Page 1

Safety • Set-Up • Operation • Adjustments • Maintenance • Troubleshooting • Parts Lists • Warranty

OPERATOR’S MANUAL

Two-Stage Snow Thrower

IMPORTANT:

READ SAFETY RULES AND

INSTRUCTIONS CAREFULLY

BEFORE OPERATION

PRINTED IN U.S.A.

MTD Products Ltd., P. O. Box 1386, KITCHENER, ONTARIO N2G 4J1

769-03245

06/05/07

Page 2

This Operator’s Manual is an important part of your new snow thrower. It will help you assemble,

-4$02/$5#43,)-)4%$

+)4#(%.%2/..'*

8888888888

88888888888

-ODEL.UMBER

.UM£RODEMODÞLE

3ERIAL.UMBER

.UM£RODES£RIE

WWWMTDCANADACOM

prepare and maintain the unit for best performance. Please read and understand what it says.

Table of Contents

Safety Labels ......................................................3

Safe Operation Practices ................................... 4

Setting Up Your Snow Thrower .......................... 6

Operating Your Snow Thrower ......................... 10

Making Adjustments ........................................14

Finding and Recording Model Number

BEFORE YOU START ASSEMBLING

YOUR NEW EQUIPMENT,

please locate the model plate on the equipment and copy the

model number and the serial number to the sample model

plate provided to the right. You can locate the model plate by

standing at the operating position and looking down at the

frame.

Maintaining Your Snow Thrower ...................... 16

Off-Season Storage .......................................... 20

Trouble Shooting .............................................. 21

Warranty ............................................................ 22

Illustrated Parts Lists ....................................... 23

Customer Support

Please do

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of this unit,

you can seek help from the experts. Choose from the options below:

1. Visit www.yardman.ca for many useful suggestions, click on Customer Support button.

2. Call a Customer Support Representative at 1-800-668-1238

3. The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual, packed separately with

your unit, for more information.

Please have your unit’s model number and serial number ready when you call. See previous section to locate this information.

You will be asked to enter the serial number in order to process your call.

NOT

return the unit to the retailer from which it was purchased,

without first contacting Customer Support.

2

Page 3

#3

Chute Clean-out

Tool

A chute clean-out tool is fastened to the top

of the auger housing with a mounting clip. The

tool is designed to clear a chute assembly of

ice and snow.

This item is fastened with a cable tie at the

factory. Cut the cable tie before operating the

snow thrower.

WARNING: Never use your

hands to clear a clogged chute

assembly. Shut off engine and

remain behind handles until

all moving parts have stopped

before using the clean-out tool

to clear the chute assembly.

1

Safety

Labels

WARNING

This symbol points

out important safety

instructions which,

if not followed, could

endanger the personal safety and/or

property of yourself

and others. Read and

follow all instructions

in this manual before

attempting to operate

this machine. Failure

to comply with these

instructions may

result in personal

injury. When you see

this symbol, HEED

ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

3

Page 4

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of California to cause cancer and

birth defects or other reproductive harm.

2

Safe

Operation

Practices

WARNING

This symbol points

out important safety

instructions which,

if not followed, could

endanger the personal safety and/or

property of yourself

and others. Read and

follow all instructions

in this manual before

attempting to operate

this machine. Failure

to comply with these

instructions may

result in personal

injury. When you see

this symbol, HEED

ITS WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

DANGER: This machine was built to be operated according to the safe operation practices in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

Training

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the instructions and safe operation practices

in this manual and on the machine and be trained and

supervised by an adult.

4. Never allow adults to operate this machine without proper

instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is to be

used. Remove all doormats, newspapers, sleds, boards,

wires and other foreign objects, which could be tripped

over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer gar

ments. Do not wear jewelry, long scarves or other loose

clothing, which could become entangled in moving parts.

Wear footwear which will improve footing on slippery

surfaces.

4. Use a grounded three-wire extension cord and receptacle

for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all control levers before starting the engine.

7. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator’s manual.

8. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes, which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is hot

or running.

e. Allow engine to cool at least two minutes before refuel

ing.

f. Never over fill fuel tank. Fill tank to no more than ½ inch

below bottom of filler neck to provide space for fuel

expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and equip

ment. Move machine to another area. Wait 5 minutes

before starting the engine.

i. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light (e.g. furnace,

water heater, space heater, clothes dryer etc.).

j. Allow machine to cool at least 5 minutes before storing.

-

-

-

4

Page 5

Operation

1. Do not put hands or feet near rotating parts, in the

auger/impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine unsafe

and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged chute assembly.

Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless and

deadly gas.

6. Do not operate machine while under the influence of alcohol

or drugs.

7. Muffler and engine become hot and can cause a burn. Do

not touch.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while operat

ing on slopes.

10. Plan your snow-throwing pattern to avoid discharge towards

windows, walls, cars etc. Thus, avoiding possible property

damage or personal injury caused by a ricochet.

11. Never direct discharge at children, bystanders and pets or

allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

14. Disengage power to the auger/impeller when transporting or

not in use.

15. Never operate machine at high transport speeds on slippery

surfaces. Look down and behind and use care when

backing up.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire and ground it against

the engine. Inspect thoroughly for damage. Repair any

damage before starting and operating.

17. Disengage all control levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the chute assembly, making any adjustments, or

inspections.

18. Never put your hand in the discharge or collector openings.

Always use the clean-out tool provided to unclog the discharge opening. Do not unclog chute assembly while engine

is running. Shut off engine and remain behind handles until

all moving parts have stopped before unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. If situations occur which are not covered in this manual, use

care and good judgment. Call customer assistance for the

name of your nearest servicing dealer.

Maintenance & Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine disengage

all control levers and stop the engine. Wait until the

auger/impeller come to a complete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original equipment

manufacturer’s (OEM) parts only. “Use of parts which do

not meet the original equipment specifications may lead to

improper performance and compromise safety!”

6. Check controls periodically to verify they engage and

disengage properly and adjust, if necessary. Refer to the

adjustment section in this operator’s manual for instructions.

7. Maintain or replace safety and instruction labels, as neces

sary.

8. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator’s manual for proper instructions

on off-season storage.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and may

include the following emission control systems: Engine Modification (EM) and Three Way Catalyst (TWC) if so equipped.

Average Useful Life

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or

60 hours of operation. At the end of the Average Useful Life,

buy a new machine or have the machine inspected annually by

an authorized service dealer to ensure that all mechanical and

safety systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

2

Safe

Operation

Practices

WARNING

-

This symbol points

out important safety

instructions, which

if not followed, could

endanger the personal safety and/or

property of yourself

and others. Read and

follow all instructions

in this manual before

attempting to operate

this machine. Failure

to comply with these

instructions may

result in personal

injury. When you see

this symbol, HEED

IT’S WARNING!

Your Responsibility

Restrict the use

of this power machine

to persons who read,

understand

and follow the warnings

and instructions

in this manual

and on the machine.

5

Page 6

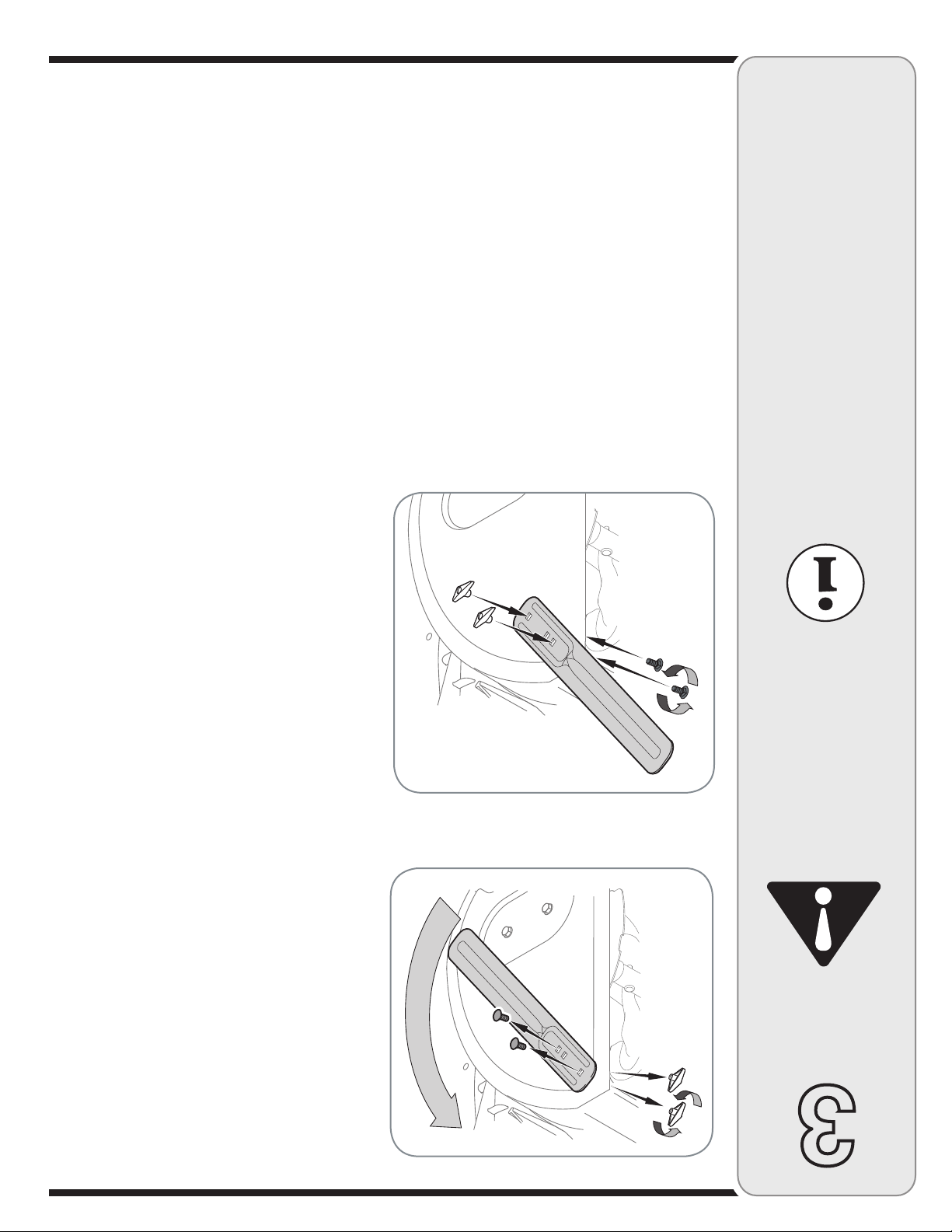

3

B

A

Setting Up

Your Snow

Thrower

NOTE: References to

right or left side of the

snow thrower are determined from behind the

unit in the operating

position.

Figure 3-1

IMPORTANT: The snow thrower is shipped with oil

and WITHOUT GASOLINE. After assembly, refer to

separate engine manual for proper fuel and engine oil

recommendations.

1. Observe the lower area of the snow thrower to be sure

both cables are aligned with roller guides.

a. Pull up and back on upper handle as shown in

Figure 3-1. Align upper handle with the lower

handle.

b. Tighten hand knobs securing upper handle to

lower handle.

2. Remove wing nut and hex screw from chute control

assembly and clevis pin and cotter pin from chute

support bracket. See Figure 3-2. Position the chute

assembly (forward-facing) over the chute base.

3. Place chute assembly onto chute base and secure

chute control assembly to chute support bracket with

clevis pin and cotter pin removed earlier. See Figure

3-3.

