Page 1

General

Specications

UT55A, UT52A

Digital Indicating Controller

(Panel Mounting Type)

GS 05P01C31-01EN

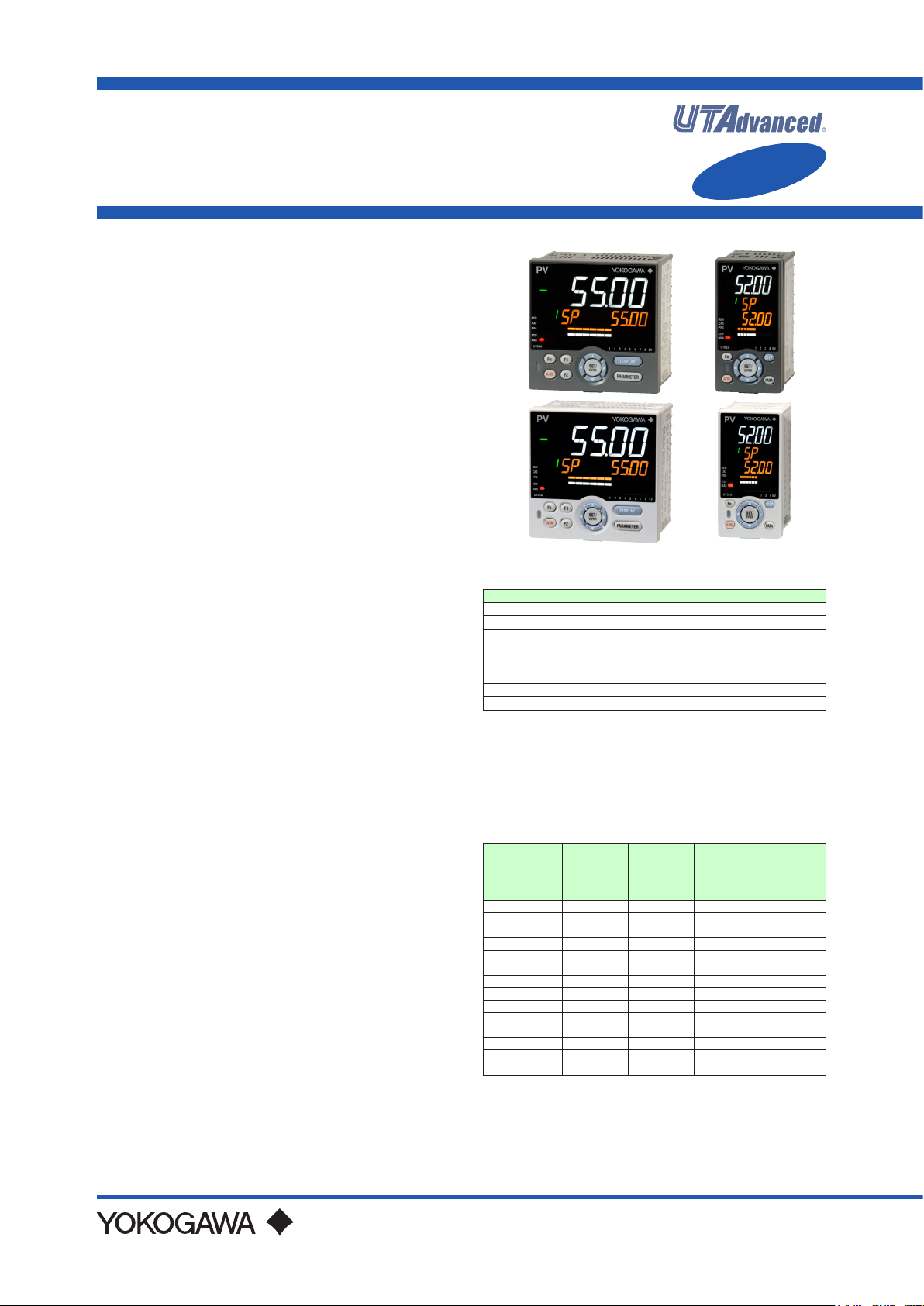

n Overview

The UT55A and UT52A digital indicating controllers employ an easy-to-read, 14-segment large color

LCD display, along with navigation keys, thus greatly

increasing the monitoring and operating capabilities.

A ladder sequence function is included as standard.

The short depth of the controller helps save instrument

panel space. The UT55A and UT52A also support

open networks such as Ethernet communication.

The UT55A and UT52A have a DIN rail mounting type

(with option code /MDL). For more details, please see

General Specication GS 05P01C81-01EN.

n Features

• A 14-segment, active (PV display color changing

function) color LCD display is employed.

Two ve-digit, high-resolution displays are possible.

Alphabet letters can be displayed in an easy-to-read

manner. The guide display shows parameter names.

• Easy to operate

Navigation keys (SET/ENTER and Up/Down/Left/

Right arrow keys) are employed to facilitate making

settings.

• 65 mm depth

The small depth enables the mounting in a thin and

small instrumented panel.

• Ladder sequence function is included as standard.

This function allows for creating a simple sequence

control. Dedicated LL50A Parameter Setting Software

(sold separatly) allows for performing programming

using a ladder language.

• Various built-in open network functions such as Ethernet are available.

Easy connection with various vendors’ PLCs is possible.

(UT52A support CC-Link and RS485 communication only.)

• Quick setting function

Setting only the minimum necessary parameters for

operation is possible. (For single-loop control only)

• Equipped with a multitude of functions

Universal I/O, eight control modes (cascade control, etc), and retransmission output are included as

standard. PID control, heating/cooling control, feed

forward control, etc. are available.

• LL50A Parameter Setting Software (sold separately)

The parameters and ladder programs of UTAdvanced

digital indicating controller can be built from a PC using

this software. It makes data management even easier.

• Dust-proof and drip-proof

IP66 (for front panel) (Not applicable to side-by-side

close mounting.)

NEMA4 (Hose-down test only)

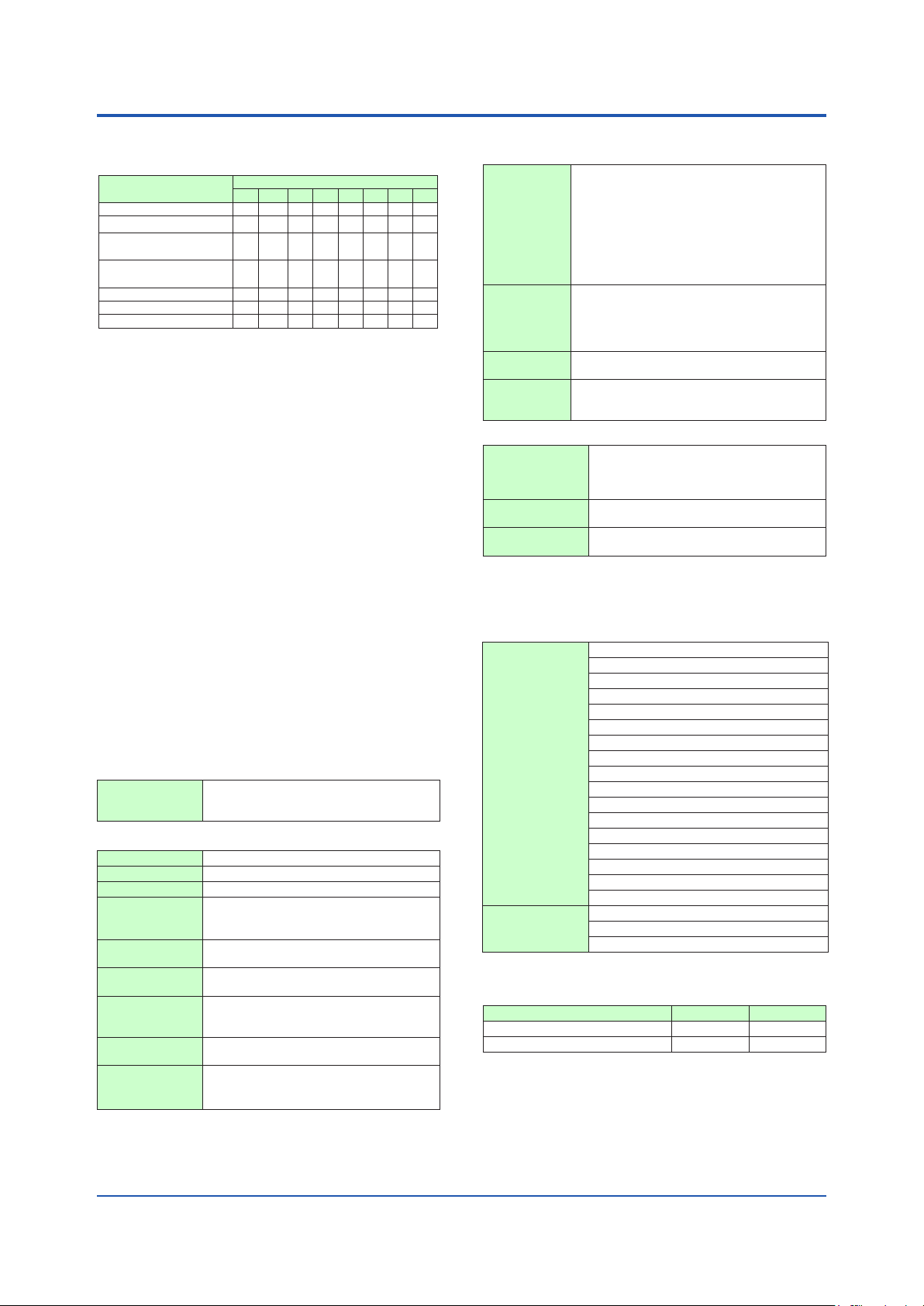

nFunctionalSpecications

ControlSpecications

(1) Control Mode

Control functions of the controller can be set as control

modes.

Functional

Enhancement

UT55A UT52A

Control mode Function

SGL (1)

CAS1 (2)

CAS2 (3)

CAS (4)

BUM (5)

PVSW (6)

PVSEL (7)

PVHD (8)

*1: Remote auxiliary analog input is required.

