Page 1

User’s

Manual

Model LL100

PC-based Parameters

Setting Tool

IM 05G01B12-01E

IM 05G01B12-01E

5th Edition

Page 2

Page 3

<Toc> <Ind> <Rev> <Introduction>

Introduction

This user’s manual describes the functions of the LL100 PC-based Parameters Setting

Tool, which are used with GREEN Series of controllers, and how to operate the tool.

This manual should also be read by users of the LL200 PC-based Custom Computation

Building Tool, which includes the functions of LL100.

■ Controllers Covered by LL100

For information about the GREEN Series controllers covered by LL100, see Section 1.3,

“Model and Suffix Codes of Applicable Controller Models.”

■ Intended Readers

This manual is intended for people familiar with the functions of the GREEN Series controllers and capable of working with Windows, such as control engineers and personnel in

charge of the maintenance of instrumentation and control equipment.

■ Related Documents

i

The following user’s manuals all relate to the LL100 PC-based Parameters Setting T ool.

Read them as necessary . The codes enclosed in parentheses are the document numbers.

● Models UT350/UT320 User’s Manual (IM 05D01D02-01E to -03E)

Explains the basic operation of the UT350/UT320 controllers.

● Models UT351/UT321 User’s Manual (IM 05D01D12-01E to -04E)

Explains the basic operation of the UT351/UT321 controllers.

● Model UT351-xA User’s Manual (IM 05D01D13-01E to -04E)

Explains the basic operation of the UT351-xA controller.

● Model UT351-x3 User’s Manual (IM 05D01D52-01E to -04E)

Explains the basic operation of the UT351-x3 controller.

● Models UT450/UT420 User’s Manual (IM 05D01C12-01E to -04E)

Explains the basic operation of the UT450/UT420 controllers.

● Models UT550/UT520 User’s Manual for Single-loop Control

(IM 05D01C02-01E to -05E)

Explains the basic operation of the UT550/UT520 controllers.

●

Model UT551 with Embedded Ethernet User’s Manual for Single-loop Control

Explains the basic operation of the UT551 controller.

Media No. IM 05G01B12-01E 5th Edition : Mar. 2005 (YK)

All Rights Reserved Copyright © 2000, Y okogawa Electric Corporation

(IM 05D01C03-01E to -06E)

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 4

<T oc> <Ind> <Rev> <Introduction>

● Model UT551 User’s Manual for Single-loop Control

(IM 05D01C04-01E to -06E)

Explains the basic operation of the UT551 controller.

● Model UT750 User’s Manual for Single-loop Control

(IM 05D01B02-01E to -05E)

Explains the basic operation of the UT750 controller.

● Model UP350 User’s Manual (IM 05E01D02-01E to -04E)

Explains the basic operation of the UP350 controller.

● Model UP351 User’s Manual (IM 05E01D12-01E to -05E)

Explains the basic operation of the UP351 controller.

●

Model UP550 User’s Manual for Single-loop Control

Explains the basic operation of the UP550 controller.

(IM 05E01C02-01E to -07E)

ii

●

Model UP750 User’s Manual for Single-loop Control

Explains the basic operation of the UP750 controller.

(IM 05E01B02-01E to -07E)

● GREEN Series User’s Manual (Reference) (IM 05D01A02-01E)

Explains the functions of the GREEN Series controllers in detail.

(Supplied with each GREEN Series controller.)

● GREEN Series Communication Functions (IM 05G01B02-01E)

Explains the communication functions and communication protocols of the GREEN Series

in detail.

● GREEN Series Communication Reference (IM 05G01B02-02E)

Provides detailed information about GREEN Series controller’s internal registers that can

be accessed by communication.

● Ethernet Communication Functions User’s Manual (IM 05G01B52-01E)

Explains the Ethernet communication functions and communication protocols of the

UT351-xA and UT551 controllers in detail.

●

Model LL200 PC-based Custom Computation Building T ool

A user’s manual for creating UT750/UP750 custom computations on a personal computer .

(IM 05G01B22-01E)

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 5

<Toc> <Ind> <Rev> <Introduction>

● Model LL200 PC-based Custom Computation Building Tool User’s

Reference for UT750 (IM 05G01B22-02E)

● Model LL200 PC-based Custom Computation Building Tool User’s

Reference for UP750 (IM 05G01B22-03E)

User’s manuals that describe the functions needed to create custom computations of

UT750 and UP750. Refer to these manuals if you are unfamiliar with the types of functions

available or how these functions work.

● Model VJET Ethernet/RS-485 Converter User’s Manual (IM 77J01E1 1-01E)

Explains the basic operation of the VJET converter .

■ T rademarks

Windows 98/2000/XP and Windows NT 4.0 are registered trademarks of Microsoft Corporation, USA.

“Ethernet” is registered trademark of XEROX Corporation, USA.

iii

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 6

<T oc> <Ind> <Rev> <Introduction>

Visual Inspection and Check of Accessories

Visually inspect the product upon delivery to make sure it is not damaged in any way . Store

the box and inner packing material of the package in a safe place - they may be needed if

there is a problem with the product and it needs to be sent back for repair.

■ Check of Model and Suffix Codes

Refer to the following table to make sure the model and suffix codes of the tool are as were

specified with your order.

iv

Model code

LL100 PC-based Parameters Setting Tool for GREEN Series controllers

Suffix code

-E10 Model for use with IBM PC/AT-compatible personal computer (English version)

■ Confirmation of the Package Contents

Make sure the delivered package contains all of the following items. If any item is missing

or found to be damaged, immediately contact the sales office or dealership from which you

purchased the product.

(1) 3.5-inch floppy disks (4 disks)

(2) Dedicated adapter, supplied with two AAA-size batteries (one unit)

(3) Dedicated cable (one cable)

(4) GREEN Series User’s manual (Reference) (CD-ROM version)

Description

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 7

<Toc> <Ind> <Rev> <Introduction>

Documentation Conventions

■ Symbols

WARNING

Indicates that operating the hardware or software in this manner may damage it or lead to

system failure.

NOTE

Draws attention to information that is essential for understanding the operation and/or

features of the product.

TIP

Gives additional information to complement the present topic.

See Also

v

Gives reference locations for further information on the topic.

■ Conventions in the T exts that Describe Tool Operation

Item

The names of named dialog box, windows, and

views are written in title caps and refer to the

exact titles.

The names of unnamed windows, dialog box, and

views are written in all lowercase letters.

Commands (including buttons) in a dialog box or

window and menu commands are written in

boldface.

Dialog box elements, such as text boxes, list

boxes, option buttons, and check boxes, are also

written in boldface and refer to their exact labels.

Characters to be typed by the user via keyboard

are written in monotype font.

Keys on a keyboard are written in all caps.

Analog Input Computation Setting dialog box

Document window

Print preview

Click OK.

Click Cancel.

From the File menu, choose Open.

Select the Spaces check box.

Click to clear the Bookmarks check box.

In the File Name box, enter a file name.

T ype UT750 in the Model box.

Press ENTER to execute.

Press ALT + CTRL.

Usage

■ Description of Displays

(1) Some of the representations of product displays shown in this manual may be exag-

gerated, simplified, or partially omitted for reasons of convenience when explaining

them.

(2) Figures and illustrations representing the controller’s displays may differ from the real

displays in regard to the position and/or indicated characters (upper-case or lowercase, for example), to the extent that they do not impair a correct understanding of the

functions and the proper operation and monitoring of the system.

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 8

<T oc> <Ind> <Rev> <Introduction>

Notices

■ Regarding This User’s Manual

(1) This manual should be passed on to the end user. Keep at least one extra copy of the

manual in a safe place.

(2) Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

(3) This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that

these functions are suited to the particular purpose of the user.

(4) Under absolutely no circumstance may the contents of this manual, in part or in whole,

be transcribed or copied without permission.

(5) The contents of this manual are subject to change without prior notice.

(6) Every effort has been made to ensure accuracy in the preparation of this manual.

Should any errors or omissions come to your attention, however, please contact your

nearest Yokogawa representative or our sales office.

vi

■ Regarding Protection, Safety , and Prohibition Against Unauthorized

Modification

(1) In order to protect the product and the system controlled by it against damage and

ensure its safe use, make certain that all of the instructions and precautions relating to

safety contained in this document are strictly adhered to. Yokogawa does not guaran-

tee safety if products are not handled according to these instructions.

(2) Modification of the product is strictly prohibited.

(3) Reverse engineering such as the disassembly or decompilation of software is strictly

prohibited.

■ Force Majeure

(1) Y okogawa assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

(2) No portion of the software supplied by Yokogawa may be transferred, exchanged,

leased or sublet for use by any third party without the prior permission of Yokogawa.

(3) Be sure to use the spare parts approved by Yokogawa when replacing parts or

consumables.

(4) Use this software with one specified computer only . You must purchase another copy

of the software for use on each additional computer.

(5) Copying this software for purposes other than backup is strictly prohibited.

(6) Store the floppy disk(s) (original medium or media) containing this software in a

secure place.

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 9

<Int> <Ind> <Rev>

Model LL100

PC-based Parameters Setting T ool

CONTENTS

Introduction........................................................................................................... i

Visual Inspection and Check of Accessories .....................................................iv

Documentation Conventions .............................................................................. v

Notices .................................................................................................................vi