NOTE: This Operator’s

Manual covers several

models, handle panels,

lights and chute cranks

are some features that

may vary by model.

Not all features referenced in this manual

are applicable to all

snow thrower models.

NOTE: Two replacement auger shear pins

are included with this

manual (or stowed

in the plastic handle

panel). Refer to Augers

in the Maintainance

Section for more

information regarding

shear pin replacement.

Figure 3-2

Figure 3-3

6

Page 7

4. Finish securing chute control assembly to chute

support bracket with wing nut and hex screw removed

earlier. See Figure 3-4.

3

Setting Up

Your Snow

Thrower

5. Check that all cables are properly routed through the

cable guide on top of the engine. See Figure 3-5.

The extension cord is fastened with a cable tie to the rear

of the auger housing for shipping purposes. Cut the cable

tie and remove it before operating the snow thrower.

CAUTION: Prior to operating your

snow thrower, refer to Auger Control

Test on page 13. Read and follow all

instructions carefully, and perform all

adjustments to verify your snow thrower

is operating safely and properly.

Figure 3-4

Figure 3-5

CAUTION

Prior to operating

your snow thrower,

refer to Auger Control

Test on page 13.

Read and follow all

instructions carefully and perform all

adjustments to verify

your unit is operating

safely and properly.

Shear Pin Storage (optional)

An area for convenient shear pin storage is located under

the plastic dash panel. See Figure 3-6.

Figure 3-6

7

Page 8

3

Setting Up

Your Snow

Thrower

WARNING

Never use your hands

to clean snow and

ice from the chute

assembly or auger

housing.

Drift Cutters (If Equipped)

Drift cutters should be used when operating the snow

thrower in heavy drift conditions.

• On models so equipped, drift cutters and hardware

are assembled to the auger housing inverted. See

Figure 3-7.

• Remove the carriage bolts and wingnuts securing the

drift cutters to the housing.

• Reposition drift cutters so they face forward as shown

in Figure 3-8. Secure with hardware previously

removed, wingnuts should be fastened on the outside

of the housing as shown.

If your unit is not equipped with drift cutters, you may

contact Customer Support as instructed on page 2 for

information regarding price and availability.

Figure 3-7

Snowthrower Model Drift Cutter Kit:

All models OEM-390-679

IMPORTANT

Under any circumstance do not exceed

manufacturer’s recommended psi. Equal tire

pressure should be

maintained at all times.

Excessive pressure

when seating beads

may cause tire/rim

assembly to burst

with force sufficient to

cause serious injury.

Refer to sidewall of

tire for recommended

pressure.

Figure 3-8

8

Page 9

Clean-Out

Tool

Clean-Out Tool

The clean-out tool is mounted to the rear of the auger

housing and is designed to clear a clogged chute. Refer

to page 11 for instructions on how to properly use it.

NOTE: This item is fastened with a cable tie to the rear

of the auger housing at the factory. Cut the cable tie

before operating the snow thrower.

3

Setting Up

Figure 3-9

WARNING: Never use your hands to

clean snow and ice from the chute

assembly or auger housing.

Lamp Wiring Harness (If equipped)

The post on the cable tie attaching the lamp wiring

harness to the lower handle should be plugged into the

hole in the lower handle. Pull the slack portion of the

wiring harness through the cable tie to prevent interference with the recoil starter handle.

Your Snow

Thrower

WARNING

Never use your hands

to clean snow and

ice from the chute

assembly or auger

housing.

Figure 3-10

Skid Shoes

Position the skid shoes based on surface conditions.

Adjust upward for hard-packed snow. Adjust downward

when operating on gravel or crushed rock surfaces. See

“Making Adjustment” Section.

Tire Pressure (Pneumatic Tires)

The tires are over-inflated for shipping purposes. Check

the tire pressure before operating the snow thrower. Refer

to the tire side wall for tire manufacturer’s recommended

psi and deflate (or inflate) the tires as necessary.

NOTE: If the tire pressure is not equal in both tires, the

unit may not travel in a straight path and the shave plate

may wear unevenly.

General Recommendations

1. Always observe safety rules when performing

any maintenance.

2. The warranty on this snow thrower does not cover

items that have been subjected to operator abuse

or negligence. To receive full value from warranty,

operator must maintain the snow thrower as

instructed here.

3. Some adjustments will have to be made periodically

to maintain your unit properly.

4. Periodically check all fasteners and make sure these

are tight.

IMPORTANT

Under any circumstance do not exceed

manufacturer’s recommended psi. Equal tire

pressure should be

maintained at all times.

Excessive pressure

when seating beads

may cause tire/rim

assembly to burst

with force sufficient to

cause serious injury.

Refer to sidewall of

tire for recommended

pressure.

9

Page 10

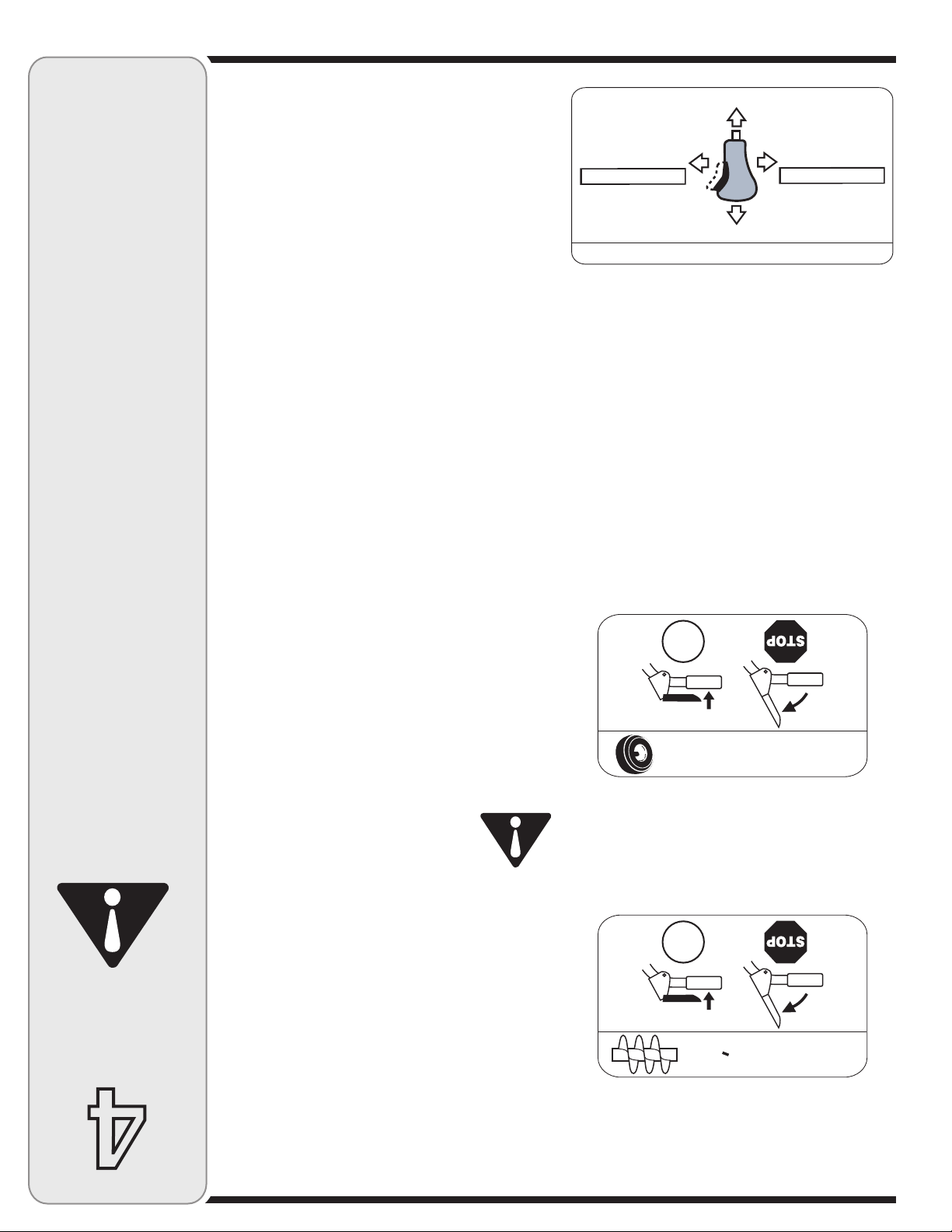

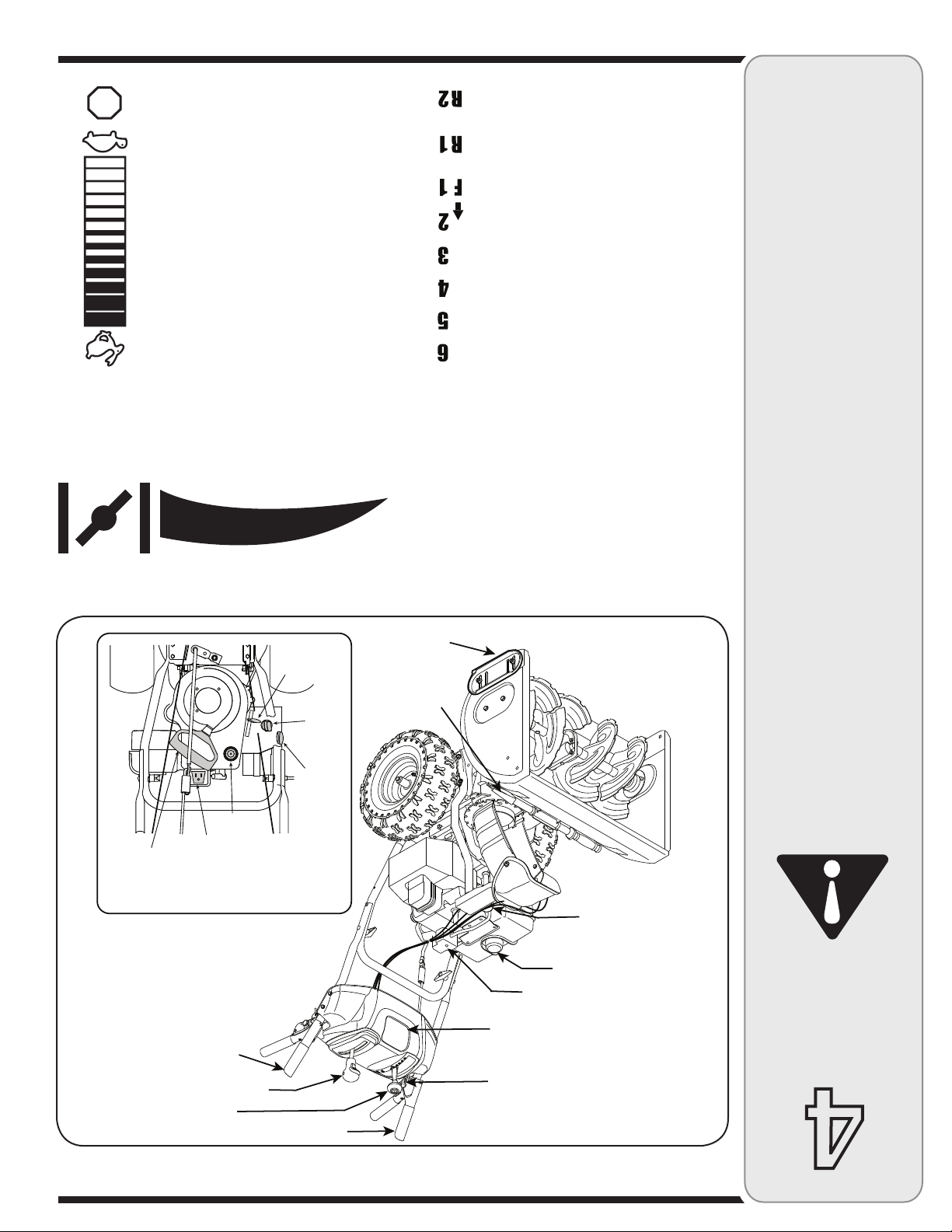

4

34/0

Engine Controls

Recoil Starter

Handle

Electric Starter Outlet

Primer

Ignition

Key

Choke

Control

Throttle

Control

Drive Control

Headlight

Fuel Tank

Gas Cap

Oil Fill

Electric Start Button

Chute

Assembly

Clean-Out

Tool

Auger Control

Shift Lever

Four-Way

Chute Control™

Skid Shoe

Heated Handles

Switch (optional)†

† If Equipped

Operating

Your Snow

Thrower

WARNING

Read, understand,

and follow all instructions and warnings

on the machine and

in this manual before

operating.

