Page 1

Instruction

Model LL1200

Manual

PC-based Custom Computation

Building Tool

IM 5G1A11-01E

IM 5G1A11-01E

2nd Edition

Page 2

Introduction

This instruction manual describes the functions of Model LL1200 PC-based Custom Computation

Building Tool (hereinafter, simply referred to as the LL1200 tool in the main text), which is used with

Model US1000 Digital Indicating Controller (hereinafter, simply referred to as the US1000 controller

in the main text), and how to operate the tool.

The LL1200 tool consists of the following component tools.

• Custom computation building tool

• Parameters setting tool

This manual focuses exclusively on the custom computation building tool. For details on the handling

of the parameters setting tool, see the Model LL1100 PC-based Parameters Setting Tool instruction

manual (IM 5G1A01-01E).

■ Intended Readers

This manual is intended for people familiar with the functions of the US1000 digital indicating

controller and capable of working with Windows 95 or Windows NT 4.0, such as instrumentation and

control engineers and personnel in charge of maintaining instrumentation and control equipment.

■ Related Documents

The following instruction manuals all relate to the LL1200 tool. Read them as necessary. The codes

enclosed in parentheses are the document numbers.

• US1000 Digital Indicating Controller-Operation (IM 5D1A01-01E)

• US1000 Digital Indicating Controller-Functions (IM 5D1A01-02E)

• US1000 Digital Indicating Controller-Communication Functions (IM 5D1A01-10E)

• LL1100 PC-based Parameters Setting Tool (IM 5G1A01-01E)

• LL1200 PC-based Custom Computation Building Tool-User’s Reference (IM 5G1A11-02E)

■ Trademarks

Windows 95 and Windows NT 4.0 are registered trademarks of Microsoft Corporation, USA.

Supplied with the US1000 controller, this manual explains the basic operations of the controller.

Supplied with the US1000 controller, this manual explains the functions of the controller in detail.

An instruction manual for the communication function of the US1000 controller. Supplied with

models having the optional communication function.

An instruction manual for setting the parameters of the US1000 controller from a personal computer. Supplied with the LL1100 PC-Based Parameters Setting Tool or the LL1200 PC-based

Custom Computation Building Tool.

An instruction manual that describes the functions needed to create US1000 custom computations.

Refer to this manual if you are not familiar with the types of functions available or how these

functions work. Supplied with the LL1200 PC-based Custom Computation Building Tool.

FD No. IM 5G1A11-01E

2nd Edition: Sep. 1998 (YG)

AllRights Reserved. Copyright © 1998. Yokogawa M&C Corporation

IM 5G1A11-01E

i

Page 3

Visual Inspection and Cross-check of Accessories

Visually inspect the purchased product upon delivery to make sure it is not damaged in any way.

Store the box and inner packing material of the package in a safe location - they may be needed

should the product fail and need to be sent back to the manufacturer for repair.

■ Cross-check of Model and Suffix Codes

Refer to the following table to make sure the model and suffix codes of the LL1200 tool are as

specified in your order.

Model Code Description

LL1200

Suffix Code

-E10

Custom computation building tool*

Model for use with IBM PC/AT-compatible personal computers

* The LL1200 tool includes the same parameter setting function as the LL1100 PC-based Parameters

Setting Tool.

■ Confirmation of the Model and Suffix Codes

Make sure the delivered package contains all of the following items. If any item is missing or found

to be damaged, immediately contact the sales office or dealership from which you purchased the

product.

• 3.5-in. floppy disks (5 disks)

• Dedicated adapter, supplied with two AAA-size batteries (one unit)

• Dedicated cable (one cable)

• Model LL1100 PC-based Parameters Setting Tool instruction manual (one copy)

• Model LL1200 PC-based Custom Computation Building Tool instruction manual (one copy)-This

manual

• Model LL1200 PC-based Custom Computation Building Tool -User’s Reference manual (one copy)

ii

IM 5G1A11-01E

Page 4

Documentation Conventions

■ Notational Conventions in This Manual

This manual uses the following notational conventions.

[ ]:

indicates the name of a dialog box or message, or a view name (name indicated in the upper-left

corner of a dialog box.)

Example: • The [Input Block] dialog box appears.

< >:

indicates the name of a command in a dialog box or the name of a tool menu (or a command in the

menu).

Examples: • Click the <OK> button.

• Click the <Cancel> button.

• Click the <Input Block> button.

• From the tool menus, choose <File>, then <Open>.

“ ”:

indicates the text typed.

Example: • Type “ABCD” in the <xxx> text box.

NOTE

Draws attention to information that is essential for understanding the operation and/or features of the

product.

TIP

Gives additional information to complement the present topic and/or describe terms used in this

document.

See Also

Gives reference locations for further information on the topic.

■ Description of Displays

(1) Some of the representations of product displays shown in this manual may be exaggerated,

simplified, or partially omitted for reasons of convenience when explaining them.

(2) Figures and illustrations representing the controller’s displays may differ from the real displays in

regard to the position and/or indicated characters (upper-case or lower-case, for example), to the

extent that they do not impair a correct understanding of the functions and the proper operation and

monitoring of the system.

IM 5G1A11-01E

iii

Page 5

Notices

■ Regarding This Instruction Manual

(1) This manual should be passed on to the end user. Keep at least one extra copy of the manual in a

safe place.

(2) Read this manual carefully to gain a thorough understanding of how to operate this product before

you start using it.

(3) This manual is intended to describe the functions of this product. Yokogawa M&C Corporation

(hereinafter simply referred to as Yokogawa M&C) does not guarantee that these functions are

suited to the particular purpose of the user.

(4) Under absolutely no circumstance may the contents of this manual, in part or in whole, be tran-

scribed or copied without permission.

(5) The contents of this manual are subject to change without prior notice.

(6) Every effort has been made to ensure accuracy in the preparation of this manual. Should any

errors or omissions come to your attention however, please contact your nearest Yokogawa

representative or our sales office.

■ Regarding Protection, Safety, and Prohibition Against Unauthorized Modification

(1) In order to protect the product and the system controlled by it against damage and ensure its safe

use, make sure that all of the instructions and precautions relating to safety contained in this

document are strictly adhered to. Yokogawa does not guarantee safety if products are not handled

according to these instructions.

(2) The following safety symbols are used on the product and/or in this manual.

●Symbols Used on the Product and in This Manual

CAUTION

This symbol on the product indicates that the operator must refer to an explanation in the instruction

manual to avoid the risk of injury or death of personnel or damage to the instrument. The manual

describes how the operator should exercise special care to avoid electrical shock or other dangers that

may result in injury or loss of life.

Protective Grounding Terminal

This symbol indicates that the terminal must be connected to ground prior to operating the equipment.

Functional Grounding Terminal

This symbol indicates that the terminal must be connected to ground prior to operating the equipment.

iv

IM 5G1A11-01E

Page 6

●Symbol Used in This Manual Only

Indicates that operating the hardware or software in this manner may damage it or lead to system

failure.

■ Force Majeure

(1) Yokogawa M&C does not make any warranties regarding the product except those mentioned in

the WARRANTY provided separately.

(2) Yokogawa M&C assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

(3) Be sure to use the spare parts approved by Yokogawa M&C when replacing parts or consumables.

(4) Modification of the product is strictly prohibited.

(5) This software may be used with one specified computer only. You must purchase another copy of

the software for use on each additional computer.

(6) Copying this software for purposes other than backup is strictly prohibited.

(7) Store the floppy disk(s) (original medium or media) containing this software in a secure place.

(8) Reverse engineering such as the disassembly or decompilation of software is strictly prohibited.

(9) No portion of the software supplied by Yokogawa M&C may be transferred, exchanged, leased or

sublet for use by any third party without the prior permission of Yokogawa M&C.

WARNING

IM 5G1A11-01E

v

Page 7

Contents

Introduction........................................................................................................................... i

Visual Inspection and Cross-check of Accessories ........................................................... ii

Documentation Conventions.............................................................................................. iii

Notices .................................................................................................................................. iv

Contents ............................................................................................................................... vi

1. Overview ..................................................................................................................... 1-1

1.1 Function Overview of the LL1200 Tool ........................................................ 1-1

1.2 Operating Environment of the LL1200 Tool and Wiring Specifications ...... 1-4

1.3 Model and Suffix Codes of Applicable US1000 Controller Models............. 1-6

2. Setup ....................................................................................................................... 2-1

2.1 Installing the LL1200 Tool ............................................................................. 2-1

2.2 Uninstalling the LL1200 Tool ........................................................................ 2-4

2.3 Connecting the US1000 Controller to the Personal Computer ...................... 2-5

3. Using the LL1200 Tool .............................................................................................. 3-1

3.1 Starting and Exiting the Tool .......................................................................... 3-1

3.1.1 Starting the Tool....................................................................................... 3-1

3.1.2 Exiting the Tool ....................................................................................... 3-2

3.2 Flow of Working with the LL1200 Tool........................................................ 3-3

3.3 Dialog Boxes and Tool Menus ....................................................................... 3-4

4. Basic Operations for Configuring Custom Computations

and Relevant Explanations ....................................................................................... 4-1

4.1 Step 1: Choosing the Way Computations Are Configured ............................ 4-2

4.2 Step 2: Configuring Custom Computations in an Input Block ...................... 4-8

4.2.1 Step 2-1: Registering Computation Modules .......................................... 4-9

4.2.2 Step 2-2: Configuring the Inputs and Parameters

of Computation Modules ....................................................................... 4-13

4.2.3 Step 2-3: Connecting Computation Modules to the Control

and Computing Section.......................................................................... 4-17

4.2.4 Step 2-4: Setting the Analog-input Burnout Function ........................... 4-22

4.3 Step 3: Configuring Custom Computations in an Output Block ................. 4-23

4.3.1 Step 3-1: Registering Computation Modules ........................................ 4-24

4.3.2 Step 3-2: Configuring the Inputs and Parameters

of Computation Modules ....................................................................... 4-28

4.3.3 Step 3-3: Connecting Computation Modules to Output Signals ........... 4-32

4.4 Step 4: Configuring the Parameters of Ten-segment Linearizers

3 and 4 (as necessary) ................................................................................... 4-36

4.5 Step 5: Configuring USER Parameters (as necessary) ................................ 4-38

vi

IM 5G1A11-01E

Page 8

5. Basic Operations for Configuring Custom Displays

and Relevant Explanations ....................................................................................... 5-1

5.1 Step 1: Choosing the Method of Custom Display Configuration .................. 5-2

5.2 Step 2: Configuring Custom Displays ............................................................ 5-8

5.2.1 Step 2-1: Choosing the Custom Display.................................................. 5-9

5.2.2 Step 2-2: Setting Conditions Needed to Switch to Custom Displays.... 5-14

5.3 Step 3: Defining the Security Function (as necessary) ................................ 5-16

6. Editing .......................................................................................................................6-1

6.1 Editing Custom Computations ........................................................................ 6-1

6.1.1 Moving Computation Modules................................................................ 6-1

6.1.2 Deleting Computation Modules............................................................... 6-3

6.1.3 Adding Computation Modules ................................................................ 6-4

6.1.4 Changing the Order in Which Computation Modules Run ..................... 6-4

6.1.5 Changing the Way Computation Modules Are Connected ...................... 6-6

6.2 Editing Custom Displays .............................................................................. 6-13

6.2.1 Deleting Custom Displays ..................................................................... 6-13

6.2.2 Adding Custom Displays....................................................................... 6-14

7. Working with Custom Computation and Custom Display Data Files ................ 7-1

7.1 Setting the File Information ............................................................................ 7-1

7.2 Setting Comments for I/O Signals.................................................................. 7-2

7.3 Reading/Saving Data from/on Disk and Comparing Data Values................. 7-3

7.3.1 Reading Data from Disk .......................................................................... 7-3

7.3.2 Saving Data on Disk ................................................................................ 7-5

7.3.3 Compare between Data Values ................................................................ 7-5

8. Uploading/Downloading Data from/to US1000 Controller

and Comparing between Data Values ..................................................................... 8-1

8.1 Uploading Data from US1000 Controller ...................................................... 8-1

8.2 Downloading Data to US1000 Controller ...................................................... 8-3

8.3 Comparing Data Values with Those of the US1000 Controller .................... 8-5

9. Printing Custom Computations................................................................................ 9-1

10. Configuring Parameters ..........................................................................................10-1

11. Custom Computation Monitor ............................................................................... 11-1

11.1 Preparations for Monitoring of Custom Computations ................................ 11-2

11.2 Monitoring Custom Computations Configured in an Input Block .............. 11-2

11.2.1 Monitoring Data Values Fed to/from an Input Block ............................ 11-3

11.2.2 Monitoring the Inputs and Parameters of Computation Modules ......... 11-5

11.3 Monitoring Custom Computations Configured in an Output Block............ 11-6

11.3.1 Monitoring Data Values Fed to/from an Output Block.......................... 11-6

11.3.2 Monitoring the Inputs and Parameters of Computation Modules ......... 11-8

IM 5G1A11-01E

vii

Page 9

12. Examples of Custom Computation and Custom Display Configurations .........12-1

12.1 Example 1: Applying Corrective Computation to the PV Input.................. 12-3

12.2 Example 2: Showing the PV Input Value

before Corrective Computation................................................................... 12-16

12.3 Example 3: Implementing Simple Logic Operations ................................. 12-25

12.4 Example 4: Applying Temperature-based Flowrate Corrections to

the PV Input ................................................................................................ 12-34

12.5 Example 5: Configuring Timers ................................................................. 12-44

12.5.1 Configuring a Four-second Timer........................................................ 12-44

12.5.2 Configuring a Fixed-interval Five-second Timer................................. 12-55

12.6 Example 6: Setting Parameters ................................................................... 12-62

12.7 Example 7: OR Function of Alarm Outputs .............................................. 12-69

13. Maintenance and Troubleshooting ......................................................................... 13-1

13.1 Replacing the Batteries ................................................................................. 13-1

13.2 Troubleshooting Problems with the Display

and Communication Functions ..................................................................... 13-3

13.2.1 Problems with the Display Functions .................................................... 13-3

13.2.2 Problems with the Communication Functions....................................... 13-3

Appendix 1. WORKSHEET ....................................................................................... A1-1

Appendix 2. DATASHEET ......................................................................................... A2-1

Appendix 3. Restrictions Imposed Depending on the Suffix Code

and/or Controller Type ......................................................................... A3-1

Appendix 4. Areas for Storing Data Output from Computation Modules ........... A4-1

Revision Record

viii

IM 5G1A11-01E

Page 10

Chapter 1 Overview

1. Overview

This chapter first explains what custom computation is and then introduces the tool used to configure

these computations and the model and suffix codes of the US1000 controller models to which the tool

applies.

