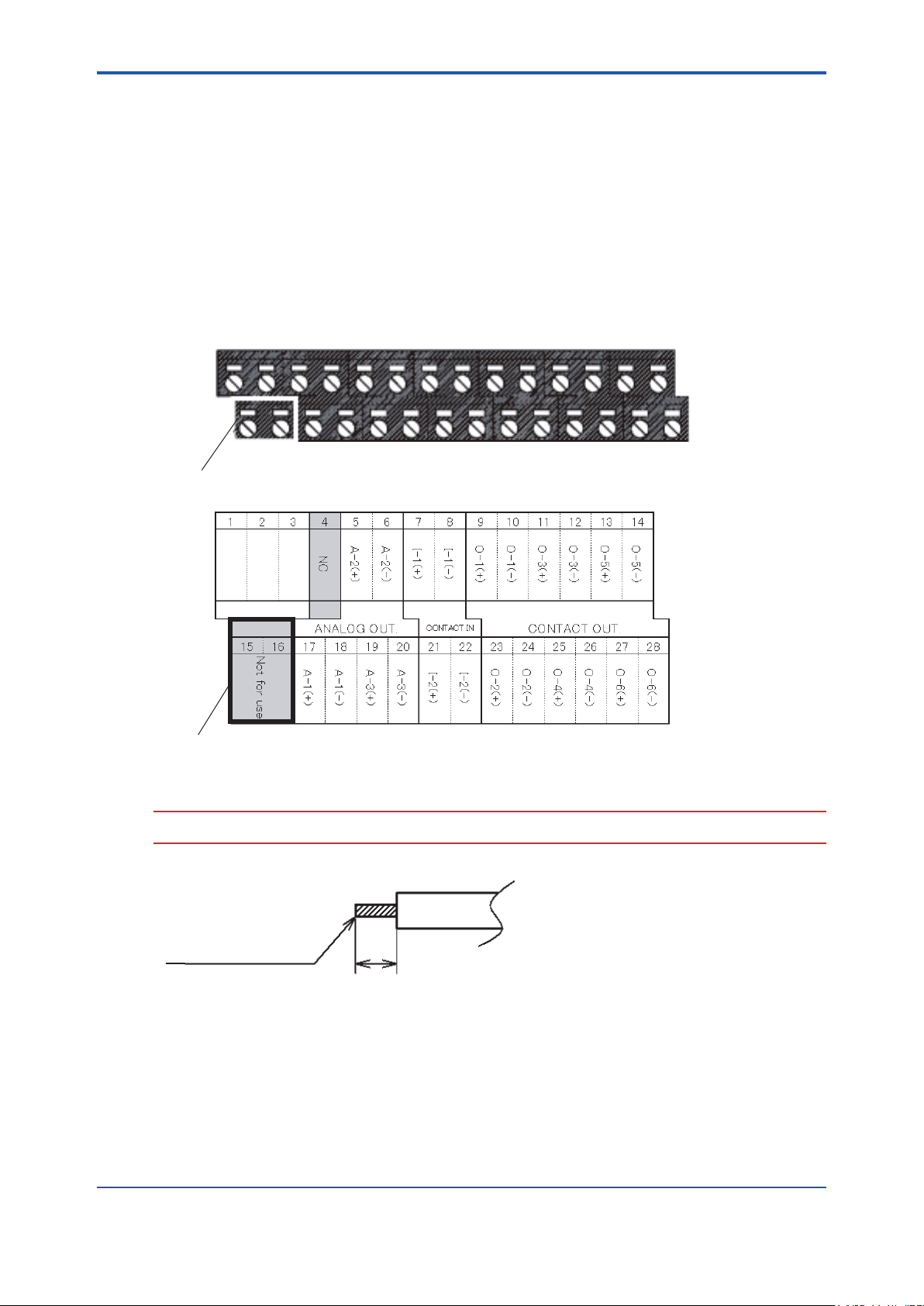

470V

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 22 23 24 25 26 27 28

1 2

Analog

Output 1

Analog

Output 3

Contact

Input 2

Contact

Output 2

Contact

Output 4

Contact Output 6

(maintenance status)

Analog

Output 2

Contact

Input 1

Contact

Output 1

Contact

Output 3

Contact Output 5

(power off)

O-6O-4O-2I-2A-3A-1

A-2 I-1 O-1 O-3 O-5

Empty

Terminal

Internal Connections

(Not for Use)

CN2

4-pin Connector

CN1

2-pin Connector

Detector

M3 Shield

Ring Terminal

Dedicated Cables

L E N

100-230 V AC 610%,

50/60 Hz, 60 VA max.

Power Supply

33M4 Ring Terminals

1

2EArrester

Converter

(Chassis)

Converter

(Door)

Float Switch

M5

Ground Bolt

Class D Grounding

Stanchion

2 1

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

2

1

2.6 Connection Diagram

2-10

IM 12K01B02-01E

Page 26

<2.Specication>

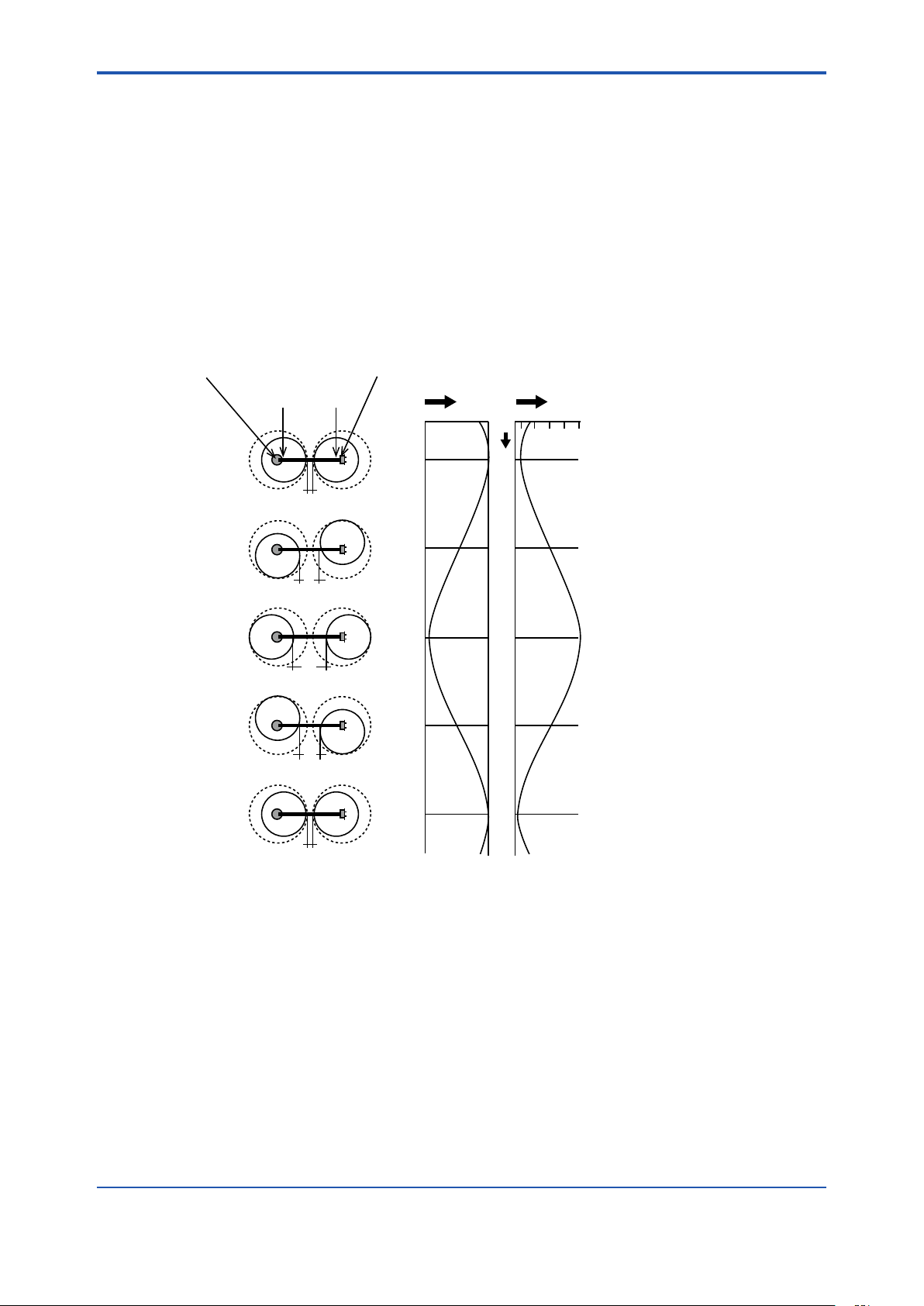

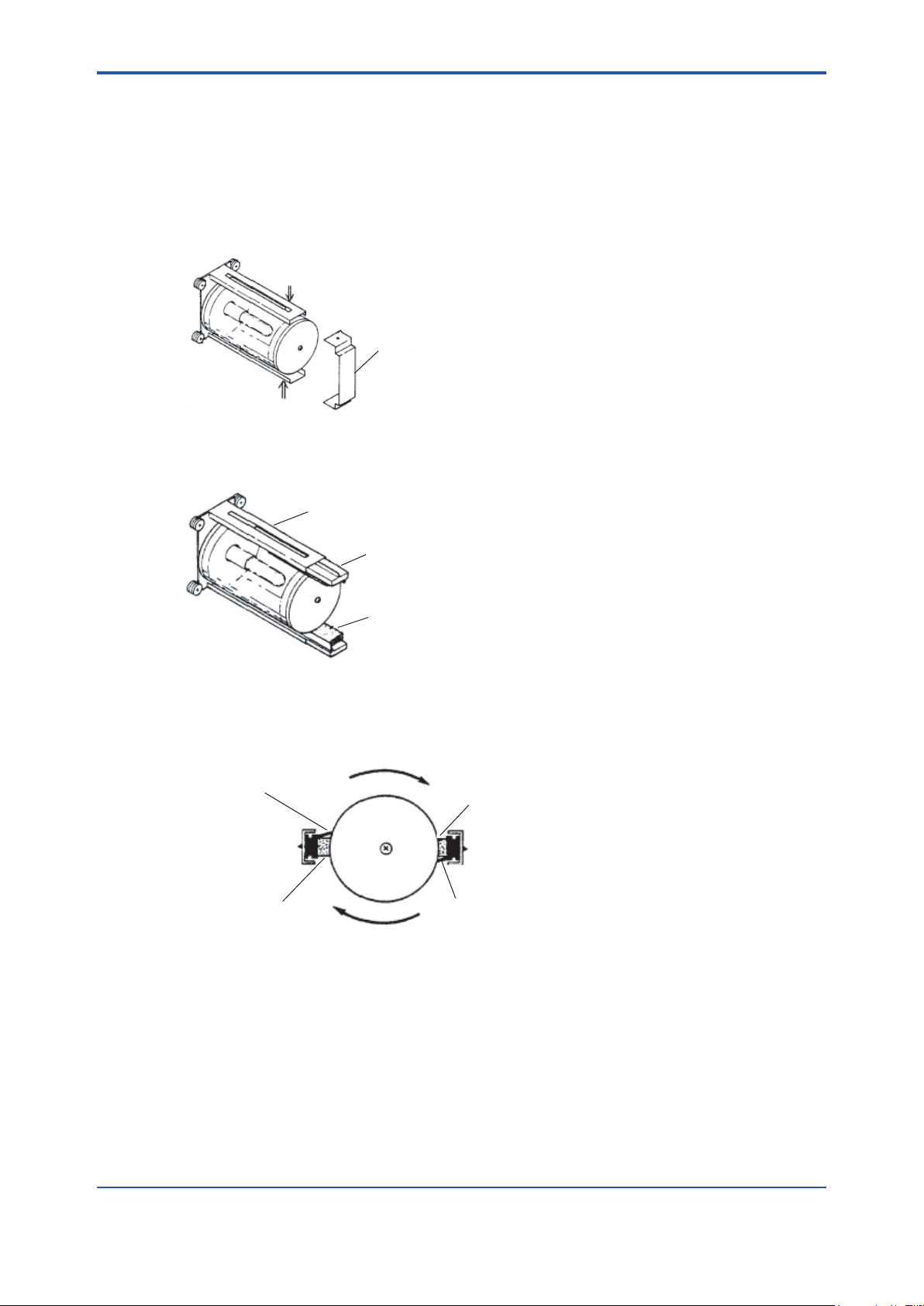

2.7 Measurement Principle

The rotary cell length modulation method, which combines high performance and reliability, is

adopted in this unit.

Two cylinder cells are placed, arranged with the light source and detector in a position where they

are decentered from the center of cylinder as shown in the gure below. By rotating these two

cylinder cells with the centers of the light source and detector as the rotation center, the distance

between the 2 cylinders (cell length) is modulated continuously and periodically. The signal input

to the detector from the light source is the signal which changes the dierence in light intensity

between the maximum cell length (θ = 180 degrees) and the minimum cell length (θ = 0 degree)

into the amplitude. Wide range measurement becomes possible by selecting the optimum cell

length and calculating according to the change of cell length.

2-11

Rotation center of decentered cell

Center of light source

Center of cylinder cell

θ=0°

L1

θ=90°

L2

θ=180°

L3

θ=270°

L2

Rotation center of decentered cell

Center of detector

Output signal Cell length

L1 L3

θ

0°

90°

180°

270°

θ=360°

L1

360°

l Optical compensation

Optical compensation is attained by the rotary cell length modulation method. Information

required for optical compensation is the change of light intensity due to the light source, detector,

contamination of the measuring cell etc. This change in light intensity information can be obtained

by monitoring the light intensity when at the minimum cell length (θ = 0 degree).

l Turbidity compensation (TURB)

This unit can measure ultraviolet (UV) and visible light (VIS) absorbances independently. UVαVIS display is possible by setting the turbidity correction factor (α), thus a more reliable turbidity

compensation can be performed.

IM 12K01B02-01E

Page 27

<2.Specication>

a=Y - bX

b=

=

S(X

i

- X)

2

nSXiY

i

- (

SX

i

)(

SY

i

)

(X

i

- X)(Yi - Y)

nSX

i

2

- (

SX

i

)

2

l TURB (turbidity) Measurement

TURB measurement is performed by using the visible light (VIS) absorbance.

The measurement method is the transmitting absorption method.

Calibration with the standard solution enables a simple measurement of TURB.

Measure in the measurement range of 200 deg. or below. If measuring in a measurement range

that exceeds the specied value, the linearity deteriorates due to the scattering light inuence.

l HowtoCalculatetheCODConversionFactor

If it is judged that there is obviously a linear function between the measurement concentration

Xi (i = 1, 2, ...n) and corresponding manual analysis value Yi (i = 1, 2, ...n), the calibration curve

formula (regression formula) is expressed as follows:

Y = a + bX

The gradient of this regression line X-axis (b) and the Y-axis segment (b) can be calculated by

using the measurement value and the least-square method as in the following formula.

2-12

“a” and “b” are rounded to a value which is larger by 1 digit according to the number of signicant

gures of the measurement value.

IM 12K01B02-01E

Page 28

<3. Installation>

3. Installation

3.1 Conditions for Installation

• The unit is weather-proofed for outdoor installation; however, do not install the unit in places

subject to direct sunlight.

• Install the unit near the water sampling point.

• Install the unit where a water-supply system, drainage facilities and a power supply are

provided.

• Install the unit in a place that is well ventilated, free from dirt or dust, and where no corrosive

gases will be generated.

• Install the unit in a place that is free from strong vibration or ferromagnetic elds.

• Install the unit where enough space is provided for conducting routine inspections and

maintenance.

• Secure the unit using anchor bolts.

• Install the unit where enough space is provided for conducting services.