Use extreme care

when handling

gasoline. Gasoline is

extremely flammable

and the vapors are

explosive. Never fuel

the machine indoors

or while the engine

is hot or running.

Extinguish cigarettes,

cigars, pipes and

other sources of

ignition.

Know Your Snow Thrower

Figure 4-1

Now that you have set up your snow thrower for operation, get acquainted with its controls and features. These

are described below and illustrated in Figure 4-1. This

knowledge will allow you to use your new equipment to

its fullest potential.

NOTE: For detailed starting instructions and more

information on all engine controls, refer to the separate

engine manual packed with your unit.

Shift Lever

The shift lever is located on the right side

of the handle panel. Place the shift lever

into any of eight positions to control the

direction of travel and ground speed.

Forward

Your snow thrower has six forward (F)

speeds, with position number one (1)

being the slowest speed.

Reverse

Your snow thrower has two reverse (R)

speeds, with position number one (R1)

being the slower speed.

Choke Control

The choke control is found on the rear of the engine and

is activated by rotating the knob clockwise. Activating the

choke control closes the choke plate on the carburetor

and aids in starting the engine.

Throttle Control

The throttle control is located on the engine.

It regulates the speed of the engine and

will shut off the engine when pushed down

completely.

Primer

Depressing the primer forces fuel directly

into the engine’s carburetor to aid in coldweather starting.

Oil Fill

Engine oil level can be checked and oil

added through the oil fill.

10

Page 11

Auger Control

!5'%2

#/.42/,

'/

$2)6%

#/.42/,

'/

#(54%$)2%#4)/.!,#/.42/,

#(54%4),4$/7.

#(54%4),450

053("544/.

#(54%2/4!4%

,%&4

053("544/.

#(54%2/4!4%

2)'(4

The auger control is located on the left handle. Squeeze

the control grip against the handle to engage the augers

and start snow throwing action. Release to stop.

Drive Control/ Auger Control Lock

(If equipped)

The drive control is located on the right handle. Squeeze

the control grip against the handle to engage the wheel

drive. Release to stop.

The drive control also locks the auger control so you can

operate the chute directional control without interrupting

the snow throwing process. If the auger control is engaged simultaneously with the drive control, the operator

can release the auger control (on the left handle) and

the augers will remain engaged. Release both controls to

stop the augers and wheel drive.

IMPORTANT: Always release the drive control before

changing speeds.

Four-Way Chute Control™

The chute directional control is located on the left side of

the dash panel.

• To change the direction in which snow is thrown,

squeeze the button on the joy-stick and pivot the

joy-stick to the right or to the left.

• To change the angle/distance which snow is thrown,

pivot the joy-stick forward or backward.

Ignition Key

The ignition key must be inserted and snapped in place

in order for the engine to start. Remove the ignition key to

prevent unauthorized use of equipment. Do NOT attempt

to turn the key.

Clean-Out Tool

WARNING: Never use your hands to

clear a clogged chute assembly. Shut

off engine and remain behind handles

until all moving parts have stopped

before unclogging.

1. Release both the auger control and the drive/auger

control lock.

2. Stop the engine by moving the throttle to the stop

position.

3. Remove the clean-out tool from the mounting clip.

4. Use the shovel-shaped end of the clean-out tool to

remove any snow and ice in the chute assembly.

5. Re-fasten the clean-out tool to the mounting clip on

the rear of the auger housing and restart engine.

6. While standing in the operator’s position (behind the

snow thrower), engage the auger control for a few

seconds to clear any remaining snow or ice from the

chute assembly before continuing to clear snow.

Heated Handles Switch (If Equipped)

This switch is located on the right side of the snow

thrower dash panel. To activate the heated handles,

toggle the switch to the “ON” position to generate heat

within the handle grips. Toggle the switch to the “OFF”

position after using the snow thrower.

NOTE: The heated handles grips are a compliment to,

not a substitute for, proper cold weather outerwear for

the operator’s hands. It is recommended that the snow

thrower operator wear gloves/mittens to avoid extremities

of winter while operating this equipment.

Augers

When engaged, the augers rotate and draw snow into the

auger housing.

4

Operating

Your Snow

Thrower

WARNING

The operation of

any snow thrower

can result in foreign

objects being thrown

into the eyes, which

can damage your

eyes severely. Always

wear safety glasses

while operating the

snow thrower, or while

performing any adjustments or repairs on it.

Be sure no one other

than the operator is

standing near the snow

thrower while starting

engine or operating

snow thrower. Never

run engine indoors or

in enclosed, poorly

ventilated areas. Engine exhaust contains

carbon monoxide, an

odorless and deadly

gas. Keep hands, feet,

hair and loose clothing

away from any moving

parts on engine and

snow thrower.

11

Page 12

4

WARNING

Gas & Oil Fill-Up

Service the engine with gasoline and oil as instructed in

the separate engine manual packed with your unit. Read

instructions carefully.

Starting The Engine

1. Attach spark plug wire to spark plug. Make certain the

metal loop on the end of the spark plug wire (inside

the rubber boot) is fastened securely over the metal

tip on the spark plug.

2. Make certain both the auger control and drive control

are in the disengaged (released) position.

3. Move throttle control up to FAST position. Insert

ignition key into slot. Make sure it snaps into place.

Do not attempt to turn the key.

7. When disconnecting the extension cord, always

unplug the end at the three-prong wall outlet before

unplugging the opposite end from the snow thrower.

Recoil Starter

1. Rotate choke control to FULL choke position (cold

engine start).

NOTE: If the engine is already warm, place choke control

in the OFF position instead of FULL.

2. Push the primer two or three times for cold engine

start, making sure to cover vent hole in the center of

the primer when pushing.

NOTE: DO NOT use primer to restart a warm engine

after a short shutdown.

Read, understand,

and follow all instructions and warnings

on the machine and

in this manual before

operating.

Use extreme care

when handling

gasoline. Gasoline is

extremely flammable

and the vapors are

explosive. Never fuel

the machine indoors

or while the engine

is hot or running.

Extinguish cigarettes, cigars, pipes

and other sources of

ignition.

If your home’s wiring

system is not a

three-wire grounded

system, do not use

this electric starter

under any conditions.

If your home

electrical system

is grounded,

but a three-hole

receptacle is not

available, do not use

your snow thrower’s

electric starter.

NOTE: The engine cannot start unless the key is

inserted into ignition switch.

Electric Starter (If Equipped)

1. Determine that your home’s wiring is a three-wire

grounded system. Ask a licensed electrician if you are

not certain.

WARNING: The optional electric starter

is equipped with a grounded three-wire

power cord and plug, and is designed

to operate on 120 volt AC household

current. It must be used with a properly

grounded three-prong receptacle at all

times to avoid the possibility of electric

shock. Follow all instructions carefully

prior to operating the electric starter.

If you have a grounded three-prong receptacle, proceed

as follows:

1. Plug the extension cord into the outlet located on the

engine’s surface. Plug the other end of extension cord

into a three-prong 120-volt, grounded, AC outlet in a

well-ventilated area.

2. Rotate choke control to FULL choke position (for a

cold engine start).

NOTE: If the engine is already warm, place choke control

in the OFF position instead of FULL.

3. Push the primer two or three times for cold engine

start, making sure to cover vent hole in the center of

the primer when pushing.

NOTE: DO NOT use primer to restart a warm engine

after a short shutdown.

4. Push starter button to start engine.

5. Once the engine starts, immediately release starter

button.

6. As the engine warms, slowly rotate the choke control

to the OFF position. If the engine falters, quickly

rotate the choke control back to FULL and then slowly

into the OFF position again.

NOTE: Additional priming may be necessary if the

temperature is below 15° F (-9° C).

3. Grasp the recoil starter handle and slowly pull the

rope out. At the point where it becomes slightly harder

to pull the rope, slowly allow the rope to recoil.

4. Pull the starter handle with a firm, rapid stroke.

release the handle and allow it to snap back. Keep a

firm hold on the starter handle and allow it to slowly

recoil.

5. As the engine warms, slowly rotate the choke control

to the OFF position. If the engine falters, quickly rotate

the choke control back to the FULL position and then

slowly into the OFF position again.

NOTE: Allow the engine to warm up for a few minutes

after starting. The engine will not develop full power until

it reaches operating temperatures.

Do not

Stopping The Engine

Run engine for a few minutes before stopping to help dry

off any moisture on the engine.

• To help prevent possible starter freeze-up, proceed as

follows:

Electric Starter (If Equipped)

1. Connect extension cord to the electric starter outlet

on the engine, then to 120 volt AC outlet.

2. With the engine running, push the starter button and

allow the starter for spin for several seconds. The

noise made by the starter is normal. The engine’s

starter is not being harmed.

3. When disconnecting the extension cord, always

unplug the end at the three-prong wall outlet before

unplugging the opposite end from the snow thrower.

4. Move throttle control to STOP position.

5. Remove the ignition key (Do not turn key) to prevent

unauthorized use of equipment.

6. Wipe all snow and moisture from the area around the

engine as well as the area in and around the drive

control and auger control. Also, engage and release

both controls several times.

12

Page 13

NOTE: Keep the key in a safe place. The engine cannot

start without the ignition key.

Recoil Starter

1. With engine running, pull starter rope with a rapid,

continuous full arm stroke three or four times. Pulling

the starter rope will produce a loud clattering sound,

which is not harmful to engine.

2. Move throttle control to STOP position.

3. Remove the ignition key (Do not turn key) to prevent

unauthorized use of equipment.

NOTE: Keep the key in a safe place. The engine cannot

start without the ignition key.

4. Wipe all snow and moisture from the area around the

engine as well as the area in and around the drive

control and auger control. Also, engage and release

both controls several times.

To Engage Drive

1. With the engine running near top speed, move

shift lever to one of six FORWARD positions or two

REVERSE positions. Select a speed appropriate for

the snow conditions that exist.

2. Squeeze drive control against the right handle and

the snow thrower will move. Release it and the drive

motion will stop.

2. In a well-ventilated area, start the snow thrower

engine as instructed on the previous page. Make sure

the throttle is set in the FAST position.

3. While standing in the operator’s position (behind the

snow thrower), engage the auger.

4. Allow the auger to remain engaged for approximately

ten (10) seconds before releasing the auger control.

Repeat this several times.

5. With the throttle control in the FAST (rabbit) position

and the auger control in the disengaged “up” position,

walk to the front of the machine.