1. Overview ................................................................................................. 1-1

1.1 Function Overview of LL100 .......................................................................... 1-1

1.2 Operating Environment and Wiring Specifications ...................................... 1-3

1.3 Model and Suffix Codes of Applicable Controller Models............................ 1-6

1.3.1 For GREEN Series ........................................................................... 1-6

1.3.2 Ethernet/RS485 Converter ............................................................... 1-8

1.3.3 For Old GREEN Series ..................................................................... 1-9

1.4 Setting Parameters ........................................................................................1-1 1

Toc-i

IM 05G01B12-01E 5th Edition

2. Setup ....................................................................................................... 2-1

2.1 Installing LL100............................................................................................... 2-1

2.2 Uninstalling LL100 .......................................................................................... 2-4

2.3 Connecting Controller to Personal Computer .............................................. 2-5

3. Using the Parameter Setting T ool .......................................................... 3-1

3.1 Starting and Quitting the Parameter Setting T ool ......................................... 3-1

3.1.1 Starting the Tool................................................................................ 3-1

3.1.2 Quitting the Tool................................................................................ 3-3

3.2 Work Flow of Parameters Setting T ool .......................................................... 3-4

3.3 Dialog Box Elements and Functions ............................................................. 3-5

3.4 Menu Commands............................................................................................ 3-6

3.5 Parameter Setting Basics ............................................................................... 3-8

3.5.1 Selecting a Parameter ...................................................................... 3-8

3.5.2 Inputting the Setting for a Parameter................................................. 3-8

3.5.3 Applying and Canceling Changes in Dialog Box................................ 3-9

3.5.4 Using the Keyboard When You Have No Mouse ............................. 3-10

4. Setting Parameters ................................................................................. 4-1

4.1 Selecting T ool and Series............................................................................... 4-2

4.1.1 Selecting the Tool ............................................................................. 4-2

4.1.2 Selecting the Series.......................................................................... 4-2

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 10

<Int> <Ind> <Rev>

Toc-ii

4.2 Selecting New/Change ................................................................................... 4-3

4.2.1 Selecting New/Change ..................................................................... 4-3

4.2.2 Creating a New File .......................................................................... 4-4

4.2.3 Opening a User File.......................................................................... 4-7

4.2.4 Reading Current Settings from Controller ......................................... 4-8

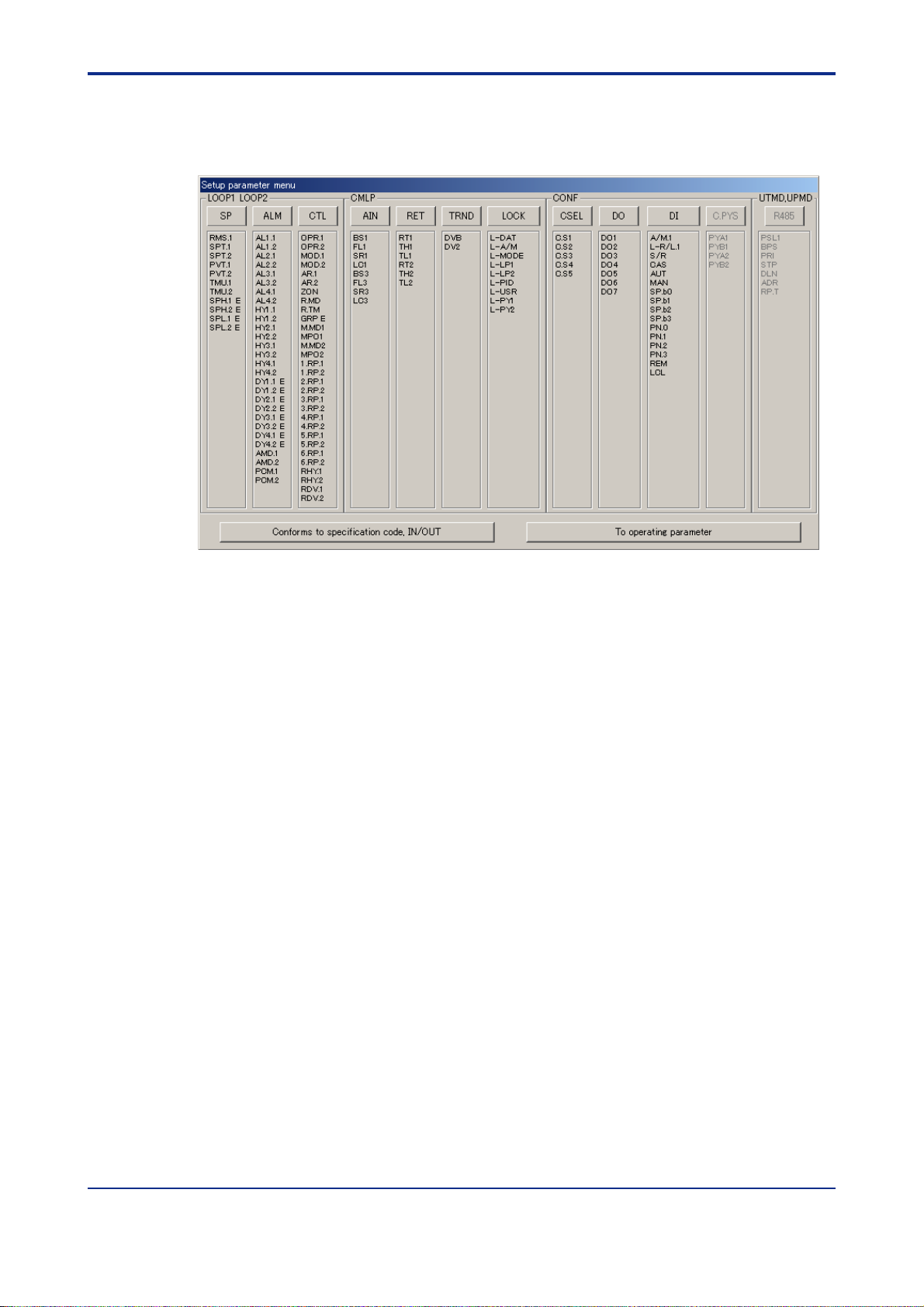

4.3 Setting Setup Parameters ............................................................................ 4-12

4.3.1 Setup Parameter Menu Configuration............................................. 4-12

4.3.2 Setup Parameter Menu................................................................... 4-13

4.3.3 Setting Target Setpoint (SP)............................................................ 4-15

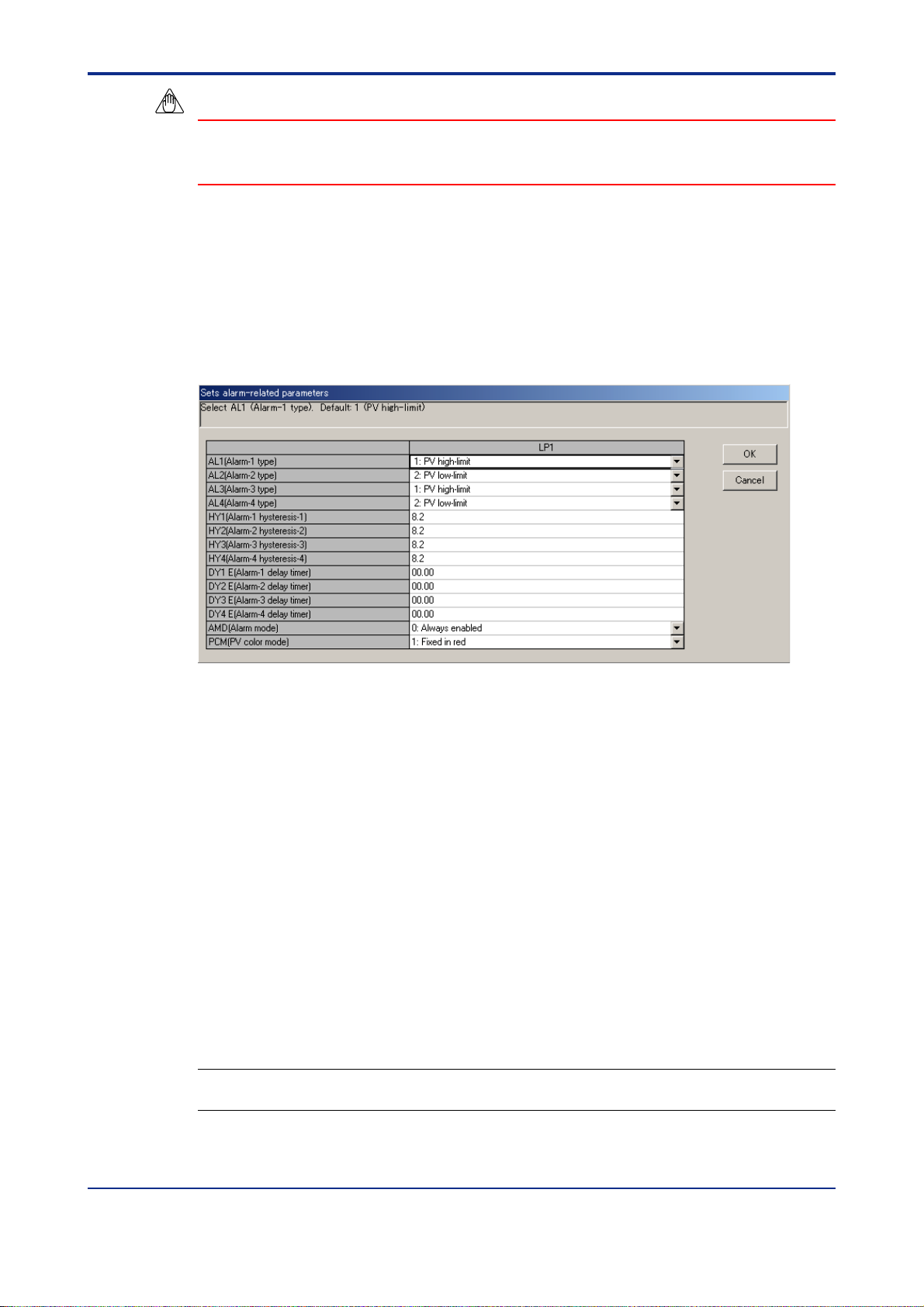

4.3.4 Setting Alarms (ALM) ...................................................................... 4-16

4.3.5 Setting Control Functions (CTL)...................................................... 4-18

4.3.6 Setting Analog Input Computations (AIN)........................................ 4-19

4.3.7 Setting Retransmission Outputs (RET) ........................................... 4-20

4.3.8 Setting Deviation Trend (TRND) ..................................................... 4-21

4.3.9 Setting Security (LOCK).................................................................. 4-22

4.3.10 Configuring SELECT Displays (CSEL)............................................ 4-23

4.3.1 1 Configuring Contact Outputs (DO) .................................................. 4-24

4.3.12 Configuring Contact Inputs (DI)....................................................... 4-25

4.3.13 Setting Units for T en-segment Linearizers (C. PYS)........................ 4-27

4.3.14 Setting Communication Protocol..................................................... 4-28

4.3.15 Confirming Specification Code, Controller Mode, IN, and

OUT Parameter Settings................................................................. 4-31

4.4 Setting Operating Parameters...................................................................... 4-33

4.4.1 Operating Parameter Menu Configuration....................................... 4-33

4.4.2 Operating Parameter Menu ............................................................ 4-34

4.4.3 Setting Operating Parameters ........................................................ 4-34

4.4.4 Setting Local Setpoint (LOC) .......................................................... 4-36

4.4.5 Setting Instrument Alarms (AL) ....................................................... 4-38

4.4.6 Setting Operation-related Parameters (P AR) .................................. 4-39

4.4.7 Setting PID Group Parameters ....................................................... 4-41

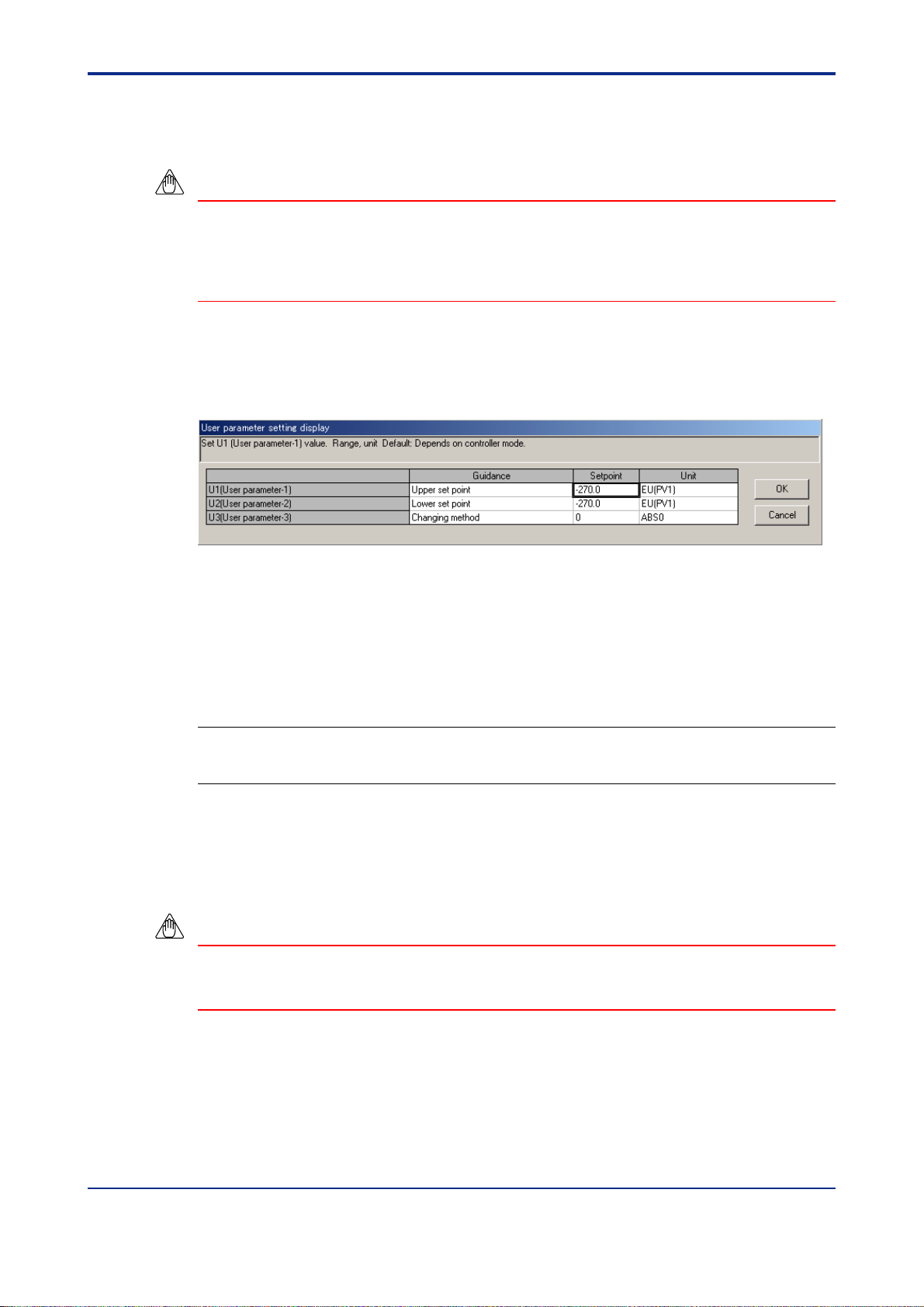

4.4.8 Setting User Parameters (USR)...................................................... 4-43

4.4.9 Setting Ten-segment Linearizer 1 and 2 (PYS1, 2) .......................... 4-44

4.5 Parameter Menu for 300 Series .................................................................... 4-45

4.5.1 Configuration of Menu Dialog Box................................................... 4-45

4.5.2 Parameter Menu............................................................................. 4-46

4.5.3 Setting Patterns PRG1 and PRG2 (for UP350 and UP351 only) ..... 4-47

4.5.4 Viewing the Input/Output Parameter Settings.................................. 4-49

5. Working with Parameter Data Files........................................................ 5-1

5.1 Setting the File Information ............................................................................ 5-1

5.2 Saving/Reading Data on/from Disk and Comparing Data Values................. 5-2

5.2.1 Saving Parameter Data on Disk ........................................................ 5-2

5.2.2 Reading Parameter Data from Disk .................................................. 5-3

5.2.3

Comparing Parameter Data V alues in LL100 with Those Saved to Disk..

IM 05G01B12-01E

5th Edition : 2005.03.25-00

5-4

Page 11

<Int> <Ind> <Rev>

Toc-iii

6.

Uploading/Downloading Data from/to Controller and Comparing Data Values ..

6.1 Uploading Parameter Data from Controller................................................... 6-1

6.2 Downloading Parameter Data to Controller .................................................. 6-5

6.3 Comparing Parameter Data Values of the Tool and Controller .................... 6-9

6.4 Address T ag .................................................................................................. 6-13

6-1

7. Printing Parameters................................................................................ 7-1

7.1 Printing Parameters........................................................................................ 7-1

7.2 Previewing the Printout .................................................................................. 7-4

7.3 Saving Printout Data as a CSV File ................................................................ 7-5

8. Tuning ..................................................................................................... 8-1

8.1 T uning the Controller...................................................................................... 8-1

8.2 T uning Guide................................................................................................... 8-6

8.2.1 What is Auto-tuning?......................................................................... 8-6

8.2.2 What is Automatic Valve Tuning?...................................................... 8-7

9. Using the Program Pattern Setting T ool ................................................ 9-1

9.1 Starting and Quitting the Program Pattern Setting T ool............................... 9-1

9.1.1 Starting the Tool................................................................................ 9-1

9.1.2 Quitting the Tool................................................................................ 9-3

9.2 Work Flow of Program Pattern Setting Tool .................................................. 9-4

9.3 Dialog Box Elements and Functions ............................................................. 9-5

9.4 Menu Commands............................................................................................ 9-6

9.5 Parameter Setting Basics ............................................................................... 9-8

9.5.1 Selecting a Parameter ...................................................................... 9-8

9.5.2 Inputting the Setting for a Parameter................................................. 9-9

9.5.3 Applying and Canceling Changes in Dialog Box................................ 9-9

9.5.4 Using the Keyboard When You Have No Mouse ............................. 9-10

10. Setting Program Patterns..................................................................... 10-1

10.1 Selecting T ool, Series, and New/Change..................................................... 10-2

10.1.1 Selecting the T ool ........................................................................... 10-2

10.1.2 Selecting the Series ........................................................................ 10-2

10.1.3 Selecting New/Change ................................................................... 10-3

10.2 Selecting New, Open File, or Upload ........................................................... 10-4

10.2.1 Creating a New Program Pattern .................................................... 10-4

10.2.2 Opening a User File ........................................................................ 10-4

10.2.3 Uploading from the Controller ......................................................... 10-6

10.2.4 Selecting the Controller Model ...................................................... 10-10

10.3 Setting a Program Pattern ...........................................................................10-11

10.3.1 Program Pattern Menu Configuration.............................................10-11

10.3.2 Program Pattern Menu ..................................................................10-1 1

10.3.3 Setting the Program Conditions .................................................... 10-12

10.3.4 Setting Start Action of the Pattern ................................................. 10-14

10.3.5 Setting a Program Pattern ............................................................ 10-16

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 12

<Int> <Ind> <Rev>

1 1. Working with Program Pattern Data Files ............................................11-1

12. Uploading/Downloading Program Pattern from/to Controller ,

Comparing Data V alues, and Batch Copy ........................................... 12-1

13. Printing a Program Pattern................................................................... 13-1

Toc-iv

11.1 Setting the File Information ...........................................................................11-1

11.2 Saving/Reading Data on/from Disk and Comparing Data Values................1 1-2

1 1.2.1 Saving Program Pattern Data on Disk..............................................1 1-2

1 1.2.2 Reading Program Pattern Data from Disk ........................................11-3

1 1.2.3 Comparing Program Pattern Data V alues in LL100 with

Those Saved to Disk........................................................................11-4

12.1 Uploading a Program Pattern from Controller ............................................ 12-1

12.2 Downloading Program Pattern Data to Controller ...................................... 12-6

12.3

12.4 Using Batch Copy Function ....................................................................... 12-14

12.5 Address T ag ................................................................................................ 12-18

13.1 Printing a Program Pattern........................................................................... 13-1

13.2 Previewing the Printout ................................................................................ 13-3

13.3 Saving Printout Data As a CSV File.............................................................. 13-4

Comparing Program Pattern Data Values between the Tool and Controller ..

12-10

14. Starting and Setting the VJET (Ethernet Converter) Setting T ool....... 14-1

15. Starting the Custom Computation Building T ool ................................ 15-1

16. Maintenance and Troubleshooting ...................................................... 16-1

16.1 Replacing the Batteries ................................................................................ 16-1

16.2

Troubleshooting Problems with Display and Communication Functions .......

16.2.1 Problems with Display Functions .................................................... 16-3

16.2.2 Problems with Communication Functions ....................................... 16-3

16-3

Revision Information ............................................................................................ i

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 13

<Toc> <Ind> <1. Overview >

1. Overview

Model LL100 PC-based Parameters Setting T ool is a software package used to set

various parameters of the GREEN Series controllers from a personal computer . This

tool makes it easy to set parameters that configure the many useful functions of

GREEN Series controllers. It is also possible to manage created parameter data on a

personal computer.

The LL100 tool can run on Windows 98/2000/XP or Windows NT 4.0. For details on using

your personal computer or Windows, see the respective manuals.

1.1 Function Overview of LL100

The LL100 offers the following functions.

● Setup parameter setting

Sets parameters that configure GREEN Series controller functions.

● Operating parameter setting

1-1

Sets control parameters such as P, I, and D. Also sets the program pattern for a UP350/

UP351 program controller.

● Ethernet parameter setting

Sets parameters such as IP address, subnet mask, default gateway , parity or port number

for GREEN Series controllers and VJET Ethernet converter .

● Download to/Upload from a controller

Downloads created parameter data to a GREEN Series controller, or uploads parameter

data contained in a GREEN Series controller to a personal computer.

● Saving parameters onto a disk

Saves parameter data created using the LL100 or parameters uploaded from a GREEN

Series controller to the hard disk of a personal computer or floppy disk.

● Printing parameter data

Prints created parameter data.

● T uning function

Performs online adjustment* of a GREEN Series controller’s PID parameters. The autotuning function allows automatic optimization of PID parameters. You can also manually

change PID parameter values, switch operation modes, and make other changes while

monitoring the trend graphs of PV , SP, and OUT (control output) on the personal computer

screen.

* Online adjustment means changes to tuning parameters while the GREEN Series

controller in question is being used for control.

● Program pattern setting

For UP750/UP550 program controllers, sets parameters that configure program patterns.