This chapter also discusses the system requirements that must be met to be able to use the LL1200

tool and shows external views of the dedicated adapter and cable.

1.1 Function Overview of the LL1200 Tool

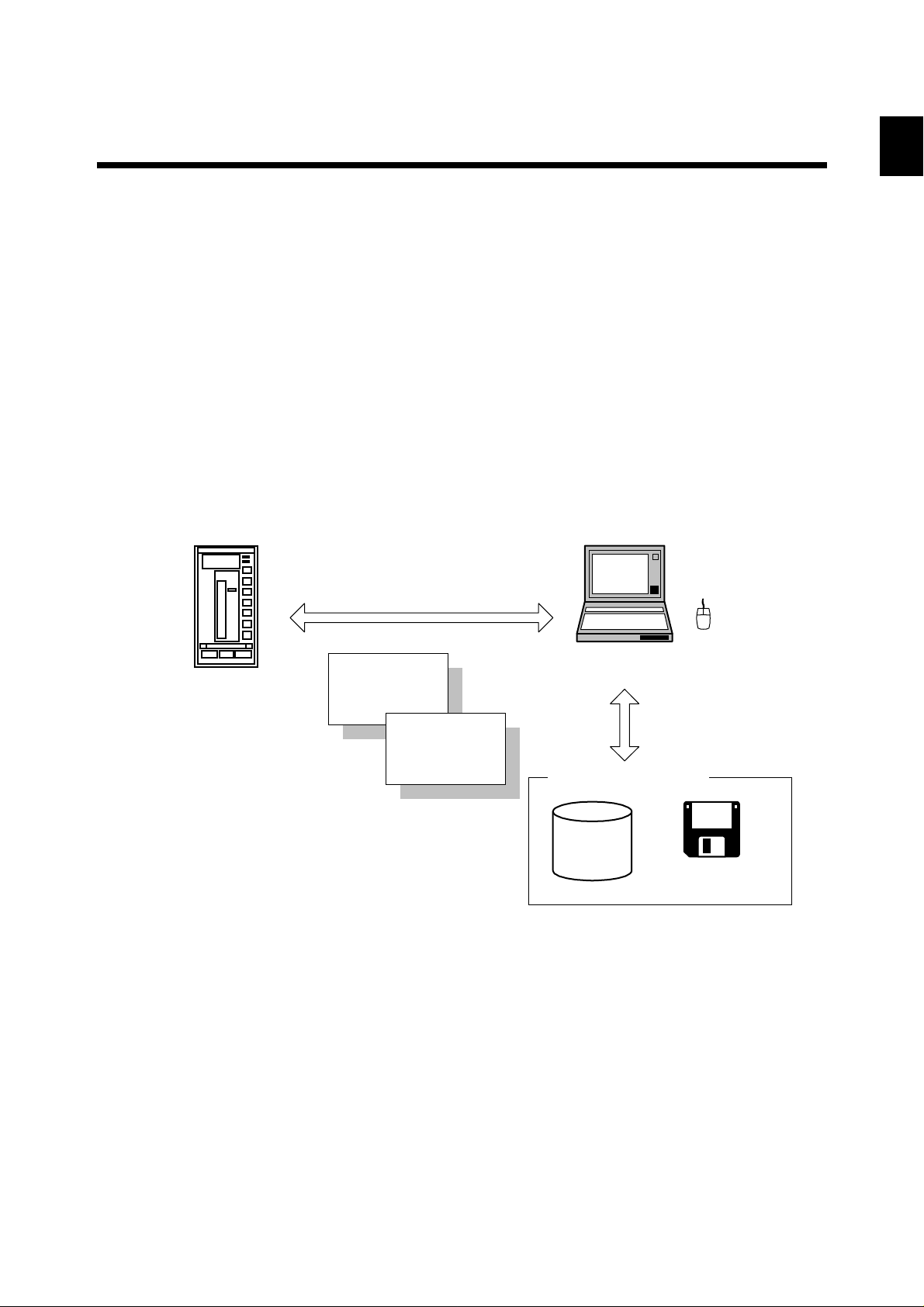

The LL1200 tool is designed to run on a personal computer connected to the US1000 controller. You

can set a variety of functions for the US1000 controller from the personal computer. Inversely, you

can read the settings from the US1000 controller.

In addition to these operations, you can set the various parameters of the US1000. This particular

function is the same as the one offered by Model LL1100 PC-based Parameters Setting Tool, another

tool used with the US1000 controller. This manual does not therefore discuss this function in particular. When you use this function in your practical applications, refer to the Model LL1100 PC-based

Parameters Setting Tool instruction manual (supplied together with this manual).

Uploading from/downloading

to US1000 controller

1

US1000 controller

(One-to-one communication)

Notebook PC

Custom computations

Custom displays

Saving to/reading from disks

Hard disk

Mouse

Reading from/saving

to disks

Floppy disk

Figure 1.1.1 Conceptual View of LL1200 Tool

The LL1200 tool is designed to run under Windows 95 or Windows NT 4.0. For details on how to

use the personal computer and Windows software, see their respective instruction manuals.

IM 5G1A11-01E 1-1

Page 11

The US1000 controller comes with built-in control functions and various controller modes (US

modes) that provide different I/O computing functions. These modes are designed to support their

respective control applications. From these choices, you can choose one that best meets your application needs.

In some control applications, however, you may want to execute special computations based upon

specific input data or have a contact output of a specific data item in a specific control sequence. To

be able to meet these needs, the US1000 controller provides a separate controller mode with which

you can freely program your own computations. Computing functions available in these modes are

referred to as custom computations.

Custom computations allow you to perform a variety of calculations based on input and output signals.

These calculations include not only the four arithmetic operations and logical operations but also tensegment linear approximations, temperature and humidity computations, temperature-based correction

coefficient computations, pressure-based correction coefficient computations, and so on.

For example, you can use the four arithmetic operations to apply the desired type of correction to

input signals, or use a logical operation to program a sequencing process that works between input and

output contacts.

Custom computations are configured using the given methods of block connection, as shown in

Figures 1.1.2 and 1.1.3.

Flowrate

Temperature-based

flowrate correction

MV output

Temperature

Fluid pressure correction

Square-root computation

Control and computing section

Pressure

A/M switching

Contact input 1

Contact input 2 Contact input 3

OR

AND

Figure 1.1.2 Custom Computations Applied to Input Signals

Control and computing section

Alarm 1

Alarm 2 Alarm 3 Alarm 4 Alarm 5 Alarm 6

1-2

Control output processing

MV output

OR

Contact output 1

Contact output 2

Figure 1.1.3 Custom Computations Applied to Output Signals

OR

IM 5G1A11-01E

Page 12

Chapter 1 Overview

When custom computations are in use, you can also freely configure the operation displays of the

US1000 controller to suit your desired view. This function is designed so that you can choose from

the preset menus the types of data items, the sequence in which the data items are shown, and the

conditions required to show them on the PV and SV digital displays of the US1000 controller. The

displays thus configured are referred to as custom displays.

Normally, the term “custom computing function” is used to include both the custom computation and

custom display functions.

1

IM 5G1A11-01E 1-3

Page 13

1.2 Operating Environment of the LL1200 Tool and Wiring Specifications

■ System Requirements

●Personal computer: Windows 95- or Windows NT 4.0-enabled IBM PC/AT-compatible model

●Operating system: Windows 95 or Windows NT 4.0

●CPU: 90-MHz Pentium processor or superior is recommended.

●Main memory: 16 MB minimum for Windows 95 or 24 MB minimum for Windows NT 4.0 is

recommended.

●Hard disk

Memory space required to store the tool’s programs: 9 MB

Memory space required to store the parameter data: 2 MB minimum

●CRT display

800 3 600 pixels or superior

Should be capable of handling at least 256 colors.

Smaller fonts should be used.

●RS-232C communication ports: One channel, with 9-pin D-Sub connector

●3.5-inch floppy drive: One drive.

●Printer: As necessary.

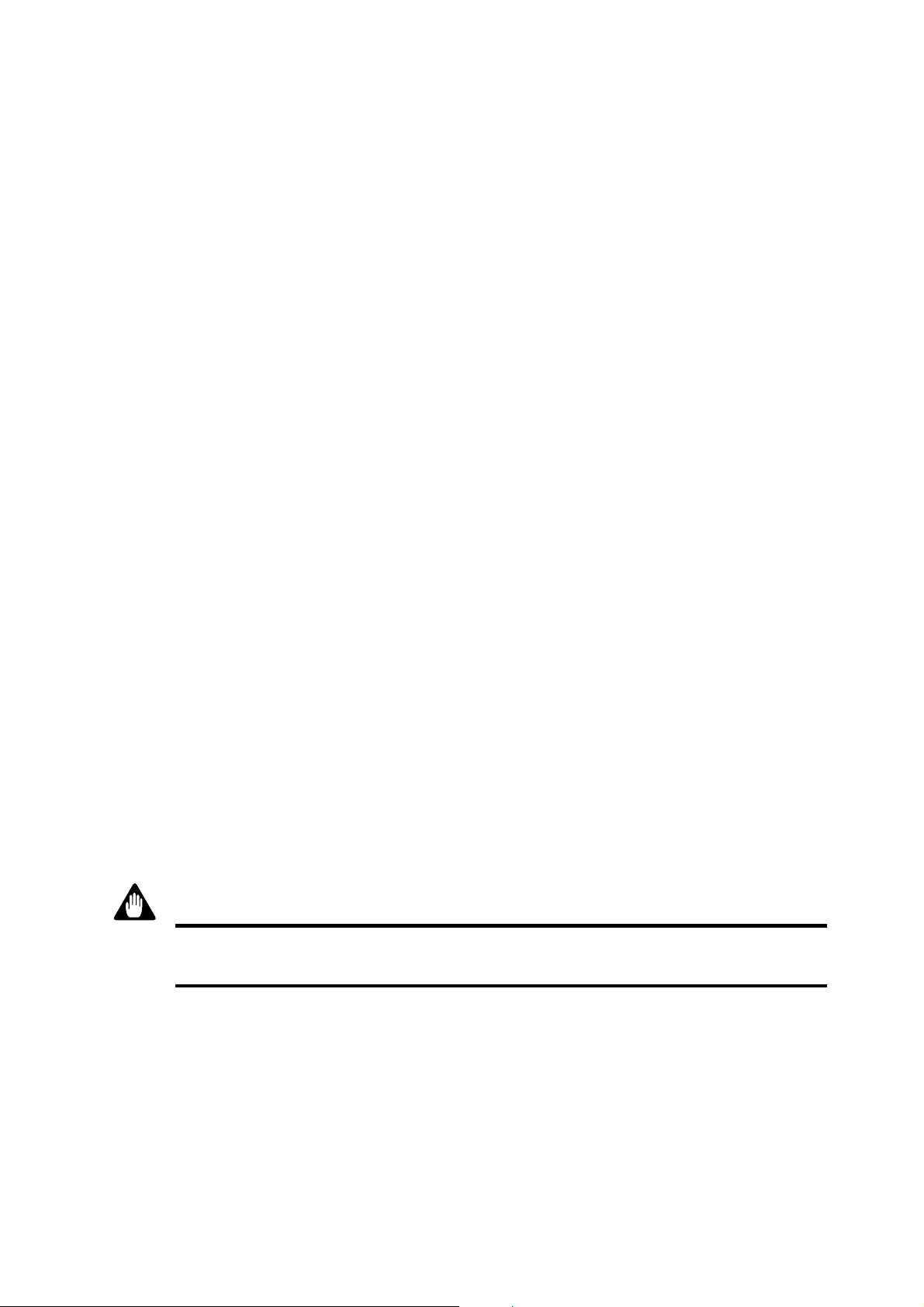

■ Dedicated Adapter

●Communication method

US1000: Optical, contactless, bidirectional serial communication

Personal computer: RS-232C half-duplex communication using the dedicated cable

●Power supply: Two AAA-size batteries or external power source

Use of an external power source is recommended for tuning over a prolonged time period.

●Battery life: Approximately 50 hours (when the adapter is continuously operated on alkaline

batteries)

●Specifications of external power source

●Should comply with EIAJ RC-6705.

Input ratings: 5 V DC/50 mA

(Purchase a commercially available plug and AC adapter for the external power source.)

●Ambient temperature range: 0 to 50˚C

●Ambient humidity range: 20 to 90%RH (non-condensing)

●Transport and storage conditions: -25 to 70˚C, 5 to 95%RH (non-condensing)

●Dust- and water-proof construction: Not applied.

●Standards: Complies with the CE Mark system (EMC standard only)

1-4

WARNING

The dedicated adapter is not waterproof. Do not use the adapter in locations that are likely to be

exposed to splashes of water or other liquids.

IM 5G1A11-01E

Page 14

Chapter 1 Overview

36 (1.42)

4

42 (1.66)

12 (0.47)

0.8

(0.03)

144 (5.69)

4.5

(0.18)

CABLE

2.8

(0.11)

72 (2.85)

45.5 (1.80)

US1000

DC POWER PLUG

144

(5.69)

52

(2.06)

Figure 1.2.1 External View of the Dedicated Adapter

Mate Plug

1.5

(0.06)

unit: mm

D' DIA

unit : mm(inch)

1

unit : mm(inch)

(0.37)

Figure 1.2.2 External View of the External Power Inlet on the Dedicated Adapter

■ Dedicated Cable

Cable with 9-pin D-Sub connector for IBM PC/AT-compatible models: 3-m long

To PC

Figure 1.2.3 External View of the Dedicated Cable

9.5

D' DIA

2.1

5.5 DIA

(0.08)

(0.22)

(EIAJ)

About 3000 (118.1)

PC/AT compatible machine

unit : mm(inch)

To adapter

IM 5G1A11-01E 1-5

Page 15

1.3 Model and Suffix Codes of Applicable US1000 Controller Models

The US1000 controller models allowing for custom computations are as follows.

Model and Suffix Code Combination Description

US1000-11

US1000-11/A10

US1000-21

US1000-21/A10

When using custom computations for any of these controller models, set the controller mode

(US mode) to “21.”

See Also

“What are the Controller Modes (US Modes)?” in Chapter 2, “Controller Modes (US Modes)” of the

US1000 Digital Indicating Controller-Functions instruction manual (IM 5D1A01-02E).

Enhanced model of digital indicating controller without communication function

Enhanced model of digital indicating controller with communication function

Position-proportional model of digital indicating controller without communication function

Position-proportional model of digital indicating controller with communication function

1-6

IM 5G1A11-01E

Page 16

2. Setup

This chapter explains how to set up the hardware and software necessary to work with the LL1200

tool.

