Instruction

Manual

Model US1000

Digital Indicating Controller

IM 5D1A01-01E

IM 5D1A01-01E

3rd Edition

Introduction

This instruction manual describes the general operation of the US1000 Digital Indicating Controller.

■ Intended Readers

This manual is intended for personnel in charge of the following:

·Installation and wiring

· Instrumentation and setup of the controller

· Operation and monitoring of the controller

· Maintenance of equipment

■ Related Documents

The following documents all relate to the US1000 Digital Indicating Controller. Read them as necessary. The codes enclosed in parentheses are the document numbers.

• US1000 Digital Indicating Controller Functions (IM 5D1A01-02E)

Provides detailed descriptions of US1000 functions.

•US1000 Digital Indicating Controller Communication Functions (IM 5D1A01-10E)

Manual for using the US1000 communication function. Supplied with models having the optional

communication function.

• LL1100 PC-Based Parameters Setting Tool (IM 5G1A01-01E)

Manual for setting US1000 parameters from a personal computer. Supplied with the LL1100 PCBased Parameters Setting Tool.

• LL1200 PC-based Custom Computation Building Tool (IM 5G1A11-01E)

Operation manual for creating custom computations of the US1000 controller. This manual also

describes examples of custom computations. The LL1200 PC-based Custom Computation Building

Tool includes the LL1100 PC- based Parameters Setting Tool.

• LL1200 PC-based Custom Computation Building Tool Reference (IM 5G1A11-02E)

This is the functions manual necessary for creating custom computations of the US1000 controller.

This manual should be referred to in order to find out and understand what functions offered by the

LL1200.

FD No. IM 5D1A01-01E

3rd Edition: Oct. 1999 (YG)

All Rights Reserved. Copyright © 1998. Yokogawa M&C Corporation

IM 5D1A01-01E

i

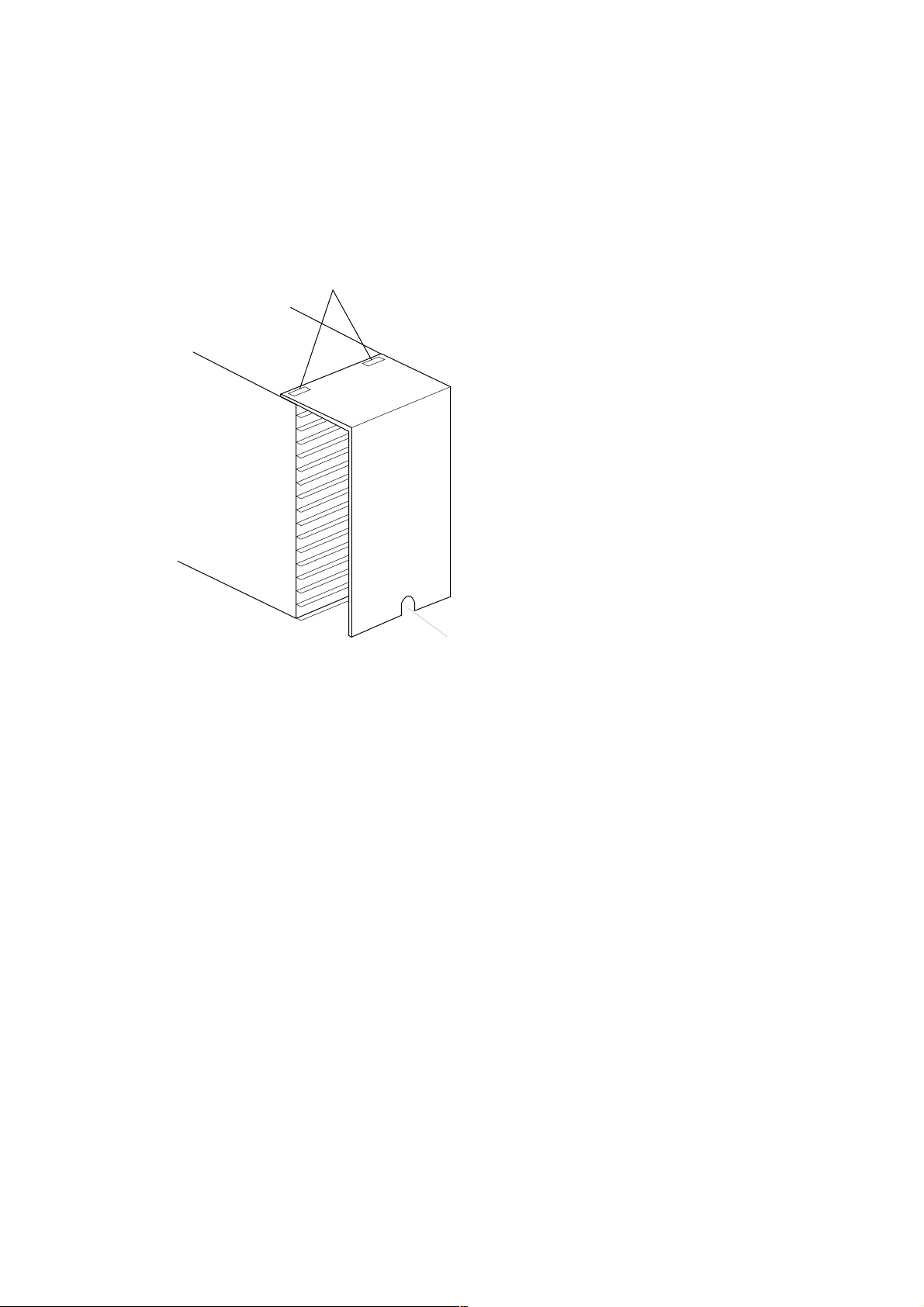

Checking Package Contents

Visually check the product for any damage upon delivery.

Keep the box and inner packaging that the product was delivered in, as you will need them if you

have to send the controller back for repair.

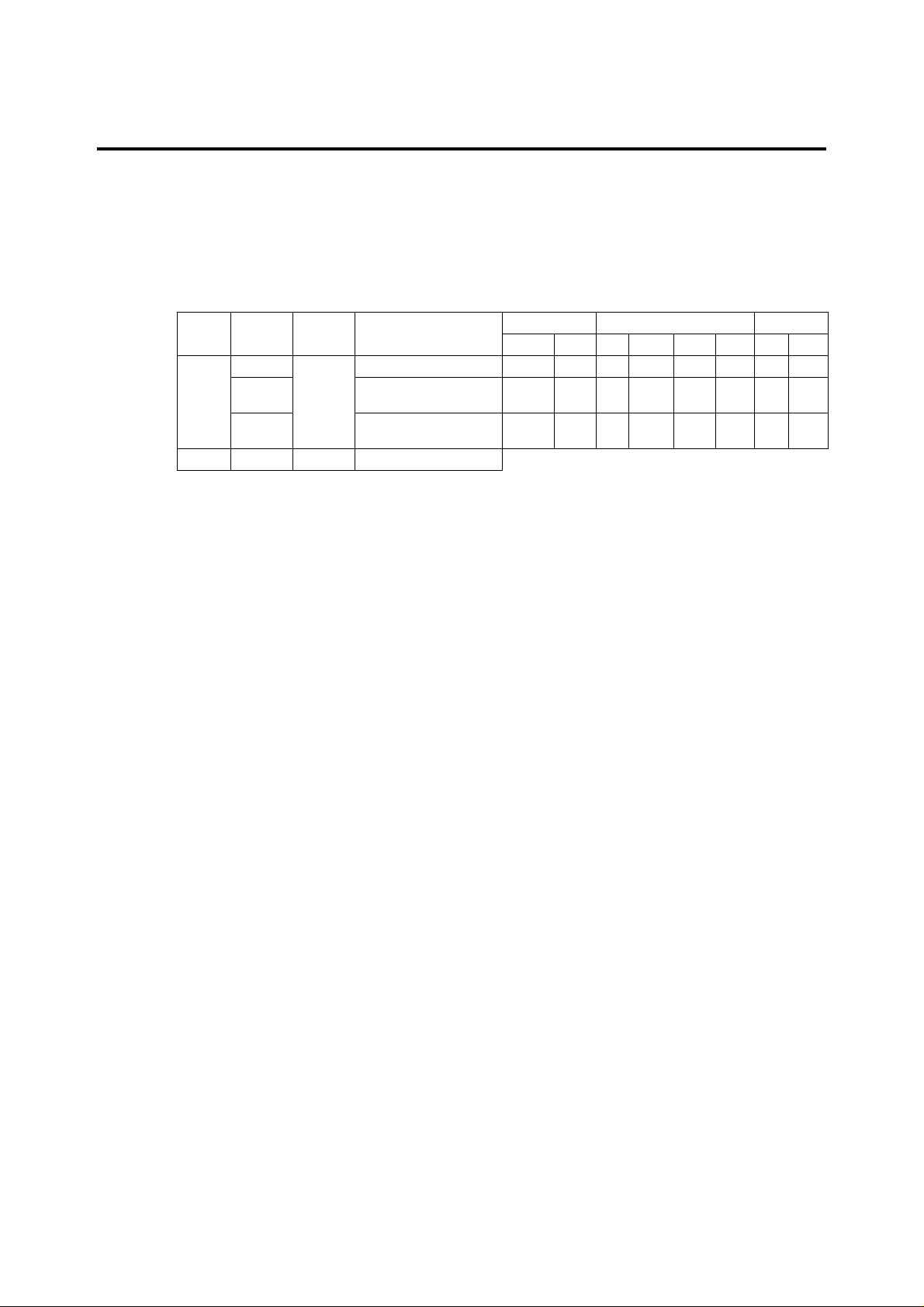

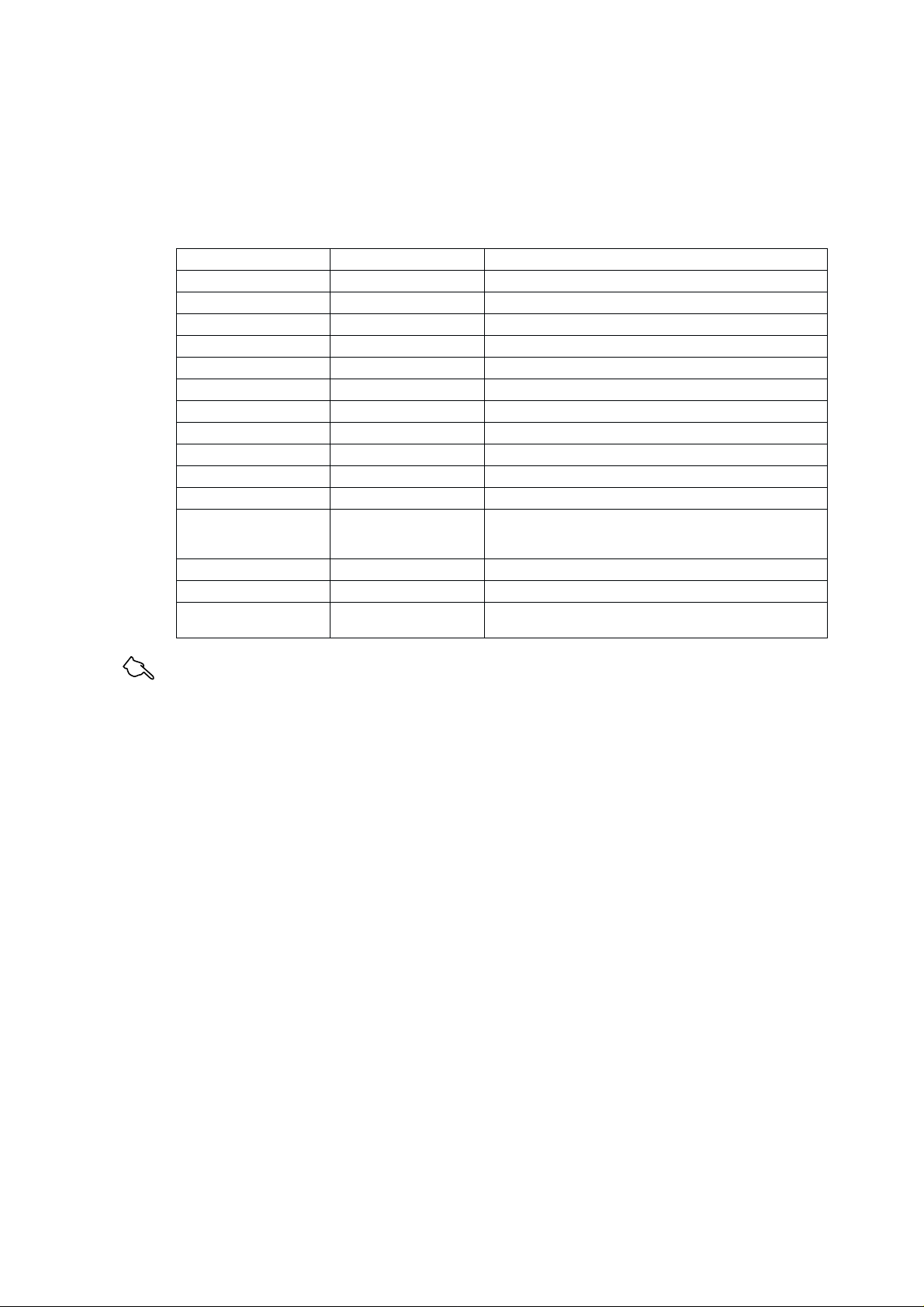

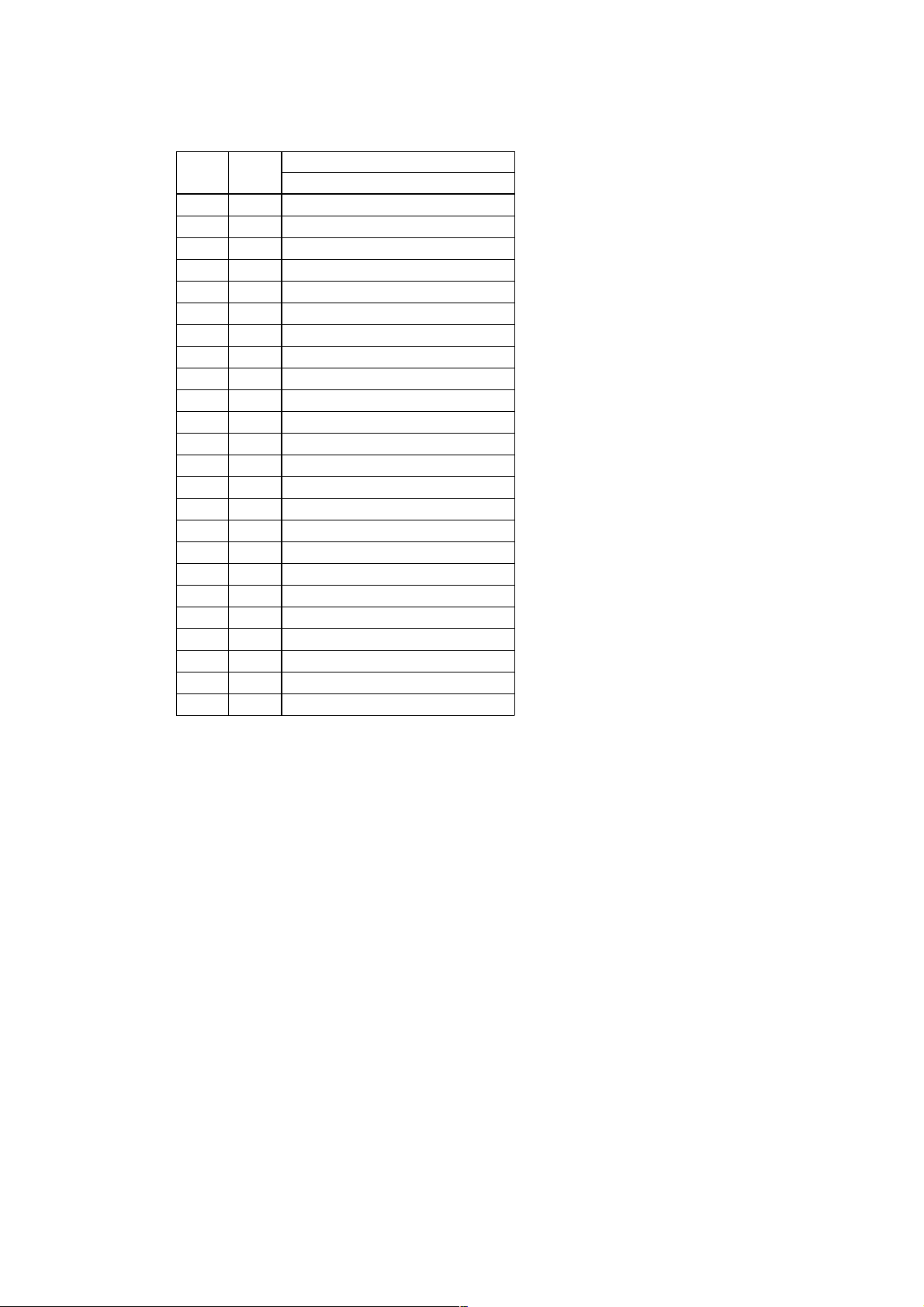

■ Checking of Model and Suffix Codes

Check the model and suffix codes of the delivered controller to ensure that it is the right model.