Single-loop control

Cascade primary-loop control

Cascade secondary-loop control

Cascade control

Loop control for backup

Loop control with PV switching

Loop control with PV auto-selector (Max./Min./Ave./Diff.)

Control with PV-hold function

(*1)

(*1)

(*1)

(*1)

(*1)

2) Control period

Selectable from 50 ms

*2: Cascade control (Control mode 4) cannot be used.

“Super” function or “Super 2” function cannot be used.

(*2)

, 100 ms, and 200 ms

Table of Number of Inputs and Outputs

Model and

sufxcode

(See the

model code)

UT55A

UT52A

*3: Excluding control output

*4: The numbers in parentheses show the numbers

*5: Excluding control output relays

Number

of analog

input

points

-×0×

-×1× 2 1 9 (8) 8

-×2× 2 1 4 (3) 3

-×3× 1 1 8 8

-×4× 2 1 4 (3) 3

-×5× 2 1 9 (8) 8

-×6× 1 1 8 18

-×7× 4 1 6 (5) 3

-×0× 1 1 3 3

-×1× 2 1 3 3

-×2× 2 1 4 (3) 3

-×3× 1 1 5 5

of points in each model with RSP direct input.(/DR

option.

1 1 3 3

Number

of analog

output

(*3)

points

Number

of contact

input

(*4)

points

Number of

contact

points

(*1)

output

(*5)

Yokogawa Electric Corporation

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

Tel.: 81-422-52-7179 Fax.: 81-422-52-6619

GS 05P01C31-01EN

1st Edition Jan. 16, 2009 (KP)

9th Edition Mar.14, 2016 (YK)

Page 2

2

ControlComputationSpecications

(1)

Combination of types of control and control modes

Types of control

PID control √ √

ON/OFF control

Two-position, two-

level control

Heating and cooling

control

(*7)

1 2 3 4 5 6 7 8

(*6)

√

√

(*7)

√

Sample PI control √

Batch PID control √

Feedforward control √

√: Available N/A: Not Available

*6: Not selectable for Position proportional type

*7: Selectable for heating and cooling control

(2) Control Computation Function

(a) Target setting point and the number of PID param-

eter groups

Respectively, eight sets of target setpoints, alarm set-

points, and PID parameters can be set. For cascade

control, respectively, eight sets can be set for main

(primary side) and slave (secondary side).

(b) Selecting the PID parameter group

The following PID parameter groups can be selected.

• Target setpoint number (SPNO) (The PID number

can be set arbitrarily.)

• Measured input zone PID

• Target setpoint zone PID

• Reached target setpoint zone PID

(c) Auto-tuning

• Tuning results can be selected from two options,

Normal or Stable.

• Tuning output limit can be set. (It cannot be used in

heating/cooling control.)

(d) “Super” function: Overshoot-suppressing function

(e) “Super 2” function: Hunting-suppressing function

(f) STOP preset output function

(g) Input ERROR preset output function

(h) MANUAL preset output function

(3) Operation Mode Switching

Operation mode

switching

AUTO/MANUAL and RUN/STOP switching

CASCADE/AUTO/MANUAL switching

REMOTE/LOCAL switching

(4) Control Parameter Setting Range

Proportional band 0.1 to 999.9%

Integral time 1 to 6000 sec. or OFF (using manual reset)

Derivative time 1 to 6000 sec. or OFF

ON/OFF control

hysteresis (one or two

hysteresis points)

Preset output

value

High/low output

limiter

Tight shut

function

Rate-of-change

limiter of output

Output

deadband

0.0 to 100.0% of measured input range width

-5.0 to 105.0% (however, 0 mA or less cannot

be output)

-5.0 to 105.0%

Low limit setpoint < high limit setpoint

When manual control is carried out with 4 to

20 mA output, control output can be reduced to

about 0 mA.

0.1 to 100.0%/sec., OFF

For heating and cooling control: -100.0 to 50.0%

For position proportional control: 1.0 to 10.0%

Control mode

(*6)

√ √ √ √ √ √

N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A N/A

N/A

√ √ √ √ √ √

N/A N/A N/A N/A

N/A N/A N/A N/A

N/A N/A N/A N/A N/A N/A

√ √

√ √ √

√ √ √

N/A

√

Alarm Functions

• Types of Alarm

PV (measured value) high/low limit alarm

Measured value

alarm

Deviation alarm

Rate-of-change

alarm

Setpoint alarm

Output alarm

Other alarms

Deviation high/low limit alarm

Deviation high and low limits alarm

Deviation within high and low limits alarm

Analog input PV high/low limit alarm

Analog input RSP (ROMOTE) SP high/low limit alarm

Auxiliary analog input high/low limit alarm

Feedback input high/low limit alarm

PV rate-of-change alarm

SP (setpoint) high/low limit alarm

Target SP high/low limit alarm

Target SP deviation high/low limit alarm

Target SP deviation high and low limits alarm

Target SP deviation within high and low limits alarm

Control output high/low limit alarm

Cooling control output high/low limit alarm

Heater disconnection alarm (for /HA option)

Self-diagnosis alarm

FAIL

• Alarm Functions

Alarm output

action

Number of alarm

settings

Number of alarm

output points

Alarm stand-by action

Alarm latch (forced reset) function

Alarm hysteresis

Alarm ON/OFF delay timer

8 (per loop)

Up to 18 (differs by model code)

Contact I/O Function

This function allows for allocating the input error

condition, operation condition, alarm condition or other

conditions to the contact input and contact output.

AUTO/MANUAL switching

REMOTE/LOCAL switching

STOP/START switching

Switching to CASCADE

Switching to AUTO

Switching to MANUAL

Switching to REMOTE

Contact input

Contact output

Switching to LOCAL

AUTO-TUNING START/STOP switching

OUTPUT TRACKING switching

Two-input switching

PV Hold

LCD backlight ON/OFF switching

Message interrupt displays 1 through 4

SP number specication

PID number specication

Manual preset output number specication

Loop 1 alarms 1 through 8

Loop 2 alarms 1 through 8 (for cascade control)

Status output

Ladder Sequence Function

(1) Number of I/O Points

UT55A UT52A

Number of digital input points Up to 9 Up to 5

Number of digital output points Up to 18 Up to 5

This is limited by the number of contact I/O signal

points. (See the model code.)

(5) Ladder computation period

Ladder computation period is the same as control period.

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 3

3

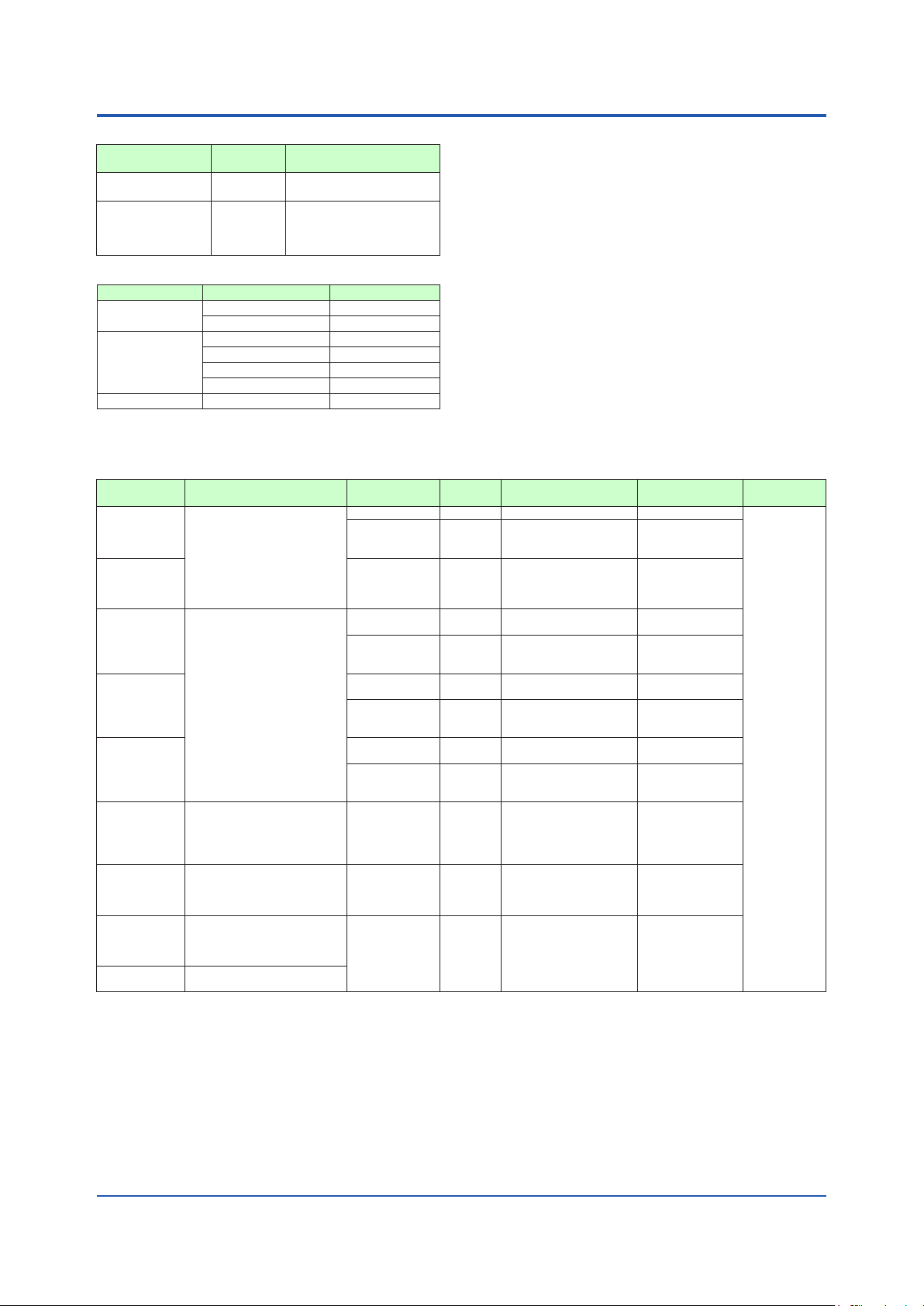

(2) Types of Command

Number of

Number of basic

command types

Number of application command types

commands

13

73

Remark

Load, AND, OR, Timer,

Counter, etc.