2.1 Installing the LL1200 Tool

(1) Insert Disk 1 of the LL1200 tool into the floppy drive.

(2) From the Start menu of Windows, choose <Run . . .>. Type the name of the floppy drive

as \Setup.exe and click the <OK> button.

(3) To continue, follow the instructions given in each dialog box.

Chapter 2 Setup

2

Figure 2.1.1 Window for Installation Operations

When installation is complete, the <LL1200> option is registered with the <Programs> command in

the <Start> menu.

IM 5G1A11-01E 2-1

Page 17

■ LL1200 File Package and Files of Information on Configured Custom Computations

The LL1200 package files comprise a set of the files that are needed to run the LL1200 tool, the

installation program, sample files, help files, and so on.

NOTE

The file names should contain no more than 16 half-byte alphanumeric characters, and their extensions

should be as shown in the following tables.

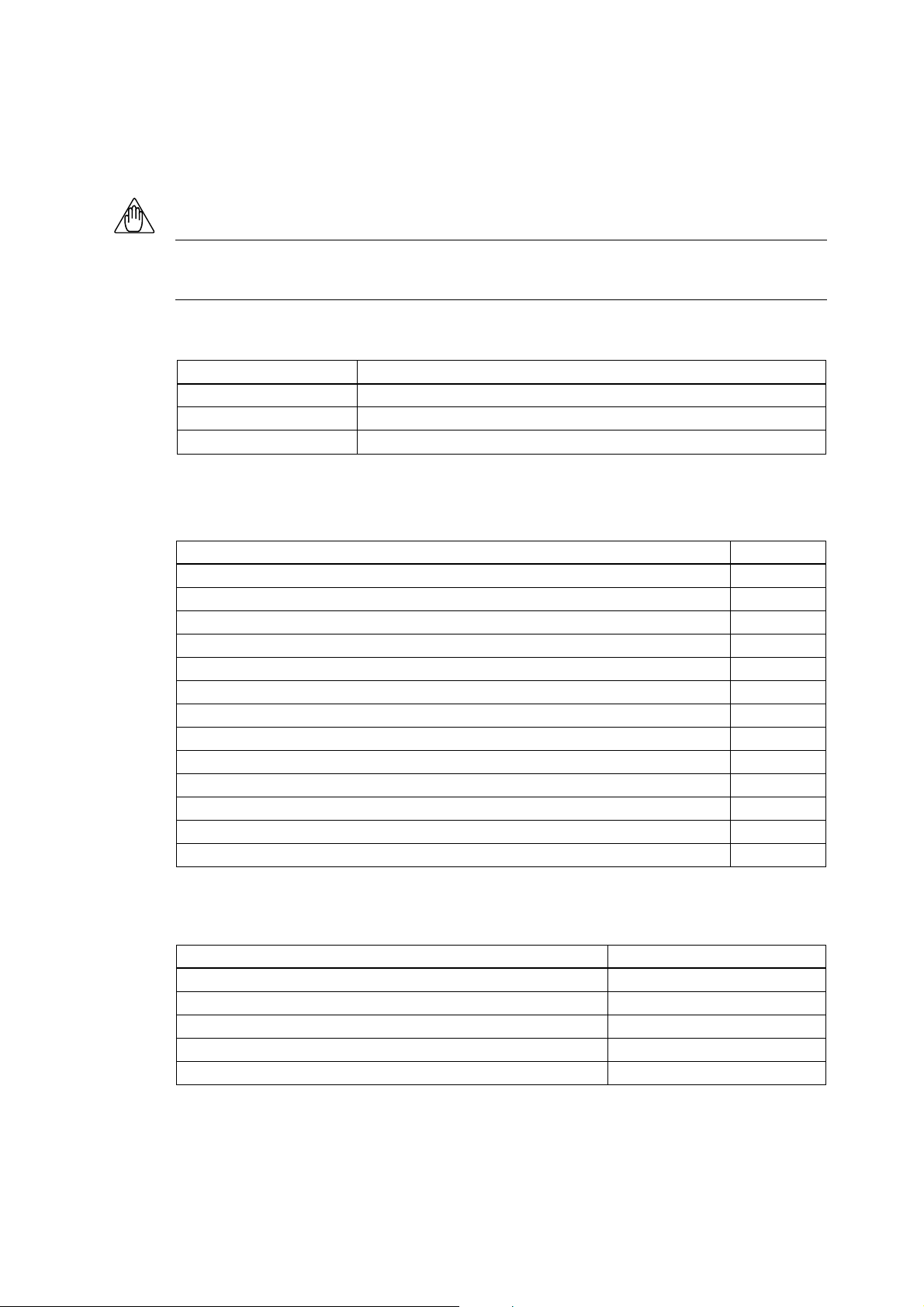

●LL1200 Package Files

When the installation of the LL1200 tool is complete, the folders in the following table are set up.

Folder Name File

US Package files (those other than the sample files)

US\SAMPLE Sample files (********.1sc)

US\USER User files (********.1sc, ********.1ec, ********.1sp, ********.1ep and ********.csv)

●Sample Files

The sample files contain information on custom computations in the I/O blocks of controller modes

(US modes) 1 to 15.

Sample File File Name

Controller mode (US mode) 1: Sample file for single-loop control USM01.1SC

Controller mode (US mode) 2: Sample file for cascade primary-loop control USM02.1SC

Controller mode (US mode) 3: Sample file for cascade secondary-loop control USM03.1SC

Controller mode (US mode) 4: Sample file for cascade control USM04.1SC

Controller mode (US mode) 5: Sample file for loop control for backup USM05.1SC

Controller mode (US mode) 6: Sample file for loop control with PV switching USM06.1SC

Controller mode (US mode) 7: Sample file for loop control with PV auto-selector USM07.1SC

Controller mode (US mode) 8: Sample file for loop control with PV-hold function USM08.1SC

Controller mode (US mode) 11: Sample file for dual-loop control USM11.1SC

Controller mode (US mode) 12: Sample file for temperature and humidity control USM12.1SC

Controller mode (US mode) 13: Sample file for cascade control with two universal inputs USM13.1SC

Controller mode (US mode) 14: Sample file for loop control with PV switching and two universal inputs USM14.1SC

Controller mode (US mode) 15: Sample file for loop control with PV auto-selector and two universal inputs USM15.1SC

2-2

●User Files

The user files contain information on user-created custom computations.

Type of User File File Name

Data file for custom computations and displays ********.1sc

Results of comparison between custom-computation data (text file) ********.1ec

Parameter data file ********.1sp

Results of comparison between parameter data (text file) ********.1ep

Data for printouts (CSV-format file) ********.csv

IM 5G1A11-01E

Page 18

●Help Files

Type of Help File File Name

Parameters setting tool help PARA.hlp

Custom computation building tool help CUST.hlp

Description of D-registers and I-relays DREG.hlp

Description of module information MODUL.hlp

Chapter 2 Setup

2

IM 5G1A11-01E 2-3

Page 19

2.2 Uninstalling the LL1200 Tool

(1) Double-click the <Add/Remove Programs> icon in the Control Panel menu of Windows.

(2) Choose <LL1200>, and then click the <Add/Remove . . .> button.

(3) To continue, follow the instructions given in each dialog box.

Figure 2.2.1 Dialog Box for Uninstallation Operations

2-4

IM 5G1A11-01E

Page 20

Chapter 2 Setup

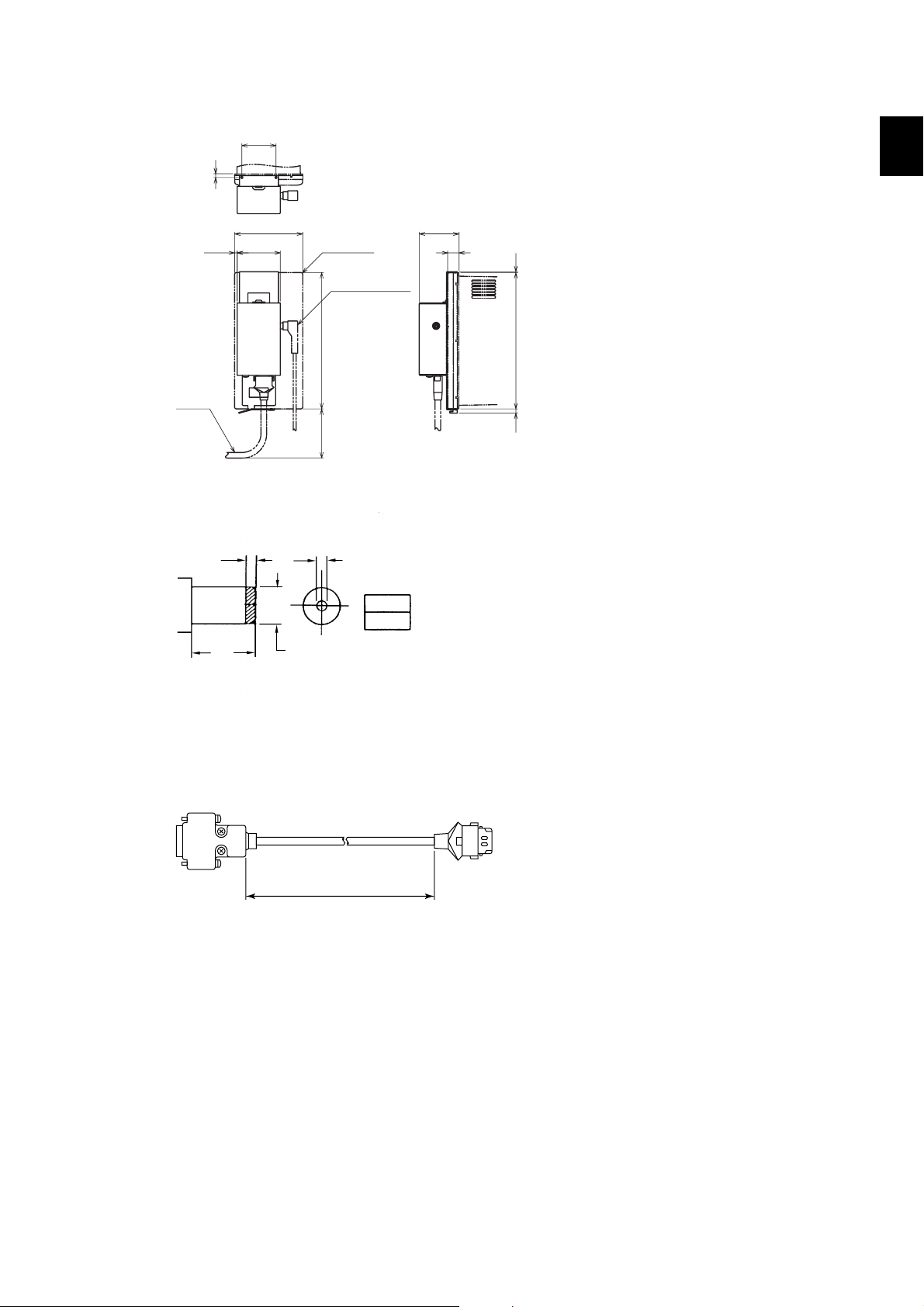

2.3 Connecting the US1000 Controller to the Personal Computer

The US1000 controller can be connected to a personal computer in two ways; using either the optical

communication interface on the controller’s front panel or the RS-485 communication terminal on the

rear panel (if the US1000 controller has the “/A10” option).

This section discusses the way the US1000 controller is connected to the personal computer using the

optical communication interface.

Connect the controller to the computer either before or after you configure the custom computations.

See Section 3.2, “Flow of Working with the LL1200 Tool,” for more information.

See Also

Chapter 1, “Setup,” in the US1000 Digital Indicating Controller-Communication Functions instruction

manual (IM 5D1A01-10E), for details on how to wire the US1000 controller using the RS-485

communication terminal.

NOTE

The dedicated adapter has an internal switch (located where the adapter comes into contact with the

US1000 controller). Exercise care to avoid breaking the switch when attaching the adapter onto the

US1000 controller. Installing the adapter in place automatically turns on the switch, causing the

batteries to discharge even if no communication is done. If you have no immediate plan to communicate, keep the adapter removed from the US1000 controller.

2

WARNING

When using an external power source, take care to ensure that the polarities of the AC adapter are

correct. Do not apply power from the AC adapter in excess of the power ratings of the dedicated

adapter. Either of these cases may result in damage to the controller.

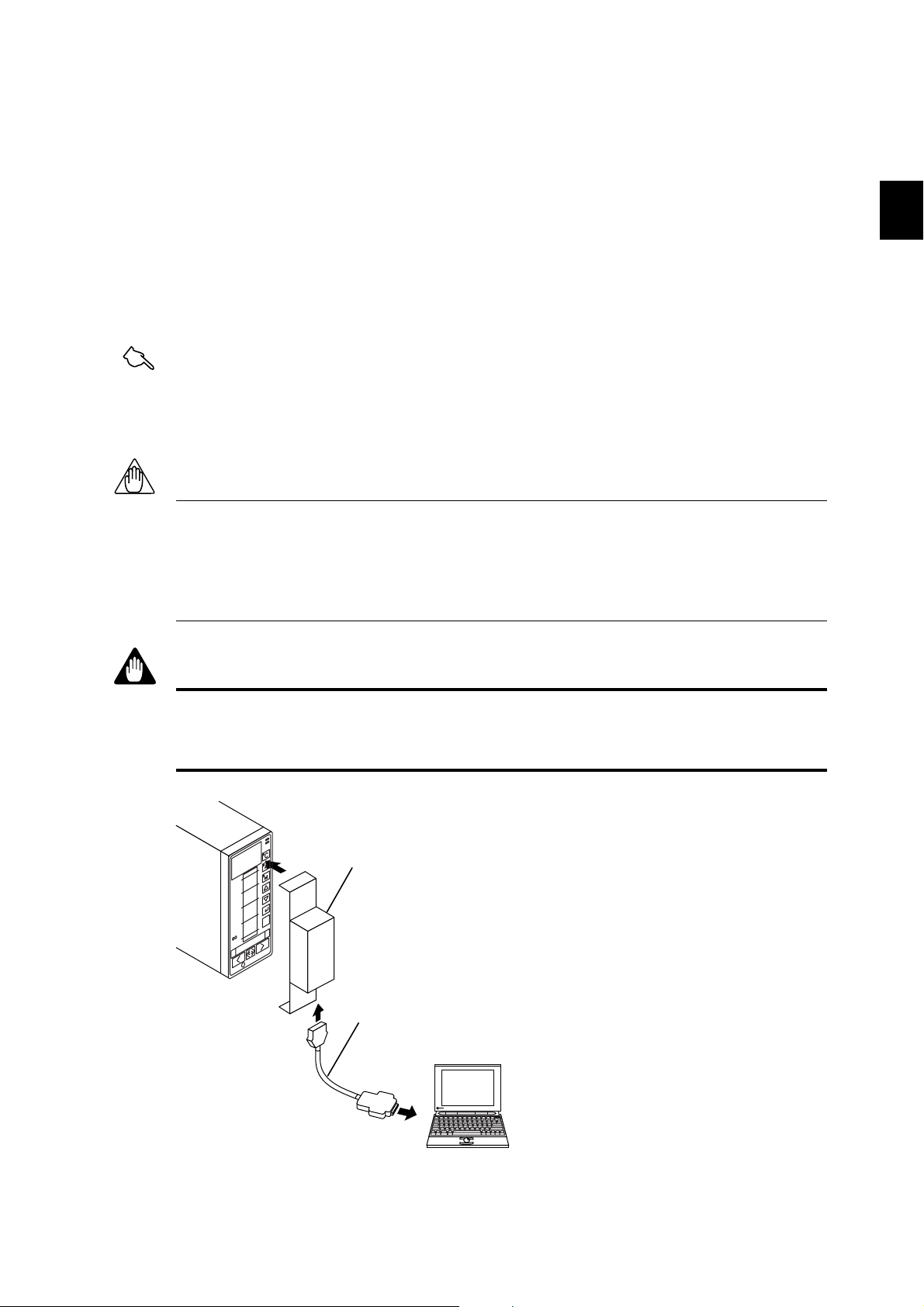

ALM

LP2

PV

SV

MV

100

0

Controller

DISP

YOKOGAWAÅŸ

Dedicated Adapter

(Optical/electrical

signal converter)

