Page 1

User’ s

Manual

GREEN Series

User ’s Manual

- Detailed Instruction -

IM 05J01B02-01E

IM 05J01B02-01E

5th Edition

Page 2

Page 3

GREEN Series

User’s Manual

- Detailed Instruction -

IM 05J01B02-01E 5th Edition

CONTENTS

Ref.1.1: References Related to PV Input ...................................................Ref. 1-1

Ref.1.1(1) Correcting the PV (1. Using PV input filter and PV input bias)............ Ref. 1-1

Ref.1.1(2) Correcting the PV (2.Using ten-segment linearizer biasing or

approximation)....................................................................................Ref. 1-4

Ref.1.1(3) Square-root extraction of PV ................................................................ Ref. 1-9

Ref.1.1(4) Changing the PV sampling period...................................................... Ref. 1-1 1

Ref.1.1(5) Checking that the changed PV sampling period is appropriate ....... Ref. 1-14

Ref.1.1(6) Correcting the input value from a sensor .......................................... Ref. 1-16

Ref.1.1(7) Using PV tracking function (UT only) .................................................Ref. 1-18

Ref.1.1(8) PV input range adjustment (When the UT/UP mode No. is 6, 7 or

12 only) ..............................................................................................Ref. 1-21

Toc-i

Ref.1.2: References Related to Remote Input......................................... Ref. 1-22

Ref.1.2(1) Setting remote input units, range and scaling................................... Ref. 1-23

Ref.1.2(2) Using square root extraction during remote input ............................ Ref. 1-27

Ref.1.2(3) Using remote setpoint filtering and ratio bias computing ................ Ref. 1-28

Ref.1.2(4)

Tracking target setpoint when switching from remote to local control .

Ref. 1-30

Ref.2.1: References Related to Control Output ........................................Ref. 2-1

Ref.2.1(1) Switching between Direct and Reverse Actions.................................. Ref. 2-2

Ref.2.1(2) Selecting PID Control Mode According to the Operating Condition ..Ref. 2-4

Ref.2.1(3) Using Control Output Limiter ...............................................................Ref. 2-8

Ref.2.1(4) Using Anti-reset Windup (Over-integration Prevention) Function ..... Ref. 2-9

Ref.2.1(5) Using “Super” (Overshoot Prevention) Function..............................Ref. 2-10

Ref.2.1(6) Using “Super2” (Hunting Prevention) Function ................................ Ref. 2-11

Ref.2.1(7) Using Split-signal Computation / Output Function ........................... Ref. 2-13

Ref.2.1(8) Setting Preset Output Values.............................................................. Ref. 2-16

Ref.2.1(9) Placing Control Output in Tracking Mode (for Cascade

Primary-loop Control or Loop Control for Backup) ........................ Ref. 2-18

Ref.2.1(10) Using Shutdown Function ................................................................ Ref. 2-19

Ref.2.2: References Related to Retransmission Output ........................ Ref. 2-20

Ref.2.2(1) Changing the type of retransmission output signal .......................... Ref. 2-21

Ref.2.2(2) Retransmitting Program Pattern 2 (for UP750/UP550 only) .............. Ref. 2-23

Ref.2.2(3) Using the Loop Power Supply Function ............................................ Ref. 2-24

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 4

Toc-ii

Ref.3.1: References Related to Contact Input........................................... Ref. 3-1

Ref.3.1(1) Changing contact input functions for the UT35h/UT32h.................... Ref. 3-2

Ref.3.1(2) Changing contact input functions for the UT450/UT420 .................... Ref. 3-5

Ref.3.1(3) Changing contact input functions for the UT550/UT551/UT520 ......... Ref. 3-9

Ref.3.1(4) Changing contact input functions for the UT750.............................. Ref. 3-14

(4-1): Changing contact input terminal assignments of the UT750 ............ Ref. 3-14

(4-2): Using contact I/O expansion module with the UT750 ...................... Ref. 3-18

(4-3): Using Interrupt-message functions with the UT750 ......................... Ref. 3-20

(4-4): Using Interrupt-operating display functions with the UT750............. Ref. 3-22

Ref.3.1(5) Changing contact input functions for the UP35h ............................. Ref. 3-24

Ref.3.1(6) Changing contact input functions for the UP550 ..............................Ref. 3-26

Ref.3.1(7) Changing contact input functions for the UP750 .............................Ref. 3-29

(7-1): Changing contact input functions for the UP750.............................. Ref. 3-29

(7-2): Using contact I/O expansion module with the UP750 ...................... Ref. 3-34

(7-3): Using Interrupt-message functions with the UP750......................... Ref. 3-36

(7-4): Using Interrupt-operating display functions with the UP750............. Ref. 3-39

Ref.3.2: References Related to Contact Output...................................... Ref. 3-40

Ref.3.2(1) Changing Contact Output Functions for the UT750, UT550, UT551

and UT520 .........................................................................................Ref. 3-41

(1) Single-loop control (UT mode 1).......................................................... Ref. 3-44

(2) Cascade, primary-loop control (UT mode 2)........................................ Ref. 3-45

(3) Cascade, secondary-loop control (UT mode 3) ................................... Ref. 3-45

(4) Cascade control (UT mode 4) ............................................................. Ref. 3-46

(5) Loop control for backup (UT mode 5) .................................................. Ref. 3-46

(6) Loop control with PV switching (UT mode 6) ....................................... Ref. 3-47

(7) Loop control with PV auto-selector (UT mode 7) ................................. Ref. 3-47

(8) Loop control with PV-hold function (UT mode 8).................................. Ref. 3-48

(9) Dual-loop control (UT mode 1 1 ) .......................................................... Ref. 3-48

(10) Temperature and humidity control (UT mode 12)............................... Ref. 3-48

(1 1) Cascade control with two universal inputs (UT mode 13)................... Ref. 3-49

Loop control with PV switching and two universal inputs (UT mode 14) ..

(12)

Loop control with PV auto-selector and two universal inputs (UT mode 15).

(13)

(14) Custom computation control (UT mode 21) ....................................... Ref. 3-49

Ref.3.2(2) Changing Contact Output Functions in the UP750 and UP550 ........Ref. 3-50

(1) Single-loop control (UP mode 1) ......................................................... Ref. 3-51

(2) Cascade, primary-loop control (UP mode 2)........................................ Ref. 3-52

(3) Cascade control (UP mode 4) ............................................................. Ref. 3-53

(4) Loop control with PV switching (UT mode 6) ....................................... Ref. 3-53

(5) Loop control with PV auto-selector (UP mode 7) ................................. Ref. 3-54

(6) Dual-loop control (UP mode 1 1) This function is for the UP750 only..... Ref. 3-55

(7) Temperature and humidity control (UP mode 12)

This function is for the UP750 only . .......................................... Ref. 3-55

Ref. 3-49

Ref. 3-49

IM 05J01B02-01E

5th Edition : Mar.25,2005-00

Page 5

Toc-iii

(8) Cascade control with two universal inputs (UP mode 13) .................... Ref. 3-56

Loop control with PV switching and two universal inputs (UP mode 14) ....

(9)

(10)

Loop control with PV auto-selector and two universal inputs (UP mode 15).

(1 1) Custom computation control (UP mode 21) ....................................... Ref. 3-56

Ref.3.2(3) Using the I/O Expansion Module with UT750 and UP750 .................. Ref. 3-57

Ref.3.3: References Related to Alarms ................................................... Ref. 3-62

Ref.3.3(1) Setting Alarm T rigger Conditions....................................................... Ref. 3-63

Ref.3.3(2) Setting Alarm hysteresis ON/OFF range............................................ Ref. 3-65

Ref.3.3(3) Using the alarm timer (Control stable signal event) .......................... Ref. 3-67

Ref.3.3(4) Using the sensor ground alarm .......................................................... Ref. 3-70

Ref.3.3(5) Using the heater burnout alarm (UT35u and UT32u only)................. Ref. 3-75

Ref.3.4: References Related to Instrument Alarms and Events............. Ref. 3-77

Ref.3.4(1) Using Instrument Alarms .................................................................... Ref. 3-78

Ref.3.4(2) Setting the Operating Conditions of Instrument Alarms................... Ref. 3-83

Ref.3.4(3) Setting Hysteresis (On-off Bandwidth) of an Instrument Alarm ....... Ref. 3-84

Ref.3.4(4) Using the Sensor Ground Alarm.........................................................Ref. 3-86

Ref.3.4(5) Using PV Events ..................................................................................Ref. 3-90

Ref.3.4(6) Using Time Events ..............................................................................Ref. 3-97

Ref.3.4(7) Using Local Events ...........................................................................Ref. 3-101

Ref. 3-56

Ref. 3-56

Ref.4.1: References Related to T arget Setpoints...................................... Ref. 4-1

Ref.4.1(1) Using Multiple T arget Setpoints (8 Max.).............................................. Ref. 4-2

Ref.4.1(2) Selecting PID selection method (T arget SP selection, Zone PID or

Selection by specified PID number)................................................. Ref. 4-10

Ref.4.1(3) Limiting Changes in T arget Setpoints................................................ Ref. 4-17

Ref.4.1(4) Setting ramp grades when switching between target setpoints ......Ref. 4-18

Ref.5.1: References Related to Segment Operation................................. Ref. 5-1

Ref.5.1(1) Selecting Segment time between Time and Ramp time ...................... Ref. 5-1

Ref.5.1(2) Selecting PID control between Zone and Segment .............................Ref. 5-7

Ref.5.2: References Related to Program Setup ...................................... Ref. 5-10

Ref.5.2(1) Selecting Program Start Condition ....................................................Ref. 5-10

Ref.5.2(2) Using the Delayed Start Timer for Programmed Operation .............. Ref. 5-17

Ref.5.2(3) Selecting Segment-end Condition .....................................................Ref. 5-18

Ref.5.2(4) Using the Wait Function......................................................................Ref. 5-24

Ref.5.2(5)

Ref.5.2(6) Using the Repeat Functions ...............................................................Ref. 5-34

Ref.5.2(7) Using the Advance Functions.............................................................Ref. 5-37

Ref.5.2(8) Signal Output at Program end ............................................................Ref. 5-39

Ref.5.2(9) Operation in Local Mode (with Constant T arget Setpoint) ................ Ref. 5-41

Ref.5.2(10) Starting the Program Operation at Any Segment ............................ Ref. 5-44

Ref.5.2(11) Operation with Linked Program Patterns (Pattern-link) .................. Ref. 5-46

Using the Hold Functions (Changing Segment Setpoint in Hold Status)

Ref. 5-30

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 6

Toc-iv

Ref.5.3: Handy Features for Creating and Editing Programs................. Ref. 5-48

Ref.5.3(1) Checking the T otal Number of Unused Segments.............................Ref. 5-48

Ref.5.3(2) Checking the number of segments in a specific Program Pattern ... Ref. 5-50

Ref.5.3(3) Checking the number of all unused events ....................................... Ref. 5-51

Ref.5.3(4) Copying Program Patterns ................................................................. Ref. 5-53

Ref.5.3(5) Deleting Program Patterns .................................................................Ref. 5-55

Ref.5.3(6) Adding (Inserting)/Deleting segments in Program Patterns............. Ref. 5-57

Ref.6.1: References Related to Displays................................................... Ref. 6-1

Ref.6.1(1) Using SELECT Displays........................................................................ Ref. 6-2

Ref.6.1(2) Changing Contents of Deviation Trend Display (for UP750, UP550

and UT750 only) .................................................................................. Ref. 6-5

Ref.6.1(3) Changing Deviation Display Range of Deviation Monitor

(for UT750, UT550, UT551 and UT450 only) .......................................Ref. 6-7

Ref.7.1: References Related to Security ...................................................Ref. 7-1

Ref.7.1(1) Setting a password to prevent unauthorized changes to

setup parameters................................................................................ Ref. 7-1

Ref.7.1(2) Using the keylock function to prevent unauthorized key operation... Ref. 7-2

Ref.8.1: Outline of Registers and I - relays................................................Ref. 8-1

Ref.8.1(1) Outline of Registers and I - relays ........................................................Ref. 8-2

Ref.8.1(2) D-register Outline and D-register Map .................................................Ref. 8-3

UP750,UP550 D-register Map.................................................................... Ref. 8-4

UP35 D-register Map .............................................................................. Ref. 8-8

UT750, UT55, UT520 D-register Map.................................................... Ref. 8-12

UT450,UT420 D-register Map .................................................................. Ref. 8-16

UT35, UT32 D-register Map .............................................................. Ref. 8-19

Ref.8.1(3) B-register Outline and B-register Map ...............................................Ref. 8-23

UP750,UP550 B-register Map.................................................................. Ref. 8-24

Ref.8.1(4) I-relay Outline and I-relay Map ............................................................ Ref. 8-26

UP750, UP550 I-relay Map...................................................................... Ref. 8-28

Ref.8.1(5) I-relay Timer setting............................................................................. Ref. 8-33

Revision Information ............................................................................................ i

IM 05J01B02-01E

5th Edition : Mar.25,2005-00

Page 7

<Toc> <Ref. 1.1: References Related to PV Input>

Ref.1.1: References Related to PV Input

Ref. 1-1

IMPORTANT

UP750

UP750-

Note: The functions discussed in this section apply to all the models of UT and UP series.

UP550

UP550-

However, some of the functions are unavailable with certain models.

Such models, if any, will be clearly noted in each of the following items from (1) to (8).

UP35

UP35-

: Applicable models of this section

UT750

UT750-

UT5

UT55-

UT520-

UT40

UT450-

UT420-

UT3

UT35-

UT32-

These sections provide references related to PV input, such as PV correction, listed below.

Only read the following descriptions if necessary and carry out the required operation.

(1) Correcting the PV (1. Using PV input filter and PV input bias)

(2) Correcting the PV (2. Using ten-segment linearizer biasing or approximation)

(3) Square-root extraction of PV

(4) Changing the PV sampling period

(5) Checking that the changed PV sampling period is appropriate

(6) Correcting the input value from a sensor

(7) Using PV tracking function (UT only)

(8) PV input range adjustment (when the UT/UP mode No. is 6, 7 or 12 only)

UM3

None

<<Ref.1.1: References Related to PV Input>>

Ref.1.1(1) Correcting the PV (1. Using PV input filter and PV input bias)

Filtering and biasing functions are available with all the UT/UP series models.

