Page 1

<<Contents>> <<Index>>

General

Specifications

MODEL UT520

Digital Indicating Controller

GS 05D01C02-02E

■General

Model UT520 Digital Indicating Controller is an intelligent,

micro-processor based digital indicating controller with

powerful control capability and the user-friendly large

numerical display. The UT520 features as standard many

functions which are necessary for various control applications, and all of these functions such as control function,

control computation function, signal computation function,

etc. can be configured by using the keys on the front panel.

The instrument has eight types of control strategies and

also an overshoot suppressing function "SUPER" and a

hunting suppressing function "SUPER 2" as well as an

auto-tuning function built in as standard. Panel size is

small, 48 mm (width)

saving space.

×

96 mm (height), and designed for

■Main Features

• High resolution display of 5 digits. Since LEDs of 12 mm

height are used for displaying measured values, the display

is clearly read.

• The front panel size is 48 mm (width) × 96 mm (height)

and the depth is 100 mm, designed for saving space.

• Eight types of control function, including single-loop

control, cascade control, loop control with PV autoselector, and loop control with PV-hold function, enabling

the operator to start control operation immediately after

simply entering the settings.

• Parameter can be easily set using a personal computer.

("Parameter setting tool (model LL100)" sold separately is

required.)

• Universal input and output enables users to set or change

freely the type of measured inputs, measurement input

range, type of control output, etc. from the front panel.

• Contact inputs (up to 4 points) and contact outputs (up to

4 points)

assigned to each contact (The maximum number of points

varies depending on the specification code.)

• Various communication function are provided.

Communication is possible with personal computer,

programable logic controller, and other controllers.

Note

can be employed and functions can be

Note: See the Hardware Specifications and Contact Outputs

described later.

■Functional Specifications

● Control Functions

UT Mode

The following types of basic control structure can be set as

the UT mode by the user.

Single-loop control (UT mode 1):

Cascade primary-loop control (UT mode 2):

Cascade secondary-loop control (UT mode 3):

The most simple and basic control function.

Output tracking function and cascade control

logic are provided. Suitable for primary-loop

cascade control.

Setpoint output and the cascade control logic

are provided. Suitable for secondary-loop

cascade control.

UT520

UT520E

“E” indicates the model

with expanded functions.

Cascade control (UT mode 4):

Dual control function for cascade control is

available in a single instrument.

Loop control for back-up (UT mode 5):

Output tracking function is provided to back

up another control instrument. The local and

remote control outputs are switched by a

contact input.

Loop control with PV switching (UT mode 6):

Two measured inputs are switched for control

depending on the status of contact input or

measured input.

Loop control with PV auto-selector (UT mode 7):

Two measured inputs are automatically

selected for control with a high, low, or

average, or temperature-difference value

selector.

Loop control with PV-hold function (UT mode 8):

This control holds a PV input and a control

output if an external sensor is switched.

● Control Computation Functions

In each UT mode, the following control computation

functions can be selected.

Continuous PID control, Time-proportional

PID control, and Relay ON/OFF control.

Target setpoint and PID parameters:

Maximum eight sets of target setpoint and PID

parameters can be set. These eight sets can be

set for both the main and slave loops in

cascade control.

Zone PID selection:

Dividing measuring range into maximum 7

zones by maximum 6-reference points, PID

parameter set switching in up to 7 measured

input zones.

Auto-tuning:

Available as standard. Possible to activate

auto-tuning for both main and slave loops for

cascade control.

GS 05D01C02-02E

© Copyright Feb. 2000 (YK)

1st Edition Mar. 2000 (YG)

Page 2

<<Contents>> <<Index>>

2

Preset output function:

When the instrument is in STOP mode,

measured input is burnt-out, or an abnormality

is found in an input circuit, a preset value is

output as a control output.

"SUPER" function:

Overshoots generated by abrupt changes in the

target setpoint or by disturbances can be

suppressed.

"SUPER 2" function:

The function stabilizes the state of control that

is unstable due to hunting, etc. without

requiring any change in PID constants, when

the load and/or gain varies greatly, or when

there is a difference between the characteristics of temperature zones.

Control cycle time

Each cycle time can be selected under the

following conditions.:

50 ms: Available for model code UT520-00, when

UT mode is set to Single-loop control and

the following functions are not used:

"SUPER" function, "SUPER 2" function,

PV input computation, setpoint rate-ofchange limiter, MV output rate-of-change

limiter, deviation alarm, sensor grounding

alarm, fault diagnosis alarm, and FAIL

output.

100 ms: Available when UT mode is not cascade

control.

200 ms: Available when UT mode is cascade control.

(Set value on shipped from the factory: 200 ms)

Operation Mode Switching

(Note: Communication enables all the following

mode switching to be executed.)

AUTO/MANUAL switching:

Bumpless switching between automatic

operation mode and manual control mode is

available by using the front keys or contact

input. The contact input has priority over

front key input or switching by communication. The contact input is invalid for Cascade

secondary-loop control or Cascade control.

RUN/STOP switching:

Switching by contact input (bumpless for

switching from STOP to RUN). The contact

input has priority over switching by communication. In RUN mode, control computation is

activated. In STOP mode, control computation ceases and a preset value is output as a

control output while other functions operate

normally.

REMOTE/LOCAL switching:

Switching between remote setpoint and local

setpoint by instrument operation or contact

input. The contact input has priority over

instrument operation or switching by

communication. For remote to local switching, either bumpless tracking (employing the

remote setpoint on switching as the local

setpoint) or without tracking (directly

switching the local setpoint) can be specified.

CASCADE/AUTO/MANUAL switching:

Switching by instrument operation or contact

input. The contact input has priority over

instrument operation or switching by

communication. Valid for Cascade second-

Output tracking ON/OFF switching:

ary-loop control or Cascade control.

Provided for Cascade primary-loop control or

Loop control for backup. External tracking

signal and internal control output are switched

by the contact input. The contact input has

priority over the switching by communication.

Control Parameters Setting Range

Proportional band: 0.1 to 999.9%

Integral time: 1 to 6,000 s, or OFF (for Manual reset)

Derivative time: 1 to 6,000 s, or OFF

ON/OFF control hysteresis:

0.0 to 100.0% of measured input range width

Preset output: -5.0 to 105.0% of the output (0 mA or less

cannot be output)

Output limiter:

Setting range: -5.0 to 105.0% for both high

and low limits

However, "low limit setpoint < high limit

setpoint" must be satisfied.

Shutdown function:

When manual control is carried out with 4 to

20 mA output, control output can be output

down to about 0 mA (shutdown is specified

for -5.0% or less).

Rate-of-change limiter for output:

OFF or 0.1 to 100.0%/s

● Configuration of Input/Output Signal

Measured Input Computations

Input processing, Square root extraction (voltage input only,

Input low cut 0.0 to 5.0%), Ten-segment linearizer function,

Ten-Segment bias, Bias addition (-100.0 to 100.0%), and

First order lag filter (OFF, time constant 1 to 120 s)

Auxiliary Input Computations

(Applied to remote setting input only)

Input processing, Square root extraction (Input low cut 0.0 to

5.0%), Bias addition (-100.0 to 100.0%), Ratio multiplication

(0.001 to 9.999), and First order lag filter (OFF, time

constant 1 to 120 s)

● Alarm Functions

Alarm types:

PV high limit, PV low limit, Deviation high

limit, Deviation low limit, Deenergized on

deviation high limit, Deenergized on deviation

low limit, Deviation high and low limits, High

and low limits within deviation, Deenergized

on PV high limit, Deenergized on PV low

limit, SP high limit, SP low limit, Output high

limit, Output low limit.

Alarm setting range:

PV/SP alarm: -100 to 100% of measured input

range

Deviation alarm: -100 to 100% of measured

input range span

Output alarm: -5.0 to 105.0% of output value

Alarm hysteresis: 0.0 to 100.0% of measured

input range span

Delay timer:

0.00 to 99.59 (minute, second)

An alarm is output when the delay timer

expires after the alarm setpoint is reached.

Setting for each alarm is possible.

