Page 1

Technical

Information

TI 05C01E02-01E

UT130, UT150/UT152/UT155

Temperature Controller

Easy-to-use Controllers f or Operators

Compact Body

Large Display

48 x 48mm

Simple Operation

Less Space

48 x 96mm

Compact Body

Full Functions

48 x 48mm

Simple Operation

Large Display

96 x 96mm

Features

• Large display

• Simple operation

• Av ailable 24V A C/DC pow er supply

• Dynamic Auto Tune control

• Full alarm functions

• Retransmission outputs

•Timer function

• RUN / ST OP s witching

TI 05C01E02-01E

© Copyright Oct. 2001

1st Edition: Oct. 2001

Page 2

Blank Page

Page 3

<T oc> <Ind> <Rev> <Introduction>

INTRODUCTION

The UT100 Series contr ollers are the contr ollers mainl y for temperature contr ol.

The UT100 Series contr ollers are developed using the ne west tec hnology based on the

Y okogawa Group’s experience f or contr ol for years and results cultiv ated from man y

applications.

■ Document Structure

This document describes the functions of UT100 Series controllers.

The document consists of the following chapters.

Chapter 1: This c hapter e xplains what a temperature contr oller is.

Chapter 2: This c hapter e xplains the model and suffix codes of the contr oller and the

information f or or dering.

Chapter 3: This c hapter e xplains the P arameter Flo wchart and Parameter Lists of UT

100 Series contr oller s.

i

Chapter 4: This c hapter e xplains the basic operating pr ocedures when using a UT100

Series contr oller at fir st

Chapter 5: This c hapter e xplains the applied operations not described in Chapter 4.

Chapter 6: This c hapter e xplains the basic functions of UT100 Series contr ollers.

Chapter 7:This c hapter e xplains a tr oubleshooting f or errors before/during operation.

Chapter 8:This c hapter e xplains the installation, wiring and har dware specifications.

■ Intended Readers

This document is intended to the following personnel:

• Instrumentation engineers or electrical engineers planning to use a temperature

controller

• Instrumentation engineers or electrical engineers who would like to know the outline

of a temperature controller

■ Trademark Ac kno wledgements

• The compan y and pr oduct names ref erred to in this document are either trademarks

or registered trademarks of their respective holders.

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 4

Blank Page

Page 5

<Int> <Ind> <Rev>

UT130, UT150/UT152/UT155

T emperature Controller

CONTENTS

INTRODUCTION .................................................................................................... i

1. DESCRIPTION OF TEMPERATURE CONTR OL ........................................... 1-1

2. INFORMATION T O ORDER A CONTROLLER .............................................. 2-1

2.1 Model and Suffix Codes ......................................................................................... 2-1

2.2 Mandatory Items to Specify ................................................................................... 2-5

2.3 Optional Suffix Codes to Specify........................................................................... 2-5

2.4 Other Items to Specify............................................................................................ 2-6

2.5 User’s Man ual .......................................................................................................... 2-8

Toc-1

TI 05C01E02-01E 1st Edition

3. NAMES AND FUNCTIONS OF EA CH PART / P ARAMETER......................... 3-1

3.1 UT130 Names and Functions of Each Part (Principles of Key Operation)........... 3-1

3.2 UT130 Parameter Flowc hart and Description ....................................................... 3-2

3.3

UT150/UT152/UT155Names and Functions of Each Part (Principles of Key Operation)....

3.4 UT150/UT152/UT155 Parameter Flowchart and Description................................ 3-8

3-6

4. B ASI C OP ERATIONS.................................................................................... 4-1

4.1 Setting Measured Input Type and Scale (Setting Fir st)......................................... 4-1

4.2 Setting Control Action............................................................................................ 4-5

4.2.1

Selecting a Control Mode (Dynamic Auto Tune Control / PID Control / ON-OFF Control) ....

4.2.2 Switching Direct / Reverse Action ............................................................ 4-6

4.2.3 Setting Cycle Time (Control Output Rene wal Period) ............................... 4-8

4.3 Setting T arget Setpoint (SP)................................................................................... 4-9

4.3.1 Setting Target Setpoint (SP) of UT130 ..................................................... 4-9

4.3.2 Setting Target Setpoint (SP) of UT150/UT152/UT155 ............................ 4-10

4.4 Setting Alarms ...................................................................................................... 4-12

4.4.1 Setting Alarm Type and Hysteresis ........................................................ 4-12

4.4.2 Setting Alarm Setpoint........................................................................... 4-16

4.4.3 Heater Disconnection Alarm Function ................................................... 4-17

4-5

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 6

<Int> <Ind> <Rev>

5. APPLIED OPERATIONS ............................................................................... 5-1

6. DESCRIPTION OF EA CH FUNCTION........................................................... 6-1

Toc-2

5.1 Changing Measured Input Type and Scale............................................................ 5-1

5.2 Correcting Measured Input Value .......................................................................... 5-1

5.3 Reducing Input Variations ...................................................................................... 5-2

5.4 Setting Maximum and Minimum V alues of Target Setpoint Range....................... 5-2

5.5 Setting Target Sepoint Ramp Rate (Rate-of-Change) ........................................... 5-3

5.6 Using Two Target Setpoints.................................................................................... 5-4

5.7 Retransmission of Measured Input Value in Current Signal ................................ 5-4

5.8 Switching RUN/ ST OP ............................................................................................ 5-5

5.9

Using Timer Function (Turning on External Contact Outputs after the Set Time Elapses).......

5.10 Setting Key Loc k................................................................................................... 5-7

5.11 Selecting Priority of PV/SP Display at P ower on (f or UT130 Only)..................... 5-8

5.12 Performing Heating/Cooling Contr ol................................................................... 5-8

5.13 Communicating with PC or PLC .......................................................................... 5-9

6.1 ON/OFF Control ...................................................................................................... 6-1

6.1.1 ON/OFF Control and Hysteresis .............................................................. 6-1

6.1.2 ON/OFF Control Application Example ..................................................... 6-1

6.2 Proportional (P) Action........................................................................................... 6-2

6.2.1 Differences between ON/OFF Action and Proportional Action ................. 6-2

6.2.2 Proportional Band (P) Details .................................................................. 6-2

6.2.3 Tuning the Proportional Band................................................................... 6-3

6.3 Integral (I) Action .................................................................................................... 6-4

6.3.1 Integral Time (I) ....................................................................................... 6-4

6.3.2 Tuning the Integral Time........................................................................... 6-4

6.4 Derivative (D) Action............................................................................................... 6-5

6.4.1 Derivative Time (D).................................................................................. 6-5

6.4.2 Tuning the Derivative Time....................................................................... 6-5

6.5 Dynamic Auto Tune Control and PID Control........................................................ 6-6

6.5.1 Dynamic Auto Tune Control ..................................................................... 6-6

6.5.2 Manually Tuning PID Constants ............................................................... 6-7

6.5.3 PID Auto-Tuning ...................................................................................... 6-7

6.6 Control Output ........................................................................................................ 6-8

6.6.1 Time Proportional PID Output (Relay Output / Voltage Pulse Output)....... 6-8

6.6.2 Cycle Time .............................................................................................. 6-8

6.6.3 Continuous PID Output (4 to 20mA DC)................................................... 6-9

6.7 Overshoot Suppressing Function “SUPER”....................................................... 6-10

6.7.1 “SUPER” Operating Principles ............................................................... 6-10

6.7.2 Effects of “SUPER”................................................................................ 6-10

5-6

TI 05C01E02-01E

1st Edition : Oct. 31, 2001-00

Page 7

<Int> <Ind> <Rev>

7. TROUBLE SHO O TI NG ................................................................................... 8-1

8. INSTALLATION AND HARD WARE SPECIFICA TIONS ................................. 8-1

Toc-3

8.1 Installation .............................................................................................................. 8-1

8.2 Panel Cutout Dimensions and External Dimensions ........................................... 8-3

8.3 Wiring ...................................................................................................................... 8-7

8.4 Hardware Specifications ...................................................................................... 8-12

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 8

Blank Page

Page 9

<T oc> <Ind>

1.

DESCRIPTION OF TEMPERATURE CONTR OL

■ Temperature Controller

The temperature controller is used to keep the fixed temperature of such as a furnace

(controlled object). In general, the temperature controller has temperature indicating

display and setpoint setting display, generates a control signal according to the difference between a indicating value (measured temperature value) and SP to finally make

the temperature agree with SP.

Sensors such as thermocouple (TC) or RTD can be connected for measuring a temperature. And output types such as rela y output or current output (4 to 20mA) are

prepared according to the operating terminal (heater, valv e, and the lik e) that actually

controls a temperature.