Comparison, reverse, addition/

subtraction/multiplication/

division, logic operation, high/

low limiter, etc.

(4) Program capacity

Max. Program capacity: 500 steps *

*: Available number of steps differs according to the

parameters, using command and control period.

(5) Ladder computation period

Ladder computation period is the same as control

period.

(3) Sequence Device

Types of device Number of points

Digital I/O

Internal device

Special device Special relay (bit data) 12

Input relay 9 (max)

Output relay 18 (max)

M relay (bit data) 256

DAT register (data) 28

P register (parameter) 10

K register (constant) 30

* Process data and process relay can be used besides

the above-mentioned.

Communication Function

Function Method Interface Targets Maxconnection

Server Ethernet PLC and others 2 connections

Modbus/TCP

A standard industry protocol

allowing communications

Gateway

Ethernet

+RS-485

between the controller and

Modbus

(RTU/ASCII)

PROFIBUSDP

CC-Link

devices such as PCs, PLCs,

and DCSs.

Used for communication

between PLCs and

remote I/O, enabling high-

speed data transmission.

Slave RS-485

Slave RS-485 PLC and others

Modbus master

function

RS-485

Slave RS-485 PLC and others

Modbus master

function

RS-485

Slave RS-485 PLC and others

DeviceNet

Modbus master

function

RS-485

A protocol allowing multiple

Peer to peer

controllers to send and

receive data between

one another. The Ladder

Multi-drop

RS-485

(2 wire

only)

Program is used.

Coordinated

Communication

A protocol to coordinate the

operation of two or more

instruments controlling the

same process.

Master/Slave RS-485

The proprietary Yokogawa

PC link

Ladder

protocol allowing

communications to PCs,

PLCs and touch panels.

A protocol to communicate

to PLCs.

Slave RS-485

*1: UT digital indicating controller, Signal conditioner JUXTA, Power monitor POWERCERT can be connected.

*2: UT digital indication controllers can be connected.

RS-485: UT75A, UT55A,

UT52A, UT35A, UT32A,

UP55A,UP35A,UM33A

(*1)

PLC and others,

UT75A, UT55A, UT52A,

UT35A, UT32A, UP55A,

UP35A, UP32A, UM33A

UT75A, UT55A,

UT52A, UT35A,

UT32A, UP55A, UP35A

UT75A, UT55A, UT52A,

UT35A, UT32A, UP55A,

UP35A, UP32A, UM33A

UT75A, UT55A,

UT52A, UT35A,

UT32A, UP55A, UP35A

UT75A, UT55A, UT52A,

UT35A, UT32A, UP55A,

UP35A, UP32A

UT75A, UT55A, UT52A,

UT35A, UT32A, UP55A,

UP35A, UP32A

(*2)

PC and others,

UT75A, UT55A, UT52A,

UT35A, UT32A, UP55A,

UP35A, UP32A, UM33A

(*2)

Number of nodes:

(Main Controller

is included.)

Number of nodes:

42 (Remote device)

(Main Controller

is included.)

Number of nodes:

(Main Controller

is included.)

Read/Write: 4

Read only : 28

Master : 1 unit

Slave : 31 units

(*2)

31 units

31 units

126

31 Units

31 Units

64

31 Units

units

units

31units

Communication

Data

PV, SP, OUT,

ALM etc

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 4

Physical Interface

Ethernet

Standard : IEEE802.3 (10BASE-T, 100BASE-TX)

Max segment length : 100m

Max. Connecting Congguration : Cascade Max. 4 level (10BASE-T), Max. 2 level (100BASE-TX)

RS-485 Standard : EIA RS-485

Communication method : Two-wire harf-duplex or four-wire harf-duplex, start-stop synchoronization

Baud rate : 600, 1200, 2400, 4800, 9600, 19200 or 38400bps

and non-procedural

(*3)

, Peer to peer communication is xed at

19200bps

Maximum communication distance : 1200m

Terminating resistor : 220Ω (External)

*3: “38400 bps” is available only for UT55A (Type 3 code = 1) and UT52A (Type 2 code = 1)

PROFIBUS-DP Standard : Field bus (IEC61158)

Corresponding version : DP V0

Baud rate : 9.6k

,

19.2k, 45.45k, 93.75k, 187.5k, 0.5M, 1.5M, 3M, 6M, 12M

, AUTO

(*4)

Communication distance : 1200m (9.6k to 93.75k) 1000m (187.5k)

400m (0.5M) 200m (1.5M)

100m (3M to 12M)

*4: AUTO automatically sets the baud rate to that of the host controller (PROFIBUS-DP master).

CC-Link Supported version : Remote device (Ver.1.10, Ver.2.00)

Baud rate : 156k, 625k, 2.5M, 5M, 10M bps

Transmission distance : 1.2km (156k bps), 600m (625k bps), 200m (2.5M bps), 150m (5M bps),

100m (10M bps)

When using optical repeater : 7.6 km (156k) to 4.3 km (10M)

DeviceNet Field bus (IEC61158)

Baud rate: 125k, 250k, 500k bps

Transmission distance: 500m (125k bps), 250m (250k bps), 100m (500k bps)

4

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 5

5

nHardwareSpecications

DisplaySpecications

• PV display

5-digit, 14-segment active color LCD (white/red)

Character height: 21.5 mm for UT55A and 13.0 mm

for UT52A

• Data display

5-digit, 11-segment color LCD (orange)

• Bar graph display

12-segment color LCD (orange and white)

UniversalInputSpecications

• Number of input points: 1

• Types of input, instrument range, and measurement

accuracy (see the table below)

Types of input

-270.0 to 1370.0°C -450.0 to 2500.0°F ±0.1% of instrument

K

-270.0 to 1000.0°C -450.0 to 2300.0°F

-200.0 to 500.0°C -200.0 to 1000.0°F

J -200.0 to 1200.0°C -300.0 to 2300.0°F

-270.0 to 400.0°C -450.0 to 750.0°F

T

0.0 to 400.0°C -200.0 to 750.0°F

B 0.0 to 1800.0°C 32 to 3300°F

S 0.0 to 1700.0°C 32 to 3100°F

R 0.0 to 1700.0°C 32 to 3100°F

N -200.0 to 1300.0°C -300.0 to 2400.0°F

E -270.0 to 1000.0°C -450.0 to 1800.0°F ±0.1% of instrument

Thermocouple

L -200.0 to 900.0°C -300.0 to 1600.0°F

-200.0 to 400.0°C -300.0 to 750.0°F

U

0.0 to 400.0°C -200.0 to 1000.0°F

(*2)

0.0 to 2300.0°C 32 to 4200°F

W

Platinel

0.0 to 1390.0°C 32.0 to 2500.0°F

2

PR20-40 0.0 to 1900.0°C 32 to 3400°F

W97

0.0 to 2000.0°C 32 to 3600°F

Re3-W75

Re25

-200.0 to 500.0°C -300.0 to 1000.0°F

JPt100

-150.00 to 150.00°C -200.0 to 300.0°F

-200.0 to 850.0°C -300.0 to 1560.0°F

(RTD) 3-wire

Resistance-temperature

detector

Standard

signal

DC voltage

DC current 0.00 to 20.00 mA -

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

-200.0 to 500.0°C -300.0 to 1000.0°F

Pt100

-150.00 to 150.00°C -200.0 to 300.0°F

0.400 to 2.0000 V -

1.000 to 5.000 V -

4.00 to 20.00 mA -

0.000 to 2.000 V -

0.00 to 10.00 V -

-10.00 to 20.00 mV -

Instrument range

°C °F

Accuracy

range ±1 digit for 0°C

or more

±0.2% of instrument

range ±1 digit for less

than 0°C

However, ±2% of

instrument range

±1 digit for less than

-200°C of thermocouple

K ±1% of instrument

range ±1 digit for less

than -200°C of thermocouple T

±0.15% of instrument

range ±1 digit for 400°C

or more

±5% of instrument

range ±1 digit for less

than 400°C

±0.15% of instrument

range ±1 digit

±0.1% of instrument

range ±1 digit

±0.25% of instrument

range ±1 digit for less

than 0°C

range ±1 digit for 0°C

or more

±0.2% of instrument

range ±1 digit for less

than 0°C

However, ±1.5% of

instrument range ±1 digit

for less than -200.0°C of

thermocouple E

±0.2% of instrument

range ±1 digit

±0.1% of instrument

range ±1 digit

±0.5% of instrument

range ±1 digit for 800°C

or more

Accuracy not guaranteed for less than 800°C

±0.2% of instrument

range ±1 digit

±0.1%

of instrument

range ±1 digit

±0.1% of instrument

range ±1 digit

±0.1%

range ±1 digit

±0.1% of instrument

range ±1 digit

±0.1% of instrument

range ±1 digit

(*1)

of instrument

(*1)

The accuracy is that in the standard operating conditions: 23 ±2°C, 55 ±10%RH, and power frequency at

50/60 Hz.

*1:

±0.3°C and ±1 digit in the range between 0 and 100°C

±0.5°C ±1 digit in the range between -100 and 200°C

*2:

W-5% Re/W-26% Re (Hoskins Mfg.Co.), ASTM E988

•

Applicable standards: JIS, IEC and DIN (ITS-90) for thermocouples and resistance-temperature detectors (RTD)

• Input sampling period: Synchronized to control period

• Burnout detection

Upscale and downscale of function, and OFF can

be specied for the standard signal of thermocouple and resistance-temperature detector (RTD).

For integrated signal input, 0.1 V or 0.4 mA or less

is judged as a burnout.

