Page 1

E7L Drive/Bypass

Technical Manual

Model: E7L Document Number: TM.E7L.01

Page 2

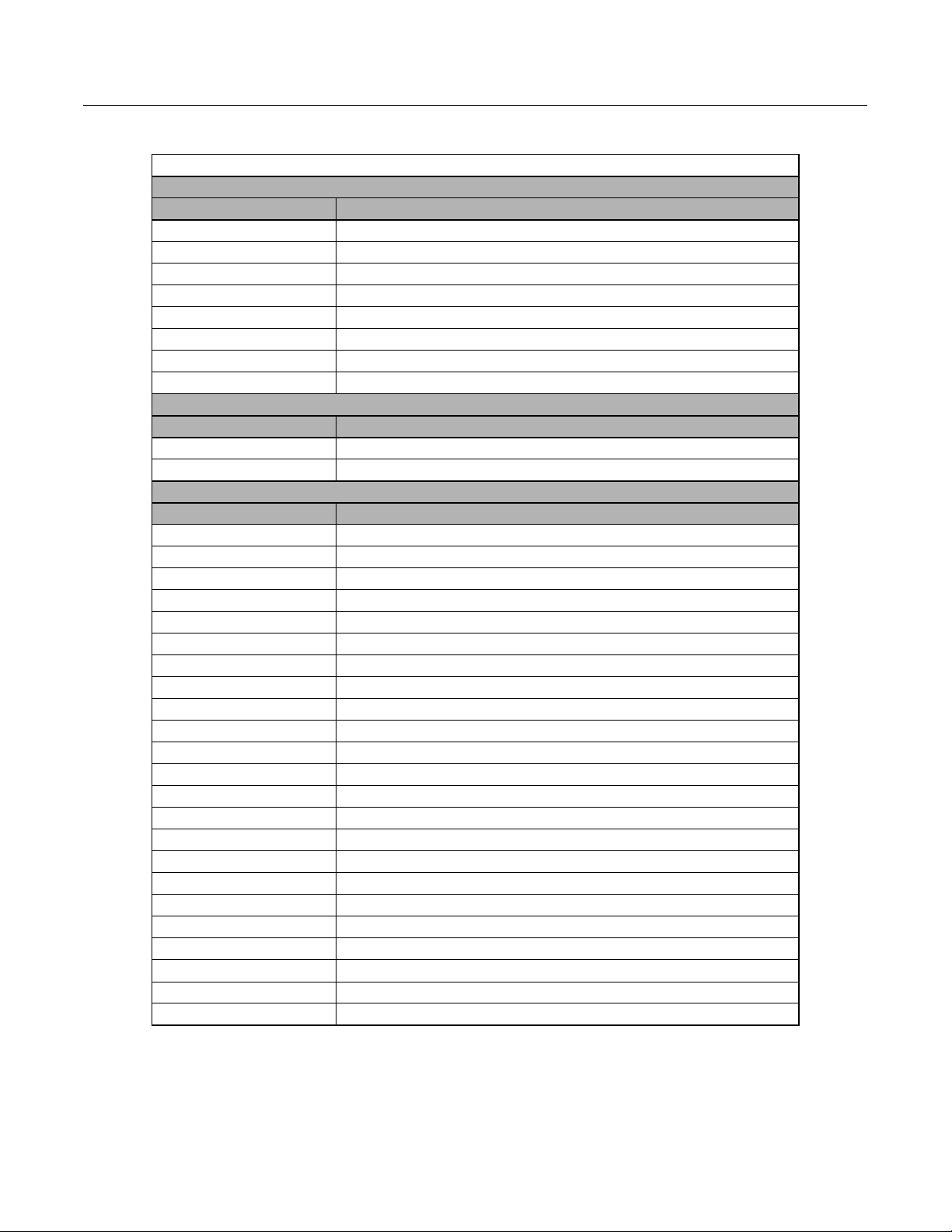

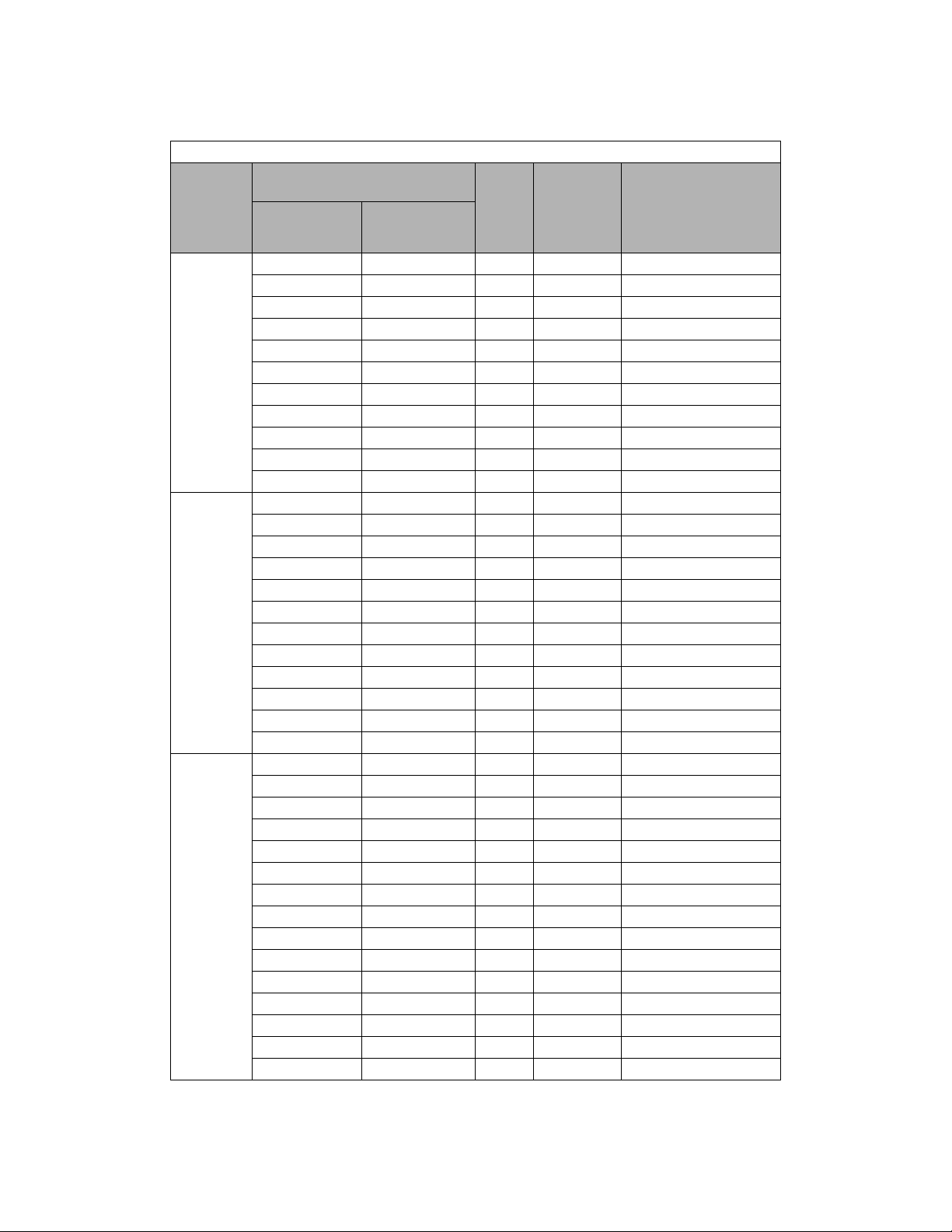

Quick Reference for Bypass Parameters

Parameter

Number

A1-00 0 b5-04 100

A1-01 2 b5-06 100

A1-03 0 b5-07 0

A1-04 0 b5-08 0

A1-05 0 b5-09 0

A2-01 b5-10 1

A2-02 b5-11 0

A2-03 b5-12 0

A2-04 b5-13 0

A2-05 b5-14 1

A2-06 b5-15 0

A2-07 b5-16 0

A2-08 b5-17 0

A2-09 b5-18 0

A2-10 b5-19 0

A2-11 b5-20 1

A2-12 b5-21 1

A2-13 b5-22 0

A2-14 b5-23 0

A2-15 b5-24 0 L6-02 15

A2-16 b5-25 0 L6-03 10

A2-17 b5-26 0

A2-18 b5-27 60

A2-19 b5-28 0

A2-20 b5-29 1

A2-21 b5-30 0

A2-22 b8-01 0 L8-10 0

A2-23 b8-04 kVA Dep. L8-11 300

A2-24 b8-05 20 H3-03 0 L8-12 45

A2-25 b8-06 0 H3-08 See Table

A2-26 C1-01 30 L8-18 1

A2-27 C1-02 30 L8-19 20

A2-28 C1-03 30 H3-09 n1-01 1

A2-29 C1-04 30 n1-02 1

A2-30 C1-09 10 n3-01 5

A2-31 C1-11 0

A2-32 C2-01 0.2

b1-01 See Table

b1-02 1 C6-02 kVA Dep. o1-03 0

b1-03 0 C6-03 kVA Dep.

b1-04 1 C6-04 kVA Dep.

b1-07 0 C6-05 0

b1-08 1 d1-01 10.0

b1-11 0 d1-02 6.0

b1-12 0 d1-03 0

b2-01 0.5 d1-04 0

b2-02 50 d1-17 6

b2-03 0 d2-01 100

b2-04 0 d2-02 0

b2-09 0 d2-03 0

b3-01 2 d3-01 0

b3-02 120 d3-02 0

b3-03 2 d3-03 0

b3-05 0.2 d3-04 1

b3-14 1 d4-01 0

b4-01 0 d4-02 10 H5-09 10 o2-15 0

b4-02 0 E1-01 208V, 240V or

b5-01 0 L1-02 8 o3-02 1

b5-02 2 E1-03 F L1-03 3 T1-02 kVA Dep.

b5-03 5 E1-04 60 L1-04 1 T1-04 kVA Dep.

Factory

Setting

5.1

User

Setting

Parameter

Number

C2-02 0.2

C4-01 1

C4-02 200 o1-02 1

Factory

Setting

480V

User

Setting

Parameter

Number

E1-05 208V, 230V or

E1-06 60

E1-07 3

E1-08 18

E1-09 1.5

E1-10 10.8

E1-11 0

E1-12 0

E1-13 0

E2-01 kVA Dep.

E2-03 kVA Dep.

E2-05 kVA Dep.

F6-01 3

F6-02 0

F6-03 1

F6-05 0

H1-01 70

H1-02

H1-03

H1-04 4

H1-05 6

H2-01 0

H2-02 3B

H3-02

H3-10 100

H3-11 0

H3-12 0.3

H3-13

H4-01 2

H4-02 100

H4-03 0

H4-04 8

H4-05 50

H4-06 0

H4-07 0

H4-08 0

H5-01 1F

H5-02

H5-03 0

H5-04 3

H5-05 1

H5-06 5

H5-07

H5-08

L1-01 1 o3-01 0

Factory

Setting

460V

See Table

5.1

100

5.1

See Table

5.1

0

See Table

5.1

See Table

5.1

See Table

5.1

User

Setting

Parameter

Number

L1-05 0.2

L2-01 2

L2-02

L2-03

L2-04

L2-05

L3-01 1

L3-02 120

L3-04 1

L3-05 1

L3-06 120

L4-01 0

L4-02 2

L4-05 0

L4-06 80

L5-01 10

L5-02 0

L5-03 10

L6-01 0

L8-01 0

L8-02

L8-03 4

L8-06

L8-09 1

L8-15 1

n3-02 150

n3-03 1

n3-04 40

o1-01 6

o1-05 3

o1-06 0

o1-07 2

o1-08 3

o2-01 0

o2-02 0

o2-03 1

o2-04 kVA Dep.

o2-05 1

o2-06 1

o2-07 0

o2-08 1

o2-09 1

o2-10 0

o2-12 0

o2-14 0

Factory

Setting

kVA Dep.

kVA Dep.

kVA Dep.

Voltage Dep.

kVA Dep.

kVA Dep.

User

Setting

Page 3

Warnings and Cautions

WARNING

WARNING

This Section provides warnings and cautions pertinent to this product, that if not

heeded, may result in personal injury, fatality, or equipment damage. Yaskawa is

not responsible for consequences of ignoring these instructions.

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and

application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

YASKAWA product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed to

incorporate a component part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and

instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the

end user. YASKAWA offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the YASKAWA manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

YASKAWA assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

•

Read and understand this manual before installing, operating, or servicing this Drive and Bypass Unit. All warnings, cautions,

and instructions must be followed. All activity must be performed by qualified personnel. The Drive must be installed accord

ing to this manual and local codes.

• Do not connect or disconnect wiring while the power is on. Do not remove covers or touch circuit boards while the power is

on.

• Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. Status indicator LEDs and Digital Operator display will be extinguished when the DC bus voltage is below

50 VDC. To prevent electric shock, wait at least five minutes after all indicators are OFF and measure DC bus voltage level

to confirm safe level.

• Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be damaged

by high voltage.

• The Drive and Bypass unit is not suitable for circuits capable of delivering more than the specified RMS symmetrical

amperes. Install adequate branch short circuit protection per applicable codes. Refer to the specification. Failure to do so

may result in equipment damage and/or personal injury.

• Do not connect unapproved LC or RC interference suppression filters, capacitors, or overvoltage protection devices to the

output of the Drive. These devices may generate peak currents that exceed Drive specifications.

