Page 1

User’s

Manual

Models LL100/LL200

Multi-monitoring Function

User ’s Manual

IM 05G01B12-02E

IM 05G01B12-02E

1st Edition

Page 2

Page 3

<Toc> <Ind> <Rev> <Introduction>

Introduction

This Multi-monitoring function of the LL100 PC-based Parameters Setting Tool and the

LL200 PC-based Custom Computation Building Tool is a software package used to monitor

data of two or more GREEN Series controllers.

This user’s manual describes how to operate the Multi-monitoring function.

For explanations other than the Multi-monitoring function, see LL100 PC-based Param-

eters Setting Tool or LL200 PC-based Custom Computation Building Tool User’s Manual of

GREEN Series User’s Manual (Reference) (CD-ROM).

The LL100 PC-based Parameters Setting Tool and the LL200 PC-based Custom Computation Building Tool can be used with Windows 98/2000/XP or Windows NT4.0 (Service Pack

3 or later). For how to use a personal computer and Windows, refer to each user’s manual.

■ Controllers Covered by LL100 and LL200

For information about the GREEN Series controllers covered by LL100 and LL200, see the

user’s manual of each controller or GREEN Series User’s Manual (Reference) (CD-ROM).

■ Intended Readers

i

This manual is intended for people familiar with the functions of the GREEN Series controllers and capable of working with Windows 98/2000/XP or Windows NT 4.0 (Service Pack 3

or later), such as control engineers and personnel in charge of the maintenance of instrumentation and control equipment.

-

■T rademarks

Windows 98/2000/XP and Windows NT 4.0 are registered trademarks of Microsoft Corporation in the United States.

“Ethernet” is registered trademark of XEROX Corporation in the United States.

Media No. IM 05G01B12-02E 1st Edition : Nov. 2004 (YK)

All Rights Reserved Copyright © 2004, Y okogawa Electric Corporation

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 4

<T oc> <Ind> <Rev> <Introduction>

Visual Inspection and Check of Accessories

Visually inspect the product upon delivery to make sure it is not damaged in any way . Store

the box and inner packing material of the package in a safe place - they may be needed if

there is a problem with the product and it needs to be sent back for repair.

■ Check of Model and Suffix Codes

Refer to the following table to make sure the model and suffix codes of the tool are as were

specified with your order.

ii

Model code

LL100 PC-based Parameters Setting Tool for GREEN Series controllers

Model code

LL200 PC-based Custom Computation Building Tool for GREEN Series controllers

Suffix code

-E10 Model for use with IBM PC/AT-compatible personal computer (English version)

Suffix code

-E10 Model for use with IBM PC/AT-compatible personal computer (English version)

■ Confirmation of the Package Contents

Make sure the delivered package contains all of the following items. If any item is missing

or found to be damaged, immediately contact the sales office or dealership from which you

purchased the product.

(1) 3.5-inch floppy disks (4 disks)

(2) Dedicated adapter, supplied with two AAA-size batteries (one unit)

(3) Dedicated cable (one cable)

(4) GREEN Series User’s Manual (Reference) (CD-ROM version)

(5) User’s manual for Multi-monitoring Function (This manual)

Description

Description

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 5

<Toc> <Ind> <Rev> <Introduction>

Documentation Conventions

■ Symbols

WARNING

Indicates that operating the hardware or software in this manner may damage it or lead to

system failure.

NOTE

Draws attention to information that is essential for understanding the operation and/or

features of the product.

TIP

Gives additional information to complement the present topic.

See Also

iii

Gives reference locations for further information on the topic.

■ Description of Displays

(1) Some of the representations of product displays shown in this manual may be exag-

gerated, simplified, or partially omitted for reasons of convenience when explaining

them.

(2) Figures and illustrations representing the controller’s displays may differ from the real

displays in regard to the position and/or indicated characters (upper-case or lowercase, for example), to the extent that they do not impair a correct understanding of the

functions and the proper operation and monitoring of the system.

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 6

<T oc> <Ind> <Rev> <Introduction>

Notices

■ Regarding This User’s Manual

(1) This manual should be passed on to the end user. Keep at least one extra copy of the

manual in a safe place.

(2) Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

(3) This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that

these functions are suited to the particular purpose of the user.

(4) Under absolutely no circumstance may the contents of this manual, in part or in whole,

be transcribed or copied without permission.

(5) The contents of this manual are subject to change without prior notice.

(6) Every effort has been made to ensure accuracy in the preparation of this manual.

Should any errors or omissions come to your attention, however, please contact your

nearest Yokogawa representative or our sales office.

iv

■ Regarding Protection, Safety , and Prohibition Against Unauthorized

Modification

(1) In order to protect the product and the system controlled by it against damage and

ensure its safe use, make certain that all of the instructions and precautions relating to

safety contained in this document are strictly adhered to. Yokogawa does not guaran-

tee safety if products are not handled according to these instructions.

(2) Modification of the product is strictly prohibited.

(3) Reverse engineering such as the disassembly or decompilation of software is strictly

prohibited.

■ Force Majeure

(1) Y okogawa assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

(2) No portion of the software supplied by Yokogawa may be transferred, exchanged,

leased or sublet for use by any third party without the prior permission of Yokogawa.

(3) Be sure to use the spare parts approved by Yokogawa when replacing parts or

consumables.

(4) Use this software with one specified computer only . You must purchase another copy

of the software for use on each additional computer.

(5) Copying this software for purposes other than backup is strictly prohibited.

(6) Store the floppy disk(s) (original medium or media) containing this software in a

secure place.

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 7

<Int> <Ind> <Rev>

Models LL100/LL200

Multi-monitoring Function

User’s Manual

CONTENTS

Introduction........................................................................................................... i

Visual Inspection and Check of Accessories ......................................................ii

Documentation Conventions ..............................................................................iii

Notices .................................................................................................................iv

1. Overview ................................................................................................. 1-1

2. Starting and Quitting the Multi-monitor T ool......................................... 2-1

2.1 Starting the Multi-monitor T ool ...................................................................... 2-1

2.2 Quitting the Multi-monitor T ool ...................................................................... 2-2

Toc-i

IM 05G01B12-02E 1st Edition

3. Work Flow of Multi-monitoring Function............................................... 3-1

4. Setting the Multi-monitoring Function................................................... 4-1

4.1 Automatic Scan............................................................................................... 4-1

4.2 Setting Trend Display ..................................................................................... 4-9

4.2.1 Setting Scale ...................................................................................4-11

4.2.2 Setting Data.....................................................................................4-1 1

5. Operating the Multi-monitoring Function .............................................. 5-1

5.1 Multi-monitor Display ..................................................................................... 5-1

5.2 Starting and Stopping Trend Display............................................................. 5-2

5.3 Saving T rend Data........................................................................................... 5-4

5.4 Setting Trend Display Cycle........................................................................... 5-5

5.5 Operating T rend Display Function................................................................. 5-6

5.5.1 Showing / Hiding Trend Data ............................................................ 5-6

5.5.2 Scrolling Trend Display ..................................................................... 5-7

5.5.3 Changing X-axis Scale ..................................................................... 5-7

5.5.4 Zooming in and Zooming out Trend Display...................................... 5-8

5.6 Panel View......................................................................................................5-11

5.7 Status Display ............................................................................................... 5-13

5.8 Printing Function .......................................................................................... 5-14

6. Tuning ..................................................................................................... 6-1

6.1 Tuning .............................................................................................................. 6-1

6.2 Saving T uning Data......................................................................................... 6-4

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 8

<Int> <Ind> <Rev>

7. T rend Data File........................................................................................ 7-1

Revision Information ............................................................................................ i