• Input bias current: 0.05 μA (for thermocouple and

resistance-temperature detector (RTD))

• Resistance-temperature detector (RTD) measured

current: About 0.16 mA

• Input resistance

1 MΩ or more for thermocouple/mV input

About 1 MΩ for voltage input

About 250 Ω for current input (with built-in shunt

resistance)

• Allowable signal source resistance

250 Ω or less for thermocouple/mV input

Effect of signal source resistance: 0.1 μV/Ω or less

2 kΩ or less for DC voltage input

Effect of signal source resistance: about

0.01%/100 Ω

• Allowable wiring resistance

Up to 150 Ω per line for resistance-temperature

detector (RTD) input (conductor resistance

between the three lines shall be equal)

Effect of wiring resistance: ±0.1°C/10 Ω

• Allowable input voltage/current

±10 V DC for thermocouple/mV/mA or resistance temperature detector (RTD) input

±20 V DC for V input

±40 mA DC for mA input

• Noise reduction ratio

40 dB or more (at 50/60 Hz) in normal mode

120 dB or more (at 50/60 Hz) in common mode

• Reference junction compensation error

±1.0°C (15 to 35°C)

±1.5°C (-10 to 5°C and 35 to 50°C)

AuxiliaryAnalogInputSpecications

• This function can be used for remote setpoint setting,

external compensating input, auxiliary input for computation, etc.

• Number of input points: see the model code table.

• For types of input, instrument range, and measure-

ment accuracy, see the table below.

Types of input Instrument range Accuracy

Integrated signal

DC voltage

DC voltage with High input

impedance

0.400 to 2.000 V

1.000 to 5.000 V

0.000 to 2.000 V

0.00 to 10.00 V

0.000 to 1.250 V

• Input sampling period: Synchronized to control period

• Input resistance: about 1 MΩ

However, 10 MΩ or more for high input impedance

• Burnout detection: Functions at standard signal

Burnout is determined to have occurred if it is

0.1 V or less.

GS 05P01C31-01EN

±0.2% of instrument range

±1 digit

±0.1% of instrument range

±1 digit

±0.2% of instrument range

±1 digit

±0.1% of instrument range

±1 digit

±0.1% of instrument range

±1 digit

Mar.14, 2016-00

Page 6

6

RemoteInputwithDirect InputSpecications

(for /DR Option)

(3-wire or 4-wire when RTD is selected)

• Number of input points: 1 point

• Types of input, instrument range, and measurement

accuracy are the same as those of universal input

(standard), except for the table below.

Types of input

-200.0 to 500.0°C -300.0 to 1000.0°F ±0.5°C ±1 digit

JPt100

-150.00 to 150.00°C -200.0 to 300.0°F ±0.2°C ±1 digit

4-wire

RTD

*: ±0.5 °C ±1 digit in the range of -200.0 to 500.0 °C

-200.0 to 850.0°C -300.0 to 1560.0°F

Pt100

-200.0 to 500.0°C -300.0 to 1000.0°F ±0.5°C ±1 digit

-150.00 to 150.00°C -200.0 to 300.0°F ±0.2°C ±1 digit

Instrument range

°C °F

Accuracy

±0.1% of instrument range ±1

digit (*)

• Input sampling period: Synchronized to control period

• Burnout detection: Same as universal input

ContactInputSpecications

• Number of points: 3 points (standard)

For the maximum number of points, see the

model and sufx code table.

• Input type: no-voltage contact input or transistor contact input

• Input contact capacity: 12 V DC, 10 mA or more

Be sure to use a contact with a minimum ON

current of 1 mA or less

• ON/OFF detection

For no-voltage contact input:

Contact resistance 1 kΩ or less in ON state

Contact resistance 50 kΩ or more in OFF state

Transistor contact input:

2 V or less in ON state

Leak current 100 μ A or less in OFF state

• Status detection minimum hold time: control period

+ 50 ms

• Application: SP switching, operation mode switching,

event input

AnalogOutputSpecications

• Number of points

Control output (heating-side output): 1 point

(standard), which is shared with transmission

output

Cooling-side output: 1 point, which is

shared with transmission output

• Output functions

Current output or voltage pulse output

• Current output

4 to 20 mA DC or 0 to 20 mA DC/load resistance

600 Ω or less

• Current output accuracy

±0.1% of span (however, ±5% of span for 1 mA

or less)

The accuracy is that in the standard operating

conditions: 23 ±2°C, 55 ±10%RH, and power

frequency at 50/60 Hz

• Voltage pulse output

Application: time proportional output

ON voltage: 12 V or more/load resistance of 600

Ω or more

OFF voltage: 0.1 V DC or less

Time resolution: 10 ms or 0.1% of output value,

whichever is larger

RetransmissionOutputSpecications

• Number of points: 1 point (standard), which is shared

with 15 V DC loop power supply

Additional 2 points when analog control output and

cooling-side analog control output are not used

• Output function: current output

4 to 20 mA DC or 0 to 20 mA DC/load

resistance 600 Ω or less

• Current output accuracy (conversion accuracy from

PV display on the set scale): ±0.1% of span (however, ±5% of span for 1 mA or less)

The accuracy is that in the basic operating

conditions: 23 ±2°C, 55 ±10%RH, and power

frequency at 50/60 Hz

This is not conversion accuracy through input

and output but the performance of transmission

output itself.

15VDCLoopPower SupplySpecications

• Number of points: 1 point (standard), which is shared

with retransmission output

Control output (1 point) can also be used.

• Supply voltage: 14.5 to 18.0 V DC

• Maximum supply current: about 21 mA (with short-

circuit current limiting circuit)

StepResponseTimeSpecications

Within 500 ms (for a control period of 50 ms or 100 ms)

Within 1 s (for a control period of 200 ms)

(Response time at 63% of transmission output when a

change is made stepwise in the range between 10 and

90% of input span)

RelayContactOutputSpecications

• Types of contact and number of points

Control relay output: one 1c-contact point

Cooling output of heating and cooling control:

one 1c-contact point (For UT55A only)

For UT52A heating/cooling output:

2 1a-contact points

Alarm output: 3 1a-contact points (Common is

separated)

• Contact rating

1c-contact: 3 A at 250 V AC or 3 A at 30 V DC

(resistance load)

1a-contact:

For alarm output: 1 A at 240 V AC or 1 A at

30 V DC (resistance load)

For UT52A control relay output: 3 A at

240 V AC or 3 A at 30 V DC (resistance load)

*: The control output should always be used with a load

of 10 mA or more.

The alarm output should always be used with a load

of 1 mA or more.

• Application: time proportional output, alarm output,

FAIL output, etc.

• Time resolution for control output: 10 ms or 0.1% of

output value, whichever is larger

TransistorContactOutputSpecications

• Number of points:

• Output form: open collector (sink current)

• Output contact capacity: Up to 24 V DC, 50 mA

• Output time resolution: min 50 ms

• Application: alarm output, FAIL output, etc.

see the model and sufx code table

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 7

7

PositionProportionalOutputSpecications

• Position signal input

Slide resistance: 100 Ω to 2.5 kΩ of total resistance

100% side and slide line: with disconnection

detection

0% side: without disconnection detection

Current input: 4 to 20 mA DC (with disconnection

detection)

Input resistance: about 330 Ω

• Sampling period: 50 ms

• Measurement resolution: 0.1% of input span

• Position proportional relay output

UT55A: Two 1a-contact points , 3 A at 250 V

AC or 3A at 30 V DC (resistance load)

UT52A: Two 1a-contact points , 3 A at 240 V

AC or 3A at 30 V DC (resistance load)

*:

This should always be used with a load of 10 mA or more.

HeaterBreakAlarmSpecications(for/HAOption)

• Function: Measures the heater current using an

external current transformer (CT) and generates a

heater break alarm when the measured value is less

than the disconnection detection value.

• Number of input points: 2 points

• Number of output points: 2 points (transistor contract

output)

• CT input resistance: about 9.4 Ω

• CT input range: 0.0 to 0.1 Arms (0.12 Arms or more

cannot be applied)

• Heater current alarm setting range: OFF, 0.1 to 300.0 Arms

Heater current measured value display range: 0.0 to

360.0 Arms

*: The CT ratio can be set. CT ratio setting range: 1 to 3300

• Recommended CT: CT from URD Co. Ltd.

CTL-6-S-H: CT ratio 800, measurable current

range: 0.1 to 80.0 Arms

CTL-12L-30: CT ratio 3000, measurable current

range: 0.1 to 180.0 Arms

• Heater current measurement period: 200 ms

• Heater current measurement accuracy: ±5% of CT

input range span ±1 digit (CT error is not included)

• Heater current detection resolution: Within 1/250 of

CT input range span

• Disconnection detection ON time: Minimum 200 ms.

(for time proportional output)

24VDCLoop PowerSupplySpecications

(for /LP Option)

•

Application: Power is supplied to the 2-wire transmitter.

• Supply voltage: 21.6 to 28.0 V DC

• Rated current: 4 to 20 mA DC

• Maximum supply current: About 30 mA (with short-

circuit current limiting circuit)

Safety and EMC Standards

• Safety:

Compliant with IEC/EN 61010-1 (CE), IEC/EN 61010-

2-201 (CE), IEC/EN 61010-2-030 (CE), approved by

CAN/CSA C22.2 No. 61010-1 (CSA), approved by UL

61010-1.

Installation category: II

Pollution degree: 2

Measurement category: I (CAT I) (UL, CSA)

O (Other) (CE)

Rated measurement input voltage: Max. 10 V DC

Rated transient overvoltage: 1500 V (

*:

This is a reference safety standard value for measurement category I of CSA/UL 61010-1, and for measurement category O of IEC/EN 61010-2-030. This value is

not necessarily a guarantee of instrument performance.

*)

• EMC standards:

Compliant with

CE marking

EN 61326-1 Class A, Table 2 (For use in industrial

locations),

EN 61326-2-3

*:

The instrument continues to operate at a measurement

accuracy of within ±20% of the range during testing.

EN 55011 Class A, Group 1

EN 61000-3-2 Class A

EN 61000-3-3

EMC Regulatory Arrangement in Australia and New Zealand

EN 55011 Class A, Group 1

• KC marking: Electromagnetic wave interference

prevention standard, electromagnetic wave protection

standard compliance

PowerSupplySpecicationsand Isolation

• Power supply

Rated voltage: 100 to 240 V AC (+10%/-15%), 50/60 Hz

/DC option is specied)

• Power consumption: UT55A: 18 VA (For the /DC

option. DC: 9 VA, AC: 14 VA)

UT52A: 15 VA (For the /DC

option. DC: 7 VA, AC: 11 VA)

• Storage: Nonvolatile memory

•

Allowable power interruption time: 20 ms (at 100 V AC)

• Withstanding voltage

2300 V AC for 1 minute between primary and

secondary terminals (UL, CSA)

3000 V AC for 1 minute between primary and

secondary terminals (CE)

1500 V AC for 1 minute between primary terminals

500 V AC for 1 minute between secondary terminals

(Primary terminals = Power (*) and relay output

terminals, Secondary terminals = Analog I/O signal

terminals, contact input terminals, communication

terminals, and functional grounding terminals.)