3-1

IM 12K01B02-01E

Page 29

<3. Installation>

3.2 InstallationMethod

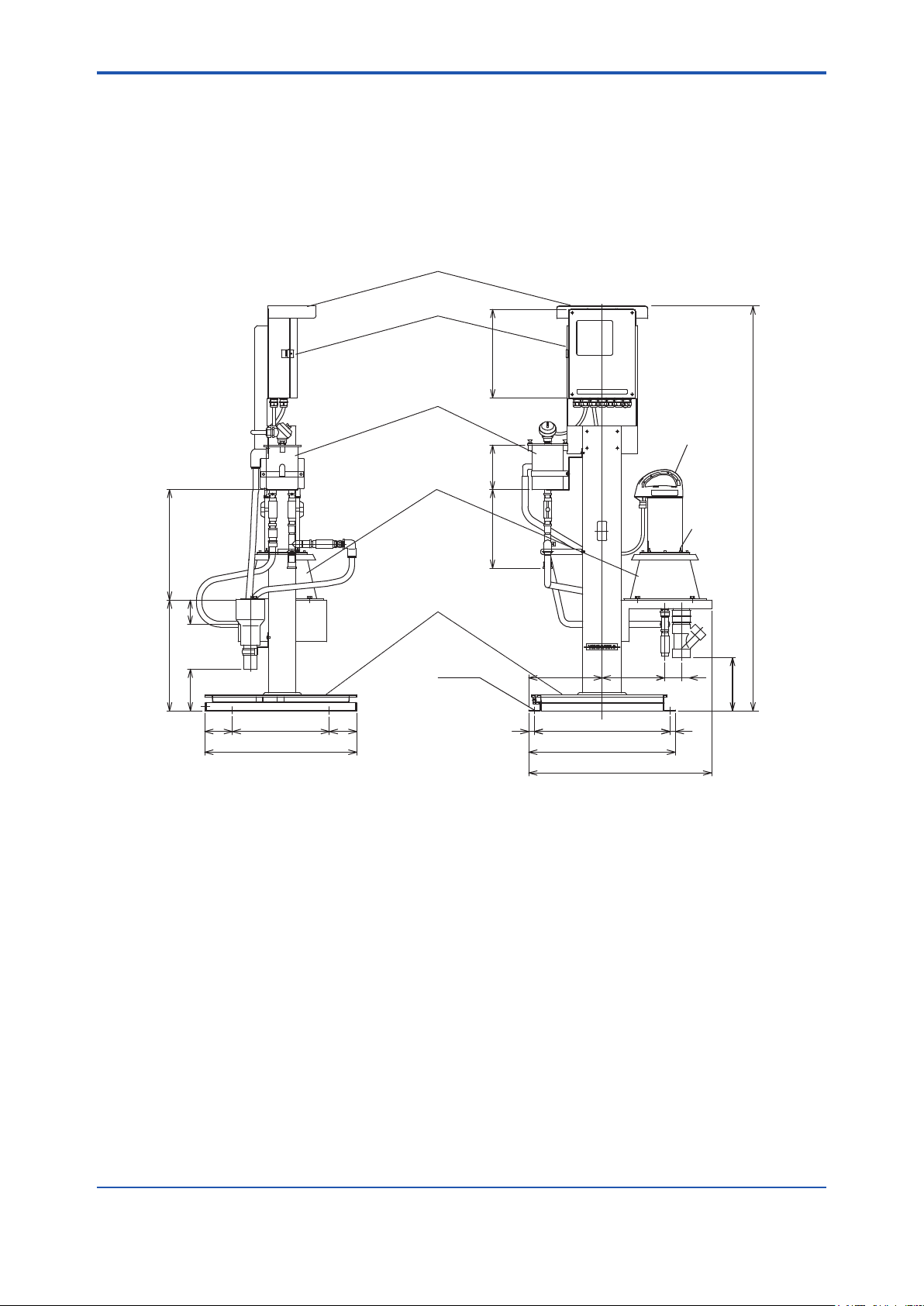

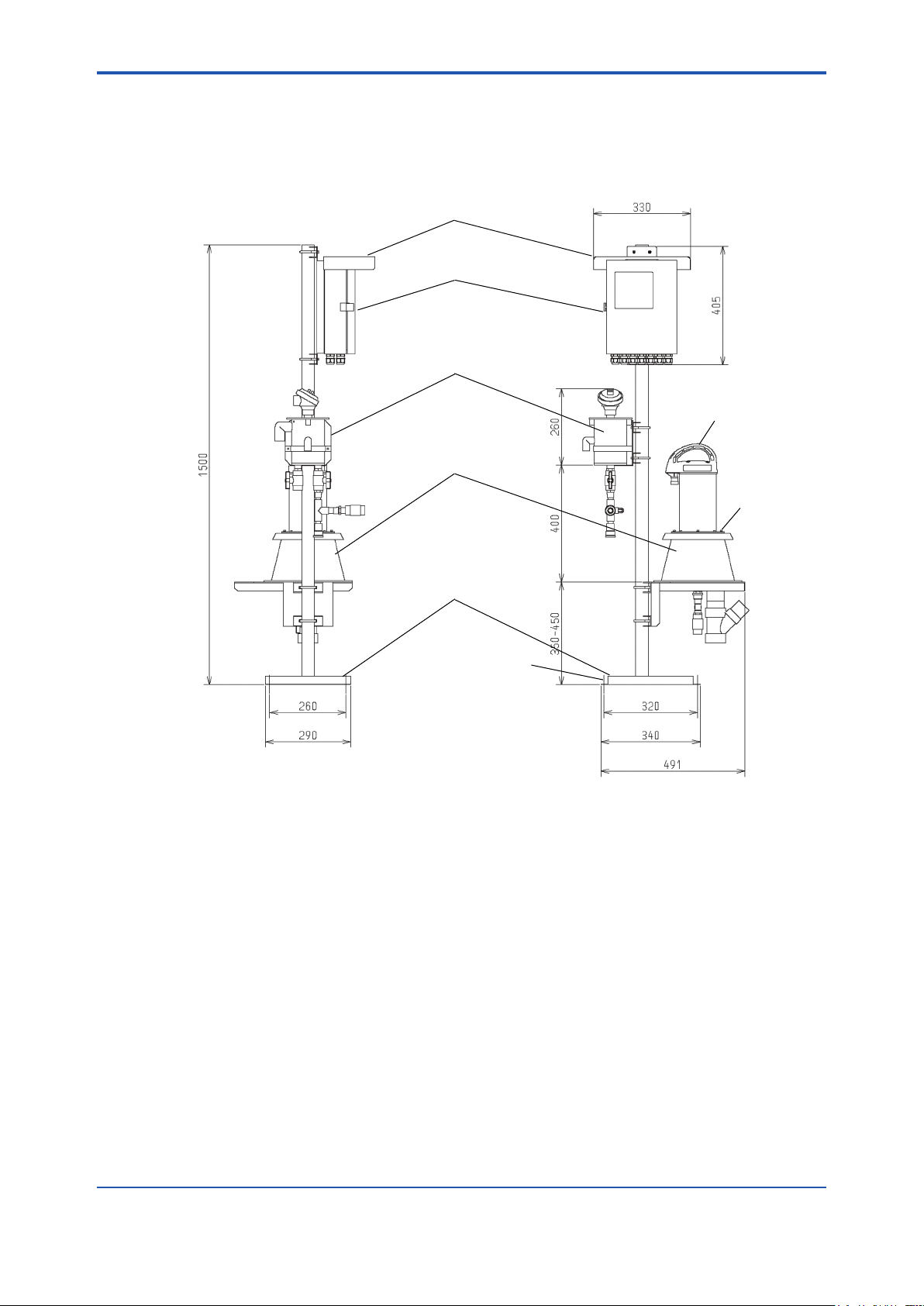

1. UVAnalyzerwithstandardself-supportingtype,UV700G-B-A

• Secure the base with the reference bolts.

• Refer to 3.3 and 3.4 for piping and wring.

Hood (optional)

Converter

320

Overflow tank

Detector

3-2

Unit: mm

400

400

87

150

100

350 (100)

550

Measuring tank

Base

4 - ø15

(160)

(285)

(265)

49020

530

665

(240)

Wing nuts

1464

(4 points)

(60)

(192)

(20)

IM 12K01B02-01E

Page 30

<3. Installation>

2. UVAnalyzerwithPole-basemounttype,UV700G-A-A

• Assemble the base, measuring tank, overow tank and converter as guided in the Appendix.

• Secure the base with the reference bolts.

Hood (optional)

Converter

Overflow tank

Detector

Measuring tank

3-3

Unit: mm

Wing nuts

(4 points)

Base

Secure with M8 bolts

(4 points)

IM 12K01B02-01E

Page 31

<3. Installation>

3.3 Pipingconguration

• Insulate the unit to protect against frozen pipes in the cold weather.

• Drain piping should be as short as possible in order not to create the backpressure. Make

the drain cock discharge the air in order to prevent water from being blocked (rising pipes

cannot be used).

• Diameters of piping sockets

Piping description Diameterofpipingsockets

1 Sample inlet Rp 1/2 female

2 Bypass outlet Rc 1/2 female

3 Overow outlet (1) Elbow tting, 13 dia. (nominal)

4 Overow outlet (2) Elbow tting, 20 dia. (nominal)

5 Drain outlet Rc 1/2 female

6 Discharge Tube coupling, 50 dia. (nominal)

4

Overflow tank

Measuring cell

V-1

Overflow line (2)

Overflow line (1)

3

3-4

Air release

6

Discharge line

V-3

V-4

5

Drain line

V-2

2

Bypass line

Sampling pump

Sample line

1

• Refer to the table below for the diameter for piping

Piping description Diameterofpiping(whenhardPVCpipingisused)

1 Sample lines Nominal diameter is 13 or larger

2 Bypass line Nominal diameter is 13 or larger

3 Overow line (1) Nominal diameter is 13 or larger

4 Overow line (2) Nominal diameter is 20 or larger

5 Drain line Nominal diameter is 13 or larger

6 Discharge line Nominal diameter is 50 or larger

IM 12K01B02-01E

Page 32

<3. Installation>

CAUTION

• Each piping diameter above is determined to go with the respective piping sockets of the

UV700G. If the measuring unit is installed in an area far from the water sampling point and

drainage point, each piping diameter should be larger than that indicated above.

• Ensure that the waste water piping, overow piping (1) and (2), and drain piping have

sucient gradient to allow drainage from the outlet of each pipe. Ensure that the end of

each piping is not immersed in water.

• When using soft PVC piping, use the braid reinforced exible PVC (pressure-resistant) type.

• It is useful to use removable pipe tubing for regular cleaning.

3-5

IM 12K01B02-01E

Page 33

<3. Installation>

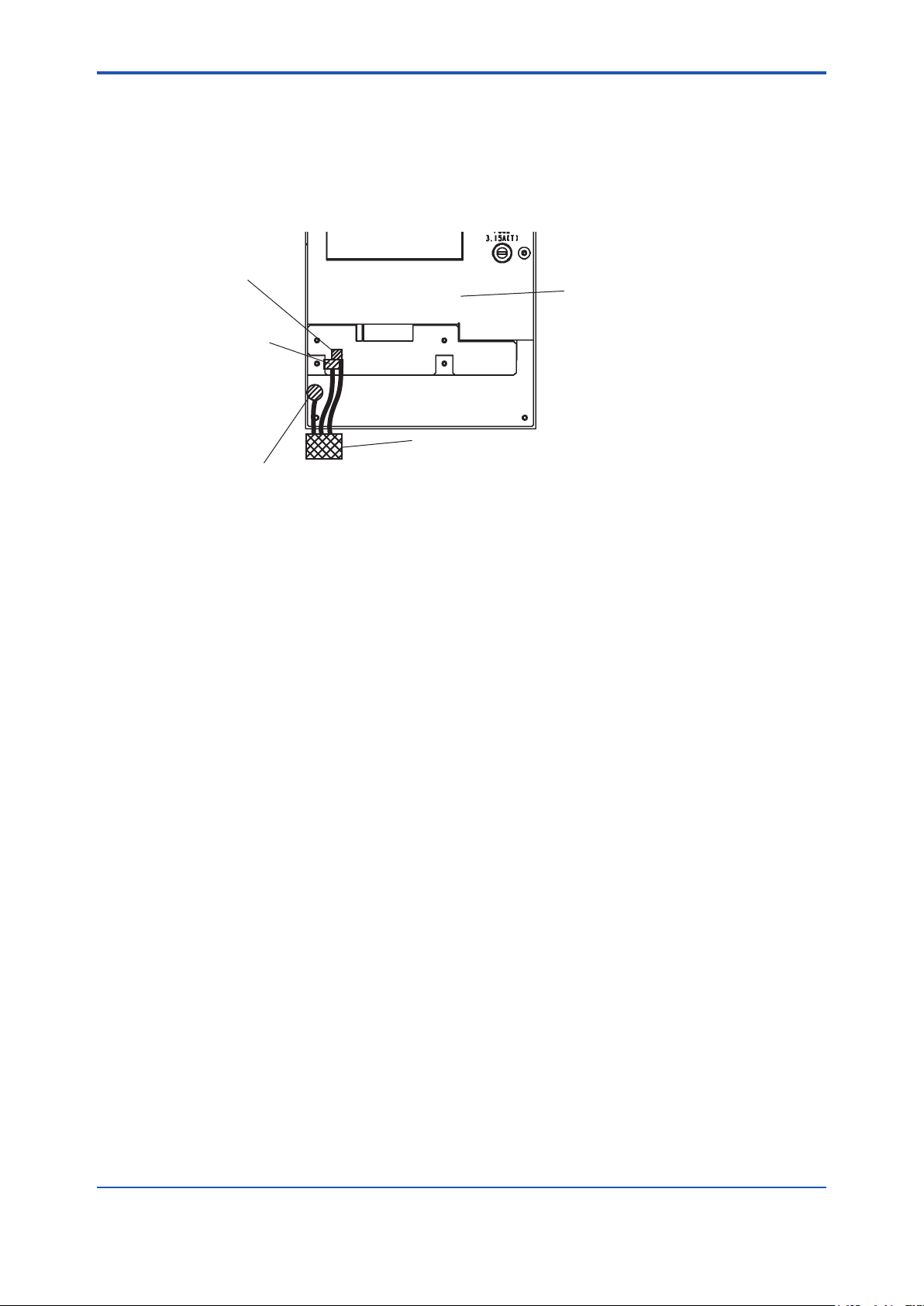

3.4 Wiring

3.4.1 Grounding

• Class D grouding (ground resistance 100 V or less) should be performed.

• Make sure to ground to the grounding bolt.

Position of grounding bolt

3-6

CAUTION

• The pole stand and base illustrated are typical examples Appearance and size may vary

depending on specications.

• Make sure to perform grounding of the installed unit to prevent electric shock.

3.4.2 Power Supply

• Connect the power cord to the power source according to “2.6 Connection Diagram”.

• Use a power cable of size 1.25 mm2 (AWG16) or larger.

• Connect a surge absorber or noise killer in parallel to the power line in order to prevent

electric power noise.

3.4.3 Connecting Signal Lines

• Connect the signal lines according to the signal table.

• Use double shield cables for current output signal lines. The shield should be grounded at

the receiver.

• Connect a surge absorber or noise killer in parallel to the contact output signal line in order

to prevent electric power noise.

CAUTION

Never connect the power line to the signal line wiring. It may cause the unit malfunction.

IM 12K01B02-01E

Page 34

<3. Installation>

3.4.4 Connecting Detector to Converter

• Run the cable connectors of detector through the cable clamps at the lower left of converter

case.

• Connect the connectors of the detector to CN1 and CN2 at the lower left of converter case.

• Securely fasten the round terminal of shield line, with a screw (M3), to the screw hole under

the connections CN1 and CN2.

CN1

2-pin connector

Converter

CN2

4-pin connector

Detector cables

Securely fasten the round terminal of shield line, with a screw (M3).

3-7

3.4.5 ConnectingFloatSwitchCableofOverowTankto

Converter

• Run the oat switch cables of the overow tank through the cable clamps at the lower left of

converter case.

• Connect the cables to the terminals No.7 and 8 at the lower center of converter inside.

IM 12K01B02-01E

Page 35

Blank Page

Page 36

<4.Operation >

Inner tank of measuring tank

4. Operation

4.1 Preparation for Operation

1. Ensure that the unit is installed properly according to “3 Installation”.

2. Remove the lid of the overow tank.

3. Remove the detector if the unit is already set to the measuring tank.

CAUTION

When removing from the measuring tank, put the detector on a at surface to prevent it from

falling. It is recommendable to put the detector on the calibration tank for safe and easy handling.

4. Operate the valves as instructed in the ow sheet and dimensional outline drawing:

V-1 and V-4: close all (CLOSE)

V-2 and V-3: open all (OPEN)

5. Supply 2 L/min to 20 L/min of sample water from the underwater pump or the header.

4-1

6. Open valve (V-1) gradually until sample water runs out of the overow outlet (1) of overow

tank. If the sample water does not run out of the overow outlet (1) even when the valve (V-

1) is fully opened, then close valve (V-2) gradually to adjust the ow from the overow outlet

(1).

7. Ensure that sample water overows from the 2 upper notches of the inner tank of measuring

tank and is discharged from the drain outlet.

8. When outlet ow from the overow tank and the inner tank of measuring tank reaches the

designated volume and keeps running consistently, attach the lid of the overow tank and

detector.

9. Make sure that the cables of detector and converter are securely connected.

10. Set the switches of control panel as follows:

POWER switch: OFF

Maintenance switch: ON

IM 12K01B02-01E

Page 37

<4. Operation>

4.2 Starting Operation

1. Turn the POWER switch ON.

The MEAS. screen appears after a while.

“WARM UP!” is indicated.

CAUTION

When the power is turned ON, the motor for detector wipers starts operation at low speed. Some

noises and vibrations may be generated when the motor starts. Note that this normal, and does

not mean any malfunction of the unit.

“WARM UP!” continues to be indicated until the measured values become stable (for about 60

minutes).

4-2

CAUTION

Never touch the cell or directly view the UV lamp of the detector when you check the unit

operation.

2. Set the clock.

Refer to “6.4.5 Time Adjustment”

3. Change the setting as necessary.

Refer to “6 Functions”

4. Calibrate the unit.

CAUTION

Calibration should be performed after the measured value becomes stable. Before the

calibration, perform the running-in operation for an hour or more using the sample water.

Refer to “5 calibration”

Complete the procedure for the preparation of operation. The measurement starts.

5. Turn OFF the maintenance switch.

IM 12K01B02-01E

Page 38

<4.Operation >

4.3 ShuttingDown

4.3.1 ForShutDownwithin7Days

1. Turn ON the maintenance switch.

2. Turn OFF the POWER switch.

4.3.2 ForShutDownover7Days

1. Close all the valves (V-1 to V-4).

2. Turn ON the maintenance switch.

3. Turn OFF the POWER switch.

4. Clean the overow tank and measuring tank.

Refer to “6.6 Maintenance-Action”

5. Clean the cell of converter.

Refer to “3.3 Piping conguration”

4.4 Restarting Operation

4-3

4.4.1 ForShutDownwithin7Days

Follow the procedure of “4.2 Starting Operation”.