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 14

<T oc> <Ind> <1. Overview >

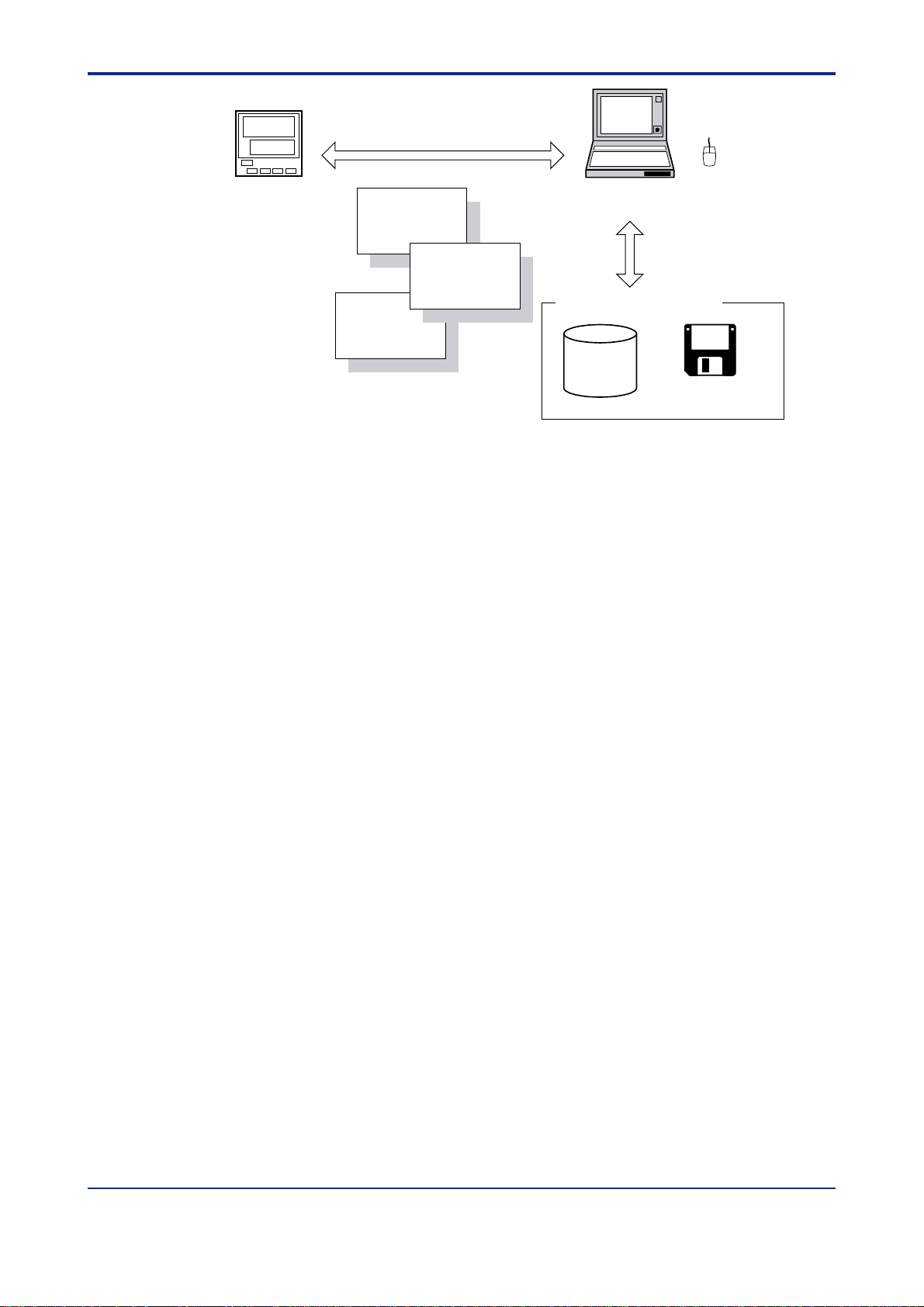

Uploading from/downloading to the controller

1-2

(Peer-to-peer communication)

GREEN Series controller

Setup

parameters

Operating

parameters

Program

patterns*

* Program controllers only

Personal computer

Reading from/writing to disks

Saving to/reading from disks

Hard disk

Figure 1.1.1 Conceptual View of LL100 PC-based Parameters Setting T ool

Mouse

Floppy disk

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 15

<Toc> <Ind> <1. Overview >

1-3

1.2

Operating Environment and Wiring Specifications

■ System Requirements

● Personal computer:

Windows 98/2000/XP or Windows NT 4.0 enabled PC-compatible model.

● Operating system:

Windows 98/2000(Professional)/XP(Home Edition/Professional) or Windows NT 4.0

(Service Pack 3 or later).

● CPU:

300 MHz Pentium processor or superior is recommended.

● Memory:

128 MB minimum when running LL100 under Windows 98/2000/XP or 24 MB minimum

under Windows NT 4.0, is recommended.

● Free hard disk space:

10 MB or more for storing the tool programs and 2 MB or more for parameter data.

● CRT display:

800 × 600 pixels or greater .

Should be capable of handling at least 256 colors.

Small fonts should be used.

● RS-232C communication port:

One channel or more (select from COM1 to COM16), with 9-pin D-Sub connector for PCcompatible model.

● Network:

10Base-T/100Base-TX (required for Ethernet communication)

● 3.5-inch floppy disk drive:

Required for installation.

● Printer:

Windows 98/2000/XP or Windows NT 4.0 compatible A4-size printer.

■ Dedicated Adapter

● Communication method:

Controller: Non-contact optical, bi-directional serial communication.

Personal computer: RS-232C half-duplex communication using dedicated cable.

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 16

<T oc> <Ind> <1. Overview >

● Power supply:

Two AAA-size batteries or external power source.

Use of an external power source is recommended when using the Tuning V iew over a

prolonged time period.

● Battery life:

Approximately 50 hours (when the adapter is continuously operated on alkaline batteries).

● Specifications of external power source:

Should comply with EIAJ RC-6705.

Input rating: 5 V DC/50 mA.

(Note: Purchase a commercially available plug and AC adapter for the external power source.)

● Ambient temperature:

0°C to 50°C

● Ambient humidity:

20 to 90% Rh (no condensation)

1-4

● T ransport and storage conditions:

-25°C to 70°C, 5 to 90% RH (no condensation).

● Dustproof and waterproof construction:

Not applicable.

● Standards:

CE Marking approved (EMC only).

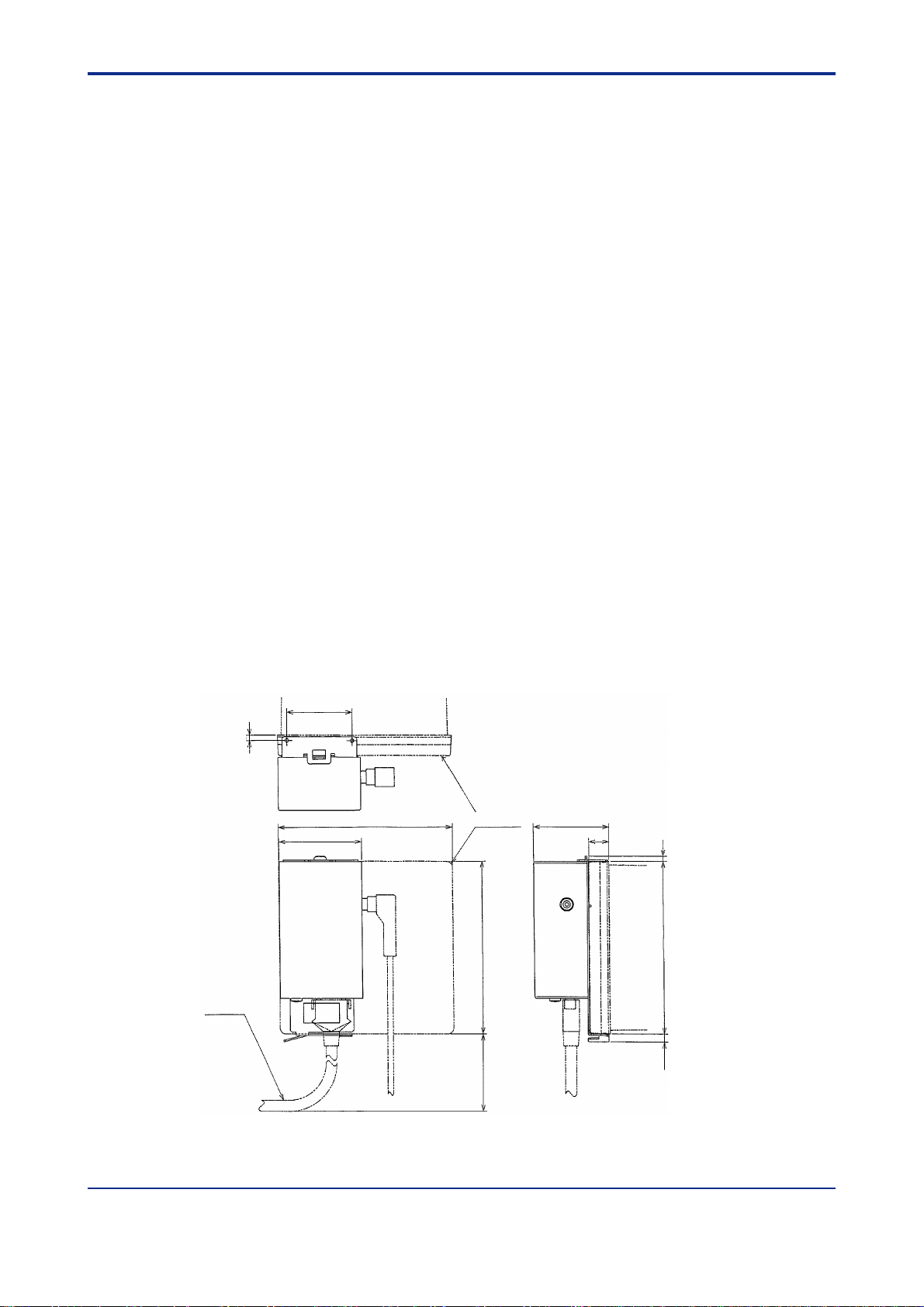

36

3

Controller

45.5

DC power plug

Unit: mm

4196

11

3

Cable

(100) 96

Figure 1.2.1 External View of the Dedicated Adapter

4.5 96

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 17

<Toc> <Ind> <1. Overview >

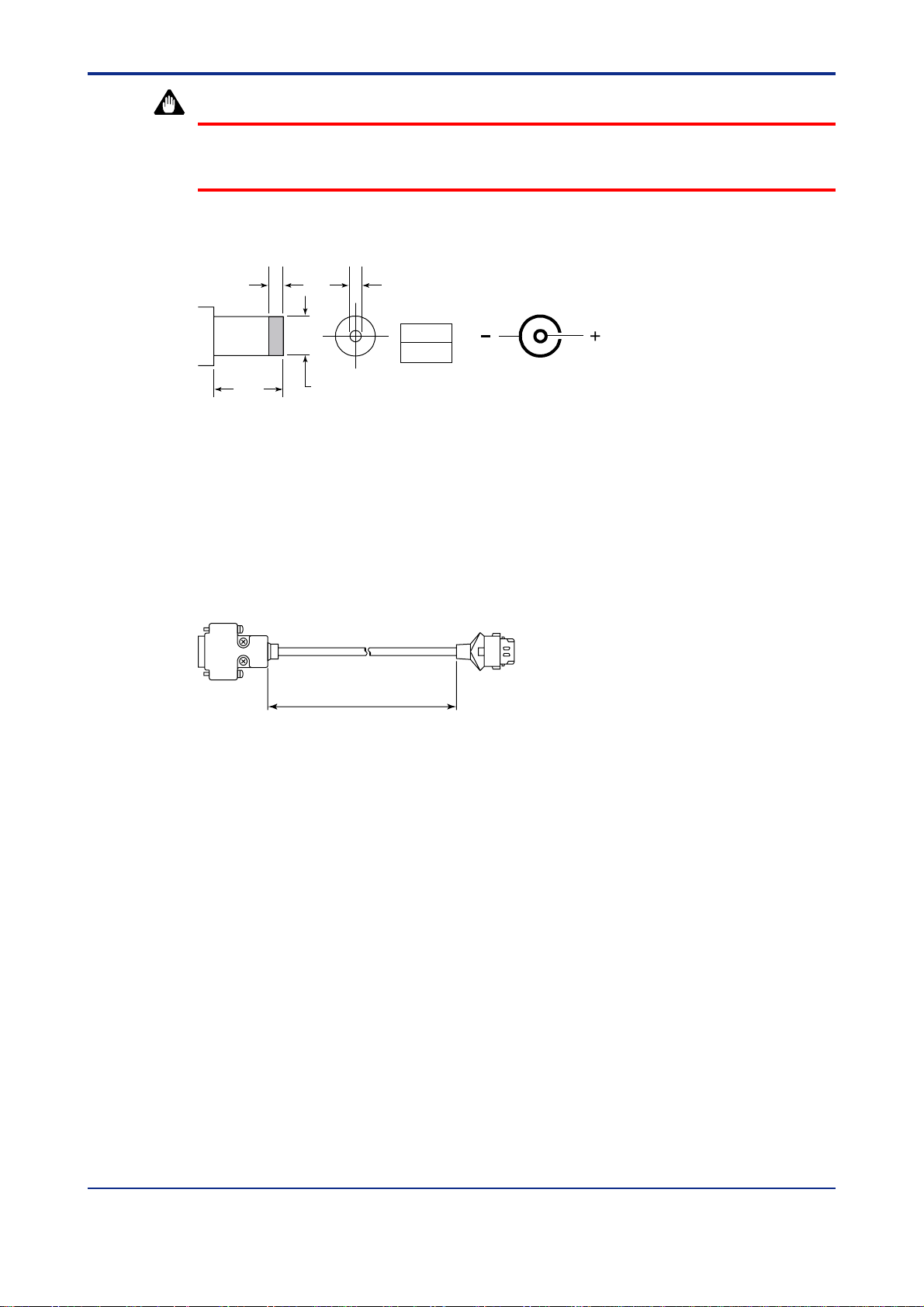

WARNING

The dedicated adapter is not waterproof. Do not use it in locations where it is likely to be

exposed to splashes of water or other liquid.

1-5

Applicable plug

1.5

9.5

Figure 1.2.2 External Power Inlet Plug of Dedicated Adapter

■ Dedicated Cable

Cable with 9-pin D-Sub connector for PC-compatible models

Cable length: 3m

To PC

Unit: mm

D’

D’

2.1

5.5 dia.

(EIAJ)

About 3000mm (118.1 inches) To dedicated adapter

Figure 1.2.3 External View of Dedicated Cable

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 18

<T oc> <Ind> <1. Overview >

1-6

1.3

Model and Suffix Codes of Applicable Controller Models

1.3.1 For GREEN Series

LL100 tool can handle parameter settings of the following models of GREEN Series controllers.