• To avoid unnecessary fault displays caused by contactors or output switches placed between Drive and motor, auxiliary

contacts must be properly integrated into the control logic circuit.

• YASKAWA is not responsible for any modification of the product made by the user; doing so will void the warranty. This

product must not be modified.

• Verify that the rated voltage of the Drive and Bypass unit matches the voltage of the incoming power supply before applying

power.

-

i

Page 4

WARNING

• Some drawings in this manual may be shown with protective covers or shields removed, to describe details. These must be

replaced before operation.

• Observe electrostatic discharge procedures when handling circuit cards to prevent ESD damage.

• The equipment may start unexpectedly upon application of power. Clear all personnel from the Drive, motor, and machine

area before applying power. Secure covers, couplings, shaft keys, and machine loads before energizing the Drive and Bypass

unit.

• Please do not connect or operate any equipment with visible damage or missing parts. The operating company is responsible

for any injuries or equipment damage resulting from failure to heed the warnings in this manual.

Intended Use

Drives and Bypass Units are intended for installation in electrical systems or machinery.

For use in the European Union, the installation in machinery and systems must conform to the following product standards of

the Low Voltage Directive:

EN 50178, 1997-10, Equipping of Power Systems with Electronic Devices

EN 60201-1, 1997-12 Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)/

EN 61010, 1997-11Safety Requirements for Information Technology Equipment

(IEC 950:1991 + A1:1992 + A2:1993 + A3:1995 + A4:1996, modified)

Other

The Drive and Bypass unit is suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical

amperes, 240VAC maximum (240V Class) and 480VAC maximum (480V Class).

This manual is for reference only and subject to change without notice.

ii

Page 5

Introduction

This Section describes the applicability of the Manual

Product Description

The E7L Bypass unit provides a means of bypassing the Drive while allowing the motor to operate at full speed, directly from

the AC line. It incorporates an AC Drive and two contactor Bypass arrangement in a single UL listed enclosure. The two

electrically interlocked IEC rated contactors isolate the Drive from the load when operating in B y p as s m o de .

Control logic provides industry standard Hand/Off/Auto functions and safety circuit interlocks in both drive and Bypass op eratin g modes.

E7L Bypass components include: a fused 120 VAC control circuit transformer, an input disconnect, motor overload relay, control keypad and indicating lights.

The E7 Drive, a component of the E7L Bypass package, is a Pulse Width Modulated Drive for 3-Phase AC induction motors.

This type of Drive is also known as an Adjustable Frequency Drive, Variable Frequency Drive, AC Drive, AFD, ASD, VFD,

and Inverter. In this manual, the E7 Drive will be referred to as the “Drive”.

The Drive is a variable torque AC drive, designed specifically for HVAC applications in building automation, including fans,

blowers and pumps. A new benchmark for size, cost, performance, benefits, and quality, the Drive includes numerous

built-in features such as network communications, H/O/A, PI, parameter storage and copy functions.

The Drive has embedded communications for the popular building automation protocols, Johnson Controls Metasys® N2 and Siemens APOGEE™ FLN, as well as Modbus®. An optional LONWORKS® interface card is also available.

The LED keypad/operator is equipped with Hand/Off/Auto functions and copy feature. User parameter settings can be recovered at any time via “User Initialization”. Optional DriveWizard software allows upload/download, as well as graphing and

monitoring of drive parameters from a PC for ease of drive management.

Built-in PI control eliminates the need for closed loop output signals from a building automation system. It includes feedback

display, inverse, square root and differential control functions, and maintains setpoint for closed loop control of fans and

pumps for pressure, flow, or temperature regulation.

This manual is applicable to E7 Drives defined by model numbers CIMR-E7U_ _ _ _ contained within Bypass units defined by model numbers E7L_ _ _ _.

This manual is subject to change as product improvements occur. The latest version of the manual can be obtained from the

Yaskawa website

of Drive software is also shown.

www.drives.com . The date shown on the rear cover is changed when revisions are made. The latest version

Introduction iii

Page 6

This manual may describe trademarked equipment, which is the property of other companies. These trademarks are the property of the registered owner companies and may include the following:

APOGEE

Metasys®, trademark of Johnson Controls Inc.

Modbus®, trademark of Schneider Automation, Inc.

LONWORKS®, trademark of Echelon Corporation

Other Documents and Manuals are available to support special use or installation of this product. These documents may be provided with the product or upon request or downloaded from www.drives.com. Documents may include the following:

TM.E7.01.USER … Manual included on CD ROM with product

TM.E7.02.Programming … Manual included on CD ROM with product

TM.E7.11.Modbus … Manual included on CD ROM with product

TM.AFD.20.LONWORKS … Manual included on CD ROM with product

TM.E7.21.APOGEE … Manual included on CD ROM with product

TM. E7.22. Metasys … Manual included on CD ROM with product

DriveWizard … Software and Manual…Included on CD ROM with product

Option Instructions … Included on CD ROM with product

TM

FLN, trademark of Siemens Building Technologies, Inc.

Definitions of Acronyms and Abbreviations

AC Alternating Current LRA Locked Rotor Amperes

AIC Amps Interrupting Capacity MCP Motor Circuit Protector

CB Circuit Breaker MTBF Mean Time Between Failures

CIMR Control Induction Motor Rotation NC Normally Closed

CN Connector NEC National Electrical Code

CPT Control Power Transformer NEMA National Electrical Manufacturers Association

CPU Central Processing Unit NO Normally Open

DIP Dual Inline Package OLR Over Load Relay

FLA Full Load Amperes PCB Printed Circuit Board

FVFF Forced Ventilated, inlet Filter, outlet Filter PI Proportional plus Integral control action

HOA Hand/Off/Auto RTS Request To Send

HP Horsepower SFS Soft Start

IEC International Electrotechnical Commission TB Terminal Block

IGV Inlet Guide Vanes THD Total Harmonic Distortion

IPM Intelligent Power Module VA Volt Amperes

KVA Kilo Volt Amperes VAC Volts Alternating Current

LED Light Emitting Diode VAV Variable Air Volume

Terminology in This Manual

“Standard” or “Configured” options - are available with standard lead times

“Engineered” or “Custom” options - are available only with extended lead times

Introduction iv

Page 7

Resources Available

Document Number Description

TM.E7.01 E7 Drive User Manual

TM.E7B.01 E7 Drive/Bypass Tech Manual

TM.E7.02 E7 Drive Programming Manual

TM.E7.21 E7 APOGEE™ FLN Technical Manual

TM.E7.22 E7 Metasys® N2 Technical Manual

IG.AFD.20 LONWORKS® Option Installation Guide

IG.AFD.50 3-15 PSI Pressure Transducer Installation Guide

CD.E7.01 CD ROM, Drives for Building Automation

Document Description

DriveWizard® Software DriveWizard® Software Version 5.5

ESP Energy Savings Predictor for E7

Document Number Description

FL.E7.01 Flyer, 2 page, E7 Drives and Bypass Packages

BL.E7.01 Bulletin, Multi-page, E7 Drives and Bypass Packages

PB.E7.01 E7 Price Book

DRG.E7 E7 Drives Resources Guide Binder for Building Automation

SG.E7.01 EngSpec15172 E7 Specification Guide, Section 15172 for Consulting Engineers

SG.E7.10 SubmittalSpec E7 Submittal Specification

SG.E7B.10 SubmittalSpec E7 Bypass Submittal Specification

SG.E7C.10 SubmittalSpec E7 Configured Submittal Specification

SG.E7E.10 SubmittalSpec E7 Engineered Submittal Specification

FL.E7L.01 Flyer

PB.E7L.01 Price Book

PP.E7L.01.Intro Power Point Introduction for Sales Use

PH.E7L.01A.blue Photo left facing pose on blue

PH.E7L.01B.white Photo left facing pose on white

PH.E7L.02A.blue Photo Keypad for E7L on blue

PH.E7L.02B.white Photo Keypad for E7L on white

E7L-00 Drive and Bypass Schematic

S5537 and S5539 Dimension Drawings

SG.E7L.10 Submittal Documents

PR.E7L.01 Press Release

PL.E7L.02.AnnounceAssoc Announcement Letter to Assocs

PL.E7L.03.AnnounceDistrib Announcement Letter to Distribs

E7 DRG Drive Resource Guide Binder

Table of Resources

Manuals, Installation Guides, and CD’s

Software

Flyers, Bulletins, Pricebook, Binders, And Specifications

See also www.drives.com.

Introduction v

Page 8

Notes:

Introduction vi

Page 9

Table of Contents

Quick Reference Parameter List ........................................................Inside front cover

Warnings and Cautions................................................................................................ i

Introduction..................................................................................................................iii

Chapter 1 - Physical Installation ...............................................................................1-1

Bypass Model Number and Enclosure Style .............................................................. 2

Enclosure Data ........................................................................................................... 3

Confirmations upon Delivery ...................................................................................... 6

Bypass Product Options ............................................................................................. 8

Bypass Component Descriptions ............................................................................. 10

Exterior and Mounting Dimensions .......................................................................... 16

Checking and Controlling Installation Site ................................................................ 19

Chapter 2 - Electrical Installation..............................................................................2-1

Termination Configuration - Power Wiring ................................................................. 2

Control Wiring ............................................................................................................. 8

Wiring Diagram ......................................................................................................... 22

Electrical Overview.................................................................................................... 24

Chapter 3 - Control Panel ..........................................................................................3-1

Digital Operator and Control Panel Display ............................................................... 2

Drive Main Menus .................................................................................................... 11

Example of Changing a Parameter .......................................................................... 22

Chapter 4 - Start Up and Operation ..........................................................................4-1

Start Up Introduction ..................................................................................................2

Bypass Unit Start Up Preparation ...............................................................................4

Bypass Unit Start Up Procedure .................................................................................5

Bypass Unit Operation Description ...........................................................................10

Chapter 5 - Programming ..........................................................................................5-1

Regarding Chapter 5................................................................................................... 2

Bypass Unit Basic Programming Parameters ............................................................ 4

Drive Parameters ......................................................................................................10

Table of Contents vii

Page 10

Chapter 6 - Diagnostics & Troubleshooting ........................................................... 6-1

E7L Bypass PCB and H/O/A Control Panel Diagnostics ........................................... 2

Drive Diagnostics .......................................................................................................6

Drive Troubleshooting .............................................................................................. 19

Drive Main Circuit Test Procedure ............................................................................ 25

Drive Date Stamp Information .................................................................................. 29

Chapter 7 - Maintenance ............................................................................................7-1

E7L Maintenance .......................................................................................................2

Removing and Replacing the Drive in a Bypass Unit .................................................7

Appendix A - Parameters.......................................................................................... A-1

Parameter List ............................................................................................................ 2

Monitor List ...............................................................................................................26

Fault Trace List ........................................................................................................28

Fault History List ......................................................................................................29

Decimal to Hex Conversion.......................................................................................30

Appendix B - Capacity Related Parameters............................................................ B-1

Drive Capacity ............................................................................................................2

Appendix C - Specifications ..................................................................................... C-1

Standard Drive and Bypass Specifications .................................................................2

Appendix D - Communication .................................................................................. D-1

E7L and Serial Communication...................................................................................2

Using Modbus Communication ..................................................................................3

Metasys N2 Point Database......................................................................................16

APOGEE FLN Point Database..................................................................................20

Appendix E - Peripheral Devices ............................................................................. E-1

Branch Circuit Short Circuit Protection........................................................................2

Branch Circuit Overload Protection............................................................................. 5

Peripheral Devices ..................................................................................................... 6

Table of Contents viii

Page 11

Appendix F - Replacement Parts ............................................................................. F-1

Primary Drive Replacement Parts - 208/230/240VAC ............................................... 2

Primary Drive Replacement Parts - 480VAC ............................................................. 3

Bypass Replacement Parts......................................................................................... 4

Index .................................................................................................................... Index-1

Table of Contents ix

Page 12

Notes:

Table of Contents x

Page 13

Chapter 1

Physical Installation

This chapter describes the checks required upon receiving

and the installation process for a Drive and Bypass unit.

Bypass Model Number and Enclosure Style .................................. 2

Enclosure Data ............................................................................... 3

Bypass Unit Enclosures ............................................................. 5

Confirmations upon Delivery .......................................................... 6

Receiving Checks ...................................................................... 6

Nameplate Information .............................................................. 6

Bypass Product Options ................................................................. 8

Bypass Component Descriptions ................................................. 10

Bypass Unit Front Control Panel ............................................. 10

Internal Bypass Panel............................................................... 12

Exterior and Mounting Dimensions .............................................. 16

Bypass Unit 30 HP and Below, 480 VAC;

15 HP and Below, 208V/240V ................................................. 16

Bypass Unit 40 HP to 60 HP, 480 VAC;

20 HP to 30 HP, 208V/240V .................................................... 17

Dimensions and Weights ......................................................... 18

Checking and Controlling Installation Site .................................... 19

Installation Site ........................................................................ 19

Controlling the Ambient Temperature ...................................... 20

Protecting the Bypass Unit from Foreign Matter ...................... 20

Installation Orientation and Enclosure Considerations ............ 20

Physical Installation 1 - 1

Page 14

Bypass Model Number and Enclosure Style

The Bypass covers two voltage ranges: 208-240 VAC and 480 VAC. Ratings applicable are from 1/2 to 60 HP.