Toc-ii

7.1 Opening a Trend Data File .............................................................................. 7-1

7.2 Operating T rend Data...................................................................................... 7-2

7.3 Example of Trend Data Saved as a CSV File ................................................. 7-2

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 9

<Toc> <Ind> <1. Overview >

1. Overview

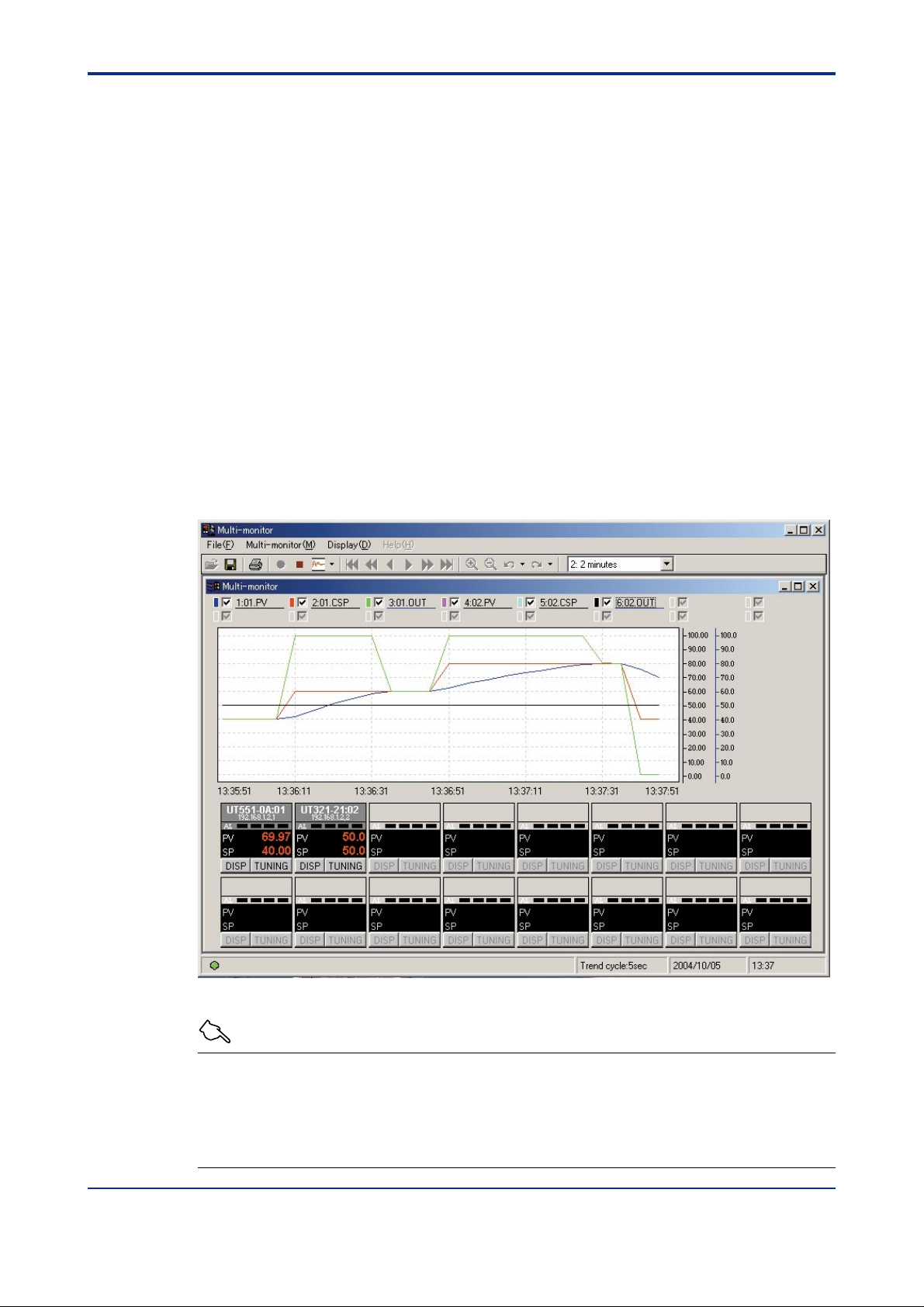

● The Multi-monitoring function allows users to display and collect “measured input

value”, “current setpoint”, “control output” and “alarm generating state” of GREEN

Series controller as trend data. The GREEN Series controllers connected to the

personal computer can be detected automatically by Automatic scan, and the trend

data is displayed on a personal computer screen. The data of a maximum of 16 loops

(*1) can be collected at the same time.

A maximum of 16 trend data can be displayed on a chart screen.

Trend display cycle: 1 to 3600 sec (variable)

Trend display times: 65000 times (fixed regardless of a trend display cycle)

● The Panel view shows measured input value, current setpoint, control output and

alarm generating state of the connected loop.

● The collected trend data can be outputted as a CSV format so that commercial spreadsheet software like Microsoft Excel can treat.

● The saved trend data can be read out and displayed as trend graph.

● T uning can be carried out for every connected loop. Auto-tuning, change of PID param-

eters, change of operation mode and the like can be carried out.

*1: One unit of the following controllers uses two loops: UT750/UP750 cascade control, dual-loop control, temperature and

humidity control and cascade control with two universal inputs, UT550/UT551/UT520/UP550 cascade control.

1-1

Figure 1.1.1 Multi-monitor Display

See Also

LL100 PC-based Parameter Setting Tool or LL200 PC-based Custom Computation Building

Tool User’s Manual of GREEN Series User’s Manual (Reference) (CD-ROM) for information

about operating conditions of personal computer, hardware specification, how to install,

maintenance, troubleshooting and the like.

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 10

Blank Page

Page 11

<Toc> <Ind> <2. Starting and Quitting the Multi-monitor T ool >

2. Starting and Quitting the Multi-monitor Tool

This chapter describes how to start and quit the Multi-monitor tool.

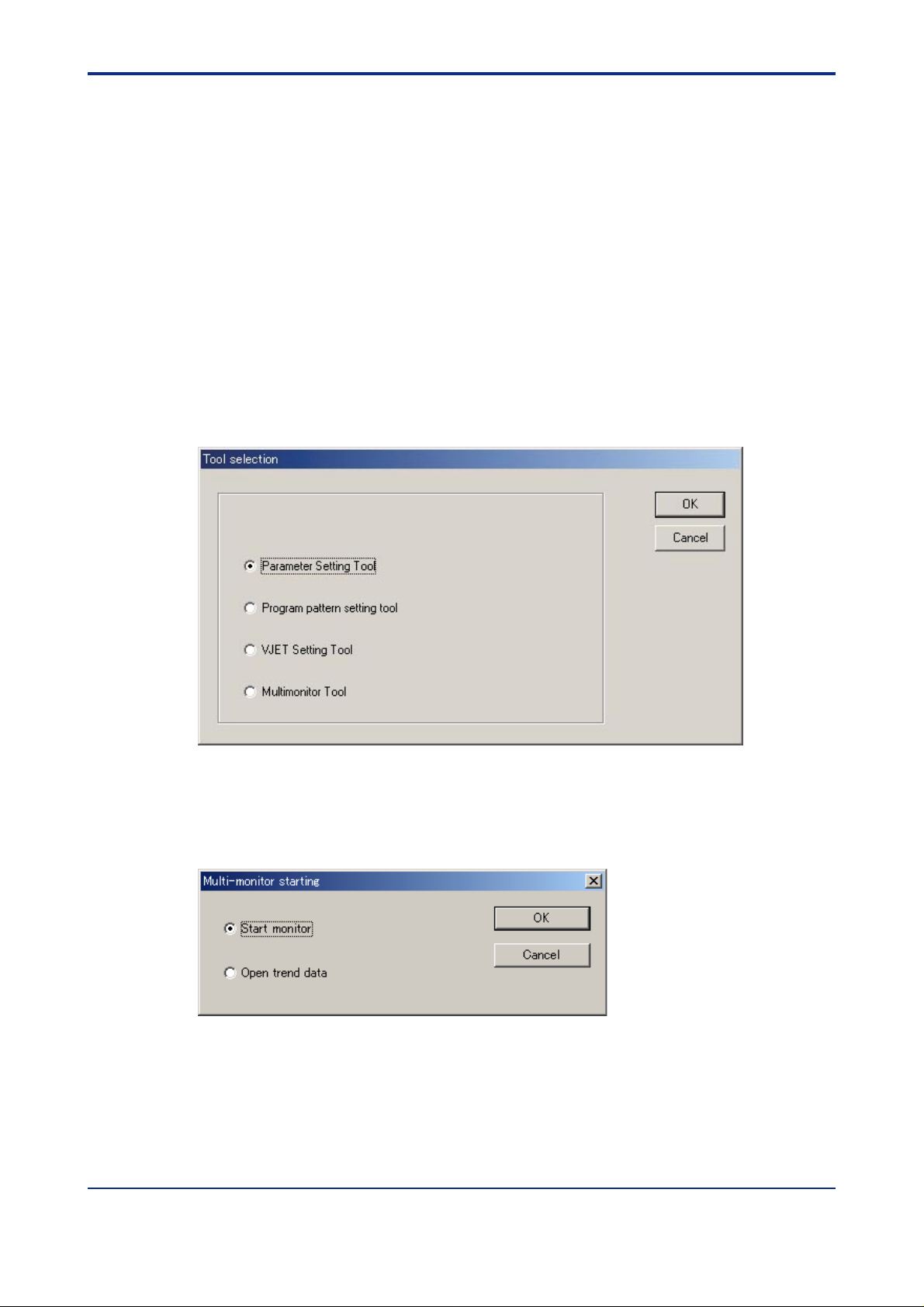

2.1 Starting the Multi-monitor T ool

● Operation Procedure

(1) Start Windows.

(2) From the Start menu of Windows, choose Programs, then Green Series, and click

Green Series LL100 or Green Series LL200.

The tool then starts and the Tool Selection dialog box (Figure 2.1.1) appears.

(For LL200, “Custom Computation Building Tool” appears at the top of dialog box.)

2-1

Figure 2.1.1 Tool Selection Dialog Box

(3) Select Multi-monitor Tool.

(4) Click OK.

(5) The Multi-monitor Starting dialog box (Figure 2.1.2) appears.

Figure 2.1.2 Multi-monitor Starting Dialog Box

(6) See Chapter 4, “Setting the Multi-monitoring Function” when Start monitor is se-

lected.

See Chapter 7, “Trend Data File” when Open trend data is selected.

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 12

<T oc> <Ind> <2. Starting and Quitting the Multi-monitor Tool >

■ Operation from the Menu Bar

LL100: From the menu bar, choose Parameter setting, then Run Multi-monitor tool.