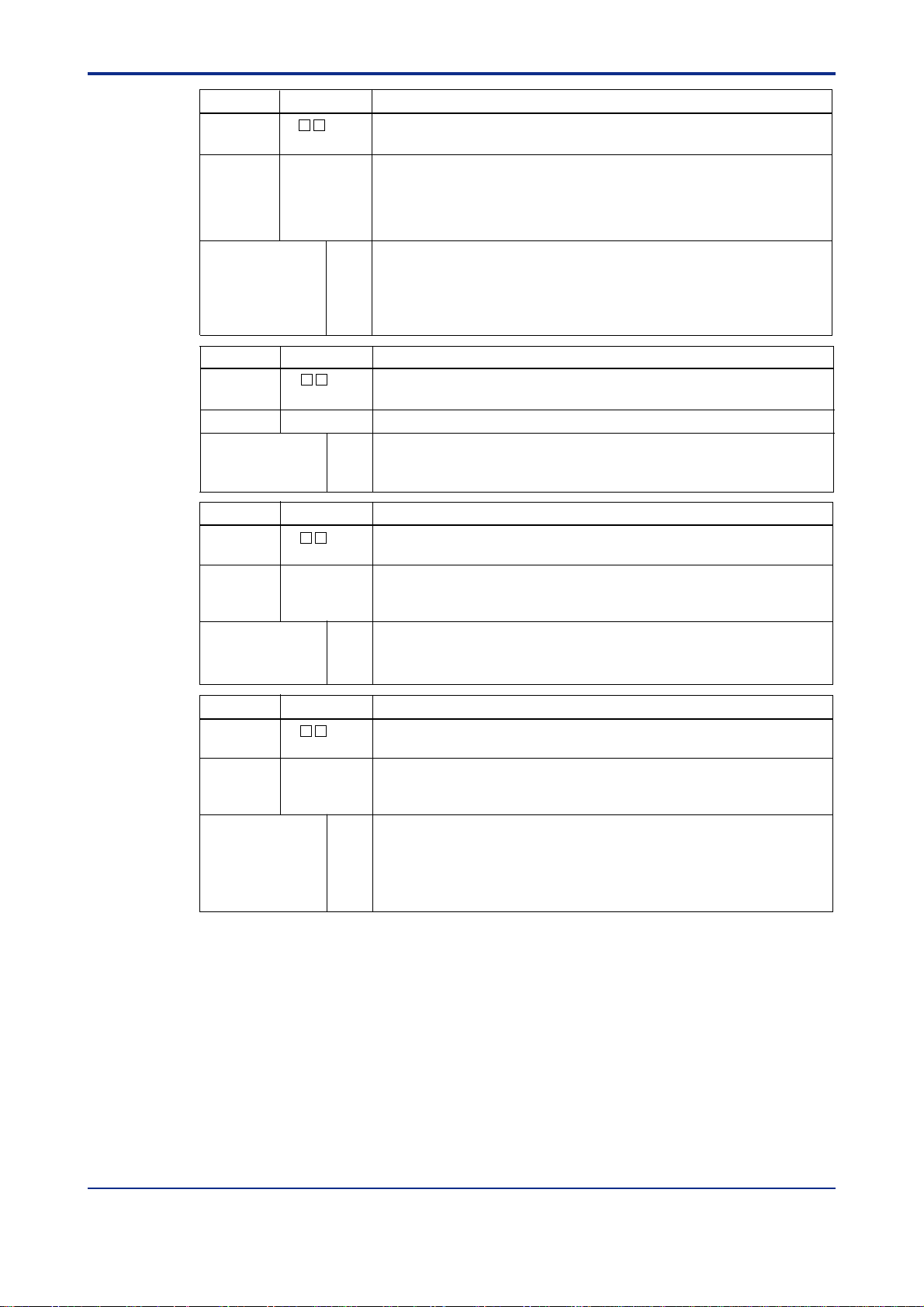

■ Digital Indicating Controllers

Model Code

UT750

Type

Optional functions

Model Code

UT550

UT551

Type

Optional functions

Suffix code Description

-

-0

-1

-5

Suffix code Description

-

-0

-1

-2

-3

-4

Digital Indicating Controller (provided with Custom Computing Function)

Single-loop type

Position proportional type

Dual-loop type

0

None

With communication, auxiliary analog (remote) input

1

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

Position proportional type

Heating/cooling type

Standard type (with 24 V DC loop power supply)

Position proportional type (with 24 V DC loop power supply)

0

None

With communication, auxiliary analog (remote) input, 6 additional DIs and

1

4 additional DOs

With communication, auxiliary analog (remote) input, and 1 additional DI

2

With 5 additional DIs and 4 additional DOs

3

With auxiliary analog (remote) input and 1 additional DI

4

Model Code

UT551

Type

Optional functions

Model Code

UT520

Type

Optional functions

Suffix code Description

-

-0

-1

Suffix code Description

-

-0

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

Position proportional type

A

With Ethernet communication

With Ethernet communication, auxiliary analog (remote) input, and

B

1 additional DIs

With Ethernet communication, 5 additional DIs and 4 additional DOs

C

D

With Ethernet communication, auxiliary analog (remote) input,

6 additional DIs and 4 additional DOs

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

None

0

With communication, auxiliary analog (remote) input, and 2 additional DIs

7

With auxiliary analog (remote) input and 2 additional DIs

8

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 19

<Toc> <Ind> <1. Overview >

1-7

Model Code

UT450

Type

Optional functions

Model Code

UT420

Type

Optional functions

Model Code

UT350

UT320

Type

Optional functions

Suffix code Description

-

-0

-1

-2

-3

-4

Suffix code Description

-

-0

Suffix code Description

-

-0

-2

-3

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

Position proportional type

Heating/cooling type

Standard type (with 24 V DC loop power supply)

Position proportional type (with 24 V DC loop power supply)

0

None

1

With communication, remote input, 5 additional DIs and 1 additional alarm

2

With communication, remote input, and 1 additional DI

3

With 4 additional DIs and 1 additional alarm

4

With remote input and 1 additional DI

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

None

0

With communication, remote input, and 2 additional DIs

7

With remote input and 2 additional DIs

8

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

Heating/cooling type

Standard type (with 24 V DC loop power supply)

None

0

1

With communication, heater burnout alarm

2

With heater burnout alarm

Model Code

UT351

UT321

Type

Optional functions

* For UT351-0x or UT351-2x only

Suffix code Description

-

-0

-2

-3

Digital Indicating Controller (provided with retransmission output and

15 V DC loop power supply as standard)

Standard type

Heating/cooling type

Standard type (with 24 V DC loop power supply)

None

0

With communication, heater burnout alarm

1

With heater burnout alarm

2

With Ethernet communication function (*)

3

With Ethernet communication(*)

A

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 20

<T oc> <Ind> <1. Overview >

/

/

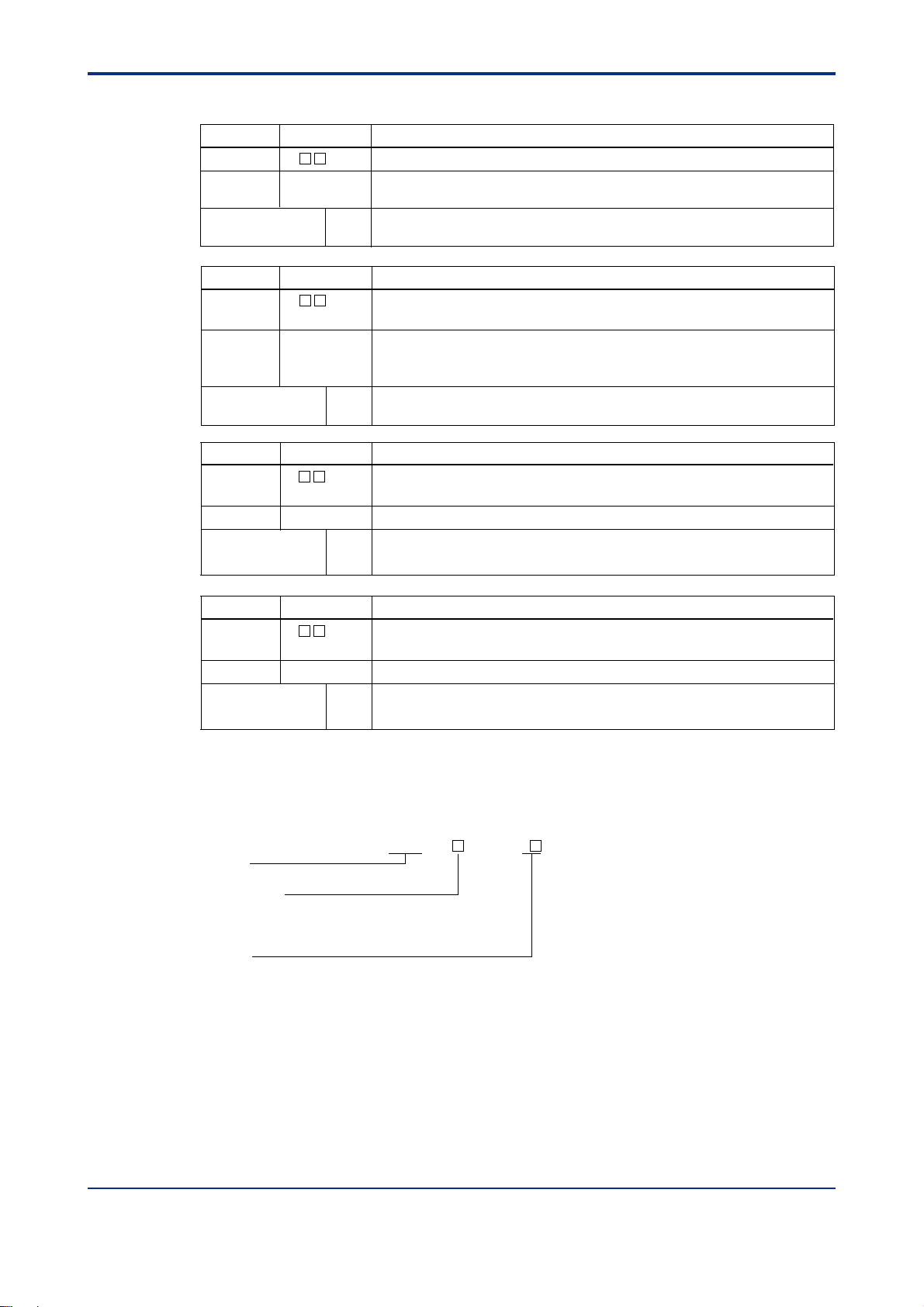

■ Program Controllers

1-8

Model Code

UP750

Type

Optional functions

Model Code

UP550

Type

Optional functions

Model Code

UP350

Type

Optional functions

Suffix code Description

-

-0

-5

Suffix code Description

-

-0

-1

-2

Suffix code Description

-

-0

Program Controller (provided with Custom Computing Function)

Single-loop type

Dual-loop type

0

None

With communication, auxiliary analog input

1

Program Controller (provided with retransmission output and 15 V DC

loop power supply as standard)

Standard type

Position proportional type

Heating/cooling type

0

None

With communication, auxiliary analog input, and 1 additional DI

1

Program Controller (provided with retransmission output and 15 V DC

loop power supply as standard)

Standard type

None

0

With communication

1

Model Code

UP351

Type

Optional functions

Suffix code Description

-

-0

Program Controller (provided with retransmission output and 15 V DC

loop power supply as standard)

Standard type

None

0

With communication

1

1.3.2 Ethernet/RS485 Converter

Only Ethernet parameters can be set to Ethernet/RS485 converter.

VJET-0 1 -1 0 0 0 /

Model

Power supply

3: 24V DC⫾10%

6: 100 to 240V AC/DC(Operating range: 85 to 264 VAC/DC)

Options

R220: Attachment of a terminator (220 Ω)

SN: Without socket

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 21

<Toc> <Ind> <1. Overview >

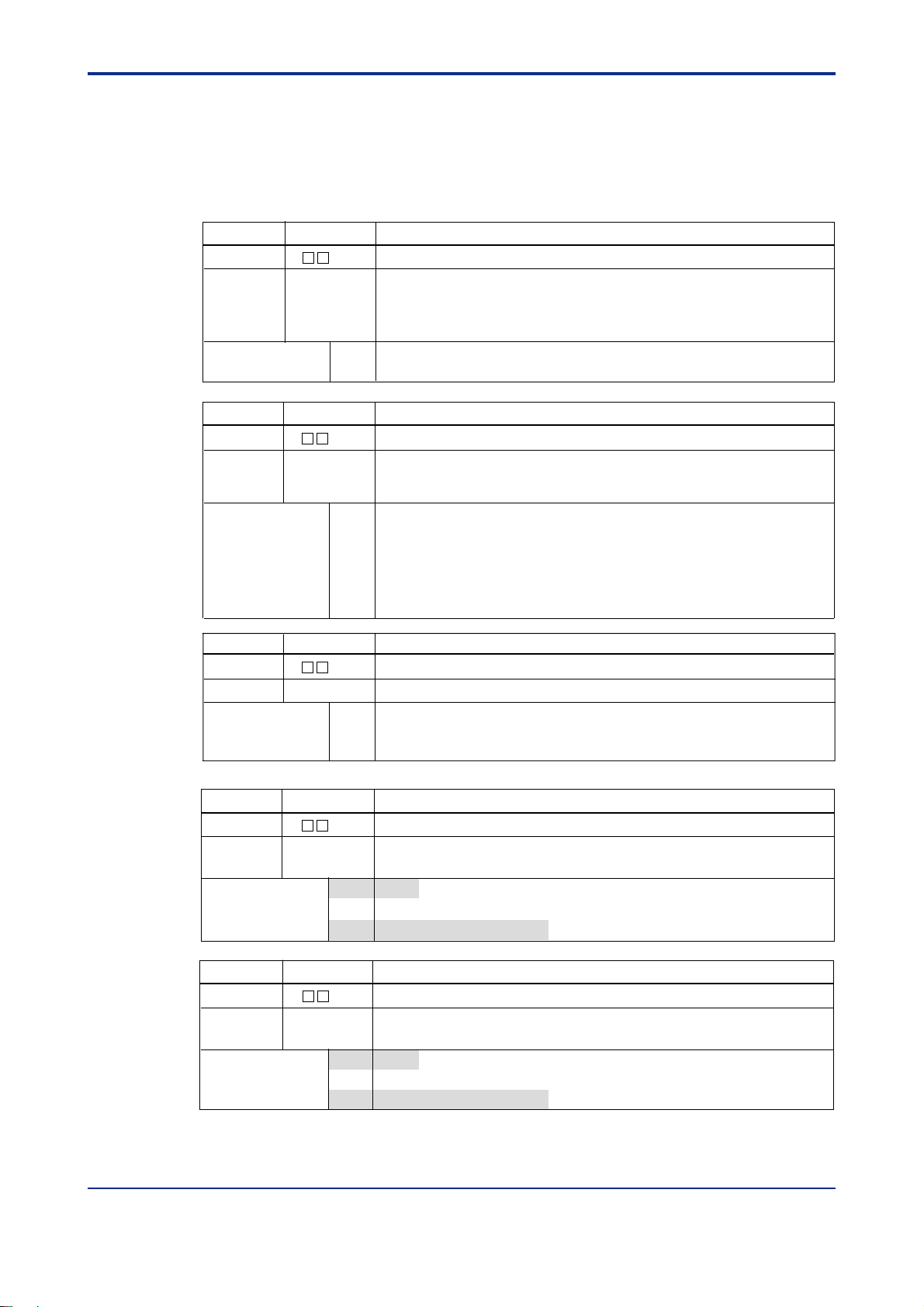

1.3.3 For Old GREEN Series

LL100 tool can handle parameter settings of the following models of old GREEN Series

controllers.

■ Digital Indicating Controllers

1-9

Model Code

UT750

Type

Optional functions

Model Code

UT550

Type

Optional functions

Model Code

UT520

Type

Optional functions

Suffix code Description

-

-0

-1

-5

-7

Suffix code Description

-

-0

-1

-2

Suffix code Description

-

-0

Digital Indicating Controller

Single-loop type

Position proportional type

Dual-loop type

Dual-loop type (provided with Custom Computation function)

0

None

With communication, auxiliary analog (remote) input

1

Digital Indicating Controller

Standard type

Position proportional type

Heating/cooling type

0

None

1

With communication, auxiliary analog (remote) input, 6 additional DIs

and 4 additional DOs

With communication, auxiliary analog (remote) input, and 1 additional DI

2

With 5 additional DIs and 4 additional DOs

3

With auxiliary analog (remote) input and 1 additional DI

4

Digital Indicating Controller

Standard type

None

0

With communication, auxiliary analog (remote) input, and 2 additional DIs

7

With auxiliary analog (remote) input and 2 additional DIs

8

Model Code

UT350

Type

Optional functions

Model Code

UT320

Type

Optional functions

Suffix code Description

-

-0

-2

Suffix code Description

-

-0

-2

Digital Indicating Controller

Standard type

Heating/cooling type

None (Not available)

0

1

With communication and heater burnout alarm

2

With heater burnout alarm (Not available)

Digital Indicating Controller

Standard type

Heating/cooling type

None (Not available)

0

With communication and heater burnout alarm

1

2

With heater burnout alarm (Not available)

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 22

<T oc> <Ind> <1. Overview >

■ Program Controllers

1-10

Model Code

UP750

Type

Optional functions

Model Code

UP550

Type

Optional functions

Model Code

UP350

Type

Optional functions

Suffix code Description

-

-0

-5

-7

Suffix code Description

-

-0

-1

-2

Suffix code Description

-

-0

Program Controller

Single-loop type

Dual-loop type

Dual-loop type (provided with Custom Computation function)

0

None

With communication and auxiliary analog input

1

Program Controller

Standard type

Position proportional type

Heating/cooling type

0

None

With communication, auxiliary analog input, and 1 additional DI

1

Program Controller

Standard type

None (Not available)