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E 1st Edition Mar. 31, 2000-00

Page 3

<<Contents>> <<Index>>

3

Stand-by action:

Stand-by action can be set to make PV/

deviation alarm OFF during start-up or after

SP change until SP reaches the normal region.

Timer function (stabilization of control status notification

event) (Alarm 1 only):

This function sets the alarm 1 output to ON

when a preset time (timer setting) elapses after

a PV has reached to the control target setpoint

hysteresis band to notify that processing has

completed. Restarted in RUN/STOP or SP

switching.

Other alarm actions:

Sensor grounding alarm: Detects sensor deterioration and

outputs an alarm.

Fault-diagnosis alarm: For input burnout, A/D conver-

sion error, or thermocouple reference

junction compensation error.

FAIL output: Abnormality in software or hardware.

Number of alarm settings: 4

The alarm status can be read via communication in addition to output as the above alarm

output.

Alarm output points (see also the item "Contact Outputs")

Number of contact (relay) outputs: 3 (standard) or 4 (if a control output relay is used for

the alarm 4 output relay.)

Any of PV alarm, deviation alarm, SP alarm, output alarm,

Fault-diagnosis alarm, sensor grounding alarm and FAIL

output can be assigned to contacts for the above number of

outputs. However, the timer delay alarm can be assigned

to the alarm 1 output only. Also, the alarm 4 only can be

assigned to the control output relay (if a relay is not used

for control output).

● Display and Operation Functions

PV Display

PV is displayed on the 5-digit display. PV1 and PV2 are

displayed by switching them in cascade control. The number

of display digits is 4 or 5. For thermocouple or RTD, data

below the decimal point can be set not to display. The

display range is -19999 to 30000 and the display span is

30000 or less. [520.00 appearing in the product photograph

on page 1 cannot actually be displayed.]

Setpoint Display

A parameter name is displayed in the 3-digit display and data

in the 5-digit display. There are four kinds of displays :

operating display, operating parameter setting display, setup

parameter setting display and SELECT display.

Operating display:

Data necessary for operations, such as setpoint

or control output, are displayed depending on

the UT mode.

Operating parameters setting display:

The Operating parameters, which are mainly

changed during operation, such as PID

constant, are displayed.

Setup parameters setting display:

The Setup parameters to configure the

functions of the instrument before starting

operation are displayed.

UT model is to be set in this display.

SELECT display:

Up to five displays which are frequently

accessed can be selected from the Operating

parameters setting display and Setup parameters setting display to be displayed in the

SELECT display.

Status Lamps

Alarm indicating lamp:

Four lamps, AL1, AL2, AL3, and AL4

Operation mode indicating lamp:

REM (remote operation), MAN (manual mode

operation), CAS (cascade operation), and LP2

(cascade secondary-loop control)

Operation Keys

n, , keys: Increases or decreases setpoints and other

parameters displayed in the setpoint display.

SET/ENT key: Used for setting or change set data,

switching the displayed contents, and

switching operation modes except for A/M.

A/M key: Operation mode switching (Auto/Man)

Security Function

Key-lock by parameters setting and prohibiting operation are available by a password

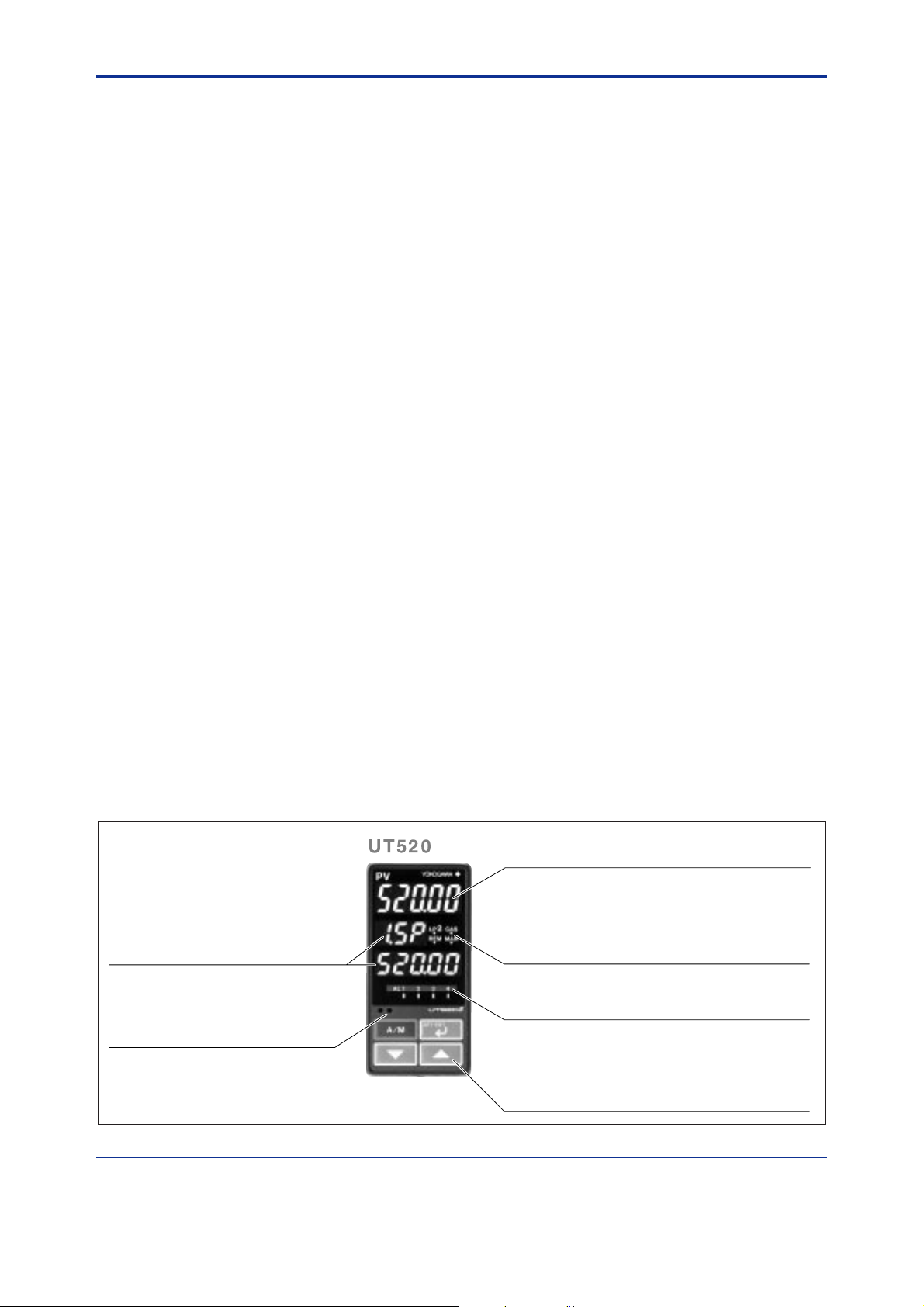

Measured value (PV) display unit

Displays PV and error codes when errors are detected.

Status lamps

Cascade operation(CAS) and

Data display unit

Displays setpoints (SP), output

values, valve opening,or parameters.

Communication port for light loader

Parameters are set via communication

from a personal computer.

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E 1st Edition Mar. 31, 2000-00

remote operation(REM)

Manual operation (MAN)

Lit for secondary parameter indication (LP2)

Alarm indicating lamps

Displays alarms

(AL1, AL2, AL3, or AL4).

