Page 1

Instruction

Manual

Model UT750

Digital Indicating Controllers

User’s Manual for

Cascade Control

IM 05D01B02-44E

IM 05D01B02-44E

1st Edition

Page 2

Blank Page

Page 3

<Toc> <Rev>

Introduction

Thank you for purchasing the UT750 digital indicating controller.

■ How to Use the Manuals

Purpose Title Description

Setup 1. Installation Describes the tasks (installation, wiring, and others) required

Basic operation

Operating

procedures

and troubleshooting

Brief operation 5.1 Parameter Map Contains the parameter map used as a guideline for setting

Function description

and setpoint recording

2. Initial Settings

3. Operations

4.1 Troubleshooting

5.2 Lists of Parameters Briefly describes the functions of parameters. In addition,

■ Controllers Applicable to Cascade Control

to make the controller ready for operations.

Describes examples of setting PV input types, control output

types, and alarm types. Making settings described herein

allows you to carry out basic control.

Describes key operation sequences. For operation control

through external contact inputs, see “1.5 Terminal Wiring

Diagrams.”

parameters.

each parameter table has a User Setting column, where you

can record your setpoints when setting them in the controller.

i

The specification codes of the UT750 applicable to cascade control are given in the table

below.

UT750-01 UT750-11 UT750-51

■ Regarding This User’s Manual

(1) This manual should be provided to the end user. Keep an extra copy or copies of the

manual in a safe place.

(2) Read this manual carefully to gain a thorough understanding of how to operate this

product before starting operation.

(3) This manual describes the functions of this product. Yokogawa M&C Corporation

(hereinafter simply referred to as Yokogawa) does not guarantee the application of

these functions for any particular purpose.

(4) Under absolutely no circumstances may the contents of this manual, in part or in

whole, be transcribed or copied without permission.

(5) The contents of this manual are subject to change without prior notice.

(6) Every effort has been made to ensure that the details of this manual are accurate.

However, should any errors be found or important information be omitted, please

contact your nearest Yokogawa representative or our sales office.

All Rights Reserved Copyright © 2000, Yokogawa M&C Corporation

IM 05D01B02-44E

1st Edition : May 31,2000-00Media No. IM 05D01B02-44E (CD) 1st Edition : May 2000 (YK)

Page 4

<Toc> <Rev>

■ Safety Precautions

The following symbol is indicated on the controller to ensure safe use.

This symbol on the controller indicates that the operator must refer to an explanation in the

user’s manual in order to avoid the risk of injury or death of personnel or damage to the

instrument. The manual describes how the operator should exercise special care to avoid

CAUTION

electric shock or other dangers that may result in injury or loss of life.

The following symbols are used in the hardcopy user’s manuals and in the user’s manual

supplied on the CD-ROM.

NOTE

Indicates that operating the hardware or software in a particular manner may damage it or

result in a system failure.

ii

IMPORTANT

Draws attention to information that is essential for understanding the operation and/or

features of the controller.

■ Regarding Force Majeure

Yokogawa M&C Corporation assumes no liability for any loss or damage, direct or indirect,

caused by the use of or unpredictable defects of the product.

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 5

<Int> <Rev>

Model UT750

Digital Indicating Controllers

User’s Manual for Cascade Control

CONTENTS

1. Installation .............................................................................................. 1-1

1.1 Model and Suffix Codes.................................................................................. 1-1

1.2 How to Install................................................................................................... 1-2

1.3 How to Connect Wires .................................................................................... 1-5

1.4 Hardware Specifications ................................................................................ 1-7

1.5 Terminal Wiring Diagrams ............................................................................ 1-13

2. Initial Settings ......................................................................................... 2-1

2.1 Names and Functions of Front Panel Parts................................................... 2-2

2.2 Setting UT mode (Setting First at Power-on) ................................................. 2-3

2.3 Changing UT mode ......................................................................................... 2-4

2.4 Setting Primary and Secondary PV Input Types ........................................... 2-6

2.5 Setting Control Output Type

(except for a Position Proportional Controller) ........................................... 2-10

2.6 Calibrating Valve Position (for a Position Proportional Controller Only) .. 2-12

2.7 Initializing Parameters .................................................................................. 2-14

2.8 Changing Alarm Type of Primary-loop ........................................................ 2-15

2.9 Description of Multiple Setpoints and PID................................................... 2-18

Toc-1

IM 05D01B02-44E 1st Edition

3. Operations .............................................................................................. 3-1

3.1 Monitoring-purpose Operating Displays Available during Operation ......... 3-1

3.2 Setting Target Setpoint (SP) of Primary-loop ................................................ 3-6

3.3 Setting Target Setpoint (SP) of Secondary-loop ........................................... 3-8

3.4 Performing/Canceling Auto-tuning of Secondary-loop .............................. 3-10

3.5 Performing/Canceling Auto-tuning of Primary-loop ................................... 3-12

3.6 Setting PID of Secondary-loop Manually ..................................................... 3-14

3.7 Setting PID of Primary-loop Manually.......................................................... 3-16

3.8 Setting Alarm Setpoints of Primary-loop ..................................................... 3-17

3.9 Selecting Target Setpoint Numbers (SPNO)................................................ 3-19

3.10 Switching between Run and Stop ................................................................ 3-20

3.11 Switching between Cascade (CAS), AUTO and MAN .................................. 3-21

3.12 Manipulating Control Output during Manual Operation ............................. 3-23

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 6

<Int> <Rev>

4. Troubleshooting and Maintenance ........................................................ 4-1

5. Parameters .............................................................................................. 5-1

6. Function Block Diagram and Descriptions............................................ 6-1

Toc-2

4.1 Troubleshooting.............................................................................................. 4-1

4.2 Maintenance .................................................................................................... 4-5

4.2.1 Cleaning ........................................................................................... 4-5

4.2.2 Replacing Brackets ........................................................................... 4-5

4.2.3 Attaching Terminal Cover .................................................................. 4-5

4.2.4 Replacing Parts with a Limited Service Life ....................................... 4-7

4.2.5 Replacing Control Output Relays ...................................................... 4-8

5.1 Parameter Map ................................................................................................ 5-1

5.2 Lists of Parameters ......................................................................................... 5-6

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 7

<Toc> <1. Installation>

1. Installation

This chapter describes installation, wiring, and other tasks required to make the

controller ready for operation.

1.1 Model and Suffix Codes

Before using the controller, check that the model and suffix codes match your order.

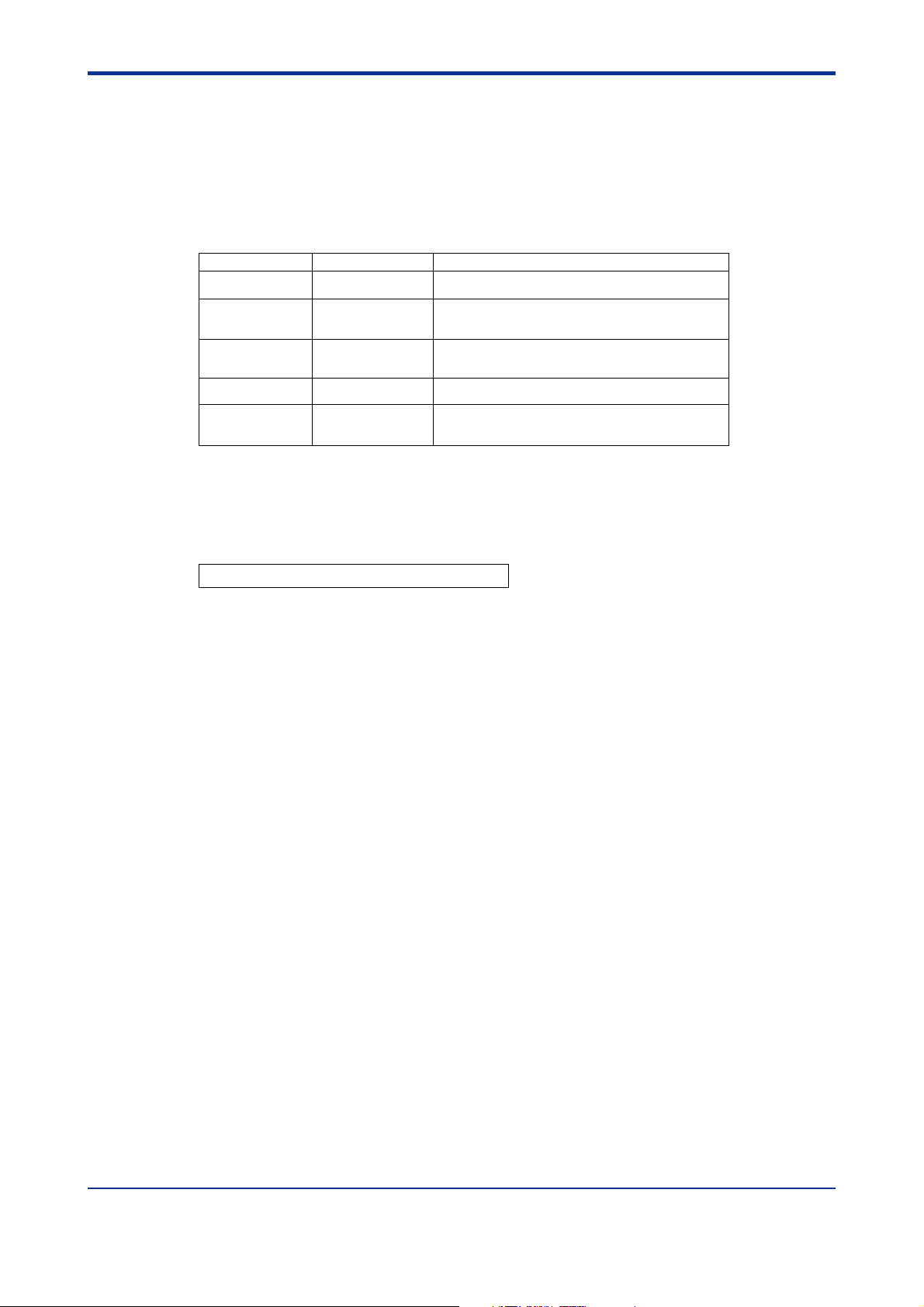

Model Suffix Code Description

UT750 Digital indicating controller (provided with Custom Computing Function*)

Type

Optional functions

Check that the following items are provided:

• Digital indicating controller (of ordered model) ........................................ 1

• Brackets (mounting hardware) ............................................................... 1 pair

-0 Single-loop type

-1 Position proportional type

-5 Dual-loop type

0 None

1 With communication, auxiliary analog input

1-1

• Unit label ................................................................................................ 1

• User’s Manuals for Single-loop Control .................................................. 5 (A2 size)

• User’s Manual (Reference) (CD-ROM version) ...................................... 1

* Using an optional custom computation building tool (Model LL200-E10) that runs on a personal computer, you can

build a variety of computations (e.g., four arithmetic operations, logical operations, ten-segment linearizer computations, temperature correction factor computations, and pressure correction factor computations) to be applied to the

controller’s I/O signals.

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 8

<Toc> <1. Installation>

1.2 How to Install

NOTE

To install the controller, select a location where:

1. no one may accidentally touch the terminals,

2. mechanical vibrations are minimal,

3. corrosive gas is minimal,

150mm

1-2

4. temperature can be maintained at about 23C and

the fluctuation is minimal,

150mm150mm

150mm

5. no direct radiant heat is present,

6. no magnetic disturbances are caused,

7. no wind blows against the terminal board (reference junction compensation element),

8. no water is splashed,

9. no flammable materials are around,

Never place the controller directly on flammable items or equipment.

If the controller has to be installed close to flammable items or equipment, be sure to

provide shielding panels all around the controller, at least 150 mm away from every side;

the panels should be made of either 1.43 mm-thick metal-plated steel plates or 1.6 mmthick uncoated steel plates.

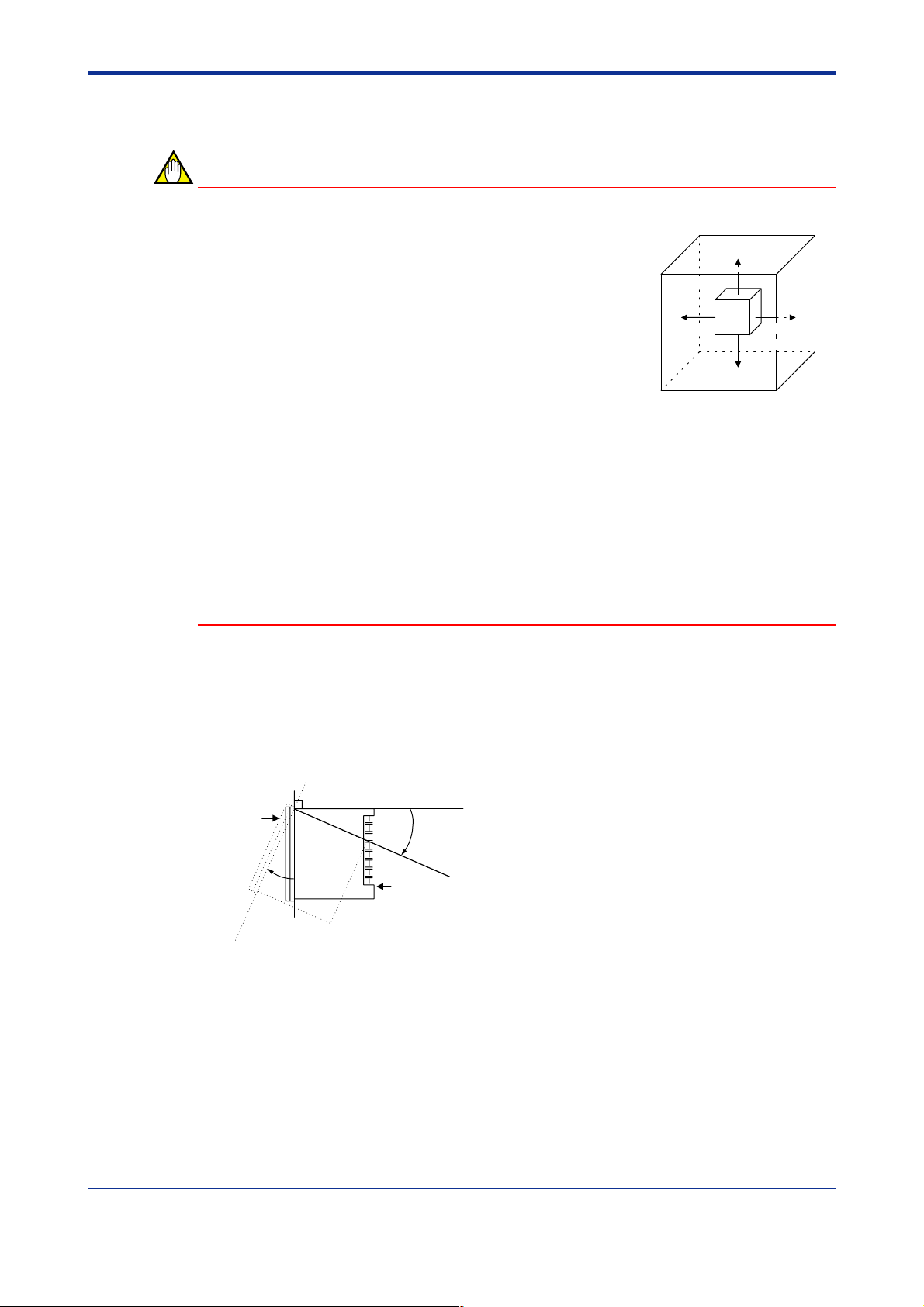

● Installation Position

Install the controller at an angle within 30 from horizontal with the front panel facing upward. Do not install it facing downward. The position of right and left sides should be horizontal.

Front panel

of controller

30°

Must not

exceed 30°

Rear of

controller

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 9

<Toc> <1. Installation>

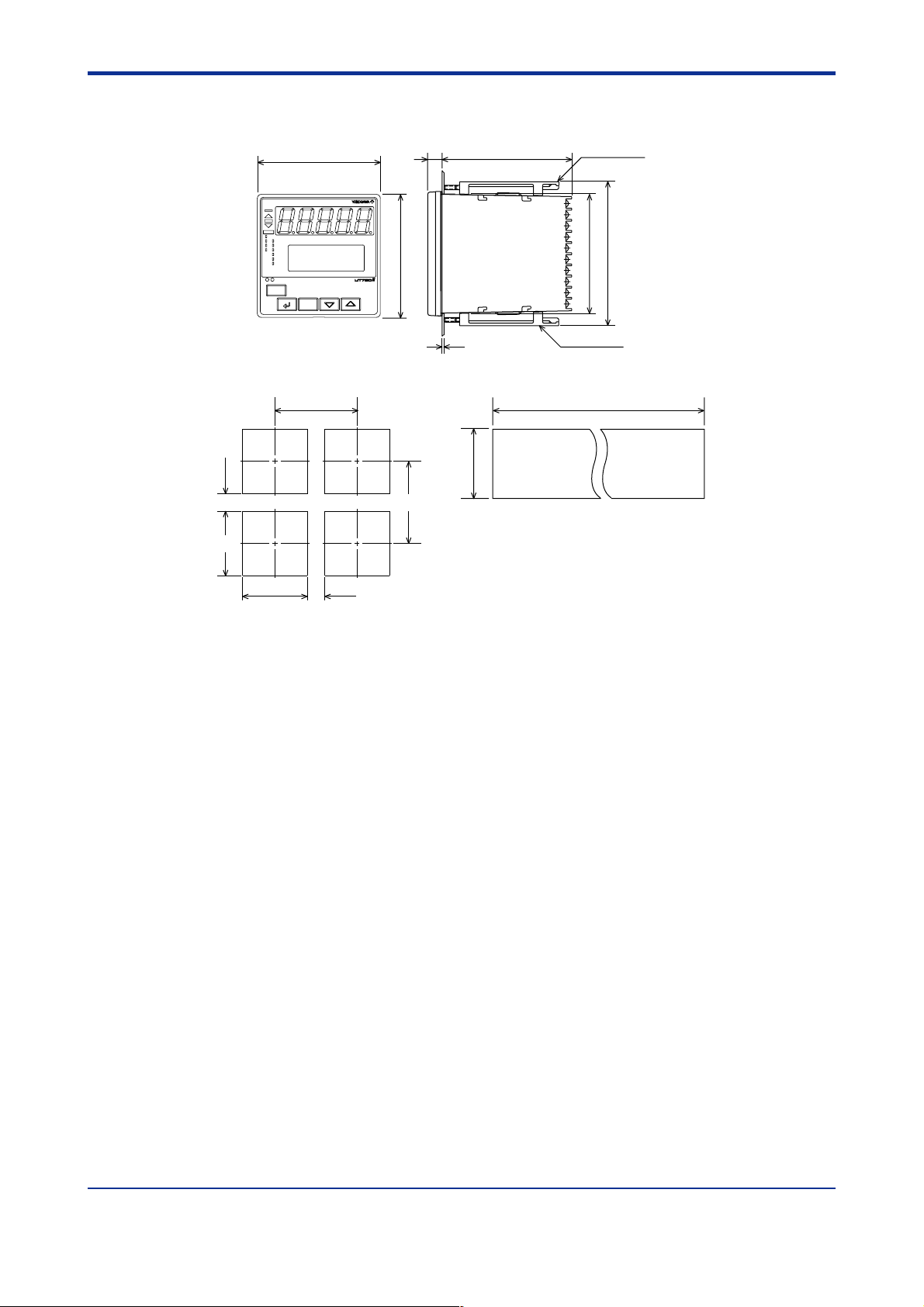

■ External Dimensions and Panel Cutout Dimensions

1-3

UT750

96

PV

PV2

AL

1

2

CAS

3

REM1

4

REM2

MAN1

MAN2

STP

A/M

SET/ENT

DISP

96

10011

Small bracket

1 to 10 mm

(Panel thickness)

General installation Side-by-side close installation

[(N-1)96+92]117 min.