The Automatic Scan dialog box (Figure 4.1.1) appears.

LL200: From the menu bar, choose Custom Computation, then Run Multi-monitor

tool. The Automatic Scan dialog box (Figure 4.1.1) appears.

2.2 Quitting the Multi-monitor T ool

● Operation Procedure

(1) From the menu bar, choose File, then Exit.

(2) The following message box (Figure 2.2.1) appears when the tool is under operation.

The following message box (Figure 2.2.2) appears when the tool is not under operation.

• T o quit after saving the current trend data, click YES. See Section 5.3, “Saving T rend

Data.”

• T o quit without saving the trend data, click NO.

• T o cancel quitting, click CANCEL.

2-2

Figure 2.2.1 Save Trend Data Confirming Message Box

(3) The message box (Figure 2.2.2) appears for confirmation.

• T o quit, click YES.

• T o cancel quitting, click NO.

Figure 2.2.2 Close Message Box

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 13

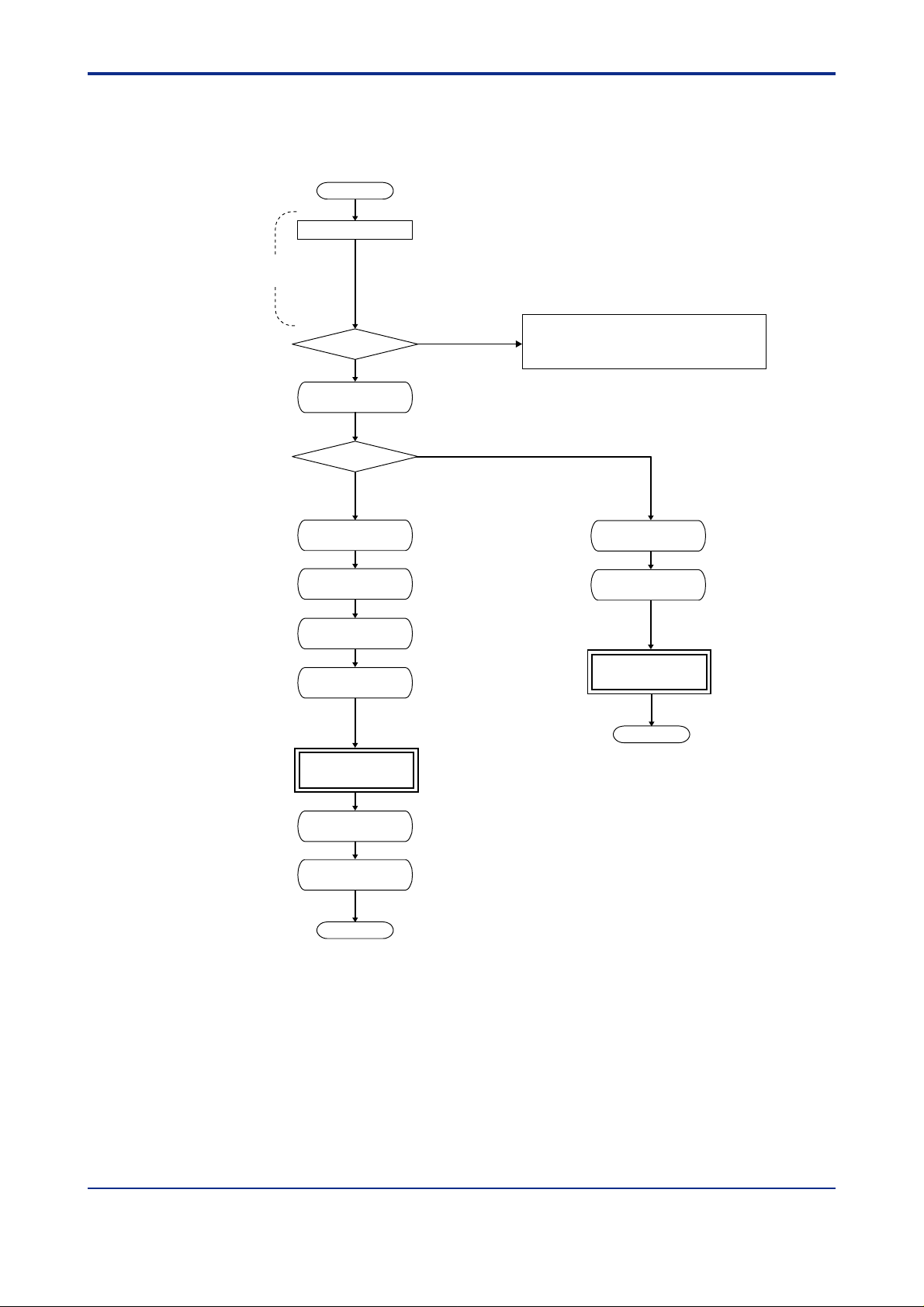

<Toc> <Ind> <3. Work Flow of Multi-monitoring Function >

3. Work Flow of Multi-monitoring Function

This chapter describes the work flow of Multi-monitoring function.

Start

Start LL100/LL200 tool

See GREEN Series User’s

Manual (Reference) (CD-ROM)

See GREEN Series User’s Manual (Reference) (CD-ROM).

See LL100 PC-based Parameter

Setting Tool, LL200 PC-based

Custom Computation Building

Tool or Ethernet Communication

Functions User’s Manual of

GREEN Series User’s Manual

(Reference) (CD-ROM) for

information about connection to

the controller.

Scan the controller

automatically and

monitor data (on-line

monitor)

Tool selection

Start Multi-monitor tool

Monitor selection

Start monitor

(2.1 Starting the Multi-monitor Tool)

Read out data file from a PC and

monitor data (off-line monitor)

(2.1 Starting the Multi-monitor Tool) (7.1 Opening a Trend Data File

- Parameter Setting Tool

- Program Pattern Setting Tool

- VJET Setting Tool

- Custom Computation Building Tool (for LL200 only)

Open Trend Data

3-1

Automatic scan

Set trend

Start trend

Multi-monitor

(on-line)

Tuning

Save trend data

End

(4.1 Automatic Scan)

(4.2 Setting Trend Dispaly)

(5.2 Starting and Stopping Trend Display)

(5. Operating Multi-monitoring Function)

(6. Tuning)

(5.3 Saving Trend Data)

Figure 3.0.1 Work Flow of Multi-monitoring Function

Set up Trend

Multi-monitor

(off-line)

End

(7.2 Operating Trend Data)

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 14

Blank Page

Page 15

<Toc> <Ind> < 4. Setting the Multi-monitoring Function >

4. Setting the Multi-monitoring Function

This chapter describes how to set the Multi-monitoring function.