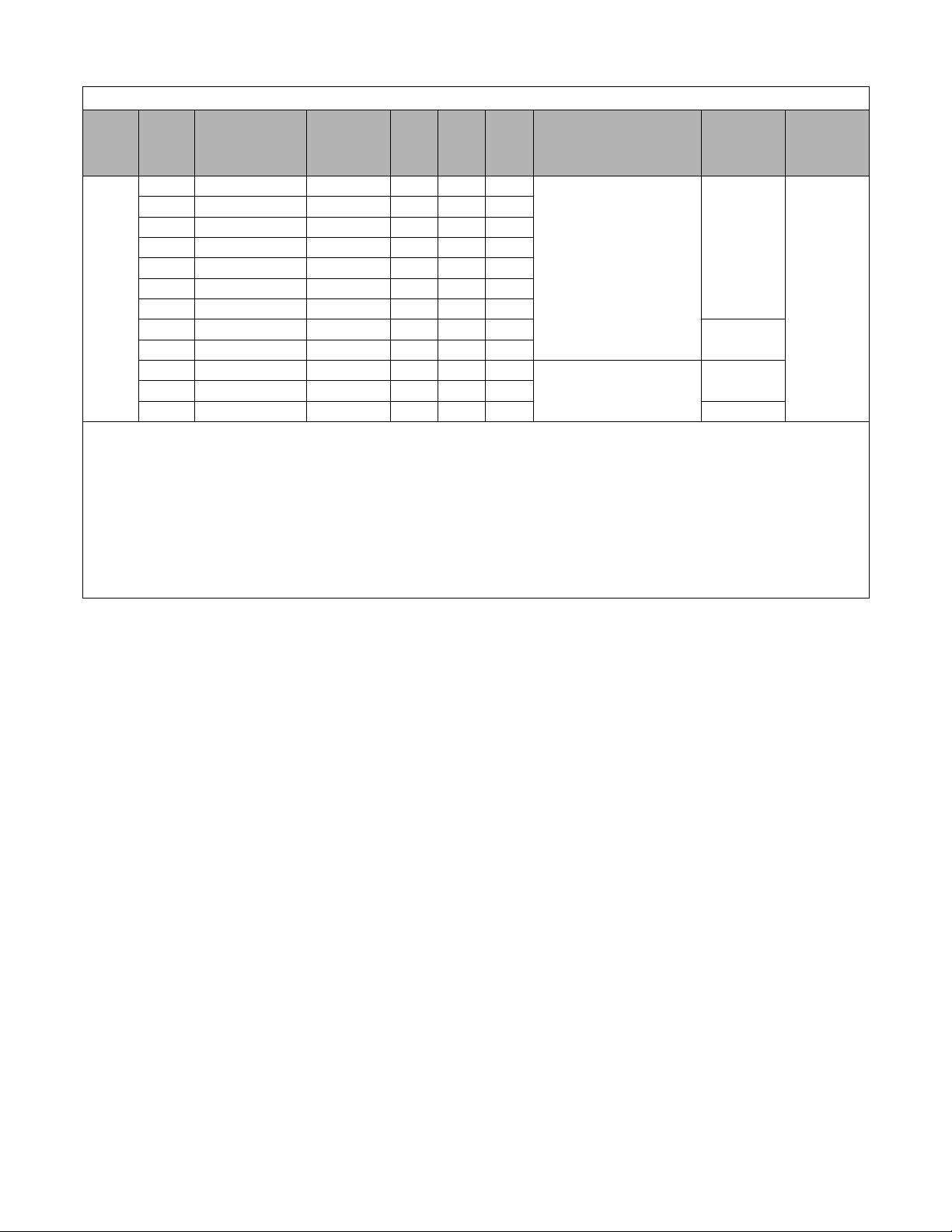

Table 1.1 Bypass

Bypass

Base Model Number

Voltage

NEMA 1

E7LVD002 E7LBD002 0.5 2.4 CIMR-E7U22P2

E7LVD003 E7LBD003 0.75 3.5 CIMR-E7U22P2

E7LVD004 E7LBD004 1 4.6 CIMR-E7U22P2

E7LVD007 E7LBD007 2 7.5 CIMR-E7U22P2

E7LVD010 E7LBD010 3 10.6 CIMR-E7U22P2

208 VAC

240 VAC

480 VAC

* The Nema 12 FVFF Enclosure is ventilated and filtered with gaskets. UL does not recognize NEMA 12

ventilated enclosures, therefore, for UL purposes, these units are designated NEMA 1.

E7LVD016 E7LBD016 5 16.7 CIMR-E7U23P7

E7LVD024 E7LBD024 7.5 24.2 CIMR-E7U27P5

E7LVD030 E7LBD030 10 30.8 CIMR-E7U27P5

E7LVD046 E7LBD046 15 46.2 CIMR-E7U2011

E7LVD059 E7LBD059 20 59.4 CIMR-E7U2015

E7LVD074 E7LBD074 25 74.8 CIMR-E7U2018

E7LVA002 E7LBA002 0.5 2.2 CIMR-E7U22P2

E7LVA003 E7LBA003 0.75 3.2 CIMR-E7U22P2

E7LVA004 E7LBA004 1 4.0 CIMR-E7U22P2

E7LVA006 E7LBA006 2 6.8 CIMR-E7U22P2

E7LVA009 E7LBA009 3 9.6 CIMR-E7U22P2

E7LVA015 E7LBA015 5 15.2 CIMR-E7U23P7

E7LVA022 E7LBA022 7.5 22 CIMR-E7U25P5

E7LVA028 E7LBA028 10 28 CIMR-E7U27P5

E7LVA042 E7LBA042 15 42 CIMR-E7U2011

E7LVA054 E7LBA054 20 54 CIMR-E7U2015

E7LVA068 E7LBA068 25 68 CIMR-E7U2018

E7LVA080 E7LBA080 30 80 CIMR-E7U2022

E7LVB001 E7LBB001 0.5 1.1 CIMR-E7U42P2

E7LVB001 E7LBB001 0.75 1.6 CIMR-E7U42P2

E7LVB002 E7LBB002 1 2.1 CIMR-E7U42P2

E7LVB003 E7LBB003 2 3.4 CIMR-E7U42P2

E7LVB004 E7LBB004 3 4.8 CIMR-E7U42P2

E7LVB007 E7LBB007 5 7.6 CIMR-E7U43P7

E7LVB011 E7LBB011 7.5 11 CIMR-E7U45P5

E7LVB014 E7LBB014 10 14 CIMR-E7U47P5

E7LVB021 E7LBB021 15 21 CIMR-E7U4009

E7LVB027 E7LBB027 20 27 CIMR-E7U4011

E7LVB034 E7LBB034 25 34 CIMR-E7U4015

E7LVB040 E7LBB040 30 40 CIMR-E7U4018

E7LVB052 E7LBB052 40 52 CIMR-E7U4024

E7LVB065 E7LBB065 50 65 CIMR-E7U4030

E7LVB077 E7LBB077 60 77 CIMR-E7U4037

*NEMA 12

FVFF

HP

Bypass

Continuous

Output

Current

(Amps)

Uses

Basic Drive

Model-Number

Physical Installation 1 - 2

Page 15

Enclosure Data

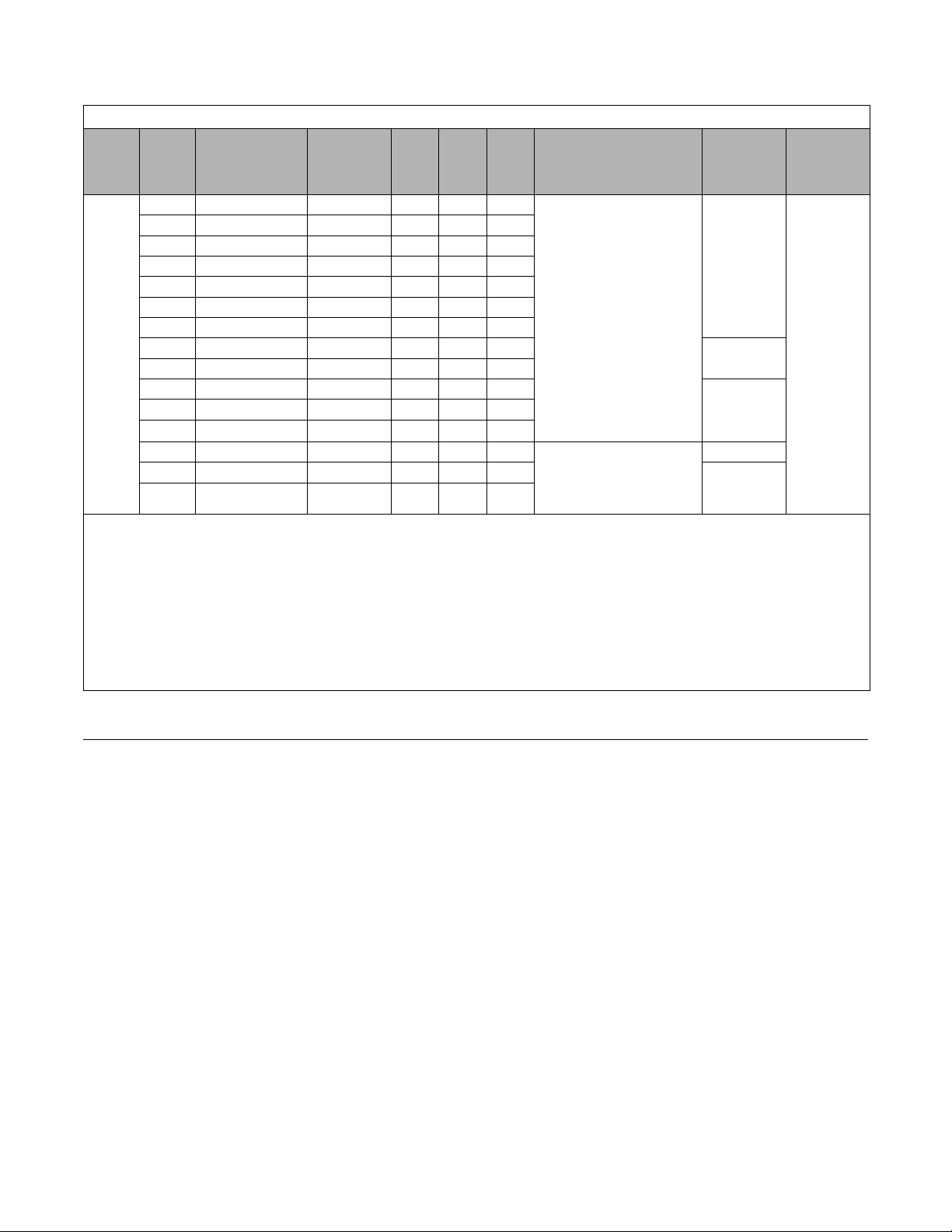

Table 1.2 208V Enclosure Data

Input

Vol ts

208

1

HP

0.5 E7U22P21 E7L_D002 2.4 2.6 68

0.75 E7U22P21 E7L_D003 3.5 3.8 68

1 E7U22P21 E7L_D004 4.6 5.1 78

2 E7U22P21 E7L_D007 7.5 8.2 110

3 E7U22P21 E7L_D010 10.6 11.7 141

5 E7U23P71 E7L_D016 16.7 18.4 202

7.5 E7U27P51 E7L_D024 24.2 26.6 273

10 E7U27P51 E7L_D030 30.8 33.9 365

15 E7U2 0111 E7L_D046 46.2 50.8 578

20 E7U20151 E7L_D059 59.4 65.3 653 40.48 25.63 14.66

25 E7U20181 E7L_D074 74.8 82.3 746

Drive

Model

CIMR-

Bypass

Model

Number

2

NEC

FLA

OL

110%

1 min

Note 1: Horsepower rating is based on a standard NEMA B 4-pole motor.

Note 2: The underscore position in these model numbers codes for the enclosure type: V = NEMA1, B = NEMA12 FVFF.

Note 3: Heat loss is the amount of heat dissipated by the drive at full load with all standard options available inside the enclosure. Drive heat sink losses are

included in the heat loss data.

Note 4: Height dimension (H) excludes the mounting screw tabs. Depth dimension (D) excludes the disconnect handle.

Note 5: This data represents the total weight with all possible standard options. Weight could be less depending on the options specified.

Note 6: All standard options are available in this size enclosure.

3

Heat

Loss

Watts

Enclosure Dimensions

NEMA 1 & NEMA 12 -FVFF

H W D

29.48 19.06 13.66

Dimension Drawing

Dimension Drawing

inches

S-5537

S-5539

4

6

6

Weight

of

Assembly

115 lbs

127 lbs

208 lbs

5

Schematic

Electrical

E7L-00

Physical Installation 1 - 3

Page 16

Table 1.3 240V Enclosure Data

Input

Volts

240

1

HP

0.5 E7U22P21 E7L_A002 2.2 2.4 68

0.75 E7U22P21 E7L_A003 3.2 3.5 68

1 E7U22P21 E7L_A004 4.0 4.4 78

2 E7U22P21 E7L_A006 6.8 7.5 110

3 E7U22P21 E7L_A009 9.6 10.6 141

5 E7U23P71 E7L_A015 15.2 16.7 202

7.5 E7U25P51 E7L_A022 22.0 24.2 273

10 E7U27P51 E7L_A028 28.0 30.8 365

15 E7U20111 E7L_A042 42.0 46.2 578

20 E7U20151 E7L_A054 54.0 59.4 653

25 E7U20181 E7L_A068 68.0 74.8 746

30 E7U20221 E7L_A080 80.0 88.0 939 221 lbs

Drive

Model

CIMR-

Bypass

Model

Number

2

NEC

FLA

OL

110 %

1 min

Note 1: Horsepower rating is based on a standard NEMA B 4-pole motor.