Model

US1000 -00 Basic type

LPS: Loop power supply for transmitter

* The two contact points in the US1000-21 relay item are the relay output and the feedback input.

■ Package Contents

Check the package contents against the list below. If anything is missing or damaged, immediately

contact the dealer at which you purchased the product or your nearest Yokogawa representative.

• US1000 controller 1

•Brackets (Part No. T9115NK) 1 pair

• Terminal board cover (Part No. L4001DA) 1

• Unit label (Part No. T9115VE) 1

Instruction manuals

• US1000 Digital Indicating Controller (this manual) 1

• US1000 Digital Indicating Controller Functions 1

•US1000 Digital Indicating Controller Communication Functions 1

(Only supplied with models having the optional communication function.)

Suffix Option

Codes Codes

-11 Enhanced type

-21 Position proportional type

/A10 RS-485 communication

Description

(with custom computation)

(with custom computation)

Analog input Analog output Contact

Universal Voltage LPS Current Voltage Relay Input Output

11111023

21221277

21211277

*

ii

IM 5D1A01-01E

Documentation Conventions

■ Symbols

The following symbols are used in this manual.

WARNING

Indicates that operating the hardware or software in a particular manner may damage it or result in a

system failure.

NOTE

Draws attention to information that is essential for understanding the operation and/or features of the

product.

TIP

Gives additional information to complement the present topic and/or describe terms specific to this

document.

See Also

Gives reference locations for further information on the topic.

■ Description of Displays

Some of the representations of product displays shown in this manual may be exaggerated, simplified,

or partially omitted for reasons of convenience when explaining them.

IM 5D1A01-01E

iii

Notice

■ This Instruction Manual

(1) This manual should be passed on to the end user. Keep at least one extra copy of the manual in a

safe place.

(2) Read this manual carefully to gain a thorough understanding of how to operate this product before

you start using it.

(3) This manual is intended to describe the functions of this product. Yokogawa M&C Corporation

(hereinafter simply referred to as Yokogawa M&C) does not guarantee that these functions are

suited to the particular purpose of the user.

(4) Under absolutely no circumstances may the contents of this manual, in part or in whole, be

transcribed or copied without permission.

(5) The contents of this manual are subject to change without prior notice.

(6) Every effort has been made to ensure accuracy in the preparation of this manual. Should any

errors or omissions come to your attention however, please contact your nearest Yokogawa

representative or our sales office.

■ Protection, Safety, and Prohibition Against Unauthorized Modification

(1) In order to protect the product and the system controlled by it against damage and ensure its safe

use, make certain that all of the instructions and precautions relating to safety contained in this

document are strictly adhered to. Yokogawa does not guarantee safety if products are not handled

according to these instructions.

(2) The following safety symbols are used on the product and in this manual.

If this symbol is indicated on the product, the operator should refer to the explanation

given in the instruction manual in order to avoid personal injury or death to either

CAUTION

(3) If protection/safety circuits are to be used for the product or the system controlled by it, they

should be externally installed on the product.

(4) When you replace the parts or consumables of the product, only use those specified by Yokogawa

M&C.

(5) Do not modify the product.

themselves or other personnel, and/or damage to the instrument. The manual describes

that the operator should exercise special care to avoid shock or other dangers that may

result in injury or loss of life.

Protective ground terminal:

This symbol indicates that the terminal must be connected to ground prior to operating

the equipment.

Function ground terminal:

This symbol indicates that the terminal must be connected to ground prior to operating

the equipment.

Alternating current.

iv

IM 5D1A01-01E

(6) This product has been approved as flameproof electrical equipment for use in a hazardous area,

and hence usable in explosive atmospheres. However, when using this product in a hazardous

area, abide by the conditions in the following standards:

• CSA standard (CSA C22.2 No. 213)

Location Class I, Division 2, Groups A, B, C & D

Temperature Code T4

NOTE: For the installation procedure, see page App. 6-1.

•FM standard (FM 3611)

Location Class I, Division 2, Groups A, B, C & D

Temperature Code T4

NOTE: For the installation procedure, see page App. 6-2.

(7) The suitability of the final installation is to be determined by the local authorities having jurisdic-

tion.

■ Force Majeure

(1) Yokogawa M&C does not make any warranties regarding the product except those mentioned in

the WARRANTY that is provided separately.

(2) Yokogawa M&C assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

WARNING

Do not change the setting of the following US1000 controller parameter.

[Setup parameter] - [Main menu: USMD] - [Submenu: Test]

Parameter: TST (Test mode)

This parameter is used to adjust a US1000 controller at the factory. If you change the setting of this

parameter, the US1000 controller may not operate normally.

NOTE

Only personnel with an understanding of the US1000 controller and custom computation fucntions are

qualified to change the settings of the following parameters as necessary. Those using the US1000

controller for the first time and those not knowledgeable about the custom computation function,

should use the default values of the following parameters assigned to the controller.

[Setup parameter] - [Main menu: CONF] - [Submenu: DO and DI]

All the parameters under the submenus above.

If you change the settings of these parameters, some of the fuctions assigned to each US1000 control-

ler mode (US mode) may not work.

IM 5D1A01-01E

v

Contents

Introduction........................................................................................................................... i

Checking Package Contents ............................................................................................... ii

Documentation Conventions.............................................................................................. iii

Notice .................................................................................................................................... iv

1. US1000 Digital Indicating Controller ...................................................................... 1-1

1.1 What is on the Front Panel? ........................................................................... 1-2

1.2 Characters and Symbols on Digital Displays ................................................. 1-3

1.3 Operation Display and Parameter Setting Display......................................... 1-4

1.4 Preparing for Operation .................................................................................. 1-5

1.5 Factory-Set Defaults........................................................................................ 1-6

1.6 Label Positions ................................................................................................ 1-7

2. Installing US1000 Controller .................................................................................... 2-1

2.1 External Dimensions and Panel Dimensions.................................................. 2-2

2.2 Mounting the Controller ................................................................................. 2-3

3. Wiring .......................................................................................................................3-1

3.1 Procedure for Wiring ...................................................................................... 3-1

3.1.1 Cables and T erminals............................................................................... 3-1

3.1.2 Direction of wiring .................................................................................. 3-2

3.1.3 Preventing Noise...................................................................................... 3-2

3.1.4 Terminal Designation............................................................................... 3-3

3.1.5 Wiring for Power Supply and Transmitter’s Loop Power Supply ........... 3-4

3.1.6 Attaching the Terminal Cover.................................................................. 3-5

3.2 Signals Assigned to Terminals ....................................................................... 3-6

3.2.1 Terminal Assignment for US1000-00 (Basic Type)................................. 3-7

3.2.2 Terminal Assignment for US1000-11 (Enhanced Type) .......................... 3-8

3.2.3 Terminal Assignment for US1000-21 (Position Proportional Type) ..... 3-20

4. Setting the Basic Functions....................................................................................... 4-1

4.1 Example of Parameter Display ....................................................................... 4-2

4.2 Procedure for Setting the Basic Functions ..................................................... 4-3

4.3 Selecting the Controller Mode (US Mode) .................................................... 4-4

4.4 Selecting the PV Input Type........................................................................... 4-6

4.5 Selecting the Control Computation and Output Types .................................. 4-9

4.6 Writing the Data Defined So Far (Parameter Initialization) ........................ 4-11

4.7 Defining the Alarm Outputs (as necessary) ................................................. 4-12

4.8 Setting the Target Setpoint, Alarm Setpoints, and PID Parameters ............ 4-15

4.9 Setting Other Functions (as necessary) ........................................................ 4-17

5. Customizing Operation Displays.............................................................................. 5-1

5.1 Registering Auxiliary Operation Displays (USER Displays) ........................ 5-2

5.2 Displaying the Alarm Status ........................................................................... 5-5

5.3 Registering Quick Parameter Call-up Functions (SELECT Displays) .......... 5-6

vi

IM 5D1A01-01E

6. Operation .................................................................................................................... 6-1

6.1 Switching the Operation Mode ....................................................................... 6-2

6.2 Changing the Target Setpoint (SV) ................................................................ 6-3

6.3 Manipulating MV............................................................................................ 6-4

6.4 Operations on Single-Loop Type of Controller ............................................. 6-5

6.5 Operations on Cascade Type of Controller .................................................... 6-6

6.6 Switching Between Cascade Open and Close ................................................ 6-8

6.7 Operations on Dual-loop Type of Controller ................................................. 6-9

6.8 Display and Operations during Heating/Cooling Computation ................... 6-11

6.9 Operation Mode Switching Using Contact Input ......................................... 6-12

6.10 Starting Controller Operation ....................................................................... 6-13

6.11 Auto-tuning ................................................................................................... 6-14

6.12 Manual Tuning .............................................................................................. 6-16

6.13 Stopping Controller Operation...................................................................... 6-17

6.14 Power Failure during Operation ................................................................... 6-18

7. Other Functions .......................................................................................................... 7-1

7.1 Communication Functions .............................................................................. 7-2

7.2 Custom Computation ...................................................................................... 7-3

7.3 D Register and I Relay .................................................................................... 7-4

8. Maintenance................................................................................................................ 8-1

8.1 Cleaning........................................................................................................... 8-1

8.2 Replacement of Mounting Bracket ................................................................. 8-1

8.3 Limited Life Components and Maintenance .................................................. 8-1

8.4 Procedure for Replacing Control Output Relays............................................ 8-2

8.5 Problems and Corrective Measures ................................................................ 8-3

8.5.1 Troubleshooting ....................................................................................... 8-3

8.5.2 Error Code Description............................................................................ 8-4

Appendix 1 Hardware Specifications................................................................... App. 1-1

Appendix 2 Engineering Units Available for the US1000 ................................. App. 2-1

Appendix 3 Operation Parameter Table ............................................................. App. 3-1

Appendix 4 Setup Parameter Table ..................................................................... App. 4-1

Appendix 5 Parameter Map.................................................................................. App. 5-1

Appendix 6 Conditions of Use in Hazardous Areas ........................................... App. 6-1

6.1 CSA standard ......................................................................................... App. 6-1

6.2 FM standard ........................................................................................... App. 6-3

IM 5D1A01-01E

vii

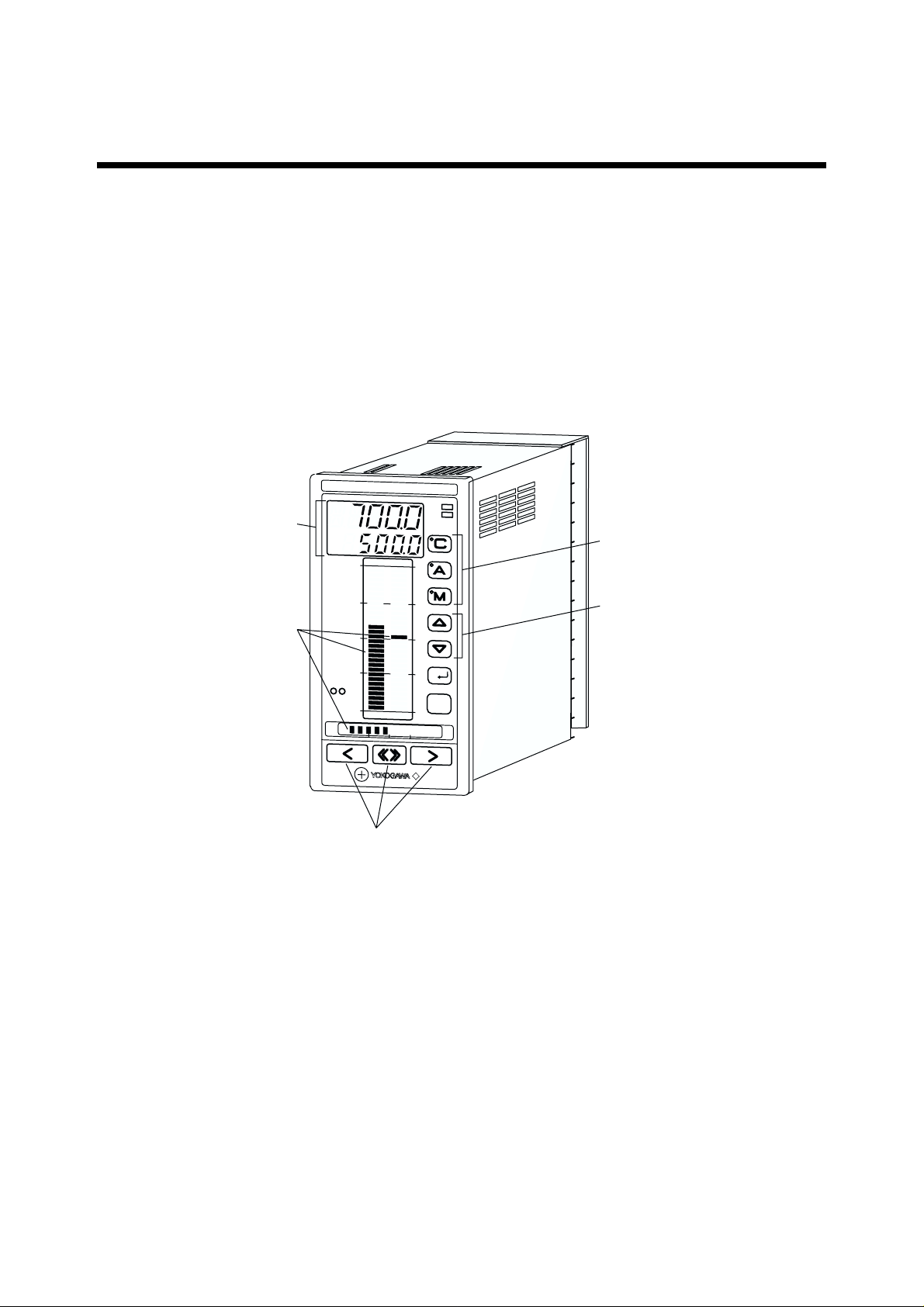

Chapter 1 US1000 Digital Indicating Controller

1. US1000 Digital Indicating Controller

The US1000 digital indicating controller is designed with sophisticated, yet user-friendly control

functions. The displays and operation keys on the front panel provide for smooth and secure operation.