*: Power terminals for 24 V AC/DC models are the

• Insulation resistance

Between power supply terminals and a grounding

terminal: 20 MΩ or more at 500 V DC

24 V AC/DC (+10%/-15%) (When the

secondary terminals.

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 8

• Isolation specications

The circuits divided by lines are insulated mutually.

PV (universal) input terminal

Remote (universal) input terminals with direct input / Remote input terminals

Aux. analog (AIN2) input terminals

Aux. analog (AIN4) input terminals

Control and transmission (analog) output terminal

(not isolated between the analog output terminals)

Valve position (feedback) input terminal

Control relay (c-contact) output terminal

Alarm-1 relay (a-contact) output terminal

Alarm-2 relay (a-contact) output terminal

Alarm-3 relay (a-contact) output terminal

Position proportional relay output terminal

Contact input terminal (All)

RS485 communication terminal (2 ports)

24 V DC loop power supply terminal

Contact output (transistor) terminal

Ethernet/PROFIBUS-DP/CC-Link/DeviceNet

communication terminal

Current transformer input terminal

Internal

circuits

Power

supply

Environmental Conditions

Normal operating conditions

• Ambient temperature: -10 to 50°C (side-by-side

mounting: -10 to 40 °C)

If the CC-Link option is specied, 0 to 50 °C for

UT55A, 0 to 40 °C for UT52A. (side-by-side mounting:

0 to 40 °C for UT55A and UT52A with CC-Link option)

• Ambient humidity: 20 to 90% RH (no condensation)

• Magnetic eld: 400 A/m or less

• Continuous vibration (at 5 to 9 Hz) Half amplitude of

1.5 mm or less

(at 9 to 150 Hz) 4.9 m/s2 or less, 1 oct/min for 90 minutes each in the three axis directions

• Rapid vibration: 14.7 m/s2, 15 s or less

• Impact: 98 m/s

2

or less, 11 msec.

• Installation altitude: 2,000 m or less above sea level

• Warm-up time: 30 minutes or more after the power is

turned on

• Start-up time within 10 s

Transportation and Storage Conditions

• Temperature: -25 to 70°C

• Temperature change rate: 20°C per hour or less

• Humidity: 5 to 95%RH (no condensation)

8

Effects of Operating Conditions

• Effect of ambient temperature

For voltage or TC input:

±1 μ V/°C or ±0.01% of F.S. (instrument

range)/°C, whichever is greater

For RTD input:

±0.05°C/°C (ambient temperature) or less

For current input:

±0.01% of F.S. (instrument range)/°C

For analog output:

±0.02% of F.S./°C or less

• Effect of power supply uctuation:

For analog input: ±0.05% of F.S. (instrument range)

or less

For analog output: ±0.05% of F.S. or less

(Each within rated voltage range)

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 9

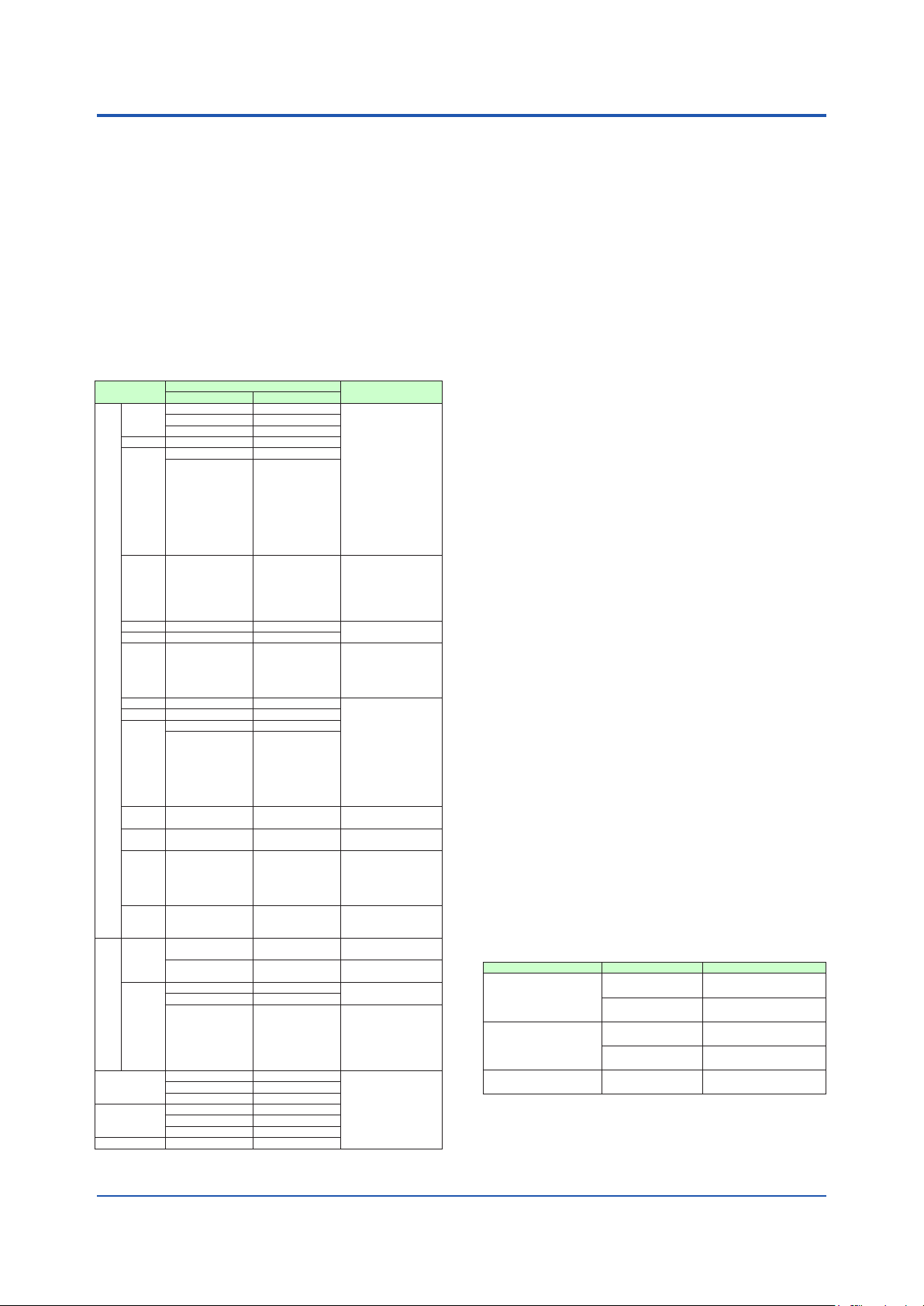

n Block Diagram

Remote input can be used when UT55A suffix

UT55A suffix code: Type 2 = 1, 2, 4, 5, or 7;

Single Loop Control (For the block diagrams of other control modes, see the user’s manual)

code: Type 2 = 1, 2, 4, 5, or 7; UT52A suffix

Equipped as standard

code: Type 2 = 1 or 2.

PV input Remote input Feedforward input Contact inputs

Communication

*1: RS-485, Ethernet, PROFIBUS-DP,

DeviceNet, CC-Link

*1

Feedforward input can be used when

UT55A suffix code: Type 2 = 7.

DI16 is equipped when

UT52A suffix code: Type 2 = 1 or 2.

9

DI16PV RSP AIN2

DI3DI2DI1

Input type

Input unit

Input range/scale

RH, RL SDP SH, SL

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

Input ladder calculation program (signal goes to the control computation as is when without ladder program). For ladder program, see the LL50A Parameters Setting Software User’s Manual.

10-seg. linearizer approx./bias

PV input bias

PV input filter

Input error preset output

Manual preset output

Manual operation

Output limiter

Preset output

IN

UNIT

A.BS

A.SR A.LC

A.FL

PMD An, Bn

PMD An, Bn

BS

FL

PV display SP display

EPO

When sensor burnout occurs

MPON

OH, OL OLMT

PO

MAN

A/M

Input type

Input unit

Input range/scale

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

Remote input filter

Anaolog input

RMS

Ratio bias computation

Control computation

CNT ALG

Output limiter

Normal

AUTO

RUNSTOP

S/R

Output terminal assignment

OUT retransmission output

IN

UNIT

RH, RL SDP SH, SL

A.BS

A.SR A.LC

A.FL

PMD An, Bn

RFL

RT RBS

LOCALREMOTE

R/L

SP limiter

SP ramp rate

OH, OL

OT

O1RS

Input type

Input unit

Input range/scale

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

COM

SPNO SP

Target setpoints 1 to 8

REMOTE (ON)/LOCAL (OFF)

SPH, SPL

UPR, DNR TMU

Filter

Gain, bias

AUTO (ON)/MAN (OFF) switch

STOP (ON)/RUN (OFF) switch

* After the control output terminal is specified by the parameter OT,

other current output terminals can be used as retransmission output.

Equipped as standard

RET retransmission output

Equipped as standard

RTS

IN

UNIT

RH, RL

A.BS

A.SR A.LC

A.FL

PMD An, Bn

switch

FLG

FGN

FBI FBO

Alarm

SDP

SH, SL

No function

is assigned

to DI3.

Output ladder calculation program (signal goes to the output as is when without ladder program). For ladder program, see the LL50A Parameter Setting Software User’s Manual.