Note 2: The underscore position in these model numbers codes for the enclosure type: V = NEMA1, B = NEMA12 FVFF.

Note 3: Heat loss is the amount of heat dissipated by the drive at full load with all standard options available inside the enclosure. Drive heat sink losses are

included in the heat loss data.

Note 4: Height dimension (H) excludes the mounting screw tabs. Depth dimension (D) excludes the disconnect handle.

Note 5: This data represents the total weight with all possible standard options. Weight could be less depending on the options specified.

Note 6: All standard options are available in this size enclosure.

3

Heat

Loss

Watts

Enclosure Dimensions

NEMA 1 & NEMA 12 -FVFF

H W D

29.48 19.06 13.66

Dimension Drawing

40.48 25.63 14.66

Dimension Drawing

inches

S-5537

S-5539

4

6

6

Weight

of

Assembly

115 lbs

127 lbs

208 lbs

5

Electrical

Schematic

E7L-00

Physical Installation 1 - 4

Page 17

Table 1.4 480V Enclosure Data

Input

Vol ts

480

1

HP

0.5 42P21 E7L_B001 1.1 1.2 57

0.75 42P21 E7L_B001 1.6 1.8 57

1 42P21 E7L_B002 2.1 2.3 62

2 42P21 E7L_B003 3.4 3.7 89

3 42P21 E7L_B004 4.8 5.3 121

5 43P71 E7L_B007 7.6 8.4 155

7.5 45P51 E7L_B011 11.0 12.1 217

10 47P51 E7L_B014 14.0 15.4 318

15 40091 E7L_B021 21.0 23.1 404

20 40 111 E7L_B027 27.0 29.7 408

25 40151 E7L_B034 34.0 37.4 485

30 40181 E7L_B040 40.0 44.0 618

40 40241 E7L_B052 52.0 57.2 1040

50 40301 E7L_B065 65.0 71.5 1045

60 40371 E7L_B077 77.0 84.7 1197

Drive

Model

CIMR-

Bypass

Model

Number

2

NEC

FLA

OL

110%

1 min

Note 1: Horsepower rating is based on a standard NEMA B 4-pole motor.

Note 2: The underscore position in these model numbers codes for the enclosure type: V = NEMA1, B = NEMA12 FVFF.

3

Heat

Loss

Watts

Enclosure Dimensions

NEMA 1 & NEMA 12 -FVFF

H W D

29.48 19.06 13.66

Dimension Drawing

40.48 25.63 14.66

Dimension Drawing

inches

S-5537

S-5539

4

6

6

Weight

of

Assembly

115 lbs

127 lbs

142 lbs

203 lbs

232 lbs

5

Electrical

Schematic

E7L-00

Note 3: Heat loss is the amount of heat dissipated by the drive at full load with all standard options available inside the enclosure. Drive heat sink losses are

included in the heat loss data.

Note 4: Height dimension (H) excludes the mounting screw tabs. Depth dimension (D) excludes the disconnect handle.

Note 5: This data represents the total weight with all possible standard options. Weight could be less depending on the options specified.

Note 6: All standard options are available in this size enclosure.

Bypass Unit Enclosures

All Bypass units are intended for non-hazardous locations. Various enclosure types are provided to protect against the application environmental conditions:

Nema Type 1 Enclosures

These are constructed for indoor use to provide a degree of protection against incidental contact with enclosed electrical equipment and falling dust or dirt.

NEMA Type 12 FVFF Enclosures

NEMA provides for both non-ventilated and ventilated NEMA 12 enclosures. When ventilated, a suffix to the type number

defines the ventilation method. A NEMA 12 FVFF enclosure has Forced Ventilation with inlet air Filter and outlet air Filter.

The internal pressure is positive with respect to the ambient pressure. UL does not recognize NEMA 12 ventilated enclosures,

therefore, these enclosures are designated NEMA 1 for UL purposes.

Physical Installation 1 - 5

Page 18

Confirmations upon Delivery

A.C. INPUT

A.C. OUTPUT

Volts: 480

Hz: 50/60

Phase: 3

Amps: 71.6

Volts: 0-480

Hz: 0-60

Phase: 3

Amps: 65

Serial No: 4W033727440-0002

Model No,: E7LVB065R

Type: E7L BYPASS

W.D.: E7L-00

Inst. Manual: TM.E7L.01, CD.E7.01

UNPN0001

Receiving Checks

Check the following items as soon as the Drive and Bypass unit is delivered.

Table 1.5 Checks

Item Method

Has the correct model of Bypass unit been

delivered?

Is the Bypass unit damaged in any way?

Are any screws or other components loose? Use a screwdriver or the appropriate tool to check for tightness.

If you find any irregularities in the above items, contact the shipping company, the distributor or representative you purchased

the Bypass unit from or your Yaskawa office immediately.

The Bypass unit is thoroughly tested at the factory. Any damages or shortages evident when the equipment is received must be

reported immediately to the commercial carrier that transported the material. Shipping damage is not covered by the Yaskawa

warranty. After unpacking and inspecting for damage, verify that internal wire connections have not come loose during

shipment by spot checking wire terminations with a screwdriver or the appropriate tool.

Check the model number on the nameplate on the right side of the Bypass unit.

Reconcile with packing slip and/or order information.

Inspect the entire exterior of the Bypass unit to see if there are any dents,

scratches or other damage resulting from shipping.

Bypass unit storage must be in a clean and dry location. Maintain the factory packaging and provide covering as needed to

protect the Bypass unit from construction site dirt, water, debris and traffic prior to and during construction.

Nameplate Information

A nameplate is attached to the right side of the enclosure and the inside of the door of each Bypass unit.

The nameplate shown below is an example for a standard Bypass unit.

Fig 1.1 Bypass Nameplate

(Example)

Physical Installation 1 - 6

Page 19

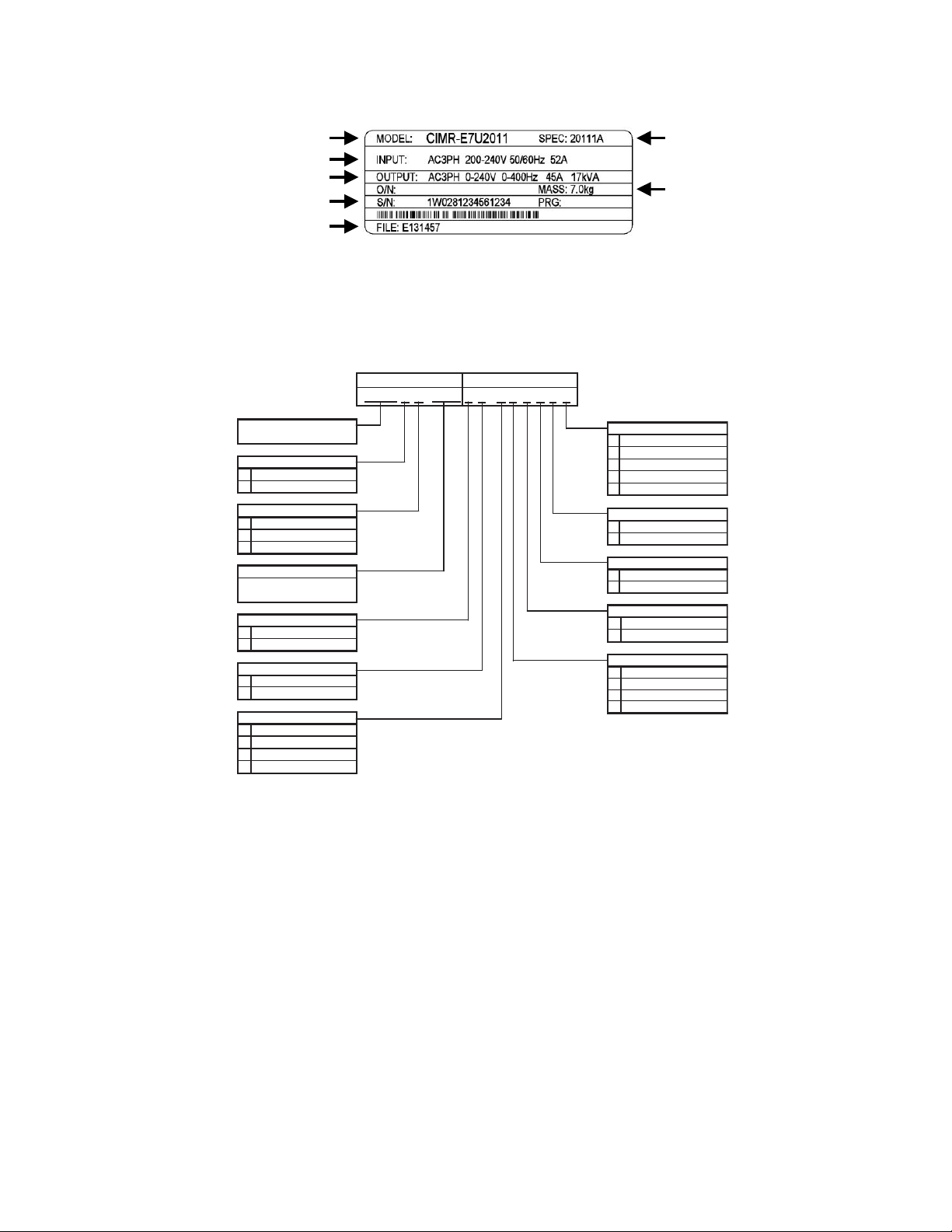

Drive Nameplate Information

Input Power Specifications

Output Power Specifications

Drive Model Number

Drive Enclosure and

Weight

Serial Number

UL File Number

V

B 0 0 GX 0 0 Y L

0

L

V

J

B

0

D

Y

A

B

0

P

0

C

0

0

W

N

0

F

G

H

0

X

Z

R

Enable Metasys N2

3-15 PSI Transducer

Rated Amps (001 - 080)

Current

Voltage

208V

230/240V

480V

E7L 2-Contactor Bypass

Configuration

E 7 L 0 2 1

Enclosure

NEMA 1

NEMA 12

MCP Circuit Breaker

Main Input Disconnect

(Ex.: "021" = 21A)

Disconnect Switch

Drive Keypad

LED Style Keypad

LCD Style Keypad

Drive Input Circuit

3% Bus Re actor

(1)

5% Bus Re actor

(1)

3% Input Reactor

(2)

None

Custom Nameplates

None

None

BASE NUMBER OPTIONS

None

Communications

Not Enabled

LonWorks

3-15 PSI Tr ansducer

Fu

Disconnect Switch

Fuses & Disc. Switch

ses

Custom Nameplates

Input Filter

None

Cap Filter

Impedance

U

V

Enable Modbus

Enable Siemens APOGEE

(1) 3% and 5% Bus Reactors are only available as an option on base numbers up to E7LVA068

and E7LVB040; larger drives have a Bus Reactor as standard

(2) 3% Input Reactor, when combined with the standard Bus Reactor (available on base numbers

E7LVA080 and E7LVB052 and above), yields a total of 5% input impedance

A nameplate is also attached to the right side of the Drive inside the Bypass enclosure. The following nameplate is an example

for a standard Drive.

Revision Code

Fig 1.2 Drive Nameplate

(Example)

Bypass Unit Model Numbers

The model number on the nameplate of the Bypass unit indicates the enclosure, voltage, Drive rated current and options of the

Bypass unit in alphanumeric codes.

Fig 1.3 Bypass Unit Model Number

Physical Installation 1 - 7

Page 20

Bypass Product Options

Option C

Motor Circuit Protector (MCP)/Disconnect: Replaces the standard input disconnect switch and provides short circuit protection

integral with the Drive and Bypass package. The MCP includes a through the door, padlockable operator mechanism. Without

this option, short circuit protection must be provided by others on the input side of the Drive and Bypass unit.

Option F

Drive Input Fuses: Fuses capable of protecting semiconductor devices, rated at 200 kAIC are connected to the line side of the

Drive, between the input disconnect and the Drive, to protect the Drive semiconductors when motor or output conductor short

circuit faults occur.

Option G

Drive Input Disconnect Switch: Provides a disconnect means for the input side of the Drive, for Drive isolation capability

during Bypass operation. This disconnect is located inside the enclosure with no external handle.

Option H

Drive Input Fused Disconnect Switch: Provides both a disconnect means and short circuit protection for the input side of the

Drive. A combination of options F and G.

Option J

Enable Embedded Serial Communications: A no cost option. The Drive in a Bypass unit is capable of network communication

via one of 3 embedded protocols. Specifying option J will enable the Metasys N2 protocol and will provide the necessary

parameter settings and wiring (jumpers) to be network ready when delivered (Project specific H5-0X parameters are setup by

the user).

Option L

Serial Communication, Echelon LonWorks: An isolated RS-422/485 circuit board provides LonTalk protocol for network

communication to a BAS. This option plugs into the CN2 connection on the Drive control circuit board.

Option N

Input Capacitive Network Radio Frequency Interference Filter: Electronic equipment can be sensitive to low levels of voltage

distortion and electrical noise. This passive wye-delta capacitve filter is intended for installation on the VFD input in order to

protect other sensitive electronic loads, it provides attenuation of conducted RFI and EMI.

Option P

Pressure to Electrical Transducer: This transducer is employed when converting a pneumatic signal to an electrical signal for

use as the Drive speed command input. The need for this option comes up on retrofit applications when the pneumatic signal

that formerly controlled the pneumatic actuator on Inlet Guide Vanes (IGV), for example, is now to be used to control the fan

speed via the Drive. This option is wired to terminals TB5-7, TB5-8 and TB5-9, parameters H3-10 and H3-11 are used for

final field calibration of this input if there is jobsite variation from the typical 3 to 15 PSIG pneumatic signal input range.