1-1

Control output

Operating

device

• SSR

• Power regulator

Measured input

•Thermocouple

• RTD

Measuring

object

Work

• Relay

• Voltage pulse

• Current

Heater

Controlled object

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 10

<T oc> <Ind>

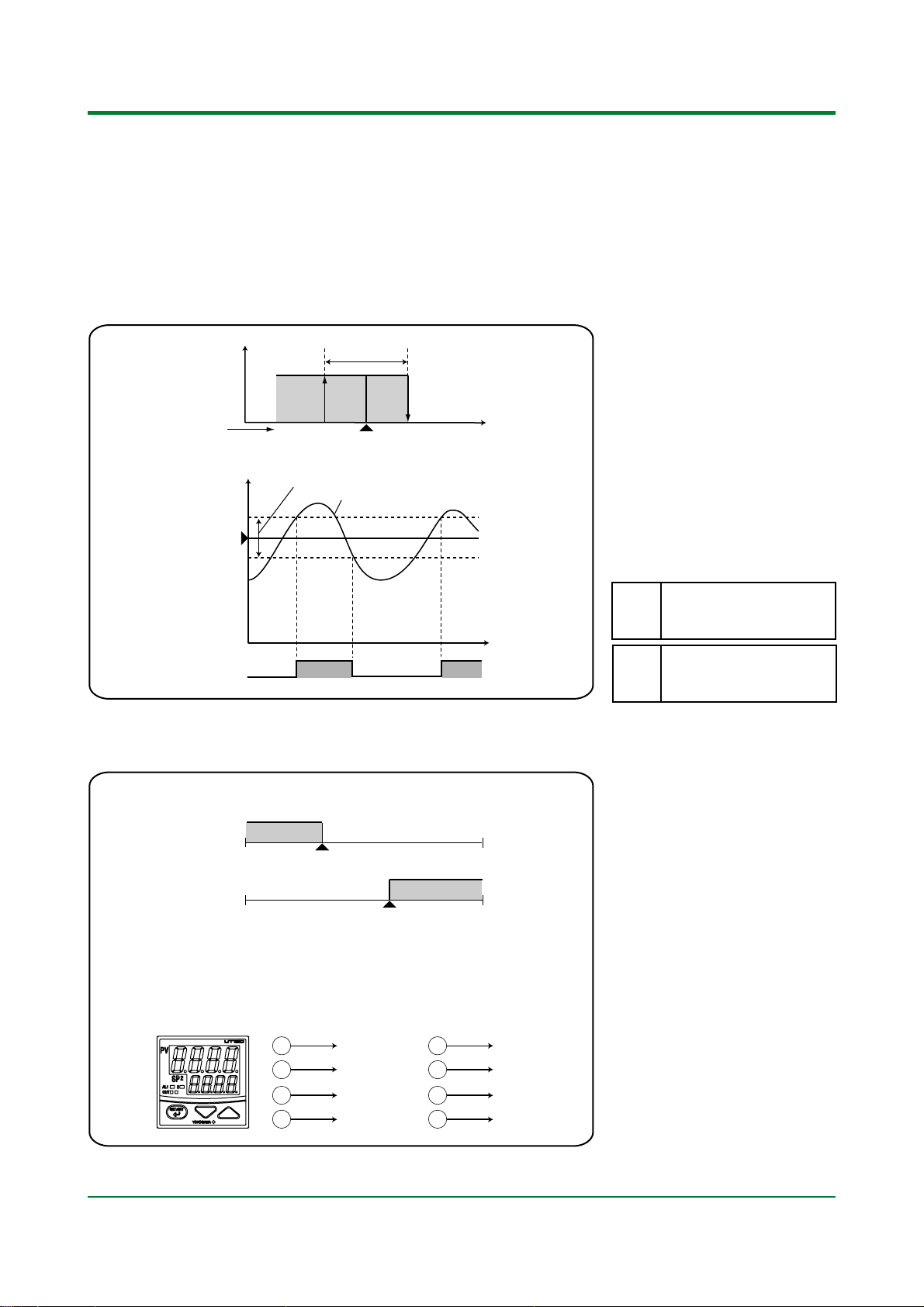

■ Types of Temperature Contr ol Action

ON/OFF action is the simplest action among the control actions. ON/OFF action of the

internal thermostat keeps the optimum temperature. But the temper ature control

output fluctuates in the fixed cycle with ON/OFF action. If this temperature cycle

causes a problem, the control action that changes the output in proportion to the deviation (the difference between the target setpoint and present value) can giv e a better

control performance. Thus the control action that moves the function part in proportion

to the deviation is referred to as a proportional action (P action). But a steady-state

deviation (offset) is inherently unav oidab le with proportional action alone. Though the

manual reset can remove the offset, the same thing can be done using the control

action together with the Integral action (I action) that will integrate the deviation as long

as the deviation exists . This combination is ref erred to as a proportional-plus-integral

action (PI action). It is the popular control method among the process control actions.

On the other hand, the derivative action (D action) is the action that changes the output

in proportion to the rate-of-change of deviation. Since the output of derivative action

depends on not the amount of deviation but its rate-of-change, the larger the rate-ofchange is, the more intensive corrective action the controller takes to correct the process response in advance. Setting each optimum value with the PID action consisted

of these three actions enables a stable control quickly.

1-2

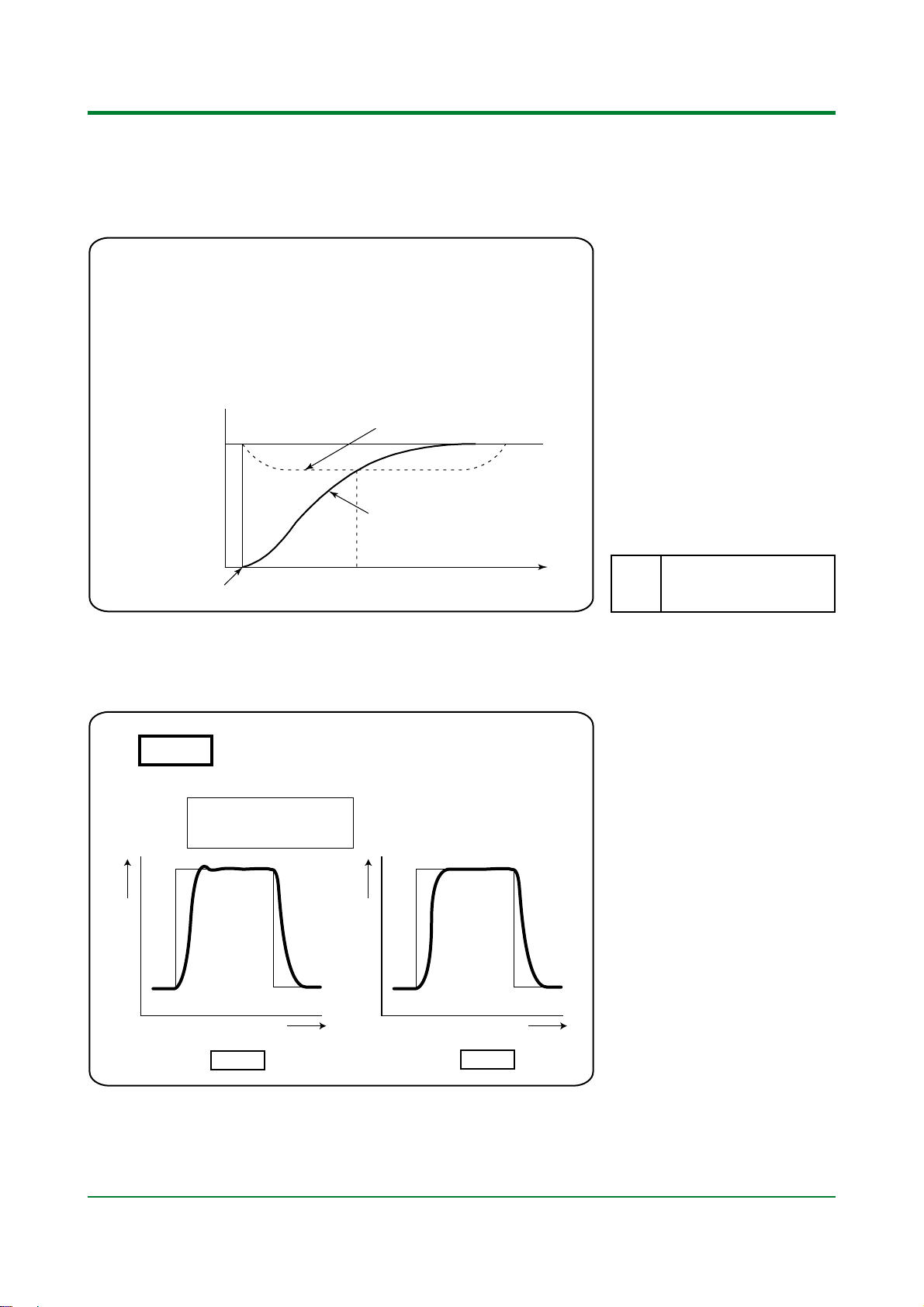

■ Dynamic A uto Tune Control

The Dynamic Auto Tune Control is the function to automatically determine the optimum

PID constants for continuing a good control when the controller is turned on or the

control conditions are unstable. This control method is gentle to the controlled object

itself because a disturbance needs not to be set forcibly lik e Auto tuning.