0

+0.8

92

92

(53)

+0.8

0

+0.8

92

0

(25)

145 min.

“N” stands for the number of controllers to be

installed.

However, the measured value applies if N 5.

Large bracket

112

91.8

+0.8

Unit: mm

0

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 10

<Toc> <1. Installation>

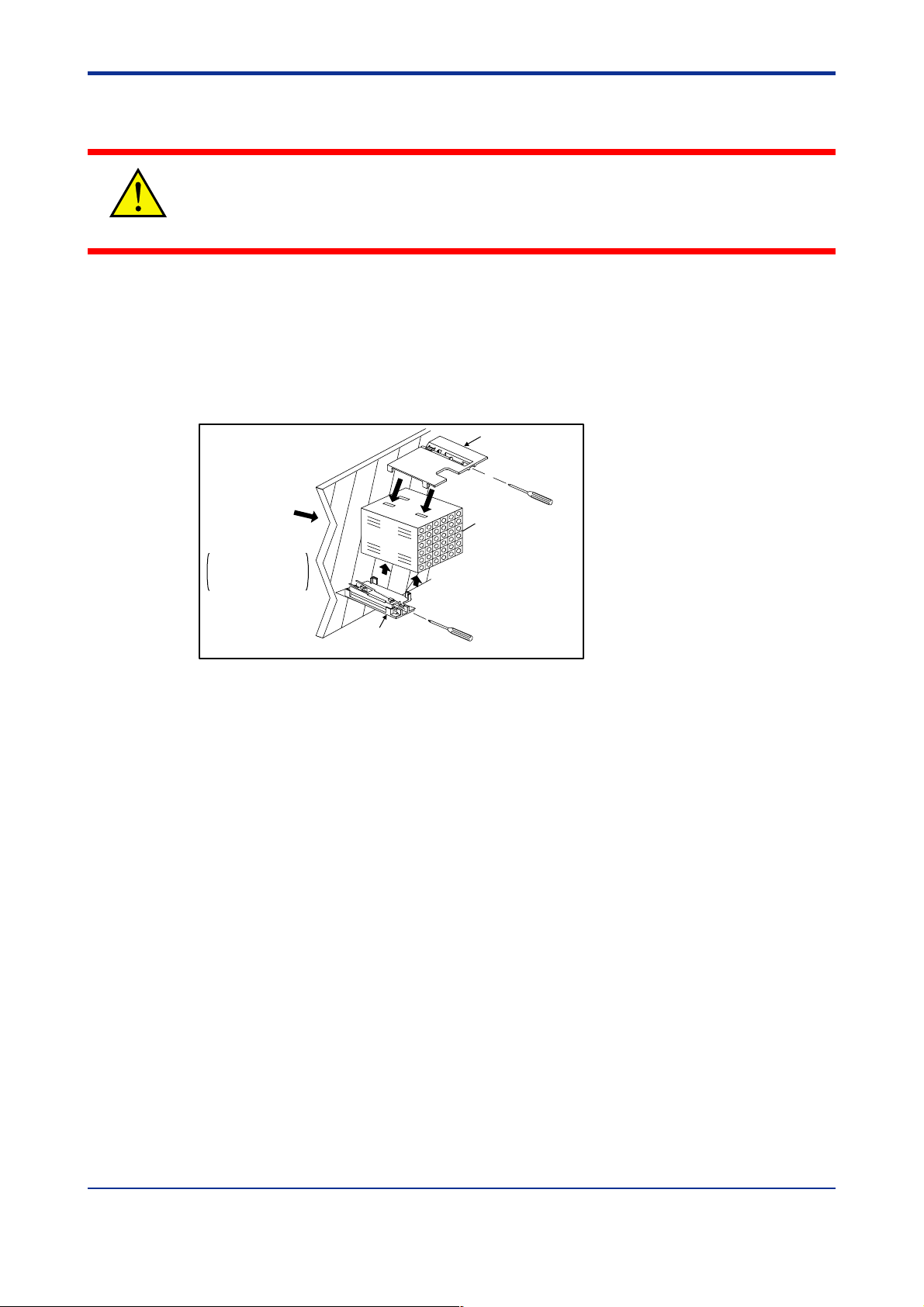

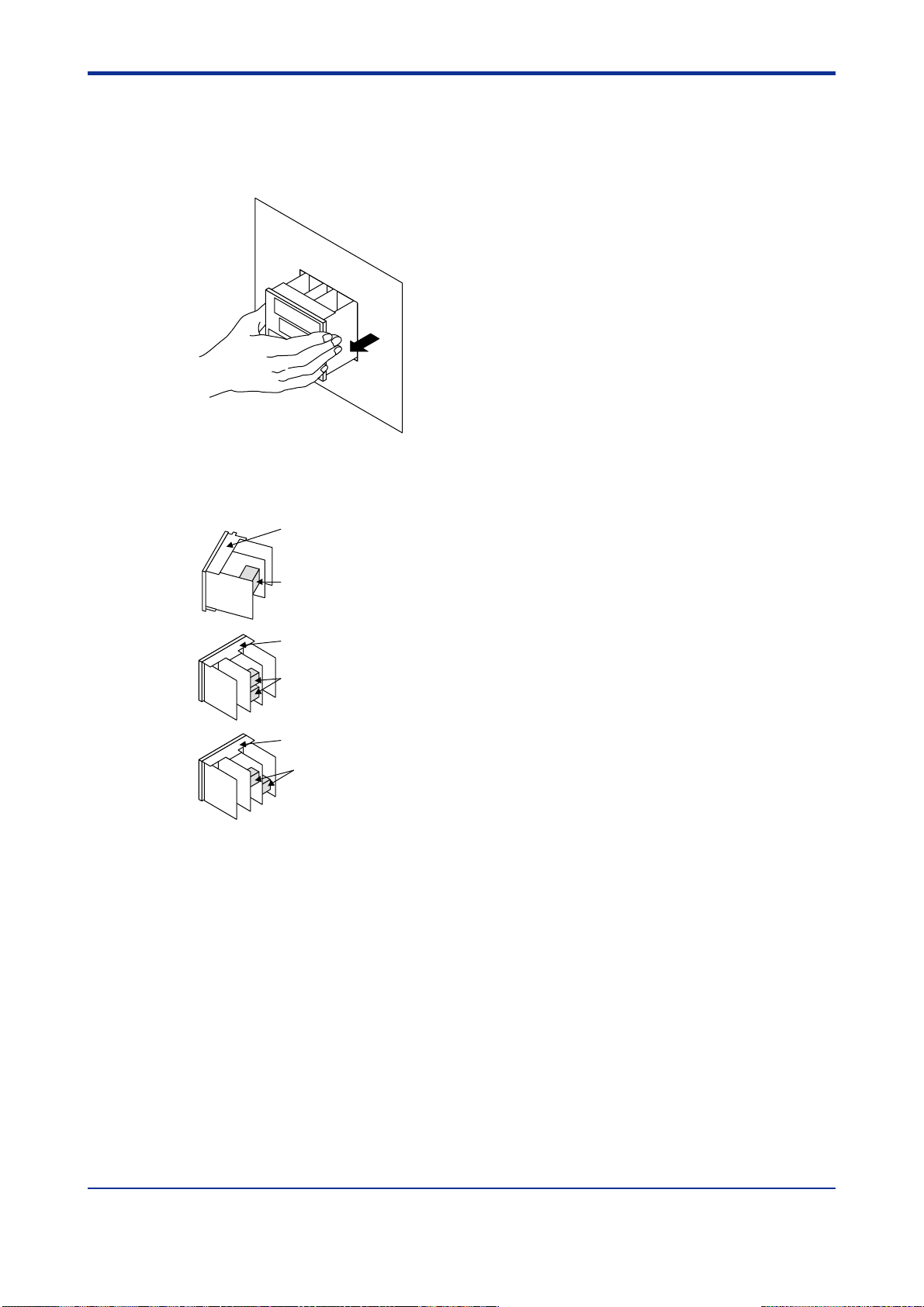

■ How to Install

Turn off the power to the controller before installing it on the panel because there is a

possibility of electric shock.

CAUTION

After opening the mounting hole on the panel, follow the procedures below to install the

controller:

1. Insert the controller into the opening from the front of the panel so that the terminal

board on the rear is at the far side.

2. Set the brackets in place on the top and bottom of the controller as shown in the figure

below, then tighten the screws of the brackets. Take care not to overtighten them.

1-4

Direction to insert the

controller

Insert the controller

into the opening at

the front of the panel.

Panel

Insert a screwdriver into the

brackets to tighten the screws.

Small bracket

(bottom mounting hardware)

Large bracket

(top mounting hardware)

Terminal board

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 11

<Toc> <1. Installation>

1.3 How to Connect Wires

1) Before carrying out wiring, turn off the power to the controller and check that the

cables to be connected are not alive with a tester or the like because there is a possibility of electric shock.

CAUTION

2) Wiring must be carried out by personnel who have basic electrical knowledge and

practical experience.

NOTE

1) Provide power from a single-phase instrument power supply. If there is a lot of noise in

the power line, insert an insulating transformer into the primary side of the line and use

a line filter (recommended part: ZAC2205-00U from TDK) on the secondary side.

As a countermeasures against noise, do not place the primary and secondary power

cables close to each other.

2) For thermocouple input, use shielded compensating lead wires for wiring. For RTD

input, use shielded wires that have low conductor resistance and cause no significant

differences in resistance between the three wires.

The cables to be used for wiring, terminal specifications, and recommended parts are

as shown below.

1-5

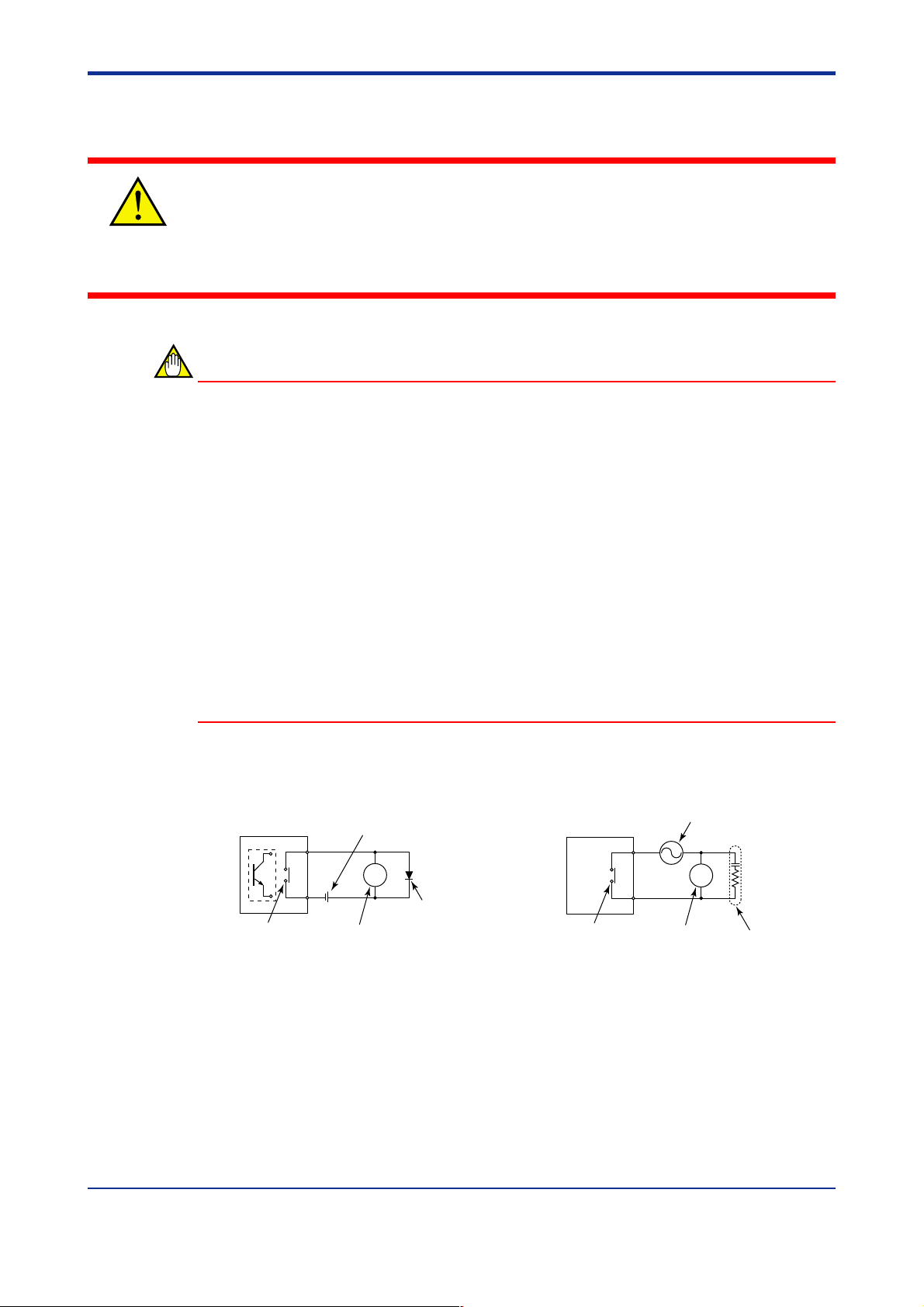

3) Control output relays may be replaced. However, because they have a life of 100,000

times that of the resistance load, use auxiliary relays to turn on/off a load.

4) The use of inductance (L) loads such as auxiliary relays, motors and solenoid valves

causes malfunction or relay failure; always insert a CR filter for use with alternating

current or a diode for use with direct current, as a spark-removal surge suppression

circuit, into the line in parallel with the load.

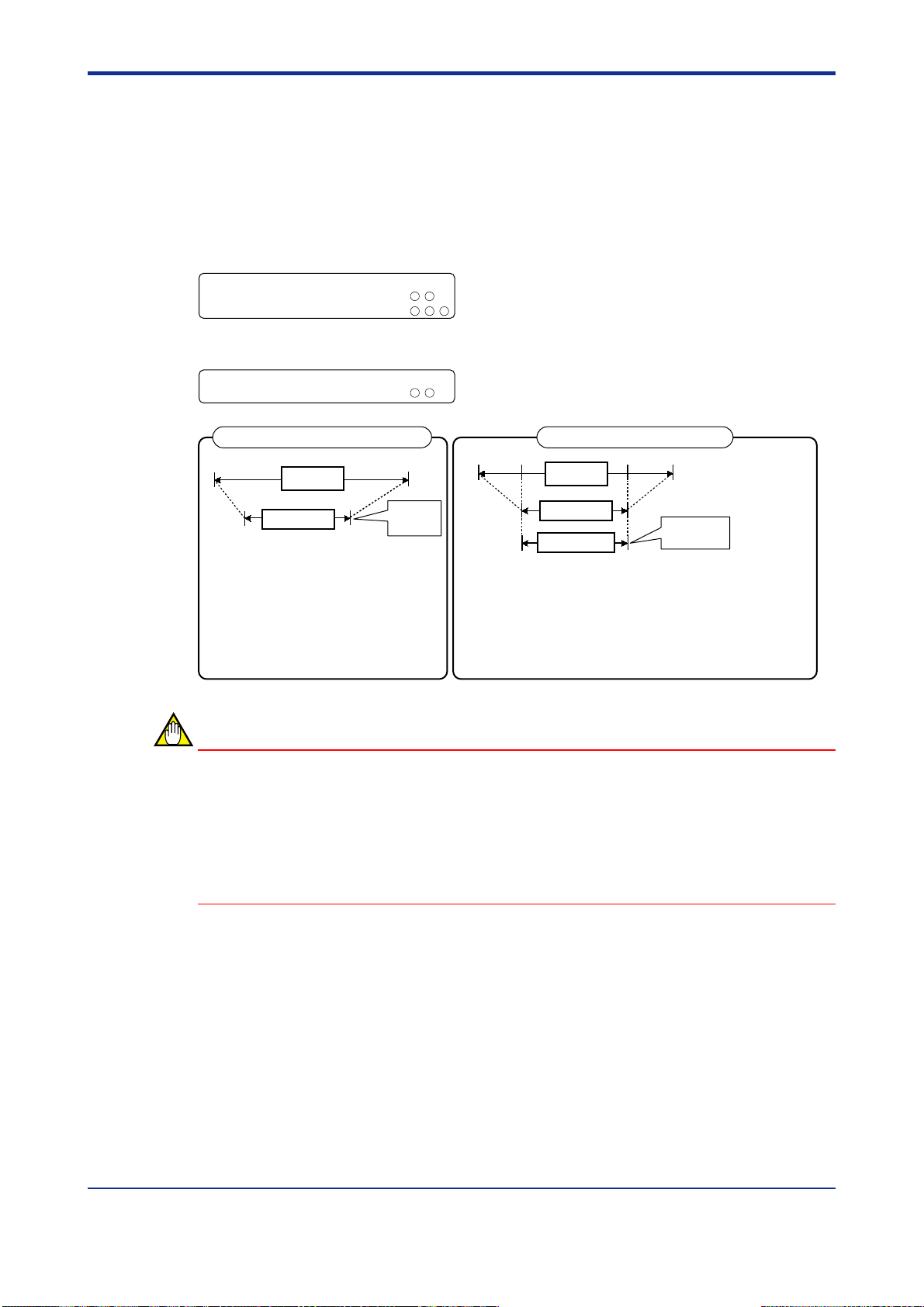

■ For DC Relay Wiring ■ For AC Relay Wiring

UT750

O.C

Relay

UT’s contact

(Use one with a relay coil rating

less than the UT’s contact rating.)