Option R

3% Input Line Reactor: Employed on the input side of the Drive for Total Harmonic Distortion (THD) suppression. A line

reactor also minimizes the potential for Drive input diode damage from line transients and reduces voltage peaks on the DC

bus capacitors. This option is installed on the input power side of the Drive, between the input contactor and the Drive.

Physical Installation 1 - 8

Page 21

Option U

Enable Embedded Serial Communications: A no cost option. The Drive in a Bypass unit is capable of network communications

via one of 3 embedded protocols. Specifying option U will enable the Siemens APOGEE protocol and provide the necessary

parameter settings and wiring (jumpers) to be network ready when delivered (Project specific H5-0X parameters are setup by

the user).

Option V

Enable Embedded Serial Communications: A no cost option. The Drive in a Bypass unit is capable of network communications

via one of 3 embedded protocols. Specifying option U will enable the Modbus protocol and provide the necessary parameter

settings and wiring (jumpers) to be network ready when delivered (Project specific H5-0X parameters are setup by the user).

Option W

Engraved Plastic Nameplate: An enclosure identification nameplate to carry the controlled equipment “tag number”.

Option X

3% DC Bus Reactor: Attenuates harmonic distortion by limiting the rate of rise of the input current. The bus reactor is wired

to the Drive (+1) and (+2) DC bus terminals to provide the equivalent impedance of a 3% input reactor. This option is only

used on the low end of the horsepower range where DC bus reactors are not a standard Drive component (25 HP and below @

208 VAC, 25 HP and below @ 240 VAC, and 30 HP and below @ 480 VAC.)

Option Y

LCD Keypad: Offers 5 lines of display with 16 characters on each line for expanded data presentation capability in English (or

other language) format.

Option Z

5% DC Bus Reactor: Attenuates harmonic distortion by limiting the rate of rise of the input current. The bus reactor is wired

to the Drive (+1) and (+2) DC bus terminals to provide the equivalent impedance of a 5% input reactor. This option is only

used on the low end of the horsepower range where DC bus reactors are not a standard Drive component (25 HP and below @

208 VAC, 25 HP and below @ 240 VAC, and 30 HP and below @ 480 VAC.)

Physical Installation 1 - 9

Page 22

Bypass Component Descriptions

Drive

Disconnect

Indicating LEDs

H/O/A Keypad

Switch

Keypad

Operator

Drive

Operational

Status

Alpha-Numeric

Menu

Indicating

LEDs

LED Display

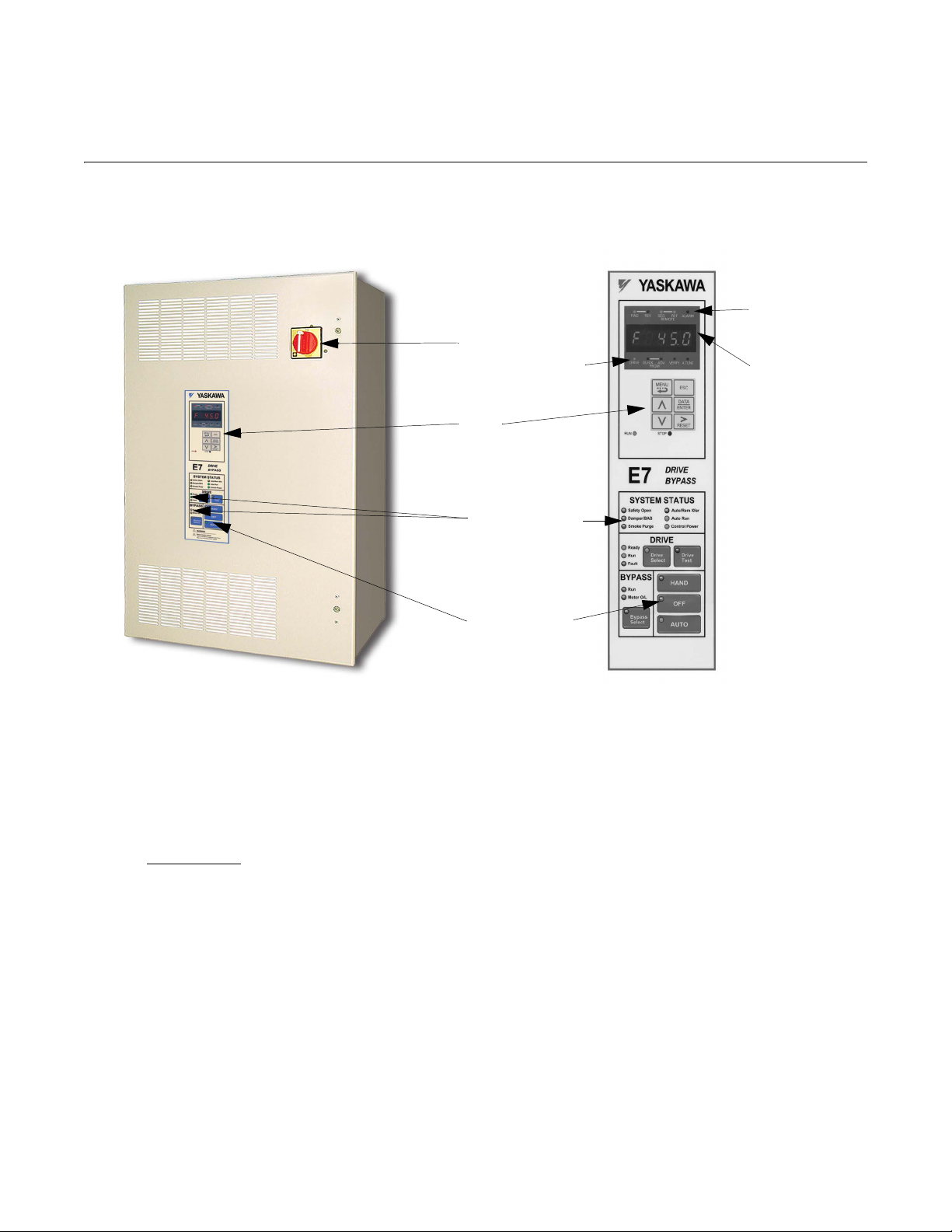

Bypass Unit Front Control Panel

The external appearance, component names, and terminal arrangement of the Bypass unit is shown in Figures 1.4 through 1.8.

Fig 1.4 E7L Bypass Unit Appearance & E7L Control Panel with Keypad Operator Controls

Keypad Control Panel Operator

In a Bypass unit the Drive keypad control panel operator is mounted flush with the hinged door of the enclosure. The Keypad

Control/Operator is equipped with 6 LED illuminated selector keys: Hand, Off, Auto, Drive Select, Bypass Select and Drive

Test. The E7L also features 11 other status LED indicators: Control Power, Drive Ready, Drive Run, Drive Fault, Bypass Run,

Motor O/L, Safety Open, Damper/BAS Interlock, Smoke Purge, Auto Transfer and Auto Run. The membrane over the Drive

keypad is

keypad, part number CDR001115).

The Keypad Control/Operator has a digital alpha/numeric display and keypad, in the upper portion, for Drive operation and

programming. The row of LEDs above the alpha/numeric display indicate Drive operational status. The row of LEDs below

the alpha/numeric display indicate the Drive menu that is presently active.

The lower portion of the Keypad Control/Operator displays the operating mode status via LEDs and controls the HAND/OFF/

AUTO functions for both the Drive and Bypass via a touchpad. The general rule for LED colors, in the lower portion of the

control panel, is:

non-removable on these Bypass units (In order to use the keypad copy function on a Bypass unit - order a separate

Green = Normal Status

Amber = Abnormal Status

Red = Fault Status

Physical Installation 1 - 10

Page 23

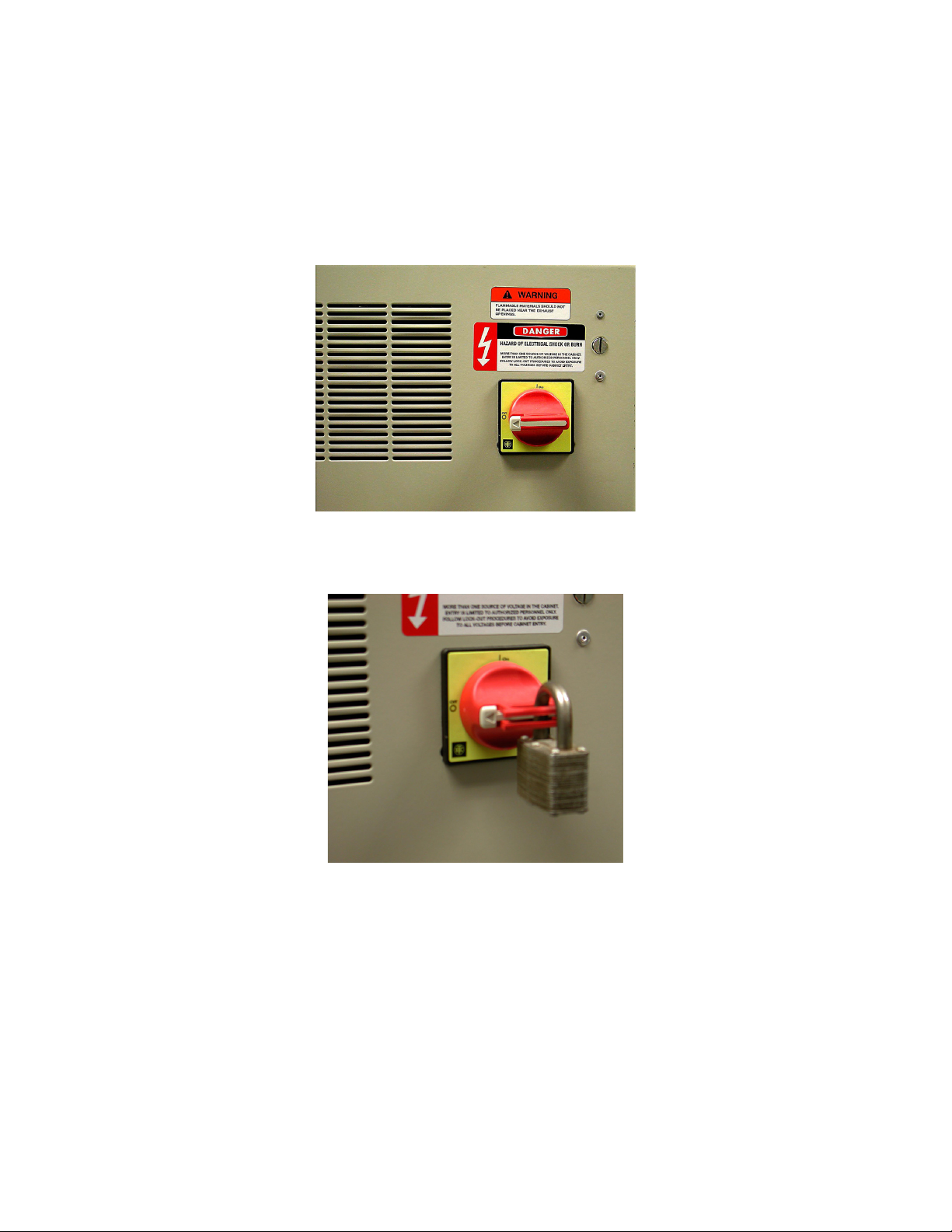

Input Disconnect Switch

Electrically located on the input power side of the Bypass unit, the disconnect provides a through the door padlockable operator

mechanism. The Bypass three phase input power connection is made to the input terminals of the disconnect. The door mounted

rotary operating mechanism is a convenient means of disconnecting the Bypass unit from line power for equipment maintenance.

The disconnect must be in the OFF position in order to open the enclosure door. The rotary handle can be padlocked in the OFF

position.

This disconnect switch DOES NOT provide branch short circuit protection. A device to provide branch short circuit protection

MUST be provided by others upstream of the E7L Bypass unit.