Operation keys

Increase/decrease of the setting data (n, ,)

Screen switching/parameter selection/entry

of set data (SET/ENT)

Auto/manual operation mode selection (A/M)

Page 4

<<Contents>> <<Index>>

4

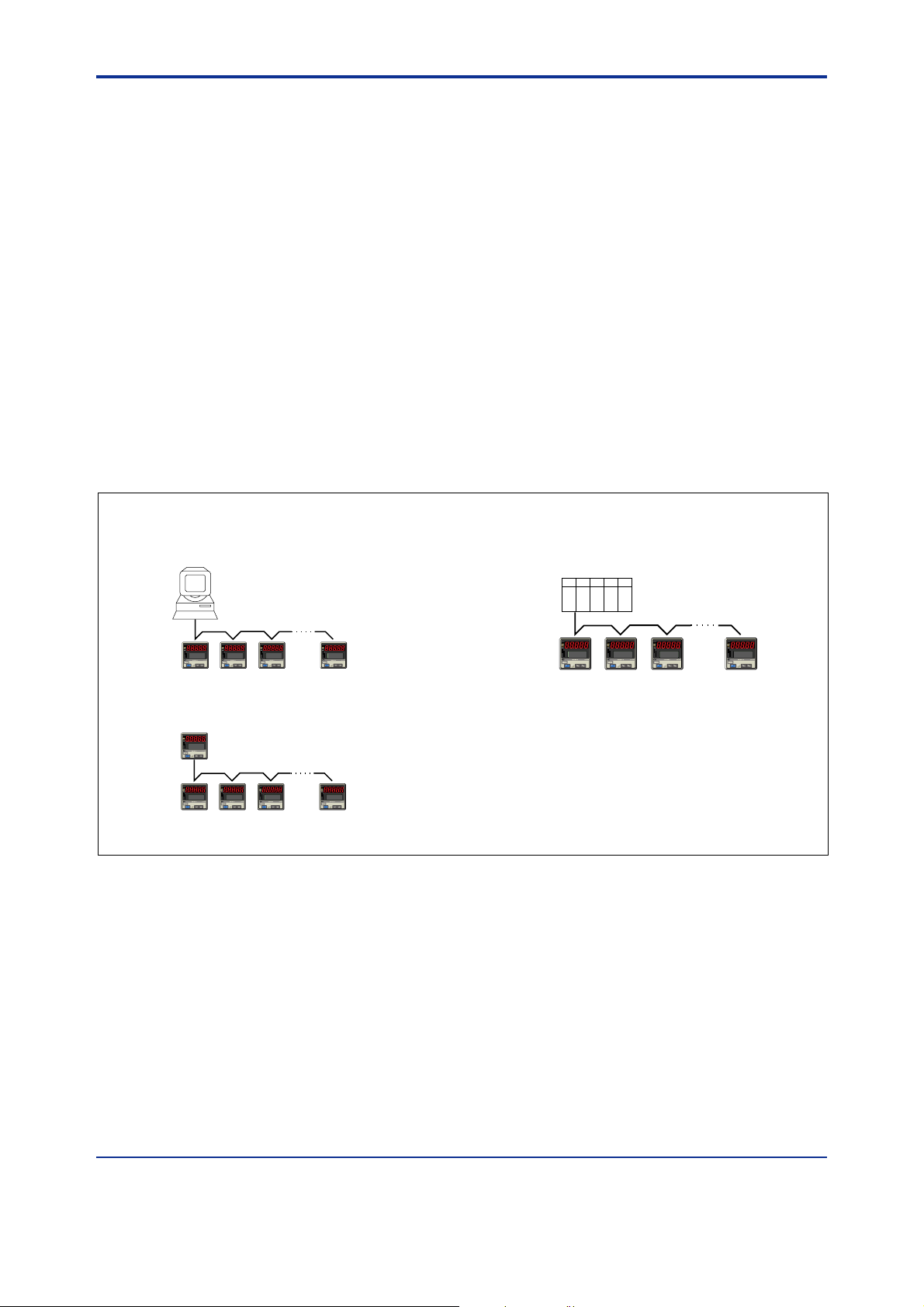

● Communication Functions

(For optional function code h7 only)

This controller has four types of communication protocol

with one communication interface. Communication is

possible with personal computer, programmable logic

controller, and other controllers.

Communication Protocol

Computer link communication:

Communication protocol with a personal

computer

Ladder communication:

Communication protocol with the ladder

program on some programmable logic

controllers.

Coordinated operation:

Protocol for coordinated operation with more

than one GREEN SERIES controller. The

UT520 controller can be connected as a

master or slave station.

MODBUS communication:

Communication protocol with a personal

computer, or PLC.

Examples of Communication System Configuration Diagram

(1)Personal computer link communication/

MODBUS communication

Personal computer

RS-485 Communication Interface

The RS485 communication interface (conforms to EIA

RS485) can be used for personal computer link, ladder

communication, MODBUS communication or for coordinated operation.

Maximum number of connectable controllers:

GREEN SERIES controller 31

Maximum communication distance: 1200 m

Communication method:

Two-wire half-duplex or four-wire half-

duplex, start-stop synchronization, and non-

procedural

Communication rate:

600, 1200, 2400, 4800, or 9600 bps

(2) Ladder communication

MELSEC-A

Programmable logic controller

PV

PV

PV2

AL

REM

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

PV

PV2

PV2

AL

AL

REM

REM

MAN1

MAN1

MAN2

MAN2

STP

STP

CAS

CAS

A/M

A/M

DISP

DISP

SET/ENT

SET/ENT

PV

PV2

AL

REM

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

UT550, UT520

Digital indicating controller

(3) Coordinated operation

PV

PV2

UP750, UP550 Program controller

AL

REM

MAN1

MAN2

STP

CAS

or

A/M

DISP

SET/ENT

UT750, UT550, UT520 Digital indicating controller

PV

PV

PV2

AL

REM

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

PV

PV2

PV2

AL

AL

REM

REM

MAN1

MAN1

MAN2

MAN2

STP

STP

CAS

CAS

A/M

A/M

DISP

DISP

SET/ENT

SET/ENT

PV

PV2

AL

REM

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

UT550, UT520

Digital indicating controller

PV

PV

PV2

PV2

AL

AL

REM

REM

MAN1

MAN1

MAN2

MAN2

STP

STP

CAS

CAS

A/M

A/M

DISP

SET/ENT

PV

PV2

AL

REM

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

DISP

SET/ENT

UT550, UT520

Digital indicating controller

PV

PV2

AL

REM

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E 1st Edition Mar. 31, 2000-00