● Simplified setup

The typical setup of the US1000’s basic control function and the I/O terminal assignment are registered as the “controller mode (US mode).” Users can easily setup the controller by selecting this

controller mode.

● A wealth of displays and operating functions

The US1000 controller has two easy-to-read digital displays and three bar graphs as analog displays.

The operation mode is switched and MV output modified using the dedicated keys.

P

Digital displays

V

SV

M

V

1

0

0

A

L

M

L

P

2

Operation mode keys

Analog bar displays

0

C

MV operation keys

SV setting keys

S

E

T

/E

N

T

D

ISP

O

IM 5D1A01-01E 1-1

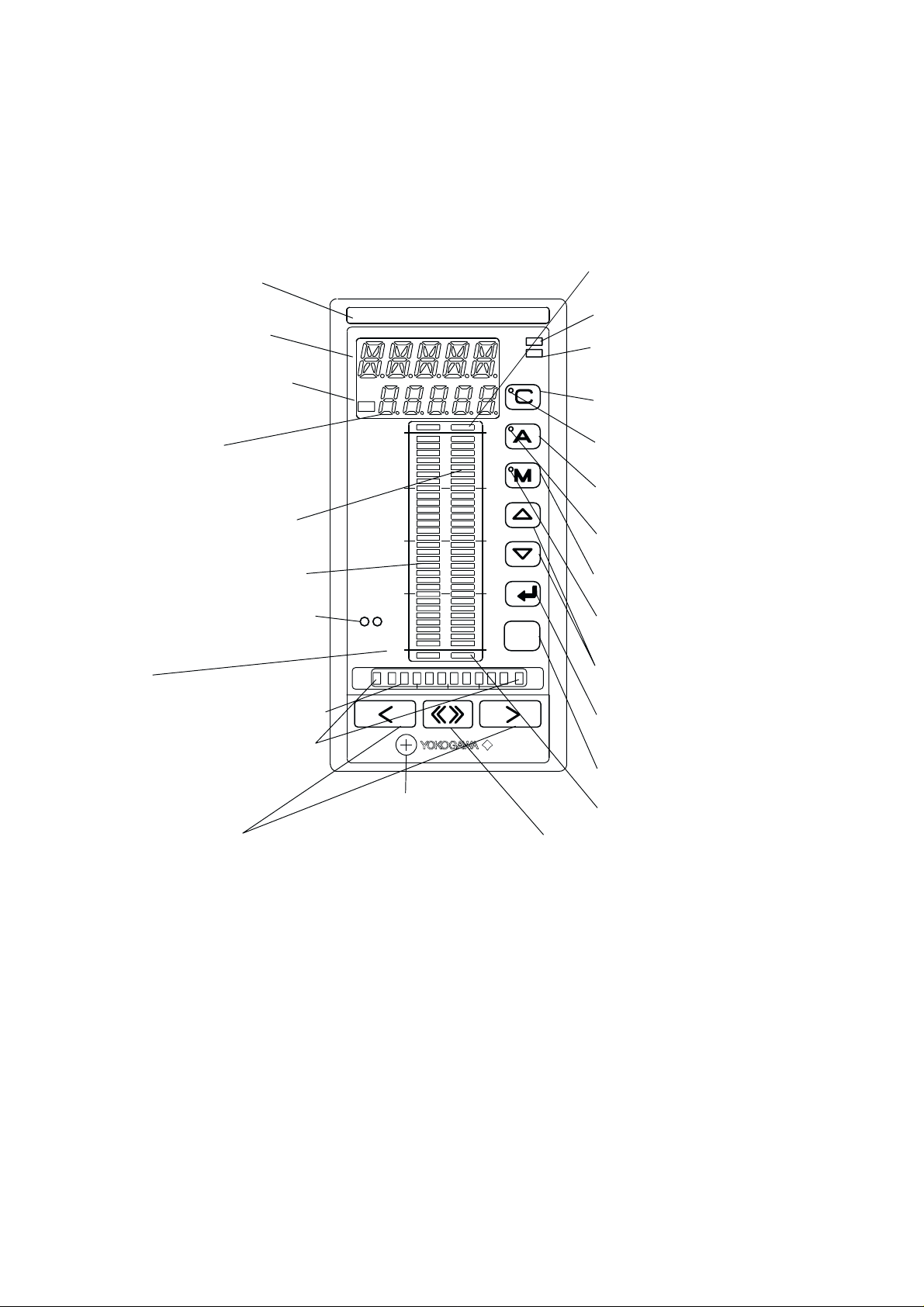

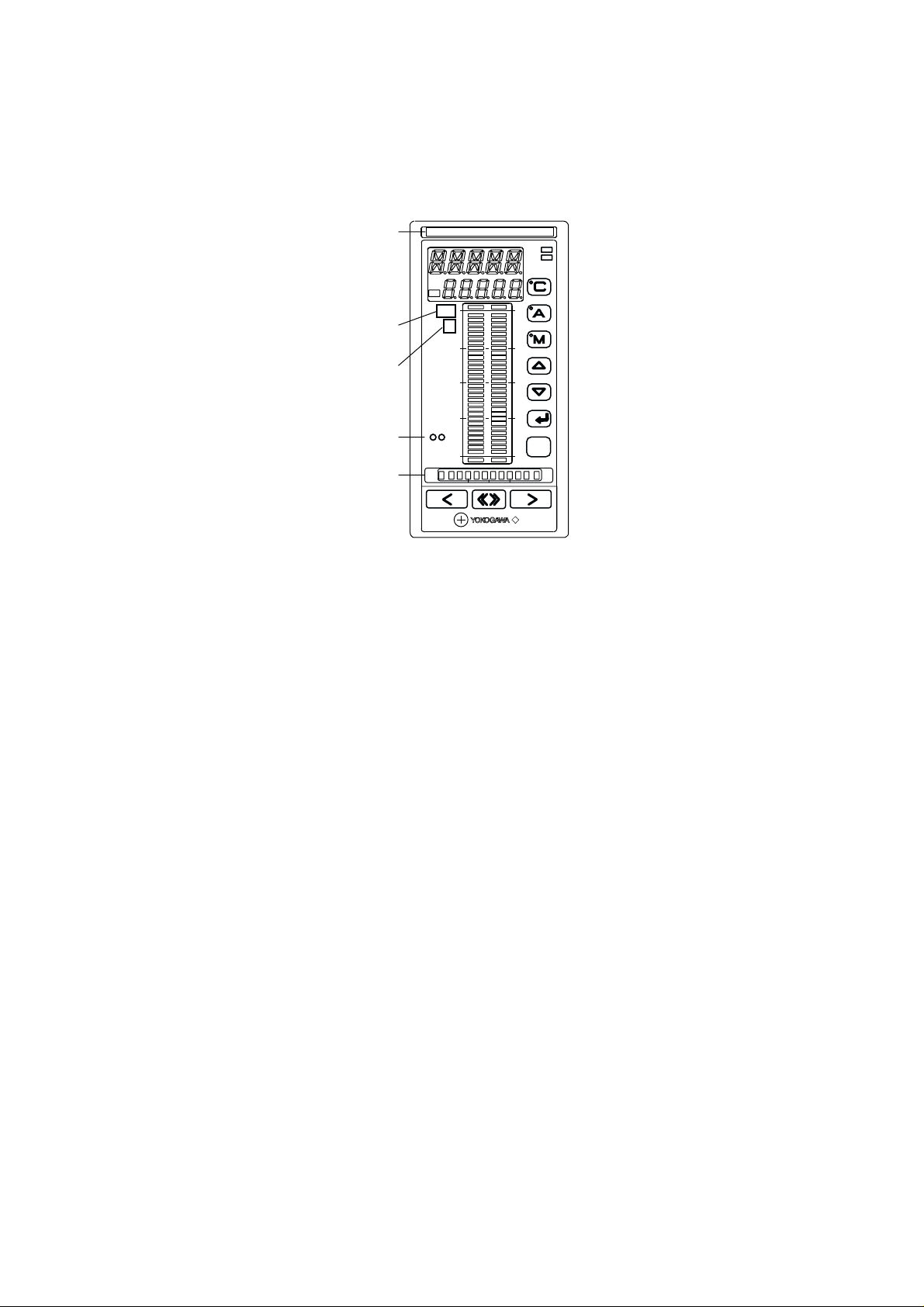

1.1 What is on the Front Panel?

The US1000 controller displays process variables (PV), target setpoint values (SV), and MV output

values (MV) in two ways: on a digital display and an analog bar display. Separate keys are provided

for switching the operation mode and changing SV and MV, thus operators will have no problems

operating the controller from the first time they use it.

Space for tag number lable

PV digital display (Indicates the process

variable.*1)

MV lamp (Lit while MV is indicated

on the SV digital display.*1)

SV digital display

(Indicates the target setpoint.*1)

SV bar display (Displays the target

setpoint.)

PV bar display (Displays the process

variable.)

Light-loader interface (Used for setting

parameters from a personal computer.)

Scale

MV bar display (Displays the MV output.)

Overflow/underflow indicators (Yellow

LEDs)

PV

SV

C

MV

100

Overflow indicator (Yellow LED)

ALM lamp (Lit when any alarm occurs.)

ALM

LP2

SET/ENT

0

DISP

O

LP2 lamp (Lit when Loop-2 data are

displayed or in the open cascade status.)

C mode key (Changes to CAS mode.)

C mode lamp (Lit in CAS mode.)

A mode key (Changes to AUTO mode.)

A mode lamp (Lit in AUTO mode.)

M mode key (Changes to MAN mode.)

M mode lamp (Lit in MAN mode.)

SV setting keys (Increases/decreases

the target setpoint.*1)

SET/ENT key (Used for parameter

setting.)

DISP key (Switches operation displays.)

Internal unit fixing screw

MV operation keys (Changes the MV output.)

*1 This function is valid during operation. A different function is given when setting parameters.

*2 This key is invalid with the US1000-21 model (position proportional type).

MV fast-change key*2 (Accelerates MV changing

when pressed with the MV operation key.)

1-2

Underflow indicator (Yellow LED)

IM 5D1A01-01E

Chapter 1 US1000 Digital Indicating Controller

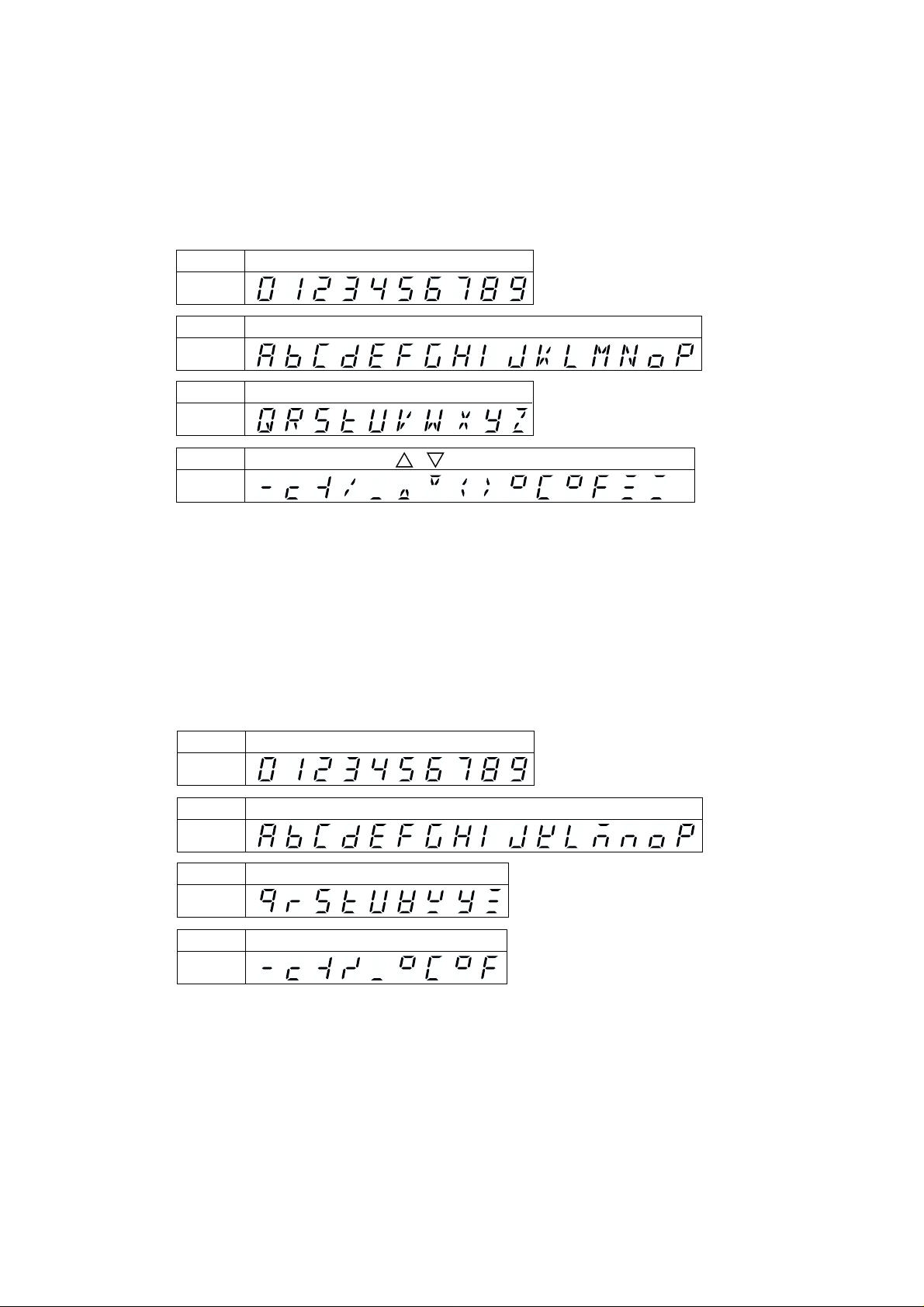

1.2 Characters and Symbols on Digital Displays

The meanings of characters and symbols that appear on the PV and SV digital displays are explained

here.

■ PV Digital Display

Meaning

Display

Meaning

Display

Meaning

Display

Meaning

Display

During parameter setting, one of the horizontal bar is displayed in the left-most digit of the PV digital

display. Each bar indicates a different level of setting, as outlined below.

*1 Main menu : The upper bar flashes.

Submenu : The middle bar flashes.

Parameter : The lower bar flashes.

*2 When no submenu exists.

Main menu : The upper bar flashes.

Parameter : The lower bar flashes.

■ SV Digital Display

0123456789

ABCDEFGHIJKLMNOP

QRSTUVWXYZ

-c-1/_ <>° C ° F

Layer*1 Layer

*2

Meaning

Display

Meaning

Display

Meaning

Display

Meaning

Display

0123456789

ABCDEFGHIJKLMNOP

QRSTUVWYZ

-c-1/_° C ° F

IM 5D1A01-01E 1-3

1.3 Operation Display and Parameter Setting Display

g

The US1000 controller shows different types of displays during operation and parameter setting. The

functions given to the keys are also different between the two situations.

● Display during operation

• The PV digital display indicates the PV value.

•The SV digital display usually indicates the SV value, but indicates the MV value when the MV

lamp is lit.

•The SV keys are used to increase and decrease the SV value.

