Page 1

<<Contents>> <<Index>>

General

Specifications

MODEL UP350

Program Controller

GS 05E01D02-01E

■General

Model UP350 program controller is a precision controller,

featuring two program profiles and universal input/output.-

For easy operation, it is provided with a large display for

process variables, two program operation keys, and a

program reset key. For excellent controll, auto-tuning, PID

control with the “SUPER” overshoot suppressing function

and the "SUPER2" hunting suppressing function are

available. It also has a retransmission output and 15V DC

loop power supply as standard.

■Main Features

• Extra-large digital display allows the indicated values to be

read even from a long distance. LEDs of 20mm height are

used for the process variable display.

• It can store two program pattern types. Programmed

operation can be started by using the two program

operation keys on the front panel and terminated by using

the reset key.

• Universal input and output enable users to set or change

freely the type of measured inputs (thermocouple, RTD, or

DCV), measurement range, type of control output (4 to 20

mA current, voltage pulse, or relay contact, etc. from the

front panel.

• Parameters can be easily set using a personal computer.

("Parameter setting tool (model LL100)" sold separately is

required.)

• Various communication function are provided.

Communication is possible with personal computer,

programable logic controller, and other controllers.

UP350

UP350E

“E” indicates with the

model with expanded

functions.

Starting/stopping (resetting) a program pattern:

A program pattern can be started or stopped

(reset) by key operation.

Temporarily stopping (holding) a program pattern:

A program pattern can be temporarily stopped

(hold) by key operation or through the contact

input.

Skipping (advancing) the segment of a program:

Available through key operation

Switching between program patterns:

Available through key operation or external

contact

Target setpoint

SP

■Function Specifications

● Program Setting Function

“Program setting” allows the controller's target setpoint to

increase or decrease along the program pattern versus time.

The instrument, provided with two program patterns, can be

operated by using the front panel key or through the external

contact. One program pattern consists of 10 broken lines

(program segments). If the two program patterns are

combined, a program pattern of up to 20 segments can be

created. The length of each segment can be specified by the

segment time. Users can also configure the number of

repeats, event outputs, etc.

Number of program patterns: 2

Number of segments/pattern: 10

Number of program repeat: Unlimited repeats

Segment time: 0 min. 0 s to 99 min. 59 s, or

0 h 0 min. to 99 h 59 min.

Segment time

t1 t2 t3 t4 t5

Segment

Segment

No.1

No.2

˙˙˙˙˙˙

GS 05E01D02-01E

© Copyright Jan. 2000 (YK)

1st Edition Mar. 2000 (YG)