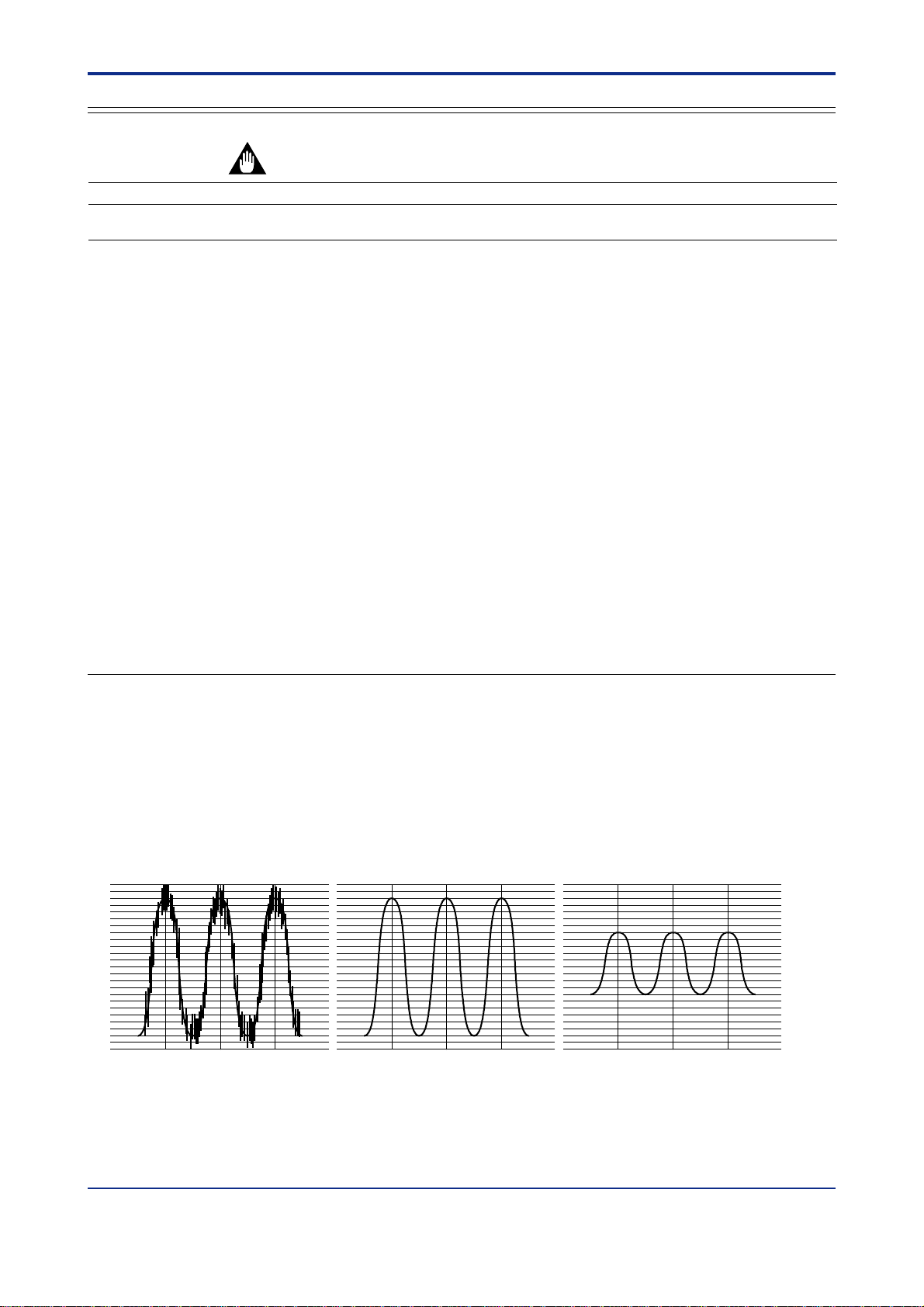

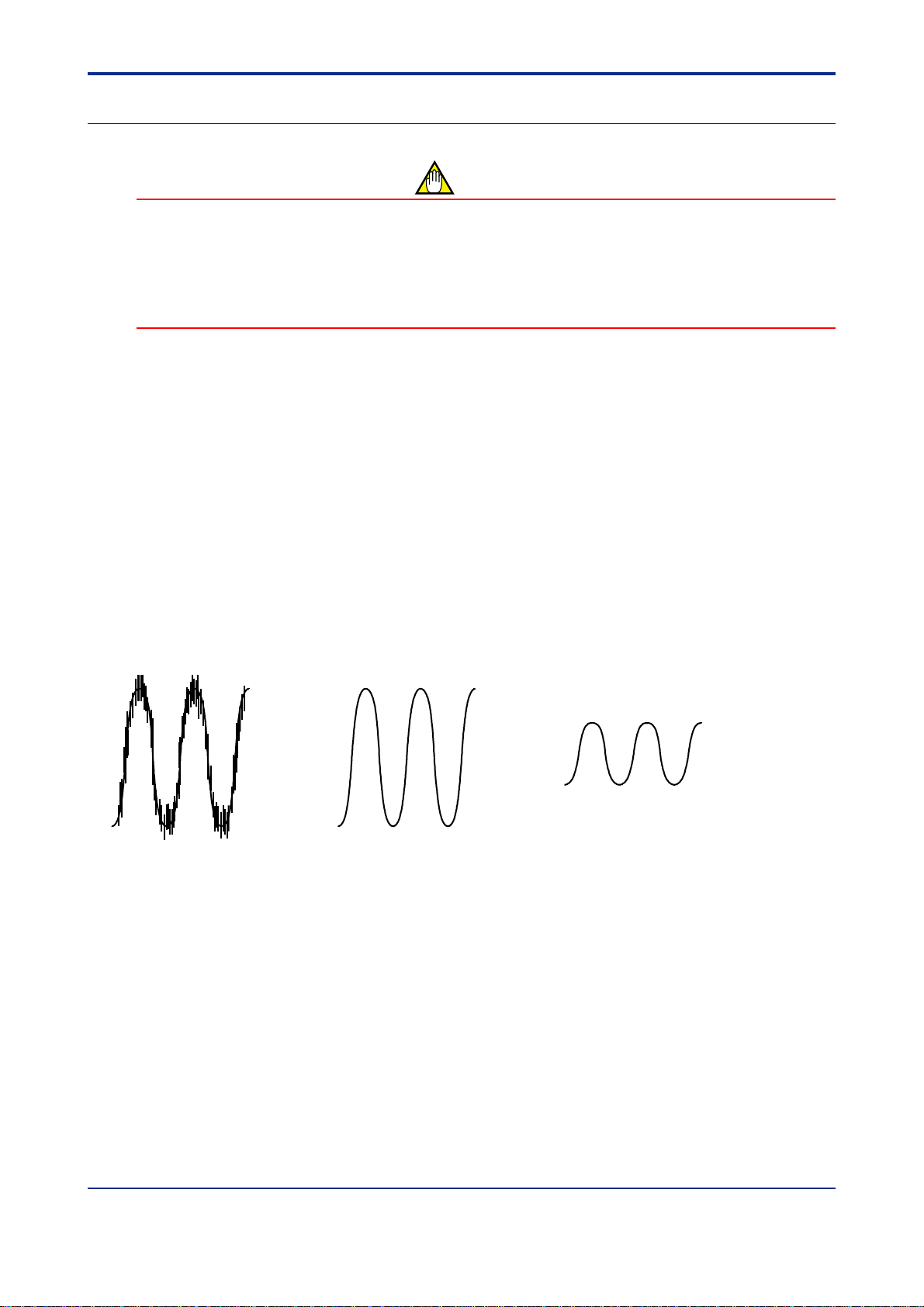

■ PV input filtering can be used to remove noise from a PV input that contains high frequency noise,

such as flow rate and pressure signals.

The PV input filter provides first-order-lag computation.

Setting a larger time constant (as a parameter value) can increase the amount of noise removed.

This filtering is also used to improve controllability and for phase compensation.

The time constant of the PV filter is offered as an operating parameter and can be changed during operation.

Actual input With a small time constant With a large time constant

Fig. 1-1-1

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 8

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-2

■ PV input biasing adds a constant bias value to the PV input value, and the result is used for the

controller display and control computation.

PV input value PV value inside the controllerPV input bias

+

=

In some cases, the measured value is smaller than the actual value by a constant amount due to the physical

circumstances at the sensor point.

For example, the ambient temperature inside a furnace is often measured instead of the material’s temperature.

In such cases, add a constant value for biasing.

When the PV value is within the allowable accuracy range but there is a dispersion in PV readings between other

equipment, it is possible to use this function for fine adjustment.

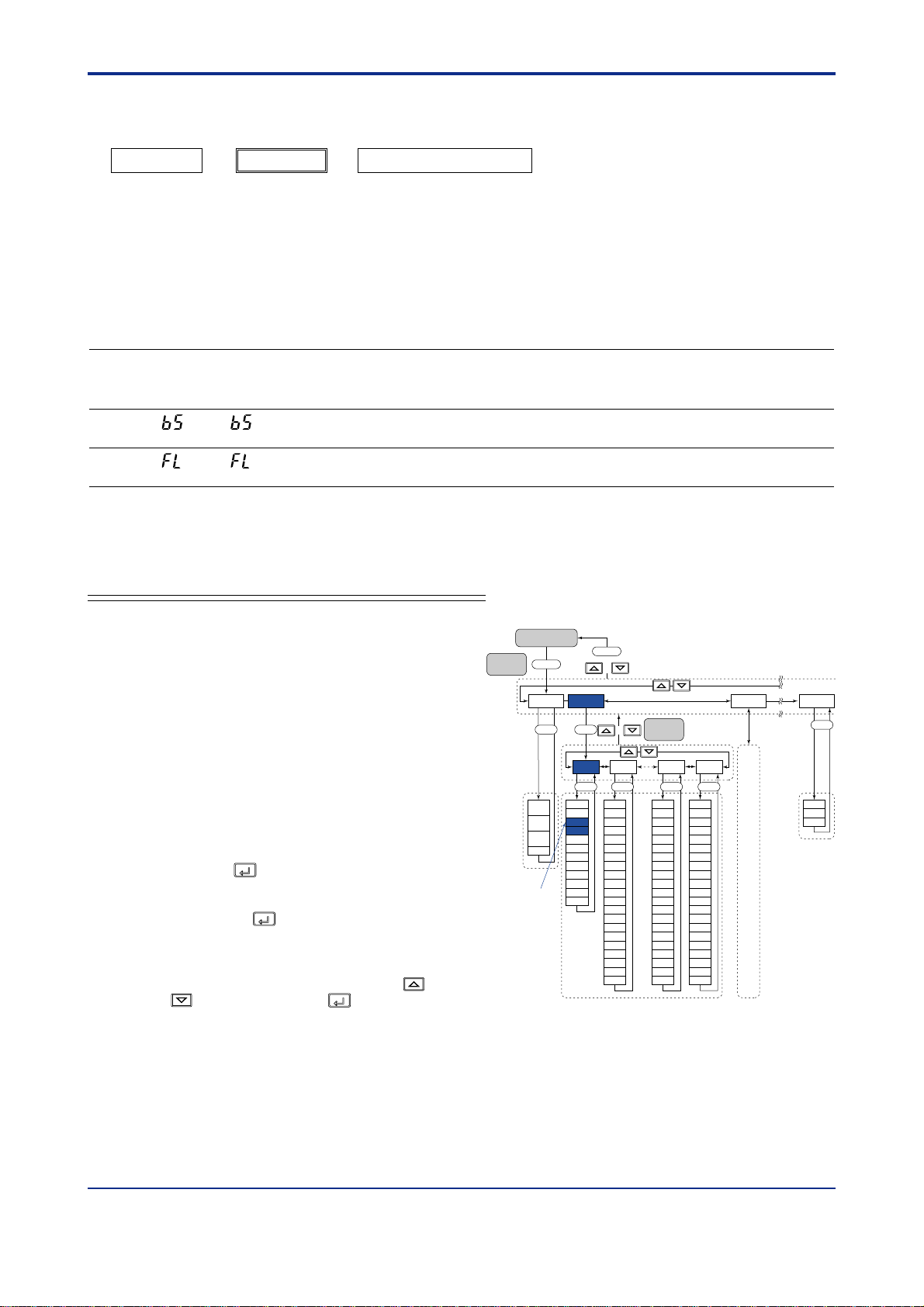

● The following parameters are used.

• Operating parameters (Operation-related parameters): BS and FL

UP750

UP550

UT750

Code

BS

FL

UT5

UT40

Code

(BS) (BS)

(FL) (FL)

UP35

UT3

Code

Description

PV input bias

PV input filter

Setting range

-100.0 to 100.0% of

input range span

OFF or 1 to 120 s

Default

0.0% of input

range span

OFF

(No filtering)

D-register No.

243,

273(Note1)

244,

274(Note2)

Note1: For dual-loop control of UP750 and UT750, the D-register number of loop-2 BS is 273.

Note2: For dual-loop control of UP750 and UT750, the D-register number of loop-2 FL is 274.

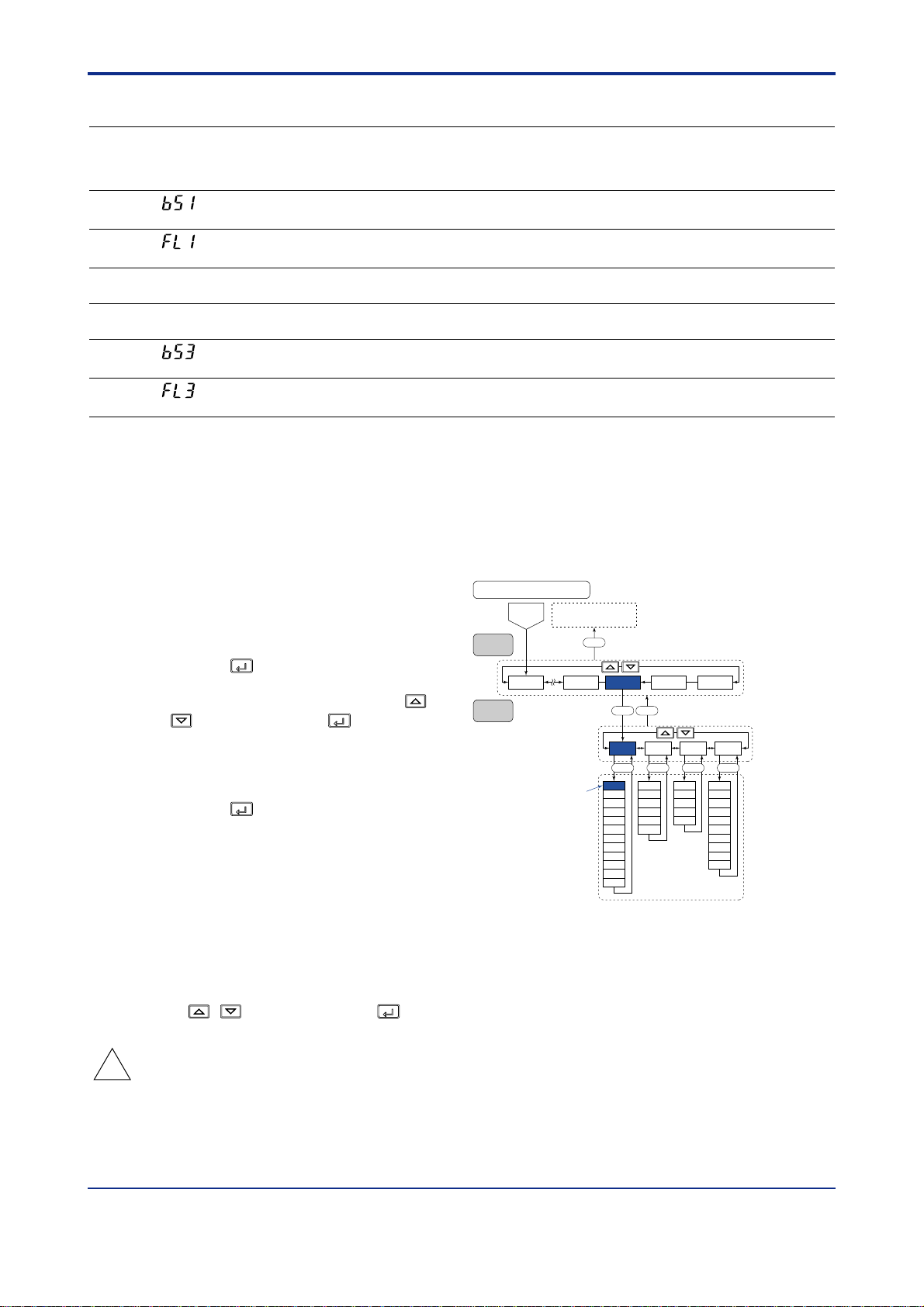

T o set the parameters, carry out the following steps.