In Dynamic Auto Tune Control, the controller automatically monitors the behavior and

determines the optimum PID constants when (1) at power on, (2) the output travels up

to 100% or down to 0% and remains there after changing a setpoint, (3) process begins

oscillating by disturbance and the like. The principle of Dynamic A uto Tune Control can

be relied on because it is based on Geglar/Nichols’s control method.

Refer to “6.5.1 Dynamic Auto Tune Control” on Page 6-6.

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 11

<T oc> <Ind>

2-1

2. INFORMATION T O ORDER A CONTR OLLER

2.1 Model and Suffix Codes

The models and suffix codes of UT130, UT150/UT152/UT155 standard types are as

follows:

Without alarm

With 2 alarms

Without alarm

With 2 alarms

Without alarm

With 2 alarms

Without alarm

With 2 alarms

Options

Without

other options

With communication

Without

other options

With

retransmission

output

With external

contact input

With communication

With retransmission

output/external

contact input

Without

other options

With

retransmission

output

With external

contact input

With communication

With retransmission

output/external

contact input

Without

other options

With

retransmission

output

With external

contact input

With communication

With retransmission

output/external

contact input

Output

Relay output

Voltage pulse output

Relay output

Voltage pulse output

Relay output

Voltage pulse output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Relay output

Voltage pulse output

Current output

Type

UT130

48x48x100mm

3-digit display

Number of SP: 2

UT150

48x48x100mm

4-digit display

Number of SP: 2

UT152

48x96x100mm

4-digit display

Number of SP: 2

UT155

96x96x100mm

4-digit display

Number of SP: 2

Note 1: Heating/cooling control type is available in addition to the standard type described above. Refer to the following pages.

Note 2: For options, the combinations other than those mentioned above are available. Refer to the following pages.

External Appearance

Standard Type Model

UT130-RN

UT130-VN

UT130-RN/AL

UT130-VN/AL

UT130-RN/AL/RS

UT130-VN/AL/RS

UT150-RN

UT150-VN

UT150-AN

UT150-RN/AL

UT150-VN/AL

UT150-AN/AL

UT150-RN/AL/RET

UT150-VN/AL/RET

UT150-AN/AL/RET

UT150-RN/AL/EX

UT150-VN/AL/EX

UT150-AN/AL/EX

UT150-RN/AL/RS

UT150-VN/AL/RS

UT150-AN/AL/RS

UT150-RN/AL/RET/EX

UT150-VN/AL/RET/EX

UT150-AN/AL/RET/EX

UT152-RN

UT152-VN

UT152-AN

UT152-RN/AL

UT152-VN/AL

UT152-AN/AL

UT152-RN/AL/RET

UT152-VN/AL/RET

UT152-AN/AL/RET

UT152-RN/AL/EX

UT152-VN/AL/EX

UT152-AN/AL/EX

UT152-RN/AL/RS

UT152-VN/AL/RS

UT152-AN/AL/RS

UT152-RN/AL/RET/EX

UT152-VN/AL/RET/EX

UT152-AN/AL/RET/EX

UT155-RN

UT155-VN

UT155-AN

UT155-RN/AL

UT155-VN/AL

UT155-AN/AL

UT155-RN/AL/RET

UT155-VN/AL/RET

UT155-AN/AL/RET

UT155-RN/AL/EX

UT155-VN/AL/EX

UT155-AN/AL/EX

UT155-RN/AL/RS

UT155-VN/AL/RS

UT155-AN/AL/RS

UT155-RN/AL/RET/EX

UT155-VN/AL/RET/EX

UT155-AN/AL/RET/EX

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 12

<T oc> <Ind>

■ Standar d type

● UT130 Standard Type: Model and Suffix Codes

Model and Suffix Codes

Model

UT130 Temperature controller (48 x 48 x 100mm)

Control

output

Fixed

Options

Note 1: The "/AL" and "/HBA" options cannot be specified at the same time. The "/HBA" option includes the function

of "/AL" option.

Note 2: When specifying the "/RS" option, be sure to order the required number of copies of the Communication

Functions User’s Manual (IM05C01E12-10E) separately. (See Page 2-8.)

Suffix codes Description

-R

-V

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

N Fixed

Alarm outputs (2 points) (Note1)

/AL

Heater disconnection alarm (includes the function of " /AL" option) (Note 1)

/HBA

Communication function (Note 2)

/RS

Power Supply 24V DC / 24V AC

/V24

Check the package contents against the list below.

• Temperature controller (of ordered model)

• Mounting bracket

• User’s Manual (IM 05C01E02-01E)

...............................

......

.............

2-2

1

1

1

● UT150 Standard Type: Model and Suffix Codes

Model and Suffix Codes

Model

UT150 Temperature controller (48 x 48 x 100 mm)

Control

output

Fixed

Option

UT150 Table of Option Combination

/AL

/HBA

/EX

/RET

/RS

/V24

Note 1: The " /HBA" option cannot be specified when selecting "4 to 20mA output" as a control output type.

Note 2: The "/AL" and "/HBA" options cannot be specified at the same time. The "/HBA" option includes the function

of "/AL" option.

Note 3: The "/HBA" and "/RET" options cannot be specified at the same time.

Note 4: "/EX" and "/RS" options cannot be specified at the same time.

Note 5: Two points of external contact inputs are available. Select 2 functions among SP1/SP2 switching, starting of

timer, and RUN.STOP switching.

Note 6: When specifying the "/RS" option, be sure to order the required number of copies of the Communication

Functions User s Manual (IM05C01E12-10E) separately. (See Page 2-8)

Suffix Codes Description

-R

-V

-A

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

4 to 20mA output ( current PID) (Note1)

N Fixed

/AL

Alarm outputs (2 points) (Note2)

Heater disconnection alarm (includes the function of " /AL" option)

/HBA

SP1/SP2 switching, starting of timer, and RUN/STOP switching byexternal contacts

/EX

PV retransmission output in 4 to 20mA (Note 3)

/RET

Communication function (Notes 4 and 6)

/RS

Power Supply 24V DC / 24VAC

/V24

Check the package contents against the list below.

• Temperature controller (of ordered model)

/AL

N/A

N/A

AA

N/A

A

/EX /RET

AA

N/AN/A

A

A

N/A

A

AA

/HBA

A

A

A

/RS

/V24

• Mounting bracket

AA

A

A

AA

• User’s Manual (IM 05C01E12-01E)

A

AN/A

A

A

A : Available

N/A : Not available

(Notes 2 and 3)

(Notes 4 and 5)

...............................

.............

......

1

1

1

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 13

<T oc> <Ind>

● UT152 / UT155 Standard Type: Model and Suffix Codes

Model and Suffix Codes

Model

UT152

UT155

Control

output

Fixed

Option

Note 1: The " /HBA" option cannot be specified when selecting "4 to 20mA output" as a control output type.

Note 2: The "/AL" and "/HBA" options cannot be specified at the same time. The "/HBA" option includes the function

of "/AL" option.

Note 3: Two points of external contact inputs are available. Select 2 functions among SP1/SP2 switching, starting of

timer, and RUN/STOP switching.

Note 4: When specifying the "/RS" option, be sure to order the required number of copies of the Communication

Functions User’s Manual (IM 05C01E12-10E) separately. (See Page 2-8)

Suffix codes Description

Temperature controller ( 48 x 96 x 100mm )

Temperature controller ( 96 x 96 x 100mm )

-R

-V

-A

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

4 to 20mA output ( current PID) (Note1)

N Fixed

/AL

Alarm outputs (2 points) (Note2)

Heater disconnection alarm (includes the function of "/AL" option)

/HBA

SP1/SP2 switching, starting of timer, and RUN/STOP switching by external contacts (Notes 4 and 5)

/EX

PV retransmission output in 4 to 20mA (Note 3)

/RET

Communication function (Notes 4 and 5)

/RS

Power Supply 24V DC / 24VAC

/V24

• Check the package contents against the list below.

• Temperature controller (of ordered model)

• Mounting bracket

• User’s Manual (IM 05C01E12-01E)

(Notes 2 and 3)

...............................

.............

......

