Yamaha YZF600RT User Manual

OWNER’S MANUAL

YZF600RT(C)

5AH-28199-19LIT-11626-18-17

EAU10041

INTRODUCTION

EAU10080

Congratulations on your purchase of the Yamaha YZF600R(C). This model is the result of Yamaha’s vast experience in the

production of fine sporting, touring, and pacesetting racing machines. It represents the high degree of craftsmanship and

reliability that have made Yamaha a leader in these fields.

This manual will give you an understanding of the operation, inspection, and basic maintenance of this motorcycle. If you

have any questions concerning the operation or maintenance of your motorcycle, please consult a Yamaha dealer.

The design and manufacture of this Yamaha motorcycle fully comply with the emissions standards for clean air applicable at

the date of manufacture. Yamaha has met these standards without reducing the performance or economy of operation of the

motorcycle. To maintain these high standards, it is important that you and your Yamaha dealer pay close attention to the

recommended maintenance schedules and operating instructions contained within this manual.

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

EAU10130

WARNING

Failure to follow WARNING instructions could result in severe injury or death

motorcycle operator, a bystander or a person inspecting or repairing the motor-

to the

cycle.

CAUTION:

NOTE:

A CAUTION indicates special precautions that must be taken to avoid damage to

the motorcycle.

A NOTE provides key information to make procedures easier or clearer.

NOTE:

● This manual should be considered a permanent part of this motorcycle and should remain with it even if the motorcycle

is subsequently sold.

● Yamaha continually seeks advancements in product design and quality. Therefore, while this manual contains the most

current product information available at the time of printing, there may be minor discrepancies between your motorcycle

and this manual. If you have any questions concerning this manual, please consult your Yamaha dealer.

EWA10010

WARNING

PLEASE READ THIS MANUAL AND THE “YOU AND YOUR MOTORCYCLE: RIDING TIPS” BOOKLET CAREFULLY

AND COMPLETELY BEFORE OPERATING THIS MOTORCYCLE. DO NOT ATTEMPT TO OPERATE THIS MOTORCYCLE UNTIL YOU HAVE ATTAINED ADEQUATE KNOWLEDGE OF ITS CONTROLS AND OPERATING FEATURES

IMPORTANT MANUAL INFORMATION

AND UNTIL YOU HAVE BEEN TRAINED IN SAFE AND PROPER RIDING TECHNIQUES. REGULAR INSPECTIONS

AND CAREFUL MAINTENANCE, ALONG WITH GOOD RIDING SKILLS, WILL ENSURE THAT YOU SAFELY ENJOY

THE CAPABILITIES AND THE RELIABILITY OF THIS MOTORCYCLE.

IMPORTANT MANUAL INFORMATION

AFFIX DEALER

LABEL HERE

YZF600RT(C)

OWNER’S MANUAL

©2004 by Yamaha Motor Corporation, U.S.A.

1st edition, May 2004

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in Japan.