Relay

External DC power supply

R

Diode

(Mount it directly

to the relay coil

terminal (socket).)

UT’s contact

UT750

Relay

(Use one with a relay coil

rating less than the UT’s

contact rating.)

External AC power supply

R

CR filter

(Mount it directly

to the relay coil

terminal (socket).)

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 12

<Toc> <1. Installation>

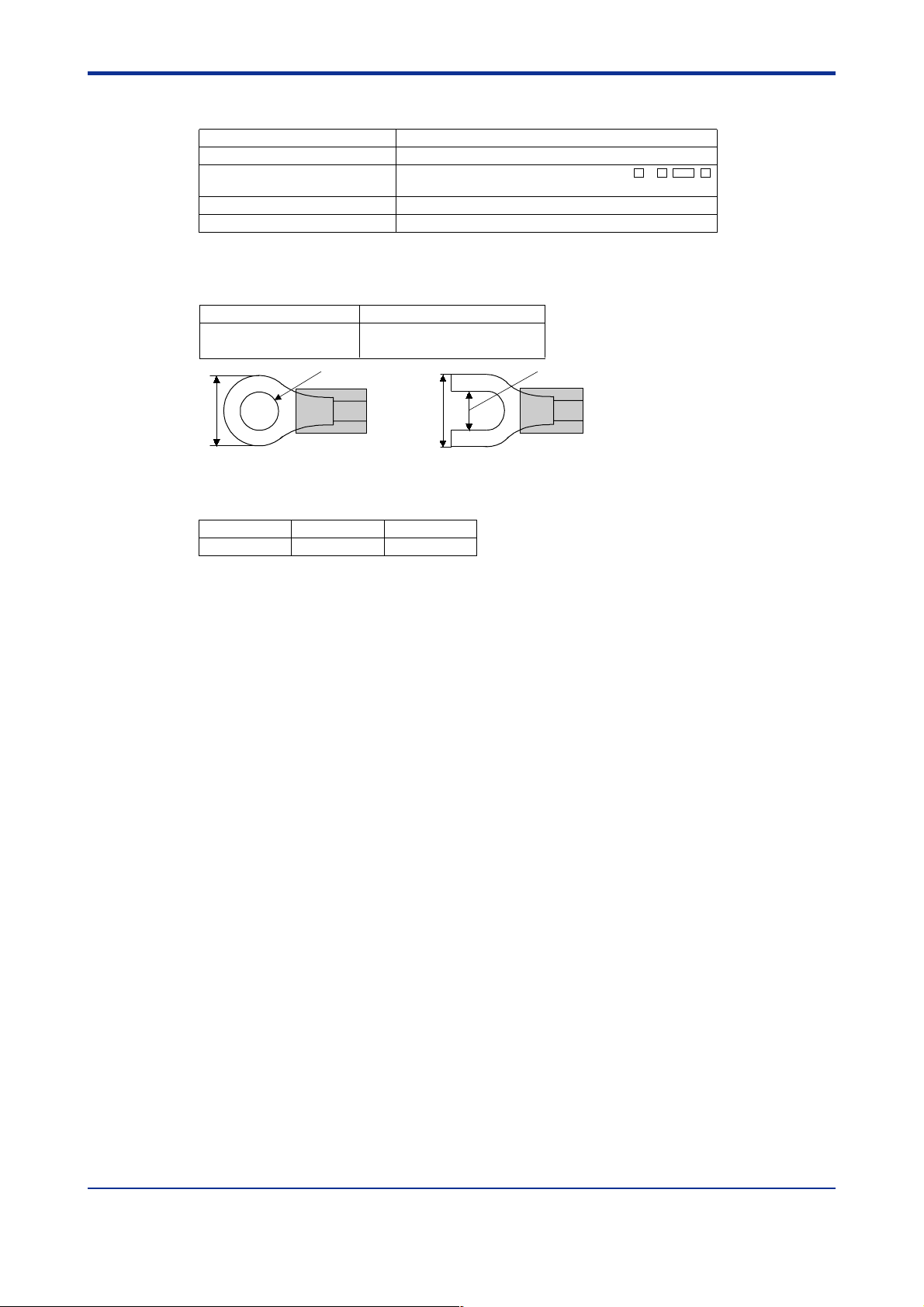

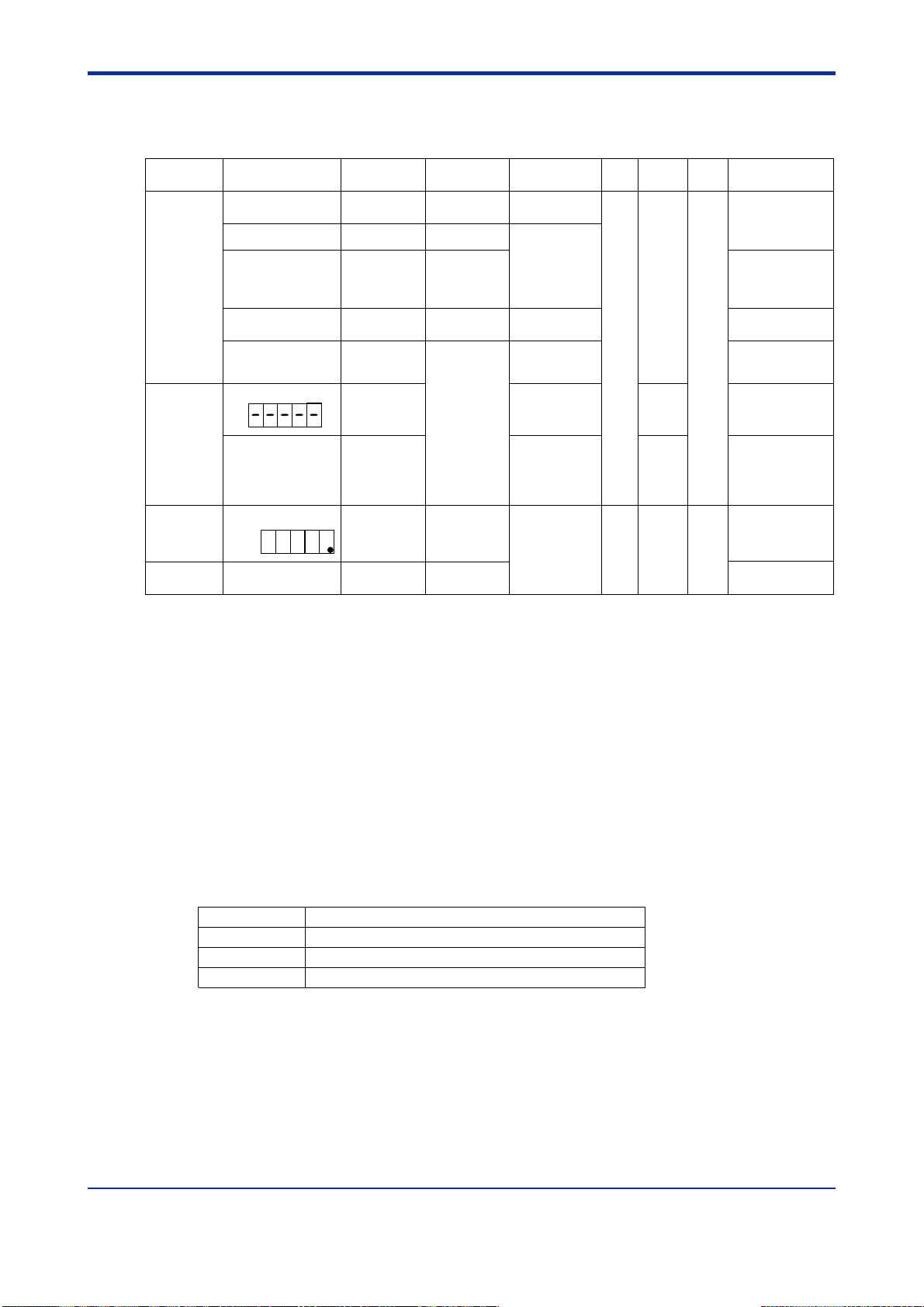

● Cable Specifications and Recommended Cables

Purpose Name and Manufacturer

Power supply, grounding, relay contact outputs

Thermocouple Shielded compensating lead wires, JIS C 1610, X- - -

RTD Shielded wires (three conductors), UL2482 (Hitachi Cable)

Other signals Shielded wires

600 V PVC insulated wires, JIS C 3307, 0.9 to 2.0 mm2

(See Yokogawa Electric’s GS 6B1U1-E.)

● Recommended Terminal Lugs

Applicable wire size Tightening torque

0.3 to 1.65 mm

2

0.8 N·m or less

1-6

3.7mm

7 mm or less

● Terminal Covers

Target Model Part Number Sales Unit

UT750 T9115YD 1

For

3.7mm

or

7 mm or less

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 13

<Toc> <1. Installation>

1.4 Hardware Specifications

PV Input Signals (Primary PV Input)

• Number of inputs: 1 (terminals 11-12-13)

• Input type: Universal input system. The input type can be selected with the software.

• Sampling period: 50, 100, 200 and 500 ms (The sampling period can be selected with

the software.)

Initial value; 200 ms

• Burnout detection: Functions at TC, RTD, standard signal (0.4 to 2 V or 1 to 5 V)

Upscale, downscale, and off can be specified.

For standard signal, burnout is determined to have occurred if it is 0.1 V or less.

• Input bias current: 0.05 A (for TC or RTD b-terminal)

• Measurement current (RTD): About 0.13 mA

• Input resistance: 1 M or more for thermocouple or mV input

About 1 M for DC voltage input

• Allowable signal source resistance: 250 or less for thermocouple or mV input

Effects of signal source resistance: 0.1 V/ or less

2 k or less for DC voltage input

Effects of signal source resistance: About 0.01%/100

1-7

• Allowable wiring resistance: for RTD input

Maximum 150 /wire: Conductor resistance between three wires should be equal

However, 10 /wire for a maximum range of -150.0 to 150.0C.

Wire resistance effect: 0.1C/10

• Allowable input voltage: 10 V DC for thermocouple, mV, or RTD input

20 V DC for DC voltage input

• Noise rejection ratio: 40 dB (50/60 Hz) or more in normal mode

120 dB (50/60 Hz) or more in common mode

• Reference junction compensation error: 1.0C (15 to 35C)

1.5C (0 to 15C, 35 to 50C)

• Applicable standards: JIS, IEC, DIN (ITS-90) for thermocouples and RTD

Auxiliary Analog Input Signals (Secondary PV Input)

Available only for controllers with auxiliary analog input terminals.

• Number of inputs: 1 (terminals

• Input type: Settable in a range of 0-2, 0-10, 0.4-2.0, or 1-5 V DC

• Sampling period: 100, 200 and 500 ms

The sampling period of an auxiliary analog input signal is associated with the PV

input’s sampling period. If the PV input’s sampling period is 50 ms, however, the

sampling period of an auxiliary analog input signal lengthens to 100 ms.

21-22

)

• Input resistance: About 1 M

• Input accuracy: 0.3% 1 digit of input span for 0 to 2 V DC

0.2% 1 digit of input span for 0 to 10 V DC

0.375% 1 digit of input span for 0.4 to 2.0 V DC

0.3% 1 digit of input span for 1 to 5 V DC

Under standard operating conditions (232C, 5510% RH, power frequency of 50/

60 Hz)

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 14

<Toc> <1. Installation>

Feedback Resistance Input

Provided for position proportional type only (terminals 45-46-47)

• Slide resistance value: 100 to 2.5 k of overall resistance (burnout detection for

sliding wire provided)

• Measuring resolution: 0.1% of overall resistance

Loop Power Supply

Power is supplied to a two-wire transmitter.

(15 V DC: terminals

14-15

)

A resistor (10 to 250 ) connected between the controller and transmitter converts a

current signal into a voltage signal, which is then read via the PV input terminal.

Supply voltage: 14.5 to 18.0 V DC, max. 21 mA (provided with a protection circuit

against a field short-circuit)

Retransmission Output

Either PV, target setpoint, or control output is output.

Either the retransmission output or the loop power supply can be used with terminals

14-15

.

1-8

• Number of outputs: 1 or 2 (terminals

14-15

, terminals 16-17)

• Output signal: 4-20, 0-20, 20-4, or 20-0 mA DC (where, outputting signal levels of less

than 0 mA is not feasible)

• Load resistance: 600 or less

• Output accuracy: 0.1% of span (5% of span for 1 mA or less.) under standard

operating conditions (232C, 5510% RH, power frequency of 50/60 Hz)

Control Output

Universal output system, The output type can be selected with the software.

Relay contact output(s) for the position proportional type.

• Current output

(Single-loop type: terminals

output: terminals

Number of outputs 1 or 2 (two for heating/cooling control),

Output signal 4-20, 0-20, 20-4, or 20-0 mA DC

Load resistance 600 or less

Output accuracy 0.1% of span

14-15

switched between a voltage pulse output

(5% of span for 1 mA or less)

Under standard operating conditions (232C,

5510% RH, power frequency of 50/60 Hz)

16-17

)

and current output.

; heating-side output: terminals 16-17, cooling-side

• Voltage pulse output

(Single-loop type: terminals

output: Not selected)

Number of

outputs1switched between a voltage pulse output and current output.

Output signal

Resolution

On-voltage = 12 V or more (load resistance: 600 Ω or more)

10 ms or 0.1% of output, whichever is larger

16-17

; heating-side output: terminals 16-17, cooling-side

Off-voltage = 0.1 V DC or less

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 15

<Toc> <1. Installation>

• Relay contact output

(Single-loop type: terminals

ing-side output: terminals

1-2-3

4-7

, heating-side output: terminals 1-2-3, cool-

, position proportional type: terminals 48-49-50)

1-9

Number of outputs

Output signal Three terminals (NC, NO, and common)

Contact rating 250 V AC or 30 V DC, 3 A (resistance load)

Resolution 10 ms or 0.1% of output, whichever is larger

1 or 2 (two for heating/cooling control)

Contact Inputs

• Purpose: Target setpoint selection, remote/local mode switching, and run/stop switching

• Number of inputs: 7

• Input type: Non-voltage contact or transistor open collector input

• Input contact rating: 12 V DC, 10 mA or more

• On/off determination: For non-voltage contact input, contact resistance of 1 k or less

is determined as “on” and contact resistance of 20 k or more as “off.”

For transistor open collector input, input voltage of 2 V or less is determined as “on”

and leakage current must not exceed 100 A when “off.”

• Minimum status detection hold time: PV input’s sampling period 3

Contact Outputs

• Purpose: Alarm output, FAIL output, and others

• Number of outputs: 7 (relay: 3, transistor: 4)

• Relay contact rating: 240 V AC, 1 A, or 30 V DC, 1 A (COM terminal is common)

• Transistor contact rating: 24 V DC, 50 mA (COM terminal is common)

Display Specifications

• PV display: 5-digit, 7-segment, red LEDs, character height of 20 mm for UT750

• Setpoint display: 32128 dot LCD display with back-light

• Status indicating lamps: LEDs

Safety and EMC Standards

• Safety: Compliant with IEC1010-1: 1990 and EN61010-1: 1992

Approved by CSA1010

CSA1010 installation category (overvoltage category): CATII (IEC1010-1)

Approved by UL508

• EMC standards: This instrument complies with the following EMC standards (the

instrument continues to operate at a measuring accuracy of within 20% of the range

during tests):

- EMI (emission), EN55011: Class A Group 1

- EMS (immunity), EN50082-2: 1995

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 16

<Toc> <1. Installation>

Construction, Installation, and Wiring

• Construction: Only the front panel is dust-proof and drip-proof (protection class IP55)

For side-by-side close installation the controller loses its dust-proof and drip-proof

protection.

• Material: ABS resin and polycarbonate

• Case color: Black

• Weight: About 1 kg or less

• Dimensions: 96 (W) 96 (H) 100 (depth from panel face) mm

• Installation: Panel-mounting type. With top and bottom mounting hardware (1 each)

• Panel cutout dimensions: 92

+0.8

(W) 92

0

+0.8

(H) mm

0

• Installation position: Up to 30 upward facing (not designed for facing downward)

• Wiring: M3.5 screw terminals (for signal wiring and power/ground wiring as well)

Power Supply Specifications

• Power supply: Rated voltage of 100 to 240 V AC (10%), 50/60 Hz

• Power consumption: Max. 20 VA (8.0 W max.)

1-10

• Data backup: Lithium cell with life expectancy of 10 years.