Segment

No.5

Page 2

<<Contents>> <<Index>>

2

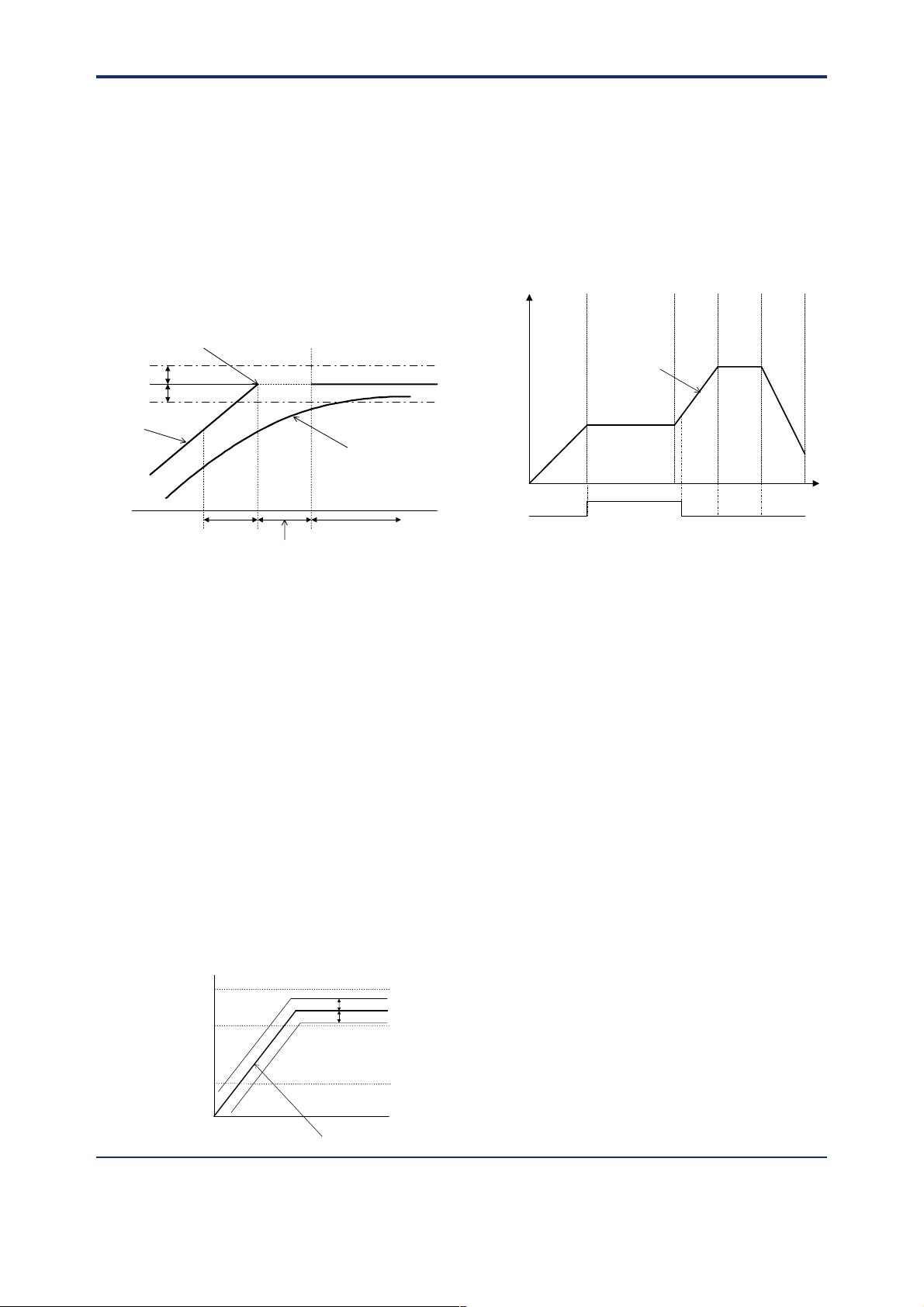

Wait Function (Guaranteed soak)

The function to delay the progress of a program pattern if the

process variable (PV) has not reached the target setpoint

(SP). The wait zone is the deviation band of acceptable PV

response is determined, and the wait time is the time to wait

for the PV to reach the wait zone. If the PV reaches the wait

zone within a certain time (the wait time), then the program

will advance to the next segment. If it does not reach the wait

zone after the wait time has elapsed, then the program will

eventually advance to the next segment.

Wait time: 0 min. 1 s to 99 min. 59 s, or

0 h 1 min. to 99 h 59 min.

Wait zone: OFF, 0.0 to 10.0 % of measured input range

width.

Wait zone

Wait zone

SP

TSP

Seg.n

EVn EVn+1

Wait time

Seg.n+1

PV

Program Setting Function and PID Parameter

Switching

PID parameter switching in accordance with the progress of

the program pattern is available.

Zone PID: PID parameter selection according to the

Reference point method:

Reference point = Measuring input range (0%)

Reference point hysteresis = Fixed to 0.5% of the

Reference deviation method:

Reference deviation = OFF, 0.1 to 100.0% of

Measuring input range (100%)

Measuring input range (0%)

value of the PV is available. Reference point

(setpoint for PID parameter switching) or

reference deviation is used for switching.

Up to two points can be set to divide the PV

range up to three zones, and this selects the

PID parameter set (PID 1 to 3) according to

zone.

Reference point 1 Reference point 2

Measuring input range (100%)

measured input range width.

Switches the group of PID parameters (PID

4) depending on whether the control

deviation is within or over the reference

preset amount. This takes priority over the

reference point.

measured input range width.

Reference deviation

Reference point 2

Reference point 1

Reference deviation

Measured value (PV)

No.3PID

No.2PID

No.1PID

Time Event: 1 point

A time event may be set thruoghout the program pattern

progress, by and uses a status lamp or a contact output.

Number of time events: 1 point for each program pattern

Time event setting points: These output time events

according to the elapsed time from the

program start.

Time event setting range(ON and OFF): 0 min. 1 s to 99

min. 59 s, or

0 h 1 min. to 99 h 59 min.

Time event display: 1 point (TIME)

Time event contact output: 1

SEG1 SEG2 SEG3 SEG4 SEG5

Program pattern

Time event

ON time OFF time

PV Event: 2 point

A PV event is a PV/deviation alarm which is configured in

accordance with the program pattern. The alarm status is

indicated by the event LED on the front of the instrument

panel.

Number of PV events:

2 points maximum per program pattern

PV event LEDs:

2 points (PVE1, PVE2)

PV event types:

PV high limit, PV low limit, Deviation high

limit, Deviation low limit, Deenergized on

deviation high limit, Deenergized on deviation

low limit, Deviation high and low limits, High

and low limits within deviation, Deenergized

on PV high limit, Deenergized on PV low

limit

PV event setting ranges:

PV alarm: -100.0 to 100% of measured input range.

Deviation alarm: -100.0 to 100% of measured input

range width.

Alarm hysteresis: 0.0 to 100.0% of measured input range

width.

● Control Computation Functions

Control computation:

Control cycle time: 250 ms

Number of PID parameter sets: 4

Auto-tuning: Available as standard. If auto-tuning is

Select from the following types of control

strategies:

Continuous PID control, time proportional

PID control, Relay ON/OFF control

enabled, the PID constant is set automatically.

