Page 1

UM330/350 CONFIGURATION GUIDE

Congratulations on your purchase of the finest indicating product

available. This Short Form Configuration Guide is designed to speed

your configuration and operation. For additional information,

please see the Instruction Manual

.

SF UM330/UM350

August 17, 1999

Page 2

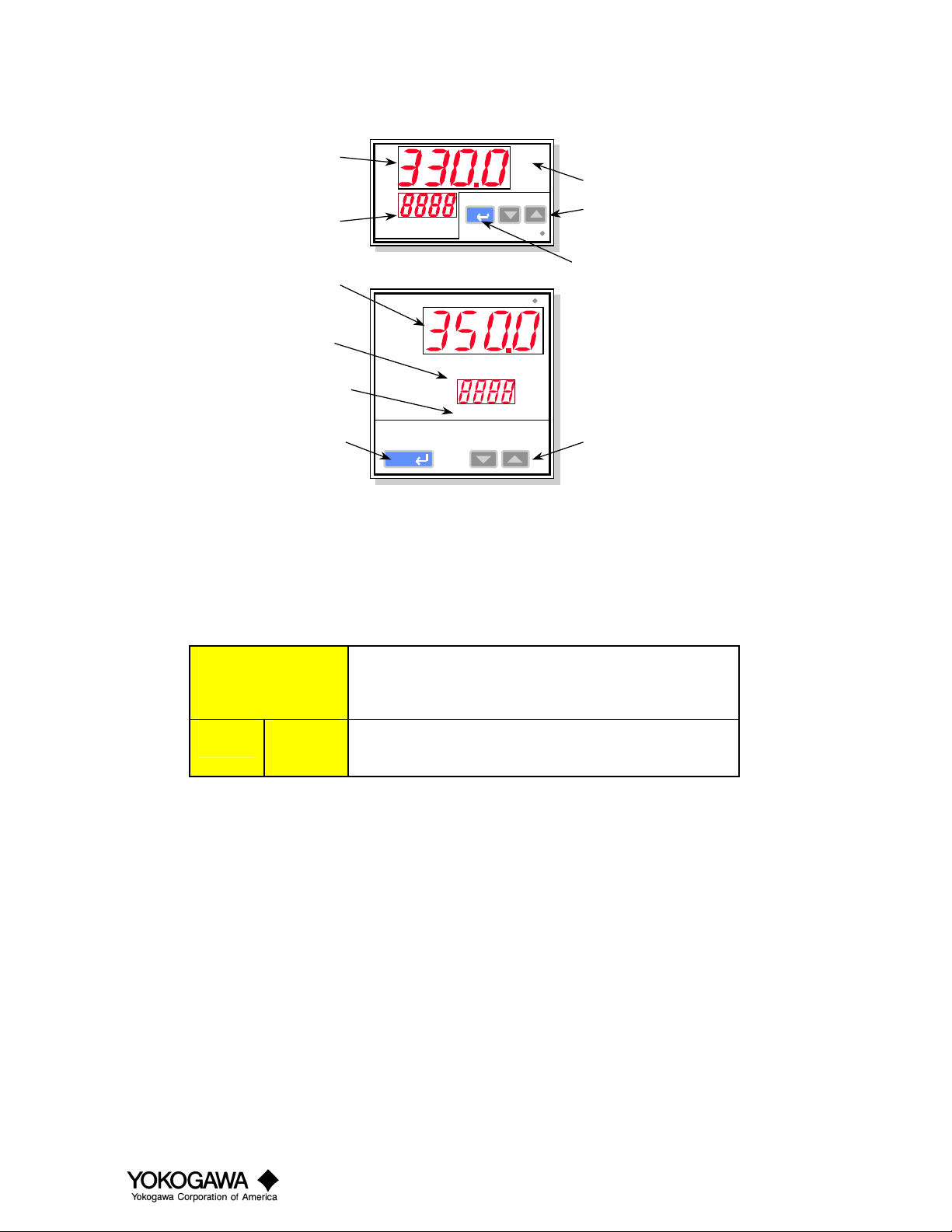

Front Panel

Process Value

parameter type

indicator

Parameter

indicator

Process Value

parameter type

indicator

Parameter

indicator

Alarm LED’s

Set/Enter

key

PV

PV

SET/ENT

SET/ENT

UM330

UM330

AL1 2 3 4

UM350

YOKOGAWA

YOKOGAWA

AL1

2

3

4

Alarm LED’s

Set keys

Set/Enter

key

UM350

Set keys

Key Function

Set/Enter

″″″″

▲

Used to select a parameter or set a parameter. Hold

down for 3 seconds to enter the configuration mode.