P/N LIT-11626-18-17

EAU10192

TABLE OF CONTENTS

SAFETY INFORMATION ..................1-1

Location of important labels ...........1-5

DESCRIPTION ..................................2-1

Left view ..........................................2-1

Right view........................................2-2

Controls and instruments ................2-3

INSTRUMENT AND CONTROL

FUNCTIONS.......................................3-1

Main switch/steering lock ................3-1

Indicator and warning lights ............3-2

Speedometer unit ...........................3-3

Tachometer ....................................3-3

Self-diagnosis device .....................3-3

Coolant temperature gauge ............3-4

Handlebar switches ........................3-4

Clutch lever ....................................3-5

Shift pedal ......................................3-6

Brake lever .....................................3-6

Brake pedal ....................................3-6

Fuel tank cap ..................................3-7

Fuel ................................................3-7

Starter (choke) lever .......................3-8

Seat ................................................3-9

Helmet holder .................................3-9

Storage compartment ...................3-10

Adjusting the front fork .................3-10

Adjusting the shock absorber

assembly ...................................3-12

Luggage strap holders ..................3-14

Sidestand ..................................... 3-14

Ignition circuit cut-off system ....... 3-15

PRE-OPERATION CHECKS ............. 4-1

Pre-operation check list ................. 4-2

OPERATION AND IMPORTANT

RIDING POINTS ................................ 5-1

Starting and warming up a cold

engine ......................................... 5-1

Starting a warm engine .................. 5-3

Shifting ........................................... 5-3

Engine break-in .............................. 5-4

Parking ........................................... 5-5

PERIODIC MAINTENANCE AND

MINOR REPAIR................................. 6-1

PERIODIC MAINTENANCE .......... 6-1

Owner’s tool kit .............................. 6-1

Periodic maintenance chart for the

emission control system ............. 6-3

General maintenance and

lubrication chart .......................... 6-4

Removing and installing

cowlings ...................................... 6-8

Checking the spark plugs ............ 6-10

Canister (for California only) ........ 6-11

Engine oil and oil filter

cartridge ................................... 6-12

Coolant ........................................ 6-15

Cleaning the air filter element ...... 6-18

Checking the air vent hose ........... 6-20

Air intake duct ..............................6-20

Adjusting the carburetors ............. 6-20

Adjusting the throttle cable free

play ...........................................6-21

Adjusting the valve clearance ......6-21

Tires .............................................6-21

Cast wheels ..................................6-24

Accessories and replacement

parts ..........................................6-24

Adjusting the clutch lever free

play ...........................................6-25

Adjusting the rear brake light

switch ........................................6-26

Checking the front and rear

brake pads ................................6-26

Checking the brake fluid level ......6-27

Changing the brake fluid .............. 6-28

Drive chain slack ..........................6-28

Lubricating the drive chain ...........6-29

Checking and lubricating the

cables .......................................6-30

Checking and lubricating the

throttle grip and cable ............... 6-30

Checking and lubricating the

brake and shift pedals ............... 6-31

Checking and lubricating the

brake and clutch levers .............6-31

Checking and lubricating the

sidestand ..................................6-31

Lubricating the rear suspension ... 6-32

TABLE OF CONTENTS

Checking the front fork .................6-32

Checking the steering ...................6-33

Checking the wheel bearings .......6-33

Battery ..........................................6-34

Replacing the fuses ......................6-35

Replacing the headlight bulb ........6-36

Replacing the tail/brake light

bulb ...........................................6-37

Replacing a turn signal light

bulb ...........................................6-37

Supporting the motorcycle ............6-38

Front wheel ...................................6-38

Rear wheel ...................................6-40

Troubleshooting ............................6-42

Troubleshooting charts .................6-43

MOTORCYCLE CARE AND

STORAGE ..........................................7-1

Care ................................................7-1

Storage ...........................................7-3

SPECIFICATIONS .............................8-1

CONSUMER INFORMATION.............9-1

Identification numbers ....................9-1

Reporting safety defects .................9-3

Motorcycle noise regulation ............9-4

Maintenance record ........................9-5

YAMAHA MOTOR CORPORATION,

U.S.A. STREET AND ENDURO

MOTORCYCLE LIMITED

WARRANTY ...............................9-7

YAMAHA EXTENDED SERVICE

(Y.E.S.) ....................................... 9-9

SAFETY INFORMATION

EAU10271

MOTORCYCLES ARE SINGLE

TRACK VEHICLES. THEIR SAFE

USE AND OPERATION ARE DEPENDENT UPON THE USE OF PROPER

RIDING TECHNIQUES AS WELL AS

THE EXPERTISE OF THE OPERATOR. EVERY OPERATOR SHOULD

KNOW THE FOLLOWING REQUIREMENTS BEFORE RIDING THIS

MOTORCYCLE.

HE OR SHE SHOULD:

● OBTAIN THOROUGH INSTRUC-

TIONS FROM A COMPETENT

SOURCE ON ALL ASPECTS OF

MOTORCYCLE OPERATION.

● OBSERVE THE WARNINGS

AND MAINTENANCE REQUIREMENTS IN THE OWNER’S MANUAL.

● OBTAIN QUALIFIED TRAINING

IN SAFE AND PROPER RIDING

TECHNIQUES.

● OBTAIN PROFESSIONAL TECH-

NICAL SERVICE AS INDICATED

BY THE OWNER’S MANUAL

AND/OR WHEN MADE NECESSARY BY MECHANICAL CONDITIONS.

Safe riding

● Always make pre-operation

checks. Careful checks may help

prevent an accident.

● This motorcycle is designed to

carry the operator and a passenger.

● The failure of motorists to detect

and recognize motorcycles in traffic is the predominating cause of

automobile/motorcycle accidents.

Many accidents have been

caused by an automobile driver

who did not see the motorcycle.

Making yourself conspicuous appears to be very effective in reducing the chance of this type of

accident.

Therefore:

• Wear a brightly colored jacket.

• Use extra caution when you are

approaching and passing

through intersections, since in-

tersections are the most likely

places for motorcycle accidents

to occur.

• Ride where other motorists can

see you. Avoid riding in another

motorist’s blind spot.

● Many accidents involve inexperi-

enced operators. In fact, many operators who have been involved in

accidents do not even have a current motorcycle license.

• Make sure that you are qualified

and that you only lend your

motorcycle to other qualified operators.

• Know your skills and limits.

Staying within your limits may

help you to avoid an accident.

• We recommend that you practice riding your motorcycle

where there is no traffic until you

have become thoroughly familiar with the motorcycle and all of

its controls.

