Page 1

<<Contents>> <<Index>>

General

Specifications

Model LL100

PC-based Parameters

Setting Tool

GS 05G01B12-01E

■General

The LL100 PC-based Parameters Setting Tool is a software

package used to set the setup parameters, operating

parameters, and program patterns* of the GREEN Series

controllers from a personal computer. This tool allows

users to download, upload, print out parameters, and

display PV trend data during PID tuning, etc.

The multi-monitoring function can detect two or more

controllers automatically, and can display or save trend

data like PV, etc.

*: For program controllers only .

■Parameters (Program) Setting

Functions

Sets and changes the controller’s parameters such as the

controller mode (UT/UP mode), universal input/output

selection, setup parameters, operating parameters, and

program pattern parameters* (program/start conditions and

patterns).

Note: Uploading/downloading/comparing parameters via

Ethernet is impossible for the controller operated by

custom computation function (UT mode 21 or UP

mode 21). Use front communication or serial

terminal communication.

*: For program controllers only .

Tuning Function:

This function is used to tune the PID parameters of the

controllers. The PID parameters can be tuned and the autotuning function can be executed while the trend graphs of

PV, SP, and control output are being displayed on a personal

computer screen.

Downloading, Uploading, and Comparing Parameters:

When the controller operation is stopped, users can download the created parameter data to the controller and upload

the parameter data from the controller. It is also possible to

compare the parameter data created using this tool with the

data in the controller.

File Management Function:

This function allows users to save the parameter data created

using this tool and those uploaded from the controller to the

hard disk of a personal computer or a floppy disk. It is also

possible to compare the parameter data created using this

tool with those in the parameter files created in the past.

Printout Function:

Parameter data can be printed out from a printer connected to

a personal computer.

(with Multi-monitoring Function)

■Multi-monitoring Function

This function allows users to display and collect PV, SP,

control output and alarm generating state as trend data. It is

possible to detect two or more controllers (a maximum of 16

loops) connected to the personal computer automatically, and

to display trend graphs on a personal computer screen.

Tuning Function:

This function is used to tune the PID parameters of the

controller. The PID parameters can be tuned, the auto-tuning

function can be excuted for every connection loop and an

operating mode can be changed while the trend graphs of

PV, SP and control output are being displayed on a personal

computer screen.

File Management Function:

The trend data collected by the monitoring function can be

saved as a CSV format so that commercial spreadsheet

software like Microsoft Excel can treat data. The saved trend

data can be read and displayed as trend graph.

■Parameter Setting Function for

Ethernet Converter

Sets the parameters related to the Ethernet communication

function of the Ethernet/RS485 converter, VJET.

■Applicable Controllers

UT750 Digital Indicating Controller

UT551 Digital Indicating Controller

UT551-xA to xD Digital Indicating Controller

UT550/520 Digital Indicating Controller

UT450/420 Digital Indicating Controller

UT351/321 Digital Indicating Controller

UT351-xA Digital Indicating Controller

UT350/320 Digital Indicating Controller

UP750 Program Controller

UP550 Program Controller

UP351 Program Controller

UP350 Program Controller

■Functions Restricted by Communication

Method

Communication

Function

Paramerter setting

Program pattern setting

Multi-monitoring function

✓:Available.

Cond.

:Not available wthen operated by custom computation function

(UT mode 21 or UP mode 21).

method

Front

communication

✓

✓

✓

Serial terminal

communication

✓

✓

✓

Ethernet

communication

Cond.

Cond.

✓

GS 05G01B12-01E

©Copyright Feb. 2000(YG)

8th Edition Nov. 2006(KP)