• Withstanding voltage

- Between primary terminals* and secondary terminals**:

At least 1500 V AC for 1 minute (Note)

- Between primary terminals* and grounding terminal:

At least 1500 V AC for 1 minute (Note)

- Between grounding terminal and secondary terminals**:

At least 1500 V AC for 1 minute

- Between secondary terminals**:

At least 500 V AC for 1 minute

* Primary terminals indicate power terminals and relay output terminals

** Secondary terminals indicate analog I/O signal, voltage pulse output, and contact

input terminals

Note: The withstanding voltage is specified as 2300 V AC per minute to provide a margin of safety.

• Insulation resistance: 20 M or more at 500 V DC between power terminals and

grounding terminal

• Grounding: Class 3 grounding (grounding resistance of 100 or less)

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 17

<Toc> <1. Installation>

Signal Isolations

• PV input (primary PV input) terminals: Isolated from other input/output terminals. Not

isolated from the internal circuit.

• Auxiliary analog input (secondary PV input) terminals: Isolated from other input/output

terminals and the internal circuit.

• 15 V DC loop power supply terminals: Not isolated from analog current output and

voltage pulse control output. Isolated from other input/output terminals and internal

circuit.

• Analog output terminals (for control output and retransmission): Not isolated between

analog outputs and from 15 V DC loop power supply and voltage pulse control output.

Isolated from other input/output terminals and internal circuit.

• Voltage pulse control output terminals: Not isolated from analog outputs and 15 V DC

loop power supply. Isolated from other input/output terminals and internal circuit.

• Relay contact control output terminals: Isolated between contact output terminals and

from other input/output terminals and internal circuit.

• Contact input terminals: Not isolated between contact input terminals and from communication terminals. Isolated from other input/output terminals and internal circuit.

• Relay contact output terminals: Not isolated between relay contact outputs. Isolated

from other input/output terminals and internal circuit.

1-11

• Transistor contact output terminals: Not isolated between transistor contact outputs.

Isolated from other input/output terminals and internal circuit.

• RS-485 communication terminals: Not isolated from contact input terminals. Isolated

from other input/output terminals and internal circuit.

• Feedback slide resistance input terminals: Not isolated from analog output terminals

(control, retransmission), 15 V DC loop power supply, and voltage pulse control

outputs. Isolated from other input/output terminals and internal circuit.

• Power terminals: Isolated from other input/output terminals and internal circuit.

• Grounding terminals: Isolated from other input/output terminals and internal circuit.

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 18

<Toc> <1. Installation>

Environmental Conditions

• Normal operating conditions:

Ambient temperature: 0 to 50C (40C or less for side-by-side close installation)

Temperature change rate: 10C/h or less

Ambient humidity: 20 to 90% RH (no condensation allowed)

Magnetic field: 400 A/m or less

Continuous vibration at 5 to 14 Hz: Full amplitude of 1.2 mm or less

Continuous vibration at 14 to 150 Hz: 4.9 m/s

Short-period vibration: 14.7 m/s

Shock: 14.7 m/s

2

or less, 11 ms

2

, 15 seconds or less

Installation height: Height above sea level of 2000 m or less

Warm-up time: 30 minutes or more after power on

• Transportation and storage conditions:

Temperature: -25 to 70C

Temperature change rate: 20C/h or less

Humidity: 5 to 95% RH (no condensation allowed)

• Effects of changes in operating conditions

- Effects from changes in ambient temperature:

- On voltage or thermocouple input, 1 V/C or 0.01% of F.S./C,

whichever is larger

2

or less

1-12

- On auxiliary analog input, 0.02% of F.S./C

- On RTD input, 0.05C/C (ambient temperature) or less

- On analog output, 0.05% of F.S./C or less

- Effects from power supply fluctuation (within rated voltage range)

- On analog input, 1 V/10 V or 0.01% of F.S./10 V, whichever is larger

- On analog output, 0.05% of F.S./10 V or less

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 19

<Toc> <1. Installation>

1.5 Terminal Wiring Diagrams

NOTE

Do not use unassigned terminals as relay terminals.

Terminal wiring diagrams are shown on and after the next page.

1-13

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 20

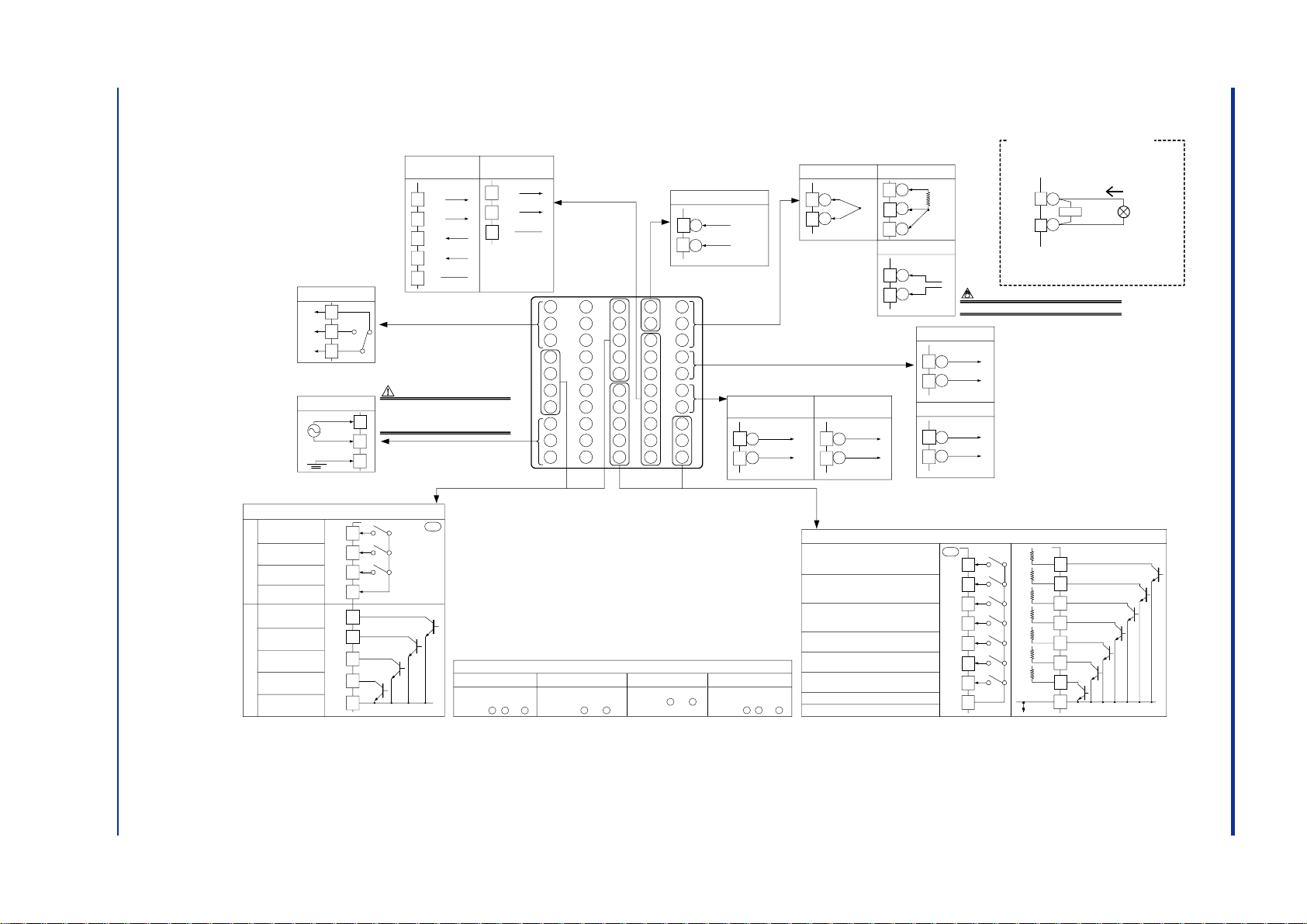

■ UT750 Cascade Control (Model UT750-01 or UT750-51)

1

2

3

4

5

6

7

8

9

10

41

42

43

44

45

46

47

48

49

50

31

32

33

34

35

36

37

38

39

40

21

22

23

24

25

26

27

28

29

30

11

12

13

14

15

16

17

18

19

20

28

29

High performance

RS-485 communication

* Wiring can only be carried out

for controllers with

communication functions.

30

RDB(+)

RDA(-)

SG

* The functions of the external contact outputs are the defaults for cascade control.

To change the functions, reconfigure the contact output registration setup parameters.

Note 1: The alarm 3 output parameters of the DO3 and DO5 outputs share the same

function.

Note 2: The alarm 4 output parameters of the DO4 and DO6 share the same function.

Communication 1

(PSL1)

Communication 2

(PSL2)

1

2

Relay contact output

3

Control output

NC

NO

COM

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

*

Time proportional PID relay contact

output is configured at factory

before shipment.

Note: Select this option from

the OT2 parameter.

8

9

Power supply

10

L

N

A

llowable range: 100-240 V AC (

10%)

(free voltage)

50/60 Hz shared

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

23

24

RS-485 communication

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

21

22

*

Wiring can only be carried out for

controllers with auxiliary analog input.

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Default: 1-5 V DC

12

13

TC input

11

12

RTD input

13

12

13

mV/V input

Installation category (overvoltage category): II (IEC1010-1)

A

b

B

NOTE

-

+

-

+

Primary

PV input

*

Not configured at factory before shipment

See “2. Initial Settings.

”

12

13

Note: Connecting a 250

Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint

“41”).

䊏

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

-

+

* Factory-set to

“PV retransmission.

”

* Retransmission output 1 is not available

if a 15 V DC loop power supply is used.

14

15

Retransmission output 1*

4-20 or

0-20 mA DC

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

Default: 4-20 mA DC

-

+

-

+

Load resistance: 600

Ω or less

16

17

Current/voltage

pulse output

0-20mADC,

4-20mADC

Voltage pulse (12 V)

Control output

* Retransmission output 2 is available

only when

“relay” is selected as the

type of control output.

16

17

Retransmission

output 2*

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

-

+

Default: Unspecified

retransmission type

Note: Select this option from the OT2 parameter.

19

18

External contact inputs

40

39

38

37

20

DI1

DI2

DI3

DI4

DI5

DI6

COM

19

18

40

39

38

37

20

DI1

DI2

DI3

DI4

DI5

DI6

COM

+5V

+5V

+5V

+5V

+5V

+5V

36

DI7

36

DI7

+5V

Contact Transistor contact

UT

OT2=0 (factory-set default)

OT2=1

Correspondence between parameter OT2 and control output types

OT2=2

OT2=3

* OT2 is a setup parameter.

You can change the settings of the parameter OT2 to change the control output types.

See

“2. Initial Settings.

”

Time proportional control

Relay output

(terminals , and )

1

2

3

Time proportional control

Voltage pulse output

(terminals and )

16 17

Current output

(terminals and )

16

17

On-off control

Relay output

(terminals , and )

1

2

3

6

5

External contact outputs

4

7

34

33

DO1

DO2

DO3

COM

DO4

DO5

Relay Transistor

Alarm 3 output

(Note 1)

Alarm 1 output

Alarm 2 output

Alarm 3 output

(Note 1)

Common

Alarm 4 output

(Note 2)

32

DO6

31

DO7

35

COM

Alarm 4 output

(Note 2)

Common

UT

No function

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

Transistor contact rating: 24 V DC, 50 mA

Auxiliary analog input

Secondary PV input

* The functions of the external contact inputs are the defaults for cascade control.

To change the functions, reconfigure the contact input registration parameters.

Contact rating: 12 V DC, 10 mA or more

Note: External Contact Input

If the power is turned on when the external contact input (either of Cascade, Automatic,

and Manual) is ON, the controller judges that the external contact input is changed to ON.

Common

No function (DI7)

Display message when

DI6 changes to on

REMORT when DI5=ON

LOCAL when DI5=OFF

STOP when DI4=ON

RUN when DI4=OFF

(both primary and

secondary)

Cascade switching when

DI1 changes to on

(primary=AUTO, secondary=cascade)

Automatic switching when

DI2 changes to on

(primary=tracking, secondary=automatic)

Manual switching when

DI3 changes to on

(primary=tracking, secondary=manual)

<Toc> <1. Installation>

IM 05D01B02-44E

1st Edition : May 31,2000-00

1-14

Page 21

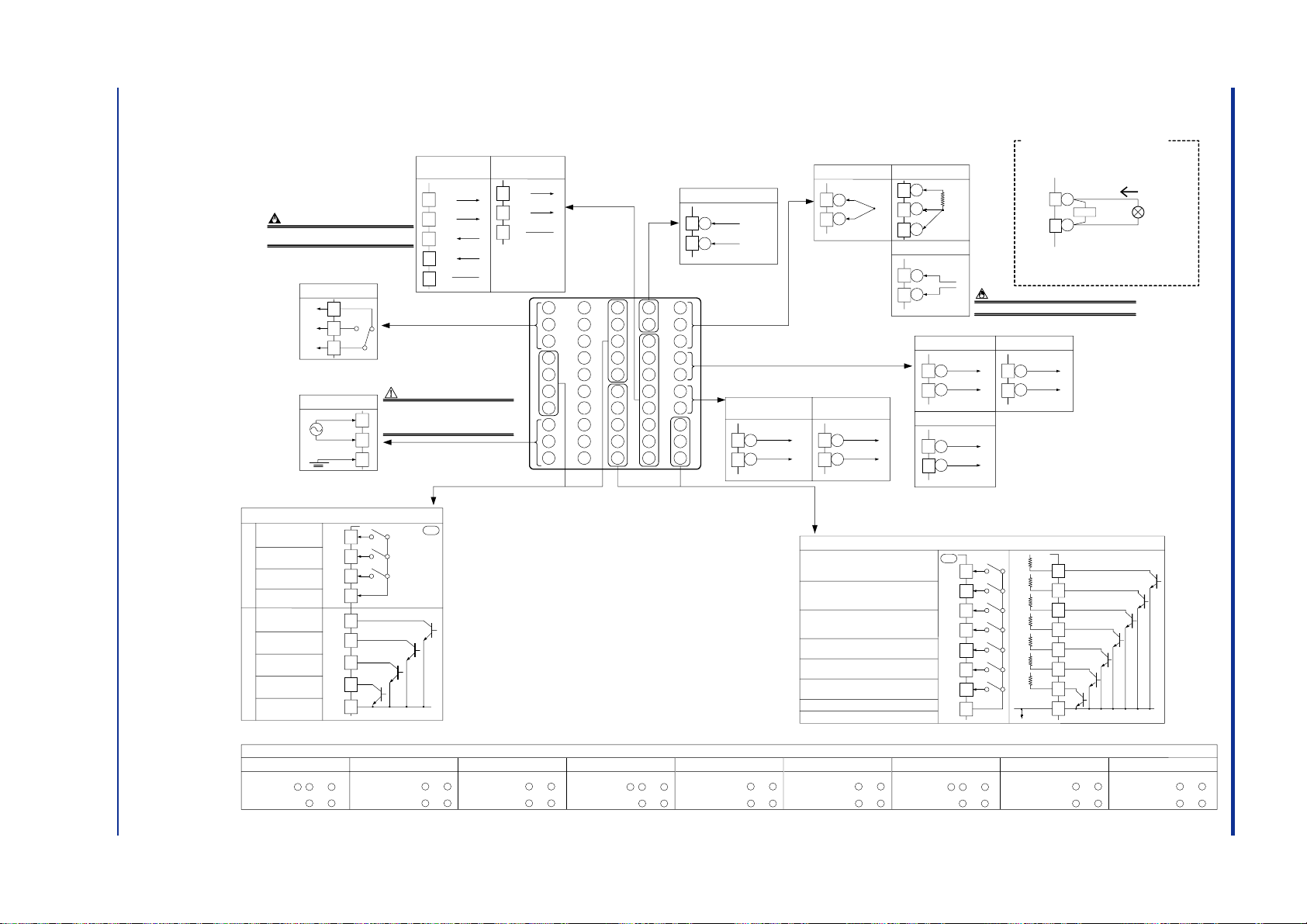

■ UT750 Cascade Heating/Cooling Control (Model UT750-01 or UT750-51)

1

2

3

4

5

6

7

8

9

10

41

42

43

44

45

46

47

48

49

50

31

32

33

34

35

36

37

38

39

40

21

22

23

24

25

26

27

28

29

30

11

12

13

14

15

16

17

18

19

20

Change the setting of the Control Output Type

(OT2) parameter to the Heating/Cooling Control.

IMPORTANT

8

9

10

L

N

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

Power supply

Power supply

A

llowable range: 100-240 V AC (

10%)

(free voltage)

50/60 Hz shared

1

2

3

NC

NO

COM

Relay contact output

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

Note: Select this option from the

OT2 parameter.

28

29

High performance

RS-485 communication

* Wiring can only be carried out

for controllers with

communication functions.

30

RDB(+)

RDA(-)

SG

Communication 1

(PSL1)

Communication 2

(PSL2)

23

24

RS-485 communication

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

21

22

*

Wiring can only be carried out for

controllers with auxiliary analog input.

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Default: 1-5 V DC

12

13

TC input

11

12

RTD input

13

12

13

mV/V input

Installation category (overvoltage category): II (IEC1010-1)

A

b

B

NOTE

-

+

-

+

Primary

PV input

*

Not configured at factory before shipment

See “2. Initial Settings.

”

12

13

Note: Connecting a 250

Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint

“41”).

䊏

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

-

+

* Retransmission output 1 is not available if a

15 V DC loop power supply is used.

* If you define the cooling-side output as

current output, retransmission output 1 and

the 15 V DC loop power supply can no longer

be used.

Cooling-side control output

Retransmission output 1*

14

15

4-20 or

0-20 mA DC

Default: 4-20 mA DC

-

+

14

15

4-20 or

0-20 mA DC

Default: 4-20 mA DC

-

+

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

-

+

* Factory-set to

“PV retransmission.

”

16

17

Current/voltage

pulse output

0-20mADC,

4-20mADC

Voltage pulse (12 V)

16

17

Retransmission

output 2*

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

-

+

Default: Unspecified

retransmission type

* Retransmission output 2 is available

only when

“relay” is selected as the

type of heating-side control output.

Note: Select this option from the OT2 parameter.

