Page 1

YASNAC PC NC

Maintenance Manual

Page 2

Contents

Chapter 1: General Installation and Electrical Connection ................... 1-1

1.1 Component Arrangement............................................................ 1-1

1.2 General Specifications ................................................................ 1-5

Chapter 2: Routine Inspection ............................................................... 2-1

2.1 Routine Inspection ...................................................................... 2-1

2.2 Battery......................................................................................... 2-1

2.3 Servo Motor ................................................................................ 2-3

2.4 Fan .............................................................................................. 2-4

2.5 Touch Screen .............................................................................. 2-5

2.6 Control Panel .............................................................................. 2-6

Chapter 3: Maintenance Instruments..................................................... 3-1

Chapter 4: Troubleshooting ................................................................... 4-1

4.1 Maintenance Data ....................................................................... 4-1

The VS-626M5..................................................................................... 4-80

4.2 Notes For Safe Operation ......................................................... 4-80

4.3 Receiving .................................................................................. 4-86

4.4 Installation ................................................................................ 4-90

4.5 Wiring ....................................................................................... 4-93

4.6 Operation ................................................................................ 4-128

4.7 Digital Operator ...................................................................... 4-133

4.8 Maintenance And Inspection .................................................. 4-147

4.9 Troubleshooting ...................................................................... 4-149

Chapter 5: Adjustments ......................................................................... 5-1

Page 3

Chapter 6: Module/Unit Replacement ................................................... 6-1

6.1 CPU Rack ................................................................................... 6-1

6.2 CRT Display Unit....................................................................... 6-8

6.3 Floppy Disk Drive Unit ............................................................ 6-17

6.4 NC Power Supply ..................................................................... 6-18

6.5 Handheld Remote Machine Pendant......................................... 6-19

6.6 Noise Filter ............................................................................... 6-20

Chapter 7: Memory Option.................................................................... 7-1

7.1 Part Numbers .............................................................................. 7-1

7.2 RAM DIMM Installation ............................................................ 7-1

Chapter 8: Fixed File Operations............................................................ 8-3

8.1 NC Data Handling ...................................................................... 8-3

8.2 Yasnac PC NC CPU Rack BIOS Setup .................................... 8-59

8.3 PLC Label in Diagnosis and Parameter Screens ...................... 8-69

8.4 CNC Card Software Update ..................................................... 8-72

8.5 Manual Page Customization ..................................................... 8-82

8.6 Properties File Customization................................................... 8-84

Page 4

Chapter 1: General Installation and Electrical Connection PC NC Maintenance Manual

Chapter 1: General Installation and Electrical Connection

This section addresses the basic system: configuration, specifications, enclosure design,

electrical connections, and installation.

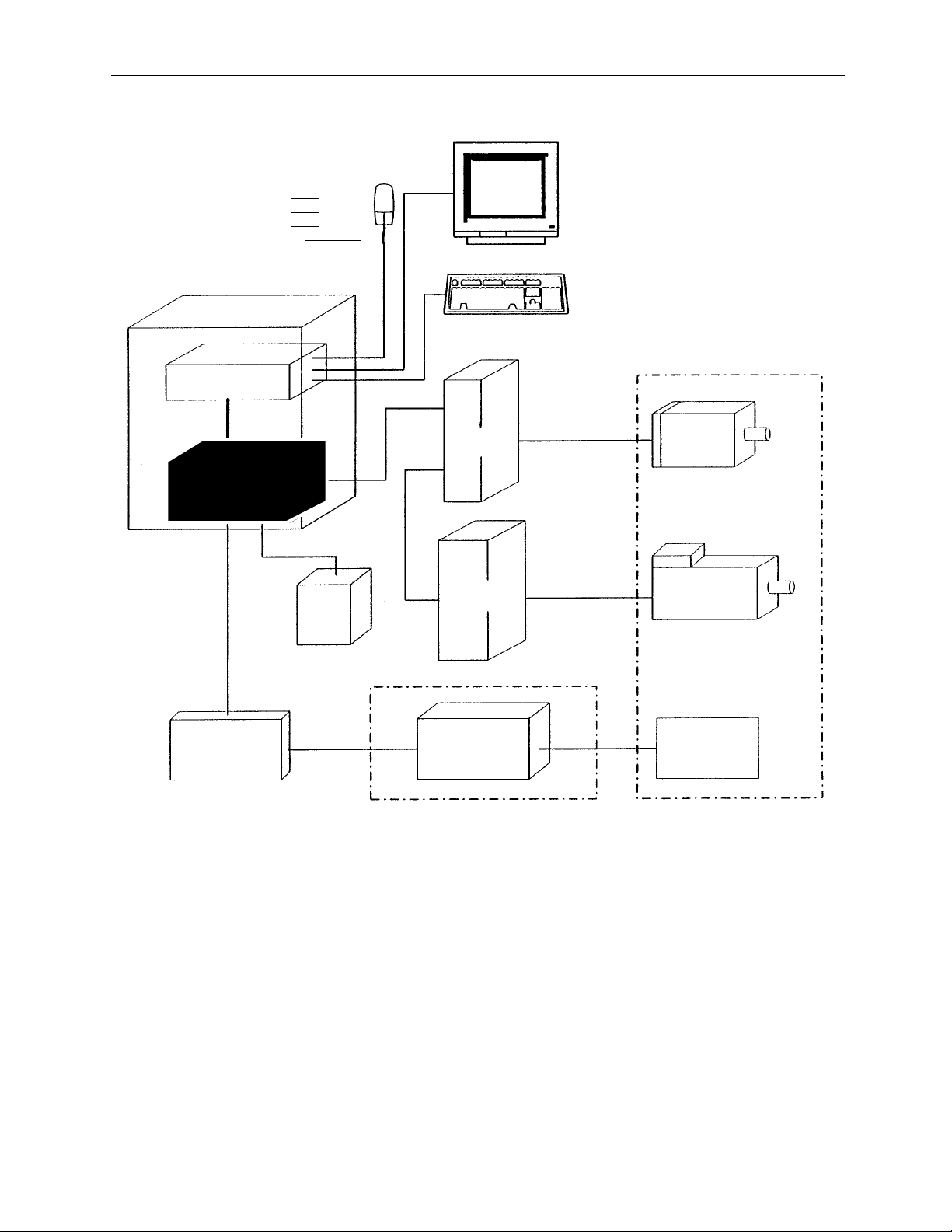

1.1 Component Arrangement

The YASNAC PC NC unit is composed of two boards: JCP20 and JFC20

(JZNC-JFC10). (Refer to the figure below.) The PC NC unit is inserted

into a PC extended bus (ISA) inside the personal computer (PC) case. The

I/O module, servo unit, spindle drive, and motor are the same as those of

the YASNAC J100 CNC UNIT.

Figure 1.1: The YASNAC PC NC Unit

1-1

Page 5

PC NC Maintenance Manual Chapter 1: General Installation and Electrical Connection

FDD

PC NC case

PC

ISA bus

JFC10

DC

+24V

power

Mouse

Monitor with Touch screen

Keyboard

Feeding

servo unit

Spindle

drive unit

Machine

Feeding

motor

Spindle motor

I/O Module

Figure 1.2: The YASNAC PC NC System Structure Diagram

High voltage

1-2

Device

on

machine side

Page 6

Chapter 1: General Installation and Electrical Connection PC NC Maintenance Manual

CPU RACK UNIT

ATX

MOTHER

BOARD

IDE I/F

KBD

COM2

FDD

COM1

PS/2 MOUSE

LPT1

PCI

ISA

FAN1

CPU

FAN

FAN3

Connection Between Devices

DATA

HDD

PWR

DC

OUT

VIDEO

CARD

VIDEO

JFC20

JCP20-1

PC POWER

CASE FAN

SUPPLY

INPU T

CN01

CN02

CN03

CN04

CN05

CN11

CN12

CN13

CN14

OUTOUT

(PO W E R

SIGNAL)

NC POWER

SUPPLY

INPU T OUTPUT

PGS

GOOD

24VDC FOR

MACHINE I/O

CN1~6

I/O BOARD

FOR MACHINE SIGNAL

(FC8 X X )

CN11

CN13

SENSOR SIGNAL

CONVERTER UNIT

5CN

CRT

KEYBOARD

MOUSE

FDD

TS

CONTROL

SERVO ON

SHUT DOWN

MACHINE

CONTROL

SIGNALS

CN14

CN12

SERVO UNIT

SG DC -**A J A

4CN

1CN

Z AXIS

52CN

51CN

SG DC -**A J A

4CN

1CN

Y AXIS

52CN

51CN

SG DC -**A J A

4CN

1CN

X AXIS

52CN

51CN

C1MR-M5N

4CN

1CN

52CN

51CN

C1MR-MR5N

PWRDATA

TOUCH

SCREEN

MACHINE OP. PANEL I/O

CN5

I/O BOARD

FOR MACHINE

OP. PNL.

(JSP02/04)

CN3

3CN

2CN

3CN

2CN

3CN

2CN

2CN

REACTOR

R/S/T

A1/A2

X0100**

TB3

CN1

CN7 ,8,9

MACHINE PANEL

M

PG

M

PG

M

PG

UAASK*-**FZ*INVERTER UNIT

M

PG

SIGNALS

SGMG-

**A2AB*

FA

HPG

N

INPUT POWER UNIT

AC230V

NFB

TB2

TB1

SVM

SVM

A1/A2

Figure 1.3: Detail Connection of PC NC Unit With Various Devices.