Fig 1.5 Disconnect Handle Positions – OFF, ON Shown in the “OFF” position

Fig 1.6 Disconnect Handle Positions – Shown OFF, With Padlock

Physical Installation 1 - 11

Page 24

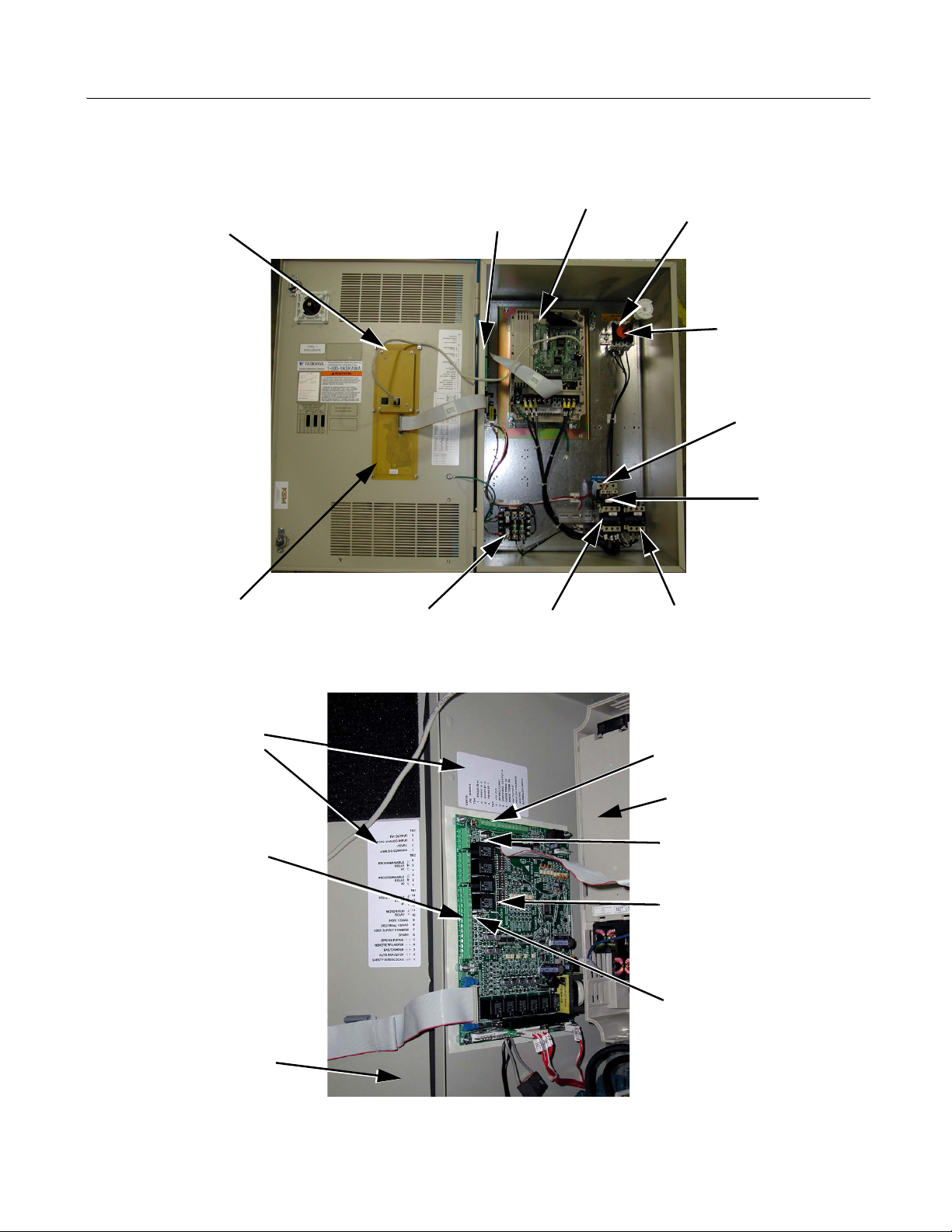

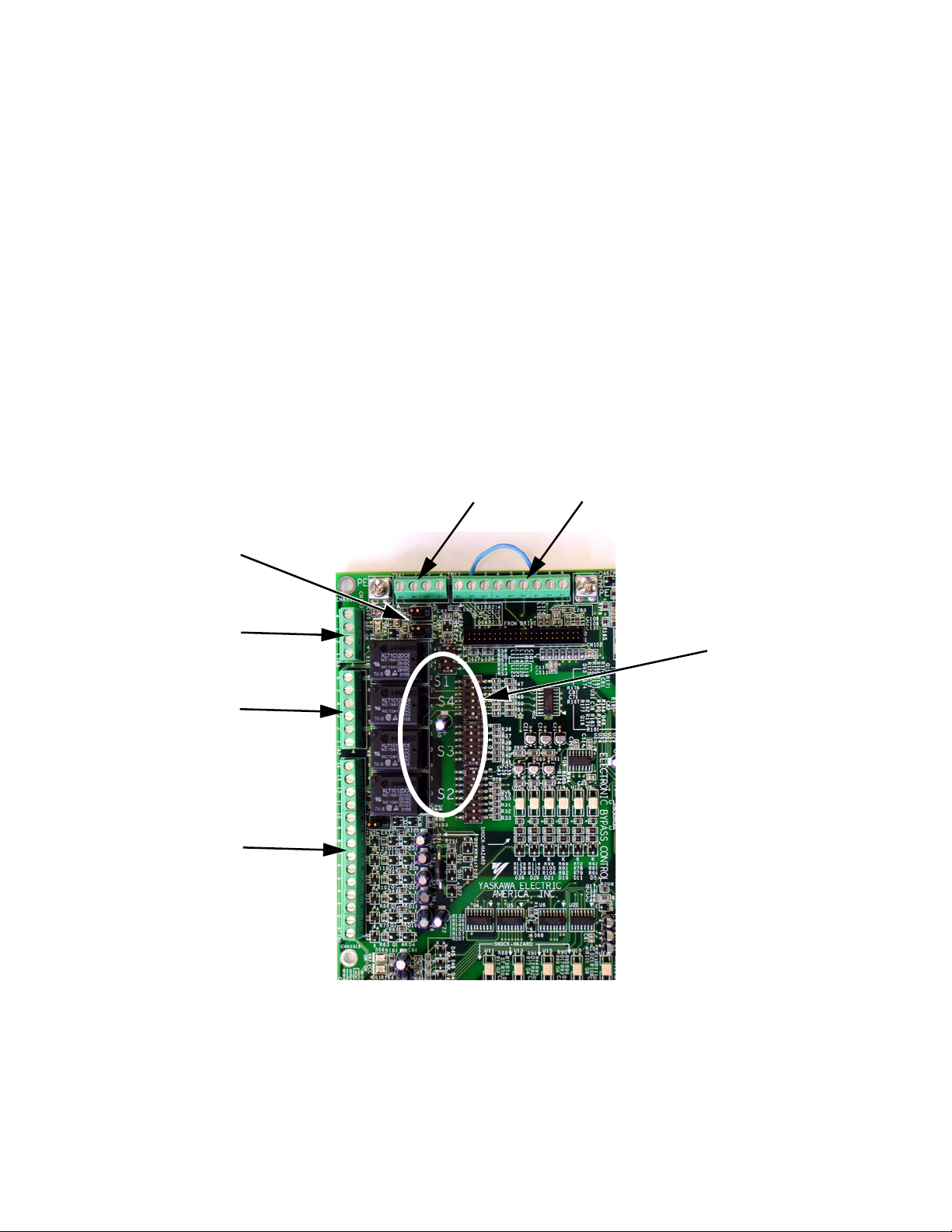

Internal Bypass Panel

Drive Digital

Keypad

PCB A3

Control Wiring

Terminal Strips

TB1 through TB5

Control Power

Transformer

Fig 1.7 Internal Bypass Panel

Bypass

Contactor

Drive

Line

Connections

Input

Disconnect

Load

Connections

Overload

Relay

Output

Contactor

Label Defining

Customer Control

Circuit Connection

Points

TB1, TB2 and TB3

Hinged Enclosure

Door

TB4, TB5 and Terminal PE

Drive

Jumpers J2 and J3,

Analog Output Signal Level

DIP Switches S1, S2, S3

and S4 for Field

Configuration of

Drive/Bypass Operation

Jumper J1, Digital Input

Voltage Source Selection

Fig 1.8 PCB A2 Control Logic and Connections

Physical Installation 1 - 12

Page 25

Contactors

The Bypass is a “2 contactor Bypass” circuit employing IEC rated contactors in an electrically interlocked arrangement to

allow mutually exclusive operation in Drive or Bypass modes. To minimize enclosure space requirements, they are mounted in

a 2 contactor assembly.

The control logic and “soft start” characteristic of the Drive limit the Drive input and output contactors to motor FLA current or

less. For this reason, the Drive output contactor has a lower current rating than the Bypass contactor. The Bypass contactor is

exposed to motor inrush current (LRA) when starting the motor across-the-line and therefore requires a higher current rating.

OverLoad Relay

The OverLoad Relay (OLR) is mounted to the contactor assembly or back panel (depending on rating), just above the Bypass

contactor (see Figure 1.7). Electrically on the output power side of the Bypass unit, the adjustable thermal OLR provides

overload protection for the motor in both the Drive and Bypass operating modes. The Bypass three phase output power

connection to the motor is made to the output terminals of the overload relay. The OLR is set up in the factory to be a manual

reset device, requiring operator attention if an overload trip-out is experienced.

Control Power Transformer

A Control Power Transformer (CPT) is provided to power the Bypass 120 VAC control circuit. The VA capacity is determined

by the control circuit and optional functions specified for the unit. The CPT primary is fused in both legs, the secondary is

fused when required by NEC (transformer VA and wire size dependent). One side of the transformer secondary is grounded to

the Bypass enclosure.

Electronic Bypass Control Logic

Operating elements such as indicating LEDs and selector buttons, as well as the control logic, have been incorporated into a

PCB assembly to eliminate the potential for loose wires after shipment and to control factory costs.

The operating elements are located on PCB A3, mounted to the inside of the enclosure door and ribbon cable connected to the

control logic PCB A2.

The control logic PCB A2 is mounted to the left hand side of the enclosure and contains the control circuit field wiring terminal strips (TB1 through TB5).

Drive/Bypass logic interlocks explained

The Bypass 120 VAC logic circuit is interconnected with the Drive multi-function digital input terminals and multifunction digital output terminals to allow a single customer interface to control both Drive and Bypass circuits. These Drive

terminals are therefore not available for other field use. All field control connections are landed at terminal strips TB1 through

TB5 on control logic PCB A2.

PCB Jumpers explained

J1 is a field configuration jumper to allow the user to select the internal 120 VAC power supply, a customer supplied 120 VAC

power supply or a customer supplied 24 VDC power supply for the digital inputs.

J2 and J3 are field configuration jumpers to allow the user to select the signal level (0 to 10 VDC or 4 to 20 mA) for the two

analog output signals.

Physical Installation 1 - 13

Page 26

DIP Switch Selectable Functions:

The DIP switches used to select these functions are located on the logic controller Printed Circuit Board (PCB) A2 (See Figure

1.9). The factory default is shown on the wiring diagram in Chapter 2 or Schematic diagram E7L-00.

DIP switches S1, S2, S3 and S4 allow the user to configure various project specific functions of the E7L including:

• Serial Communication terminating resistor

• Speed command source

• Analog input signal level

• Activate or inactivate functions:

Auto transfer to Bypass on Drive Fault

Safety interlock circuit

BAS interlock circuit

• Power-up mode selection

• Function of 3 SPDT programmable output relays:

Annunciate Running in Bypass mode

Damper actuator energized - employed to energize damper actuator

Annunciate Auto-Transfer to Bypass

Annunciate Running in Drive mode

Annunciate Run command received from serial comm

Annunciate Hand mode

Annunciate Auto mode

Annunciate Drive, motor or control fault

TB4

TB5

J2 and J3

TB3

TB2

TB1

DIP Switch

Location on

PCB A2

Fig 1.9 Printed Circuit Board A2, DIP Switches for Drive/Bypass Operational Configuration

Physical Installation 1 - 14

Page 27

DIP Switches are “ON” when moved toward the enclosure door.