• The analog bar graphs show PV, SV, and MV.

● Display during parameter setting

• The PV digital display indicates the parameter menu or parameter name.

•The SV digital display indicates the set data of a parameter.

• The SV keys are used to increase and decrease the set data of a parameter.

• The analog bar graphs remain the same as they were during operation.

SET/ENT

To change from operation to parameter setting, press the

time is described as just “for 3 seconds” hereafter). To change from the parameter setting display back

to the operation display, press the

DISP

key.

Indicates a parameter menu or parameter name.

key for 3 to 6 seconds (this period of

PV

SV or MV

PV

SV

MV

100

ALM

LP2

Press for 3 seconds.

SET/ENT

PV

SV

MV

100

ALM

LP2

SV setting keys

SET/ENT

0

C

DISP

O

DISP

SET/ENT

0

C

DISP

O

Display during operation Initial display for parameter settin

Indicates the set data.

(No display for menu.)

Data setting keys

1-4

IM 5D1A01-01E

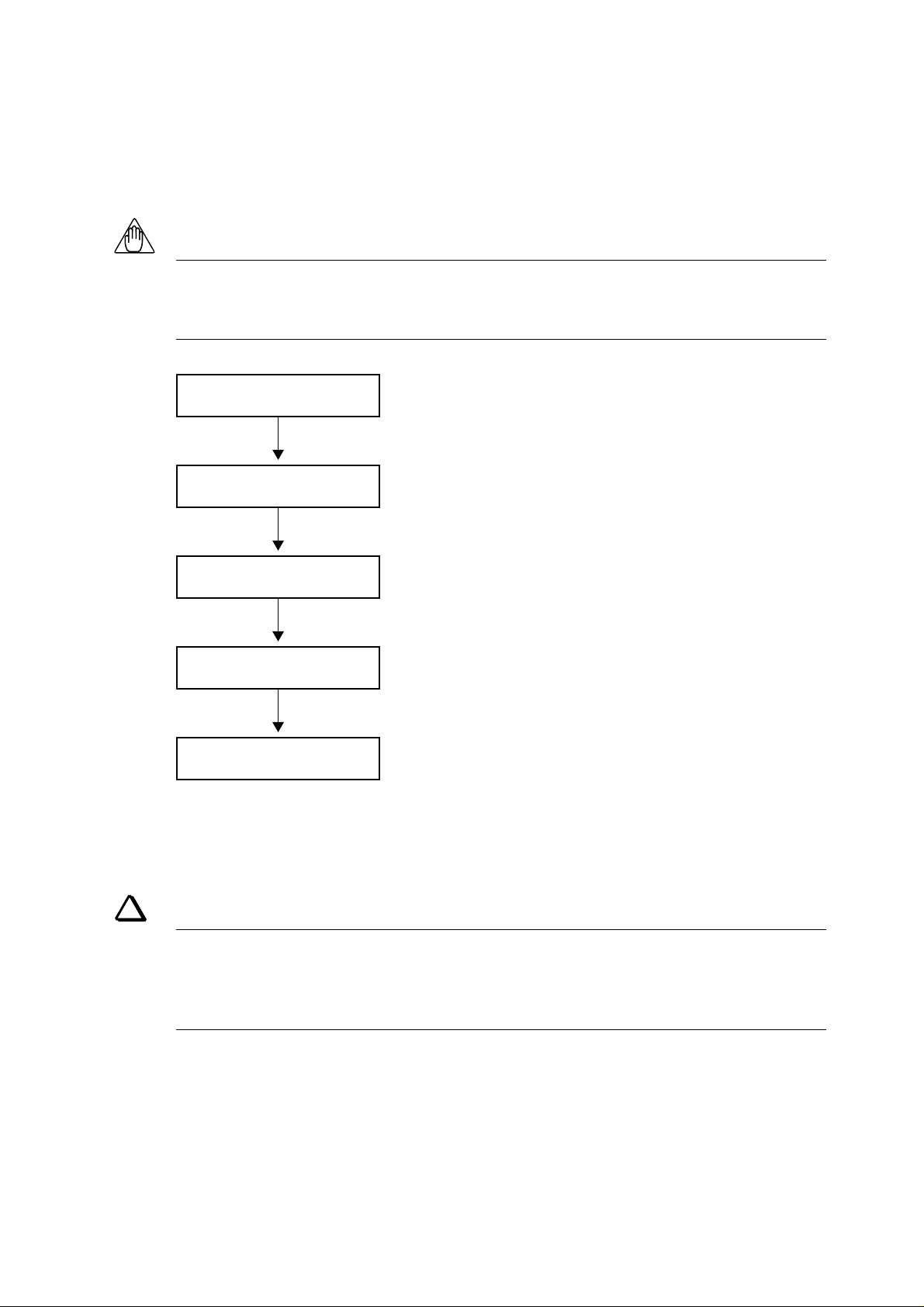

1.4 Preparing for Operation

The US1000 controller must be set up before it can be operated. Set up the controller in the sequence

shown below.

NOTE

The US1000 controller has no power switch. It starts operating and its control action as soon as it is

plugged in, i.e., connected to its power source. Thus, the controller output should not be connected to

the controlled equipment until just before operation.

Chapter 1 US1000 Digital Indicating Controller

Installation

Wiring

Setup of controller functions

Setting the target setpoint

Operation

Also read section 4.9, “Setting Other Functions,” and chapter 5, “Customizing Operation Displays” as

necessary.

See chapter 2

See chapter 3

See sections 4.1 to 4.7

See section 4.8

See chapter 6

TIP

• If you use the custom computation function, setup the controller functions and set the target setpoint

using the LL1200 PC-Based Custom Computation Building Tool (optional).

•If you use the communication function, you should also read the ‘US1000 Digital Indicating

Controller Communication Functions (IM 5D1A01-10E)’ manual.

IM 5D1A01-01E 1-5

1.5 Factory-Set Defaults

When the US1000 controller is delivered from the factory, it is set up in the controller mode (US

mode) for “single-loop control.” That is, it is set up to perform PID control for a single loop. The

other items set are as listed below. To change the factory-set defaults, refer to the sections shown in

the table.

Item Factory-set default Reference

Controller mode (US mode) Single-loop control Section 4.3, ‘Selecting the controller mode (US mode).’

Input type Standard signal Section 4.4, ‘Selecting the PV input type.’

Input terminal AIN1 Section 4.4, ‘Selecting the PV input type.’

Input range 1.000 to 5.000 V Section 4.4, ‘Selecting the PV input type.’

Engineering unit °C Section 4.4, ‘Selecting the PV input type.’

Input computation None Section 4.9, ‘Setting other functions.’

Analog burnout action Off Section 4.9, ‘Setting other functions.’

Direct/reverse control action Reverse Section 4.9, ‘Setting other functions.’

Control computation type Continuous PID Section 4.5, ‘Selecting the control computation and output types.’

Output type Current output Section 4.5, ‘Selecting the control computation and output types.’

Output terminal OUT1A (4-20 mA) Section 4.5, ‘Selecting the control computation and output types.’

Alarm output terminals DO1 (PV high limit alarm) Section 4.7, ‘Defining the alarm output.’

DO2 (PV low limit alarm)

DO3 (PV high limit alarm)

Auto-tuning Off Section 6.11, ‘ Auto-tuning.’

SUPER function Off Section 4.9, ‘Setting other functions.’

Control period 200 ms

The separate ‘US1000 Digital Indicating Controller Functions’

(IM 5D1A01-02E) manual.

See Also

The initial values of all parameters listed in Appendix 3 and Appendix 4.

1-6

IM 5D1A01-01E

1.6 Label Positions

Stick the accessory labels in the positions shown below. Be careful not to cover the light-loader

interface or any display with the labels.

Chapter 1 US1000 Digital Indicating Controller

Tag number label

Numeric label

Unit label

Light-loader interface

O/C mark labels (Attach when the

valve’s open and close direction differs.)

TIC0001A

PV

SV

MV

200

°C

0

C

ALM

LP2

SET/ENT

DISP

O

IM 5D1A01-01E 1-7

Chapter 2 Installing US1000 Controller

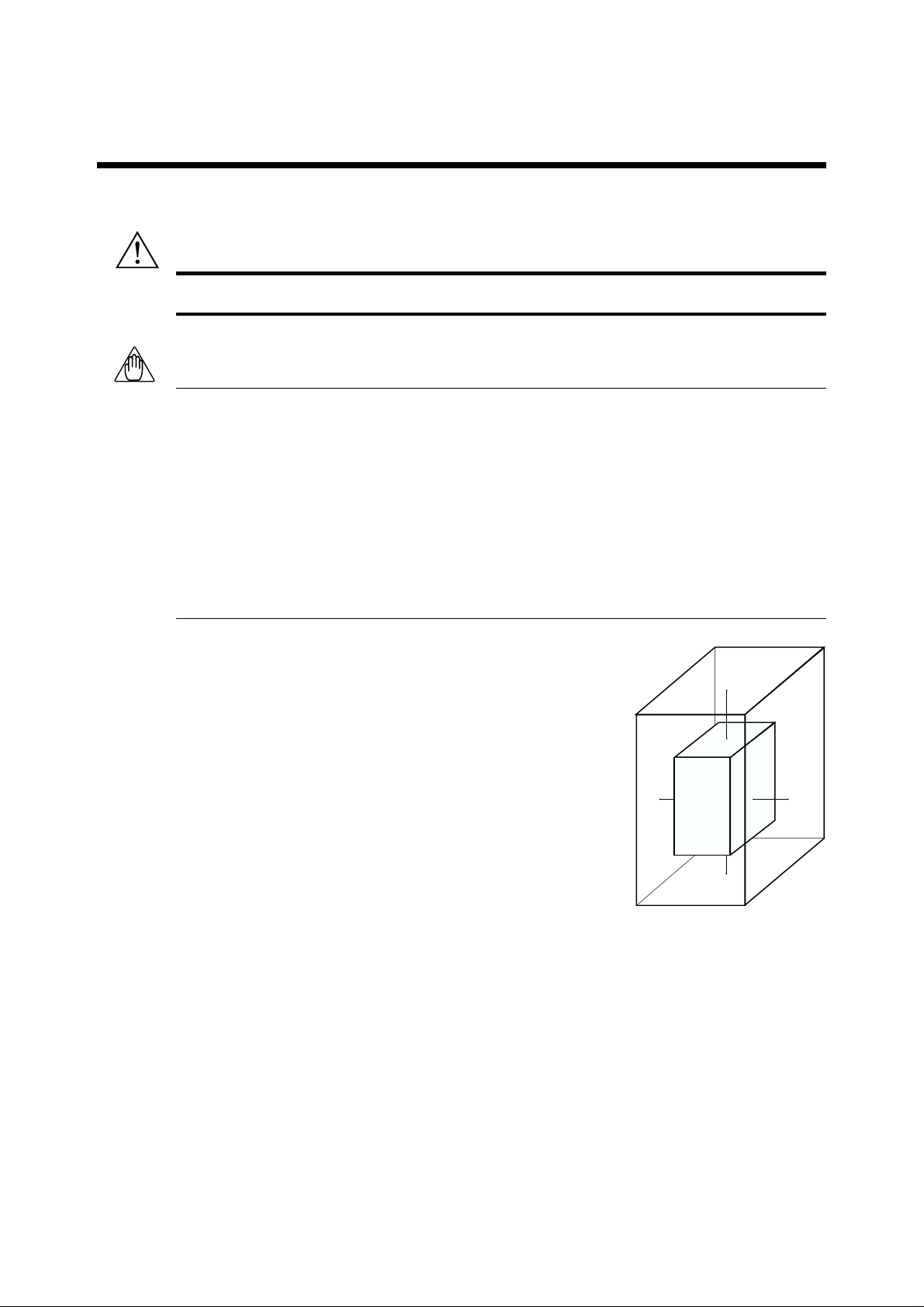

2. Installing US1000 Controller

Before using the controller, install it according to the instructions given in this chapter.

CAUTION

To prevent electrical shock, only apply power to the controller when it is mounted on the panel.

NOTE

To install the controller, select a location where:

· no-one may accidentally touch the terminals

·mechanical vibrations are minimal

· no corrosive gas

· temperature can be maintained at about 23°C and with minimal fluctuation

· no direct heat radiation

· no magnetic disturbances result

· no splashing water

· no flammable materials

·the terminal board (reference junction compensation element, etc.) is protected from wind

The housing of the controller is made of modified polyphenylenether resin and polycarbonato. Be sure to install the controller away

from highly flammable items. Never place the controller directly on

highly flammable items.

If the controller has to be installed close to highly flammable items

or equipment, be sure to surround the controller with shielding

panels, placed at least 150 mm away from every side. These panels

should be made of either 1.43-mm thick metal-plated iron plates or

1.6-mm thick uncoated iron plates.

150mm

150mm

150mm

150mm

IM 5D1A01-01E 2-1

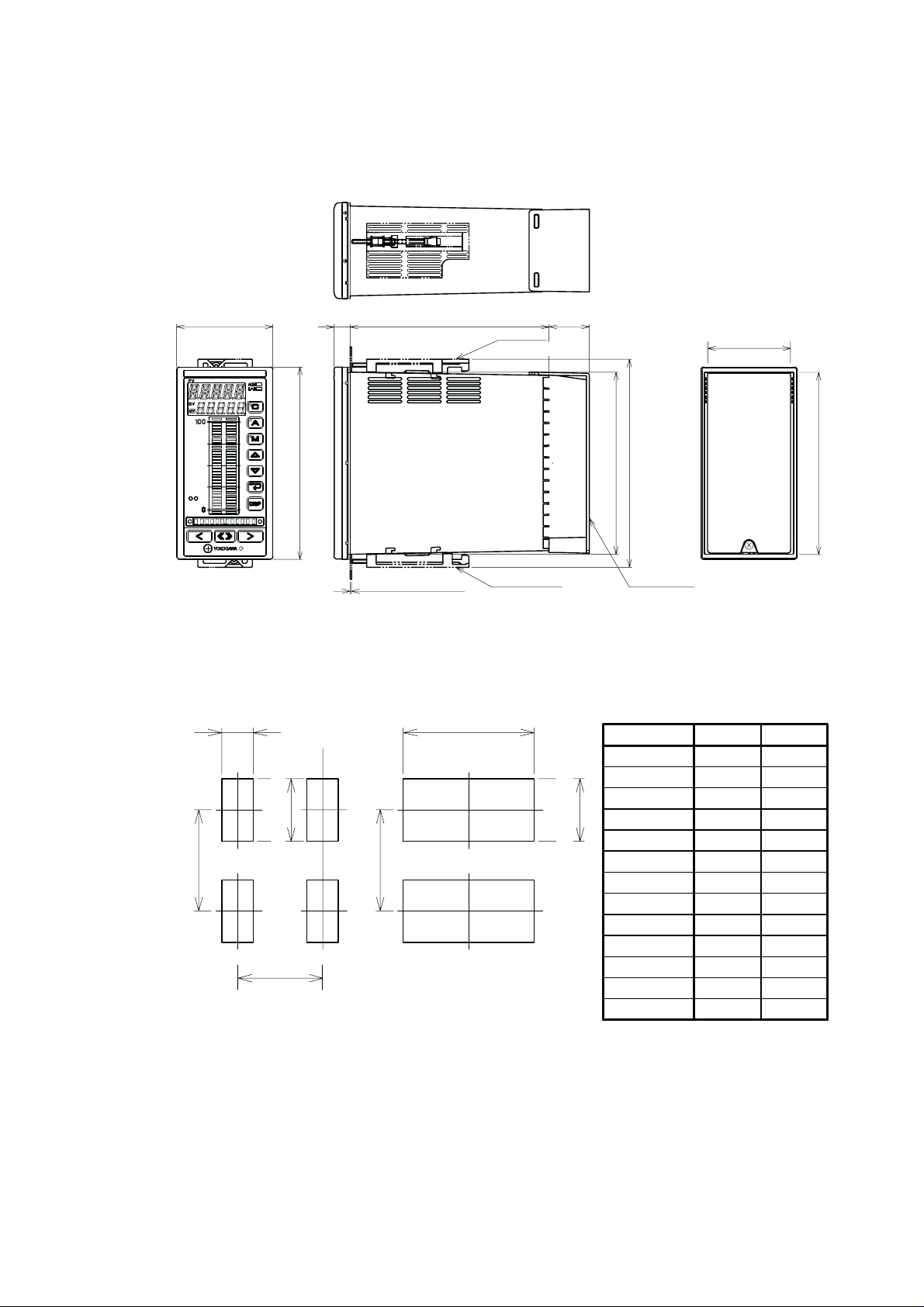

2.1 External Dimensions and Panel Dimensions

The external dimensions and panel cutout dimensions are as shown below.