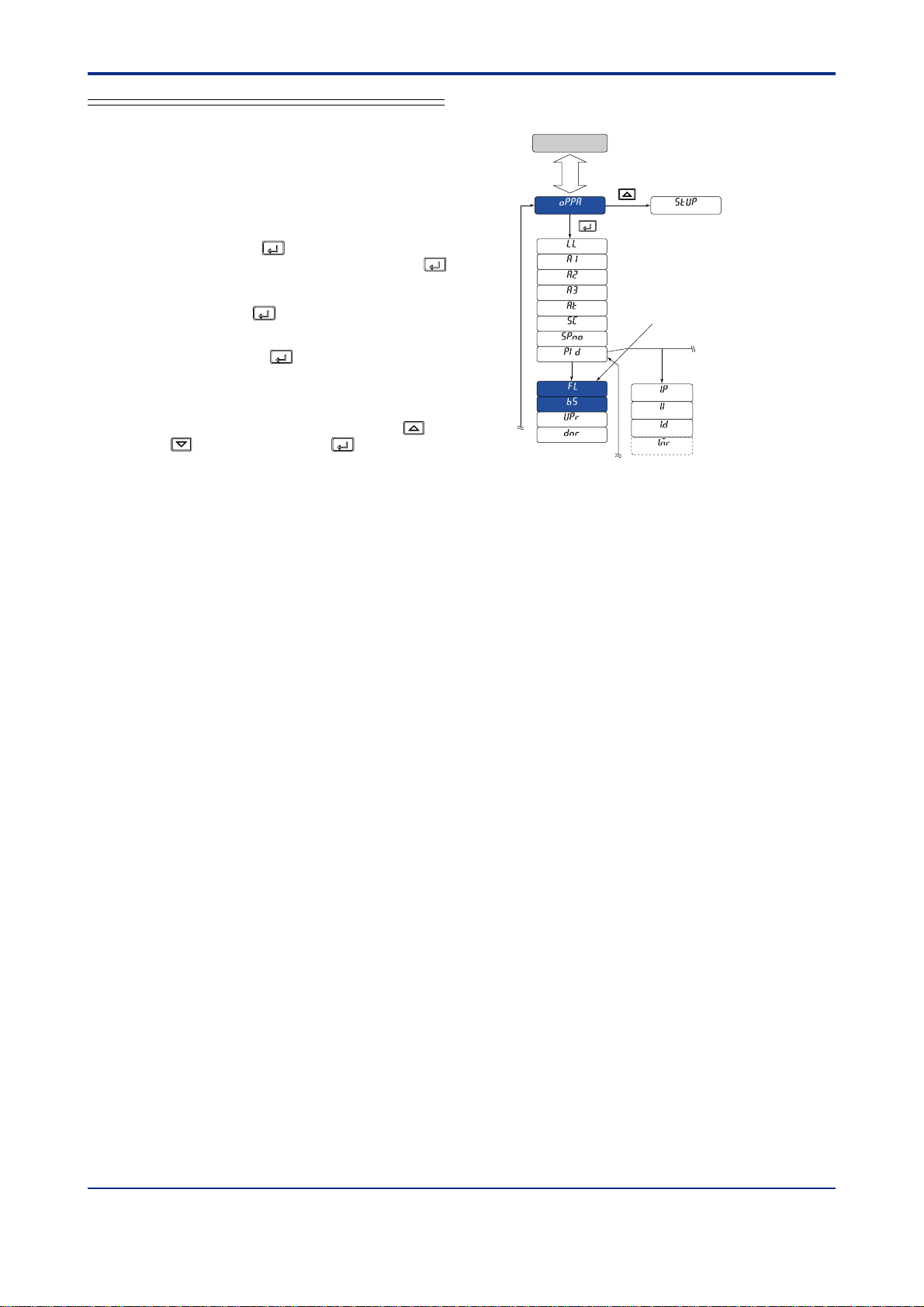

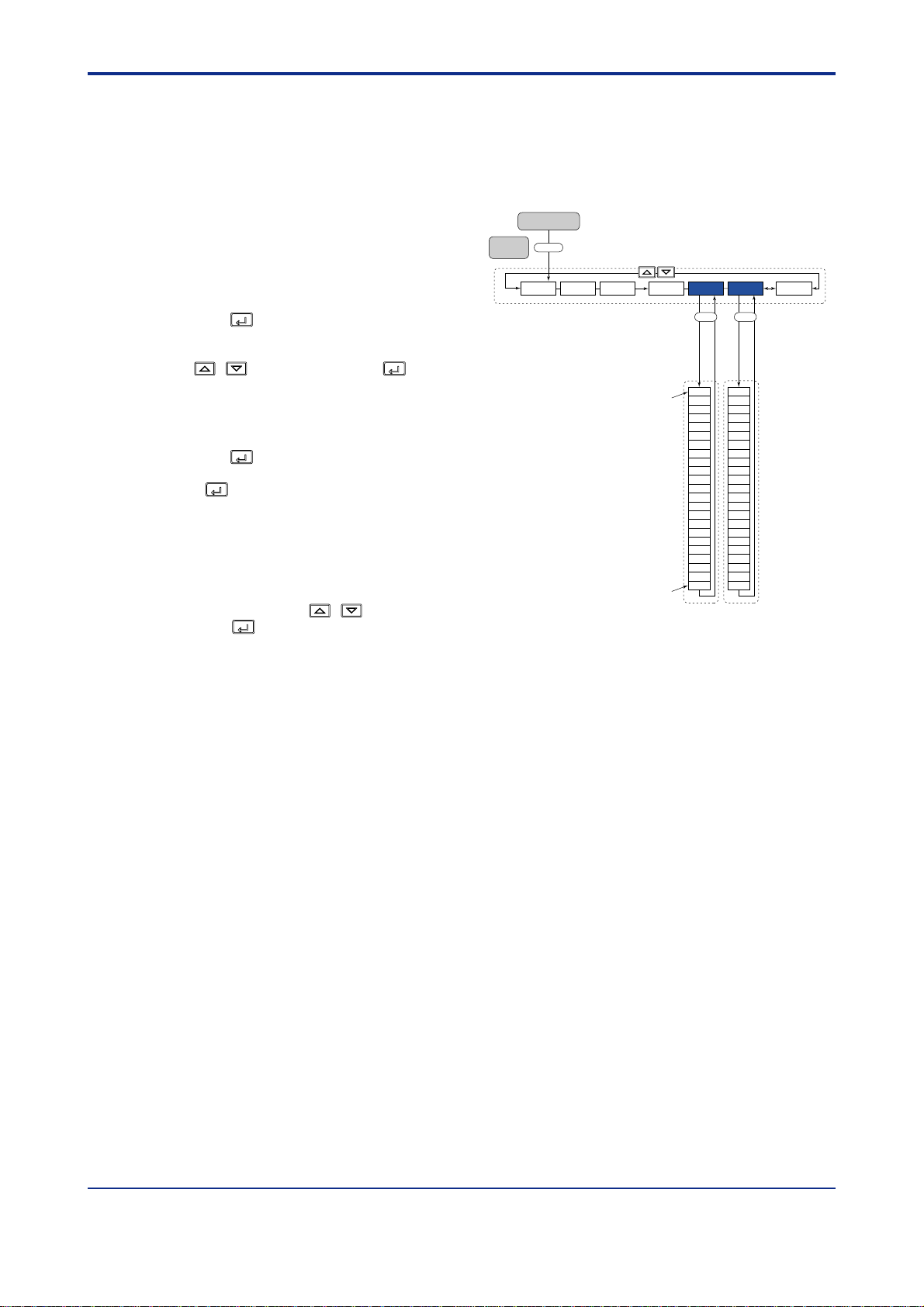

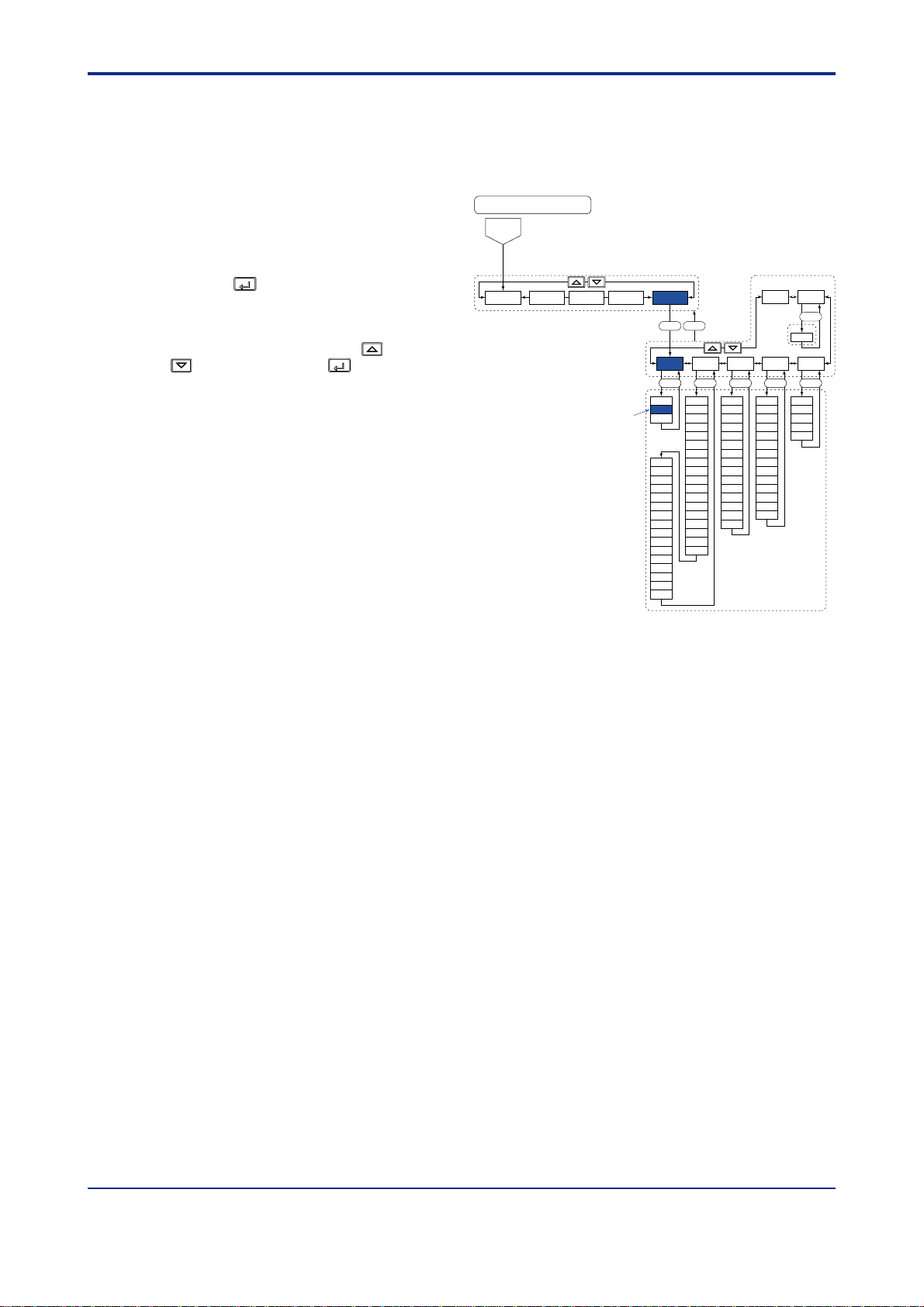

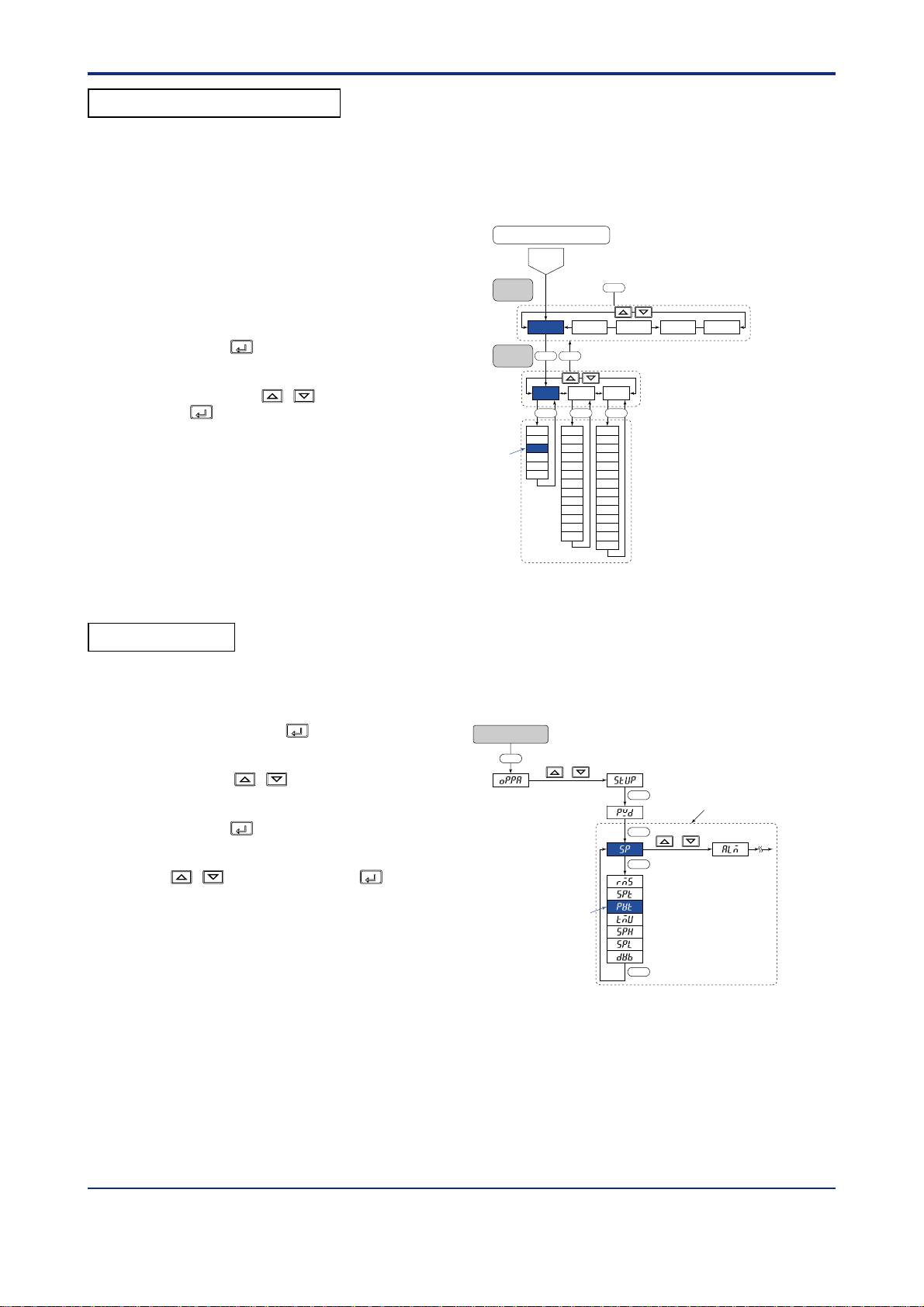

■ For UP750, UP550, UT750, UT550, UT551, and UT520

Here we explain how to display the parameter setting

display and to change the parameter values. Before

carrying out these operations be sure to refer to the

User’s Manuals Initial Settings and Parameter Map of

the controller.

The parameter map is very helpful in finding the path to

the setting display for a particular parameter.

1: Referring to the User’s Manual above, display

the operating parameter main menu [LP1]

(Note1).

Then, display the submenu [P AR].

Note1: If the UP/UT mode has been set for using loop-2 or the

secondary loop, also set the corresponding parameters under

the main menu [LP2] in the same way.

2: Press the

SET/ENT

key 3 times* to display the PV

input bias parameter BS.

* Depends on the controller mode.

Pressing the

SET/ENT

key one more time displays

the PV input filter parameter FL.

3: In each of these parameter setting displays,

adjust the parameter value using the

keys, then press the

SET/ENT

key to register it.

/

Parameter map (UT550/UT520)

Operating display

Main

SET3S

menu

MODE

SET

MOD

(C.A.M)

MOD

(R/L)

MOD

(S/R)

SPN

“BS”

SET3S

or

+

LP1 LP2 USR

1.SP

1.A1

1.A2

1.A3

1.A4

1.P

1.D

1.OH

1.OL

1.MR

1.H

1.DR

1.Pc

1.Ic

1.Dc

1.Hc

1.DB

1.RP

1.PO

1.Oc

Sub menu

+

SET

1.I

7.SP

7.A1

7.A2

7.A3

7.A4

7.P

7.D

7.OH

7.OL

7.MR

7.H

7.DR

7.Pc

7.Ic

7.Dc

7.Hc

7.DB

RHY

7.PO

7.Oc

SET

SET

8.SP

8.A1

8.A2

8.A3

8.A4

8.P

7.I

8.I

8.D

Same

8.OH

8.OL

8.MR

8.H

8.DR

8.Pc

8.Ic

8.Dc

8.Hc

8.DB

RDV

8.PO

8.Oc

as

LP1

SET

PAR 1.PID 7.PID 8.PID

SET

AT

SC

BS

FL

UPR

DNR

RT

RBS

RFL

ORB

ORH

ORL

SET

U1

U2

U3

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 9

<Toc> <Ref. 1.1: References Related to PV Input>

■ For UP35, UT450, UT420, UT35, and UT32

Here we explain how to display the parameter setting

display and to change the parameter values. Before

carrying out these operations be sure to refer to the

User’s Manuals Initial Settings and Parameter Map of

the controller.

Parameter map (UT350/UT320/UT351/UT321)

Operating display

SET

3S

The parameter map is very helpful in finding the path

to the setting display for a particular parameter.

1: With the operating display shown, press and

hold down the

SET/ENT

key for 3 seconds or

longer to call up [oP.P A]. Then press the

SET/ENT

SET/ENTSET/ENT

key repeatedly (Note) until the PV filter

parameter FL appears.

Pressing the

the PV input bias parameter BS.

Note: The number of times a

depending on the model of the controller. See the parameter

map of your controller.

SET/ENT

key one more time displays

SET/ENT

key is pressed differs

PID = 0

“FL”

PID = 1

2: In each of these parameter setting displays,

adjust the parameter value using the

keys, then press the

SET/ENT

key to register

/

it.

Ref. 1-3

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 10

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-4

<<Ref.1.1: References Related to PV Input>>

Ref.1.1(2) Correcting the PV (2.Using ten-segment linearizer biasing or approximation)

Ten-segment linearizer biasing and approximation are available with UP750, UP550, UT750, UT550, UT551, and

UT520.

Whether to use the biasing or approximation function is specified by the parameter 1.PMD (Note), which is set to

specify

As shown in the following “Operating parameters (Ten-segment linearizer input parameters)” table, the setting

display of parameter 1.PMD is located after the ten-segment linearizer input 1 to 1 1 and ten-segment linearizer

output 1 to 1 1.

Note: •“1.PMD” is the parameter for UP750, UP550, and UT750.

→ For how to set the parameters required for the functions discussed here, see “■ Setting the Required Param-

ten-segment linearizer biasing at the time of shipping.

•“1.MD” is the parameter for UT550, UT551 and UT520.

•“2.PMD” can also be used if the UP/UT mode is set for using loop-2 or the secondary loop.

eters” in the end of this subsection.