2-3

1

1

1

■ Heating/Cooling Type

● UT130 Heating/Cooling Type: Model and Suffix Codes

Model and Suffix Codes

Model

UT130 Temperature controller (48 x 48 x 100mm)

Control

output

for heating

Control

output

for cooling

Option

Note 1: The "/AL" and "/HBA" options cannot be specified at the same time. The "/HBA" option includes the function

of "/AL" option.

Note 2: For heating/cooling type, the "/HBA" and "/RS" options cannot be specified at the same time.

Note 3: When specifying the "/RS" option, be sure to order the required number of copies of the Communication

Functions User’s Manual (IM05C01E12-10E) separately. (See Page 2-8)

Suffix codes Description

-R

-V

R

V

/AL

/HBA

/RS

/V24

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

Alarm outputs (2 points) (Note1)

Heater disconnection alarm (includes the function of "/AL" option) (Notes 1 and 2)

Communication function (Notes 2 and 3)

Power Supply 24V DC / 24V AC

Check the package contents against the list below.

• Temperature controller (of ordered model)

• Mounting bracket

• User’s Manual (IM 05C01E02-01E)

...............................

......

.............

1

1

1

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 14

<T oc> <Ind>

● UT150 Heating/Cooling Type: Model and Suffix Codes

Model and Suffix Codes

Model

UT150

Control

output

for heating

Control

output

for cooling

Option

UT150 Heating/cooling Type Table of Option Combination

/AL

/HBA

/EX

/RS

/V24

Note 1: The " /HBA" option cannot be specified when selecting "4 to 20mA output" as a control output type.

Note 2: The "/AL" and "/HBA" options cannot be specified at the same time. The "/HBA" option includes the function

of "/AL" option.

Note 3: The "/HBA", "/EX" and "/RS" options cannot be specified at the same time.

Note 4: Two points of external contact inputs are available. Select 2 functions among SP1/SP2 switching, starting of

timer, and RUN/STOP switching.

Note 5: When specifying the "/RS" option, be sure to order the required number of copies of the Communication

Functions User’s Manual (IM05C01E12-10E) separately. (See Page2-8)

Suffix codes Description

Temperature controller (48 x 48 x 100mm)

/AL

N/A

-R

-V

-A

R

V

A

/HBA

N/A

A

N/A

N/A

A

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

4 to 20mA output ( current PID) (Note1)

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

4 to 20mA output ( current PID) (Note1)

Alarm outputs (2 points) (Note2)

/AL

Heater disconnection alarm (includes the function of " /AL" option)

/HBA

SP1/SP2 switching, starting of timer, and RUN/STOP switching byexternal contacts

/EX

PV retransmission output in 4 to 20mA

/RS

Power Supply 24V DC / 24VAC

/V24

/EX

N/A

N/A

/V24

/RS

AAA

N/A

N/A

AAA

A

A

A

A

Check the package contents against the list below.

• Temperature controller (of ordered model)

• Mounting bracket

• User’s Manual (IM 05C01E12-01E)

A : Available

N/A : Not available

(Notes 2 and 3)

(Notes 3 and 4)

...............................

.............

......

2-4

1

1

1

● UT152 / UT155 Heating/Cooling Type: Model and Suffix Codes

Model and Suffix Codes

Model

UT152

UT155

Control

output

for heating

Control

output

for cooling

Option

Note 1: The " /HBA" option cannot be specified when selecting "4 to 20mA output" as control output type.

Note 2: The "/AL" and "/HBA" options cannot be specified at the same time. The "/HBA" option includes the function

of "/AL" option.

Note 3: Two points of external contact inputs are available. Select 2 functions among SP1/SP2 switching, starting of

timer, and RUN/STOP switching.

Note 4: When specifying the "/RS" option, be sure to order the required number of copies of the Communication

Functions User’s Manual (IM05C01E12-10E) separately. (See Page 2-8)

Suffix codes Description

Temperature controller ( 48 x 96 x 100mm )

Temperature controller ( 96 x 96 x 100mm )

-R

-V

-A

R

V

A

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

4 to 20mA output ( current PID) (Note1)

Relay output (time-proportional PID or on/off control)

Voltage pulse output (time-proportional PID control)

4 to 20mA output ( current PID) (Note1)

Alarm outputs (2 points) (Note2)

/AL

Heater disconnection alarm (includes the function of "/AL" option) (Note 2)

/HBA

SP1/SP2 switching, starting of timer, and RUN/STOP switching by external contacts (Note 3)

/EX

Communication function (Note 4)

/RS

Power Supply 24V DC / 24V AC

/V24

Check the package contents against the list below.

• Temperature controller (of ordered model)

• Mounting bracket

• User’s Manual (IM 05C01E12-01E)

...............................

.............

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

......

1

1

1

Page 15

<T oc> <Ind>

2.2 Mandatory Items to Specify

Specify the following necessary items on ordering

● Specify the power suppl y volta ge

When using 100 to 240V AC, no need to specify the item.

When using 24V AC/DC, specify the “/V24” option.

The frequency for both of them is 50/60Hz.

● Specify the control output

<Example 1>

Specify “ UT150-RN” for UT150 standard type with relay output.

<Example 2>

Specify “UT150-RV” f or UT150 heating/cooling type with heating-side rela y output and

cooling-side voltage pulse output.

2-5

2.3 Optional Suffix Codes to Specify

The following options are a vailab le. But some of them are not availab le according to

the model. See “2.1 Model and Suffix Codes” f or combinations of options.

● When using one or two Alarms, specify the “ /AL “ option.

<Example> Model and Suffix Codes: UT130-RN/AL

● When using Heater Disconnection Alarm, specify the “/HBA” option. The

“/HBA” option includes the function of “/AL” option.

<Example> Model and Suffix Codes: UT150-RN/HBA

● When using Retransmission Output, specify the “ /RET” option.

<Example> Model and Suffix Codes: UT150-AN/RET

● When using two Target Setpoints, specify the “ /EX” option.

<Example> Model/Suffix Codes: UT150-RN/EX

● When using Timer Function, specify the “ /AL /EX” or “/HBA /EX” options.

<Example> Model/Suffix Codes: UT150-VN/AL/EX

● When using RUN/ST OP Switching Function, specify the “/EX” option.

<Example> Model/Suffix Codes: UT150-RN/EX

● When using Communication Function, specify the “ /RS” option.

<Example> Model/Suffix Codes: UT150-RN/RS

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 16

<T oc> <Ind>

2.4 Other Items to Specify

■ Quality Inspection Certificate (QIC) and Traceability

The Quality Inspection Certificate (QIC) of the product at shipping is prepared.

And the Traceability , which certificates that the measuring instruments and generator

used for the product inspection conforms to the inspection of national standards, is also

prepared.

● Quality Inspection Certificate(QIC)

Model: DOCTC

● Calibration certificate (traceability)

“Traceability declaration to the national standards” and “Explanation of the Yokogawa’s

internal system for traceability”

Model: Q62188-B

2-6

■ A uxiliary Equipment and Spare Parts

● 250Ω Resistor

When a measured input signal is 4 to 20mA DC, the temperature controllers (UT150/

UT152/UT155) receive it after converting to a 1 to 5V DC signal.

Model Description

X010-250-2

Receiving 4-20mA DC Current

Signals with UT150

*

When receiving 4-20mA DC current signals,

set the PV input type to 1-5V DC (range code "22")

Note: Connecting a

Model: X010-250-2(resistor with M3.5 crimp-on terminal lugs)

Resistor with M3.5 crimp-on terminal lugs

7

+

4-20mA

250Ω

—

8

250‰

resistor to the terminals is optional.

Receiving 4-20mA DC Current

Signals with UT152/UT155

*When receiving 4-20mA DC current signals,

set the PV input type to 1-5V DC (range code "22")

12

+

250Ω

4-20mA

—

13

Note: Connecting a

Model: X010-250-2(resistor with M3.5 crimp-on terminal lugs)

250‰

resistor to the terminals is optional.

● Heater Disconnection Sensor (for 1 to 80A)

The heater current sensor used here is the “CTL-6-S-H” or “CTL-12-S36-8” sensor of

U.R.D., Ltd.

This sensor is to be purchased by the users themselves.

Model: CTL-6-S-H or CTL-12-S36-8

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 17

<T oc> <Ind>

● T erminal Co ver

Model Description

L4000FB

T9115YE

T9115YD

Terminal cover for models UT130 and UT150 (1 set)

Terminal cover for model UT152 (1 piece)

Terminal cover for model UT155 (1 piece)

● Mounting Bracket

Model Description

L4000FA

T9115NK

T9115NL

Mounting bracket for models UT130 and UT150 (1 piece)

Mounting bracket for model UT152 (1 set)

Mounting bracket for model UT155 (1 set)

■ Measured Input Type, Scaling and Direct/Rever se Action can be Speci-

fied on Ordering

Measured input type, displayed scale at voltage input, and direct/reverse action for the

temperature controller can be specified on ordering.