Heating-side

control output

Contact rating: 12 V DC, 10 mA or more

19

18

External contact inputs

40

39

38

37

20

DI1

DI2

DI3

DI4

DI5

DI6

COM

19

18

40

39

38

37

20

DI1

DI2

DI3

DI4

DI5

DI6

COM

+5V

+5V

+5V

+5V

+5V

+5V

36

DI7

36

DI7

+5V

Contact Transistor contact

UT

6

5

External contact outputs

4

7

34

33

DO1

DO2

DO3

COM

DO4

DO5

Relay Transistor

Alarm 3 output

Alarm 1 output

Alarm 2 output

Cooling-side control

output (Note)

Common

Cooling-side control

output (Note)

32

DO6

31

DO7

35

COM

Alarm 4 output

Common

UT

No function

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

Transistor contact rating: 24 V DC, 50 mA

* The functions of the external contact outputs are the defaults for cascade

heating/cooling control. To change the functions, reconfigure the contact output

registration setup parameters.

Note: If you define the DO3 output as the cooling-side control output, the DO4 output

serves as the alarm 4 output. Inversely, if you define the DO4 output as the

cooling-side control output, the DO3 output serves as the alarm 3 output.

OT2=4 OT2=5

Correspondence between parameter OT2 and heating-side output types/cooling-side output types

OT2=6

OT2=7 OT2=8 OT2=9 OT2=10 OT2=11 OT2=12

The types of control output,

“relay output

” and “voltage pulse output

” shown in the table above refer to those of time proportional control.

To change to a relay output for on-off control, select

“Relay Terminals

” and change the setpoint of the proportional band to

“0.”

Heating side: Relay output

(terminals , and )

Cooling side: Relay output

(terminals and )

1

2

3

Heating side: Voltage pulse output

(terminals and )

Cooling side: Relay output

(terminals and )

16 17

Heating side: Current output

(terminals and )

Cooling side: Relay output

(terminals and )

16

17

Heating side: Relay output

(terminals , and )

Cooling side: Transistor output

(terminals and )

1

2

3

Heating side: Relay output

(terminals , and )

Cooling side: Current output

(terminals and )

1

2

3

Heating side: Voltage pulse output

(terminals and )

Cooling side: Transistor output

(terminals and )

16 17

Heating side: Current output

(terminals and )

Cooling side: Transistor output

(terminals and )

16

17

Heating side: Voltage pulse output

(terminals and )

Cooling side: Current output

(terminals and )

16 17

Heating side: Current output

(terminals and )

Cooling side: Current output

(terminals and )

16

17

* OT2 is a setup parameter.

You can change the settings of the parameter OT2 to change the control output types. See

“2. Initial Settings.

”

35

34

35

34

35

34

15

14 15

14

15

14

4

7

4

7

4

7

Heating-side control output

Auxiliary analog input

Secondary PV input

Note: External Contact Input

If the power is turned on when the

external contact input (either of

Cascade, Automatic, and Manual) is ON,

the controller judges that the external

contact input is changed to ON.

Common

No function (DI7)

Display message when

DI6 changes to on

REMORT when DI5=ON

LOCAL when DI5=OFF

STOP when DI4=ON

RUN when DI4=OFF

(both primary and

secondary)

Cascade switching when

DI1 changes to on

(primary=AUTO, secondary=cascade)

Automatic switching when

DI2 changes to on

(primary=tracking, secondary=automatic)

Manual switching when

DI3 changes to on

(primary=tracking, secondary=manual)

* The functions of the external contact inputs are the defaults for cascade heating/cooling control.

To change the functions, reconfigure the contact input registration parameters.

<Toc> <1. Installation>

IM 05D01B02-44E

1st Edition : May 31,2000-00

1-15

Page 22

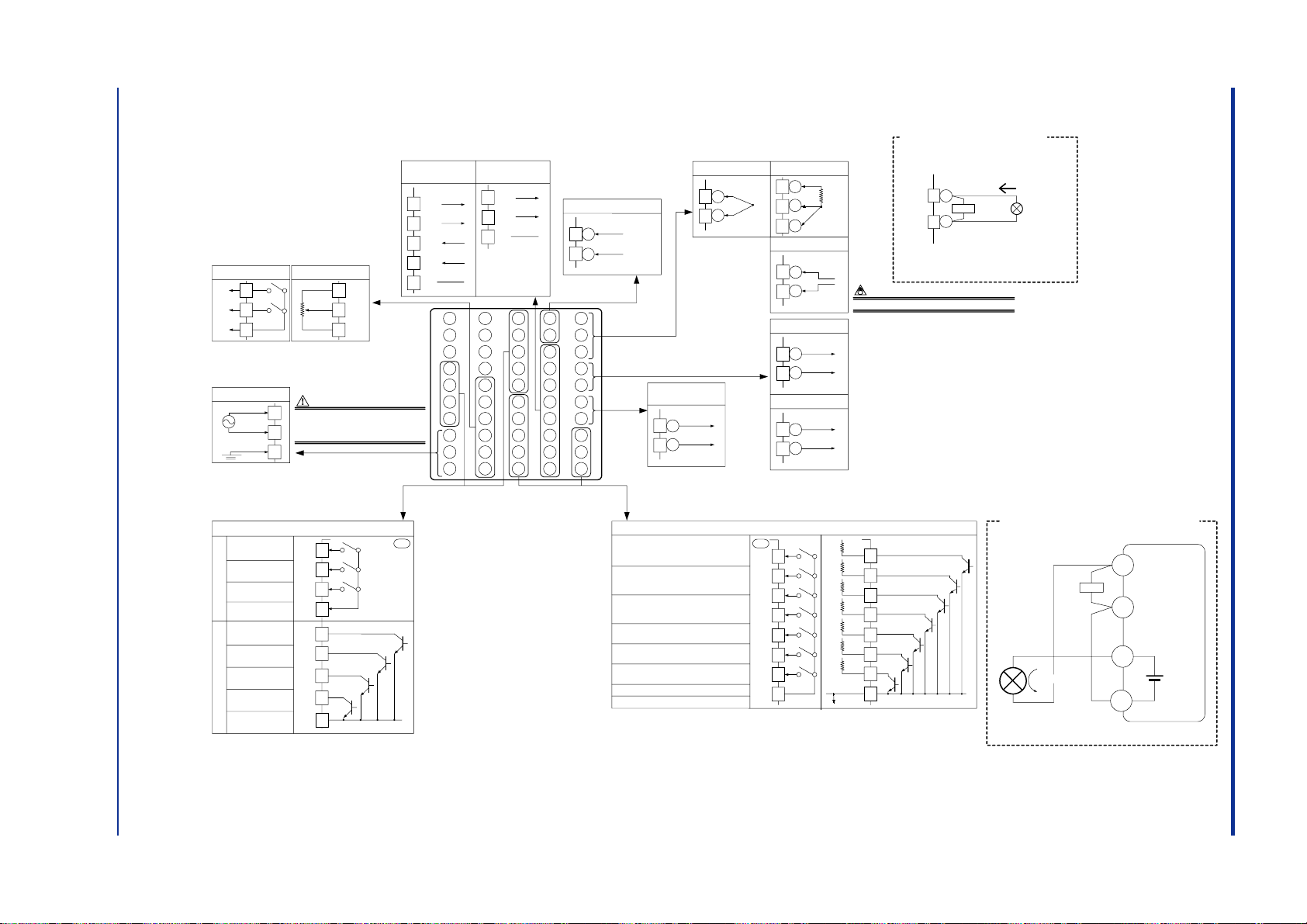

1

2

3

4

5

6

7

8

9

10

41

42

43

44

46

47

48

49

50

31

32

33

34

35

36

37

38

39

40

21

22

23

24

25

26

27

28

29

30

11

12

13

14

15

16

17

18

19

20

45

28

29

High performance

RS-485 communication

* Wiring can only be carried out

for controllers with

communication functions.

30

RDB(+)

RDA(-)

SG

Communication 1

(PSL1)

Communication 2

(PSL2)

23

24

RS-485 communication

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

21

22

*

Wiring can only be carried out for

controllers with auxiliary analog input.

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Default: 1-5 V DC

* PV retransmission is configured at factory

before shipment.

* If 15 V DC loop power supply is used,

retransmission output 1 cannot be used.

14

15

Retransmission output 1*

4-20 or

0-20 mA DC

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

Default: 4-20 mA DC

-

+

-

+

Load resistance: 600

Ω or less

Contact rating: 12 V DC, 10 mA or more

19

18

External contact inputs

40

39

38

37

20

DI1

DI2

DI3

DI4

DI5

DI6

COM

19

18

40

39

38

37

20

DI1

DI2

DI3

DI4

DI5

DI6

COM

+5V

+5V

+5V

+5V

+5V

+5V

36

DI7

36

DI7

+5V

Contact Transistor contact

UT

* The functions of the external contact outputs

are the defaults for cascade position

proportional control. To change the functions,

reconfigure the contact output registration

setup parameters.

Note 1: The alarm 3 output parameters of

the DO3 and DO5 outputs share the

same function.

Note 2: The alarm 4 output parameters of

the DO4 and DO6 share the same

function.

6

5

External contact outputs

4

7

34

33

DO1

DO2

DO3

COM

DO4

DO5

Relay Transistor

Alarm 3 output

(Note 1)

Alarm 1 output

Alarm 2 output

Alarm 3 output

(Note 1)

Common

Alarm 4 output

(Note 2)

32

DO6

31

DO7

35

COM

Alarm 4 output

(Note 2)

Common

UT

No function

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

Transistor contact rating: 24 V DC, 50 mA

8

9

Power supply

10

L

N

A

llowable range: 100-240 V AC (

10%)

(free voltage)

50/60 Hz shared

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

16

17

Retransmission

output 2

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

Default: Unspecified

retransmission type

Feedback input

Resistance: 100

to 2.5 k

Position proportional control output

48

49

Relay contact output

50

H

(Direct)

L

(Reverse)

COM

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

0%

100%

47

46

45

䊏 15 V DC Power Supply Wired to Sensor in

Two-wire System Configuration

12

13

14

15

100

Two-wire

transmitter

PV input

0.4-2.0 V DC

signal

Loop power

supply

14.5-

18.0 V DC

External

resistor

(Note)

4-20mADC

Note: Connecting a 100

resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

Auxiliary analog input

Secondary PV input

12

13

TC input

11

12

RTD input

13

12

13

mV/V input

Installation category (overvoltage category): II (IEC1010-1)

A

b

B

NOTE

-

+

-

+

*

Not configured at factory before shipment

See “2. Initial Settings.

”

12

13

Note: Connecting a 250

Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint

“41”).

䊏

Receiving 4-20 mA DC Current

Signals with the Controller

250

Ω

4-20mA

-

+

Primary

PV input

Common

No function (DI7)

Display message when

DI6 changes to on

REMORT when DI5=ON

LOCAL when DI5=OFF

STOP when DI4=ON

RUN when DI4=OFF

(both primary and

secondary)

Cascade switching when

DI1 changes to on

(primary=AUTO, secondary=cascade)

Automatic switching when

DI2 changes to on

(primary=tracking, secondary=automatic)

Manual switching when

DI3 changes to on

(primary=tracking, secondary=manual)

* The functions of the external contact inputs are the defaults for cascade position

proportional control.

To change the functions, reconfigure the contact input registration parameters.

Note: External Contact Input

If the power is turned on when the external contact input (either of Cascade, Automatic,

and Manual) is ON, the controller judges that the external contact input is changed to ON.

IM 05D01B02-44E

1st Edition : May 31,2000-00

■ UT750 Cascade Position Proportional Control (Model UT750-11)

<Toc> <1. Installation>

1-16

Page 23

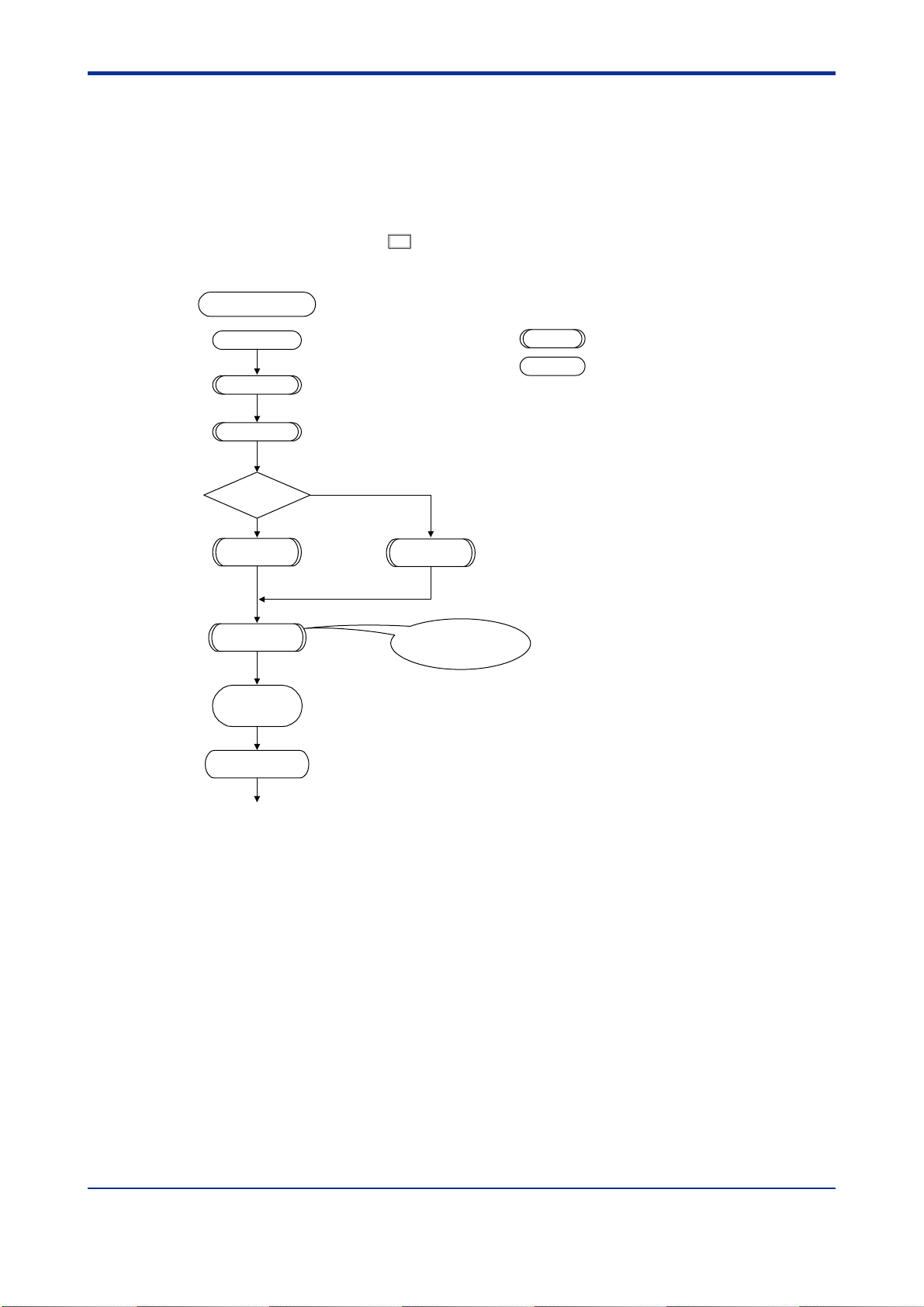

<Toc> <2. Initial Settings>

2. Initial Settings

This chapter describes examples of setting PV input types, control output types, and

alarm types. Carrying out settings described herein allows you to perform basic

control. Refer to examples of various settings to understand how to set parameters

required. Refer to “5.1 Parameter Map” for an easy to understand explanation of

setting various parameters. If you cannot remember how to carry out an operation

during setting, press the

display (operating display) that appears at power-on.

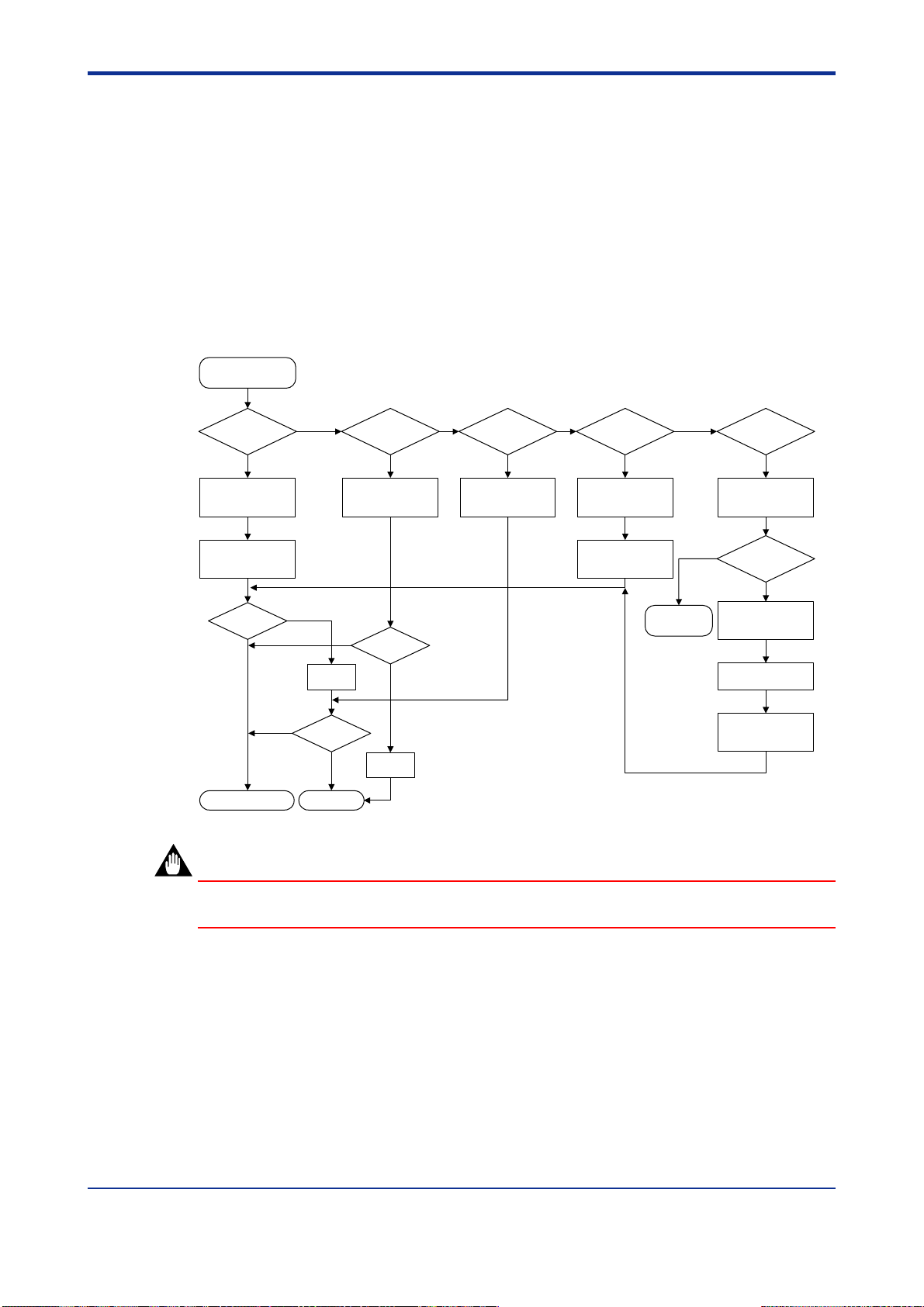

Setup Procedure

DISP

key no more than four times. This brings you to the

2-1

Power-on

Set UT mode “4”

Set PV input

Position

proportional

controller?