1-3

Page 7

PC NC Maintenance Manual Chapter 1: General Installation and Electrical Connection

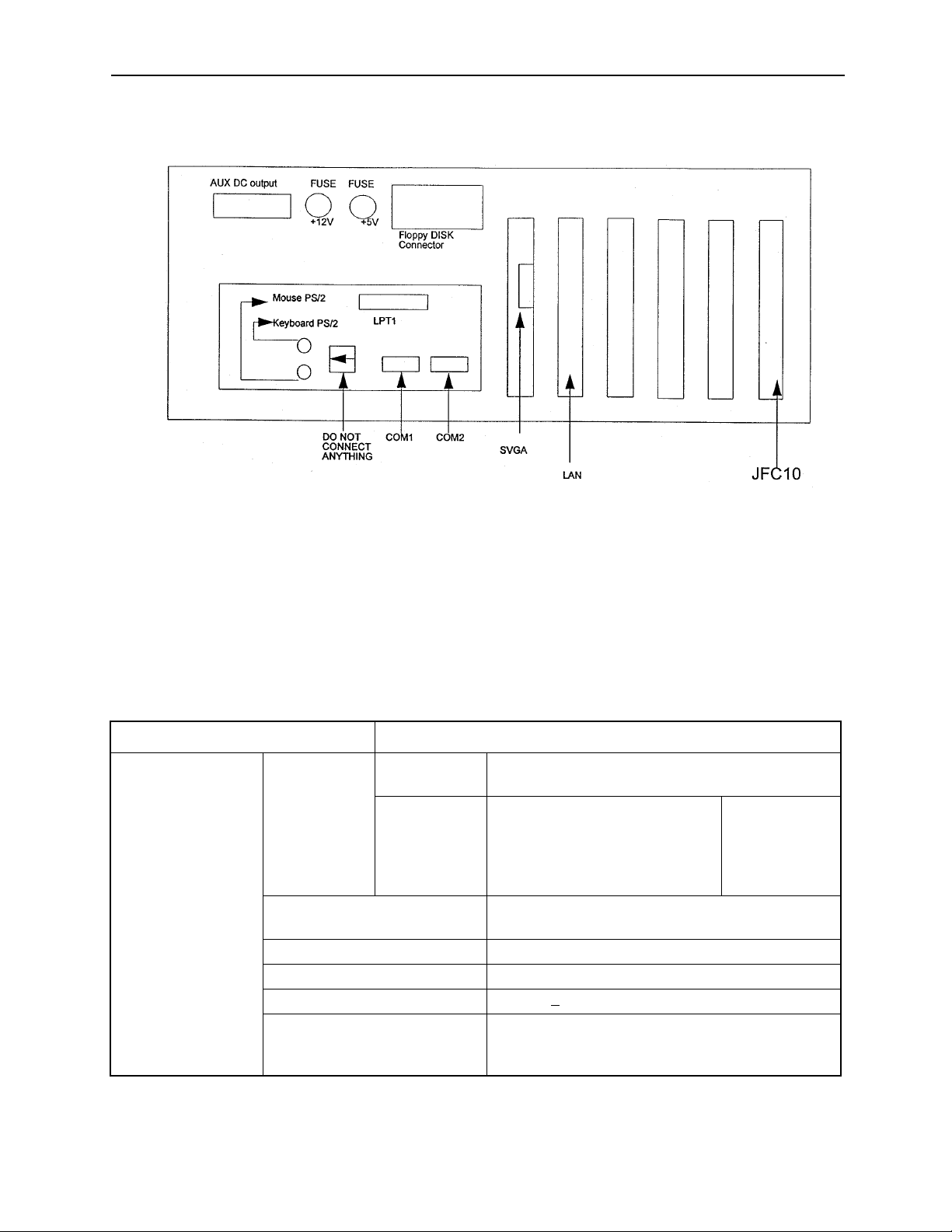

Connector Layout NC Side

The following figure provides a detailed Connectors Layout of the YASNAC JZNC-JFC10 board.

Servo controller connector (CN01)

I/O module connector (CN02)

Power good signal connector (CN03)

Interruption setting short pin (S11)

emory address setting rotary swi t ch (S12)

I/O module power output verification LED

I/O module power output connector (CN04)

Servo controller I/O connector (CN11)

Power On/Off co nne cto r (C N12)

Fuse (HM03, 0.3A) (F1)

RS232C connector (CN14)

Direct IN/OUT connector (CN14)

System load switch (S1)

I/O module power input connector (CN05)

I/O module power input verification LED

ttery power reply supply connector (CN06)

Battery

Figure 1.4: Detailed Layout of the YASNAC JZNC-JFC10 Board

System load switch (S1)

(from top: 1, 2, 3, 4)

Battery alarm LED

LITHIUM

System load rot ary switch (S1)

1-4

Page 8

Chapter 1: General Installation and Electrical Connection PC NC Maintenance Manual

Connector Layout (PC Side)

Figure 1.5: Connector Layout of the PC NC CPU Rack (top view)

1.2 General Specifications

The enclosure must be designed to meet all of the following conditions.

Table 1.1: Specifications

Item Specifications

Ambient Conditions Temperature* Storage and

Transportation

Operating

(around

enclosure)

Humidity 20% to 80% RH (with operation)

Vibration during operation Less than 4.9m/s

Others Free from dust, coolant, or organic solvent

PC NC Unit input power supply +24VDC+

Power Supply Unit

UPS000004

o

-15

C to +65oC

PC NC unit

I/O module

Servo Amplifier

14” Color monitor with touch

screen

10% to 90% RH (with non-operation)

10% 180V-264VAC

Input power supply voltage: 180V ~ 264VAC

Frequency: 47Hz to 63Hz

Momentary interruption: 0.5 cycle (0VDC)

o

0

C to +53oC

Note: Avoid installing the control panel in a location subject to direct sunlight, near heat generating

1-5

Page 9

PC NC Maintenance Manual Chapter 1: General Installation and Electrical Connection

devices, or outdoors, even if the ambient temperature is within the specified range.

Design of the enclosure should be made on the basis that the average temperature

increase of air within the enclosure (containing the PC NC unit and other compo-

nents) should be 10oC below the external air temperature.

(1) Temperature Increase within the Enclosure (Average Temperature Increase)

The internal temperature increase (sheet metal enclosure) is generally as follows: where,

∆Τ: Internal temperature increase (oC)

P: Heat generation in enclosure (W)

qe: Enclosure heat percolation ratio (W/oC)

k: Heat transit ratio of sheet metal (W/m2oC)

6W/m2oC: With internal cooling fan

4W/m2oC: Without internal cooling fan

A: Efficient heat diffusion area of enclosure (m2)

Area capable of diffusing heat in surface area of the enclosure

(Excluding area contacting other devices)

Example: Allowable heat generation in the enclosure with internal circulating fan

1200

All dimensions in millimeters

800

700

Figure 1.6: Enclosure Dimensions

Efficient heat diffusion area is independently located, so bottom area is

excluded.

A=4.16m

2.

If the heat generation in the enclosure is supposed to be 246W (113W in the

1-6

Page 10

Chapter 1: General Installation and Electrical Connection PC NC Maintenance Manual

CNC portion, 104W in the servo portion, and 29W in the I/O portion):

P

∆Τ=

P

=

qe

246

6 x 4.16

.

k A

= 9.9 (oC)

Therefore, the above value is within the temperature increase value.

When it exceeds 10oC, separate cooling countermeasures must be arranged.

(2) Heat Exchanger Cooling Capacity

Yaskawa can provide heat exchangers where the cooling capacity is insufficient even with a circulating fan mounted in the enclosure.

Table 1.2: Heat Exchangers

Heat Exchanger Cooling Capacity External Dimensions (mm)

REX1550

HEATEX02

100W /10

250W /10

o

C

o

C

295 width x 890 height x 50 depth

440 width x 924 height x 50 depth

The heat generation indicated in the above table is the allowable heat generated

when the internal temperature increase in the enclosure is limited to under

10oC.

1-7

Page 11

PC NC Maintenance Manual Chapter 1: General Installation and Electrical Connection

Example: Allowable Heat Generated in the Enclosure with Heat Exchanger

The amount of internal heat generated to make the internal temperature under

10oC when the enclosure is equipped with a HEATEX02 Heat Exchanger is

expressed by the following equation:

.A.

P= k

∆Τ+ 250 W/10oC

= 6 x 4.16 x 10 + 250

= 499 W/10

o

C

Therefore, the amount of internal heat generated must be less than 499W.

(3) Mounting Heat Exchanger

The heat exchanger must be mounted on the enclosure provided by the

machine tool builder, as shown in the figure below. Mount the exchanger so

that the internal air is drawn from the upper portion and discharged through the

lower portion, while the external air is drawn in from the lower portion and discharged through the upper portion.

Internal air

Enclosure

External air

Heat exchanger

Figure 1.7: Mounting of Heat Exchanger on the Machine Builder’s Enclosure

1-8

Page 12

Chapter 1: General Installation and Electrical Connection PC NC Maintenance Manual