4.4.2 ForShutDownover7Days

1. Follow the procedure of “4.1 Preparation for Operation”.

2. Follow the procedure of “4.2 Starting Operation”.

IM 12K01B02-01E

Page 39

Blank Page

Page 40

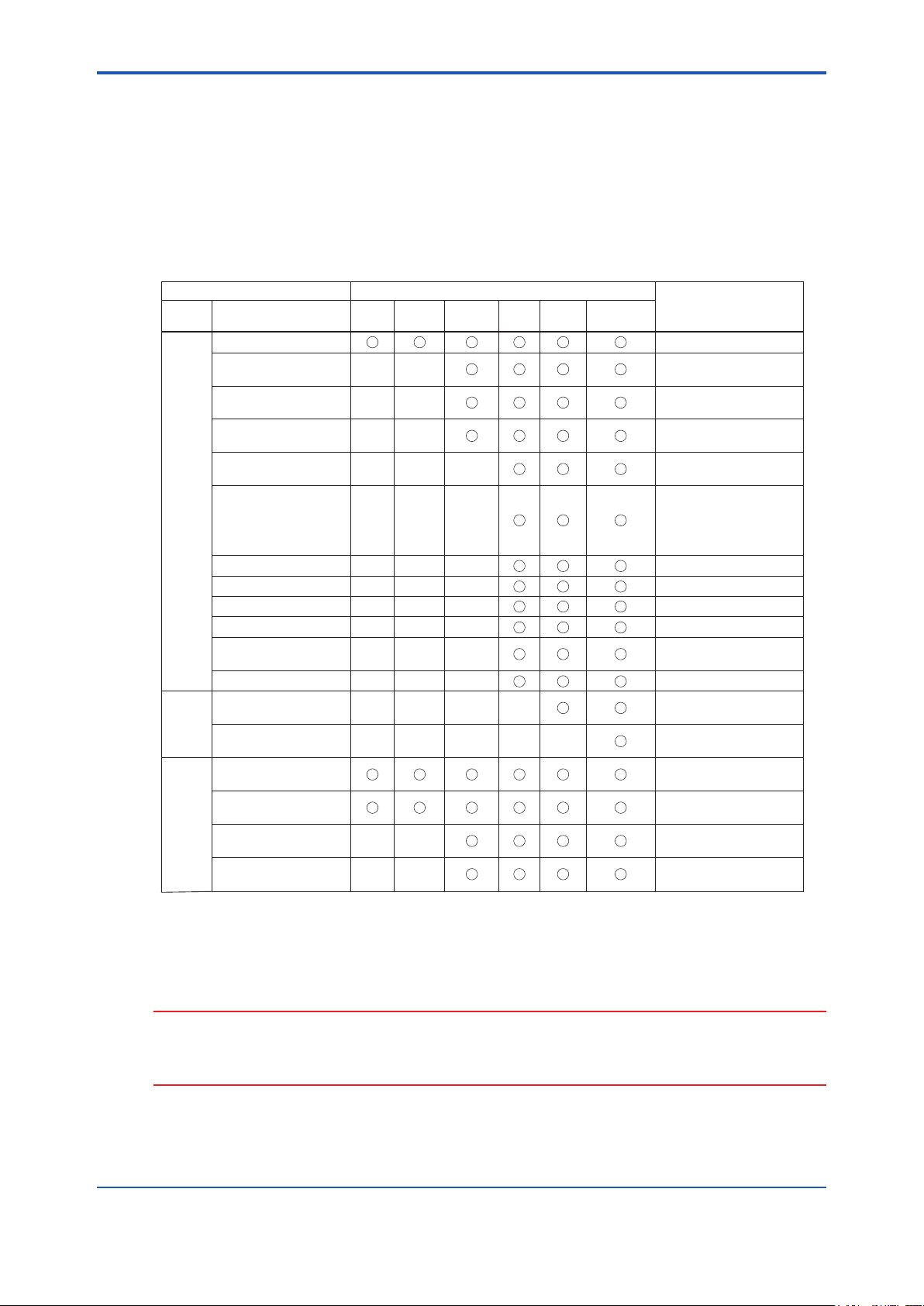

<5. Calibration>

Measuring

item

Calibration pattern

Targeted calibration cycle

Before

operation

Every

week

Every

month

When

problems

occur

Procedure

Reference

UV/VIS

Common zero calibration 5.4.2

Common span calibration 5.4.3

Individual (UV) span calibration

5.4.4

TURB

(turbidity)

Span calibration 5.5.2

—

—

—

: Recommended cycle, : Calibration as necessary – : Unnecessary

5. Calibration

Calibration is the adjustment so that the value indicated by the unit corresponds to the actual

value. It is necessary to obtain measurements of high accuracy and maintain the performance of

the unit.

5.1 Calibration Pattern and its Cycle

It is necessary to perform the calibration periodically.

Perform calibration by following the cycle shown below.

5-1

Perform the calibration in the order of “Common zero calibration,” “Common span calibration,”

(“Individual (UV) span calibration” as necessary), and “TURB Span calibration.”

l DescriptionsforeachCalibration

DescriptionCalibration

Common zero calibration of UV/VIS using the zero calibration solution

Common zero calibration

Common span calibration

Individual (UV) span

calibration

Span calibration

(distilled watter).

Put the zero calibration solution in the calibration tank. After the

measurement value has stabilized, perform calibration by operating the zero

button.

Common span calibration of UV/VIS using the exclusive common span

calibration solution. Put the span calibration solution in the calibration tank.

After setting the calibration value of UV/VIS and the measurement has

stabilized, perform calibration by operating the span button.

If performing either one of calibrations, set the span calibration value to "0"

for the component that is not being calibrated. By doing this, the span

calibration for one component becomes possible.

Individual span calibration of UV using the acid potassium phthalate

standard solution (standard solution for UV calibration).

Put the individual span calibration solution in the calibration tank. After

setting the calibration value of UV and the measurement has stabilized,

perform calibration by operating the span button.

Make sure to set the span calibration value of VIS to "0" before performing

the calibration.

Span calibration of turbidity using the span calibration solution.

Zero calibration is not required is not required as the common zero

calibration for UV/VIS is performed.

Put the span calibration solution for turbidity in the calibration tank. After

setting the calibration value of TURB (turbidity) and the measurement has

stabilized, perform calibration by operating the span button.

IM 12K01B02-01E

Page 41

<5. Calibration>

[CAL.]

l AbouttheCalibrationCoecient

DescriptionCalibration coefficient

Zero calibration coefficient

Span calibration coefficient

Indicates misalignment of zero point

Indicates the gradient of sensitivity

5.2 Notes regarding Calibration

• Perform the calibration in the order of “Common zero calibration,” “Common span

calibration,” and “TURB Span calibration.”

• If the calibration coecient exceeds the specied range during the calibration, an error

occurs and the calibration value is not updated. The previous calibration value remains.

• Use distilled water for the common zero calibration solution. If a solution other than distilled

water is used, the measurement error becomes larger in the low concentration range (0.1

Abs to 0.5 Abs).

If the ion-exchanged water is used, the measurement error also becomes larger.

• Whenever diluting the span calibration solution, make sure to dilute by adding distilled

water.

• When disposing of the common span calibration solution, follow the rules and regulations in

your country / area. As the solution is colored, we recommend disposing of it by diluting with

tap water unless otherwise specied.

• Store the common span calibration solution ampoule in a dark and cold place.

• Use the common span calibration solution ampoule immediately after opening.

• Never ingest the common span calibration solution ampoule or its contents.

• If the common span calibration solution comes into contact with clothes, the clothes may be

stained.

• Never reuse the calibration solution. If the solution is altered, an accurate calibration may

not be obtained.

• Prepare the span calibration solution by following the description in this manual.

5-2

5.3 Calibration Screen Display

1. Press [CAL.] on the MEAS. screen (main screen).

The CALIBRATION screen that shows the calibration menu is displayed.

IM 12K01B02-01E

Page 42

<5. Calibration>

2. Press the measurement items to be calibrated on the CALIBRATION screen.

The CALIBRATION screen for each measurement item is displayed.

Example when the calibration item is UV/VIS:

Calibration item

[UV/VIS]

3. Perform calibration by following the calibration procedure for each measurement item.

5.4 Calibration of UV/VIS

There are three kinds of calibration method for UV/VIS: common zero calibration, common span

calibration, and individual span calibration.

Refer to “5.1 Calibration Pattern and its Cycle”

5-3

5.4.1 How to Prepare Calibration Solution

Use distilled water for the zero calibration solution, and exclusive calibration solution for the

common span calibration solution.

The calibration solution ampoule (H calibration solution (blue label)) for 1 Abs

(100 m-1) is attached to this unit. An attached calibration solution ampoule covers the

measurement range up to 1 Abs. Full scale can be covered from 0.1 Abs to 5.0 Abs (10 m-1 to

500 m-1) by using the 2 or 4 calibration solution ampoules.

Select the measurement full scale you use from the following, and compound the calibration

solution.

Calibration solution

H calibration

solution (blue label)

0 to 1 Abs for

calibration

Measurement full

scale range

0.1 Abs to 1.0 Abs

-1

to 100 m-1)

(10 m

1.1 Abs to 2.5 Abs

-1

to 250 m-1)

(110 m

2.6 Abs to 5.0 Abs

-1

to 500 m-1)

(260 m

Also, our calibration solution ampoule (H II calibration solution (green label)) for 2 Abs (200 m-1)

is also available. If using in the measurement full scale of 1.1 Abs (110 m-1) or over, it is more

economical to buy H II calibration solution ampoules as the number of ampoules used is fewer.

Calibration solution

H II calibration solution

(green label)

0 to 2 Abs

for calibration

Measurement full

scale range

1.1 Abs to 2.5 Abs

-1

to 250 m-1)

(110 m

2.6 Abs to 5.0 Abs

-1

to 500 m-1)

(260 m

Qty. of calibration

solution ampoule

1

2

4

Qty. of calibration

solution ampoule

1

2

Concentration of calibration

solution when diluted with 2 L

UV: 0.690 Abs (69.0 m-1)

VIS: 0.880 Abs (85.0 m-1)

UV: 1.380 Abs (138.0 m-1)

VIS: 1.760 Abs (170.0 m-1)

UV: 2.760 Abs (276.0 m

VIS: 3.520 Abs (340.0 m

Concentration of calibration

solution when diluted with 2 L

UV: 1.380 Abs (138.0 m-1)

VIS: 1.760 Abs (170.0 m-1)

UV: 2.760 Abs (276.0 m-1)

VIS: 3.520 Abs (340.0 m-1)

-1

)

-1

)

l Common zero calibration solution

Preparation:

Distilled water: 2 L

Make sure to use the distilled water.

IM 12K01B02-01E

Page 43

<5. Calibration>

l How to prepare common span calibration solution

Preparation:

Calibration solution ampoule: 1 to 4

Zero solution (distilled water): approximately 3 L

2 L Measuring ask: 1

Cleaning bottle: 1

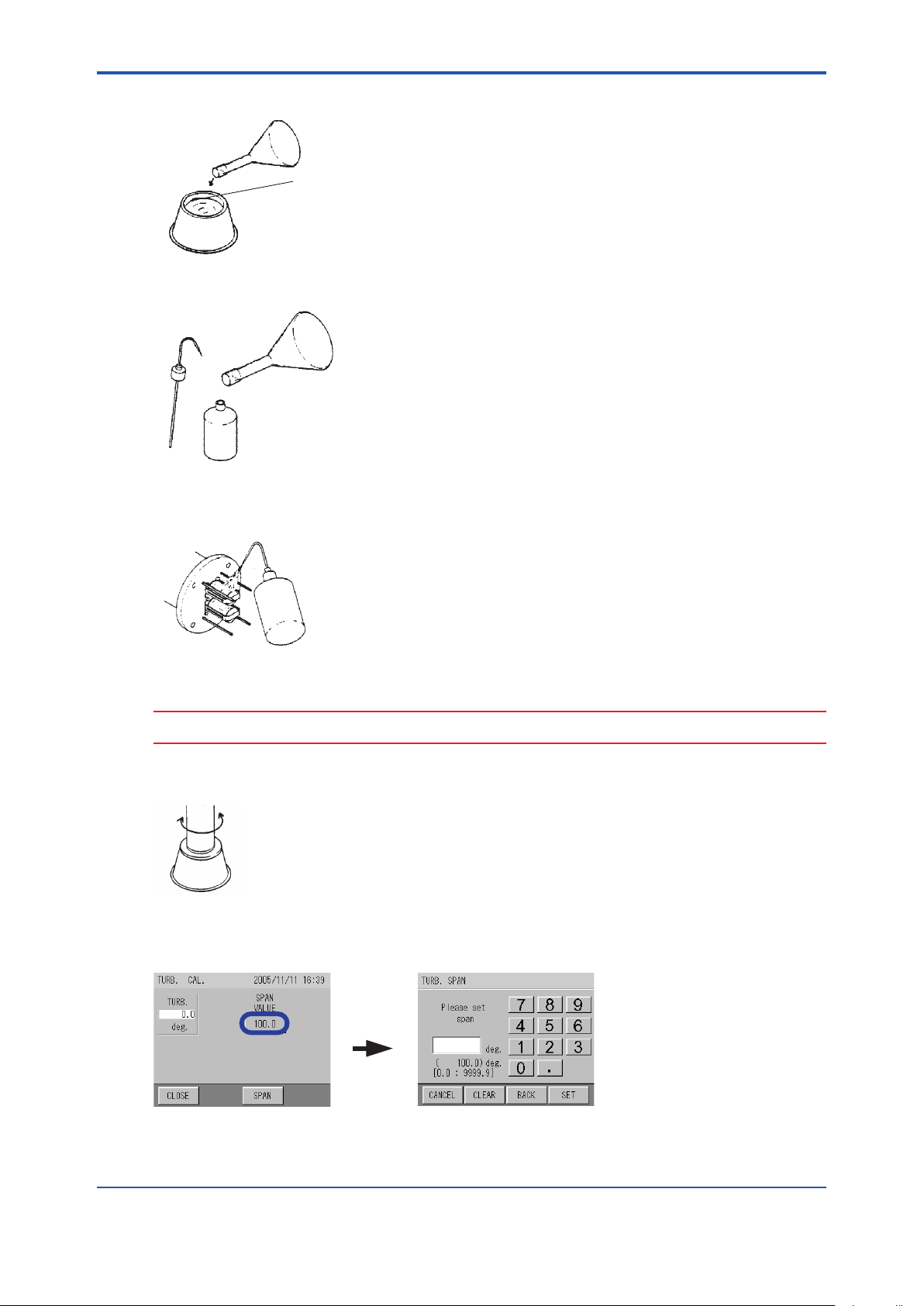

1. Drain the solution remaining in the top of ampoule to the bottom part.

Drain the solution remaining in the top of the ampoule

as much as possible by flicking with a finger.

2. Make a cut line on the ampoule with a cutter knife, knife of other sharp object.

5-4

Make a cut line all the way around the ampoule.

3. Break the ampoule.

Hold the ampoule and break off the top part.

Be careful not to spill the solution.

Hold the bottom part of ampoule on the table.

4. Pour the contents from the ampoule into a 2 L measuring ask that was cleaned using zero

solution in advance.

Squeeze the ampoule several times.

5. Pour the zero solution up to the gauge line of 2 L measuring ask, and dissolve the solution

IM 12K01B02-01E

Cleaning bottle

Dissolve the solution left in the ampoule

by adding zero solution, and pour into

the measuring flask. (Repeat 2 or 3 times.)

Also dissolve the solution left in the top of

ampoule by adding zero solution, and pour

into the measuring flask.

by shaking thoroughly.

Page 44

<5. Calibration>

CAUTION

• Make sure to use distilled water to dilute the span calibration solution. Never use the tap

water, groundwater, or industrial water.

• Use 2 ampoules of H calibration solution when preparing the span calibration solution of 1.1

Abs to 2.5 Abs (110 m-1 to 250 m-1). In this case, the concentration value of span calibration

solution is double the concentration value described on the ampoule.

• Use 4 ampoules of H calibration solution or 2 ampoules of H II calibration solution when

preparing the span calibration solution of 2.6 Abs to 5.0 Abs (260 m-1 to 500 m-1). In this

case, the concentration value of span calibration solution is 4 times the concentration value

described on the ampoule for H calibration solution, and double the H II calibration solution

ampoule.

l Howtopreparespancalibrationsolutionofacidpotassiumphthalatestandard

solution (standard solution for UV calibration)

Normally calibration with the common span calibration solution is available; also, UV calibration

with acid potassium phthalate is possible.

Preparation:

Acid potassium phthalate: using the special grade chemicals, dried for 1 hour at a

temperature of 120 8C, and cooled in desiccators

Zero solution (distilled water): approximately 3 L

1L Beaker: 1

2L Measuring ask: 1

Electronic balance: 1 (accuracy shall be within 1 mg)

Cleaning bottle: 1

1. Determine the requirement of acid potassium phthalate from the following table according to

the measurement range.

5-5

UV measurement

range

0.1 Abs to 0.5 Abs

(10 m-1 to 50 m-1)

0.6 Abs to 1.0 Abs

(60 m-1 to 100 m-1)

1.1 Abs to 2.5 Abs

(110 m-1 to 250 m-1)

2.6 Abs to 5.0 Abs

(260 m-1 to 500 m-1)

Requirement of

acid potassium

phthalate when

compounded in

2 L

100 mg 50 mg/L

200 mg 100 mg/L

400 mg 200 mg/L

800 mg 400 mg/L

Concentration

of span

calibration

solution

Light absorption

when the

temperature of

calibration

solution is 25 8C

(absorption factor)

0.44 Abs

(44 m-1)

0.87 Abs

(87 m-1)

1.74 Abs

(174 m-1)

3.48 Abs

(348 m-1)

Light absorption

when the

temperature of

calibration

solution is 20 8C

(absorption factor)

0.43 Abs

(43 m-1)

0.85 Abs

(85 m-1)

1.70 Abs

(170 m-1)

3.40 Abs

(340 m-1)

Light absorption

when the

temperature of

calibration

solution is 30 8C

(absorption factor)

0.45 Abs

(45 m-1)

0.89 Abs

(89 m-1)

1.78 Abs

(178 m-1)

3.56 Abs

(356 m-1)

CAUTION

The calibration solution of acid potassium phthalate has a temperature characteristic. The

temperature characteristic is (4.5 3 10-3) Abs/ 8C at a temperature of 5 8C to 30 8C. Measure the

temperature of calibration solution to calculate the light absorption during calibration.

Calculation method:

Light absorption of calibration solution = Light absorption of calibration solution at a temperature

of 25 8C 3 (1 + (temperature of calibration solution - 25) 3 0.0045)

(The above table shows light absorptions also at 20 8C and 30 8C as a reference.)

IM 12K01B02-01E

Page 45

<5. Calibration>

Calibration item

[UV/VIS]

Pour the tap water to a depth of approximately 9 cm

(so that the base of the detector imay not soak in the water).

2. Measure the requirement of acid potassium phthalate (special grade chemicals) following

the table above.

3. Pour approximately 500 mL of the zero solution (distilled water) into the 1 L beaker, and add

the measured acid potassium phthalate to dissolve thoroughly.

NOTE

The acid potassium phthalate dissolves easily when setting the temperature of the zero solution

from 40 8C to 50 8C.