Dedicated cable

Personal computer

To RS-232C

terminals

Figure 2.3.1 Connection of the US1000 Controller to the Personal Computer using the

Optical Communication Interface

IM 5G1A11-01E 2-5

Page 21

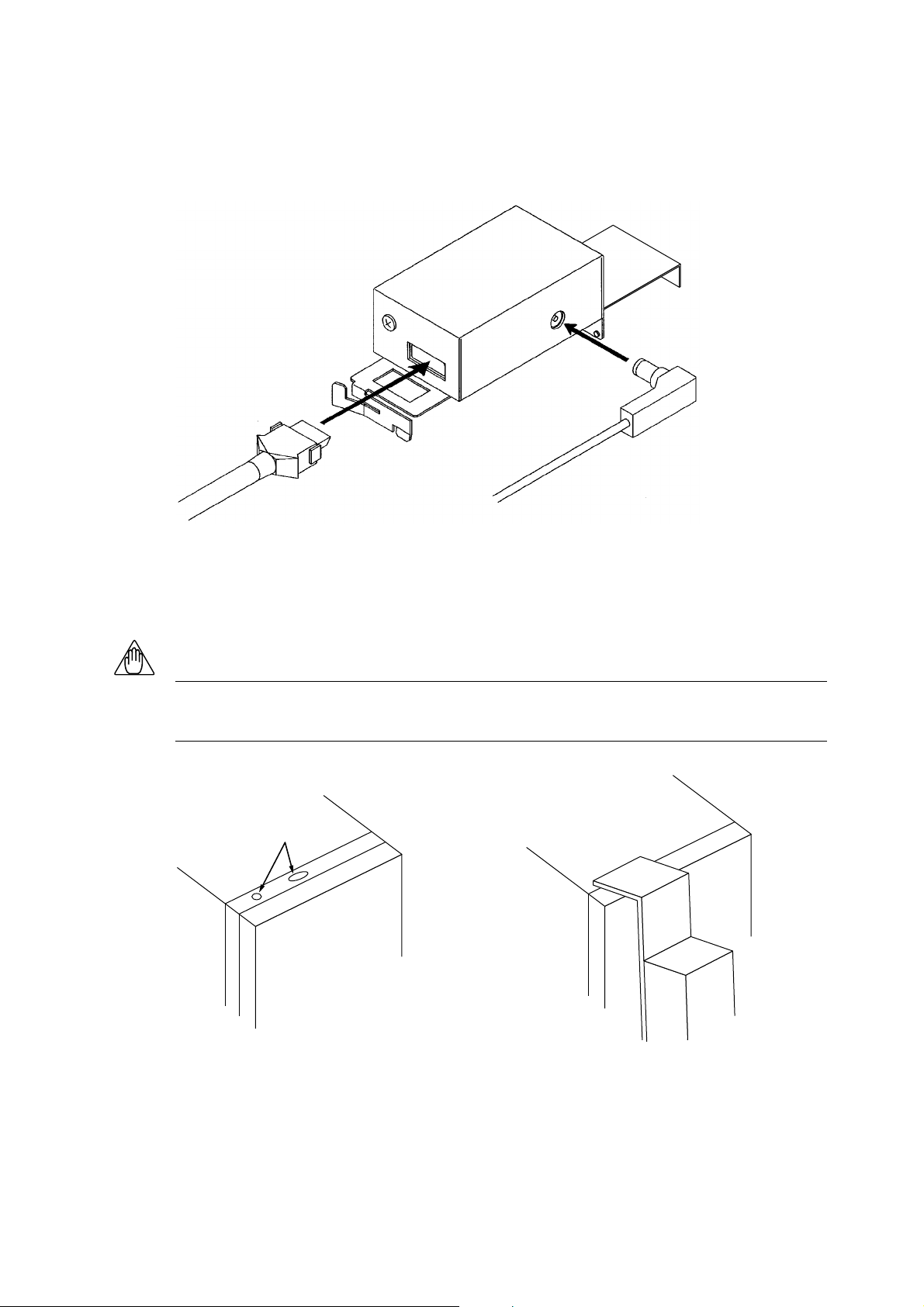

Follow the steps below to connect the dedicated adapter to the US1000 controller.

(1) Wire the dedicated adapter to the RS-232C communication port on the personal computer using the

dedicated cable.

Dedicated Cable

Power supply plug

Figure 2.3.2 Connection of the Dedicated Cable to the Dedicated Adapter

(2) Hang the dedicated adapter on the top notches of the US1000 controller, as shown in Figure 2.3.3.

(3) Push the adapter on to the controller’s front panel so it is securely fixed.

NOTE

Communication is not possible if the dedicated adapter on the US1000 controller is not horizontally

aligned in the correct position. Install the adapter in an upright position on the US1000 controller.

Notch

2-6

Figure 2.3.3 Installation of the Dedicated Adapter

IM 5G1A11-01E

Page 22

3. Using the LL1200 Tool

This chapter explains how to use the LL1200 tool. Be sure to read this chapter before you proceed

any further.

Chapter 3 Using the LL1200 Tool

3.1 Starting and Exiting the Tool

3.1.1 Starting the Tool

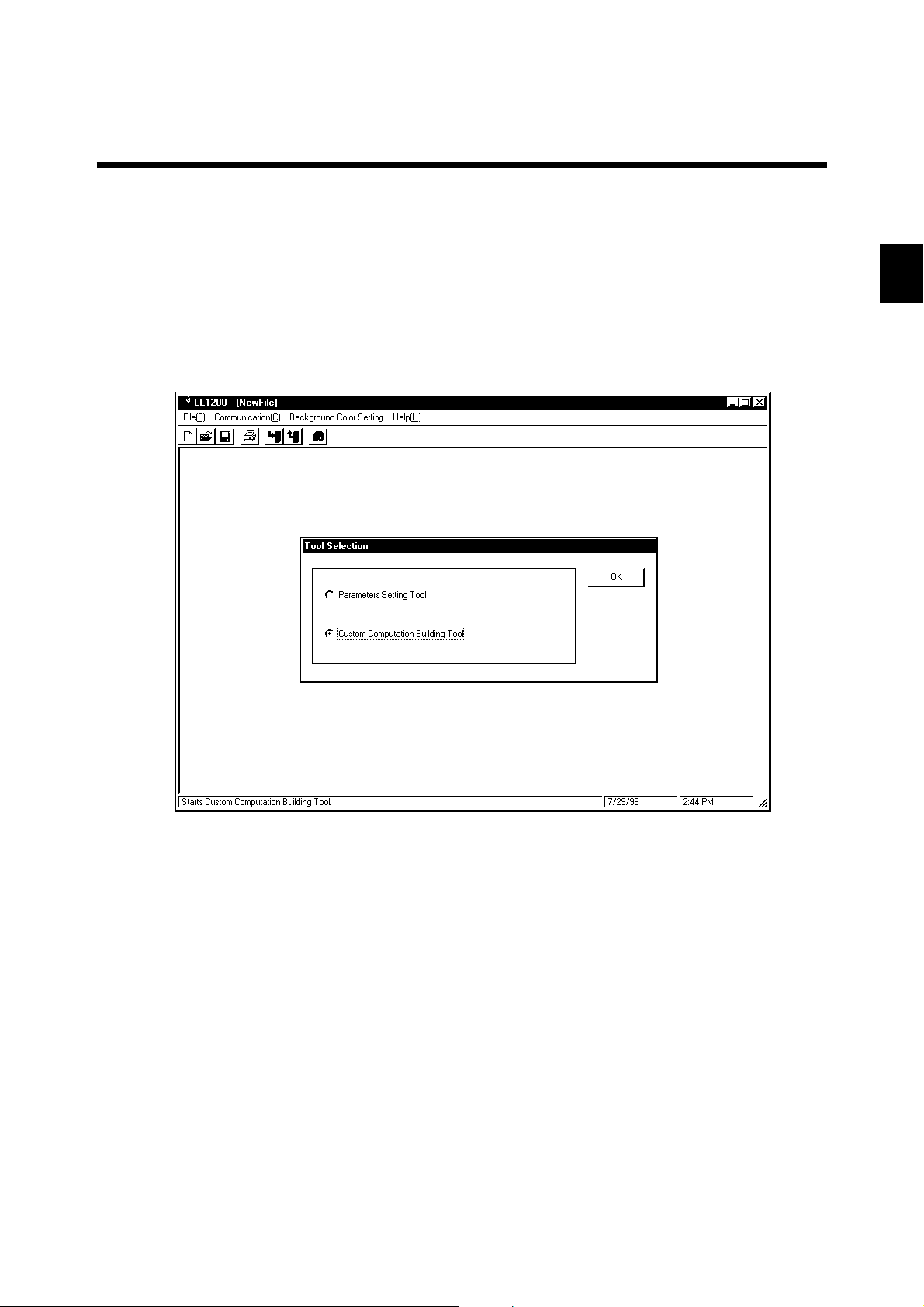

(1) From the Start menu of Windows, choose <Programs>, then <LL1200>.

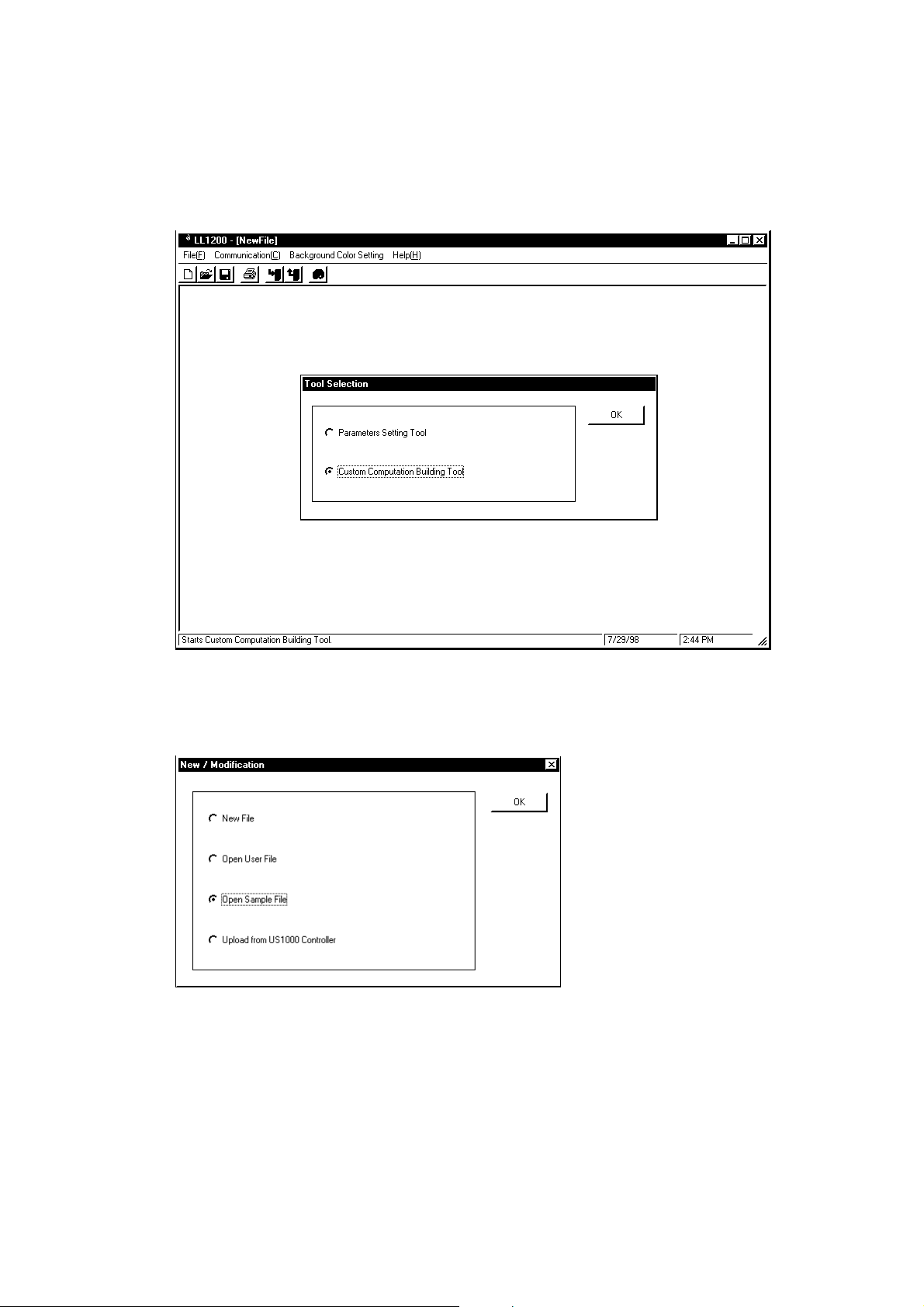

(2) The LL1200 tool starts up and the following dialog box appears.