24 V loop

power supply

LPS

10-seg. linearizer approx./bias

Split computation

OUTOUT RET AL3AL2AL1

Current or voltage pulseRelay

(Current when retransmission output)

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

PMD

An, Bn

OU.H OU.L

10-seg. linearizer approx./bias

PMD An, Bn

Split computation

RET.H RET.L

Current

Legend

Terminal Parameter Function

Analog signal Contact signal Front panel key

Alarm 1

Alarm 3

Alarm 2

(PV high limit)

(PV low limit)

(PV high limit)

GS 05P01C31-01EN

Heater break alarm

Heater break

alarm 1

HAL2HAL1

Heater break

alarm 2

Mar.14, 2016-00

Page 10

n Terminal Arrangement

(Suffix code: Type1=-1)

(Suffix code:

(Equipped

Contact rating: 250 V AC, 3A

30 V DC, 3 A

(resistance load)

When feedback input is current

E4-terminal area

E1-terminal area

Terminal Arrangement for UT55A Single Loop Control (for the terminal arrangements of other control

modes, see the user’s manual.)

Control output

Relay contact output

NC

101

NO

102

COM

103

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

Contact output

External contact output (relay)

Alarm-3 output

(PV high limit)

Common

Alarm-2 output

( PV low limit)

Common

Alarm-1 output

(PV high limit)

Common

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

Power supply

100-240 V AC power supply

Allowable range:

100-240 V AC (+10%/-15%)

(free voltage)

50/60 Hz shared

Position proportional control output

Relay contact output

HIGH

507

(direct)

LOW

508

(reverse)

COM

509

OUT

Type1=-0 or -2)

In Heating/cooling control,

relay contact output is

heating-side output.

Factory default: Control

output is relay.

(Equipped

ALM

as standard)

UT

104

AL3

105

106

AL2

107

108

AL1

109

24 V AC/DC power supply

N

L

N

110

111

112

110

-

L

+

111

112

(24 V AC/DC power supply: Option code /DC)

VALV

Feedback input

100%

510

511

512

0%

Resistance: 100 Ω to 2.5 kΩ

Feedback input

Current (mA)

+

510

input

511

-

512

Factory default: PV input

type is undefined.

PV input

TC input RTD input

202

+

-

203

Current (mA) input

E4-terminal area

101

-112

101

102

103

104

105

106

107

108

109

110

111

112

-

203

+

204

501

-512

501

502

503

504

505

506

507

508

509

510

511

512

Voltage (mV, V) input

401

-412

E3-terminal area E2-terminal area

(Suffix code: Type 1=-2)

Cooling-side control output

Relay contact output

NC

507

NO

508

COM

509

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

Current/voltage pulse output

OUT2

0-20 mA DC,

4-20 mA DC,

Voltage pulse (12V)

511

+

-

512

PV RET

as standard)

A

201

b

202

203

B

+

202

-

203

E1-terminal area

301

201

-312

-212

201

301

202

302

203

303

204

304

205

305

206

306

207

307

407

208

308

408

209

309

409

210

310

410

311

411

211

312

412

212

OUT2

Factory default: Cooling-side control output is

relay.

Can be used for retransmission output or 15 V

DC loop power supply when current/voltage

pulse output is not used for control output.

Current output range can be changed.

Retransmission output

Default: Undefined

0-20 mA DC,

4-20 mA DC

Default: 4-20 mA DC

15 V DC loop power supply

511

+

14.5-18.0 V DC

(Max. 21 mA DC)

-

512

Retransmission output

Retransmission output

Default: PV

retransmission

4-20 mA DC or

0-20 mA DC

Load resistance 600 Ω or less

Default: 4-20 mA DC

Control output

Current/voltage pulse output

0-20 mA DC,

4-20 mA DC,

Voltage pulse (12 V)

Can be used for retransmission output or 15 V DC loop power supply when

current/voltage pulse output is not used for control output.

Current output range can be changed.

In Position proportional type, can be used for retransmission output or 15 V

DC loop power supply.

15 V DC loop power supply

205

+

14.5-18.0 V DC

(Max. 21 mA DC)

-

206

Retransmission output

Default: Undefined

+

207

-

208

Default: 4-20 mA DC

Contact input

Factory default: No function

STOP when DI2=ON

RUN when DI2=OFF

AUTO when DI1=ON

MAN when DI1=OFF

Common

Function can be assigned to the terminals with no function.

(Option code /HA)

Heater break alarm

External contact output (transistor)

Heater break alarm-1

output

Heater break alarm-2

output

Common

Transistor contact rating: 24 V DC, 50 mA

511

+

-

512

Heater current detection input

CT1

CT2

COM

(Equipped as standard)

Can be used for 15 V DC loop

power supply when not used for

retransmission output.

205

+

-

206

(Suffix code: Type1=-0, -1 or -2)

OUT

15 V DC loop power supply

207

+

0-20 mA DC,

4-20 mA DC

14.5-18.0 V DC

(Max. 21 mA DC)

-

208

(Equipped as standard)

DI

External contact input

No-voltage

contact

209

210

211

212

COM

Contact rating: 12 V DC, 10 mA or more

HBA

UT

507

HAL1

508

HAL2

509

COM

510

511

512

UT

DI3

DI2

DI1

207

+

-

208

Transistor contact

UT

DI3

209

DI2

210

DI1

211

COM

212

10

+5V

+5V

+5V

101

-112

101

102

103

104

105

106

107

108

109

110

111

112

501

401

-512

-412

501

502

503

504

505

506

507

407

508

408

509

409

510

410

511

411

512

412

E3-terminal area

E2-terminal area

301

-312

201

-212

301

302

303

304

305

306

307

308

309

310

311

312

201

202

203

204

205

206

207

208

209

210

211

212

(Suffix code: Type 2=3)

Contact input

Common

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

(Suffix code: Type 2=1, 2, 4, 5, or 7

and without option code /DR)

Remote input / Contact input

Common

REMOTE when DI16=ON

LOCAL when DI16=OFF

Remote input

Specify within a

range of 1-5 V DC,

0-2 V DC,0-10 V DC

Default: 1-5 V DC

DI

External contact input

No-voltage contact

UT UT

301

COM

DI11

302

303

DI12

304

DI13

305

DI14

306

Contact rating: 12 V DC, 10 mA or more

DI15

301-306

External contact input

No-voltage contact

UT UT

303

COM

DI16

304

Contact rating: 12 V DC, 10 mA or more

305

+

-

306

Transistor contact

301

302

303

304

305

306

Function can be assigned to the

terminals with no function.

E1-Terminal Area

(Suffix code: Type 2=1, 2, 4, 5, or 7

and with option code /DR)

Universal input (Remote input)

TC input RTD input

COM

+5V

DI16

Current (mA) input

(Suffix code: Type 2=6)

Contact output

External contact output (transistor)

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Common

Transistor contact rating: 24 V DC, 50 mA

Transistor contact

COM

+5V

DI11

+5V

DI12

+5V

DI13

+5V

DI14

+5V

DI15

RSP

303

304

A

b

302

+

-

-

+

303

4-wire

Voltage (mV, V) input

303

304

B

a

+

DO

UT

301

DO15

302

DO14

303

DO13

304

DO12

305

DO11

306

COM

Function can be assigned to the

terminal with no function.

-

307-312

(Suffix code: Type 2=1, 3, 5, or 6)

RSP

301

302

303

305

302

303

Contact output

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Alarm 4 (PV low limit)

Transistor contact rating: 24 V DC, 50 mA

(Suffix code: Type 2=7)

Aux. analog input / Contact input

Factory default: No function

Aux. analog input

Specify within a

range of 1-5 V DC,

0-2 V DC,0-10 V DC

Default: 1-5 V DC

Aux. analog input can be used for

feedforward input in Single-loop control and

Single-loop position proportional control.

E2-Terminal Area

DO

External contact output

UT

307

DO25

308

DO24

309

DO23

310

DO22

311

DO21

312

COM

Common

Function can be assigned

to the terminals with no

function.

External contact input

No-voltage contact

UT UT

309

Common

Contact rating: 12 V DC, 10 mA or more

+

311

-

312

COM

DI26

310

AIN2

Transistor contact

COM

309

DI26

310

Function can be assigned

to the terminals with no

function.

+5V

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 11

11

401-412

(Suffix code: Type 2=1)

Contact input

Common

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Contact rating: 12 V DC, 10 mA or more

Contact output

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Common

Transistor contact rating: 24 V DC, 50 mA

DI

External contact input

No-voltage contact

UT UT

407

COM

DI31

408

409

DI32

410

DI33

411

DI34

412

DI35

(Suffix code: Type 2=6)

DO

External contact output

UT

407

DO35

408

DO34

409

DO33

410

DO32

411

DO31

412

COM

Function can be assigned to the

terminals with no function.

Transistor contact

407

408

409

410

411

412

Function can be assigned to the

terminals with no function.

(Suffix code: Type 3=1, except Type 2= 1 or 6)

RS-485

communication

RS-485

RS485

SDB(+)

407

SDA(-)

408

SG

409

RDB(+)

410

RDA(-)

411

PROFIBUS-DP communication (with Modbus master)

1

2

3

4

5

Pin

Signal name Description

1

VP

2

RxD/TxD-P

3 RxD/TxD-N

4 DGND

5 SHIELD

LED

Lit Unlit

CHK

User profile error Normal

(red)

Normal

RDY

Communicating

(green)

successfully

Not connected, or

ERR

communication

(red)

failure (flashing)

VP

390Ω

Data

CHK

line

RxD/TxD-P

RDY

Data

220Ω

line

ERR

RxD/TxD-N

390Ω

DGND

+5V bus power

Data signal

(positive data receive/transmit)

Data signal

(negative data recive/transmit)

Signal ground

Shield ground

No power, or

Communication

failure

Normal

PROF

(Suffix code: Type 3=4,

except Type 2= 1 or 6)

If the UT is located at

the end of a segment

for the PROFIBUS

communication wiring,

terminating resistors

are separately

needed.

These are to be

prepared by users.

(390 Ω: 2 pcs. 220 Ω:

1 pc., or an active

terminator.)