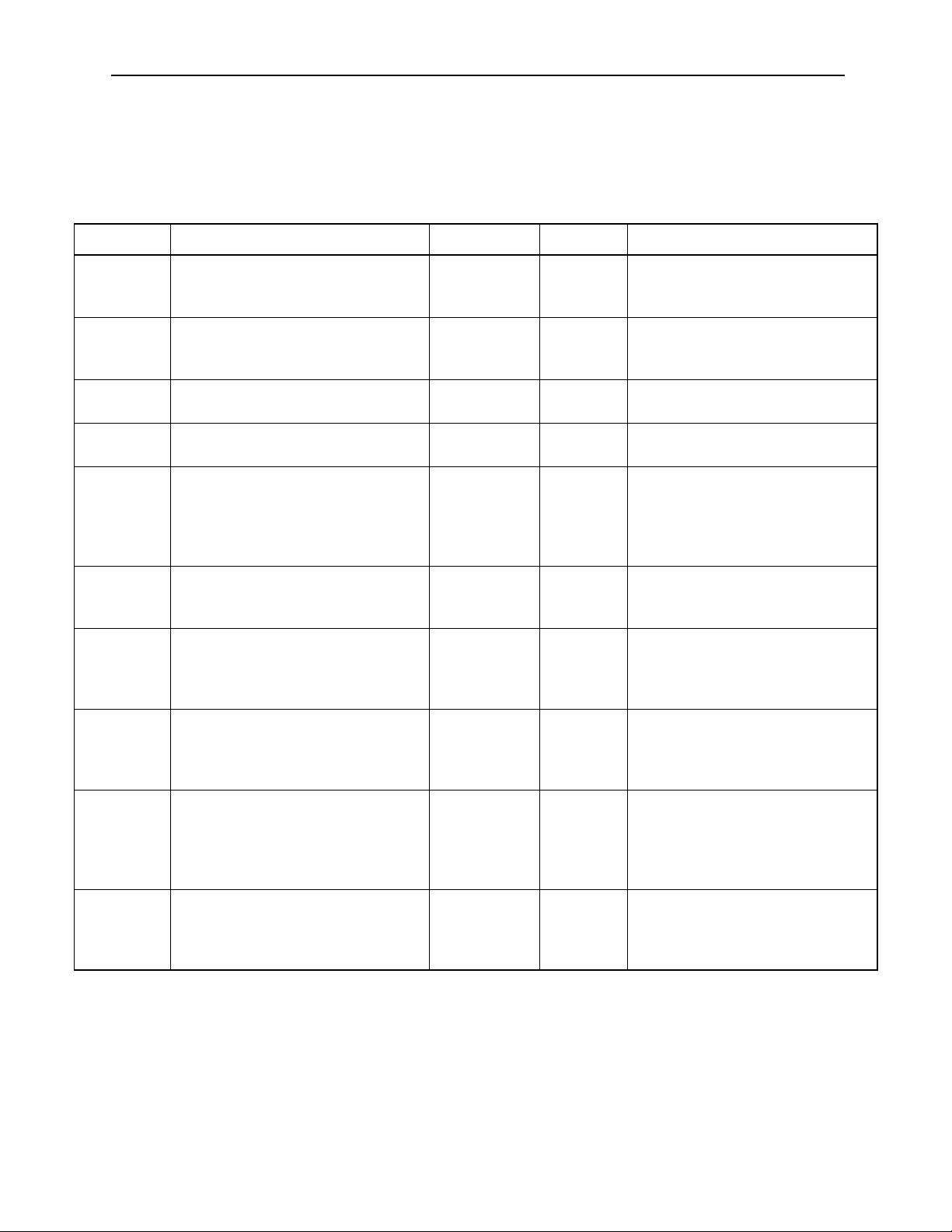

(4) Heat Generation by Respective Units

Table 1.3: Heat Generation

Unit Type

PC NC rack JZNC-JPCRKM_-_ — — —

14” Color CRT with

Touchscreen

I/O Module JANCD-FC810* 29 29 0

Converter CIMR-MR5N23P7 84 44 2.5

Spindle Inverter CIMR-MR5N23P7 84 44 2.5

Reactor UZBA-B 20A 0.53 mH 35 35 0

JZNC-JPCOP-_ _ _ — — —

JANCD-FC860* 29 29 0

JANCD-FC861* 14.5 14.5 0

CIMR-MR5N25P5 84 44

CIMR-MR5N27P5 119 61

CIMR-MR5N2011 152 70

CIMR-MR5N2015 204 88

CIMR-MR5N2018 273 108

CIMR-MR5N2022 335 132

CIMR-MR5N2030 392 160

CIMR-MR5N25P5 185 58

CIMR-MR5N27P5 244 77

CIMR-MR5N2011 307 89

CIMR-MR5N2015 454 119

CIMR-MR5N2018 565 144

CIMR-MR5N2022 717 180

CIMR-MR5N2030 869 219

UZBA-B 30A 0.35 mH 45 45 0

UZBA-B 40A 0.265 mH 50 50 0

UZBA-B 60A 0.18 mH 65 65 0

UZBA-B 80A 0.13 mH 75 75 0

UZBA-B 90A 0.12 mH 90 90 0

UZBA-B 120A 0.09 mH 90 90 0

UZBA-B 160A 0.07 mH 100 100 0

Total Heat

Generation (W)

Internal Heat

Generation (W)

Minimum Wind

Velocity for

Cooling

1-9

Page 13

PC NC Maintenance Manual Chapter 1: General Installation and Electrical Connection

Table 1.3: Heat Generation (Continued)

Unit Type

SGDC-05AJ A 28 10 2.5

SGDC-10AJ A 48 12

Servo Unit

SGDC-15AJ A 73 15

SGDC-20AJ A 108 18

SGDC-30AJ A 148 22

SGDC-50AJ A 208 28

1. The heat generated by the CNC unit varies depending on the addition of

options. The heat generated by the I/O module varies with I/O status.

2. Internal heat generation is the heat remaining inside of the enclosure when the

fin of the servo is exposed outside of the enclosure, and when the external air is

applied to the fin at greater than 2.5m/s

3. The thermal design of the enclosure to house the servo unit varies with

machine specifications, but is acknowledged to use a value of 70% of the load

factor.

Total Heat

Generation (W)

Internal Heat

Generation (W)

Minimum Wind

Velocity for

Cooling

1-10

Page 14

Chapter 2: Routine Inspection PC NC Maintenance Manual

Chapter 2: Routine Inspection

This chapter includes the requirements to maintain optimum operating conditions over

time.

2.1 Routine Inspection

The table below details routine inspection of the PC NC.

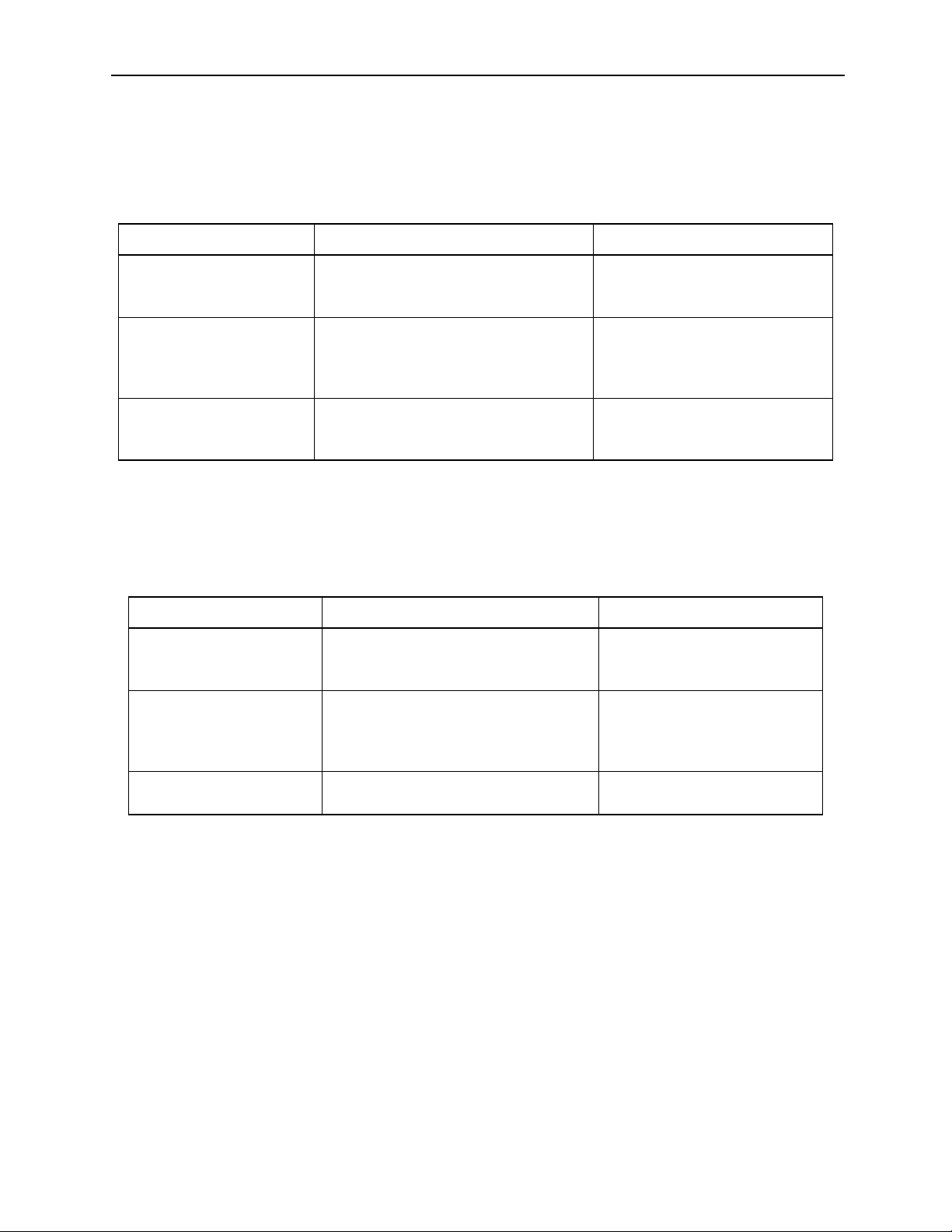

Table 2.1: Routine Inspection

Area Inspect Item Frequency

Battery Verify battery alarm

LED is on.

Servo motor Vibration and noise Daily ON Feel by hand; listen by ear.

Motor contamina-

tion and damage

Fan Air flow Monthly ON and OFF Feel by hand; listen by ear.

Touch screen Clean Daily ON and OFF Use clean rag.

Calibrate Monthly ON Use Calibration Screen.

Control panel Verify doors are

tightly closed.

Verify tight fit, no

gaps in the side

plates, and door

gaskets are not

worn.

* With the exception of inspections made while the NC is in the energized state (i.e., external cleanliness,

vibration, noise, etc.) , turn of f the source p ower suppl y to the NC before undertaking routine maint enance

service. To remove power completely from the NC, turn off the main circuit breaker on the power panel

of the machine.

At power on ON If alarm LED is on, replace battery.

Daily (or as

required)

Daily OFF Visual inspecti on

Monthly OF F Visu al ins pe ction

System

OFF/ON*

ON and OFF Visual inspection

Remarks

2.2 Battery

To determine whether the battery must be replaced, and replacement directions,

follow the steps below.

1. Press the Power OFF button.

2-1

Page 15

PC NC Maintenance Manual Chapter 2: Routine Inspection

2. Turn OFF the door interlock switch, if provided. (The power can be turned ON

with the door open.)

3. Open the door to view the NC rack.

4. Turn the power ON. If the Battery Alarm LED is displayed in the Message Bar

on the top portion of the screen, the battery must be replaced within 16 hours.

Do not use commercially-available batteries. Contact a Yaskawa customer service representative.

5. If the battery must be replaced, turn the power OFF. Remove the battery from

the battery holder.

6. Place the new battery in the holder and set the connector. (Note: the direction

of the connector is unimportant; however, poor connection may result in a lack

of conduction.). Refer to the figure below.

Correct Correct Incorrect

Figure 2.1: Battery Connection

Figure 2.2: Replacement Battery

2-2

Page 16

Chapter 2: Routine Inspection PC NC Maintenance Manual

Note: • Replace the battery as soon as possible after the power goes OFF to avoid

data loss.

• Do not turn the power ON and OFF in rapid sequence.

• Wait 4 to 5 seconds after the power has been turned ON before turning the

power OFF.

7. With the power ON, ensure that the “Message Alarm” display on the CRT and

the red LED at the front of the JZNC-JFC10 PCB is OFF.

Note: If the “Message Alarm” display on the CRT or the red LED on the front are

still illuminated, the probable cause is improper battery connection, or a

defective battery.