● Many accidents have been

caused by error of the motorcycle

operator. A typical error made by

the operator is veering wide on a

1

1-1

SAFETY INFORMATION

turn due to EXCESSIVE SPEED

or undercornering (insufficient lean

angle for the speed).

1

• Always obey the speed limit and

never travel faster than warranted by road and traffic conditions.

• Always signal before turning or

changing lanes. Make sure that

other motorists can see you.

● The posture of the operator and

passenger is important for proper

control.

• The operator should keep both

hands on the handlebar and

both feet on the operator footrests during operation to maintain control of the motorcycle.

• The passenger should always

hold onto the operator, the seat

strap or grab bar, if equipped,

with both hands and keep both

feet on the passenger footrests.

• Never carry a passenger unless

he or she can firmly place both

feet on the passenger footrests.

● Never ride under the influence of

alcohol or other drugs.

● This motorcycle is designed for on-

road use only. It is not suitable for

off-road use.

Protective apparel

The majority of fatalities from motorcycle accidents are the result of head

injuries. The use of a safety helmet is

the single most critical factor in the prevention or reduction of head injuries.

● Always wear an approved helmet.

● Wear a face shield or goggles.

Wind in your unprotected eyes

could contribute to an impairment

of vision that could delay seeing a

hazard.

● The use of a jacket, heavy boots,

trousers, gloves, etc., is effective in

preventing or reducing abrasions

or lacerations.

● Never wear loose-fitting clothes,

otherwise they could catch on the

control levers, footrests, or wheels

and cause injury or an accident.

● Never touch the engine or exhaust

system during or after operation.

They become very hot and can

cause burns. Always wear protective clothing that covers your legs,

ankles, and feet.

● A passenger should also observe

the above precautions.

Modifications

Modifications made to this motorcycle

not approved by Yamaha, or the removal of original equipment, may render the motorcycle unsafe for use and

may cause severe personal injury.

Modifications may also make your

motorcycle illegal to use.

Loading and accessories

Adding accessories or cargo to your

motorcycle can adversely affect stability and handling if the weight distribution

of the motorcycle is changed. To avoid

the possibility of an accident, use extreme caution when adding cargo or

accessories to your motorcycle. Use

extra care when riding a motorcycle

that has added cargo or accessories.

Here are some general guidelines to

follow if loading cargo or adding accessories to your motorcycle:

1-2

SAFETY INFORMATION

Loading

The total weight of the operator, passenger, accessories and cargo must

not exceed the maximum load limit.

Maximum load:

YZF600RT 182 kg (401 lb)

YZF600RTC 180 kg (397 lb)

When loading within this weight limit,

keep the following in mind:

● Cargo and accessory weight

should be kept as low and close to

the motorcycle as possible. Make

sure to distribute the weight as

evenly as possible on both sides of

the motorcycle to minimize imbalance or instability.

● Shifting weights can create a sud-

den imbalance. Make sure that accessories and cargo are securely

attached to the motorcycle before

riding. Check accessory mounts

and cargo restraints frequently.

● Never attach any large or heavy

items to the handlebar, front fork,

or front fender. These items, including such cargo as sleeping

bags, duffel bags, or tents, can

create unstable handling or a slow

steering response.

Accessories

Genuine Yamaha accessories have

been specifically designed for use on

this motorcycle. Since Yamaha cannot

test all other accessories that may be

available, you must personally be responsible for the proper selection, installation and use of non-Yamaha

accessories. Use extreme caution

when selecting and installing any accessories.

Keep the following guidelines in mind,

as well as those provided under “Load-

ing” when mounting accessories.

● Never install accessories or carry

cargo that would impair the perfor-

mance of your motorcycle. Care-

fully inspect the accessory before

using it to make sure that it does

not in any way reduce ground

clearance or cornering clearance,

limit suspension travel, steering

travel or control operation, or obscure lights or reflectors.

• Accessories fitted to the handlebar or the front fork area can

create instability due to improper

weight distribution or aerodynamic changes. If accessories

are added to the handlebar or

front fork area, they must be as

lightweight as possible and

should be kept to a minimum.

• Bulky or large accessories may

seriously affect the stability of

the motorcycle due to aerodynamic effects. Wind may attempt to lift the motorcycle, or

the motorcycle may become unstable in cross winds. These accessories may also cause

instability when passing or being

passed by large vehicles.

• Certain accessories can displace the operator from his or

her normal riding position. This

improper position limits the freedom of movement of the opera-

1

1-3

SAFETY INFORMATION

tor and may limit control ability,

therefore, such accessories are

not recommended.

1

● Use caution when adding electri-

cal accessories. If electrical accessories exceed the capacity of the

motorcycle’s electrical system an

electric failure could result, which

could cause a dangerous loss of

lights or engine power.