Calibrate valve

position.

See “2.6 Calibrating Valve Position.”

Initialize

parameters.

See “2.7 Initializing Parameters.”

Set the alarm

type and other setup

parameters.

Set operating

parameters.

(Factory-set to Single-loop Control “UT mode 1”)

See “2.2 Setting UT mode (Setting First at Power-on)”

or “2.3 Changing UT mode.”

(Factory-set to : Primary PV input is “not configured”,

Secondary PV input is “standard signal (1-5 V DC).”)

See “2.4 Setting Primary and Secondary PV Input Types.”

No

Yes

step whenever a chang of setting

Set the control

output.

See “2.5 Setting Control Output Type.”

Be sure to follow this

is made to the UT mode or

PV input type.

(Factory-set to “Time Proportional Relay Output.”)

Denotes a step that must always be followed.

Denotes a step that should be followed as necessary.

Controller operation

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 24

<Toc> <2. Initial Settings>

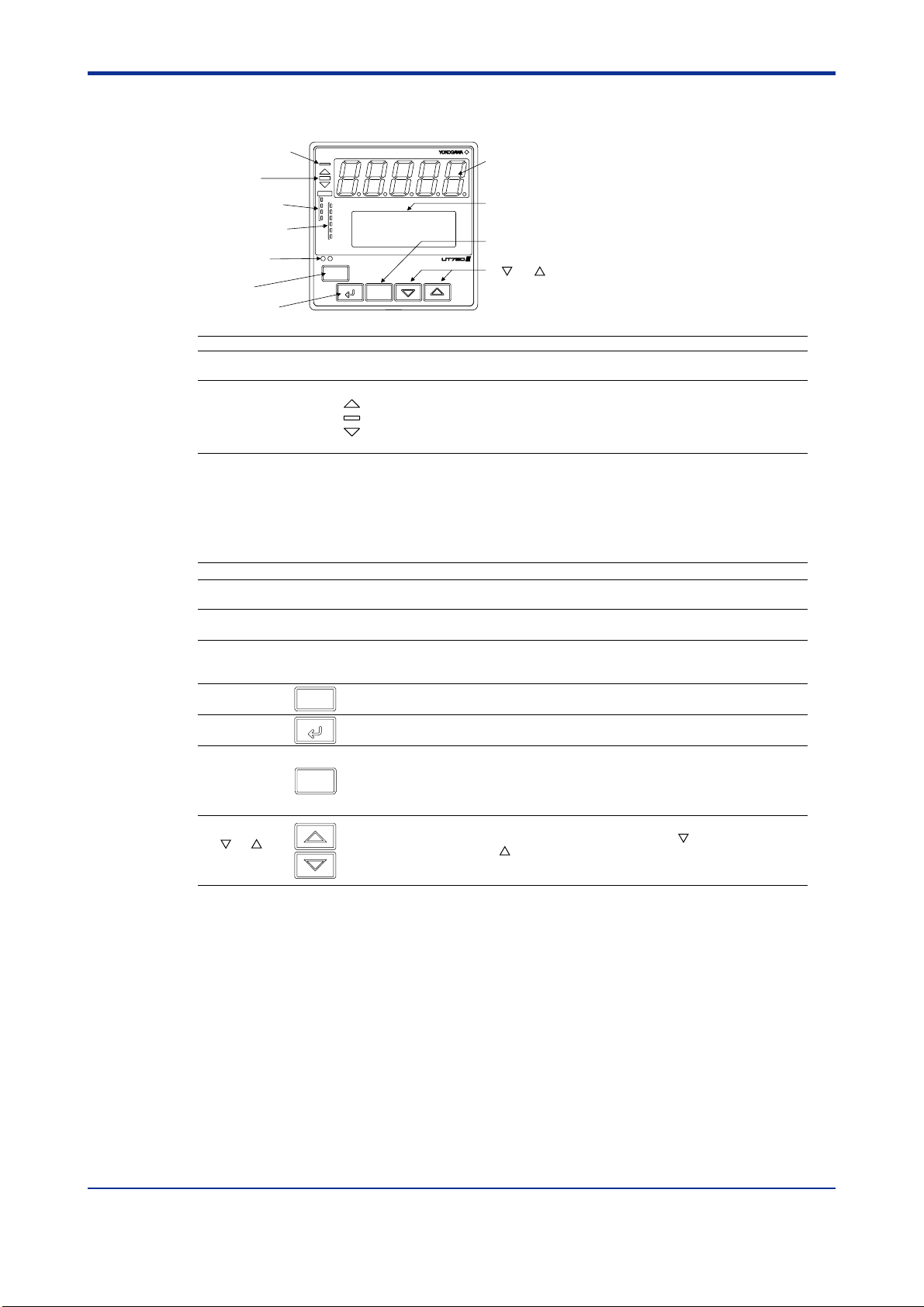

2.1 Names and Functions of Front Panel Parts

2-2

1. Indicator lamp

for display of PV2

2. Deviation

monitor

4. Alarm indicator

lamps

3. Status indicator

lamps

5. Light-loader

interface

8.A/M key

9.SET/ENT key

Name of Part

Indicator lamp for

1.

display of PV2

2. Deviation monitor

Status indicator

3.

lamps

4. Alarm indicator lamps

5. Light-loader interface

Process variable (PV)

6.

display

7. Setpoint display (LCD)

8. A/M key

9. SET/ENT key

10.

DISP key

and

11.

keys

A/M

SET/ENT

DISP

PV

PV2

AL

1

2

CAS

3

REM1

REM2

4

MAN1

MAN2

STP

A/M

SET/ENT

DISP

6.Process variable

(PV) display

7.Setpoint

display

10

.DISP key

11

. and keys

Function

Is lit when secondary PV is displayed on PV display.

When lit, indicates the status of a deviation (PV - SP).

: Is lit (in orange) if a deviation exceeds the deviation display range.

: Is lit (in green) when a deviation is within the deviation display range.

: Is lit (in orange) if a deviation falls below the deviation display range.

The deviation monitor goes off if any display other than the operating display or SELECT display is shown.

Is lit (in green) to indicate the status of operation or control.

CAS: Is lit when in

cascade

mode.

REM1: Is lit when in remote mode.

cascade

REM2: Not used in

control.

MAN1: Is lit when in manual mode. Blinks during auto-tuning of the primary-loop.

MAN2: Blinks during auto-tuning of the secondary-loop.

STP: Is lit when operation stopped.

Is unlit when a setup parameter setting display is shown.

If any of alarms 1 to 4 occurs, the respective alarm indicator lamp (AL1 to AL4) is lit (in orange).

Interface for an adapter cable used when setting and storing parameters from a PC.

This requires an optional parameter setting tool.

Displays PV.

Displays an error code (in red) if an error occurs.

the name and value of a target setpoint (SP), output (OUT), deviation (DV), deviation

Displays

trend, valve opening or a parameter.

Displays

an error code if the controller fails.

Used to switch between the AUTO and MAN modes. Each time you press the key, it switches to the

AUTO or MAN mode alternately.

Used to switch or register a parameter. Pressing the key for more than 3 second allows you to switch

between the operating display and the main menu for operating parameter setting display alternately.

Used to switch between displays. Pressing this key while any operating display is shown lets

you switch to another prearranged operating display. Pressing this key while any display other

than an operating display is shown lets you go back one display. (One to four presses (maximum)

of this key lets you return to the current operating display, though the number of presses depends

on the operating status.)

Used to change numerical values. On setting displays for various parameters, you can change target

setpoints, parameters, and output values (in manual operation). Pressing the key decreases a

numerical value, while pressing the key causes it to increase. You can hold down a key to gradually

increase the speed of change. These keys also switch between menu displays when a main menu or

submenu of parameter setting display is shown.

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 25

<Toc> <2. Initial Settings>

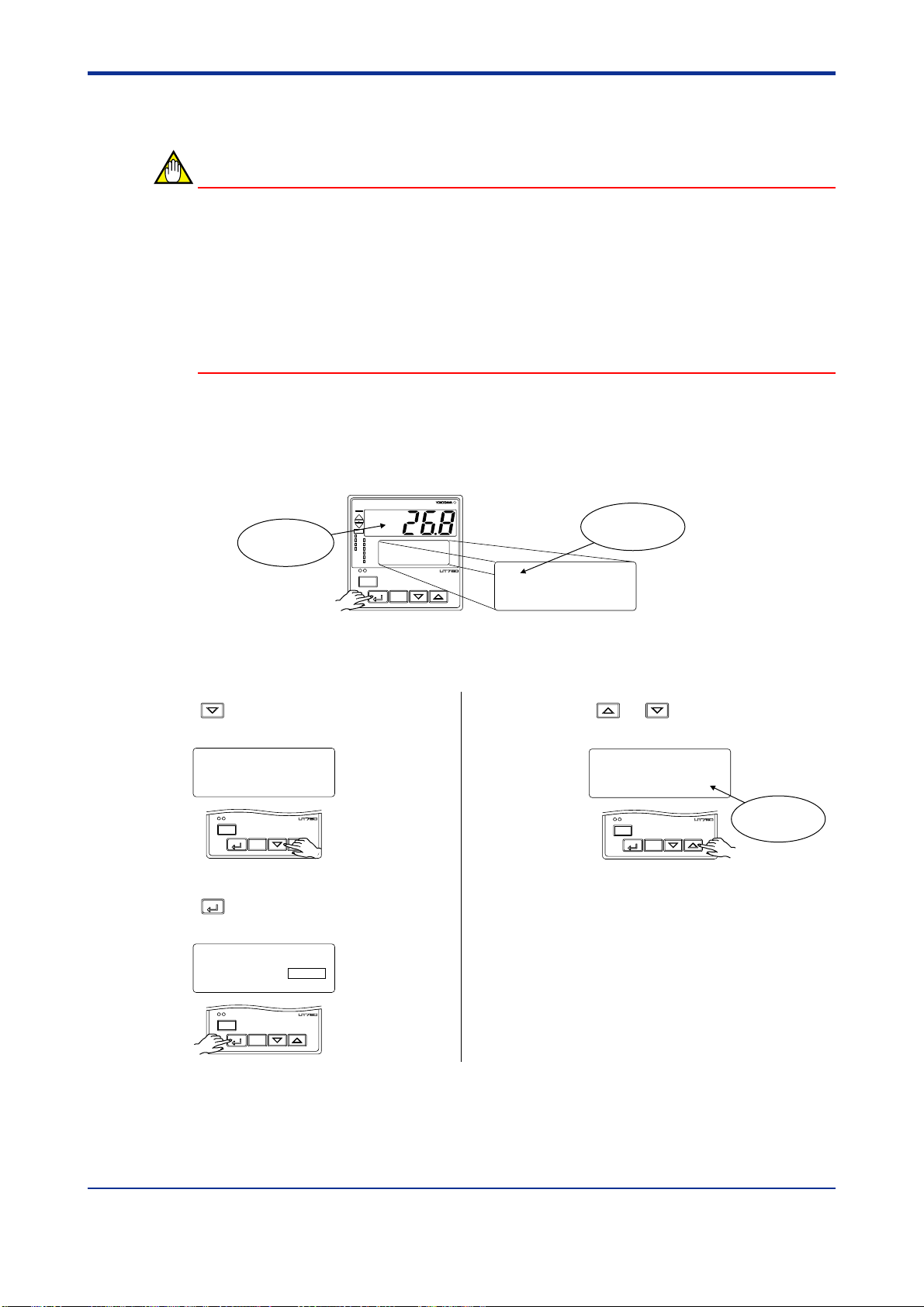

2.2 Setting UT mode (Setting First at Power-on)

NOTE

• The controller displays an operating display when the power is turned on. The

submenu “IN” appears at this point if the type of PV input has not been defined yet.

In this case, set a UT mode to “Cascade Control,” following the operating procedure

described below. Then, set PV input type, control output type and others.

• The controller is configured to the default of each parameter at the factory before

shipment.

First check these defaults listed in “5.2 Lists of Parameters” and change their values if

necessary.

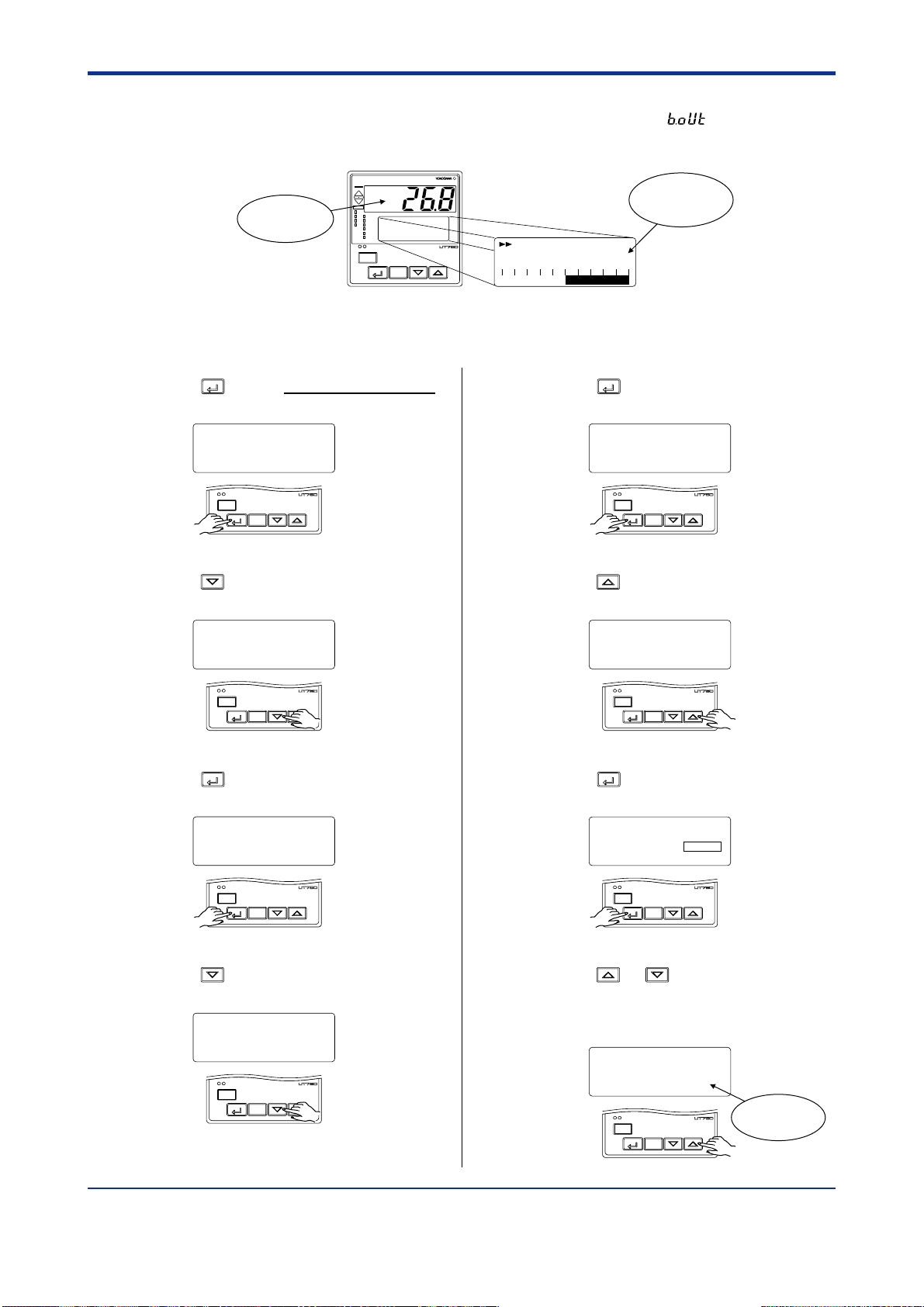

The following operation describes a procedure of setting a UT mode to “Cascade Control.”

(set “4”)

Display view at power on

1.

PV

Displays PV.

PV2

AL

AL

1

2

CAS

REM1

3

REM2

4

MAN1

MAN2

STP

A/M

SET/ENT

DISP

IN

input set

SETUP sub menu

Displays

submenu “IN”.

2-3

In steps 2 and later, illustrations of the LCD are cited to explain the procedure.

Press the key once to display the

2.

submenu “MD”.

Press the or key to display the

4.

setpoint “4”.

MD

UT mode set

SETUP sub menu

A/M

SET/ENT

DISP

Press the

3.

parameter “UTM” (controller mode).