6. Confirm that the auger has completely stopped

rotating and shows NO signs of motion. If the auger

shows ANY signs of rotating, immediately return to

the operator’s position and shut off the engine. Wait

for ALL moving parts to stop before re-adjusting the

auger control.

7. To readjust the control cable, loosen the upper hex

nut on the auger cable bracket. See Figure 4-2.

8. Position the bracket upward to provide more slack (or

downward to increase cable tension).

9. Retighten the upper hex nut.

10. Repeat Auger Control Test to verify proper adjustment

has been achieved.

4

WARNING

Never use your hands

to clean snow and

ice from the chute

assembly or auger

housing.

The muffler, engine

and surrounding

areas become hot

and can cause a

burn. Do not touch.

To Engage Augers

1. To engage augers and start snow throwing, squeeze

the left hand auger control against the left handle.

Release to stop augers.

2. While the auger control is engaged, squeeze the drive

control to move, release to stop. Do not shift speeds

while the drive is engaged.

NOTE: This drive lever also locks auger control so you

can turn the chute control without interrupting the snow

throwing process.

3. Release the auger control; the interlock mechanism

should keep the auger control engaged until the drive

control is released.

4. Release the drive control to stop both the augers and

the wheel drive. To stop the auger, both levers must

be released.

Auger Control Test

Perform the following test before operating your snow

thrower for the first time and at the start of each winter.

Check the adjustment of the auger control as follows:

1. When the auger control is released and in the

disengaged “up” position, the cable should have very

little slack. It should NOT be tight.

When selecting a

Drive Speed, use the

slower speeds until

you are comfortable

and familiar with the

operation of the snow

thrower.

Figure 4-2

NEVER reposition the

shift lever (change

speeds or direction

of travel) without first

releasing the drive

control and bringing

the snow thrower

to a complete stop.

Doing so will result in

premature wear to the

snow thrower’s drive

system.

13

Page 14

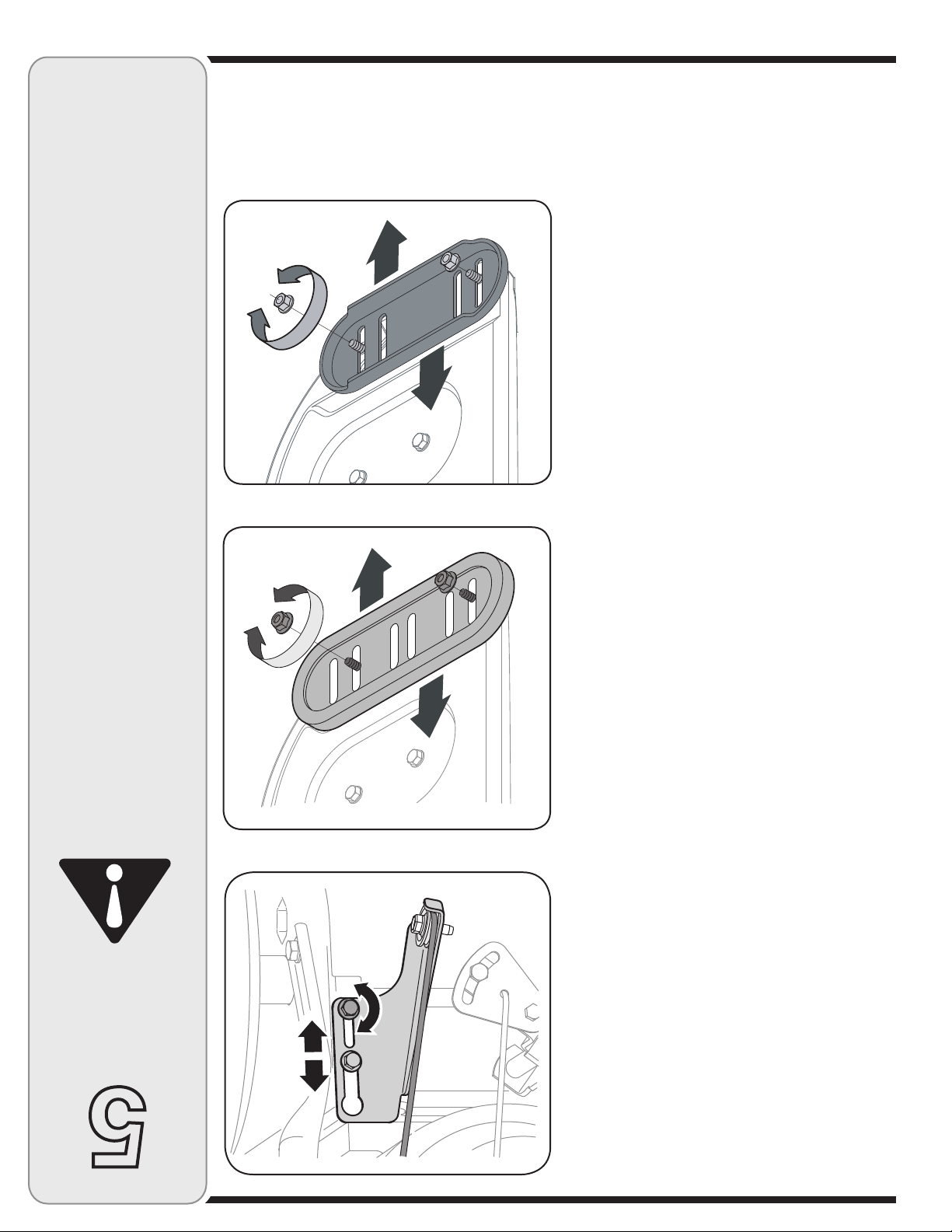

5

Making

Adjustments

Shift Cable

If the full range of speeds (forward and reverse) cannot

be achieved, refer to the figure to the left and adjust the

shift cable as follows:

1. Place the shift lever in the fastest forward speed

position.

2. Loosen the hex nut on the shift cable index bracket.

See Figure 5-1.

3. Pivot the bracket downward to take up slack in the

cable.

4. Retighten the hex nut.

5. Check for correct adjustment before operating the

snow thrower.

WARNING

Read, understand,

and follow all instructions and warnings

on the machine and

in this manual before

operating.

Never attempt to

make any adjustments while the

engine is running,

except where specified in operator’s

manual.

Figure 5-1

Figure 5-2

Figure 5-3

Chute Control

Once a season or every 25 hours of operation, whichever

is earlier, check whether the four-way chute control™

cables have slackened. If the chute does not rotate

fully or its pitch cannot be moved up or down, the chute

control cables will have to be adjusted.

To adjust these cables, proceed as follows:

1. To tighten cable, loosen the top nut and tighten the

bottom nut on the cable.

2. Adjust equally on both sides by working on both

cables. See Figure 5-2.

Drive Control & Shift Lever

When the drive control is released and in the disengaged

“up” position, the cable should have very little slack. It

should NOT be tight.

Check the adjustment of the drive control as follows:

1. With the drive control released, push the snow thrower

gently forward. The unit should roll freely.

2. Engage the drive control and gently attempt to push

the snow thrower forward. The wheels should not turn.

The unit should not roll freely.

3. With the drive control released, move the shift lever

back and forth between the R2 position and the F6

position several times. There should be no resistance

in the shift lever.

4. If any of the above tests failed, the drive cable is in

need of adjustment. Proceed as follows:

5. Loosen the lower hex nut on the drive cable bracket.

See Figure 5-3.

6. Position the bracket upward to provide more slack (or

downward to increase cable tension).

7. Retighten the lower hex nut.

You can also check the adjustment as follows:

1. With the snow thrower tipped forward (be certain to

drain gasoline or place plastic film under the gas cap if

the snow thrower has already been operated), remove

the frame cover underneath the snow thrower by

removing the self-tapping screws. Refer to step 2 on

page 17.

14

Page 15

2. With the drive control released, there must be 1/8”

clearance between the friction wheel and the drive

pulley in all positions of the shift lever.

3. With the drive control engaged, the friction wheel must

contact the drive pulley.

4. If adjustment is necessary, loosen the lower hex nut

on the drive cable index bracket and pivot the bracket

upward or downward as necessary. Refer to Figure

5-3. Tighten the lower hex nut to secure the bracket

when correct adjustment is reached.

5. Reassemble the frame cover and return the unit back

to its operating position.

NOTE: If you placed plastic under the gas cap, be certain

to remove it now.

5

Making

Adjustments

Skid Shoes

The space between this shave plate and the ground can

be adjusted. For close snow removal, place skid shoes in

the low position. Use middle or high position when area to

be cleared is uneven.

1. Adjust skid shoes by loosening the four lock nuts

and carriage bolts and moving skid shoes to desired

position. See Figure 5-4 or 5-5.

2. Make certain the entire bottom surface of skid shoes

are against the ground to avoid uneven wear on the

skid shoes.

3. Tighten nuts and bolts securely.

NOTE: Units are equipped with reversible skid shoes

and may be turned over to increase their lifespan. If steel

shoes are turned they must also change sides to ensure

the “A” on the shoe is towards the front of the unit.

Auger Control

To adjust the auger control, refer to page 13.

Figure 5-4 - Reversible Plastic Skid Shoe

Figure 5-5 - Reversible Steel Skid Shoe

IMPORTANT

It is not recommended

that you operate this

snow thrower on gravel

as loose gravel can be

easily picked up and

thrown by the auger

causing personal injury

or damage to the snow

thrower.

If for some reason,

you have to operate

the snow thrower on

gravel, keep the skid

shoe in the highest

position for maximum

clearance between the

ground and the shave

plate.

15

Page 16

Engine

3HEAR0IN

"EARING

3PACERS

Refer to the separate engine manual packed with your

unit for all engine maintenance.

6

Maintaining

Your Snow

Thrower

WARNING

Before lubricating,

repairing, or inspecting, disengage all

controls and stop

engine. Wait until all

moving parts have

come to a complete

stop.

Lubrication

Engine

Refer to the separate engine manual packed with your

unit for all engine lubrication instructions.

Gear Shaft

The gear (hex) shaft should be lubricated at least once

a season or after every 25 hours of operation.

1. Carefully pivot the snow thrower up and forward so

that it rests on the auger housing.

2. Remove the lower frame cover by removing the two

screws which secure it.

3. Apply a light coating of an all-weather multi-purpose

oil to the hex shaft. See Figure 6-1.

NOTE: Avoid getting oil on rubber friction wheel and

aluminum drive plate.

Wheels

At least once a season, remove both wheels. Clean and

coat the axles with a multipurpose automotive grease

before reinstalling wheels.

Chute Directional Control (optional)

Once a season, the joystick should be lubricated with

petroleum jelly, linseed oil, mineral oil, paraffin wax or

3-in-1 oil.

Auger Shaft

At least once a season, remove the shear pins on auger

shaft. Spray lubricant inside shaft, around the spacers.

Also lubricate the flange bearings found at either end of

the shaft. See Figure 6-2.

Figure 6-1

Figure 6-2

Keep all grease and oil

off of the rubber friction

wheel and aluminum

drive plate.

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary.

To remove skid shoes:

1. Remove the four carriage bolts and hex flange nuts

which secure them to the snow thrower.

2. Reassemble new skid shoes with the four carriage

bolts (two on each side) and hex flange nuts. Refer

to Figure 6-3.

To remove shave plate:

1. Remove the carriage bolts and hex nuts which attach

it and the skid shoes to the snow thrower housing.

2. Reassemble new shave plate, making sure heads of

carriage bolts are to the inside of housing. Tighten

securely.