▼

Used to change values. Pressing and holding causes the

speed of charging to increase.

Configuration

It is important that the controller be set up in the following manner. Failure to do so could result in incorrect

operation, as changing some parameters will change other related parameters.

1. Apply power (See Wiring Diagram, page 8)

2. Set I.O. parameters

3. Set functional parameters

4. Set operation parameters

5. Operate your process

1

SF UM330/UM350

August 17, 1999

Page 3

Parameter Flow Charts

The UM330/UM350 have a number of software parameters which may or may not be required depending on your

particular application.

A1

A2

A3

A4

PEAK

BOTM

FL

BS

Operating Display

Press the SET/ENT for 3 seconds.

OP.PA STUP

Press the

Press the SET/ENT key (for less than

3 seconds) to move between any of the

parameters.

*

These are the operating

parameters. They may

be set after I/O and

functional parameters.

key

These are the

functional

parameters set

them second.

These are the

input/output

parameters.

Set them first.

Enter the

password

FUNC I/O

AL1

AL2

AL3

AL4

HY1

HY2

HY3

HY4

P.SL

BPS

PRI

STP

DLN

ADR

RP.T

TEST

*

*

*

*

*

*

*

*

IN

UNIT

RH

RL

SDP

SH

SL

RJC

BSL

RET

RTH

RTL

DIS

C.S1

C.S2

C.S3

C.S4

LOCK

PWD

* Available on units with options.

2

SF UM330/UM350

August 17, 1999

Page 4

SF UM330/UM350

August 17, 1999

Input/Output I/O Menu

Type Symbol

IN

UNIT

RH

RL

SDP

SH

SL

3

RJC

BSL

Setup parameters

RET

RTH

RTL

DIS

C.S1

CS2

C.S3

C.S4

LOCK

PWD

Input type

Input unit selection

Range high

Range low

Scale decimal point selection

Scale high (displays when voltage input

is selected)

Scale low

Reference junction compensation

Burnout selection

Retransmission type

Retransmission high

Retransmission low

Digital input s election

Custom SELECT display 1 selection

Custom SELECT display 2 selection

Custom SELECT display 3 selection

Custom SELECT display 4 selection

Key lock

Password

Description

Select from table I

ΕF, ΕC

Thermocouple and RTD: Decimal point

position of instrument range is fixed

(cannot be changed.) DC voltage: 0 to 3

DC voltage: -1999 to 9999

OFF, ON

0 (OFF); 1 (upscale); 2 (down scale)

1: PV; 4: LPS (Power supply for sensor)

EU (0.0 to 100.0%) however, RTL<RTH

0: OFF

1: Resets peak/bottom when DI1 is on.

Custom SELECT display definition;

Allows the operator access to any selected

parameters.

OFF; Parameter changes prohibited; 2:

Holding down SET/ENT key 3 seconds

prohibited; 3.

0: OFF

1 to 9999

Setting range

Default value

1

ΕC

Maximum of

instrument range

Minimum of

instrument range

Location of decimal

point for scale range;

DC voltage 1

When DC voltage is

selected: 100.0

When DC voltage is

selected: 0.0

ON

1

1

RH

RL

OFF

OFF

OFF

OFF

OFF

0

This sets the type of sensor input connected to the controller,

such as a type K thermocouple, 100 Ω RTD or 1-5 VDC signal.

Any range may be selected from table 1.

Select from ΕF or ΕC look up tables for thermocouples and

RTD=s only. Not used for linear inputs.

Maximum/minimum of selected range for thermocouples and

RTD=s. This will default to the range listed in table 1 but may

be set to any number within the setting range. For DCV inputs

this is used to set the voltage-input range. All within the

measurement range are acceptable.

This selects the number of decimal places used for instrument

scaling. 0: limits -1999 to 9999, 1: limits -199.9 to 999.9, 2:

limits -19.99 to 99.99, 3: limits -1.999 to 9.999.

For DCV inputs only. Allows setting of properly scaled units

such as for flow, temperature, level and pH applications. If 1-5

VDC represents 0 to 250.0 set SDP = 1, SH = 250.0 , and SL =

0.0

The RJC must be Αon≅ for thermocouples inputs to read

properly; Αoff≅ for multi thermocouple connections such as for

thermocouple bucking. RJC is not used for RTD or DCV

applications.