RS-485

RSB(+)

407

RSA(-)

408

SG

409

E3-Terminal Area

(Suffix code: Type 3=2, except Type 2= 1 or 6)

Ethernet communication (with gateway function)

10BASE-T/100BASE-TX

COM

DI31

DI32

DI33

DI34

DI35

RJ45 connector

+5V

+5V

+5V

+5V

+5V

Upper side LED (baud rate)

Color

Lit

Unlit

Lower side LED (link activity)

Color

Lit

Blink

Unlit

CC-Link communication (with Modbus master)

1

2

3

4

5

Pin

Signal name Description

FG

1

2

SLD

3

DG

4

DB

DA

5

LED

User profile error/

CHK

Address error

(red)

Communication failure

L ERR

(CRC error)

(red)

L RUN

Normal

(green)

Communicating successfully

DeviceNet communication (with Modbus master)

1

2

3

4

5

Pin

Signal name Description

V+

1

2

CAN_H

3

DRAIN

4

CAN_L

V-5

LED

CHK

User profile error

(red)

Normal. Communicating

successfully (green, lit).

Not connected (green, flashing).

MNS

Critical link failure (red, lit).

(green/

Communication timeout (red,

red)

flashing)

At power-on/Communication

faulted (green/red, flashing)

Amber

100M bps

10M bps

Green

Linked

Active

Link failure

DA

110Ω

CHK

DB

L ERR

L RUN

Frame ground

Shield

RX/TX signal ground

RX/TX - signal

RX/TX + signal

Lit

Normal

Normal

No carrier

detected/

Connection

timeout

CAN_H

CAN_L

CHK

MNS

DeviceNet power supply 24V

RX/TX + signal

Shield/Drain wire

RX/TX - signal

DeviceNet power supply common

Lit/flashing

Unlit

121Ω

Unlit

Normal

No electricity

RS-485

ETHR

RSB(+)

407

RSA(-)

408

SG

409

CC-L

(Suffix code: Type 3=3,

except Type 2= 1 or 6)

If the UT is located at

the end of a segment

for the CC-Link

communication wiring,

terminating resistors

are separately needed.

These are to be

prepared by users.

(110 Ω: 1 pc.)

RS-485

407

RSB(+)

RSA(-)

408

SG

409

DNET

(Suffix code: Type 3=5,

except Type 2=1 or 6)

If the UP is located at the

end of a segment for the

DeviceNet

communication wiring,

terminating resistors are

separately needed.

These are to be

prepared by users. (121

Ω: 1 pc.)

RS-485

407

RSB(+)

RSA(-)

408

SG

409

501-506

E4-Terminal Area

RS-485

communication

RS-485

RS485

(Suffix code: Type 2=1 or 2

SDB(+)

501

and without option code /LP)

SDA(-)

502

SG

503

RDB(+)

504

RDA(-)

505

RS-485 communication/24 V DC loop power supply

RS-485

RSB(+)

501

RSA(-)

502

SG

503

Contact input

Common

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Contact rating: 12 V DC, 10 mA or more

24 V DC loop power supply

21.6-28.0 V DC

(Max. 30 mA DC)

DI

No-voltage contact

RS485/LPS24

(Suffix code: Type 2=1 or 2

505

+

and with option code /LP)

-

506

(Suffix code: Type 2=5 or 6)

External contact input

UT UT

Transistor contact

501

COM

DI41

502

503

DI42

504

DI43

505

DI44

506

DI45

Function can be assigned to the

terminals with no function.

(Suffix code: Type 2=7)

Aux. analog input/Contact input

Factory default: No function

Aux. analog input

Specify within a

range of 1-5 V DC,

0-2 V DC,0-10 V DC

Default: 1-5 V DC

24 V DC loop power supply

24 V DC loop power supply

21.6-28.0 V DC

(Max. 30 mA DC)

External contact input

No-voltage contact

Common

503

504

Contact rating: 12 V DC, 10 mA or more

505

+

Aux. analog input can be used for feedforward input in

-

506

Single-loop control and Single-loop position proportional

control.

(Suffix code: Type 2=other than 1, 2, 5, 6, or 7

505

+

and with option code /LP)

-

506

AIN4

Transistor contact

UT UT

503

COM

504

DI46

Function can be assigned to the

terminals with no function.

LPS24

COM

DI46

COM

501

+5V

DI41

502

+5V

DI42

503

+5V

DI43

504

+5V

DI44

505

+5V

DI45

506

+5V

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 12

Terminal Arrangement for UT52A Single Loop Control (for the terminal arrangements of other control

(Suffix code: Type1=-1)

(Suffix code:

(Equipped

100-240 V AC

Allowable range:

100-240 V AC (+10%/-15%)

(free voltage)

50/60 Hz shared

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

Relay contact rating: 240 V AC, 1 A

When feedback input is current

In Position proportional type, can be used for retransmission output or 15 V DC

modes, see the user’s manual.)

Control output

Relay contact output

NC

101

NO

102

COM

103

Contact output

External contact output (relay)

Alarm-3 output

(PV high limit)

Common

Alarm-2 output

(PV low limit)

Common

Alarm-1 output

(PV high limit)

Common

Power supply

OUT

Type1=-0)

Terminal wiring differs in Heating/cooling

control and Position proportional control.

Refer to the terminals of Position

proportional control output and

Heating/cooling control output below.

Factory default: Control output is relay.

(Equipped

ALM

as standard)

104

AL3

105

106

AL2

107

108

AL1

109

30 V DC, 1 A (resistance load)

24 V AC/DC power supply

power supply

N

L

N

110

L

111

112

UT

-

110

+

111

112

(24 V AC/DC power supply: Option code /DC)

Position proportional control output

Relay contact output

HIGH

(direct)

LOW

(

reverse

)

COM

Contact rating: 240 V AC, 3A

30 V DC, 3 A

(resistance load)

101

102

103

Feedback input

100%

310

311

312

0%

Resistance: 100 Ω to 2.5 kΩ

Feedback input

Current (mA)

input

310

+

311

-

312

VALV

Factory default:

PV input type is

undefined.

PV input

TC input RTD input

Current (mA) input

E1-terminal area

101

-112

101

102

103

104

105

106

107

108

109

110

111

112

OUT2

OUT

OUT2

PV

as standard)

A

202

+

-

203

-

203

+

204

(Suffix code: Type 1=-2)

Heating/cooling control output

Heating/cooling relay contact output

Cooling

NO

-side

Heating

NO

-side

COM

Contact rating: 240 V AC, 3 A

30 V DC, 3 A (resistance load)

Current/voltage pulse output

0-20 mA DC,

4-20 mA DC,

Voltage pulse (12 V)

201

b

202

B

203

Voltage (mV, V) input

202

+

-

203

301

201

-312

-212

301

201

302

202

303

203

304

204

305

205

306

206

207

307

208

308

209

309

310

210

211

311

312

212

101

102

103

Retransmission output

Default: Undefined

311

+

0-20 mA DC,

4-20 mA DC

-

312

Default: 4-20 mA DC

Factory default: Cooling-side control output is

relay.

Can be used for retransmission output or 15 V DC

loop power supply when current/voltage pulse

output is not used for control output.

Current output range can be changed.

+

311

-

312

15 V DC loop power supply

+

311

14.5-18.0 V DC

(Max. 21 mA DC)

-

312

Retransmission output

Retransmission output

Default: PV retransmission

4-20 mA DC or

0-20 mA DC

Load resistance 600 Ω or less

Default: 4-20 mA DC

Control output

Current/voltage pulse output

0-20 mA DC,

4-20 mA DC,

Voltage pulse (12 V)

Can be used for retransmission output or 15 V DC loop power suppy when

current/voltage pulse output is not used for control output.

Current output range can be changed.

loop power supply.

15 V DC loop power supply

205

+

14.5-18.0 V DC

(Max. 21 mA DC)

-

206

Retransmission output

Default: Undefined

+

207

0-20 mA DC,

4-20 mA DC

-

208

Default: 4-20 mA DC

Contact input

Factory default: No function

STOP when DI2=ON

RUN when DI2=OFF

AUTO when DI1=ON

MAN when DI1=OFF

Common

Function can be assigned to the terminals with no function.

(Option code /HA)

Heater break alarm

Heater break alarm-1

Heater break alarm-2

Transistor contact rating: 24 V DC, 50 mA

Heater current detection input

(Equipped as standard)

RET

Can be used for 15 V DC loop

power supply when not used for

retransmission output.

+

205

-

206

(Suffix code: Type1=-0, -1 or -2)

OUT

15 V DC loop power supply

+

207

14.5-18.0 V DC

(Max. 21 mA DC)

-

208

(Equipped as standard)

DI

External contact input

No-voltage

contact

Contact rating: 12 V DC, 10 mA or more

External contact output (transistor)

output

output

Common

CT1

CT2

COM

Transistor contact

UT

DI3

209

210

DI2

211

DI1

212

COM

HBA

307

HAL1

308

HAL2

309

COM

310

311

312

+

207

-

208

UT

DI3

209

DI2

210

DI1

211

COM

212

UT

12

+5V

+5V

+5V

301-306

(Suffix code: Type 2=1)

RS-485 communication / Remote input / Contact input

RS-485

RSB(+)

301

RSA(-)

302

SG

303

External contact input

No-voltage contact

Common

REMOTE when DI16=ON

LOCAL when DI16=OFF

(Suffix code: Type 2=2

and without option code /DR)

Contact rating: 12 V DC, 10m A or more

Remote input/ Contact input

External contact input

No-voltage contact

Common

REMOTE when DI16=ON

LOCAL when DI16=OFF

Contact rating: 12 V DC, 10m A or more

RSP/RS485

Specify within a

range of 1-5 V DC,

0-2 V DC,0-10 V DC

Default: 1-5 V DC

Transistor contact

UT UT

303

COM

DI16

304

RSP

Transistor contact

UT UT

303

COM

DI16

304

Remote input

COM

303

DI16

304

COM

303

DI16

304

Remote input

305

+

Specify within a

range of 1-5 V DC,

0-2 V DC,0-10 V DC

-

306

Default: 1-5 V DC

(Suffix code: Type 2=2

and with option code /DR)

305

+

-

306

+5V

(Option code /LP)

24 V DC loop power supply

+5V

21.6-28.0 V DC

(Max. 30 mA DC)

E1-Terminal Area

Universal input (Remote input)

TC input RTD input

302

+

-

303

Current (mA) input

-

303

+

304

24 V DC loop power supply

305

+

-

306

RSP

301

A

302

b

303

B

a

305

4-wire

Voltage (mV, V) input

302

+

-

303

LPS24

(Suffix code: Type 3=3)

CC-Link communication (with Modbus master)

Shield

- signal

+ signal

Not used

CHK(red)

CC-L

301

302

303

304

305

306

307

308

309

If the UT is located at the end of a

segment for the CC-Link

communication wiring,terminating

resistors are separately needed.