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 11

<Toc> <Ref. 1.1: References Related to PV Input>

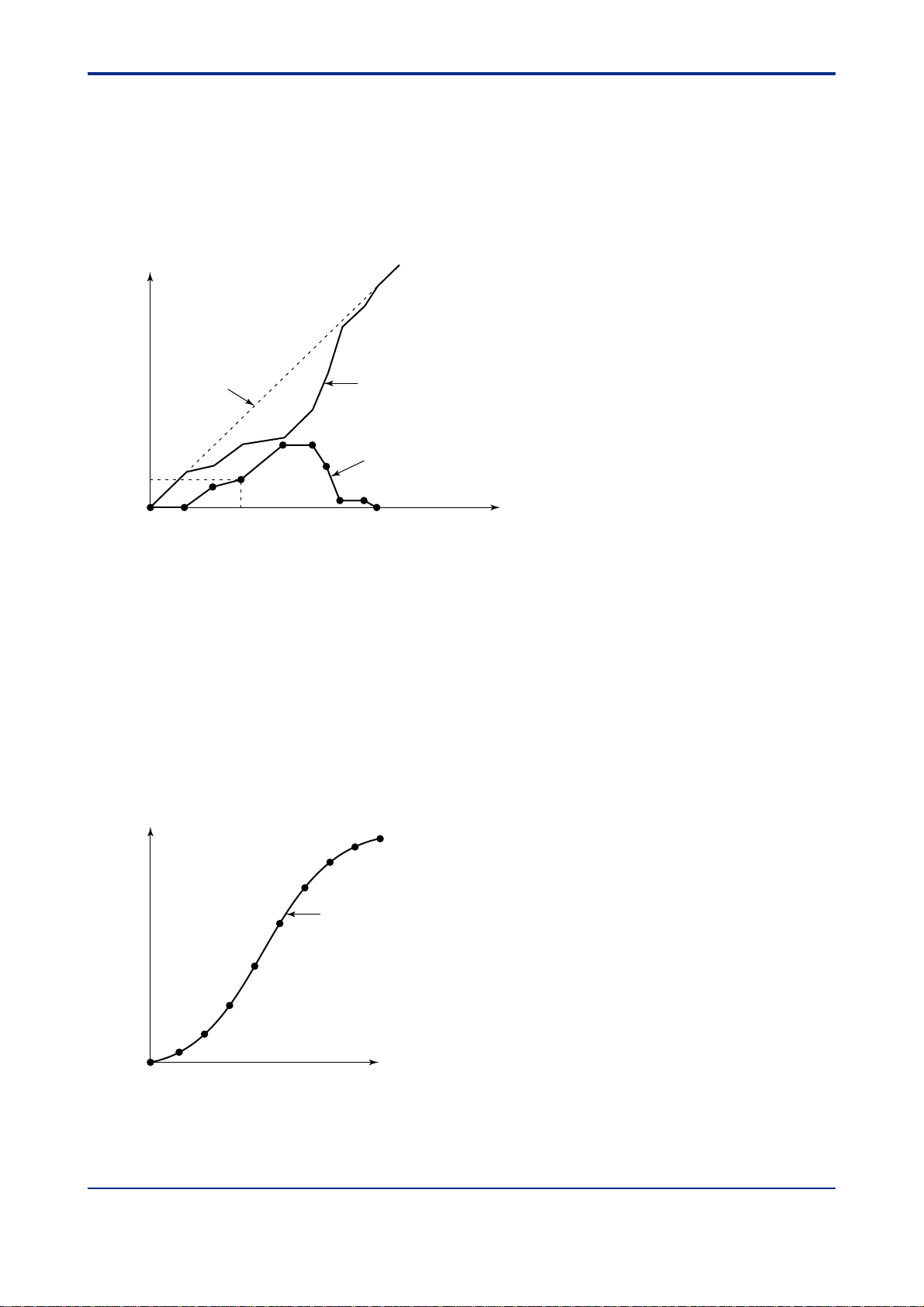

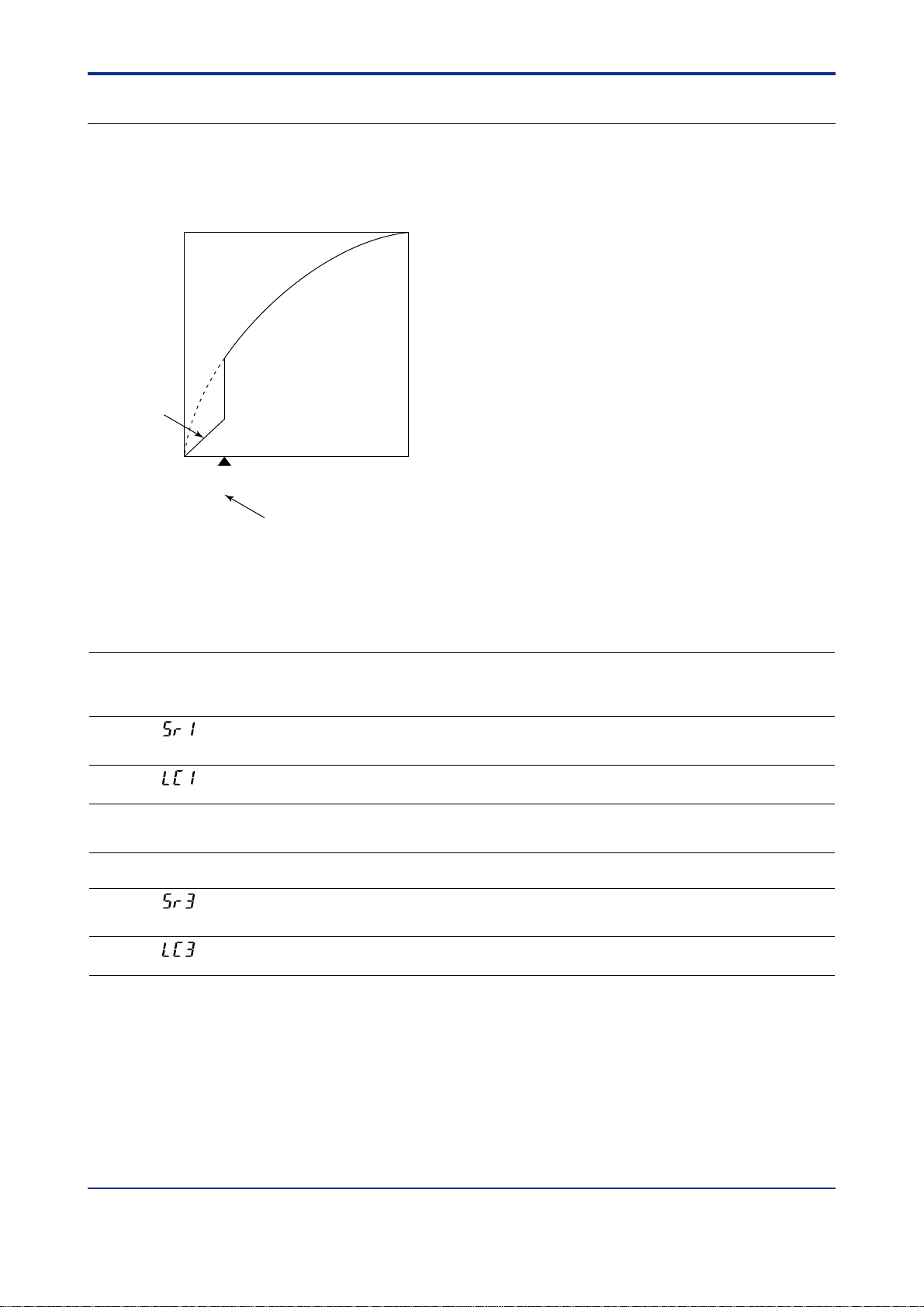

■ Ten-segment Linearizer Biasing

This function is used to correct an input signal affected by sensor deterioration. The corrected values (b) are

obtained by adding the corresponding bias values to each of the 1 1 points of optionally set input values (a).

The input values used to configure the ten-segment linearizer are set with parameters 1.a1 to 1.a1 1 (Note). The

bias values (b-axis) for each of the input values (a) are set with parameters 1.b1 to 1.b1 1 (Note).

Note: • 1.a1 to 1.a11 and 1.b1 to 1.b1 1 are the parameters for UP750, UP550, and UT750.

• 1.A1 to 1.AB and 1.B1 to 1.BB are the parameters for UT550, UT551 and UT520.

• If the UP/UT mode is set for using loop-2 or the secondary loop, “2.a1 to 2.a11 and 2.b1 to 2.b11,” and “2.A1 to 2.AB and 2.B1 to

2.BB” can also be used.

Output

(b)

Corrected value

(the sum of actual

input and bias

values)

n.b4

Actual input

Ten-segment linearizer

bias

Ref. 1-5

n.a2 n.a4 Input

(a)

Fig. 1-1-2 T en-segment Linearizer Biasing

■ Ten-segment Linearizer Approximation

This function is used when the input signal and the required measurement signal have a non-linear relationship.

For example, when trying to obtain the volume from a sphere tank level.

As shown in the figure below, the output values (b) can be optionally set to 11 points of the optionally set input

values (a).

The input values used to configure the ten-segment linearizer are set with parameters 1.a1 to 1.a1 1 (Note). The

corrective values (b-axis) of ten-segment linearizer approximation for each of the input values (a) are set with

parameters 1.b1 to 1.b1 1 (Note).

Note: • 1.a1 to 1.a11 and 1.b1 to 1.b1 1 are the parameters for UP750, UP550, and UT750.

• 1.A1 to 1.AB and 1.B1 to 1.BB are the parameters for UT550, UT551 and UT520.

• If the UP/UT mode is set for using loop-2 or the secondary loop, “2.a1 to 2.a11 and 2.b1 to 2.b11” and “2.A1 to 2.AB and 2.B1 to 2.BB”

can also be used.

Output

(b)

Ten-segment

linearizer approximation

Input

(a)

Fig. 1-1-3 T en-segment Linearizer Approximation

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 12

<T oc> <Ref. 1.1: References Related to PV Input>

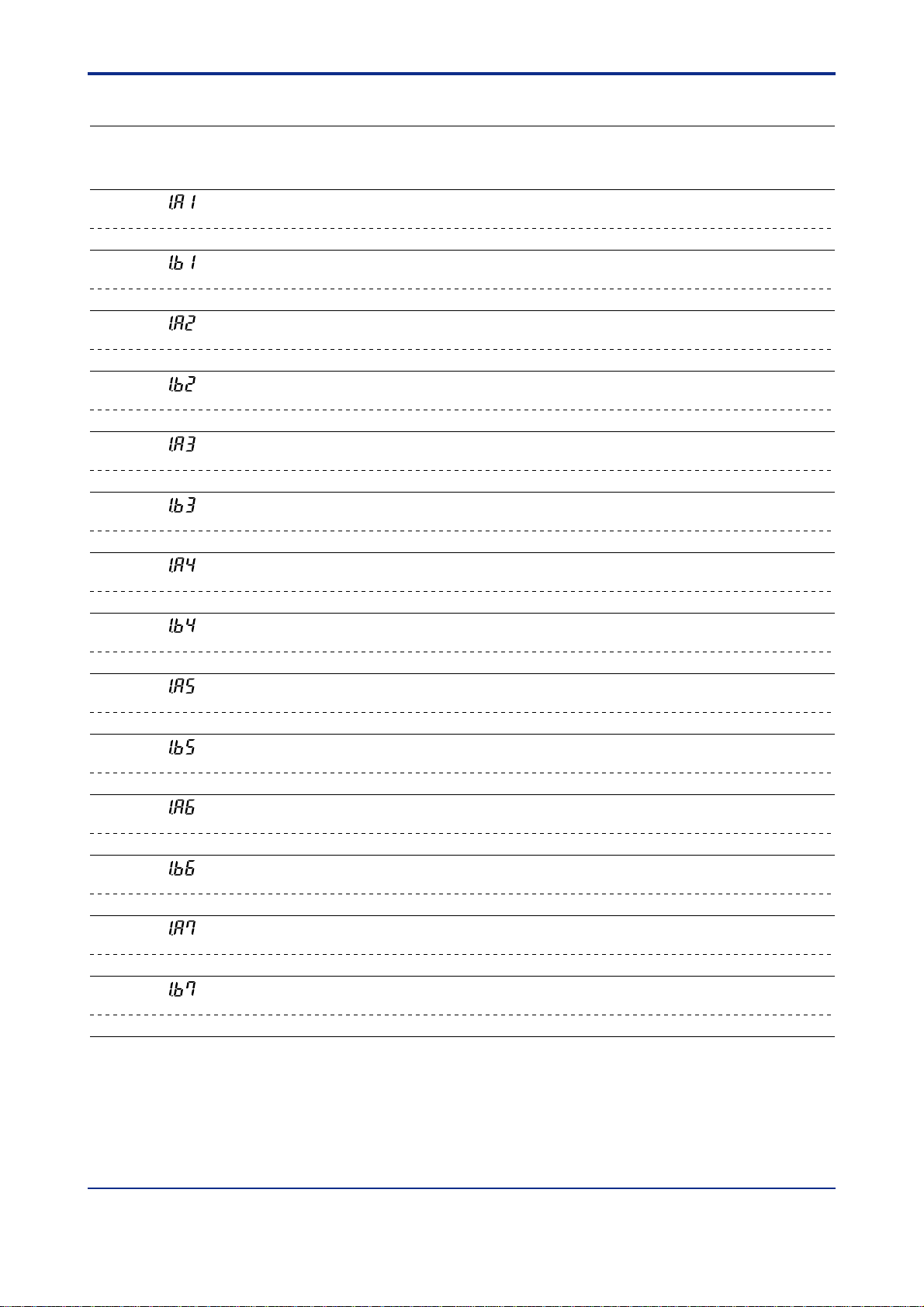

● The following parameters are used.

• Operating parameters (T en-segment Linealizer Parameters)

UP750

UP550

UT750

Code

1.a1

2.a1

1.b1

2.b1

1.a2

2.a2

1.b2

2.b2

1.a3

2.a3

1.b3

2.b3

1.a4

2.a4

1.b4

2.b4

1.a5

2.a5

1.b5

2.b5

1.a6

2.a6

1.b6

2.b6

1.a7

2.a7

1.b7

2.b7

UT5

Code

(1.A1)

2.A1 (for 2nd loop)

(1.B1)

2.B1 (for 2nd loop)

(1.A2)

2.A2 (for 2nd loop)

(1.B2)

2.B2 (for 2nd loop)

(1.A3)

2.A3 (for 2nd loop)

(1.B3)

2.B3 (for 2nd loop)

(1.A4)

2.A4 (for 2nd loop)

(1.B4)

2.B4 (for 2nd loop)

(1.A5)

2.A5 (for 2nd loop)

(1.B5)

2.B5 (for 2nd loop)

(1.A6)

2.A6 (for 2nd loop)

(1.B6)

2.B6 (for 2nd loop)

(1.A7)

2.A1 (for 2nd loop)

(1.B7)

2.B7 (for 2nd loop)

Description Setting range

Ten-segment

linearizer 1 input-1

(Note 1)

Ten-segment

linearizer 1 output-1

(Note 1)

Ten-segment

linearizer 1 input-2

(Note 1)

Ten-segment

linearizer 1 output-2

(Note 1)

Ten-segment

linearizer 1 input-3

(Note 1)

Ten-segment

linearizer 1 output-3

(Note 1)

Ten-segment

linearizer 1 input-4

(Note 1)

Ten-segment

linearizer 1 output-4

(Note 1)

Ten-segment

linearizer 1 input-5

(Note 1)

Ten-segment

linearizer 1 output-5

(Note 1)

Ten-segment

linearizer 1 input-6

(Note 1)

Ten-segment

linearizer 1 output-6

(Note 1)

Ten-segment

linearizer 1 input-7

(Note 1)

Ten-segment

linearizer 1 output-7

(Note 1)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

Default D-register

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

Ref. 1-6

No.

726

751

727

752

728

753

729

754

730

755

731

756

732

757

733

758

734

759

735

760

736

761

737

762

738

763

739

764

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 13

<Toc> <Ref. 1.1: References Related to PV Input>

Ref. 1-7

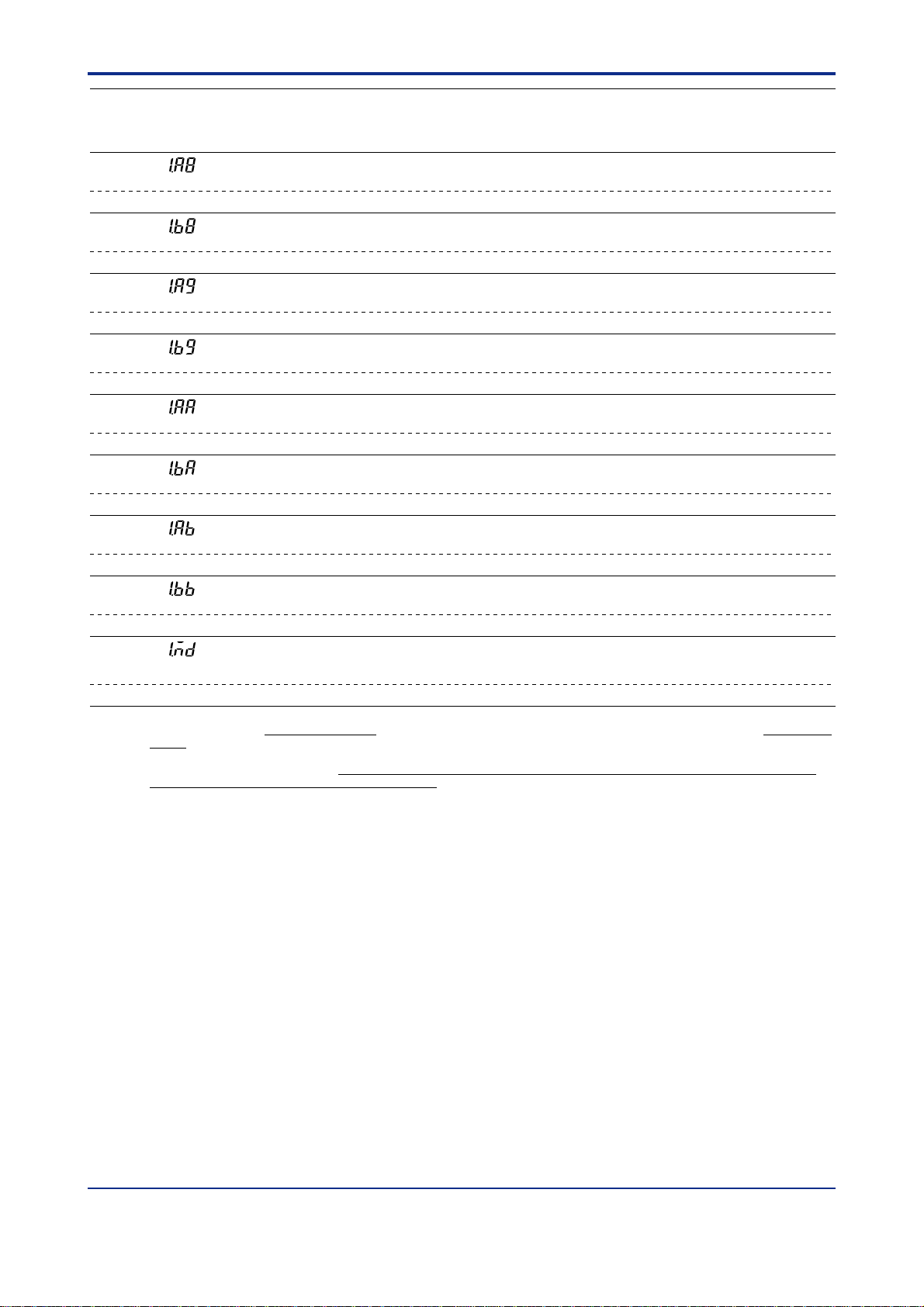

UP750

UP550

UT750

Code

1.a8

2.a8

1.b8

2.b8

1.a9

2.a9

1.b9

2.b9

1.a10

2.a10

1.b10

2.b10

1.a11

2.a11

1.b11

2.b11

1.PMD

2.PMD

Note1: These parameters are used for loop-2 when the UP/UT mode is set for using loop-2 or the secondary loop.

Note2: As shown in the table,

UT5

Description Setting range

Code

Ten-segment

(1.A8)

2.A8 (for 2nd loop)

(1.B8)

2.B8 (for 2nd loop)

(1.A9)

2.A9 (for 2nd loop)

(1.B9)

2.B9 (for 2nd loop)

(1.AA)

2.AA (for 2nd loop)

(1.BA)

2.BA (for 2nd loop)

(1.AB)

2.AB (for 2nd loop)

(1.BB)

2.BB (for 2nd loop)

(1.MD)

2.MD (for 2nd loop)

biasing. In this mode, the ten-segment linearizer output parameters are bias values; therefore, their setting ranges at the time of

shipping are -66.7 to 105.0% of measurement range span.