When alarms 2121 or higher (encoder battery errors) occur, DGN #35024

(*BALM) is not output. When DGN #35024 (*BALM) is output, the LED

goes on only when the CMOS backup battery is exhausted. This battery differs from the encoder batter.

2.3 Servo Motor

Inspect the servo motor daily as follows.

Table 2.2: Servo Motor Inspection

Inspect Item Remarks

Vibration and noise Vibration can be checked by resting the hand on the motor.

Noise can be checked by using a listening stick. Contact maintenance personnel immediately when any abnormality is found.

Motor contamination and damage Visually check the motor exterior. If dirt or damage are

observed, inspect the motor by removing the machine cover.

Refer to the machine manufacturer’s manual.

2-3

Page 17

PC NC Maintenance Manual Chapter 2: Routine Inspection

2.4 Fan

Verify the CPU rack cooling fan is running by placing a hand on the outside case in

the path of the airflow.

Figure 2.3: CPU Rack and Fan

If the cooling fan speed falls below 2000rpm, a “Slow Fan” warning message

appears. When this occurs, open the CPU rack and check the fan for any obstacles

that may inhibit the fan rotation. If no obstacles are present, call a Yaskawa customer service representative.

If the CPU rack cooling fan speed falls below 1800rpm, a “Fan Alarm of CNC

Unit” message appears. When this occurs, Cycle Start is not possible. Open the

CPU rack and check the fan for any obstacles that may inhibit the fan rotation. If

no obstacles are present, call a Yaskawa customer service representative.

2-4

Page 18

Chapter 2: Routine Inspection PC NC Maintenance Manual

2.5 Touch Screen

Clean the touch screen daily. Select PC Settings from the Utilities Menu. Select

the Touch Screen Cleaning button. When the screen below appears, proceed to

clean the touch screen.

1. Ensure there are no metal or other hard particles on the touch screen that may

scratch the screen.

2. Use a general purpose liquid glass cleaner and a clean rag.

3. Never spray glass cleaner directly onto the touch screen. Always spray onto

the clean rag.

4. Wipe the touch screen completely.

5. When finished, press the Escape key.

2-5

Page 19

PC NC Maintenance Manual Chapter 2: Routine Inspection

2.6 Control Panel

Details of the standard cabinet are explained below. Questions on customized cabinets should be referred to the manual issued by the machine manufacturer.

Follow the steps below for routine daily maintenance of the control panel.

1. Inspect the door(s) daily to ensure tight closure. The control panel is constructed as a dust-proof, sheet-steel enclosure with gasketed doors to keep out

dust and oil mists. Keep the door(s) tightly closed at all times.

2. Following inspection of the control with the door open, close the door and fasten the door locks (two per door) securely using the key provided (Number

YE001). When opening (counter-clockwise rotation) or closing (clockwise

rotation), insert the key all the way into the keyhole and turn until it clicks

(approximately a quarter-turn). The key can be removed from an open or

closed position.

Left-hand Hinge Door Right-hand Hinged Door

closed position

Note: If the optional door interlocking switch is provided, opening the door shuts

The following monthly maintenance must be performed.

1. Inspect the gaskets on the rims of the front and rear doors for openings or damage.

2. Inspect the inside of the enclosure; clean it if necessary.

open position

closed position

open position

Figure 2.4: Open and Closed Positions

off the main power supply and stops all operations.

3. Look for any opening in the door base when the doors are tightly shut.

2-6

Page 20

Chapter 3: Maintenance Instruments PC NC Maintenance Manual

Chapter 3: Maintenance Instruments

Measuring instruments, tools, and replacement parts are described in this chapter.

Table 3.1: Measuring Instruments

Name

Tester

or multi-purpose digital meter

Allowable Measuring

10 to 33VAC (at 40 to 100Hz)

Tolerance: ±2%

Several mV to 100VDC

Tolerance: ±2%

Up to multiples of 10MΩ To measure currents

The only required tools are those listed below.

• Phillips screwdrivers (large, medium, and small)

Range

Purpose

To measure AC power voltages

To measure DC power voltages

• Standard screwdrivers (medium and small)

• ROM extractor: IC extractor model GX-6

3-1

Page 21

PC NC Maintenance Manual Chapter 3: Maintenance Instruments

Maintenance/replacement parts are:

• Fuse model HMO3, 0.3A; approximate mass: 0.4g

• NC card fuse

• CPU rack fuse: 1A 250V 3AG fast-acting type glass body cartridge fuse; or

250V 3AG fast-acting type glass body cartridge fuse

Note: The current CPU rack fuse is 1A Littlefuse #312001, but will change to

3A Littlefuse #312003 fuse per ECO #N-9910-020.

• Motherboard battery: coin-type 3V lithium battery,

part # Mitsubishi #CR2032, or Maxell #CR2032

3-2

Page 22

Chapter 4: Troubleshooting PC NC Maintenance Manual

Chapter 4: Troubleshooting

4.1 Maintenance Data

To locate the cause of problems or when contacting your Yaskawa customer service representative for advice, users must precisely understand the actual situation.

To minimize the downtime, check the following points carefully.

CAUTION

• When an alarm occurs, eliminate the fault and assure operation safety before resetting it. Failure to

observe this caution could result in equipment malfunction.

• For details on the machine-related sequence, refer to the machine tool manual.

Checking the Status of Problems

(1) Understanding the Situation

To identify the nature of the problem, first check the following items.

• Type of operation that causes a problem.

Do other types of operations not cause problems?

• Q Details of problems

How, frequency (always or sometimes), and when?

• Unusual situation when the problem occurred.

• Was there an unusual external occurrence (such as power failure or

lightning) when the problem occurred?

• Timing of problem occurrence.

Did the problem occur during or after the operation of the keys, or in

a specific operation mode?

(2) Check Items

(a) Problems related with axis feed and spindle drive

Check the following items.

• Indication status of the LEDs on the drive unit

• Fuses and breakers

4-1

Page 23

PC NC Maintenance Manual Chapter 4: Troubleshooting

• Timing of problem occurrence – when the power is turned ON, during acceleration, during deceleration or during fixed speed spindle

rotation, etc.?

(b) Problems related to part program

Record the program block data, offset data, workpiece coordinate system offset data, coordinate system setting data, etc.

Checking the NC Information

Aside from the specific problem, the following information must be

obtained regarding the hardware environment.

• Machine tool builder’s name

• Delivery date of machine tool

• Type and model name of the machine tool

• Type and model name of the NC and units

Example

NC unit YASNAC PC NC

Servo drive SGDC-AJA

Servo motor SGMG

Spindle drive CIMR-M5N20155

Spindle motor UAASKD-11HB11

Display of Alarm Information

If an alarm occurs, the top priority alarm number and alarm comment are

displayed in the normal display area disregarding the selected mode and

the screen.

4-2

Page 24

Chapter 4: Troubleshooting PC NC Maintenance Manual

Cause of Alarm and Corrective Action

The following shows the listing of YASNAC PC NC alarms.

Table 4.1: Alarm Numbers and Classification

Number Contents Stop Mode Output How To Reset

0000 to

0049

0050 to

0099

0100 to

0499

1000 to

1099

2000 to

2199

3000 to

3299

8000 to

8049

9000 to

9049

No number

indication

BAT

indication

BAT, AXIS

No number

indication

Warning

message

Errors related to edit and operation

Occurring in the background mode

also.

Errors related to edit and operation

Not occurring in the background

mode.

Program error Block stop Input error

Program error

DNC, COMS total, etc.

Machine related error

OT, reference point return, machine

ready, in-position, etc.

Servo and spindle related alarm

ESP, CPU mutual monitoring

Memory check error

Watchdog timer error

Offline error

Error occurring in background editing (basically the same as with 0000

to 0049)

Battery error

Encoder alarm

Key operation error, edit operation

error (not serious operation error)

Block stop Input error

alarm

Block stop Input error

alarm

alarm

Block stop Input error

alarm

Stop after

deceleration,

or immediate

stop

Immediate

stop, or se rve,

OFF

Immediate

stop, or serve

OFF

Not stopped Back-

Not stopped No output Changing the battery

Not stopped Warning Next key operation

Alarm Reset operation after removing the

Alarm Reset after removing the cause.

Alarm For maintenance

ground

error

output

Reset

Reset

Power OFF for #0050 and #0051

Reset

Reset

cause. With the alarm caused by

the machine ready signal, if it

occurs in the first power ON operation, it is automatically reset.

With the SVOFF alarm, it is automatically reset by the SVON.

CPU halt

Switching to the maintenance

screen

Reset or with reset soft-key

4-3

Page 25

PC NC Maintenance Manual Chapter 4: Troubleshooting

Troubleshooting (1)

(1) Alarm Number 1099 (High Temperature)

Table 4.2: Countermeasures - Alarm #1099 (High Temperature)

Cause Check Item Countermeasures

Ambient temperature of the

NC rack exceeded the

specified value* due to the

failure of the cooling fan.

* 70ºC ± 3ºC when mea-

sured above CPS-18.

Internal temperature of the

power supply unit is high.

Ambient temperature of the

l NC unit is high.*

*: Allowable temperature

range for operation is

0 to 40ºC.

Open the NC unit door to check

whether the cooling fan is operating

correctly.

• Ensure that air is blowing out

through the ventilation port of

the cooling duct.

• Ensure that the ventilation port

of the cooling duct is not

blocked.

Allow the power supply unit to cool

by turning OFF the power with the

PC NC unit door opened. If the

alarm occurs even after the power

supply unit has been cooled for 30

minutes, the power supply unit is

faulty.

Measure the ambient temperature.

• If the NC unit is placed in direct

sunlight, the NC unit temperature may exceed the allowable

limit.

If the fan is faulty, it must be

replaced. Contact your Yaskawa

customer service representative.

If the cooling duct is blocked,

remove the interfering object and

start the cooling fan.

The power supply unit must be

changed. Contact your Yaskawa

customer service representative.

This is not the failure of the NC

unit. Remove the cause.

4-4

Page 26

Chapter 4: Troubleshooting PC NC Maintenance Manual

(2) Alarm Numbers 2061 to 2068 (Reference Point Return Area

Error)

Table 4.3: Troubleshooting - Alarm #2061 ~ 2068 (Reference Point Return Area Error)

Cause Check Item Countermeasures

The reference

point return start

point is at the

zero point side

of the deceleration limit switch.

Approach

feedrate is too

fast.