(Limit cycle method)

Time

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05E01D02-01E 1st Edition Mar.31, 2000-00

Page 3

<<Contents>> <<Index>>

3

“SUPER” function: This suppresses overshooting caused

by the sudden change of the target setpoint or

disturbance.

“SUPER2” function:

This stabilizes the state of control that is

unstable due to hunting, etc. without requiring

any change in PID constants, when the load

and/or gain varies greatly, or when there is a

difference between the characteristics of

temperature zones.

Control Parameters Setting Range

Proportional band: 0.1 to 999.9%

Integral time: 1 to 6,000 s, or OFF (for Manual Reset)

Derivative time: 1 to 6,000 s, or OFF

Manual reset value: -5.0 to 105.0% of output range

(functions when integral time is off)

ON/OFF control hysteresis: 0.0 to 100.0% of measured

input range width

Direct/Reverse action:

Defining the direction of an increase/decrease

in output corresponding to a positive or

negative deviation is available.

Anti-reset windup:

When the output of the controller is limited,

this stops normal integration to suppress overintegration; instead, it performs anti-reset

windup computation.

Control output cycle time: 1 to 1000 s

Preset output value: -5.0 to 105.0% of output range

Output tracking:

Selecting output with bump or without bump

is available by changing the PID control

mode.

Output limiter:

high limit: Low limit to 105.0% of output range

low limit: -5.0% of output range to high limit

● Signal Computation Functions

Measured input configuration:

Bias addition (-100.0 to 100.0% of measured

input range width.), first order lag filter (time

constant: off, 1 to 120 s)

Contact input function:

Program pattern switching operation, program

operation hold mode switching, display key-

lock parameter enabled/disabled switching

For program pattern operation, select from the

dual-pattern switching operation and single-

pattern operation.

• If the single-pattern operation is selected,

program operation hold mode switching can

also be used.

• If the dual-pattern switching operation is

selected, program operation hold mode

switching cannot be used.

If displaying key-lock parameter enabled/

disabled switching is used, switching between

the single-pattern operation and dual-pattern

switching operation is not available.

Status indicating lamps:

2 PV event (alarm) LEDs: PVE1, PVE2

1 time event LED: TME

2 program operation number LEDs: PRG1, PRG2

1 program operation hold LED: HLD (lights up during

hold mode)

Operation key:

▲, ▼ key: Increases/decreases the value of setpoint or

other parameters which appear on LED

display.

SET/ENT key: Sets/changes the setting value, and calls/

switches between parameters.

PRG1, PRG2: Program operation control key

RESET: Program operation stop key

SELECT display:

Allows selection and registration of

frequently changed parameters from the

operation parameters during operation. For

example, if the bias parameter is registered

in the SELECT display, the setpoint can

easily be displayed during operation.

Security function:

An operation inhibiting mode using a

password is available.

● Communication Functions (optional)

The communication function, provided with the instrument,

allows connection to personal computer, programmable logic

controller, and other GREEN series controllers.

Communication protocol:

Computer link communication:

Communication protocol with a personal

computer

Ladder communication:

Communication protocol with programmable

logic controller

MODBUS communication:

Communication protocol with a personal

computer or PLC.

Coordinated operation:

Protocol to realize coordinated operation

with more than one UT controller in the

GREEN series. The UP350 is always

configured as a master unit.

Communication interface:

Communication protocol:

Computer link, ladder communication,

MOBUS or coordinated operation

Standard: EIA RS485

Maximum number of connectable controllers:

31 Green series controllers

Maximam communication distance: 1,200 m

Communication method:

Two-wire half duplex or four-wire half

duplex, start-stop synchronization system,

handshaking

Communication rate:

600, 1200, 2400, 4800, 9600 bps

● Display and Operation Function

PV display: 4-digit digital display for engineering data

Setpoint display:

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05E01D02-01E 1st Edition Mar.31, 2000-00

Various types of data, including setpoint (SP),

are available selectively on 4-digit digital

display.

Page 4

<<Contents>> <<Index>>

Status lamps

PV event (PVE1, PVE2), time event (TME),

operation status of Program pattern 1 or 2

(PRG1, PRG2) hold status (HLD).

Communication port for light loader

Parameters and programs are set via

communication from a personal computer.

Operational keys

Increase/Decrease the setting data (䉱, 䉲)

Select parameter/Enter the setting data (SET/ENT)

Start program operation or set a program(PRG1, PRG2)

Reset to preset output(RESET)

Sample structures of communication systems

(1) Computer link communication/MODBUS communication (2) Ladder communication

4

LED display unit (for PV)

Display PV, and error code when

error is detected.

LED display unit (for SP)

Display setpoint (SP),

setting item/value of parameters.