Page 5

<<Contents>> <<Index>>

5

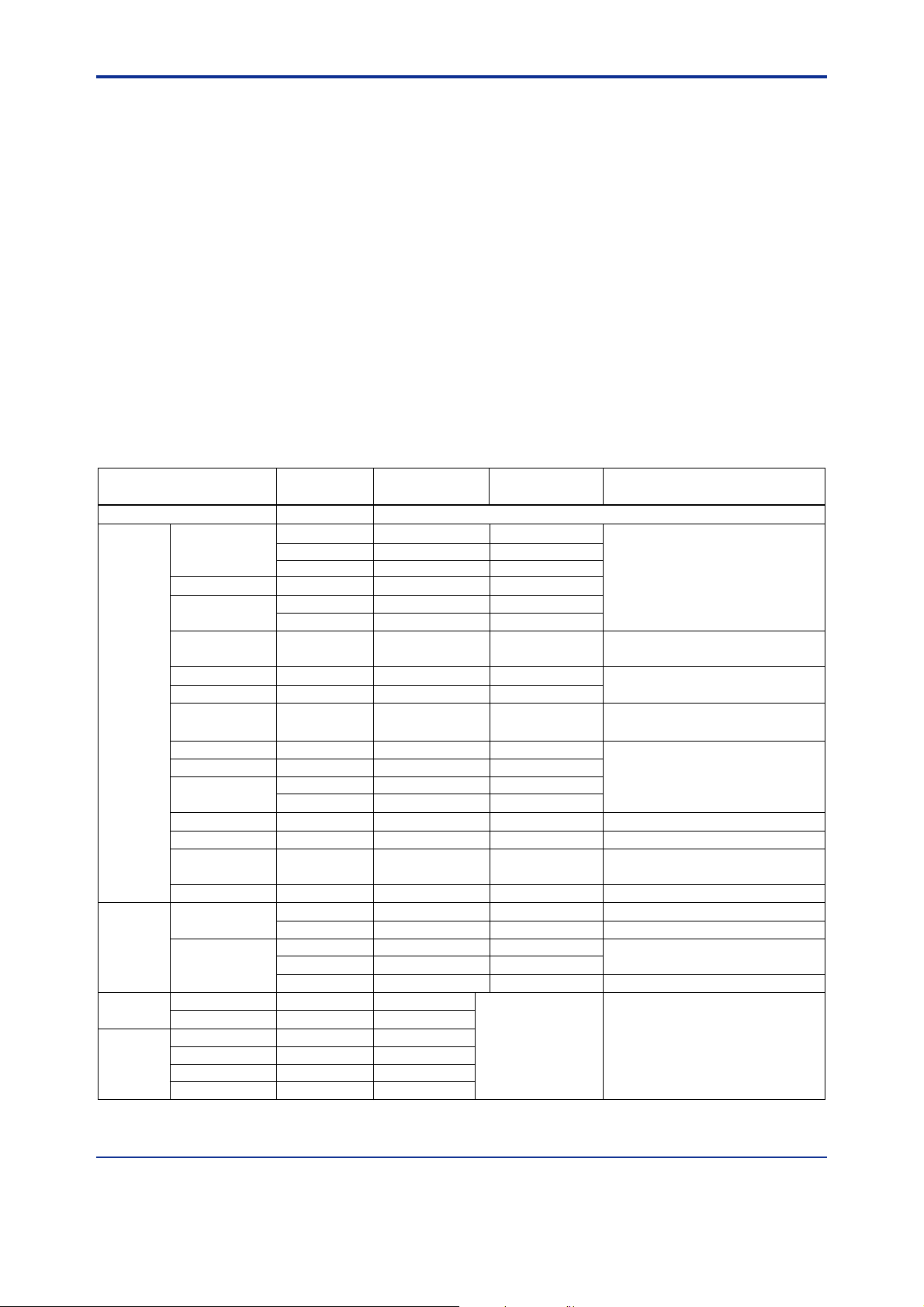

■Hardware Specifications

● Input/Output Signal Specifications

Measured Input Signal

Number of input points: 1

Type of input, measurement range, and measurement

Sampling period: 50, 100, 200 or 500 ms (selectable)

Burnout detection:

Input bias current: 0.05 µA (for TC or RTD b-terminal)

Measurement current(RTD): about 0.13 mA

Input resistance:

Unspecified (When shipped from the factory)

Thermocouple

RTD

Standard

signal

DC voltage

accuracy:

The type of input and measurement range can

be specified from the input range code shown

in the table below.

Activated for thermocouple (TC) input, RTD

input, or standard signal of 0.4 to 2 V DC or

1 to 5 V DC.

Possible to specify a travel of upscale,

downscale, or off.

For standard signal input (see the table

below), set to burn out at 0.1 V or less.

1 MΩ or more for TC or mV input

About 1 MΩ for DC voltage input

Input type

K

J

T

B

S

R

N

E

L (DIN)

U (DIN)

W (DIN)

Platinel 2

PR20-40

W97Re3-W75Re25

JPt100

Pt100

0.4 to 2V

1 to 5V

0 to 2V

0 to 10V

-10 to 20mV

0 to100mV

Input range

code

OFF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

30

31

35

36

37

40

41

50

51

55

56

Set the data item PV input type “IN 1” to the OFF option to leave the PV input type undefined.

-10.00 to 20.00 mV

Instrument

range (°C)

-270.0 to 1370.0°C

-270.0 to 1000.0°C

-200.0 to 500.0°C

-200.0 to 1200.0°C

-270.0 to 400.0°C

0.0 to 400.0°C

0.0 to 1800.0°C

0.0 to 1700.0°C

0.0 to 1700.0°C

-200.0 to 1300.0°C

-270.0 to 1000.0°C

-200.0 to 900.0°C

-200.0 to 400.0°C

0.0 to 400.0°C

0.0 to 2300.0°C

0.0 to 1390.0°C

0.0 to 1900.0°C

0.0 to 2000.0°C

-200.0 to 500.0°C

-150.00 to 150.00°C

-200.0 to 850.0°C

-200.0 to 500.0°C

-150.00 to 150.00°C

0.400 to 2.000 V

1.000 to 5.000 V

0.000 to 2.000 V

0.00 to 10.00 V

0.0 to 100.0 mV

Allowable signal source resistance:

250 Ω or less for TC or mV input

Signal source resistance effect

0.1 µV/Ω or less

2 kΩ or less for DC voltage input

Signal source resistance effect

Approx. 0.01%/100 Ω

Allowable leadwire resistance (for RTD input):

Maximum 150 Ω/one wire (Lead resistances

of three wires must be equal.)

However, it must be 10 Ω/one wire for the

range of -150.0 to 150.0°C.

Effect of wiring resistance: ±0.1°C/10 Ω

Allowable input voltage:

±10 V DC for TC/mV/RTD input

±20 V DC for DC voltage input

Noise rejection ratio:

Normal mode 40 dB (50/60 Hz) or more

Common mode 120 dB (50/60 Hz) or more

Reference junction compensation error:

±1.0°C (15 to 35°C), ±1.5°C (0 to 15°C and

35 to 50°C)

Applicable standards: JIS, IEC, and DIN (ITS-90) for TC

and RTD

Instrument

range (°F)

-450.0 to 2500.0°F

-450.0 to 2300.0°F

-200.0 to 1000.0°F

-300.0 to 2300.0°F

-450.0 to 750.0°F

-200.0 to 750.0°F

32 to 3300°F

32 to 3100°F

32 to 3100°F

-300.0 to 2400.0°F

-450.0 to 1800.0°F

-300.0 to 1600.0°F

-300.0 to 750.0°F

-200.0 to 1000.0°F

32 to 4200°F

32.0 to 2500.0°F

32 to 3400°F

32 to 3600°F

-300.0 to 1000.0°F

-200.0 to 300.0°F

-300.0 to 1560.0°F

-300.0 to 1000.0°F

-200.0 to 300.0°F

Display range

-19999 to 30000

Display span 30000 or

less (Decimal point

position changeable)

±0.1% ±1 digit of instrument range at 0°C or more

±0.2% ±1 digit of instrument range at less than 0°C

• However, ±2% ±1 digit of instrument range for type K

at temperatures less than -200°C.

However, ±1% ± 1 digit of instrument range for type T

•

at temperatures less than -200°C.

±0.15% ±1 digit of instrument range at 400°C or more

±5% ±1 digit of instrument range at less than 400°C

±0.15% ± 1 digit of instrument range

±0.1% ± 1 digit of instrument range

±0.25% ±1 digit of instrument range for

temperature at less than 0°C

±0.1% ±1 digit of instrument range at 0°C or more

±0.2% ±1 digit of instrument range at less than 0°C

• However, ±1.5% ±1 digit of instrument range for

type E at temperature less than -200°C.

±0.2% ±1 digit of instrument range

±0.1% ± 1 digit of instrument range

±0.5% ±1 digit of instrument range at 800°C or more

Accuracy not guaranteed for temperature less than

800°C

±0.2% ± 1 digit of instrument range

±0.1% ± 1 digit of instrument range (Note 1) (Note 2)

±0.2% ± 1 digit of instrument range (Note 1)

±0.1% ± 1 digit of instrument range (Note 1) (Note 2)

±0.2% ± 1 digit of instrument range (Note 1)

±0.1% ± 1 digit of instrument range

Note 1 : The accuracy is ±0.3°C of instrument range ±1 digit for a temperature range from 0 to 100°C.

Note 2 : The accuracy is ±0.5°C of instrument range ±1 digit for a temperature range from –100 to 200°C.

*1: Performance in the standard operating conditions (at 23±2°C, 55±10% RH, and 50/60Hz power frequency)

Instrument accuracy

*1

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 6

<<Contents>> <<Index>>

6

Auxiliary Analog Input Signal

(UT520-h7 or -h8 only)

Functions: Remote setting input, tracking input, cascade

control secondary-loop PV input, etc.

Input type: Settable within the range of voltage input 0 to

2 V DC, 0 to 10 V DC, 0.4 to 2.0 V DC or

1 to 5 V DC.

Number of inputs: 1 point

Sampling period: 100, 200 or 500 ms

Auxiliary analog input period is linked with

PV sampling period.