SET/ENT

key once to display the

MENU:UTMD/MD #1

UT mode select

UTM = 1

A/M

SET/ENT

SETUP

DISP

MENU:UTMD/MD #1

UT mode select

UTM = 4

A/M

SET/ENT

changing

DISP

Blinks during

change.

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 26

<Toc> <2. Initial Settings>

2-4

5.

Press the

SET/ENT

key once to register the

6.

setpoint “4”.

MENU:UTMD/MD #1

UT mode select

UTM = 4

A/M

SET/ENT

SETUP

DISP

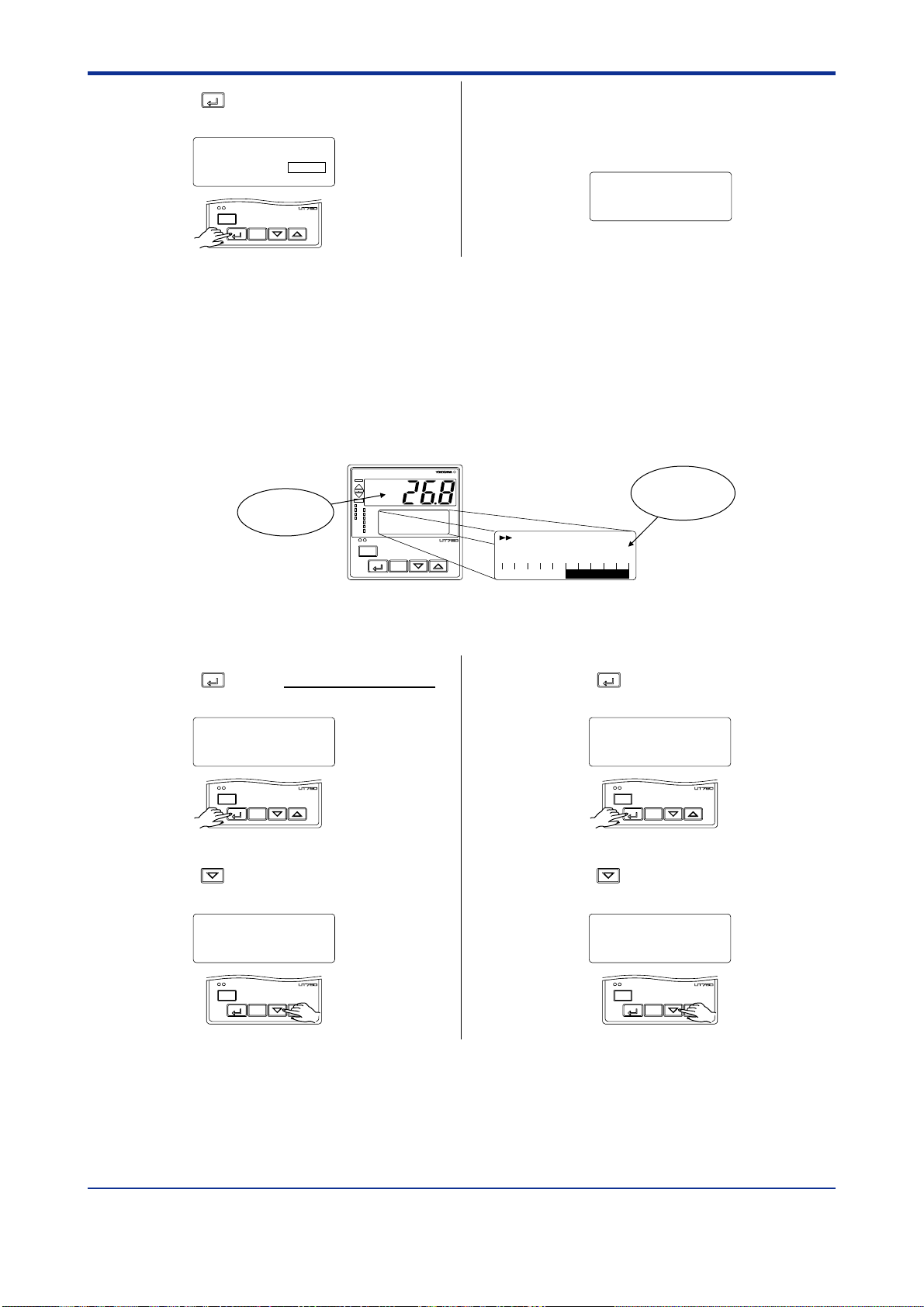

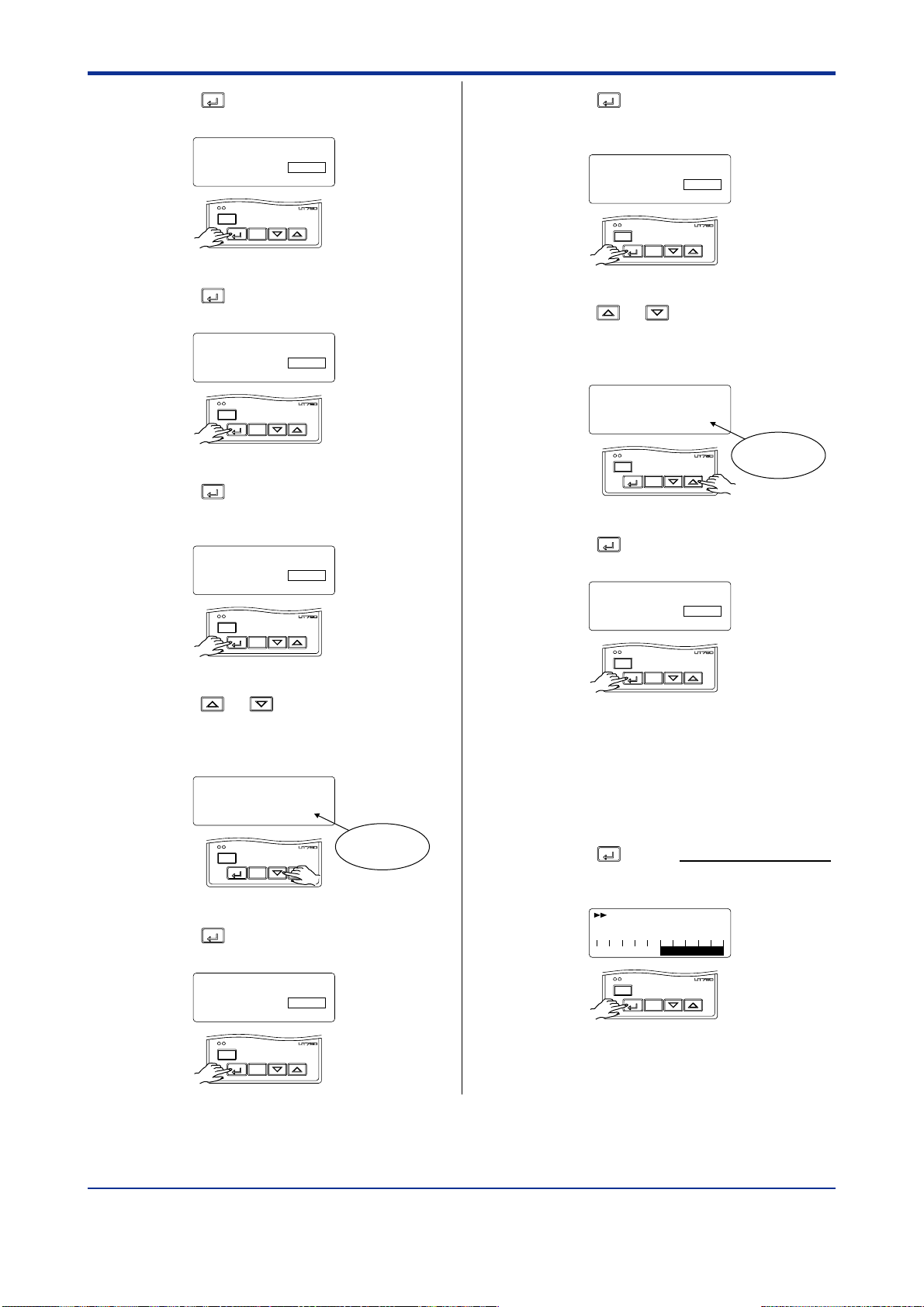

2.3 Changing UT mode

The following operation describes a procedure of changing a UT mode to “Cascade Control.” (set “4”)

Bring the operating display into view (display appears at power-on).

1.

PV

PV2

AL

AL

1

2

CAS

REM1

Displays PV.

3

REM2

4

MAN1

MAN2

STP

A/M

SET/ENT

DISP

SP :1.

-10 0 +10

DV

The controller re-starts (which is normal).

Then, set the primary and secondary PV

input types. See “2.4 Setting Primary and

Secondary PV Input Types.”

IN

input set

SETUP sub menu

Displays

target setpoint-1

“1.SP”.

-270.0°C

In steps 2 and later, illustrations of the LCD are cited to explain the procedure.

Press the

2.

to call up the main menu “MODE”.

SET/ENT

key for more than 3 seconds

Press the

4.

menu “LOOP1”.

MODE

mode parameter

Press the key once to display the main

3.

menu “STUP”.

A/M

SET/ENT

main menu

DISP

Press the key once to display the main

5.

menu “UTMD”.

STUP

password input

A/M

SET/ENT

main menu

DISP

SET/ENT

key once to display the main

LOOP1

loop 1 setup para

SETUP main menu

A/M

SET/ENT

DISP

UTMD

UT750 configuration

SETUP main menu

A/M

SET/ENT

DISP

IM 05D01B02-44E 1st Edition : May 31,2000-00

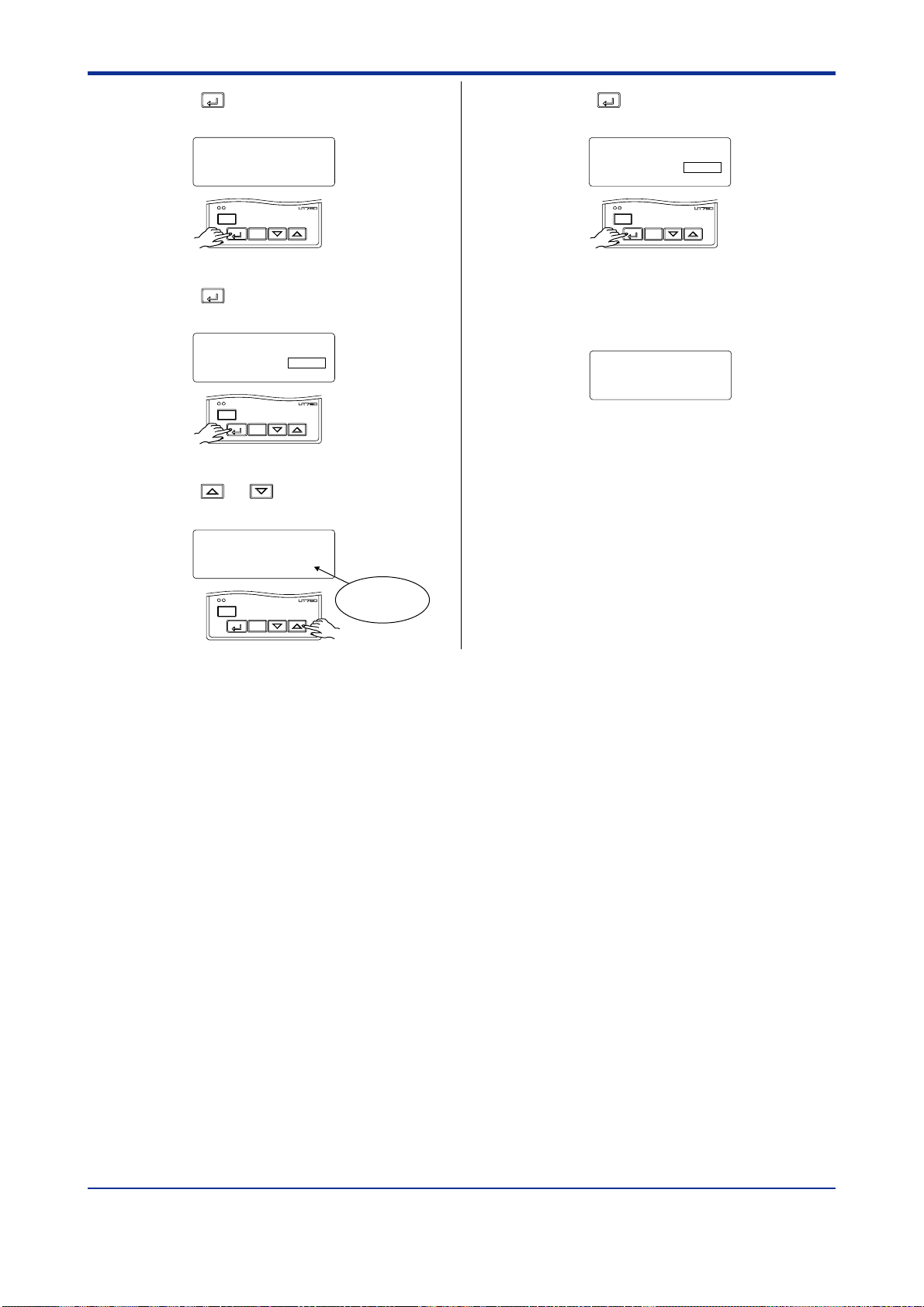

Page 27

<Toc> <2. Initial Settings>

2-5

6.

Press the

SET/ENT

key once to display the

submenu “MD”.

MD

UT mode set

SETUP main menu

A/M

SET/ENT

DISP

Press the

7.

parameter “UTM”.

Press the or key to display the set-

8.

point “4”.

SET/ENT

key once to display the

MENU:UTMD/MD #1

UT mode select

UTM = 1

A/M

SET/ENT

MENU:UTMD/MD #1

UT mode select

UTM = 4

A/M

SET/ENT

SETUP

DISP

changing

DISP

Blinks during

change.

9.

Press the

SET/ENT

key once to register the

setpoint.

MENU:UTMD/MD #1

UT mode select

UTM = 4

A/M

SET/ENT

The controller re-starts (which is normal).

10.

SETUP

DISP

Then, set PV input type. See “2.4 Setting

Primary and Secondary PV Input Types.”

IN

input set

SETUP sub menu

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 28

<Toc> <2. Initial Settings>

2.4 Setting Primary and Secondary PV Input Types

The following operating prcedure describes an example of setting the primary PV input

type to K-type thermocouple (-200.0 to 500.0⬚C) and measurement range of 0.0 to

200.0⬚C.

You can take the same steps for the secondary PV input type (IN3) and PV input scale

(SH3, SL3) that are displayed after the primary PV input related parameters.

Primary PV input (Factory-set default: Not specified)

2-6

PV input terminal

Thermocouple/mV/V input

RTD input .................................................. --

..............................

1312

-

131211

Secondary PV input (Factory-set default: 1 to 5 V DC)

PV input terminal

mV/V input

...................................................

2221

-

Example of Temperature Input Example of Voltage Input

1V 5V

-270.0°C 1370.0°C

0.0°C 800.0°C

Minimum value of

PV input range (RL1)

Parameters to be set for temperature input

1. PV input type (IN1): Set according to a sensor

2. Maximum value of PV input range (RH1): Set the

maximum value of the range to be controlled.

3. Minimum value of PV input range (RL1): Set the

minimum value of the range to be controlled.

Instrument

input range

PV input range

Maximum value of

PV input range (RH1)

Set a range

to be

controlled

Parameters to be set for voltage input

1. PV input type (IN1): Set according to an input signal

2. Maximum value of PV input range (RH1): Set the maximum value of an input signal.

3. Minimum value of PV input range (RL1): Set the minimum value of an input signal.

4.

Position of PV input decimal point (SDP1): Set the position of the decimal point for PV input display.

5. Maximum value of PV input scale (SH1): Set the maximum value of the scale to be controlled.

6. Minimum value of PV input scale (SL1): Set the minimum value of the scale to be controlled.

2V 4V

Instrument

input range

PV input range

RL1

PV input scale

0.0m3/h 50.0m3/h

Minimum value of

PV input scale (SL1)

RH1

Set a range to

be controlled

Maximum value of

PV input scale (SH1)

NOTE

The controller may automatically initialize the registered operating parameter setpoints if

any change is made to the data item PV Input Type (IN1), Maximum Value of PV Input

Range (RH1), Minimum Value of PV Input Range (RL1), PV Input Decimal Point Position

(SDP1), Maximum Value of PV Input Scale (SH1) or Minimum Value of PV Input Scale

(SL1). After a change has been made to any of these data items, be sure to verify the

registered operating parameter setpoints to ensure that they are correct. If any data item

has been changed to its default, set it to a required value.

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 29

<Toc> <2. Initial Settings>

Bring the operating display into view (display appears at power-on).

1.

The PV display in the figure below shows the error code for input burnout ( ) if PV input

wiring is not yet complete. The error code disappears when you wire the PV input terminals correctly.

PV

Displays

primary PV.

PV2

AL

AL

1

2

CAS

REM1

3

REM2

4

MAN1

MAN2

STP

A/M

SET/ENT

DISP

SP1 :1.

-10 0 +10

DV

-270.0°C

Displays

target setpoint-1

“1.SP1”.

In steps 2 and later, illustrations of the LCD are cited to explain the procedure.

2-7

2.

Press the

SET/ENT

key for more than 3 seconds

to call up the main menu “MODE”.

MODE

mode parameter

Press the key once to display the main

3.

menu “STUP”.

A/M

SET/ENT

main menu

DISP

STUP

Press the

4.

menu “LOOP1”.

password input

SET/ENT

main menu

A/M

SET/ENT

DISP

key once to display the main

LOOP1

loop 1 setup para

SETUP main menu

6.

Press the

SET/ENT

key once to display the

submenu “MD”.

MD

UT mode set

SETUP main menu

A/M

SET/ENT

DISP

Press the key once to display the

7.

submenu “IN”.

IN

input set

SETUP sub menu

A/M

SET/ENT

DISP

Press the

8.

parameter “IN1” (primary PV input type).