Deceleration limit switch (DECLS)

#3073 DO (1st axis)

#3073 D1 (2nd. ax is)

#3073 D2 (3rd axis)

#3073 D3 (4th axis)

#3073 D4 (5th axis)

If reference point return is started from a point

located at the reference point side of DECL (point

C) as shown below, an alarm occurs.

Note: This error check is not made before the

execution of manual reference point

return after the power is turned ON.

Compare the setting for the approach feedrate

parameter with the parameter list.

Execute reference

point return again

while observing the

I/O signal monitor

screen

Return the axis to a position on

the deceleration LS or away

from it and, then execute reference point return once again.

Change the setting for parameters pm2521 to pm2525 to an

appropriate value.

Table 4.4: Troubleshooting - Alarm Numbers 2071 ~ 2078, 2081 ~ 2088

Cause Check Item Countermeasures

Alarm in manual reference

point return operation

Alarm in automatic reference

point return operation

(3) Alarm Numbers 2071 to 2078, 2081 to 2088 (Reference Point

Return Position Error)

(Reference Point Return Position Error)

Determine w h e the r th e er r or occurs every

time.

G28: Determine whether the alarm

occurs every time.

G27: Check the point specified in the

program to determine whether it

agrees with the zero point.

4-5

Contact a Y askawa customer

service representative.

Contact a Y askawa customer

service representative.

Review the program.

Page 27

PC NC Maintenance Manual Chapter 4: Troubleshooting

(4) Alarm Numbers 2101 to 2108 (P-SET Error)

The P-SET alarm occurs if the error between the position specified in the program and the actual machine position is lar ger than

the value set for parameterspm1321 (1st axis) to pm 1325 (5th

axis) in the following modes of operation.

At the completion of positioning in G00, G27, G28, G29, G30,

etc., error detect ON (1/O monitor parameter #3004 D4 = 1), and

G04 (dwell).

If error pulses have been accumulated, check the number of accumulated pulses on the Error Pulse Display Screen before contacting a Yaskawa customer service representative.

(5) Alarm Number 3000 (Servo Power Not Ready)

Table 4.5 Troubleshooting - Alarm #3000 (Servo Power Not Ready)

Cause Check Item Countermeasures

Secondary power supply is not

applied

With the secondary power ON,

I/O input specification is not

turned ON (for automatic servo

power ON)

Emergency stop signal stays

ON.

The secondary power ON signal is turned OFF due to some

other alarm.

If the NC RESET switch is depressed

after depressing the POWER ON button once, or after clearing the emergency stop or alarm state, the alarm

message is displayed. This does not

indicate the occurrence of an alarm.

Verify the following on the I/O monitor

screen:

#3005 DO = 1 (SVON)

#3503 DO = 1 (SVONS)

Determine whether alarm Number

3002 is displayed (#3503 D4 = 1) on

the screen.

Check the alarm indication for other

alarms.

Press the POWER ON button again.

Contact your Yaskawa

customer service

representative.

Reset the emergency stop

input signal.

Take appropriate measures by referring to the

alarm code.

4-6

Page 28

Chapter 4: Troubleshooting PC NC Maintenance Manual

(6) Alarm Number 3001 (Control Not Ready)

The PC NC executes self-diagnosis after power ON. This alarm

occurs when the positioning error checked during this self-diagnosis exceeds the values set for parameters pm 1321 (1st axis) to

pm1325 (5th axis).

Table 4.6: Troubleshooting - Alarm Number 3001 (Control Not Ready)

Cause Check Item Countermeasures

Machine axes have moved. Select the error pulse display screen

from the present position display

PG signal remains output. PG or AC servo must be

screen in the common process and

check the error pulse value.

Contact a Yaskawa customer

service representative.

changed. Contact a Yaskawa

customer service representative.

(7) Alarm Numbers 3041 to 3048 (Excessive Follow-up Error)

If the follow-up error between the co mmand values and the ac tual

position values exceeds 120% of the error in rapid traverse

(100%) operation, this alarm occurs. Check the values set for

parameters pm1671 to pm1675, pm1681 to pm1685 and contact a

Yaskawa customer service representative.

(8) Alarm Number 3051 (Excessive Follow-up Error: Spindle)

If the follow-up error between the co mmand values and the ac tual

position values exceeds the value set for parameter pm1351, this

alarm occurs. Check the values set for parameter pm1351 and

contact a Yaskawa customer service representative.

(9) Alarm Numbers 3061 to 3068 (Overload)

Table 4.7: Troubleshooting - Alarm Numbers 3061 ~ 3068 (Overload)

Cause Check Item Countermeasures

Cutting conditions Determine whether the alarm occurred during

machining.

Guideways are not lubricated properly, causing

heavy axis movements.

Inspect the guideways to determine whether

they are lubricated properly.

4-7

Turn OFF the power and

allow the servomotor to cool.

Then change to lighter

machining conditions and

restart the operation.

Contact the mac hine

tool builder, or a Yaskawa

customer service representative.

Page 29

PC NC Maintenance Manual Chapter 4: Troubleshooting

(10) Alarm Numbers 3081 to 3088 (Broken PG Cable)

The A and B phase signal cables are checked for breakage.

Table 4.8: Troubleshooting - Alarm Numbers 3081 ~ 3088 (Broken PG Cable)

Cause Check Item Countermeasures

Signal cables between the

NC and the AC servo drive

unit are broken or loose.

Faulty PG cable breakage

detection circuit.

Error in motor type parameter setting

Ensure that the cable connectors are

plugged into the connectors securely.

Determine whether the alarm occurs in

the first pressing of the POWER ON

button even when the cables are connected c orrectly.

Determine whether the motor type setting parameters (pm 1061 to pm 1065)

has been set to “0”.

If they are loose or disconnected,

re-connect them correctly.

Contact your Yaskawa

customer service representative.

Correct the setting for the motor

type parameters (pm1061 to

pm1065).

(11) Alarm Number 3091 (Broken Spindle PG Cable)

The A, B, and C phase signal cables are checked for breakage.

Table 4.9: Troubleshooting - Alarm Number 3091 (Broken Spindle PG Cable)

Cause Check Item Countermeasures

Signal cables between the

NC and the AC servo drive

unit are broken or loose.

Faulty PG cable breakage

-detection circuit

Faulty PG If an alarm occurs during low speed

Ensure that the cable connectors are

plugged into the connectors securely.

Determine w hether the alarm oc curs in

the first pressing of POWER ON button

even when the cables are connected

correctly.

operation, the PG may be faulty.

If they are loose or disconnected, re-connect them correctly.

Contact a Yaskawa customer

service representativ e.

Contact a Yaskawa customer

service representativ e.

(12) Alarm Numbers 3121 to 3125 (Excessive Speed)

This alarm is detected if the motor speed exceeds 1.2 times the

maximum motor speed.

Contact a Yaskawa customer service representative.

(13) Alarm Numbers 3161 to 3165 (Absolute Error)

Malfunction of the absolute encoder is detected. Contact a

Yaskawa customer service representative after checking the following:

4-8

Page 30

Chapter 4: Troubleshooting PC NC Maintenance Manual

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether the alarm is cleared when the power is turned

OFF and then turned ON again.

• Whether the battery alarm occurs at the same time.

(14) Alarm Numbers 3181 to 3185 (Position Error)

Malfunction of the PG pulse (counter in the absolute encoder) is

detected. Contact your Yaskawa customer service representative

after checking the following:

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether the alarm occurs frequently during operation.

(15) Alarm Numbers 3201 to 3205 (Servo Drive Unit Communication

Error)

Communication error between the NC and the AC servo drive

unit is detected. Contact your Yaskawa representative.

(16) Alarm Numbers 3301 to 3305 (Overcurrent)

Contact your Yaskawa customer service representative after

checking the following:

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether the alarm occurs after turning ON the main

power.

(17) Alarm Number 3311 to 3315 (MCCB Trip)

• Contact your Yaskawa customer service representative

after checking the following:

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether the alarm occurs after turning ON the main

power.

4-9

Page 31

PC NC Maintenance Manual Chapter 4: Troubleshooting

(18) Alarm Number 3321 to 3325 (Regeneration Error)

Contact your Yaskawa customer service representative after

checking the following:

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether the alarm occurs after turning ON the main

power.

(19) Alarm Numbers 3331 to 3335 (Over Voltage)

Contact your Yaskawa customer service representative after

checking the following:

• Whether the alarm occurs at the start of motor rotation.

• Whether the alarm occurs during deceleration.

(20) Alarm No.: 3341 to 3345 (Under Voltage)

Contact your Yaskawa customer service representative after

checking the following:

• Whether the alarm occurs after turning ON the main

power.

(21) Alarm Numbers 3351 to 3355 (Heat Sink Overheat)

Table 4.10: Troubleshooting - Alarm # 3351 ~ 3355 (Heat Sink Overheat)

Cause Check Item Countermeasures

Faulty control board Check whether the alarm occurs imme-

diately after the control power is turned

ON.

Fan stop Check whether the alarm occurs during

operation (alarm recurs if the control

power is turned ON after turning it OFF

once, or the operation restarts when the

NC is reset after several minutes.)

Check whether the fan is rotating.

Contact your Yaskawa

representative.

Contact your Yaskawa

customer service representative.

4-10

Page 32

Chapter 4: Troubleshooting PC NC Maintenance Manual

(22) Alarm Numbers 3361 to 3365 (Wire Break in Current Instruction

Cable)

Contact your Yaskawa customer service representative after checking

the following:

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether an alarm other than the current instruction cable

breakage alarm occurs.

(23) Alarm Numbers 3371 to 3375 (Open Phase Detection)

Contact your Yaskawa customer service representative after

checking the following:

• Whether the alarm occurs immediately after the control

power is turned ON.

• Whether the alarm occurs after turning ON the main

power.

Troubleshooting (2)

Check both the drive unit and the PC NC unit for systems equipped with a

drive unit compatible with YENET1 200. If a fault is detected, the drive

unit notifies the PC NC unit of the alarm information in both systems.

The drive unit first gives the PC NC unit the information on the occurrence

of an alarm (Alarm Number 3101 to 3105 and Number 3201) and then the

content of the alarm. The NC unit displays alarm Number 3100 when it

receives the alarm information from the drive units.

Therefore, three alarms usually occur if an error is detected in the drive

unit. If a blown fuse occurs with the X-axis servo unit, Alarm Numbers

3100, 3101, and 3021 occur.