If the ten-segment linearizer mode is

parameters will be -66.7 to 105.0% of the PV input range (corrective values for approximation).

linearizer 1 input-8

(Note 1)

Ten-segment

linearizer 1 output-8

(Note 1)

Ten-segment

linearizer 1 input-9

(Note 1)

Ten-segment

linearizer 1 output-9

(Note 1)

Ten-segment

linearizer 1 input-10

(Note 1)

Ten-segment

linearizer 1 output-10

(Note 1)

Ten-segment

linearizer 1 input-11

(Note 1)

Ten-segment

linearizer 1 output-11

(Note 1)

Ten-segment

linearizer 1 mode

(Note 1)

at the time of shipping, the ten-segment linearizer mode parameter (1.PMD and others) is set to 0, which selects

changed to 1, which selects approximation, the setting ranges of ten-segment linearizer output

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

-66.7% to 105.0% of

PV input range

-66.7% to 105.0% of

PV input range span (Note 2)

0:Ten-segment linearizer biasing

1:Ten-segment linearizer

approximation (Note 2)

Default D-register

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0.0% of PV input range

0.0% of PV input range

span (Note 2)

0:Ten-segment

linearizer biasing

No.

740

765

741

766

742

767

743

768

744

769

745

770

746

771

747

772

748

773

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 14

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-8

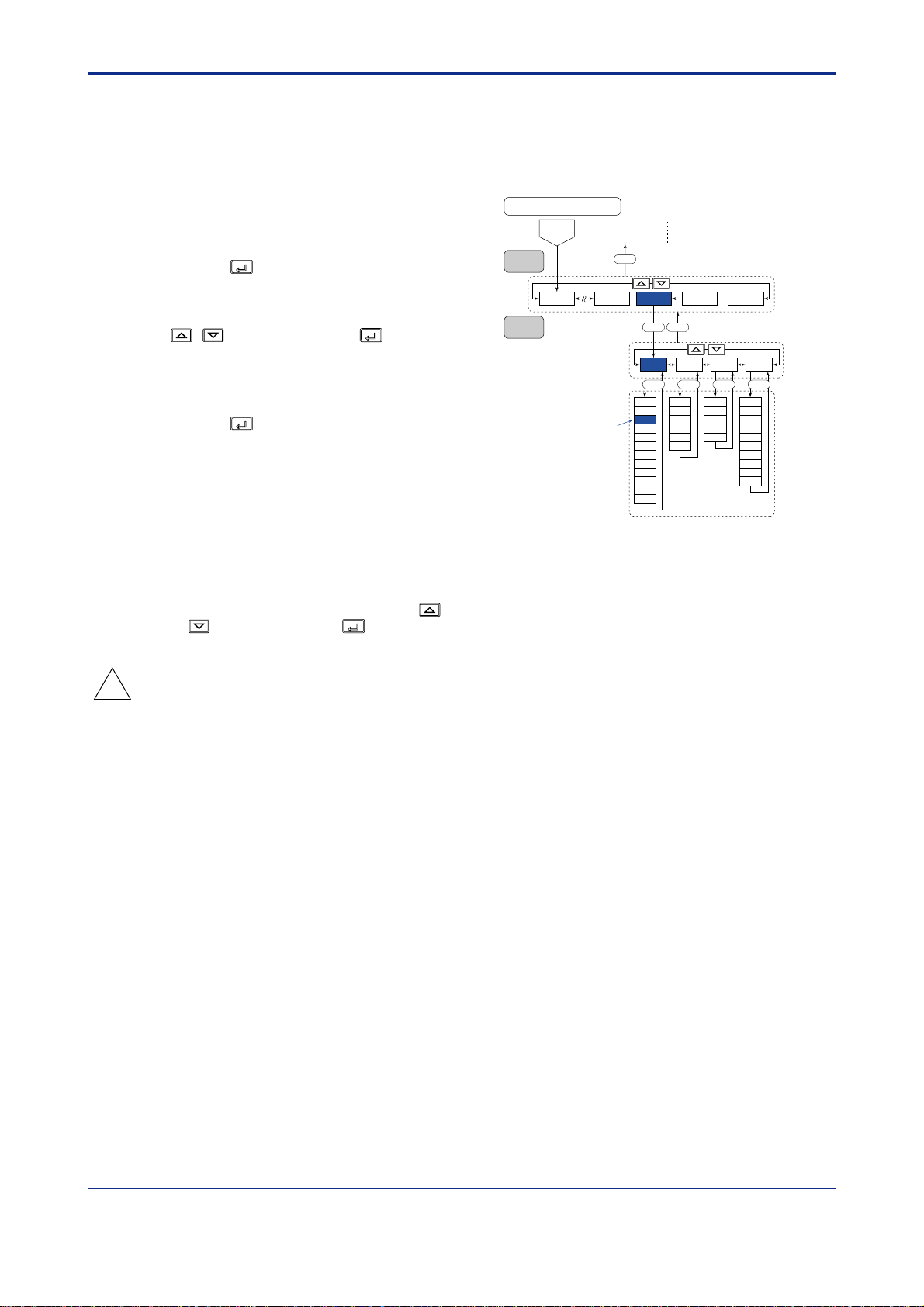

■ Setting the Required Parameters

T o set the parameters, carry out the following steps.

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter .

1: Referring to the User’s Manuals above, display

the operating parameter main menu [PSY1]

(Note 1).

Note1: If the UP/UT mode has been set for using loop-2 or the

secondary loop, also set the corresponding parameters under

the main menu [PYS2] in the same way .

SET/ENT

2: Press the

key 23 times to display the

UT750's Parameter Map

Operation dilplay

Main

SET3S

menu

PYS1

LP1MODE

USRLP2 PYS2PYS1 STUP

SETSET

parameter “1.PMD”. (Note2)

And adjust the parameter value(0 or 1) using

the

/ keys, then press the

register it.

Note2: “1.PMD” is the parameter for UP750, UP550 and UT750.

“1.MD” is the parameter for UT550, UT551 and UT520.

SET/ENT

3: Press the

eter main menu [PYS1], and then

SET/ENT

press

key once to display the param-

key again to display the parameter

“1.a1” (Note3).

Note3: “1.a1” is the parameter for UP750,UP550 and UT750.

“1.A1” is the parameter for UT550, UT551 and UT520.

4: Thereafter, adjust the display value for each

parameter in the order shown in the parameter

table above, using the

press the

SET/ENT

key to register them.

/ keys then

SET/ENT

key to

“1.a1”

“1.PMD”

1.a1

1.b1

1.a2

1.b2

1.a3

1.b3

1.a4

1.b4

1.a5

1.b5

1.a6

1.b6

1.a7

1.b7

1.a8

1.b8

1.a9

1.b9

1.a10

1.b10

1.a11

1.b11

1.PMD

2.a1

2.b1

2.a2

2.b2

2.a3

2.b3

2.a4

2.b4

2.a5

2.b5

2.a6

2.b6

2.a7

2.b7

2.a8

2.b8

2.a9

2.b9

2.a10

2.b10

2.a11

2.b11

2.PMD

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 15

<Toc> <Ref. 1.1: References Related to PV Input>

Ref. 1-9

<<Ref.1.1: Reference Related to PV Input>>

Ref.1.1(3) Square-root extraction of PV

Square-root extraction is available with UP750, UP550, UT750, UT550, UT551 and UT520.

This calculation is used to convert, for example, a differential pressure signal from a throttling flow meter such as

an orifice and nozzle into a flow-rate signal. A low signal cut off point can also be set.

100.0%

Slope = 1

Input 100.0%0.0%

Low signal cut off point (0.0 - 5.0%)

The low signal cut off point is

set using parameter A.LC1 or

other (see table below).

Fig. 1-1-4 Square-root Extraction

● The following parameters are used.

• Setup parameters (Analog Input Computation Parameters)

UP750

UP550

UT750

Code

A.SR1

A.LC1

A.SR2

(Note 1)

A.LC2

(Note 1)

A.SR3

(Note 2)

A.LC3

(Note 2)

Note 1: These parameters are used for 2-loop type of UP750 or UT750. Not displayed for UP550, UT550, UT551 and UT520.

Note 2: These parameters can be used when the controller has Remote input function.

UT5

Description Setting range

Code

Analog input-1

(SR1)

(LC1)

no function OFF or ON

no function 0.0 to 5.0% of PV input range

(SR3)

(LC3)

spuare-root

computation

Analog input-1

low signal cutoff

Analog input-2

spuare-root

computation

Analog input-2

low signal cutoff

Analog input-3

spuare-root

computation

Analog input-3

low signal cutoff

OFF or ON

(ON: Compute the square root)

0.0 to 5.0% of PV input range

(ON: Compute the square root)

OFF or ON

(ON: Compute the square root)

0.0 to 5.0% of PV input range

Default

D-register

No.

1003OFF

10041.0%

1007OFF

10081.0%

1011OFF

10121.0%

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 16

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-10

■ Setting the Required Parameters

T o set the parameters, carry out the following steps.

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter .

1: Referring to the User’s Manuals above, display

the Setup parameter main menu [CMLP].

Then, display the submenu [AIN].

SET/ENT

2: Press the

key 3 times to display the param-

Main

menu

Parametre Map

Password

OK

(UT750)

Operation parameters

display

DISP

eter “A.SR1”. (Note1)

When you use the “Spuare-root extraction of

PV”, set the parameter value to “ON” using the

/ keys, then press the

SET/ENT

key to

register it.

Note1: “A.SR1” is the parameter for UP750, UP550 and UT750.

“SR1” is the parameter for UT550, UT551 and UT520.

SET/ENT

3: Press the

key once to display the parameter

“A.LC1”. (Note2)

Set the “Analog input-1 low signal cutoff” if

necessary .

Note2: “A.LC1” is the parameter for UP750, UP550 and UT750.

“LC1” is the parameter for UT550, UT551 and UT520.

Sub menu

LOOP2LOOP1 CMLP

“A.SR1”

A.BS1

A.FL1

A.SR1

A.LC1

A.BS2

A.FL2

A.SR2

A.LC2

A.BS3

A.FL3

A.SR3

A.LC3

CONF UTMD

SET DISP

AIN RET TRND LOCK

SETSETSET SET

RET1

DVB1

DVB2

TSC1

TSC2

TTM

/

A/M

MODE

LP1

LP2

PID

USR

PYS1

PYS2

PWD

RTH1

RTL1

RET2

RTH2

RTL2

4: After the above operation, repeat the following

operation if necessary .

• Display the parameter setting display which

you want to set the value. (ex.“A.LC2”)

• Adjust the parameter value using the

keys, then press the

SET/ENT

key to register

/

it.

TIP

Descriptions of other parameters that belong to submenu AIN, such as parameter A.FL1, are given in “Ref. 1.1 (6)

Correcting the Input V alue from a Sensor” of this section. Refer to it as necessary.

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 17

<Toc> <Ref. 1.1: References Related to PV Input>

<<Ref. 1.1: References Related to PV Input>>

Ref.1.1(4) Changing the PV sampling period

CAUTION

When the controller is shipped, the PV sampling period is already set to values suitable for implementing the

model’s functions and specifications. Therefore, under normal conditions, the default sampling period should

be used with the controller and changing it to a shorter one may disable some of the controller’s functions.

The sampling period should only be changed if you fully understand the procedures described in the following

section.

CAUTION

The response time in communication may be longer when change the PV sampling period shorter. In this

case, reset the PV sampling period longer.

The PV sampling period can be changed with UP750, UP550, UT750, UT550, UT551 and UT520.

Ref. 1-11

■ For UP750 and UP550 (Program Controllers)

The PV sampling period can be selected from 100 ms (the fastest), 200 ms, and 500 ms.

(The factory-set default is 200 ms.)

■ For UT750, UT550, UT551 and UT520 (Digital Indicating Controllers)

The PV sampling period can be selected from 50 ms (the fastest), 100 ms, 200 ms, and 500 ms.

(The factory-set default is 200 ms.)

The following tables show the limitations of controller functions for each value of the PV sampling period.

(1) UP750 (Program controller)

PV sampling period Limitations of controller functions

100 ms (the fastest) Possible with single-loop models (UP750-0) when neither cascade control (UP mode = 4)

200 ms (factory-set default) Possible with single-loop models (UP750-0) when cascade control is used.

500 ms

Note: • To check that the selected PV sampling period is appropriate, use the setup parameter SMEC described later.

• Set the PV sampling period as 200ms when the “SUPER 2” function is used.

Set the PV sampling period as 500ms when the “SUPER 2” function is used in Cascade control, dual loop control or Temperature and

Humidity control mode.

nor custom computation function is used.

Possible with single-loop models (UP750-0) and dual-loop models (UP750-5) when

about less than 50 custom computation modules are used. ← “50” is given as a rough guide (Note).

When 50 or more custom computation modules are used. ← “50” is given as a rough guide (Note).

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 18

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-12

(2) UP550 (Program controller)

PV sampling period Limitations of controller functions

100 ms (the fastest) Possible when cascade control (UP mode = 4) is not used and also none of the following

200 ms (factory-set default) When any of the functions prohibited (listed above) with a 100 ms sampling period are used.

500 ms Note

Note: • To check that the selected PV sampling period is appropriate, use the setup parameter SMEC described later.

• Set the PV sampling period as 200ms when the “SUPER 2” function is used.

Set the PV sampling period as 500ms when the “SUPER 2” function is used in Cascade control, dual loop control or Temperature and

Humidity control mode.

functions are used. ← This is given as a rough guide (Note).

• SUPER function • Heating/cooling control • PV input computation

• Deviation alarm • Sensor grounding alarm • Self-diagnostic alarm

• FAIL output • SP rate-of-change limiter • Output rate-of-change limiter

When Cascade control mode is used.

(3) UT750 (Digital indicating controller)

PV sampling period Limitations of controller functions

50 ms (the fastest) Possible with UT750-00 (single-loop model with no optional specification) when single-loop

100 ms

200 ms (factory-set default) Possible with single-loop models (UT750-0) when cascade control is used.

500 ms

Note: • To check that the selected PV sampling period is appropriate, use the setup parameter SMEC described later.

• Set the PV sampling period as 200ms when the “SUPER 2” function is used.

Set the PV sampling period as 500ms when the “SUPER 2” function is used in Cascade control, dual loop control or Temperature and

Humidity control mode.

control (UT mode = 1) is used and none of the following functions are used.

← This is given as a rough guide (Note).

• SUPER function • Heating/cooling control • PV input computation

• Deviation alarm • Sensor grounding alarm • Self-diagnostic alarm

• FAIL output • SP rate-of-change limiter • Output rate-of-change limiter

Possible with single-loop models (UT750-0) when cascade control (UP mode = 4) is not used.

Possible with position-proportional models (UT750-1).

Possible with single-loop models (UT750-0) and dual-loop models (UT750-5) when

about less than 50 custom computation modules are used. ← “50” is given as a rough guide (Note).

When 50 or more custom computation modules are used. ← “50” is given as a rough guide (Note).

←

This is given as a rough guide (Note).

(4) UT550, UT551, UT520 (Digital indicating controller)

PV sampling period Limitations of controller functions

50 ms (the fastest) Possible with UT5

100 ms

200 ms (factory-set default) When cascade control mode is used.

500 ms

Note: • To check that the selected PV sampling period is appropriate, use the setup parameter SMC described later.

• Set the PV sampling period as 100ms when the “SUPER 2” function is used.

Set the PV sampling period as 200ms when the “SUPER 2” function is used in Cascade control.

control (UT mode = 1) is used and none of the following functions are used.

← This is given as a rough guide (Note).

• SUPER function • Heating/cooling control • PV input computation

• Deviation alarm • Sensor grounding alarm • Self-diagnostic alarm

• FAIL output • SP rate-of-change limiter • Output rate-of-change limiter

Possible when cascade control (UP mode = 4) is not used and any of the fumctions prohibited

(listed above) with a 100ms sampling period are used.

Note

(single-loop model with no optional specification) when single-loop

● The following parameters are used

• Setup parameters (UP Mode/UT Mode parameters):SMP

UP750

UP550

UT750

Code

SMP

Note 1: Only UT750, UT550, UT551 and UT520 can select “50ms”.

Note 2: The D-register No. of UP750, UP550 (UP mode) is 1281 and the No. of UT750, UT5 is 1181.

UT5

Code

(SMP)

Description Setting range

PV sampling

period settig

50 (Note1), 100, 200

or 500

Default

200

D-register

No.

1281(UP mode)

1181(UT mode)

(Note 2)

(Note 2)

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 19

<Toc> <Ref. 1.1: References Related to PV Input>

Ref. 1-13

■ Setting the Required Parameters

T o set the parameters, carry out the following steps.

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter.

1: Referring to the User’s Manual above,

display the setup parameter main menu

[UTMD].

Parameter map

Password

(UT750)

Then, display the submenu [MD].

SET/ENT

2: Press the

parameter “SMP”.

3: In the parameter setting displays, adjust

the parameter value using the

keys, then press the

register it.

key 2 times to display the

SET/ENT

/

key to

LOOP1

CONF UTMDLOOP2 CMLP

“SMP”

TEST

SET DISP

MD IN OUT VALV

SET

UTM

IN1

SMP

UNI1

SMEC

RH1

RL1

SDP1

SH1

SL1

IN3

BSL1

UNI3

RJC1

IN2

RH3

UNI2

RL3

RH2

SDP3

RL2

SH3

SDP2

SL3

SH2

BSL3

SL2

P.UN1

BSL2

P.DP1

RJC2

P.RH1

P.RL1

P.UN2

P.DP2

P.RH2

P.RL2

OT1

OT2

CT1

CT2

CTc1

CTc2

AO1

AO2

AO3

A1H

A1L

A2H

A2L

A3H

A3L

PSL1

BPS1

PRI1

STP1

DLN1

ADR1

RP.T1

PSL2

BPS2

PRI2

STP2

DLN2

ADR2

RP.T2

R485

SETSET

INI

V.RS

V.L

V.H

TR.T

V.MOD

INIT

SET

SETSET

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 20

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-14

<<Ref. 1.1: References Related to PV Input>>

Ref.1.1(5) Checking that the changed PV sampling period is appropriate

CAUTION

When you have changed the PV sampling period according to “Ref. 1.1 (4) Changing the PV sampling period”

in this section, be sure to check that the new period is appropriate by referring to the following descriptions.