Gasoline and exhaust gas

● GASOLINE IS HIGHLY FLAMMA-

BLE:

• Always turn the engine off when

refueling.

• Take care not to spill any gasoline on the engine or exhaust

system when refueling.

• Never refuel while smoking or in

the vicinity of an open flame.

● Never start the engine or let it run

for any length of time in a closed

area. The exhaust fumes are poisonous and may cause loss of

consciousness and death within a

short time. Always operate your

motorcycle in an area that has adequate ventilation.

● Always turn the engine off before

leaving the motorcycle unattended

and remove the key from the main

switch. When parking the motorcycle, note the following:

• The engine and exhaust system

may be hot, therefore, park the

motorcycle in a place where pedestrians or children are not likely to touch these hot areas.

• Do not park the motorcycle on a

slope or soft ground, otherwise it

may fall over.

• Do not park the motorcycle near

a flammable source, (e.g., a kerosene heater, or near an open

flame), otherwise it could catch

fire.

● When transporting the motorcycle

in another vehicle, make sure that

it is kept upright. If the motorcycle

should lean over, gasoline may

leak out of the carburetor or fuel

tank.

● If you should swallow any gaso-

line, inhale a lot of gasoline vapor,

or allow gasoline to get into your

eyes, see your doctor immediately.

If any gasoline spills on your skin

1-4

or clothing, immediately wash the

affected area with soap and water

and change your clothes.

Location of important labels

Please read the following important labels carefully before operating this vehicle.

SAFETY INFORMATION

EAU10381

1

1-5

SAFETY INFORMATION

1

1

CAUTION

Cleaning with alkaline or

acid cleaner, gasoline or

solvent will damage

windshield.

Use neutral detergent.

5JW-00

2

5

6

3

7

4

1-6

Left view

DESCRIPTION

EAU10410

2

1. Air intake duct (page 6-20)

2. Fuel tank (page 3-7)

3. Shock absorber assembly spring preload adjusting ring (page 3-12)

4. Shock absorber assembly rebound damping force adjusting knob

(page 3-12)

5. Shock absorber assembly compression damping force adjusting screw

(page 3-12)

6. Storage compartment (page 3-10)

7. Helmet holder (page 3-9)

8. Grab bar

9. Shift pedal (page 3-6)

10.Radiator (page 6-15)

2-1

DESCRIPTION

Right view

2

1. Luggage strap holder (page 3-14)

2. Rear brake fluid reservoir (page 6-27)

3. Coolant reservoir (page 6-15)

4. Front fork spring preload adjusting bolt (page 3-10)

5. Front fork rebound damping force adjusting screw (page 3-10)

6. Radiator cap (page 6-15)

7. Front fork compression damping force adjusting screw (page 3-10)

8. Engine oil level check window (page 6-12)

9. Brake pedal (page 3-6)

10.Engine oil filler cap (page 6-12)

EAU10420

2-2

Controls and instruments

1. Clutch lever (page 3-5)

2. Left handlebar switches (page 3-4)

3. Starter (choke) lever (page 3-8)

4. Speedometer unit (page 3-3)

5. Tachometer (page 3-3)

6. Coolant temperature gauge (page 3-4)

7. Right handlebar switches (page 3-4)

8. Brake lever (page 3-6)

9. Throttle grip (page 6-21)

10.Main switch/steering lock (page 3-1)

DESCRIPTION

EAU10430

2

2-3

INSTRUMENT AND CONTROL FUNCTIONS

Main switch/steering lock

3

The main switch/steering lock controls

the ignition and lighting systems, and is

used to lock the steering. The various

positions are described below.

ON

All electrical systems are supplied with

power, and the headlight, meter lighting, taillight and position lights come

on, and the engine can be started. The

key cannot be removed.

OFF

All electrical systems are off. The key

can be removed.

EAU10460

EAU10510

EAU10660

LOCK

EAU10680

The steering is locked, and all electrical

systems are off. The key can be removed.

To lock the steering

1. Push.

2. Turn.

1. Turn the handlebars all the way to

the left.

2. Push the key in from the “OFF” position, and then turn it to “LOCK”

while still pushing it.

3. Remove the key.

To unlock the steering

1. Push.

2. Turn.

Push the key in, and then turn it to

“OFF” while still pushing it.

EWA10060

WARNING

Never turn the key to “OFF” or

“LOCK” while the vehicle is moving,

otherwise the electrical systems will

be switched off, which may result in

loss of control or an accident. Make

sure that the vehicle is stopped before turning the key to “OFF” or

“LOCK”.