Figure 6-3

16

Page 17

Auger Belt Replacement

To remove and replace your snow thrower’s auger belt,

proceed as follows:

1. Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws. See

Figure 6-4.

Figure 6-4

NOTE: Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

2. Carefully pivot the snow thrower up and forward so

that it rests on the auger housing. Remove the frame

cover from the underside of the snow thrower by

removing four self-tapping screws which secure it.

See Figure 6-5.

3. Roll the auger belt off the engine pulley. See Figure

6-6.

4. a. Loosen and remove the shoulder screw which

acts as a belt keeper. See Figure 6-7.

b. Unhook the support bracket spring from the

frame.

5. Remove the belt from around the auger pulley, and

slip the belt between the support bracket and the

auger pulley. Reassemble auger belt by following

instructions in reverse order. See Figure 6-8.

NOTE: Do NOT forget to reinstall the shoulder screw

and reconnect the spring to the frame after installing

a replacement auger belt and to remove the piece of

plastic from under the gas cap.

6

Maintaining

Your Snow

Thrower

NOTE: Although

multi-viscosity oils

(5W30, 10W30 etc.)

improve starting in cold

weather, these multiviscosity oils also result

in higher oil consumption when used above

32ºF (0ºC). Check your

snow thrower’s engine

oil level more frequently

to avoid possible

engine damage from

running low on oil.

Figure 6-5

Figure 6-6

17

Figure 6-7

Figure 6-8

NOTE: Do not sandblast spark plug. Spark

plug should be cleaned

by scraping or wire

brushing and washing

with a commercial

solvent.

IMPORTANT

NEVER replace the

auger shear pins with

standard pins. Any

damage to the auger

gearbox or other components, as a result of

doing so, will NOT be

covered by your snow

thrower’s warranty.

Page 18

6

c

b

a

Maintaining

Your Snow

Thrower

NEVER replace the

auger shear pins with

standard hex pins.

Any damage to the

auger gearbox or

other components

as a result of failing

to do so will NOT be

covered by your snow

thrower’s warranty.

Figure 6-9

Augers

• The augers are secured to the spiral shaft with two

shear pins and cotter pins. If the auger should strike a

foreign object or ice jam, the snow thrower is designed

so that the pins may shear. Refer to Figure 6-9.

• If the augers will not turn, check to see if the pins have

sheared. One set of replacement shear pins has been

provided with the snow thrower. When replacing pins,

spray an oil lubricant into shaft before inserting new

pins.

Drive Belt Replacement

To remove and replace your snow thrower’s auger belt,

proceed as follows:

1. Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws. See

Figure 6-9.

• Drain the gasoline from the snow thrower, or place a

piece of plastic under the gas cap.

• Carefully pivot the snow thrower up and forward so

that it rests on the auger housing. See Figure 6-10.

2. Remove the frame cover from the underside of the

snow thrower by removing four self-tapping screws

which secure it.

3. a. Use a wrench to pivot the idler pulley toward the

right. See Figure 6-11.

b. Roll the auger belt off the engine pulley.

c. Lift the drive belt off engine pulley.

4. Slip the drive belt off the pulley and between friction

wheel and friction wheel disc. See Figure 6-12.

• Remove and replace belt in the reverse order.

Figure 6-10

Figure 6-11

Figure 6-12

18

Page 19

Figure 6-13

Figure 6-14

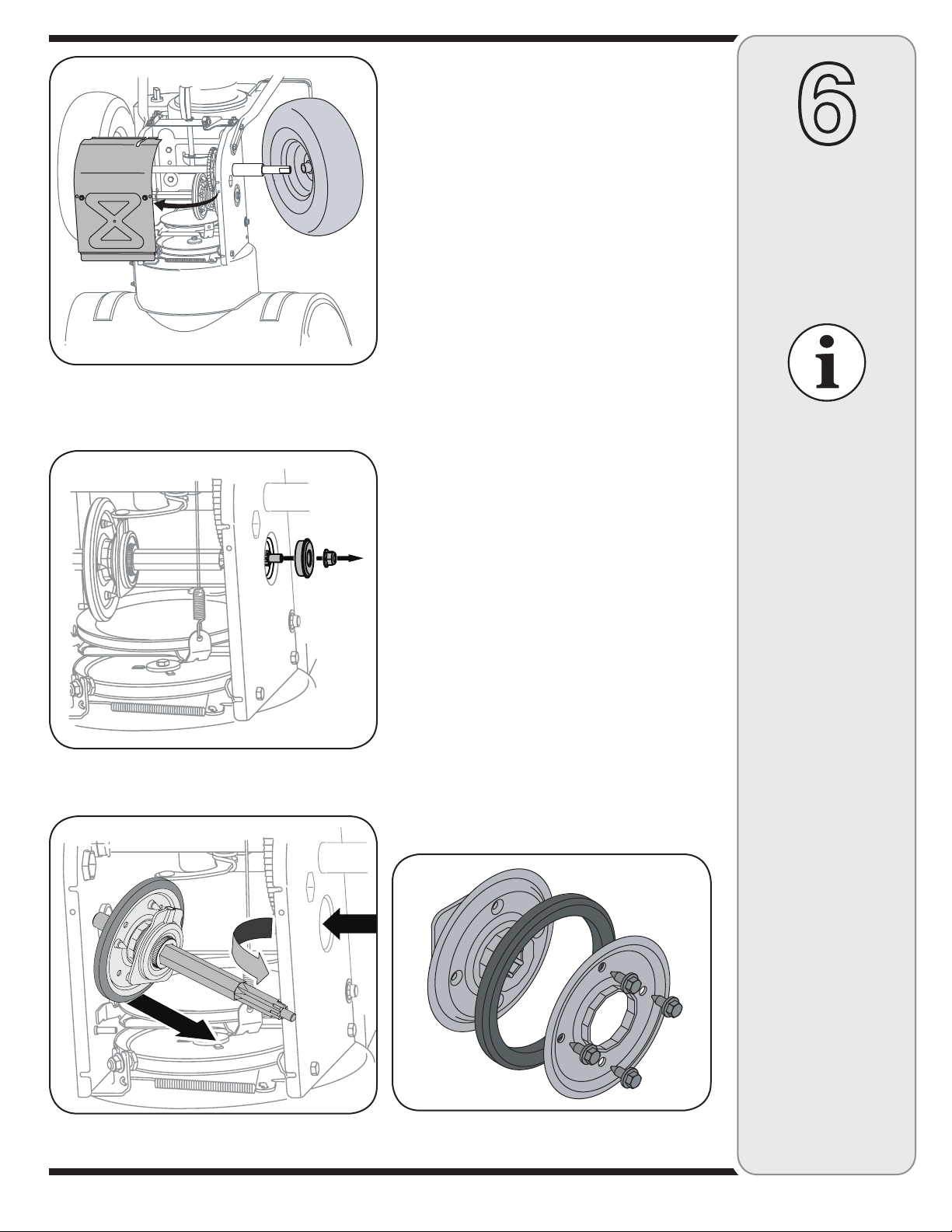

Friction Wheel Removal

If the snow thrower fails to drive with the drive control

engaged, and performing the drive control cable adjustment on page 12 fails to correct the problem, the friction

wheel may need to be replaced. Follow the instructions

below. Examine the friction wheel for signs of wear or

cracking and replace if necessary.

• Place the shift lever in third Forward (F3) position.

• Drain the gasoline from the snow thrower, or place a

piece of plastic under the gas cap.

• Carefully pivot the snow thrower up and forward so

that it rests on the auger housing.

1. a. Remove the frame cover from the underside of

the snow thrower by removing four self-tapping

screws which secure it. See Figure 6-13.

b. Remove the right-hand wheel by removing the

screw and cupped washer which secure it to the

axle.

2. Carefully remove the hex nut and washer which

secures the hex shaft to the snow thrower frame and

lightly tap the shaft’s end to dislodge the ball bearing

from the right side of the frame. See Figure 6-14.

3. Carefully position the hex shaft downward and to

the left before carefully sliding the friction wheel

assembly off the shaft. See Figure 6-15.

NOTE: If you’re replacing the friction wheel assembly

as a whole, discard the worn part and slide the new part

onto the hex shaft. Follow the steps above in reverse

order to reassemble components. If you’re disassembling the friction wheel and replacing only the rubber

ring, proceed as follows:

4. Remove the four screws which secure the friction

wheel’s side plates together. See Figure 6-16.

• Remove the rubber ring from between the plates.

• Reassemble the side plates with a new rubber ring.

• Slide the friction wheel assembly back onto the hex

shaft and follow the steps above in reverse order to

reassemble components.

6

Maintaining

Your Snow

Thrower

When reassembling

the friction wheel assembly, tighten each

screw only one rotation before turning the

wheel clockwise and

proceeding with the

next screw. Repeat

this process several

times to ensure the

plates are secured

with equal force.

NEVER replace the

auger shear pins with

standard hex pins.

Any damage to the

auger gearbox or

other components

as a result of failing

to do so will NOT be

covered by your snow

thrower’s warranty.

Figure 6-15

Figure 6-16

19

Page 20

7

Off-Season

Storage

WARNING

Never store snow

thrower with fuel

in tank indoors or

in poorly ventilated

areas, where fuel

fumes may reach an

open flame, spark

or pilot light as on a

furnace, water heater,

clothes dryer or gas

appliance.

Observe the following, when preparing your snow thrower

for off-season storage:

• Drain fuel into an approved container outdoors, away

from any open flame. Allow engine to cool. Extinguish

cigarettes, cigars, pipes and other sources of ignition

prior to draining fuel. Fuel left in engine during warm

weather deteriorates and will cause serious starting

problems.

• If unit is to be stored over 30 days, prepare for storage

as instructed in the separate engine manual packed

with your unit.

• Run engine until fuel tank is empty and engine stops

due to lack of fuel.

• Remove gasoline from carburetor and fuel tank to

prevent gum deposits from forming on these parts and

causing possible malfunction of engine.

• Drain carburetor by pressing upward on bowl drain,

located below the carburetor cover.

• Fuel stabilizers, such as STA-BIL®, are an acceptable

alternative in minimizing the formation of fuel gum

deposits during storage. Do not drain carburetor if

using a fuel stabilizer.

• Wipe equipment with an oiled rag to prevent rust.

• Remove spark plug and pour one ounce of engine oil

through spark plug hole into cylinder. Cover spark plug

hole with rag. Crank engine several times to distribute

oil. Replace spark plug.

• Follow the lubrication recommendations found in the

Maintenance Section.

• Always store the snow thrower in a clean, dry area.

Drain fuel into an

approved container

outdoors, away from

any open flame. Be

certain engine is

cool. Do not smoke.

Fuel left in engine

during warm weather

deteriorates and will

cause serious

starting problems.

Do not drain

carburetor if

using fuel stabilizer.

Never use engine or

carburetor cleaning

products in the fuel

tank or permanent

damage may occur.

20

Page 21

Engine fails to start

CauseProblem Remedy

1. Choke not in ON position.

2. Spark plug wire disconnected.

3. Fuel tank empty or stale fuel.

4. Engine not primed.

5. Faulty spark plug.

6. Blocked fuel line.

7. Safety key not in ignition on engine.

8. Fuel shut-ff valve closed. (If Equipped)

1. Move choke to ON position.

2. Connect wire to spark plug.

3. Fill tank with clean, fresh gasoline.

4. Prime engine as instructed in

“Operating Your Snow Thrower”.