2-7

Items to specify Description

Specify "1" to "7", "12", "13", and "15 to "19" for UT130.

Specify "1" to "23" for UT150/UT152/UT155.

If no input type is specified at the time of ordering, the temperaturecontroller

Measured

input type

Scaling

(at voltage input)

Direct/reverse

action

is shipped with the parameter set to OFF (unidentified).

In this case, set the input type on customer side.

See "4.1 Setting Measured Input Type and Scale (Setting First)" for details.

The displayed scale can be specified when specifying "20" to "23"

for UT150/UT152/UT155. If no scaling is specified, the temperature controller

is shipped with the parameter set to "0.1 to 100.0".

Specify "1" for direct action. If no action is specified, the temperature

controller is shipped with the parameter set to "0" (reverse action).

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 18

<T oc> <Ind>

2.5 User’s Manual

User’s Manuals in A-2 size and A-4 size are prepared.

User’s Manuals supplied along with the product is in A-2 size. Both Man uals in A-4 size

and A-2 size have the same contents e xcept f or their appearances.

When specifying the ”/RS” option, be sure to order the required number of copies of

Communication Functions User’s Manual separately .

The following User’s Manuals can be purchased separately.

● User’s Manual for UT130 (A4 size)

Document Number: IM05C01E02-41E

● User’s Manual for UT150/UT152/UT155 (A4 size)

2-8

A4-size Manual

Document Number: IM05C01E12-41E

● Communication Functions User’s Manual for UT130, UT150/UT152/UT155

(A4 size)

Document Number: IM05C01E12-10E

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 19

<T oc> <Ind>

3-1

3. NAMES AND FUNCTIONS OF EACH PART / PARAMETER

3.1 UT130 Names and Functions of Each P art (Principles of Ke y Operation)

SP display lamp (orange)

• Lit when SP is displayed or being changed.

• Flashes slowly (approx. once every second) when

a parameter code is displayed.

• Flashes fast when a parameter value is being changed.

Alarm 1 (AL1) / Alarm 2 (AL2) lamps (red)

AL1: Lit when the alarm 1 is activated.

AL2: Lit when the alarm 2 is activated.

SET /ENT key (data registering key)

• In the operating display, it switches between the PV (measured value)

and SP (target setpoint) displays.

• Registers the data value changed using the data change keys.

• Switches between operating displays or parameter setting display

sequentially.

• Pressing the key for 3 seconds or more in the operating display

retrieves the operating parameter setting display. You can transfer to

the setup parameter setting display form the operating parameter

setting display.

• Pressing the key for 3 seconds or more in either an operating or setup

parameter setting display transfers back to the operating display.

Data display (red)

• In the operating display, either PV (measured value) or

SP (target setpoint) is indicated.

Which parameter takes precedence over the other

depends on the parameter "DSP" value.

• In the parameter setting display, either the parameter

codes or parameter value is indicated.

• If an error occurs, the error code is displayed.

Output (OUT) display lamps

(Left: orange; right: green)

Lit while control output is being output.

Flashes according to the control output value during timeproportional output.

value is small; flashes fast when control output value is large.)

• The left lamp lights up in orange during control output of

standard type.

• In heating/cooling control, the left lamp lights up in orange

when the heating-side output is active; while the right lamp

lights up in green when the cooling-side output is active.

(Flashes slowly when control output

Data change keys

• When PV is displayed in the operating display, a press of

the or key switches to the SP display.

• When a parameter code is displayed, pressing either key

once displays the parameter value (which can then be

changed).

• Changes SP and the parameter values.

• Pressing the key decreases the data value and

pressing the key increases it. Holding down the key

will gradually increase the speed of the change.

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 20

<T oc> <Ind>

3.2 UT130 Parameter Flo wchart and Description

3-2

A

When the measured input range code has

been already set, the operating display shown

below appears.

Power ON

Operating Display

Displays PV Displays SP

The data (PV or SP) selected in "DSP" is

displayed at first. (Default: PV display)

Press the key

for at least 3 seconds.

(To operating parameter

setting display)

To switch between PV and SP,

press the key.

Press the key

for at least 3 seconds.

(To operating display)

Note

Operating parameter setiing dispaly

Displayed only for the "/AL" or "/HBA" option.

Press the

key to move

between items.

CTL

A1

Not displayed when AL1, AL2 = OFF

A2

Not displayed when AL1, AL2 = 21 or 22

HC

Displayed only for the "/HBA" option and when AL1 = 25

CTL=SLF

(Dynamic Auto Tune)

Note

CTL=SLF is not

permitted for heating/

cooling type.

CTL=PID

AT

(PIDcontrol)

P

I

D

Displayed when I = OFF

MR

Displayed for heating/

COL

cooling type

is displayed

?

SP display lamp

is on.

NOTE

When IN appears, press the

key to display the measured input

YesNo

A

SP (target setpoint) can be

changed in the operating display.

Note: If no key is pressed for a period of 2 minutes or more

while in the operating or setup parameter setting display,

the controller automatically returns to operating display.

CTL=ONF

(on/off control)

range code you want to use, then

press the key to register it.

After this operation, the controller

shows the operating display.

* Refert to the Measured Input Ranges on

Page 4-1.

FL

BS

LOC

LOC=

Displayed for heating/cooling type

DB

) Displayed for time-proportional PID control

CT

Displayed for time-proportional PID control

CTC

of heating/cooling type

When LOC=-1

HYS

When LOC=-1,

transfers to the

setup parameter

setting display

To Page 3-4

B

Set "-1" to enter the setup parameter setting

display. But if "LOC=1 or 2" is already set, the

parameter value can not be changed by setting

"LOC=-1" only. To change the parameter value,

set "LOC=0" at first (for disabling keylock),

then set "LOC=-1" once again.

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

NOTE

Page 21

<T oc> <Ind>

(1) Target Setpoint (SP)

Code Name

(SP value display)

Target

setpoint

Minimum value (SPL) to maximum value (SPH) of target setpoint

range

Unit: °C/°F

Setting range and unit

Default User setting

SPL

Numbers in ( ) are the parmeter setpoints that apply

when the communication function is used.

Ex. OFF(0), ON(1)

(2) Operating Parameters: Parameters changed rather frequently during operation.

Code Name Setting range and unit Default User setting

A1

A2

HC

CTL

AT

P

I

D

MR

COL

DB

HYS

CT

CTC

FL

BS

LOC

Alarm 1

setpoint

Alarm 2

setpoint

Heater disconnection

current measured

value

Control mode

Auto-tuning

Proportional

band

Integral time

Derivative

time

Manual reset

Cooling-side

gain

Dead band

Hysteresis for

on/off control

Control

output cycle

time

Cooling-side

control output

cycle time

PV input filter

PV input bias

Key lock

■ PV alarm Unit: °C/°F

Setting range: Minimum value to maximum value of

measured input range

■ Deviation alarm Unit: °C/°F

Setting range: —100 to 100% of measured input range

span

■ Heater disconnection alarm Unit: A (ampere)

Setting range: OFF(0), 1 to 80

(can be set for the alarm 1 setpoint only)

HC is not a parameter to be set. The current value (0 to 80) of heater

disconnection detector is displayed. Unit: A (ampere)

When the display value is ———, the heater current is not being measured.

Settings:

ONF(0): On/off control

PID(1): PID control

SLF(2): Dynamic auto tune control

OFF(0): Stop auto-tuning(AT)

ON(1): Start auto-tuning(AT)

1°C/°F to the temperature that corresponds to 100% of

the measured input range span

1 to 999 seconds;

OFF(0): no integral action

1 to 999 seconds;

OFF(0): no derivative action

-19.9 to 99.9 % : Standard type

-100 to 100 % : Heating/cooling type

0.01 to 9.99 times

■ PID control Unit: °C/°F

Setting range: —(proportional band setting) to +(proportional band setting)

■ On/off control Unit: °C/°F

Setting range: —50 to +50% of measured input range span

0°C/°F to the temperature that corresponds to 100% of

the measured input range span

1 to 240 seconds

1 to 240 seconds 30 seconds

OFF(0), 1 to 120 seconds OFF(0)

—100 to 100% of measured input range span

0: No key lock

1: Prevents operations from being changed except for the

changing of SP in the operating display

2: Prevents all parameter changing operations

—1: Set -1 to enter the setup parameter setting display.

But if LOC=1 or 2 is already set, the parameter

value can not be changed by setting LOC=-1 only. To

change the parameter value, set LOC=0 at first (for

disabling keylock), then set LOC=-1 once again.