4. Pour the solution in the 1 L beaker into the 2 L measuring ask, add zero solution to the

gauge line, and shake to dissolve the solution.

5.4.2 Common Zero Calibration

[CAL.] [UV/VIS]

5-6

MEAS. screen

Refer to “5.3 Calibration Screen Display”

CALIBRATION screen

UV/VIS CAL. screen

• Preparation

Plastic bucket: 1 (diameter: approximately 30 cm)

Zero solution (distilled water): approximately 3 L

Calibration tank: 1

2 L Measuring ask: 1

Cleaning bottle: 1

• Calibration procedure

1. Press [UV/VIS] on the CALIBRATION screen of converter.

2. Clean the attached calibration tank with zero solution thoroughly, and pour the zero solution

to the scale.

3. Prepare the plastic bucket and pour the tap water.

4. Remove the detector from the measurement tank.

CAUTION

• When removing the detector, make sure not to lose wing nuts.

• As the UV lamp is illuminated, work with an eye protector. The UV lamp should not be

viewed directly as your eyes may be damaged.

IM 12K01B02-01E

Page 46

<5. Calibration>

Dip the cell unit in the water and shake it from side to side

and up and down to remove contamination.

Clean the cell unit using the zero solution in the cleaning bottle.

Allow the solution to adhere by shaking from side to side

for several times.

[X.XX]

5. Clean the cell unit of the detector.

• If there is any extraneous matter around the cell, remove it.

• Next, dip the cell unit in the plastic bucket to remove contamination.

• Clean the cell unit using the zero solution in the cleaning bottle again.

• If the cell unit is contaminated heavily, clean the cell unit by referring to “8.2.1 Cleaning

Method for Measuring Cell”

5-7

CAUTION

Do not spill any solution on the base of the cell rotary shaft (V-ring seal part).

6. After cleaning the cell unit, dip the cell in the calibration tank.

7. Press the button for [ZERO VALUE] for UV on the UV/VIS CAL. screen.

The screen changes to the UV ZERO screen.

8. Enter “0” with numeric keypad, and press [SET],

Input range: 0.000 Abs to 5.000 Abs or 0.0 m-1 to 500.0 m

The screen returns to the UV/VIS CAL. screen.

-1

NOTE

[CLEAR]: Cleans all input numeric values.

[BACK]: Cleans the rightmost number.

IM 12K01B02-01E

Page 47

<5. Calibration>

CAUTION

The decimal place of input range varies according to the setting in “6.5.2 Setting of Decimal Place

for each Component”

9. Press the button for [ZERO VALUE] for VIS on the UV/VIS CAL. screen.

10. Enter “0” with numeric keypad, and press [SET].

Input range: 0.000 Abs to 5.000 Abs or 0.0m-1 to 500.0m

The screen returns to the UV/VIS CAL. screen.

-1

CAUTION

Though any number can be entered for the zero calibration value, normally, enter “0”.

5-8

11. After waiting for 3 minutes and conrming that the measurement value has stabilized, press

[ZERO].

The “Start zero cal.?” screen is displayed.

12. Press [YES] to start the zero calibration.

The “Calibrating” screen is displayed.

After calibration, the “Calibration nished” screen is displayed.

13. Press [YES].

The zero calibration value for UV/VIS is updated.

14. The common zero calibration is complete.

If performing the common span calibration subsequently, start the common span calibration

with the detector still in the zero calibration tank.

If nishing calibration, set the detector in the measuring tank.

CAUTION

IM 12K01B02-01E

• When the measurement value increases gradually after stabilization, the solution may be

contaminated. Replace the zero solution and calibrate again.

• If the temperature dierence of the sample water and zero solution is large, the

measurement value may be unstable. Calibrate under the conditions where temperature

dierence is as small as possible.

Page 48

<5. Calibration>

Calibration item

[UV/VIS]

Pour approximately 100 mL

of span solution.

Clean the tank inside. Discard the solution.

Shake up and down

Scale

Amount to the scale is approximately 1.3 L.

5.4.3 Common Span Calibration

[CAL.] [UV/VIS]

5-9

MEAS. screen

Refer to “5.3 Calibration Screen Display”

CALIBRATION screen

UV/VIS CAL. screen

Perform the common span calibration after nishing the common zero calibration.

• Preparation

Calibration tank: 1

Span calibration solution: 2 L (measureing ask)

Cleaning bottle: 1

• Calibration procedure

1. Press [UV/VIS] on the CALIBRATION screen of the converter.

2. Clean the attached calibration tank with zero solution thoroughly, pour approximately 100

mL of span solution (in the 2 L measuring ask), which is prepared by following “5.4.1 How

to Prepare Calibration Solution”, and clean the tank inside.

3. After cleaning, pour the span solution up to the scale.

IM 12K01B02-01E

Page 49

<5. Calibration>

Cleaning bottle

Residual common span solution

Clean the cell unit using the common span solution

in the cleaning bottle.

Allow the solution to adhere by shaking from side to side

for several times.

[X.XX]

4. Pour the residual common span solution into the cleaning bottle.

When performing span calibration, the calibration work can be performed smoothly if the

preparation through step 4. is performed together with the preparation for the common zero

calibration.

5. Take the detector from the zero calibration tank, and clean the cell unit using the common

span solution in the cleaning bottle.

5-10

CAUTION

Do not spill any solution on the base of cell rotary shaft (V-ring seal part).

6. After cleaning the cell unit with the common span solution, dip it in the calibration tank.

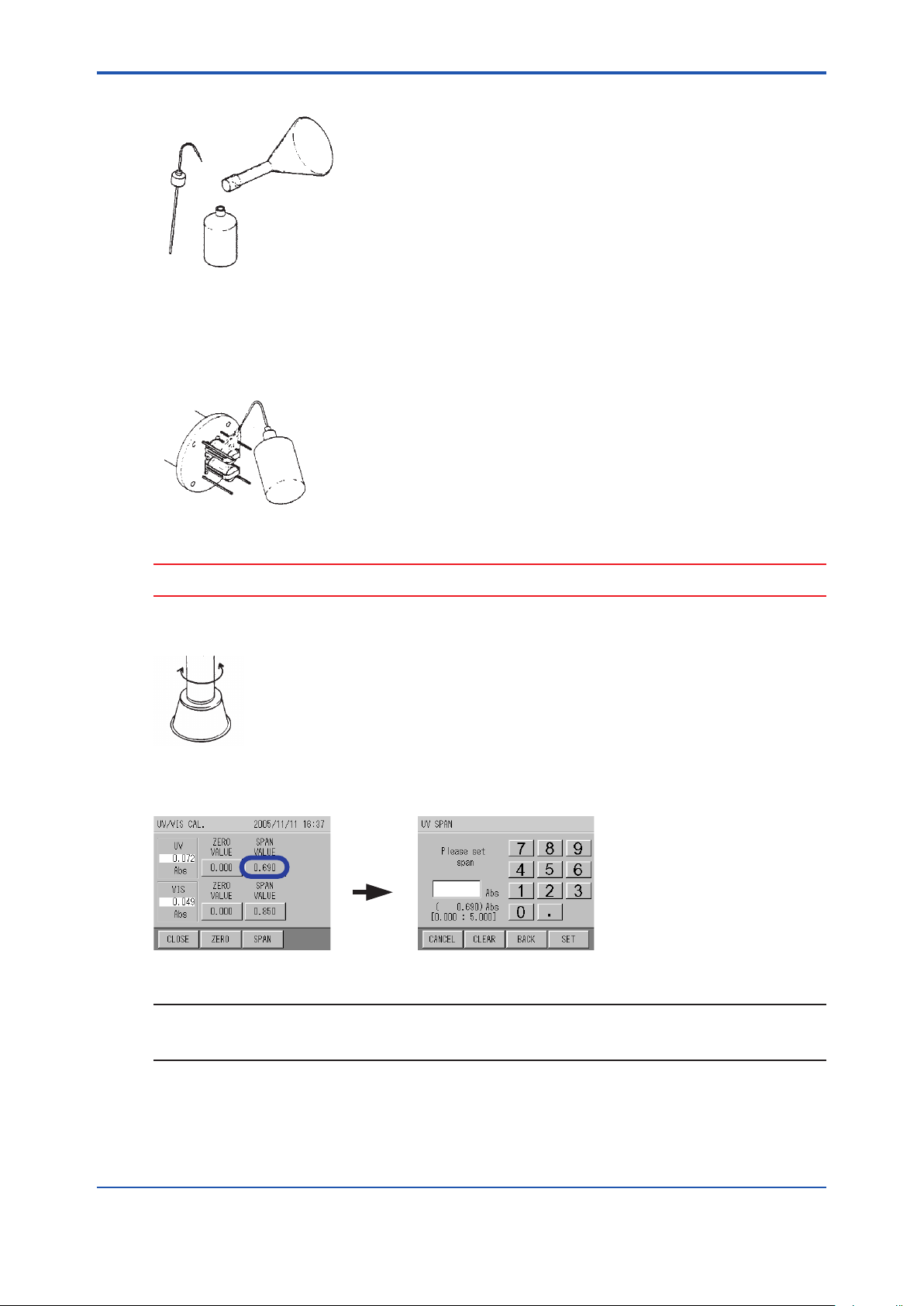

7. Press the button for [SPAN VALUE] for UV on the UV/VIS CAL. screen.

The screen changes to the UV SPAN screen.

NOTE

[CLEAR]: Clears all input numeric values.

[BACK]: Clears the rightmost number.

8. Enter the concentration value of compounded span calibration solution with the numeric

keypad, and press [SET].

Input range: 0.000 Abs to 5.000 Abs or 0.0 m-1 to 500.0 m

IM 12K01B02-01E

-1

Page 50

<5. Calibration>

The screen returns to the UV/VIS CAL. screen.

CAUTION

• The decimal place of the input range varies according to the setting in “6.5.2 Setting of

Decimal Place for each Component”.

• Refer to “5.4.1 How to Prepare Calibration Solution” for the concentration value of

compounded span calibration solution.

• If performing either one of the calibrations, set the span calibration value to “0” for the

component that is not being calibrated. By doing this, the span calibration for single

component becomes possible.

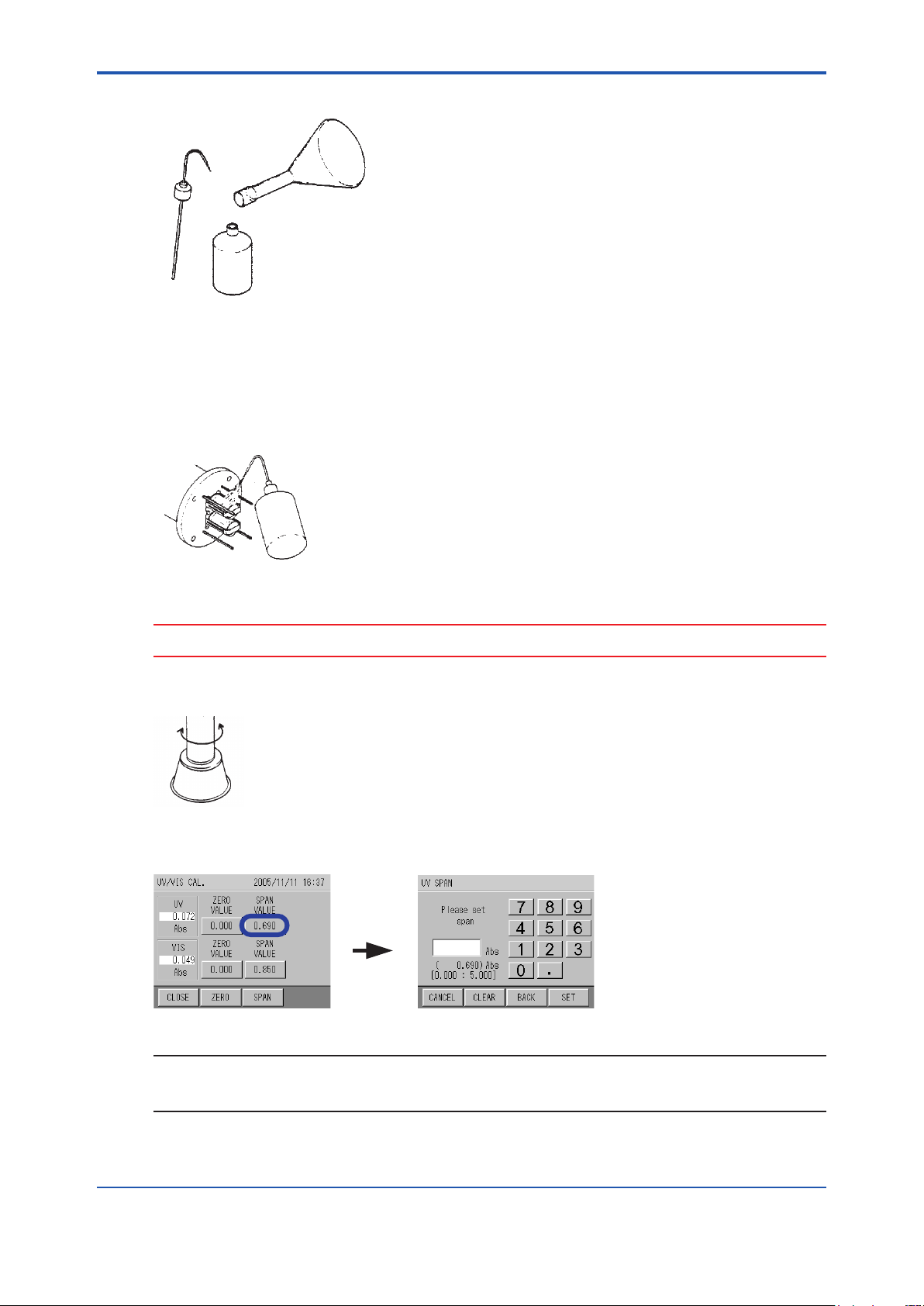

9. Press the button for [SPAN VALUE] for VIS on the UV/VIS CAL. screen.

5-11

10. Enter the concentration value of compounded span calibration solution with the numeric

keypads, and press [SET],

Input range: 0.000 Abs to 5.000 Abs or 0.0 m-1 to 500.0 m

The screen returns to the UV/VIS CAL. screen.