3

Figure 3.1.1 Dialog Box that Appears When the LL1200 Tool Starts Up

IM 5G1A11-01E 3-1

Page 23

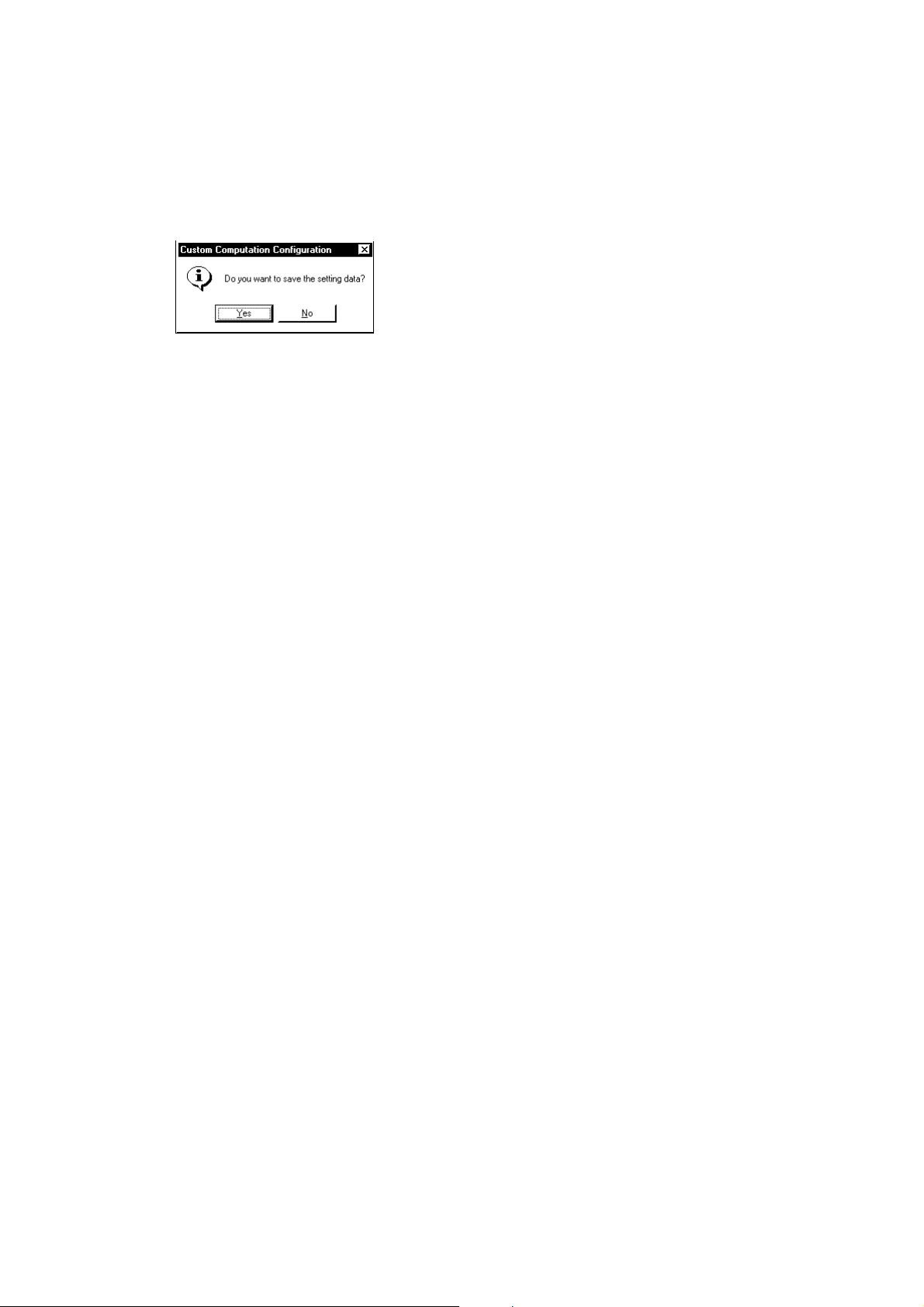

3.1.2 Exiting the Tool

(1) From the LL1200 tool menus, choose <File>, then <Exit>.

(2) The following message box appears.

To save the data of your current work, click the <Yes> button and save the file.

If the data need not be saved, click the <No> button.

Figure 3.1.2 [Exit LL1200 Tool] Message Box

3-2

IM 5G1A11-01E

Page 24

3.2 Flow of Working with the LL1200 Tool

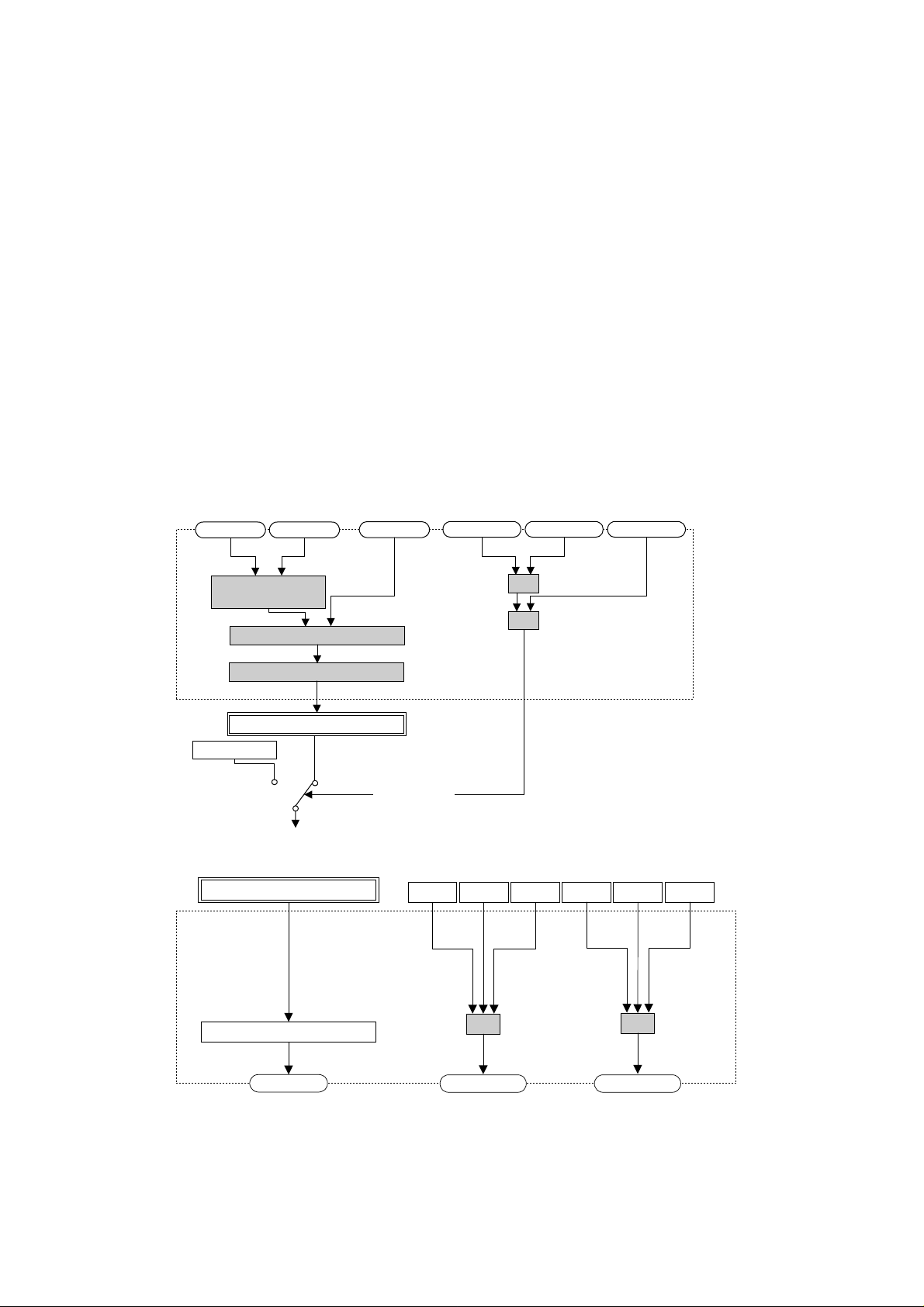

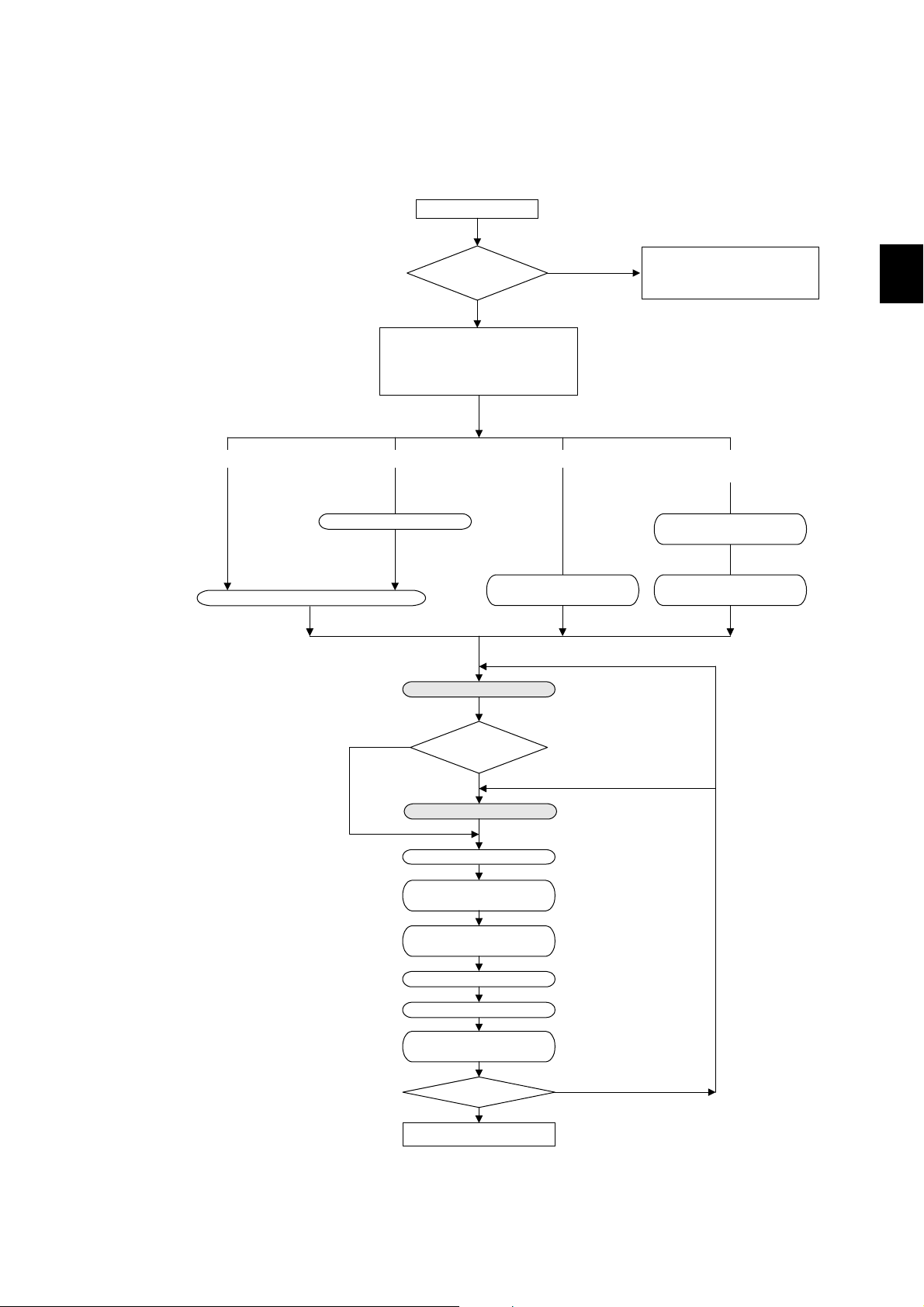

Figure 3.2.1 shows the flow of work for configuring custom computations and displays.

Startup of LL1200 tool

Custom computation or

parameter setting?

Configuration of custom computations

Uploading data from US1000 controller?

Opening user file?

Opening sample file?

Creating new file?

Parameter setting

(Section 4.1)

Chapter 3 Using the LL1200 Tool

See the

Model LL1100 PC-based

Parameters

Setting Tool instruction

manual (IM 5G1A01-01E)

3

(Creating new file) (Opening sample file) (Opening user file) (Uploading data from

US1000 controller)

(Subsection 7.3.1)

Open a sample file

Connect the US1000 controller

(Section 2.3)

to a personal computer

(Section 8.1)(Subsection 7.3.1)

(Section 4.1)

Specify the suffix code and controller type

Configure the custom computations

No

Configure the custom displays

Save data in the user file

Connect the US1000 controller

to the personal computer

Open a user file of

custom computations

Configuring custom

displays?

Yes

(Modifying custom computations)

(Chapter 4)

(Modifying custom displays)

(Chapter 5)

(Subsection 7.3.2)

(Section 2.3)

Upload custom-computation data

from the US1000 controller

Download data to the

US1000 controller

Set parameters.