5. Clean, adjust gap, or replace.

6. Clean fuel line.

7. Insert key fully into the switch.

8. Open fuel shut-off valve.

8

Trouble-

Shooting

Engine runs erratic

Engine overheats

Excessive

Vibration

Loss of power

1. Unit running on CHOKE.

2. Blocked fuel line or stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

1. Loose parts or damaged auger.

1. Spark plug wire loose.

2. Gas cap vent hole plugged.

3. Exhaust port plugged.

1. Move choke lever to OFF position.

2. Clean fuel line; fill tank with clean,

fresh gasoline.

3. Drain fuel tank. Refill with

fresh fuel.

4. Contact Service Center.

1. Contact Service Center.1. Carburetor not adjusted properly.

1. Stop engine immediately and

disconnect spark plug wire. Tighten

all bolts and nuts. If vibration

continues, have unit serviced by a

Service Center.

1. Connect and tighten spark plug

wire.

2. Remove ice and snow from gas

cap. Be certain vent hole is clear.

3. Contact Service Center.

NOTE: This section

addresses minor

service issues. For

further details,

contact customer

assistance.

Unit fails

to propel itself

Unit fails

to discharge snow

1. Drive control cable in need of adjustment.

2. Drive belt loose or damaged.

1. Chute assembly clogged.

2. Foreign object lodged in auger.

3. Auger control cable in need of adjustment.

4. Auger belt loose or damaged.

5. Shear pin(s) sheared.

21

1. Adjust drive control cable. Refer to

“Adjustments”.

2. Replace drive belt.

1. Stop engine immediately and

disconnect spark plug wire. Clean

chute assembly and inside of

auger housing with clean-out tool

or a stick.

2. Stop engine immediately and

disconnect spark plug wire.

Remove object from auger with

clean-out tool or a stick.

3. Refer to “Auger Control Test” .

4. Refer to Maintenance section.

5. Replace with new shear pin(s).

Page 22

9

Warranty

Failure to comply

with suggested

maintenance

and lubrication

specifications will

void warranty.

FOUR YEAR SUPREME WARRANTY:

For four years from date of retail purchase within Canada, MTD PRODUCTS LIMITED will,

at its option, repair or replace, for the original purchaser, free of charge, any part or parts

found to be defective in material or workmanship. This warranty covers units which have

been operated and maintained in accordance with the owner’s instructions furnished with the

unit, and which have not been subject to misuse, abuse, commercial use, neglect, accident

improper maintenance or alteration. Normal wear parts or components thereof are subject to

special terms as noted below in the Ninety Day Consumer Warranty clause.

The engine, starter motor or component parts thereof carry separate warranties from their

manufacturers. Please refer to the applicable manufacturer’s warranty policy for these items.

Ninety Day Consumer Warranty on Normal Wear Parts: All normal wear part failures

will be covered on this product for a period of 90 days. After 90 days but within the four year

warranty period, normal wear part failures will be covered if caused by defects in material or

workmanship of other component parts. Normal wear parts are defined as batteries, belts,

blades, blade adaptors, grass bags, rider deck wheels, seats, tires and clutch parts (friction

wheels).

Full Ninety Day Warranty on Battery (if equipped): For ninety (90) days from the

date of retail purchase, if any battery included with this unit proves defective in material

or workmanship and our testing determines the battery will not hold a charge, MTD

PRODUCTS LIMITED will replace the battery at no charge to the original purchaser.

Additional Limited Thirty Day Warranty on Battery (if equipped): After ninety (90) days

but within one hundred twenty (120) days from the date of purchase, MTD PRODUCTS

LIMITED will replace the defective battery, for the original purchaser, for a cost of one-half

(½) of the current retail price of the battery in effect at the date of return.

Personal use: THE FOREGOING PARAGRAPHS CONSTITUTE THE MANUFACTURER’S

ENTIRE WARRANTY WITH RESPECT TO ANY PRODUCT PURCHASED AND USED

FOR PERSONAL FAMILY, HOUSEHOLD/RESIDENTIAL PURPOSES, AS DISTINGUISHED

FROM COMMERCIAL USAGE.

Commercial use: ALL APPLICATIONS OTHER THAN PERSONAL USE AS OUTLINED

ABOVE, ARE CONSIDERED COMMERCIAL USAGE.

New products purchased for commercial usage are warranted in the same manner and to the

same extend EXCEPT the term of warranty will be 90 DAYS from date of purchase.

How to Obtain Service: Warranty service is available, with proof of purchase, through

your local MTD Authorized Service Dealer. If you do not know the dealer in your area,

please write to the Service Department of MTD PRODUCTS LIMITED, P.O. BOX 1386,

KITCHENER, ONTARIO N2G 4J1. The return of a complete unit will not be accepted by the

factory unless prior written permission has been extended by MTD PRODUCTS LIMITED.

Other Warranties: All other warranties, express or implied, including any implied warranty

of merchantability is limited in its duration to that set forth in this express limited warranty.

The provisions as set forth in this warranty provide the sole and exclusive remedy of MTD

PRODUCTS LIMITED obligations arising from the sale of its products. MTD PRODUCTS

LIMITED will not be liable for incidental or consequential loss or damage.