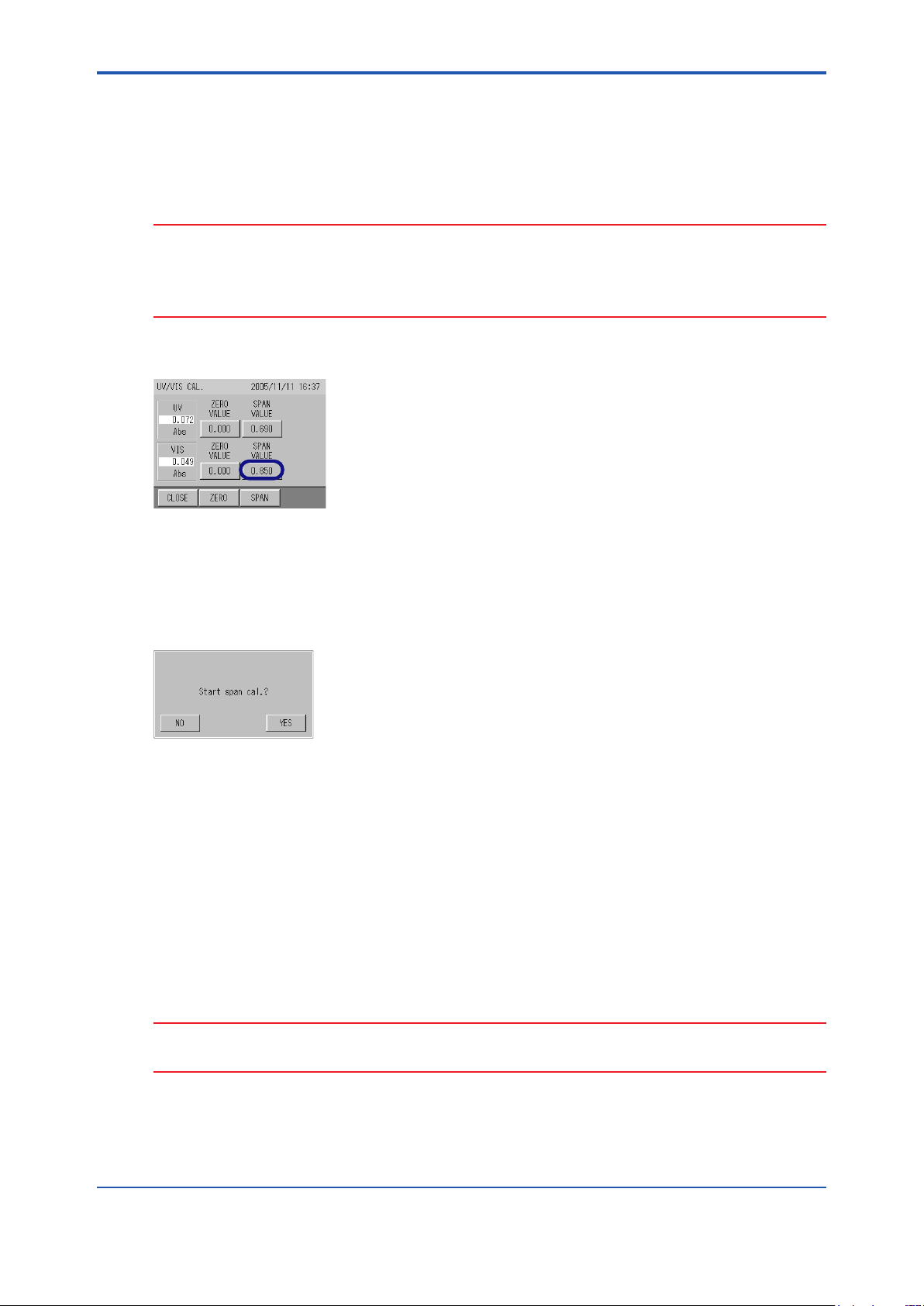

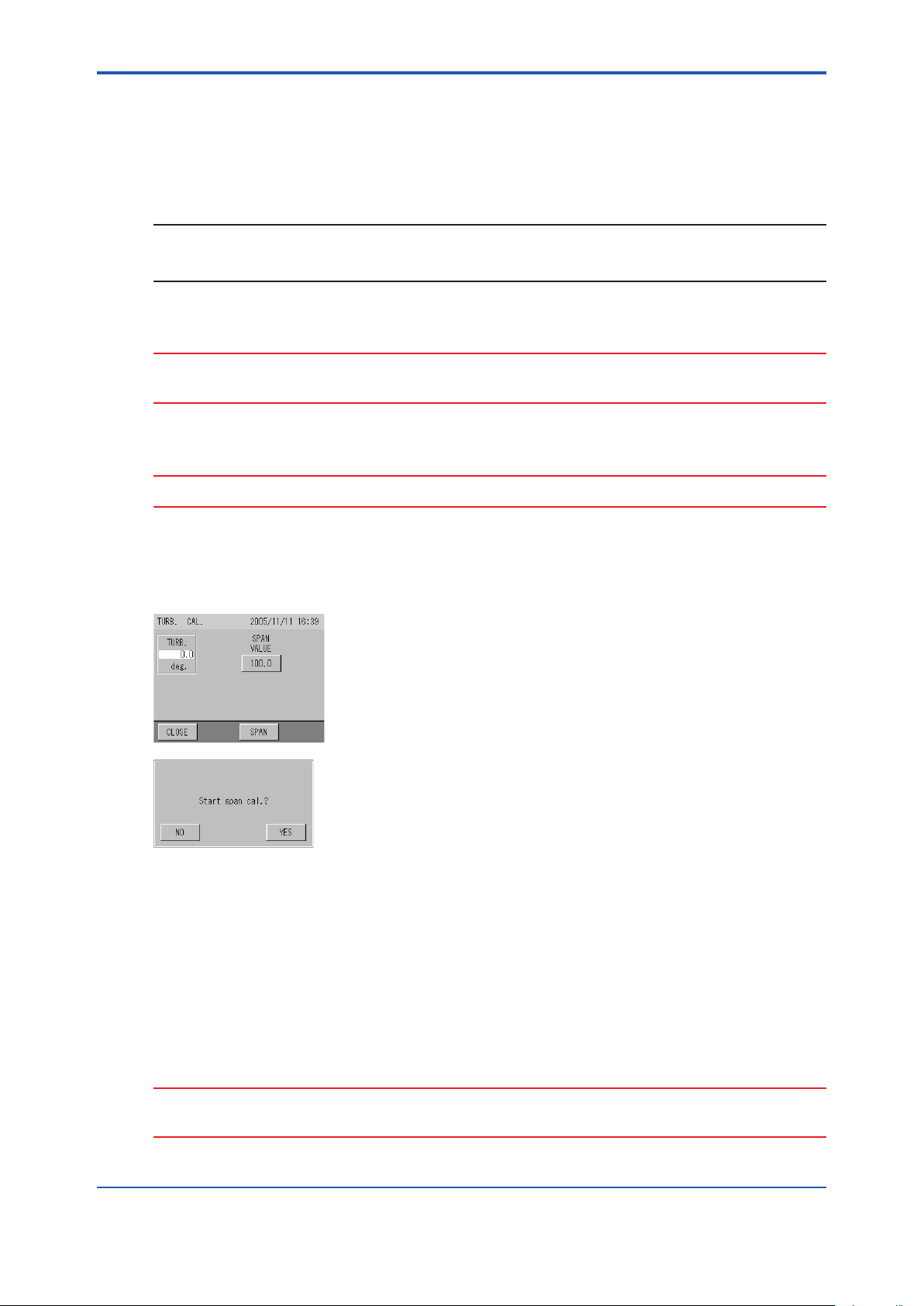

11. After waiting for 3 minutes and conrming that the measurement value is stabilized, press

[SPAN].

The “Start span cal.?” screen is displayed.

12. Press [YES] to start the span calibration.

The “Calibrating” screen is displayed.

After calibration, the “Calibration nished” screen is displayed.

13. Press [YES].

The span calibration value for UV/VIS is updated.