Personal computer

PV

PV

PV2

AL

1

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

PV

PV2

PV2

AL

AL

1

1

2

2

3

3

REM

REM

4

4

MAN1

MAN1

MAN2

MAN2

STP

STP

CAS

CAS

A/M

A/M

DISP

DISP

SET/ENT

SET/ENT

PV

PV2

AL

1

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

UP350

Program coutroller

(3) Coordinated operation

PV

PV2

AL

1

UP350 Program controller

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

or UT350/UT320 Digital indicating controller

PV

PV

PV2

AL

1

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

PV

PV2

PV2

AL

AL

1

1

2

2

3

3

REM

REM

4

4

MAN1

MAN1

MAN2

MAN2

STP

STP

CAS

CAS

A/M

A/M

DISP

DISP

SET/ENT

SET/ENT

PV

PV2

AL

1

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

UT350/UT320

Digital indicating controller

■Hardware Specifications

Measured Input Signal

Number of inputs: 1 point

Input type: Possible to select input type/measurement

Input type, measurement ranges, and measurement accuracy:

Burnout detection:

Input bias current: 0.05 µA (for TC and RTD b-terminal)

Measuring current(RTD): about 0.13mA

Input resistance:

Allowable signal source resistance:

Allowable leadwire resistance:

ranges from the input list with software.

Refer to the table in the next page.

Available with TC, RTD, stadard signal, 0.4 to

2 V DC and 1 to 5 V DC.

Up-scale, down-scale, and off can be set.

For standard signal, an input of 0.1V or less is

regarded as burnout.

1 MΩ or more for TC/mV input

About 1 MΩ for DC voltage input

250 Ω or less; effect of permissible signal

source resistance 0.1 µV/Ω or less for TC/mV input

2 kΩ or less; effect of permissible signal

source resistance 0.01%/100 Ω or less for DC

voltage input

Max. of 150 Ω/wire (resistance in each of

three wires must be equal) for RTD input

However, 10 Ω/wire in the range of -150.0 to

150.0°C.

MELSEC-A

PLC

PV

PV

PV2

PV2

AL

AL

1

1

2

2

3

3

REM

REM

4

4

MAN1

MAN1

MAN2

MAN2

STP

STP

CAS

CAS

A/M

A/M

DISP

SET/ENT

PV

PV2

AL

1

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

DISP

SET/ENT

PV

PV2

AL

1

2

3

REM

4

MAN1

MAN2

STP

CAS

A/M

DISP

SET/ENT

UP350

Plogram controller

Effect of permissible leadwire resistance

±0.1°C/10 Ω or less

Allowable input voltage:

±10 V DC for TC/mV/RTD input

±20 V DC for DC voltage input

Noise rejection ratio:

Normal mode 40 dB (50/60 Hz) or more

Common mode 120 dB (50/60 Hz) or more

Reference-junction compensation error:

±1.0°C (15 to 35°C), ±1.5°C (0 to 15°C, 35 to

50°C)

Applicable standards: JIS, IEC, or DIN (ITS-90) for TC

and RTD

15V DC Loop Power Supply

The controller supplies power to a two-wire transmitter.

Place a resistor (10 to 250 Ω, optional) between the controller and the transmitter, convert a current signal to a voltage

signal, and read it from the PV input. Either the retransmission output or the loop power supply can be used.

Supply voltage is 14.5 to 18.0 V DC. Maximum supply

current is about 21 mA (with a protection circuit for a field

short-circuit).

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05E01D02-01E

1st Edition Mar.31, 2000-00

Page 5

<<Contents>> <<Index>>

5

■

15 V DC Power Supply Wiring to Two-wire Sensor

Control Outputs

The control output is of a universal scheme and can be

selected from the following types of outputs.

Two-wire transmitter

4-20mADC

External

resistor

(Note)

12

100Ω

13

14

15

PV input

0.4 to 2.0 V DC signal

Loop power

supply

14.5 to

18.0 V DC

Current output

Number of output points: 1

Output signal: 4 to 20 mA

Load resistance: 600 Ω or less

Output accuracy: ±0.3% of span

Performance in the standard operating

conditions (at 23± 2°C, 55± 10% RH, and

50/60 Hz power frequency)

Voltage pulse output

Number of outputs: 1

Note: Connecting a 100 Ω resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

Output signal: ON voltage 12 V DC (for load resistance

of 600Ω or more, short-circuit current

approximately 30 mA)

Retransmission Output

Either PV, target setpoint, or control output is output. Either

the retransmission output or the 15 V DC loop power supply

can be used.

Number of output points: 1 point

Output signal: 4 to 20 mA DC

Load resistance: 600 Ω or less

Output accuracy: ±0.3% of span

Resolution: 10 ms

Relay contact output

Number of outputs: 1

Output signal: Transfer contact, including NC, NO, and

Standard rating: 250V AC 3A or 30V DC 3A

Resolution: 10ms

OFF voltage 0.1V DC or less

Common.

(Load resistance)

Performance in the standard operating

conditions (at 23± 2°C, 55± 10% RH, and 50/

60 Hz power frequency)

Input type

Unspecified(when shipped from the factory)

Thermocouple

RTD

Standard

signal

DC voltage

K

J

T

B

S

R

N

E

L (DIN)

U (DIN)

W (DIN)

Platinel 2

PR20-40

W97Re3-W75Re25

JPt100

Pt100

0.4 to 2V

1 to 5V

0 to 2V

0 to 10V

-10 to 20mV

0 to100mV

Input range

code

OFF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

30

31

35

36

37

40

41

50

51

55

56

Note1:The accuracy is ±0.3°C of instrument range ±1 digit for a temperature range from 0 to 100°C.