22

12.08.06

Page 23

Model Wheel As sem bly De scrip tion Tire Rim Axle

Modèle En sem ble de roue De scrip tion Roue Jante Essieu

31AE6GLF590 634-04145 16 x 4.8 x 8 LH X-Trac 734-2038 634-04173 738-04168

31AE6GLF596 634-04146 16 x 4.8 x 8 RH X-Trac 734-2038 634-04173

31AE6GLF597

31AH6KLG

31AH6NKG

31AH5IQ4 634-04136 16 x 6.5 x 8 LH X-Trac 734-2031 634-04174 738-04180

31AH5MLH 634-04137 16 x 6.5 x 8 RH X-Trac 734-2031 634-04174 738-04180

31AH5NQ5

31AE6MLG 634-04136 16 x 6.5 x 8 LH X-Trac 734-2031 634-04174 738-04168

634-04137 16 x 6.5 x 8 RH X-Trac 734-2031 634-04174 738-04168

31AS6ACE 634-04144A 13 x 4 Snow Hog 734-1732 634-04172A 738-04168

31AE6FFF 634-04141 16 x 4.8 Snow Hog 734-1530 634-04173 738-04168

31AE6FHF

31AS6LCG

31AE6GKG

31AE6MFH

31AE6MKH

31AE6LHG

31AS6FEE 634-04142A 15 X 5 Snow Hog 734-1859 634-04172A 738-04168

31AS6FEF

31AE6LHH 634-04135 16 X 6.5 Snow Hog 734-1525 634-04174 738-04168

31AE5LKH 634-04135 16 X 6.5 Snow Hog 734-1525 634-04174 738-04180

31AE63KE 634-04147A 15 X 5 X 6 LH X-Trac 734-04012 634-04172A 738-04168

31AH6DLE 634-04148A 15 X 5 X 6 RH X-Trac 634-04172A

31AH6DQ3

31AE6GLF501

7.24.07

AU GER HOUS ING COM PO NENTS/COMPOSANTS DU LOGEMENT DES TARIÈRES

SIZE

TAILLE

AU GER HOUS ING/

LOGEMENT DES

TARIÈRES

AU GER AXLE/

ESSIEU DES

TARIÈRES

SHAVE PLATE

LAME

PLATE

GEAR BOX ASS’Y/

EN SEM BLE DE LA

VIS SANS FIN

SPAC ERS/

ENTRETOISE

WORM GEAR/

ENGRENAGE

24

684-04065 711-04285 790-00120 618-04171A 731-04870 (1) 717-04449

26

684-04264 711-04284 790-00121 618-04172A 731-04870 (2) 717-04449

28

684-04268 711-04283 790-00118 618-04173A 731-04870 (3) 717-0528A

30

684-04067 711-04282 790-00119 618-04165A 731-04871 (2) 717-0528A

23

Page 24

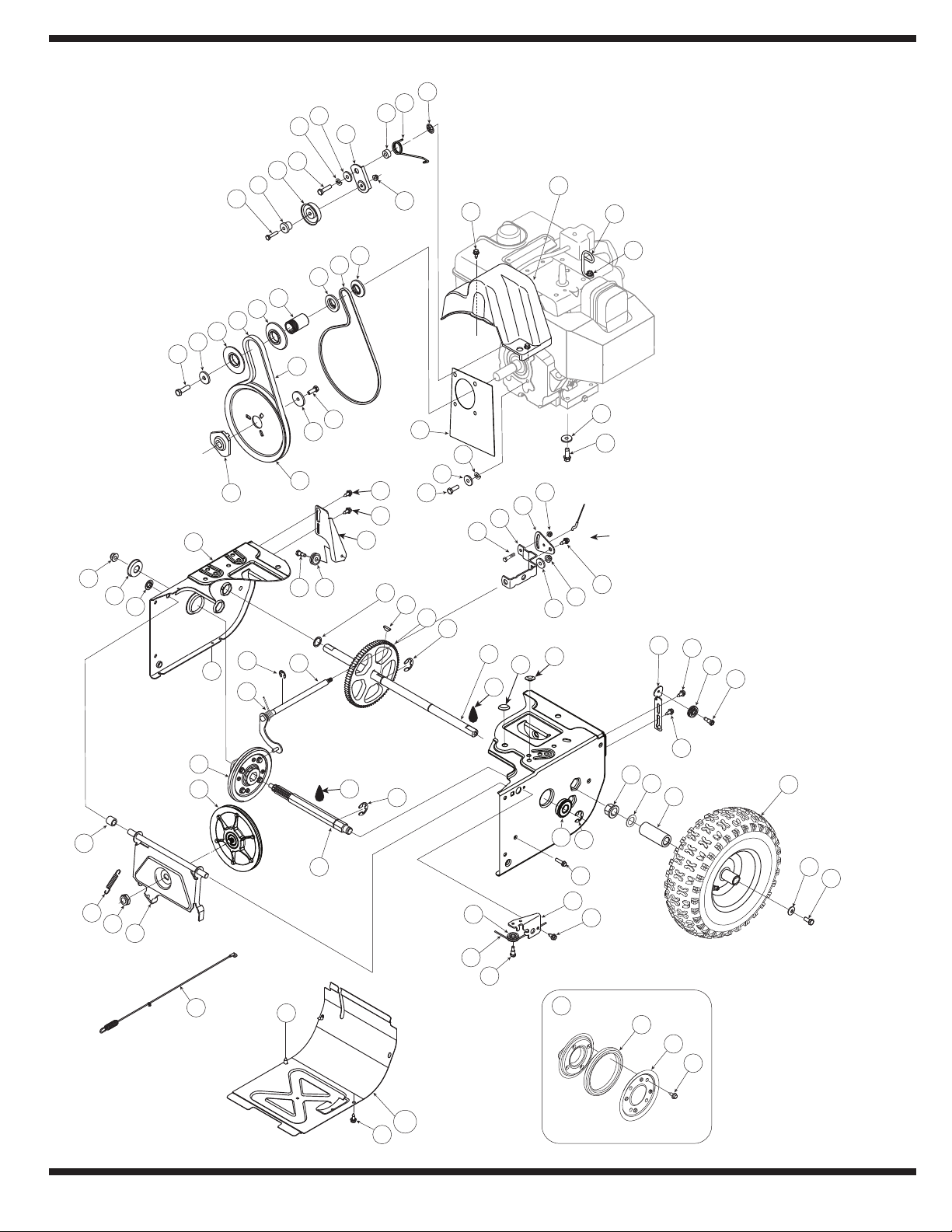

23

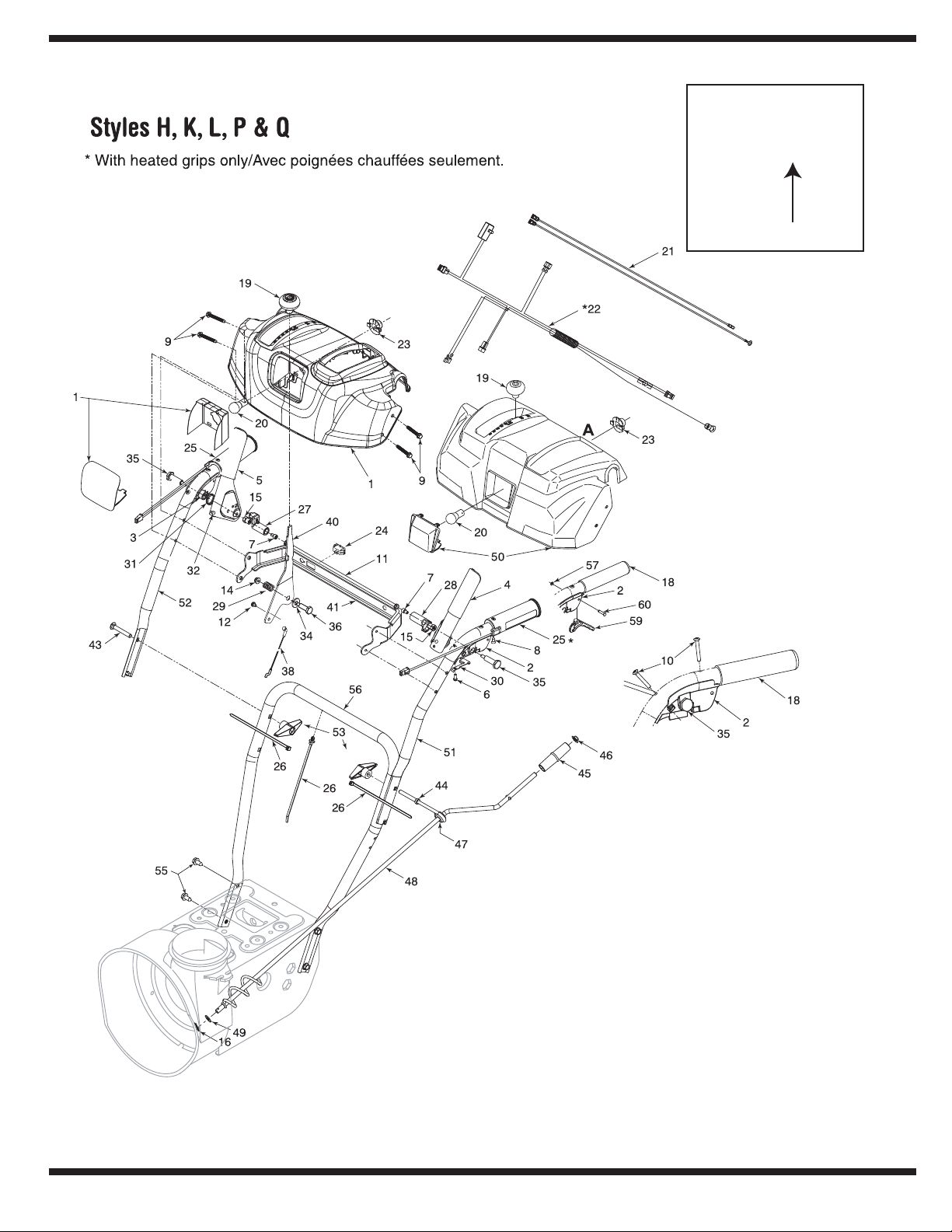

8

19

13

25

40

34

6

20

13

18

17

Manual Chute Control/

Commande de la goulotte

manuelle

12

14

11

7

29

26

41

22

9

4

13

21

16

5

10

6

2

13

15

28

55

4

4

30

35

38

32

33

39

16

38

31

36

37

37

7

24

Page 25

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DE SCRIP TION DE SCRIP TION

1 631-04131B Lower Chute (2 Way) Goulotte inférieur (2 fonctions)

2 731-04861B Lower Chute (4 Way) Goulotte inférieur (4 fonctions)

3 684-04117A 2 Way Chute Con trol As sembly Ens. - commande de la goulotte à 2 fonctions

4 684-04116B 4 Way Chute Con trol As sembly Ens. - commande de la goulotte à 4 fonctions

5 710-0262 Carriage Bolt 5/16-18 x 1.50 Gr. 2 Boulon ordi naire 5/16-18 x 1,50 Qual. 2

6 710-04071 Carriage Screw 5/16-18 x 1.0 Vis ordinaire 5/16-18 x 1,0

7 710-04187 Hi-Lo Screw 1/4-15 x .5 Vis 1/4-15 x 0,5

8 710-0276 Carriage Bolt 5/16-18 x 1.00" Lg Boulon ordi naire de 5/16-18 x 1,00 po de lg

9 738-04194 Shoulder Screw .312 x 1.7:1/4-20 Vis épaulement 0,312 x 1,7:1/4-20

10 710-0895 Hex Tapp Scr 1/4 x .75" Lg. Vis taraudée à tête hex. de 1/4 x 0,75 po de lg

11 711-04469A Clevis Pin 3/8 x 1.87 Axe de chape 3/8 x 1,87

12 714-04040 Bow Tie Cot ter Pin Goupille fendue

13 712-04063 Flange Locknut 5/16-18 Gr. F Ny lon Contre-écrou à embase 5/16-18 Qual. F ny lon

14 712-03087 Wing Nut 1/4-20 Écrou en oreilles 1/4-20

15 731-04425B Upper Chute w/Ex port La bel, Re mote Goulotte sup.,étiquette d’exp., comm. a dis tance

16 731-1313C Ca ble Guide Guide de la câble

17 731-04869 Chute Flange Keeper Garde-bride de la goulotte

18 731-04912B Lower Chute Goulotte inférieur

19 741-0475 Plastic Bush ing .380 ID Manchon en plastique de 0,38 po de D.I.

20 720-0284 Han dle Knob As sem bly Bou ton

21 784-5594 Cable Bracket Chute Tilt Sup port de câble

22 712-04064 Hex L-Flanged Nut 1/4-20 Gr. F Ny lon Contre-écrou à embase 1/4-20 Qual. F ny lon

23 784-5647 Chute Crank Brkt. Support du bras de goulotte d’ejection

24 790-00131 Bracket: Chute Con trol Sup port: Commande de la goulotte

25 736-0159 Flat Washer .349 ID x .879 OD x .063 Rondelle plate 0,349 DI x 0,879 DE x 0,063

26 684-04162B Sup port Bracket Sup port

27 710-04187 Hi-Lo Screw 1/4-15 x .50 Vis 1/4-15 x 0,50

28 710-0606 Hex Hd. Cap Screw 1/4-20 x 1.5 Gr. 5 Vis à tête hex. 1/4-20 x 1,5 Qual. 5

29 710-0627 Hex Hd. Cap Screw 5/16-24 x .75 Vis à tête hex. 5/16-24 x 0,75

30 736-0463 Flat Washer .25 ID x .63 OD x .0515 Rondelle plate 0,25 DI x 0,63 x 0,0515

31 712-04064 Flange Locknut 1/4-20 Gr. F, Ny lon Contre-écrou à embase 1/4-20 Qual. F, ny lon

32 720-04039 Knob Bou ton

33 731-05307 Control Cover - 2 Way Couvercle (2 fonctions)

34 710-0451 Carriage Bolt 5/16-18 x .75 Boulon ordi naire 5/16-18 x 0,75

35 736-0413 Spring Washer .390 x .625 x .012 Rondelle ressort .390 x .625 x .012

36 738-04185 Flg Shlder Spacer .310 x .995 x 1/4-20 Entretoise epaulée 0,390 x 0,995 x 1/4-20

37 746-04238 Cable - 2 Way Câble - 2 fonctions

38 790-00200 Mounting Bracket - 2 Way Bracket - 2 fonctions

39 790-00210A Lever - 2 Way Levier - 2 fonctions

40 731-04354B Up per Chute Goulotte supérieur

31A-6004

6.22.07

25

Page 26

39

33

30

24

38

18

5

25

6

31

7

28

24

13

23

46

44

23

70

46

64

68

65

80

43

7

24 30

52

58

54

63

27

7

14

57

49

47

61

61

60

58

50

41

2

1

11

4

A

A

8

26

16

29

17

3

9

56

62

59

62

35

22

7

34

32

79

45

48

67

36

19

66

2

82

55

42

40

20

10

15

12

37

72

71

30

Optional/en option

73

74

75

5

77

55

26

21

78

76

77

81

12

26

Page 27

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DE SCRIP TION DE SCRIP TION

1 656-04025A Friction Wheel Disc As sembly Disque de roue du fric tion

2 684-04153 Friction Wheel Ass’y, Bear ing 5.5 OD Roue du friction, roulement 5,5 DE

3 684-04154 Friction Wheel Support Brkt Ass’y Support de la roue du fric tion

4 684-04156A Shift Rod Ass’y Tige de changement de la vitesses

5 710-0627 Hex L-Bolt 5/16-24 x .75 Gr. 5 Boulon hex 5/16-24 x 0,75 Qual. 5

6 710-0788 Hex Bolt 1/4-20 x 1.00 Vis à tête hex. 1/4-20 x 1,00

7 710-1652 Hex Wash Hd TT Scr. 1/4-20 x .625 Vis taraudée 1/4-20 x 0,625

8 712-04065 Flange Lock-Nut 3/8-16 Gr. F Ny lon Contre-écrou à embase 3/8-16 Qual. F ny lon

9 712-0413 Jam L-Nut 5/8-18 Gr. 5 Ny lon Écrou de blocage 5/8-18 Qual. 5 Ny lon

10 714-0126 #9 HI-Pro Key 3/16 x 3/4 Dia HT Clavette HI-Pro n°. 9 - 3/16 x 3/4 dia.

11 716-0104 Re tain ing Ring Anneau de retenue

12 716-0136 Re tainer Ring Bague de retenue

13 716-0231 “E” Ring Bague en «E»

14 717-04209A Hex Shaft .8125 - 7 tooth Arbre hex. 0,8125 - 7 dents

15 717-04230 Gear - 80 Tooth Engrenage - 80 dents

16 726-0221 Cap Speed Nut 1/4 Rod Chapeau à enfoncer

17 732-0264 Extension Spring 3/8 OD x 2.50 Ressort d’extension 3/8 DE x 2,50

18 736-0242 Cupped Washer .345 ID x .88 OD x .060 Rondelle creuse 0,345 DI x 0,88 DE x 0,060

19 736-0287 Flat Washer .79 ID x 1.25 OD x .06 Rondelle frein 0,79 DI x 1,25 DE x 0,06

20 736-04161 Flat Washer .75 x 1.00 x .06 Rondelle plate 0,75 x 1,00 x 0,06

21 737-0288 Grease Graisse

22 737-04166 Rust Pre ven ta tive Oil Huile

23 738-04184A Shoulder Screw .373 x .105:TT 1/4-20 Vis à épaulement 0,373 x 0,105:1/4-20

24 738-0924A Hex Shld.Scr.1/4-28 x .375 Vis à épaulement 1/4-28 x 0,375

25 741-0245 Hex. Flange Bear ing.751" ID Roulement à bride à six pans 0,751 DI

26 741-0563 Ball Bearing w/snap ring Roulement à billes avec bague

27 746-04229 Drive Clutch Cable 44.83" Lg. Câble de l’entraînement 44,83 po de lg.