3-1

INSTRUMENT AND CONTROL FUNCTIONS

EAU11001

Indicator and warning lights

1. Neutral indicator light “”

2. Oil level warning light “”

3. Fuel level warning light “”

4. Turn signal indicator light “”

5. High beam indicator light “”

EAU11020

Turn signal indicator light “”

This indicator light flashes when the

turn signal switch is pushed to the left or

right.

EAU11060

Neutral indicator light “”

This indicator light comes on when the

transmission is in the neutral position.

High beam indicator light “”

EAU11080

This indicator light comes on when the

high beam of the headlight is switched

on.

EAU11140

Oil level warning light “”

This warning light comes on when the

engine oil level is low.

The electrical circuit of the warning light

can be checked according to the following procedure.

1. Set the engine stop switch to “”

and turn the key to “ON”.

2. Shift the transmission into the neutral position or pull the clutch lever.

3. Push the start switch. If the warning light does not come on while

pushing the start switch, have a

Yamaha dealer check the electrical circuit.

NOTE:

Even if the oil level is sufficient, the

warning light may flicker when riding on

a slope or during sudden acceleration

or deceleration, but this is not a malfunction.

Fuel level warning light “”

EAU11320

This warning light comes on when the

fuel level drops below approximately

3.1 L (0.82 US gal) (0.68 Imp.gal).

When this occurs, refuel as soon as

possible.

The electrical circuit of the warning light

can be checked according to the following procedure.

1. Set the engine stop switch to “”

and turn the key to “ON”.

2. Shift the transmission into the neutral position or pull the clutch lever.

3. Push the start switch. If the warning light does not come on, have a

Yamaha dealer check the electrical circuit.

NOTE:

This model is equipped with a self-diagnosis device for the fuel level warning

light circuit. (See page 3-3.)

3

3-2

INSTRUMENT AND CONTROL FUNCTIONS

Speedometer unit

3

1. Odometer

2. Tripmeter reset knob

3. Tripmeter

The speedometer unit is equipped with

a speedometer, an odometer and a

tripmeter. The speedometer shows

riding speed. The odometer shows the

total distance traveled. The tripmeter

shows the distance traveled since it

was last set to zero with the reset knob.

The tripmeter can be used to estimate

the distance that can be traveled with a

full tank of fuel. This information will enable you to plan future fuel stops.

EAU11630

EAU11851

Tachometer

1. Tachometer

2. Tachometer red zone

The electric tachometer allows the rider

to monitor the engine speed and keep it

within the ideal power range.

ECA10031

CAUTION:

Do not operate the engine in the tachometer red zone.

Red zone: 13200 r/min and above

EAU11981

Self-diagnosis device

This model is equipped with a self-diagnosis device for the following electrical

circuits:

● throttle position sensor

● fuel level warning light

If any of those circuits are defective, the

tachometer will repeatedly display the

following error code:

0 r/min for

3 seconds

Circuit-specific

number of r/min

for 2.5 seconds

(See the table

below.)

Use the table below to identify the faulty

electrical circuit.

Specific r/min for the faulty circuit

Throttle position sensor:

3000 r/min

Fuel level warning light:

8000 r/min

If the tachometer displays such an error

code, note the circuit-specific number

of r/min, and then have a Yamaha dealer check the vehicle.

Current

engine

speed for

3 seconds

3-3

INSTRUMENT AND CONTROL FUNCTIONS

ECA10040

CAUTION:

When the tachometer displays an error code, the vehicle should be

checked as soon as possible in order to avoid engine damage.

EAU12171

Coolant temperature gauge

1. Coolant temperature gauge

2. Coolant temperature gauge red zone

With the key in the “ON” position, the

coolant temperature gauge indicates

the temperature of the coolant. The

coolant temperature varies with changes in the weather and engine load. If

the needle reaches or enters the red

zone, stop the vehicle and let the engine cool. (See page 6-43.)

ECA10020

CAUTION:

Do not operate the engine if it is

overheated.

EAU12343

Handlebar switches

Left

3

1. Dimmer switch “ / ”

2. Turn signal switch “ / ”

3. Horn switch “”

Right

1. Engine stop switch “ / ”

2. Start switch “”

3-4

INSTRUMENT AND CONTROL FUNCTIONS

Dimmer switch “ / ”

Set this switch to “” for the high

beam and to “” for the low beam.

Turn signal switch “ / ”

To signal a right-hand turn, push this

switch to “”. To signal a left-hand

3

turn, push this switch to “”. When re-

leased, the switch returns to the center

position. To cancel the turn signal

lights, push the switch in after it has returned to the center position.

Horn switch “”

Press this switch to sound the horn.

Engine stop switch “ / ”

Set this switch to “” before starting

the engine. Set this switch to “” to

stop the engine in case of an emergency, such as when the vehicle overturns

or when the throttle cable is stuck.