(cannot be set for heating/cooling control)

Max. value of

measured input

range (PV alarm)

Min. value of

measured input

range (PV alarm)

SLF(2) : standard type;

PID(1) : heating/cooling

type

OFF(0)

5% of measurd

input range span

240 seconds

60 seconds

50.0% :

Standard type;

Heating/cooling

0.0% :

type

1.00 time

0% of measured

input range span

0.5% of measured

input range span

30 seconds

0% of measured

input range span

0

3-3

Reference page

P.4-9

Reference page

P.4-12

P.4-16

P.4-17

P.4-5

P.6-1

P.6-6

P.6-7

P.6-2

P.6-4

P.6-5

P.6-4

P.5-8

P.5-8

P.6-1

P.4-8

P.6-8

P.6-8

P.5-2

P.5-1

P.5-7

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 22

<T oc> <Ind>

NOTE

Changing certain setup parameter may automatically initialize the operating parameters. Therefore,

after you change the setup parameters, always check the operating parameter settings to find out if

appropriate values have been set for them. If the operating parameters have been initialized, set

them to their appropriate values.

To Page 3-2

Operating display

Note

Press the key

for at least 3 seconds.

(To operating display)

3-4

Note: If no key is pressed for a period of 2 minutes or more

while in the operating or setup parameter setting display,

the controller automatically returns to operating display.

From

Page 3-2

B

Press the key

to move between items.

Setup parameter setting display

IN

SPH

SPL

AL1

AL2

HY1

HY2

SC

DR

DSP

Displayed for the "/AL" or

"/HBA" option

Not displayed when "CTL"=ONF (on/off control)

Not displayed for heating/cooling type

PSL

ADR

BPS

PRI

STP

DLN

Displayed for the "/RS" option

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 23

<T oc> <Ind>

Numbers in ( ) are the parmeter setpoints that apply

when the communication function is used.

Ex. OFF(0), ON(1)

(3) Setup Parameters: Parameters rarely changed in normal use after once having been set.

Code Name Setting range and unit Default User setting

Measured

IN

SPH

SPL

AL1

AL2

HY1

HY2

SC

DR

DSP

PSL

ADR

BPS

PRI

STP

DLN

input type

Maximum

value of target

setpoint range

Minimum value

of target

setpoint range

Alarm 1 type

Alarm 2 type

Alarm 1

hysteresis

Alarm 2

hysteresis

SUPER

function

Direct/reverse

action

Priority of

PV/SP

display

Protocol

selection

Controller

address

Baud rate

Parity

Stop bit

Data length

1 to 7, 12, 13, 15 to 19, 31 to 37, 42, 43, 45 to 48 (See the

measured input range code list.) OFF(0): No input

(If no input type is specified at the time of ordering, you must set the input type.)

(SPL+1°C) to the maximum value of measured input

range; Unit: °C/°F

Minimum value of measured input range to (SPH—1°C)

Unit: °C/°F

OFF(0), 1 to 22 (See the alarm function list.)

25 (for the heater disconnection alarm /HBA option only)

OFF(0), 1 to 22 (See the alarm function list.)

0 to 100% of measured input range span

Unit: °C/°F

ON(1): Uses the SUPER function

OFF(0): Does not use SUPER function

Note: Not displayed when on/off control

0: Reverse action

1: Direct action

Note: Not displayed for heating/cooling type

0: Displays PV

1: Displays target setpoint (SP)

0: PC-link communication

1: PC-link communication with sum check

2: Ladder communication

3: MODBUS in ASCII mode

4: MODBUS in RTU mode

1 to 99

However, the number of controllers that can be connected

per host device is 31 at the maximum.

2.4(0): 2400 bps

4.8(1): 4800 bps

9.6(2): 9600 bps

NON(0): Disabled

EVN(1): Even parity

ODD(2): Odd parity

1 or 2 bits 1 bit

7 or 8 bits

• 8 bits when ladder, MODBUS (RTU)

• 7 bits when MODBUS (ASCII)

OFF(0), or the

input range code

specified with

Maximum value of

measured input

range

Minimum value of

measured input

range

1

(PV high limit alarm)

2

(PV low limit alarm)

0.5% of measured

input range span

OFF(0)

0

0

0

1

9.6(2)

EVN(1)

8 bits

3-5

Reference page

P.4-1

P.5-1

P.5-2

P.4-12

P.4-16

P.4-17

P.6-10

P.4-6

P.

P.5-9

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 24

<T oc> <Ind>

3.3 UT150/UT152/UT155Names and Functions of Each P art (Principles of Ke y Operation)

3-6

SP2 lamp (green)

Lit when SP2 is being used for control operation.

Alarm 1 (AL1), Alarm 2 (AL2) lamps (red)

AL1: Lit when the alarm 1 is activated.

AL2: Lit when the alarm 2 is activated.

Output (OUT) display lamps

Lit while control output is being output.

Flashes according to the control output value during timeproportional output or current output. (Flashes slowly when

current control output value is small; flashes fast when it is large.)

•

The left lamp is lit in orange during control output of standard type.

• In heating/cooling control, the left lamp lights up in orange when

the heating-side output is active; while the right lamp lights up in

green when the cooling-side output is active.

(Left: orange; right: green)

SET / ENT key (data registering key)

• Registers the data value changed using the data change keys.

• Switches between operating displays or parameter setting

displays sequentially.

• Pressing the key for 3 seconds or more in the operating display

retrieves the operating parameter setting display. You can transfer

to the setup parameter setting display form the operating

parameter setting display.

• Pressing the key for 3 seconds or more in either an operating or

setup parameter setting display transfers back to operating display.

PV display (red)

Indicates PV (measured value) and character information

such as parameter codes and error codes.

UT150

SP display (green)

Indicates SP (target setpoint) and parameter values.

Data change keys

• Change SP and the parameter values.

• Pressing the key decreases the data value and pressing

the key increases it. Holding down the key will gradually

increase the speed of the change.

SP2 lamp (green)

Lit when SP2 is being used for control operation.

Alarm 1 (AL1), Alarm 2 (AL2) lamps (red)

AL1: Lit when the alarm 1 is activated.

AL2: Lit when the alarm 2 is activated.

Output (OUT) display lamps

Lit while control output is being output.

Flashes according to the control output value during timeproportional output or current output. (Flashes slowly when current

control output value is small; flashes fast when it is large.)

•

The uppert lamp is lit in orange during control output of standard type.

• In heating/cooling control, the upper lamp lights up in orange

when the heating-side output is active; while the lower lamp lights

up in green when the cooling-side output is active.

(Upper: orange: lower: green)

SET / ENT key (data registering key)

• Registers the data value changed using the data change keys.

• Switches between operating displays or parameter setting

displays sequentially.

• Pressing the key for 3 seconds or more in the operating display

retrieves the operating parameter setting display. You can

transfer to the setup parameter setting display form the

operating parametersetting display.

• Pressing the key for 3 seconds or more in either an operating or

setup parameter setting display transfers back to operating

display.

UT152

PV display (red)

Indicates PV (measured value) and character information

such as parameter codes and error codes.

SP display (green)

Indicates SP (target setpoint) and parameter values.

Data change keys

• Change SP and the parameter values.

• Pressing the key decreases the data value and pressing

the key increases it. Holding down the key will gradually

increase the speed of the change.

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 25

<T oc> <Ind>

3-7

SP2 lamp (green)

Lit when SP2 is being used for control operation.

Alarm 1 (AL1), Alarm 2 (AL2) lamps (red)

AL1: Lit when the alarm 1 is activated.

AL2: Lit when the alarm 2 is activated.

Output (OUT) display lamps

(Upper: orange; lower: green)

Lit while control output is being output.

Flashes according to the control output value during

time-proportional output or current output. (Flashes

slowly when current control output value is small;

flashes fast when it is large.)

• The upper lamp is lit in orange during control output

of standard type.

• In heating/cooling control, the upper lamp lights up in

orange when the heating-side output is active; while

the lower lamp lights up in green when the cooling side output is active.

SET / ENT key (data registering key)

• Registers the data value changed using the data change keys.

• Switches between operating displays or parameter setting

displays sequentially.

• Pressing the key for 3 seconds or more in the operating display

retrieves the operating parameter setting display. You can

transfer to the setup parameter setting display form the

operating parameter setting display.

• Pressing the key for 3 seconds or more in either an operating or

setup parameter setting display transfers back to operating

display.

UT155

PV display (red)

Indicates PV (measured value) and character

information such as parameter codes and error codes.

SP display (green)

Indicates SP (target setpoint) and parameter values.

Data change keys

• Change SP and the parameter values.

• Pressing the key decreases the data value and

pressing the key increases it. Holding down the

key will gradually increase the speed of the change.

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 26

<T oc> <Ind>

3.4 UT150/UT152/UT155 P arameter Flowchart and Description

Power ON

A

When measured input range code has been already set,

the operating display 1 shown below appears.

Press the key to

move between items.

Operating display

Operating display 1

SP1 or SP2 value can be changed at

operating display1.