SET/ENT

key once to display the

MENU:UTMD/IN #1

input 1 type select

IN1 = OFF

SETUP

A/M

SET/ENT

DISP

Press the key once to display the main

5.

menu “UTMD”.

UTMD

UT750 configuration

SETUP main menu

A/M

SET/ENT

DISP

A/M

SET/ENT

DISP

Press the or key to display the

9.

required setpoint. The figure below shows

an example of setting the PV input type to a

K-type thermocouple (-200.0⬚C to 500.0⬚C).

MENU:UTMD/IN #1

input 1 type select

IN1 = typeK3

A/M

SET/ENT

IM 05D01B02-44E 1st Edition : May 31,2000-00

changing

Blinks during

DISP

change.

Page 30

<Toc> <2. Initial Settings>

2-8

10.

Press the

SET/ENT

key once to register the

setpoint.

MENU:UTMD/IN #1

11.

Press the

input 1 type select

IN1 = typeK3

A/M

SET/ENT

SET/ENT

key once to display the

SETUP

DISP

parameter “UNI1” (primary PV input unit).

MENU:UTMD/IN #2

12.

Press the

input 1 unit select

UNI1 = °C

A/M

SET/ENT

SET/ENT

key once to display the

SETUP

DISP

parameter “RH1” (maximum value of

primary PV input range).

MENU:UTMD/IN #3

input 1 range high

RH1 = 500.0

A/M

SET/ENT

SETUP

DISP

15.

Press the

SET/ENT

key once to display the

parameter “RL1” (minimum value of primary PV input range).

MENU:UTMD/IN #4

input 1 range low

RL1 = -200.0

A/M

SET/ENT

Press the or key to display the

16.

SETUP

DISP

required setpoint. The figure below shows

an example of setting the minimum value

of the PV input range to 0.0⬚C.

MENU:UTMD/IN #4

17.

Press the

input 1 range low

RL1 = 0.0

A/M

SET/ENT

SET/ENT

key once to register the

changing

DISP

setpoint.

MENU:UTMD/IN #4

input 1 range low

RL1 = 0.0

A/M

SET/ENT

SETUP

DISP

Blinks during

change.

Press the or key to display the

13.

required setpoint. The figure below shows

an example of setting the maximum value

of the PV input range to 200.0⬚C.

MENU:UTMD/IN #3

14.

Press the

input 1 range high

RH1 = 200.0

A/M

SET/ENT

SET/ENT

key once to register the

changing

DISP

setpoint.

MENU:UTMD/IN #3

input 1 range high

RH1 = 200.0

A/M

SET/ENT

SETUP

DISP

Blinks during

change.

If the type of input is voltage, also configure the Primary PV Input Decimal Point

Position (SDP1), Maximum Value of Primary PV Input Scale (SH1) and Minimum

Value of Primary PV Input Scale (SL1)

parameters that are displayed after this.

18.

Press the

SET/ENT

key for more than 3 seconds.

This returns you to the display shown at

power-on (figure below).

SP1 :1.

-10 0 +10

DV

A/M

SET/ENT

0.0°C

DISP

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 31

<Toc> <2. Initial Settings>

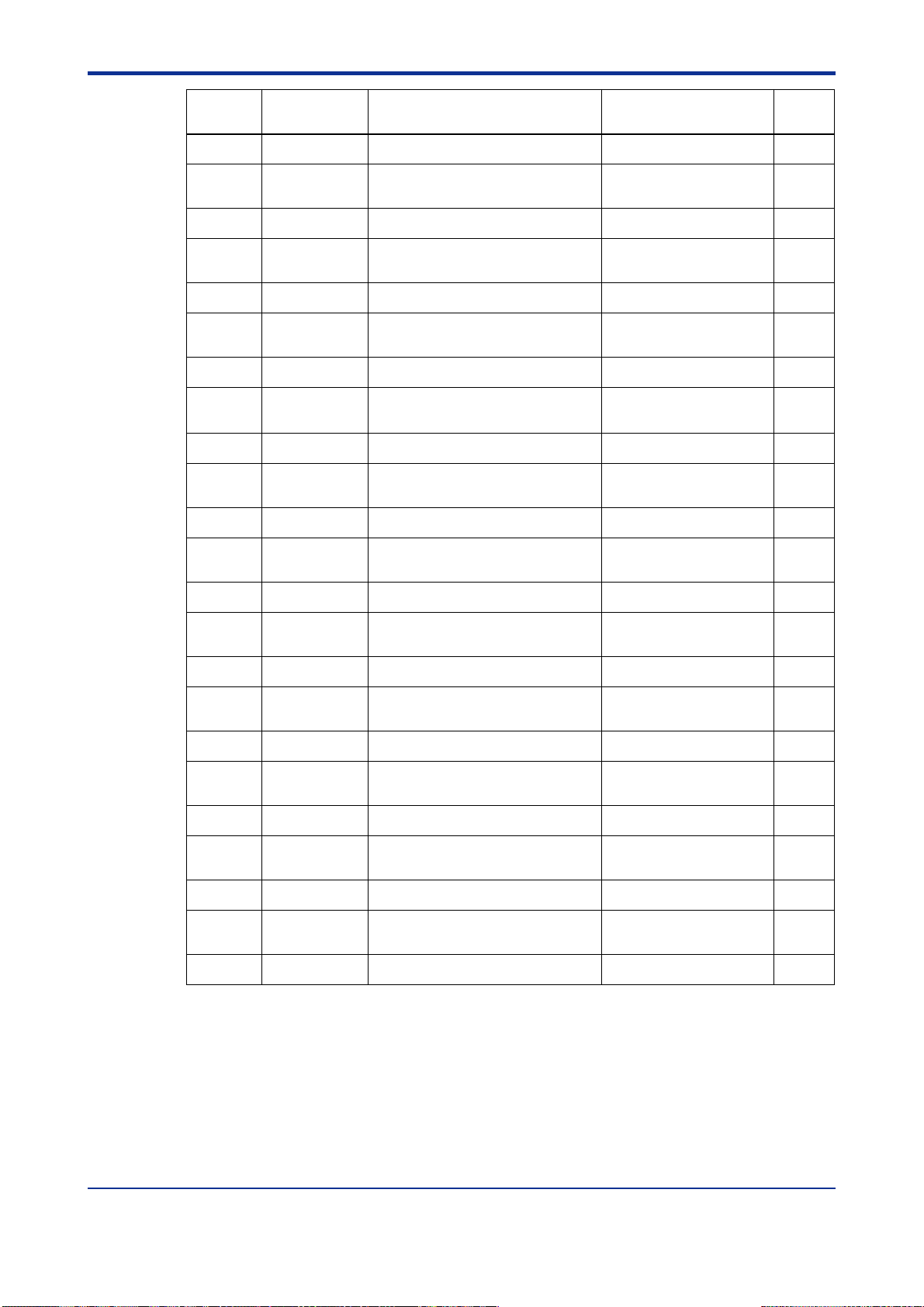

■ Instrument Input Range Codes

2-9

Input Type

Unspecified

Thermocouple

RTD

Standard

signal

DC voltage

K

J

T

B

S

R

N

E

L(DIN)

U(DIN)

W

Platinel 2

PR20-40

W97Re3W75Re25

JPt100

Pt100

0.4 to 2 V

1 to 5 V

0 to 2 V

0 to 10 V

0.00 to 1.25 V

(Note 3)

-10 to 20 mV

0 to 100 mV

Instrument Input

Range Code

OFF (0)

typeK1 (1)

typeK2 (2)

typeK3 (3)

typeJ (4)

typeT1 (5)

typeT2 (6)

typeB (7)

typeS (8)

typeR (9)

typeN (10)

typeE (11)

typeL (12)

typeU1 (13)

typeU2 (14)

typeW (15)

Plati2 (16)

PR2040 (17)

W97Re3 (18)

JPt1 (30)

JPt2 (31)

Pt1 (35)

Pt2 (36)

Pt3 (37)

0.4 to 2 V (40)

1 to 5 V (41)

0 to 2 V (50)

0 to 10 V (51)

0.00 to 1.25 V (52)

mV1 (55)

mV2 (56)

Instrument

Input Range

Set the data item PV Input Type “IN1” to the OFF option to leave the PV input

type undefined.

-270.0 to 1370.0°C

-450.0 to 2500.0⬚F

-270.0 to 1000.0°C

-450.0 to 2300.0⬚F

-200.0 to 500.0°C

-200.0 to 1000.0⬚F

-200.0 to 1200.0°C

-300.0 to 2300.0⬚F

-270.0 to 400.0°C

-450.0 to 750.0⬚F

0.0 to 400.0°C

-200.0 to 750.0⬚F

0.0 to 1800.0°C

32 to 3300⬚F

0.0 to 1700.0°C

32 to 3100⬚F

0.0 to 1700.0°C

32 to 3100⬚F

-200.0 to 1300.0°C

-300.0 to 2400.0⬚F

-270.0 to 1000.0°C

-450.0 to 1800.0⬚F

-200.0 to 900.0°C

-300.0 to 1600.0⬚F

-200.0 to 400.0°C

-300.0 to 750.0⬚F

0.0 to 400.0°C

-200.0 to 1000.0⬚F

0.0 to 2300.0°C

32 to 4200⬚F

0.0 to 1390.0°C

32 to 2500.0⬚F

0.0 to 1900.0°C

32 to 3400⬚F

0.0 to 2000.0°C

32 to 3600⬚F

-200.0 to 500.0°C

-300.0 to 1000.0⬚F

-150.00 to 150.00°C

-200.0 to 300.0⬚F

-200.0 to 850.0°C

-300.0 to 1560.0⬚F

-200.0 to 500.0°C

-300.0 to 1000.0⬚F

-150.00 to 150.00°C

-200.0 to 300.0⬚F

0.400 to 2.000 V

1.000 to 5.000 V

0.000 to 2.000 V

0.00 to 10.00 V

0.000 to 1.200 V

-10.00 to 20.00 mV

0.0 to 100.0 mV

⫾0.1% of instrument range ⫾1 digit at 0°C or more

⫾0.2% ⫾1 digit for temperatures below 0°C,

where the accuracy is: ⫾2% of instrument range ⫾1

digit for temperatures below -200.0°C for a type-K

thermocouple, or ⫾1% of instrument range ⫾1 digit for

temperatures below -200.0°C for a type-T thermocouple.

⫾0.15% of instrument range ⫾1 digit at 400°C or more

⫾5% of instrument range ⫾1 digit at less than 400°C

⫾0.15% of instrument range ⫾1 digit

⫾0.1% of instrument range ⫾1 digit

⫾0.25% of instrument range ⫾1 digit for temperatures

below 0°C

⫾0.1% of instrument range ⫾1 digit at 0°C or more

⫾0.2% ⫾1 digit for temperatures below 0°C, where the

accuracy is:⫾1.5% of instrument range ⫾1 digit for

temperatures below -200.0°C for a type-E thermocouple.

⫾0.2% of instrument range ⫾1 digit

⫾0.1% of instrument range ⫾1 digit

⫾0.5% of instrument range ⫾1 digit at 800°C or more

No accuracy is guaranteed at less than 800°C

⫾0.2% of instrument range ⫾1 digit

⫾0.1% of instrument range ⫾1 digit (Note 1) (Note 2)

⫾0.2% of instrument range ⫾1 digit (Note 1)

⫾0.1% of instrument range ⫾1 digit (Note 1) (Note 2)

⫾0.2% of instrument range ⫾1 digit (Note 1)

⫾0.1% of instrument range ⫾1 digit

Display range is scalable in a range of -19999 to 30000.

Display span is 30000 or less.

Measurement Accuracy

Performance in the standard operating conditions (at 23⫾2⬚C, 55⫾10%RH, and 50/60 Hz power frequency)

Note 1: The accuracy is ⫾0.3⬚C of instrument range ⫾1 digit for a temperature range from 0⬚C to 100⬚C.

Note 2: The accuracy is ⫾0.5⬚C of instrument range ⫾1 digit for a temperature range from -100⬚C to 200⬚C.

Note 3: Not used in cascade control.

* To receive a 4-20 mA DC signal, select a standard signal of 1 to 5 V DC and connect it to a 250 ⍀ resistor. This resistor

is optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal lugs)

IM 05D01B02-44E

1st Edition : May 31,2000-00

Page 32

<Toc> <2. Initial Settings>

2.5 Setting Control Output Type (except for a Position

Proportional Controller)

The following operating procedure describes an example of changing time proportional PID

relay output (0: factory-set default) to current output (2).

2-10

Control output terminal

Time proportional PID relay (0)/on-off(3) output

Current (2)/time proportional PID voltage pulse (1) output

For details on the output terminals for heating/cooling control, see “1.5

Terminal Wiring Diagrams”.

Bring the operating display into view (display appears at power-on).

1.

Displays

primary PV.

Values in parentheses are setpoints

PV2

AL

AL

1

2

3

4

PV

CAS

REM1

REM2

MAN1

MAN2

STP

A/M

SET/ENT

...........................

.............

DISP

1 2 3

--

16

17

-

SP1 :1.

-10 0 +10

DV

0.0°C

In steps 2 and later, illustrations of the LCD are cited to explain the procedure.

Press the

2.

to call up the main menu “MODE”.

SET/ENT

key for more than 3 seconds

Press the key once to display the main

5.

menu “UTMD”.

MODE

mode parameter

main menu

Displays

target setpoint-1

“1.SP1”.

UTMD

UT750 configuration

SETUP main menu

A/M

SET/ENT

DISP

Press the key once to display the main

3.

menu “STUP”.

STUP

Press the

4.

menu “LOOP1”.

password input

SET/ENT

main menu

A/M

SET/ENT

DISP

key once to display the main

LOOP1

loop 1 setup para

SETUP main menu

A/M

SET/ENT

DISP

A/M

SET/ENT

DISP

6.

Press the

SET/ENT

key once to display the

submenu “MD”.

MD

UT mode set

SETUP sub menu

A/M

SET/ENT

DISP

Press the key twice to display the

7.

submenu “OUT”.

OUT

output set

SETUP sub menu

A/M

SET/ENT

DISP

IM 05D01B02-44E 1st Edition : May 31,2000-00

Page 33

<Toc> <2. Initial Settings>

2-11

8.

Press the

SET/ENT

key once to display the

parameter “OT2” (control output type).

MENU:UTMD/OUT #2

output 2 select

OT2 = 0

A/M

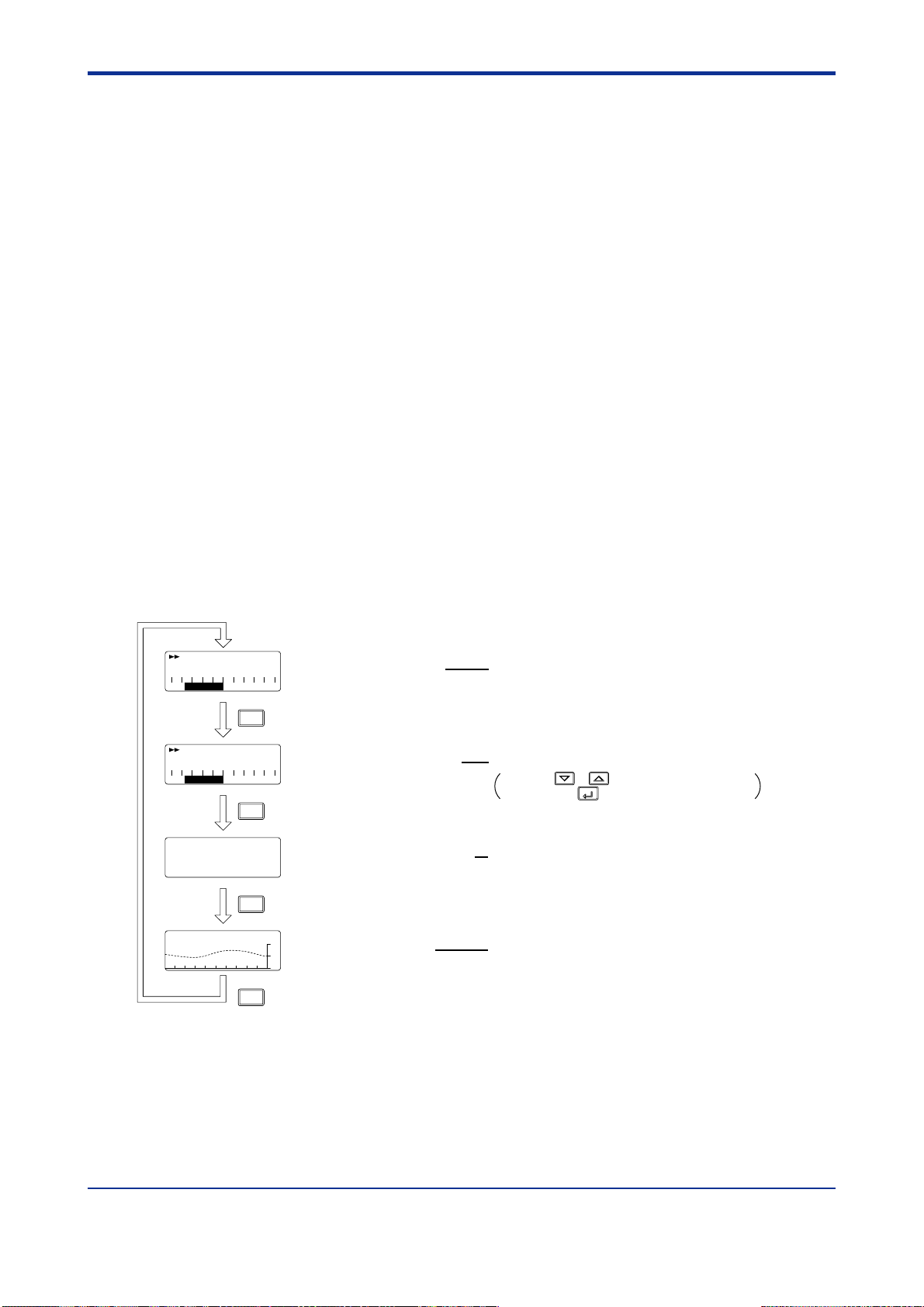

SET/ENT