EAU12400

EAU12460

EAU12500

EAU12660

ECA10050

CAUTION:

See page 5-1 for starting instructions prior to starting the engine.

EAU12820

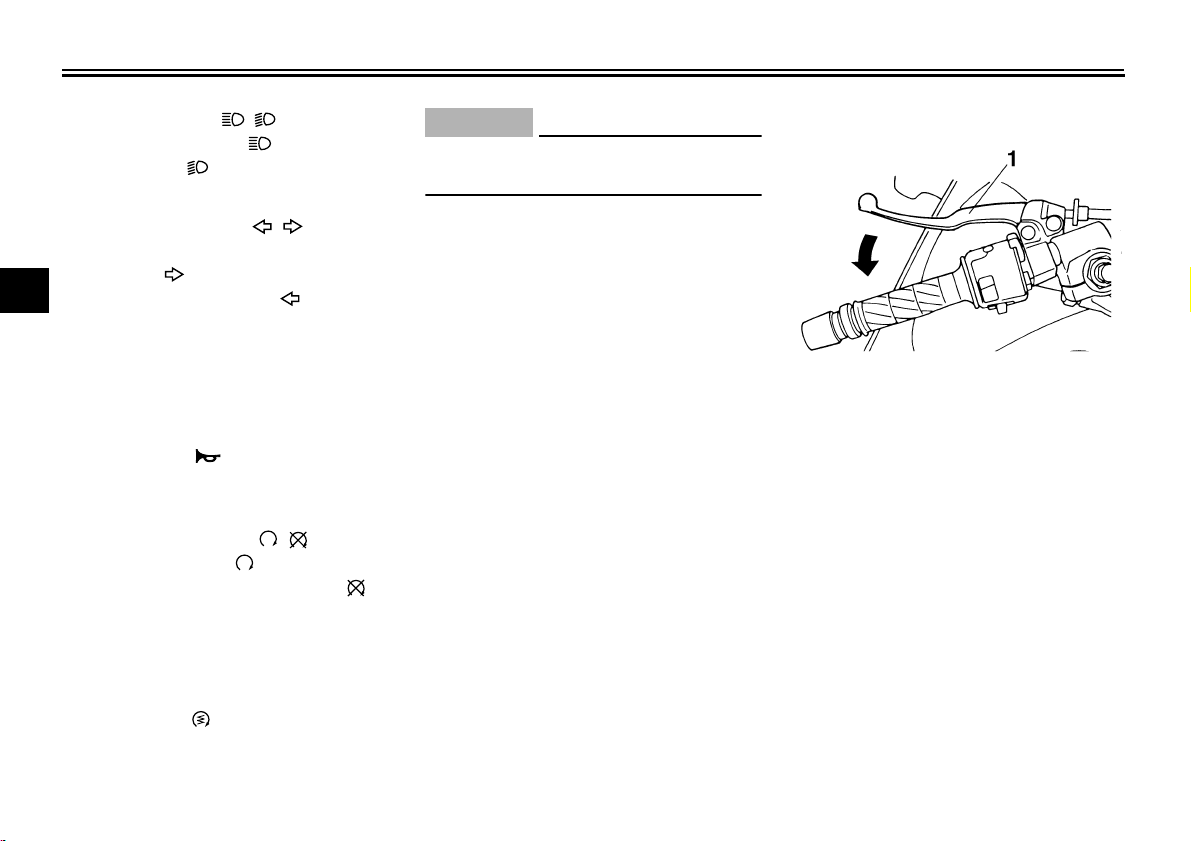

Clutch lever

1. Clutch lever

The clutch lever is located at the left

handlebar grip. To disengage the

clutch, pull the lever toward the handlebar grip. To engage the clutch, release

the lever. The lever should be pulled

rapidly and released slowly for smooth

clutch operation.

The clutch lever is equipped with a

clutch switch, which is part of the ignition circuit cut-off system. (See page

3-15.)

Start switch “”

EAU12710

Push this switch to crank the engine

with the starter.

3-5

INSTRUMENT AND CONTROL FUNCTIONS

EAU12870

Shift pedal

1. Shift pedal

The shift pedal is located on the left

side of the engine and is used in combination with the clutch lever when

shifting the gears of the 6-speed constant-mesh transmission equipped on

this motorcycle.

EAU12930

Brake lever

The brake lever is located at the right

handlebar grip. To apply the front

brake, pull the lever toward the handlebar grip.

1. Arrow mark

2. Brake lever position adjusting dial

3. Brake lever

4. Distance between brake lever and handlebar

grip

The brake lever is equipped with a position adjusting dial. To adjust the distance between the brake lever and the

handlebar grip, turn the adjusting dial

while holding the lever pushed away

from the handlebar grip. Make sure that

the appropriate setting on the adjusting

dial is aligned with the arrow mark on

the brake lever.