(when PV input period is 50ms , auxiliary

analog input period is 100ms)

Input resistance: Approx. 1 MΩ

Input accuracy: ±0.3% ± 1 digit of input span for 0 to 2 V

DC input

±0.2% ± 1 digit of input span for 0 to 10 V

DC input

±0.375% ± 1 digit of input span for 0.4 to 2.0

V DC range

±0.3% ± 1 digit of input span for 1 to 5 V DC

range

Performance in the standard operating

conditions (at 23±2°C, 55±10% RH, and 50/

60Hz power frequency)

Retransmission Output

Any of the PV, target setpoint or control output is output.

Or this can be used for 15 V DC loop power supply.

Number of output points: 1 or 2

Output signal: 4 to 20 mA DC, 0 to 20 mA DC, 20 to 4 mA

DC or 20 to 0 mA DC (0 mA or less cannot be

output)

Load resistance: 600 Ω or less

Output accuracy: ±0.1% of span (±5% for 1 mA or less)

Performance in the standard operating

conditions (at 23±2°C, 55±10% RH, and 50/

60Hz power frequency)

When using for 15 V DC loop power supply:

Supply voltage 14.5 to 18.0 V DC, maximum supply

current about 21 mA (with the protection circuit at field

short-circuit)

Control Outputs

Select the control output from the following output types

depending on the product model and UT mode.

Current output

Number of output points: 1 (switchable to voltage pulse

output)

Output signal: 4 to 20 mA DC, 0 to 20 mA DC, 20 to

4 mA DC or 20 to 0 mA DC (0 mA or less

cannot be output)

Load resistance: 600 Ω or less

Output accuracy: ±0.1% of span (±5% for 1 mA or less)

Performance in the standard operating

conditions (at 23±2°C, 55±10% RH, and 50/

60Hz power frequency)

Voltage pulse output

Number of output points:

1 (switchable to current output)

Output signal:

ON voltage 12 V DC or more (load

resistance 600 Ω or more; current on shortcircuiting about 30 mA)

OFF voltage 0.1 V DC or less

Resolution: 10 ms or 0.1% of output value, whichever is

greater

Relay contact output

Number of output points: 1

Output signal: At three terminals of NC, NO, and

Common

Contact rating: 250 V AC, 3 A or 30 V DC, 3 A

(resistive load)

Resolution: 10 ms or 0.1% of output value, whichever is

greater

Contact Inputs

Usage: Target setpoint switching, C/A/M mode

switching, REMOTE/LOCAL switching,

RUN/STOP switching, or Measured input

switching

Number of input points:

Varies with optional codes (as shown below):

UT520-■■0: 2 points

UT520-■■7: 4 points

UT520-■■8: 4 points

Input type: Non-voltage contact input or transistor open

collector input

Input contact rating: 12 V DC, 10 mA or more

ON/OFF detection:

For non-voltage contact input,

On .. contact resistance 1 kΩ or less;

Off.. contact resistance 20 kΩ or more

For transistor contact input,

On .. 2 V or less;

Off.. leak current 100 µA or less

Minimum retention time for status detection: PV input

sampling period ×3

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 7

<<Contents>> <<Index>>

7

Contact Outputs

Usage: Alarm output, FAIL output

Number of output points:

3 (relay output)

However, when a relay is not used for control

output, the relay for control output can be used

for the alarm 4. For this reason, the number of

relay output points can be changed to 4 by

adding to the above 3.

Relay contact rating: 240 V AC, 1 A or 30 V DC, 1 A

● Display Specifications

Measured value (PV) display:

5-digit seven-segment red color LED display;

height of letters 12 mm

Data display:

3 digits + 5 digits, seven-segment red color

LED display; height of letters 9.3 mm

Status indicating lamps: LEDs

● Conformance to Safety and EMC Standards

Safety standard:

Conforms to IEC1010-1: 1990 and EN610101: 1992

Certified for CSA 1010

The overvoltage category of each input is

CAT II (IEC1010-1)

Certified for UL508 application

EMC standard:

To the following EMC standards. During test,

the controller continues to operate with the

measurement accuracy within ±20% of the

range:

For EMI (emission), EN55011: Class A Group 1

For EMS (immunity), EN50082-2: 1995

● Construction, Installation, and Wiring

Construction: Dust-proof and Drip-proof front panel

conforming to IP55.

For side-by-side close installation, controller

loses its dust-proof and drip-proof protection.

Material of the body: ABS resin and polycarbonate

Case color: Black

Weight: Approx. 1 kg or less

External dimensions:

48W × 96H × 100D (from the panel face)

(mm)

Mounting: Direct panel mounting; mounting bracket, one

each for upper and lower mounting

Panel cutout dimensions:

Mounting attitude:

Wiring connection:

45

+0.6

0

W ×

92

+0.8

H (mm)

0

Up to 30 degrees from horizontal; Must not

face downward.

With M3.5 screw terminals (for signal, power

and grounding wiring)

● Power Supply and Isolation

Power supply: Rated voltage 100 to 240 V AC (±10%),

50/60 Hz

Power consumption: MAX. 20 VA or less (MAX. 8.0W)

Memory backup: Non-volatile memory. Service life

approx. 100000 times of writings.

Withstanding voltage:

1500 V AC for 1 min.

between primary terminals and secondary

terminals

1500 V AC for 1 min.

between primary terminals and ground

terminal

1500 V AC for 1 min.

between ground terminal and secondary

terminals

500 V AC for 1 min.

between secondary terminals

where primary terminals stand for power

and relay output terminals and secondary

terminals stand for analog input and output

signal terminals, voltage pulse output

terminals, and contact input terminals.

Note: The withstanding voltage is specified as

2300 V AC per minute to provide a mar gin

of safety.

Isolation resistance:

20 MΩ or more for 500 V DC applied

between power terminals and ground terminal

Grounding: Class 3 grounding (grounding resistance of

100 Ω or less)

Isolation Specifications

Measured input terminal : Isolated from other input/output

terminals but not isolated from internal

circuits.

Auxiliary analog input terminal: Isolated from other input/

output terminals and internal circuits.

Control output (current output or voltage pulse output) and

retransmission output: Not isolated between

controll outputs and retransmission output, but

isolated from other input/output terminals and

internal circuits.

Relay contact control output terminals: Isolated from other

input/output terminals and internal circuits.

Contact input terminals: Not isolated from other contact

input terminals, and communication terminals,

but isolated from other input/output terminals

and internal circuits.

Relay contact alarm output terminals: Not isolated from

other relay contact alarm outputs, but isolated

from other input/output terminals and internal

circuits.

RS-485 communication terminals: Not isolated from

contact input terminals, but isolated from

other input/output terminals and internal

circuits.

Power terminals: Isolated from other input/output

terminals and internal circuits.

Ground terminal: Isolated from other input/output

terminals and internal circuits.

(Note)

(Note)

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 8

<<Contents>> <<Index>>

● Environmental Conditions

Normal operating conditions:

Ambient temperature: 0 to 50°C (40°C or less in close

Temperature change rate limit: 10°C/h or less

Ambient humidity: 20 to 90% RH (no condensation)

Magnetic field: 400 A/m or less

Continuous vibration (5 to 14 Hz):

Continuous vibration (14 to 150 Hz):

Short period vibration: 14.7 m/s

Shock: 147 m/s

Installation altitude: 2000 m or less above sea level

Warm-up time: 30minutes or more

Transportation and storage conditions:

Temperature: -25 to 70°C

Temperature change rate limit: 20°C/h or less

Humidity: 5 to 95% RH (no condensation)

Effects of operating conditions

Effect of ambient temperature:

Effect of power supply fluctuation (within rated voltage

mounting side-by-side)

However, 0 to 45°C (35°C or less in close

mounting side-by-side) if two analog current

output points and the control relay output

are used simultaneously.

Peak-to-peak amplitude 1.2 mm or less

2

or less

4.9 m/s

2

or less, 11 ms

2

, 15 s or less

Whichever is greater, ±1 µV/°C or ±0.01%

of F.S./°C for voltage or thermocouple

inputs.