Note2:The accuracy is ±0.5°C of instrument range ±1 digit for a temperature range from –100 to 200°C.

*1: Performance in the standard operating conditions (at 23±2°C, 55±10% RH, and 50/60Hz power frequency)

Instrument

range (°C)

Set the data item PV input type “IN” to the OFF option to leave the PV input type undefined.

-200 to 1370˚C

-199.9 to 999.9˚C

-199.9 to 500.0˚C

-199.9 to 999.9˚C

-199.9 to 400.0˚C

0.0 to 400.0˚C

0 to 1800˚C

0 to 1700˚C

0 to 1700˚C

-200 to 1300˚C

-199.9 to 999.9˚C

-199.9 to 900.0˚C

-199.9 to 400.0˚C

0.0 to 400.0˚C

0 to 2300˚C

0 to 1390˚C

0 to 1900˚C

0 to 2000˚C

-199.9 to 500.0˚C

-150.0 to 150.0˚C

-199.9 to 850.0˚C

-199.9 to 500.0˚C

-150.0 to150.0˚C

0.400 to 2.000 V

1.000 to 5.000 V

0.000 to 2.000 V

0.00 to 10.00 V

-10.00 to 20.00 mV

0.0 to 100.0 mV

Instrument

range (°F)

-300 to 2500˚F

0 to 2300˚F

-199.9 to 999.9˚F

-300 to 2300˚F

-300 to 750˚F

-199.9 to 750.0˚F

32 to 3300˚F

32 to 3100˚F

32 to 3100˚F

-300 to 2400˚F

-300 to 1800˚F

-300 to 1300˚F

-300 to 750˚F

-199.9 to 750.0˚F

32 to 4200˚F

32 to 2500˚F

32 to 3400˚F

32 to 3600˚F

-199.9 to 999.9˚F

-199.9 to 300.0˚F

-300 to 1560˚F

-199.9 to 999.9˚F

-199.9 to 300.0˚F

Scaling is enable in the

following 4 range.

-1999 to 9999

-199.9 to 999.9

-19.99 to 99.99

-1.999 to 9.999

At or above 0˚C ±0.1% ±1 digit of F.S.

Below 0˚C, ±0.2% ±1 digit of F.S.

At or above 400˚C ±0.15% ±1 digit of F.S.

Below 400˚C ±5% ±1 digit of F.S.

±0.15% ±1 digit of F.S.

±0.1% ±1 digit of F.S.

Below 0˚C ±0.25% ±1 digit of F.S.

At or above 0˚C ±0.1% ±1 digit of F.S.

Below 0˚C ±0.2% ±1 digit of F.S.

±0.2% ±1 digit of F.S.

±0.1% ±1 digit of F.S.

At or above 800˚C ±0.5% ±1 digit of F.S.

Below 800˚C, not guaranteed

±0.2% ±1 digit of F.S.

±0.1% ±1 digit of F.S. (Note1) (Note2)

±0.2% ±1 digit of F.S. (Note1)

±0.1% ±1 digit of F.S. (Note1) (Note2)

±0.2% ±1 digit of F.S. (Note1)

±0.1% ±1 digit of F.S.

Instrument accuracy

*1

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05E01D02-01E

1st Edition Mar.31, 2000-00

Page 6

<<Contents>> <<Index>>

6

Contact Inputs

Usage: Program pattern selection, program operation

hold mode switching, display key lock

parameter enabled/disabled switching

Number of inputs: 2 points

Input type: non-voltage contact input or transistor open

collector input

Input contact capacity: 12 V DC, 10 mA or more (for non-

voltage contact input)

On/off detection:

For non-voltage contact input,

ON=contact resistance of 1kΩ or less,

OFF=contact resistance of 20kΩ or more.

For transistor open collector input,

ON=2V or less,

OFF=leak current of 100µA or less.

Minimum retention time for status detection: about 1 s

Contact Outputs

Usage: Event output

Number of relay contact outputs: 3 points

Relay contact rating: 240 V AC 1A, or 30 V DC 1A,

make contact

● Display Specifications

Process variable display unit:

4-digit 7-segment red LED; each digit 20 mm

in height

Parameter display:

4-digit 7-segment red LED; each digit 9.3 mm

in height

Status indicating lamps: LEDs

● Conformance to Safety and EMC Standards

Safety standard:

Conforms to IEC1010-1: 1990 and EN61010-

1: 1992.

Certified for CSA1010. The voltage category

of each input is CAT II (IEC1010-1)

Certified for UL 508 application

EMC standards:

Conforms to the following standards.

During test, the controller continues to operate

with the measurement accuracy within ±20%

of the range.