4

3

2

1

Fig 1.10 DIP Switches S1 to S4 for Drive/Bypass Operational Configuration

DIP Switch S1 example

Physical Installation 1 - 15

Page 28

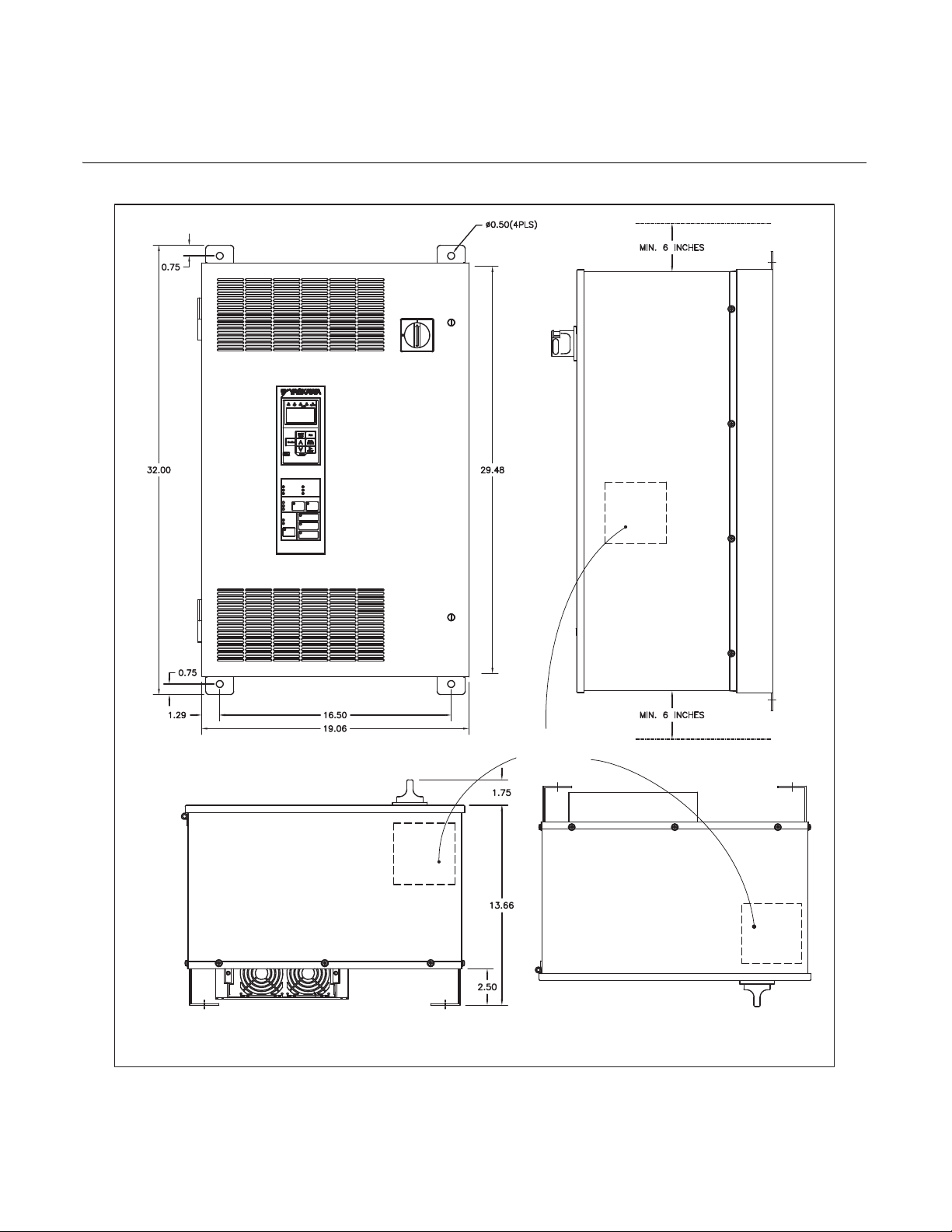

Exterior and Mounting Dimensions

RECOMMENDED

CONDUIT

ENTRANCE AREA

TOP, BOTTOM

AND SIDE

DIMENSIONS IN INCHES (MM), FOR REFERENCE ONLY

TOP VIEW

Bypass Unit 30 HP and Below, 480 VAC; 15 HP and Below, 208V/240V

Fig 1.11 Enclosure 1 for up to 30HP, 480 VAC

NEMA 1 and NEMA 12 FVFF Enclosures

Physical Installation 1 - 16

Page 29

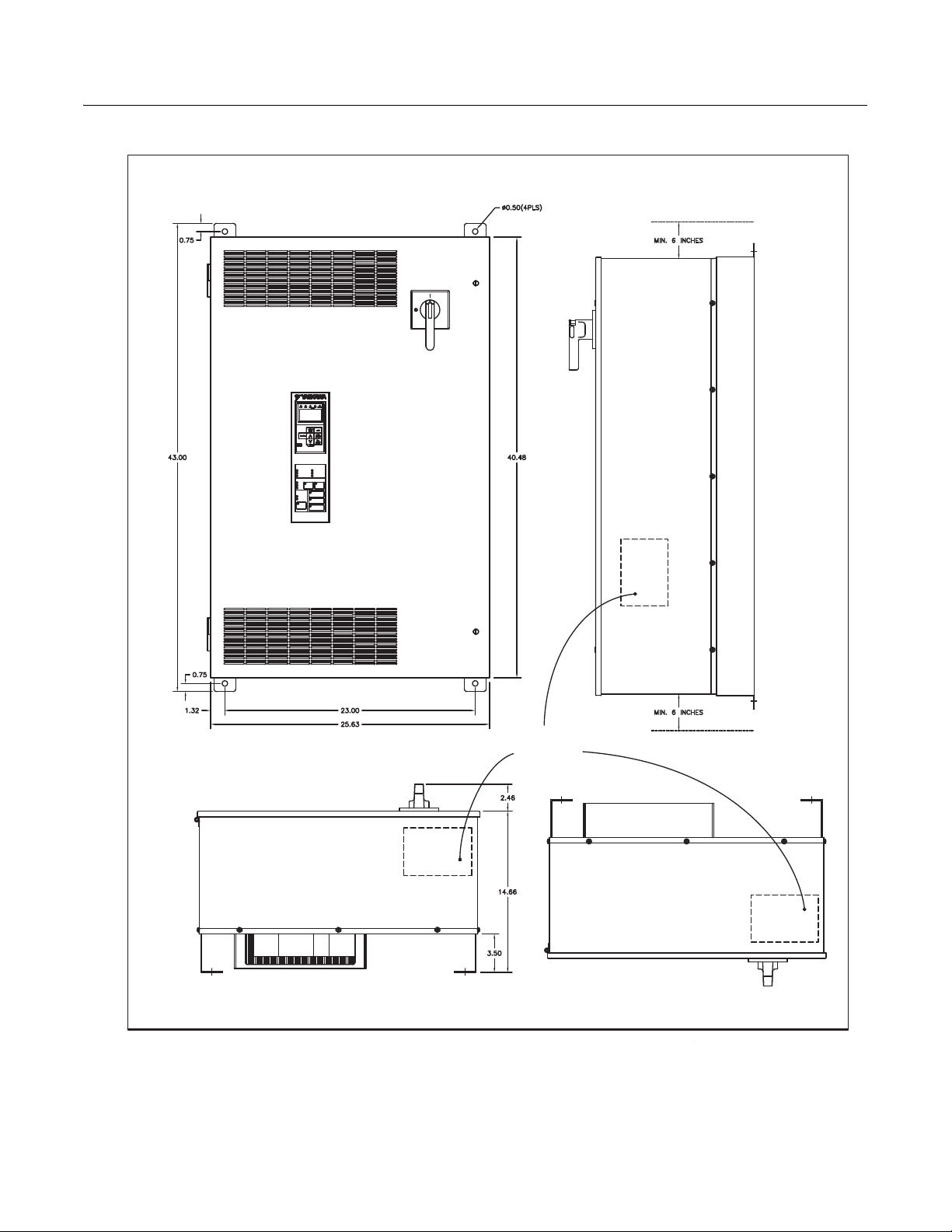

Bypass Unit 40 HP to 60 HP, 480 VAC; 20 HP to 30 HP, 208V/240V

DIMENSIONS IN INCHES (MM), FOR REFERENCE ONLY

RECOMMENDED

CONDUIT

ENTRANCE AREA

TOP, BOTTOM

AND SIDE

TOP VIEW

Fig 1.12 Enclosure 2, for 40HP to 60HP, 480 VAC

NEMA 1 and NEMA 12 FVFF Enclosures

Physical Installation 1 - 17

Page 30

Dimensions and Weights

Rated

Input

Voltage

208V

240V

480V

Continuous

Output

Current

(Amps)

2.4 1/2 D002

3.5 3/4 D003

4.6 1 D004

7.5 2 D007

10.6 3 D010

16.7 5 D016

24.2 7.5 D024

30.8 10 D030

46.2 15 D046

59.4 20 D059

74.8 25 D074

2.2 1/2 A002

3.2 3/4 A003

4.0 1 A004

6.8 2 A006

9.6 3 A009

15.2 5 A015

22 7.5 A022

28 10 A028

42 15 A042

54 20 A054

68 25 A068

80 30 A080 221

1.1 1/2 B001

1.6 3/4

2.1 1 B002

3.4 2 B003

4.8 3 B004

7.6 5 B007

11 7.5 B011

14 10 B014

21 15 B021

27 20 B027

40 30 B040

52 40 B052

65 50 B065

77 60 B077

Nominal

(1)

HP

Bypass

_ _ _

Table 1.6 Bypass Dimensions and Weights

NEMA 1 and NEMA 12

_

Dimensions inches (mm)

(2)

Height

32.00

(812.8)

43.00

(1092.2)

32.00

(812.8)

43.00

(1092.2)

32.00

(812.8)

43.00

(1092.2)

Width Depth

19.06

(484.1)

25.63

(651.0)

19.06

(484.1)

25.63

(651.0)

19.06

(484.1)

25.63

(651.0)

16.03

(407.2)

17.03

(432.6)

16.03

(407.2)

17.03

(432.6)

16.03

(407.2)

17.03

(432.6)

Mounting Dimen

Wall

sions

H x W

30.5 x 16.5

(774.7) x (419.1)

41.5 x 23.0

(1054.1 x 584.2)

30.5 x 16.5

(774.7) x (419.1)

41.5 x 23.0

(1054.1 x 584.2)

30.5 x 16.5

(774.7) x (419.1)

41.5 x 23.0

(1054.1 x 584.2)

-

Drawing

Number

S-5537

S-5539 208

S-5537

S-5539

S-5537

S-5539

Weight

(3)

(lbs)

115

127

115

127

208

115

127

14234 25 B034

203

232

(1) Horsepower rating is based on standard NEMA B 4-pole motor design

(2) Height dimension includes the mounting screw tabs.

(3) Data represents the total weight of the drive with all possible standard options, not shipping weight.

Physical Installation 1 - 18

Page 31

Checking and Controlling Installation Site

Install the Bypass unit as described below and maintain the specified operating conditions.

Installation Site

Location of the Bypass unit is important to achieving proper performance and design operating life. Install the Bypass unit as

close as possible to the motor. The NEMA type 1 & 12 enclosed units should be installed in an area where it will be protected

from: Direct sunlight, rain or moisture, corrosive gasses or liquids, vibration and dust or metallic particles. The ambient air

available for cooling the unit should be 104° F (40° C) or less.

Wall mount units require a minimum 6 inch clearance above and below, to achieve adequate heat sink cooling.

No side clearance is required for cooling because the cooling air flow is in and out of the enclosure door at the front surface of

the unit (do not block the air flow louvers). Clearance for the opening swing of the enclosure door should be considered when

placing these units. The door is hinged on the left and must open through at least a 90 degree swing with a 120 to 180 degree

swing being preferable (minimum clearance is 1.5”).

Install the Bypass unit under the following conditions in UL pollution degree 1 & 2 environments. This excludes wet locations

where surfaces may become conductive due to moisture and contaminant loading.

Table 1.7 Installation Site

Type Ambient Operating Temperature Humidity Plenum Rated

NEMA Type 1 & 12 14 to 104°F (-10-to-+ 40°C) 95%-RH-or-less-(no-condensation) Ye s

Observe the following precautions when mounting the Bypass unit.

• Install the Bypass unit in a clean location that is free from oil mist and dust.

• Install the Bypass unit in an environment where metal shavings, oil, water, or other foreign matter will not get into the

Bypass enclosure.

• Install the Bypass unit in a location free from radioactive materials.

• Install the Bypass unit in a location free from harmful gasses and liquids.

• Install the Bypass unit in a location without excessive vibration.

• Install the Bypass unit in a location free from chlorides.

• Install the Bypass unit in a location not in direct sunlight.

• Install the Bypass unit on a non-combustible surface.

Physical Installation 1 - 19

Page 32

Controlling the Ambient Temperature

To enhance the reliability of operation, the Bypass unit should be installed in an environment free from extreme temperature

variations. Do not store this Technical Manual or any other documents on the top surface of the Bypass unit, they may cover

the heat sink cooling air discharge opening and cause the unit to overheat.

If the Bypass unit is installed in an enclosure (such as an electrical control box in an air handling unit), use a cooling fan or air

conditioner to maintain the Bypass unit internal air temperature below 113°F (45°C).

Protecting the Bypass Unit from Foreign Matter

During Bypass unit installation and project construction, it is possible to have foreign matter, such as metal shavings or wire

clippings, fall inside the Bypass unit. To prevent foreign matter from falling into the Bypass unit, place a temporary cover over

the unit.

Always remove the temporary cover from the Bypass unit before start-up. Otherwise, ventilation will be reduced, causing the

Bypass unit to overheat.

Installation Orientation and Enclosure Considerations

Install the Bypass unit vertically so as not to reduce the cooling efficiency. When installing the Bypass unit, always provide the

recommended installation clearances to allow normal heat dissipation.

When preparing to mount the unit, lift it by the base (or lifting rings when provided), never by the enclosure door. For effective

cooling and proper maintenance, the wall mounted units must be installed on a flat non-flammable vertical surface using four

mounting screws.

For all units, the Disconnect handle should be in the OFF position to open the enclosure door. The wall mount units have two

full turn fasteners, CCW to open, that require a flat blade screwdriver to open the enclosure door.

Physical Installation 1 - 20

Page 33

Chapter 2

Electrical Installation

This chapter describes wiring and the electrical installation process for a Drive and

Bypass unit.

Termination Configuration - Power Wiring ..................................... 2

Field Wiring, Pressure Wire Connector, Wire Type, Range

and Tightnening Torque Specifications ..................................... 3

Cable Length between Drive and Motor .................................... 4

Grounding ................................................................................. 5

Wire Routing ............................................................................. 6

E7 Drive Main Circuit Configurations 208-240 VAC .................. 7

E7 Drive Main Circuit Configurations 480 VAC ......................... 7

Control Wiring ................................................................................ 8

Bypass Field Control Wire Landing ........................................... 8

Annunciation Contacts .............................................................. 9

Building Automation System Run/Stop Circuit: ....................... 10

Safety Interlock Circuit: ........................................................... 10

Building Automation System Interlock Circuit

(Drive and Bypass enable input): ............................................ 10

Analog Inputs .......................................................................... 11

Analog Outputs ........................................................................ 13

Serial Communications ............................................................ 14

Remote Transfer to Bypass...................................................... 16

Smoke Purge Operation........................................................... 16

Multi-Function Digital Inputs..................................................... 16

DIP Switch Programmable Functions Summary...................... 17

Bypass Controller PCB ........................................................... 18

Wiring Checks ......................................................................... 19

Control Circuit Wiring Precautions .......................................... 19

Bypass Control Circuit Terminal Functions ............................. 20

Wiring Diagram ............................................................................ 23

Electrical Overview ....................................................................... 25

Electrical Installation 2 - 1

Page 34

Termination Configuration - Power Wiring

Overload

Relay

The input disconnect switch is located in the upper right hand side of the Bypass unit. The three phase input power

connection is made to the input terminals of the disconnect. See Figure 2.1 for a representative example.