3-6

EAU12941

Brake pedal

3

1. Brake pedal

The brake pedal is on the right side of

the motorcycle. To apply the rear

brake, press down on the brake pedal.

INSTRUMENT AND CONTROL FUNCTIONS

Fuel tank cap

3

1. Fuel tank cap lock cover

2. Unlock.

To open the fuel tank cap

Open the fuel tank cap lock cover, insert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be released and the fuel tank cap can be

opened.

To close the fuel tank cap

1. Push the fuel tank cap into position

with the key inserted in the lock.

2. Turn the key counterclockwise to

the original position, remove it, and

then close the lock cover.

EAU13070

NOTE:

The fuel tank cap cannot be closed unless the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

EWA11090

WARNING

Make sure that the fuel tank cap is

properly closed before riding.

EAU13210

Fuel

1. Fuel tank filler tube

2. Fuel level

Make sure that there is sufficient fuel in

the tank. Fill the fuel tank to the bottom

of the filler tube as shown.

EWA10880

WARNING

● Do not overfill the fuel tank, oth-

erwise it may overflow when the

fuel warms up and expands.

● Avoid spilling fuel on the hot en-

gine.

3-7

INSTRUMENT AND CONTROL FUNCTIONS

ECA10070

CAUTION:

Immediately wipe off spilled fuel

with a clean, dry, soft cloth, since

fuel may deteriorate painted surfaces or plastic parts.

EAU13300

Recommended fuel:

UNLEADED GASOLINE ONLY

Fuel tank capacity:

19.0 L (5.02 US gal) (4.18 Imp.gal)

Fuel reserve amount:

3.1 L (0.82 US gal) (0.68 Imp.gal)

ECA11400

CAUTION:

Use only unleaded gasoline. The use

of leaded gasoline will cause severe

damage to internal engine parts,

such as the valves and piston rings,

as well as to the exhaust system.

Your Yamaha engine has been designed to use regular unleaded gasoline with a pump octane number

[(R+M)/2] of 86 or higher, or a research

octane number of 91 or higher. If

knocking (or pinging) occurs, use a

gasoline of a different brand or premium unleaded fuel. Use of unleaded fuel

will extend spark plug life and reduce

maintenance costs.

Gasohol

There are two types of gasohol: gasohol containing ethanol and that containing methanol. Gasohol containing

ethanol can be used if the ethanol content does not exceed 10%. Gasohol

containing methanol is not recommended by Yamaha because it can

cause damage to the fuel system or vehicle performance problems.

EAU13610

Starter (choke) lever “”

3

1. Starter (choke) lever “”

Starting a cold engine requires a richer

air-fuel mixture, which is supplied by

the starter (choke).

Move the lever in direction (a) to turn on

the starter (choke).

Move the lever in direction (b) to turn off

the starter (choke).

ECA10990

CAUTION:

Do not use the starter (choke) for

more than 3 minutes as the exhaust

pipe may discolor from excessive

heat. In addition, extended use of

the starter (choke) will cause afterburning. If this occurs, turn off the

starter (choke).

3-8

INSTRUMENT AND CONTROL FUNCTIONS

Seat

To remove the seat

1. Insert the key into the helmet holder lock, and then turn it as shown.

3

1. Unlock.

2. Pull the seat off.

To install the seat

1. Insert the projections on the front

of the seat into the seat holder as

shown.

EAU13920

1. Seat holder

2. Projection

2. Push the rear of the seat down to

lock it in place.

3. Remove the key.

NOTE:

Make sure that the seat is properly secured before riding.

EAU14290

Helmet holder

1. Helmet holder

2. Unlock.

To open the helmet holder, insert the

key into the lock, and then turn the key

as shown.

To lock the helmet holder, turn the key

to the original position, and then remove it.

EWA10160

WARNING

Never ride with a helmet attached to

the helmet holder, since the helmet

may hit objects, causing loss of control and possibly an accident.

3-9

INSTRUMENT AND CONTROL FUNCTIONS

EAU14451

Storage compartment

1. Storage compartment

The storage compartment is located

under the seat. (See page 3-9.)

EWA10961

WARNING

● Do not exceed the load limit of 3

kg (7 lb) for the storage compartment.

● Do not exceed the maximum

load of YZF600RT 182 kg (401

lb)

YZF600RTC 180 kg (397 lb) for

the vehicle.

When washing the vehicle, be careful

not to let any water enter the storage

compartment.

EAU14741

Adjusting the front fork

This front fork is equipped with spring

preload adjusting bolts, rebound damping force adjusting screws and compression damping force adjusting

screws.

EWA10180

WARNING

Always adjust both fork legs equally, otherwise poor handling and loss

of stability may result.