Burnout selection determines which way the PV will drive when

the sens or input circuit is opened. 1 will cause PV to drive to

maximum of range and display burnout. 2 will cause PV to

drive to minimum of range and display burnout.

Selects what is retransmitted to a recorder or other analog

device or whether loop power supply is to be used.

The maximum and minimum values for the retransmitted signal.

Up to 4 parameters may be set that operator level personnel may

need to access. Use the CS# in this manual or appendix 3 in the

IM. Ente r any address and the assigned parameter will appear

by pressing SET/ENT during normal operation.

Restricts access to various functions by locking out certain keys.

Password prohibits access to setup menus (I/O and functional)

for those who don t know the password.

Explanation

CS#

1201

1202

1204

1205

1206

1207

1208

1210

1209

1013

1014

1015

932

1036

Page 5

August 17, 1999

Functional (Func) Menu

Type

4

Note 1: These parameters will be displayed on the models with optional specifications.

The parameters in the table below are displayed in the ΑI/O≅ setting scree sub menu for setup parameters.

* See additional information in appendix, Page 8.

Symbol

AL1

AL2

AL3

AL4

HY1

HY2

HY3

HY4

P.SL

Setup Parameters

BPS

PRI

STP

DLN

ADR

RP.T

Description

Alarm 1 type

Alarm 2 type

Alarm 3 type

Alarm 4 type (see note 1)

Alarm 1 hysteresis

Alarm 2 hysteresis

Alarm 3 hysteresis

Alarm 4 hysteresis (see note

1)

Protocol selection (see note 1)

Communication speed (see

note 1)

Parity (see note 1)

Stop bit (see note 1)

Data length (see note 1)

Address (see note 1)

Minimum res ponse time (se e

note 1)

Off, 1, 2, 9, 10, 11, 12, 19, 20, 21, and 22

EUS (0.0 to 100.0%)

0: Personal computer linked communication

1: Personal computer linked communication

(sum checked)

2: Ladder communication

0: 600, 1: 1200, 2: 2400, 3: 4800, 4:9600

0: None, 1: Even 2: Odd

1, 2

Other than 7 or 8 (personal computer link)

1 to 99; however the maximum number of units

that can be connected is 31

0 to 10x10ms

Setting Range

Default value

EUS (0.5%)

1

2

1

1

0

4

1

1

8

1

0

Sets the type of alarm action desired as described in table II.

Sets the dead band or hysteresis of the alarms to avoid relay chattering or frequent

on/off/on/off activation. These are set in Engineering units.

Protocol selection - prompt appears only for units with communications option. Choices:

0: Connection to computer, basic module or touch screen.

1: Same as 0 when driver was written to use sum check capability. Consult driver

developer.

2: Direct connection to devices that support special BCD protocol such as Mitsubishi

Melsec PLC and some Yokogawa devices.

In most cases these communications parameters do not need to be adjusted other than the

address. Consult the developer of the driver or software package for the exact requirements.

Explanation

CS#

915

916

917

918

919

920

921

922

1247

1248

1249

1250

1251

1252

1253

SF UM330/UM350

Page 6

August 17, 1999

Operating Parameters

Type

Note 1: These parameters will be displayed on the models with optional specifications.

The parameters in the table below are displayed in the ΑI/O≅ setting scree sub menu for setup parameters.

* See additional information in appendix, Page 8.

5

Symbol

A1

A2

A3

A4

PEAK

BOTM

FL (*)

BS

Operating parameters

Setpoint value for alarm 1

Setpoint value for alarm 2

Setpoint value for alarm 3

Setpoint value for alarm 4 (see note 1)

Max value

Min value

PV inp ut filter

PV input bias

Description

Alarm for process variable value and setpoint

value: EU (-100.0 to 100.0%)

Deviation alarm: EUS (-100.0 to 100.0%)

Output value alarm: -5.0% to 105.0%

Displa y only

Displa y only

OFF, 1 to 120 sec.

EUS (-100.0 to 100.0%)

Setting range

Alarm fo r proc ess v aria ble valu e and

setpoint value: EU: (100.0%) Other

proce ss variable values and setp oint values:

EU (0.0%) Deviation alarm: EUS (0.0%)

OFF

EUS (0.0%)

Default value

This is the set poin t fo r yo ur a larms , and is se t in t he e nginee ring unit s us ed

(like ΕF)

Displa y max va lue o f inpu t since la st r ese t.

Displa ys min va lue o f inpu t sin ce la st r ese t.