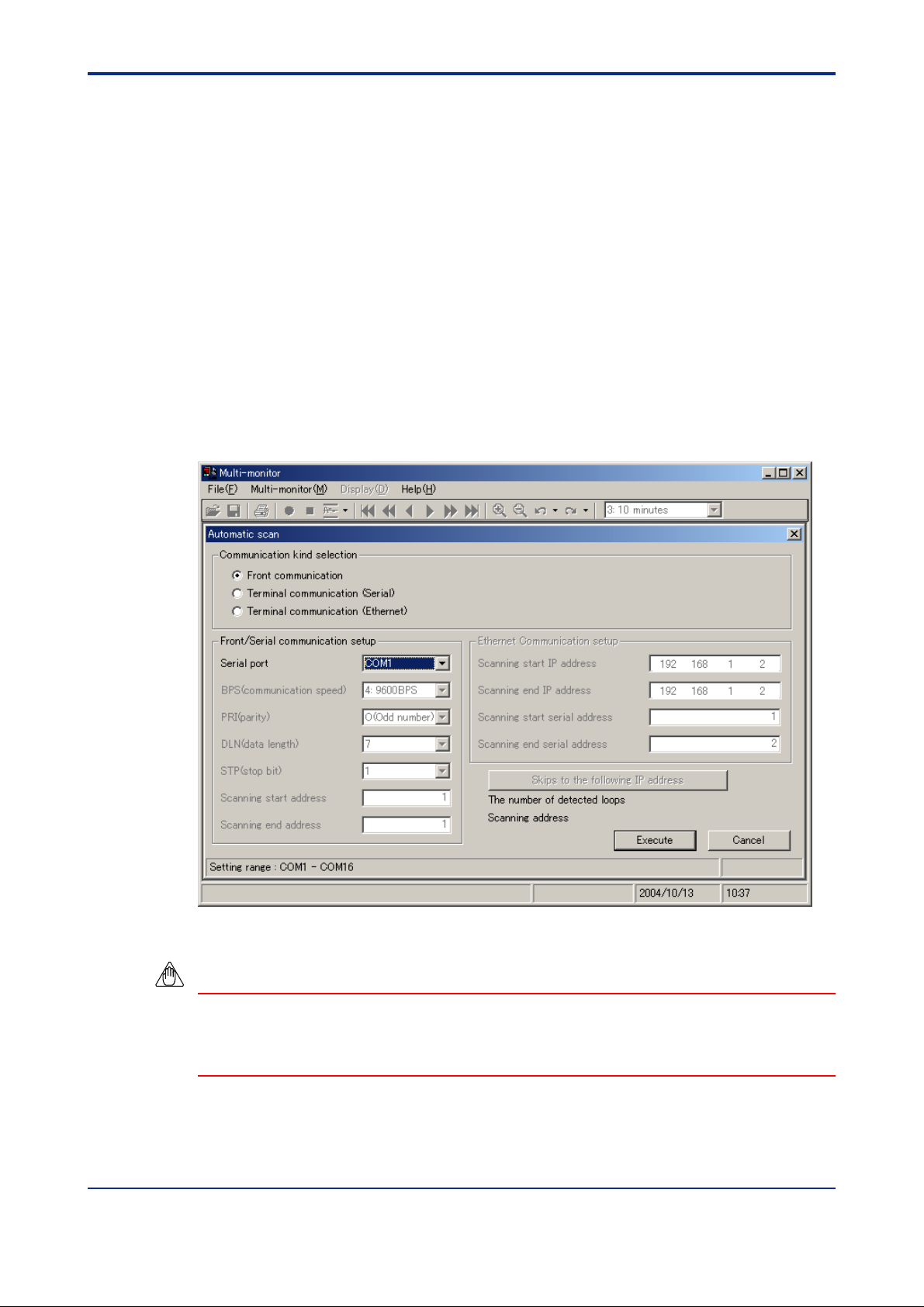

4.1 Automatic Scan

This function allows to detect the GREEN Series controllers connected to the personal

computer automatically .

After you choose Start Monitor in the Multi-monitor Starting dialog box (Figure 2.1.2), the

Automatic Scan dialog box (Figure 4.1.1) appears.

The following three ways can be used for communication.

• Front communication (Optical communication adapter)

• Terminal communication (Serial communication)

• Terminal communication (Ethernet communication)

4-1

Figure 4.1.1 Automatic Scan Dialog Box

NOTE

Front communication (Optical communication adapter), Terminal communication (Serial

communication) and Terminal communication (Ethernet communication) cannot be used

for communication (monitoring) at the same time.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 16

<T oc> <Ind> < 4. Setting the Multi-monitoring Function >

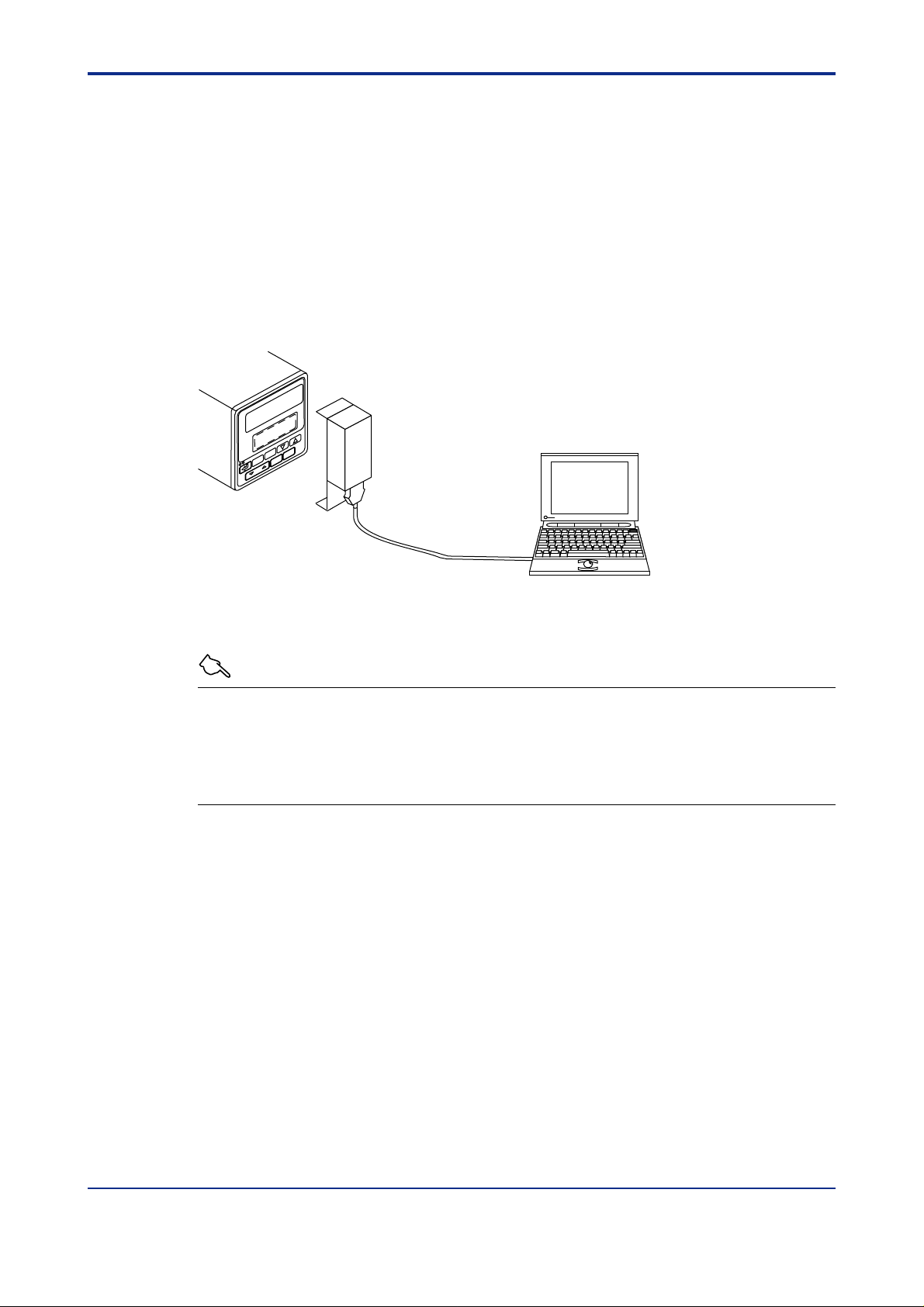

■ T o Monitor via Supplied Optical Communication Adapter

● Operation Procedure

(1) Click Front communication.

(2) From the Serial port list, select the communication port of the personal computer from

COM1 to COM16.

(3) Connect the controller to the personal computer, and then click Execute.

(4) The T rend Setup dialog box (Figure 4.2.1) appears after Automatic scan is completed.

● Connection

Optical communication adapter

(Light loader adapter)

4-2

Controller

Personal computer

Figure 4.1.2 Connection via Optical Communication Adapter (Light Loader Adapter)

See Also

Section 2.3, “Connecting Controller to Personal Computer” of LL100 PC-based Parameter

Setting Tool or LL200 PC-based Custom Computation Building T ool User’s Manual of

GREEN Series User’s Manual (Reference) (CD-ROM) for details how to connect the optical