Unit: mm

(approx inch)

144(5.67)

External Dimensions

(General mounting)

68(2.68)

+0.7

0

+2

0

137(5.39)

220(8.66) or more

93(3.66) or more

12(0.47)72(2.83) 30(1.18)

Panel thickness:1(0.04) to

10(0.39)mm

149(5.87)

Mounting bracket

Leave 5(0.20) mm or

more space above.

Mounting bracket

Leave 5(0.20) mm or

more space below.

(Side-by-side close mounting)

L

+2

0

137(5.39)

220(8.66) or more

L : refer to the Table 1

62(2.44)

156(6.14)

136.4(5.37)

Terminal Cover

Weight : 0.8kg

135.5(5.33)

Panel cutout width for side-by-side

close mounting

[Table 1]

Number of units L (mm) L (inch)

2 140

3 212

4 284

5 356

6 428

7 500

8 572

9 644

10 716

11 788

12 860

13 932

14 1004

5.51

8.35

11.18

14.02

16.85

19.69

22.52

25.35

28.19

31.02

33.86

36.69

39.53

2-2

Panel Cutout Dimensions

IM 5D1A01-01E

2.2 Mounting the Controller

■ Mounting Procedure

1. Cut the mounting panel as specified by the panel cutout dimensions on the previous page.

2. Insert the controller into the opening on the rear terminal board.

3. Attach the mounting brackets to the top and bottom of the controller, and fix the controller to the

mounting panel.

Chapter 2 Installing US1000 Controller

3.2.

NOTE

·Do not over-tighten the screws; doing so may damage the controller housing and brackets. (Recommended tightening torque: 0.2 N•m (2 kgf•cm) or less)

· Mount the controller within 30 degrees from horizontal so that it faces upward. Do not mount it

facing downward.

Keep this angle

within 30°

IM 5D1A01-01E 2-3

3. Wiring

This chapter describes the wiring procedure and terminal assignment of the US1000 controller. The

optimum sets of signals are automatically assigned to the terminals according to the model and suffix

code of your controller, the controller mode (US mode), and the type of control computation output.

See Also

• Section 4.3, “Selecting the Controller Mode (US Mode),” for information on the controller modes

(US modes).

• Section 4.5, “Selecting the Control Computation and Output Types,” for information on the control

computations.

CAUTION

• Before you start wiring, turn off the power supply source and use a tester to check that the controller and cables are not receiving any power.

•Never touch a terminal when power is being supplied; you will get an electrical shock if you do.

• Be careful to connect the correct polarities. Connecting the wrong polarity may result in a serious

accident.

• If the controller and any external equipment connected to it are to be used in a hazardous area (as

non-incendive equipment), the external equipment and the wiring conditions must satisfy the

requirements specified in Appendix 6, "Conditions of Use in Hazardous Areas." If these conditions

are not satisfied, the controller itself may be the source of a fire.

Chapter 3 Wiring

3.1 Procedure for Wiring

This section describes the cables used for wiring, the terminal assignment, and the wiring for power

supply. Once wiring is complete, a terminal cover should be attached as outlined in subsection 3.1.6.

3.1.1 Cables and Terminals

For the thermocouple input, use shielded compensating lead wires. The resistance temperature detector

(RTD) input requires shielded cables with low resistance and no resistance differential between the

three wires. The specifications for the cables and terminals used in the wiring are as follows.

• Power supply wiring: 600 V vinyl insulation electric wire, JIS C 3307, 0.9 to 2.0 mm

• Thermocouple wiring: Shielded compensating lead wire, JIS C 1610

• RTD input wiring: Shielded 3-core wire, UL2482 (product of Hitachi Cable)

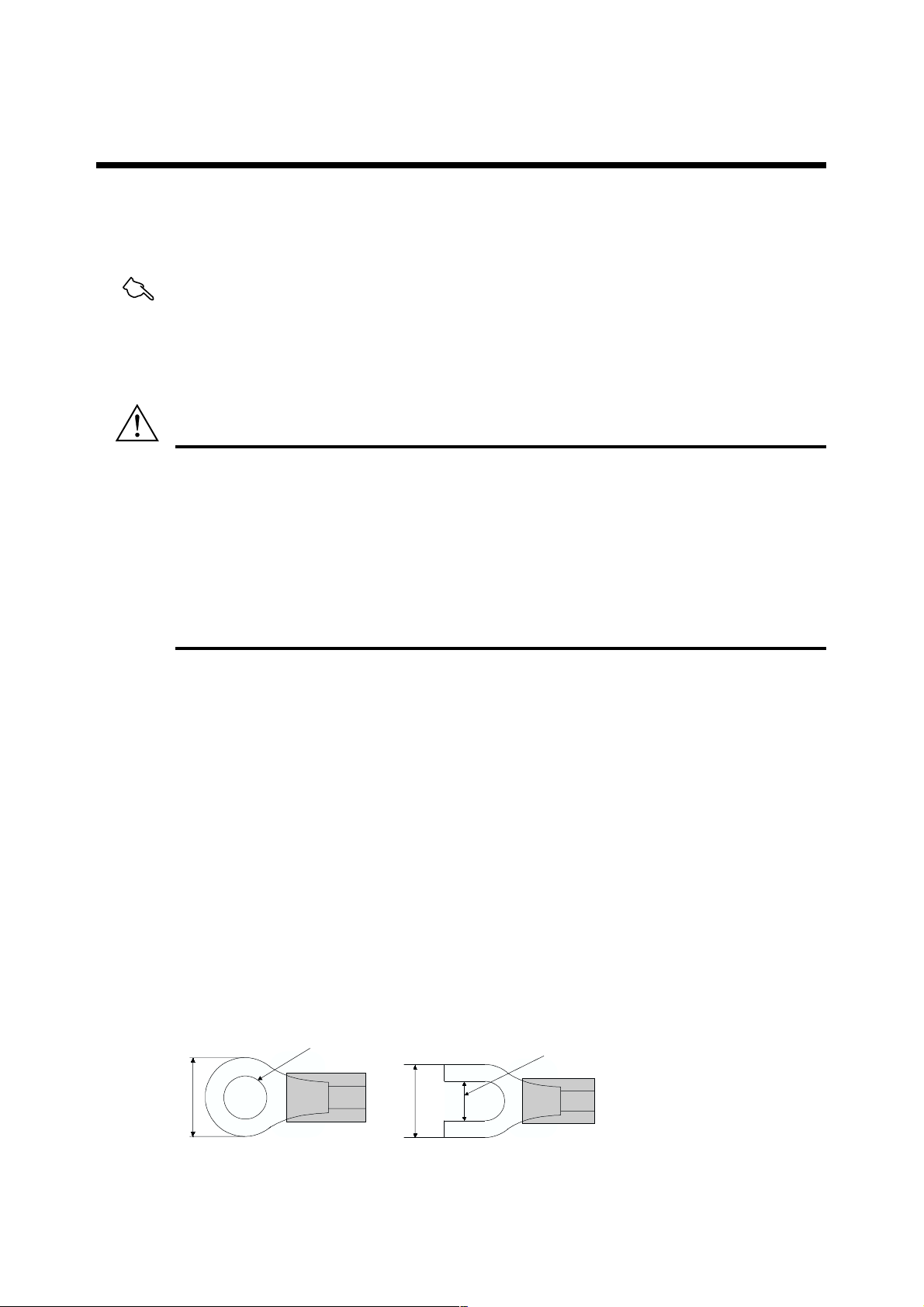

•Terminal: Crimp-on terminals with insulation sleeves and of a size suitable for

M3.5 screws (see the figure below).

• Terminal tightening torque: 0.8 N•m (8 kgf•cm) or less

3.7 mm

Max.7mm

Max.7mm

3.7mm

2

IM 5D1A01-01E 3-1

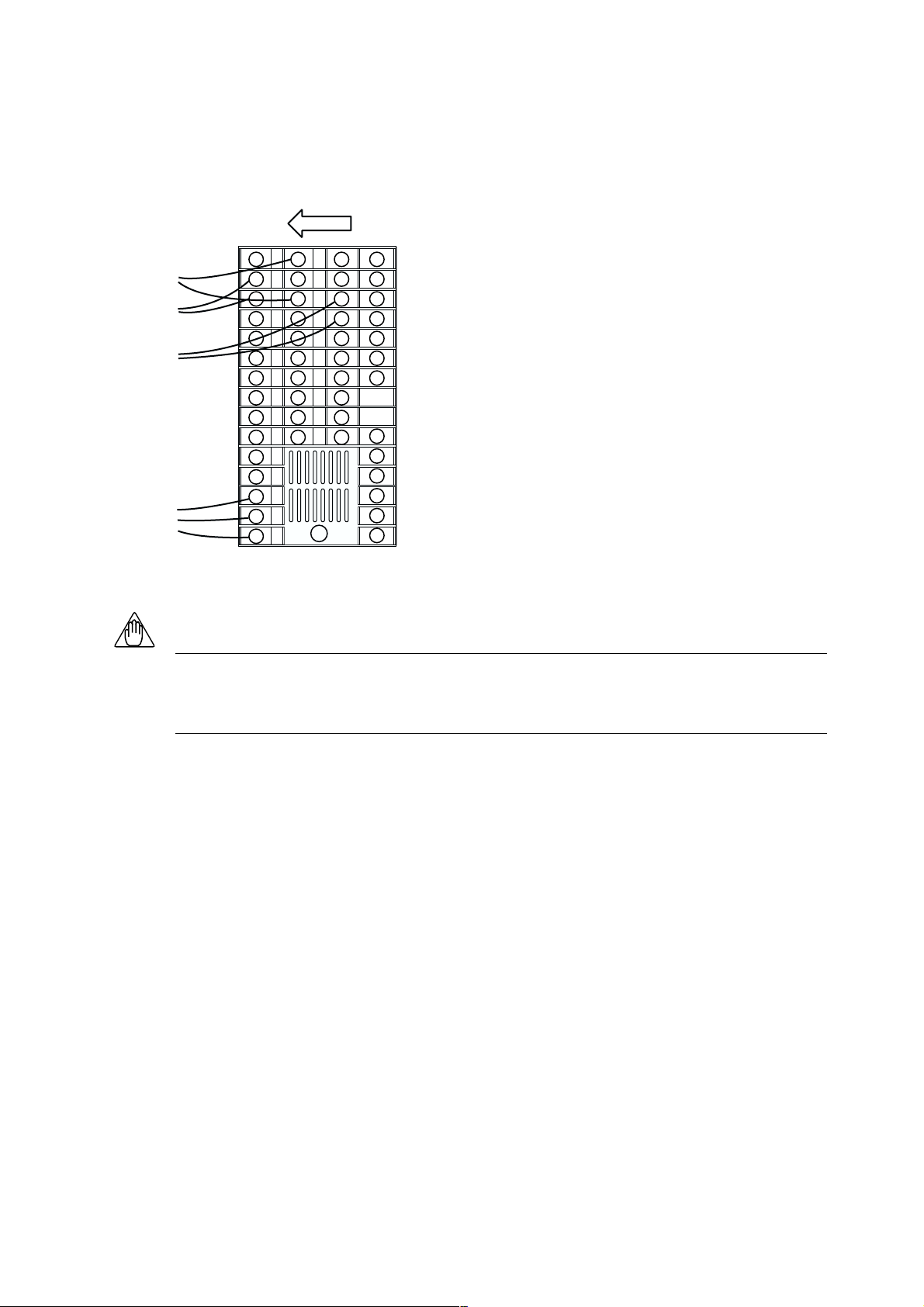

3.1.2 Direction of wiring

After connecting cables to the rear terminals, adjust the wiring so that the cables run in the direction

shown below.

1

16

2

17

3

18

4

19

5

20

6

21

7

22

8

23

9

24

10

25

11

12

13

14

15

31

46

32

47

33

48

34

49

35

50

36

51

37

52

38

39

55

40

56

57

58

59

60

3.1.3 Preventing Noise

NOTE

• To prevent electromagnetic wave radiation, use shielded wires for the wiring for the thermocouple

input, RTD input, DC input, current output or voltage pulse output. The shiled must be grounded.

• Bundle the connected cables together tightly.

Consider the following noise-prevention points when performing wiring.

• Keep the input circuit wires as far away as possible from the power lines of other equipment.

• The use of shielded wires is effective against noises from electrostatic induction. Connect shielding

to the grounding terminal if necessary. Be sure to ground each wire independently.

• Twining input wires at short regular intervals can be quite effective at eliminating the noise from

electromagnetic induction.

• Keep the power supply wiring more than 10 cm away from the signal wiring.