0

With communication

1

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 23

<Toc> <Ind> <1. Overview >

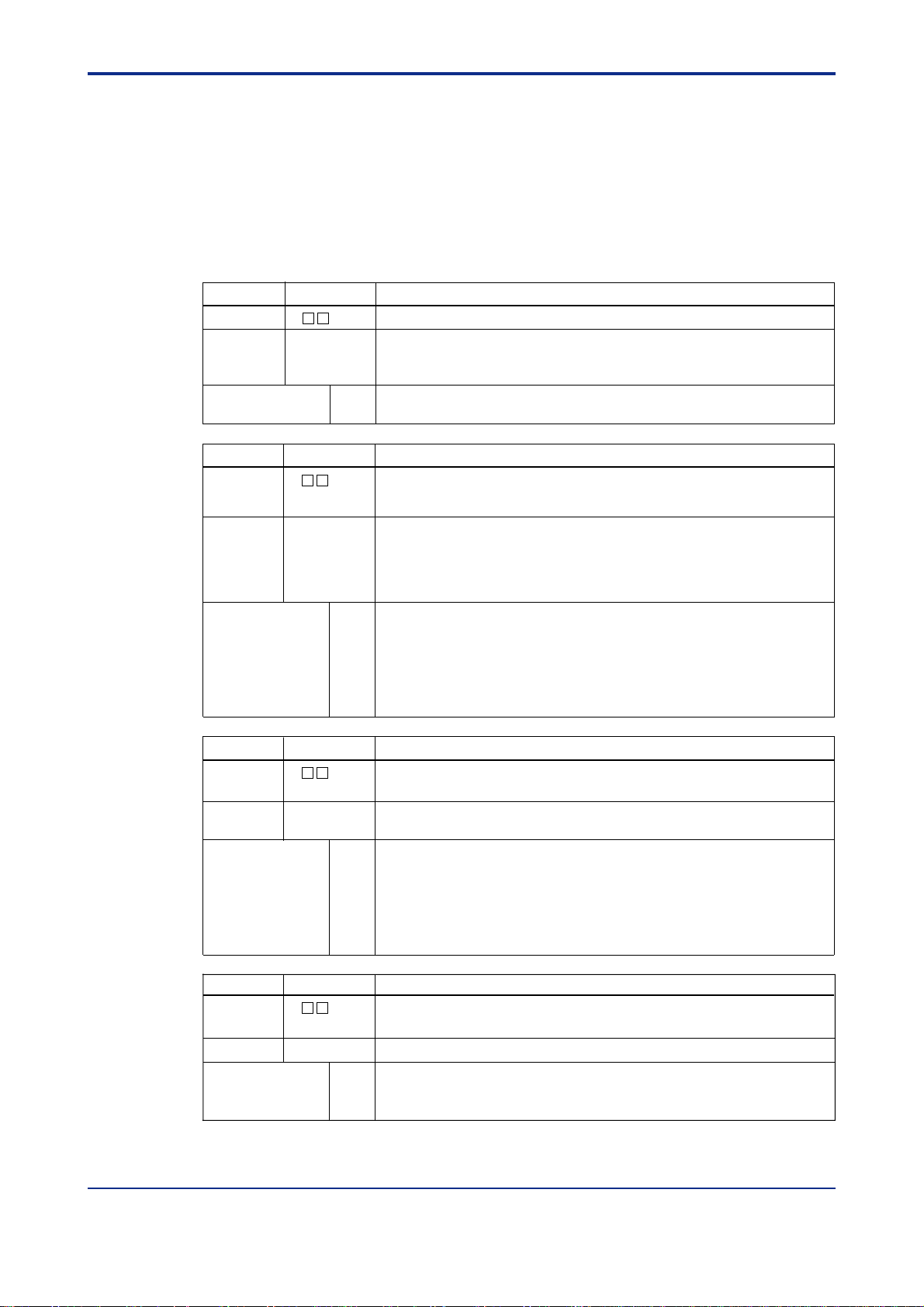

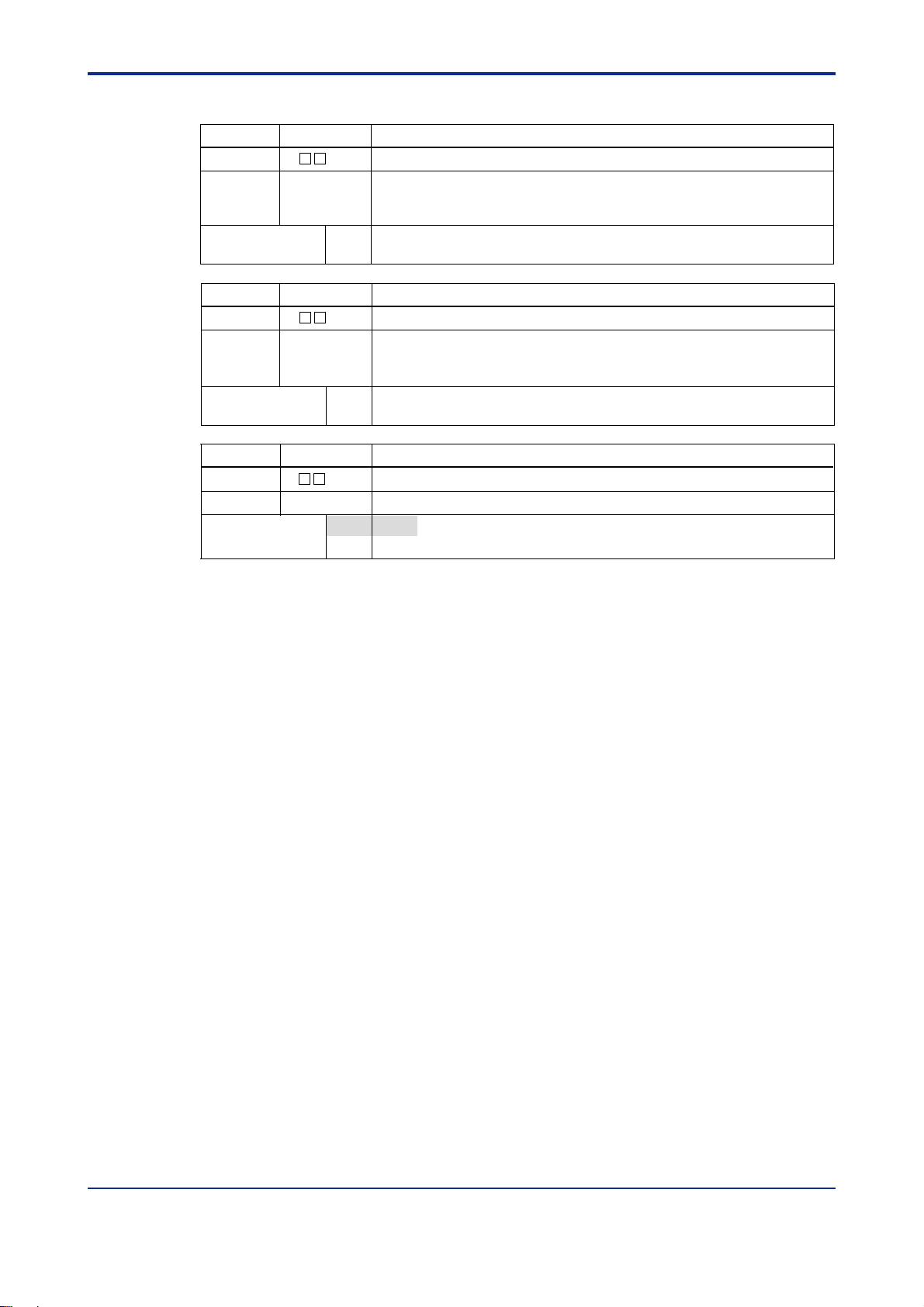

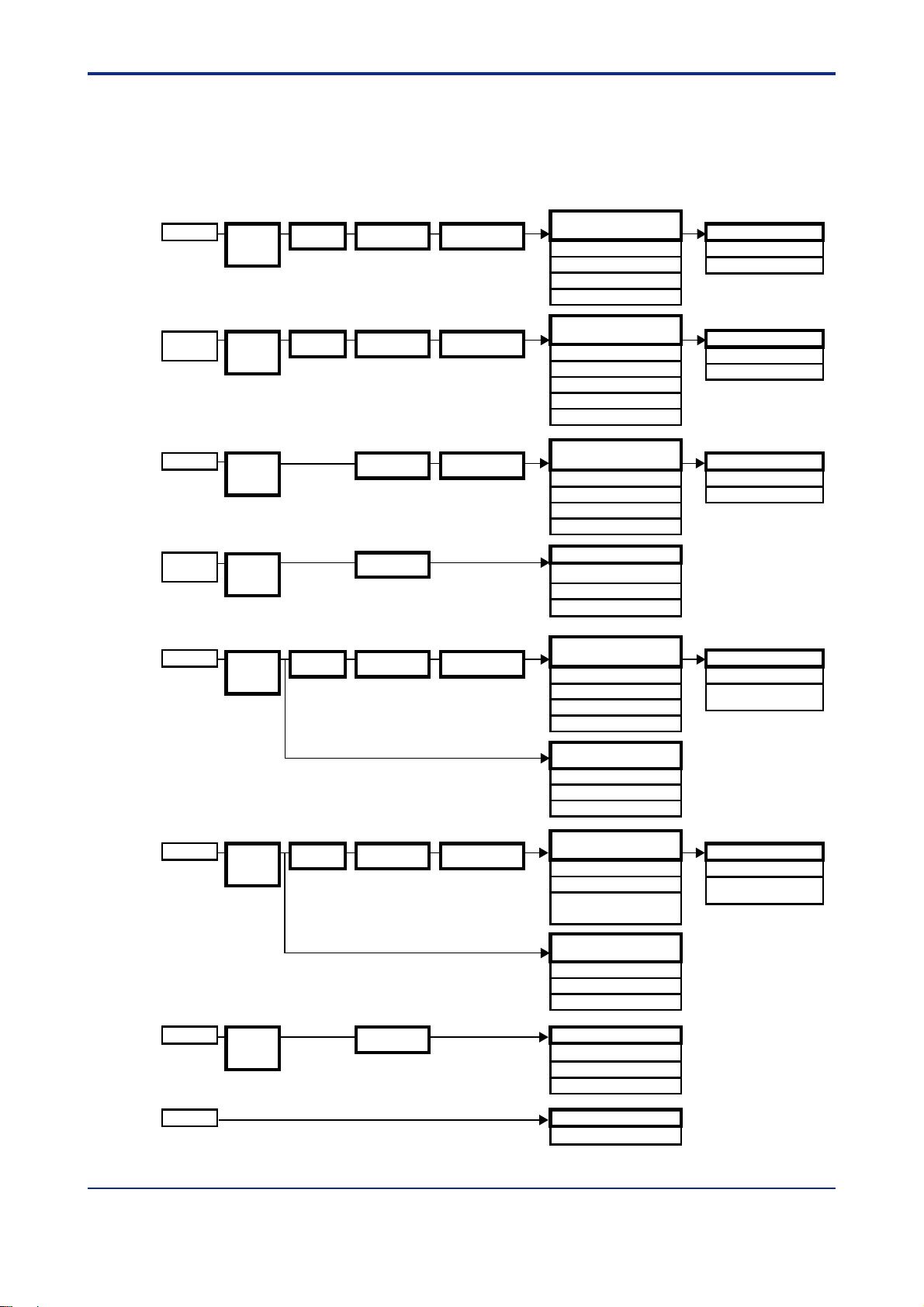

1.4 Setting Parameters

The sequence for setting parameters differs depending on the selected controller model.

In the Menu dialog box, buttons and parameters (SP for example) vary depending on the

model and specification codes, and controller mode you choose.

1-11

UT750

UT550/520

UT551

UT450/420

UT350/320

UT351/321

UP750

Model/

Specification

Code

Selection

Model/

Specification

Code

Selection

Model/

Specification

Code

Selection

Model/

Specification

Code

Selection

Model/

Specification

Code

Selection

Controller

Mode Setting

Controller

Mode Setting

Controller

Mode Setting

PV Parameter

Setting

PV Parameter

Setting

PV Parameter

Setting

Input/Output

Setting

PV Parameter

Setting

Control Output/

Valve Mode Setting

Control Output/

Valve Mode Setting

Control Output/

Valve Mode Setting

Control Output/

Valve Mode Setting

Setup Parameter Menu

Operating Parameter Menu

SP, ALM, CTL PAR

AIN, RET, TRND, LOCK

PID, USR, PYS1/2

CSEL, DO, DI, C.PYS

R485

Setup Parameter Menu

SP, ALM, CTL

AIN, RET, TRND, LOCK

Operating Parameter Menu

PAR

PID, USR, PYS1/2

CSEL, DO, DI, C.PYS

R485

Ethernet parameters

Setup Parameter Menu

SP, ALM, CTL

RET, LOCK

(for UT551-xA to xD only)

Operating Parameter Menu

Operating parameter

PID

CSEL

R485

Parameter Menu

Setup parameter

Ethernet parameter

(for UT351-xA and UT351-x3 only)

Operating parameter, PID

Setup Parameter Menu

SP, ALM, CTL

AIN, RET, TRND, LOCK

CSEL, DO, DI, C.PYS

Operating Parameter Menu

AL, PAR

LOC, PID, USR,

PYS1/2

R485

UP550

UP350/351

Model/

Specification

Code

Selection

Model/

Specification

Code

Selection

Controller

Mode Setting

PV Parameter

Setting

Input/output

Setting

VJET

Figure 1.4.1 Sequence for Setting Parameters

Control Output/

Valve Mode Setting

Program Pattern Menu

Program condition

Pattern start action

Program pattern

Setup Parameter Menu

SP, ALM, CTL

AIN, RET, TRND, LOCK

CSEL, DO, DI, C.PYS

R485

Program Pattern Menu

Program condition

Pattern start action

Program pattern

Parameter Menu

Setup parameter

Operating parameter, PID

PRG1/2 pattern

Parameter Menu

Ethernet parameter

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Operating Parameter Menu

AL, PAR

LOC, PID, USR,

PYS1/2

Page 24

Blank Page

Page 25

<Toc> <Ind> <2. Setup >

2. Setup

This chapter explains how to set up the hardware and software necessary to work

with the LL100 tool.

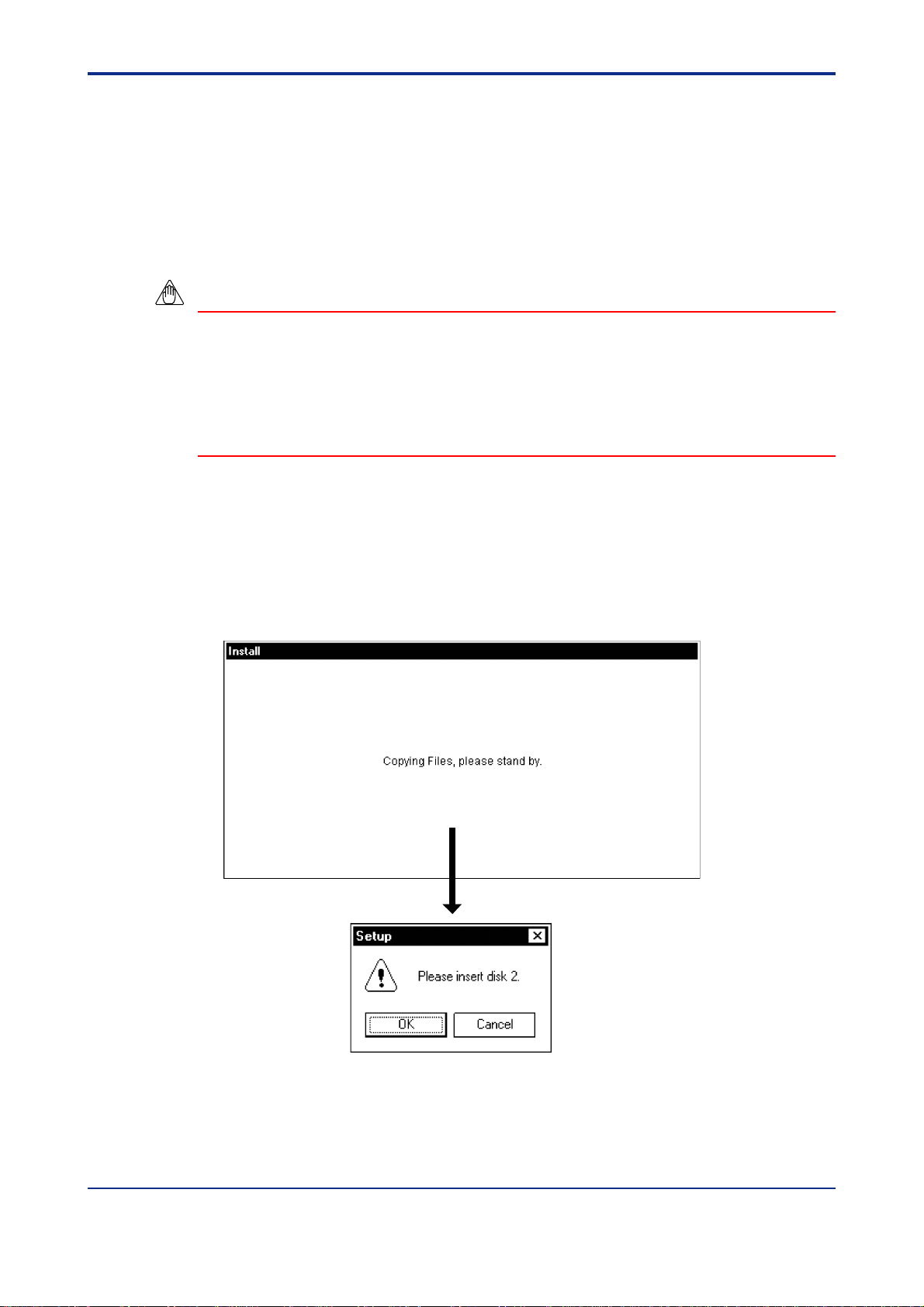

2.1 Installing LL100

NOTE

Before installing LL100, quit all running applications.