Spring preload

1. Spring preload adjusting bolt

3

When storing the owner’s manual or

other documents in the storage compartment, be sure to wrap them in a

plastic bag so that they will not get wet.

To increase the spring preload and

thereby harden the suspension, turn

the adjusting bolt on each fork leg in direction (a). To decrease the spring pre-

3-10

INSTRUMENT AND CONTROL FUNCTIONS

load and thereby soften the

suspension, turn the adjusting bolt on

each fork leg in direction (b).

NOTE:

Align the appropriate groove on the adjusting mechanism with the top of the

front fork cap bolt.

3

1. Current setting

2. Front fork cap bolt

Spring preload setting:

Minimum (soft):

8

Standard:

5

Maximum (hard):

1

Rebound damping force

1. Rebound damping force adjusting screw

To increase the rebound damping force

and thereby harden the rebound damping, turn the adjusting screw on each

fork leg in direction (a). To decrease the

rebound damping force and thereby

soften the rebound damping, turn the

adjusting screw on each fork leg in direction (b).

Rebound damping setting:

Minimum (soft):

10 click(s) in direction (b)*

Standard:

7 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned

in direction (a)

Compression damping force

1. Compression damping force adjusting screw

To increase the compression damping

force and thereby harden the compression damping, turn the adjusting screw

on each fork leg in direction (a). To decrease the compression damping force

and thereby soften the compression

damping, turn the adjusting screw on

each fork leg in direction (b).

Compression damping setting:

Minimum (soft):

10 click(s) in direction (b)*

Standard:

7 click(s) in direction (b)*

Maximum (hard):

1 click(s) in direction (b)*

* With the adjusting screw fully turned

in direction (a)

3-11

INSTRUMENT AND CONTROL FUNCTIONS

ECA10100

CAUTION:

Never attempt to turn an adjusting

mechanism beyond the maximum or

minimum settings.

NOTE:

Although the total number of clicks of a

damping force adjusting mechanism

may not exactly match the above specifications due to small differences in

production, the actual number of clicks

always represents the entire adjusting

range. To obtain a precise adjustment,

it would be advisable to check the number of clicks of each damping force adjusting mechanism and to modify the

specifications as necessary.

EAU15011

Adjusting the shock absorber assembly

This shock absorber assembly is

equipped with a spring preload adjusting ring, a rebound damping force adjusting knob and a compression

damping force adjusting screw.

ECA11220

CAUTION:

Never attempt to turn the spring preload and rebound damping force adjusting mechanisms beyond the

maximum or minimum settings.

Spring preload

To increase the spring preload and

thereby harden the suspension, turn

the adjusting ring in direction (a). To decrease the spring preload and thereby

soften the suspension, turn the adjusting ring in direction (b).

NOTE:

● Align the appropriate notch in the

adjusting ring with the position indicator on the shock absorber.

● Use the special wrench included in

the owner’s tool kit to make the adjustment.

Spring preload setting:

Minimum (soft):

1

Standard:

3

Maximum (hard):

7

3

1. Spring preload adjusting ring

2. Position indicator

3-12

INSTRUMENT AND CONTROL FUNCTIONS

Rebound damping force

3

1. Rebound damping force adjusting knob

To increase the rebound damping force

and thereby harden the rebound damping, turn the adjusting knob in direction

(a). To decrease the rebound damping

force and thereby soften the rebound

damping, turn the adjusting knob in direction (b).

Rebound damping setting:

Minimum (soft):

25 click(s) in direction (b)*

Standard:

10 click(s) in direction (b)*

Maximum (hard):

3 click(s) in direction (b)*

* With the adjusting knob fully turned

in direction (a)

NOTE:

Although the total number of clicks of

the rebound damping force adjusting

mechanism may not exactly match the

above specifications due to small differences in production, the actual number

of clicks always represents the entire

adjusting range. To obtain a precise adjustment, it would be advisable to check

the number of clicks of the rebound

damping force adjusting mechanism

and to modify the specifications as necessary.

Compression damping force

1. Compression damping force adjusting screw

2. Position indicator

To harden the compression damping,

decrease the setting by turning the adjusting screw. To soften the compression damping, increase the setting by

turning the adjusting screw. Make sure

that the position indicator is aligned

with the appropriate setting.

Compression damping setting:

Minimum (soft):

6

Standard:

4

Maximum (hard):

1

EWA10220

WARNING

This shock absorber contains highly

pressurized nitrogen gas. For proper handling, read and understand

the following information before

handling the shock absorber. The

manufacturer cannot be held responsible for property damage or

personal injury that may result from

improper handling.

● Do not tamper with or attempt to

open the gas cylinder.

3-13

Loading...

Loading...