SP2 is displayed when the lamp

is flashing.

Timer 1 (T1) operating

display is shown when "AL1"

= 23 or 24 with the "/AL" and

"/EX" options. The value is

the remaining time.

Operating display 2

Timer 2 (T2) operating display

is shown when "AL2" = 23 or

24 with the "/AL" and "/EX"

options. The value is the

time.

remaining

is displayed

YesNo

?

NOTE

In STOP mode, or PV

value is displayed on PV

display alternately.

* Refer to the Measured Input Ranges on

Page 4-1.

A

NOTE

When IN appears, press the

key to display the measured input

range code you want to use, then

press the key to register it.

After this operation, the controller

shows the operating display.

3-8

Press the key

for at least 3 seconds.

(To operating parameter

setting display)

Press the key to

move between items.

Operating parameter setting display

A1

A2

HC

CTL

CTL=SLF

(Dynamic Auto Tune)

NOTE: CTL = SLF

is not permitted for

heating/cooling type.

DB

CT

CTC

SP1

SP2

FL

BS

LOC

LOC=

When LOC = -1

AT

Note

Note: If no key is pressed for a period of two minutes or more

while in the operating or setup parameter setting display, the

controller automatically returns to operating display 1.

CTL=PID

(PID control)

CTL=ONF

(on/off control)

Press the key

for at least 3 seconds.

(To operating display)

Displayed only for the /AL" or "/HBA" options

Not displayed when "AL1", "AL2" = OFF.

Not displayed when "AL1", "AL2" = 21 or 22

Displayed only for the "/HBA" option and when "AL1" = 25

P

I

D

Displayed when I = OFF

MR

COL

Displayed for heating/

cooling type

Displayed for heating/cooling type

HYS

Displayed for time-proportional PID control

Displayed for time-proportional PID control

of heating/cooling type

Displayed for the "/EX" option.

When LOC=-1,

transfers to the

setup parameter

setting display

To Page 3-10

B

Set "-1" to enter the setup parameter setting

display. But if "LOC=1 or 2" is already set, the

parameter value can not be changed by setting

"LOC=-1" only. To change the parameter value,

set "LOC=0" at first (for disabling keylock),

then set "LOC=-1" once again.

NOTE

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 27

<T oc> <Ind>

(1) Target Setpoint (SP) and Timer Settings 1 and 2

Code Name

(SP value display)

T1

T2

Target

setpoint

Timer

setting 1

Timer

setting 2

Minimum value (SPL) to maximum value (SPH) of target setpoint

range

0.0 to 99.59

Unit: minutes and seconds or hours and minutes

Set the timer time unit using the parameter TTU.

For example, 15.25 sets 15 minutes and 25 seconds when

the unit is minutes and seconds.

Setting range and unit

(T1 is for AL1, and T2 is for AL2)

Default User setting

SPL

0.00

0.00

Numbers in ( ) are the parmeter setpoints that apply

when the communication function is used.

Ex. OFF(0), ON(1)

(2) Operating Parameters: Parameters changed rather frequently during operation.

Code Name Setting range and unit Default User setting

A1

A2

HC

CTL

AT

P

I

D

MR

COL

DB

HYS

CT

CTC

SP1

SP2

FL

BS

LOC

Alarm 1

setpoint

Alarm 2

setpoint

Heater disconnection

current measured

value

Control mode

Auto-tuning

Proportional

band

Integral time

Derivative

time

Manual reset

Cooling-side

gain

Dead band

Hysteresis for

on/off control

Control

output

cycle time

Cooling-side

control output

cycle time

Target

setpoint 1

Target

setpoint 2

PV input filter

PV input bias

Key lock

■ PV alarm Unit: °C/°F

Setting range: minimum value to maximum value of measured input

range (scale)

■ Deviation alarm Unit: °C/°F

Setting range: —100 to 100%

■ Heater disconnection alarm Unit: A (ampere)

Setting range: OFF(0), 1 to 80

HC is not a parameter to be set. The current value (0 to 80) of heater disconnection

detector is displayed. Unit: A (ampere)

Settings: When the display value is ————, the heater current is not being measured.

ONF(0): On/off control

PID(1): PID control

SLF(2):

Dynamic auto tune control (cannot be set for heating/cooling control)

OFF(0): Stop auto-tuning

ON(1): Start auto-tuning

1°C/°F to the temperature that corresponds to 100% of

the measured input range (scale) span

1 to 3600 seconds;

OFF(0): no integral action

1 to 3600 seconds;

OFF(0): no derivative action

—100 to 100%

0.01 to 9.99 times

■ PID control Unit: °C/°F

Setting range: —(proportional band setting) to +(proportional band setting)

■ On/off control Unit: °C/°F

Setting range: —50 to +50% of measured input range (scale)span

0°C/°F to the temperature that corresponds to 100% of

the measured input range (scale) span

1 to 240 seconds

1 to 240 seconds

Minimum value (SPL) to maximum value (SPH) of target

setpoint range

Unit: °C/°F

There are also optional engineering units for voltage input.

OFF(0), 1 to 120 seconds

—100 to 100% of measured input range (scale) span

0: No key lock

1: Prevents operations from being changed except for the

changing of SP in the operating display

2: Prevents all parameter changing operations

—1: Set -1 to enter the setup parameter setting display.

But if LOC=1 or 2 is already set, the parameter value

can not be changed by setting LOC=-1 only. To

change the parameter value, set LOC=0 at first (for

disabling keylock), then set LOC=-1 once again.

of measured input range (scale) span

(can be set for the alarm 1 setpoint only)

Max. value of

measured input range

(scale) (PV alarm)

Min. value of

measured input range

(scale) (PV alarm)

SLF(2) :

for standard type;

PID(1) :

for

heating/cooling type

OFF(0)

5% of measured

input range (scale)

240 seconds

60 seconds

50.0%

for standard type;

for heating/cooling type

0.0%

1.00 times

0% of measured

input range (scale)

span

0.5% of measured

input range (scale)

span

30 seconds

30 seconds

SPL

SPL

OFF(0)

0% of measured input

range (scale) span

0

3-9

Reference page

P.4-10

P.5-6

Reference page

P.4-12

P.4-16

P.4-17

P.4-5

P.6-1

P.6-6

P.6-7

P.6-2

P.6-4

P.6-5

P.6-4

P.5-8

P.5-8

P.6-1

P.4-8

P.6-8

P.6-8

P.4-10

P.5-4

P.5-2

P.5-1

P.5-7

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 28

<T oc> <Ind>

NOTE

Changing certain setup parameter may automatically initialize the operating parameters. Therefore,

after you change the setup parameters, always check the operating parameter settings to find out if

appropriate values have been set for them. If the operating parameters have been initialized, set

them to their appropriate values.

To Page 3-8

Operating display

Press the key

for at least 3 seconds.

(To operating display)

Note: If no key is pressed for a period of 2

minutes or more while in the operating or

setup parameter setting display, the

controller automatically returns to operating

display 1.

3-10

From

Page 3-8

B

Press the key to

move between items.

Setup parameter setting display

IN

DP

Displayed when DC voltage input range code is set

RH

RL

SPH

SPL

UPR

DNR

TMU

DIS

Displayed for the "/EX" option

EOT

Displayed for the "/AL/EX" of "/HBA/EX" option

TTU

RTH

Displayed for the "/RET" option

RTL

AL1

AL2

Displayed for the "/AL" or "/HBA" option

HY1

HY2

SC

Not displayed when CTL = ONF (on/off control)

Not displayed for heating/cooling type

DR

PSL

ADR

BPS

Displayed for the "/RS" option

PRI

STP

DLN

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 29

<T oc> <Ind>

(3) Setup Parameters: Parameters rarely changed in normal use after once having been set.

Code Name Setting range and unit Default User setting

IN

DP

RH

RL

SPH

SPL

UPR

DNR

TMU

DIS

EOT

TTU

RTH

RTL

AL1

AL2

HY1

HY2

SC

DR

PSL

ADR

BPS

PRI

STP

DLN

Measured

input type

Decimal point

position of

measured

input

Maximum value

of measured

input scale

Minimum value

of measured

input scale

Maximum

value of target

setpoint range

Minimum value

of target

setpoint range

Setpoint

ramp-up-rate

Setpoint

ramp-downrate

Setpoint ramprate time unit

DI-function

selection

Output in

STOP mode

Timer time unit

Maximum value

of retransmission

output

Minimum value

of retransmission

output

Alarm 1 type

Alarm 2 type

Alarm 1

hysteresis

Alarm 2

hysteresis

SUPER

function

Direct/reverse

action

Protocol

selection

Controller

address

Baud rate

Parity

Stop bit

Data length

1 to 23, 31 to 48 (See input range code list.)