When using Windows 2000 or XP :

Log on using the user name of Administrators group.

The program does not start normally if the user name not belonging to the Administrators

group is used for logging on.

(1) Start Windows.

2-1

(2) Insert Disk 1 of LL100 into the floppy disk drive.

(3) From the Start menu of Windows, choose Run. T ype the floppy disk drive name

followed by a backslash, then Setup.exe (for example, a:\Setup.exe if the floppy

disk drive of your PC is “a”). Click OK.

(4) To continue, follow the instructions appearing on screen.

Figure 2.1.1 Dialog Boxes Appearing When Running Installer

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 26

<T oc> <Ind> <2. Setup >

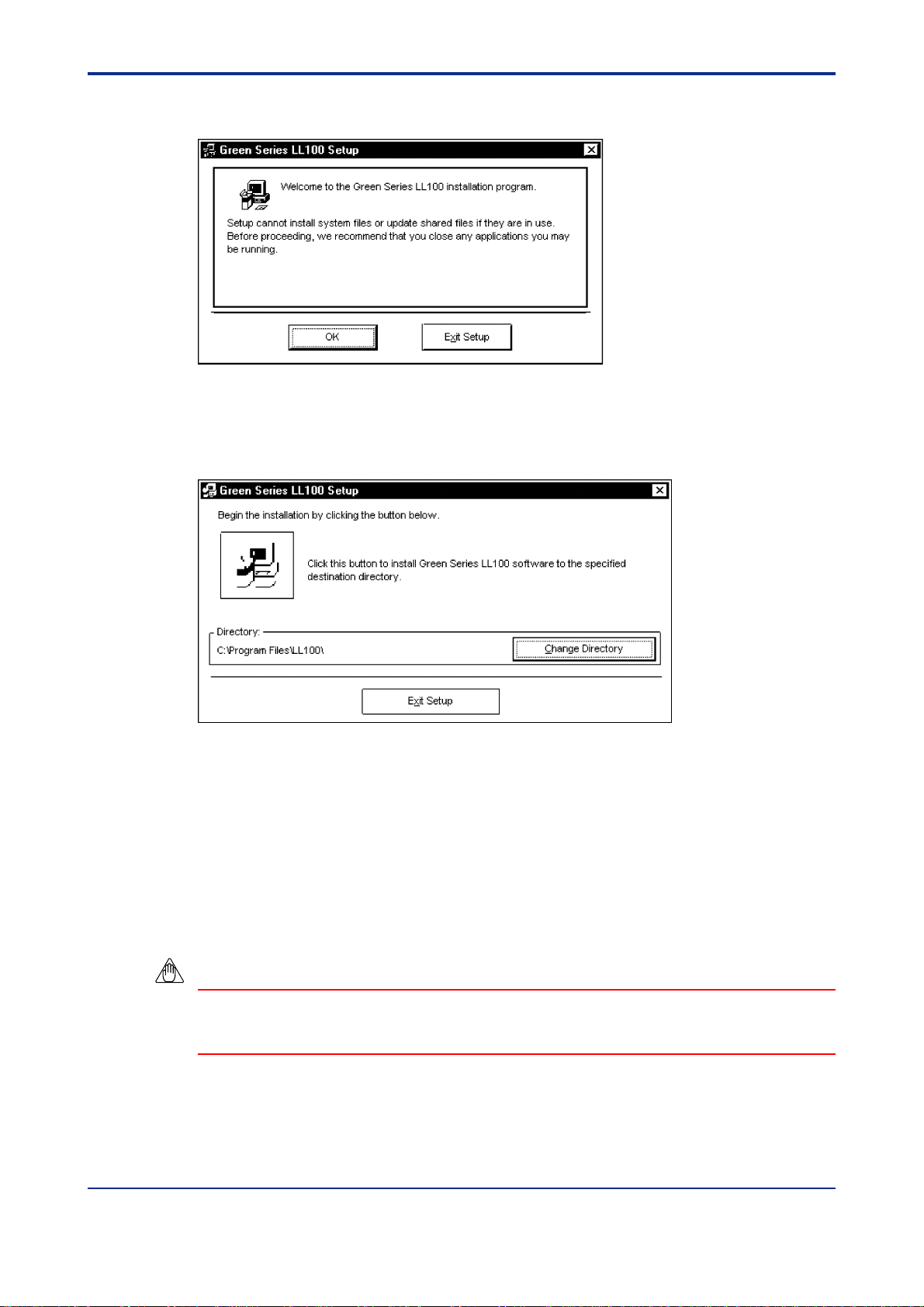

(5) When installation is ready to proceed, the setup wizard starts and the Green Series

LL100 Setup dialog box shown in Figure 2.1.2 appears.

Figure 2.1.2 Green Series LL100 Setup Dialog Box

(6) To continue the setup, click OK. The dialog box contents change as shown in Figure

2.1.3. Or, to quit the setup, click Exit.

2-2

Figure 2.1.3 Dialog Box Announcing Start of Installation of LL100

(7) To continue the setup, click the button with a symbol of a personal computer. The

dialog box named Green Series LL100 – Choose Program Group, shown in Figure

2.1.4, appears.

• If you do not want to install LL100 in the default location, click Change Directory and

specify the installation location in the Change Directory dialog box appearing consequently .

NOTE

Avoid entering just the drive as the installation location, such as D:\. Enter the full directory path.

• T o quit the setup, click Exit Setup.

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 27

<Toc> <Ind> <2. Setup >

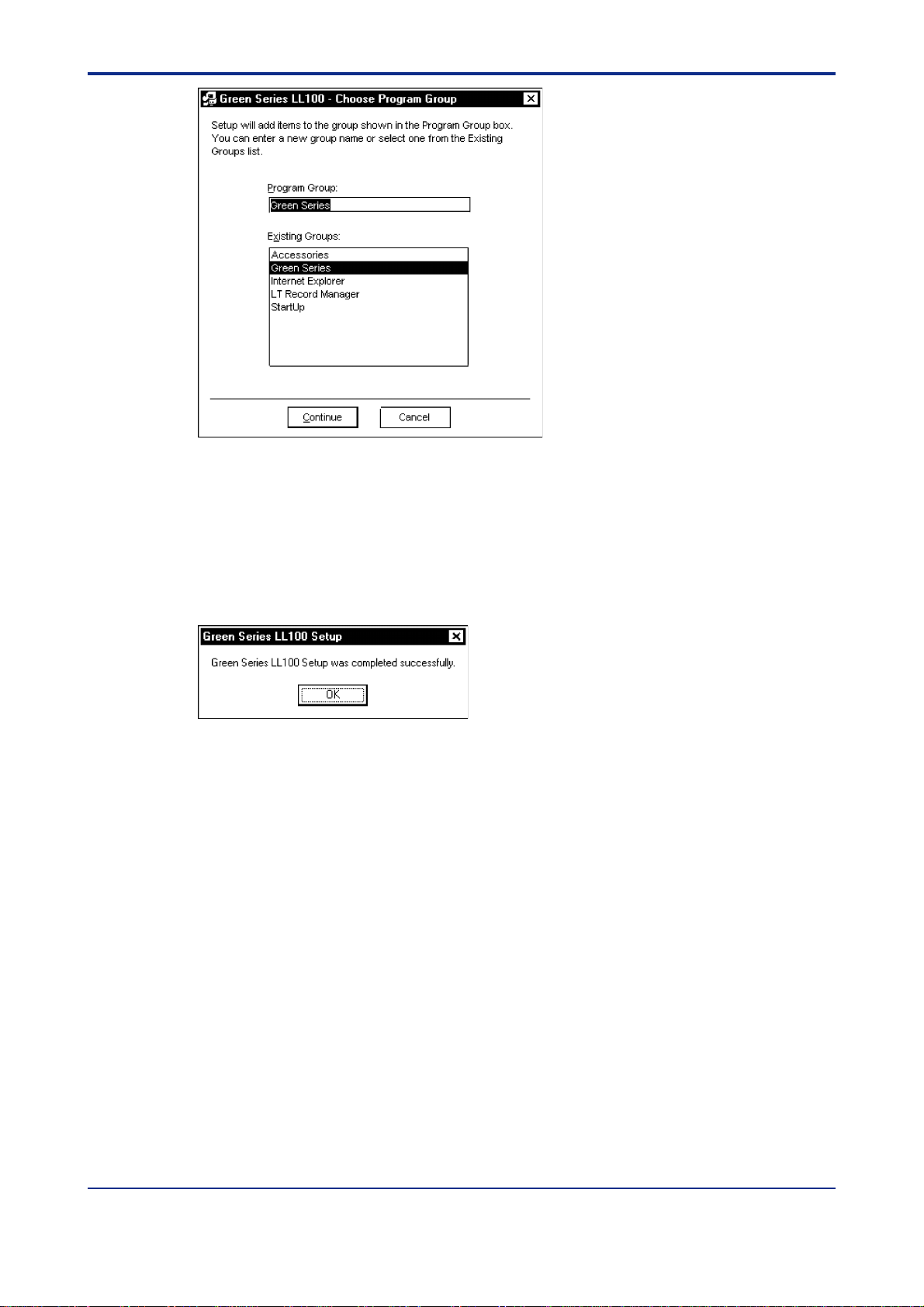

Figure 2.1.4 Green Series LL100 – Choose Program Group Dialog Box

(8) To continue the setup, click Continue. Subsequently, a dialog box requesting you to

insert Disk 4 appears. Insert Disk 4 into the floppy drive and click Continue.

2-3

• Clicking Cancel aborts the setup without updating the system file; in this case, the

LL100 tool is not installed.

(9) When a message announcing completion of installation appears, click OK.

Figure 2.1.5 Dialog Box Announcing Completion of Installation of LL100

(10) Finally , check that Green Series has been added to the Programs submenu of the

Start menu, and the Green Series submenu contains Green Series LL100.

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 28

<T oc> <Ind> <2. Setup >

2.2 Uninstalling LL100

(1) Start Windows.

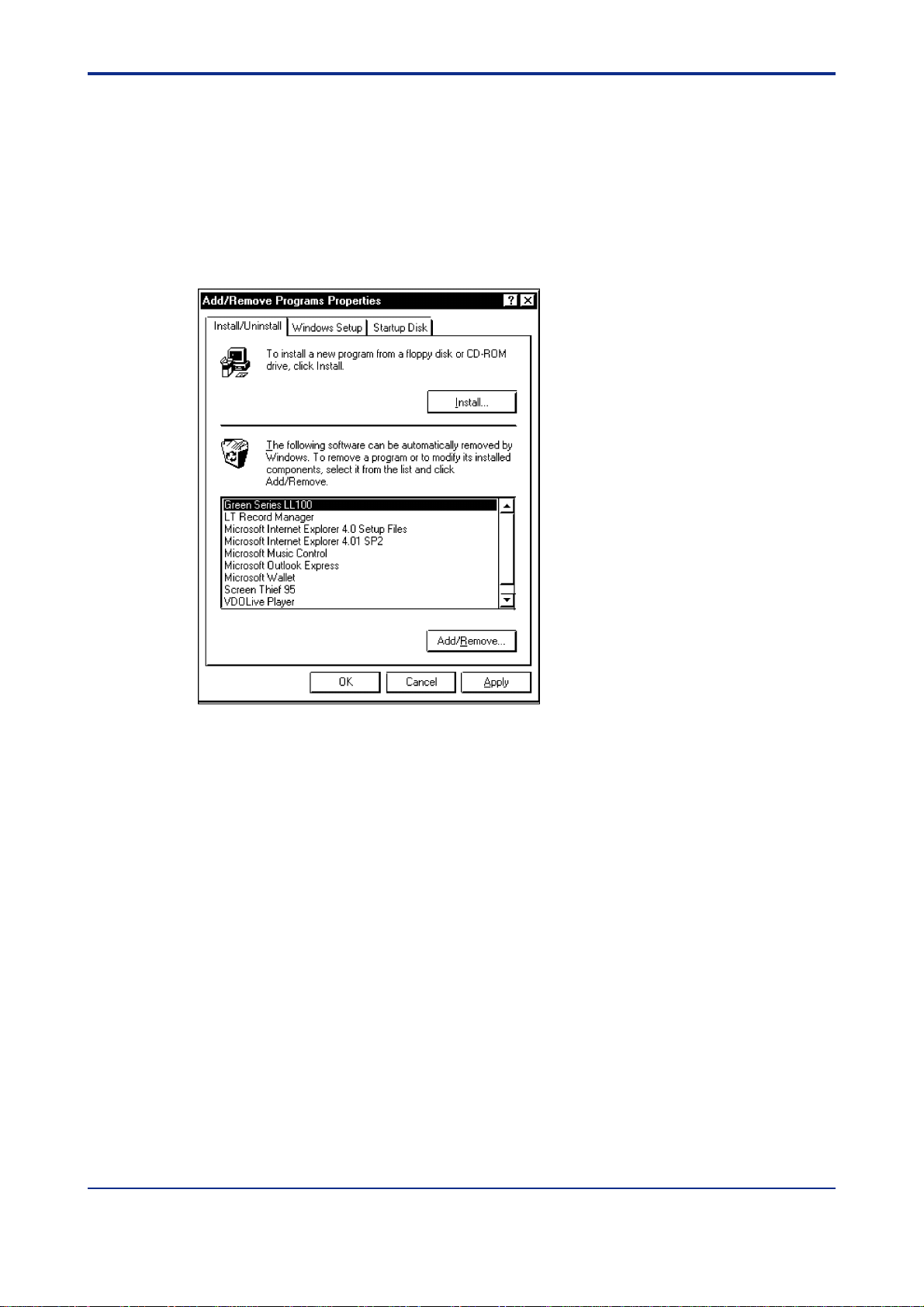

(2) In Control Panel of Windows, double-click the Add/Remove Programs icon. The

Add/Remove Programs Properties dialog box shown below appears.

(3) On the Install/Uninstall page, choose Green Series LL100, and click Add/Remove.

(4) Then, follow the instructions appearing consequently .