The filt er will set tle dow n an e rra tic or b usy P V disp lay. Use t he smallest

filter to get the smooth result. Note: Excessive filter can be dangerous.

The bia s func tio n will co rrect t he PV rea ding for p oo r se nsor placement or

sensor errors. Use it to co rrect the reading to the value you want to read.

Explanation

CS#

231

232

233

234

235

236

244

243

SF UM330/UM350

Page 7

Table I - Input Selection

Input

Thermocouple

RTD

DC Voltage

Type

K

T

B

S

R

N

E

L (DIN)

U (DIN)

W (DIN)

Platinel 2

PR20-40

W97Re3W75Re25

Jpt100

Pt100

-10.00 to

20.00mV

0.0 to

100.0mV

0.400 to

2.000V

1.000 to

5.000V

0.000 to

2.000V

0.00 to

10.00V

Measurement range (ΕΕΕΕC) Measurement range (ΕΕΕΕF)

-200 to 1370ΕC

-199.9 to 999.9ΕC

-199.9 to 500.0ΕC

J

-199.9 to 999.9ΕC

-199.9 to 400.0ΕC

0.0 to 400.0ΕC

0 to 1800ΕC

0 to 1700ΕC

0 to 1700ΕC

-200 to 1300ΕC

-199.9 to 999.9ΕC

-199.9 to 900.0ΕC

-199.9 to 400.0ΕC

0.0 to 400.0ΕC

0 to 2300ΕC

0 to 1390ΕC

0 to 1900ΕC

0 to 2000ΕC

-199.9 to 500.0ΕC

-150.0 to 150.0ΕC

-199.9 to 640.0ΕC

-199.9 to 500.0ΕC

-150.0 to 150.0ΕC

Display range -1999 to 9999

-300 to 2500ΕF

0 to 2300ΕF

-199.9 to 999.9ΕF

-300 to 2300ΕF

-300 to 750ΕF

-199.9 to 750.0ΕF

32 to 3300ΕF

32 to 3100ΕF

32 to 3100ΕF

-300 to 2400 ΕF

-300 to 1800ΕF

-300 to 1300ΕF

-300 to 750ΕF

-19.9 to 750.0ΕF

32 to 4200ΕF

32 to 2500Ε

32 to 3400ΕF

32 to 3600ΕF

-300 to 1180ΕF

-199.9 to 300.0ΕF

-300 to 1180ΕF

-199.9 to 999.9ΕF

-199.9 to 300.0ΕF

At or above 400ΕC ∀ 0.15% ∀ 1 digit of F.S.

Measuring Accuracy

At or above 0Ε ∀0.1% ∀1 digit of F.S.

below 400ΕC ∀ digit of F.S.

∀0.15% ∀ 1 digit of F.S.

∀0.2% ∀ 1 digit of F.S.

At or above 0ΕC ∀ 0.1% ∀1 digit of F.S.

Below 0ΕC ∀0.2% ∀ 1 digit of F.S.

∀0.1% ∀ 1 digit of F.S.

∀ 0.1% ∀ 1 digit of F.S.

At or above 800ΕC ∀0.5% ∀ 1 digit of F.S.

below 800ΕC not guarante ed

∀0.2% ∀ 1 digit of F.S.

∀0.1% ∀1 digit of F.S.

∀0.2% ∀1 digit of F.S.

∀0.1% ∀ 1 digit of F.S.

∀0.2% ∀ 1 digit of F.S.

∀0.1% ∀ 1 digit of F.S.

Input range code

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

30

31

35

36

37

55

56

40

41

50

51

6

SF UM330/UM350

August 17, 1999

Page 8

TABLE II - ALARMS

Type of Alarm

Process Variable Alarms

High Level Alarm

Low Leve l Alarm

High Level Alarm

Low Leve l Alarm

Diagnosis Alarms

Self Diagnosis

Fail

Normally Open Closes on Alarm

Normally Open Closes on Alarm

Normally Closed Opens on Alarm

Normally Closed Opens on Alarm

Normally Open Closes on Alarm

Normally Closed Opens on Alarm

Action of Relay

Alarm always Active

1

2

9

10

21

22

Code

Standby on Startup

11

12

19

20

7

SF UM330/UM350

August 17, 1999

Page 9

Appendix

FL - Filter: The input filter will reduce the oscillation or fluctuation of the process value. Use the smallest filter that

accomplishes the desired result.

Wiring Diagram

8

SF UM330/UM350

August 17, 1999

Loading...

Loading...