Ground Lug

Drive

Fig 2.1 Typical Input Power Connection

The OverLoad Relay (OLR) is mounted to the contactor assembly or back panel (depending on rating), just above the bypass

contactor. The Bypass three phase output power connection to the motor is made to the output terminals of the OverLoad

Relay. See Figure 2.3 for representative examples.

Input Power Terminals

Input Disconnect

Switch

Disconnect Switch

“Through the Door”

Handle

Overload Relay

Motor Connections

Bypass

Contactor

Output Contactor

Fig 2.3 Typical Output Power Connection

Electrical Installation 2 - 2

Motor Connections

Bypass

Contactor

Output Contactor

Page 35

Field Wiring, Pressure Wire Connector, Wire Type, Range and Tightnening

208V 480V

MFG.

PART

NUMBER

WIRE SIZE

RANGE

(AWG)

MFG.

PART

NUMBER

WIRE SIZE

RANGE

(AWG)

208V

TIGHTENING

TORQUE

(LB.-IN.)

240V

480V240V

D002

D003

D004

D007

D010

D016

D024

D030

D046

D059

D074

A002

A003

A004

A006

A009

A015

A022

A028

A042

A054

A068

A080

B001

B002

B003

B004

B007

B011

B014

B021

B027

B034

B040

B052

B065

B077

FAL36003

FAL36007

FAL36030

FAL36015

FAL36050

FAL36100

KAL36150

14 - 4

12 - 4

12 - 1/0

4 - 350 kcmil

35

35

80

250

TIGHTENING

TORQUE

(LB.-IN.)

D002

D003

D004

D007

D010

D016

D024

D030

D046

D059

D074

A002

A003

A004

A006

A009

A015

A022

A028

A042

A054

A068

A080

B001

B002

B003

B004

B007

B011

B014

B021

B027

B034

B040

B052

B065

B077

LR2 D13

LR2 D15

LR2 D25

LR2 D35

18 - 10

18 - 10

14 - 6

10 - 1/0

15

CURRENT

RATING

(AMPS)

3

7

15

30

50

100

150

=

=

V (NEMA 1) OR B (NEMA 12)

V (NEMA 1) OR B (NEMA 12)WHERE

WHERE

100

E7 BYPASS MODEL NO.

BASE NUMBER

E7L XXXX

E7 BYPASS MODEL NO.

BASE NUMBER

E7L XXXX

35

12 - 4

30FAL36030

80

12 - 1/0

50FAL36050

80

12 - 1/0

100FAL36100

FAL36100 100

12 - 1/0

80

MFG.

PART

NUMBER

V0

V3

V4

V5

V6

CURRENT

RATING

(AMPS)

WIRE SIZE

RANGE

(AWG)

TIGHTENING

TORQUE

(LB.-IN.)

20

45

63

100

115

14 - 8 19

8 - 2/0 200

40

6 - 2 50

12 - 6

STANDARD INPUT DISCONNECT SWITCHOPTIONAL MOTOR CIRCUIT PROTECTOR - OPTION C

WIRE SIZE

RANGE

(AWG)

TIGHTENING

TORQUE

(LB.-IN.)

V4 63

6 - 2 50

V6 115

8 - 2/0 200

14 - 10 35

8

6 - 4 45

GROUND LUG

12 - 1/0

80

CUSTOMER CONTROL WIRING

TERMINAL BLOCKS TB1 - TB5

WIRE SIZE

RANGE

(AWG)

TIGHTENING

TORQUE

(LB.-IN.)

4.422 - 14

MOTOR OVERLOAD RELAY

EARTH GND. WIRINGCUSTOMER A.C. LINE WIRING

CUSTOMER A.C. MOTOR WIRING

FOR 0 TO 100 AMPS, USE 60-75 C COPPER WIRE, AND ABOVE 100 AMPS, USE 75 C COPPER WIRE.

40

Torque Specifications

IMPORTANT

WARNING

Determine the wire size for the main circuit so that line voltage drop is within 2% of the rated voltage. Line

voltage drop is calculated as follows:

Line voltage drop(V) = √3 x wire resistance (Ω/km) x wire length (m) x current (A) x 10

Prior to removing any protective cover or wiring any part of the Drive, remove all power sources, including

main input power and control circuit power. Wait a minimum of 5 minutes after power removal, before

removing any cover. The charge lamp located within the Drive should be off prior to working inside. Even if

the charge lamp is off, one must measure the AC input, output, and DC Bus potential to insure safe levels

prior to resuming work. Failure to adhere to this warning may result in personal injury or death.

Electrical Installation 2 - 3

-3

Page 36

Cable Length between Drive and Motor

The Bypass unit should be installed as close as possible to the motor to minimize the length of load side power cable needed

between the Drive and the motor. If the cable between the Drive and the motor is long, the high-frequency leakage current will

increase, causing the Drive output current to increase as well. This may affect peripheral devices. To prevent this, reduce cable

length, or if necessary, adjust the carrier frequency (set in C6-02) as shown in Table 2.1.

The line side power cables, load side power cables and the control wiring should all be run in a separate conduit. Careful

attention to this recommended design practice will avoid many potential motor and Drive related problems.

Table 2.1 Motor Cable Length vs. Carrier Frequency (C6-02)

Motor Cable Length 164 ft. (50m) maximum 328 ft. (100m) maximum More than 328 ft.(100m)

Carrier Frequency 15kHz maximum 10kHz maximum 5kHz maximum

(See the limitations on carrier frequency, based on Drive capacity and model number in Appendix B).

Electrical Installation 2 - 4

Page 37

Grounding

NO

Drive and Motor Ground Wire Landing

The Drive ground lug (terminal ) is connected to the enclosure. The enclosure ground lug must be connected to earth

ground. See Figure 2.1.

The Drive has a second ground lug to accept the motor ground lead.

Ground Wiring Precautions

Observe the following precautions when connecting the ground wire:

1. 208-240 VAC Drives should have a ground connection with resistance of less than 100 Ω..

2. 480 VAC Drives should have a ground connection with resistance of less than 10 Ω..

3. Do not share the ground wire with other devices, such as large-current electrical equipment.

4. Always use a ground wire that complies with technical standards on electrical equipment and minimize the length of the

ground wire. Leakage current flows through the Drive. Therefore, if the distance between the ground rod and the ground

terminal is too long, potential on the ground terminal of the Drive will become unstable.

5. When using more than one Drive, be careful not to loop the ground wire.

OK

For grounding connection to earth ground see Figure 2.1.

NO

OK

Fig 2.4 Ground Wiring Examples

NO

Control Circuit Ground Terminals

The control logic PCB A2 provides a ground terminal (marked PE) to accept the control wire shield connection. Terminal PE

is located at the top left of PCB A2, near TB4. The control wire shield should be connected on this end only, the opposite end

should be isolated with electrical tape.

IMPORTANT

Grounding of the Bypass enclosure and motor is required for proper system operation.

Electrical Installation 2 - 5

Page 38

Wire Routing

Input

power

Motor

connection

Control

circuit

wiring

The following Figures indicate suggested wire entry and bending areas for representative wall mount enclosures.

Fig 2.5 Typical Wall Mount Enclosure

Electrical Installation 2 - 6

Page 39

E7 Drive Main Circuit Configurations 208-240 VAC

Power

supply

Control

circuits

{

1

Note

CIMR-_ _ _ 20P4 to 2018

(1/2 Hp to 25 Hp)

Power

supply

Control

circuits

{

Note

1

CIMR-_ _ _ 4030 to 4037

(40 Hp to 60 Hp)

Power

supply

Control

circuits

{

Notes

1 & 3

Table 2.2 Drive Main Circuit Configurations

208-240 VAC

Notes

1 & 3

{

Note 1. Input fuses or molded case circuit breakers are required for proper branch circuit protection for all Drives. Failure

to use recommended fuses/circuit breakers (See Appendix E) may result in damage to the wiring, Drive and/or

personal injury.

2. Control power is supplied internally from the main circuit DC power supply for all Drives.

3. Consult your Yaskawa representative before using 12-pulse rectification.

E7 Drive Main Circuit Configurations 480 VAC

CIMR-_ _ _ 2022 (30 Hp)

Control

Power

circuits

supply

CIMR-_ _ _ 40P4 to 4018

Note 1. Input fuses or molded case circuit breakers are required for proper branch circuit protection for all Drives. Failure

to use recommended fuses/circuit breakers (See Appendix E) may result in damage to the wiring, Drive and/or

personal injury.

2. Control power is supplied internally from the main circuit DC power supply for all Drives.

3. Consult your Yaskawa representative before using 12-pulse rectification.

Table 2.3 Drive Main Circuit Configurations

480 VAC

(1/2 Hp to 30 Hp)

Electrical Installation 2 - 7

Page 40

Control Wiring

Bypass Field Control Wire Landing

The Bypass field control wiring is terminated on the control PCB A2, Terminal blocks TB1 through TB5. The terminal designations are labeled on the enclosure, adjacent to PCB A2 (see Figure 2.6). Route the control wiring as shown in Figure 2.5.

Fig 2.6 TB1 Control Terminal Locations, All Models

Electrical Installation 2 - 8

Page 41

Annunciation Contacts

Contacts for customer use are provided and wired to TB1 and TB2 as follows for use as annunciators of Bypass unit operation.

All are 5 amp at 120 VAC contacts.

Table 2.4 Output Relays - Factory Defaults

Function Name (E7L-00) Terminal Block Terminals Type

Motor Run Motor Run * TB1 10-11 Form A

Hand Mode Relay 1 @ TB1 12-13-14 Form C

Auto Mode Relay 2 @ TB2 1-2-3 Form C

System Fault Relay 3 @ TB2 4-5-6 Form C

* = Dedicated

@ = Programmable

Programmable Output Relays 1, 2 and 3 may be re-programmed via DIP switches S2 and S3 on the Bypass Control PCB A2.

These relays provide form C “dry contacts” for customer use in annunciation to Building Automation Systems or general duty

in other control logic circuits. Each contact is rated for 5 amps at 120 VAC.

The additional programmable output relay functions are described in the table below:

Table 2.5 Programmable Output Relay Functions

Function Description Factory Default

Bypass Run Annunciates running in Bypass mode No

Intended to close a contact in a damper actuator circuit

Damper Actuator

Auto Transfer

Drive Run Annunciates running in Drive mode No

Serial Com Run

Hand Mode

Auto Mode

System Fault

whenever the motor is commanded to run (operation similar

to the dedicated “Motor Run” relay)

Annunciates automatic transfer to Bypass operation due to a

Drive fault

Annunciates that the run command is coming from serial

communications

Annunciates that the Drive or Bypass is being operated in

Hand (local) mode

Annunciates that the Drive or Bypass is being operated in

Auto (remote) mode

Annunciates that a Drive, motor overload or control circuit

fault has occurred

No

No

No

Relay 1

Relay 2

Relay 3

See Table 2.6 for DIP switch positions required to achieve these functions.

Table 2.6 DIP Switch Settings for Output Relay Functions

Programmable

No. Function

1 Bypass Run OFF OFF OFF OFF OFF OFF OFF OFF OFF ENERGIZED Running in Bypass mode

2 Damper Coil OFF OFF ON OFF OFF ON OFF OFF ON ENERGIZED Damper actuator activation

3 Auto Transfer OFF ON OFF OFF ON OFF OFF ON OFF ENERGIZED Auto-Transfer is active

4 Drive Run OFF ON ON OFF ON ON OFF ON ON ENERGIZED Drive is in the Run mode

5 Serial Com. Run ON OFF OFF ON OFF OFF ON OFF OFF ENERGIZED Serial Comm. Run command

6 Hand Mode ON OFF ON ON OFF ON ON OFF ON ENERGIZED Manual mode operation

7 Auto Mode ON ON OFF ON ON OFF ON ON OFF ENERGIZED Auto mode operation

8 System Fault ON ON ON ON ON ON ON ON ON DEENERGIZED Drive, motor or control fault

Factory Settings ON OFF ON ON ON OFF ON ON ON

* ACTIVE = RELAY CONDITION DURING FUNCTION

Relay 1

S2(6) S2(5) S2(4) S3(3) S3(2) S3(1) S3(6) S3(5) S3(4)

Programmable

Relay 2

Programmable

Relay 3

Active*

Function

Description

Electrical Installation 2 - 9

Page 42

Building Automation system Run/Stop circuit:

A control terminal block position (TB1, terminals 2 and 9) is provided to connect the Normally Open (NO) Run/Stop contact

from a BAS or other remote controller for auto mode control.

There must be continuity between these terminals in order for the motor to run, in auto mode.

Safety Interlock Circuit:

A control terminal block position (TB1, terminals 1 and 9) is provided to connect the series circuit of Normally Closed (NC)

safety devices such as: freeze up thermostats, smoke/fire sensors, high pressure limits, temperature limits or vibration

detectors.

On power up the E7L will display a red “Safety Open” LED in the “System Status” area of the front control panel if a normally

closed “Safety Circuit” has not been installed between TB1-1 and TB1-9 on PCB A2. This condition will prevent Drive or

Bypass operation.

1 of 3 items needs to be done before the motor can be started:

1) Install a NC “Safety Circuit” between TB1-1 and TB1-9 on PCB A2.

2) Install a jumper between TB1-1 and TB1-9 on PCB A2. This method should be used if a “Safety Circuit” will be

added later in the installation.

3) De-activate these terminals by moving DIP switch S2-7 to the ON position (toward the enclosure door). This solution

is only suggested if a “Safety Circuit” will

never be applied to the drive system.

Building Automation System Interlock Circuit (Drive and Bypass enable input):