OFF(0): No input

(If no input type is specified at the time of ordering, you must set the input

0: No decimal place (nnnn)

1: One decimal place (nnn.n)

2: Two decimal places (nn.nn)

3: Three decimal places (n.nnn)

(RL + 1) to 9999 100.0

—1999 to (RH —1)

(SPL+1°C) to the maximum value of measured input

range (scale) ; Unit: °C/°F

Minimum value of measured input (scale) range to (SPH

—1°C)

Unit: °C/°F

OFF(0)

or a value from the minimum to the maximum value of t

measured input range (scale)

Unit: °C/min or °C/hour, °F/min or °F/hour

Set the ramp-rate time unit using parameter TMU.

0 : °C or °F / hour

1 : °C or °F / min

External Contact Inputs

UT152

UT150

UT155

TMR

STOP

3

21

SP2

STOP

4

22

COM

5

23

In STOP mode by contact input, fixed control output can

be generated.

0 : 0%, 1 : 100%

0 : hour, minute

1 : minute, second

(Displayed at voltage input)

(Displayed at voltage input)

(Displayed at voltage input)

Parameter DIS

0

Timer starts

when DI=ON

Timer stops

when DI=OFF

SP1/SP2

switching

SP2

when DI=ON

Timer starts

when DI=ON

Timer stops

when DI=OFF

RUN/STOP

switching

STOP

when DI=ON

TMR

STOP

SP2

STOP

1

RUN/STOP

switching

STOP

when DI=ON

Temperature input : Within measured input range

Voltage input : RTL+1digit to max. value of measured

input scale (RH)

Min. value of measured input scale (RL) to RTH-1digit

However, RTL<RTH

OFF(0) or a value from 1 to 22 (see the table of alarm function list),

and either 23 or 24 (if the timer function [/EX option] is included), and

25 (if the heater disconnection function [/HBA option] is included)

OFF(0) or a value from 1 to 22 (see the table of alarm

function list), and either

23 or 24 (if the timer function [/EX option]) is included)

0 to 100% of measured input range (scale) span

Unit: °C/°F

ON(1): Uses the SUPER function

OFF(0): Does not use SUPER function

Note: Not displayed when on/off control

0: Reverse action

1: Direct action

Note: Not displayed for heating/cooling type

0: PC-link communication

1: PC-link communication with sum check

2: Ladder communication

3: MODBUS in ASCII mode

4: MODBUS in RTU mode

1 to 99 However, the number of controllers that

can be connected per host device is 31 at the maximum.

2.4(0): 2400 bps

4.8(1): 4800 bps

9.6(2): 9600 bps

NON(0): Disabled

EVN(1): Even parity

ODD(2): Odd parity

1 or 2 bits

7 or 8 bits

• 8 bits when ladder, MODBUS (RTU)

• 7 bits when MODBUS (ASCII)

2

SP1/SP2

switching

SP2

when DI=ON

OFF(0), or the input

range code

specified with order

1

0.0

Maximum value of

measured input

range (scale)

Minimum value of

measured input

range (scale)

OFF(0)

OFF(0)

1

0

0

1

Maximum value of

measured input

range (scale)

Minimum value of

measured input

range (scale)

1

(PV high limit alarm)

2

(PV low limit alarm)

0.5% of measured

input range (scale)

span

OFF(0)

0

0

1

9.6(2)

EVN(1)

1 bit

8 bits

3-11

Reference page

P.4-1

P.5-1

P.5-2

P.5-3

P.5-4

P.5-5

P.5-6

P.5-5

P.5-6

P.5-4

P.4-12

P.4-16

P.4-17

P.5-6

P.6-10

P.4-6

P.5-9

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

Page 30

Blank Page

Page 31

<T oc> <Ind>

4. BASIC OPERATIONS

This chapter describes an operating procedure using temperature controllers UT130

and UT150 of standard type with the alarm option as an example. Regarding the

operating procedure for the heating/cooling type controller or for the controller with the

options other than the alarm, confirm whether the some parameters appear or not

referring to the parameter flowchart in “3. NAMES AND FUNCTIONS OF EACH PART /

PARAMETERS.” The operating procedure for UT152/UT155 is the same as that for

UT150.

4-1

4.1

Setting Measured Input T ype and Scale (Setting First)

The operating procedure to set first after purchasing a controller is described in this

section. The procedure is for the parameter “IN” (measured input type) = OFF.

UT130 Measured Input Ranges

Input type Range (°C

—199 to 999°C

K

—199 to 200°C

J

—199 to 999°C

T

—199 to 400°C

E

L

U

—199 to 999°C

—199 to 900°C

—199 to 400°C

—199 to 850°C

—199 to 200°C

—19.9 to 99.9°C

—199 to 500°C

Thermocouple

Pt100

RTD

JPt100

Unspecified

0 to 600°C

0 to 400°C

0 to 400°C

)

Range code (°C

OFF

1

2

3

4

5

6

7

12

13

15

16

17

18

19

)

—199 to 999°F

—199 to 400°F

—199 to 999°F

—199 to 750°F

—199 to 999°F

—199 to 999°F

—199 to 750°F

—199 to 999°F

—199 to 400°F

—199 to 999°F

Range (°F

32 to 999°F

32 to 750°F

32 to 750°F

)

The following operating procedure describes an e xample of setting “K-type thermo-

couple” (0.0 to 400.0°C) for the measured input type. For voltage input of UT150/

UT152/UT155, the display scale can be set using the parameters “DP” (decimal point

position of measured input), “RH” (maximum value of measured input scale) and “RL”

(minimum value of measured input scale).

UT150/UT152/UT155 Measured Input Ranges

Range code (°F

31

32

33

34

35

36

37

42

43

45

46

47

48

)

Input type Range (°C

K

—199.9 to 200.0°C

J

—199.9 to 999.9°C

T

—199.9 to 400.0°C

E

—199.9 to 999.9°C

R

S

Thermocouple

B

N

L

—199.9 to 900.0°C

U

Platinel 2

Pt100

RTD

JPt100

0 to 100mV

0 to 5V

1 to 5V

0 to 10V

DC voltage

—199.9 to 400.0°C

—199.9 to 850.0°C

—199.9 to 200.0°C

—199.9 to 500.0°C

0.0 to 100.0

0.000 to 5.000

1.000 to 5.000

0.00 to 10.00

—270 to 1370°C

—200 to 1300°C

—19.9 to 99.9°C

Unspecified

0.0 to 600.0°C

0.0 to 400.0°C

0 to 1700°C

0 to 1700°C

0 to 1800°C

0 to 1390°C

0.0 to 400.0°C

User-scalable

)

Range code (°C

OFF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

)

Range (°F

—300 to 2500°F

32.0 to 999.9°F

32.0 to 750.0°F

—300 to 400°F

—300 to 2100°F

—300 to 750°F

—300 to 1800°F

32 to 3100°F

32 to 3100°F

32 to 3200°F

—300 to 2400°F

—300 to 1600°F

—300 to 750°F

32 to 2500°F

—199.9 to 999.9°F

32.0 to 750.0°F

—300 to 400°F

—199.9 to 999.9°F

)

Range code (°F

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

)

Example of Temperature Input

-270

°C

Measured input range

Display scale

-270

°C

Parameters to be set for temperature input

1. Measured input type (IN): Set according to a sensor.

Note: The display scale cannot be changed.

1370

1370

°C

°C

Minimum value of measured

1V 5V

RL

input scale (RL)

0.0m

Parameters to be set for voltage input

1. Measured input type (IN): Set according to input signal.

2. Decimal point position of measured input (DP): Set the decimal

point position of measured input display.

3. Maximum value of measured input scale (RH): Set the maximum

value of the scale to be controlled. (Set the displayed value at the

maximum value of input signal.)

4. Minimum value of measured input scale (RL): Set the minimum

value of the scale to be controlled. (Set the displayed value at the

minimum value of input signal.)

Example of Voltage Input

(Input signal)

Measured input range

Measured input scale

Maximum value of measured

3

/h

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

RH

input scale (RH)

50.0m3/h

Page 32

<T oc> <Ind>

4-2

● Setting a Type of T emperature Input

The following operating procedure describes an e xample of setting “K-type thermo-

couple” (0.0 to 400.0°C) for the measured input type.

<Operating Procedure>

Step 1:

The parameter "IN" (measured input type)

appears at power on.

Step 2

Press the or key once to display

the setpoint.

Step 3:

Press the or key to set the required

setpoint for the measured input type. The

measured input type is set using a range

code. (See Page 4-1)

The period flashes while the value is being

changed. In this example, "K-type

thermocouple" (0.0 to 400.0°C) is set for the

measured input type.

Step 4:

Press the key once to register the setpoint.

The operating display appears automatically.

(for UT130 only)

UT130

Display example

UT150/UT152/UT155

Display example

:

Flashes during change.

Flashes during change.