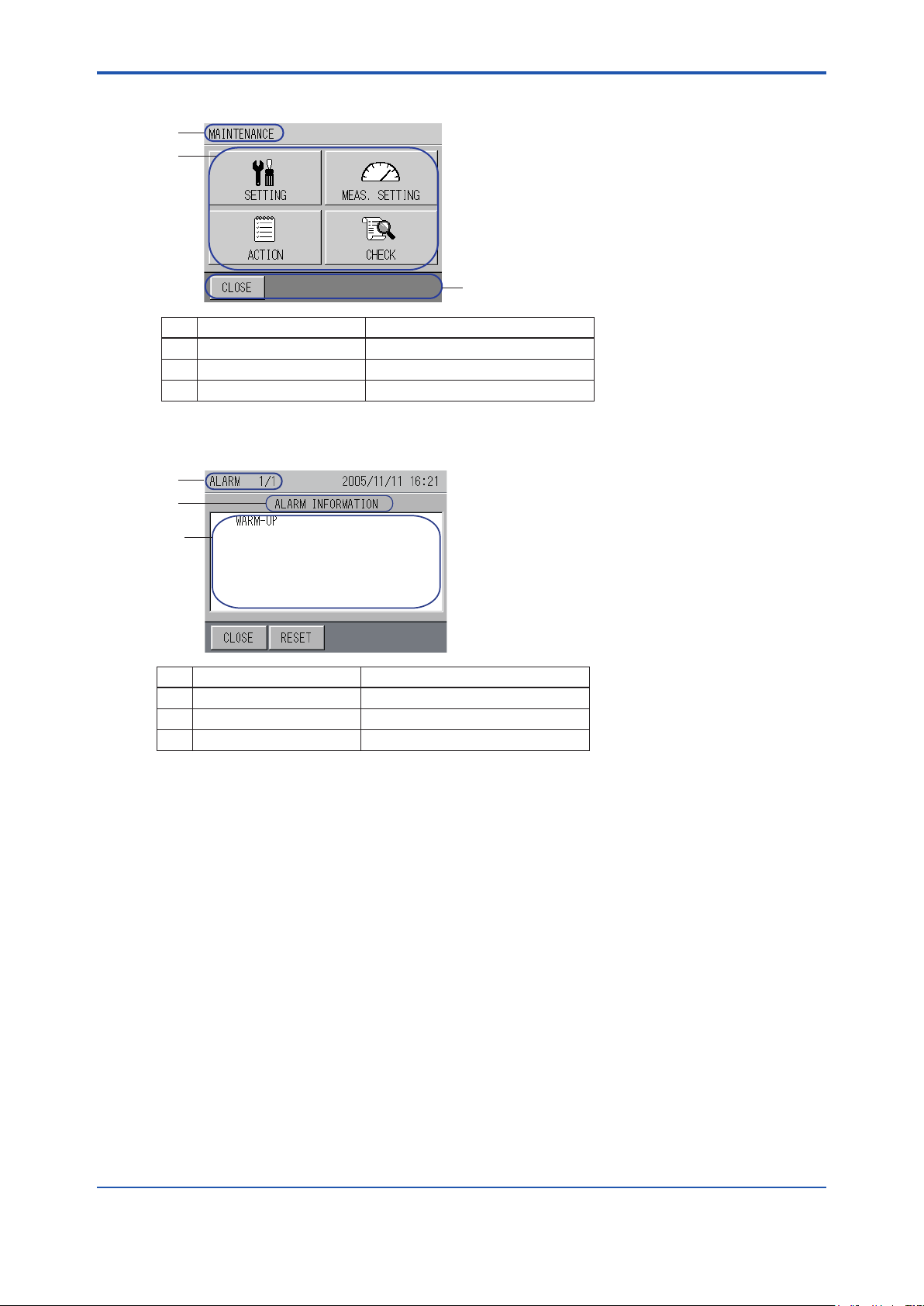

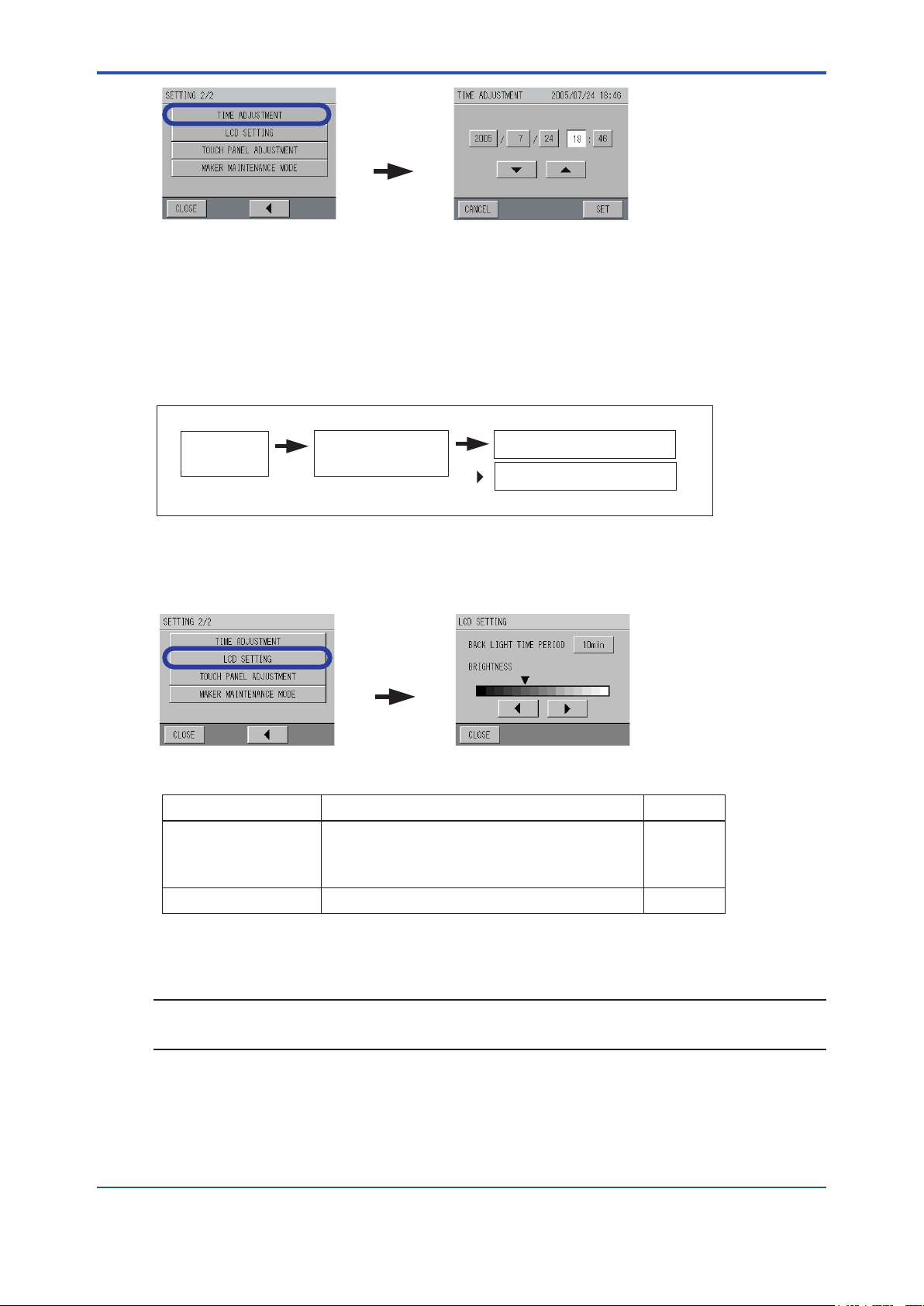

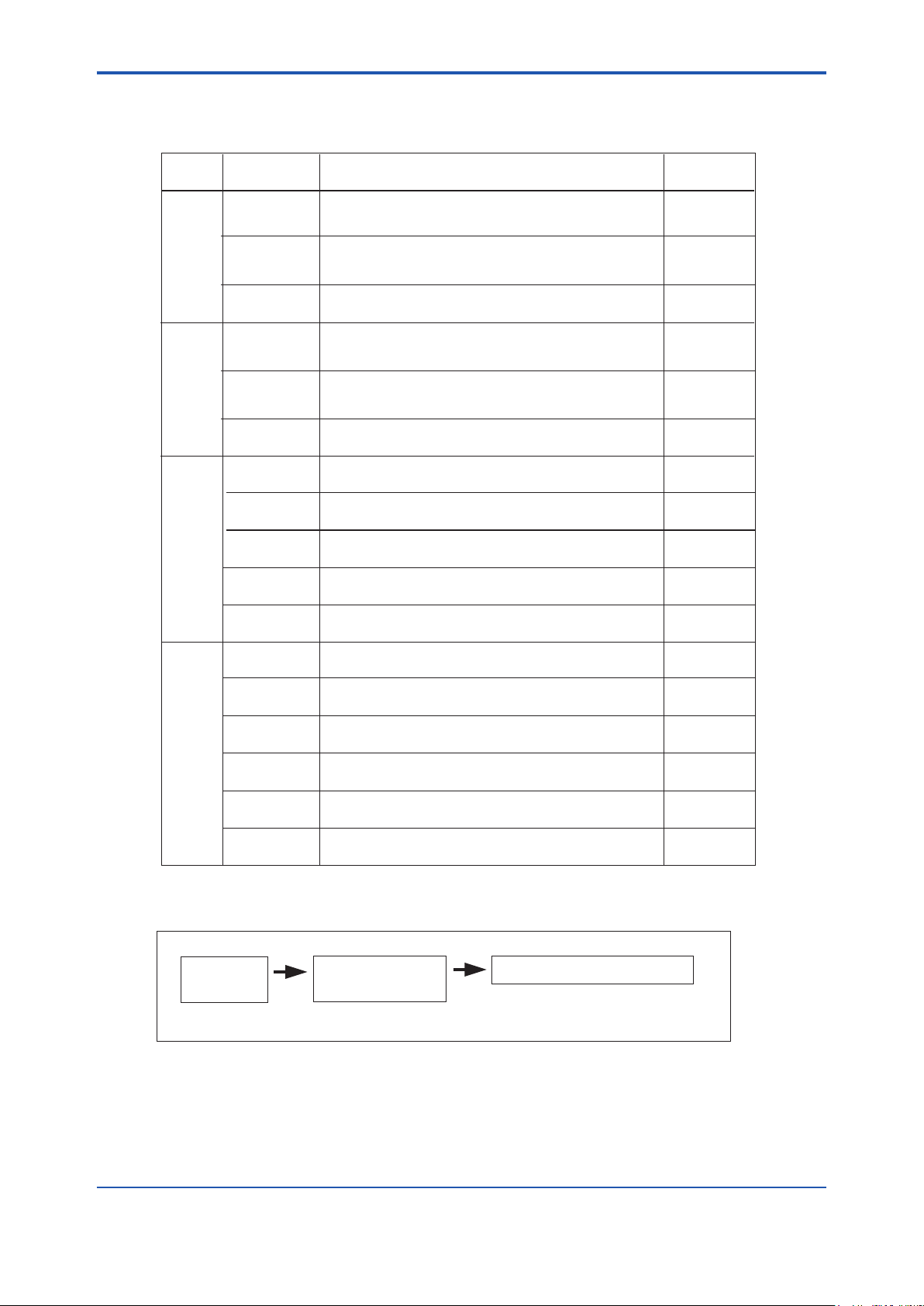

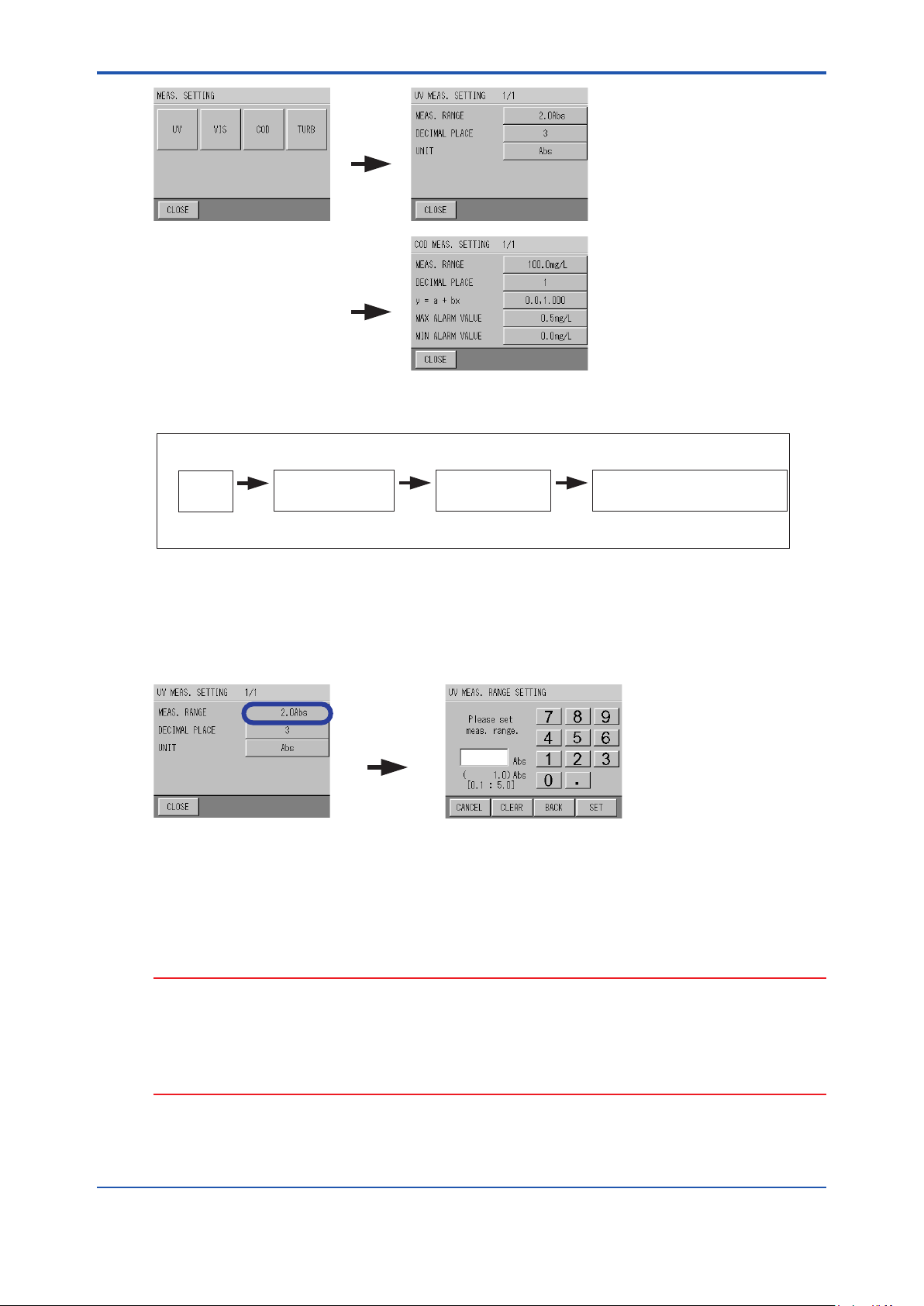

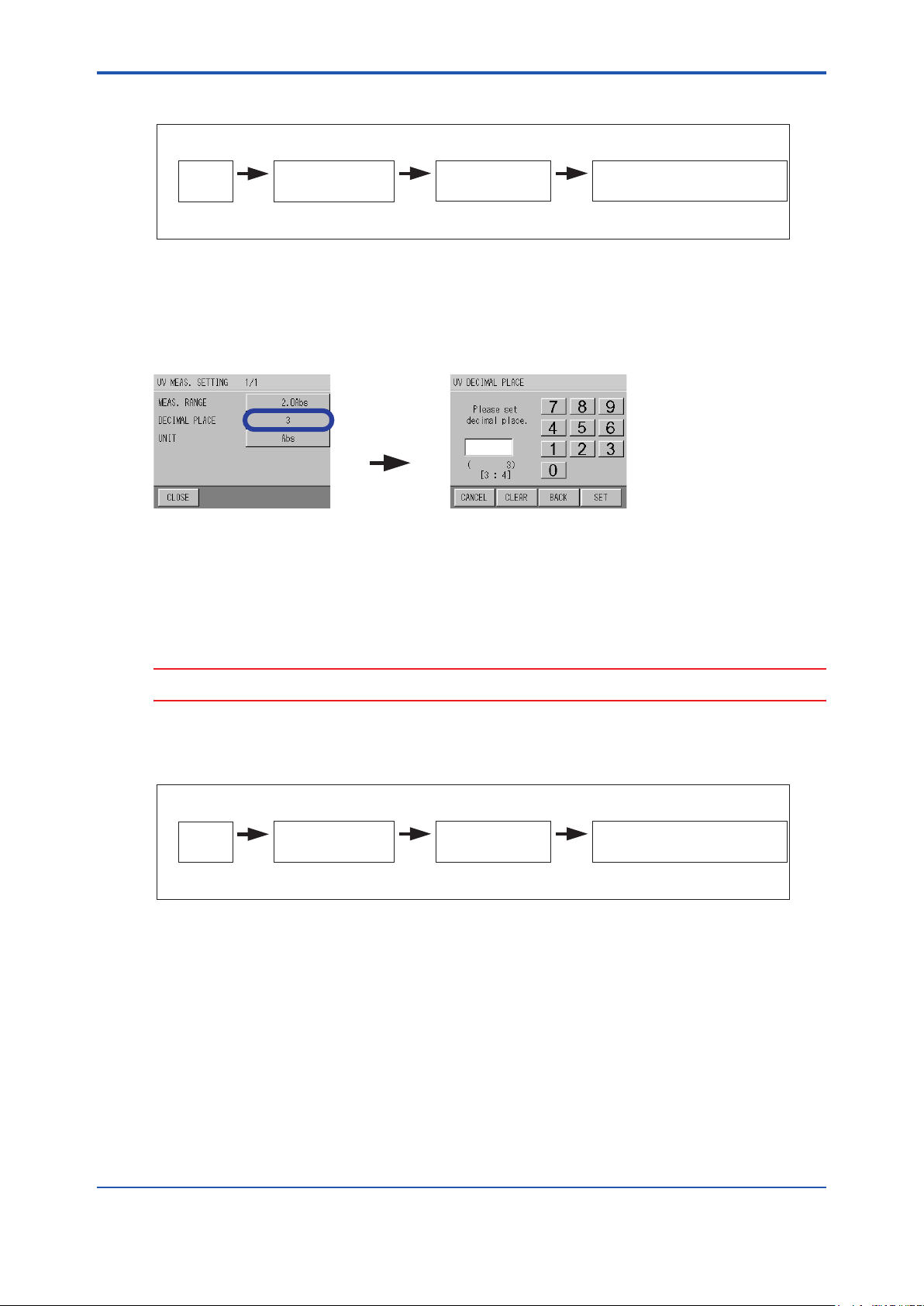

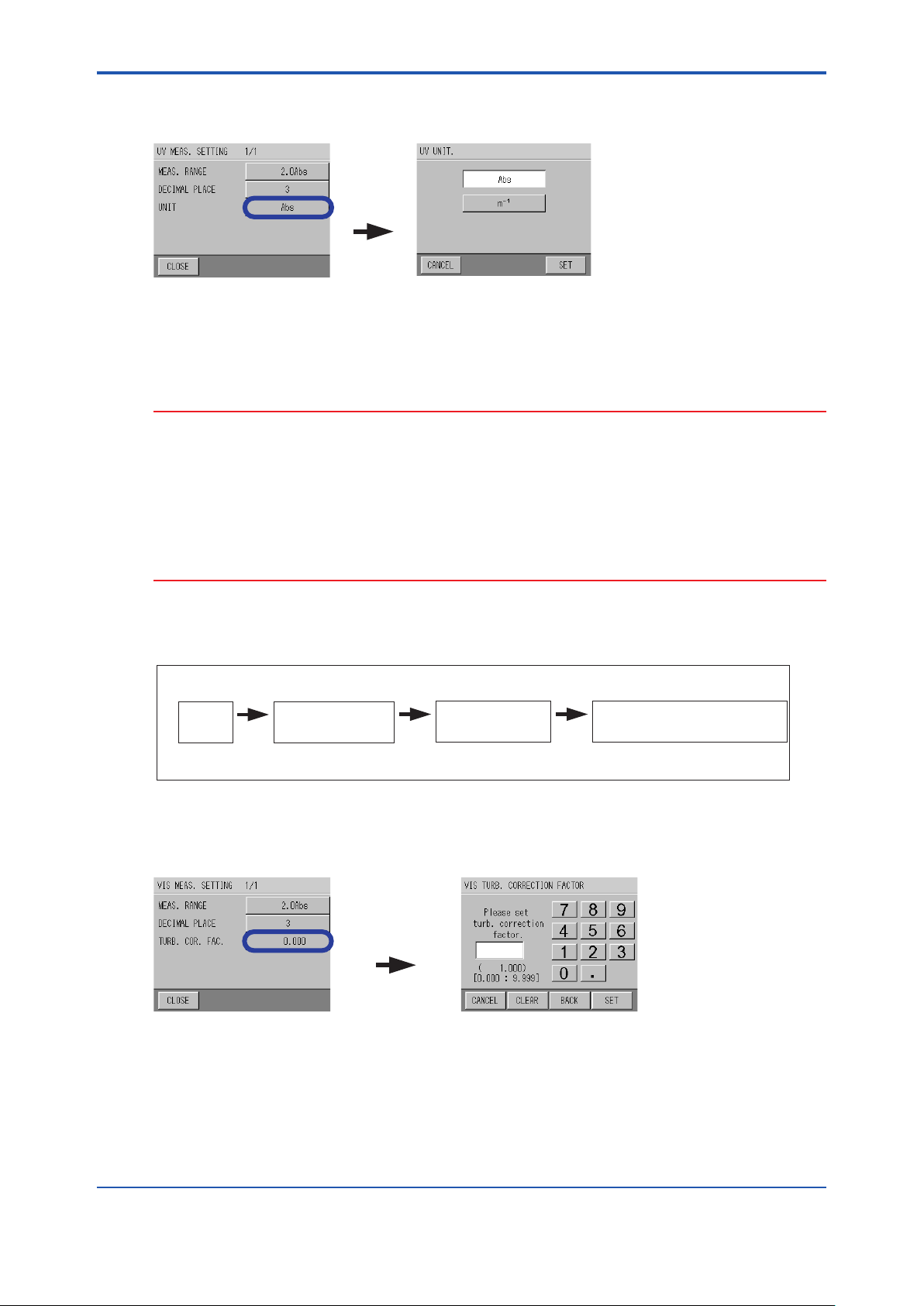