EMI (Emission) EN61326-1: 1997+Am1: 1998

EMS (immunity) EN61326-1: 1997+Am1: 1998

● Construction, Installation, and Wiring

Structure: Dust-proof and Drip-proof front panel

conforming to IP55.

For side-by-side close installation, the

controller loses its dust-proof and drip-proof

Body construction: ABS resin and polycarbonate

Case color: Black

Weight: Approx. 1 kg or less

Dimensions: 96W × 96H × 100D (from the front panel)

Mounting: Direct panel mounting; mounting bracket, one

Panel cutout dimensions:

Mounting attitude: Up to 30 degrees above the horizontal.

Wiring: M3.5 screw terminal (signals, power supply/

protection.

(mm)

each for upper and lower mounting.

92

+0.8

0

(W) ×

92

+0.8

(H) mm

0

No downward tilting allowed.

ground)

● Power Supply / Isolation

Power supply: Voltage rating at 100 to 240 V AC (±10%),

50/60 Hz

Power consumption: MAX. 20VA (MAX. 8.0W)

Memory back-up: Non-volatile memory (Service life

approx. 100,000 times of writings)

Withstanding voltage:

Between primary terminal and secondary terminal:

1500V AC for 1 min. (Note)

Between primary terminal and ground terminal:

1500V AC for 1 min. (Note)

Between ground terminal and secondary terminal:

1500V AC for 1 min.

Between two secondary terminals:

500V AC for 1 min

Primary terminal: Power supply, relay output

Secondary terminal:

Analog input/output signal terminals,

voltage pulse output terminal, contact

input terminal

Note. The withstanding voltage is specified as 2300V AC

perminute to provide amargin of safety .

Isolation resistance:

Between power supply terminal and ground

terminal, 500 V DC 20 MΩ

Ground: class 3 grounding (grounding resistance of

100Ω or less)

Isolation Specifications:

Measured input terminal:

Isolated from other input/output terminals.

Not isolated from internal circuit.

Control output (current or voltage pulse output) and

retransmission terminals: Not isolated

between control and retransmission output

terminal mutvally, output terminals, Isolated

from other input/output terminals and

internal circuit.

Relay contact control output terminals:

Isolated from other I/O terminals and

internal circuits.

Contact input terminal:

Not isolated from contact input terminals

mutually and communication terminals.

Isolated from other input/output terminals

and internal circuit.

Relay contact event output terminal:

Isolated from other input/output terminals

and internal circuit.

RS-485 communication terminal:

Not isolated from contact input terminals.

Isolated from other input/output, ground and

internal terminals.

Power supply terminal:

Isolated from other input/output and ground

terminals, and internal circuit.

Ground terminal:

Isolated from other input/output and ground

terminals, and internal circuit.

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05E01D02-01E

1st Edition Mar.31, 2000-00

Page 7

<<Contents>> <<Index>>

7

● Environmental Conditions

Normal operating conditions:

Ambient temperature: 0° to 50°C (less than 40°C when

Ambient temperature change limit:10°C/h or less

Ambient humidity: 20 to 90% RH (non-condensing)

Magnetic field: 400 A/m or less

Continuous vibration (5 to 14 Hz):

Continuous vibration (14 to 150 Hz):

Short-period vibration: 14.7 m/s2, 15s. or less

Shock: 147 m/s

Installation altitude:

Warm-up time: 30minutes or more

mounted side by side)

Amplitude of 1.2 mm or less

2

or less

4.9 m/s

2

or less, 11 ms.

2,000 m above sea level maximum

Transit/storage conditions:

Temperature: -25° to 70°C

Temperature change limit:20°C/h or less

Humidity: 5 to 95% RH (non-condensing)

Effects on operating conditions

Effect of ambient temperature:

For voltage/TC input, within ±1µV/°C and ±0.01% of

F.S./°C, whichever is greater.

For RTD input, within ±0.05 °C/°C (ambient tempera-

ture)

For analog output, ±0.05% of F.S./°C or less

Effect of power supply fluctuation (within rated voltage

range):

For analog input, within ±1µV/10V and ±0.01% of

F.S./10V, whichever is greater.

For analog output, within ±0.05% of F.S./10V

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05E01D02-01E

1st Edition Mar.31, 2000-00

Page 8

<<Contents>> <<Index>>

■Function Block Diagram for Single-loop Control

PV input

terminals , and

12 1311

Contact input

8

INPUT

Input selection

Unit selection

Input range conversion

Input bias

Input filter

Preset output

Program

pattern selection

Start program 1

when DI1=ON

Program 1

operation

Control computation

Output limiter

RUNSTOP

RESET

OT

PRG1

PRG2

Start program 2

when DI2=ON

Program 2

operation

Loop

power supply

DI2DI1

Hold program

Retransmission

output

PV event output

Time event output

Control

output

OUTPUT1 OUTPUT1

Current or pulse

terminals

1716

and

Relay

terminals

2 31

, and

Terminal Parameter Function

Legend

Analog signal Contact signal Front panel key

* DIS is a setup parameter.

Changing DIS setpoint allows you to change the function of external contact input.