(1) Alarm Numbers 3021 to 3025 (Fuse Blown)

The main circuit of the servo unit may be faulty.

The servo unit detects the error.

Contact your Yaskawa customer service representative.

4-11

Page 33

PC NC Maintenance Manual Chapter 4: Troubleshooting

(2) Alarm Numbers 3041 to 3045, 3051 (Excessive Follow-up Error)

This alarm occurs if the follow-up error exceeds 120% of the

error in rapid traverse (100%) operation.

The servo unit detects the alarm.

Improper gain adjustment is one of the reasons.

Contact a Yaskawa customer service representative.

(3) Alarm Numbers 3061 to 3065 (Overload)

This alarm occurs if the load exceeds the rated torque considerably.

The servo unit detects the error.

Review the cutting conditions. Contact a Yaskawa customer service representative after checking whether the alarm occurred

simply after turning the control power ON.

(4) Alarm Nos.: 3081 to 3085 and 3091 (Broken PG Cable)

The encoder signal cable or the encoder itself will be faulty.

The servo unit or the inverter detects the error.

Contact a Yaskawa customer service representative.

(5) Alarm Numbers 3101 to 31051 (Servo Alarm)

This alarm occurs when the NC unit detects the alarm signal output from the servo unit.

Check the contents of the alarm by displaying the servo alarm display screen (press [F2] of the alarm job in the common process.).

4-12

Page 34

Chapter 4: Troubleshooting PC NC Maintenance Manual

(6) Alarm Numbers 3111 to3115 (Servo Communication Alarm)

Probable causes of this alarm are a broken YENET1 200 communication cable, loose cable connection and communication processing error.

The servo unit detects the alarm.

Contact a Yaskawa customer service representative after making

sure that the cable is securely connected.

(7) Alarm Numbers 3121 to 3125 (Excessive Speed)

This alarm occurs if the motor speed exceeds 4950 r/rein or the

value set for the parameter.

The servo unit detects the alarm.

Check whether the connection to the encoder is correct.

Contact a Yaskawa customer service representative.

(8) Alarm Numbers 3141 to 3145 (Overrun, Run-away Prevention)

The encoder will be faulty.

The servo unit detects the alarm.

Contact a Yaskawa customer service representative.

(9) Alarm Numbers 3151 to 3155 (Phase Detection Error)

The encoder signal cable or the encoder itself will be faulty.

The servo unit detects the error.

Contact a Yaskawa customer service representative.

(10) Alarm Numbers 3161 to3165 (Absolute Error)

This alarm occurs if the absolute value data cannot be received

correctly in one to two seconds after turning ON the power to the

encoder.

The servo unit detects the error.

4-13

Page 35

PC NC Maintenance Manual Chapter 4: Troubleshooting

The encoder or the servo unit will be faulty.

Contact a Yaskawa customer service representative.

(11) Alarm Numbers 3181 to 3185 (Absolute Position Error)

The number of feedback pulses is checked every turn of the

encoder, and this alarm occurs if there is an error in the number of

pulses counted.

The servo unit detects the alarm.

The encoder or the servo unit will be fa ulty, or malfunction could

have occurred due to noises.

Contact a Yaskawa customer service representative.

(12) Alarm Number 3201 (Inverter Alarm)

This alarm occurs when the NC unit detects the alarm signal output from the inverter.

Check the contents of the alarm by displaying the servo alarm display screen (press [F2] of the alarm job in the common process.).

(13) Alarm Numbers 3281 to 3285, 3291 (YENET1 200 command

time-out)

This alarm occurs when the YENET1200 communication lines

fail to get ready.

The NC units detects the alarm.

The servo unit or the inverter unit is faulty.

Contact a Yaskawa customer service representative.

(14) Alarm Numbers 3301 to 3305 (Overcurrent)

The servo unit detects the alarm.

The servo unit may be faulty if the alarm occurs before the operation is started after turning the power ON.

If the alarm occurs during operation, a ground fault of the motor

is the cause.

4-14

Page 36

Chapter 4: Troubleshooting PC NC Maintenance Manual

Contact a Yaskawa customer service representative.

(15) Alarm Numbers 3331 to 3335 (Over Voltage)

The servo unit detects the alarm.

If the alarm occurs when the power is turned ON to the spindle,

the input voltage may be too high.

If the alarm occurs during motor operation, the operation conditions (i.e., lower motor speed) must be reviewed.

If the alarm occurs when the servo control power is turned ON,

the servo unit will be faulty.

Contact a Yaskawa customer service representative.

(16) Alarm Numbers 3351 to 3355 (Heat Sink Overheat)

This alarm occurs when the heat sink temperature is abnormally

high.

The servo unit detects the alarm.

If this alarm occurs, turn OFF the power and allow the heat sink

to cool. After that, turn the power ON again.

If the alarm occurs immediately after turning the power ON, the

servo unit is faulty.

Contact a Yaskawa customer service representative.

(17) Alarm Numbers 3381 to 3385, 3391 (YENET1200 Communica-

tion Error)

This is an communication error between the NC unit and the

servo unit or between the NC unit and the inverter unit; the NC

unit detects the alarm when no answer is returned for the command output by the NC unit.

The servo unit or the inverter unit may be faulty, or the cable may

not be connected securely.

Contact a Yaskawa customer service representative.

4-15

Page 37

PC NC Maintenance Manual Chapter 4: Troubleshooting

(18) Alarm Numbers 3401 to 3405 (Converter Alarm)

This alarm occurs due to the following reasons: blown fuse,

regeneration alarm, open phase, or faulty board.

The servo unit detects the alarm.

Contact a Yaskawa customer service representative.

(19) Alarm Numbers 3411 to 3415 (Servo Unit Alarm)

This alarm occurs due to the following: destroyed parameter setting, faulty current detector, encoder battery alarm, memory error

or sensor error.

The servo unit detects the alarm.

The servo unit or the motor is faulty.

Contact a Yaskawa customer service representative.

(20) Alarm Number 3421 (Inverter Unit Alarm)

This alarm occurs when the inverter detects an alarm other than

the converter alarm, broken PG cable, excessive follow-up error

and communication error.

Contact a Yaskawa customer service representative.

(21) Alarm Numbers 3425, 3431 to 3435 (YENET1 200 Watchdog

Error)

This alarm occurs when the NC unit detects the watchdog error

with the inverter unit or the servo unit.

The inverter unit or the servo unit will be faulty.

Contact a Yaskawa customer service representative.

(22) Alarm Numbers 3441 to 3445 (Ground Fault)

This alarm occurs when the servo unit detects the alarm when the

power is turned ON.

The motor insulation is faulty.

4-16

Page 38

Chapter 4: Troubleshooting PC NC Maintenance Manual

Contact a Yaskawa customer service representative.

(23) Alarm Number 3451 and 3452 (Follow-up Error)

This alarm occurs when the follow-up error exceeds the value set

for the servo unit parameter.

The servo unit detects the alarm.

If this alarm occurs during axis feed over a long distance, either

the command speed must be lowered or the gain must be

increased.

If the motor does not rotate, the servo unit may be faulty.

Contact a Yaskawa customer service representative.

Alarms Not Indicated by Alarm Numbers

(1) No Display is Given on the CRT

If nothing is displayed on the CRT, the CRT itself may be faulty,

or the display circuit or connection cables may be faulty. When

nothing is displayed even if the PC NC power can be turned ON,

check the cable connection to the operation panel and also the

connectors.

(2) Handle Mode Operation is Impossible

(a) Handle mode signal is not input

• Verify the bit status of UO monitor #3000.

D2 = 1

Other bits (DO, D1, D3 to D7) = 0

• Verify the mode display given in the normal display area

on the screen.

4-17

Page 39

PC NC Maintenance Manual Chapter 4: Troubleshooting

(b) Axis selection signal is not input

• I/O monitor

Verify whether one of the following bits is ON.

#3070

D

= l 1st axis

0

D

= l 2nd axis

l

= 1 3rd axis

D

2

= 1 4th axis

D

3

D

= 1 5th axis

4

• No. 2 handle

Verify whether one of the following bits is ON.

#3080

= l 1st axis

D

0

= l 2nd axis

D

l

D

= 1 3rd axis

2

= 1 4th axis

D

3

D

= 1 5th axis

4

• No. 3 handle

Verify whether one of the following bits is ON.

#3081

= l 1st axis

D

0

= l 2nd axis

D

l

D

= 1 3rd axis

2

= 1 4th axis

D

3

D

= 1 5th axis

4

4-18

Page 40

Chapter 4: Troubleshooting PC NC Maintenance Manual

(c) There is no input to handle PG

• Check the input voltage (5V) at the handle PG terminal.

• Check the handle PG signal cable connector to see if it is

securely plugged in.

(d) Handle PG is faulty

Verify the following (counter monitor) on the I/O screen if the

values change according to the operation of the pulse handle.

#3037 (No. 1 handle)

#3038 (No. 2 handle)

#3039 (No. 3 handle)

(e) Other related parameters

Verify the setting for the following parameters.

Maximum feedrate for handle operation Parameter pm2860 (linear axis) Parame-

ter pm2861 (rotary axis)

Acceleration/deceleration time constant Parameters pm2561 to pm2565

Pulse multiplication ratio of “×100” is set (pm2003

D7 = 1)

Parameter pm2549

(3) Jog Operation is Impossible

(a) Jog mode signal is not input

Verify the bit status of I/O monitor #3000.

Dl = l

Other bits (DO, D2 to D7) = O

4-19

Page 41

PC NC Maintenance Manual Chapter 4: Troubleshooting

(b) Axis move direction signal is not input.

Verify the bit status of I/O monitor #3071 and #3072.

#3071 #3072

D0 +1st axis D0 -1st axis

Dl +2nd axis Dl -2nd axis

D2 +3rd axis D2 -3rd axis

D3 +4th axis D3 -4th axis

D4 +5th axis D4 -5th axis

(c) Jog feedrate signal is not input, or job feedrate setting param-

eter is incorrect

Verify the bit status on the I/O monitor screen to determine

whether it changes according to the operation of the JOG

FEEDF.ATE switch, and also verify whether the setting for

the parameters is correct.