communication adapter.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 17

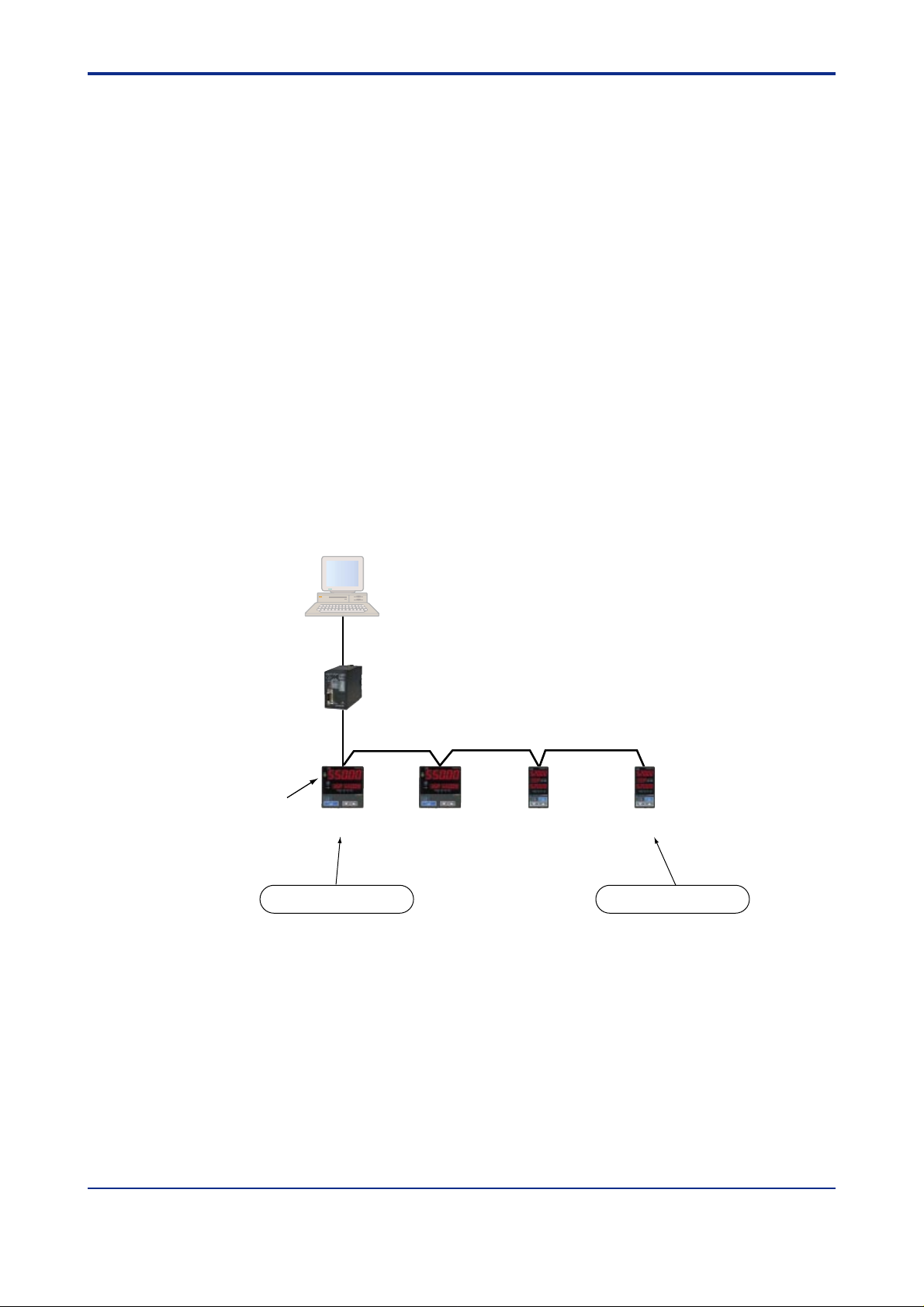

<Toc> <Ind> < 4. Setting the Multi-monitoring Function >

■ T o Monitor via Serial Communication Terminals

● Operation Procedure

(1) Click T erminal communication (Serial).

(2) From the Serial port list, select the communication port of the personal computer from

COM1 to COM16.

(3) Set the RS485 communication parameters.

Select communication speed, parity , data length and stop bit from the drop-down lists.

Make the same RS485 communication settings in the target controller.

(4) Set the Scanning start address and Scanning end address

(5) Connect the controller to the personal computer, and then click Execute.

(6) The Scanning address and the Number of detected loops are displayed during Auto-

matic scan.

(7) When the 16 loops are detected after starting scanning, the scanning to the Scanning

end serial address is completed or Cancel is clicked, Automatic scan stops and the

Trend Setup dialog box (Figure 4.2.1) appears. When interrupted on the way, the

loops already detected by that time can be monitored.

4-3

● Example of Connection

Personal Computer

ML2

RS232C/RS485 converter

RS485

RS485 rear

communication

connection

Figure 4.1.3 Example of Serial Communication Connection

Seiral Address

(ADR) = 1

Scanning start serial address

Seiral Address

(ADR) = 2

Seiral Address

(ADR) = 3

Seiral Address

(ADR) = 4

Scanning end serial address

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 18

<T oc> <Ind> < 4. Setting the Multi-monitoring Function >

● Setting Example of Automatic Scan Dialog Box

4-4

Figure 4.1.4 Setting Example of Serial Communication

NOTE

Discontinuous values like 1, 3, and 5 can be set for each controller as serial address.

However, continuous values can shorten time required for Automatic scan.

NOTE

One unit of the following controllers uses two loops:

UT750/UP750 cascade control, dual-loop control, temperature and humidity control and

cascade control with two universal inputs

UT550/UT551/UT520/UP550 cascade control.

If the controller above is connected to the 16th loop for Automatic scan, the 16th loop is

judged that it does not exist, and Automatic scan stops. The detected 15 loops can be

monitored.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 19

<Toc> <Ind> < 4. Setting the Multi-monitoring Function >

NOTE

Communication via serial terminal communication is possible only for GREEN Series

controllers with RS485 communication (optional function). For controllers without RS485

communication, always select Front communication.

To communicate via serial terminal communication, set the target controller’s RS485

communication protocol to PC-link communication. With other protocol, the serial terminal

communication is unavailable. In addition, the RS485 communication parameters (communication speed, parity , stop bit and data length) of both the target controller and the personal computer must be the same.

For the 300 series of old GREEN Series, communication via serial terminal communication

is possible only for the controllers with the communication function.

For the 300 series of GREEN Series, select Front communication or Serial terminal communication using the LL operating parameter . To select Serial terminal communication, set

the LL parameter to OFF.

See Also

4-5

Chapter 2, “Setup” of GREEN Series Communication Functions (IM 05G01B02-01E) of

GREEN Series User’s Manual (Reference) (CD-ROM) for information about connection for

terminal communication.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 20

<T oc> <Ind> < 4. Setting the Multi-monitoring Function >

■ T o Monitor via Ethernet Terminal Communication

● Operation Procedure

(1) Click T erminal communication (Ethernet).

(2) Set the target controller’s IP address (Scanning start IP address and Scanning end IP

address), and RS485 communication address (Scanning start serial address and

Scanning end serial address) in the text box.

(3) Connect the controller to the personal computer, and then click Execute.

(4) The Scanning address and the Number of detected loops are displayed during Auto-

matic scan.

(5) Automatic scan starts at the Scanning start serial address of the Scanning start IP

address. After scanning the Scanning end serial address, the scanning of the next IP

address is started. Clicking Skips to the following IP address during scanning

transfers to the next IP address regardless of the serial address at that time.

(6) When the 16 loops are detected after starting scanning, the scanning to the Scanning

end serial address is completed or Cancel is clicked, Automatic scan stops and the

Trend Setup dialog box (Figure 4.2.1) appears. When interrupted on the way, the

loops already detected by that time can be monitored.

4-6

NOTE

Consult your network administrator on routing settings.

● Example of Connection

Personal Computer

Ethernet

IP Address=192.168.1.1

Serial Address (ADR)=1

IP Address=192.168.1.2

Serial Address (ADR)=1

10BASE-T Cable

IP Address=192.168.1.3

Serial Address (ADR)=1

Scanning start IP address

Scanning start serial address

Figure 4.1.5 Example of Ethernet Communication Connection

Scanning end IP address

Scanning end serial address

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 21

<Toc> <Ind> < 4. Setting the Multi-monitoring Function >

● Setting Example of Automatic Scan Dialog Box

4-7

Figure 4.1.6 Setting Example of Ethernet Communication

● Example of Connection when Gateway Function is Used

Personal Computer

UT551

RS485

Serial Address

(ADR) = 2

Ethernet

IP Address=192.168.1.1

Serial Address (ADR)=1

10BASE-T Cable

RS485 rear

terminal

communication

connection

VJET

IP Address=192.168.1.2

Serial Address

(ADR) = 1

RS485

Serial Address

(ADR) = 2

Serial Address

(ADR) = 3

Scanning start serial address:

The minimum serial address of the connected controllers.

In the example above, Serial address (ADR) = 1 connected to the VJET is the Scanning

start serial address.

Scanning end serial address:

The maximum serial address of the connected controllers.

In the example above, Serial address (ADR) = 3 connected to the VJET is the Scanning

end serial address.

Figure 4.1.7 Example of Ethernet Communication (Gateway Function) Connection

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 22

<T oc> <Ind> < 4. Setting the Multi-monitoring Function >

● Setting Example of Automatic Scan Dialog Box

4-8

Figure 4.1.8 Setting Example of Ethernet Communication (Gateway Function)

NOTE

Set the minimum serial address of all serial instruments as the Scanning start serial address.

Set the maximum serial address of all serial instruments as the Scanning end serial address.

NOTE

One unit of the following controllers uses two loops:

UT750/UP750 cascade control, dual-loop control, temperature and humidity control and

cascade control with two universal inputs

UT550/UT551/UT520/UP550 cascade control.

If the controller above is connected to the 16th loop for Automatic scan, the 16th loop is

judged that it does not exist, and Automatic scan stops. The detected 15 loops can be

monitored.

See Also

Chapter 2, “Setup” of Ethernet Communication Functions (IM 05G01B52-01E) of GREEN Series User’s

Manual (Reference) (CD-ROM) for information about connection for terminal communicaiton.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 23

<Toc> <Ind> < 4. Setting the Multi-monitoring Function >

4.2 Setting T rend Display

● Operation Procedure at the time of the Multi-monitor Start

(1) The T rend Setup dialog box (Figure 4.2.1) appears after Automatic scan is completed.

● Operation Procedure on the Menu Bar

(1) From the menu bar, choose Multi-monitor, then Set trend display. The scale of trend

display can be changed by the operation from the menu bar.

NOTE

The Trend Setup dialog box appears when the operation in Section 7.1, “Opening a Trend

Data File” is carried out.

Select the trend data item to be displayed in the Multi-monitor display , scale type and

display color in the Trend Setup dialog box.

The figure below shows the setting example of trend display for measured input value (PV),

current setpoint (CSP) and control output (OUT) of the controller with Serial gateway

function and the controller connected to it.

4-9

The connection for the setting example below is shown on the next page.

Figure 4.2.1 Trend Setup Dialog Box

Double-clicking the Display color displays the Color Setup dialog box (Figure 4.2.2).