3-2

IM 5D1A01-01E

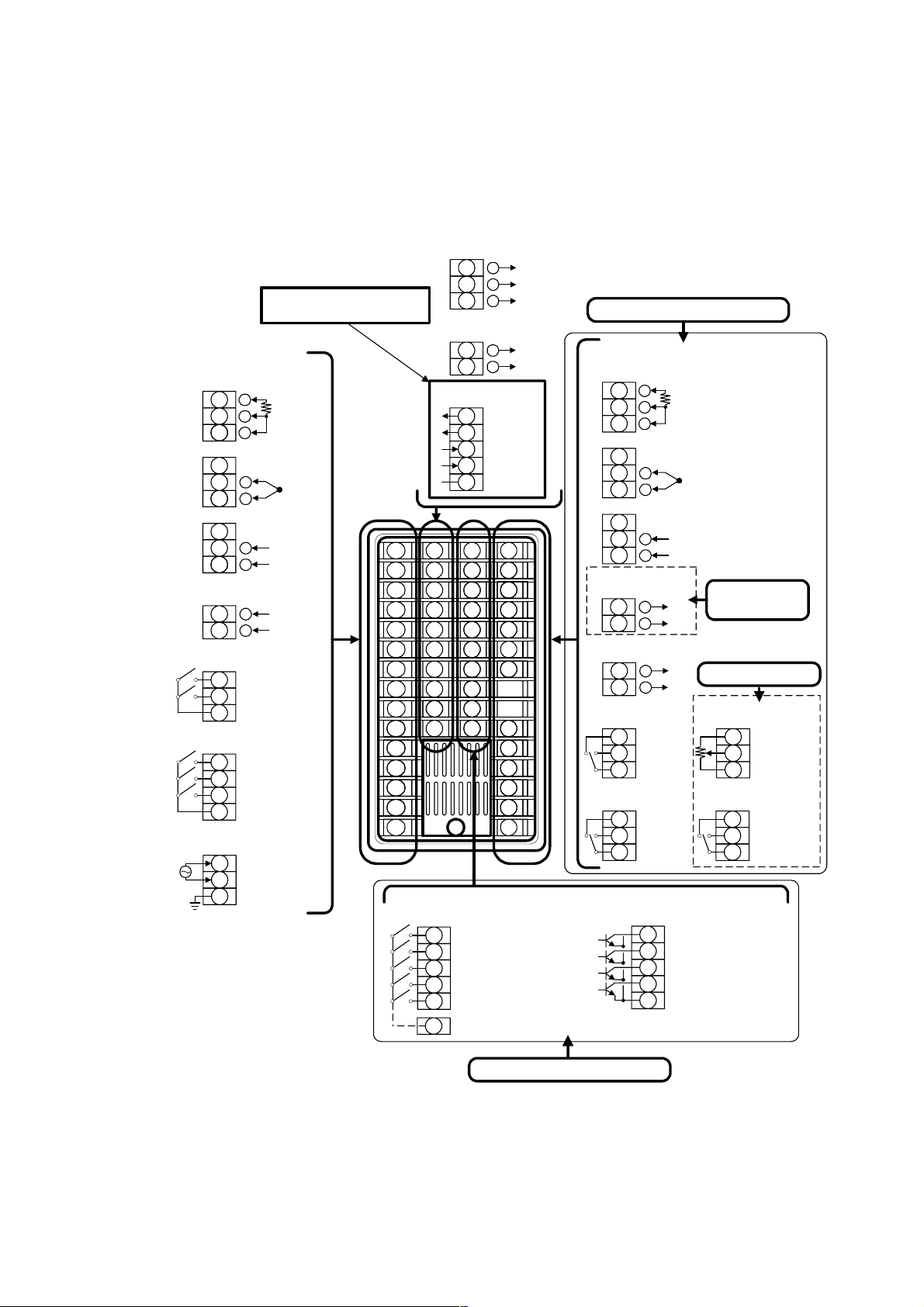

3.1.4 Terminal Designation

The terminals at the rear of the US1000 controller are arranged as shown below. Perform wiring

according to this figure. For information on the wiring for the power supply and the transmitter’s loop

power supply, read subsection 3.1.5. Refer to section 3.2 to find the signal assigned to each terminal.

Available for models with

option code /A10 only

AIN1

Analog input 1

• RTD input

A

1

2

b

B

3

• Thermocouple input

1

+

2

3

–

• Voltage input (mV, V)

1

+

2

3

–

AIN3

Analog input 3

4

+

5

–

DI1,2

Contact input 1, 2

6

DI1: Contact input 1

7

DI2: Contact input 2

8

COM

DO1-3

Relay contact output 1-3

9

DO1: Contact output 1

10

DO2: Contact output 2

11

DO3: Contact output 3

12

COM

SUPPLY

Power supply

13

L

14

N

15

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

OUT1A, 3A

MV output/ Retransmission output

+

16

+

17

–

18

LPS1

Loop power supply for

transmitter 1

+

19

20

–

RS-485

RS-485 communication

21

SDB(+)

22

SDA(-)

23

RDB(+)

24

RDA(-)

25

SG

31

16

17

18

19

20

21

22

23

24

25

46

32

47

33

48

34

49

35

50

36

51

37

52

38

39

40

55

56

57

58

59

60

DI3-7

Contact input 3-7

31

DI3: Contact input 3

32

DI4: Contact input 4

33

DI5: Contact input 5

34

DI6: Contact input 6

35

DI7: Contact input 7

8

COM

OUT1A: MV output 1

OUT3A: Retransmission output

COM

Unavailable for US1000-00

AIN2

Analog input 2

• RTD input

46

47

48

• Thermocouple input

46

47 +

48

• Voltage input (mV, V)

46

47

48

OUT2A

MV output 2

49

50

LPS2

Loop power supply for transmitter 2

51

52

OUT1R

Control relay output 1

55

56

57

OUT2R

Control relay output 2

58

59

60

Transistor open-collector output 4-7

A

b

B

–

+

–

+

–

+

–

NC

NO

COM

NC

NO

COM

DO4-7

36

DO4: Contact output 4

37

DO5: Contact output 5

38

DO6: Contact output 6

39

DO7: Contact output 7

40

COM

Chapter 3 Wiring

Unavailable for

US1000-21

For US1000-21:

FBIN

Feedback input

55

100% side

56

IN

57

0% side

OUTR

Control relay output

58

H (Direct)

59

L (Reverse)

60

COM

Unavailable for US1000-00

Figure Terminal Assignment

IM 5D1A01-01E 3-3

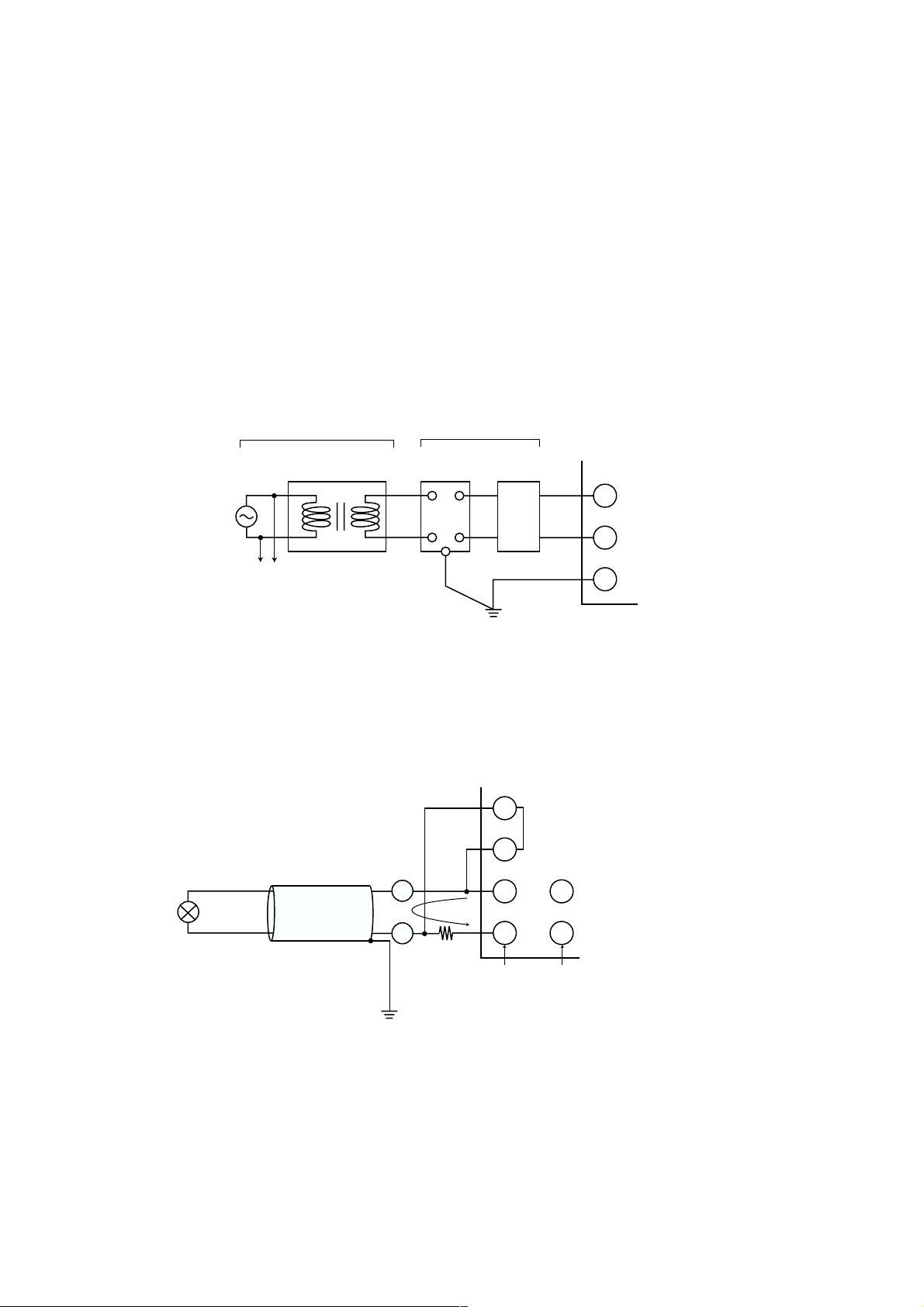

3.1.5 Wiring for Power Supply and Transmitter’s Loop Power Supply

Perform wiring for the power supply and the transmitter’s loop power supply as instructed below.

■ Wiring for Power Supply

• Use a single-phase power source.

•Use wires or cables with a minimum performance equivalent to that of 600 V vinyl insulation

electric wires (JIS C 3307).

• If the source has a lot of noise, use an insulation transformer and line filter as shown in the figure

below.

The recommended line filter is TDK’s ZAC2205-00U.

• When this noise-prevention measure is taken, keep the primary and secondary power cables well

apart.

• To ensure safety, install a circuit breaker switch or an equivalent safety device and be sure that

usage instructions for the device are clearly displayed.

Primary side Secondary side

Insulation transformer

Controller

power

■ Wiring for Loop Power Supply of Transmitter

Approximately 25.5 V DC power can be supplied to a two-wire sensor requiring a power supply.

Yokogawa’s Brain transmitter with communication function and the dedicated Brain terminal can be

used.

Shielding

+

Sensor

-

Class 3 grounding

Line filter

G

Class 3 grounding

100 Ω

Note

Terminal numbers are 2 and 3 for AIN1 terminal,

47 and 48 for AIN2 terminal

and 4 and 5 for AIN3 terminal.

Circuit

breaker

(Note)

2

1-5 V

3

19

20

RET1 RET2

51

or

52

or

13

14

15

L

N

G

3-4

IM 5D1A01-01E

3.1.6 Attaching the Terminal Cover

When you complete the wiring, attach the terminal cover as follows to prevent electrical shocks.

1. Fit the holes in the upper part of the terminal cover over the protrusions in the upper part of the

housing.

2. Insert the screw at the bottom of the terminal cover into the screw hole in the rear of the controller

and tighten it.

Fit the holes and the protrusions

Chapter 3 Wiring

Insert the screw and tighten it

IM 5D1A01-01E 3-5

3.2 Signals Assigned to Terminals

The US1000 controller has different signals assigned to terminals depending on the controller’s model

and suffix code, the controller mode (US mode), and the type of the control computation. Refer to the

relevant subsection according to your controller’s model and suffix code.

Model US1000-00: Subsection 3.2.1

Model US1000-11: Subsection 3.2.2

Model US1000-21: Subsection 3.2.3

In each subsection, tables are given for each controller mode (US mode) and control computation type.

Refer to the table that applies to your controller’s settings.

See Also

• Section 4.3, “Selecting Controller Mode (US Mode),” for information on the controller modes (US

modes).

•Section 4.5, “Selecting Control Computation and Output Types,” for information on the control

computations.

● Contact Input Function

The functions assigned to the contact inputs are as follow.

• RUN/STOP switchover: The controller is in STOP status when the contact is on, and in the

RUN status when the contact is off.

•CAS/AUTO/MAN mode selection:

When the contact is turned from off to on, the operation mode changes

to the corresponding mode.

•Tracking switching: Tracking signal of AIN2 or AIN3 is effective when the contact is on.

• OPEN/CLOSE switchover: Cascade control is disabled (OPEN) when the contact is on; cascade

control is enabled (CLOSE) when contact is off.

• ‘PV-hold and MAN mode’ or ‘AUTO mode’:

The controller holds PV in MAN mode when the contact is on, and is

in the AUTO mode when contact is off.

3-6

● Alarm Output 1 to 4

The initial alarm types of the alarm output 1 to 4 are:

Alarm output 1: PV high limit

Alarm output 2: PV low limit

Alarm output 3: PV high limit (secondary)

Alarm output 4: PV low limit (secondary)

To change the alarm type assignments, refer to section 4.7, “Defining Alarm Outputs.”