28 746-04230 Auger Clutch Cable 47.23" Lg. Câble de la tarière 47,23 po de lg.

29 748-0190 Spacer .513 ID x 1.0 Entretoise 0,513 DI x 1,0

30 756-0625 Cable Guide Roller Guide du câble

31 790-00096 Auger Cable Guide Bracket Support, guide de la câble de la tarière

32 790-00180A Frame Bâti

33 790-00206A Guide Bracket - Au ger Cable Support - câble de tarière

34 790-00207A Guide Bracket - Drive Ca ble Support - câble de l’entraînement

35 790-00316 Frame Cover Couvercle

36 731-04873 Spacer Entretoise

37 738-04168 Axle .75 x 22" Lg. Essieu 0,75 x 22 po de lg.

38 See chart on page 23. Voir tab leau de la page 23.

39 684-04169 Idler Pul ley As sembly 1.917 OD Poulie tendeur 1,917 DE

40 710-0809 Hex Screw 1/4-20 x 1.25 Vis à tête hexagonale 1/4-20 x 1,25

41 710-0191 Hex Screw 3/8-24 x 1.25 Vis à tête hexagonale 3/8-24 x 1,25

42 710-0672 Hex Hd Cap Scr. 5/16-24 x 1.25 Gr. 5 Vis à tête hex. 5/16-24 1,25 Qual. 5

43 710-0654A Hex Wash HD Tap Scr 3/8-16 x .88 Vis autotaraudée 3/8-16 x 0,88

44 710-1245B Hex Bolt 5/16-24 x 0.875 Boulon hex. 5/16-24 x 0,875

45 710-1652 Hex Wash Hd TT Scr. 1/4-20 x .625 Vis taraudée 1/4-20 x 0,625

46 712-04064 Hex L-Flanged Nut 1/4-20 Gr. F Ny lon Contre-écrou à embase 1/4-20 Qual. F ny lon

47 726-04012 Push Nut Écrou à enfoncer

48 731-04792A Belt Cover Couvercle de la courroie

731-05353 Belt Cover (w/4 way chute con trol) Couvercle de la courroie (avec commande de la

goulotte à 4 fonctions)

49 732-04308A Torsion Spring .850 ID x .354" Lg. Ressort de tor sion 0,850 DI x 0,354 po de lg.

50 736-0247 Flat Washer .40 ID x 1.25 OD x .160 Rondelle plate 0,40 DI x 1,25 DE x 0,160

52 736-0505 Flat Washer .34 x 1.50 x .150 Rondelle plate 0,34 x 1,50 x 0,150

53 737-0318 Grease:Arctic:EP NLGI 1-58F Graisse

54 748-04053 Pul ley Adapter Adaptateur de la poulie

55 736-0119 Lockwasher 5/16 Rondelle frein 5/16

56 750-04303 Spacer .875 ID x 1.185 OD Entretoise 0,875 DI x 1,185 DE

57 750-04477 Spacer .340 x .750 x .360" Lg. Entretoise 0,340 x 0,750 x 0,360 po de lg.

58 754-04050 Belt .5 x 35.0" Lg. Courroie 0,5 x 35,0 po de lg.

59 754-0367 Belt 34.4" Lg. Courroie trapezoïdale 34,4 po de lg.

60 756-04109 Au ger Pul ley Poulie de la tarière

61 756-04113 Pul ley Half Moitié poulie

62 756-04252 Pulley Half 3/8 V x 1.71 OD Poulie, demi 1,7 DE

63 790-00208A Wheel Drive Idler Bracket Sup port

64 710-0751 Hex Bolt 1/4-20 x .62 Gr. 5 Boulon hexagonale 1/4-20 x 0,62 Qual. 5

65 712-04063 Flange Locknut 5/16-18 Gr. F, Ny lon Contre-écrou à embase 5/16-18 Qual. F, ny lon

66 735-04054 Friction Wheel Rubber Roue du friction en caou tchouc

67 732-04311 Torsion Spring .750 ID x .968" Lg. Ressort de tor sion 0,750 DI x 0,968 po de lg.

68 738-04184A Shoulder Screw .373 x .105:TT 1/4-20 Vis à épaulement 0,373 x 0,105:1/4-20

70 790-00217A Pivot Bracket Support de pivot

71 790-00218A Shift Bracket Support de changement de la vitesses

72 790-00174 Fric tion Plate Plaque du fric tion

73 748-04112A Shld. Spacer .3175 x .5 x .1025 Entretoise 0,3175 x .50 x 0,1025

74 750-04571 Spacer Entretoise

75 790-00289A Cover Plate (op tional) Plaque (en op tion)

76 732-0705 Ca ble Con trol Wire Fil de commande de la câble

77 748-0234 Shoul der Spacer Entretoise à épaulement

78 735-04100 Plug 1/2" Bouchon 1/2 po

79 735-04099 Plug 3/8" Bouchon 3/8 po

80 736-3015 Flat Washer .469 x .875 x .105 Rondelle plate 0,469 x 0,875 x 0,105

81 736-0320 Flat Washer .38 x 1.38 x .125 (Rear left hole) Rondelle plate 0,38 x 1,28 x 0,125 (arriere gauche trou)

31A-6003

6.19.07

27

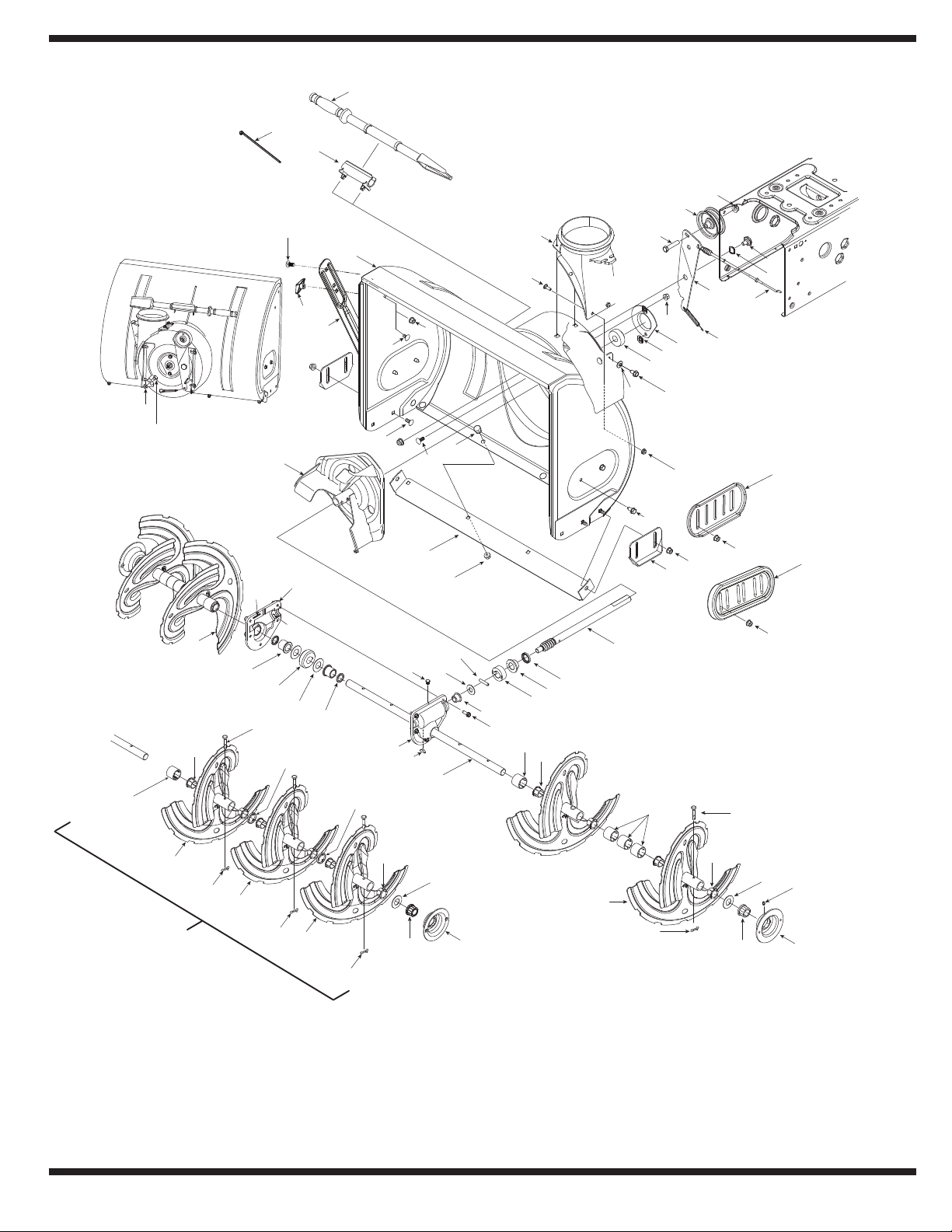

Page 28

30

7

35

4

2

8

25

5

21

23

12

7

18

24

43

14

22

3

9

25

1

10

16

44

7

65

7

9

17

13

4

19

15

32

33

53

57

48

55

49

60

50

51

46

47

58

54

42

45

28

52

59

56

31

29

31

33

33

41

32

27

27

27

11

11

34

27

29

29

29

20

20

34

38

33

41

40

NOTE: Housing may not be exactly as shown.

REMARQUE : L'habitacle peut être légèrement

différent.

61

30 in/po

7

39

64

62

63

26

38

7

4

9

28

Page 29

REF PART

NO. NO.

N° DE N° DE

RÉF PIÈCE DE SCRIP TION DE SCRIP TION

1 731-2643 Clean-Out Tool Outil de dégagement de la goulotte

2 684-04057A Impeller Ass'y 12 po Ventilateur

3 710-0347 Hex Screw 3/8-16 x 1.75 Vis à tête hex 3/8-16 x 1,75

4 710-0451 Carriage Bolt 5/16-18 x .75 Boulon ordi naire 5/16-18 x 0,75

5 710-0703 Carriage Screw 1/4-20 x .75 Gr. 5 Boulon ordi naire 1/4-20 x 0,75 Qual. 5

7 712-04063 Flange Locknut 5/16-18 Gr. F Ny lon Contre-écrou à embase 5/16-18 Qual. F ny lon

8 712-04064 Hex L-Flanged Nut 1/4-20 Gr. F Ny lon Contre-écrou à embase 1/4-20 Qual. F ny lon

9 712-04065 Hex L-Flanged Nut 3/8-16 Gr. F Ny lon Contre-ecrou à embase 3/8-16 Qual. F ny lon

10 725-0157 Ca ble Tie Attache câble

11 731-04871 Spacer 1.25 x .75 x 3/16" Lg. Entretoise 1,25 x 0,75 x 3/16 po de lg.

12 726-04012 Push-on Nut .25 dia. Écrou pousser 0,25 diam.

13 731-04705 Chute Adapter Adaptateur de goulotte d'éjection

14 732-04460 Extension Spring .38 OD x 4.59" Lg. Ressort d’extension 0,38 DE x 4,59 po de lg.

15 736-0174 Wave Washer .660 ID x .88 OD x .010 Rondelle ondulée 0,660 DI x 0,88 DE x 0,010

16 731-2635 Cleanout Tool Mount Montage de la outil de dégagement de la goulotte

17 738-0143 Shld. Scr. .500 Dia. x .335" Lg. Vis à épaulement dia. 0,500 po x 0,335 po de lg.