It is necessary to check the new period with UP750, UP550, UT750, UT550, UT551 and UT520 after the PV

sampling period has been changed.

It is possible to check whether or not the currently set PV sampling period is appropriate for the controller to

perform its required functions.

For example, with UT550, the PV sampling period can be selected from 4 periods as shown in Table 1-1-1.

However, some of the controller functions will be restricted under the use of each period.

Although these limitations are given as “Limitations of controller functions” in “Ref. 1.1 (4) Changing the PV

sampling period”, they should be taken only as rough guides.

Therefore, you must check whether or not the period is appropriate before you use the controller.Carry out this

check at the time of the operation test of the system that uses the controller.

This check is performed by monitoring the sampling error counter.

The counter value shows how many times the controller failed to process its operation at the current PV sampling

period.(The controller increments the counter value by 1 per 10 ms of control period delay when it cannot execute

all the processing within the specified period.)

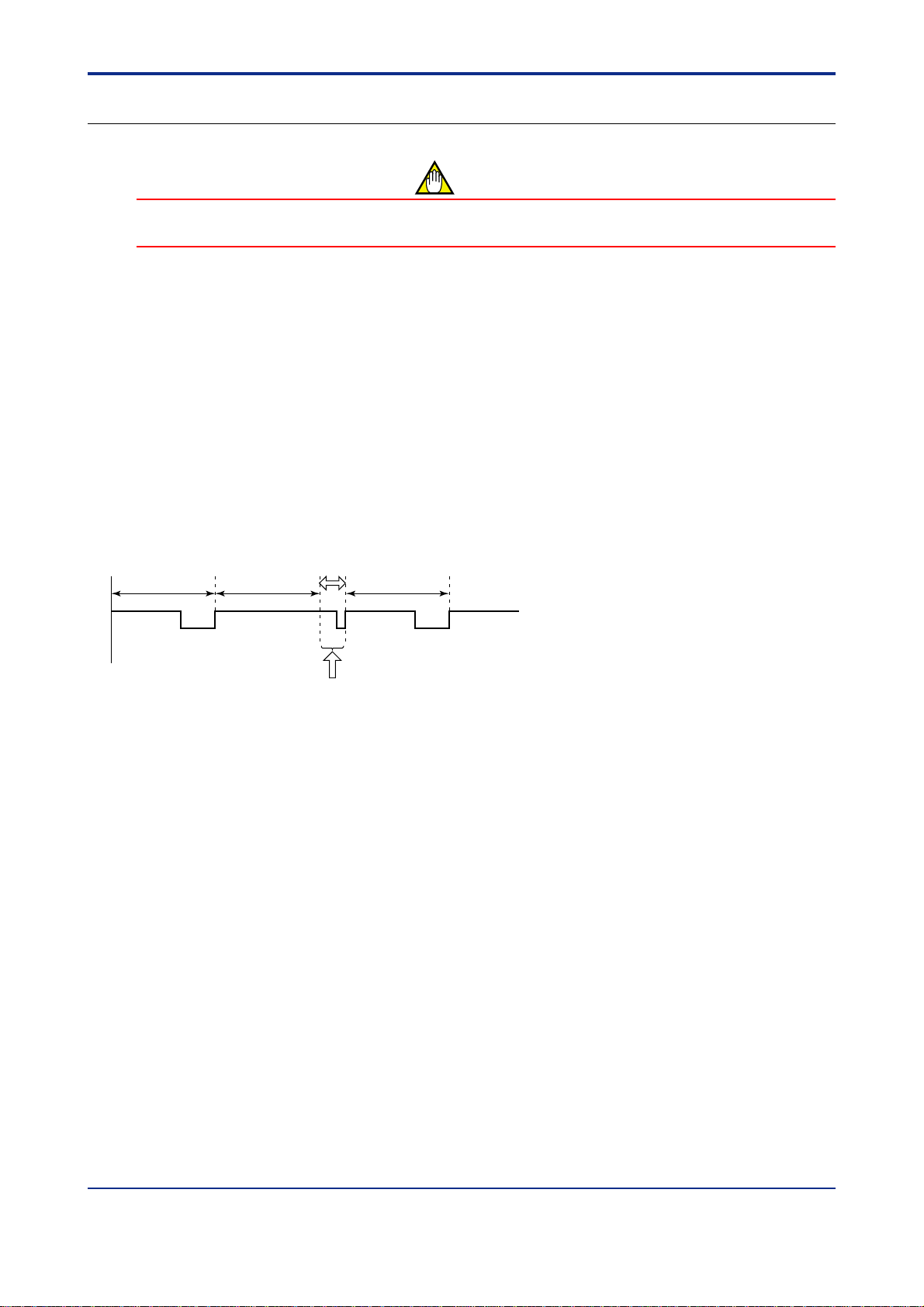

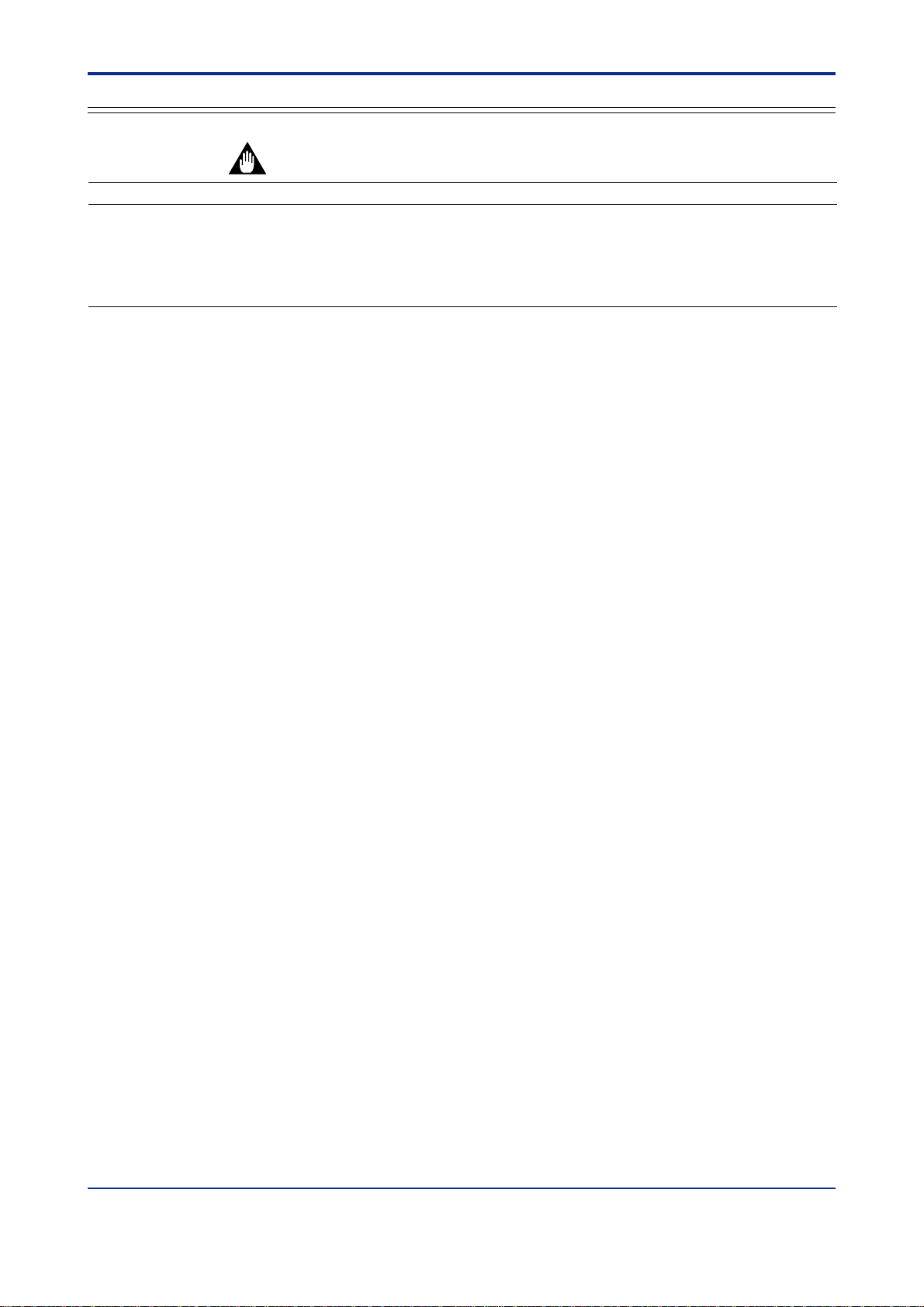

PV sampling

period

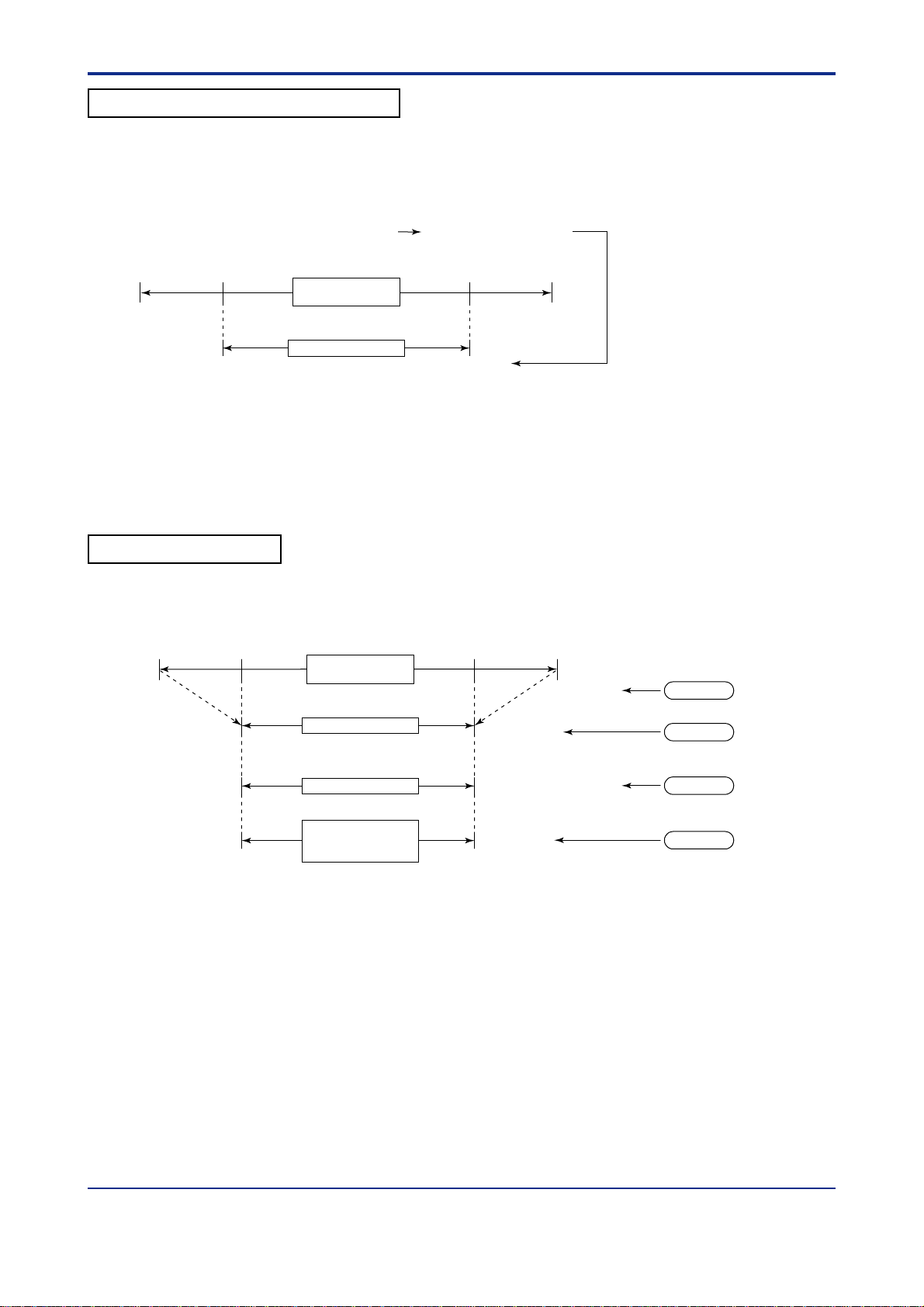

Processing

This chart shows that processing cannot be executed within

the specified sampling period.

In this example, the processing is delayed by 30 ms so the sampling

error counter is incremented by 3.

Fig. 1-1-5 PV Sampling Period

Processing Processing

30ms

If the counter value is not “0,” it means that some of the processing of the controller remains unprocessed.

For this reason, if an exact control is required, set the sampling period so that the counter value will not increase

unless a long time has elapsed.

If the counter value increases in a short period of time, change the sampling period to a larger value.

Y ou can monitor the counter value through the display of setup parameter SMEC (or SMC for UT5) as shown

in the following.

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 21

<Toc> <Ref. 1.1: References Related to PV Input>

Ref. 1-15

Table 1-1-1

PV sampling period Limitations of UT750 functions

50 ms (the fastest) Possible with UT750-00 (single-loop model with no optional specification) when single-loop

control (UT mode = 1) is used and none of the following functions are used.

← This is given as a rough guide (Note).

• SUPER function • Heating/cooling control • PV input computation

• Deviation alarm • Sensor grounding alarm • Self-diagnostic alarm

• FAIL output • SP rate-of-change limiter • Output rate-of-change limiter

100 ms

Possible with single-loop models (UT750-0) when cascade control (UP mode = 4) is not used.

←

Possible with position-proportional models (UT750-1).

This is given as a rough guide (Note).

200 ms (factory-set default) Possible with single-loop models (UT750-0) when cascade control is used.

Possible with single-loop models (UT750-0) and dual-loop models (UT750-5) when

about less than 50 custom computation modules are used. ← “50” is given as a rough guide (Note).

500 ms

When 50 or more custom computation modules are used. ← “50” is given as a rough guide (Note).

Note: • To check that the selected PV sampling period is appropriate, use the setup parameter SMEC described later.

• Set the PV sampling period as 200ms when the “SUPER 2” function is used.

Set the PV sampling period as 500ms when the “SUPER 2” function is used in Cascade control, dual loop control or Temperature and

Humidity control mode.

● The following parameters are used.

• Setup parameters (UP Mode / UT Mode Parameters): SMEC (SMC)

UP750

UP550

UT750

Code

SMEC

Note: Since parameter SMEC is display only, it has no setting range.

UT5

Description Setting range

Default

D-register

No.

Code

320 (Note)

(SMC)

Sampling period

error counter

0 to 30000 (Note)

When the controller is powered on for the first time, the error counter value is 0. The counter value displayed can increase up to 30000

as errors occur. T urning the power of f resets the counter value to 0.

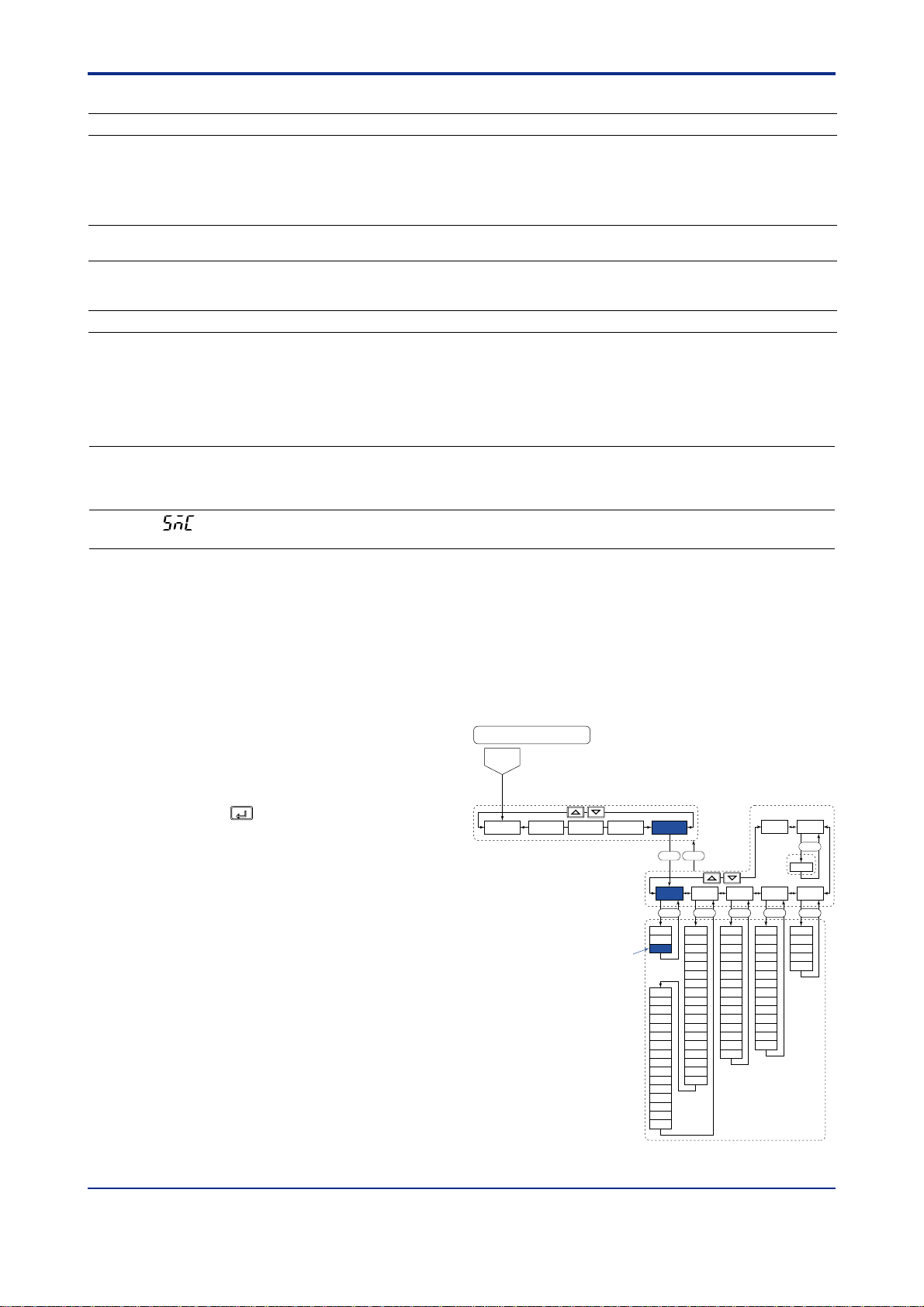

■ Setting the Required Parameters

T o check that the selected PV sampling period is appropriate.