Correspondence between parameter DIS and external contact input functions

When DIS=OFF (Factory-set default)

No function

No function

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

Reset program 1 when DI1 = OFF

Reset program 2 when DI2 = OFF

When DIS=1

Start program 1 when DI1 = ON

Start program 2 when DI2 = ON

Hide setup parameter lock when DI1 = ON

Show setup parameter lock when DI1 = OFF

RET

Current

terminals

and

RET

1514

When DIS=2

No function

PVE1

PV

event 1

GS 05E01D02-01E

PVE2

PV

event 2

When DIS=3

Start program 1 when DI1 = ON

Reset program 1 when DI1 = OFF

Hold program when DI2 = ON

Cancel hold when DI2 = OFF

1st Edition Mar.31, 2000-00

TME

Time

event

Page 9

<<Contents>> <<Index>>

1

2

3

4

5

6

7

8

9

10

21

22

23

24

25

26

27

28

29

30

11

12

13

14

15

16

17

18

19

20

12

13

14

15

100

Two-wire transmitter

PV input

0.4 to 2.0 V DC signal

Loop power

supply

14.5 to

18.0 V DC

External

resistor

(Note)

Note: Connecting a 100

resistor to the terminals is optional.

Model: X010-100-2 (resistor with M3.5 crimp-on terminal lugs)

15 V DC Power Supply Wiring to Two-wire Sensor

4-20mADC

OT=0 (factory-set default)

Time proportional control

Relay output (terminals , and )

OT=1

Correspondence

between parameter OT and control output types

Time proportional control

Voltage pulse output (terminals and )

OT=2

Current output

(terminals and )

OT=3

On-off control

Relay output (terminals , and )

* OT is a setup parameter.

You can change the settings of the parameter OT to change the control output types.

1

2

3

16

17

16

17

1

2

3

Contact rating: 12 V DC, 10 mA or more

19

18

Correspondence between parameter DIS and external contact input functions

20

When DIS=3

DI1

DI2

COM

Common

Start program 1 when DI1 = ON

Reset program 1 when DI1 = OFF

Hold program when DI2 = ON

Cancel hold when DI2 = OFF

When DIS=2

Hide setup parameter lock when DI1 = ON

Show setup parameter lock when DI1 = OFF

Common

When DIS=OFF (Factory-set default)

No function

No function

Common

When DIS=1

Start program 1 when DI1 = ON

Reset program 1 when DI1 = OFF

Start program 2 when DI2 = ON

Reset program 2 when DI2 = OFF

Common

19

18

20

DI1

DI2

COM

+5V

+5V

Contact

Transistor contact

* DIS is a setup parameter.

Changing DIS setpoint allows you to change the function of external contact input.

No function

6

5

Event output

4

7

PVE1

PVE2

TME

COM

Relay contact rating: 240 V AC, 1 A

30 V DC, 1 A (resistance load)

Relay

PV event-1 output

PV event-2 output

Time event output

Common

UP

UP

8

9

Power supply

10

L

N

Allowable range: 100 to 240 V AC (

10%)

(free voltage)

50/60 Hz shared

Power supply

CAUTION

Before carrying out wiring, turn off the power

to the controller and check that cables to be

connected are not alive with a tester or the like

because there is a possibility of electric shock.

16

17

Current/voltage

pulse output

4-20 mA DC,

voltage pulse

(12 V)

Control output

+

-

Note:Select the control output

type from the OT

parameter.

14

15

Retransmission output

4-20 mA DC

14

15

15 V DC loop power supply

14.5-18.0VDC

(21 mA DC max.)

* PV retransmission is configured at factory

before shipment.

Load resistance: 600

Ω or less

* If 15 V DC loop power supply is used,

retransmission output cannot be used.

-

+

-

+

12

13

TC input

11

12

RTD input

13

12

13

mV/V input

Installation category (overvoltage category): II (IEC1010-1)

A

b

B

NOTE

-

+

-

+

12

13

Note: Connecting a 250

Ω resistor to the terminals is

optional.

Model: X010-250-2 (resistor with M3.5 crimp-on terminal

lugs)

*

When receiving 4-20 mA DC current signals,

set the PV input type to 1-5 V DC (setpoint 41 ).

䊏

Receiving 4-20 mA DC Current

Signals with the Controller

250 Ω

4-20mA

PV input

* Not configured at factory before shipment

-

+

23

24

RS-485 communication

* Wiring can only be carried out

for controllers with communication

functions.

Maximum baud rate: 9600 bps

25

26

27

SDB(+)

SDA(-)

RDB(+)

RDA(-)

SG

1

2

Relay contact output

3

Control output

NC

NO

COM

Contact rating: 250 V AC, 3 A

30 V DC, 3 A (resistance load)

Note: Select the control output type

from the OT parameter.

* Time proportional PID relay contact

output is configured at factory

before shipment.

9

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation GS 05E01D02-01E

■UP350 Standard Type, Terminal Arrangements.