2-4

Figure 2.2.1 Add/Remove Programs Properties dialog box

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 29

<Toc> <Ind> <2. Setup >

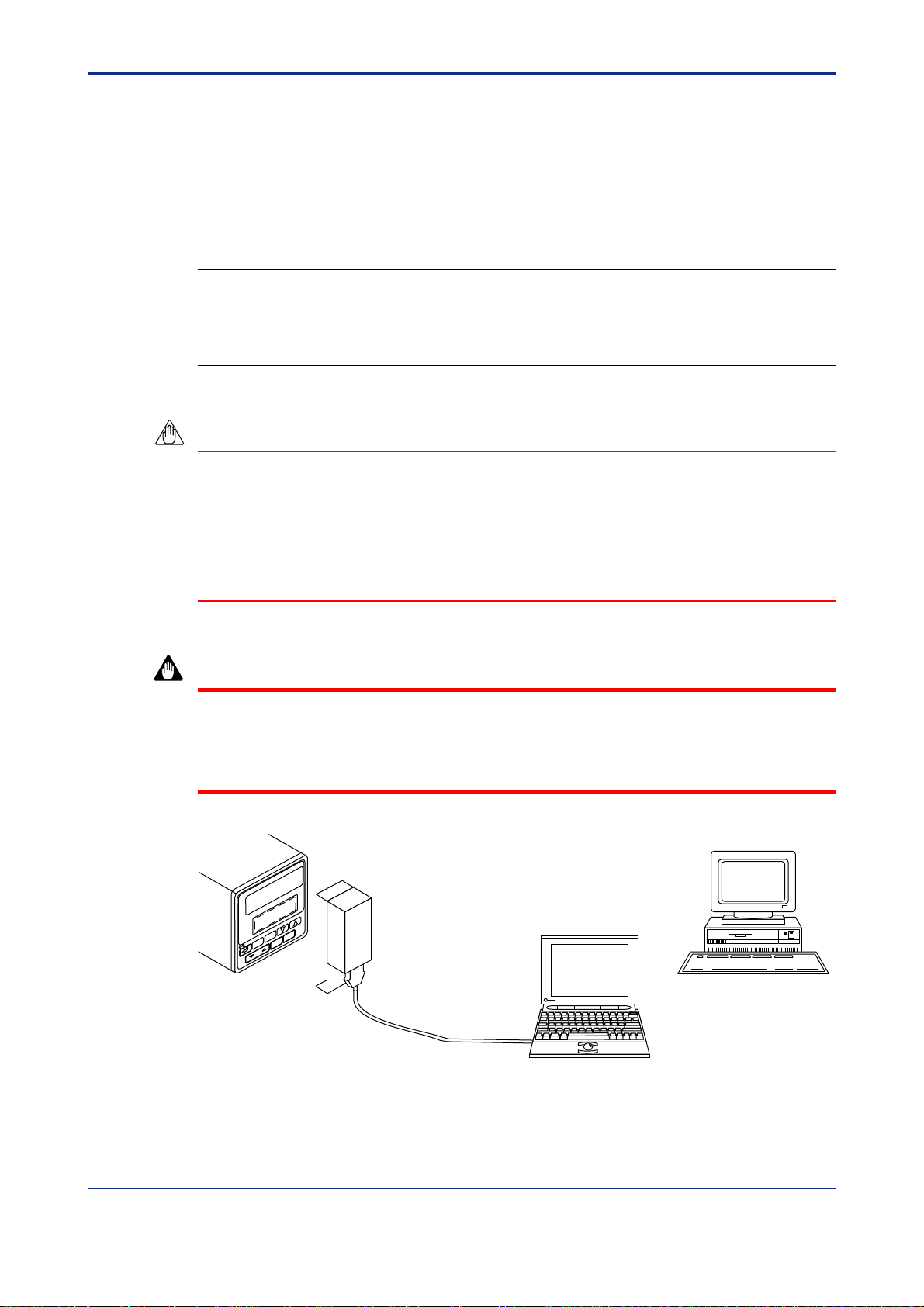

2.3 Connecting Controller to Personal Computer

A GREEN Series controller can be connected to a personal computer in three ways:

using either the optical communication interface on the controller’s front panel, the

RS-485 communication terminals on the rear panel or the Ethernet communication

terminal on the rear panel. This section describes how to connect to the optical

communication interface.

See Also

• Chapter 2, “Setup” in the GREEN Series Communication Functions user’s manual (IM 05G01B02-01E),

for how to connect to RS-485 communication terminals.

• Chapter 2, “Setup” in the Ethernet Communication Functions user’s manual (IM 05G01B52-01E), for

how to connect to Ethernet communication terminal.

NOTE

• The dedicated adapter has an internal switch (located where the adapter comes into

contact with the controller). Be careful not to break this switch when attaching the

adapter to the controller.

2-5

• Attaching the adapter in place automatically turns on this switch, causing the batteries

to discharge even if no communication is done. Therefore, if you have no immediate

plans to perform communication, keep the adapter removed from the controller.

WARNING

When using an external power source, take care to ensure that the polarities of the AC

adapter are correct (see Figure 1.2.2). Do not apply power from the adapter in excess of

the power ratings of the controller. Either of these cases can result in damage to the controller.

Dedicated adapter

(Optical/electrical signal converter)

Controller

Figure 2.3.1 Connecting GREEN Series Controller to Personal Computer via Front Optical

Communication Interface

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Personal computer

Page 30

<T oc> <Ind> <2. Setup >

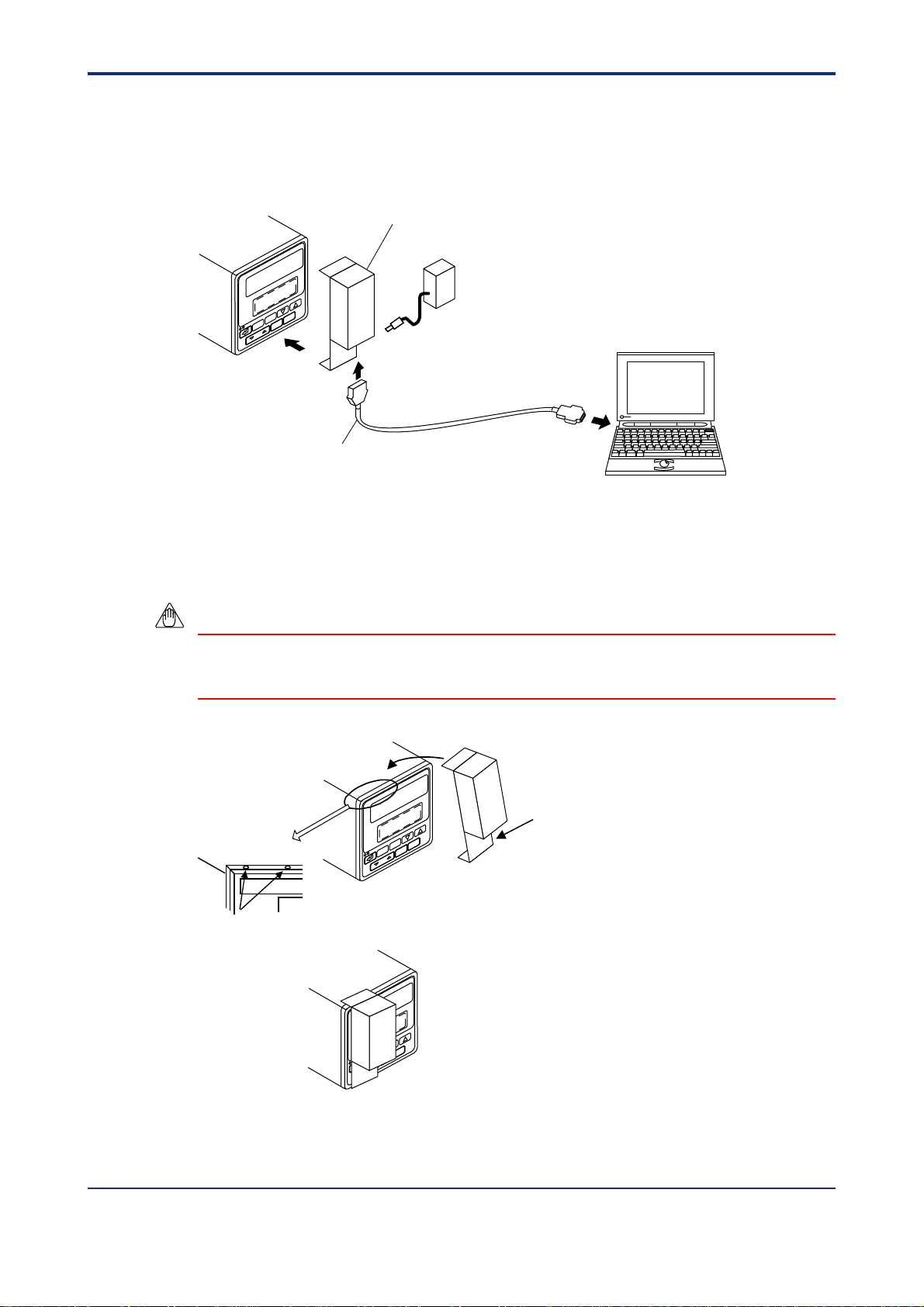

Follow the steps below to connect the controller to a personal computer.

(1) Connect the dedicated adapter to the RS-232C communication port of a personal

computer using the dedicated cable.

Dedicated adapter

(Optical/electrical signal converter)

AC adapter (optional)

for using an external power source

Personal computer

(1) Connect the dedicated cable to

the dedicated adapter and

Controller

Dedicated cable

Figure 2.3.2 Connection via Dedicated Adapter

connect the other cable end to

the PC’s communication port.

To RS-232C port.

2-6

(2) As shown in Figure 2.3.3, hang the dedicated adapter from the top groove of the

controller.

(3) Push the adapter to the controller’s front panel to securely fix it in place.

NOTE

Make sure the adapter is attached to the controller in a vertical orientation. Communication

is not possible if the dedicated adapter is attached in a slanting position.

Controller

Top of the controller

Groove

(3) Bring the dedicated adapter into contact

with the controller’s front panel.

(2) Hang the dedicated adapter’s

bracket from the groove.

Push

Figure 2.3.3 Attaching the Dedicated Adapter

IM 05G01B12-01E 5th Edition : 2005.03.25-00

Page 31

<Toc> <Ind> <3. Using LL100 >

3-1

3. Using the Parameter Setting T ool

This chapter describes how to use the parameter setting tool, showing the procedures of parameter setting via dialog boxes, notes on tool operations, and other

common operations. Be sure to read through this chapter before use.

3.1 Starting and Quitting the Parameter Setting T ool

NOTE

Before installing the tool, quit all running applications.

When using Windows 2000 or XP :

Log on using the user name of Administrators group.

The program does not start normally if the user name not belonging to the Administrators

group is used for logging on.

3.1.1 Starting the T ool

(1) Start Windows.

(2) From the Start menu of Windows, point to Programs, then Green Series, and click

Green Series LL100.

(3) LL100 then starts and the Tool Selection dialog box (Figure 3.1.1) appears.

(For LL200, “Custom Computation Building Tool” appears at the top of dialog box.)

Figure 3.1.1 Tool Selection Dialog Box

(4) Select Parameter Setting T ool and click OK.

(5) The Select Series dialog box (Figure 3.1.2) appears.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 32

<T oc> <Ind> <3. Using LL100 >

Figure 3.1.2 Select Series Dialog Box

(6) Select a controller model and click OK.

3-2

(7) The New/Change Selection dialog box appears (Figure 3.1.3).

Figure 3.1.3 New/Change Selection Dialog Box

To start the parameter setting tool while you are using another tool, click Set ****(P) from

the menu bar, then choose Run Parameter Setting Tool. (**** varies depending on the

tool)

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 33

<Toc> <Ind> <3. Using LL100 >

3.1.2 Quitting the T ool

(1) From the menu bar, click File then choose Terminate.

(2) If the current setting data has not been saved, the following message box appears

(Figure 3.1.4).

• T o quit after saving the current parameter data, click Yes.

The Save As dialog box appears. Enter a file name of up to 16 alphanumeric charac-

ters, and then click Save.

• T o quit without saving the parameter data, click No.

Figure 3.1.4 Data Save Confirming Dialog Box

(3) The message box in Figure 3.1.5 appears for confirmation.

• T o exit, click YES.

3-3

• T o cancel exit, click NO.

Figure 3.1.5 Close Dialog Box

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 34

<T oc> <Ind> <3. Using LL100 >

3.2 Work Flow of Parameters Setting T ool

There are three parameter setting procedures:

● Create new parameter data and download it to the controller.

● Upload parameter data from the controller, modify it, and then download it to the

controller.

● Read parameter data saved on disk, modify it, and then save it to the disk.

Start

Start LL100 tool

Tool Selection

(See section 3.1)

(See section 4.1)

Parameters setting tool

3-4

(See section 4.2)

New

Select model and suffix codes

Set the controller mode

Set input/PV parameters

Set control output and valve mode

Open user file

Set operating parameters

Series selection

New/Change

Open user file

Set setup parameters

Connect controller to

personal computer

Download parameters

to controller

Upload from

controller

Connect controller to

personal computer

(See section 2.3)

Upload data

from controller

(See section 6.1)

(See section 4.3)

(See section 4.4)

(See section 2.3)

(See section 6.2)

Program pattern

setting tool

(See chapter 9)

Tuning

Connect controller to

personal computer

(See section 2.3)

Tuning

(See chapter 8)

When setting the parameters of

UT351-xA, UT351-x3 and UT551-xA

to xD via Ethernet communication,

set the Ethernet parameters such as

IP address, subnet mask and

default gateway before writing other

parameters.

Tuning

Upload parameters

from controller

Save parameters

to a disk

Print parameters

End

(See chapter 8.1)

(See section 6.1)

(See section 5.2)

(See chapter 7)

(See section 3.1)

Figure 3.2.1 Work Flow of Parameters Setting T ool

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 35

<Toc> <Ind> <3. Using LL100 >

3.3 Dialog Box Elements and Functions

3-5

1) Title bar

3) Toolbar

2) Menu bar

5) Menu button

6) Dialog box for parameter menu

8) Text box

7) Dialog box for

parameter setting

11) Guidance

Figure 3.3.1 Dialog Box Elements and Functions

4) Guidance bar

9) OK button

10) Cancel button

1) Title bar

Shows the tool name (Parameters Setting Tool) and the file name of the parameter file

being used.

2) Menu bar

Contains the various tool functions that can be selected.

3) Toolbar

Displays the frequently used tool menu items as command buttons.

4) Guidance bar

Provides helpful guidance for operation.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 36

<T oc> <Ind> <3. Using LL100 >

5) Menu button

Command buttons placed in a parameter menu dialog box. These buttons open their

corresponding parameter setting dialog boxes when clicked, and the color of the

button changes.

6) Dialog box for parameter menu

There are two menu dialog boxes: one for setup parameters and the other for operat-

ing parameters. (The figure 3.3.1 shows the menu dialog box for operating parameters.)

7) Dialog box for parameter setting

Y ou can set parameters via a dialog box. When you select the text box for a param-

eter in a parameter setting dialog box, a description, range of setting, and initial value

of the parameter are shown for guidance.

8) Text box

A text box is a cell in a parameter setting dialog box, in which a parameter value is

entered and set. Clicking in a text box of a parameter that cannot be set (a bar “-” is

displayed in such text boxes) does not produce any effect.

9) OK button

Clicking this button will update the parameters shown in the parameter setting table

and close the parameter setting dialog box.

3-6

10) Cancel button

Clicking this button will discard the changes made and close the parameter setting

dialog box. This operation will not update the parameter settings.

1 1) Guidance

The parameter name, range of setting, and initial value of parameter are shown for

guidance.

When range of setting and initial value make a difference, according to model code

and the other setting parameter value, see also the controller’s user’s Manual for

GREEN Series.

3.4 Menu Commands

In the parameters setting tool, you can use the menu commands when the Setup Parameter Menu, Operating Parameter Menu or Program Pattern Menu dialog box is displayed.

Most of the menu names and commands provided for the program pattern setting tool are

the same.

● Using menu commands

(1) Click a name on the menu bar.

(2) The corresponding menu (see Figure 3.4.1) appears; select the command you wish to

carry out.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 37

<Toc> <Ind> <3. Using LL100 >

3-7

Menu Names

File

Parameter

setting

* Available only

with LL200

Menus

Open

Close

Save

Save as

Parameter

compare

Information

Terminate

Model/specification

code selection

Controller

mode setting

IN parameter

setting

OUT/VALV

parameter setting

IN/OUT

parameter setting

Setup

parameter setting

Operating

parameter setting

Run program

pattern setting

Run custom

computing tool*

Run VJET

setting tool

New

Print

tool

Dialog Boxes

Select Series

Open User File

Main Window

Save As

Parameter

Comparing

File Information

Print Parameter

(*1)

Model/Specification

Code Selection

Controller Mode

Setting Display

PV Parameter

Setting

Sets Input/Output

(for 300 series)

Program Pattern Setting Tool

Custom computation

building tool

VJET setting tool

Go to (*1)

Setup Parameter Menu

Print

Print Preview

Output to File

Control Output/Valve

Mode Setting

Setup Parameter Menu

Operating

Parameter Menu

Printer Settings

Communi-

cation

Background

color setting

Help

Download to

controller

Upload from

controller

Parameter

comparing

Tuning

Address Tag

Help Parameter

setting T ool

Version

information

Download Parameter

Upload Paramete

Parameter Comparing

r

Tuning

Sets address tag

Color

User's Manual - Reference

(CD-ROM)

Version Information

Figure 3.4.1 Tool Menu Items (for Setup and Operating Parameter Menu)

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 38

<T oc> <Ind> <3. Using LL100 >

3.5 Parameter Setting Basics

This section describes the basic operation procedure for parameter setting. This procedure

also applies to some of the program pattern setting operations.

Set parameters as shown in the flowchart below.

Select a menu button in Parameter Setting Menu

Select a parameter

Input data

Select the next

command button

Click OK

Figure 3.5.1 Parameter Setting Flowchart

3-8

3.5.1 Selecting a Parameter

(1) In a parameter setting dialog box, click the text box of the parameter you wish to

change.