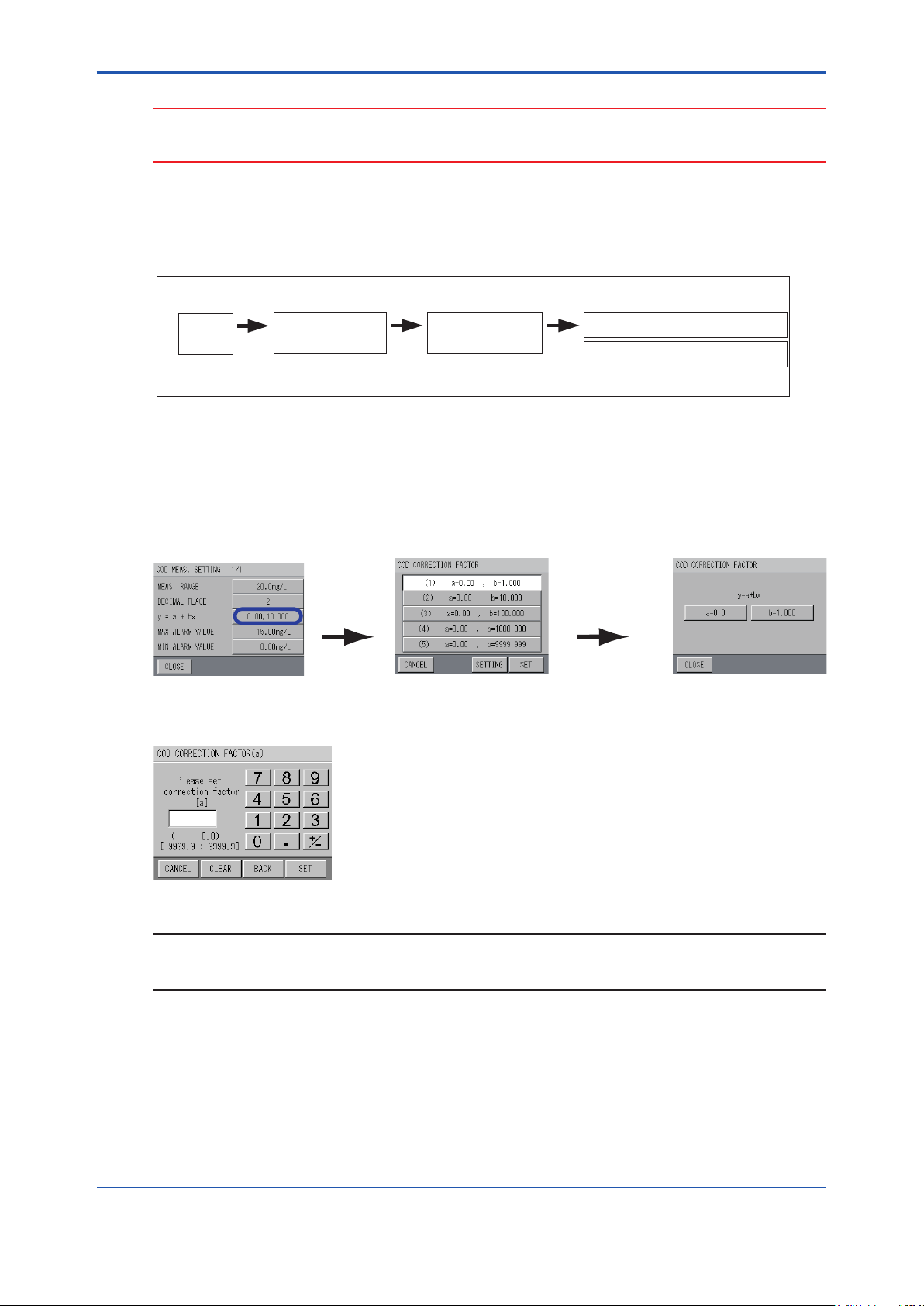

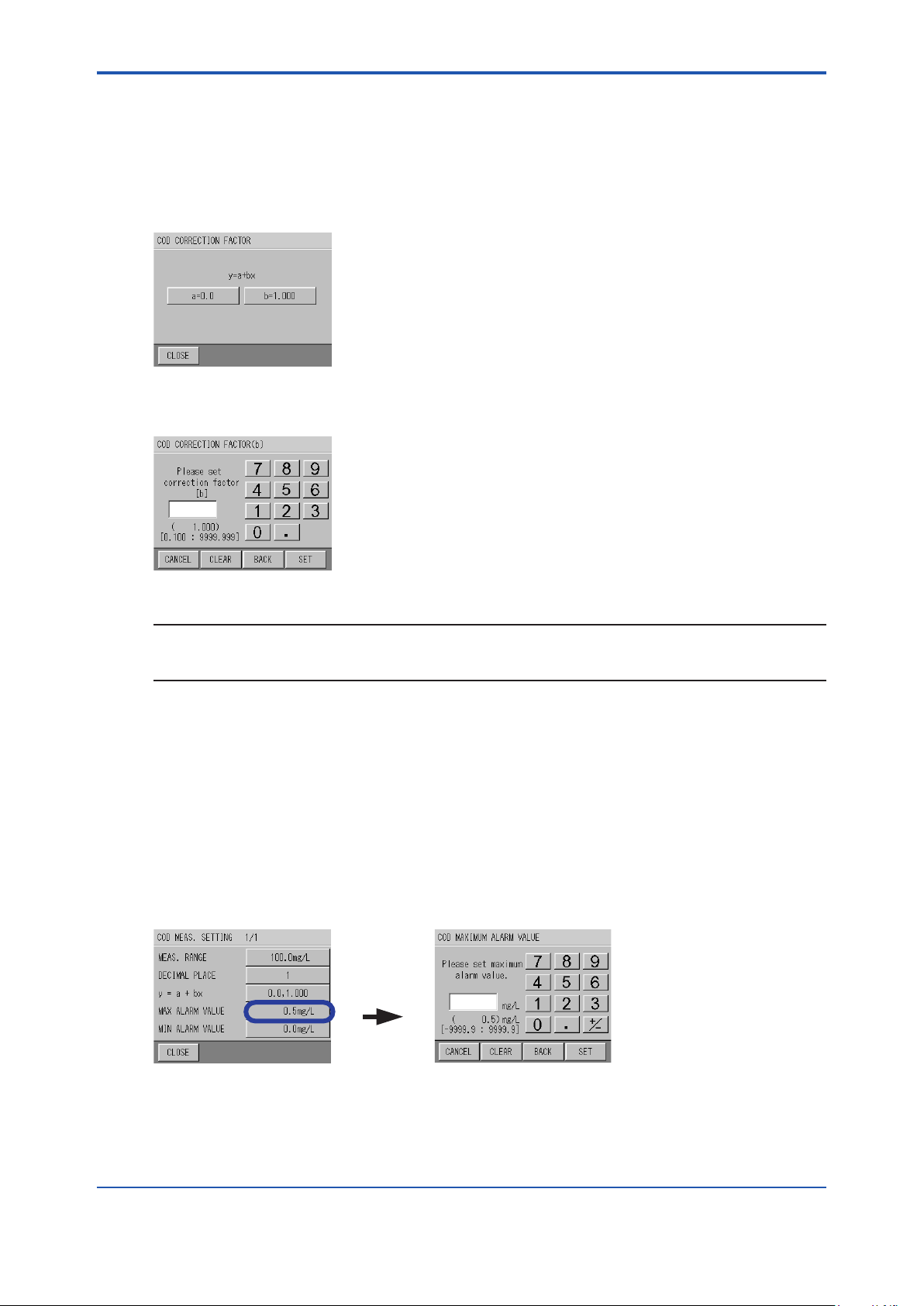

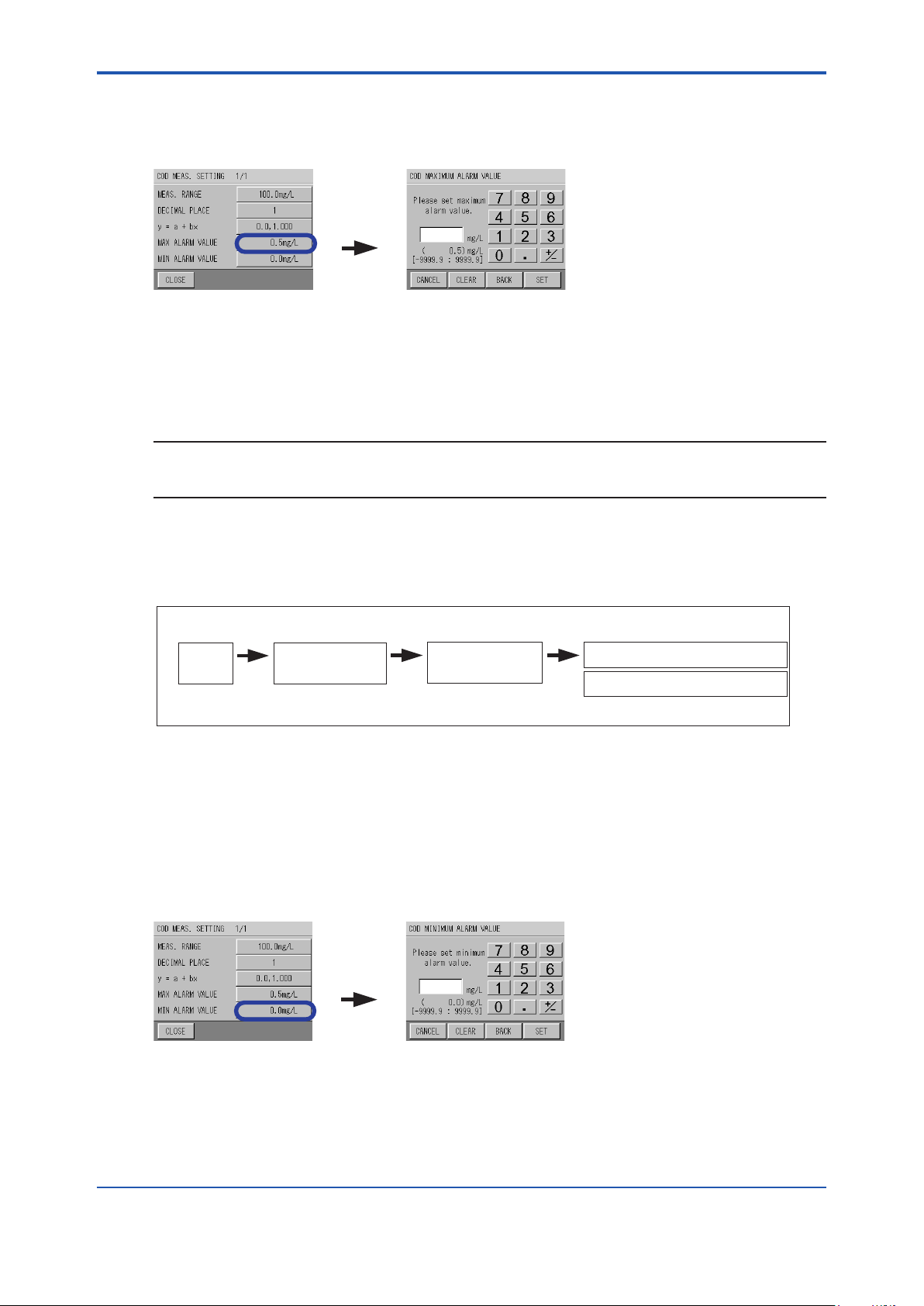

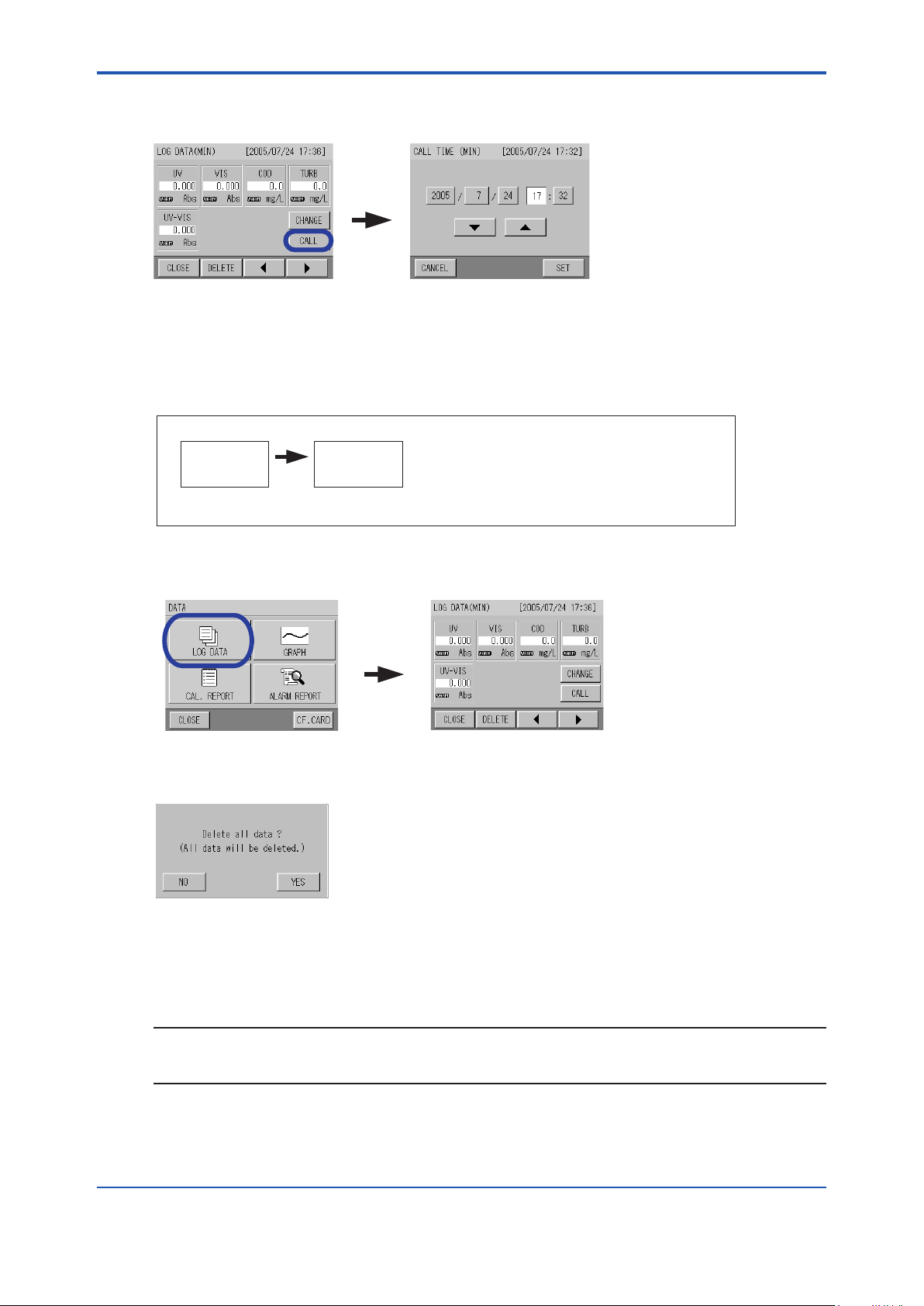

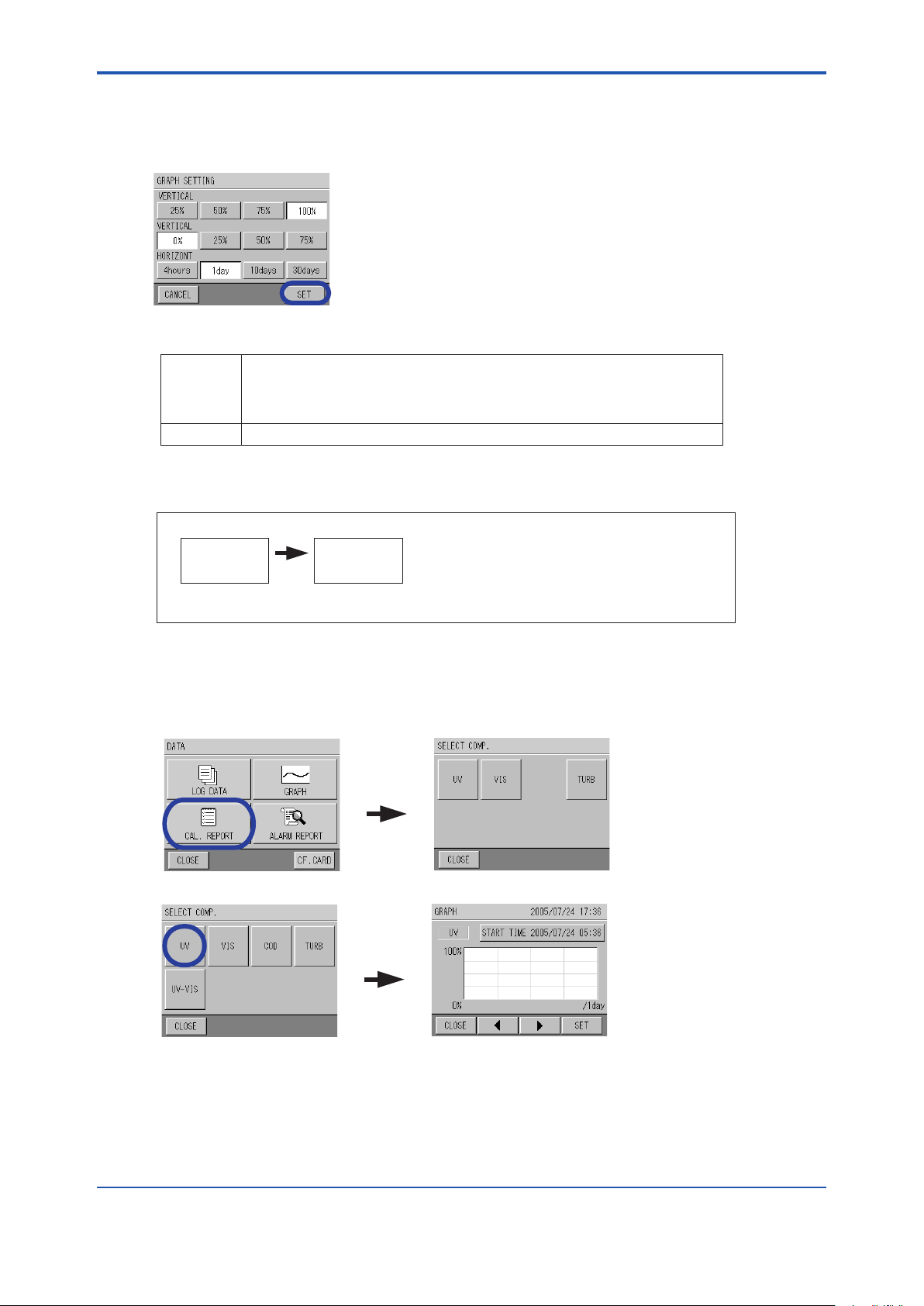

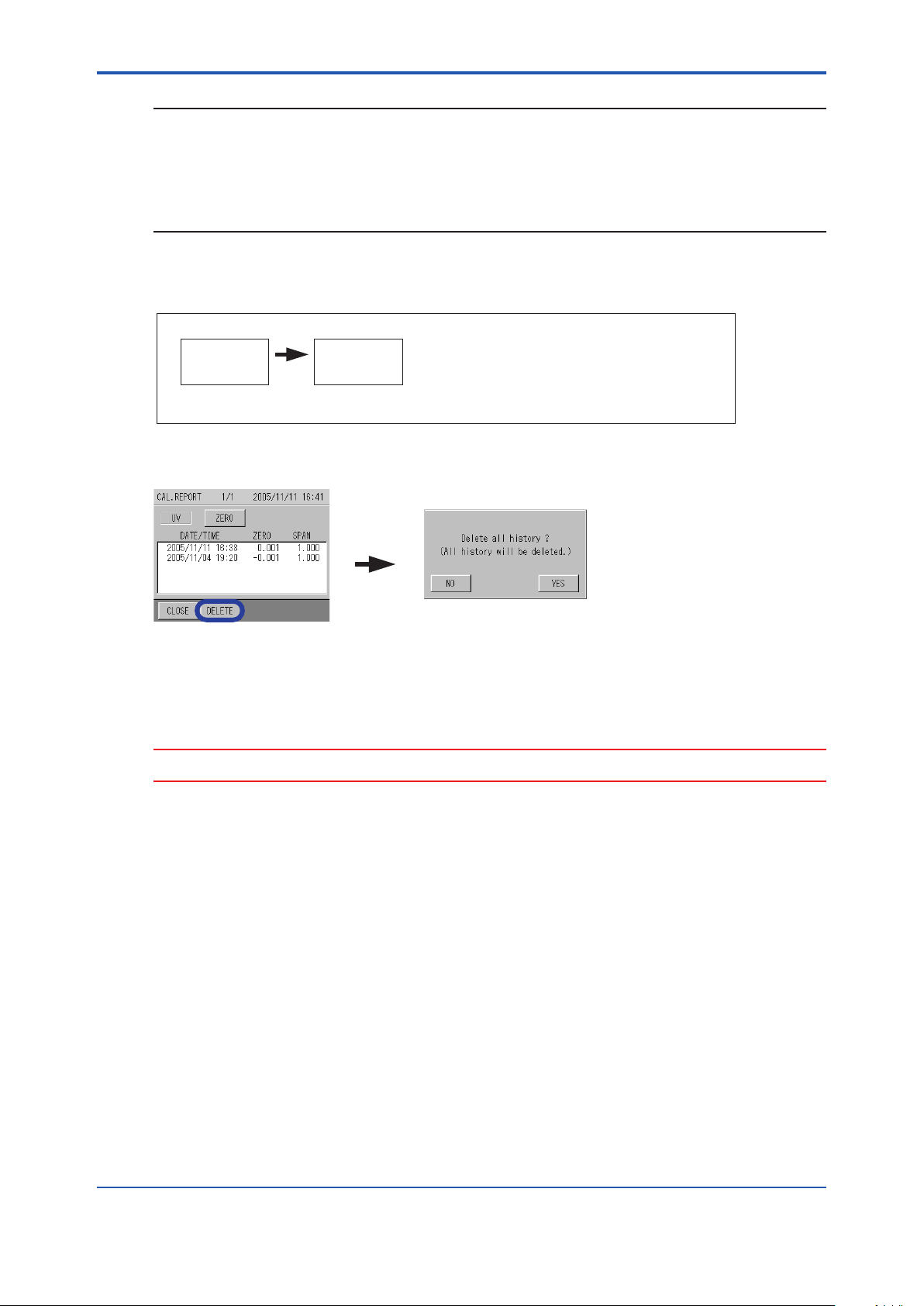

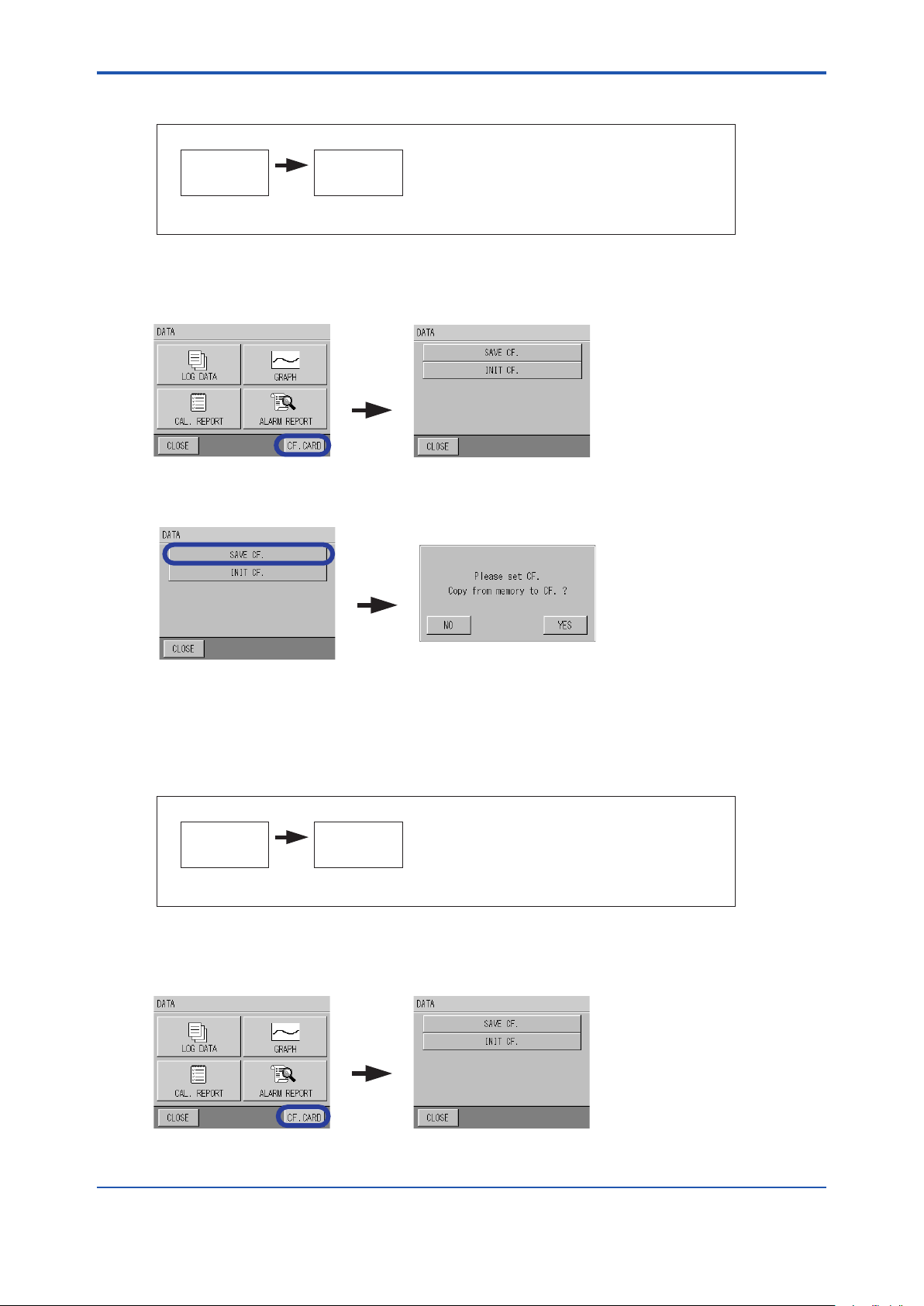