4-20

Page 42

Chapter 4: Troubleshooting PC NC Maintenance Manual

Table 4.11: Jog Feedrate

I/O MONITOR #3002

STEP

JV16 JV8 JV4 JV2 JV 1

1 00000Set for parameter pm2400

2 00001Set for parameter pm2401

3 00010Set for parameter pm2402

4 00011Set for parameter pm2403

5 00100Set for parameter pm2404

6 00101Set for parameter pm2405

7 00110Set for parameter pm2406

8 00111Set for parameter pm2407

9 01000Set for parameter pm2408

1001001Set for parameter pm2409

1101010Set for parameter pm2410

1201011Set for parameter pm2411

1301100Set for parameter pm2412

1401101Set for parameter pm2413

1501110Set for parameter pm2414

1601111Set for parameter pm2415

1710000Set for parameter pm2416

1810001Set for parameter pm2417

1910010Set for parameter pm2418

2010011Set for parameter pm2419

2110100Set for parameter pm2420

2210101Set for parameter pm2421

2310110Set for parameter pm2402

2410111Set for parameter pm2423

2511000Set for parameter pm2424

2611001Set for parameter pm2425

2711010Set for parameter pm2426

2811011Set for parameter pm2427

2911100Set for parameter pm2428

3011101Set for parameter pm2429

3111110Set for parameter pm2430

3211111Set for parameter pm2431

JOG FEEDRATED4 D3 D2 D1 D0

4-21

Page 43

PC NC Maintenance Manual Chapter 4: Troubleshooting

(d) Axis interlock is input

Check the bit status on the I/O monitor screen. If “0”, the corresponding axis cannot move.

#3078

D

= l 1st axis

0

D

= l 2nd axis

l

= 1 3rd axis

D

2

= 1 4th axis

D

3

D

= 1 5th axis

4

(e) Machine lock is ON

• Even when the machine lock function is ON, the position

display changes. Check the input of the machine lock

switch (1/O monitor, #3006 D5 = 0). If “1”, the axes

do not move.

• Check the internal toggle switch (parameter pm0000 D 1

= 0). If “1”, the axes do not move.

(4) Manual Rapid Traverse is Impossible

(a) The rapid mode is not selected

Check the bit status of I/O monitor #3000.

DO = l

Other bits (D1 to D7) = 0

(b) Axis move direction signal is not input.

Check the bit status of I/O monitor #3071 and #3072.

#3071 #3072

D0 +1st axis D0 -1st axis

Dl +2nd axis Dl -2nd axis

D2 +3rd axis D2 -3rd axis

D3 +4th axis D3 -4th axis

D4 +5th axis D4 -5th axis

4-22

Page 44

Chapter 4: Troubleshooting PC NC Maintenance Manual

(c) Rapid traverse override is not input

• Check the bit status on the I/O monitor screen to determine whether it changes according to the operation of the

RAPID TRAVERSE RATE OVERRIDE switch, and also

verify whether the setting for the parameters is correct.

Table 4.12: Input Status and Rapid Traverse Rate

Input Status Of #3003 Rapid Traverse Rate

ROV2 ROV1 1st axis 2nd axis 3rd axis 4th axis 5th axis

11Set for

pm2801

1 0 [Set for

pm2801] × 1/

2

0 1 [Set for

pm2801]

× 1/4

00F

(set for pm2447)

0

Set for

pm2802

[Set for

pm2802] × 1/

2

[Set for

pm2802]

× 1/4

Set for

pm2803

[Set for

pm2803] × 1/

2

[Set for

pm2803]

× 1/4

Set for

pm2804

[Set for

pm2804] × 1/

2

[Set for

pm2804]

× 1/4

Set for

pm2805

[Set for

pm2805] × 1/

2

[Set for

pm2805]

× 1/4

Table 4.13: Input Status and Rapid Traverse Rate

Input Status Rapid Traverse Rate

ROV4 ROV2 ROV1 1st to 5th Axis I

101F

100F

0 1 1 100%

01050%

00123%

000F

(set for prn2449)

2

(set for pm2448)

1

(set for pm2447)

0

(d) Parameter related to Rapid traverse is set incorrectly.

4-23

Page 45

PC NC Maintenance Manual Chapter 4: Troubleshooting

(e) Axis interlock is input

Check the bit status on the I/O monitor screen. If “O”, the

corresponding axis cannot move.

#3078

D

= l 1st axis

0

= l 2nd axis

D

l

D

= 1 3rd axis

2

= 1 4th axis

D

3

= 1 5th axis

D

4

(f) Machine lock is ON

• Even when the machine lock function is ON, position display changes. Check the inpu t of the mac hine lock switc h

(I/O monitor, 3006 D5 = 0). If “1”, the axes do not move.

• Check the internal toggle switch (parameter pm0000 D1 =

0). If “1”, the axes do not move.

(5) Manual Reference Point Return is Incorrect

The following explanation is given assuming that jog and rapid

traverse are executed correctly.

(a) Manual reference point return signal is not input

Check the I/O monitor #3007 D0. The status must be” 1”.

Otherwise, the axis continues moving to OT at the same feedrate even if it reaches point A.

(b) Jog or rapid traverse mode is not selected.

I/O monitor #3000 D0 or D1 must be”1”.

(c) Deceleration limit switch signal is not input.

Check I/O monitor #3073 DO to D4 while moving an axis at a

slow feedrate such as in jog operation.

4-24

Page 46

Chapter 4: Troubleshooting PC NC Maintenance Manual

Deceleration switch signal

(*DCX signal)

Figure 4.1: Reference Point Return Control I/O Signals

(d) Parameter setting is incorrect.

Check the setting for the related parameters against the

parameter sheet.

(e) Position of the dog for the deceleration limit switch is incor-

rect. If the dog position is incorrect, the zero point could be

shifted by one turn of the motor.

(f) Others (loose coupling or dog)

If another adjustment is incorrect, zero point could shift at

random.

(6) Cycle Start is Impossible

(a) Cycle start signal is not input or feed hold signal is open.

Determine whether the I/O monitor #3003 D0 is “1” when the

cycle start switch is pressed. In this case, the feed hold signal

must be open; this can be confirmed by I/O monitor #3003

D1 = 1.

(b) Start interlock signal is input.

If I/O monitor #3004 D2 = 1, cycle start is impossible.

(c) The NC is in the reset status.

Normal status: I/O monitor #3500 D1 = 0.

Also check the external reset signal status.

Normal status: I/O monitor #3004 D1 = 0

4-25

Page 47

PC NC Maintenance Manual Chapter 4: Troubleshooting

(7) G01, G02, or G03 Mode Operation is Impossible

(a) The spindle is in the speed agreed status.

Verify whether parameter pm 1000 D7 = 1.

If it is “1”, check whether the spindle is in the speed agreed

status by I/O monitor #3111.

(b) FEEDRATE OVERRIDE switch setting is 0%.

Determine whether the setting for I/O monitor #311 1 D0 to

D4 is correct.

(c) ln the dry run mode, setting for jog feedrate is incorrect.

Table 4.14: I/O Monitor and Feedrate Override

I/o Monitor #3040

D4 D3 D2 D1 D0

OV16 OV8 OV4 OV2 OV 1

Feedrate Override

(Automatic Operation)

000000%

0000110%

0001020%

0001130%

0010040%

0010150%

0011060%

0011170%

0100080%

0100190%

01010100%

01011110%

01100120%

01101130%

01110140%

01111150%

10000160%

10001170%

10010180%

10011190%

10100200%

10101220%

10110240%

10111260%

4-26

Page 48

Chapter 4: Troubleshooting PC NC Maintenance Manual

Table 4.14: I/O Monitor and Feedrate Override (Continued)

11000280%

11001300%

11010340%

11011380%

11100420%

11101460%

11110500%

11111540%

(d) Start interlock signal is input.

If I/O monitor #3004 D2 = 1, start interlock is ON.

Normal: #3004 D2 = 0

(e) Axis interlock is input.

Verify I/O monitor #3087 D0 to D4.

Normal: #3078 D0 to D4 = 1

(f) Setting of the servo system is incorrect.

Verify whether the axes can be moved manually.

(8) Spindle Rotation is Impossible

(a) Error in a program (no S command or no spindle start M

code)

Verify the contents of the program on the [RUN] screen.

(b) Start signal has not been input.

Verify the output signals (#1100s) on the I/O monitor screen.

(c) Spindle rotation command has not been output.

Verify #3654 to #3656 on the 110 monitor screen.

(d) The spindle drive is in the alarm status.

Verify the alarm indication of the spindle drive.

(e) Combination of GRO and SOR is incorrect, or “0’ is input for

parameter pm1412 or pm1413.

4-27

Page 49

PC NC Maintenance Manual Chapter 4: Troubleshooting

Table 4.15: Input of GRO and SOR and S4-digit Command Analog Voltage

I/O Monitor #3110

S4-digit Command Analog VoltageD7 D6

GRO Input SOR Input

0 0 Voltage corresponding to the spindle speed

specified in the NC program.

0 1 Voltage corresponding to parameter pm 1412

1 0 Voltage corresponding to parameter pm 1413

110V

Note: If “1” is set for parameter pm1000 D5, SSTP input is reversed.

(f) Setting for the parameters related to spindle operation is

incorrect.

Verify the setting for the related parameters.

#3110 D0 GR1

#3110 D1 GR2

#3110 D2 GR3

#3110 D3 GR4

Figure 4.2: Spindle Rotation

4-28

Page 50

Chapter 4: Troubleshooting PC NC Maintenance Manual

(9) FIN Wait Status after Execution of Spindle Related Commands

If sequence processing is interrupted waiting for a signal, the NC

enters the FIN wait status.

(a) Spindle speed agree signal is not input.

If the NC enters this status after the execution of a command

such as “M03 S100”, verify whether #311 1 D6 = 1 (waiting

for FIN).

Verify the I/O signals of #1000s at the I/O section by referring

to the ladder chart supplied by the machine tool builder.

(b) Spindle zero speed signal is not input.

If the NC enters this status after the execution of the “M05”

command, check the I/O signals of #1000s at the I/O section

by referring to the ladder chart supplied by the machine tool

builder.

(c) Others

If the NC enters this status after the execution of “M19” or

“M20” (spindle orientation command), check the I/O signals

related with spindle orientation by referring to the ladder chart

supplied by the machine tool builder.

(10) Edit Operation is Impossible

(a) The edit lock signal is input.

Check I/O monitor #3007 D2.

Normal: #3007 D2 = 0

If “#3007 D2 = 1”, program edit is impossible.

(b) Edit lock is set by the parameter (pm0000 D7).

Set “pm0000 D7 = 0” to cancel the edit lock setting.

(c) Others

The corresponding alarm message is displayed.

OVER MEM CAP !