IM 5D1A01-01E

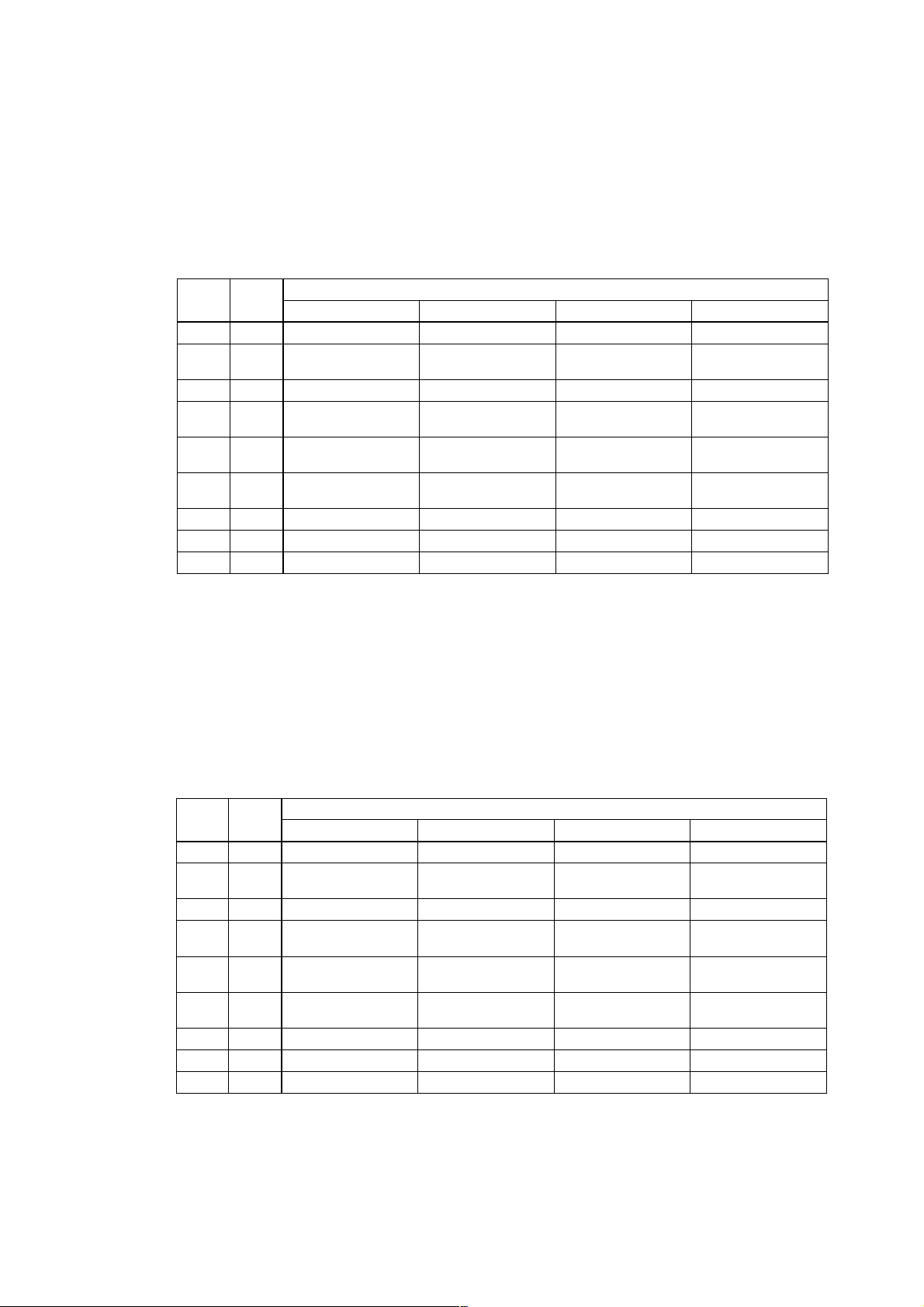

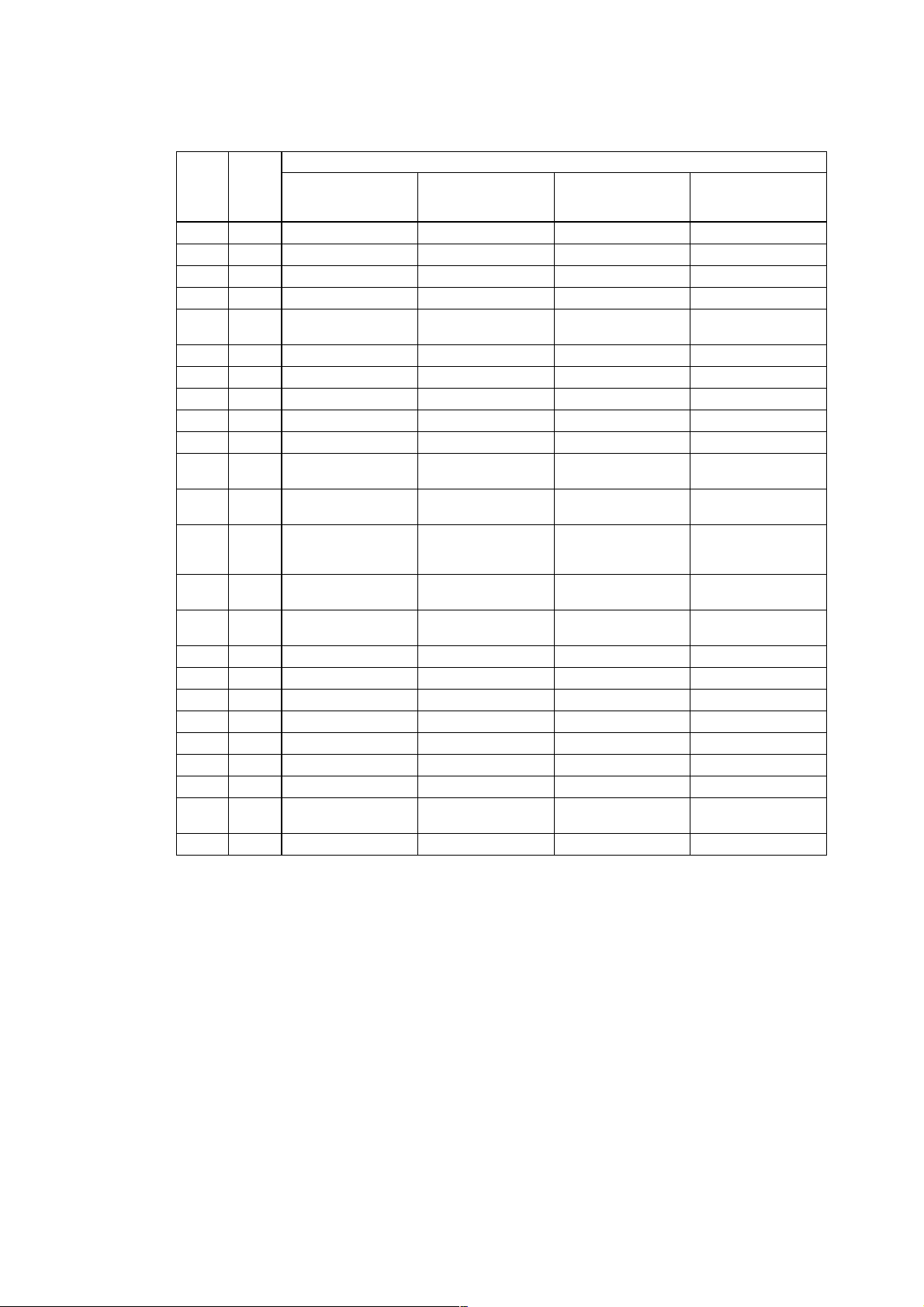

3.2.1 Terminal Assignment for US1000-00 (Basic Type)

■ US1000-00: Single-loop control (US mode 1)

US1000-00: Cascade primary-loop control (US mode 2)

US1000-00: Cascade secondary-loop control (US mode 3)

US1000-00: Cascade control (US mode 4)

Chapter 3 Wiring

Terminal

OUT1A 16, 18

Terminal

Code

AIN1 1 - 3 PV input PV input PV input Primary-side PV input

AIN3 4, 5

DI1 6, 8 RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

DI2 7, 8 MAN mode selection Tracking switching

LPS1 19, 20

DO1 9, 12 Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

DO2 10, 12 Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

DO3 11, 12 Alarm output 3 Contact off during error

No.

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Voltage pulse or

current output

US Mode 1 US Mode 2 US Mode 3 US Mode 4

Tracking input Cascade input Secondary-side PV input

Loop power supply for

transmitter 1

Current output

The output from the OUT1A terminal will be voltage pulse output when the control computation is

"time proportional PID," and current output when it is "continuous PID."

■ US1000-00: Loop control for backup (US mode 5)

US1000-00: Loop control with PV switching (US mode 6)

Controller mode (US mode)

CAS → AUTO mode

when the contact is off

Loop power supply for

transmitter 1

Voltage pulse or

current output

Contact off when CAS mode

OPEN/CLOSE

switchover

Loop power supply for

transmitter 1

Voltage pulse or

current output

Alarm output 3

US1000-00: Loop control with PV auto-selector (US mode 7)

US1000-00: Loop control with PV-hold function (US mode 8)

Terminal

OUT1A 16, 18

Terminal

Code

AIN1 1 - 3

AIN3 4, 5

DI1 6, 8

DI2 7, 8

LPS1 19, 20

DO1 9, 12

DO2 10, 12

DO3 11, 12

No.

US Mode 5 US Mode 6 US Mode 7 US Mode 8

PV input PV input 1 PV input 1 PV input

Tracking input PV input 2 PV input 2

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

Tracking switching PV switching MAN mode selection

Loop power supply for

transmitter 1

Voltage pulse or current

output

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Contact off during error Alarm output 3 Alarm output 3 Alarm output 3

Loop power supply for

transmitter 1

Voltage pulse or current

output

Controller mode (US mode)

The output from the OUT1A terminal will be voltage pulse output when the control computation is

“time proportional PID,” and current output when it is “continuous PID.”

Loop power supply for

transmitter 1

Voltage pulse or current

output

Cascade input, feedforward

input, or tracking input

'PV-hold and MAN

mode' or 'AUTO mode'

Loop power supply for

transmitter 1

Voltage pulse or current

output

IM 5D1A01-01E 3-7

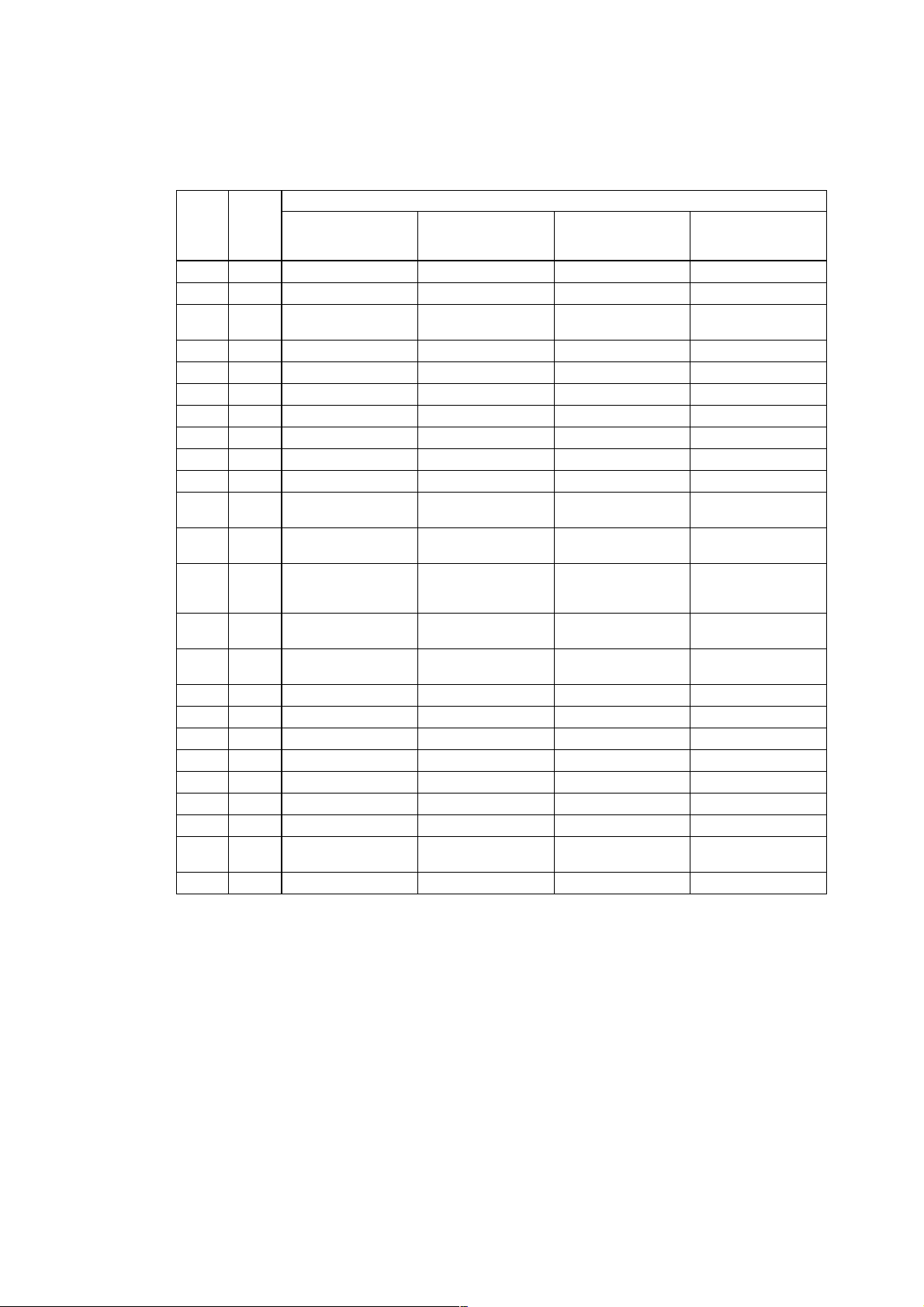

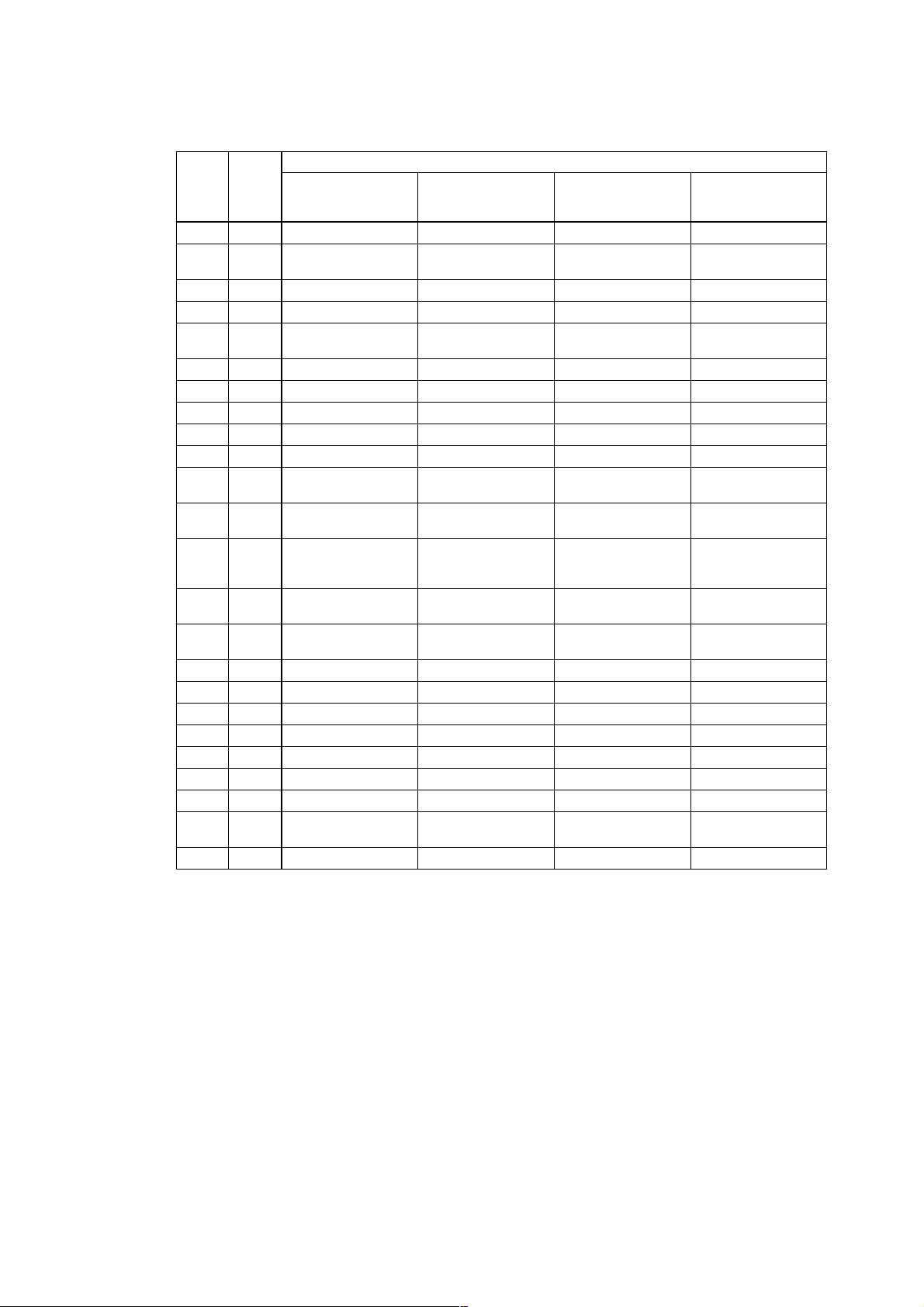

3.2.2 Terminal Assignment for US1000-11 (Enhanced Type)

■ US1000-11: Single-loop control (US mode 1)

Control Computation (MVS1 Set Value)

Terminal

AIN1 1 - 3 PV input PV input PV input PV input

AIN2 46 - 48 No function No function No function No function

AIN3 4, 5

DI1 6, 8 RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

DI2 7, 8 MAN mode selection MAN mode selection MAN mode selection MAN mode selection

DI3 31, 8 AUTO mode selection AUTO mode selection AUTO mode selection AUTO mode selection

DI4 32, 8 Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting

DI5 33, 8 Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting

DI6 34, 8 Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting

DI7 35, 8 Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12 Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

DO2 10, 12 Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

DO3 11, 12 Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

DO4 36, 40 Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

DO5 37, 40 No function No function No function No function

DO6 38, 40 No function No function No function No function

DO7 39, 40 FAIL output FAIL output FAIL output FAIL output

OUT1R 55 - 57

OUT2R 58 - 60 Alarm output 3

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Control relay output (0, 3)

Alarm output 4 (1, 2)