(2) The text box of the selected parameter is displayed with a thick frame, indicating that it

is ready for input.

3.5.2 Inputting the Setting for a Parameter

Data entry in text boxes is a fundamental operation in every Windows-based application.

There are two types of text boxes in a parameter setting dialog box.

● T ext box with arrow button on the right:

Click the arrow button to open a list of available selections. Select an item from the list.

● T ext box without arrow button:

Click in the text box and type appropriate characters. See the guidance bar for the setting

range, initial value, and other information on that parameter. If an illegal value is input for a

numeric setting, a message box will appear, stating that an “Illegal value has been en-

tered.” Click OK and input a proper value.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 39

<Toc> <Ind> <3. Using LL100 >

Drop-down list

Arrow button

Text boxes

Enter a numeral or character string.

Figure 3.5.2 Parameter Setting Table Elements (Example of UT551)

3.5.3 Applying and Canceling Changes in Dialog Box

● T o apply the changes:

3-9

Click OK after all the settings have been made in the current dialog box.

● T o cancel the changes:

Click Cancel to cancel the changes.

NOTE

Be sure to click OK to apply changes to the parameter settings. Clicking Cancel discards

all changes you made in the dialog box.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 40

<T oc> <Ind> <3. Using LL100 >

3.5.4 Using the Keyboard When Y ou Have No Mouse

● Menu bar operation

(1) Press the F10 or ALT key on the keyboard. A border line appears around the menu

name File on the menu bar (like a button).

(2) Using the LEFT (←) and RIGHT (→) keys, move the border line on the menu bar to

select the menu name that contains the desired command, and press the ENTER key .

Then, the menu opens.

(3) Using the UP (↑) and DOWN (↓) keys, select the desired command in the menu and

press the ENTER key . (You can also open the File menu by simply pressing ALT and

F keys at the same time.)

(4) To cancel the operation, press ESC.

● Selecting a parameter menu

(1) Press the T AB key to select Menu button for parameter setting.

(2) Press the ENTER key .

● Selecting a parameter

3-10

(1) Pressing the T AB key switches the active element in the following sequence: OK

button, Cancel button, text box for a parameter , then back to the OK button.

(2) When a text box is active, you can move between text boxes (parameters) using the

UP, DOWN, RIGHT , and LEFT (↑/↓/←/→) keys. A selected text box is displayed with

a thick frame around it and is ready for input.

● Data input operation

After you select a parameter, do either of the following:

• Selecting from a drop-down list

(1) Press the CTRL + ENTER keys to open the drop-down list.

(2) Select an item using the UP and DOWN (↑/↓) keys.

(3) Press the ENTER key to set the item.

• Setting a numeral

(1) Type a numeral in the text box.

(2) Press the ENTER key to set the numeral in the parameter.

● Button operation (OK, Execute, Cancel, and other buttons)

(1) Press the T AB key repeatedly until the desired button becomes active.

(2) Press the ENTER key to carry out the command.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 41

<Toc> <Ind> < 4. Setting Parameters >

4. Setting Parameters

This chapter describes how to use the LL100 tool for making parameter settings.

This chapter is divided into the following topic areas:

(1) T ool and Series Selection

(2) New/Change Selection

(3) Setup Parameter Menu

(4) Operating Parameter Menu

Section 4.1, “Selecting

Tool and Series”

Tool

Selection

dialog box

New

Select Series

dialog box

Section 4.2.2, “Creating a New File”

Model/

Specification

Code Selection

dialog box

Section 4.2.3, “Opening a User File”

Mode Setting

Except 400 series controllers

Setting Display

For 300 series

Controller

Display

dialog box

IN/OUT

Parameter

dialog box

PV Parameter

Setting

dialog box

Section 4.3, “Setting Setup Parameters”

Control

Output/Valve

Mode Setting

dialog box

Setup

Parameter

Menu

dialog box

4-1

Operating

Parameter

Menu

dialog box

Open user file

Section 4.2.4, “Reading Current

Settings from Controller”

Uploading from

controller

Tuning

Chapter 8, “Tuning”

New/Change

Selection dialog box

Section 4.2.1,

“Selecting New/Change”

Figure 4.0.1 Configuration of Dialog Boxes Related to LL100 Parameter Setting

Open User File dialog box

Upload Parameter

dialog box

Section 4.2, “Selecting New/Change”

Section 4.5, “Parameter Menu for 300 Series”

Menu

(300 series)

(400/500/700 series)

Section 4.4, “Setting the Operating Parameters”

When setting the parameters of

UT351-xA, UT351-x3 and UT551-xA

to xD via Ethernet communication, set

the Ethernet parameters such as IP

address, subnet mask and default

gateway before writing other

parameters.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 42

<T oc> <Ind> < 4. Setting Parameters >

4.1 Selecting T ool and Series

4.1.1 Selecting the Tool

After the LL100 tool is started, the Tool Selectioin dialog box appears (Figure 4.1.1).

(For LL200, “Custom Computation Building Tool” appears at the top of dialog box.)

Figure 4.1.1 Tool Selection Dialog Box

4-2

● To select the tool

(1) Click Parameter Setting Tool.

(2) Click OK. (Go on to section 4.1.2)

4.1.2 Selecting the Series

After you select the Tool, the Select Series dialog box appears (Figure 4.1.2).

Figure 4.1.2 Select Series Dialog Box

● To select the controller model

(1) Click the controller model you wish to start.

(2) Click OK. (Go on to section 4.2.1)

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 43

<Toc> <Ind> < 4. Setting Parameters >

4.2 Selecting New/Change

4.2.1 Selecting New/Change

After you select the controller model, the New/Change Selection dialog box appears

(Figure 4.2.1).

Figure 4.2.1 New/Change Selection Dialog Box

● T o create a file of new parameter settings

4-3

(1) Click New.

(2) Click OK. (Go on to section 4.2.2)

● T o make changes to parameter settings

• T o make changes to an existing parameter setting file saved in your PC:

(1) Click Open user file.

(2) Click OK. (Go on to section 4.2.3.)

• T o read and change the current parameter settings in a controller:

(1) Click Uploading from controller.

(2) Click OK. (Go on to section 4.2.4.)

• T o change the current PID control parameter settings (also referred to as “tuning

parameters”) in a controller:

(1) Click Tuning.

(2) Click OK. (Go on to chapter 8.)

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 44

<T oc> <Ind> < 4. Setting Parameters >

4.2.2 Creating a New File

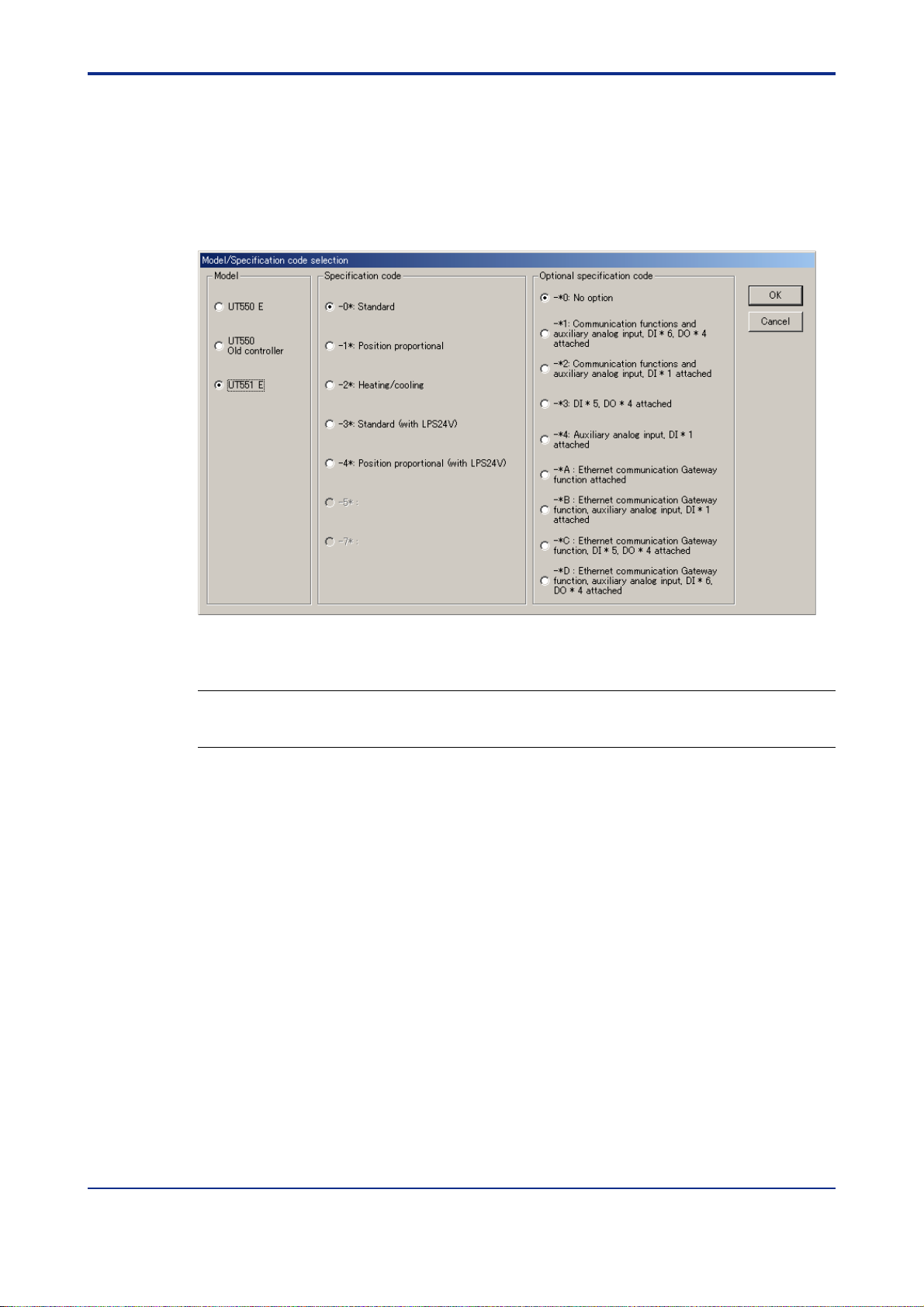

If you select New, the Model/Specification Code Selection dialog box (Figure 4.2.2) appears.

● Creating new parameter data

(1) Select the desired specification code and optional specification code.

4-4

Figure 4.2.2 Model/Specification Code Selection Dialog Box (Example of UT551)

TIP

If you are not sure of your controller’s model and specification codes, see the model and suffix indications

on the nameplate attached to the left side of the controller.

(2) Click OK.

If you click Cancel instead, the tool returns to the New/Change Selection dialog box,

discarding any settings you have made.

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 45

<Toc> <Ind> < 4. Setting Parameters >

(3) The Controller Mode Setting Display dialog box (Figure 4.2.3) opens.

Figure 4.2.3 Controller Mode Setting Display Dialog Box (Example of UT551)

4-5

(4) Select the desired controller mode.

(5) Click OK.

If you click Cancel instead, the tool returns to the Model/Specification Code Selection

dialog box.

(6) The PV Parameter Setting dialog box (Figure 4.2.4) opens.

Figure 4.2.4 PV Parameter Setting Dialog Box (Example of UT551)

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 46

<T oc> <Ind> < 4. Setting Parameters >

(7) Set the parameters in the following ways.

• For text boxes with an arrow button on the right: Click the arrow button to open a list of

available selections. Select an item from the list.

• For text boxes without an arrow button: Click in the text box and type appropriate

characters.

Select from the list.

Arrow button

Text boxes

Enter a numeral or character string.

Figure 4.2.5 Setting Parameters (Example of UT551)

4-6

(8) When you have finished setting the parameters, click OK.

If you click Cancel instead, the tool returns to the Controller Mode Setting Display

dialog box.

(9) The Control Output/V alve Mode Setting dialog box (Figure 4.2.6) opens.

(10) Set the parameters.

(1 1) When you have finished setting the parameters, click OK.

If you click Cancel instead, the tool returns to the PV Parameter Setting dialog box.

Figure 4.2.6 Control Output/Valve Mode Dialog Box (Example of UT551)

(12) The Setup Parameter Menu dialog box (Figure 4.3.2) opens. (Go on to section 4.3.2.)

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 47

<Toc> <Ind> < 4. Setting Parameters >

4.2.3 Opening a User File

After you click Open user file in the New/Change Selection dialog box (Figure 4.2.1), the

Open User File dialog box (Figure 4.2.7) appears.

Can read a user file created and saved using old LL100.

Figure 4.2.7 Open User File Dialog Box (Example of UT750)

● T o open a parameter setting file

4-7

(1) On the menu bar, click File then choose Open. The Open User File dialog box (Figure

4.2.7) opens.

(2) Click in the Look in box.

(3) From the list thus appearing, locate the folder in which the desired parameter setting

file resides and select it.

(4) The files contained in the folder you selected are listed in the box beneath. Click to

select the parameter setting file, and click Open. When LL100 has successfully

finished reading the parameter settings from the file, a dialog box displaying the

“Uploading from file have finished.” message appears.

(5) Click OK. The Setup Parameter Menu dialog box (Figure 4.3.2) then appears. (Go on

to section 4.3.2.)

● File configuration of GREEN series

The filename extension of parameter setting files are either t*d or p*d. The filenames

preceding the extension must be up to 16 alphanumeric characters. The tool automatically sets the filename extension according to the model of the GREEN Series

controller as shown below.

Table 4.2.1 Filename Extensions

Type of File

Parameter setting file

Parameter comparison

result file

Program pattern file

Program-pattern

comparison result file

Print image file

UT750 UP750 UT550/520/551 UP550 UT450/420 UT350/320 UT351/321 UP350 UP351

t7d p7d t5d p5d t4d t3d ttd p3d ptd

e7d e5d e4d e3d

- p7p - p5p - - - - -

- e7p - e5p - - - - -

Controller Model

csv

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 48

<T oc> <Ind> < 4. Setting Parameters >

4.2.4 Reading Current Settings from Controller

Clicking Uploading from controller in the New/Change Selection dialog box (Figure

4.2.1), opens the Upload Parameter dialog box (Figure 4.2.8).

Can read current settings from old GREEN series controller.

4-8

Figure 4.2.8 Upload Parameter Dialog Box

● To upload via the supplied optical communication adapter

(1) On the menu bar, click Communication, and then choose Upload from controller.

The Upload Parameter dialog box (Figure 4.2.8) opens.

(2) Click Front communication (this means to use the

the controller).

(3) From the Serial port list, select the communication port of the personal computer from

COM1 to COM16.

(4) Connect the controller to the personal computer, and then click Execute.

(5) When the parameter data has been successfully uploaded, the tool displays a mes-

sage stating “Parameter data has been uploaded from the controller .”

(6) Click OK. The Setup Parameter Menu dialog box (Figure 4.3.2) then appears. (Go on

to section 4.3.2.)

See Also

Section 2.3, “Connecting Controller to Personal Computer,” for how to connect the optical communication

adapter.

communication port at the front of

IM 05G01B12-01E

5th Edition : 2005.03.25-00

Page 49

<Toc> <Ind> < 4. Setting Parameters >

● T o upload via serial communication terminals

(1) On the menu bar, click Communication, and then choose Upload from controller.

The Upload Parameter dialog box (Figure 4.2.8) opens.

4-9

(2) Click Terminal communication (this means to use the

communication terminals at

the rear of the controller).

(3) Click Serial communication.

(4) From the Serial port list, select the communication port of the personal computer from

COM1 to COM16.

(5) Set the RS485 communication conditions:

• Communication speed, parity and address: Select from drop-down lists.

• Stop bit and data length: Select with option buttons.

Use the same settings for the target controller’s RS485 communication parameters.

(6) Connect the controller to the personal computer, and then click Execute .

(7) When the parameter data has been successfully uploaded, the tool displays a mes-

sage stating “Parameter data has been uploaded from the controller .

(8) Click OK. The Setup Parameter Menu dialog box (Figure 4.3.2) appears. (Go on to

section 4.3.2.)

NOTE

Communication via serial communication terminals is possible only for GREEN Series

controllers with the RS485 communication optional function. For controllers without the

RS485 communication optional function, always select Front communication.

To communicate via serial communication terminals, set the target controller’s RS485

communication protocol to PC-link communication. With other protocol, the serial terminal

communication is unavailable. Also note that the RS485 communication parameters