±0.02% of F.S./°C for Auxiliary input

±0.05°C/°C (ambient temperature) or less

for RTD inputs.

±0.05% of F.S./°C or less for analog

outputs.

range):

Whichever is greater, ±1 µV/10 V or

±0.01% of F.S./10 V for analog inputs.

±0.05% of F.S./10 V or less for analog

outputs.

8

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 9

<<Contents>> <<Index>>

■Function Block Diagram for Single-loop Control

9

PV input terminals

12 1311

, and

Input selection

Unit selection

Analog input range conversion

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

PV input bias

PV input filter

Remote input

terminals and

Input selection

Unit selection

Analog input range conversion

Analog input bias

Square root extraction

Analog input filter

Remote setting filter

Ratio/bias calculation

2221

CommunicationAux. Input

RMS=COMRMS=RSP

R/L

Target setpoint ramp-rate function

Communication

terminals to

RS485

2723

SPN

Target setpoints 1 to 8

LOCALREMOTE

REMOTE(ON)/LOCAL(OFF) switching

Contact input

DI1 DI2 DI8INPUT1 INPUT3

Manual operation

Preset output Output limiter

Control computation

AUTOMAN

A/M

AUTO(ON)/MAN(OFF) switching

RUNSTOP

S/R

OT1

Control output

OUTPUT1 OUTPUT1 OUTPUT1 OUTPUT3

Current or pulse

terminals and

STOP(ON)/RUN(OFF) switching

15V loop power supply Retransmission output

Relay terminals

, and

1716

2 31

terminals

and

* Unavailable when control output is current or pulse.

RT2 RT1

Current*

Alarm function

DO3DO2DO1

Current

terminals

1716

and

Alarm 1 Alarm 2 Alarm 3

1514

Legend

Terminal Parameter Function

Analog Signal Contact Signal Front Panel Key

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 10

<<Contents>> <<Index>>

■Function Block Diagram for Cascade Control

10

Cascade primary PV

input terminals

, and

12 1311

INPUT1 INPUT3

Communication

terminals

2723

to

RS485

Input selection Ratio/bias

Unit selection

calculation

Analog input range conversion

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

PV input bias

PV input filter

Secondary PV

input terminals

2221

and

Input selection

Unit selection

Analog input range conversion

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

PV input bias

PV input filter

RMS=COM

R/L

SPN

Primary target setpoint

LOCALREMOTE

Target setpoint ramp-rate function

Control computation 1

Cascade

(OFF➝ON)

If receives the FAIL signal

(burnout or A/D converter error)

from primary PV input, operation

is switched to AUTO.

SPN

Secondary target setpoint

Contact inputs

DI8DI1 DI2

Manual

(OFF➝ON)

Automatic

(OFF➝ON)

Output limiter

Tracking in

C/A/M

AUTO or MAN

Tracking signal

Preset output

Output limiter

RUNSTOP

S/R

15V loop

OT2

power supply

Control

output

OUTPUT1 OUTPUT1 OUTPUT1 OUTPUT3

Current or

pulse terminals

1716

and

Relay

terminals

2 31

, and

RT2 RT1

Current*1

terminals

and

*1 Unavailable when control output is current or pulse.

AUTO, MANCAS

Cascade switching

Manual operation

Retransmission

output

Current

terminals

1716

and

1514

Control computation 2

CAS, AUTOMAN

C/A/M

A/M

MAN switching

Alarm function

DO3DO2DO1

Alarm 1 Alarm 2 Alarm 3

Legend

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

Terminal Parameter Function

Analog Signal Contact Signal Front Panel Key

GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 11

<<Contents>> <<Index>>

■Function Block Diagram for Loop Control for Backup

11

PV input

Communication

terminals

12 1311

, and

Input selection

Unit selection

Analog input range conversion

Analog input bias

Square root extraction

Analog input filter

10-seg. linearizer approx./bias

PV input bias

PV input filter

terminals

to

RS485

(Manipulated output from host)

2723

terminals and

Input selection

Unit selection

Analog input range conversion

Analog input bias

Tracking signal

Ratio/bias

calculation

RMS=COM

Analog input filter

Target setpoints

1 to 8

R/L

LOCALREMOTE

Target setpoint ramp-rate function

SPN

2221

Contact inputs

DI1 DI2 DI8INPUT1 INPUT3

Tracking switching signal

Manual operation

Control output

can not be

changed when

contact input 8 (DI8)

is set to ON.

Preset output

Control computation

AUTOMAN

A/M

AUTO(ON)/MAN(OFF) switching

Tracking (ON)

Output limiter

RUNSTOP

S/R

OT1

OUTPUT1 OUTPUT1 OUTPUT1 OUTPUT3

Current or

pulse terminals

and

STOP(ON)/RUN(OFF) switching

Control

output

Relay

terminals

1716

2 31

, and

15V loop

power supply

RT2 RT1

Current *1

terminals

and

Retransmission

1716

*1 Unavailable when control output is current or pulse.

output

Current

terminals

and

Alarm function

DO4DO2DO1

Alarm 1 Alarm 2 Alarm 3

1514

Legend

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E

Terminal Parameter Function

Analog Signal Contact Signal Front Panel Key

1st Edition Mar. 31, 2000-00

Page 12

<<Contents>> <<Index>>

■Function Block Diagram for Loop Control with PV Switching

12

PV input 1

terminals

12 1311

, and

Input selection

Unit selection

Analog input range conversion

Analog input range conversion

Analog input bias

Square root extraction

Square root extraction

Analog input filter

PV input 2

terminals

22

21

and

Input selection

Unit selection

Analog input bias

Analog input filter

Communication

10-seg. linearizer approx./bias 10-seg. linearizer approx./bias

PV input Switching (Temp. range, Temp. upper limit, or DI)

Burnout occurs when

the burnout of PV

input 1 or PV input 2

occurs.

PV input bias

PV input filter

RMS=COM

R/L

Target setpoint ramp-rate function

Control computationManual operation

AUTOMAN

A/M

AUTO(ON)/MAN(OFF) switching

terminals

2723

to

RS485

Ratio/bias

calculation

U1

Upper limit

U2

Lower limit

U3

Operation

SPN

Target setpoints 1 to 8

LOCALREMOTE

Contact inputs

DI1 DI2 DI8INPUT1 INPUT3

PV input

switching

(U3=2)

PV input 1(OFF)/

PV input 2(ON)

Preset output

Output limiter

RUNSTOP

S/R

OT1

OUTPUT1 OUTPUT1 OUTPUT1 OUTPUT3

Current or

pulse terminals

and

STOP(ON)/RUN(OFF) switching

Control

output

Relay

terminals

1716

2 31

, and

15V loop

power supply

RT2 RT1

Current *1

terminals

and

Retransmission

terminals

1716

*1 Unavailable when control output is current or pulse.

Legend

Terminal Parameter Function

Analog Signal Contact Signal Front Panel Key

output

Current

and

Alarm function

DO3DO2DO1

Alarm 1 Alarm 2 Alarm 3

1514

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 13

<<Contents>> <<Index>>

1

2

3

4

5

6

789

10

21

22232425262728

29

30

111213141516171819

20

19

18

20

29

28

30

DI1

DI2

COM

DI3

COM

DI8

No function

Common

Common

19

18

20

DI1

DI2

COM

+5V

+5V

29

28

30

DI3

DI8

COM

+5V

+5V

23

24

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

12

13

11

12

13

A

b

B

8

9

10

L

N

1

2

3

NC

NO

COM

6

5

4

7

DO1

DO2

DO3

COM

RS-485 communication

* Wiring can only be carried out

for controllers with communication

functions.

Maximum baud rate: 9600 bps

Power supply

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

Relay contact output

Control output

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

*Time proportional PID relay contact

output is configured at factory

before shipment.

Note: Select this option from the

OT1 parameter.

External contact outputs

Relay

Alarm 1 output

Alarm 2 output

Alarm 3 output

Common

* The functionality of a contact input can be varied by changing the setting of

the contact input registration parameter.