Heating/cooling

computation (4 - 6)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Heating/cooling

computation (7 - 9)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Heating/cooling

computation (10 - 12)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

3-8

IM 5D1A01-01E

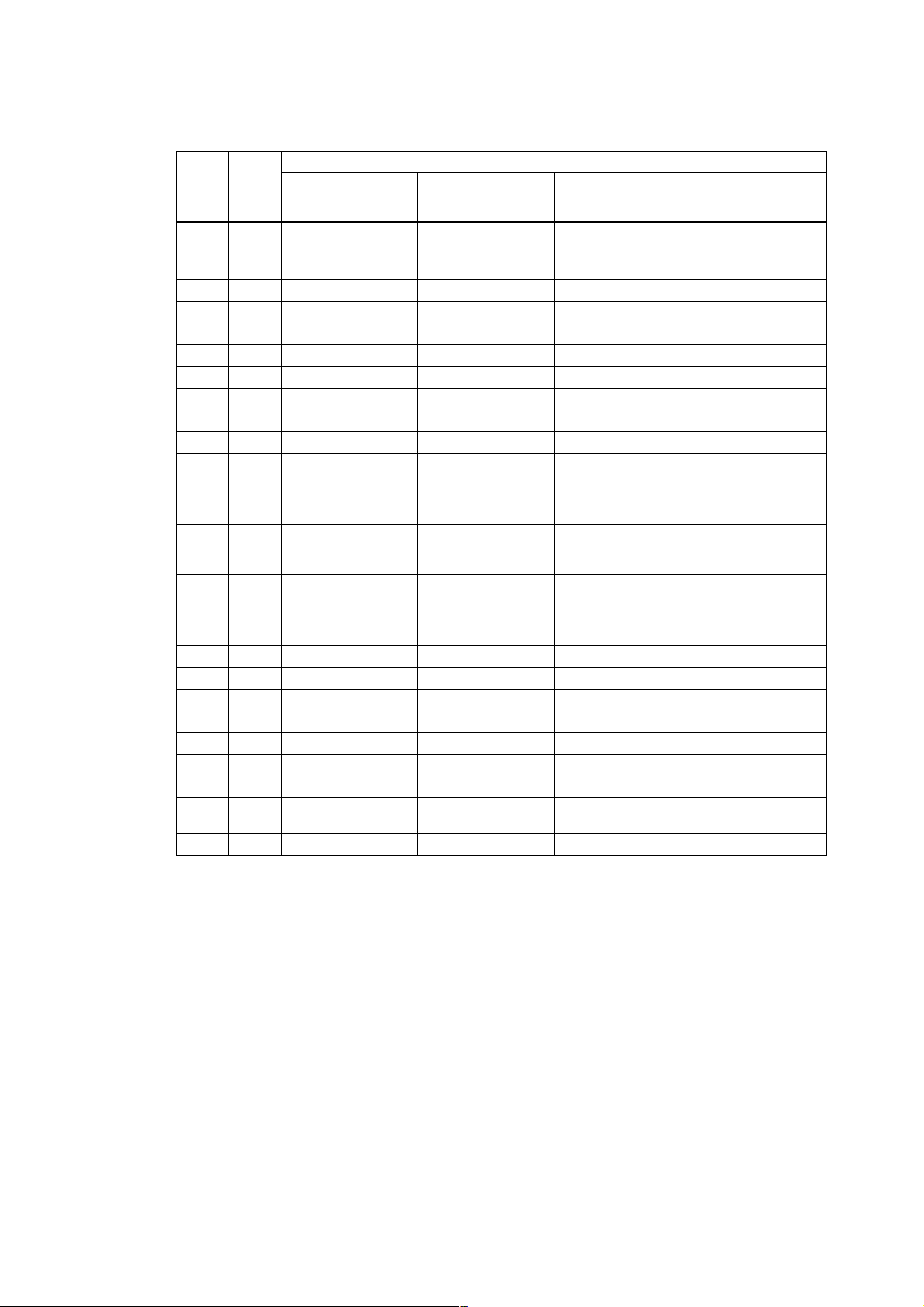

■ US1000-11: Cascade primary-loop control (US mode 2)

Chapter 3 Wiring

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Code

Terminal

No.

Control Computation (MVS1 Set Value)

Continuous PID (2)

PV input

Cascade input or feedforward input

Tracking input

RUN/STOP switchover

Tracking switching

MAN mode selection

Bit-0 of SV No. setting

Bit-1 of SV No. setting

Bit-2 of SV No. setting

Bit-3 of SV No. setting

Loop power supply for transmitter 1

Loop power supply for transmitter 2

Current output

Retransmission current output 2

Retransmission voltage output 3

Alarm output 1

Alarm output 2

Contact off during error

Alarm output 4

Alarm output 3

No function

FAIL output

Alarm output 4

Alarm output 3

IM 5D1A01-01E 3-9

■ US1000-11: Cascade secondary-loop control (US mode 3)

Control Computation (MVS1 Set Value)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

PV input PV input PV input PV input

Feedforward input Feedforward input Feedforward input Feedforward input

Cascade input Cascade input Cascade input Cascade input

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

CAS → AUTO mode

when the contact is off

MAN mode selection MAN mode selection MAN mode selection MAN mode selection

AUTO mode selection AUTO mode selection AUTO mode selection AUTO mode selection

CAS mode selection CAS mode selection CAS mode selection CAS mode selection

Message input Message input Message input Message input

No function No function No function No function

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

CAS output CAS output CAS output CAS output

Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

No function No function No function No function

FAIL output FAIL output FAIL output FAIL output

Control relay output (0, 3)

Alarm output 4 (1, 2)

Alarm output 3

Heating/cooling

computation (4 - 6)

CAS → AUTO mode

when the contact is off

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Heating/cooling

computation (7 - 9)

CAS → AUTO mode

when the contact is off

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Heating/cooling

computation (10 - 12)

CAS → AUTO mode

when the contact is off

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

3-10

IM 5D1A01-01E

■ US1000-11: Cascade control (US mode 4)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

Primary-side PV input Primary-side PV input Primary-side PV input Primary-side PV input

Cascade input or

feedforward input

Secondary-side PV input Secondary-side PV input Secondary-side PV input Secondary-side PV input

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

OPEN/CLOSE

switchover

MAN mode selection MAN mode selection MAN mode selection MAN mode selection

AUTO mode selection AUTO mode selection AUTO mode selection AUTO mode selection

CAS mode selection CAS mode selection CAS mode selection CAS mode selection

Message input Message input Message input Message input

No function No function No function No function

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

No function No function No function No function

No function No function No function No function

FAIL output FAIL output FAIL output FAIL output

Control relay output (0, 3)

Alarm output 4 (1, 2)

Alarm output 3

Control Computation (MVS2 Set value)

Heating/cooling

computation (4 - 6)

Cascade input or

feedforward input

OPEN/CLOSE

switchover

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Heating/cooling

computation (7 - 9)

Cascade input or

feedforward input

OPEN/CLOSE

switchover

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Chapter 3 Wiring

Heating/cooling

computation (10 - 12)

Cascade input or

feedforward input

OPEN/CLOSE

switchover

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

IM 5D1A01-01E 3-11

■ US1000-11: Loop control for backup (US mode 5)

Control Computation (MVS1 Set value)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

PV input PV input PV input PV input

Cascade input or

feedforward input

Tracking input Tracking input Tracking input Tracking input

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

Tracking switching Tracking switching Tracking switching Tracking switching

MAN mode selection MAN mode selection MAN mode selection MAN mode selection

Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting

Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting

Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting

Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Error output Error output Error output Error output

Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

No function No function No function No function

FAIL output FAIL output FAIL output FAIL output

Control relay output (0, 3)

Alarm output 4 (1, 2)

Alarm output 3

Heating/cooling

computation (4 - 6)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Heating/cooling

computation (7 - 9)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Heating/cooling

computation (10 - 12)

Cascade input or

feedforward input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

3-12

IM 5D1A01-01E

■ US1000-11: Loop control with PV switching (US mode 6)

Control Computation (MVS1 Set Value)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

PV input 1 PV input 1 PV input 1 PV input 1

Cascade input, feedforward

input, or tracking input

PV input 2 PV input 2 PV input 2 PV input 2

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

Dual-PV switching Dual-PV switching Dual-PV switching Dual-PV switching

MAN mode selection MAN mode selection MAN mode selection MAN mode selection

Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting

Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting

Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting

Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

No function No function No function No function

No function No function No function No function

FAIL output FAIL output FAIL output FAIL output

Control relay output (0, 3)

Alarm output 4 (1, 2)

Alarm output 3

Heating/cooling

computation (4 - 6)

Cascade input, feedforward

input, or tracking input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Chapter 3 Wiring

Heating/cooling

computation (7 - 9)

Cascade input, feedforward

input, or tracking input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Heating/cooling

computation (10 - 12)

Cascade input, feedforward

input, or tracking input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

IM 5D1A01-01E 3-13

■ US1000-11: Loop control with Dual PV auto-selector (US mode 7)

Control Computation (MVS1 Set Value)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

PV input 1 PV input 1 PV input 1 PV input 1

Cascade input, feedforward

input, or tracking input

PV input 2 PV input 2 PV input 2 PV input 2

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

MAN mode selection MAN mode selection MAN mode selection MAN mode selection

AUTO mode selection AUTO mode selection AUTO mode selection AUTO mode selection

Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting

Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting

Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting

Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

No function No function No function No function

No function No function No function No function

FAIL output FAIL output FAIL output FAIL output

Control relay output (0, 3)

Alarm output 4 (1, 2)

Alarm output 3

Heating/cooling

computation (4 - 6)

Cascade input, feedforward

input, or tracking input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Heating/cooling

computation (7 - 9)

Cascade input, feedforward

input, or tracking input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Heating/cooling

computation (10 - 12)

Cascade input, feedforward

input, or tracking input

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

3-14

IM 5D1A01-01E

■ US1000-11: Loop control with PV-hold function (US mode 8)

Control Computation (MVS1 Set Value)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

PV input PV input PV input PV input

No function No function No function No function

Cascade input, feedforward

input, or tracking input

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

'PV-hold and MAN

mode' or 'AUTO mode'

CAS mode selection CAS mode selection CAS mode selection CAS mode selection

Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting

Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting

Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting

Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3

Alarm output 4 Alarm output 4 Alarm output 4 Alarm output 4

No function No function No function No function

No function No function No function No function

FAIL output FAIL output FAIL output FAIL output

Control relay output (0, 3)

Alarm output 4 (1, 2)

Alarm output 3

Heating/cooling

computation (4 - 6)

Cascade input, feedforward

input, or tracking input

'PV-hold and MAN

mode' or 'AUTO mode'

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (4)

Heating pulse output (5)

Heating current output (6)

Retransmission current

output 2

Retransmission voltage

output 3

Heating control relay output (4)

Alarm output 4 (5, 6)

Cooling control relay output

Chapter 3 Wiring

Heating/cooling

computation (7 - 9)

Cascade input, feedforward

input, or tracking input

'PV-hold and MAN

mode' or 'AUTO mode'

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (7)

Heating pulse output (8)

Heating current output (9)

Cooling pulse output Cooling current output

Retransmission voltage

output 3

Heating control relay output (7)

Alarm output 4 (8, 9)

Alarm output 3 Alarm output 3

Heating/cooling

computation (10 - 12)

Cascade input, feedforward

input, or tracking input

'PV-hold and MAN

mode' or 'AUTO mode'

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (10)

Heating pulse output (11)

Heating current output (12)

Retransmission voltage

output 3

Heating control relay output (10)

Alarm output 4 (11, 12)

IM 5D1A01-01E 3-15

■ US1000-11: Dual-loop control (US mode 11)

US1000-11: Temperature and humidity control (US mode 12)

Control Computation (Set Value for MVS1 and MVS2)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

Loop-1 PV input Loop-1 PV input Loop-1 PV input

Loop-2 PV input Loop-2 PV input Loop-2 PV input

Cascade input, feedforward

input, or tracking input

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

Loop-2 MAN mode

selection

Loop-1 MAN mode

selection

Bit-0 of SV No. setting Bit-0 of SV No. setting Bit-0 of SV No. setting

Bit-1 of SV No. setting Bit-1 of SV No. setting Bit-1 of SV No. setting

Bit-2 of SV No. setting Bit-2 of SV No. setting Bit-2 of SV No. setting

Bit-3 of SV No. setting Bit-3 of SV No. setting Bit-3 of SV No. setting

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Loop-1

Retransmission output 1 (0, 3)

Voltage pulse output (1)

Current output (2)

Loop-2

Retransmission output 2 (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2

Alarm output 3 Alarm output 3 Alarm output 3

Alarm output 4 Alarm output 4 Alarm output 4

No function No function No function

No function No function No function

FAIL output FAIL output FAIL output

Loop-1

Control relay output (0, 3)

Alarm output 4 (1, 2)

Loop-2

Control relay output (0, 3)

Alarm output 4 (1, 2)

Heating/cooling

computation (4, 5)

Cascade input, feedforward

input, or tracking input

Loop-2 MAN mode

selection

Loop-1 MAN mode

selection

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Loop-1

Heating pulse output (4)

Cooling pulse output (5)

Loop-2

Heating pulse output (4)

Cooling pulse output (5)

Retransmission voltage

output 3

Loop-1

Cooling control relay output (4)

Heating control relay output (5)

Loop-2

Cooling control relay output (4)

Heating control relay output (5)

Heating/cooling

computation (6, 7)

Cascade input, feedforward

input, or tracking input

Loop-2 MAN mode

selection

Loop-1 MAN mode

selection

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Loop-1

Heating current output (6)

Cooling current output (7)

Loop-2

Heating current output (6)

Cooling current output (7)

Retransmission voltage

output 3

Loop-1

Cooling control relay output (6)

Heating control relay output (7)

Loop-2

Cooling control relay output (6)

Heating control relay output (7)

3-16

IM 5D1A01-01E

■ US1000-11: Cascade control with two universal inputs (US mode 13)

Control Computation (MVS2 Set Value)

Terminal

AIN1 1 - 3

AIN2 46 - 48

AIN3 4, 5

DI1 6, 8

DI2 7, 8

DI3 31, 8

DI4 32, 8

DI5 33, 8

DI6 34, 8

DI7 35, 8

LPS1 19, 20

LPS2 51, 52

OUT1A 16, 18

OUT2A 49, 50

OUT3A 17, 18

DO1 9, 12

DO2 10, 12

DO3 11, 12

DO4 36, 40

DO5 37, 40

DO6 38, 40

DO7 39, 40

OUT1R 55 - 57

OUT2R 58 - 60

Terminal

Code

Time proportional PID (0, 1)

Continuous PID (2)

No.

ON/OFF computation (3)

PV input 1 PV input 1 PV input 1 PV input 1

PV input 2 PV input 2 PV input 2 PV input 2

Cascade input or

feedforward input

RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover RUN/STOP switchover

OPEN/CLOSE

switchover

MAN mode selection MAN mode selection MAN mode selection MAN mode selection

AUTO mode selection AUTO mode selection AUTO mode selection AUTO mode selection

CAS mode selection CAS mode selection CAS mode selection CAS mode selection

Message input Message input Message input Message input

No function No function No function No function

Loop power supply for

transmitter 1

Loop power supply for

transmitter 2

Retransmission output (0, 3)

Voltage pulse output (1)

Current output (2)

Retransmission current

output 2

Retransmission voltage

output 3

Alarm output 1 Alarm output 1 Alarm output 1 Alarm output 1

Alarm output 2 Alarm output 2 Alarm output 2 Alarm output 2

Alarm output 3 Alarm output 3 Alarm output 3 Alarm output 3