Page 2

<<Contents>> <<Index>>

2

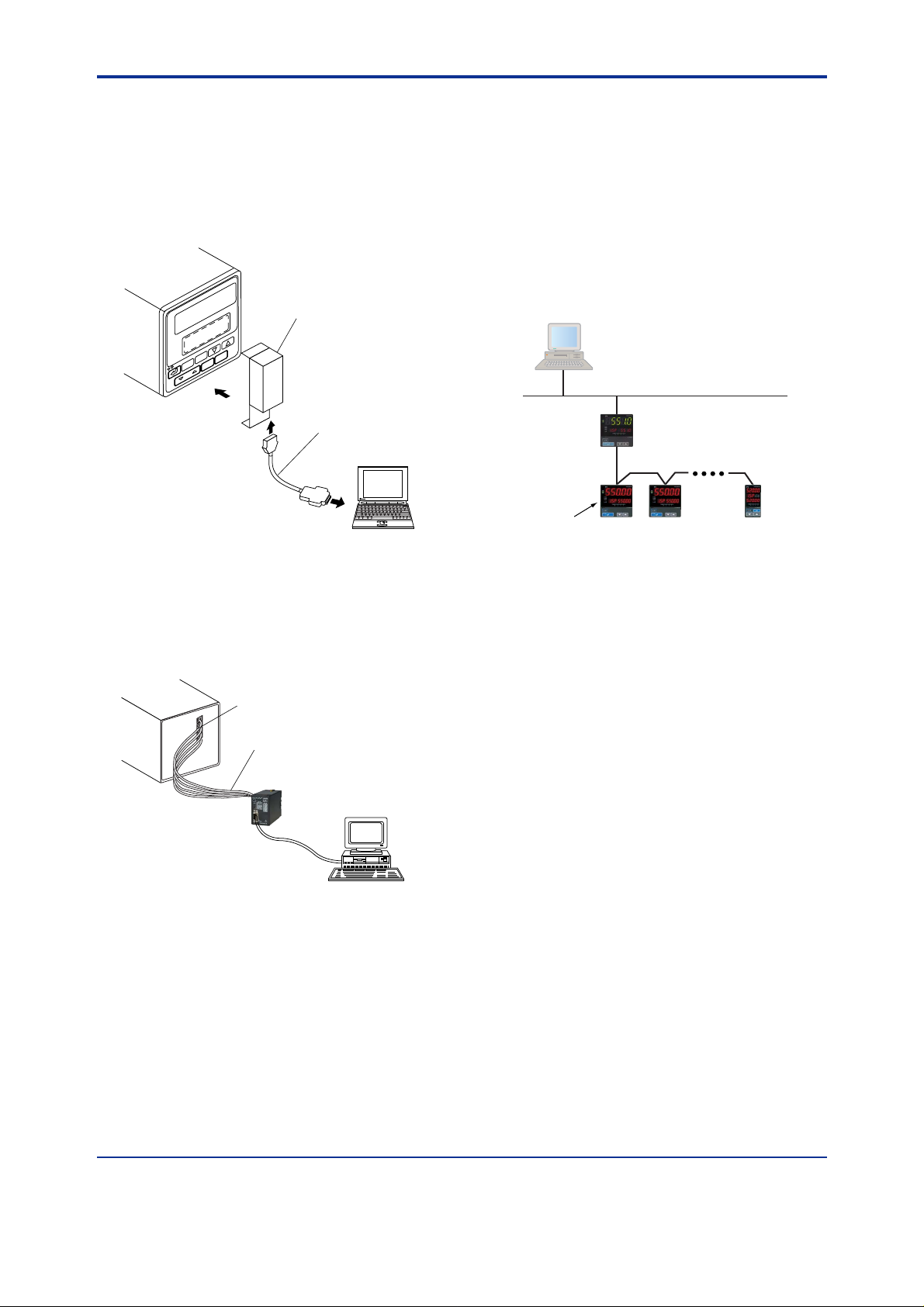

■Connection between the Controller and a Per-

sonal Computer

[Via Dedicated Adapter]

By attaching a dedicated adapter to the controller’s front

panel, users can upload and download parameter data to and

from a personal computer.

To communicate via the dedicated adapter:

Dedicated adapter

(optical/electrical signal converter)

Controller

Dedicated cable

Personal

computer

USB terminals

[Via RS-485 Communication Terminals]

Users can also upload and download parameter data to and

from a personal computer via the rear communication

terminals of the controller. This connection requires an RS232C/RS-485 converter (ML2).