+

-

TC input

RTD input

Installation category (overvoltage category): II (IEC1010-1)

NOTE

Contact

Transistor contact

External contact inputs

AUTO when DI1=ON

MAN when DI1=OFF

STOP when DI2=ON

RUN when DI2=OFF

Contact rating: 12 V DC, 10 mA or more

Remote when DI8=ON

Local when DI8=OFF

* Wiring can only be carried out for

controllers with remote input.

21

22

Remote input

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

j

15 V DC Power Supply Wired to Sensor in

Two-wire System Configuration

12

13

14

15

100V

Two-wire

transmitter

PV input

0.4-2.0 V DC

signal

Loop power

supply

14.5-

18.0 V DC

External

resistor

(Note)

4-20mADC

OT1=0 (factory-set default)

Time proportional control

Relay output (terminals , and )

OT1=1

Correspondence between parameter OT1 and control output types

Time proportional control

Voltage pulse output (terminals and )

OT1=2

Current output

(terminals and )

OT1=3

On-off control

Relay output (terminals , and )

* OT1 is a setup parameter.

You can change the settings of the parameter OT1 to change the control output type.

1 2 3

16 17

16 17

1 2 3

Default: 1-5 V DC

UT

UT

12

13

+

-

mV/V input

* Factory-set to

PV retransmission.

* Retransmission output 1

is not available if a

15 V DC loop power

supply is used.

Control output

14

15

Retransmission output 1*

4-20 or

0-20 mA DC

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

* Retransmission output 2 is available

only when relay is selected as the

type of control output.

Default: 4-20 mA DC

-

+

-

+

PV input

16

17

Continuous/voltage

pulse output

0-20mADC,

4-20mADC

Voltage pulse (12 V)

16

17

Retransmission

output 2*

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

-

+

* Not configured at factory before shipment

12

13

Note: Connecting a 250 Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint 41 ).

j

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

-

+

Default: Unspecified

retransmission type

Load resistance: 600 Ω or less

A

llowable range: 100-240 V AC (610%)

(free voltage)

50/60 Hz shared

Note: Connecting a 100 V resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

Note: Select this option from the OT1 parameter.

Note: External Contact Input

If the power is turned on when

the external contact input is OFF,

the mode (SPN, R/L, or A/M)

existing before the power is turned

off will be continued.

(except for RUN/STOP)

13

■UT520 Single-loop Control (Factory-set to Single-loop Control), Terminal Arrangements

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 14

<<Contents>> <<Index>>

1

2

3

4

5

6

789

10

21

22232425262728

29

30

111213141516171819

20

19

18

20

29

28

30

DI1

DI2

COM

DI3

COM

DI8

No function

Common

Common

19

18

20

DI1

DI2

COM

+5V

+5V

29

28

30

DI3

DI8

COM

+5V

+5V

23

24

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

12

13

11

12

13

A

b

B

8

9

10

L

N

1

2

3

NC

NO

COM

6

5

4

7

DO1

DO2

DO3

COM

RS-485 communication

* Wiring can only be carried out

for controllers with communication

functions.

Maximum baud rate: 9600 bps

Power supply

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

Relay contact output

Control output

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

*Time proportional PID relay contact

output is configured at factory

before shipment.

Note: Select this option from the

OT2 parameter.

External contact outputs

Relay

Alarm 1 output

Alarm 2 output

Alarm 3 output

Common

* The functionality of a contact input can be varied by changing the setting of

the contact input registration parameter.

* The functionality of a contact output can be

varied by changing the setting of the contact

output registration parameter.

+

-

TC input

RTD input

Installation category (overvoltage category): II (IEC1010-1)

NOTE

Contact

Transistor contact

External contact inputs

Cascade switching when

DI1 changes to on

Automatic switching when

DI2 changes to on

Contact rating: 12 V DC, 10 mA or more

Manual switching when

DI8 changes to on

Secondary PV input

21

22

Auxiliary input

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

j

15 V DC Power Supply Wired to Sensor in

Two-wire System Configuration

12

13

14

15

100V

Two-wire

transmitter

PV input

0.4-2.0 V DC

signal

Loop power

supply

14.5-

18.0 V DC

External

resistor

(Note)

4-20mADC

OT2=0 (factory-set default)

Time proportional control

Relay output (terminals , and )

OT2=1

Correspondence between parameter OT2 and control output types

Time proportional control

Voltage pulse output (terminals and )

OT2=2

Current output

(terminals and )

OT2=3

On-off control

Relay output (terminals , and )

* OT2 is a setup parameter.

You can change the settings of the parameter OT2 to change the control output type.

1 2 3

16 17

16

17

1 2 3

Default: 1-5 V DC

UT

UT

12

13

+

-

mV/V input

* Factory-set to

PV retransmission.

* Retransmission output 1

is not available if a

15 V DC loop power

supply is used.

Control output

14

15

Retransmission output 1*

4-20 or

0-20 mA DC

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

* Retransmission output 2 is available

only when relay is selected as the

type of control output.

Default: 4-20 mA DC

-

+

-

+

Primary PV input

16

17

Continuous/voltage

pulse output

0-20mADC,

4-20mADC

Voltage pulse (12 V)

16

17

Retransmission

output 2*

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

-

+

* Not configured at factory before shipment

12

13

Note: Connecting a 250 Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint 41 ).

j

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

-

+

Default: Unspecified

retransmission type

Load resistance: 600 Ω or less

A

llowable range: 100-240 V AC (610%)

(free voltage)

50/60 Hz shared

Note: Connecting a 100 V resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

Note: Select this option from the OT2 parameter.

Note: External Contact Input

If the power is turned on when

the external contact input

(either of Cascade, Automatic,

and Manual) is ON,the controller

judges that the external contact

input is changed to ON.

14

■UT520 Cascade Control, Terminal Arrangements

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 15

<<Contents>> <<Index>>

1

2

3

4

5

6

789

10

21

22232425262728

29

30

111213141516171819

20

19

18

20

29

28

30

DI1

DI2

COM

DI3

COM

DI8

No function

Common

Common

19

18

20

DI1

DI2

COM

+5V

+5V

29

28

30

DI3

DI8

COM

+5V

+5V

23

24

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

12

13

11

12

13

A

b

B

8

9

10

L

N

1

2

3

NC

NO

COM

6

5

4

7

DO1

DO2

DO3

COM

RS-485 communication

* Wiring can only be carried out

for controllers with communication

functions.

Maximum baud rate: 9600 bps

Power supply

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

Relay contact output

Control output

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

*Time proportional PID relay contact

output is configured at factory

before shipment.

Note: Select this option from the

OT1 parameter.

External contact outputs

Relay

Alarm 1 output

Alarm 2 output

FAIL output

(ON when normal)

Common

* The functionality of a contact input can be varied by changing the setting of

the contact input registration parameter.

* The functionality of a contact output can

be varied by changing the setting of the

contact output registration parameter.

+

-

TC input

RTD input

Installation category (overvoltage category): II (IEC1010-1)

NOTE

Contact

Transistor contact

External contact inputs

AUTO when DI1=ON

MAN when DI1=OFF

STOP when DI2=ON

RUN when DI2=OFF

Contact rating: 12 V DC, 10 mA or more

Output of tracking signal when DI8=ON

Output of PID computation when DI8=OFF

Tracking Signal

(host device operation output)

21

22

Auxiliary input

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

j

15 V DC Power Supply Wired to Sensor in

Two-wire System Configuration

12

13

14

15

100V

Two-wire

transmitter

PV input

0.4-2.0 V DC

signal

Loop power

supply

14.5-

18.0 V DC

External

resistor

(Note)

4-20mADC

OT1=0 (factory-set default)

Time proportional control

Relay output (terminals , and )

OT1=1

Correspondence between parameter OT1 and control output types

Time proportional control

Voltage pulse output (terminals and )

OT1=2

Current output

(terminals and )

OT1=3

On-off control

Relay output (terminals , and )

* OT1 is a setup parameter.

You can change the settings of the parameter OT1 to change the control output type.

1 2 3

16 17

16 17

1 2 3

Default: 1-5 V DC

UT

UT

12

13

+

-

mV/V input

* Factory-set to

PV retransmission.