These are to be prepared by

users. (110 Ω: 1 pc.)

DB

110Ω

DA

(Lit: User profile error/Adress error, Unlit: Normal)

(Lit: Communication failure(CRC error), Unlit: Normal)

(Lit: Normal, Unlit: No carrier detected/Communication timeout)

FG:

DG:

TX/RX signal ground

DB:

RX/TX signal

RX/TX signal

DA:

Flame ground

SLD:

L ERR(red)

L RUN(green)

(Suffix code: Type 2=3)

Contact input / Contact output

External contact input

No-voltage contact

Common

Factory default: No function

Factory default: No function

Factory default: No function

Factory default: No function

Transistor contact rating: 24 V DC, 50 mA

External contact output

Common

Contact rating: 12 V DC, 10 mA or more

304

DO12

305

DO11

306

COM

DI/DO

Transistor contact

UT UT

301

COM

DI11

302

303

DI12

Function can be

assigned to the

UT

terminals with no

function.

COM

301

+5V

DI11

302

+5V

DI12

303

RS-485

RSB(+)

RSA(-)

310

311

SG

312

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 13

nExternalDimensionsandPanelCutoutDimensions

92

“N” stands for the number of controllers to be

However, the measured value applies if N≥5.

11

11

• General mounting

“N” stands for the number of controllers to be

5.

UT55A

96

65

Bracket

20

13

Unit: mm

Terminal cover

UT52A

96

• General mounting • Side-by-side close mounting

117 min.

(53)

+0.8

0

+0.8

92

(25)

0

48

145

min.

96

1 to 10 mm (panel thickness)

0

+0.8

92

installed.

Normal tolerance:

±(value of JIS B 0401-1998 tolerance class IT18)/2

65

91.6

Bracket

[(N-1)×96+92]

Bracket

20

Terminal cover

91.6

94.6

94.6

+0.8

105.2

105.2

0

Unit: mm

70 min.

(25)

145

min.

(53)

+0.8

92

0

+0.6

45

0

n Construction, Mounting, and Wiring

• Dust-proof and drip-proof: IP66 (Front panel) (Except

for side-by-side close mounting)/NEMA4 *

*: Hose-down test only

•

Material: Polycarbonate resin (Flame retardancy: UL94 V-0)

• Case color: White (Light gray) or Black (Light Charcoal gray)

• Weight: 0.5 kg or less

• External dimensions (mm):

UT55A: 96 (width) x 96 (height) x 65 (depth from the

panel surface)

UT52A: 48 (width) x 96 (height) x 65 (depth from the

panel surface)

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

Bracket

1 to 10 mm (panel thickness)

• Side-by-side close mounting

0

+0.8

92

installed.

However, the measured value applies if N≥

Normal tolerance:

±(value of JIS B 0401-1998 tolerance class IT18)/2

[(N-1)×48+45]

+0.6

0

• Mounting: Direct panel mounting; mounting bracket,

one each for upper and lower mounting

• Panel cutout dimensions (mm):

UT55A: 92+

UT52A: 45+

0.8/0

(width) x 92+

0.6/0

(width) x 92+

0.8/0

(height)

0.8/0

(height)

• Mounting position: Up to 30 degrees above the hori-

zontal. No downward titling allowed.

• Wiring: M3 screw terminal with square washer (signal

wiring and power)

GS 05P01C31-01EN

Mar.14, 2016-00

Page 14

nModelandSufxCode

Option

Model Sufxcode

UT55A

Type 1:

Basic

control

-0 Standard type

-1 Position proportional type

-2 Heating/cooling type

0 None

1

Type 2:

Functions

2

3 5 additional DIs and 5 additional DOs

4 Remote (1 additional aux. analog) input and 1 additional DI

5 Remote (1 additional aux. analog) input, 6 additional Dls, and 5 additional DOs

6 5 additional DIs, and 15 additional DOs

7 3 additional aux. analog inputs and 3 additional DIs

0 None

1 RS-485 communication (Max. 38.4 kbps, 2-wire/4-wire)

Type 3:

Open networks

2 Ethernet communication (with serial gateway function)

3 CC-Link communication (with Modbus master function)

4 PROFIBUS-DP communication (with Modbus master function)

5 DeviceNet communication (with Modbus master function)

-1 English (Default. Can be switched to other language by the setting.)

-2 German (Default. Can be switched to other language by the setting.)

Display language

(*3)

-3 French (Default. Can be switched to other language by the setting.)

-4 Spanish (Default. Can be switched to other language by the setting.)

Case color

0 White (Light gray)

1 Black (Light charcoal gray)

Fixed code -00 Always “-00” (for Standard Code Model)

Option codes

*1: When the Type 2 code is “1” or “6”, only “0” can be specied for the Type 3 code.

*2: When the /LP option is specied, the RS-485 communication of the Type 2 code “1” or “2” is 2-wire system.

*3: English, German, French, and Spanish are available for the guide display.

*4: The /DR option can be specied when the Type 2 code is any of “1”, “2”, “4”, “5”, or “7.”

*5:

The /LP option can be specied in the combination of Type 2 code (any of

be specied in the combination of Type 2 code “1” and Type 3 code “0”.

*6: The /HA option can be specied only when the Type 1 code is “-0.”

*7:

When the /CT option is specied, the UT55A does not conform to the safety standards (UL and CSA) and CE marking (Products with /CT option are not intended for EEA-market).

Model Sufxcode

UT52A

Type 1:

Basic

control

-0

-1

-2

0

Type 2:

Functions

1

2

3 2 additional DIs, and 2 additional DOs

Type 3:

Open networks

0 None

3 CC-Link communication (with Modbus master function)

-1 English (Default. Can be switched to other language by the setting.)

-2 German (Default. Can be switched to other language by the setting.)

Display language

(*2)

-3 French (Default. Can be switched to other language by the setting.)

-4 Spanish (Default. Can be switched to other language by the setting.)

Case color

0 White (Light gray)

1 Black (Light charcoal gray)

Fixed code -00

Option codes

*1: The Type 3 code “3” can be specied only when the Type 1 code is “-0” and the Type 2 code is “0.”

*2: English, German, French, and Spanish are available for the guide display.

*3: The /DR option can be specied only when the Type 2 code is “2” and the Type 3 code is “0.”

*4: The /LP option can be specied only when the Type 1 code is “-0” or “-1.” Furthermore both Type 2 and Type 3 codes should be “0.”

*5: The /HA option can be specied only when the Type 1 code is “-0” and the Type 3 code is “0.”

*6:

When the /CT option is specied, the UT52A does not conform to the safety standards (UL and CSA) and CE marking (Products with /CT option are not intended for EEA-market).

code

Description

Digital Indicating Controller (Power supply 100-240 V AC)

(provided with retransmission output or 15 V DC loop power supply , 3 DIs, and 3 DOs)

Remote (1 additional aux. analog) input, 6 additional DIs, 5 additional DOs, and RS-485 commuication

(Max. 19.2 kbps, 2-wire/4-wire)

Remote (1 additional aux. analog) input, 1 additional DI, and RS-485 communication (Max. 19.2 kbps,

2-wire/4-wire)

Additional direct input (TC &, 3-wire/4-wire RTD) and current to Remote (1 additional aux. analog) input, 1

/DR

DI to be deleted

/LP 24 V DC loop power supply

/HA Heater break alarm

/DC Power supply 24 V AC/DC

/CT Coating

Mount on DIN rail (without the display parts and keys) (please see the General Specications GS

/MDL

05P01C81-01EN.)

Option

(*2)

(*4)

(*6)

(*7)

code

(*1) (*2)

(*1)

(*5)

“0”, “2”, “3”, or “4”) and Type 3 code (any of “0” or “1”). Additionally the /LP option can

Description

Digital Indicating Controller (Power supply 100-240 V AC)

(provided with retransmission output or 15 V DC loop power supply , 3 DIs, and 3 DOs)

Standard type

Position proportional type

Heating/cooling type

None

Remote (1 additional aux. analog) input, 1 additional DI, and RS-485 commuication (Max. 38.4 kbps, 2-wire )

Remote (1 additional aux. analog) input and 1 additional DI

(*1)

Always “-00” (for Standard Code Model)

Additional direct input (TC & 3-wire/4-wire RTD) and current to Remote (1 additional aux. analog) input, 1

/DR

DI to be deleted

24 V DC loop power supply

/LP

Heater break alarm

/HA

Power supply 24 V AC/DC

/DC

Coating

/CT

Mount on DIN rail (without the display parts and keys) (please see the General Specications GS

/MDL

05P01C81-01EN.)

(*3)

(*6)

(*4)

(*5)

14

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

GS 05P01C31-01EN

Mar.14, 2016-00

Page 15

nItemstobespeciedwhenordering

Model and sufx codes, whether User’s Manual and

QIC required.

n Standard accessories

Terminal cover, Brackets (mounting hardware), Unit

label, and Operation Guide for Single-loop Control.

n Special Order Items

Model code

LL50A

X010

*: Necessary to input the current signal to the voltage

input terminal.

Name

Terminal cover (for UT55A) UTAP001

Terminal cover (for UT52A) UTAP002

User’s Manual (CD) UTAP003

User’s Manual

Product user’s manuals can be downloaded or viewed

at the following URL. To view the user’s manual, you

need to use Adobe Reader 7 or later by Adobe Systems.

URL: http://www.yokogawa.com/ns/ut/im/

Sufxcode Description

-00 Parameter Setting Software

See the General Specications

Resistance Module

(*)

Model

15

All Rights Reserved. Copyright © 2009, Yokogawa Electric Corporation

Subject to change without notice.

GS 05P01C31-01EN

Mar.14, 2016-00

Loading...

Loading...