1st Edition Mar.31, 2000-00

Page 10

<<Contents>> <<Index>>

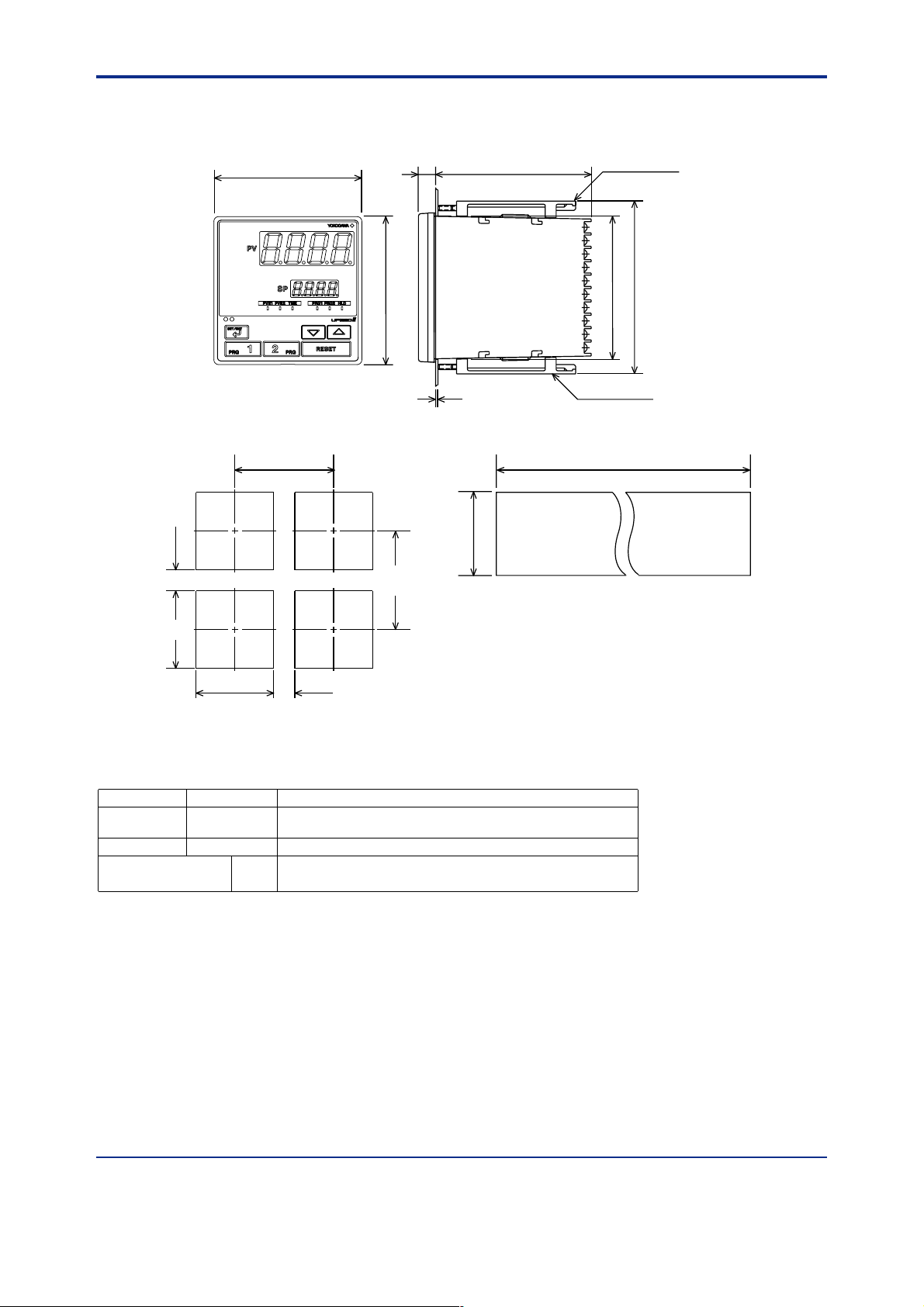

■ External Dimensions and Panel Cutout Dimension

10

UP350

(53)

+0.8

92

0

96

96

11

100

Large bracket

112

91.8

Small bracket

1 to 10 mm (Panel thickness)

General installation Side-by-side close installation

+0.8

0

145 min.

[(N-1)96+92]117 min.

0

+0.8

92

"N" stands for the number of controllers to be

installed.

However, the measured value applies if N 5.

Unit: mm

92

+0.8

0

(25)

■Model and Suffix Codes

Model Suffix Code Description

UP350

Type -0 Standard type

Optional functions

Program controller (provided with retransmission output and

15 V DC loop power supply as standard)

0 None

1 With communication

Standard accessories: Brackets (mounting hardware), unit label, User’s Manuals, and User’s Manual (reference) (CD-ROM

version).

■Items to be specified when ordering

Model and suffix codes, necessary/unnecessary of User’s Manual or QIC.

All Rights Reserved. Copyright © 2000, Y okogawa M&C Corporation

GS 05E01D02-01E 1st Edition Mar.31, 2000-00

Loading...

Loading...