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 24

<T oc> <Ind> < 4. Setting the Multi-monitoring Function >

Figure 4.2.2 Color Setup Dialog Box

● Example of Connection

4-10

The connection for the setting example of the Trend Setup dialog box (Figure 4.2.1) is

shown below. A maximum of 16 data items can be displayed in the Multi-monitor display. In

this example, the 6 data items of measured input value (PV), current setpoint (CSP) and

control output (OUT) of two controllers are displayed.

Personal Computrer

Ethernet

10BASE-T Cable

UT551

IP Address=192.168.1.1

Serial Address (ADR) = 1

RS485

rear treminal

communication

connection

UT321

Serial Address

(ADR) = 2

Figure 4.2.3 Example of Connection

Loop-1 Controller

Measured input value (PV), Terget setpoint (CSP), Control output (OUT)

Loop-2 Controller

Measured input value (PV), Terget setpoint (CSP), Control output (OUT)

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 25

<Toc> <Ind> < 4. Setting the Multi-monitoring Function >

4.2.1 Setting Scale

Set the Y-axis scale of the trend data to be displayed in the Multi-monitor display in the

Scale Setup.

Select either of “PV range of the loop detected automatically”, “0.0% - 100.0%” or “User

scale”. Up to four scale types can be registered.

The maximum value and minimum value can be changed only when the scale type is set to

“User scale.”

The maximum value and minimum value for each scale type are as follows.

Table 4.2.1 Scale Type

Scale type Remarks

PV range

of loop1 to loop16

0 to 100%

User scale

Scale setup becomes effective when OK is clicked in the T rend Setup dialog box.

Minimum value

Lower limit of the PV input

range of the corresponding loop

0

User scale

Upper limit of the PV input

range of the corresponding loop

100

User scale

Maximum value

Upper and lower limits

cannot be changed.

Upper and lower limits

cannot be changed.

Upper and lower limits can

be changed on condition

that lower limit < upper limit.

4-11

4.2.2 Setting Data

Select the trend data item to be displayed in the Multi-monitor display in the Data Setup. A

maximum of 16 data item can be displayed.

The trend data items are measured input value (PV), current setpoint (CSP), (heating-side)

control output (OUT) and cooling-side control output (OUTc) of the loop detected automatically.

Two or more same data items cannot be registered.

Table 4.2.2 Data Setup

Loop Display colorData Scale

Select loops

from loop 1 to

loop 16.

NOTE

Measured input value (PV), current setpoint (CSP), (heating-side) control output (OUT),

cooling-side control output (OUTc) and alarm generating state of all the loops detected

automatically by Automatic scan are collected while the trend display is working.

Select data item from measured

input value (PV), current setpoint

(CSP), (heating-side) control

output (OUT) and cooling-side

control output (OUTc) of the

controller of the corresponding

loop.

Select the type set in the

Scale Setup.

Select the

display color for

each data item.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 26

Blank Page

Page 27

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

5-1

5. Operating the Multi-monitoring Function

This chapter describes how to operate the Multi-monitoring function.

5.1 Multi-monitor Display

The followings can be carried out in the Multi-monitor display .

● Showing / hiding, scrolling, zooming in and zooming out of trend data

● Start / stop of trend display and saving of trend data

● Display in the Panel view of measured input value (PV), current setpoint (CSP),

(heating-side) control output (OUT), cooling-side control output (OUT c) and

alarm generating state of the connected loop

● Tuning of the controller of connected loop

● Pop-up display of tuning data on a chart

Displays the data items selected in the Data Setup

Chart

Scroll

Showing / hiding of trend data

Zoom in/Zoom out

X-axis scale of chart

Panel view

Figure 5.1.1 Multi-monitor Display while Trend Display is Stopped

Status display bar

Scale type

Scale 1, scale 2, scale 3

and scale 4 from the left

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 28

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

5.2 Starting and Stopping T rend Display

■ Starting T rend Display

● Operation Procedure

(1) From the toolbar, click the [ ] shortcut, or from the menu bar, choose Multi-monitor,

then Start trend display while the trend display is stopped.

(2) Trend display starts.

Shortcut button

5-2

Figure 5.2.1 Multi-monitor Display while Trend Display is W orking

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 29

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

■ Stopping T rend Display

● Operation Procedure

(1) From the toolbar, click the [ ] shortcut, or from the menu bar, choose Multi-monitor,

then choose Stop trend display while the trend display is working.

(2) The following message box (Figure 5.2.2) appears for confirmation.

• T o stop trend display after saving the current trend data, click YES. See Section 5.3,

“Saving Trend Data.”

• T o stop trend display without saving the trend data, click NO.

• T o cancel stopping trend display, click CANCEL.

Figure 5.2.2 Save Trend Data Confirming Message Box

5-3

NOTE

By stopping the trend display , it will be in a trend display stop state. In this manual, the state

where the trend display is not performed and the trend data file is opened is named generically “The trend display is stopped.”

NOTE

If opening a saved trend data file while the trend display is stopped, and then starting the

trend display again, the Automatic Scan dialog box appears. T rend display can be started

after Automatic scan and the setup for trend display are completed.

NOTE

The Multi-monitor tool can hold a maximum of 65000 times of trend data regardless of a

trend cycle. When exceeds 65000 times, trend data is discarded from old data. Periodical

saving of monitored data as a file is recommended. The saved data is the trend data of the

time of data saving. If the trend cycle is 5 seconds (data acquisition per 5 seconds), data

saving of about 90 hours is continuously possible.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 30

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

5.3 Saving T rend Data

Trend data can be saved while trend display is working or stopped.

Measured input value (PV), current setpoint (CSP), (heating-side) control output (OUT),

cooling-side control output (OUTc), alarm generating state and tuning data (if recorded in

the Tuning display) of all the loops detected automatically can be saved as a CSV file.

● Operation Procedure

(1) From the toolbar, click the [ ] shortcut, or from the menu bar, choose File, and then

Save trend data.

(2) The Save T rend Data dialog box (Figure 5.3.1 or Figure 5.3.2) appears. In the File

name text box, enter a file name then click Save.

5-4

Figure 5.3.1 Save Trend Data Dialog Box while Trend Display is Stopped

Figure 5.3.2 Save Trend Data Dialog Box while Trend Display is Working

NOTE

If stopping the trend display , and then starting it again without saving the current trend data,

the trend data is discarded.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 31

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

5.4 Setting T rend Display Cycle

Trend display cycle can be changed while trend display is working or stopped.

● Operation Procedure

(1) From the status display bar, double-click T rend cycle, or from the menu bar , choose

Multi-monitor, then Change trend cycle while trend display is working or stopped.

(2) The T rend Cycle dialog box (Figure 5.4.1) appears. The setting range is 1 to 3600 sec.

The initial value is 5 sec.

(3) Change the trend display cycle, and then click OK.

5-5

Communication status lamp

Green: Data acquisition state is good.

Red: Data acquisition state is bad.

Figure 5.4.1 Trend Data Cycle Dialog Box

NOTE

Status display bar

If trend display cycle is shortened, data acquisition may not be completed within the trend

display cycle when many loops are connected. The communication status lamp on the

status display bar becomes red. In this case, set a longer trend display cycle to complete

data acquisition within the trend display cycle.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 32

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

5.5 Operating T rend Display Function

5.5.1 Showing / Hiding T rend Data

Showing / hiding of trend data to be displayed in the Multi-monitor display can be switched

while trend display is working or stopped.

Checked: Shows trend data

Control output trend of loop 1 is displayed.

5-6

Blank: Hides trend data

Control output trend of loop 1 is not displayed.

Figure 5.5.1 Showing / Hiding of Trend Data

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 33

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

5.5.2 Scrolling T rend Display

The displayed trend data can be scrolled while the trend display is stopped. click the

shortcut button from the toolbar, or operate from the menu bar (Table 5.5.1).

Table 5.5.1 Scroll of Trend Display

Function Name Remarks

Start

Shortcut Button Menu Bar Operation

[Display(D)]-[Move(M)]-[Start]

The left end of a chart is displayed as start data.

5-7

-1/2 scrolling

-1/4 scrolling

1/4 scrolling

1/2 scrolling

Newest

[Display(D)]-[Move(M)]-[-1/2 scrolling]

[Display(D)]-[Move(M)]-[-1/4 scrolling]

[Display(D)]-[Move(M)]-[1/4 scrolling]

[Display(D)]-[Move(M)]-[1/2 scrolling]

[Display(D)]-[Move(M)]-[Newest]

5.5.3 Changing X-axis Scale

The X-axis to be displayed in the Multi-monitor display can be changed while the trend

display is working or stopped. Select from the drop-down list on the toolbar (Figure 5.5.2) or

operate from the menu bar (Table 5.5.2).

On the present X-axis scale, it scrolls 1/2 of

the X-axis scale to the past.

On the present X-axis scale, it scrolls 1/4 of

the X-axis scale to the past.

On the present X-axis scale, it scrolls 1/4 of

the X-axis scale to the future.

On the present X-axis scale, it scrolls 1/2 of

the X-axis scale to the future.

The right end of a chart is displayed as the newest

data.