Print (if necessary)

Check the custom computation

monitor/custom displays

Modify

End of work

(Section 8.2)

(Chapter 10)

(Chapter 9)

(Chapter 11)

(Modify)

Figure 3.2.1 Flow of Work for Configuring US1000 Functions Using the LL1200 Tool

IM 5G1A11-01E 3-3

Page 25

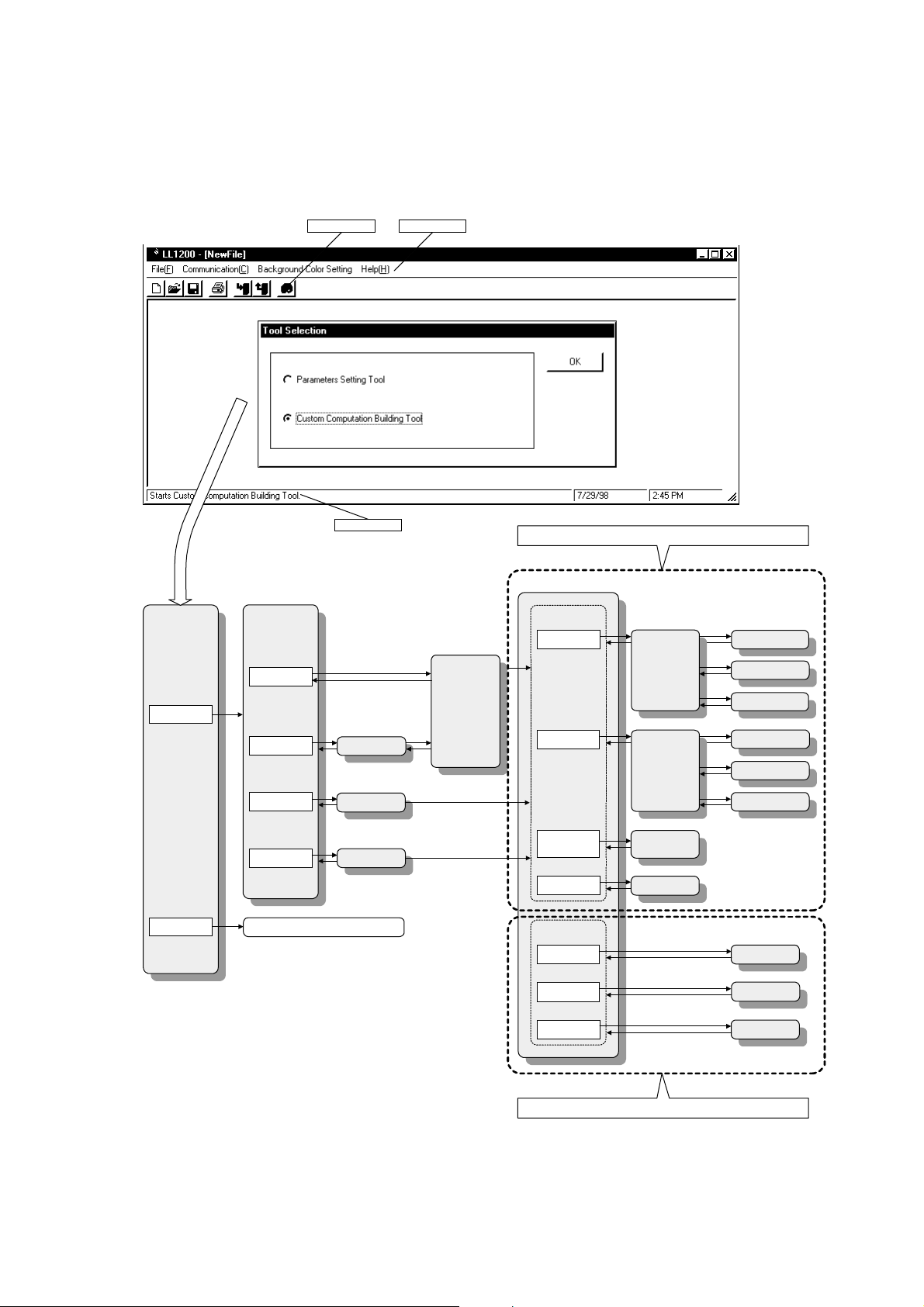

3.3 Dialog Boxes and Tool Menus

Figures 3.3.1 and 3.3.2 show how the dialog boxes and tool menus are organized within the LL1200

tool.

Tool Selection

Custom computation

building tool

New/Modification

New File

Open Sample File

Open User File

Upload from

US1000 Controller

Toolbar

Status bar

(Subsection 7.3.1)

Open

(Sample file)

(Subsection 7.3.1)

Open

(User file)

(Section 8.1)

Upload from

US1000 Controller

Tool menus

Specify Suffix Code

and Controller Type

Dialog boxes that appear when custom computations are configured

➀

Custom Computation

Configuration Menu

Input Block

Output Block

Ten-segment

Linearizer 3 and 4

Parameters

USER

Parameters

(Section 4.2)

Input Block

(Section 4.3)

Output Block

(Section 4.4)

Parameter Setting for

Ten-segment

Linearizers 3 and 4

(Section 4.5)

USER Parameters

Definition

(Subsection 4.2.1)

Module Configuration

(Subsection 4.2.2)

Module Setting

(Subsection 4.2.3)

Setting of Input Block

Connection Assignment

(Subsection 4.3.1)

Module Configuration

(Subsection 4.3.2)

Module Setting

(Subsection 4.3.3)

Setting of Output Block

Connection Assignment

3-4

Parameters

setting tool

Model LL1100 PC-based Parameters Setting

instruction manual (IM 5G1A01-01E)

Tool

Figure 3.3.1 Paths for Moving among Dialog Boxes

Custom Display

Configuration Menu

Custom Display

Selection

Custom Display

Switching Condition

Security Definitions

(Subsection 5.2.1)

Custom Display

Selection

(Subsection 5.2.2)

Custom Display

Switching Conditions

(Section 5.3)

Security Definition

Dialog boxes that appear when custom displays are configured

IM 5G1A11-01E

Page 26

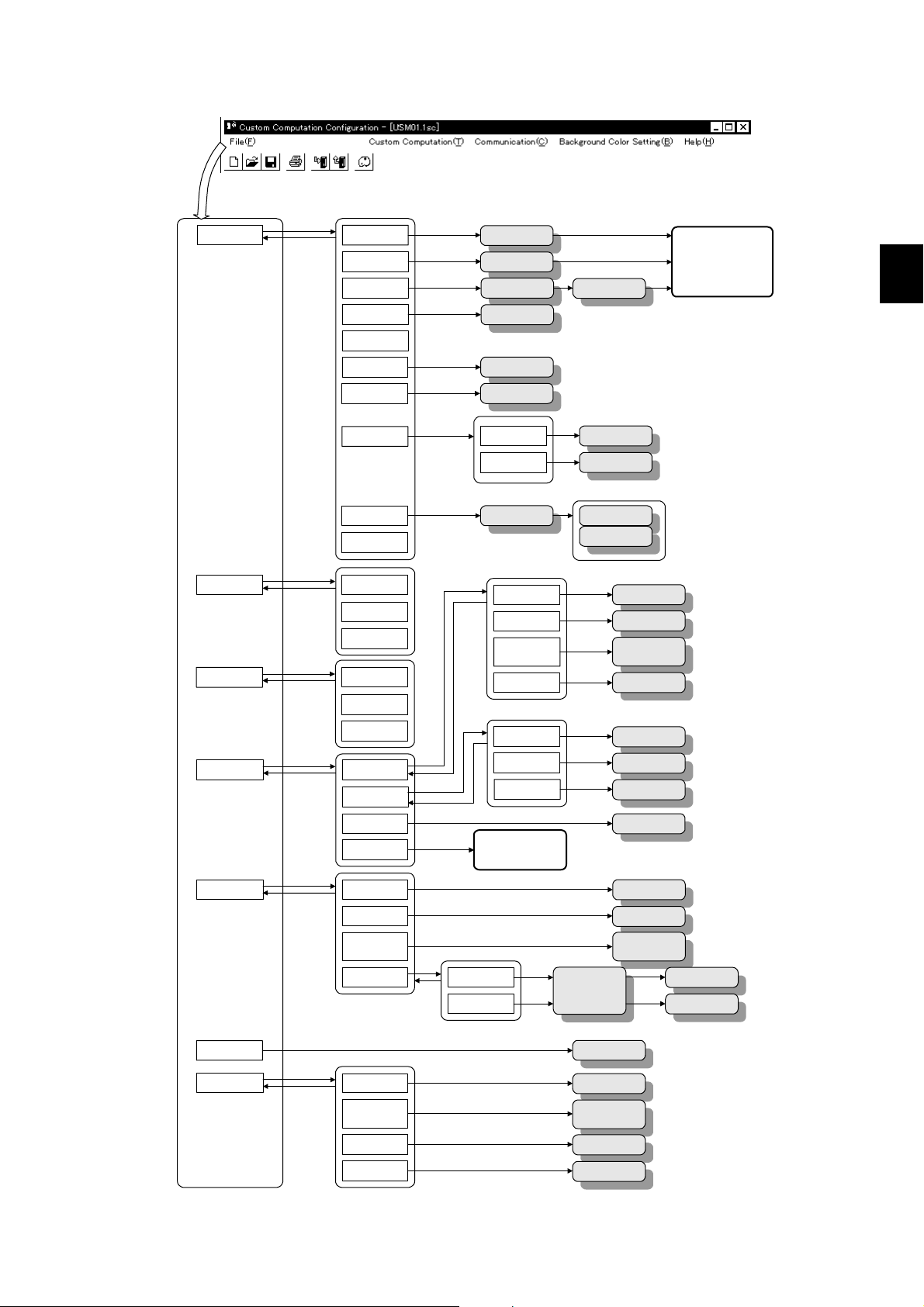

Tool menus

File

New

Open

Open Sample File

Close

Save

Save As

Compare

Specify Suffix Code

and Controller Type

Open

(User file)

Open

(Sample file)

Main Window

Save As

Compare

Specify Suffix Code

and Controller Type

Chapter 3 Using the LL1200 Tool

Choosing any of these options

switches to the window marked

➀ in Figure 3.3.1.

For information on the

subsequent windows, see the

paragraphs describing the way

the windows are organized.

3

Editing

Modify Configuration

Display Vertical Division

Horizontal Division

Custom Computation

Communication

Background

Color Setting

Help

Custom Computation

Custom Display

Configuration

Controller Type

Start Parameters

US1000 Controller

US1000 Controller

Custom Computation

Custom Computation

Description of

Description of

Module Information

Version Information

Information

Print

Exit

Connection

Delete

Cancel

Configuration

Changing of

Setting Tool

Download to

Upload from

Compare

Monitor

Building Tool

D-registers

and I-relays

File Information

I/O Signal Information

(Chapter 9)

Setting of Print Range

Input Block

Output Block

Ten-segment

Linearizers 3 and 4

Parameters

USER Parameters

Display Selection

Display Switching

Condition

Security Definition

Exit the custom computation

building tool and start the

parameters setting tool.

Input Block

Output Block

File Information

I/O Signal Information

Setting

Printer Setting

Print Preview

(Chapter 10)

Communication

Condition Setting

Background Color

Setting

Custom Computation

Building Tool

Description of

D-registers

and I-relays

Description of

Module Information

Version Information

Input Block

Output Block

Parameter Setting for

Ten-segment

Linearizer 3 and 4

USER Parameters

Custom Display

Selection

Custom Display

Switching Conditions

Security Definition

Specify Suffix Code

and Controller Type

Download to

US1000 Controller

Upload from US1000

Controller

Compare with

US1000 Controller's

Custom Data

Input Block Monitor

Output Block Monitor

(Chapter 8)

(Chapter 11)

Figure 3.3.2 Paths for Moving among the Options in the Tool Menus

IM 5G1A11-01E 3-5

Page 27

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

4.

Basic Operations for Configuring Custom

Computations and Relevant Explanations

This chapter explains the procedure for configuring custom computations.

For details on the preparatory work for using the LL1200 tool, see Chapter 2, "Setup." Likewise, for

an overview of the procedure for configuring custom computations and displays, see Chapter 3,

"Using the LL1200 Tool."

Also refer to Chapter 4, "List of Computation Modules and Their Functions," in the Model LL1200

PC-based Custom Computation Building Tool-User's Reference instruction manual (IM 5G1A11-02E),

for detailed specifications of the computation modules.

In order to configure custom computations, you must follow the steps shown below.

●Step 1: Choosing the Way Computations Are Configured --------------------------- (Section 4.1)

●Step 2: Configuring Custom Computations in an Input Block ----------------------- (Section 4.2)

●Step 3: Configuring Custom Computations in an Output Block --------------------- (Section 4.3)

●Step 4: Setting Ten-segment Linearizers 3 and 4 Parameters (as necessary)- (Section 4.4)

●Step 5: Setting USER Parameters (as necessary) ------------------------------------- (Section 4.5)

When you are finished with these steps, download the configured custom computations to the US1000

controller (see Section 8.2). Then, verify their performance by means of custom computation monitoring (see Chapter 11).

4

IM 5G1A11-01E 4-1

Page 28

4.1 Step 1: Choosing the Way Computations Are Configured

When you start the LL1200 tool, a dialog box appears as shown in Figure 4.1.1.

Figure 4.1.1 [Tool Selection] Dialog Box

Click the <Custom Computation Building Tool> option button, and then the <OK> button. The [New/

Modification] dialog box (Figure 4.1.2) appears.

Figure 4.1.2 [New/Modification] Dialog Box

4-2

IM 5G1A11-01E

Page 29

Chapter 4

There are four ways of configuring custom computations, as described below. Choose one of these

four ways.

TIP

If you are configuring custom computations for the first time, it is advisable that you use a sample file.

For your information, Section 4.2, “Step 2: Configuring Custom Computations in an Input Block,”

uses the sample file (USM01.1SC) for single-loop control to explain all the operating procedures that

follow that particular section.

Basic Operations for Configuring Custom Computations and Relevant Explanations

① If you are configuring a custom computation from scratch, choose <New File>.

Click the <New File> option button, then the <OK> button. The [Specify Suffix Code and

Controller Type] dialog box (Figure 4.1.3) appears.

② If you are configuring a custom computation using a user file, choose <Open User File>.

Click the <Open User File> option button, and then the <OK> button. The [Open User File]

dialog box (Figure 4.1.4) appears.

③ If you are configuring a custom computation using a sample file, choose <Open Sample File>.

Click the <Open Sample File> option button, and then the <OK> button. The [Open Sample File]

dialog box (Figure 4.1.5) appears.

④ If you are configuring a custom computation by uploading data from the US1000 controller,

choose <Upload from US1000 Controller>.

Click the <Upload from US1000 Controller> option button, and then the <OK> button. The

[Upload from US1000 Controller] dialog box (Figure 4.1.6) appears.

NOTE

When uploading custom computation information from US1000 controller, set the controller mode

(US mode) to “21.”