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter.

1: Referring to the User’s Manual above,

display the setup parameter main menu

[UTMD].

Parameter map

Password

(UT750)

Then, display the submenu [MD].

2: Press the

parameter “SMEC”, and check the counter

value.

Note1: “SMC” is the parameter for UT550, UT551 and UT520.

SET/ENT

key 3 times to display the

LOOP1

CONF UTMDLOOP2 CMLP

“SMEC”

TEST

SET DISP

MD IN OUT VALV

SET

UTM

IN1

SMP

UNI1

SMEC

RH1

RL1

SDP1

SH1

SL1

IN3

BSL1

UNI3

RJC1

IN2

RH3

UNI2

RL3

RH2

SDP3

RL2

SH3

SDP2

SL3

SH2

BSL3

SL2

P.UN1

BSL2

P.DP1

RJC2

P.RH1

P.RL1

P.UN2

P.DP2

P.RH2

P.RL2

OT1

OT2

CT1

CT2

CTc1

CTc2

AO1

AO2

AO3

A1H

A1L

A2H

A2L

A3H

A3L

PSL1

BPS1

PRI1

STP1

DLN1

ADR1

RP.T1

PSL2

BPS2

PRI2

STP2

DLN2

ADR2

RP.T2

R485

SETSET

INI

V.RS

V.L

V.H

TR.T

V.MOD

INIT

SET

SETSET

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 22

<T oc> <Ref. 1.1: References Related to PV Input>

<<Ref. 1.1: References Related to PV Input>>

Ref. 1-16

Ref.1.1(6) Correcting the input value from a sensor

CAUTION

The “analog input bias” and “analog input filter” described here are similar to the functions described in “Ref.

1.1 (1) Correcting the PV (1. Using PV filter and PV bias)” of this section.

To use the PV filter and PV bias, operating parameters FL and BS are used. As they are operating parameters, their settings can be changed during operation. Therefore, it is recommended that under normal

circumstances you use FL and BS.

As for “analog input bias” and “analog input filter ,” read the following description and only set them if necessary .

Sensor input value correction is available with UP750, UP550, UT750, UT550, UT551 and UT520.

Analog input bias is used to correct sensor-input characteristics, compensating lead wire errors, and so on.

Normally , the PV biasing (BS) is convenient as mentioned in the CAUTION above, however, use the analog input

bias (A.BS) in cases where a constant correction is required due to sensor deterioration or for other reasons.

Since this biasing is set using a setup parameter , it is suitable for input correction where once the parameter is set,

it will not be changed for a long time.

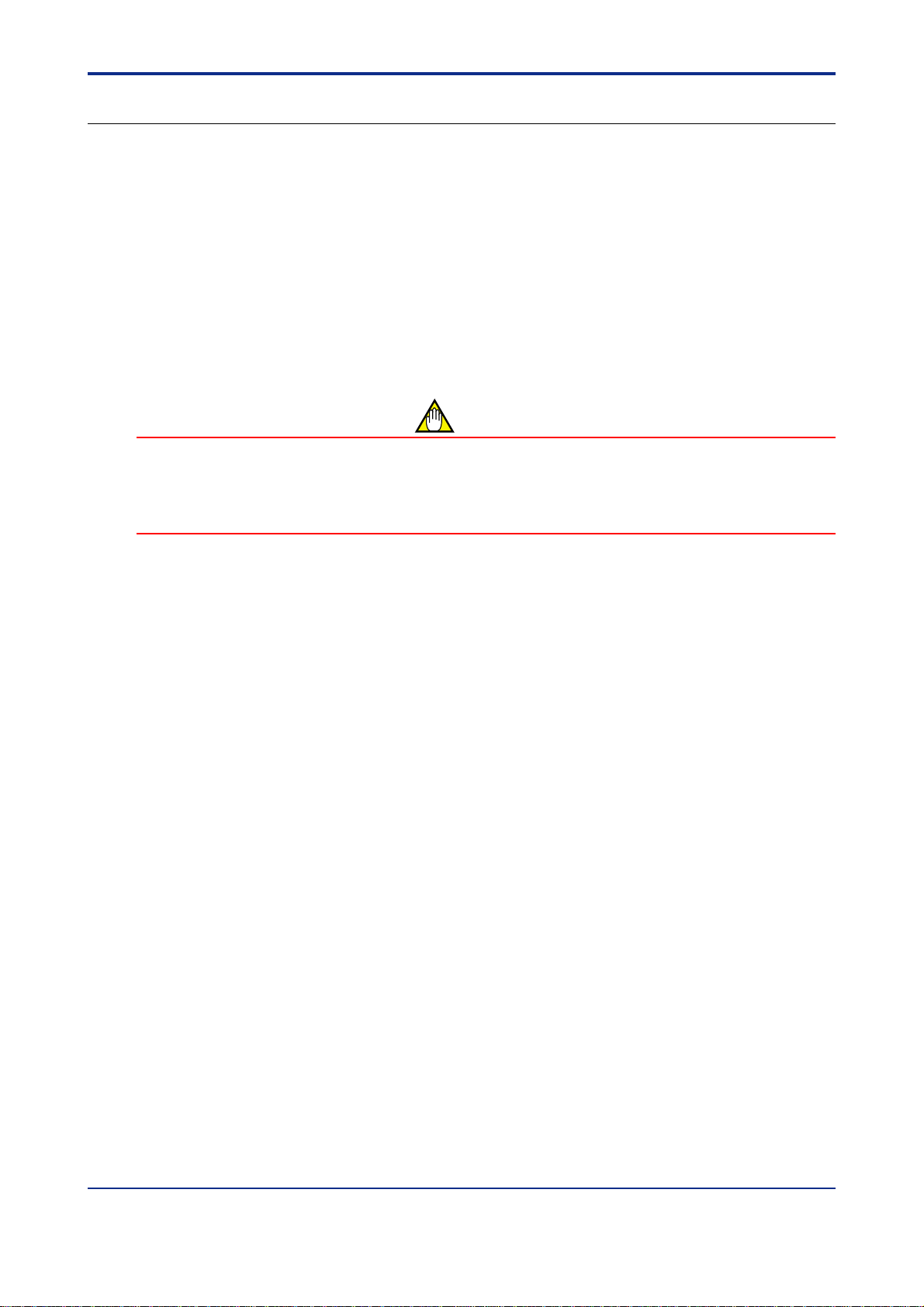

The analog input filter is used to remove noise from a PV input signal that contains high frequency noise such as

flow rate and pressure signals.

This filter provides a first-order-lag calculation, which can remove more noise the larger the time constant becomes (see the figure below).

However, an excessively large time constant will distort the waveform. (See the figure below)

As mentioned in the CAUTION above, a similar effect can be obtained by using the PV filter (FL).

However, an analog input filter should be used in the cases where a constant level of correction is required, such

as in an environment that contains a lot of noise.

Actual input With a small time constant With an excessively

Fig. 1-1-6 Image of PV Input Correction by Analog Input Filter

large time constant

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 23

<Toc> <Ref. 1.1: References Related to PV Input>

● The following parameters are used.

• Setup parameters (Analog Input Computation Parameters) : A.BS1, A.FL1, etc.

UP750

UP550

UT750

Code

A.BS1

A.FL1

A.BS2

(Note1)

A.FL2

(Note1)

A.BS3

(Note2)

A.FL3

(Note2)

Note 1: These parameters are used for 2-loop type of UP750 or UT750. Not displayed for UP550, UT550, UT551 and UT520.

Note 2: These parameters can be used when the controller has Remote input function.

UT5

Description Setting range

Code

Analog input 1

(BS1)

bias

Analog input 1

(FL1)

no function -100.0% to 100.0% of

filter

Analog input 2

bias

no function OFF or 1 to 120 (sec)

Analog input 2

-100.0% to 100.0% of

input range span

OFF or 1 to 120 (sec)

input range span

filter

(BS3)

(FL3)

Analog input 3

bias

Analog input 3

filter

-100.0% to 100.0% of

input range span

OFF or 1 to 120 (sec)

Default

input range span

(no filter)

input range span

(no filter)

input range span

(no filter)

■ Setting the Required Parameters

T o set the parameters, carry out the following steps.

Ref. 1-17

D-register

No.

10010.0% of

1002OFF

10050.0% of

1006OFF

10090.0% of

1010OFF

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter.

1: Referring to the User’s Manual above,

display the setup parameter main menu

[CMLP].

Then, display the submenu [AIN].

2: Press the

SET/ENT

key once to display the

parameter “A.BS1”. (Note1)

Adjust the parameter value using the /

keys, then press the

SET/ENT

key to

register it.

Note1: “A.BS1” is the parameter for UP750,UP550 and UT750.

“BS1” is the parameter for UT550, UT551 and UT520.

SET/ENT

3 : Press the

key once to display the

parameter “A.FL1”. (Note2)

Set the “Analog input-1 filter” if necessary .

Note2: “A.FL1” is the parameter for UP750,UP550 and UT750.

“FL1” is the parameter for UT550, UT551 and UT520.

Main

menu

Sub menu

Parameter map

Password

OK

“A.BS1”

(UT750)

Operation parameter's

Setting display

DISP

LOOP2LOOP1 CMLP

A.BS1

A.FL1

A.SR1

A.LC1

A.BS2

A.FL2

A.SR2

A.LC2

A.BS3

A.FL3

A.SR3

A.LC3

CONF UTMD

SET DISP

AIN RET TRND LOCK

SETSETSET SET

RET1

DVB1

DVB2

TSC1

TSC2

TTM

/

A/M

MODE

LP1

LP2

PID

USR

PYS1

PYS2

PWD

RTH1

RTL1

RET2

RTH2

RTL2

4: After the above operation, repeat the

following operation if necessary .

• Display the parameter setting display

which you want to set the value.

(ex.“A.BS2”)

• Adjust the parameter value using the

/ keys, then press the

SET/ENT

key

to register it.

TIP

Descriptions of other parameters that belong to submenu AIN, such as parameter A.SR1, are given in “Ref.

1.1 (3) Square-root extraction of PV” of this section. Refer to it as necessary .

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 24

<T oc> <Ref. 1.1: References Related to PV Input>

<<Ref. 1.1: References Related to PV Input>>

Ref. 1-18

Ref.1.1(7) Using PV tracking function (UT only)

The PV tracking function is available with UT750, UT550, UT551. UT520, UT450, and UT420.

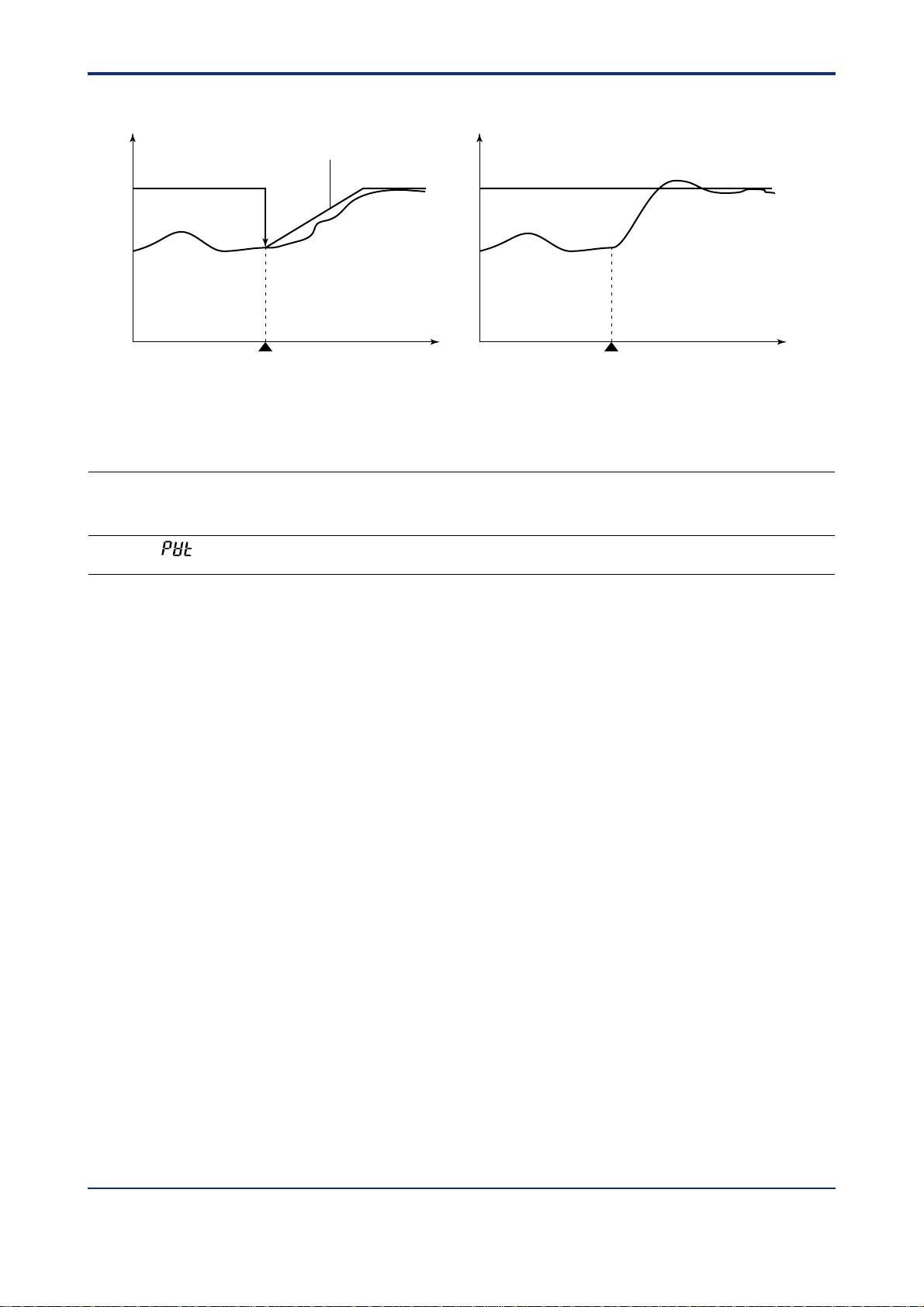

PV tracking is used to prevent a sudden change in PV .

Note: As shown below, PV tracking is turned OFF at the time of shipment. T urn it ON if necessary.

When PV tracking is ON, the controller sets the SP equal to PV temporarily in the event of the following:

• Power-on

• Switching from MAN to AUTO mode

• Switching from STOP to RUN

• Switching the number of setpoint (SP No.)

After SP is equalized to PV, the SP is gradually changed toward the original SP value at a constant rate-of-change

(for ramp rate; see the CAUTION below and the following Fig. 1-1-7).

CAUTION

The SP rate-of-change (ramp rate) is set using parameter UPR and/or DNR, which is set to OFF at the time of

shipment. To use PV tracking, you must set parameter UPR and/or DNR to a desired ramp rate value.

→ See “Ref.4.1(4) Changing SP at a ramp rate when SP is switched” in Ref. 4-1: References Related to Target

Setpoint (SP).

With these parameters OFF, which specifies no ramp rate (ramp rate = 0), PV tracking will not operate.

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 25

<Toc> <Ref. 1.1: References Related to PV Input>

Ref. 1-19

● PV tracking enabled

SP

PV

SP ramp-rate

(UPR or DNR)

MAN AUTO MAN AUTO

mode change mode change

Time Time

● PV tracking disabled

SP

PV

Fig. 1-1-7 PV tracking function

● The following parameters are used.

• Setup parameters (Target Setpoint-related Parameters) : PVT

UP750

UP550

UT750

Code

PVT

Note 1: This parameter is used for loop-2 when the UP/UT mode is set for using loop-2 or secondary loop.

UT5

UT40

Code

(PVT)

Description Setting range

PV tracking selection OFF or ON

Default

OFF

D-register

No.

903(for loop-1)

943(for loop-2)

(Note1)

■ Setting the Required Parameters

T o use the PV tracking function (to turn ON/OFF the PV tracking function), carry out the operation shown below.

Since the operation differs between UT750/UT550/UT551/UT520 and UT450/UT420, instructions will be given

separately in [1] and [2]. Follow either of them according to your controller’s model.

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 26

<T oc> <Ref. 1.1: References Related to PV Input>

Ref. 1-20

[1] UT750, UT550, UT551, UT520

T o set the parameters, carry out the following steps.

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter .

1: Referring to the User’s Manual above,

display the setup parameter main menu

[LOOP1] (Note1).

Then, display the submenu [SP].

Note 1: To set PVT for loop-2, go to the main menu [LOOP2],

then the submenu [SP] and carry out the same procedure.

SET/ENT

2: Press the

key 3 times (Note 2) to

display the parameter “PVT”.

And adjust the parameter value (OFF or

ON) using the

SET/ENT

the

key to register it. (When “ON” is

/ keys, then press

set, PV tracking operate.)

Note 2: The times of key operation may change by the condition

of controller’s setting.