X-axis scale on a chart

Figure 5.5.2 X-axis Scale

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 34

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

Table 5.5.2 X-axis Scale

Function Name Remarks

1-minute display

2-minute diplay

10-minute diplay

1-hour display

2-hour diplay

12-hour diplay

24-hour diplay

All data display

Automatic

[Display(D)]-[X-axis scale(X)]-[1:1 minute]

[Display(D)]-[X-axis scale(X)]-[2:2 minutes]

[Display(D)]-[X-axis scale(X)]-[3:10 minutes]

[Display(D)]-[X-axis scale(X)]-[4:1 hour]

[Display(D)]-[X-axis scale(X)]-[5:2 hours]

[Display(D)]-[X-axis scale(X)]-[6:12 hours]

[Display(D)]-[X-axis scale(X)]-[7:24 housrs]

[Display(D)]-[X-axis scale(X)]-[8:All data]

None

Menu Bar Operation

The X-axis scale to be displayed on a chart is 1 minute.

The X-axis scale to be displayed on a chart is 2 minutes.

The X-axis scale to be displayed on a chart is 10 minutes.

The X-axis scale to be displayed on a chart is 1 hour.

The X-axis scale to be displayed on a chart is 2 hours.

The X-axis scale to be displayed on a chart is 12 hours.

The X-axis scale to be displayed on a chart is 24 hours.

All data is displayed. The left end of a chart is displayed as

the start time, the right end as the newest time.

Automatic is selected automatically when the scale is changed

by Zoom in or Zoom out. (Cannot be changed)

5.5.4 Zooming in and Zooming out T rend Display

Trend display can be zoomed in or zoomed out while the trend display is stopped.

● T oolbar Shortcut Operation or Menu Bar Operation

Table 5.5.3 Zoom in and Zoom out

Function Name Remarks

Zoom in

Zoom out

Shortcut Button Menu Bar Operation

[Display(D)]-[Zoom(Z)]-[Zoom in(I)]

[Display(D)]-[Zoom(Z)]-[Zoom out(O)]

Trend display is zoomed in by changing

the scale of the X-axis nX% and Y-axis

nY%.

5-8

● Mouse Operation

Mouse operaiton is described in Figure 5.5.3 and Figure 5.5.4.

Table 5.5.4 Zoom in and Zoom out

Function Name

Zoom in

Zoom out

On a chart, move a mouse to the right with the left click of the mouse carried out, and then

cancel the left click.

On a chart, move a mouse to the left with the left click of the mouse carried out, and then

cancel the left click.

Operation

● Operation to Reset Display Scale

To reset the zoomed in or zoomed out display, on the toolbar , choose Display, Zoom, then

Reset. In this case, X-axis is set to 10 minutes. Change it as necessary .

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 35

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

Dragging a mouse cursor in the direction of an arrow

zooms in the trend display as shown below.

5-9

Figure 5.5.3 Zoom in

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 36

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

Dragging a mouse cursor in the direction of an arrow

zooms out the trend display as shown below.

5-10

Figure 5.5.4 Zoom out

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 37

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

5.6 Panel View

Data of each loop are displayed in the Panel view (Figure 5.6.1) on the lower part of Multimonitor display .

While the trend display is working: Displays the newest data.

While the trend display is stopped: Displays the data of the position where a mouse cursor

is placed.

All data of X-axis where a mouse cursor is placed are displayed.

Mouse cursor

5-11

Figure 5.6.1 Confirmation of Trend Data

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 38

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

5-12

Alarm 1 to 4 lamps

Alarm On: Lights up (red)

Alarm Off: Goes off (black)

For UP350/UP351,

PV evnet 1, PV event 2 and

Time evnet are displayed and

the right end lamp is not used.

the instrument alarms are displayed.

(Heating-side) control output (OUT)

Cooling-side control output (OUTc)

displays of current setpoint (SP),

(heating-side) control output (OUT),

cooling-side control output (OUTc).

For UP550/UP750,

Measured input value (PV)

Current setpoint (SP)

Display switching button

Clicking the button switches

Figure 5.6.2 Panel View

NOTE

For UP350 and UP351, alarm status lamps indicate PV event 1, PV event 2 and Time

event. The right end lamp is always off.

Model : Loop number (01 to 16)

Address

For optical communication adapter or serial communication:

Serial communication address

For Ethernet communication:

0 to 255

0 to 255

0 to 255

IP1

IP2

IP address

Tuning button

Operation mode such as Auto/Manual or

Run/Stop, SP No. and PID parameter can be checked.

See Chapter 6, “Tuning.”

IP3

0 to 255

IP4

01 to 99

ADR

01 to 99

ADR

Serial communication address

For UT550, alarms 5 to 8 are not displayed when eight alarms are used.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 39

<Toc> <Ind> < 5. Operating the Multi-monitoring Function >

5.7 Status Display

5-13

1 2

Status display bar

Figure 5.7.1 Status Display

Table 5.7.1 Status Display

StatusDisplay Position Remarks

1

1

2

1

3

4

Under communication

Communication delay occurs

Trend cycle

Progress

Date

Time

Display

Green lamp lights up

Red lamp lights up

Trend cycle

Progress bar display

PC system date

PC system time

3

Blinks for every trend cycle

Blinks for every trend cycle

Double-clicking displays the Trend Cycle dialog box by

pop-up one.

Rate of Progress is displayed when processing

takes time.

Year/month/day

Time: minute

4

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 40

<T oc> <Ind> < 5. Operating the Multi-monitoring Function >

5.8 Printing Function

The Multi-monitor display (Figure 5.8.1) can be printed or copied to a cliploard.

Print: On the menu bar, click File, and then choose Print.

Hard copy: On the menu bar, click File, and then choose Copy to clipboard.

● Operation Procedure for Printing

(1) On the menu bar, Click File, and then choose Print.

(2) The Printer Selection dialog box appears. However , not appears while trend data is

working.

(3) The Multi-monitor display is printed.

● Operation Procedure for Copying to Clipboard

(1) From the menu bar, choose File, then Copy to clipboard .

(2) The Multi-monitor display can be pasted on drawing software and the like.

5-14

Figure 5.8.1 Example of Hard Copy

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 41

<Toc> <Ind> < 6. T uning >

6. Tuning

This chapter describes how to tune the Multi-monitoring function.

6.1 T uning

Tuning of the loop detected automatically by Automatic scan can be tuned.

● Operation Procedure

(1) Click TUNING button in the Panel view of the loop to be tuned, or select the loop to be

tuned from the [

(2) The T uning dialog box of the corresponding loop appears (Figure 6.1.1).

(3) The current setpoint is displayed. Select the value of the parameter to be changed from

the drop-down list, or double-click the text box to enter the required value.

(4) Data change of the controller is activated when ENTER key is pressed.

(5) Refer to Section 6.2, “Saving Tuning Data” when saving the tuning data. Click Close

when not saving the tuning data.

] drop-down list on the toolbar while trend display is working.

6-1

NOTE

Tuning can be carried out only when trend display is working. T uning cannot be carried out

for the saved data opened by selecting Open trend data.

Dispalys model, IP address, serial

communication address

Displays measured input value (PV), current

setpoint (CSP), (heating-side) control output

(OUT) and cooling-side control output (OUTc).

Displays and changes mode parameters such

as RUN/STOP or REMOTE/LOCAL, current

setpoint (SP), parameters such as control

output at manual operation (MOUT) and PID

parameters such as P, I, D, Pc, Ic and Dc.

Close button: Quits without recording the tuning

data on trend data.

Figure 6.1.1 Tuning Dialog Box

Record tuning data button: Tuning data is

recorded on trend data. However, it is not saved

as a file. Save data as a file as necessary. (See

Section 6.2, “Saving Tuning Data.”

Displays the guidance for setting range and unit.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 42

<T oc> <Ind> < 6. Tuning >

■ Displaying and Setting Modes

Select a value from the drop-down list for the following mode.

Loop 1/2: Displays the loop when the controller is in dual-loop control, temperature and

humidity control or cascade control.

RUN/STOP: Displays and changes the RUN/STOP status of the controller

REMOTE/LOCAL: Displays and changes the Remote/Local mode of the controller

MAN/AUTO/CAS: Displays and changes the Manual/Auto (/Cascade) mode of the

controller. (CAS is not provided for UT450/UT420.)

A T ON/OFF: Starts and stops auto-tuning. After you start auto-tuning, optimized PID

parameter values are set in the controller.

V .AT ON/OFF: Starts and stops automatic valve tuning. (Only for position proportional

type controllers)

RESET/PROG1/PROG2: Displays and changes the Program 1 start/Program 2 start/

Operation stop of the controller.

RESET/PROG/LOCAL: Displays and changes the Program operation start/Local opera-

tion start/Operation stop of the controller.

6-2

■ Displaying and Setting Parameters

Enter a value in the text box for the following data.

See the User’s Manual of each controller for the setting contents of parameters.

SP No: Displays and changes the SP number .

PID No.: Displays the PID group number.

SP: Displays and changes the current setpoint.

LSP: Displays and changes the local setpoint.

LPID: Displays and changes the PID number in LOCAL mode.

PTN: Displays the program pattern number.

PID No.: Displays the PID number.

MOUT: Displays and changes the control output (heating-side control output) in Manual

mode.

MOUTc: Displays and changes the cooling-side control output in Manual mode.

P: Displays and changes the (heating-side) proportional band.