4

IM 5G1A11-01E 4-3

Page 30

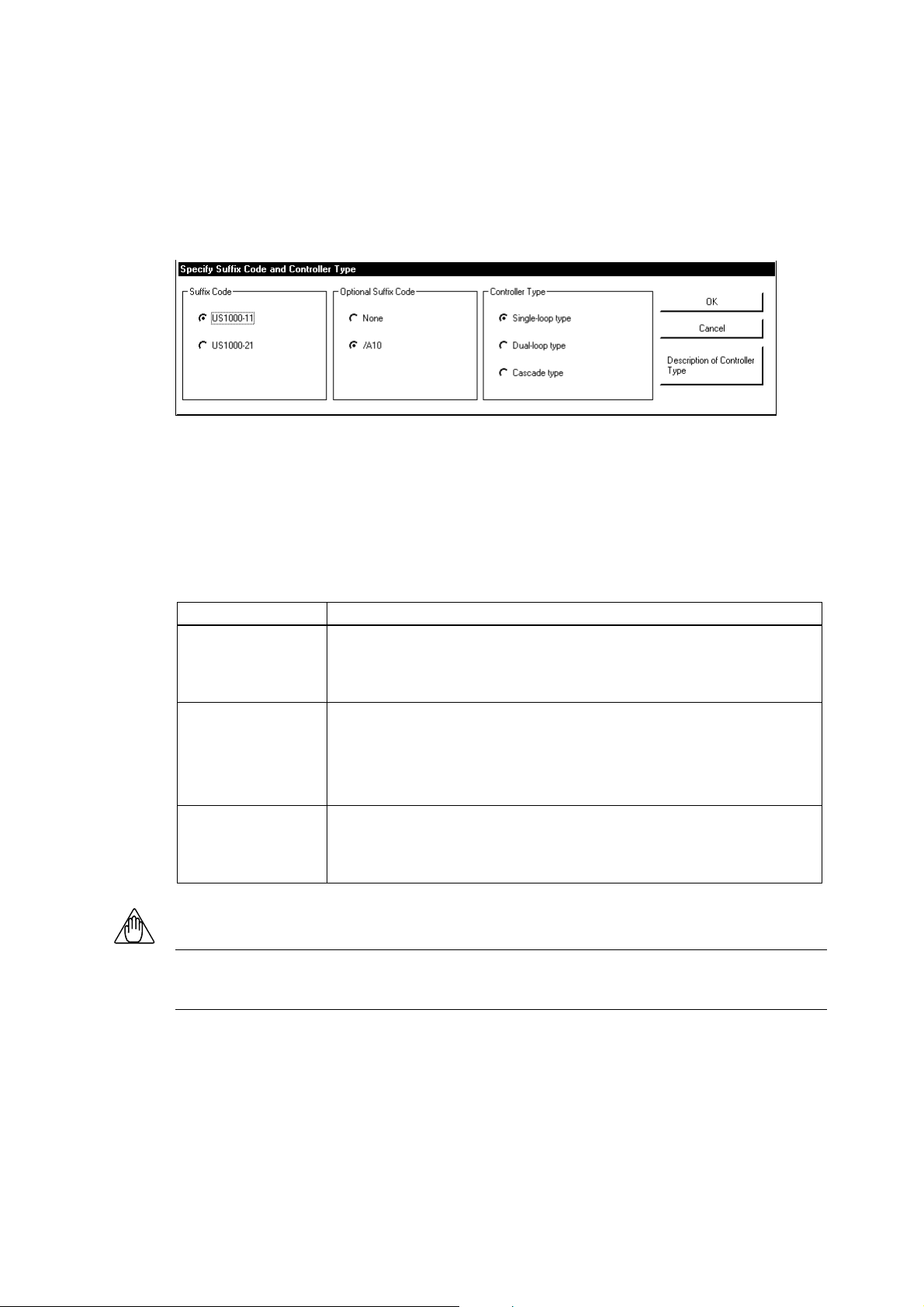

■ [Specify Suffix Code and Controller Type] Dialog Box

If you choose <New File> in the [New/Modification] dialog box (Figure 4.1.2), the [Specify Suffix

Code and Controller Type] dialog box (Figure 4.1.3) appears. This dialog box also appears if you

choose <Open Sample File>.

In the [Specify Suffix Code and Controller Type] dialog box, click the <OK> button. The [Custom

Computation Configuration Menu] dialog box (Figure 4.1.7) appears.

Figure 4.1.3 [Specify Suffix Code and Controller Type] Dialog Box

● Explanation of the [Specify Suffix Code and Controller Type] Option

The suffix code must be specified because the code needs to be verified when you download information on the custom computations you configured using the LL1200 tool, to the US1000 controller.

Likewise, the controller type must be specified because you must decide upon the desired operating

conditions for the US1000 controller.

Criteria for ChoiceController Type

Single-loop type

Dual-loop type

Cascade type

The following are used:

• One PID computation

• Switching among loop-1 CAS, AUTO and MAN modes

• Switching between RUN/STOP modes

• Switching between the loop-1 Open/Close modes

The following are used:

• Two PID computations

• Switching among loop-1 CAS, AUTO and MAN modes

• Switching among loop-2 CAS, AUTO and MAN modes

• Switching between RUN/STOP modes

• Switching between the loop-1 Open/Close modes

• Switching between the loop-2 Open/Close modes

The following are used:

• Two PID computations

• Switching between RUN/STOP modes

• Switching among the loop-1 CAS, AUTO and MAN modes

• Switching between the loop-2 Open/Close modes

NOTE

Data cannot be downloaded to US1000 controllers whose suffix codes do not match the one specified.

Check the suffix and optional suffix codes of the US1000 controller to which you download data.

4-4

IM 5G1A11-01E

Page 31

■ Open User File

In the [Open User File] dialog box, choose the file you wish to use and click the <Open> button. The

[Custom Computation Configuration Menu] dialog box (Figure 4.1.7) appears.

Figure 4.1.4 [Open User File] Dialog Box

■ Open Sample File

In the [Open Sample File] dialog box, choose the file you wish to use and click the <Open> button.

The [Specify Suffix Code and Controller Type] dialog box (Figure 4.1.3) appears. In the dialog box,

click the <OK> button. The [Custom Computation Configuration Menu] dialog box (Figure 4.1.7)

appears.

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

4

Figure 4.1.5 [Open Sample File] Dialog Box

IM 5G1A11-01E 4-5

Page 32

■ Upload from US1000 Controller

If you choose <Upload from the US1000 Controller> in the [New/Modification] dialog box, the

[Upload from US1000 Controller] dialog box (Figure 4.1.6) appears.

Option button

Drop-down list box

Figure 4.1.6 [Upload from US1000 Controller] Dialog Box

You can communicate with the US1000 controller in either of the following two ways.

●Communication Using the Front-panel Optical Interface

① In the [Upload from US1000 Controller] dialog box, click the <Front Terminal> option button.

② From the <Serial Port> drop-down list box, choose either COM1, COM2, COM3 or COM4.

③ Click the <Execute> button. Data are uploaded from the US1000 controller.

④ When uploading is complete, the [Custom Computation Configuration Menu] dialog box (Figure

4.1.7) appears.

⑤ For the subsequent operations, see Section 4.2 and the sections/subsections that follow.

●Communication Using the RS-485 Interface

① In the [Upload from US1000 Controller] dialog box, click the <Rear Terminal> option button.

② From the <Serial Port> drop-down list box, choose either COM1, COM2, COM3 or COM4. Then,

from the <Baud Rate>, <Parity> and <Address> drop-down list boxes, choose the options of the

three communication conditions, the baud rate, parity and address. Also choose the options of the

two communication conditions, the stop bit and data length, by clicking the appropriate option

buttons in the <Stop Bit> and <Data Length> sections.

Match the communication conditions of the US1000 controller with those of the personal computer.

③ Click the <Execute> button. The LL1200 tool begins uploading data from the US1000 controller.

④ When uploading is complete, the [Custom Computation Configuration Menu] dialog box (Figure

4.1.7) appears.

⑤ For the subsequent operations, see Section 4.2 and the sections/subsections that follow.

4-6

NOTE

If you have chosen RS-485 communication, set the communication protocol of the US1000 controller

to [PC-link Communication]. Communication is not possible if you set the protocol to [PC-link

Communication with Sum Check], [Modbus (RTU)] or [Modbus (ASCII)].

IM 5G1A11-01E

Page 33

Chapter 4

■ Custom Computation Configuration Menu

The dialog box shown below is the first to appear when you configure custom computations. For

further operations after this Custom Computation Configuration Menu dialog box, see Section 4.2 and

the sections/subsections that follow.

Basic Operations for Configuring Custom Computations and Relevant Explanations

4

Options in Custom Computation Configuration Menu

Figure 4.1.7 [Custom Computation Configuration Menu] Dialog Box

IM 5G1A11-01E 4-7

Page 34

4.2 Step 2: Configuring Custom Computations in an Input Block

The flow of work in step 2 is as follows.

This section explains the work flow using the single-loop control sample file (USM01.1SC).

Read the sample file onto your personal computer before you start this step.

Start of custom computation

configuration

Register computation modules

Configure the inputs and parameters

of computation modules

Connect the input block to the control

and computing section

Set the analog-input burnout prevention

function (as necessary)

End of custom computation

configuration

(Subsection 4.2.1)

(Subsection 4.2.2)

(Subsection 4.2.3)

(Subsection 4.2.4)

Figure 4.2.1 Flow of Work for Configuring Custom Computations in an Input Block

Figure 4.2.2 shows the [Custom Computation Configuration Menu] dialog box used to configure

custom computations.

Option chosen to

configure custom

computations in an

input block

4-8

Figure 4.2.2 [Custom Computation Configuration Menu] Dialog Box

IM 5G1A11-01E

Page 35

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

4.2.1 Step 2-1: Registering Computation Modules

- Explanation

This step involves registering the computation modules you want to perform operations in an input

block, in the order they are executed. You can register a maximum of 30 computation modules.

Figure 4.2.3 shows an input block for single-loop control where a module for a logical “NOT”

operation is added. The following paragraphs explain how to add a NOT module to the diagram of an

input block for single-loop control.

Computation module

ranked first in the

order of execution

(i.e., first-run module)

Computation module

ranked

second

third

in the

in the

order of execution

(i.e., second-run module)

Computation module

ranked

order of execution

(i.e., third-run module)

PV input

IN1

P1=0 (AIN1)

41:EUCONV

33:PLINE1

PVIN. 1 R/S

P2=0 (PV1)

1

1401

IN1

2

1403

41:EUCONV

feedforward input

IN1

1405

CSVIN. 1

Cascade or

AIN3AIN1

13031301

P1=2 (AIN3)

P2=0 (PV1)

3

FF

Control and computing section

Output block

SV number selection

AUT1 MAN1

R/S

DI1. st

DI2. st DI3. st DI4. st DI5. st DI6. st DI7. st

5161

5162 5163 5164 5165 5166 5167

NOT module registered as one

IN1

17:NOT

4

1407

AUT. 1

ranked fourth in the order of

execution (i.e., fourth-run module)

MAN. 1

SV. B0 SV. B1

SV. B2

SV. B3

Input

block

4

Figure 4.2.3

Addition of a NOT Module to the Diagram of an Input Block for Single-loop Control

IM 5G1A11-01E 4-9

Page 36

- Operation: Registering the Modules

TIP

Computation modules can be positioned anywhere within the input block. You should however locate

them as close as possible to the input signals (AIN1 to AIN3 and DI1.st to DI7.st) for the input block

connected to the modules. This strategy makes wiring between module I/Os visible and simple.

① In the [Custom Computation Configuration Menu] dialog box (Figure 4.2.2), click the <Input

Block> button. The [Input Block] dialog box appears. Figure 4.2.4 illustrates the [Input Block]

dialog box for single-loop control.

4-10

Figure 4.2.4 [Input Block] Dialog Box for Single-loop Control

② In the [Input Block] dialog box, double-click a blank box. The [Module Configuration] dialog box

(Figure 4.2.5) appears. For ease of selection, modules are classified into four types; arithmetic

operation, logical operation, special operation and special function.

IM 5G1A11-01E

Page 37

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

Indexes

Figure 4.2.5 [Module Configuration] Dialog Box

③ Click the index that contains the computation module you register.

④ Double-clicking the module registers it.

Figure 4.2.6 shows an example where the <17: NOT> option in the <Logical Operation> index is

registered.

4

Indicates the registered NOT module

Figure 4.2.6 Example where a NOT Module Is Registered as the Fourth-Run Module

IM 5G1A11-01E 4-11

Page 38

TIP

To view an explanation on the selected module, click the right mouse button in the [Module Configuration] dialog box. And then click the [Module Description]. The [Custom Computation Module

Help for US1000] view appears. Figure 4.2.7 shows an explanation on a NOT module.

Figure 4.2.7 [Custom Computation Module Help for US1000] View

Repeat steps ② to ④ to register other necessary computation modules also.

When you have finished registering modules, proceed to subsection 4.2.2, “Step 2-2: Configuring the

Inputs and Parameters of Computation Modules.”

4-12

IM 5G1A11-01E

Page 39

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

4.2.2 Step 2-2: Configuring the Inputs and Parameters of Computation Modules

- Explanation

Each computation module has inputs (8 maximum), parameters (4 maximum) and an output. This step

involves configuring inputs and parameters only. The results of computation provided by the output

are automatically stored, according to the module’s order of execution, in the data storage area of the

US1000 controller.

Inputs (8 maximum)

• • •

IN1 IN2

OUT

Output (one)

Module

No. xx

IN8

P1

• • •

P4

Parameters

(4 maximum)

Figure 4.2.8 Conceptual View of Module Configuration

4

IM 5G1A11-01E 4-13

Page 40

As was the case in the previous subsection, Figure 4.2.9 shows an input block for single-loop control

where a logical NOT operation module is added.

In this block diagram, analog input 1 (AIN1) is connected to the input of an EUCONV module ranked

first in the order of execution. Since the EUCONV module requires parameters, a constant data value

of 0 is set for both parameters P1 and P2.

For more information on the handling of P1 and P2 parameters, see Chapter 4, “List of Computation

Modules and Their Functions,” in the Model LL1200 PC-based Custom Computation Building Tool-

User’s Reference instruction manual (IM 5G1A11-02E).

The output of the EUCONV module, which is ranked first in the order of execution, is connected to

the input of the PLINE1 module which is ranked second in the order of execution. The PLINE1

module has no parameters. Analog input AIN3 is connected to the input of the EUCONV module

ranked third in the order of execution. The constant data values of 2 and 0 are set in parameters P1

and P2 of the EUCONV module. In addition, contact input 1 is connected to the input of the NOT

module which was registered in the previous subsection and is ranked fourth in the order of execution.

Input of PLINE1 module

Input and parameters of EUCONV module

PV input

IN1

P1=0 (AIN1)

41:EUCONV

33:PLINE1

PVIN. 1 R/S

P2=0 (PV1)

1

1401

IN1

2

1403

feedforward input

IN1

41:EUCONV

1405

CSVIN. 1

Cascade or

AIN3AIN1

13031301

P1=2 (AIN3)

P2=0 (PV1)

3

Control and computing section

Contact input 1 (DI1) is

connected to the input of

the NOT module

AUT1 MAN1

R/S

DI1. st

DI2. st DI3. st DI4. st DI5. st DI6. st DI7. st

5161

5162 5163 5164 5165 5166 5167

IN1

17:NOT

4

1407

Input and parameters of EUCONV module

FF

MAN. 1 SV. B0 SV. B1

AUT. 1

SV number

selection

SV. B2

SV. B3

Input

block

4-14

Output block

Figure 4.2.9 Contact Input 1 Connected to the Input of the NOT Module

IM 5G1A11-01E

Page 41

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

- Operation: Configuring the Modules

This operation involves configuring the inputs and parameters of the computation modules.