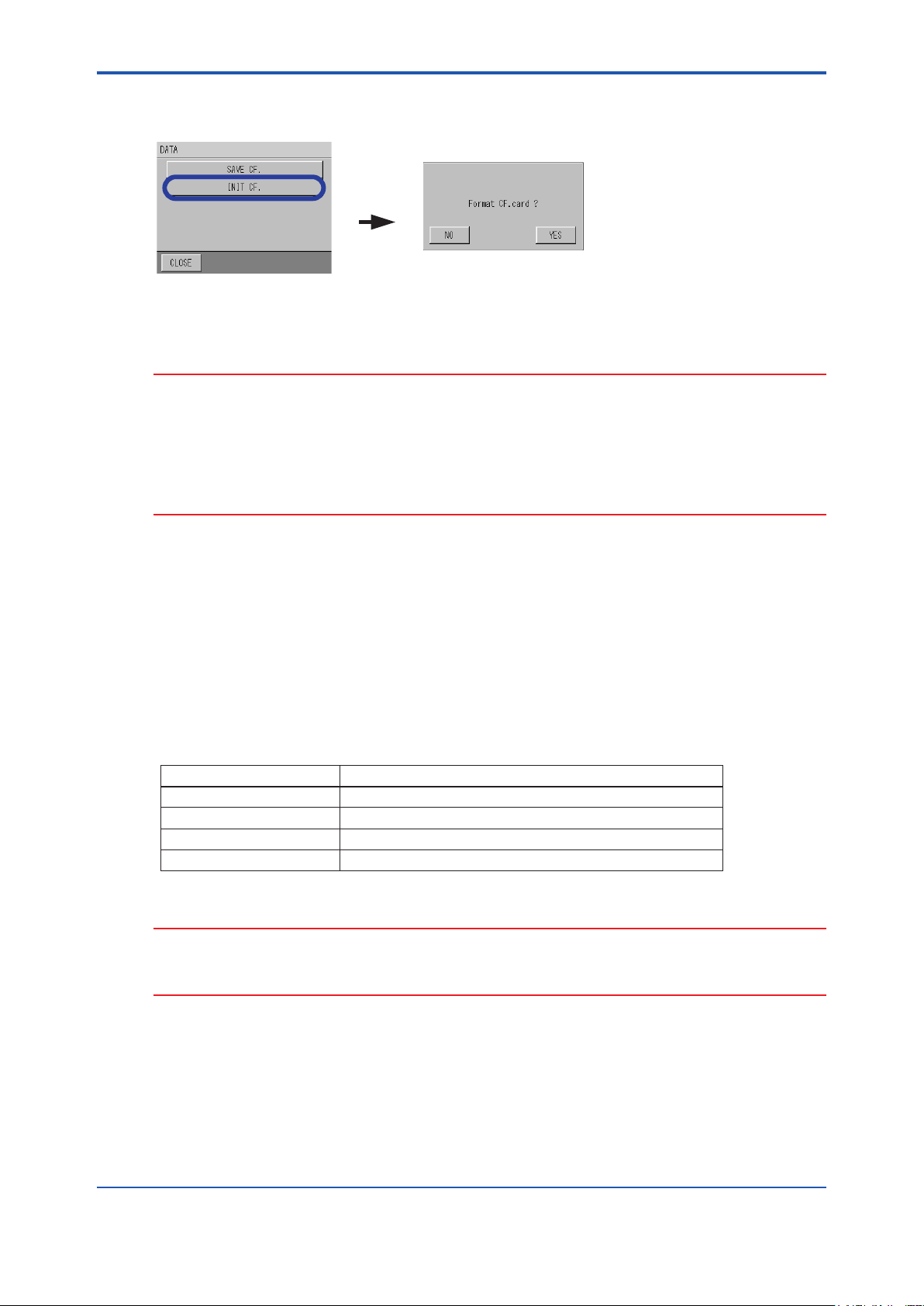

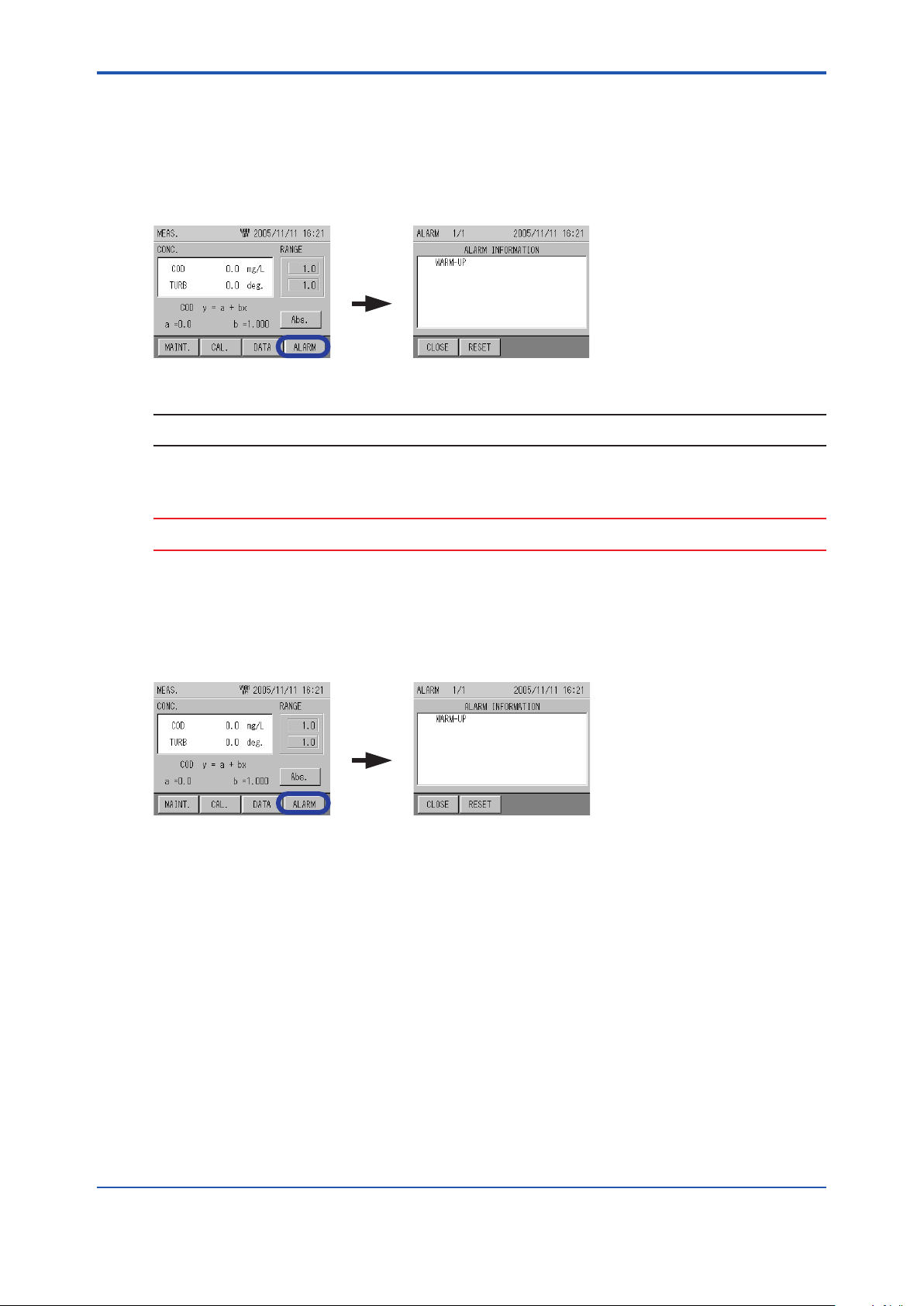

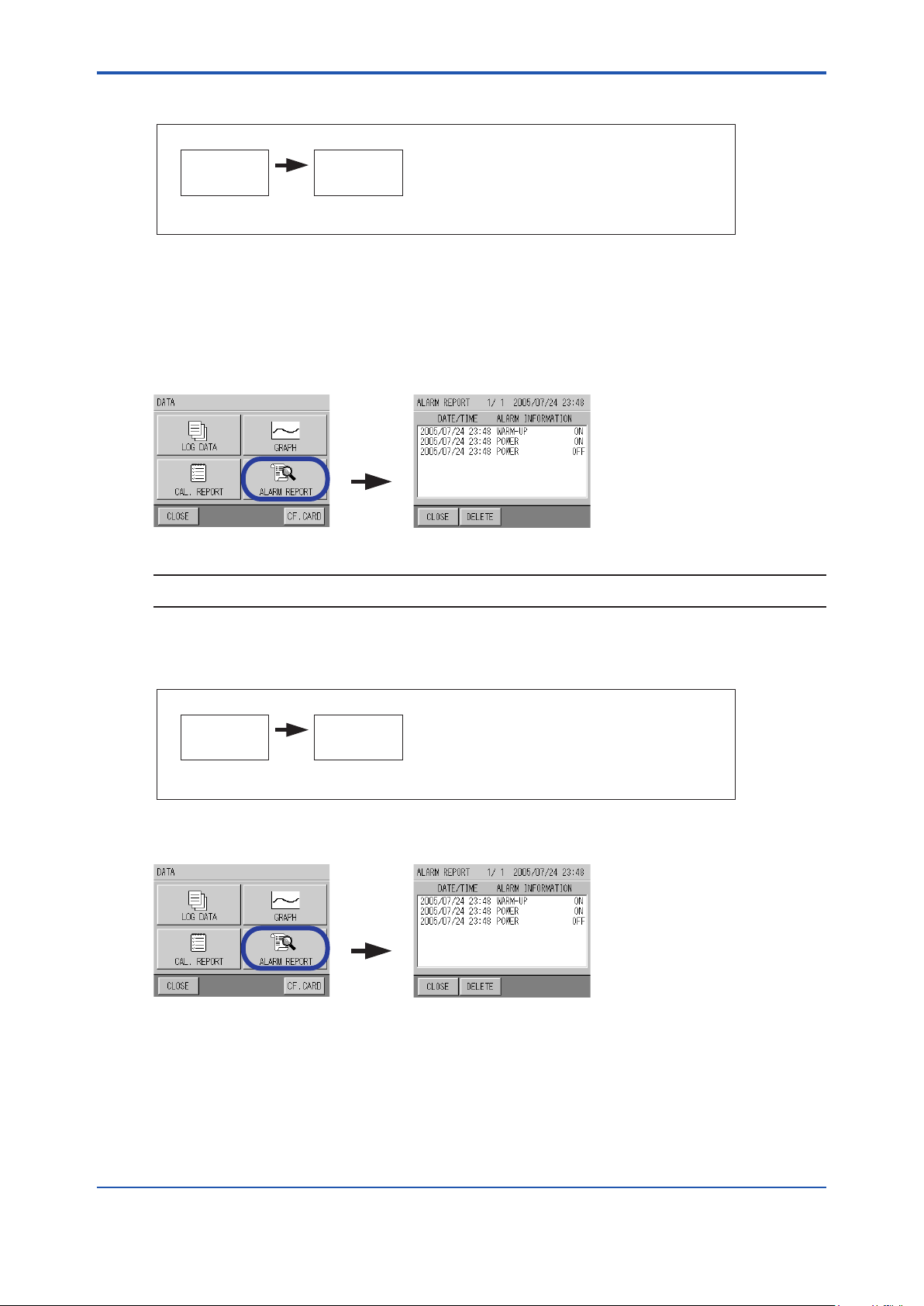

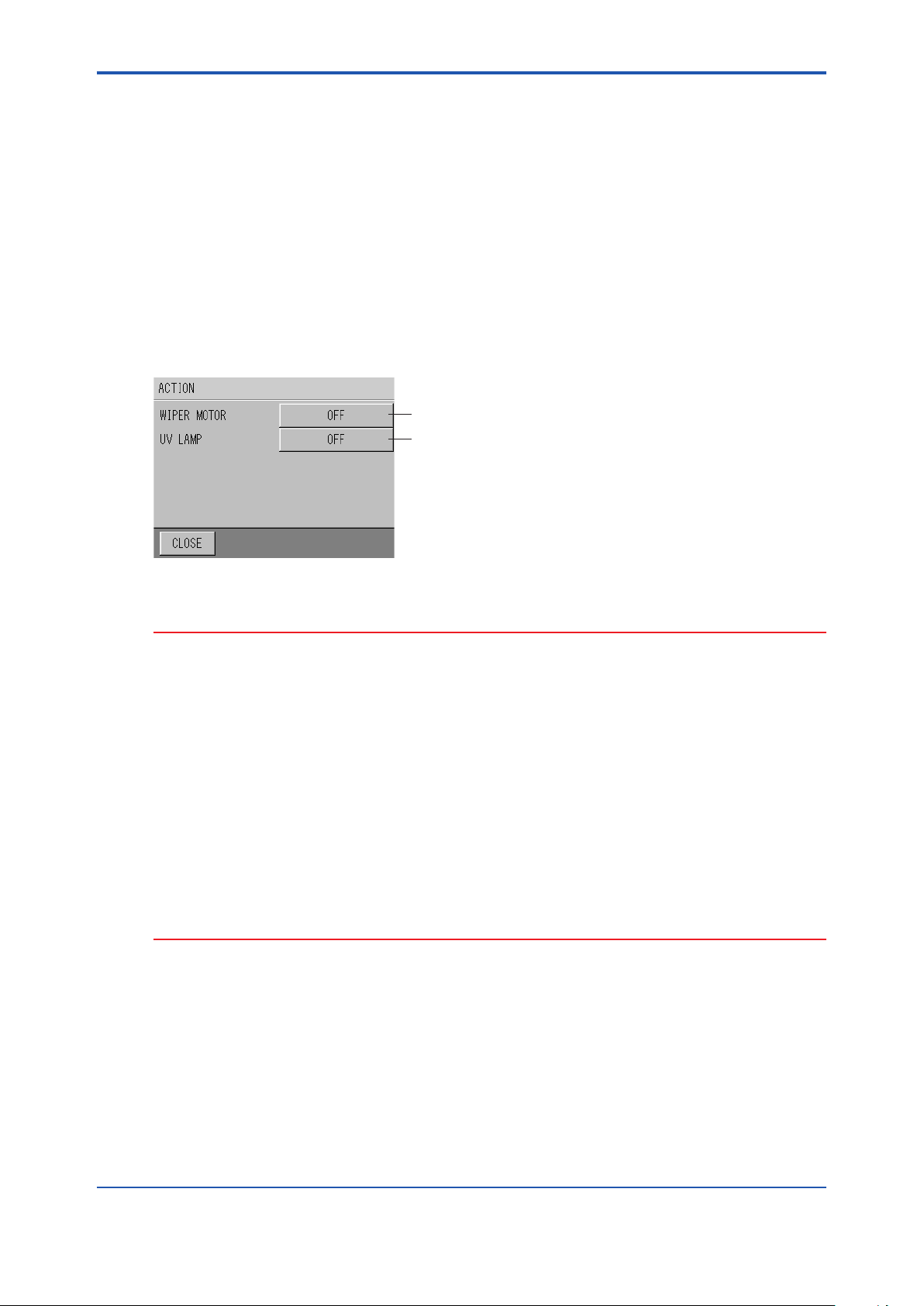

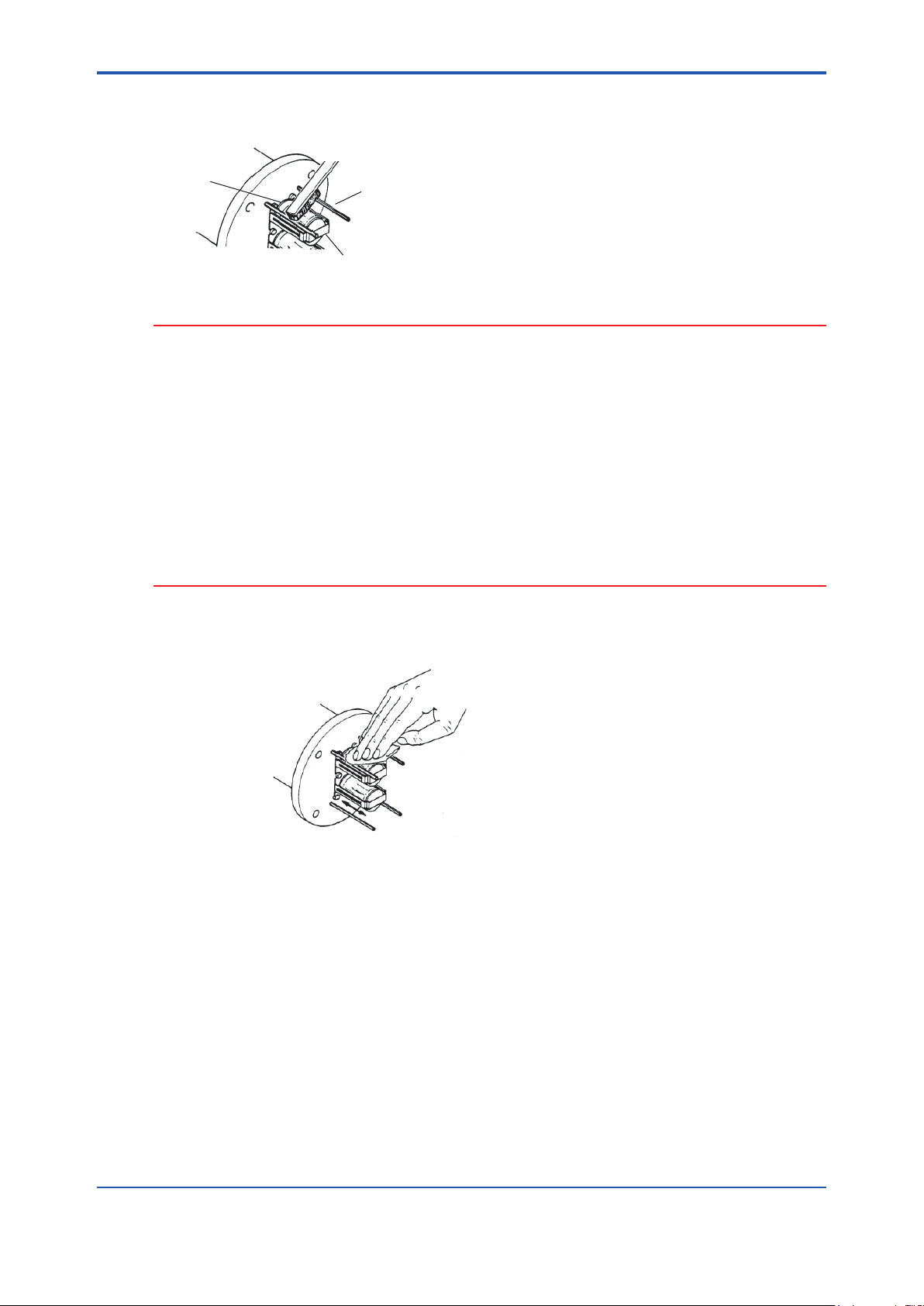

14. The common span calibration is nished.