TOO MANY PROGS !

ALREADY IN !

Delete unnecessary programs and edit the program again.

4-29

Page 51

PC NC Maintenance Manual Chapter 4: Troubleshooting

(11) Skip Function (G31) Failure

The skip signal has not been input.

• Check the ON/OFF status of the skip signals.

• Check the operation of proximity switches.

PC NC Alarms Not Indicated By Alarm Numbers

(1) Fuse F1 blown on JZNC-JFC 10 card of CPU Rack.

When the 0.3 A F1 Fuse is blown on the JFC 10 card, the “3002

Emergency stop” Alarm occurs on the CNC.

In the diagnostic, when the # 3500 bit 2 * ESPS signal is ON, and

the “3002 Emergency stop” alarm still occurs on the PC NC Status bar, check the 0.3 A F1 Fuse on the JFC 10 card.

(2) Fuse F2 blown on JZNC-JFC 10 card of CPU Rack.

When the 5A F2 fuse is blown on the JFC 10 card, the “3001

Servo Alarm and 3002 Emergency stop” alarms occur. Check the

LED D4, just above CN04 Connector of the JFC 10 card of CPU

Rack. If this LED is not lit, the F2 Fuse has blown. Replace the

fuse.

(3) The Servo ON and Shut Down button connections are not con-

nected, or are wrongly connected.

When the Servo ON and Shut Down buttons are not connected to

the CN12 Connector, or are wrongly connected, “3002 Emergency stop and 3001 Servo alarms” is displayed on the PC NC.

Check that the Servo ON and Shut Down buttons are properly

connected to the CN12 Connector.

Note: When the F1 or F2 fuses are blown, replace them with

the same type of fuse.

Touch Screen Maintenance

The touch screen requires periodic cleaning as follows.

1. Whenever chips fall on the display unit.

2. Whenever coolant falls.

4-30

Page 52

Chapter 4: Troubleshooting PC NC Maintenance Manual

3. Whenever dust has accumulated on the screen.

4. Whenever greasy, or when any mist, or dust appears on the

screen.

5. If the display is not clear or clean.

Clean the touch screen as follows:

Go to Utilities, → PC Se ttings . Touch the Touch Screen Cleaning icon. A

blank screen display appears. A blank screen display appears, thereby

making any dust on the screen easy to view, and easy to clean.

Do:

1. Use standard glass cleaning liquid, applied to a clean cloth, to

wipe the touch screen.

2. Use only a clean, soft cloth.

Don’t:

1. Spray glass cleaning liquid directly on the touch screen. Apply

cleaning fluid only with clean cloth.

2. Use any hard or sharp materials to clean the touch screen.

3. Use a sponge or hands to clean the touch screen.

4. Apply pressure while cleaning the touch screen

PC NC Mode of Operation

The PC NC operation modes can be broadly divided into two categories:

the online mode and the offline mode. Although the operation mode can be

switched using the switch settings, it cannot be switched during operation.

(The PC NC references the system number switches only at system startup.)

** If the system is started after the system number switches are set into

undefined numbers, or the hardware check program has not been booted

and the system number switches are set as B &C, a “Boot Log” message

appears and the system will not start normally.

4-31

Page 53

PC NC Maintenance Manual Chapter 4: Troubleshooting

Table 4.16: Operation Mode Content

System Number

Switch

0 Normal operation mode O

1 Normal operation mode O

2 Normal operation mode O

4 Ladder development mode O

E Memory operation mode **

Online = O, Offline = * *

Self - Diagnosis Function Specification

Processing

classification

number display

1 LED PORT WRITE

2 YENET RAM CHECK

3 SYSTEM-SW READ

4 FLASH TOTAL CHECK

5 JIF PORT READ

6 REV.READ

7 ISA-RAM CHECK

8 YENET INITIAL

9CMOS CLEAR

10 CMOS TOTA L CHECK

11 PARAMETER READ

12 MOTION INITIAL

13 LADDER START

14 INTEX INITIAL

15 TASK SETUP

16 JTABLE SET

Progress message display

corresponding to the content of

NC power input processing.

Mode of operation

During boot up of the PC NC

LED Display

4321

OO O

OO O

O

OO O

OO O

OO O

OO O

O O

O O

O O

O OO

O

O

O

O

OOO

O

O

OO

Operation Mode

Type

System

number SW

0, 1, 2, 4, E JCP20 PCB

0, 1, 2, 4, E JCP20 PCB

0, 1, 2, 4, E JCP20 PCB

0, 1, 2 JCP20 PCB

0, 1, 2, 4, E JCP20 PCB

0, 1, 2, 4, E JCP20 PCB

0, 1, 2, 4, E JCP20 PCB

0, 1, 2, 4, E JCP20 PCB

0, 1, 2, 4, JCP20 PCB

0, 1, 2, JCP20 PCB

0, 1, 2, 4, JCP20 PCB

0, 1, 2, 4, JCP20 PCB, SERVO

0, 1, 2, 4 JCP20 PCB

0, 1, 2, 4, E

0, 1, 2, 4, E

0, 1, 2, 4, E JCP20 PCB

Cause of failure

4-32

Page 54

Chapter 4: Troubleshooting PC NC Maintenance Manual

Parameter setting is incorrect.

• Verify the setting for parameter pm2001 DO. If the setting for

pm2440 is “0” while “pm2001 D0 = 1”, an axis does not move.

pm2001 D0 = 1 The feedrate in the skip feed mode (G31) is the feedrate set for

parameter pm 2440.

pm2001 D0 = 0 The feedrate in the skip feed mode (G31) is the feedrate speci-

fied with an F code.

• Verify the setting for parameters pm5011 D0 to D2.

• Set the signal status at the start of the processing when the SKIP

signal is input.

• If “0”, processing starts at the point at which 24V faI1s to 0V.

• After changing the setting, turn OFF the power once and turn it ON

again.

• Verify the setting for parameters pm5010 D0 to D0.

The setting for this parameter determines ENABLE/DISABLE of the control circuit for the “SKIP” input.

•Set “1” to use the skip function.

•

•

•After changing the setting for this parameter always turn OFF the

power - once and then turn it ON again.

4-33

Page 55

PC NC Maintenance Manual Chapter 4: Troubleshooting

VS-626MR5 Alarm List

In the VS-626MR5, the protective functions operate according to the error

content when a fault and an error phenomenon are generated during a drive

operation when the drive is stopped. This error content is displayed on the

7 segment LED, according to alarm number.

Table 4.17: Alarm List

Alarm

Number

01 Overcurrent Output current flowed more than the overcurrent detection level.

04 Main circuit fuse is blown Main circuit fuse is blown.

05 Overload Output current exceeded the overload level.

11 Output overvoltage Output voltage exceeded the overvoltage setting value.

12 Main circuit low voltage Main circuit input voltage went below the low voltage detection level

13 Control circuit low voltage Control circuit power supply went below the low voltage detection

14 Power failure for servo

driver

15 Power supply frequency

error

16 An initial charge defect Main circuit condenser charge was not completed in the setting time.

23 Built-in MC defective per-

formance

43 Heat sink over heating 1

(minor fault)

44 Heat sink overheating 2 Heat sink temperature exceeded the upper limit and has passed one

45 Heat sink thermistor dis-

connection

46 Control card temperature

error (minor fault)

47 Control card temperature

error 2

d2 CPU built-in A/D defective Built-in A/D converter is defective.

F0 ROM defect Memory (PROM) is defective.

F1 EEPROM defect Memory (EEPROM) is defective.

F5 CPU defect Internal RAM check error (at initialization).

• • Control card fault WDT time-out

Name Content

while driving.

level.

Control voltage supplied to the servo driver is abnormal.

Power supply frequency excessive deviation (50Hz or 60Hz±6%)

Magnetic contactor does not work.

Heat sink temperature exceeded the upper limit.

minute or more.

Thermistor for the heat sink temperature detection was discon-

nected.

Control card temperature exceeded +80ºC.

Control card temperature exceeded +85ºC.

4-34

Page 56

Chapter 4: Troubleshooting PC NC Maintenance Manual

01:Overcurrent

Error Contents The output current flowed more than the overcurrent detection level.

Detection Methods If the output current exceeds 180% of the rated current of transistor

(IGBT), the gate is instantaneously blocked (regeneration operation

stop) and the overcurrent detection signal is turned ON.

Cause and measures

Cause Measures

Main power (R, S, T) open phase, momentary

power failure

Servo/inverter control parameter setting defect Set a correct value referencing with the shipm ent se ttin g.

Servo and inverter fault Check the input current of the servo and the inverter.

Reactor selection defect Perform the proper selection (correspond to the con-

Converter capacity selection defect Check the capacity connected to servo and inverter.

Current detection signal connector contact

defect

Control card fault Exchange unit exchange (exchange control card)

Check the main power supply ripple.

Exchanged the servo and the inverter.

verter capacity).

Exchange the converter.

Check that there are no loose connectors.

04:The main circuit fuse fusion

Error Contents The main circuit fuse has fused.

Detection Methods The main circuit fuse signal consists of the gate driver and outputs to

the control card (2CN-6). If the main circuit fuse disconnection detection signal has been turned ON, the current is intercepted.

Cause and measures

Cause Measures

Fuse fusion Check fuse (R phase / T phase) continuity.

Exchange the fuse (R phase / T phase).

Gate driver fault Confirm that the fuse (R phase and T phase) does not fuse.

Exchange unit (gate driver exchange)

Control card fault Exchange unit (control card exchange)

4-35

Page 57

PC NC Maintenance Manual Chapter 4: Troubleshooting

05: Overload

Error Contents The output current exceeded the overload level.

Detection Methods Converter output over load level: 120% per one minute of the converter

rated output current [= 30 minutes rating]

Cause and measures

Cause Measures

Servo and inverter fault Check the input current of the converter.

Check that there are no errors in the servo and inverter.

Converter capacity selection defect Check the capacity connected to the servo and inverter.

Exchanged the converter.

The frequency of the acceleration/

deceleration drive is high.

Control card fault Exchange unit (exchange control card)

Check the acceleration/deceleration drive frequency from the

drive pattern.

11:Output overvoltage

Error Contents Output voltage exceeded the overvoltage setting value.

Detection Methods The main circuit DC voltage signal [VDET] consists of the gate driver

and outputs to the control card (2CN-20).

If VDET exceeds the main circuit DC voltage detection signal level

[411V], the gate is blocked (regeneration operation stop), and the main