① In the [Input Block] dialog box, click the module whose inputs and parameters you want to

configure. In the example shown in Figure 4.2.6, click the NOT module.

② From the tool menus, choose <Editing>, then <Connection>.

The [Module Setting] dialog box (Figure 4.2.10) appears.

Indexes

4

Figure 4.2.10 [Module Setting] Dialog Box

③ Click the input from among <IN1> to <IN8> or the parameter from among <P1> to <P4>, that

need to be configured.

④ Click the appropriate index.

Indexes are classified into <AINn>,<DIn.st>, <Module Output>, <D-register>, <I-relay> and

<Constant Value>.

IM 5G1A11-01E 4-15

Page 42

●Description of Indexes

Index Remarks

AINn

DIn.st

Module Output

D-Register

I-Relay

Constant Value

AIN1: Analog Input 1

AIN2: Analog Input 2

AIN3: Analog Input 3

DI1.st: Contact Input 1

DI2.st: Contact Input 2

DI3.st: Contact Input 3

DI4.st: Contact Input 4

DI5.st: Contact Input 5

DI6.st: Contact Input 6

DI7.st: Contact Input 7

IMO1L to IMO30L (outputs of input-block computation modules)

OMO1L to OMO30L (outputs of output-block computation modules)

Process data, mode data, operation parameters, setup parameters

ON/OFF status, ON status, OFF status, SVNO, PIDNO, timer flags,

power-on flags, alarm flags, etc.

Configurable range: -19999 to 30000

Description

Analog input data fed to input block

Contact input data fed to input block

See Appendix 4, “Areas for Storing

Data Output from Computation

Modules.”

See Sections 5.3 to 5.9 in the Model

LL1200 PC-based Custom Computation

Building Tool—User’s Reference

instruction manual (IM 5G1A11-02E).

See Sections 5.10 to 5.13 in the Model

LL1200 PC-based Custom Computation

Building Tool—User’s Reference

instruction manual (IM 5G1A11-02E).

⑤ Double-clicking the appropriate input source configures the selected index.

To configure the <Constant Value> index, type a value in the text box, and then press the <Enter>

key. The figure below shows an example of how to configure contact input 1 <DI1.st>.

➀ Click <IN1>

➁ Click the <DIn.st> index

➂ Click <DI1.st>.

Figure 4.2.11 Configuring Contact Input 1 <DI1.st>

⑥ Repeat steps ③ to ⑤ to configure the other necessary inputs among <IN1> to <IN8> or parameters

among <P1> to <P4>.

⑦ Clicking the <OK> button closes the [Module Setting] dialog box. When the dialog box closes,

the computation modules are automatically wired according to the inputs and parameters you

configured.

⑧ Repeat steps ① to ⑦ to configure other computation modules also.

4-16

IM 5G1A11-01E

Page 43

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

When you have finished configuring the inputs and parameters of computation modules, proceed to

subsection 4.2.3, “Step 2-3: Connecting Computation Modules to the Control and Computing Section.”

4.2.3 Step 2-3: Connecting Computation Modules to the Control and Computing Section

- Explanation

This step involves making the settings needed to pass the results of computation to the control and

computing section after completing the module configuration and settings discussed so far.

As was the case in the previous subsection, Figure 4.2.12 shows an input block for single-loop control

where a logical NOT operation module is added.

In this block diagram, the output of the ten-segment linearizer 1 (PLINE1) module ranked second in

the order of execution is connected to the loop-1 PV input (PVIN.1). The output of the EU range

conversion (EUCONV) module ranked third in the order of execution is connected to the loop-1

cascade input (CSVIN.1). AIN3 is connected to the feedforward input (FF). In addition, the output of

the NOT module ranked fourth in the order of execution is connected to the RUN/STOP mode (R/S)

output signal.

PV input

IN1

41:EUCONV

1401

IN1

33:PLINE1

1403

P1=0 (AIN1)

P2=0 (PV1)

1

2

feedforward input

IN1

41:EUCONV

1405

Cascade or

AIN3AIN1

13031301

P1=2 (AIN3)

P2=0 (PV1)

3

AUT1 MAN1

R/S

DI1. st

DI2. st DI3. st DI4. st DI5. st DI6. st DI7. st

5161

5162 5163 5164 5165 5166 5167

The AIN3 input signal is passed to the FF output signal

IN1

17:NOT

4

1407

The output from the

NOT module is passed

to the R/S output signal

SV number selection

Input

block

4

SV. B3

SV. B2

The output from the PLINE1

module is passed to the

PVIN.1 output signal

PVIN. 1 R/S

The output from the

EUCONV module is passed

to the CSVIN.1 output signal

CSVIN. 1

FF

Control and computing section

Output block

AUT. 1

MAN. 1

SV. B0 SV. B1

Figure 4.2.12 Connection of the NOT Module’s Output to the Control and Computing

Section

IM 5G1A11-01E 4-17

Page 44

- Operation: Connecting to the Control and Computing Section

This operation involves making the settings needed to pass the results of computation in the input

block to the control and computing section.

① In the [Input Block] dialog box (Figure 4.2.13), click the appropriate output signal. Click <R/S> in

the example shown in Figure 4.2.13.

Output signals fed by the input block

Figure 4.2.13 Output Signals Fed by the Input Block

4-18

IM 5G1A11-01E

Page 45

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

●Description of Output Signals Fed by the Input Block

Output Signal Fed by Input Block Description

PVIN.1

PVIN.2

CSVIN.1

CSVIN.2

GAIN.1

GAIN.2

TRK.1

TRK.2

FF

CAS.1

AUT.1

MAN.1

CAS.2

AUT.2

MAN.2

O/C

R/S

TRF.1

TRF.2

Loop-1 PV input

Loop-2 PV input

Loop-1 cascade input

Loop-2 cascade input

Loop-1 gain setting value

Loop-2 gain setting value

Loop-1 tracking input

Loop-2 tracking input

Feedforward input

Loop-1 CAS mode

Loop-1 AUTO mode

Loop-1 MAN mode

Loop-2 CAS mode

Loop-2 AUTO mode

Loop-2 MAN mode

OPEN/CLOSE mode

RUN/STOP mode

Loop-1 tracking flag

Loop-2 tracking flag

② From the tool menus, choose <Editing>, then <Connection>.

The [Setting of Input Block Connection Assignment] dialog box (Figure 4.2.14) appears.

4

Indexes

Figure 4.2.14 [Setting of Input Block Connection Assignment] Dialog Box

③ Click the appropriate index.

Indexes are classified into <AINn>,<DIn.st>, <Module Output>, <D-register>, <I-relay> and

<Constant Value>.

IM 5G1A11-01E 4-19

Page 46

●Description of Indexes

Index Remarks

AINn

DIn.st

Module Output

D-Register

I-Relay

Constant Value

AIN1: Analog Input 1

AIN2: Analog Input 2

AIN3: Analog Input 3

DI1.st: Contact Input 1

DI2.st: Contact Input 2

DI3.st: Contact Input 3

DI4.st: Contact Input 4

DI5.st: Contact Input 5

DI6.st: Contact Input 6

DI7.st: Contact Input 7

IMO1L to IMO30L (outputs of input-block computation modules)

OMO1L to OMO30L (outputs of output-block computation modules)

Process data, mode data, operation parameters, setup parameters

ON/OFF status, ON status, OFF status, SVNO, PIDNO, timer flags,

power-on flags, alarm flags, etc.

Configurable range: -19999 to 30000

Description

Analog input data fed to input block

Contact input data fed to input block

See Appendix 4, “Areas for Storing

Data Output from Computation

Modules.”

See Sections 5.3 to 5.9 in the Model

LL1200 PC-based Custom Computation

Building Tool—User’s Reference

instruction manual (IM 5G1A11-02E).

See Sections 5.10 to 5.13 in the Model

LL1200 PC-based Custom Computation

Building Tool—User’s Reference

instruction manual (IM 5G1A11-02E).

④ Double-clicking the appropriate input source configures the selected index.

To configure the <Constant Value> index, type a value in the text box, and then press the <Enter>

key. The figure below shows an example of how to configure <IMO4L>, the module that is the

fourth input-block computation module to be carried out.

Indexes

Figure 4.2.15 Configuring <IMO4L>, the Fourth Input-block Computation Module to Be

Carried Out

⑤ Clicking the <OK> button after the configuration is completed closes the [Setting of Input Block

Connection Assignment] dialog box. When the dialog box closes, the computation modules are

automatically wired according to the settings you defined.

⑥ Repeat steps ① to ⑤ to define the connection of other necessary output signals also.

4-20

IM 5G1A11-01E

Page 47

Chapter 4

Figure 4.2.16 shows the input block with the configuration and setting of computation modules, as

well as their connection to the control and computing block, completed.

Basic Operations for Configuring Custom Computations and Relevant Explanations

4

Figure 4.2.16 Registration of a NOT Module in the Diagram of an Input Block for Single-

loop Control (Finished View)

IM 5G1A11-01E 4-21

Page 48

4.2.4 Step 2-4: Setting the Analog-input Burnout Function

- Explanation

The US1000 controller has a function designed to switch the output of a loop in use to the preset

value in the event of an A/D conversion failure or analog-input burnout. This function is configured

in the following step.

To use the function, determine which output signal among PV1, PV2, CSV1 and CSV2 should be

coupled with signals coming in through the AIN1, AIN2 and AIN3 inputs.

In the example shown in the [Connection of Analog Input Burnout Information] dialog box (Figure

4.2.17), AIN1 is coupled with PVIN.1 and AIN3 with CSV.1. This configuration switches the loop-1

MV output value to the preset one if a burnout occurs at either the AIN1 or AIN3 input.

Figure 4.2.17 [Connection of Analog Input Burnout Information] Dialog Box

- Operation

① The [Connection of Analog Input Burnout Information] dialog box appears when you finish

configuring custom computations in the [Input Block] dialog box and click the <OK> button.

If you do not need to set any analog-input burnout information, simply click the <OK> button.

② In the [Connection of Analog Input Burnout Information] dialog box, click the appropriate blank

box. A check mark (✔) appears in the box. The setting is complete if the box shows a check

mark.

③ When the setting is complete, click the <OK> button. The display returns to the [Custom Compu-

tation Configuration Menu] dialog box (Figure 4.2.2).

If you also want to configure custom computations in the output block after you finish configuring the

input-block custom computations, proceed to the next section.

4-22

IM 5G1A11-01E

Page 49

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

4.3 Step 3: Configuring Custom Computations in an Output Block

The flow of work in step 3 is as follows.

Start of custom computation

configuration

Register computation modules

Configure the inputs and parameters

of computation modules

Connect the computation modules'

outputs with the output signals

End of custom computation

configuration

(Subsection 4.3.1)

(Subsection 4.3.2)

(Subsection 4.3.3)

Figure 4.3.1 Flow of Work for Configuring Custom Computations in an Output Block

Figure 4.3.2 shows the [Custom Computation Configuration Menu] dialog box used to configure

custom computations.

4

Option chosen to

configure custom

computations in an

output block

Figure 4.3.2 [Custom Computation Configuration Menu] Dialog Box

IM 5G1A11-01E 4-23

Page 50

4.3.1 Step 3-1: Registering Computation Modules

- Explanation

This step involves registering the computation modules you want to perform operations in an output

block, in the order they are executed. You can register a maximum of 30 computation modules.

NOTE

It is recommended that the output blocks included in the US mode of the US1000 be used as they are.

The output selection modules listed below can be used to select the output type using the output

selection parameter (MVS1 or MVS2). If you make any change to the way an output selection

module is connected, the output in question may fail to function correctly.

Available output selection modules: OUTSEL1, OUTSEL11, OUTSEL12, OUTSEL13, OUTSEL2

and OUTSEL21

NOTE

When applying time-proportional PID computation, do not allow the computation to be carried out

between the output selection module and an output signal (OUT1A, OUT2A, OUT1R or OUT2R).

Figure 4.3.3 shows an output block for single-loop control where a logical OR operation module is

added. The following paragraphs explain how to add an OR module to the diagram of an output block

for single-loop control.

These signals are automatically connected

according to the setting in the MV output selection

parameter (MVS1 setup parameter)

Computation module

ranked first in the

order of execution

(i.e., first-run module)

Computation module

ranked second in the

order of execution

(i.e., second-run module)

Computation module

ranked third in the

order of execution

(i.e., third-run module)

Control and computing section

HMV. 1 CMV. 1MV. 1 RET1

1505

1507 1509 1511 1512

ALO13 ALO14

5691 5693

IN1 IN2 IN3 IN4

46:OUTSEL1

47:OUTSEL11348:OUTSEL12449:OUTSEL13

2

1603 1605

OUT1A

OUT2A OUT2ROUT1R

IN5 IN6 IN7

1601

1

1607

Computation module

ranked fourth in the

order of execution

(i.e., fourth-run module)

Input block

The OUTSEL1, OUTSEL11, OUTSEL12 and OUTSEL13 modules

must always be used together as a set when you use the MV output

as a time-proportional output or heating/cooling output

RET2

OR module registered as one

ranked sixth in the order of execution

(i.e., sixth-run module)

OUT3A

RET3

1513

ALO11 ALO12

5689 5690 5691 5693

IN4IN1IN2 IN3

15:OR

6

1613

DO1 DO2

ALO13

ALO14

Computation module

ranked sixth in the

order of execution

(i.e., sixth-run module)

DO3

DO4

1

IN1

13:CONST

5

1611

Computation module

ranked fifth in the

order of execution

(i.e., fifth-run module)

DO7

Output

block

4-24

Figure 4.3.3 Addition of an OR Module to the Diagram of an Output Block for Single-loop

Control

IM 5G1A11-01E

Page 51

Chapter 4

Basic Operations for Configuring Custom Computations and Relevant Explanations

- Operation: Registering the Modules

TIP

Computation modules can be positioned anywhere within the output block. You should however locate

them as close as possible to the output signals (PV.1, PV.2, CSV.1, CSV.2, MV.1, MV.2, HMV.1,

HMV.2, CMV.1, CMV.2, RET1, RET2 and RET3) for the output block connected to the modules.

This strategy makes wiring between module I/Os visible and simple.

① In the [Custom Computation Configuration Menu] dialog box (Figure 4.3.2), click the <Output

Block> button. The [Output Block] dialog box appears. Figure 4.3.4 illustrates the [Output Block]

dialog box for single-loop control.

4

Figure 4.3.4 [Output Block] Dialog Box for Single-loop Control

② In the [Output Block] dialog box, double-click a blank box. The [Module Configuration] dialog