I: Displays and changes the (heating-side) integral time.

D: Displays and changes the (heating-side) derivative time.

Pc: Displays and changes the cooling-side proportional band.

I: Displays and changes the cooling-side integral time.

D: Displays and changes the cooling-side derivative time.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 43

<Toc> <Ind> < 6. T uning >

Table 6.1.1 Tuning Parameter

Function

Run / Stop switching

Remote / Local switching

Manual / Automatic (/ Cascade) switching

Auto-tuning

Automatic valve tuning

SP No.

PID No.

Target (Current) Setpoint

(Heating-side) control output

Cooling-side control output

(Heating-side) Proportional band

(Heagting-side) Integral time

(Heating-side) Derivative time

Cooling-side proportional band

Cooling-side integral time

Cooling-side derivative time

UT350/UT320/UT351/UT321

-

MAN/AUTO

AT ON/OFF

-

SP. No

PID No. (display only)

SP

MOUT

MOUTc

P

I

D

Pc

Ic

Dc

UT450/UT420

RUN/STOP

REMOTE/LOCAL

MAN/AUTO

AT ON/OFF

V.AT ON/OFF

SP. No

PID No. (display only)

SP

MOUT

MOUTc

P

I

D

Pc

Ic

Dc

UT550/UT520/UT551/UT750

REMOTE/LOCAL

MAN/AUTO/CAS

V.AT ON/OFF

PID No. (display only)

6-3

RUN/STOP

AT ON/OFF

SP. No

SP

MOUT

MOUTc

P

I

D

Pc

Ic

Dc

Program start / stop switching

Manual / Automatic switching

Auto-tuning

Automatic valve tuning

Local setpoint

Local PID No.

Program pattern No.

PID No.

(Heating-side) control output

Cooling-side control output

(Heating-side) Proportional band

(Heagting-side) Integral time

(Heating-side) Derivative time

Cooling-side proportional band

Cooling-side integral time

Cooling-side derivative time

UP350/UP351Function

RESET/PROG1/PROG2

-

AT ON/OFF

-

-

-

-

PID No. (display only)

-

-

P

I

D

-

-

-

UP550/UP750

RESET/PROG/LOCAL

MAN/AUTO

AT ON/OFF

V.AT ON/OFF(UP550 only)

LSP

LPID

PTN (display only)

PID No. (display only)

MOUT

MOUTc

P

I

D

Pc

Ic

Dc

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 44

<T oc> <Ind> < 6. Tuning >

6.2 Saving T uning Data

■ Recording T uning Data on Trend Data

The tuning data can be recorded on trend data. The data to be recorded are RUN/STOP,

RESET/PROG1/PROG2, RESET/PROG/LOCAL, MAN/AUTO/CAS, REMOTE/LOCAL,

SP No., PID No., LSP, P, I, D, Pc, Ic, Dc, MOUT and MOUTc.

When the tuning data is recorded, a tuning mark appears on a chart. Pointing a mouse to

the tuning mark displays the tuning data by pop-up one.

NOTE

Clicking Record tuning data records the tuning data on the trend data on a memory.

However, it is not saved as a file. Save the trend data when stopping the trend display or as

necessary .

● Operation Procedure

6-4

(1) After tuning is completed, click Recorded tuning data in the T uning dialog box (Figure

6.1.1) of the corresponding loop.

(2) The Record T uning Data message box (Figure 6.2.1) appears, and the tuning mark

appears in the trend display .

Figure 6.2.1 Record T uning Data Dialog Box

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 45

<Toc> <Ind> < 6. T uning >

Tuning mark

Tuning data is displayed by pop-up one for a constant period (5 to 10 sec)

when pointing a mouse to the tuning mark after tuning is completed.

6-5

Figure 6.2.2 Tuning Mark

(3) Click OK.

(4) From the toolbar, click the [

] shortcut, or from the menu bar, choose File, then Save

trend data.

(5) The Save T rend Data dialog box (Figure 6.2.3) appears. In the File name text box,

enter a file name then click Save.

Figure 6.2.3 Save Trend Data Dialog Box

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 46

Blank Page

Page 47

<Toc> <Ind> < 7. Trend Data File >

7. T rend Data File

This chapter describes how to operate a trend data file of Multi-monitoring function.

7.1 Opening a T rend Data File

A trend data file saved to a PC can be read out and displayed in the Multi-monitor display

while the trend display is stopped.

● Operation Procedure

(1) Select Open trend data in the Start Multi-monitor starting dialog box, or from the Menu

bar, choose File, then Open trend data while the trend display is stopped

(2) The Open T rend Data dialog box (Figure 7.1.1) appears.

(3) Select a trend data file and click Open. The T rend Setup dialog box appears. See

Section 4.2, “Setting Trend Display .”

(4) Select the trend data item to be displayed in the Multi-monitor display , scale and display

color, and then click OK. The Multi-monitor display appears. See Section 5.5, “Operat-

ing Trend Display Function” for how to operate in the Multi-monitor display.

7-1

Figure 7.1.1 Open Trend Data Dialog Box

NOTE

If starting the trend display after opening a saved trend data file, the Automatic Scan dialog

box appears. Trend display can be started after Automatic scan and the setup for trend

display are completed.

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 48

<T oc> <Ind> < 7. Trend Data File >

7.2 Operating T rend Data

The trend display function at the time of off-line is same as that when the trend display is

working at the time of on-line. However, trend cycle cannot be set and tuning cannot be

carried out. See Section 5.5, “Operating T rend Display Function.”

7.3 Example of T rend Data Saved as a CSV File

The example when reading a CSV file to Excel is shown below. As for actual CSV data,

each data is divided by “ , .”

1. Connection Information, Scale Setup and T rend Setup

Connection Information

7-2

Scale Setup

T rend Setup

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 49

<Toc> <Ind> < 7. Trend Data File >

2. T rend Data

7-3

IM 05G01B12-02E

1st Edition : 2004.11.05-00

Page 50

Blank Page

Page 51

<Int> <Toc> <Ind>

Revision Information

● Manual Title: Models LL100/LL200 Multi-monitoring Function User’s Manual

● Manual No. : IM 05G01B12-02E

1st Edition/Nov . 2004

Newly published.

i

Written by Yokogawa Electric Corporation

Published by Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, JAPAN

IM 05G01B12-02E 1st Edition : 2004.11.05-00

Page 52

Blank Page

Page 53

Page 54

YOKOGAWA ELECTRIC CORPORATION

Network Solutions Business Division

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 JAPAN

Phone: +81-422-52-7179 Facsimile: +81-422-52-6793

Sales Branch Offices

Tokyo, Nagoya, Osaka, Hiroshima, Fukuoka

YOKOGAWA CORPORATION OF AMERICA

Headquaters

2 Dart Road, Newnan, GA. 30265-1094 U.S.A.

Phone: +1-770-253-7000 Facsimile: +1-770-251-0928

Sales Branch Offices / Texas, Chicago, Detroit, San Jose

YOKOGAWA EUROPE B. V.

Headquaters

Databankweg 20, 3821 AL Amersfoort THE NETHERLANDS

Phone: +31-334-64-1611 Facsimile: +31-334-64-1610

Sales Branch Offices / Houten (The Netherlands), Wien (Austria), Zaventem

(Belgium), Ratingen (Germany), Madrid (Spain), Bratislava (Slovakia), Runcorn (United

Kingdom), Milano (Italy), Velizy villacoublay(France), Johannesburg(Republic of South

Africa)

YOKOGAWA AMERICA DO SUL S.A.

Headquarters & Plant

Praca Acapulco, 31-Santo Amaro, Sao Paulo/SP, BRAZIL CEP-04675-190

Phone: +55-11-5681-2400 Facsimile: +55-11-5681-4434

YOKOGAWA ENGINEERING ASIA PTE. LTD.

Head office

5 Bedok South Road, Singapore 469270 SINGAPORE

Phone: +65-6241-9933 Facsimile: +65-6241-2606

YOKOGAWA ELECTRIC KOREA CO., LTD.

Seoul Sales office

395-70, Shindaebang-dong, Dongjak-gu, Seoul,156-010, KOREA

Phone: +82-2-3284-3000 Facsimile: +82-2-3284-3019

YOKOGAWA TAIWAN CORPORATION

Head office

17F, No.39, Sec. 1, Chung Hwa Road Taipei, 100 TAIWAN

Phone: +886-2-2314-9166 Facsimile: +886-2-2314-9918

YOKOGAWA AUSTRALIA PTY. LTD.

Head office

Centrecourt D1, 25-27 Paul Street North, North Ryde, N. S. W. 2113, AUSTRALIA

Phone: +61-2-9805-0699 Facsimile: +61-2-9888-1844

YOKOGAWA INDIA LTD.

Head office

40/4 Lavelle Road, Bangalore, 560 001, INDIA

Phone: +91-80-227-1513 Facsimile: +91-80-227-4270

LTD. YOKOGAWA ELECTRIC

Grokholskiy per. 13, Build. 2, 4th Floor, 129010, Moscow, RUSSIA FEDERATION

Phone: +7-095-737-7868 Facsimile: +7-095-737-7869

Loading...

Loading...