To communicate via the communication terminals:

[Via Ethernet Communication Terminal]

The UT351-xA/UT551-xA to xD controllers can communicate with a personal computer via the Ethernet communication terminal. Connect a personal computer and a communicable network using a cable that meets the 10BASE-T/

100BASE-TX standards. Also, the UT351-xA/UT551-xA to

xD controllers and VJET converter can use the Ethernetserial gateway function to communicate with the GREEN

Series controllers equipped with the communication

functions via network. In this case, cross-connect the rear

communication terminals of the UT351-xA/UT551-xA to

xD/VJET and of the GREEN Series controllers.

PC

ETHERNET

10BASE-T/100BASE-TX cable

UT351-xA,

UT551-xA to xD

or VJET

Connect the RS485

rear communication

terminals.

GREEN Series controllers

RS485

Communication terminals

Shielded cables

Model ML2

RS-232C/RS-485

converter

Not available for UT551-xA to xD

and UT351-xA.

Personal

computer

All Rights Reserved. Copyright © 2000, Yokogawa Electric Corporation

GS 05G01B12-01E 8th Edition Nov.30,2006-00

Page 3

<<Contents>> <<Index>>

3

■Operating Environment

Personal Computer:

Windows 2000/XP-enabled IBM PC/AT compatible machine

Operating system: Windows 2000 (Professional)/XP

(Home Edition/Professional)

CPU: 300-MHz Pentium processor or superior is

recommended.

Main memory: 128 MB minimum is recommended.

Hard disk: Memory space required to store the tool’s

programs; 10 MB

Memory space required to store the parameter

data; 2 MB minimum

Memory space required to store the driver for

USB-Serial converter; 1 MB

CRT display: 800 ⫻ 600 pixels or superior

Smaller fonts should be used.

Should be capable of handling at least 256

colors.

USB communication port: One channel (COM1 to

COM16), with SeriesA connector, compliant

with USB Specification Rev1.1.

Network: 10BASE-T/100BASE-TX (required for

Ethernet communication)

CD-ROM drive: Required for installation.

Printer: Required for printing. Windows 2000/XP-

compatible A4-size printer

Dedicated Adapter

Communication method:

Controller side; optical, contactless, bidirec-

tional serial communication

Personal computer side; compliant with USB

Specification Rev1.1

Power supply: Supplied from USB bus power (no internal

battery)

Input rating; 4.4 to 5.25 V DC, 100 mA

(including a dedicated cable)

* No plug for external power source, no power switch

Ambient temperature range: 0 to 50°C

Ambient humidity range: 20 to 90% RH (no condensation)

Transport and storage conditions: -20 to 65°C, 10 to

90%RH (no condensation)

Dust- and water-proof construction: Not applied.

Standard: CE Marking (EMC only)

Dedicated Cable

Built-in USB-Serial converter

Personal computer side: USB SeriesA plug

Adapter side: RJ45 (8-pin) plug

Cable length: Approx. 2.7 m

■External Dimensions

Dedicated Adapter

3

Cable

36

45.5

96

Controller

96

(100)

Unit: mm

41

11

Dedicated Cable

107 350±102240±50

To adapter

Unit: mm

To PC (USB)

■Model and Suffix Codes

Model

LL100

Trademarks

• Windows 2000/XP are registered trademarks of Microsoft

• Pentium is a registered trademark of Intel Corporation,

• Ethernet is a registered trademark of XEROX Corporation,

• Other company and product names are trademarks or

Suffix

Description

code

PC-based Parameters Setting Tool

Model for use with IBM PC/AT compatible

-U10

machine (common to English and

Japanese version), USB connection

Corporation, USA.

USA.

USA.

registered trademarks of their respective holders.

3

96

2

■Packaged Contents

CD (2 disks):

LL100/USB converter driver software (1 disk)

User’s Manual (Reference) (CD version) (1 disk)

Dedicated adapter and dedicated cable:

For connecting a personal computer to optical

communication interface on the front of

controller (1 set)

All Rights Reserved. Copyright © 2000, Yokogawa Electric Corporation GS 05G01B12-01E 8th Edition Nov.30,2006-00

Loading...

Loading...