* Retransmission output 1

is not available if a

15 V DC loop power

supply is used.

Control output

14

15

Retransmission output 1*

4-20 or

0-20 mA DC

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

* Retransmission output 2 is available

only when relay is selected as the

type of control output.

Default: 4-20 mA DC

-

+

-

+

PV input

16

17

Continuous/voltage

pulse output

0-20mADC,

4-20mADC

Voltage pulse (12 V)

16

17

Retransmission

output 2*

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

-

+

* Not configured at factory before shipment

12

13

Note: Connecting a 250 Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint 41 ).

j

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

-

+

Default: Unspecified

retransmission type

Load resistance: 600 Ω or less

A

llowable range: 100-240 V AC (610%)

(free voltage)

50/60 Hz shared

Note: Connecting a 100 V resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

Note: Select this option from the OT1 parameter.

Note: External Contact Input

If the power is turned on when

the external contact input is OFF,

the mode (SPN, R/L, or A/M)

existing before the power is turned

off will be continued.

(except for RUN/STOP)

15

■UT520 Loop Control for Backup, Terminal Arrangements

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 16

<<Contents>> <<Index>>

1

2

3

4

5

6

789

10

21

22232425262728

29

30

111213141516171819

20

19

18

20

29

28

30

DI1

DI2

COM

DI3

COM

DI8

No function

Common

Common

19

18

20

DI1

DI2

COM

+5V

+5V

29

28

30

DI3

DI8

COM

+5V

+5V

23

24

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

12

13

11

12

13

A

b

B

8

9

10

L

N

1

2

3

NC

NO

COM

6

5

4

7

DO1

DO2

DO3

COM

RS-485 communication

* Wiring can only be carried out

for controllers with communication

functions.

Maximum baud rate: 9600 bps

Power supply

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

Relay contact output

Control output

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

*Time proportional PID relay contact

output is configured at factory

before shipment.

Note: Select this option from the

OT1 parameter.

External contact outputs

Relay

Alarm 1 output

Alarm 2 output

Alarm 3 output

Common

* The functionality of a contact input can be varied by changing the setting of

the contact input registration parameter.

* The functionality of a contact output

can be varied by changing the

setting of the contact output

registration parameter.

+

-

TC input

RTD input

Installation category (overvoltage category): II (IEC1010-1)

NOTE

Contact

Transistor contact

External contact inputs

AUTO when DI1=ON

MAN when DI1=OFF

STOP when DI2=ON

RUN when DI2=OFF

Contact rating: 12 V DC, 10 mA or more

NOTE 1: When operating paramter U3 set to "2", effective

to contact input.

PV input 2 when DI8=ON

PV input 1 when DI8=OFF

(NOTE 1)

21

22

Auxiliary input

Specify in a range of

1-5 V DC, 0-2 V DC,

or 0-10 V DC.

-

+

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

j

15 V DC Power Supply Wired to Sensor in

Two-wire System Configuration

12

13

14

15

100V

Two-wire

transmitter

PV input

0.4-2.0 V DC

signal

Loop power

supply

14.5-

18.0 V DC

External

resistor

(Note)

4-20mADC

OT1=0 (factory-set default)

Time proportional control

Relay output (terminals , and )

OT1=1

Correspondence between parameter OT1 and control output types

Time proportional control

Voltage pulse output (terminals and )

OT1=2

Current output

(terminals and )

OT1=3

On-off control

Relay output (terminals , and )

* OT1 is a setup parameter.

You can change the settings of the parameter OT1 to change the control output type.

1 2 3

16 17

16 17

1 2 3

Default: 1-5 V DC

UT

UT

12

13

+

-

mV/V input

* Factory-set to

PV retransmission.

* Retransmission output 1

is not available if a

15 V DC loop power

supply is used.

Control output

14

15

Retransmission output 1*

4-20 or

0-20 mA DC

14

15

15 V DC loop power supply*

14.5-18.0 V DC

(21 mA DC max.)

* Retransmission output 2 is available

only when relay is selected as the

type of control output.

Default: 4-20 mA DC

-

+

-

+

PV input 1

PV input 2

16

17

Continuous/voltage

pulse output

0-20mADC,

4-20mADC

Voltage pulse (12 V)

16

17

Retransmission

output 2*

Default: 4-20 mA DC

0-20mADC,

4-20mADC

-

+

-

+

* Not configured at factory before shipment

12

13

Note: Connecting a 250 Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint 41 ).

j

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

-

+

Default: Unspecified

retransmission type

Load resistance: 600 Ω or less

A

llowable range: 100-240 V AC (610%)

(free voltage)

50/60 Hz shared

Note: Connecting a 100 V resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

Note: Select this option from the OT1 parameter.

Note: External Contact Input

If the power is turned on when

the external contact input is OFF,

the mode (SPN, R/L, or A/M)

existing before the power is turned

off will be continued.

(except for RUN/STOP)

16

■UT520 Loop Control with PV Switching, Terminal Arrangements

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E

1st Edition Mar. 31, 2000-00

Page 17

<<Contents>> <<Index>>

■External Dimensions and Panel Cutout Dimensions

PV

AL1 2 3 4

A/M

SET/ENT

LP2 CAS

REM MAN

11

96

10048

1 to 10 mm

(Panel thickness)

Small bracket

112

91.8

Small bracket

17

Unit: mm

General installation

70 min.

Side-by-side close installation

[(N-1)348+45]

0

+0.8

+0.6

0

92

(53)

145 min.

“N” stands for the number of controllers to be

installed.

+ 0.8

92

0

+ 0.6

45

(25)

0

However, the measured value applies if N $ 5.

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05D01C02-02E 1st Edition Mar. 31, 2000-00

Page 18

<<Contents>> <<Index>>

■Model and Suffix Codes

Model Suffix Code Description

UT520

Type

Optional functions

Standard accessories: Brackets (mounting hardware), unit label, User’s Manuals, and User’s Manual (reference) (CD-ROM

version).

Specify the required optional function codes according to the UT mode to be used.

Correspondence between UT mode and suffix code

Digital indicating controller (provided with retransmission output and 15 V DC loop power supply as standard)

-0 Standard type

0 None

7 Communication, auxiliary analog (remote) input, and 2 additional DIs

8 Auxiliary analog (remote) input and 2 additional DIs

18

Single-loop control (UT mode 1)

Cascade primary loop control (UT mode 2)

Cascade secondary loop control (UT mode 3)

Cascade control (UT mode 4)

Loop control for backup (UT mode 5)

Loop control with PV switching (UT mode 6)

Loop control with PV auto-selector (UT mode 7)

Loop control with PV-hold function (UT mode 8)

00 07 08UT mode Specification code →

Cond.

N/A

N/A

N/A

N/A

N/A

N/A

Cond.

App.

App.

App.

App.

App.

App.

App.

App.

Cond.: Remote target setting not available

App.

App.

App.

App.

App.

App.

App.

App.

The remote target setting function requires the auxiliary analog input

(optional function) to be specified.

Auxiliary analog input is used for the cascade input.

Auxiliary analog input is used for the tracking input.

Auxiliary analog input is used for the PV input 2.

Auxiliary analog input is used for the PV input 2.

Cond.: Remote target setting not available

The remote target setting function requires the auxiliary analog input

(optional function) to be specified.

Remarks

App.: Function available, Cond.: Function available conditionally, N/A: Function not available

■Correspondence between the Model and Suffix Codes, and the Contact Input/Output

Terminals Provided

Check the model ordered and the presence/absence of contact inputs and outputs in the following table.

✓ indicate that the contacts are available.

Model and Suffix

Codes

UT520-00

UT520-07

UT520-08

DI1 DI2 DI3 DI4 DI5 DI6 DI7 DO1 DO2 DO3 DO4

✓

✓

✓

Contact input terminals Contact output terminals

DI8 DO5

✓

✓

✓✓✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

DO6 DO7

■Items to be Specified When Ordering

Model and suffix codes, necessary/unnecessary of User’s Manual or QIC.

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05D01C02-02E 1st Edition Mar. 31, 2000-00

Loading...

Loading...