“PVT”

Main

menu

Sub menu

Parameters map

Password

OK

LOOP1

LOOP2 CMLP

SET DISP

SP ALM CTL

RMS

AL1

SPT

AL2

PVT

AL3

TMU

AL4

SPH

HY1

HY2

SPL

HY3

HY4

DY1

DY2

DY3

DY4

AMD

OPR

MOD

AR

ZON

R.MD

R.TM

1.RP

2.RP

3.RP

4.RP

5.RP

6.RP

RHY

RDU

(UT750)

DISP

CONF UTMD

SETSET SET

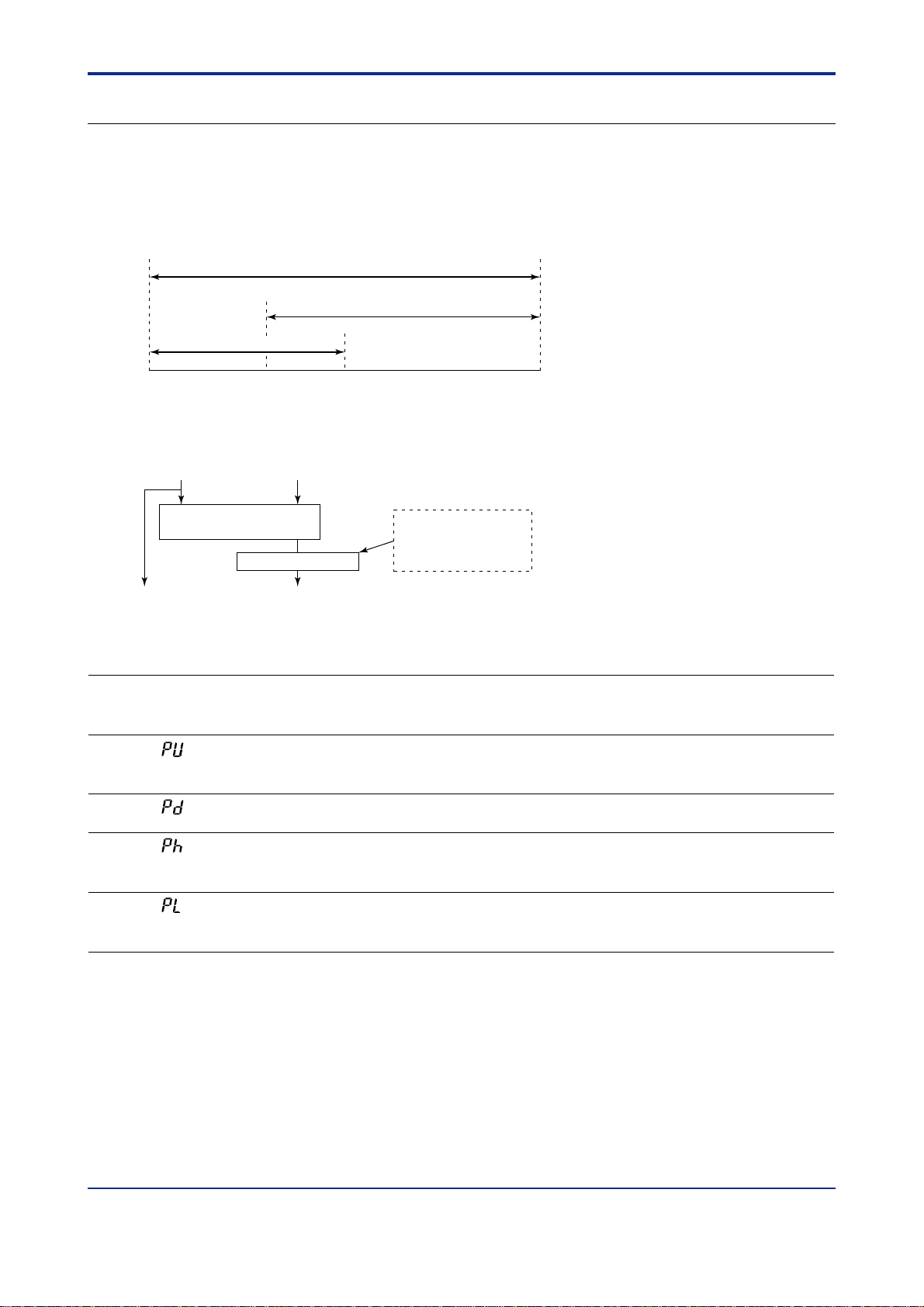

[2] UT450, UT420

Here we explain how to display the parameter setting display and to change the parameter values. Before carrying

out these operations be sure to refer to the User’s Manuals Initial Settings and Parameter Map of the controller.

The parameter map is very helpful in finding the path to the setting display for a particular parameter .

1: With the operating display shown, press

and hold down the

SET/ENT

key for 3 seconds or

longer to call up [oP.PA].

2: Press the

/ key one time to call up

[STUP].

3: Press the

SET/ENT

key 5 times (Note) to display

the parameter “PVT”. And adjust the

parameter value (OFF or ON) using the

/ keys, then press the

SET/ENT

key to

Parameters map

Operating display

SET

3 sec or more

/

SET

SET

SET

Setup parameters

/

register it. (When “ON” is set, PV tracking

operate.)

Note: The times of key operation may change by the condition

of controller’s setting.

“PVT”

SET

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 27

<Toc> <Ref. 1.1: References Related to PV Input>

Ref. 1-21

<<Ref. 1.1: References Related to PV Input>>

Ref.1.1(8) PV input range adjustment (When the UT/UP mode No. is 6, 7 or 12 only)

Parameters RH1 to RL3 are used to set the range used for control within the instrument range.

Parameters P.RH1 to P.RL2 (PV range) are used to set the PV ranges used for the controller’s internal computation when the controller performs loop control with PV switching or loop control with PV auto-selector which

receives two inputs of different measurement ranges (see Fig. 1-1-8). The parameters are also used to set the PV

range for relative humidity data obtained from dry- and wet- bulb calculations in temperature and humidity control.

The decimal point position of the PV range can be set with parameters P.DP1 and P.DP2.

P.RL1 P.RH1

RL2 or 3

RL1 RH1

Range of analog input 1

0 300 500 1000C

PV range

Range of analog input 2 or 3

Fig. 1-1-8 PV Range for a Control Having More than One Input

Dry bulb (Input 1)

-50 to 100C

Dry- and wet-bulb

PV1

-50 to 100C

Wet bulb (Input 2)

-50 to 100C

calculation

PV range convention

30.0 to 100.0%

<Example>

Sets

• _ _ _ _. _ for P.DP2,

• 100.0 for P.RH2, and

• 30.0 for P.RL2.

PV2

Fig. 1-1-9 PV Range for T emperature and Humidity Control

• Setup parameters (Input-related Parameters): P.UNn, P.RLn, etc

UP750

UP550

UT750

Code

P.UNn

(Note1)

P.DPn

P.RHn

UT55

UT520

Code

(P.Un)

(P.D1)

(P.H1)

Description

n

n

n

PVn Unit C : Degree Celsius

PVn decimal

Maximum value

of PVn range

Setting range

% : Percent

C : Degree Celsius

F : Fahrenheit

– : No unit

0 to 4 (Note2)

-19999 to 30000

(Note3)

RH2 or 3

Default

–

Maximum value

of PVn range

or scale

D-register No.

1230 (for loop-1)

1234 (for loop-2)

1231 (for loop-1)

1235 (for loop-2)

1232 (for loop-1)

1236 (for loop-2)

P.RLn

Note1: The “n” in the table is 1 or 2. The number 1 or 2 indicates the number of loop.

Note2: The number 0 to 4 of setting range means that: 0: no decimal point, 1: one digit below decimal point, 2: two digits below

decimal point, 3: three digits below decimal point, 4: four digits below decimal point

Note3: Under normal operation, keep the value of these parameters between the maximum and minimum values of the PV range.

n

(P.L1)

• When UP750,UP550 or UT750, P .RL1< P.RH1, where (P.H1-P.RL1)30000

• When UT550, UT551 or UT520, P .L1< P.H1, where (P.H1-P.RL1)30000

Minimum value

of PVn range

-19999 to 30000

(Note3)

Minimum value

of PVn range

or scale

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

1233 (for loop-1)

1237 (for loop-2)

Page 28

<T oc> <Ref. 1.2: References Related to Remote Input>

Ref.1.2: References Related to Remote Input

Ref. 1-22

IMPORTANT

UP750 UP550 UP35 UT750 UT5 UT40 UT3

None None None UT750-1 UT450-1

Note: Some of the functions below are not available on certain models. For more information, see those sections.

: Applicable models of this section

UT55-1

UT55-2

UT55-4

UT551-B

UT551-D

UT52-7

UT52-8

UT450-2

UT450-4

UT420-7

UT420-8

None

This section contains reference information on the following aspects of remote input. Refer to this information and

change parameters only if necessary .

(1) Setting remote input units, range and scaling

(2) Using square root extraction during remote input

(3) Using remote setpoint filtering and ratio bias computing

(4) Tracking target setpoint when switching from remote to local control

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 29

<Toc> <Ref. 1.2: References Related to Remote Input>

<<Ref.1.2: Reference Related to Remote Input>>

Ref.1.2(1) Setting remote input units, range and scaling

T o use these remote input functions, the controller must have auxiliary analog input capabilities.

Auxiliary analog input is indicated as “input-3” in the parameter table below.

● The following parameters are used.

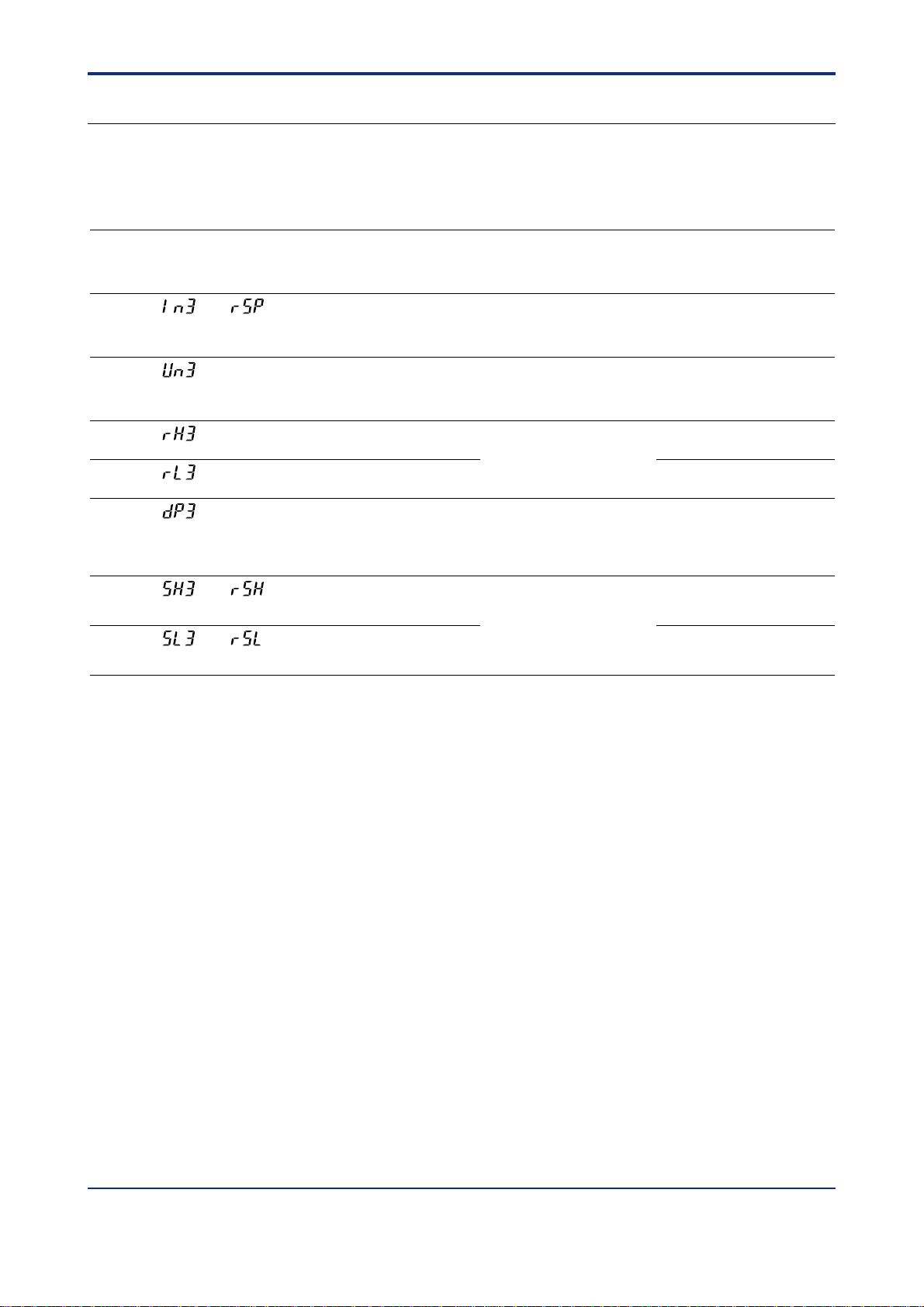

• Setup parameters (Input-related Parameters) : IN3, UN3, RH3, RL3, SDP3, SH3, SL3

UT750

Code

UT5

Code

IN3

(IN3)

UNI3

(UN3)

RH3

(RH3)

RL3

(RL3)

SDP3

(DP3)

SH3

(SH3)

SL3

(SL3)

Note 1: UT450/UT420 do not have these parameters.

For UT450/UT420, use “DPC”, “RSH” and “RSL” parameters for the settings.

For UT551, revers range can be set.

UT40

Code

(RSP)

–

–

–

–

(RSH)

(RSL)

Description Setting range

Remote Input type

(Input-3 type)

Remote Input unit

(Note 1)

Maximum value of remote

input range (Note 1)

Minimum value of remote

input range (Note 1)

Remote input decimal

point position

(Note 1)

Max. value of

remote input scale

Min. value of

remote input scale

0.4 to 2V (40)

1 to 5V (41)

0 to 2V (50)

0 to 10V (51)

%

C

– (no unit)

F

Within the PV input range

0: 99999 (no decimal point)

1: 9999.9

2: 999.99

3: 99.999

4: 9.9999

-19999 to 30000

However, SL1<SH,

SH1-SL130000

Default

UT5: 41

UT40 : 41

%

5.000

1.000

1

Maximum value

of remote

input range

Minimum value

of remote

input range

Ref. 1-23

D-register

No.

1221UT750 : 1 to 5V

1222

1224

1225

1226

1227

1228

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 30

<T oc> <Ref. 1.2: References Related to Remote Input>

Ref. 1-24

Setting Example (1) For UT750 and UT5

The example below shows signal type, units, range and scaling setpoints used for remote input with the UT750,

UT550, UT551 and UT520.

For example, with analog input-3 (IN3) = 41, the remote input range is 1.000 to 5.000 for standard signals (1 to 5

V).

Here, for an input range of 2 to 4 V , set as follows.

Maximum value of analog input-3 range (RH3) = 4,000 (Ref.: “3,500” means 3.5 V.)

Minimum value of analog input-3 range (RL3) = 2,000

1V 2V 5V4V

Input range of

analog input-3

Remote input range

EU (100)%EU (0)%

4.000 (RH3)2.000 (RL3)

Fig. 1-2-1

In the above example, remote input range was set to 2 to 4 V . To change the input voltage signal to the physical

unit of the actual controlled condition (hereinafter, “ scaling”), see the Setting Scaling Procedure.

Setting Scaling Procedure

(1) For UT750 and UT5

The following procedure shows how to change setpoints from the factory-set defaults.

1V 2V 5V4V

EU (0) %

Input range of

analog input-3

(IN=41)

EU (100) %

Step1

Minimum value of PV

input range or PV input

scale (i.e.:-270.0)(SL3)

10.00 (SL3)

Remote input range

Physical quantity range

Remote input range

after scaling

4.000V (RH3)2.000V (RL3)

For UT551, reverse range can be set.

RL3=4.000V, RH3=2.000V

Maximum value of PV

input range or PV input

scale (i.e.:1370.0)(SH3)

50.00 (SH3)

Fig. 1-2-2

Step1: This example shows a remote input range of 1.000 to 5.000 for standard signals

(1 to 5 V) for an analog input -3 type (IN3) = 41.

Step2: In this example, the remote input range is set as 2.000 to 4.000V using the parameters

RL3 and RH3.

Step3: With the UT750/UT5 the same units and decimal point position set for the PV

input range are used for the remote input range. For this reason, if the PV input range

is set to a thermocouple type K ( -270.0 to 1370.0 C) the initial value of SL3 is set

to “-270.0” and that of SH3 is set to “1370.0” .

Step4: Change the initial settings of SDP3,SL3 and SH3 to the actual values for the remote

Input range. In this example, the SDP3 is set to “2” and SL3 is set to “10.00” and the

SH3 is set to “50.00”.

Step2

Step3

Step4

IM 05J01B02-01E 5th Edition : Mar.25,2005-00

Page 31

<Toc> <Ref. 1.2: References Related to Remote Input>

Ref. 1-25

Setting Example (2) For UT40

The example below shows signal type, units, range and scaling setpoints used for remote input with the UT40.

For example, with remote input type (RSP) = 41, the remote input range is 1.000 to 5.000 for standard signals (1 to

5 V).

Note: Unlike the UT750 and UT5, the UT40 does not have RH3 and RL3 parameters, therefore input signal range cannot be changed.

T o change the input voltage signal (1 to 5 V in this case) to the physical unit of the actual controlled condition (hereinafter, “scaling”),

see the Setting Scaling Procedure.

Setting Scaling Procedure

(2) For UT40

The following procedure shows how to change setpoints from the factory-set defaults.

1V 2V 5V4V

EU (0)%

Minimum value of PV

input range or PV input

scale (i.e.: -270.0)(

10.0 (R.SL)

R.SL)

Input range of

analog input-3

Remote input range

after scaling

(IN = 41)

EU (100)%

Maximum value of PV

input range or PV input

scale (i.e.: 1370.0)

50.0 (R.SH)

(R.SH)

Fig. 1-2-3

Step1: This example shows a remote input range of 1.000 to 5.000 for standard signals

(1 to 5 V) for a remote input type (RSP) = 41.

Step2: With the UT450/UT420, the same units and decimal point position set for the PV input